Page 1

SERVICE

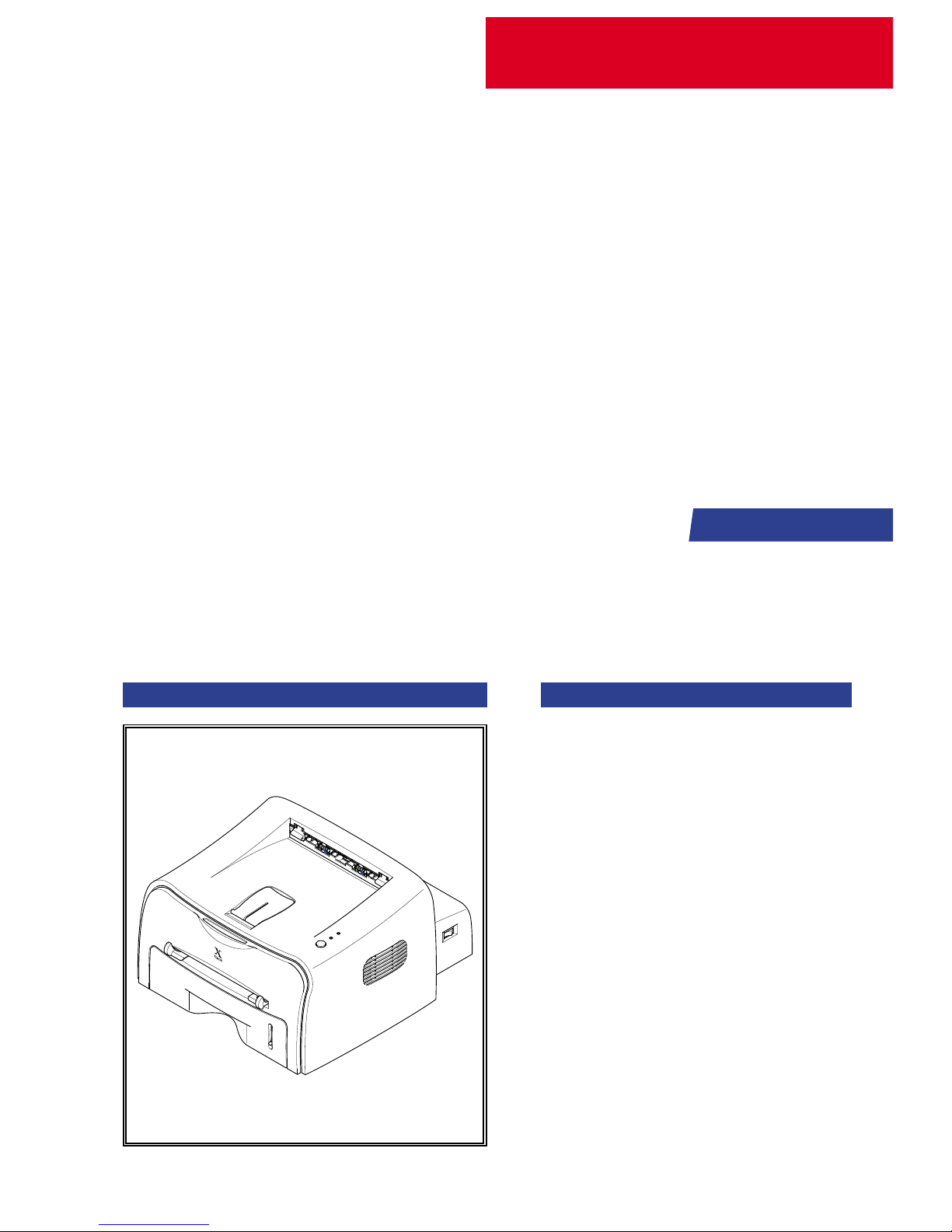

LASER PRINTER

Phaser 3120

Phaser 3130

Manual

LASER PRINTER CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Block Diagram

7. Connection Diagram

8. Schematic Diagram

Page 2

1

1

1-1

Precautions

Service Manual

1. Precautions

The cautions in the below are items needed to keep in mind when maintaining and servicing.

Please read carefully and keep the contents in mind to prevent accidents while servicing and to prevent

that the machine gets damage.

1.1 Warning for safety.

(1) Request the service by qualified service person.

The service for this machine must be performed by a service person who took the additional education of

this field.

It is dangerous if unqualified service person or user tries to fix the machine.

(2) Do not rebuild it discretionary.

Do not attach or change pats discretionary. Do not dissemble, fix, and rebuilt it. If do, printer will abnormally

work and electric shock or a fire can be occurred.

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J

for Class 1(1) laser products, and elsewhere, is certified as a Class I laser product conforming to the

requirements of IEC 825.

Class I laser products are not considered to be hazardous. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I level during normal operation, user

maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The reflected

beam, although invisible, can damage your eyes. When using this product, these basic safety precautions should

always be followed to reduce risk of fire, electric shock, and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GE FFNET .

NICHT DEM STRAHL AUSSETZEN.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

D OUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE LESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTR LNING VED BNING, N R

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDG UDSAETTELSE FOR STRLNING.

ADVARSEL. - USYNLIG LASERSTR LNING NR DEKSEL

PNES. STIRR IKKE INN I STR LEN.

UNNG EKSPONERING FOR STRLEN.

VARNING - OSYNLIG LASERSTR LNING NR DENNA DEL

R PPNAD OCH SPRREN R URKOPPLAD.

BETRAKTA EJ STR LEN. STRLEN R FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA N KYM TTM LLE LASERS TEILYLLE L KATSO S TEESEEN.

Page 3

1-2

Precautions

Service Manual

1.2 Caution for safety

1.2.1 Precaution related noxious material

The toner in a printer cartridge contains a chemical material, which might harm human body if it is swallowed.

Please keep children out of the toner cartridge.

1.2.2 Precaution related electric shock or fire

It is possible to get electric shock or burn by fire if you don't fallow the instructions of the manual.

(1) Use exact voltage. Please do use an exact voltage and wall socket. If not, a fire or an electric leakage can

be caused.

(2) Use authorized power code. Do use the power code supplied with PRINTER. Afire can be occurred when

over current flows in the power code.

(3) Do not insert many codes in an outlet. If do, a fire can be occurred due to flow over current in an outlet.

(4) Do not put water or extraneous matter in the PRINTER. Please do not put water, other liquid, pin, clip, etc.

It can cause a fire, electric shock, or malfunction. If it is happened, turn off the power and remove the

power plug from outlet immediately.

(5) Do not touch the power plug with wet hand. When servicing, do remove the power plug from outlet. And

do not insert or take off it with wet hand. Electric shock can be occurred.

(6) Caution when inserting or taking off the power plug. The power plug has to be inserted completely. If not,

a fire can be caused due to poor contact. When taking off the power plug, do grip the plug and take it off.

If grip the line and pull over, it could be damaged. A fire or electric shock could cause.

(7) Management of power code. Do not bend, twist, or bind it and place other materials on it. Also, do not fix

it with staples. If the power code gets damage, a fire or electric shock can be caused. Adamaged power

code must be replaced immediately . Do not repair the damaged part and reuse it. Arepaired part with plas-

tic tape can be occurred a fire or electric shock. Do not spread chemicals on the power code. Do not

spread insecticide on the power code. Afire or electric shock can be occurred due to thinner(weak) cover

of the power code.

(8) Check whether the power outlet and the power plug are damaged, pressed, chopped, or blazing fire or

not. When such inferiorities are found, repair it immediately. Do not make it pressed or chopped when

moving the machine.

(9) Caution when thundering, and being flash of lightening. It causes a fire or electric shock. Take the power

plug off when thundering. Do not touch cable and device when thundering and being flash of lightening.

(10) Do avoid the place where is moisture or has dust. Do not install the printer in where have lots of dust or

around humidifier. A fire can be occurred. A plug part need to clean well with dried fabric to remove dust.

If water drops are dripped on the place covered with dust, a fire can be occurred.

(11) Avoid direct sunlight. Do not install the printer near to window where directly contacts to the sunlight. If

the machine contacts sunlight long time, the machine cannot work properly because inner temperature

of the machine is getting higher. A fire can be caused.

(12) Turn off the power and take off the plug when a smoke, strange smell, or sound from the machine. If you

keep using it, a fire can be occurred.

(13) Do not insert steel or metal piece inside/outside of the machine. Do not put steel or metal piece into a

ventilator. An electric shock could be happened.

Page 4

1-3

Precautions

Service Manual

1.2.3 Precaution related handling the machine.

If you ignore this information, you could get harm and machine could be damaged.

(1) Do not install it on the different levels, or slanted floor.

Please confirm whether it is balanced or not after installation. If it is unbalanced, an accident can be happened due to the machine fell over.

(2) Be careful not to insert a finger or hair in the rotating unit.

Be careful not to insert a finger of hair in the rotating unit (motor, fan, paper feeding part, etc) while the

machine is operating. Once it happens, you could harm.

(3) Do not place a pot contains water/chemical or small metals. If those are got into the inner side of machine,

a fire or electric shock can be occurred.

(4) Do not install it in where lots of moisture or dust exists or where raindrop reaches. Afire or electric shock

can be caused.

(5) Do not place a candlelight, burning cigarette, and etc. on the machine. Do not install it near to heater. A

fire can be occurred.

1.2.4 Precaution when assembly/disassembly

When replace parts, do it very carefully. Do memorize the location of each cable before replace parts for

reconnecting it afterwards. Do memorize. Please perform the below before replace or disassembly the parts.

(1) Check the contents stored in the memory. All the information will be erased after replace main board. The

information needed to keep has to be written down.

(2) Before servicing or replacing electric parts, take off a plug.

(3) Take off printer cables and power code connected to printer.

(4) Do use formal parts and same standardized goods when replacing parts.Must check the product name,

part code, rated voltage, rated current, operating temperature, etc.

(5) Do not give an over-force when release or tighten up the plastic parts.

(6) Be careful not to drop the small parts such as screws in the printer.

(7) Be careful not to change the location of small parts such as screws when assembling and disassembling.

(8) Do remove dust or foreign matters completely to prevent fire of tracking, short, or etc.

(9) After finished repair, check the assembling state whether it is same as before the repair or not.

Page 5

1-4

Precautions

Service Manual

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called “Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits,

some field effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused

by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface,

such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity

of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to

damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed,

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the

brushing together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to damage an ESD.

Page 6

1-5

Precautions

Service Manual

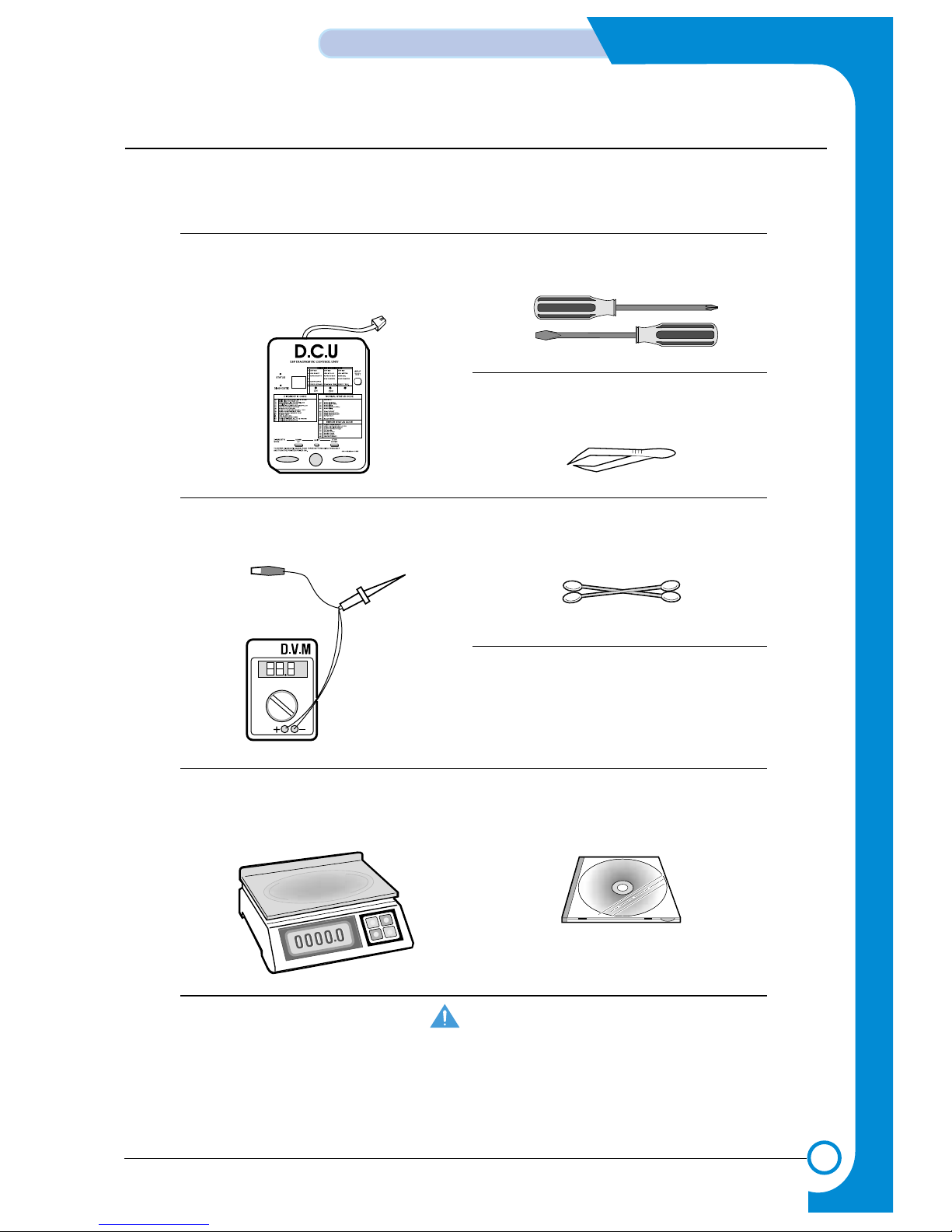

1.4 Tool for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

DCU(Diagnostic Control Unit)

Standard : Test equipment to diagnose the Laser

printer supplied by Samsung Electronics.

1

Driver

Standard : "-" type, "+" type (M3 long, M3 short, M2 long,

M2 short).

4

Cotton Swab

Standard : For general home use, for medical ser-vice

6

Software(Driver) installation CD ROM

8

Cleaning Equipments a IPA(Isopropyl

Alcohol)dry cloth or a soft stuff neutral

detergent

7

Pinset

Standard : For general home use, small type.

5

DVM(Digital Volt Meter)

Standard : Indicates more than 3 digits.

2

Electronic Scale

Standard : Equipment to check the weight of consumables(toner cartridge) supplied by Samsung

Electronics. (The gram unit can be measured.)

3

Mind your hands not to be touched when you

disassemble and reassemble PBAASS'Y, such

as the main board, SMPS, HVPS.

Page 7

2

2

2-1

Specifications

Service Manual

2. Specifications

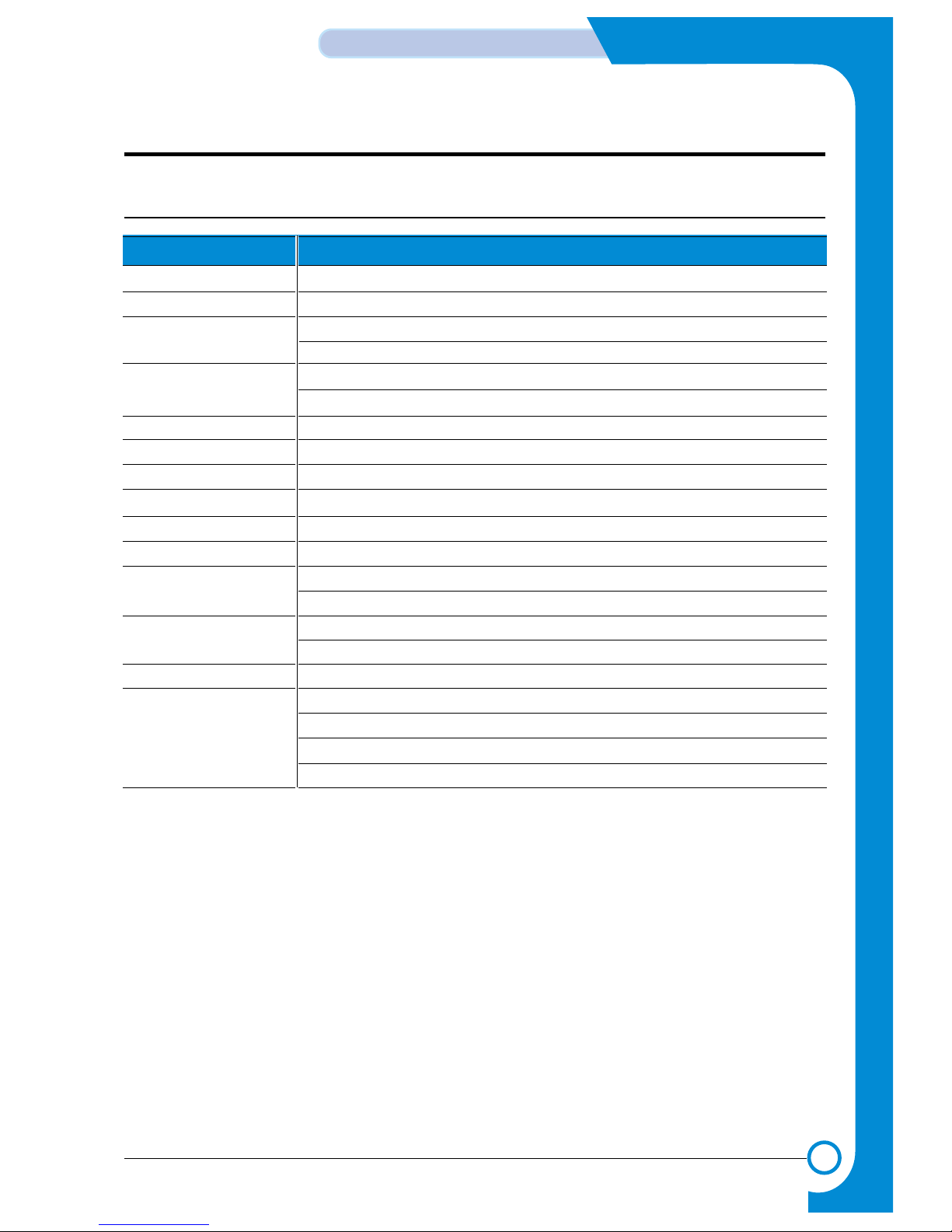

2.1 General Specifications

ITEM DESCRIPTION

Print Technology Non-impact Electro-photograpic Printing

Developing system Non-Magnetic, Mono-Component Developing System

Print Speed

(1)

16 PPM : A4 size , 5% Character pattern

17 PPM : Letter size , 5% Character pattern

Resolution Phaser 3120 : True 600 X 600 DPI

Phaser 3130 : 1200 X 600 DPI

Source of Light Laser diode (LSU : Laser Scanner Unit)

Warm-Up Time Power-on boot : 30 seconds or less

First Print Out Time Less than 1 1 seconds (Ready to 1st page out)

Media Size 75 X 125 (3” X 5”) mm to 216 X 356 (8.5” X 14”)mm

Media Thickness 16 ~ 24 lb

Dimension(W X D X H) 348 X 355 X 193mm / 13.7 X 14 X 7.6 inch

Weight Net : 7 Kg /15.4 lb

Gross : 9.5 Kg (Max.)

Acoustic Noise

(1)

Stand by : Less than 35 dB

Printing: Less than 50 dB

Machine Life 120,000 Sheets

Periodic Replacing Parts

(2)

Pick Up Roller : 60,000 Sheets

Feed Roller : 60,000 Sheets

Transfer Roller: 60,000 Sheets

Fuser Assembly : 60,000 Sheets

(1)

For measuring the printing speed, count the papers which outputted within one minute from when the

second page starts to be printed. (A4, 5% character pattern standard)

(2)

The life span of the consumption parts can be checked by printing the demo page or the system list.

(Refer to the 6.3 Receive the service information)

Page 8

2-2

Specifications

Service Manual

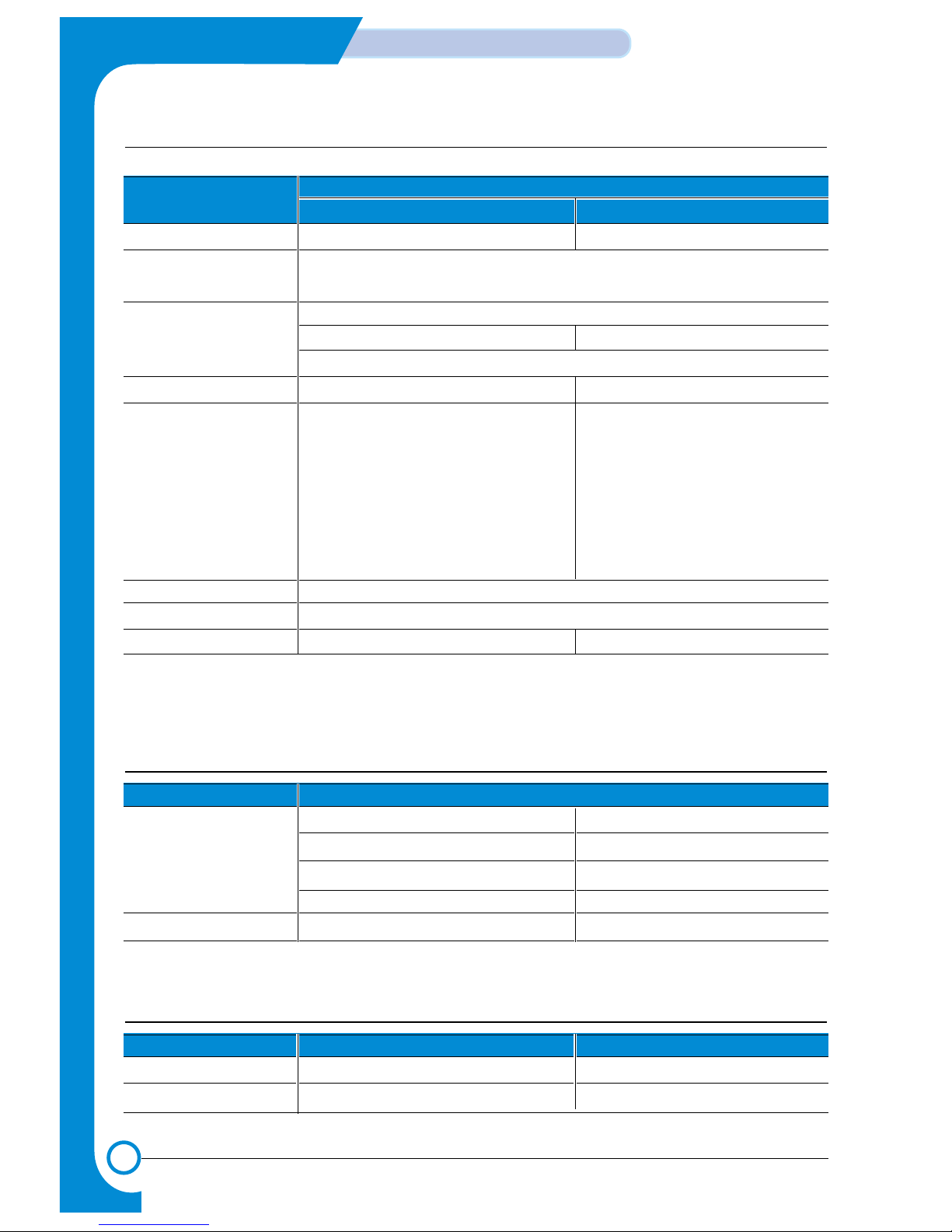

2.3 Electrical Specification

2.2 Controller Specification

ITEM

DESCRIPTION

Phaser 3120 Phaser 3130

Processor(CPU) Samsung Jupiter4 90MHz Samsung SPGPm 166MHz

OS Compatibility

(1)

Win 98x/NT4.0/ME/2000/XP,

Various Linux OS,Mac(Mac OS 8.6 ↑)

Memory FLASH ROM(PROGRAM) : 0.5MB flash

RAM : 8 MB RAM : 32 MB

EEPROM(NVRAM) : 512byte

Emulation SPL(Samsung Printer Language) PCL6, IBMProPrinter, EPSON

Interface USB 1.1 USB

- USB 2.0

- 12 Mbps 1 port

Parallel : IEEE 1284

- Modes supported :

Compatible,Nibble,Byte,ECP

External Network Adaptor(Optional)

Interface switching Automatic

Interface time-out 5min(Max.)

Font Windows Font 45 Scalable, 1 Bitmap

ITEM DESCRIPTION

Input Voltage Nominal input voltage 200-240 VAC / 100~127VAC

Input voltage range 189-264 VAC/ 90~132VAC

Nominal frequency 50/60 Hz

Frequency tolerance +3Hz

Power Consumption Printing : 280W Avg or less Power Save : 10W Avg or less

2.4 Environmental Range

ITEM OPERA TING STORAGE

Temperature 10~32

o

C(50-90 oF) -20~40 oC (-4~104 oF)

Humidity 20~80%RH 10~80%RH

(1) The SPL series model is USB exclusive use, so it supports the environment beyond the WIN 98.

Page 9

2-3

Specifications

Service Manual

• Input capacity

Cassette: 250 sheets

Manual : 1 sheet

• Output capacity

Face Down : 50 sheets(20lb)

Face Up : 1 sheet(OHP, Lavbel, Cut Sheet, Envelope)

2-Paper Handling Specifications

Please refer to "Paper Specifications" on user guide

• Input Paper Size

2.5 TONER Cartridge (Developer)

ITEM DESCRIPTION REMARK

Life span 3,000 sheets IDC 5% pattern

Developing Non-magnetic Mono Conponent Contact Developing

Charging Conductive Roller Charging

Toner checking sensor Not Available

Ozone 0.1PPM or less 8 hours

Style Single cartridge

P APER DIMENSIONS WEIGHT

A4 210 X 297 mm 60 to 90 g/m2 bond(16 to 24 lb)

Letter 216 X 279(8.5 X 11")

Legal(Legal14") 216 X 356(8.5 X14")

JIS B5 182 X257mm (7.2 X 10")

Folio(Legal13") 216 X 330mm (8.5 X 13")

Minimum size (Custom) 76 X 127mm (3 X 5") 60 to 163 g/m2bond(16 to 43 lb)

Maximum size (Custom) 216 X 356mm (8.5 X 14")

Transparency(OHP) Same minimum and maximum Thickness:

Label paper sizes as listed above 0.10 X 0.14 mm (0.0039 X 0.0055")

Envelopes Up to 90 g/m2 bond(16 to 24 lb)

Page 10

2-4

Specifications

Service Manual

Page 11

3

3

3-1

Disassembly and Reassembly

Service Manual

3. Disassembly and Reassembly

3.1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close

proximity of cables to moving parts makes proper

routing a must.

If components are removed, any cables disturbed

by the procedure must be restored as close as

possible to their original positions. Before removing any component from the machine, note the

cable routing that will be affected.

Whenever servicing the machine, you

must perform as follows:

1. Check to verify that documents are not stored

in memory.

2. Be sure to remove the toner cartridge before

you disassemble parts.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace only with authorized components.

6. Do not force plastic-material components.

7. Make sure all components are in their proper

position.

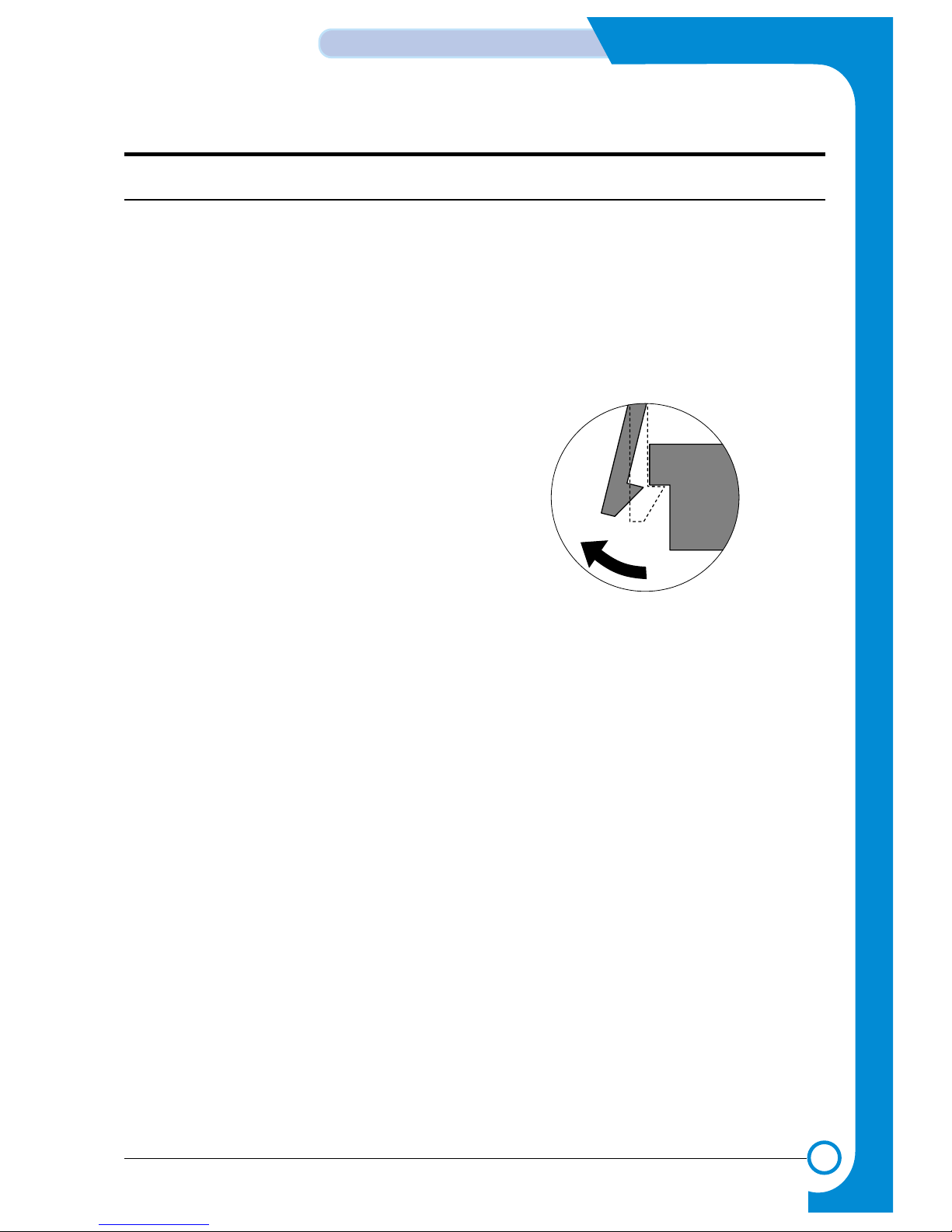

Releasing Plastic Latches

Many of the parts are held in place with plastic

latches. The latches break easily; release them

carefully.

To remove such parts, press the hook end of the

latch away from the part to which it is latched.

Page 12

3-2

Disassembly and Reassembly

Service Manual

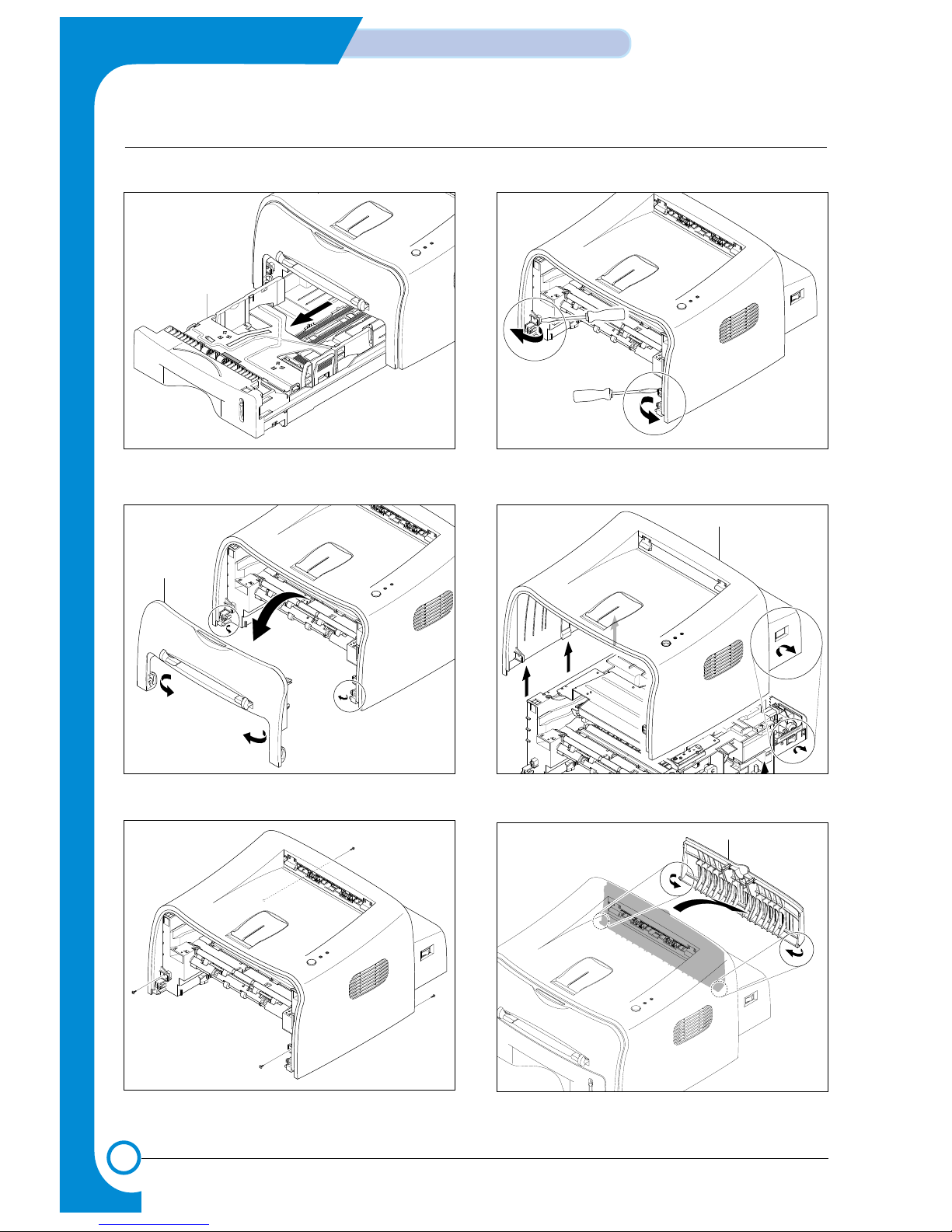

1. Pull the Cassette out of the printer.

2. Remove the Front Cover in the direction of

arrow.

3. Remove four screws.

4. Unlatch the front ends of the Top Cover.

5. Remove the Top Cover in the direction of arrow.

6. Remove the Rear Cover from the Top Cover.

Cassette

Top Cover

Rear Cover

Front Cover

3.2 Top Cover

Page 13

3-3

Disassembly and Reassembly

Service Manual

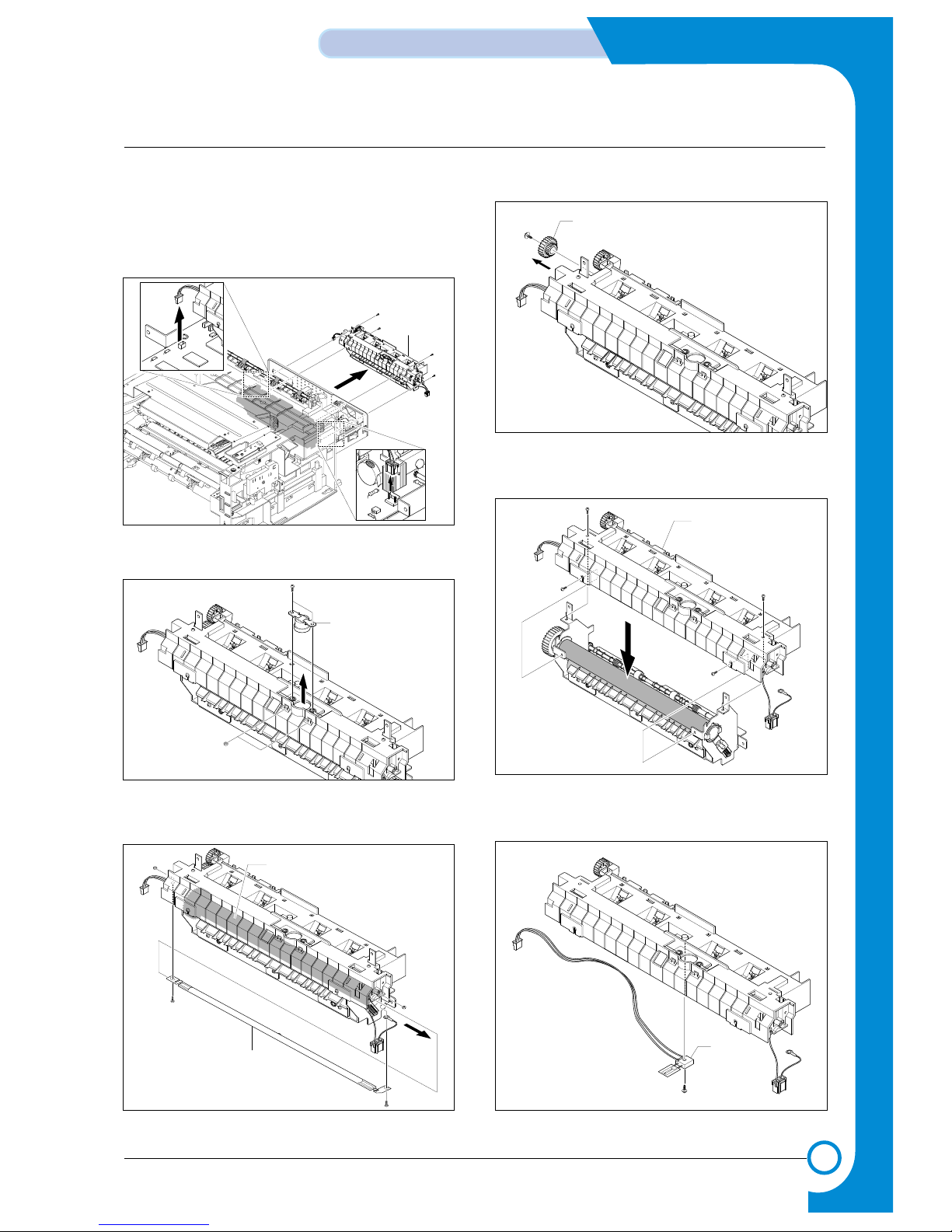

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

2. Unplug two connectors(Block) from the boards,

then remove four screws.

3. Remove two screws and take the Thermostat

out of the Fuser.

4. Remove two screws and take the Halogen

Lamp out of the Heat Roller.

5. Remove one screw and take the Idle Gear out.

6. Remove four screws and divide the Fuser into

two parts

7. Remove the Thermister from the Fuser Cover.

Idle Gear

Fuser Cover

Fuser Ass'y

Thermostat

Halogen Lamp

Heat Roller

3.3 Fuser

Thermister

Page 14

3-4

Disassembly and Reassembly

Service Manual

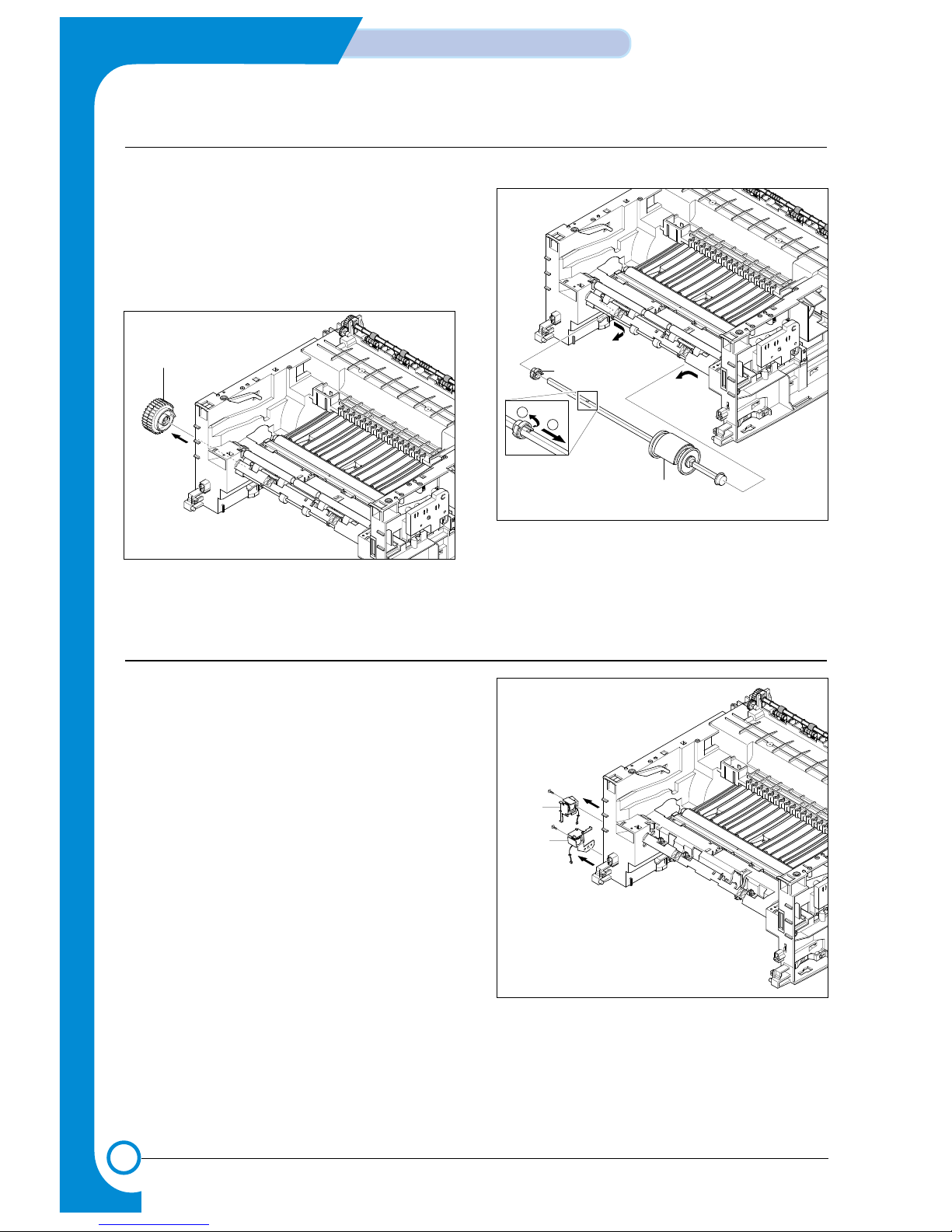

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

2.Remove the Exit Gear, Bearing and Exit Roller.

Exit Gear

Bearing

Exit Roller

1

2

3.4 Exit Roller

3.5 LSU

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

2. Remove two screws and unplug one connector

from the Frame.

3. Remove the LED PBAAss’y as shown below.

4. Unplug two connector from the LSU

5. Unplug four screws and take the LSU out.

LSU

LED PBA Cover

Page 15

3-5

Disassembly and Reassembly

Service Manual

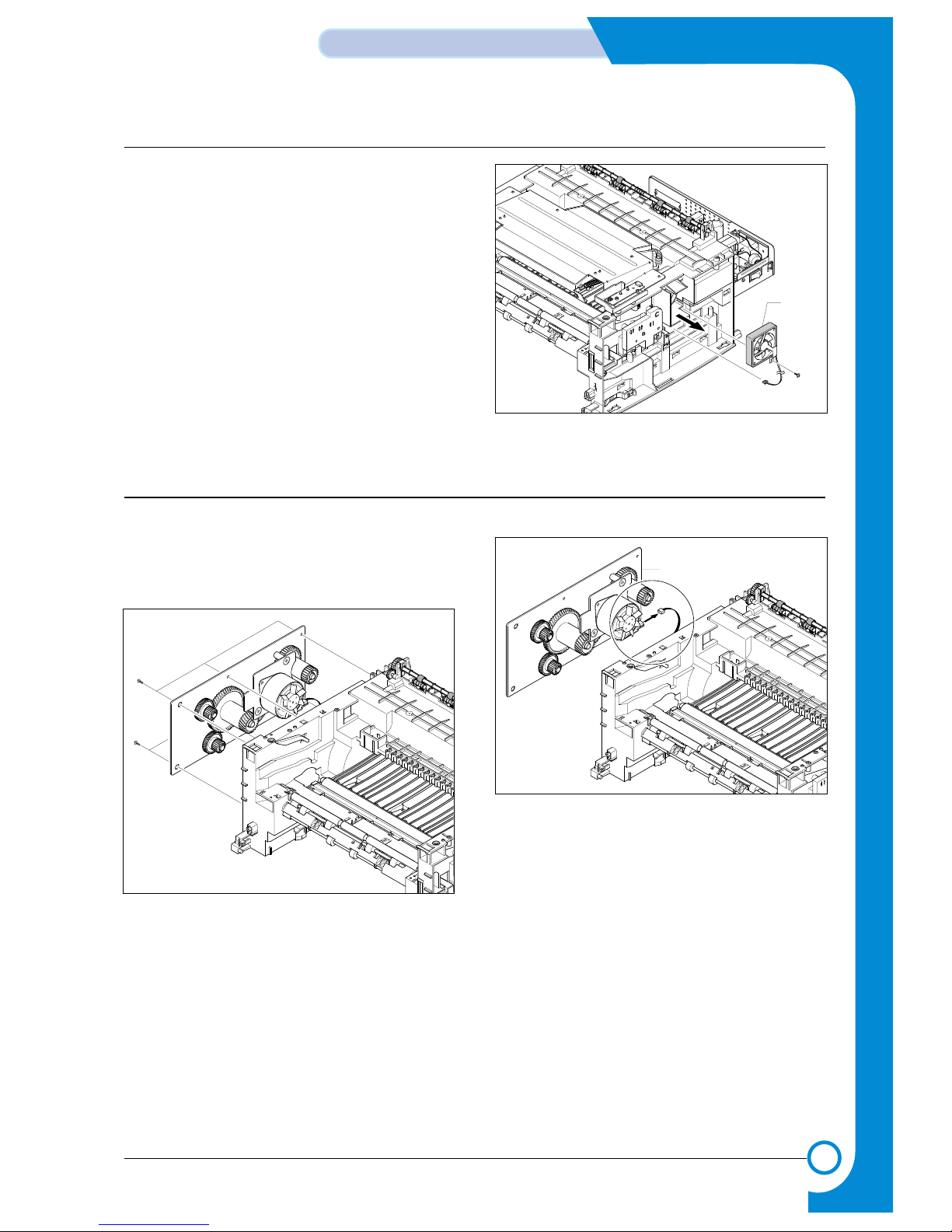

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

2. Unplug the connector from the SMPS and

remove the one screw. Then take out the Fan.

DC Fan

3.6 Fan

3.7 Driver Ass’y

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

2. Remove the six screws from the Drive Ass’y.

3. Unplug one connector from the Driver Ass’y

Drive Ass'y

Page 16

3-6

Disassembly and Reassembly

Service Manual

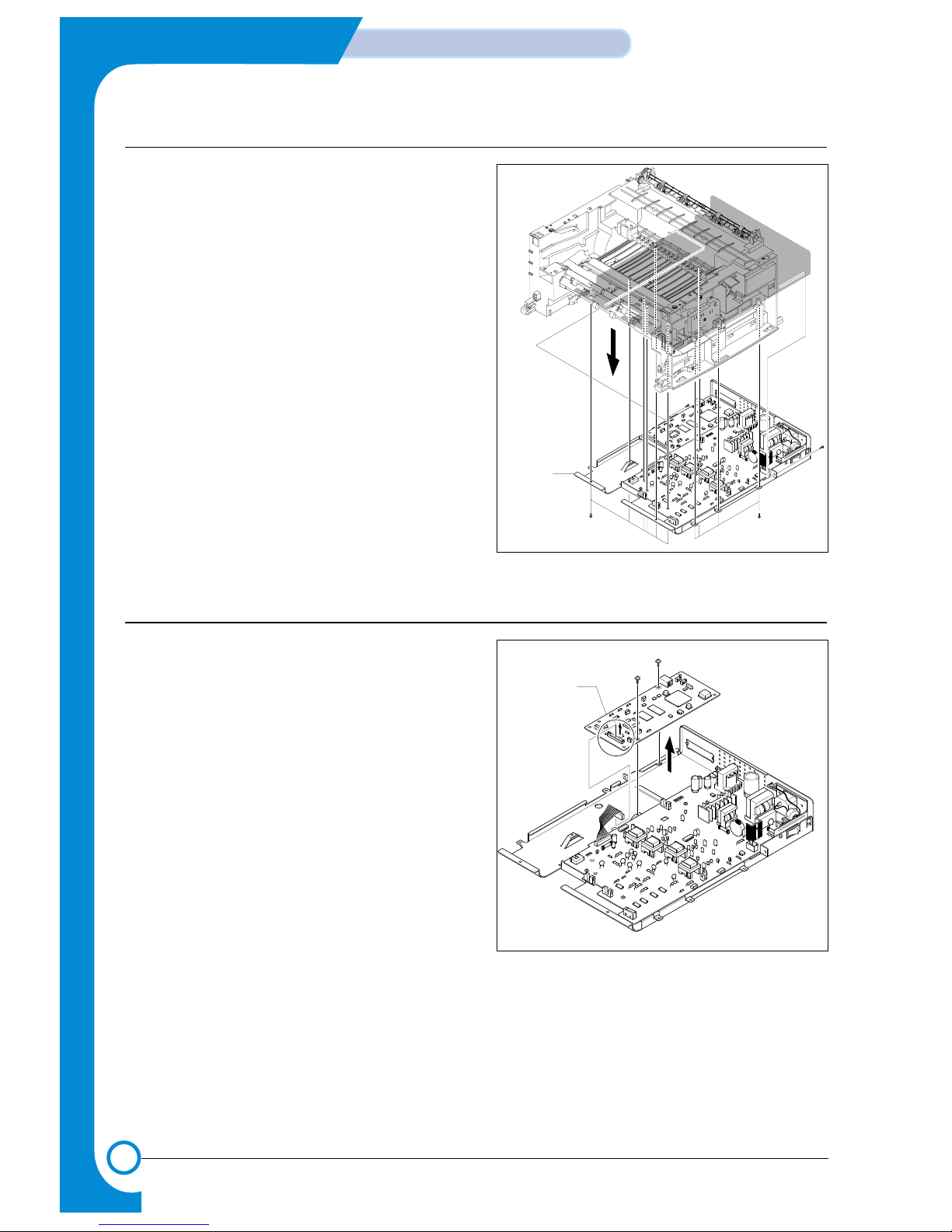

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

- Fuser Connector(see page 3-3)

2. Remove the fourteen screws securing from the

Engine Shield Ass’y and unplug the all connectors. Then take the Engine Shield Ass’y.

Engine Shield

Ass'y

3.8 Engine Shield Ass’y

3.9 Main PBA

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

- Engine Shield Ass’y(see page 3-6)

2. Unplug one connector and remove five screws

from the Main PBA. Then lift the Main PBA out,

as shown below.

Main PBA

Page 17

3-7

Disassembly and Reassembly

Service Manual

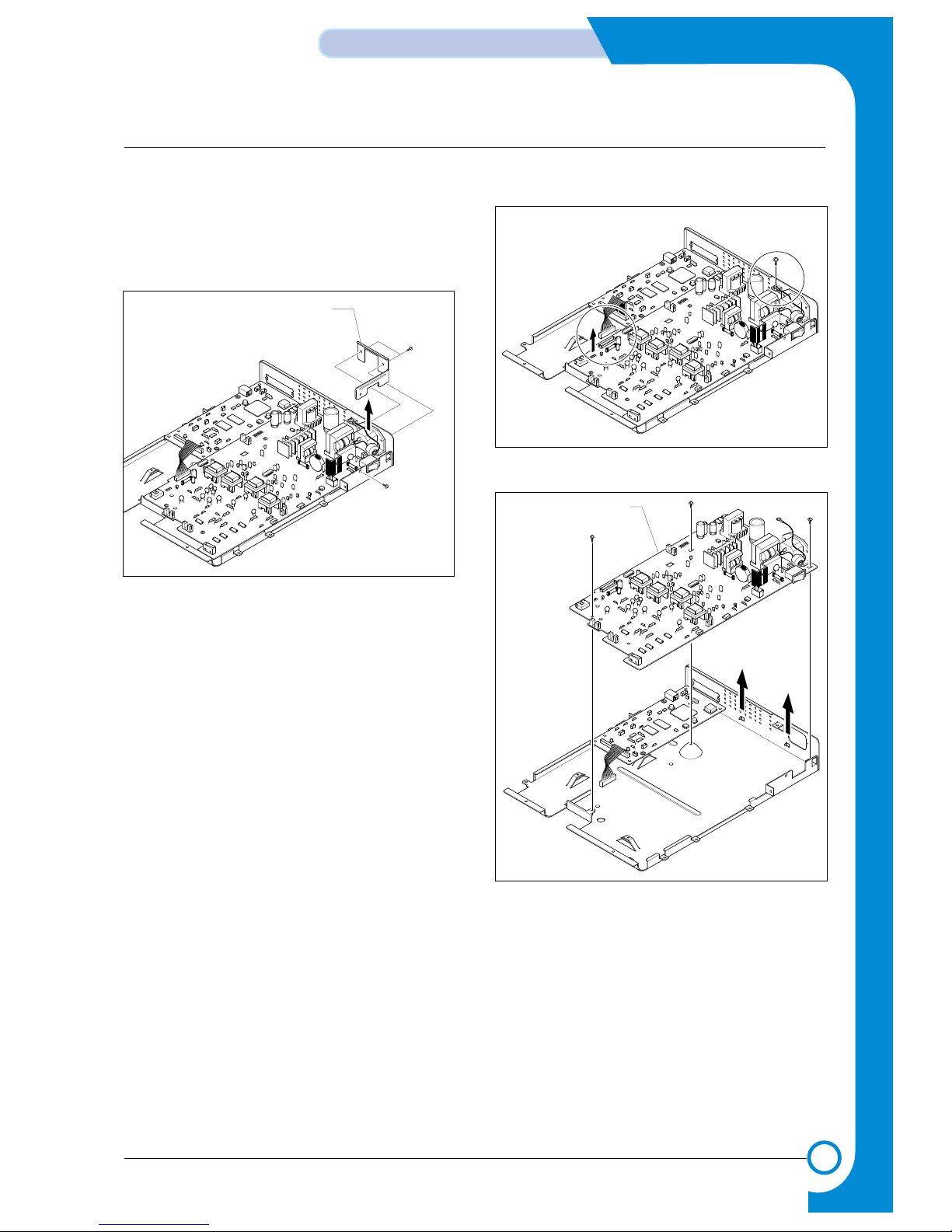

3.10 SMPS

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

- Engine Shield Ass’y(see page 3-6)

2. Unplug one connector and remove three screws

then take the Inlet Ass’y out.

3. Remove one screw and unplug one connector

from the Main PBA.

4. Remove three screws and take The SMPS out.

Inlet Bracket

SMPS

Page 18

3-8

Disassembly and Reassembly

Service Manual

3.11 Transfer Roller

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

- LSU(see page 3-4)

2. Remove three screws and take the Transfer

Earth out.

3. Unplug the PTL Holder Connector, then remove

the PTL Holder and PTL Lens, as shown below.

4. Unlatch the Bush and remove it. Then lift the

Transfer Roller out, as shown below.

Transfer

Earth

PTL

Holder

PTL

Lens

Transfer

Roller

Bush

Page 19

5-11

Disassembly and Reassembly

Service Manual

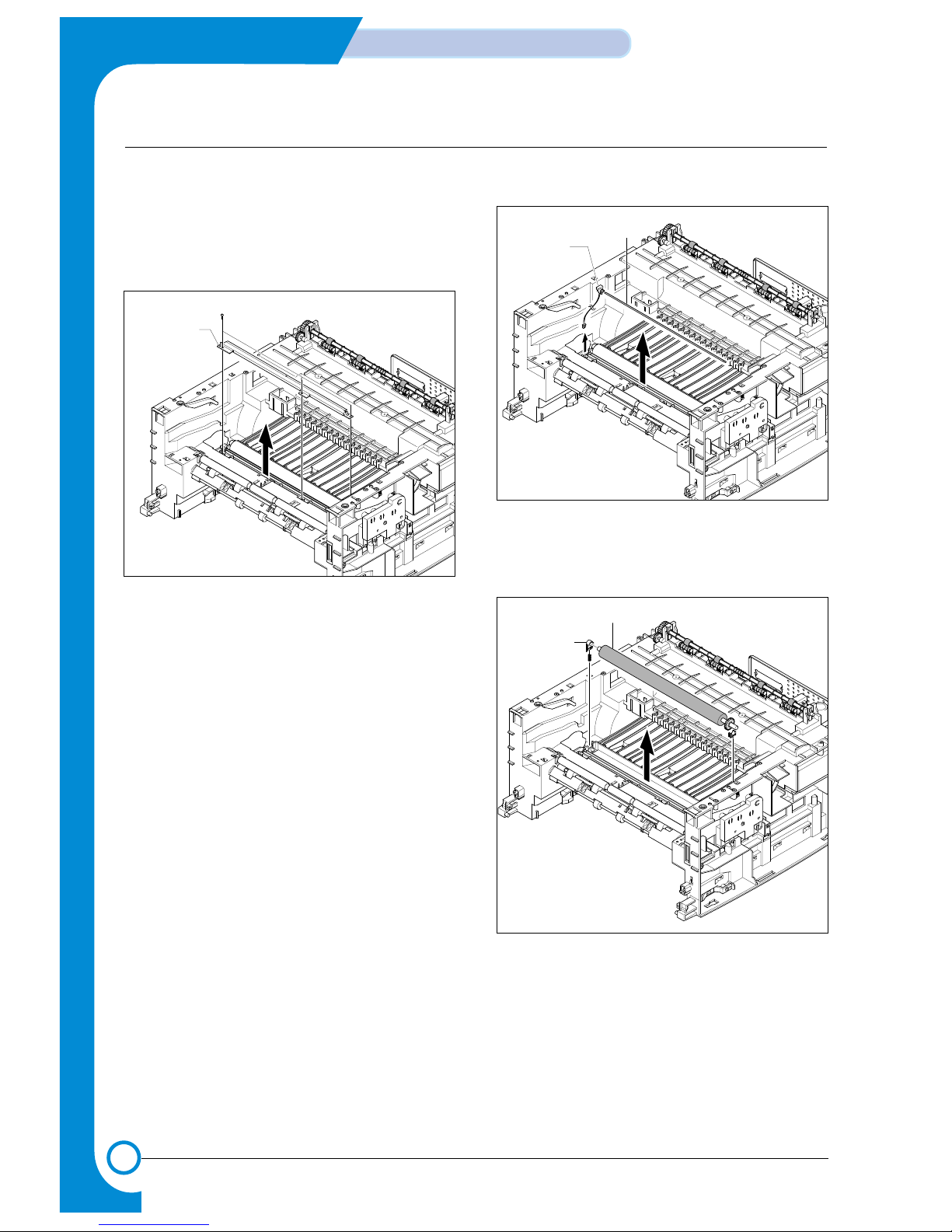

3.12 Feed Roller

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 5-2)

- Drive Ass’y(see page 5-7)

2. Remove two screws from the Guide Paper and

take it out.

3. Pull up the Feed Idle Bush and Feed Idle Shaft,

as shown below.

4. Remove three screws from the Feed Bracket

and take it out.

5. Remove the Idle Gear and Feed Gear2.

6. Remove the Feed Gear 1 Ass’y, as shown

below.

7. Remove the Feed Roller and Feed Roller 1, as

shown below.

Guide paper

Bush

Feed Idle

Shaft

Feed Bracket

Feed Gear2

Idle Gear

Feed Gear1

Ass'y

Feed Roller1

Feed Roller

Page 20

3-10

Disassembly and Reassembly

Service Manual

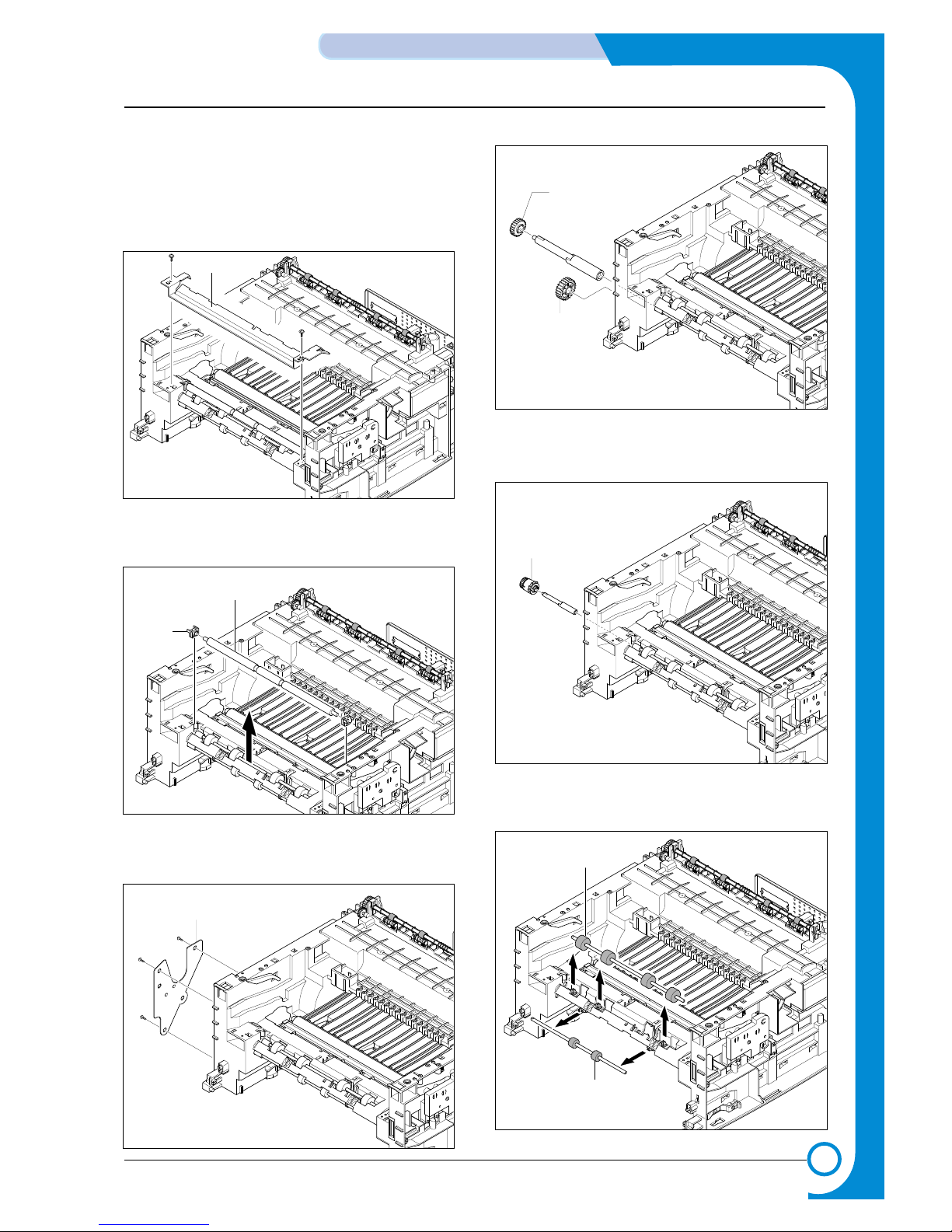

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

- Drive Ass’y(see page 3-5)

- Engine Shield Ass’y(see page 3-6)

2. Remove the Pick up Gear Ass’y, as shown

below.

3. Remove the Pick up Ass’y, as shown below.

Pick up Gear

Ass'y

Pick up Ass'y

1

2

Bush

3.13 Pick Up Roller

3.14 Solenoid

1. Before you remove the Fuser, you should

remove:

- Top Cover(see page 3-2)

- Drive Ass’y(see page 3-5)

- Engine Shield Ass’y(see page 3-6)

- Pick Up Roller(see page 3-10)

2. Remove two screw then remove The Manual

Solenoid and Pick Up Solenoid.

(Pick up)

Solenoid

(Manual)

Solenoid

Page 21

4-1

TROUBLESHOOTING

Service Manual

4

4

4. Troubleshooting

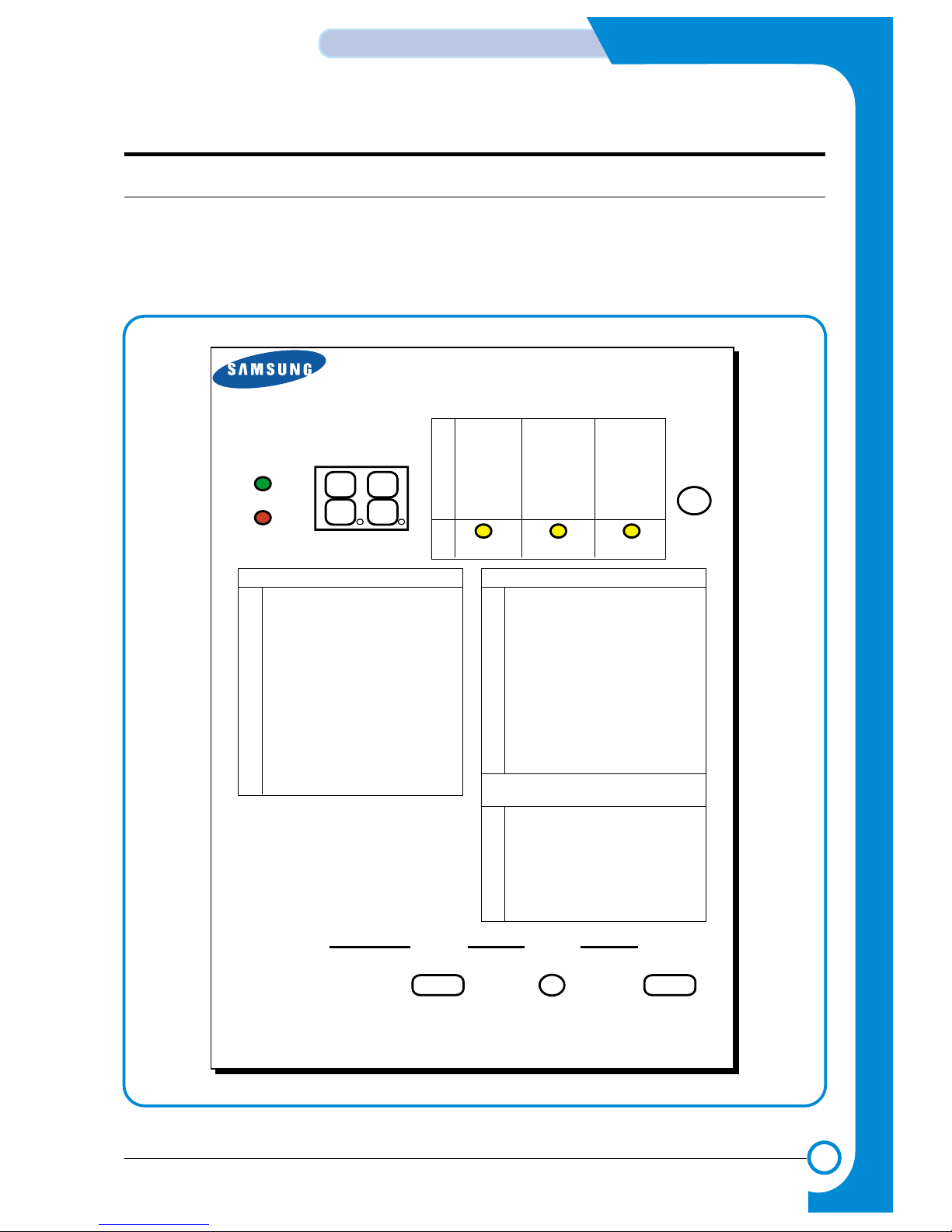

4.1 How to use DCU

4.1.1 DCU Setup

You can examine the malfunction of the printer. To perform DCU, open the front discharge cover and leave

the connect the harness wire(10 pin/4 pin) to the CN10(4 pin) of the Main control board.

ML SERIES DIAGNOSTIC CONTROL UNIT

04

05

07

08

09

10

DEV 300

LSU READY

PAPER EMPTY

COVER OPEN

COER HEATING

DEV 350

LSU MT & LD

PAPER WIDTH

EXIT SENSOR

PRINTING TEMP

DEV 350

LSU MOTOR

NEW CRU

FEED SENSOR

READY HEAT

ON

OFF

STATUS

SELF

TEST

DIAGNOSTIC

DIAGNOSTIC CODE

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

61

00

01

02

03

04

20

30

40

50

69

60

62

68

64

70

71

72

73

95

MAIN MOTOR OPERATING SYSTEM

MAIN HIGH-VOLTAGE ON

TRNSFER HIGH-VOLTAGE (-)ON

THV(+) REFERANCE VOLTAGE

DEV/SUPPLY HIGH-VOLTAGE ON/PTL ON

LSU OPERATING SYSTEM

PICKUP CLUTCH ON

PEEMPTY/PWITH/NEW CRU TEST

FEED & EXIT SENSOR TEST

COVER OPEN SENSOR TEST

FUSER TEST

HOT BURN TEST

CLEAN MODE PRINT

THV(+)TRIGGER, ALL HV & FAN ON

THV(+) REFERENCE ON

ERROR STATUS CODE

STATUS CODE

WARM UP

READY (REGAL)

READY (LETTER)

READY (A4)

READY (EXECUTIVE)

READY (B5)

PRINT START

FEED SENSOR ON

FEED SENSOR OFF

PAPER OUT

SLEEP MODE

OPEN FUSER ERROR

LOW TEMPERATURE ERROR

OVER HEATING ERROR

COVER OPEN ERROR

NO PAPERR

PAPER JAM 0

PAPER JAM 1

PAPER JAM 2

LSU NOT READY

DIAGNOSTIC

MODE

DOWN

UP ENTER

SHIFT STOP

TO ENTER DIAGNOSTIC MODE, PUSH THREE BUTTONS SIMUL ANEOUSL

AND TURN THE PRINTER POWER ON.

Page 22

4-2

TROUBLESHOOTING

Service Manual

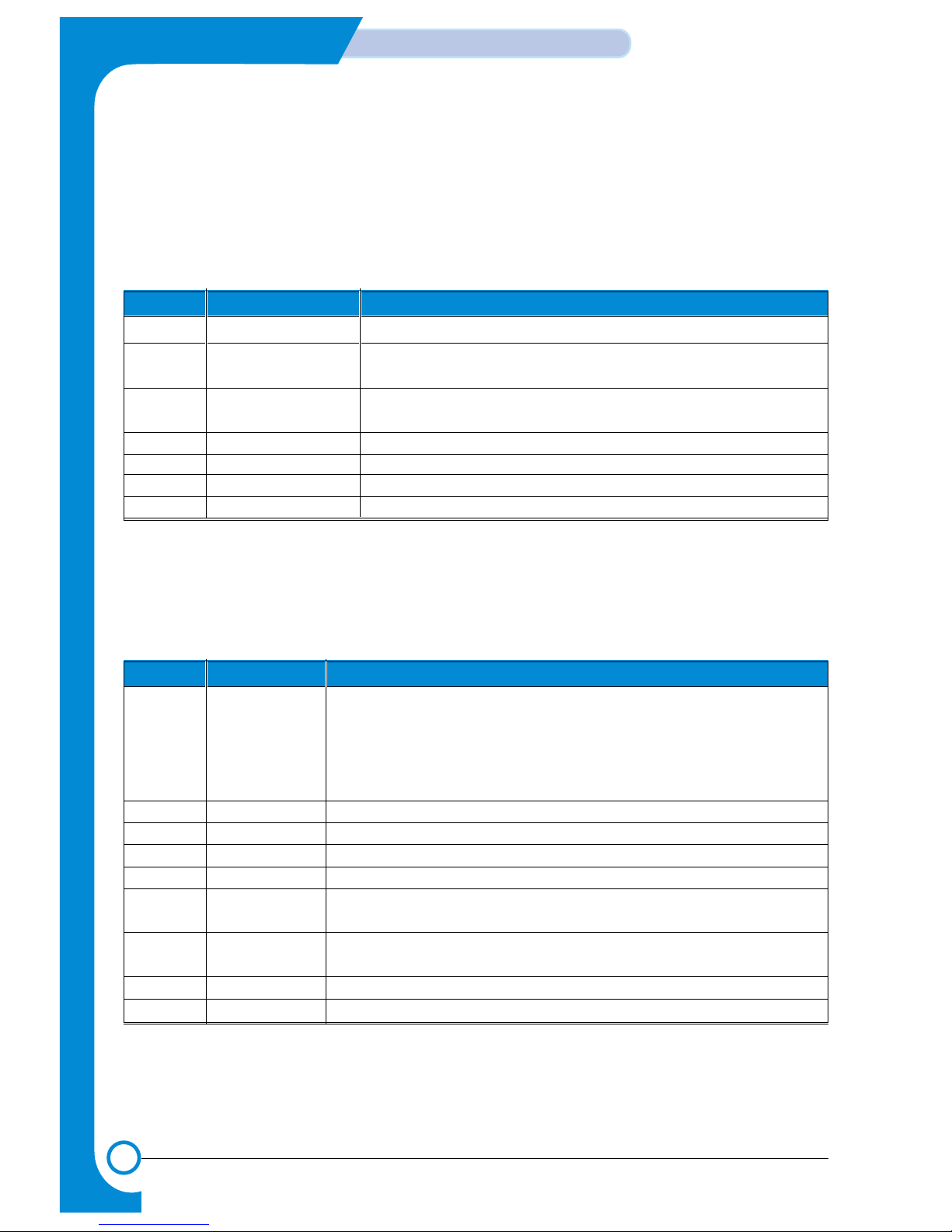

4.1.2 Code

Connect DCU to the printer and turn the power on. It show 7 Segment FND on the panel and each code

tells the function of the printer.

1) Normal Code

While printing or warming up, it indicate the position of the paper

2) Error Code

When detecting the malfunction, the printing is stopped to indicate error code.

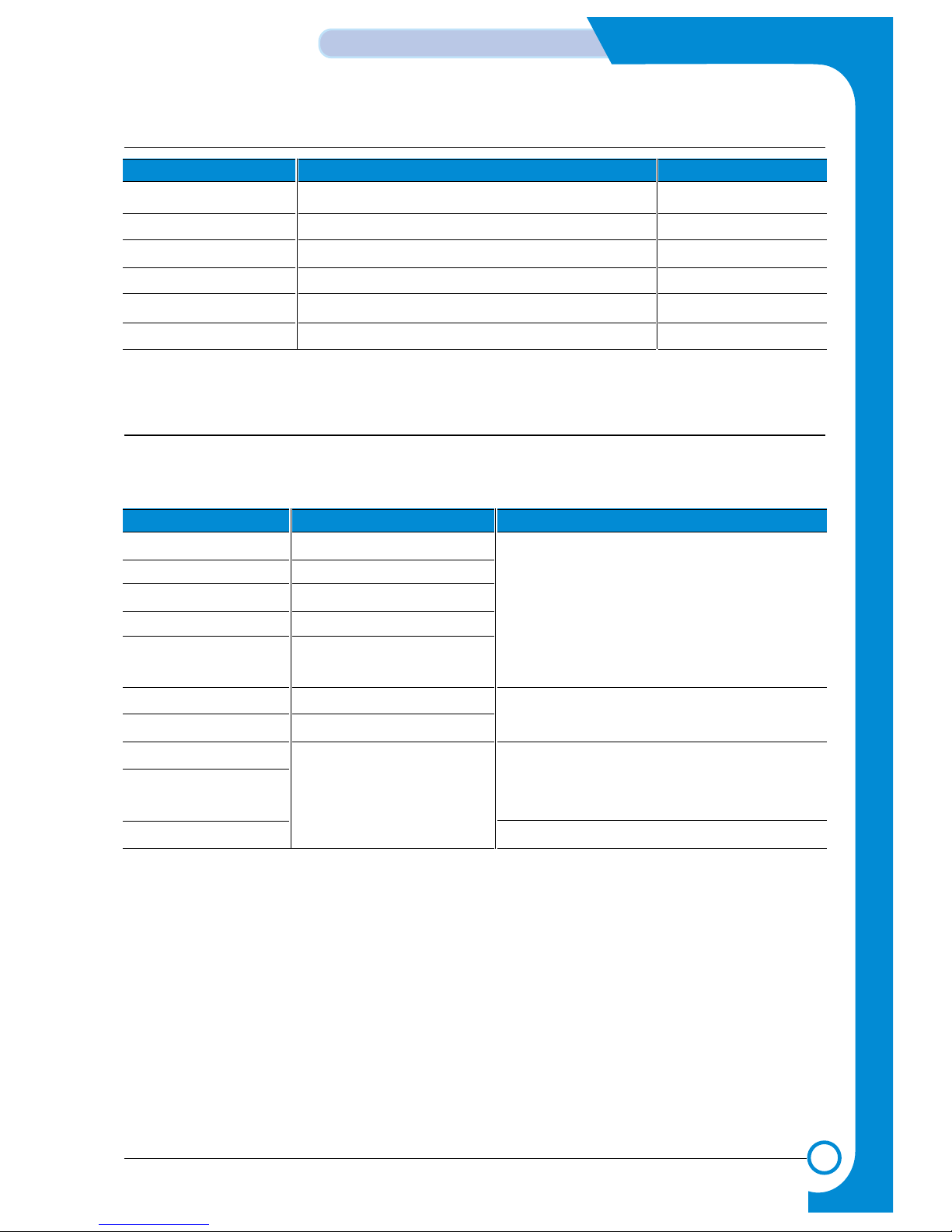

Code State Description

61 Warm up The printer is on, the cover is open or close.

00~05 Ready(kind of paper) The printer is ready, the paper is detected when the first paper is printed.

00: Legal ,01: Letter ,02: A4 ,03: EXEC ,04: B5 ,05: Folio, 06: A5/A6

20, 21, 22 Print Start The engine controller received the print order from the video controller.

20: 1st, 21: MP, 22: SCF

30 Feed Sensor On The paper is passing out of the Feed Sensor.

40 Feed Sensor off The paper has passed out of the Feed Sensor.

50 Paper Out The paper has passed out of Exit Sensor.

69 Sleep Mode The fuser power turned off to minimize the power consumption.

Code State Description

60, 62, 68 Fuser Error The error in the fuser occurred. There is a short circuit in the thermistor

and the thermostat while printing, Low Temperature Error occurs.

• 60: Open Fuser Error

• 62: Low Heat Error

• 68: Over Heat Error

64 Cover Open The Printer Cover is open.

65 CRU Error The Toner Cartridge not installed,

70 No Paper No paper in the paper cassette.

71 Paper Jam 0 The front part of paper is jammed between pickup unit and Feed sensor.

72 Paper Jam 1 The front part of paper is jammed between the Discharge sensor and

Feed sensor.

73 Paper Jam 2 The front part of paper is jammed just after passing through the discharge

sensor.

76 Out Bin Full The Out bin is filled with paper.

95 LSU Not Ready LSU Scanner Motor not ready or Hsync signal not output.

Page 23

4-3

TROUBLESHOOTING

Service Manual

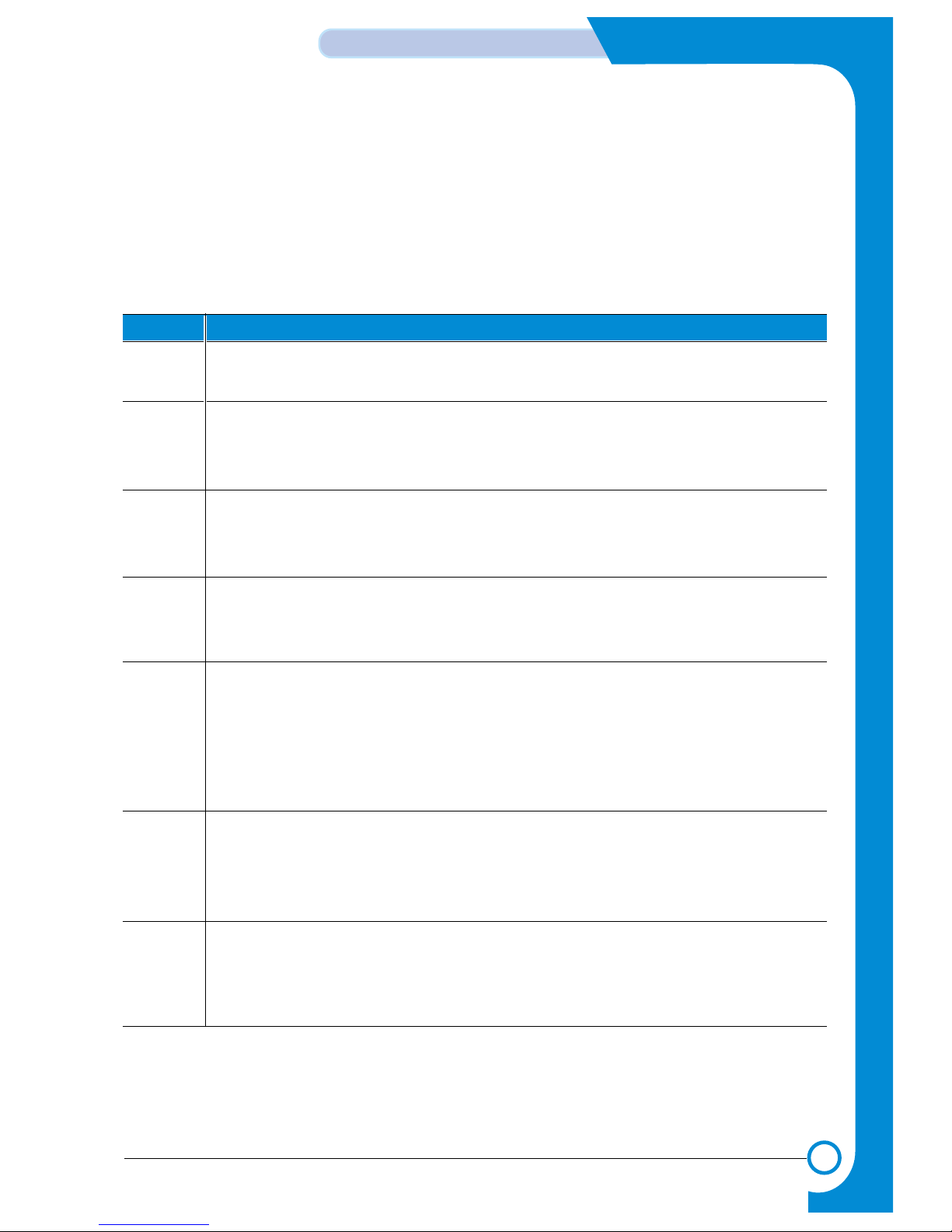

4.1.3 Self Diagnostic Mode

If Error code occurs due to malfunction of the printer, perform Self Diagnostic Mode to solve the problem.

The printer works only in the self-test mode to solve the malfunction problem.

To enter the self-test mode, turn the power on pressing the buttons of [Down], [Shift] and [Stop] at the same

time.

Release the button within 2 or 3 seconds if 78 shows in the DCU. If 00 shows in the DCU, press the button

[Up] or [Shift] to select the self+test , and press the button of [Enter] to operate. To stop, press the button of

[shift] and [Enter] together.

Code Description

00 Main Motor Operating System

Only the main motor is in operation.

01 Main High Voltage On(THV-)

-1400 voltage output by MHV terminal.

Caution : High voltage probe should be used.

02 Transfer High Voltage(-)On(THV-)

-1000 voltage output by MHV terminal.

Caution : High voltage probe should be used.

03 Transfer High Voltage (+)Reference on (THV +)

+800 voltage output by MHV terminal.

Caution : High voltage probe should be used.

04 DEV/supply High Voltage : DEV/Supply High Voltage Test.

The left one of the three LEDs in the self-test panel is on when DEV high voltage Supply

high voltage output by each HV terminal(-500V). Press the [Up] button to switch the voltage. The middle and right one of the three LEDs are on and -650 voltage output by DEV

HV terminal.

Caution : High voltage probe should be used.

05 LSU Operating System

The scanning motor of LSU is in operation, the right LED of the three buttons on. Press

the [Up] button to Check LD. LD is functioning and the middle button is on. If the LD is

normal, all LEDs are on.

06 Pickup clutch on

The Solenoid in the printer is in operation. To stop the operation, Press the button [shift]

and [Enter] together.

Page 24

4-4

TROUBLESHOOTING

Service Manual

Code Description

07 Paper Empty Sensor Test :

If activate the Actuator of the PEMPTY Sensor, the left and right of the three LEDs are

on.

Paper Empty Sensor ON/OFF 1st LED ON/OFF

08 Feed & Exit Sensor Test

Test the Feed sensor and Discharge sensor in the same way as '07'.

Feed Sensor ON/OFF 2nd LED ON/OFF

Exit Sensor ON/OFF 3rd LED ON/OFF

09 Cover Open Sensor Test

Test the Cover Open Sensor in th same way as code '07’

Cover Open Sensor ON/OFF 1st LED ON/OFF

10 Fuser Test

If the [Enter] button pressed, the right LED is on and temperature of the fuser is up to

READY Mode. If the [Up] button pressed, the middle LED is on and temperature of the

fuser is up to Printing Mode.

If you press the button once more, the left LED is on and temperature of the fuser is up

to overheat Mode.

11 Hot Burn Test

If the [enter] button pressed, the printer is continuously printing without detection.

Turn the power off to stop operation.

12 Cleaning Mode Print Mode

Print the paper to clean the OPC Drum in the Cartridge.

13 THV(+) TRIGGER. ALL HV :

All high voltage output by each HV terminal and LSU and the fan is in operation. In this

mode, electronic resistance of transfer roller and high voltage is detected.

14 PTL Test :

Indicates the function of the PTL, same method of the code ‘07’.

15 Fan Test :

Indicates the function of the Fan, same method of the code ‘07’.

16 Manual Pickup Test :

Indicates the function of th Manual Pickup, same method of the code ‘07’.

17 Manual Sensor Test :

Indicates the function of the Manual Sensor, same method of the code ‘07’.

Page 25

4-5

TROUBLESHOOTING

Service Manual

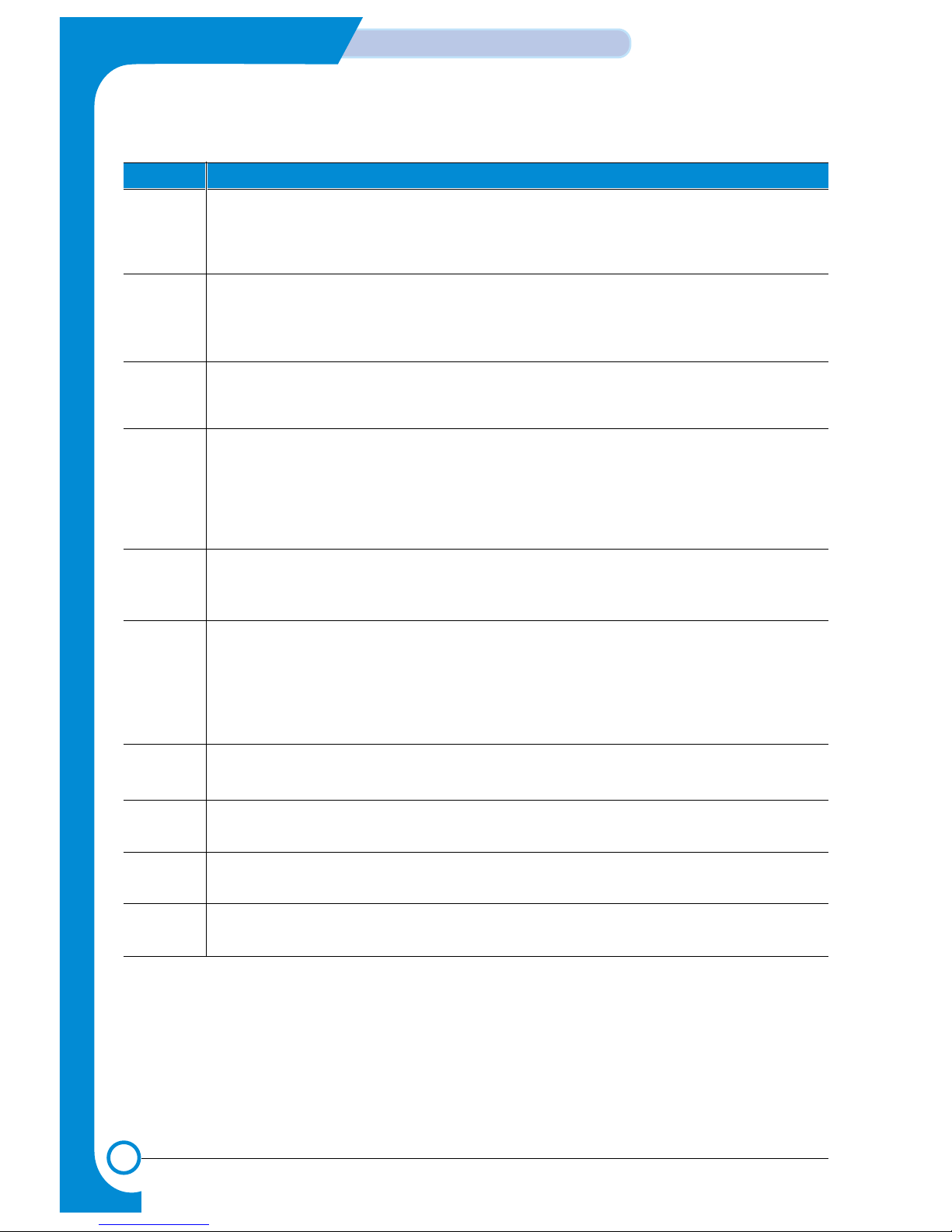

4.1.4 Self Test Button

If the Self-Test button pressed, vertical lines are printed.

Turn the power on while pressing this button, '89' shows in the DCU and the printer is warming up. After

warming-up the printer is in READY Mode, and '88' shows in the DCU. In this mode, without any detection,

the printer begins printing(trial printing and data from the PC). It is convenient to use this mode when the

engine malfunction is detected in the control board.

No. Function Enter Up/ Dow n Stop Remark

00

Mot or

Motor Run Motor Stop

01

MHV

Mhv On Mhv Off -1550V

02

THV(-)

Thv Negative On Thv Negative Off

03

THV(+)

Thv On Thv Off +1300V

04

DEV

Dev On

Supply DEV

Dev Of f

0:-630V 0:-430V

05

LSU

LSU Run

On Off Ready

LSU Stop

06

PickUp

Pickup On Pickup Off

07

PEmpty

Paper Empty

08

Sensor

Exi t Feed

09

Cover

Cover Open

10

Fuser

Fuser On Fuser Off

11

HotB urn

HotBurn O n

12

Clean Print

Clean Printing

13

Thv

Ref erence

low adequate high

14

PTL

PTL On PTL Off

15

FAN

Fan On Fan Off

16

Man ual

PickUp

Manual Pickup On Manual Pickup Off

17

Man ual

Sensor

Manual Sensor

Page 26

4-6

TROUBLESHOOTING

Service Manual

4.2 Bad image

4.2.1 Vertical Black Line and Band

• Description

1. Straight thin black vertical line occurs in the printing.

2. Dark black vertical band occur in the printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Damaged develop roller in the Developer.

Deformed Doctor-blade or cleaningblade.

2. Scratched surface of the discharge roller

in the developer.

3. Partly depression or deformation on the

surface of the transfer roller.

1. If causes 1 and 2 occur in the developer

cartridge, replace the developer and try to

print out.

2. Replace the transfer roller if occurred as

No. 3.

4.2.2 Vertical White Line

• Description White vertical voids in the image.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Foreign matter stuck onto the window of

internal lenses of LSU mirror.

2. Foreign matter or toner particles between

the developer roller and blade.

(In case the life of the developer has

been expired, white lines or light image

occur in front of the image.)

3. It may occur when Burr and foreign substances are on the window of the developer frame.

4. If the fuser is defective, voids occur periodically at the top of a black image.

1. Foreign matter stuck onto the window :

Clean the LSU window with recommended cleaner(IPA) Clean the window with a

clean cotton swab.

2. Foreign matter in the LSU : Open the

cover of LSU and clean with a cotton

swab on the surface of the reflex mirror.

3. No 3. : Remove the foreign matter and

burr of the exposure window.

(Developer cartridge)

4. No. 4. : Open the front cover and check

ribs that corresponds to the position of

the voids. Remove if found.

5. If the problems are not solved, replace

the developer cartridge.

Page 27

4-7

TROUBLESHOOTING

Service Manual

4.2.3 Horizontal Black Band

• Description

1. Dark or blurry horizontal stripes occur in the printing periodically.

(They may not occur periodically.)

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Bad contacts of the voltage terminals to

developer.

2. The rollers of developer may be stained.

Charge roller = 37.7mm

Supply roller = 37mm

Develop roller = 35.3mm

Transfer roller = 45.3mm

1. Clean each voltage terminal of the Charge,

Supply, Develop and Transfer roller.

(remove the toner particles and paper particles)

2. Clean the right Gear that has relatively

small gap of the teeth in the OPC.

3. If the malfunction persists, replace the

developer.

4.2.4 Black/White Spot

• Description

1. Dark or blurry black spots occur periodically in the printing.

2. White spots occur periodically in the printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. If dark or blurry black spots occur periodically, the rollers in the Developer may be

contaminated with foreign matte or paper

particles.

( Charge roller : 37.7 mm interval

OPC drum : 75.5 mm interval)

2. If faded areas or voids occur in a black

image at intervals of 75.5 mm, or black

spots occur elsewhere, the OPC drum

surface is damaged.

3. If a black image is partially broken, the

transfer voltage is abnormal or the transfer roller's life has expired.

1. Run OPC cleaning Mode Print and run the

Self-test 2 or 3 times.

2. In case of 75.5 mm interval unremovable in

1, cleanly remove foreign substances stuck

on the OPC location equivalent to black

spots and white spots with a dry duster.

3. The transfer roller guarantees 60.000

sheets printing. If the roller's life is expired,

replace it.

4. In case of 37.7 mm interval unremovable in

1, take measures as to replace the developer cartridge and try to print out.

5. Clean the inside of the set against the paper

particles and foreign matter in order not to

cause the trouble.

Page 28

4-8

TROUBLESHOOTING

Service Manual

4.2.5 Light Image

• Description The printed image is light, with no ghost.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Develop roller is stained when the toner

of developer cartridge is almost consumed.

2. Ambient temperature is below than 10°C.

3. Bad contact caused by the toner stains

between the high voltage terminal in the

HVPS and the one in the set.

4. Abnormal output from the HVPS.

1. Check if the Toner Save mode is off.

2. R

eplace the developer cartridge and try to

print out.

3. Wait 30 minutes after printer is powered on

before you start printing.

4. Clean up the contaminated area by the

toner.

5. Replace the HVPS if the problems are not

solved by the above four directions.

4.2.6 Dark Image or a Black

• Description The printed image is dark.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. No charge voltage in the engine board.

( Perform DCU diagnostic code 01)

2. Charge voltage is not turned on due to

the bad contacts between power supply

in the side of the Developer and charge

terminal of HVPS.

1. Clean the high voltage charge terminal.

2. Check the state of the connector which

connects the engine board and HVPS.

3. Replace the HVPS if not solved by the

above direction 1 and 2.

Page 29

4-9

TROUBLESHOOTING

Service Manual

4.2.7 Uneven Density

• Description Print density is uneven between left and right.

Check and Cause Solution

1. The pressure force on the left and right

springs of the transfer roller is not even,

the springs are damaged, the transfer

roller is improperly installed, or the transfer roller bushing or holder is damaged.

2. The toner level is not even on the developer roller due to the bad blade.

1. Replace both the left and right Spring

Holder.

2. Occur in the developer cartridge, replace

the developer and try to print out.

4.2.8 Background

• Description Light dark background appears in whole area of the printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1.

Does character exist less than 2%

per a page, and hasn’t it been used

long time?

2.

Does recycle paper be used?

3.

Has the life span of the developer

ended?

4.

Is the movement(Up and Down) of

the transfer roller smooth?

5. Is the HVPS normal?

1.

The toner cartridge is basically

designed to print 3,000 sheets with

5% image. If it prints more than

3,000 sheets (around 5,000 sheets)

with 2% image, a background can be

occurred.

2.

The B/S is not guaranteed if using

recycle paper.

3.

Replace the developer when the life

span of it has been ended.

4.

Clean the bushing part of the transfer

roller.

5. If the problem is still not solved,

replace the developer.

Page 30

4-10

TROUBLESHOOTING

Service Manual

4.2.9 Ghost (1)

• Description Ghost occurs at 75.5 mm intervals of the OPC drum in the whole printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

75.5mm

Check and Cause Solution

1. Bad contacts caused by contamination

from toner particles between high voltage

terminal in the main body and the electrode of the Developer.

2. Bad contacts caused by contamination

from toner particles between high voltage

terminal in the main body and the one in

the HVPS board.

3. The life of developer is expired.

4. Transfer roller lifetime(60.000 sheets) has

expired.

5. Abnormal low temperature(below 10°C).

1. Clean the terminals when contaminated by

toner particles.

2. Occur in the developer cartridge, replace

the developer and try to print out.

3. Replace the engine board if not solved by

the above directions 1-2.

4. If not solved by the direction 3, check the

transfer roller lifetime and replace it.

5. Wait about 1 hour after power on before

using printer.

4.2.10 Ghost (2)

• Description

Ghost occurs at 75.5 mm intervals of the OPC drum in the whole printing.

(When printing on card stock or transparencies using manual feeder)

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

75.5mm

Check and Cause Solution

When printing on card stock thicker than normal paper or transparencies such as OHP,

higher transfer voltage is required.

Select 'Thick Mode' on paper type menu from

the software application and after using returning to the original mode is recommended.

Page 31

4-11

TROUBLESHOOTING

Service Manual

4.2.11 Ghost (3)

• Description White ghost occurs in the black image printing at 32mm intervals.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

37mm

Check and Cause Solution

1. The life of the developer may be expired.

2. The abnormal voltage and bad contact of

the terminal of the supply roller

1. Occur in the developer cartridge, replace

the developer and try to print out.

2. Check the approved voltage of the supply

roller and contact of the terminal and adjust

if necessary.

4.2.12 Ghost (4)

• Description Ghost occurs at 47 mm intervals.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

47mm

Check and Cause Solution

The temperature of the fuser is maintained

high.

1. Disassemble the fuser and remove the

contaminated toner particles on the roller

and clean the foreign matter between

Thermistor and Heat roller.

( Caution : can be deformed)

4.2.13 Satins on the Face of Page

• Description The background on the face of the printed page is stained.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Toner leakage due to improperly sealed

developer.

2. If the transfer roller is contaminated, satins

on the face of page will occur.

1. Replace the developer cartridge.

2. If the transfer roller is contaminated, run PC

Cleaning Mode Print 2 or 3 times.

And perform Self-Test 2 or 3 times to

remove contamination.

Page 32

4-12

TROUBLESHOOTING

Service Manual

4.2.14 Satins on Back of Page

• Description The back of the page is stained at 47 mm intervals.

Digital

Digital Pri

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Transfer roller is contaminated.

2. Pressure roller is contaminated.

1. Perform the OPC Cleaning Mode Print 2 or

3 times. Run Self-Test to remove the contamination of the transfer roller.

2. Replace the transfer roller if contaminated

severely.

3. Disassemble the fuser and clean the

H/R(Heat Roller) and P/R(Pressure roller).

And check the area between H/R and

Thermistor. If contaminated, clean the area

not to be deformed.

4.2.15 Blank Page Print out (1)

• Description Blank page is printed.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

Bad ground contacts in OPC and/or developer.

Remove contamination of the terminals of the

developer and the unit.

4.2.16 Blank Page Print out (2)

• Description

1. Blank page is printed.

2. One or several blank pages are printed.

3. When the printer turns on, several blank pages print.

Check and Cause Solution

1. Bad ground contacts in OPC and/or

developer.

2. Abnormal solenoid.

1. Remove contamination of the terminals of

the developer.

2. Perform the engine self test using DCU to

check

if the Solenoid is normal.(refer to code 06)

3. If not solved by the above directions 1-2,

Replace the engine board.

4. Turn the power off, delete the data of PC

and try printing again.

Page 33

4-13

TROUBLESHOOTING

Service Manual

4.3.1 Wrong Print Position

• Description Printing begins at wrong position on the paper.

Check and Cause Solution

Wrong sense time caused by defective feed sensor

actuator.

Replace the defective actuator

Check and Cause Solution

1. Check the Solenoid by using DCU diagnostic mode

06.

2. Check if the pad is loose due to bad sealing of the

side-pad.

3. Check the surface of the roller-pickup for foreign matter.

4. If the paper feeds into the printer rand Jam 0 occurs,

perform DCU to check feed-sensor of the engine

board.

1. Replace the solenoid.

2. Replace the side-pad Assembly Lor R, if necessary.

3. Clean with soft cloth dampened with IPA(Isopropyl

Alcohol) or water.

4. Replace the SMPS-HVPS and/or Sensor.

4.3.2 JAM 0

• Description

1. Paper is not exited from the cassette.

2. Jam-0 occurs if the paper feeds into the printer.

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

4.3 bad discharge

Page 34

4-14

TROUBLESHOOTING

Service Manual

Check and Cause Solution

1. If the recording paper is jammed in front of or inside

the fuser. (Perform DCU diagnostic code 08)

2. If the recording paper is stuck in the discharge roller

and the fuser just after passing through the ActuatorFeed, Feed Actuator may be defective.

1. Replace the SMPS.

2. Reassemble the Actuator-Feed and Spring-Actuator

if the returning is bad.

4.3.3 JAM 1

• Description

1. Recording paper is jammed in front of or inside the fuser.

2. Recording paper is stuck in the discharge roller and in the

fuser just after passing through the Actuator-Feed.

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Check and Cause Solution

1. If the paper is completely fed out of the printer, but Jam

2 occurs : Exit sensor is defective.

• After the paper is completely discharged, actuator

Exit should return to the original position to shut the

photo-sensor. Sometimes it takes longer hour than it

should and does not return.

2. If the paper is rolled in the Fuser Roller:

• This occurs when a Guide claw is broken away or

transformed.

• It occurs when the Spring of a Guide claw is broken

away or transformed.

• It occurs when the Heat-Roller or Pressure-Roller is

seriously contaminated with the toner.

3. Paper is accordion in the fuser.

1. Check if the exit sensor actuator is defective.

• Check if the actuator exit is unformed (Check if the

lever part is unformed in shape).

• Check whether burrs occur in the assembly part of

the actuator exit or not and if the actuator is

smoothly operated.

• Check if foreign matters and wire get caught in the

actuator exit's operation.

2. If the paper is stuck in the fuser : disassemble the

fuser and remove the jammed paper, and clean the

surface of the pressure roller with dry gauze.

3. Remove the jammed paper after disassembling the

fuser : Clean the surface of the pressure roller with

dry gauze.

• Remove the toner particles stained on the rib.

• Check the assemblage and performance of the exit.

4.3.4 JAM 2

• Description

1. Recording paper is jammed in front of or inside the fuser.

2. Recording paper is stuck in the discharge roller and in the

fuser just after passing through the Actuator-Feed.

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Page 35

4-15

TROUBLESHOOTING

Service Manual

4.3.5 Multi-Feeding

• Description Multiple sheets of paper are fed at once.

Check and Cause Solution

1. Solenoid malfunction(the solenoid does not work

properly): Perform DCU Diagnostic Code 06.

2. Pad-Friction is contaminated with foreign matter.(oil...)

3. The face of paper is blended.

1. Replace the solenoid if necessary.

2. Clean the pad friction with soft clothe dampened

with IPA(Isopropyl Alcohol).

3. Use the smooth paper.

4.3.6 Paper rolled in the Fuser

• Description If contaminated at intervals of 57mm on the back of a paper.

Check and Cause Solution

1.

Contamination of the pressure roller or heat

roller (Background, Hot off set).

2.

Check the claw of the fuser whether it is unfitted.

1.

After disassembling the fuser, clean contamination between the heat roller and the thermostor and remove the contamination of the

pressure roller.

2.

If there is heavy background, repair it by the

background troubleshooting method.

3. The surface of the heat roller with IPA or

water

4. Check the warp or separation of the sprint

claw and the holder plate claw, and then manage it.

Page 36

4-16

TROUBLESHOOTING

Service Manual

4.3.7 Paper rolled in the Toner Cartridge (OPC Drum)

• Description Paper is rolled up in the OPC.

Check and Cause Solution

1. Paper is too much thin.

2. The face of paper is curled.

1. Recommend to use normal paper.

2. How to remove the rolled in the OPC Drum.

• Remove the paper while turning the OPC

Drum against the ongoing direction.

• C;eam fomger[romts on the OPC Drum

spft;u with IPA(Isopropyl Alcohol) or tissue.

Page 37

4-17

TROUBLESHOOTING

Service Manual

4.4 Malfunction

4.4.1 All LEDs blinking (Fuser Error)

• Description

1. All the lamps on the operator panel blink.

2. Gear of the fuser does not work and breaks away melt away.

When printing, motor breaks away from its place due to defective fuser gear.

Check and Cause Solution

1. Check if the thermostat, AC wire and Heat Lamp is

open.

2. Check if the thermistor sensor is in place.

3. Check if the heat lamp works properly.

4. Check if the overheat circuit works properly.

5. The fuser gear is defective due to melting away.

1. If the thermostat is open replace the fuser and

check following items.

2. If the thermistor sensor device is located deep in the

sponge, replace the fuser.

3. Check if the circuit of overheat mode works properly.

4. Run DCU mode : Perform DCU diagnostic code 10.

5. Replace Fuser.

4.4.2 All LEDs blinking (Scan Error)

• Description

1. All lamps on the operator panel blink.

Check and Cause Solution

DCU Mode : Perform DCU diagnostic code 05. If the DCU

error code 95 is displayed, replace LSU.

Replace LSU.

If you cannot solve the problem after you replace LSU,

replace the main board.

Page 38

4-18

TROUBLESHOOTING

Service Manual

4.4.3 Not function of the gear of the fuser due to melting away

• Description

The motor breaks away from its place due to gear melting away.

Check and Cause Solution

DCU Mode : Check if the Error States '60' '62' '68' occur.

Check the operation of Fuser Erasing Lamp

On/Off with the Error Code Check -10-.

1. Replace the Fuser.

2. Replace the Main Control board.

4.4.4 Paper Empty

• Description

The paper lamp on the operator panel is on even when paper is loaded in the cassette.

Check and Cause Solution

1. Bending or deformation of the actuator of the paper sensor.

2. The function of the engine board is defective Perform

DCU mode : Perform DCU diagnostic code 8.

1. Replace the defective actuator.

2. Replace the engine board.

4.4.5 Paper Empty without indication

• Description

The paper lamp on the operator panel does not come on when the paper cassette is empty.

Check and Cause Solution

1. Bending or deformation of the actuator of the paper sensor.

2. The function of the engine board is defective Perform.

DCU mode : Perform DCU diagnostic code 8.

1. Replace the defective actuator.

2. Replace the engine board.

Page 39

4-19

TROUBLESHOOTING

Service Manual

4.4.6 Cover Open

• Description

The ERROR lamp is on even when the print cover is closed.

Check and Cause Solution

1. The Hook Lever in the top cover may be defective.

2. Check the connector (Engine B’d↔HVPS) and circuit of

the cover switch department in the Main Control board.

Perform DCU mode : If Error state '64' occurs, Check the

related codes of the Cover Open Error.

1. Replace the hook lever, if defective.

2. Check the insertion of the Cover Open S/W

Connect.

3. Replace the Main Control board or Cover Open

S/W.

4.4.7 No lamp on when the cover is open

• Description

The ERROR lamp does not come on even when the printer cover is open

Check and Cause Solution

1. Check the connector(CN8) and circuit of the cover switch

department in the Main Control board. Perform DCU

mode : If Error state '64' occurs, Check the related codes

of the Cover Open Error

1. Check the insertion of the Cover Open S/W

Connect.

2. Replace the Main Control board or Cover Open

S/W.

Page 40

4-20

TROUBLESHOOTING

Service Manual

4.4.8 Defective motor operation

• Description

Main motor is not driving when printing, and paper does not feed into the printer, resulting 'Jam 0'.

Check and Cause Solution

1. Motor harness or sub PCB may be defective.

2. Perform DCU diagnostic code 00 and Check the motor

operation.

1. Check the motor harness, replace it, if defective.

2. Replace the SMPS, if necessary.

4.4.9 No Power

• Description

When system power is turned on, all lamps on the operator panel do not come on.

Check and Cause Solution

1. Check if the power input and SMPS output are normal.

2. Check the inferiority of LED-Panel on the front-cover if

the LED of Panel does not appear after normal warmingup.

1. Replace the power supply cord or SMPS.

2. Replace the control board.

3. Replace the LED-panel.

Page 41

4-21

TROUBLESHOOTING

Service Manual

4.4.10 Vertical Line Getting Curved

• Description

When printing, vertical line gets curved.

Check and Cause Solution

1. If the supply of +24v is unstable in the Main Control board

linking with LSU, check drive by DCU Mode : LSU Check

-05- LSU Motor on.

1. Replace LSU.

2. Replace the Main Control board.

Page 42

4-22

TROUBLESHOOTING

Service Manual

4.5 Toner Cartridge Service

It is not guaranteed for the default caused by using other toner cartridge other than the cartridge supplied

by the Samsung Electronic or caused by non-licensed refill production.

4.5.1 Precautions on Safe-keeping of Toner Cartridge

Excessive exposure to direct light more than a few minutes may cause damage to the cartridge.

4.5.2 Service for the Life of Toner Cartridge

If the printed image is light due to the life of the toner, you can temporarily improve the print quality by

redistributing the toner(Shake the toner cartridge), however, you should replace the toner cartridge to solve

the problem thoroughly.

4.5.3 Redistributing Toner

When toner is low, faded or light areas may appear on a printed page. You may be able to temporarily

improve the print quality by redistributing the toner. The following procedures may allow you to finish the

current print job before replacing the toner cartridge.

1) Grasp the front cover and pull it toward you to

open.

2) Remove the toner cartridge from the printer

3) Gently shake the toner cartridge from side to side

five or six times to redistribute the toner.

4) Reinsert the toner cartridge into the printer.

Ensure that the toner cartridge snaps into place.

5) Close the front cover. Make sure that the cover is

securely closed.

1.7

Note :

Avoid reaching too far into the printer. The fusing

area may be hot.

To prevent damage to the toner cartridge, do not

expose it to light for more than a few minutes.

Note :

If the toner gets on your clothing, wipe it off with a dry

cloth and wash clothing in cold water. Hot water sets

toner into fabric.

Page 43

4-23

TROUBLESHOOTING

Service Manual

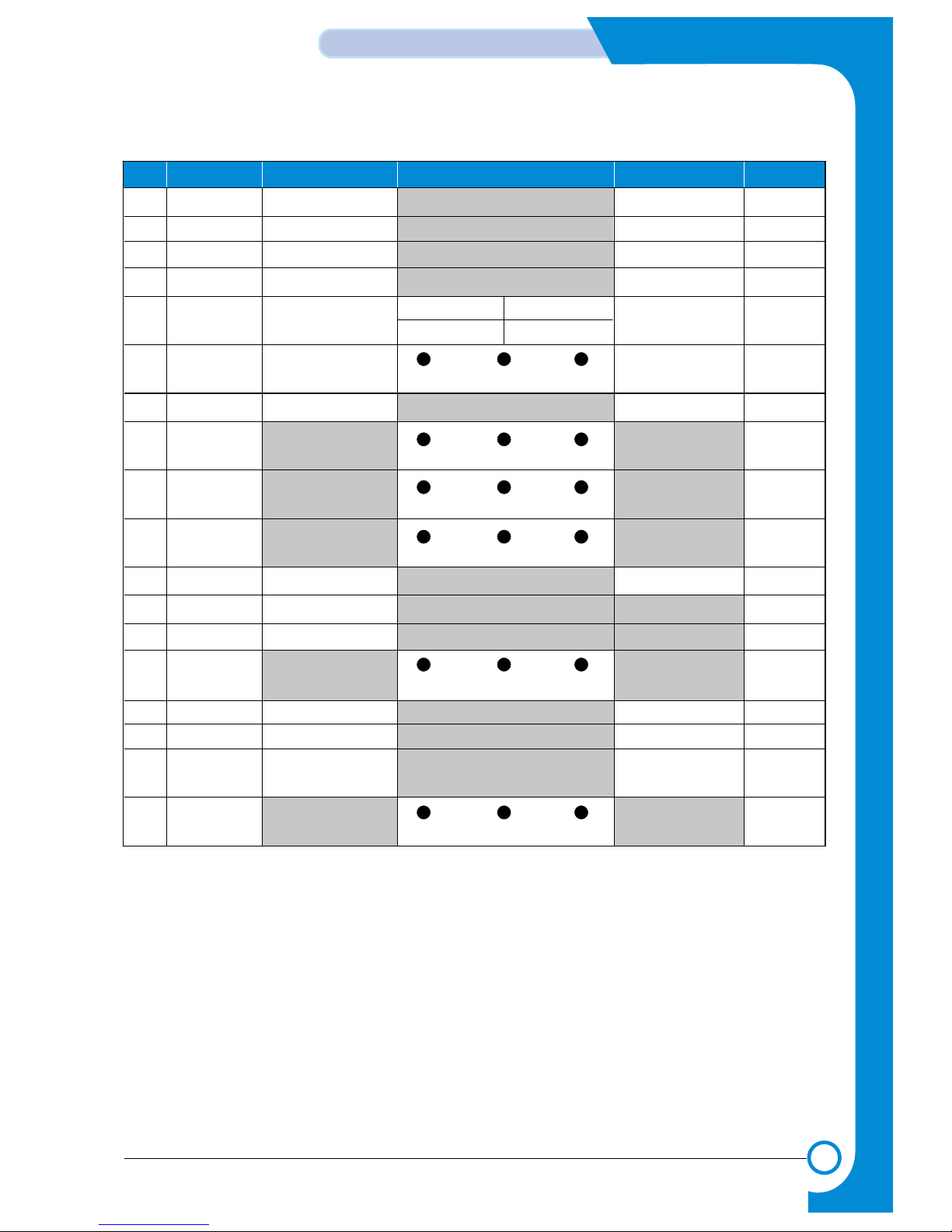

4.5.4 Signs and Measures at Poor toner cartridge

Fault Signs Cause & Check Solution

Light image and

partially blank

image

(The life is ended.)

T oner

Contamination

• The printed image

is light or unclean

and untidy.

• Some part of the

image is not printed.

• Periodically a noise

as "tick tick" occurs.

• Toner is fallen on

the papers periodically .

• Contaminated with

toner on prints partly or over the whole

surface.

1. If the image is light or unclean

and untidy printed image Shake the developer and

then recheck.

(1)NG : Check the weight of

the developer

(2)OK : Lack of toner, so the

life is nearly closed.

2. Some part of image is not

printed - Shake the developer and then recheck.

(1)NG : Check the weight of

the developer and

clean the LSU window

with a cotton swab,

then recheck.

(2)OK : Lack of toner, so the

life is nearly closed.

3. Periodically a noise as "tick

tick" occurs - Measure the

cycle and the weight of the

developer.

4. White vertical stripes on the

whole screen or partly :

Check the weight of the

developer.

1. Toner is fallen on the paper

periodically .

(1)Check the cycle of the

falling of the toner.

(2)Check the appearance of

both ends of the developer

OPC drum.

2.The center of the printed mat-

ter is contaminated with toner.

(1)Check whether foreign sub-

stances or toner are stuck

to the terminal (contact

point) of the developer.

(2)Check whether the state of

the terminal assembly is

normal.

1. All of 1, 2, 3 aboveIf it become better by shaking,

replace with a new developer

after 35.3-100 sheets in the

closing state of the life span.

2. In case of 2-

If it becomes better after cleaning the LSU window, then the

developer is normal.

(Because of foreign substance

on the LSU window, the image

has not been printed partly.)

3. In case of 3-

If the cycle of noise is about 2

seconds, the toner inside the

developer has been nearly

exhausted.( Purchase and

replace with a new developer

after using about 200 sheets at

the point of occurrence)

4. In case of 3-

This is a phenomenon caused

by lack of toner, so replace with

a new developer.

1. If both ends of the OPC drum

are contaminated with toner:

Check the life of the developer.

2. Check whether it could be recycled.

3. If it cannot be recycled:

Replace the developer.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 44

4-24

TROUBLESHOOTING

Service Manual

Fault Signs Cause & Check Solution

White Black spot

Recycled product

• Light or dark black

dots on the image

occur periodically.

• White spots occur

in the image periodically .

• Poor appearance of

the developer.

• Unclean and rough

printouts.

• Bad background in

the image.

1. If light or dark periodical black

dots occur, this is because the

developer rollers are contaminated with foreign substance

or paper particles.

(1)37.7mm interval : Charged

roller

(2)75.5mm interval : OPC cycle

2. If white spots occur in a black

image at intervals of 75.5mm,

or black spots occur elsewhere, the OPC drum is damaged or foreign substance is

stuck to the surface.

3. If a black and white or graphic

image is partially broken at

irregular intervals, the transfer

roller's life has been expired or

the transfer voltage is abnormal.

1. Poor appearance of the developer.

(1)Check the damage to label

and whether different materials are used.

(2)Check the appearance of

parts of the developer, such

as frame, hopper.

2. Unclean and rough printouts.

(1)Check whether foreign sub-

stance or toner are stuck to

the terminal (contact point) of

the developer.

(2)Check whether the state of

the terminal assembly is normal.

1. In case of 1 above Run OPC Cleaning Mode Print

4-5 times repeatedly to remove.

Especially check foreign substance on the OPC surface, then

remove them with a clean gauze

moistened with IPA(Isopropyl

Alcohol) not to damage OPC if

necessary .

Never use usual alcohol.

2. In case of 2

If they are not disappeared by

running OPC Cleaning Mode

Print 4-5 times.

:

at intervals of 37.7mm

- Replace

the developer.

: at intervals of 75.5mm - Remove

foreign substance.

: Broken image - Replace the

developer according to carelessness.

3. In case of 3 - Exchange the

transfer roller because the life of

the transfer roller in use has been

expired. (Check the transfer voltage and readjust if different.)

1. In case of 1 -

(1)If there is an evidence of disas-

sembling the developer.

(2)If materials other than normal

parts of the developer are

added or substituted.

2. In case of 2 - If there are any

abnormals in connection with the

situation of 1.

(1)It occurs when the developer

is recycled over 2 times.

(2)If toner nearly being expired

are collected to use, it is

judged as the recycled developer.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 45

4-25

TROUBLESHOOTING

Service Manual

4.6 Bad Environment of The Software

4.6.1 The printer is not working (1)

• Description

While Power turned on, the printer is not working in the printing mode.

Check and Cause Solution

1. Run Self-Test Mode : Turn the power on while pressing

the test printing button for 2 or 3 seconds before printing

works.

2. Check if the PC and the printer is properly connected

and the toner cartridge installed.

3. Printing is nor working in the Windows.

4. Check if the printer cable is directly connected to peripheral devices

1.Check the power of the printer and perform the SelfTest. If the test printing works, that means no problems in the printer itself. If the test printing does not

work, that means bad functioning of the printer(not

because of software). Perform DCU to check the

Error Status.

2. Replace the printer cable. If the problems not solved

even after the cable replaced, check the amount of

the remaining tone.

(refer to Toner Cartridge Service 7.4)

3. Check if the connection between PC and printer port

is proper. If you use windows, check if the printer dri ver in the controller is set up. If the printer driver is

properly set up, check in which program the printing

is not working. The best way to find out is to open the

memo pad to check the function of printing. If it is not

working in a certain program, adjust the setup the

program requires. Sometimes, the printout is normal

within the Windows basic programs, but it's not working in a particular program. In such case, install the

new driver again. If not working in the Windows basic

program, Check the setup of the port of CMOS is on

ECP. And check the address of IRQ 7 and 378

4. If the scanner needs to be connected to the printer,

first the remove the scanner from the PC to see if the

printer is properly working alone.

Page 46

4-26

TROUBLESHOOTING

Service Manual

4.6.2 The printer is not working (2)

• Description

After receiving the printing order, no response at all or the low speed of printing

occurs due to wrong setup of the environment rather than malfunction of the printer itself.

Check and Cause Solution

1. Secure more space of the hard disk.

2. Printing error occurs even if there is enough space in

the hard disk.

3. Check the parallel-port-related items in the CMOS

Setup.

4. Reboot the system to print.

1. Not working with the message 'insufficient printer

memory' means hard disk space problem rather than

the RAM problem. In this case, provide more space

for the hard disk. Secure more space using the disk

utilities program.

2. The connection of the cable and printer port is not

proper. Check if the connection is properly done and

if the parallel port in CMOS is rightly set up.

3. As a printer port, Select ECP or SPP among

SPP(Normal), ECP, and EPP modes(increase printing speed) SPP normal mode support 8-bit data

transfer, while ECPMode transfer the 12-bit data.

4. If the regular font is not printing, the cable or the

printer driver may be defective.

Turn the PC and printer off, and reboot the system

to print again. If not solved, double-click the printer in

my computer If the regular fonts are not printed this

time again. the cable must be defective so replace

the cable with new one.

Page 47

4-27

TROUBLESHOOTING

Service Manual

4.6.3 Abnormal Printing

• Description

The printing is not working properly even when the cable has no problem.

(even after the cable is replaced)

If the printer won't work at all or the strange fonts are repeated, the printer driver may be defective or wrong setup in the CMOS Setup.

Check and Cause Solution

1. Set up the parallel port in the CMOS SETUP.

2. Printer Driver Error.

3. Error message from insufficient memory.

(The printing job sometimes stops or due to insufficient

virtual memory, but it actually comes from the insufficient space of the hard disk.)

1. Select SPP(Normal) or ECP LPT Port the among

ECP, EPP or SPP in the CMOS Setup.

2. Check the printer in My Computer.(to see if the

printer driver is compatible to the present driver or

delete

the old driver, if defective and reinstall the new

driver)

3. Delete the unnecessary files to secure enough

space of the hard disk and start printing job again.

Page 48

4-28

TROUBLESHOOTING

Service Manual

4.6.4 SPOOL Error

• Description

To spool which stands for "simultaneous peripheral operations online" a computer document or

task list (or "job") is to read it in and store it, usually on a hard disk or larger storage medium so

that it can be printed or otherwise processed at a more convenient time (for example, when a

printer is finished printing its current document).

Check and Cause Solution

1. Insufficient space of the hard disk in the directory

assigned for the basic spool.

2. If the previous printing error not solved.

3. When expected to collide with other program.

4. When an application program or the printer driver is

damaged.

5. When some files related to OS are damaged or virus

infected.

6. Memory is less than suggested one.

1. Delete the unnecessary files to provide more space

to start printing job.

2. If there are some files with the extension name of

****.jnl, Delete them and Reboot the Windows to

restart printing job.

3. Shut down all other programs except the current

one, if possible.

4. Delete the printer driver completely and reinstall it.

5 After rebooting the computer, check for viruses,

restore the damaged files and reinstall the program

to do the printing job.

6. Add up enough memory to the PC.

How to delete the data in the spool manager.

In the spool manager, the installed drivers and the list of the documents waiting to be printed are shown.

Select the document to be deleted and check the delete menu.

If you intend to delete the current document being printed, the data being transferred to the printer will be put

out and then the document is removed. Before choosing the document, the menu is still inactive.

Or put the document out of the list and repeat the routine as in the above or finish the spool manager.

Page 49

5

5

5-1

EXPLODED VIEWS AND PARTS LIST

Service Manual

5. Exploded Views and Parts List

5.1 Main Assembly Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page(5-2)

5.2 Frame Assembly Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page(5-4)

5.3 Drive Unit Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page(5-7)

5.4 Fuser Unit Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page(5-8)

5.5 Cassette Unit Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page(5-10)

Update on January .10.2003 by SEC

Page 50

5-2

EXPLODED VIEWS AND PARTS LIST

Service Manual

5.1 Main Assembly Exploded view

0

9

6

7

8

2-2

2-3

2-4

2-5

2-6

2-6

15-1

15-2

5

2-1

2-7

2-10

1

2

10

4

11-1

11

11-2

11-3

11-4

11-5

11-3

12

13

14-1

14-2

14-3

14

14-4

3

15

Page 51

5-3

EXPLODED VIEWS AND PARTS LIST

Service Manual

< Main Assembly Parts List >

SA. : Service Available

NO DESCRIPTION SEC CODE Q’TY SA REMARK

0 SET

1 ELA UNIT-FRAME LOWER, 110V, XRX JC96-02732A 1 O 110V

ELA UNIT-FRAME LOWER, 220V, XRX JC96-02734A 1 O 220V

2 ELA HOU-COVER TOP JC97-01748D 1 O

2-1 LENS LED-LED JC67-00026A 1 X

2-2 COVER-TOP JC63-00102A 1 X

2-3 COVER-REAR JC63-00101A 1 X

2-4 PMO-STACKER_RX JC72-00973A 1 X

2-5 PMO-BUSHING_F/DOWN JC72-00387A 1 X

2-6 PMO-SUB STACKER JC72-01001A 1 X

2-7 SPRING-KEY 6107-001169 1 X

2-8 KEY-ON LINE JC64-00039A 1 X

2-9 SCREW-TIPTITE 6003-000264 2 X

3 PLATE-P-CHANNEL JC61-00606A 1 O

4 CBF HARNESS-MOTOR JC39-00241A 1 O

5 FAN-DC JC31-00027A 1 O

6 UNIT-LSU JC59-00018A 1 O

7 PBA MAIN-P ANEL JC92-01439A 1 O

8 COVER PCB-M-PCB JC63-00104A 1 O

9 CBF HARNESS-LSU 1400 JC39-00242A 1 O

10 ELA HOU-RX DRIVE 1400 JC96-02733A 1 O

11 MEA UNIT-COVER FRONT, XEROX JC97-01748D 1 O P3120

MEA UNIT-COVER FRONT, XEROX JC97-01749K 1 O P3130

11-1 COVER-FRONT JC63-00103A 1 X

11-2 ADJUST-MANUALL JC70-00302A 1 X

11-3 ADJUST RACK-MANUAL JC70-00304A 1 X

11-4 GEAR-RACK_PINION JC66-00387A 1 X

11-5 ADJUST-MANUALR JC70-00303A 1 X

11-6 SCREW-TIPTITE 6003-000264 3 X

12 MEA ETC-CASSETTE 1400 TBD 1 O

13 PBA MAIN-CONTROLLER,GDI JC92-01426B 1 O P3120

PBA MAIN-CONTROLLER,PCL JC92-01424B 1 O P3130

14 MEA ETC-SHIELD ENGINE JC96-02663A 1 X

14-1 CBF HARNESS-ENGINE JC39-00240A 1 O P3120

CBF HARNESS-ENGINE, JC39-00240B 1 O P3130

14-2 SMPS-HVPS JC44-00046A 1 O 110V

SMPS-HVPS JC44-00047A 1 O 220V

14-3 BRACKET-INLET JC61-00601A 1 O

14-4 SHIELD-ENGINE JC63-00107A 1 O

14-5 SCREW-TIPTITE 6003-000264 6 X

14-6 SCREW-TIPTITE 6003-000119 2 X

14-7 SCREW-TIPTITE 6003-000301 1 X

15 TRANSFER ROLLER ASS’Y TBD 1 O

15-1 ROLLER-TRANSFER ROLLER JC66-00528A 1 X

15-2 GEAR-TRANSFER JC66-00395A 1 X

O: Service available X: Service not available

Page 52

5-4

EXPLODED VIEWS AND PARTS LIST

Service Manual

5.2 Frame Assembly Exploded view

0

1

2

4

3

5

6

7

12

6

9

53

9

51

13

14

15

16

17

57

18

19

20

20

21

22

23

24

25

26

37

31

27

28

29

29

30

58

58-1

58-2

58-3

58-4

58-5

58-6

58-6

58-4

40

41

56

42

44

53

45

46

47

48

59

59-1

59-2

59-3

59-4

50

52

52

54

55

11

10

8

35

36

Transfer Roller

38

60

39

43

32

34

33

49

49-3

49-2

49-1

Page 53

5-5

EXPLODED VIEWS AND PARTS LIST

Service Manual

< Frame Assembly Parts List >

SA. : Service Available

O: Service available X: Service not available

NO DESCRIPTION SEC CODE Q’TY SA REMARK

0 ELA UNIT-FRAME ASSY JC96-02732A 1 X

1 FRAME-Base JC61-00579A 1 X

2 GUIDE-TR JC61-00607A 1 X

3 PLATE-SA W JC61-00604A 1 X

4 GUIDE-TR RIB JC61-00594A 1 X

5 GEAR-EXIT F/DOWN JC66-00038A 1 X

6 MEC-BEARING,EXIT JC75-10529A 2 X

7 ROLLER-EXIT_F/DOWN JC66-00378A 1 X

8 SPRING-EXIT_F/DOWN 6107-001 163 1 X

9 PMO-GEAR_EXIT_DRV16 JC72-00143A 2 X

10 HOLDER-EXIT_F/DOWN JC61-00582A 4 X

11 PMO-ROLLER_EXIT ,MAIN JC72-41081A 4 X

12 PMO-ROLLER_EXIT ,FR JC72-41082A 4 X

13 MEC-TERMINAL JC75-00049A 4 O

14 IPR-TERMINAL CON JC70-00312A 3 X