Page 1

XEROX

Document FaxCentre 165

and

Document WorkCentre 165c

SERVICE MANUAL

Part Number : 602E48370

Page 2

Page 3

PREFACE

This manual is intended for service engineers responsible for installing, servicing and

repairing the facsimile machines described herein. The manual consists of thirteen

chapters which describe:

• Chapter 1: the General Features and Technical Specifications

• Chapter 2: the facsimile machine's Internal and external structure

• Chapter 3: the Installation and setup procedures

• Chapter 4: how to set the Software Parameters

• Chapter 5: the Diagnostic and testing procedures

• Chapter 6: the Settings and adjustments

• Chapter 7: the Maintenance and replacement procedures

• Chapter 8: the Optional devices

• Chapter 9: the Installation of the LinkFax 8 module in Windows 95

environment

• Chapter 10: the User Guide of the LinkFax 8 module in Windows 95

environment

• Chapter 11: the Installation of the LinkFax 8 module in Windows 3.1x

environment

• Chapter 12: the User Guide of the LinkFax 8 module in Windows 3.1x

environment

• Chapter 13: the Spares List

FIRST EDITION: April 1998

REFERENCES: User Manual

Page 4

CONTENTS

1. INTRODUCTION.................................................1-1

1.1 MAIN FEATURES.....................................................................1-1

1.2 TECHNICAL SPECIFICATIONS...................................................1-2

1.3 QUICK REFERENCE GUIDE.........................................................1-5

1.3.1 Sending a Fax......................................................................................1-5

1.3.2 Receiving a Fax....................................................................................1-5

1.3.3 Using the Facsimile Machine as a Photocopier ........................................1-5

2. GENERAL DESCRIPTION ....................................2-1

2.1 EXTERNAL PARTS...................................................................2-1

2.1.1 Console...............................................................................................2-2

2.1.2 Functions of the console keys ...............................................................2-3

2.2 ELECTROMECHANICAL PARTS.................................................2-6

2.2.1 Motors ................................................................................................2-6

2.2.2 Sensors ...............................................................................................2-7

2.2.3 Speaker...............................................................................................2-8

2.3 ELECTRONIC PARTS................................................................2-9

2.3.1 General Block Diagram .......................................................................2-10

2.3.2 Block Diagram of the Motherboard......................................................2-11

2.3.3 Block Diagram of the Network Control Unit Board ................................2-14

2.3.4 Block Diagram of the Power Supply Board ...........................................2-15

2.3.6 Printer Unit .......................................................................................2-17

3. INSTALLATION AND INITIALIZATION

PROCEDURES.....................................................3-1

3.1 PRELIMINARY OPERATIONS....................................................3-1

3.1.1 Unpacking the Facsimile Machine ..........................................................3-1

3.1.2 Connecting to the Telephone Line .........................................................3-2

3.1.3 Connecting the Power Cord ..................................................................3-4

3.1.4 Installing the Print Head.......................................................................3-4

3.1.5 Inserting the Output Trays ....................................................................3-9

3.1.6 Loading Paper ...................................................................................3-10

3.1.7 Feeding special papers manually on the LinkFax model .........................3-10

XEROX DFC165 & DWC165c Service Manual v

Page 5

3.2 INSTALLING AND SETTING UP THE MACHINE...........................3-12

3.2.1 Organization of the Installation and Setup Parameters ..........................3-12

3.2.2 Setting the Country Parameters ...........................................................3-15

3.2.3 Storing the User's Number and Name ..................................................3-16

3.2.4 Setting Up the Telephone Line ............................................................3-17

3.2.5 Completing Installation ......................................................................3-19

3.2.6 Resetting the Fax Machine ..................................................................3-19

4. SERVICE SWITCHES...........................................4-1

4.1 SERVICE SWITCH TABLES.......................................................4-3

5. DIAGNOSTICS....................................................5-1

5.1 SELF-DIAGNOSTICS ................................................................5-1

5.1.1 Description of the Self-Diagnostic Program ............................................5-2

5.2 ERROR CODES........................................................................5-3

5.2.1 Meaning of Protocol Signal Codes.........................................................5-4

5.2.2 Meaning of Error Codes ........................................................................5-6

5.2.3 Printing the Communication Protocol ....................................................5-9

5.2.4 Printing the Counters .........................................................................5-11

5.3 REPORTS .............................................................................5-12

5.3.1 Transmission Report (LAST TX REPORT) ..............................................5-12

5.3.2 Broadcast Transmission Report (LAST BROAD. REP.) .............................5-14

5.3.3 Activity Report (ACTIVITY REPORT) ....................................................5-14

5.3.4 Power Failure Report ..........................................................................5-15

5.4 REMOTE DIAGNOSTICS..........................................................5-16

5.4.1 Enabling the Facsimile Machine as a "Slave Station" .............................5-16

6. SYSTEM TEST AND ADJUSTMENTS.....................6-1

6.1 SYSTEM TEST .........................................................................6-1

6.1.1 ALIGNMENT TEST................................................................................6-2

6.1.2 NOZZLES TEST ...................................................................................6-4

6.1.3 CLEANING...........................................................................................6-6

6.1.4 PRINT CHART ......................................................................................6-7

6.1.5 ASF TEST ............................................................................................6-9

6.1.6 ADF TEST ...........................................................................................6-9

6.1.7 LOAD DEFAULT .................................................................................6-10

vi XEROX DFC165 & DWC165c Service Manual

Page 6

6.1.8 SCANNER SHADING ...........................................................................6-10

6.1.9 CARRIAGE TEST ................................................................................6-11

6.2 CHECKS AND ADJUSTMENTS..................................................6-12

6.2.1 Checking the Direct Voltages ..............................................................6-12

6.3 ADJUSTING THE CCD.............................................................6-13

6.3.1 Preparing for the CCD Adjustment.......................................................6-13

6.3.2 Checking the Alignment of the CCD Board ...........................................6-14

6.3.3 Checking the Lens Focus ....................................................................6-16

6.3.4 Checking that the Document and the CCD are centred ..........................6-17

7. MAINTENANCE AND REPLACEMENT

PROCEDURES.....................................................7-1

7.1 MAINTENANCE ........................................................................7-1

7.1.1 OUT OF INK Message ...........................................................................7-1

7.1.2 Replacing the rechargeable Ink Cartridge ...............................................7-2

7.1.3 Replacing the Print Head ......................................................................7-3

7.1.4 Cleaning the Print Head ........................................................................7-3

7.1.5 Cleaning the Electrical Contacts ............................................................7-4

7.1.6 Cleaning the Print Head Cleaning Pad ....................................................7-5

7.1.7 Cleaning the Optical Unit ..................................................................... 7-6

7.2 DISASSEMBLY AND REPLACEMENT PROCEDURES...................7-10

7.2.1 Wirings .............................................................................................7-10

7.2.2 Removing the Casing .........................................................................7-12

7.2.3 Removing the Power Supply/NCU Assembly ........................................7-13

7.2.4 Removing the Power Supply and NCU Boards ......................................7-15

7.2.5 Removing the Motherboard ................................................................7-16

7.2.6 Removing the Console .......................................................................7-18

7.2.7 Removing the Console Board ..............................................................7-19

7.2.8 Removing the Display .........................................................................7-19

7.2.9 Removing the Scanner Unit ................................................................7-20

7.2.10 Removing the CCD Board ...................................................................7-21

7.2.11 Removing the LED Array ....................................................................7-21

7.2.12 Removing the Printer Unit ..................................................................7-22

7.2.13 Removing the Carriage, Paper and Ink Drain Motors .............................7-23

7.2.14 Removing the Scanner Motor ..............................................................7-24

7.2.15 Removing the Print Carriage ...............................................................7-24

8. OPTIONAL DEVICES ...........................................8-1

8.1 SETTING UP A BACK TO BACK CONNECTION.............................. 8-2

XEROX DFC165 & DWC165c Service Manual vii

Page 7

8.2 CONNECTING A TELEPHONE ANSWERING DEVICE.......................8-2

8.3 CONNECTING A TELEPHONE EXTENSION.....................................8-3

8.4 HANDSET ...............................................................................8-4

9. INSTALLATION OF THE LINKFAX 8 MODULE

IN WINDOWS 95 ENVIRONMENT.......................9-1

10. USER GUIDE OF THE LINKFAX 8 MODULE

IN WINDOWS 95 ENVIRONMENT.....................10-1

11. INSTALLATION OF THE LINKFAX 8 MODULE

IN WINDOWS 3.1X ENVIRONMENT..................11-1

12. USER GUIDE OF THE LINKFAX 8 MODULE

IN WINDOWS 3.1X ENVIRONMENT..................12-1

13. SPARE PARTS LISTINGS.................................... 13-1

viii XEROX DFC165 & DWC165c Service Manual

Page 8

1. INTRODUCTION

The two models referred to in this manual are desktop facsimile machines with a

bubble ink jet printing system which complies with the ITU-TS G3 standard for document

transmission and reception.

The most suitable factor to distinguish between the two models, similar in appearance, is the possibility of using a monochrome print head only or both monochrome and

colour print heads.

The colour model, once connected to a PC equipped with the LinkFax 8 software

communication module, can be transformed into a multifunctional product able to

perform both printer and scanner functions in addition to the facsimile traditional

features. The colour print head must be used only for printing purposes. All standard

facsimile functions require a monochrome print head. In this manual, the two models

are referred to as follows:

standard model (monochrome) LinkFax model (colour)

1.1 MAIN FEATURES

• Bubble ink jet printing

The facsimile machine prints on plain paper (standard model) or special paper

(LinkFax model) in various formats (A4, Letter, Legal).

• Memory capacity

The facsimile machine has a memory which enables operations such as Onetouch Dialling, Speed Code Dialling, Broadcasting Transmission, Delayed Transmission and Substitute Reception, as well as the storage of parameters, data and

documents. This memory is powered by a backup battery in the event of a power

failure.

• Half tones

In the scanning of documents, a scale of 64 half tones can be used for a higher

XEROX DFC165 & DWC165c Service Manual

1-1

Page 9

quality reproduction of photographs and pictures.

• Automatic document feeder (ADF)

This device enables up to 10 sheets of A4, A5, Letter US or Legal paper, with a

maximum thickness of 0.1 mm/sheet, to be fed in automatically.

• Telephone answering device (TAD)

The model without a built-an TAD can be connected to an external one.

1.2 TECHNICAL SPECIFICATIONS

Physical characteristics

Type

Dimensions (L, D, H)

Weight

Operator console

Display

Keypad

Power supply

Operating range

Average consumption

Desktop transceiver

324 x 325 (+ 1701 + 1182) x 230 (+ 602)mm

6.3 kg

2 lines of 16 characters

- 11 function keys of which 7 are dual function

- 12 dual-function keys for normal dialling

and user name setting

- 10 one-touch dialling keys

- 1 error LED

220-240V, 50/60Hz

11W (in standby); less than 30W (copying)

Communication characteristics

Type of connection

Compatibility

Type of modulation

Transmission speed

Public telephone network (PSTN) or private branch exchange (PBX)

ITU-TS G3 standard

CCITT V29 / V27ter

2400 / 4800 / 7200 / 9600 bps

(1) with the document output tray (2) with extension >>

1-2

XEROX DFC165 & DWC165c Service Manual

Page 10

Type of communication

Half duplex

Coding methods

Transmission time

Scanner

Scanning system

Resolution

Document size

(width x length)

Actual scanning area

Automatic document feeder (ADF)

MH, MR

About 15 s for ITU-TS test sheet n°1 (Slerexe Letter)

at 9600 bps in standard resolution

CCD (Charge Coupled Device)

Vertical: 3.85 (standard) / 7.7 (fine) lines/mm

Horizontal: 8 dots/mm

From 148 x 105 mm (minimum length) to 216 x 2000 mm

(maximum length)

Horizontal: 210 mm

Vertical: within 4 mm of the edge of the document

Capacity: 10 sheets of A4 / Letter US / Legal format

(thickness max 0.1 mm/sheet)

Thickness of sheets: min 0.06 mm, max 0.12 mm

Half tones

Contrast

Printer

Printing method

Printing speed

Automatic sheet feeder

Print resolution

Actual printing area

The facsimile machine can emphasize the contrast of text

areas and reproduce pictures with 64 half tones.

Three levels are handled: dark, normal and light

Bubble ink jet on plain paper (standard model) or special

paper (LinkFax model)

ITU-TS test sheet n°1 (Slerexe Letter) / about 40 s

Capacity: 80 sheets of A4 / Letter US / Legal format

(weight 70-90g/m2)

200 x 100 / 200 dpi

208 x 290 (A4) / 273 (Letter US) / 349 (Legal) mm

Memory

Capacity

XEROX DFC165 & DWC165c Service Manual

512 kbytes (about 360 kbytes as user memory) powered by a backup battery

>>

1-3

Page 11

Dialling

Dialling mode

Dialling on facsimile machine

Redialling

One-touch dialling

Speed code dialling

Delayed transmission

Broadcasting transmission

Other features

Automatic reception

Pulse and tone

The number can be dialled directly on the facsimile machine's

keypad

A number can be redialled in automatic or manual mode

There are 10 one-touch dialling keys

There are 32 memory locations, each of which may be as-

signed a facsimile ID

A document can be sent automatically at a preset time

A document may be sent automatically to several correspond-

ents (max 10).

The facsimile machine can be set to receive a document

automatically

Polling

Reports

Environmental conditions

Temperature

Relative humidity

Polling reception and free polling trasmission features are

available

Various kinds of reports may be printed (transmission, activity,

etc.)

Operating: from 5°C to 35°C

Storage:from 0°C to +45°C

Transport:from -15°C to +45°C

Operating: from 15% to 85 % (without condensation)

Storage: from 15% to 85 % (without condensation)

Transport: from 5% to 95 % (without condensation)

1-4

XEROX DFC165 & DWC165c Service Manual

Page 12

1.3 QUICK REFERENCE GUIDE

1.3.1 Sending a Fax

1. Insert the document into the automatic document

feeder.

2. Press the HOOK key and dial the correspondent's

number on the numeric keypad.

3. Wait for the answering tone from the correspondent's machine and then press START.

1.3.2 Receiving a Fax

S. DIAL

î

HOOK

ê

RX MODE

LAST TX

REDIAL

RESOL.

- VOLUME +

EXT.

PAUSE 2.TONE

í

START

CONTR.

HOLD

ERROR

STOP

1. The facsimile machine is normally set for automatic

reception: the message AUTOMATIC RX is dis-

played.

S. DIAL

2. If you want to receive a fax in manual mode, press

the RX MODE key: the message MANUAL RX will

be displayed.

1.3.3 Using the Facsimile Machine as a Photocopier

1. Insert the document into the automatic document

feeder.

S. DIAL

2. Type on the numeric keypad the number of copies

to start (max. 50 copies)

3. Press the START key.

HOOK

ê

RX MODE

LAST TX

REDIAL

RX MODE

LAST TX

REDIAL

RESOL.

- VOLUME +

EXT.

PAUSE 2.TONE

START

RESOL.

- VOLUME +

EXT.

PAUSE 2.TONE

ê

START

CONTR.

HOLD

STOPHOOK

CONTR.

HOLD

STOP

ERROR

ERROR

XEROX DFC165 & DWC165c Service Manual

n

1-5

.

Page 13

2. GENERAL DESCRIPTION

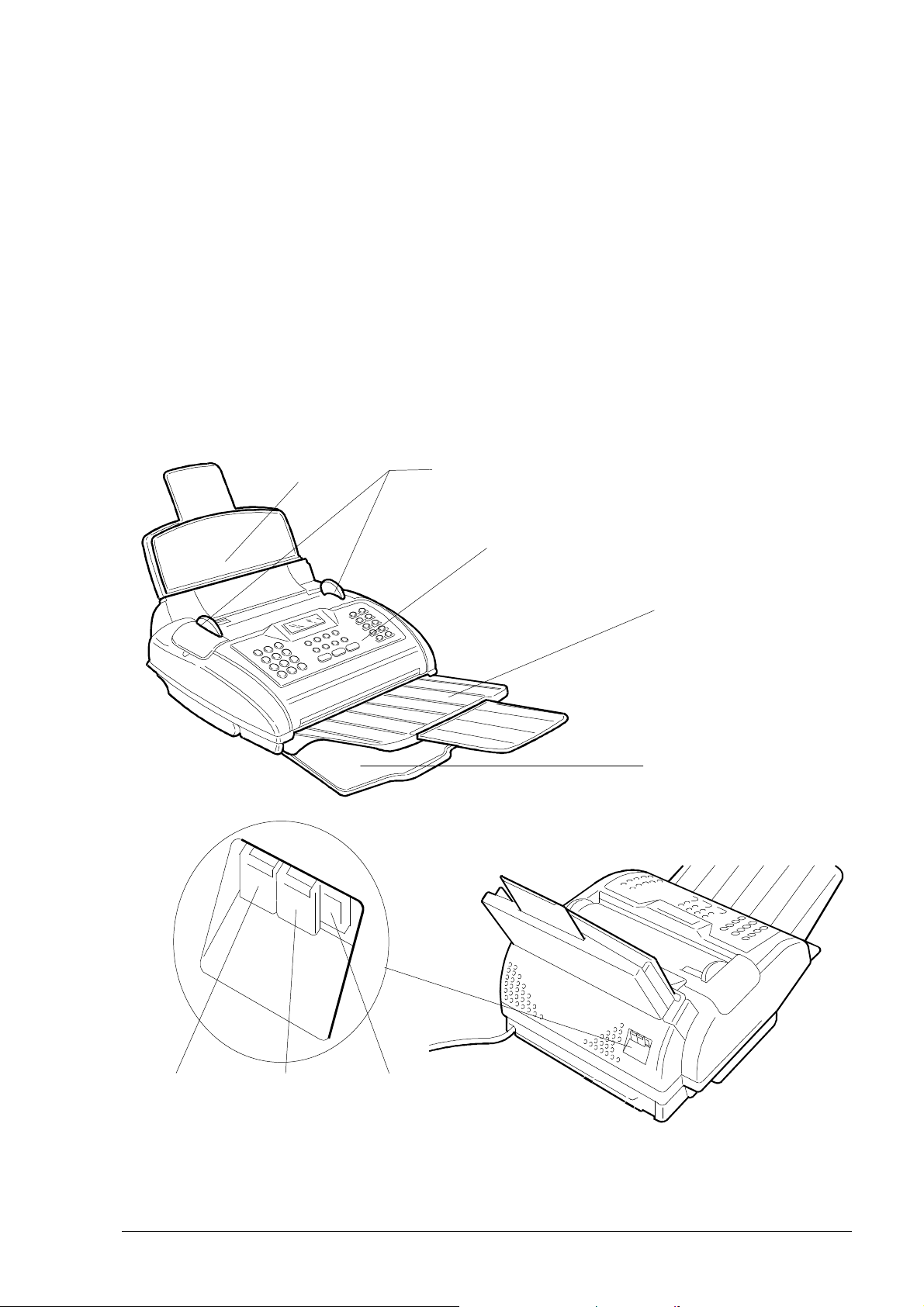

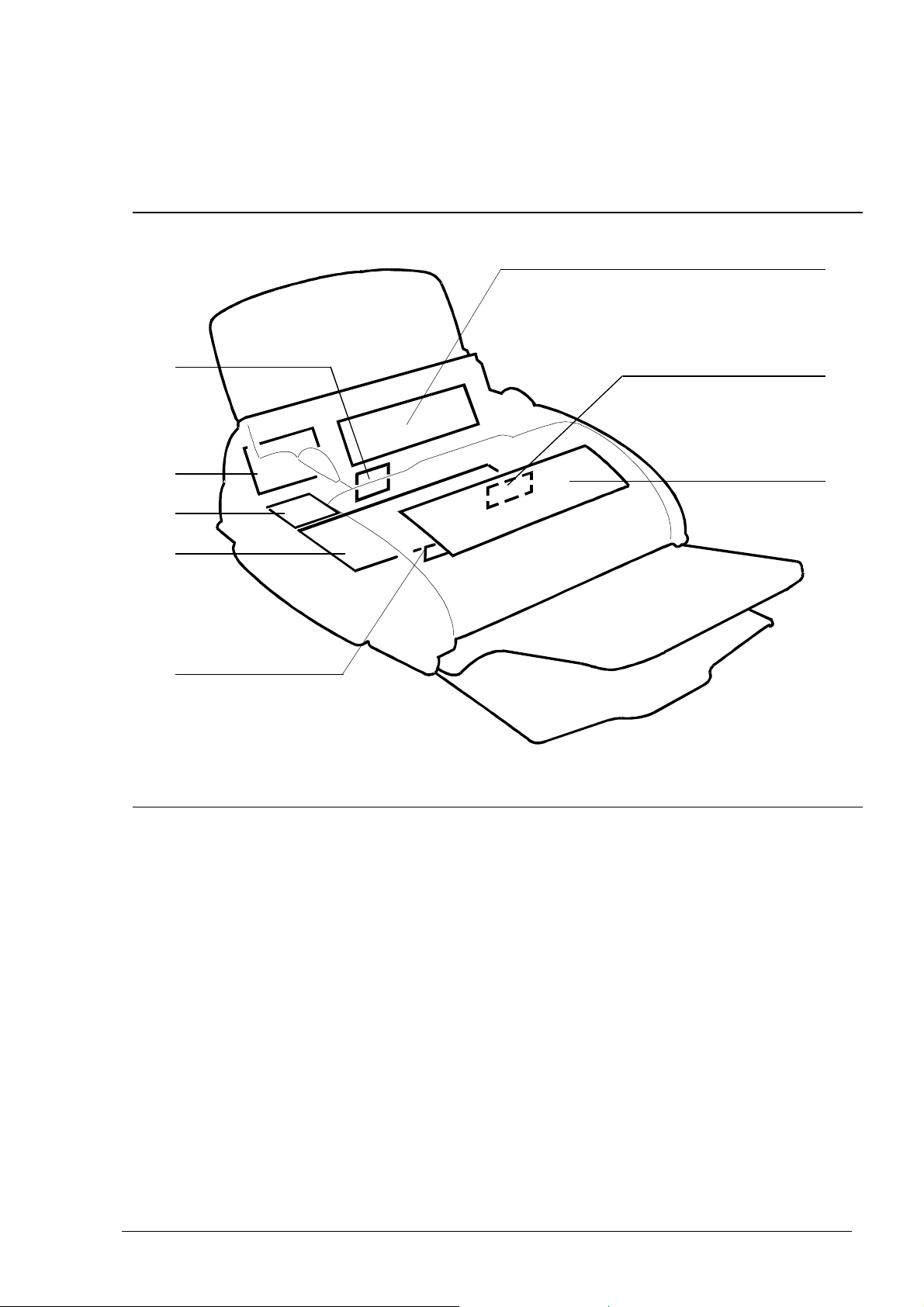

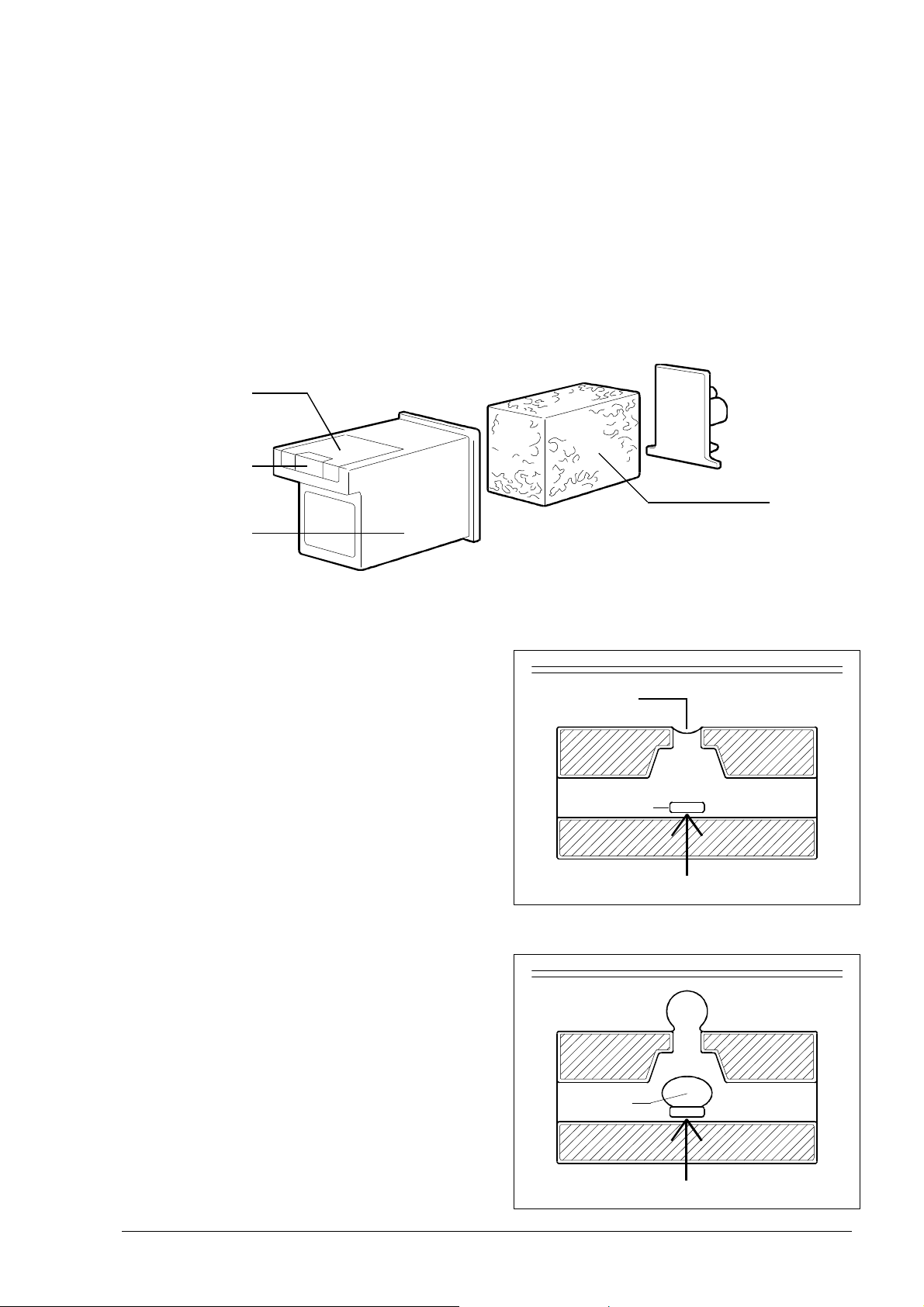

2.1 EXTERNAL PARTS

The figure shows the main external parts, of the facsimile machine.

Automatic sheet feeder

(ASF) cover

Automatic Document

Feeder (ADF) guides

Console

Document

tray

Received and copied

document tray

TAD socket

TEL2

XEROX DFC165 & DWC 165c Service Manual

Telephone

socket

TEL1

Fig. 2-1 External parts of the facsimile machine

Line

socket

LINE

2-1

Page 14

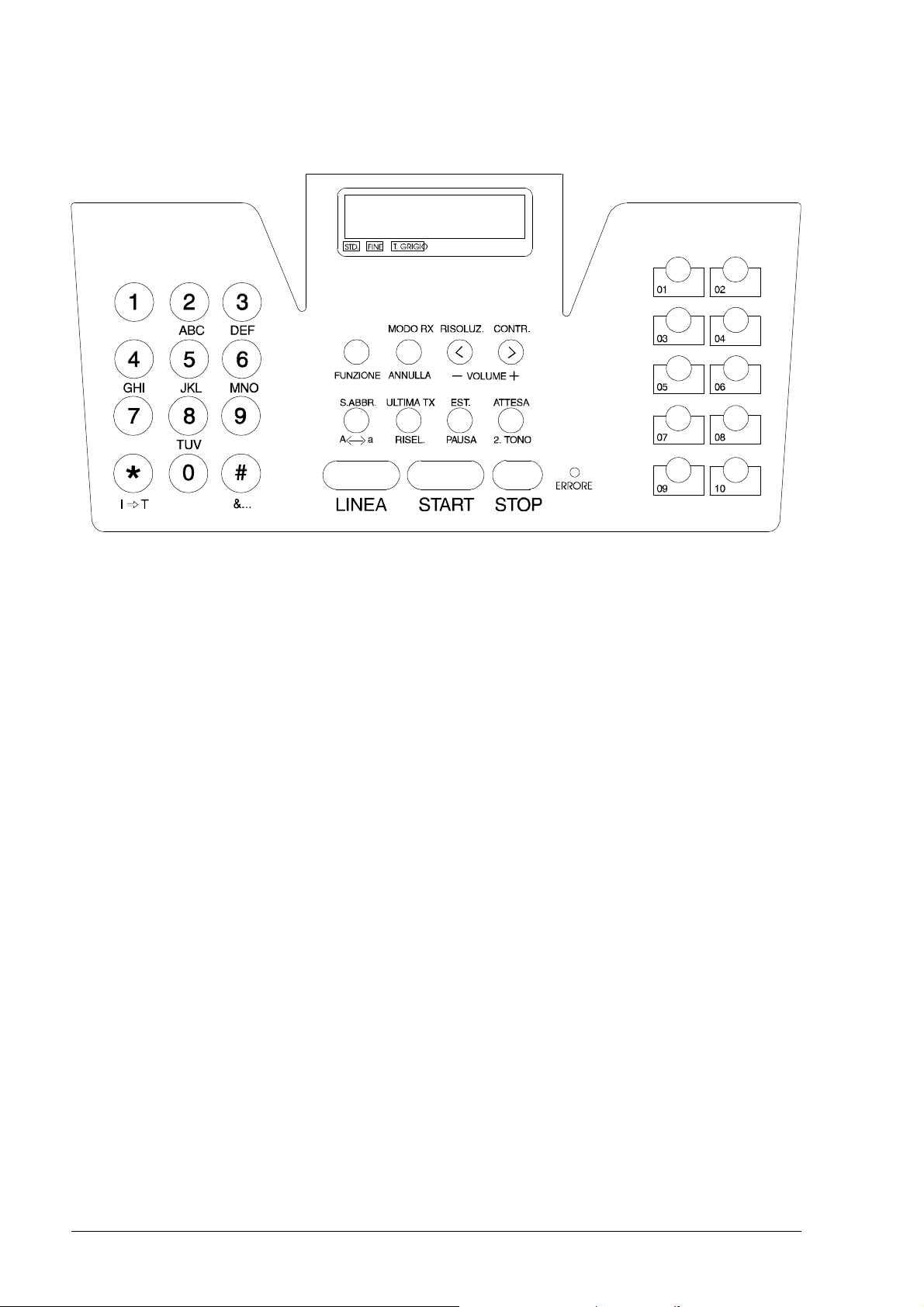

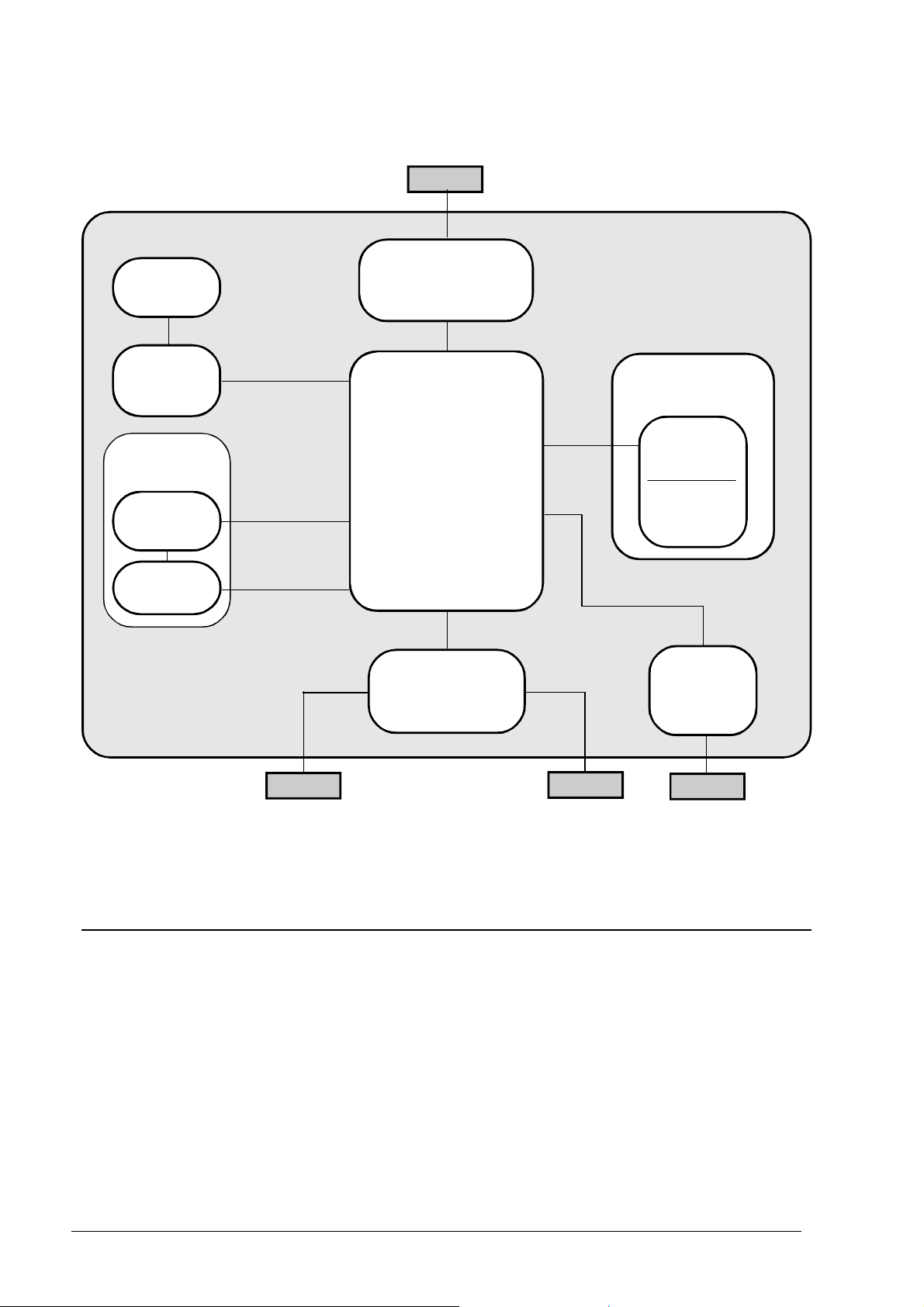

2.1.1 Console

PQRS

WXYZ

Fig. 2-2 Console layout

The console comprises:

• a display consisting of 2 lines of 16 characters each

• a keypad consisting of:

- 11 function keys ( HOOK - START - STOP - S. DIAL - LAST TX - EXT. - HOLD -

FUNCTION - RX MODE - RESOL. - CONTR.) of which 7 are dual function keys

(CLEAR - VOLUME+ - VOLUME- - A↔a - REDIAL - PAUSE - 2.TONE)

- 12 dual-function keys: for normal dialling (0 - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 -

* - #) or user name setting (ABC - DEF - GHI - JKL - MNO - PQRS - TUV

- WXYZ - P→T - &...)

- 10 keys for one-touch dialling

- 1 LED for indicating an ERROR.

2-2 XEROX DFC165 & DWC165c Service Manual

Page 15

2.1.2 Functions of the console keys

Some keys perform different functions according to the current operating mode of the

facsimile machine:

• Stand-by mode with document on the ADF

‚ Stand-by mode without document on the ADF

ƒ Function mode (activated by pressing the FUNCTION key), irrespective of

the presence of a document on the ADF

„ Hook mode (activated by pressing the HOOK key).

Key Mode Functions

•„ Used for dialling numbers.

Number keys ƒ Select alphanumeric characters for inclusion in the mne-

monic ID.

•„ In pulse dialling mode, changes the dialling mode to tone.

In tone dialling mode, emits a tone on line for special network

servces.

« ƒ Scrolls forwards through the special characters and sym-

bols available for the mnemonic ID or selects the + character

for the user's telephone number.

•„ In tone dialling mode, emits a tone on line for special network

services.

# ƒ Scrolls backwards through the special characters and

symbols available for the mnemonic ID.

FUNCTION •‚ Provides access to operator selection menus and

submenus.

RX MODE •‚ Changes the reception mode : automatic, manual, FAX/

TEL, FAX/TAD.

CLEAR •‚ƒ Clears incorrect settings.

RESOL. • Selects the type of resolution.

< ƒ Moves the cursor left during entry of the user's name and

number.

- VOLUME „ Reduces the volume of the speaker.

XEROX DFC165 & DWC 165c Service Manual

>>

2-3

Page 16

Key Mode Functions

CONTR. • Selects the type of contrast.

> ƒ Moves the cursor right during entry of the user's name and

number.

VOLUME + ‚„ Increases the volume of the speaker.

S. DIAL •‚ Enables the setting of a two-digit code for speed dialling.

A↔a ƒ Changes from capitals to small letters (or vice versa)

during entry of the mnemonic ID.

LAST TX •‚ Pressed once, displays the result of the last transmission.

REDIAL •‚ Pressed twice, redials the last number.

EXT. • When the facsimile machine is connected to a private branch

exchange, enables access to the public line .

PAUSE •‚ƒ Inserts a pause in automatic dialling and in speed and one-

touch dial settings.

HOLD • Puts a telephone call on hold.

2. TONE •‚ Sets the second tone in automatic dialling and in speed and

one-touch dial settings.

HOOK •‚ Enables the user to dial the number without lifting the

receiver and to monitor the tones through the speaker.

• Start one-touch dialling the fax number associated with

the key.

Keys 01-10 ‚ Enable the telephone number associated with the key to be

dialled when the START key is pressed.

ƒ Used for programming a one-touch dialling number.

• Switches off the ERROR LED.

Stops copying, sending or receiving a document.

STOP ƒ Sets the facsimile machine in standby mode.

>>

2-4 XEROX DFC165 & DWC165c Service Manual

Page 17

Key Mode Functions

• Starts copying the document on the ADF.

After the number has been dialled, starts sending the

document on the ADF.

START ‚ After a one-touch dial key has been pressed, starts dialling

the programmed telephone number.

After the receiver has been lifted, sets the facsimile machine

in manual reception mode.

ƒ Confirms menus, submenus, parameters and values.

„ Sets the facsimile in manual reception mode.

XEROX DFC165 & DWC 165c Service Manual

2-5

Page 18

2.2 ELECTROMECHANICAL PARTS

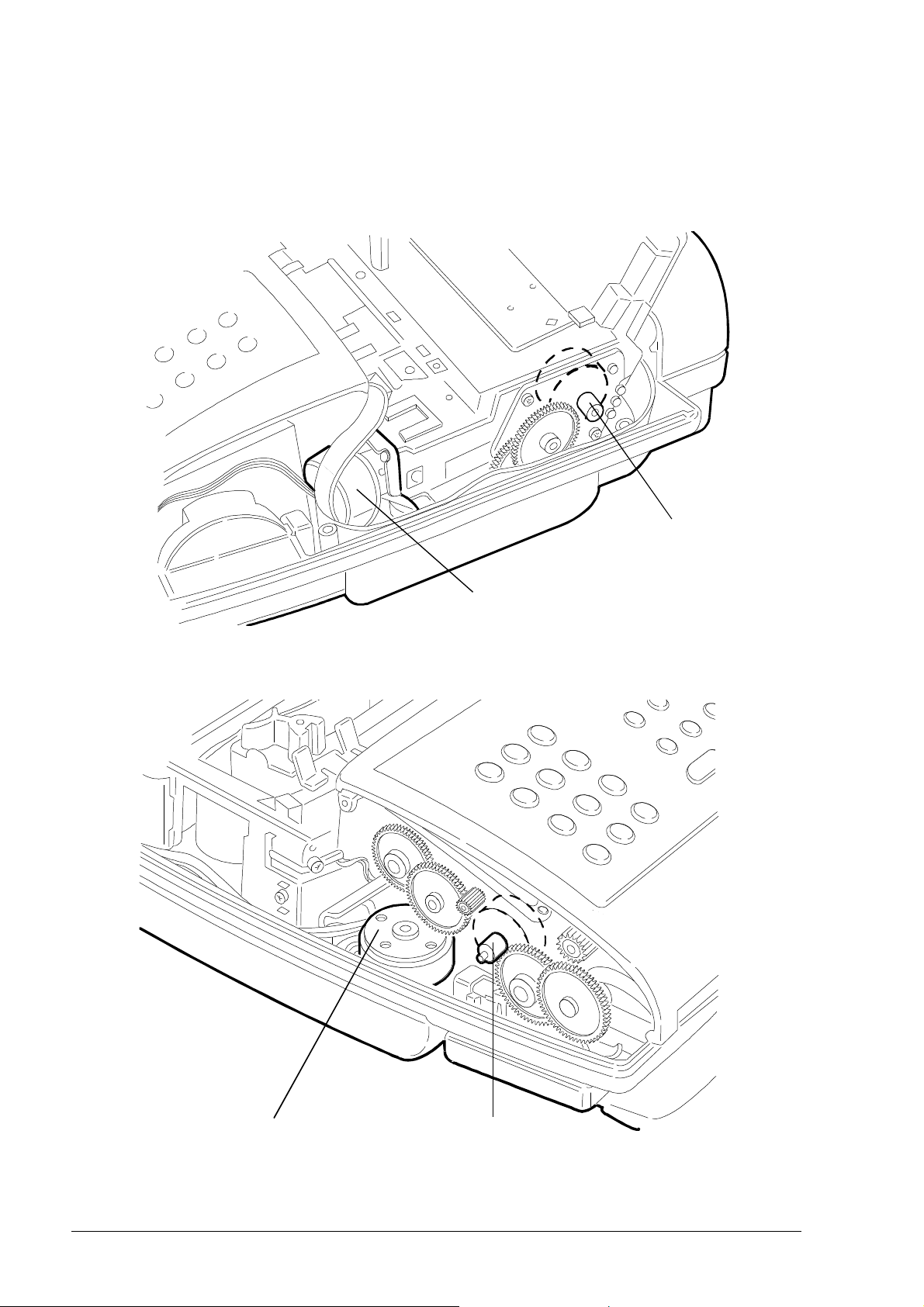

2.2.1 Motors

Rear right-hand side

paper motor

Rear left-hand side

carriage motor

ink drain motor

Fig. 2-3 Locating the motors

2-6 XEROX DFC165 & DWC165c Service Manual

scanner motor

Page 19

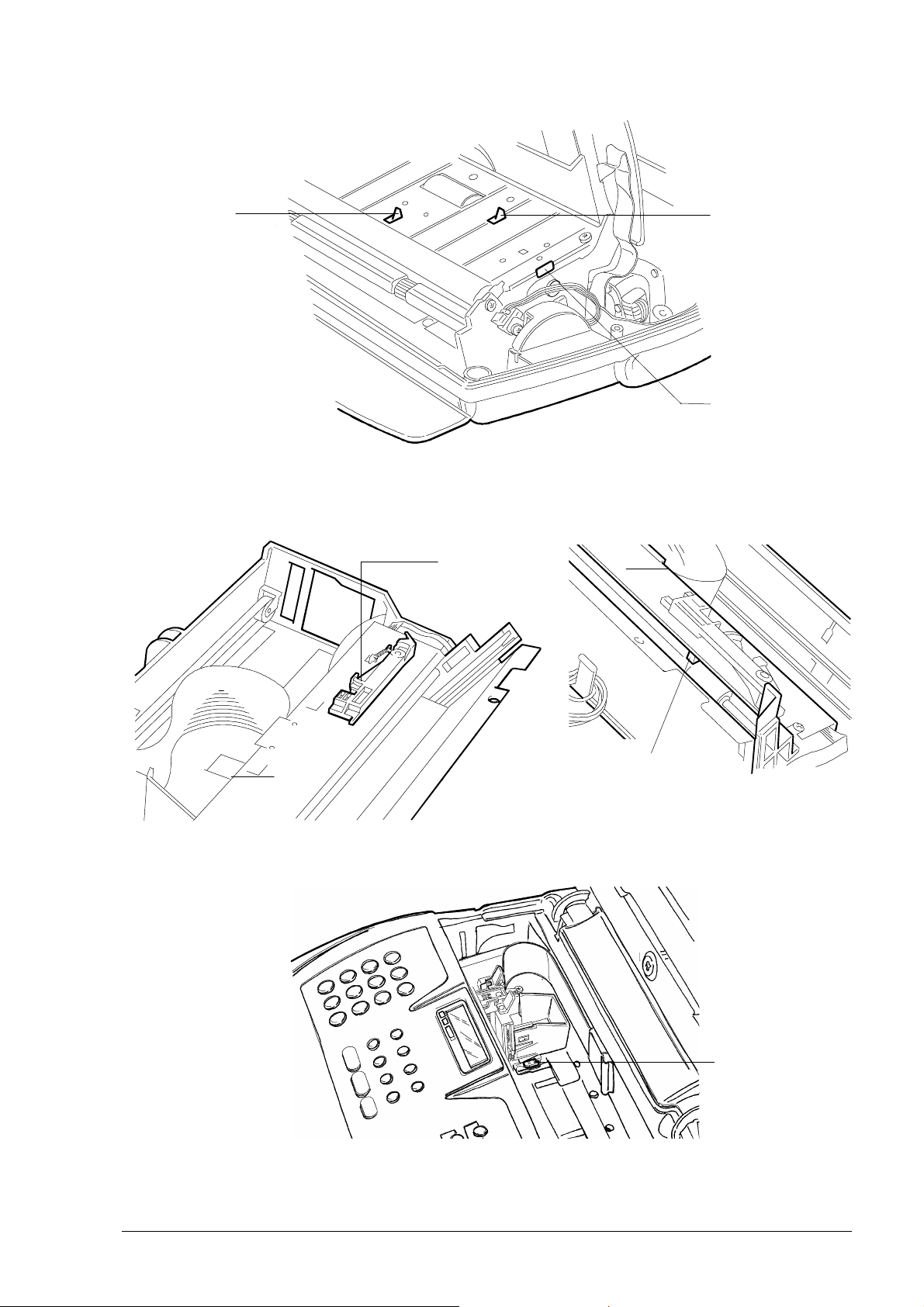

2.2.2 Sensors

document

end sensor

document

sensor

console

sensor

Fig. 2-4 Locating the console sensors

Printer

cover

sensor

paper sensor

(under paper

guide cradle)

Fig. 2-5 Locating the paper and printer sensors

Fig. 2-6 Locating the carriage sensor

paper

edge

sensor

XEROX DFC165 & DWC 165c Service Manual

2-7

Page 20

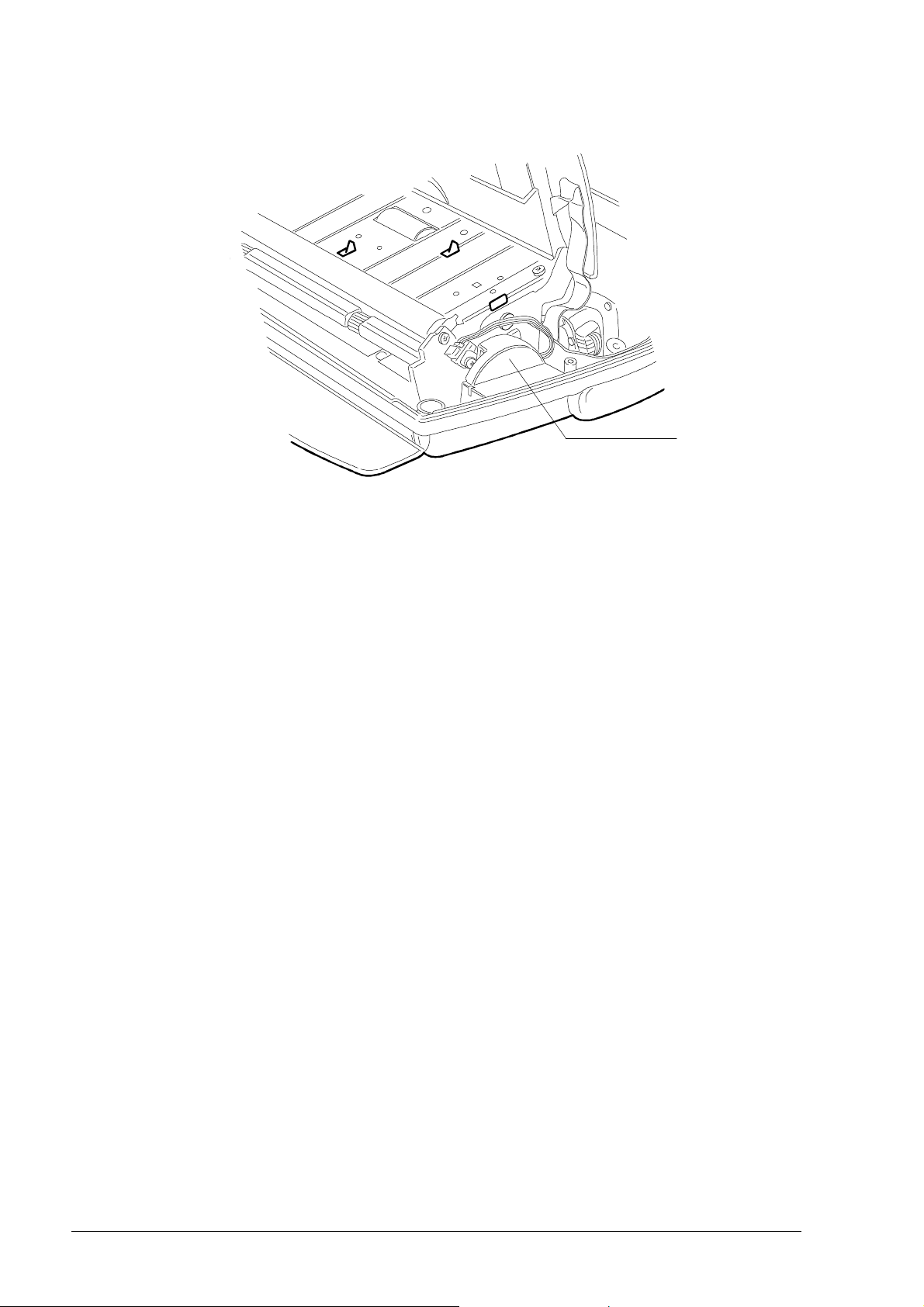

2.2.3 Speaker

speaker

Fig. 2-7 Locating the speaker

2-8 XEROX DFC165 & DWC165c Service Manual

Page 21

2.3 ELECTRONIC PARTS

Figure 2-8 shows the boards assembled on the facsimile machine.

3

4

5

6

7

8

2

1

Fig. 2-8 Locating the boards

1. Console board

2. CCD board

3. Power supply board

4. Print head driver board (in the print carriage)

5. Network control unit (NCU) board

6. Parallel port card (LinkFax model, only)

7. Motherboard

8. LED array for illuminating the documents.

XEROX DFC165 & DWC 165c Service Manual

2-9

Page 22

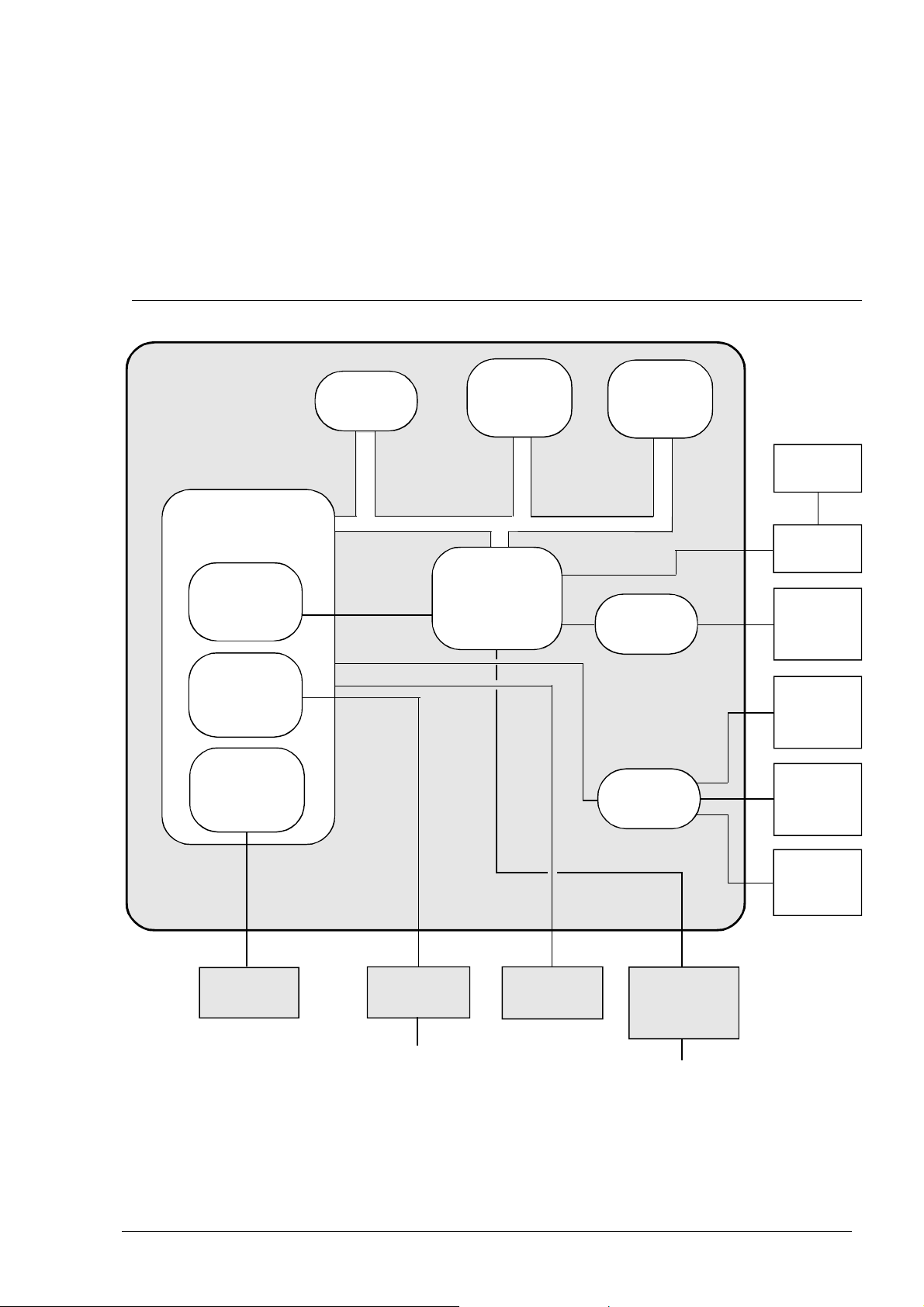

2.3.1 General Block Diagram

Mains voltage

Display

Power supply

board

Console

board

Optical

unit

Scanner

unit

CCD

board

Telephone

network

Motherboard

NCU

board

Telephone

Telephone

orTAD

Print unit

Print

carriage

Driver

board

Parallel

port card

PC

(LinkFax model

only)

Fig. 2-9 General block diagram

The facsimile machine comprises the following main units:

• Motherboard

• Network control unit (NCU) board

• Console board, with the display

• Power supply board

• Parallel port card, for connectiion

to the PC (LinkFax model, only)

2-10 XEROX DFC165 & DWC165c Service Manual

• Optical unit, consisting of the scanner unit and CCD board

• Printer unit, consisting of the print

head driver board (in the carriage)

and the carriage drive mechanism.

Page 23

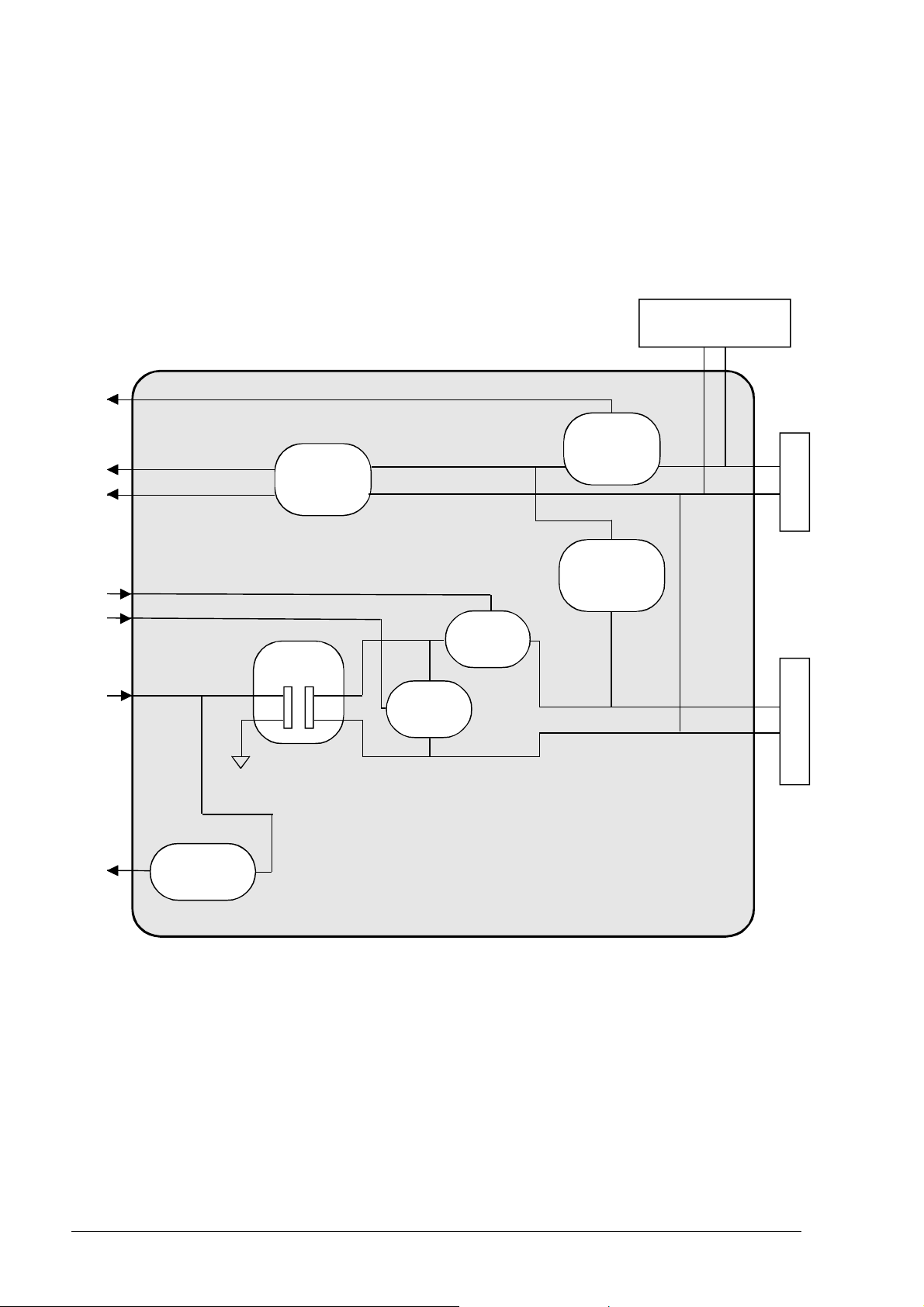

2.3.2 Block Diagram of the Motherboard

The motherboard controls the entire machine by means of a central processing unit

(CPU) which uses special circuits to handle four main functional units: the image

processor (for processing the scanned document), the motors (for activating all the

mechanical parts), the print head (for printing both received and copied documents)

and the modem (for controlling the signals to and from the telephone network).

CPU

I/O channel

controller

Modem

Image

processor

256 kB

EPROM

8 kB

static

memory

Custom

component

ASIC

512 kB

dynamic

memory

Step motor

driver

Step motor

driver

to print

head

to print

head

driver

to carriage

motor

to paper

motor

to scanner

motor

to CCD

board

to NCU

board

Telephone

network

Fig. 2-10 Block diagram of the motherboard

XEROX DFC165 & DWC 165c Service Manual

to console

board

to ink drain

motor

to the

parallel

port card

PC

2-11

Page 24

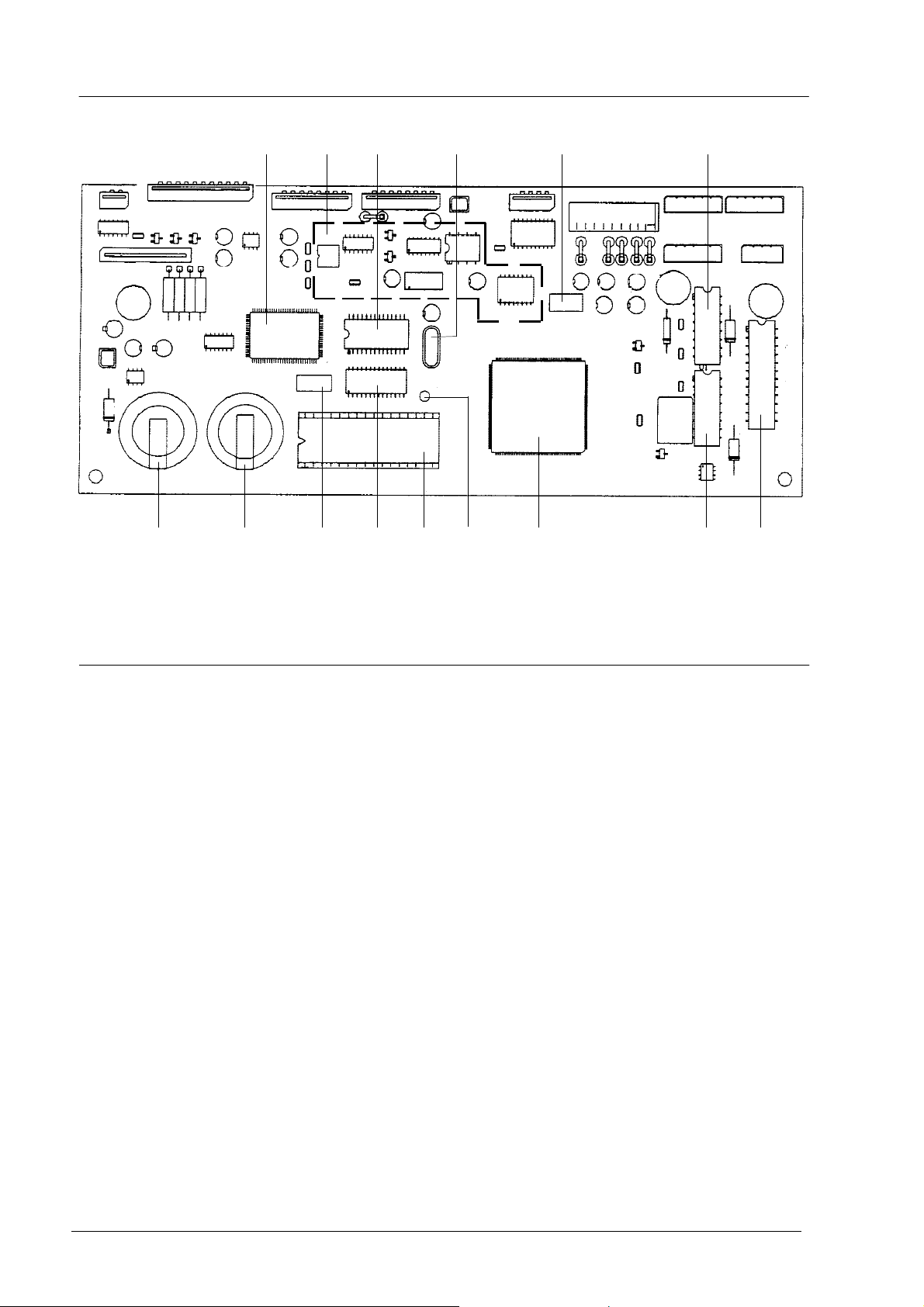

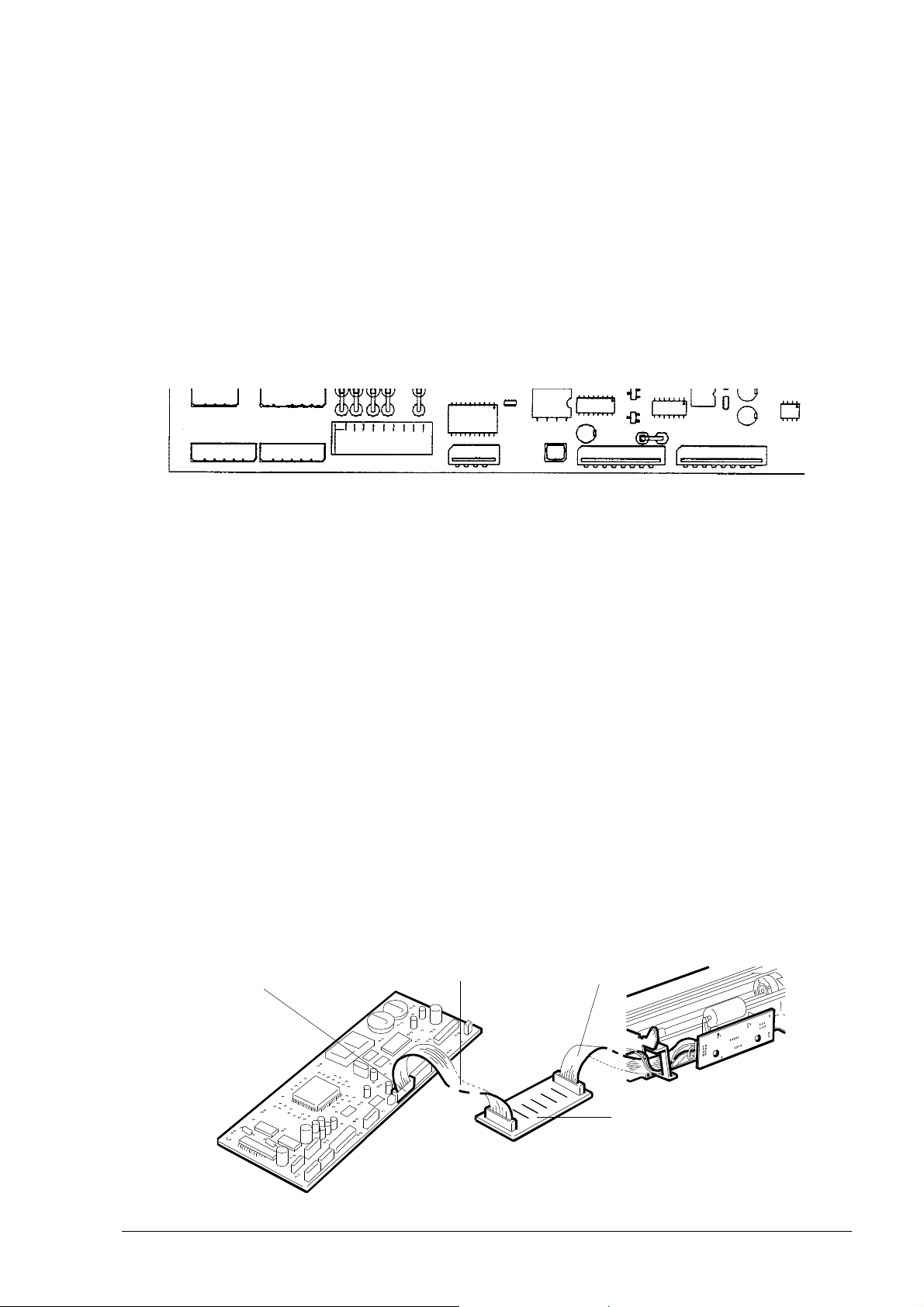

1 2 3 4 5 6

7 8 9 10 11 12 13 146

Fig. 2-11 Locating the motherboard components

1 CUSTOM COMPONENT ASIC

2 MODEM CIRCUITS

3 STATIC RAM (8 x 8 kbytes)

4 QUARTZ CRYSTAL FOR MODEM

CLOCK (20.736 MHz)

5 QUARTZ CRYSTAL FOR SYSTEM

CLOCK (16 MHz)

6 PAPER, SCANNER AND INK DRAIN

MOTOR DRIVERS

7 BACK-UP RECHARGEABLE BATTERY

FOR DYNAMIC RAM (Ni-Cd, 3 volts,

72-hour duration)

8 SYSTEM BATTERY (Lithium, 3

volts, 5-year duration)

9 QUARTZ CRYSTAL FOR ASIC (16

MHz)

10 DYNAMIC RAM (512 kbytes)

11 SYSTEM FIRMWARE EPROM (256

kbytes)

12 QUARTZ CRYSTAL FOR RTC

(32.768 kHz)

13 CPU (WITH BUILT-IN MODEM AND

IMAGE PROCESSOR)

14 CARRIAGE MOTOR DRIVER

2-12 XEROX DFC165 & DWC165c Service Manual

Page 25

The memory block, divided into the following three sections, is an integral part of

the motherboard:

EPROM

Static

RAM

• EPROM (256 Kbytes), this memory contains the system firmware, the default

settings of the software parameters and the messages in the various languages

• STATIC RAM (8 kbytes), this memory contains:

- the current user and service software parameters

- the calibration settings (alignment settings, CCD settings)

- the telephone number list (one-touch dialling numbers, speed code

dialling numbers, broadcasting lists)

- the power failure repor .

• DYNAMIC RAM (512 kbytes), this memory contains:

Dynamic

RAM

- the compression and decompression buffer

- the scanning buffer

- the print buffer

- the transaction memory (activity reports)

- the user memory (documents to send, documents received in the memory).

The data is retained in the dynamic memory even during a power failure by a backup

battery capable of powering the system for 72 hours. The facsimile machine must

be left powered for 24 hours to recharge this battery.

The data is retained in the static memory by the 5-year duration system battery.

XEROX DFC165 & DWC 165c Service Manual

2-13

Page 26

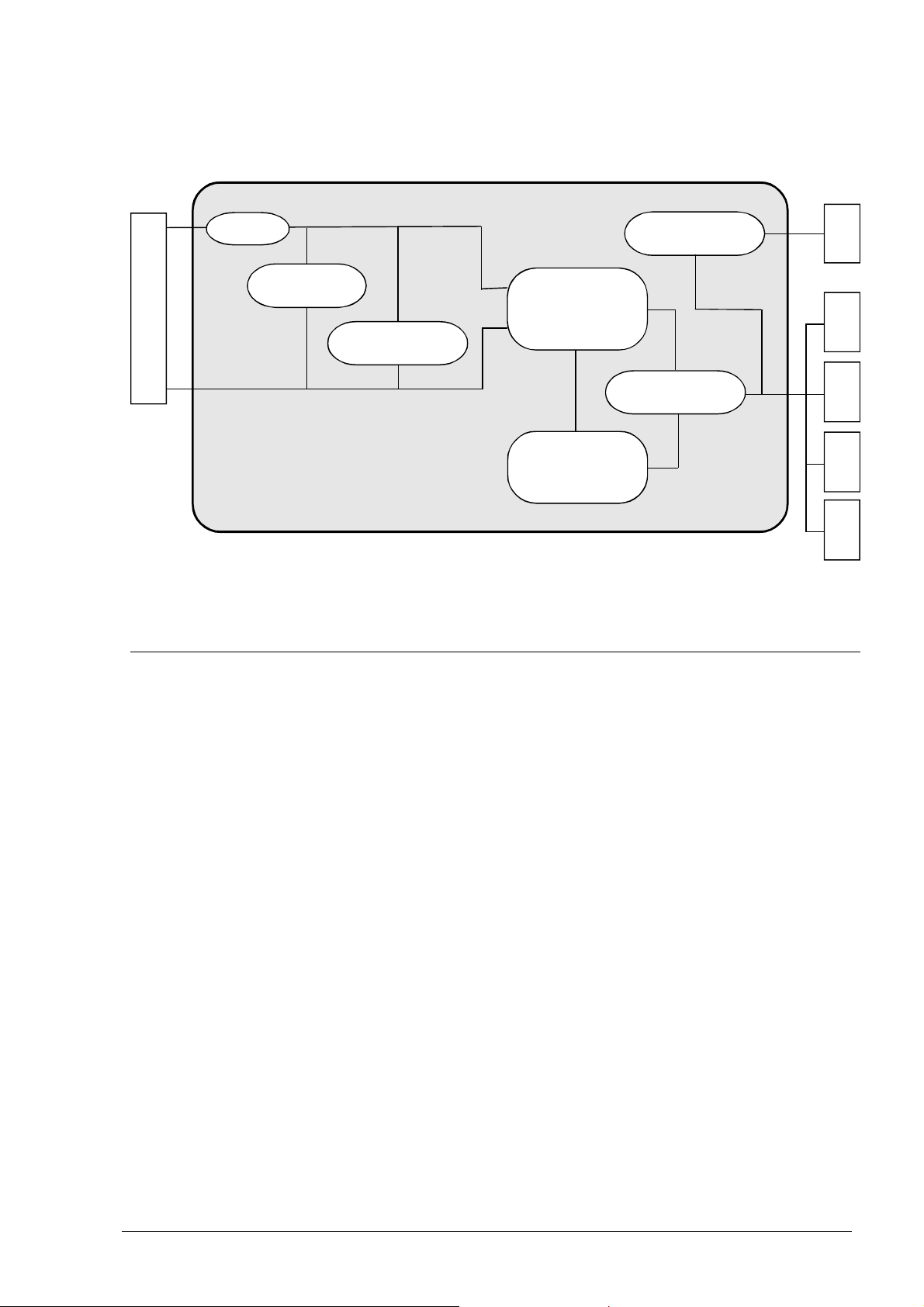

2.3.3 Block Diagram of the Network Control Unit Board

The NCU (Network Control Unit) board acts as the physical interface with the

telephone line. The NCU board is available in several versions, to suit the specific needs

of each country.

The figure shows the block diagram of a generic NCU board.

external TAD

interface

Current

Call

detector

detector

Receiver

detector

relay

Motherboard

TX

Amplifier

RX

Selector

Line

transf.

Selector

relay

relay

Fig. 2-12 Block diagram of a generic NCU board

Telephone line Telephone

2-14 XEROX DFC165 & DWC165c Service Manual

Page 27

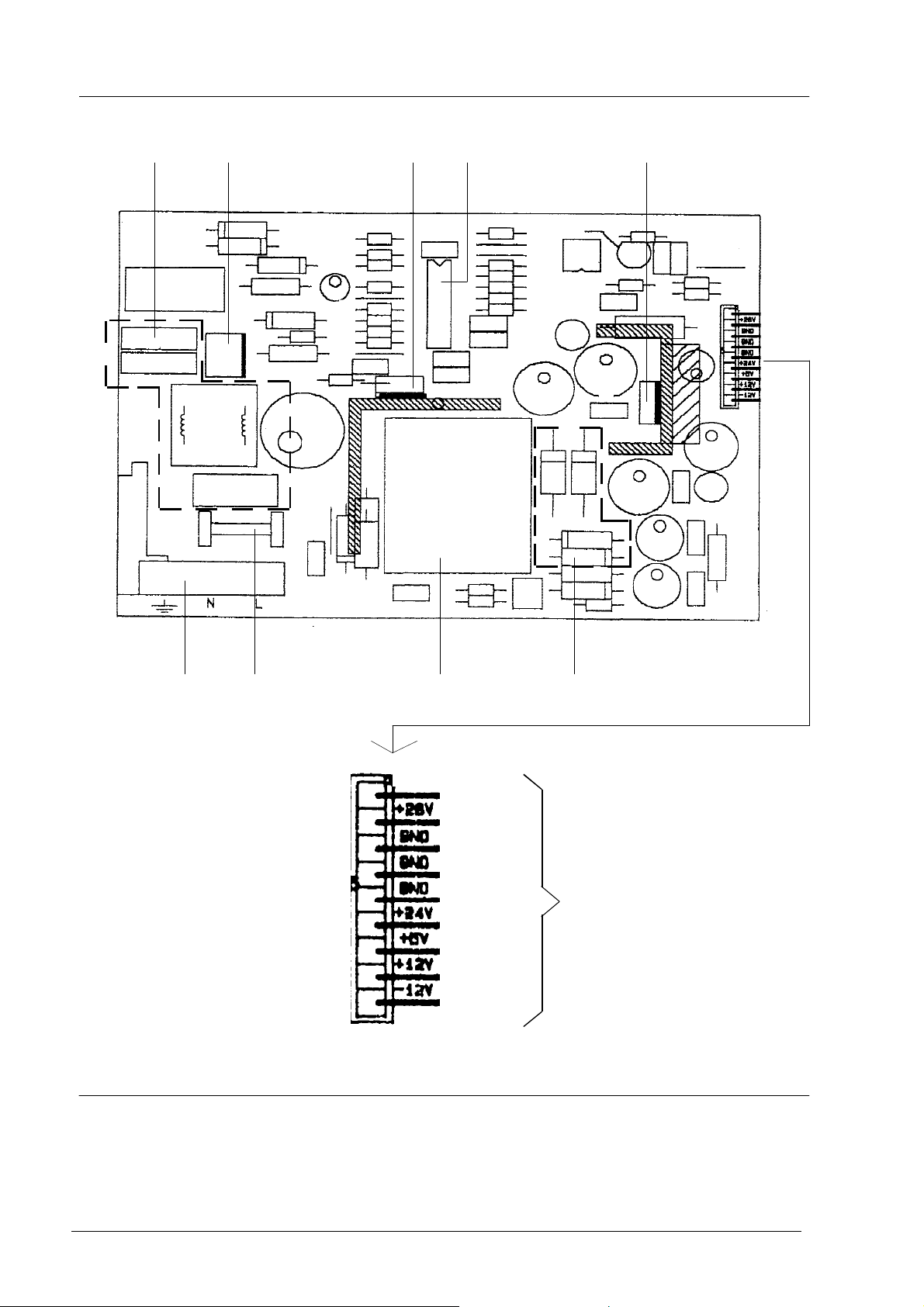

2.3.4 Block Diagram of the Power Supply Board

2 A

Fuse

Mains voltage

Voltage reg.

Mains filter

Switching

transformer

Primary rectifier

Diode rectifier

Switching

controller

MOS

Fig. 2-13 Block diagram of the power supply board

+24 V

+28 V

+5 V

+12 V

-12 V

The power supply board provides a maximum power of 35 Watts and supplies, via

the switching circuit, the following direct voltages:

- +28 VDC (±10%), for the motors, variable according to the load

- +24 VDC (±2%), for the print head

- +12 VDC (±10%), for CCD, NCU and logic circuits

- -12 VDC (+10% -15%), for CCD and logic circuits

- +5 VDC (±5%) for sensors and logic circuits.

XEROX DFC165 & DWC 165c Service Manual

2-15

Page 28

1 2 3 4 5

6 7 8 9

Fig. 2-12a Locating the power supply components

1 Mains filter

PF

+28 V

GND

GND

GND

+24 V

+5 V

+12 V

-12 V

4 Stabilizer

to motherboard

7 Fuse (2 A)

2 Primary rectifier

3 Switching controller MOS

2-16 XEROX DFC165 & DWC165c Service Manual

5 +24 VDC regulator

6 Mains connector

8 Transformer

9 Diode rectifier

Page 29

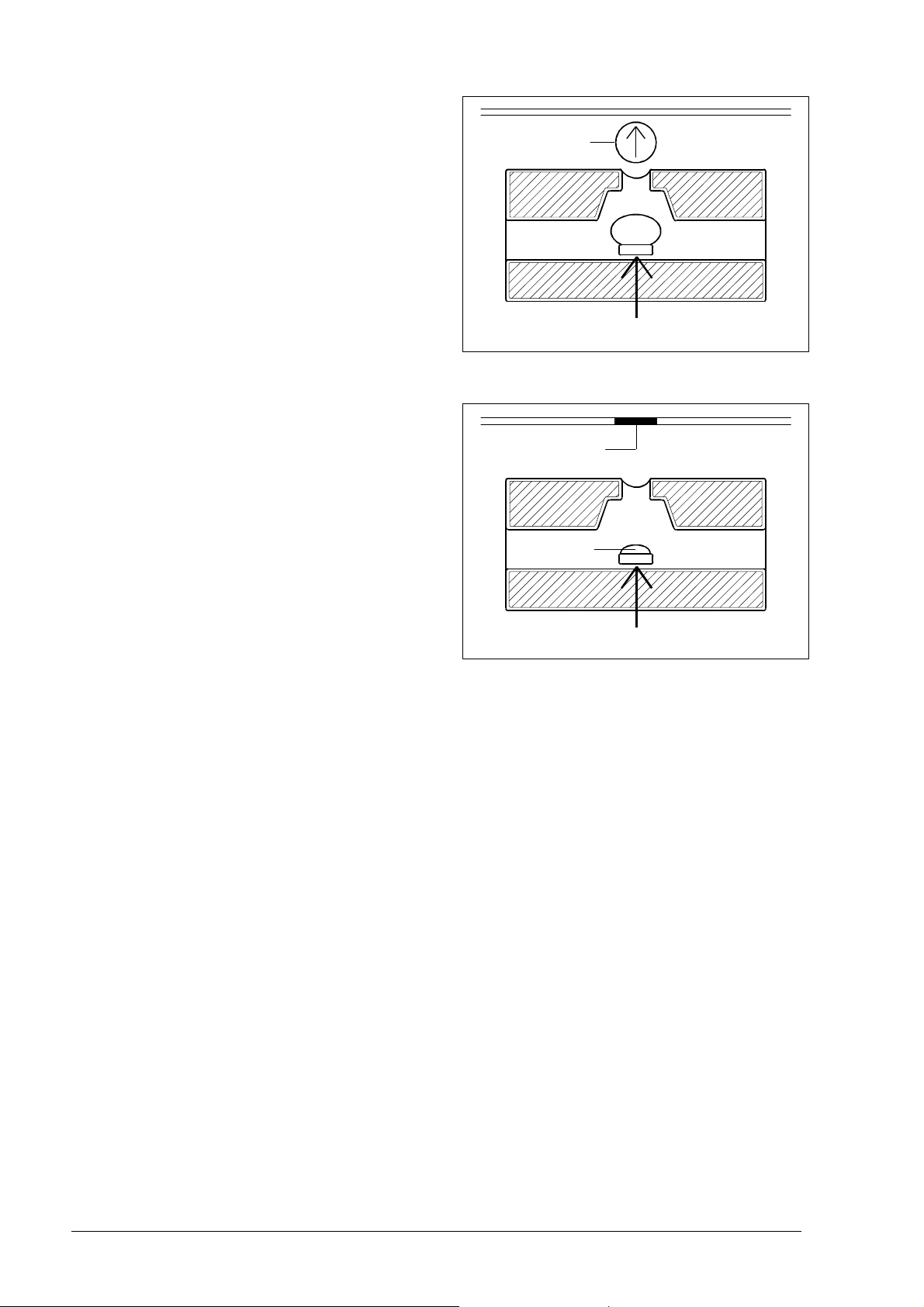

2.3.5 Printer Unit

The facsimile machine has a bubble ink jet system which uses a special head and prints

on plain paper.

The bubble ink jet print head consists of an interchangeable cartridge, which

contains a sponge soaked with liquid ink, which is ejected from 50 nozzles made of a

nickel and gold component, under the control of the signals that reach an electrical

circuit consisting of 50 resistors (Fig. 2-13).

electrical

circuit

nozzles

sponge

cartridge

Fig. 2-13 Composition of the print head

Each nozzle generates a drop of ink

when the corresponding resistor is powered (+24 Volt) for a few microseconds.

The resistor is heated and the ink that is

in direct contact with it evaporates, expanding like a bubble and pressing the rest

of the ink against the nozzle.

nozzle

resistor

bubble

+24V

ink

XEROX DFC165 & DWC 165c Service Manual

+24V

2-17

Page 30

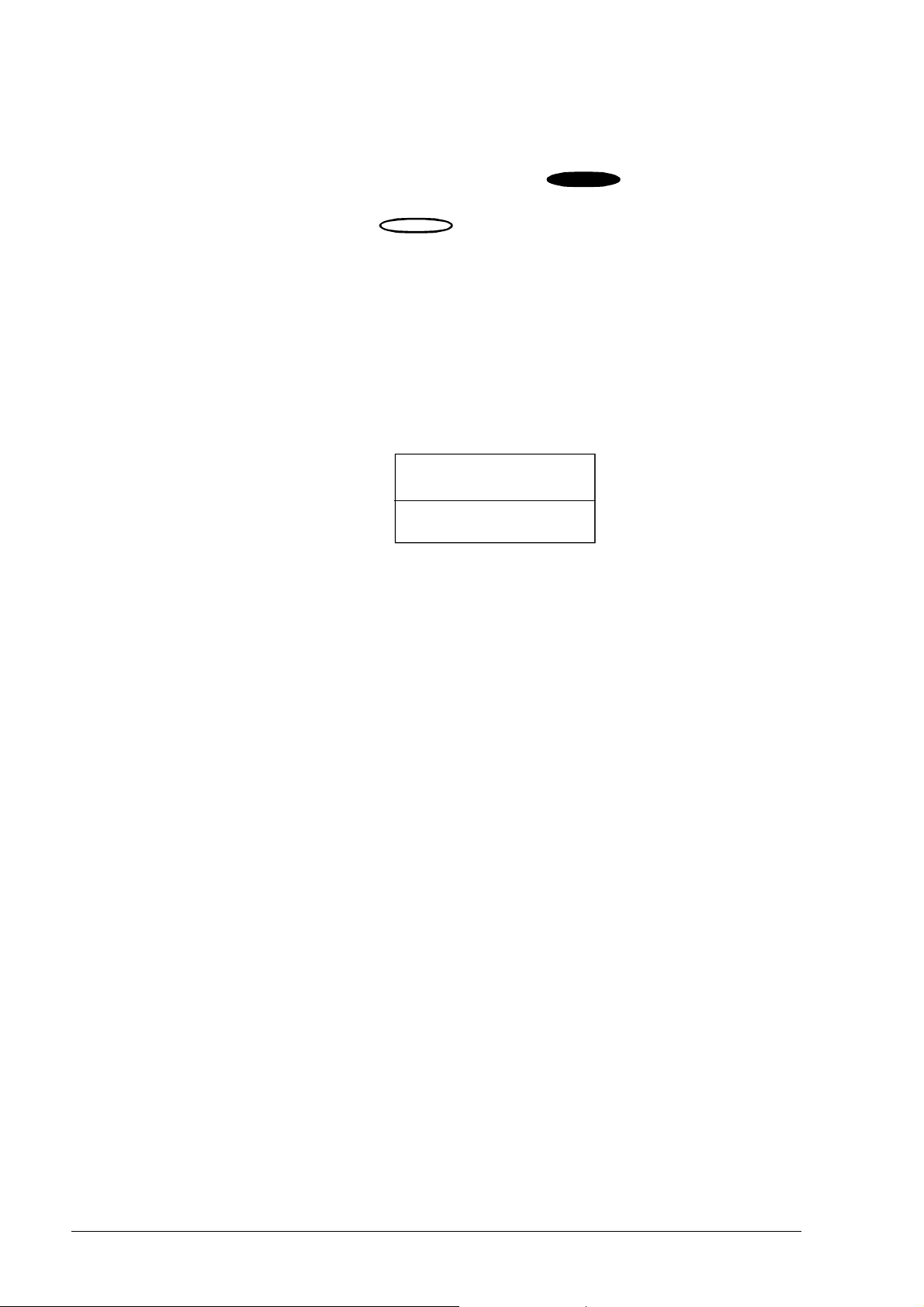

As a result, a drop of ink is ejected from

the nozzle at a speed of 15 metres a second

until it strikes the paper on which it makes

a dot.

drop

15 m/s

+24V

When the resistor is powered off, the

bubble collapses quickly, drawing from

the sponge a quantity of ink equal to the

amount ejected. 800 microseconds after

the ink has been ejected, the nozzle is ready

to eject another drop.

dot

bubble

0V

2-18 XEROX DFC165 & DWC165c Service Manual

n

Page 31

3. INSTALLATION AND INITIALIZATION PROCEDURES

Installation of the facsimile machine consists of three separate phases:

1. PRELIMINARY OPERATIONS, or fitting together the parts supplied in the

packaging and subsequent connection of the facsimile machine and telephone,

if present, to the telephone network

2. INSTALLATION, or setting the parameters indispensable for the facsimile

machine's operation.

3. SETUP, or setting the customization parameters.

3.1 PRELIMINARY OPERATIONS

3.1.1 Unpacking the Facsimile Machine

Having removed the facsimile machine and the other parts from the packaging, check

that the following elements are present:

• the facsimile machine (complete with power cord)

• a packet containing the print head

• the telephone cable (with two international RJ11 connectors)

• an adapter for the telephone cable (only required in some countries)

• the document tray, with a pull-out extension

• the received or copied document tray

• the automatic sheet feeder (ASF), with a pull-out extension

• the User Guide, complete with the Quick Reference Guide.

XEROX DFC165 & DWC165c Service Manual 3-1

Page 32

3.1.2 Connecting to the Telephone Line

WARNING: check that the power cable is plugged into the power outlet,

before connecting the facsimile machine to the telephone line.

To connect the facsimile machine to the telephone line, plug one end of the

telephone cable to the line socket (LINE) on the facsimile machine and the other end

into a wall socket (see Fig. 3-1, a) or using the adapter if necessary (see Fig. 3-1, b).

a)

line socket

(LINE)

b)

Fig. 3-1 Connecting the facsimile machine to the telephone line

To connect a telephone to the telephone network, proceed in either of the following

two ways:

a) if the telephone has a national plug (case a), insert the plug into the adapter

(see Fig. 3-2, a) or specific wall telephone socket (see Fig. 3-2, b)

b) if the telephone has an international connector (case b), remove the precut

tab that covers the telephone socket (TEL1) of the facsimile machine, then

insert the connector directly into the telephone socket (see Fig. 3-3).

Important

As the telephone connection depends on regulations that vary from one country to

another, figures 3-2 and 3-3 show an intentionally generic connection: for a detailed

description of the procedure, see the regulations in force in your own country.

3-2

XEROX DFC165 & DWC165c Service Manual

Page 33

Fig. 3-2 Connecting the telephone (case a)

to telephone

socket on

facsimile

machine

telephone socket

(TEL1)

Fig. 3-3 Connecting the telephone (case b)

XEROX DFC165 & DWC165c Service Manual 3-3

Page 34

3.1.3 Connecting the Power Cord

Plug the power cord into the wall socket.

3.1.4 Installing the Print Head

1) Power on the facsimile machine and wait for the following message to appear:

CHECK PRINT HEAD

WARNING : if the message does not appear in your language, carry out the country

setup procedure described in section 3.2.2 and continue with this

procedure from step 2

2) Open the print head packet and remove the sealed box containing the print head.

3) Open the box and remove the print head, holding it by the grip, then remove the

label covering the nozzles (see Fig. 3-4)

Fig. 3-4 Removing the protective label

WARNING : do not touch the electrical contacts or the print head nozzles

NO

3-4

XEROX DFC165 & DWC165c Service Manual

Page 35

In addition, if the print head has an interchangeable cartridge, do

not separate the cartridge from the print head

NO

4) Tilt the printer cover, then insert the print head in position with the electrical

contacts facing the front of the machine (Fig. 3-5)

Fig. 3-5 Inserting the print head

5) Taking care not to obstruct the hole on the top, insert your index finger in the

recess on the print head and pull it until you hear it clearly click into position

(Fig. 3-6)

Fig. 3-6 Fixing the print head in position

XEROX DFC165 & DWC165c Service Manual 3-5

Page 36

6) Having inserted the print head, close the printer cover

WARNING : if a disposable print head has been inserted, the following

message generally appears:

NEW PRINT HEAD?

1=YES 0=NO

Should this message not appear, press the FUNCTION key three

times, then press the START key to make it appear. Now type 1 and

press the START key.

7) The facsimile machine automatically loads a sheet of paper and starts the nozzle

cleaning and checking procedure, which ends by:

• printing out the following print chart on the automatically loaded sheet (*)

numbered scale

black areas

which contains:

− a numbered scale, for checking the flow of ink and the electrical

circuits controlling the print head nozzles

3-6

− a section of graphics and text, for evaluating print quality

• the following message appears

CHECK PRINTOUT

1=EXIT 0=REPEAT

(*) only if bit 2 of SW09 is set to 1.

XEROX DFC165 & DWC165c Service Manual

Page 37

8) Analyse the print chart as follows:

• Check that there are no gaps in the numbered scale and that there are no

horizontal white lines in the black areas: under these conditions, which

indicate that the print head has been inserted correctly and is in perfect

working order, type 1: the facsimile machine returns to stand-by and is ready

for use

• If there are gaps or white lines, type 0 to repeat the nozzle cleaning proce-

dure: if the new print chart is still unsatisfactory, repeat the procedure again

• If the printing quality is still not up to the required standard after the procedure has been performed three times, proceed as follows until a satisfactory

print chart is obtained:

- Make a copy of a document with the desired type of graphics and text

and assess its quality.

- Change the type of paper (the paper you are using may be too porous)

and repeat the procedure.

- Remove and reinsert the print head.

- Remove the print head and check that there is no foreign body on the

printing nib; if there is, remove it with care, taking care not to touch the

electrical contacts; slide the print carriage to the right, then clean the print

head cleaning pad using a cotton swab soaked in water, taking care not

to leave any fluff (Fig. 3-7);

print head

cleaning pad

Fig. 3-7 Cleaning the print head cleaning pad

reinsert the print head.

XEROX DFC165 & DWC165c Service Manual 3-7

Page 38

- Remove the print head and clean the contacts with a piece of felt, pressing firmly (see Fig. 3-8);

Fig. 3-8 Cleaning the print head contacts

clean the contacts on the print carriage with a soft, dry cloth (see Fig. 3-9);

3-8

contacts

on print

carriage

Fig. 3-9 Cleaning the contacts on the print carriage

reinsert the print head.

- Replace the print head

- Replace the print carriage (see section 7.2.15).

XEROX DFC165 & DWC165c Service Manual

Page 39

3.1.5 Inserting the Output Trays

Place the received or copied document tray on the guide tabs, and the document

output tray between the two slots on the sides (see Figs. 3-10 and 3-11)

guide tabs

Fig. 3-10 Inserting the received or copied document tray

received or copied

document tray

slot

document

tray

slot

Fig. 3-11 Inserting the document tray

XEROX DFC165 & DWC165c Service Manual 3-9

Page 40

3.1.6 Loading Paper

When adding paper to print received and copied documents, the following three

factors must be taken into consideration and must always match for the facsimile

machine to work properly:

- paper size, i.e. the width of the paper used

- ASF tray width, i.e. the distance between the inner sides of the ASF tray

- printing format, i.e. the setting of the FORMAT parameter in the PRINTER

PARAMETERS menu

1) Check that the ASF is set for the paper size you wish to use, i.e. that the distance

between the inner sides coincides with the width of the paper used. If it does

not, remove the cover of the ASF by gripping it at the centre of its lower edge,

position the two inner sides (using a screwdriver to release them at the bottom)

to fit the paper used (Fig. 3-12):

l on the inner guides (1), for A4 format

l on the outer guides (2), for LETTER and LEGAL formats

2 1

left inner side

right inner side

1 2

Fig. 3-12 Preparing the automatic sheet feeder

2) Reassemble the cover and insert the ASF in its housing, then tilt the cover forward

and load the paper of the desired size (max 70 sheets)(Fig. 3-13)

3-10

XEROX DFC165 & DWC165c Service Manual

Page 41

cover

automatic

sheet

feeder

Fig. 3-13 Inserting the ASF and the paper

3) Close the cover of the ASF and set the FORMAT parameter in the PRINTER

PARAMETERS menu to the value that corresponds to the size of the paper and

width of the tray (see section 3.2.1).

4) Make a copy to check that the job has been carried out correctly: if any of the

factors do not coincide, the following message will appear:

PAPER ERROR

PRESS STOP

5) To eliminate the error, proceed as follows:

l switch off the facsimile machine

l remove the ASF and check that the distance between the inner sides corre-

sponds to the width of the paper used

l power on the facsimile machine and check that the FORMAT parameter

corresponds to the previous setting made

l reinsert the ASF.

3.1.7 Feeding special papers manually on the LinkFax model

When you use the LinkFax model as a printer, the following special papers can be

used: Transparency film (with backing), Transparency film with border, Glossy

paper, Coated paper, and Thick paper.

If the paper to be used is not easily fed into the facsimile machine (i.e. it is too thick,

too heavy or too smooth, as when transparency films with border and thick paper

are used), it is necessary to feed it manually (see chapter 10, Using the facsimile

machine as a printer, Printing with LinkFax 8).

XEROX DFC165 & DWC165c Service Manual 3-11

Page 42

3.2 INSTALLING AND SETTING UP THE MACHINE

The procedures used for installing and setting up the machine may be divided into

indispensable procedures (marked by the background ) and procedures that

depend on the characteristics of the telephone exchange or the user's requirements (marked by the background ).

3.2.1 Organization of the Installation and Setup Parameters

The installation and setup parameters are organized into menus and submenus,

shown on the display as follows:

top line

DISPLAY

bottom line

- the top line is used for displaying:

• menu and submenu items, which represent the operating selections available

on the facsimile machine

• parameters, to which a value is to be assigned to make an operating selection

- the bottom line is used for displaying the keys that handle the items indicated

on the top line, that is:

FUNCTION for selecting menu and submenu items, which can be scrolled

cyclically forwards only, i.e. from the first to the last and then

skipping straight back to the first again

START for confirming menu and submenu items, parameters and

values:

• by confirming a menu, you access the corresponding submenu

3-12

• by confirming a submenu, you access the corresponding

parameters

• by confirming a parameter or its value, you access the next

parameter

XEROX DFC165 & DWC165c Service Manual

Page 43

< > for selecting the values of a parameter, scrolling forwards and

backwards through those available on the machine, or for moving

along the characters that make up the parameter value. In the latter

case, the value must then be set using the numeric keypad

STOP for exiting from installation or setup mode.

A schematic diagram of parameter management is provided below:

OPERATING SELECTION PARAMETER SETTING

FUNCTION

MENU

)FUNC

)FUNC

)FUNC

START

SUBMENU

)FUNC

START

PARAMETER

SELECTION

PARAMETERS

STOP

EXIT FROM

MODE

)START

)START

< >

START

SETTING OF

VALUE

VALUES

)>

)>

The figure that follows provides a detailed illustration of the organization of the

installation and setup parameters.

XEROX DFC165 & DWC165c Service Manual 3-13

Page 44

SUBMENU

INSTALLATION

TEL. LINE SET-UP

LANGUAGE

STATION NAME

PHONE NUMBER

DIAGNOSTICS

PRINT INSTALL.

MENU

TX FROM MEMORY

PRINT OUT REPORT

FAX SET-UP

DELAYED TX

POLLING RX

POLLING TX

INSTALLATION

(*) These parameters

are not displayed in

some national versions.

SUBMENU

SERVICE PARAM.

PARAMETERS

TEL. LINE SET-UP

PUBL. LINE (PSTN) (*)

PRIV. LINE (PBX) (*)

PBX DIAL

PSTN DIAL.

EXT. LINE

REMOTE START

RING COUNT (*)

FAX/TEL TIMER

SILENCE LAPSE (*)

LANGUAGE

ITALIAN

ENGLISH

etc.

STATION NAME

TYPE YOUR NAME

PHONE NUMBER (*)

TYPE YOUR NUMBER

DIAGNOSTICS

REMOTE DIAG.

LINE MONITOR

SERVICE PARAM.

TYPE PASSWORD

COUNTRY SET-UP

SERVICE SWITCHES

SYSTEM TEST

PRINT SERV. SW

PRINT PROT. DUMP

PRINT COUNTERS

VARIOUS SETTINGS

PRINTER PARAMET.

CODED SPEED DIAL

PRINT OUT SET-UP

HEAD MAINTENANCE

PARAMETERS

VARIOUS SETTINGS

ECM

FAILED TX REPORT

BROADC. REP.

DELAY LIST

TX SPEED

HEADER

RETRANS.DOC.

CONF. TEL. NUM.

COPY/TX RES.

BUZZER VOL.

PRINTER PARAMET.

SIZE

REDUCTION

SURPLUS

DATE AND TIME

FORMAT: DD/MM/YY

FORMAT: 24H

FAX SET-UP

DATE AND TIME

ONE TOUCH DIAL

ONE TOUCH DIAL

TYPE ONE TOUCH

NUMBER

SPEED

OVERSEAS

NAME

EDIT ANOTHER

CODED SPEED DIAL

TYPE SPEED NO.

NUMBER

SPEED

OVERSEAS

NAME

EDIT ANOTHER

PRINTOUT SET -UP

PRINT SETTINGS

PRINT: ONE TOUCH

PRINT: SPEED DIAL

PRINT: EXIT

HEAD MAINTENANCE

CLEANING

3-14

XEROX DFC165 & DWC165c Service Manual

Page 45

3.2.2 Setting the Country Parameters

This procedure enables you to adapt some specific parameters automatically to the

values preset for a particular country.

Setting

a) The facsimile machine is in stand-by mode

b) Press FUNCTION to access the main menu

c) Select the SERVICE SWITCHES submenu of the IN-

STALLATION menu.

d) Press START

e) Enter the number 1 1 0 0 and press START to enter

"service" mode

Display

AUTOMATIC RX

09-05-95 14:58

FAX SET-UP

FUNC/START/STOP

SERVICE SWITCHES

FUNC/START/STOP

TYPE PASSWORD

z

COUNTRY SETUP

START/STOP/←/→

f) Press START to confirm the COUNTRY SETUP item

g) Select the desired country (for example, U.K.), and then

press START: the values for the selected country are

automatically loaded, then the facsimile machine returns

to stand-by mode.

WARNING: After setting the country parameters it

is possible, whenever necessary, to

reload the default values for the current country, by means of the following

simplified procedure;

- press in rapid sequence STOP # #

- press START.

AMERICA

START/STOP/←/→

U.K.

START/STOP/←/→

AUTOMATIC RX

09-05-95 14:58

COUNTRY SETUP

START/STOP/←/→

AUTOMATIC RX

09-05-95 14:58

XEROX DFC165 & DWC165c Service Manual 3-15

Page 46

3.2.3 Storing the User's Number and Name

Setting

a) The facsimile machine is in stand-by mode

b) Access the main menu and select the STATION NAME

item on the INSTALLATION menu

c) Press START

d) Enter the user's mnemonic ID:

- you can use a maximum of 16 alphanumeric charac-

ters

- select one character at a time using the numeric keys,

as shown below:

key 1, characters: 1

key 2, characters: 2 A B C

key 3, characters: 3 D E F

key 4, characters: 4 G H I

key 5, characters: 5 J K L

key 6, characters: 6 M N O

key 7, characters: 7 P R S

key 8, characters: 8 T U V

key 9, characters: 9 W X Y

key 0, characters: 0 Q Z

key *, characters: symbols (selected "forwards")

key #, characters: symbols (selected "backwards")

Display

AUTOMATIC RX

09-05-95 14:58

STATION NAME

FUNC/START/STOP

TYPE YOUR NAME

z

Example

TYPE YOUR NAME

JOHN

- each key selects the characters cyclically, starting

from the numeric character and displaying each of the

other characters when pressed

- to change a capital letter into a lower case letter, or

vice versa, press the key A↔a after entering it: the new

mode will remain set until the same key is pressed

again.

- confirm the character selected by pressing the > key:

the cursor will move one place to the right

- to correct an error, move the cursor to the character to

be changed using the > and < keys, and select the

desired character.

3-16

XEROX DFC165 & DWC165c Service Manual

Page 47

Setting

- to delete the entire entry, press CLEAR

Display

- having made the entry, press START to access the

PHONE NUMBER item

e) Press START

f) Enter your number:

- you can enter a maximum of 16 characters using the

numeric keys (0 : 9), the * key (to enter the + character)

and the > key (to enter a space)

- to correct or delete, proceed as for the mnemonic ID

- having made the entry, press START

g) Press STOP to return to stand-by mode.

PHONE NUMBER

FUNC/START/STOP

TYPE YOUR NUMBER

z

Example

TYPE YOUR NUMBER

+39 125 524598

DIAGNOSTICS

FUNC/START/STOP

AUTOMATIC RX

09-05-95 14:58

3.2.4 Setting Up the Telephone Line

According to the type of network to which the facsimile machine is connected

(PUBLIC NETWORK or PRIVATE BRANCH EXCHANGE), the following specific

parameters must be set:

- type of dialling (established by the Telephone Service Manager):

· tone (or multifrequency) (PBX/PSTN DIAL: TONE)

· pulse (PBX/PSTN DIAL: PULSE)

- type of access from private line to public line:

· numeric prefix (EXT. LINE: PREFIX)

· earth pulse (EXT. LINE: EARTH)

· flash pulse (EXT. LINE: FLASH).

XEROX DFC165 & DWC165c Service Manual 3-17

Page 48

In addition to these indispensable parameters, the following parameters may also be

set:

- enabling of extension telephone for activating the facsimile machine ( REMOTE

START), by means of a one-digit code (0-9)

- number of rings after which the facsimile machine prepares for automatic

reception (RING COUNT: 01 / 02 / 04 / 08)

- time (in seconds) after which the facsimile machine with the fax/phone feature

enabled switches to fax mode (FAX/TEL TIMER: 15 / 20 / 30 / 40)

- time (in seconds) after which the facsimile machine connected to an external

telephone answering machine switches to fax mode, when there is no incoming

message (SILENCE LAPSE: 3 / 4 / 6 / 8 / 10 / NO).

Setting

a) The facsimile machine is in stand-by mode

b) Access the main menu and select the TEL.LINE SETUP

submenu of the INSTALLATION menu.

c) Press START

d) Set the parameters to the desired values, following the

explanatory flow chart shown below:

TEL.LINE SET UP

PRIV. LINE (PBX) PUBL. LINE (PSTN)

PBX DIAL:PULSE PBX DIAL:TONE

Display

AUTOMATIC RX

09-05-95 14:58

TEL.LINE SETUP

FUNC/START/STOP

PUBL.LINE (PSTN)

START/STOP/←/→

EXT.LINE:PREFIX EXT.LINE EARTH EXT.LINE: FLASH

TYPE PREFIX

PSTN DIAL:PULSE PSTN DIAL:TONE

REMOTE START:ON REMOTE START:OFF

TYPE CODE

RING COUNT: 01 RING COUNT 02 RING COUNTY:04 RING COUNT:08

FAX/TEL/FAX: 15 FAX/TEL TIMER: 20 FAX/TEL TIMER: 30 FAX/TEL TIMER: 40

E LAPSE: 3 SILENCE LAP

3-18

SILENCE LAPSE: 4 SILENCE LAPSE: 6 SILENCE LAPSE 8 SILENCE LAPSE: 10

XEROX DFC165 & DWC165c Service Manual

Page 49

3.2.5 Completing Installation

Installation may be completed by setting the FAX SET-UP to suit the user's needs.

See the User Manual for a description of the procedure to be followed.

3.2.6 Resetting the Fax Machine

Having installed the machine, if it does not work properly in reception and transmission, reset the parameters to restore the default values and repeat the installation

procedure from the start.

Setting

a) The facsimile machine is in stand-by mode

b) Access the main menu and select the SERVICE

SWITCHES submenu of the INSTALLATION menu.

c) Press START

d) Enter the number 1 1 0 0 and press START to enter

"service" mode

e) Select the SYSTEM TEST item and press START

Display

AUTOMATIC RX

09-05-95 14:58

SERVICE SWITCHES

FUNC/START/STOP

TYPE PASSWORD

z

COUNTRY SETUP

START/STOP/←/→

SYSTEM TEST

START/STOP/←/→

f) Select LOAD DEFAULT and press START twice: the

default values for U.K./SOUTH AFRICA are loaded

LOAD DEFAULT

START/STOP/←/→

automatically in place of those set previously

g) Press STOP to return to stand-by mode.

AUTOMATIC RX

09-05-95 14:58

WARNING: having installed the machine successfully, never repeat the

reset procedure or you will have to reset all personal data set by

the user.

XEROX DFC165 & DWC165c Service Manual 3-19

n

.

Page 50

4. SERVICE SWITCHES

The term service switches is intended to mean parameters that cannot be

accessed by the user and that can only be accessed by service technicians with

the facsimile machine in "service" mode (see section 3.2.2).

These parameters are given default values which depend on the country specifications made by the telephone network manager. As a result, the technician should only

change these values in order to correct the functioning of the machine or to adapt it to

particular local features.

Before changing any of the service switch settings, it is advisable to print them, as

described below:

Setting

Display

a) The facsimile machine is in standby mode

b) Access the main menu and select the SERVICE

SWITCHES submenu of the INSTALLATION menu

c) Press START

d) Enter the number 1 1 0 0 and press START to enter

"service mode"

e) Select the PRINT SERV. SW option

f) Press the START key: the current default values will be

printed (see fig. 4-1)

AUTOMATIC RX

09-05-95 14:58

SERVICE SWITCHES

FUNC/START/STOP

TYPE PASSWORD

z

COUNTRY SETUP

START/STOP/←/→

PRINT SERV. SW

START/STOP/←/→

PRINTING...

STOP

g) Press STOP to return to standby mode.

XEROX DFC165 & DWC165c Service Manual 4-1

AUTOMATIC RX

09-05-95 14:58

Page 51

Fig. 4-1 Example of a printout of the service switch settings

Two types of service switches are available in the SERVICE SWITCHES menu:

- SW01 - SW11: these switches consist of 8 bits and can

be programmed either individually or in group

SERVICE SWITCHES

SW01 01010101

bit no. 76543210

- SWA - SWR: these switches consist of a value ranging

from 1 to 3 digits

SERVICE SWITCHES

SWR 120

Warning: 1) Whenever no value is printed in correspondence with a service

switch SWA-SWR, this means that the value is 0 (zero).

2) Some of the service switches can be set by the user; in these cases,

the user setting takes priority over the service setting. The

parameters concerned are:

User parameter Software parameter

RING COUNT SWB

FAX/TEL TIMER SWM

SILENCE LAPSE SWO

4-2

XEROX DFC165 & DWC165c Service Manual

Page 52

4.1 SERVICE SWITCH TABLES

The tables that follow describe the functions carried out by the bits and combinations

of bits for each service switch. In order to correctly interpret some of the functions

required, a knowledge of the communication protocol is required. The default values

may undergo some modifications due to both homologation and user's peculiarities. For

this reason, you are recommended to print out the service switches of the facsimile

machine to be serviced, always before modifying them.

Switch SW01

bit Function set to 1 set to 0

7 Error code generated YES NO

on failed reception

Next page sent from the ADF

or resent from memory

6 despite bad reception signal YES NO

(RTN) from the receiver

Multifrequency bit 5 4 = 0 0, -11 / -9

5 output level bit 5 4 = 0 1, -8 / -6

4 (dBm) bit 5 4 = 1 0, -12 / -10

bit 5 4 = 1 1, -10 / -8

Cable equalizer bit 3 2 = 0 0, 0 km (0 dB)

3 in reception bit 3 2 = 0 1, 1.8 km (4 dB)

2 (radius of cable = 0.4 mm) bit 3 2 = 1 0, 3.6 km (8 dB)

bit 3 2 = 1 1, 5.6 km (12 dB)

Cable equalizer bit 1 0 = 0 0, 0 km (0 dB)

1 in transmission bit 1 0 = 0 1, 1.8 km (4 dB)

0 (radius of cable = 0.4 mm) bit 1 0 = 1 0, 3.6 km (8 dB)

bit 1 0 = 1 1, 5.6 km (12 dB)

XEROX DFC165 & DWC165c Service Manual

4-3

Page 53

Switch SW02

bit Function set to 1 set to 0

7 Answer to second

6 Tone duration / pause bit 6 5 4 = 0 0 0, 70 / 70

5 in tone dialling bit 6 5 4 = 0 0 1, 70 / 140

4 (ms / ms) bit 6 5 4 = 0 1 0, 87 / 87

3 Disable non standard YES NO

signal from the receiver YES NO

(anti-echo device)

bit 6 5 4 = 0 1 1, 120 / 120

bit 6 5 4 = 1 0 0, 200 / 200

features (NSF)

2 Reception 9600-2400 4800-2400

start speed (V.29,V.27ter)(V.27ter only)

bit 1 0 = 0 0, 9600 bps

1 Transmission bit 1 0 = 0 1, 7200 bps

0 start speed bit 1 0 = 1 0, 4800 bps

bit 1 0 = 1 1, 2400 bps

4-4

XEROX DFC165 & DWC165c Service Manual

Page 54

Switch SW03

bit Function set to 1 set to 0

7 Page loss when 12 mm 8 mm

Automatic transmission in

6 HOOK mode without pressing YES NO

START at the end of dialling

5 emitted by the receiver NO YES

SURPLUS = AUTO

Transmission of the tone

during reception (CED)

4 Anti-echo protect tone YES NO

in transmission

3 Reception sensitivity -47 dBm -43 dBm

bit 2 1 = 0 0, 35 s (*)

2 Wait time for signal from bit 2 1 = 0 1, 60 s (*)

1 receiver during transmission bit 2 1 = 1 0, 90 s (*)

bit 2 1 = 1 1, 130 s (*)

Frequency of the tone

0 emitted by the receiver 1100 Hz 2100 Hz

during reception (CED)

(*) In some countries these bits are set to a single specific value.

XEROX DFC165 & DWC165c Service Manual

4-5

Page 55

Switch SW04

bit Function set to 1 set to 0

7 Reception channel bit 7 6 = 0 1, average

6 evaluation criteria bit 7 6 = 1 0, moderate

5 Pause between digits 800 ms 900 ms

4 Dial pulses bit 4 3 = 0 0, N

3 (N = digits dialled) bit 4 3 = 0 1, N + 1

bit 7 6 = 0 0, strict

bit 7 6 = 1 1, loose

in pulse dialling

bit 4 3 = 1 0, 10 - N

2 Pulse dialling frequency 20 p/s (*) 10 p/s

1 Report printing inhibited always (**)

0 PBX dialling tone YES NO

detection

(*) only valid if the value of switch SWP is halved.

(**) as programmed via TX REPORT user parameter.

4-6

XEROX DFC165 & DWC165c Service Manual

Page 56

Switch SW05

bit Function set to 1 set to 0

7 Earth pulse duration 100 ms 300 ms

6 Flash pulse duration 110 ms 270 ms

5 Pause time bit 5 4 = 0 1, 3 s

4 bit 5 4 = 1 0, 4 s

3 PAUSE key enabling NO YES

bit 5 4 = 0 0, 2 s

bit 5 4 = 1 1, 5 s

2 Limit to the number of unlimited for 11 s

pauses that may be inserted number max

bit 1 0 = 0 0, 1 s

1 Predialling pause bit 1 0 = 0 1, 2 s

0 (*) bit 1 0 = 1 0, 3 s

bit 1 0 = 1 1, 4 s

(*) only valid if dial tone detection is not enabled (SW06, bit 2 = 0).

XEROX DFC165 & DWC165c Service Manual

4-7

Page 57

Switch SW06

bit Function set to 1 set to 0

7 Dialling tone bit 7 6 = 0 1, 360 / 520 Hz

6 frequency range bit 7 6 = 1 0, 300 / 640 Hz

5 bit 5 4 3 = 0 0 1, 800 ms

4 Dialling tone bit 5 4 3 = 0 1 0, 900 ms

3 detection time bit 5 4 3 = 0 1 1, 1200 ms

bit 7 6 = 0 0, 320 / 570 Hz

bit 7 6 = 1 1, 300 / 640 Hz

bit 5 4 3 = 0 0 0, 400 ms

bit 5 4 3 = 1 0 0, 1800 ms

bit 5 4 3 = 1 0 1, 2000 ms

2 PSTN dialling tone YES NO

detection

Shortcircuit

1 between digits YES NO

in pulse dialling

Shortcircuit time

0 on relay, before and after 260 / 70 ms 86 / 48 ms

dialling pulse

4-8

XEROX DFC165 & DWC165c Service Manual

Page 58

Switch SW07

bit Function set to 1 set to 0

7 detected after YES NO

Exchange tones detected

6 during preliminary YES NO

5 Rapid preamble recognition YES NO

during the handshake phase

Busy tone

dialling

phase of reception

4 Minimum memory space 128 kbytes 17 kbytes

reserved to receiving

3 Report always printed YES NO

on failed transmission

2 Busy tone seek time 20 s standard

after dialling (*)

1 Frequency range of 1120: 1160 Hz as for the 1st

second dialling tone Belgian type dialling tone

0 Dialling tone 40 s 10 s

wait time

(*) i.e., as established by the couple of bits 1 and 2 of switch SW03.

XEROX DFC165 & DWC165c Service Manual

4-9

Page 59

Switch SW08

bit Function set to 1 set to 0

7 Full line monitoring YES NO

6 Transmission retries limited YES NO

within a fixed time range (*)

4 detection bit 5 4 = 0 1, -30 dBm

5 threshold bit 5 4 = 1 0, -26 dBm

3 Line feed (*) 1/300" 1/150"

Dialling tone bit 5 4 = 0 0, -40 dBm

bit 5 4 = 1 1, -35 dBm

2 Exit from HOOK mode after 1 h after 1 min

1 Busy tone detected YES NO

before dialling

0 Busy tone sequence 4 sequences 2 sequences

(*) LinkFax model, only

4-10

XEROX DFC165 & DWC165c Service Manual

Page 60

Switch SW09

bit Function set to 1 set to 0

7 Switching off manual automatic

5 reception/transmission bit 6 5 = 0 1, 16 min

6 time for one page bit 6 5 = 1 0, 32 min

4 Size of data block 64 bytes 256 bytes

ERROR LED after 1 min

Maximum bit 6 5 = 0 0, 8 min

bit 6 5 = 1 1, unlimited

packets in ECM (*)

3 Compression method MR & MH MH

2 Print chart enabled YES NO

1 Frequency and sequence of Type B Type A

answer tone in FAX/TEL mode (**) (***)

0 Extended error codes YES NO

(*) only to be used on lines with interference

(**) Frequency: 425 Hz

Sequence: 1 s 4 s

(***) Frequency: 700 Hz

Sequence: 0.1 s 0.1 s 0.1 s 0.1 s 0.1 s 2 s

XEROX DFC165 & DWC165c Service Manual

4-11

Page 61

Switch SW10 (to enable / disable user-level functions)

bit Function set to 1 set to 0

Change in dialling mode

7 by pressing the YES NO

¬ key disabled

6 MMR compression method (*) YES NO

5 Enable remote diagnostics YES NO

4 Set number of rings YES NO

3 Enable pulse mode YES NO

during dialling

2 Set silence time detection YES NO

1 FAX/TEL switch YES NO

0 Set call time YES NO

in FAX/TEL mode

(*) LinkFax model, only

4-12

XEROX DFC165 & DWC165c Service Manual

Page 62

Switch SW11 (to enable / disable user-level functions)

bit Function set to 1 set to 0

7 Enable FAX/TAD NO YES

6 Not used

5 Reserved

4 Protection for YES NO

telephone credit card (*)

3 How the console key always in the selected

names are displayed in English language

2 Linking between fixed to 1

letters and numeric keys (never set to 0)

1 Disable "second tone" NO YES

function of HOLD - 2.TONE key

0 Enable entry of YES NO

sender's number

(*) In order to prevent the secret card code from being either

displayed or printed, only the last 10 digits of the telephone

number are displayed or printed.

XEROX DFC165 & DWC165c Service Manual

4-13

Page 63

Switch SWA

Switch SWB

Switch SWC

Format Function

1 digit Time before answering

(0 : 9) (in seconds)

Format Function

2 digits Number of rings before answering

(01 : 10)

Switch SWD

Switch SWE

Format Function

max 3 digits First ring detection time (in tens of ms)

(001 : 255)

Format Function

max 3 digits Second ring detection time

(001 : 255) (in tens of ms)

Format Function

4-14

max 3 digits Ring reset time (in hundreds of ms)

(001 : 255)

XEROX DFC165 & DWC165c Service Manual

Page 64

Switch SWF

Switch SWG

Format Function

Maximum percentage of

max 2 digits incorrect lines on a page

(00 : 15) without an error message

(00 = function disabled)

Format Function

Maximum number of

max 2 digits incorrect lines on a page

(00 : 15) without an error message

(00 = function disabled)

Switch SWH

(*) 03 : 15 for Italy.

Switch SWI

Switch SWJ

Format Function

max 2 digits Transmission level code

(00 : 15) (*) (in dBm)

Format Function

max 3 digits Minimum ring duration

(010 : 100) (in ms)

Format Function

max 3 digits Maximum ring duration

(010 : 100) (in ms)

XEROX DFC165 & DWC165c Service Manual

4-15

Page 65

Switch SWK

Switch SWL

Format Function

max 2 digits Number rings before answering

(00 : 99) in manual reception mode

(00 = no answer in manual RX)

Format Function

max 2 digits Wait time of the tone emitted by the

(01 : 99) sender before alarm to the operator

in FAX/TEL mode (in seconds)

Switch SWM

Switch SWN

Format Function

max 2 digits Alarm duration

(01 : 99) in FAX/TEL mode (in seconds)

Format Function

max 2 digits Time between two calls while

(01 : 99) broadcasting (in seconds)

Switch SWO

4-16

Format Function

max 2 digits Silence recognition time in

(01 : 59) FAX/TAD mode (in seconds)

XEROX DFC165 & DWC165c Service Manual

Page 66

Switch SWP

(*) with a pulse dialling frequency of 20 p/s, halve the value used with

the 10 p/s frequency.

Switch SWQ

Format Function

max 2 digits Break time

(50 : 80) in pulse dialling (in ms) (*)

Format Function

max 2 digits Number of redials

(00 : 99)

Switch SWR

Format Function

max 3 digits Time between redials (in seconds)

(000 : 999) (000 = no redials)

XEROX DFC165 & DWC165c Service Manual

n

4-17

.

Page 67

5. DIAGNOSTICS

5.1 SELF-DIAGNOSTICS

The facsimile machine automatically runs a diagnostic program (SELF-DIAGNOSTIC TEST) the first time it is powered on and on reactivation after a power failure

or disconnection from the mains:

- if the self-diagnostic test is passed, the facsimile machine enters standby mode

- if the self-diagnostic test is failed as a result of a correctable error, the facsimile

machine displays an error code on the display.

If this occurs, you must always replace the motherboard, unless a keyboard

error occurs (in this case you must replace the console board or the flat cable that

connects it to the motherboard).

The self-diagnostic routine tests the following components:

• EPROM

• keyboard

• printer.

The self-diagnostic test stops at the first test in which a fault is detected.

XEROX DFC165 & DWC165c Service Manual 5-1

Page 68

5.1.1 Description of the Self-Diagnostic Program

Diagnostic step Error message

1) The facsimile machine is powered on: the error LED lights up.

2) The EPROM is tested.

3) The keyboard RAM is tested.

4) The keyboard EPROM is tested.

5) The display is tested.

6) Communication between the keyboard and motherboard is tested.

7) Printer startup: check that the

print carriage is reset.

8) The paper edge sensor is tested.

SYSTEM ERROR 93

SYSTEM ERROR 06

SYSTEM ERROR 07

SYSTEM ERROR 08

SYSTEM ERROR 09

SYSTEM ERROR 03

SYSTEM ERROR 04

(*)

9) The position of the print carriage

is tested.

10)The facsimile machine enters

stand-by mode: the error LED

SYSTEM ERROR 05

AUTOMATIC RX

09-05-95 14:58

gets off.

(*)This error also occurs if the print head is mounted the wrong way round, that is, with

the contacts facing the rear; consequently, start by checking that the print head is

positioned correctly.

5-2

XEROX DFC165 & DWC165c Service Manual

Page 69

5.2 ERROR CODES

The error codes are printed on the journals (see section 5.3).

The format of these error codes, excluding those referring to the self-diagnostic test

(described in section 5.1.1), may be:

- one group of two digits (xx)

- two groups of two digits separated by a dot ( xx.xx); this extended format:

• indicates the category to which the error belongs, by means of the first group,:

01 Document incorrectly positioned

02 Unable to connect

03 No answer from correspondent

04 Failed transmission

05 Incomplete transmission

07 Document too long

08 Document jam

10 Failed or incomplete reception

11 No reception due to memory full

13 Failed polling reception

16 Power failure

• provides more detailed information about the error, by means of the second

group, and may be requested by the technician with the machine in "service"

mode (see section 3.2.2), by setting bit 0 of switch SW09 to 1 (see section 4.1).

In the tables that follow, the error codes are indicated in their extended format and

in ascending numeric order.

For an explanation of the meaning of the protocol signal codes that appear in the

description of the causes of errors, see the next section (5.2.1).

Important: to ensure correct identification of the cause of the error, we recom-

mend you always print the communication protocol (PROTOCOL

DUMP, see section 5.2.3).

XEROX DFC165 & DWC165c Service Manual 5-3

Page 70

5.2.1 Meaning of Protocol Signal Codes

Code Name Type of signal

CRP Command Repeat GENERIC

CED Called (Station Identification)

CIG Calling (Subscriber Identification)

CSI Called asubscriber Identification

DIS Digital Identification Signal

NSC Non-Standard Command INITIAL

IDENTIFICATION

NSF Non-Standard Facilities

NSS Non-Standard Set-up

TCF Training Check Frame

TSI Transmitting Subscriber Identification

DTC Digital Transmit Command POLLING

COMMANDS

DCS Digital Command Signal TRANSMISSION

COMMANDS

CFR Confirmation To Receive PRE-MESSAGE

ANSWERS

FTT Failure To Train

CTC Continue To Correct

EOM End-of-Message

EOP End-of-Procedure

EOR End-of-Retransmission POST-MESSAGE COMMANDS

MPS Multipage Signal

PPS Partial Page signal

5-4

XEROX DFC165 & DWC165c Service Manual

>>

Page 71

PRI Procedure Interrupt

RR Receive Ready

CTR Response to CTC

ERR Response to EOR

MCF Message Confirmation

PIN Procedure Interrupt Negative

PIP Procedure Interrupt Positive POST-MESSAGE ANSWERS

PPR Partial Page Request

RNR Receive Not ready

RTN Retrain Negative

RTP Retrain Positive

DCN Disconnect DISCONNECTION

XEROX DFC165 & DWC165c Service Manual 5-5

Page 72

5.2.2 Meaning of Error Codes

Code Cause of Error Action

02.00 Unable to connect None

03.00 No answer from correspondent Call again

04.00 No connection due to Call again

disconnected correspondent

(DCN received)

04.01 No connection due to incompatible Call again

correspondent

(during handshake phase)

04.02 No connection due to incompatible Call again

correspondent

04.03 No connection due to incompatible Call again

correspondent

(incompatible confirmation signal)

04.04 No connection due to incompatible Call again

correspondent

(DCN instead of confirmation signal)

04.05 Line error as no further speed Call again

fall-back is possible

04.06 No connection due to problems Call again

on receiver's side (no answer)

04.07 No answer during Call again

post-message phase

04.08 Answer not allowed during Call again

post-message phase

04.09 No development of protocol Call again

04.10 Answer not allowed during Call again

post-message phase in ECM

5-6

XEROX DFC165 & DWC165c Service Manual

>>

Page 73

Code Cause of Error Action

04.11 No answer during Call again

post-message phase in ECM

04.12 Insufficient memory Call again

on receiver's side

05.00 Transmission incomplete Call again

07.00 Document too long Call again

08.00 Document jam Remove document

09.00 STOP pressed during TX or RX None

10.00 Text coding error None

at start of message

10.01 No connection due to None

incompatible correspondent

10.02 No reception due to no answer None

from correspondent during

handshake, or at the end of the block, or at

the end of a page with change in resolution

10.03 Line error due to incompatible None

speed

10.04 No commands received Call again

from correspondent

10.05 Text coding error None

(5 seconds without data)

10.06 No signal during Call again

reception of the message

10.07 No commands received Call again

from correspondent at start of message

10.08 No document present on None

polling request

>>

XEROX DFC165 & DWC165c Service Manual 5-7

Page 74

Code Cause of Error Action

10.09 Page received incorrectly Call again