Page 1

Xerox DocuPrint Network Printer Series

Troubleshooting Guide

for Models 96/4635/180 NPS

Version 7.1

August 2000

721P86651

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©1997, 1998, 1999, 2000 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 721P86651

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of other

companies are also acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent

editions.

Page 3

Laser safety

Warning: Adjustments, use of controls, or performance of

!

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance standards of the U.S. Department of Health, Education,

and Welfare for Class 1 laser products. Class 1 laser products do not

emit hazardous radiation. The DocuPrint printers do not emit

hazardous radiation because the laser beam is completely enclosed

during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must be

removed with a tool. DO NOT REMOVE LABELED PANELS OR

PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

Ozone information

Operation safety

This product produces ozone during normal operation. The amount

of ozone produced depends on copy volume. Ozone is heavier than

air. The environmental parameters specified in the Xerox installation

instructions ensure that concentration levels are within safe limits. If

you need additional information concerning ozone, call 1-800-8286571 to request the Xerox publication 600P83222, OZONE.

Your Xerox equipment and supplies have been designed and tested

to meet strict safety requirements. They have been approved by

safety agencies, and they comply with environmental standards.

Please observe the following precautions to ensure your continued

safety.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

Warning: Improper connection of the equipment grounding

!

conductor may result in risk of electrical shock.

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE iii

Page 4

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result in

poor performance and may create a hazardous situation.

• Never move either the printer or the Printer Controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety at

the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your local Xerox

operating company.

iv XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 5

Table of contents

Laser safety iii

Ozone information iii

Operation safety iii

Introduction vii

About this guide vii

Contents vii

Conventions viii

Related publications ix

1. Calling for service 1-1

Information to have on hand when calling for service 1-1

Enabling and disabling the modem for remote service 1-2

2. Fault masking 2-1

3. Troubleshooting Xerox Client Software installation 3-1

4. Troubleshooting a Novell implementation 4-1

5. Clearing paper misfeeds and jams 5-1

Clearing a feeder tray fault 5-1

Frequent misfeeds 5-3

Clearing paper jams 5-4

Checking job integrity following a paper jam 5-5

Printer areas 5-6

Clearing bypass transport paper jams 5-16

Paper curl and paper jams 5-18

Measuring the paper curl 5-18

Adjusting the decurler lever 5-19

6. Using sample documents 6-1

Listing and printing sample documents 6-1

List Sample Documents 6-1

Print Sample Document 6-2

7. Adjusting print quality and speed 7-1

Installing the custom transfer assist blade 7-1

Correcting skewed printing 7-2

Measuring performance 7-4

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE v

Page 6

TABLE OF CONTENTS

Calculating throughput 7-5

Minimizing the start-up latency 7-7

300 dpi versus 600 dpi performance 7-9

Setting page order 7-10

Product features that affect print quality 7-10

Proprietary PostScript extensions 7-10

Device-dependent operators 7-11

Gray shading—setscreen and setcolorscreen 7-11

Gray shading—settransfer and transfer function 7-11

Smooth curves—setflat 7-12

Invisible strokes—0 setlinewidth 7-12

Scan conversion—fill, eofill, and stroke 7-12

8. Correcting stacking problems 8-1

9. System unresponsive 9-1

Index INDEX-1

vi XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 7

About this guide

Introduction

This Xerox DocuPrint Network Printer Series Troubleshooting Guide

describes how to solve some specific problems that may occur when

you are using the Xerox DocuPrint 96, 4635, or 180 Network Printing

System (NPS).

This guide is designed for Xerox DocuPrint 96/4635/180 NPS

operators whose job consists of the routine operation of one of these

systems.

Users should have an understanding of Printer Controller operations.

Before using this guide, become familiar with its contents and

conventions.

Contents

This section lists the contents of this guide:

• Chapter 1, “Calling for service,” describes the information to

have on hand when calling for support service.

• Chapter 2, “Fault masking,” describes how the Model 96/4635/

180 NPS masks a problem so that the job will continue to print.

• Chapter 3, “Troubleshooting Xerox Client Software installation,”

provides solutions to common problems with software

installation.

• Chapter 4, “Troubleshooting a Novell implementation,”

describes some ways to troubleshoot a Novell implementation

by viewing log messages.

• Chapter 5, “Clearing paper misfeeds and jams,” illustrates how

to clear paper misfeeds and jams from various parts of the

paper path.

• Chapter 6, “Using sample documents,” describes how you can

print sample documents to test the printing capability of your

system.

• Chapter 7, “Adjusting print quality and speed,” provides various

methods for optimizing print quality and speed.

• Chapter 8, “Correcting stacker problems,” provides solutions to

common stacker problems.

• Chapter 9, “System unresponsive,” provides solutions to

specific printer problems.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE vii

Page 8

INTRODUCTION

Conventions

This guide uses the following conventions:

• All caps and angle brackets—Within procedures, the names of

keys are shown in all caps within angle brackets (for example,

press <RETURN>).

• Angle brackets—Variable information, or the position of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold—Within procedures, text and numbers that you enter are

shown in bold (for example, enter privilege operator).

• “Enter”—Within procedures, the two-step process of keying in

data and pressing <RETURN> (for example, enter y).

• Italics—Document and library names are shown in italics (for

example, the Xerox DocuPrint Network Printer Series

Troubleshooting Guide).

• Quotes—Keywords you can enter as arguments appear in

quotes (for example, “USLetter”).

• Vertical bars—Alternatives to specified arguments are

separated by vertical bars (for example, Set Time <Time |

Remote Host Name | IP Address>).

Note: Notes are hints that help you perform a task or understand

the text.

Caution: Cautions alert you to an action that could damage

hardware or software.

Warning: Warnings alert you to conditions that may affect the

!

safety of people.

viii XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 9

Related publications

INTRODUCTION

The Xerox DocuPrint Network Printer Series includes the following

documents:

Decomposition Service and Tools Guide

Guide to Configuring and Managing the System

Guide to Managing Print Jobs

Guide to Performing Routine Maintenance

Guide to Submitting Jobs from the Client

Guide to Using Page Description Language

Installation Planning Guide

Messages Guide

System Overview Guide

Troubleshooting Guide

Glossary

Master Index

Customer Information Quick Reference Card

Printer Controller Commands Quick Reference Card

Submitting your Jobs from Macintosh Quick Reference Card

Submitting your Jobs from UNIX & DOS Quick Reference Card

Submitting your Jobs from Windows NT 4.0 (QuickPrint) Quick

Reference Card

Submitting your Jobs Using Windows NT 4.0 Drivers Quick

Reference Card

The documentation set also includes an electronic version, the

DocuPrint NPS Interactive Customer Documentation CD.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE ix

Page 10

INTRODUCTION

x XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 11

1. 1Calling for service

Before calling your customer service support center, make sure you

have read this chapter and have tried the corrective actions

described here. If the problem persists, gather the necessary

information and call the customer support center.

Information to have on hand when calling for service

To report DocuPrint hardware or software problems in the United

States, call the following number:

1-800-822-2979

For customers outside the United States, call your local service

representative.

Note: A model-specific phone number is attached to your printer at

installation time.

Before calling, make note of the following:

• Status code numbers and messages that appear on the

controller screen and the printer console

• Indicator lights that are lit

• Name of your printer: DocuPrint 96, 4635, or 180 NPS

• Serial number for your printing system (a 9-digit alphanumeric

code located on the frame inside the printer, behind the narrow

door to the far left, on the front of the printer).

• Problems you are having with the system.

Additional information you may wish to note prior to calling includes:

• An explanation of how output differs from what was expected.

• An assessment of whether the symptoms follow a pattern or

occur randomly.

• A list of special conditions that may be related to the problems:

— New applications

— Changes made to the software

— Recent service performed

— Previous conditions under which the application has

printed properly.

Give this information to a customer service representative, who will

discuss the information and give you an estimated time of arrival or

assist you over the phone to resolve the problem.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 1-1

Page 12

CALLING FOR SERVICE

Enabling and disabling the modem for remote service

Your system may be set up to use Sixth Sense Technology—a

remote communication capability. Sixth Sense Technology is a suite

of tools that allow service personnel to connect with a system and

evaluate its performance. The service person can troubleshoot

problems remotely, transfer, apply, and remove patches remotely,

and, if an on-site call is required, arrive with the solution to fix the

problem.

An external modem allows your system to be accessed by remote

service technicians.

You may be instructed to enable the modem so that the technician

can dial into your system. Prior to enabling the modem, be sure to

use the Stop All command so that printing and queueing are stopped

during the remote service session.

When the remote service session is complete, disable the modem

and enter the Start All command to resume printing and queueing.

Refer to the Guide to Configuring and Managing the System chapter

“Using utility commands” for more information on the commands

used for remote service.

If security is a concern, you can turn off the modem, or you can

physically disconnect the cable from the system when it is not being

used.

Caution: Depending on the commands used by the technician, the

printer may start up during the remote service session. You should

not attempt to operate the system or perform any tasks at the printer

during the remote service session.

1-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 13

2. 2Fault masking

This chapter describes the behavior of the 96/4635/180 NPS while

printing with fault conditions in existence.

The DocuPrint 96, 4635, and 180 NPS enable you to continue

printing while certain faults or conditions exist in parts of the printer

not currently in use. Such faults or conditions are said to be masked.

If, for example, you are printing a job using feeder tray 1 and stacker

bin A, the printer continues printing even if feeder tray 2 is jammed or

if stacker bin B is full.

When there is a masked fault or condition, the Hint icon (a light yellow

circle with an asterisk inside) appears on the printer console and the

Attention light goes on. A message, preceded by an asterisk, also

appears in line 3 of the message area of the printer console. To

display the area containing the masked fault (for example, the

location of the paper jam), touch the Fault List icon (shown below) on

the printer console to display the Fault List screen.

Figure 2-1. Fault List icon

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 2-1

Page 14

FAULT MASKING

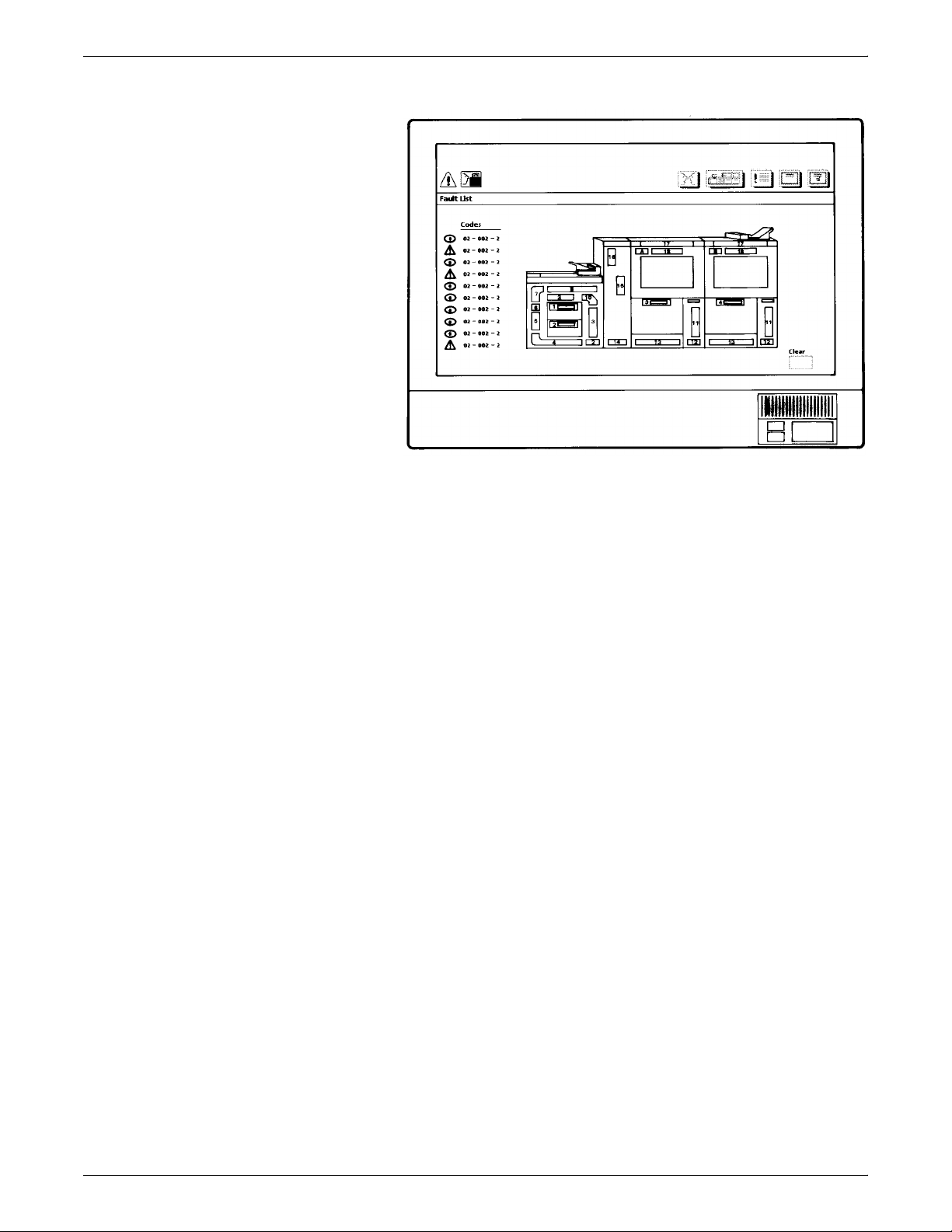

Figure 2-2. Fault List screen

The Fault List screen displays any outstanding fault codes and

shows a mimic of the printer; the area containing the masked fault is

highlighted in light yellow. For greatest printer productivity, clear any

masked faults at your earliest opportunity.

When the printer stops because of a fault, display the Fault List

screen after clearing the fault to see if there are any masked faults.

Clear these masked faults before continuing with the print job.

When there is a fault that cannot be masked and therefore causes

the printer to stop, the Fault icon (a dark yellow triangle with an

exclamation point inside) appears on the printer console and the

Attention light flashes. The Fault screen appears on the printer

console, highlighting (in dark yellow) the area(s) of the printer

containing the fault and giving instructions for clearing the fault.

If a fault exists in the system at the time that a masked fault occurs,

the printer console displays only the Fault icon. The remaining

masked fault condition messages still display in the message area of

the printer console.

2-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 15

3. 3Troubleshooting Xerox Client

Software installation

If you are unable to install the Xerox Client Software, or if you install

it and all requests submitted fail, try the following:

• Make sure the Xerox Client print command does not clash with

the local print command on the client system. To verify this, at

the prompt (or on a new shell window prompt, for Sun clients),

enter print. You should see the usage message for the Xerox

Client print command.

If not, make sure the environment variable path includes the

subdirectory /usr/xerox/nps/client/bin and /usr/bin before the

subdirectory containing the local print command. Also, resolve

any print command aliases that might be set in the.cshrc file.

If you see the message “Server or Directory Unreachable” after

executing a print command, perform the following steps:

1. If the Printer Controller software is newly installed, verify

that job processing has been started at the Printer

Controller.

2. At the client, verify the host file exists and contains the

Printer Controller name and TCP/IP address.

3. Verify the network connections between the Printer

Controller and the client. Enter ping <Printer Controller

name>; if that fails, enter ping <Printer Controller name

TCP/IP address>. Verify that the TCP/IP address of the

Printer Controller is the same as the one in the host file on

the client.

4. Check for hardware problems.

• Verify that the cconf file (/usr/xerox/nps/client/cconf) contains

the default Printer Controller name that most recently

performed the client installation. Try submitting requests to

another Printer Controller by using the server override switch in

the print command.

• If you are unable to install the software, make sure the client

hard disk meets the minimum requirements. Otherwise, you

may run out of disk space during the installation, and you may

get misleading error messages.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 3-1

Page 16

TROUBLESHOOTING XEROX CLIENT SOFTWARE INSTALLATION

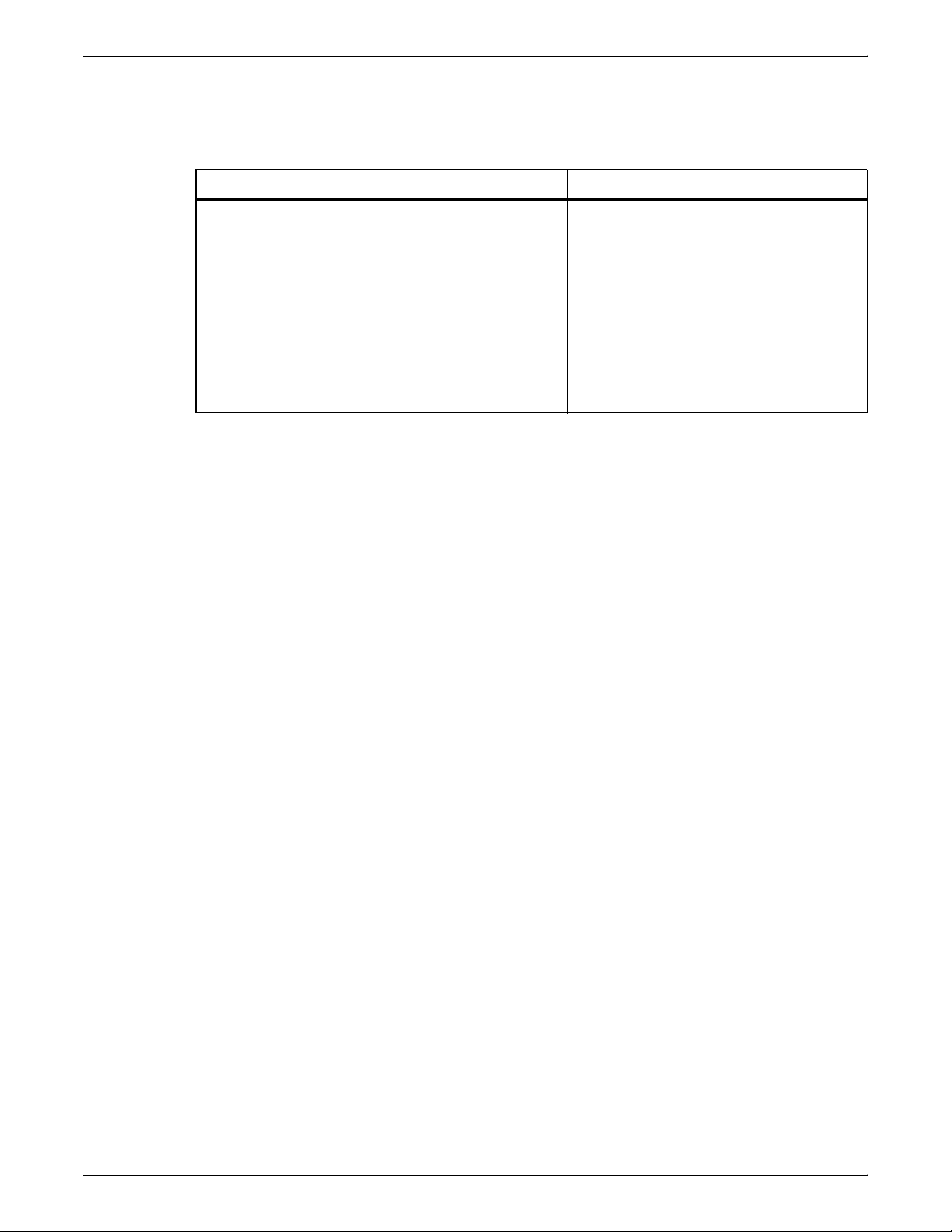

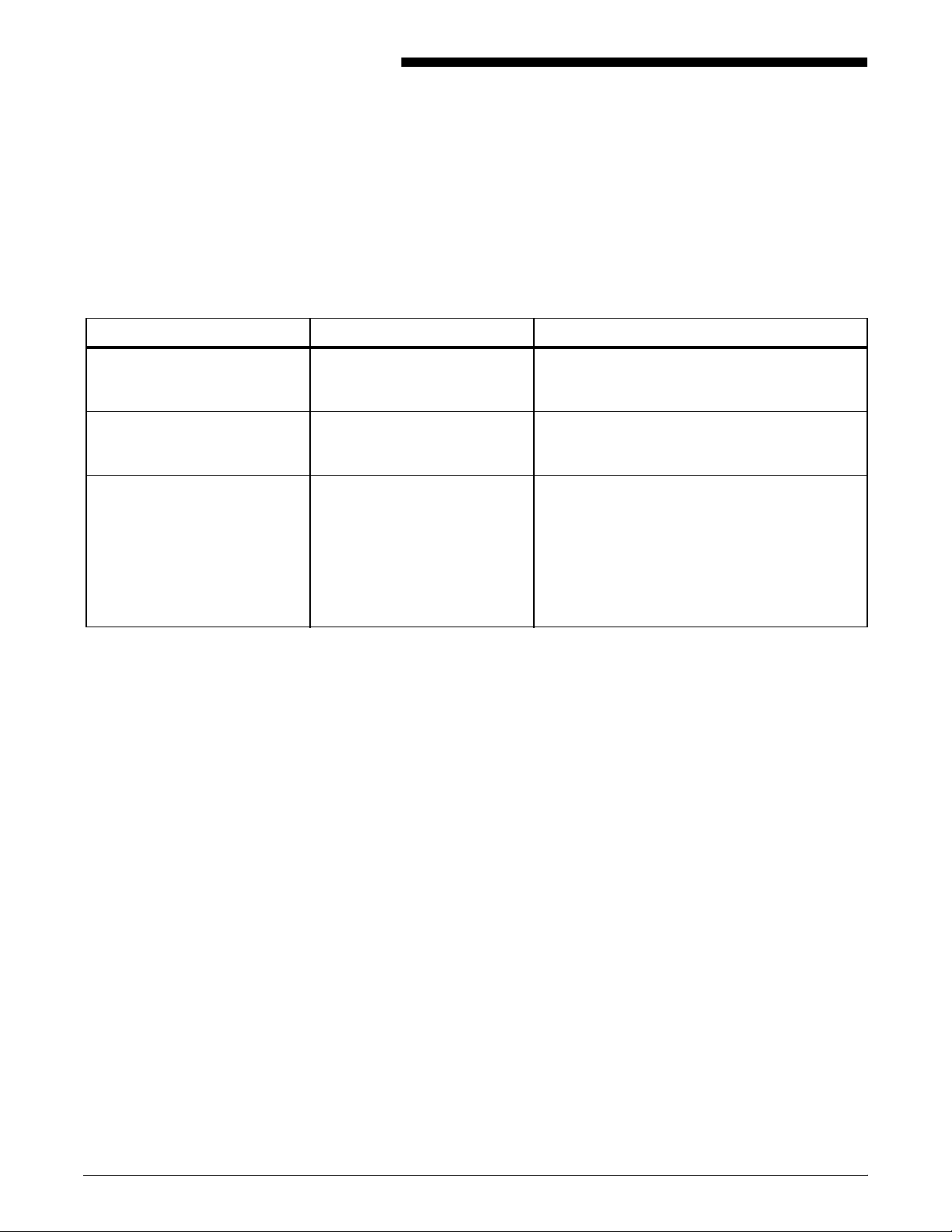

The following table, “Xerox Client Software installation error

messages” provides a reference to error messages that may display

during installation of Xerox Client Software.

Table 3-1. Xerox Client Software installation error messages

Error message Description

Installation not complete. Problems may have

occurred during the transfer of files. Please verify that

all files have been transferred and contact your

system administrator for assistance.

Usage: <Printer__Controller__Name> or

Usage: instsun4 <Printer__Controller__Name> or

Usage: instsun3 <Printer__Controller__Name> or

Usage: instult <Printer__Controller__Name>

Appears if any of the client files are missing

at the end of installation.

Appears when the Printer Controller Name

is not used as the argument to the

installation commands. The

<Printer__Controller__Name> is the name

of the Printer Controller that the installation

commands use to install the Client

Software.

3-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 17

4. 4Troubleshooting a Novell

implementation

The following tables describe some ways to troubleshoot a Novell

implementation from the log messages that appear in the DocuPrint

NPS log /varnog/DocuPrint.

Table 4-1. PSERVER problems

Problem Probable Cause Resolution

Log message says there is a

problem locating a NetWare

server.

Log message says there is an

error in connecting to the file

server.

DocuPrint is not getting SAP

packets for the server.

• There is a basic

connectivity or routing

problem.

• The framing type has

been set incorrectly

during installation.

• The file server name has

been set incorrectly

during installation.

DocuPrint NPS is getting SAP

packets with information about

the server, but cannot

communicate with it.

• There is a basic

connectivity or routing

problem.

• DocuPrint NPS has an

incorrect network

number.

If there is an external

connectivity problem:

• Check Novell file server

console screen for

messages.

• Check that the server is

running and connected to

the network.

If it is an incorrect framing type

or server name, your Xerox

service representative must

change the configuration on

the DocuPrint NPS Printer

Controller.

If there is an external

connectivity problem:

• Check Novell file server

console screen for

messages.

• Check that the server is

running and connected to

the network.

If it is an incorrect network

number, your Xerox service

representative must change

the configuration on the

DocuPrint NPS Printer

Controller

Log message says there is a

failure to log in.

Password problem.

• Server does not accept

unencrypted logins

• DocuPrint NPS does not

have the correct

password.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 4-1

If the server is not properly

configured, enter SET

ALLOW UNENCRYPTED

PASSWORDS=ON at the

server console.

If DocuPrint has the wrong

password, your Xerox service

representative must change

the password.

Page 18

TROUBLESHOOTING A NOVELL IMPLEMENTATION

Problem Probable Cause Resolution

Table 4-1. PSERVER problems (continued)

Log message indicates failure

to login and password settings

are correct.

Log message says "Error

finding queue."

Log message says "Netware

PServer <name> not found.

Log message says that there

was an error attaching to the

queue.

A PSERVER with DocuPrint’s

Stop the PSERVER instance.

PSERVER name is running on

the file server or on another

machine (this could even be

another DocuPrint configured

to use the same PSERVER

name). The file server should

only have a PSERVER

defined with the same name

as the DocuPrint PSERVER,

there should not be an

instance of PSERVER running

under that PSERVER

definition.

Queue not created. At the file server, create the

queue, set up the printer for

the PSERVER and be sure it

will service the appropriate

queue.

The PSERVER has not been

defined on the file server.

Define a PSERVER with the

correct name on the file server

and restart the system.

DocuPrint does not have

access to the queue.

Ensure that there is a printer

defined for the PSERVER on

the file server and that the

printer is defined to service the

desired queue.

4-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 19

TROUBLESHOOTING A NOVELL IMPLEMENTATION

The following table describes troubleshooting RPRINTER problems.

Table 4-2. RPRINTER problems

Problem Probable Cause Resolution

Log message says:

• "Cannot locate any

Netware print server from

the net."

• "Requested server

<name> not responding.

DocuPrint NPS is not getting

SAP packets advertising the

print server.

• There is a basic

connectivity or routing

problem.

• The incorrect framing

type has been set.

• The print server is not

running. For RPRINTER,

there must be a

PSERVER running on the

file server with the name

specified to DocuPrint

NPS at installation time.

If there is an external

connectivity problem:

PSERVER should work when

it is repaired.

If it is an incorrect framing

type, your Xerox service

representative must change

the configuration on the

DocuPrint NPS Printer

Controller.

If print server is not running,

start one.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 4-3

Page 20

TROUBLESHOOTING A NOVELL IMPLEMENTATION

4-4 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 21

Clearing a feeder tray fault

5. 5Clearing paper misfeeds and

jams

This chapter shows the steps for clearing paper misfeeds and jams

from various areas of the printer.

When paper is misfed from the paper trays, complete the following

steps:

1. Go to the paper tray indicated by the message and graphic

displays of the printer control console.

2. Press the Tray Unlock button on the front left of the paper tray.

3. When the Ready To Open indicator is lit, pull the bar up and out

to open the tray. Pull the tray all the way out for best results.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-1

Page 22

CLEARING PAPER MISFEEDS AND JAMS

4. Press the green lever to unlatch the paper feeder assembly.

5. Remove and discard any partially fed paper. Make sure the

paper supply is neatly stacked and the stack is not higher than

the MAX line on the length guide. Make sure the length guide

is firmly touching the back edge of the stack.

6. Latch the paper feeder assembly by pressing the green dot until

the assembly clicks into place.

5-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 23

Frequent misfeeds

CLEARING PAPER MISFEEDS AND JAMS

7. Slide the tray back into the printer until the tray latches and

press the Continue button to resume printing.

8. Discard any pages sent to the sample tray or unused stacker

tray when the paper jam was detected.

Note: If the 96/4635/180 NPS does not continue printing after a

paper tray fault or after paper is loaded, open then close the tray. The

system should resume printing.

Frequent misfeeds may be caused by a glazed feed belt, especially

if one tray feeds the same kind of paper better than another tray

does. (Glazing is caused by a buildup of the chemicals found on most

papers.)

If you suspect that the belt is glazed, try cleaning it with film remover

obtained from your service representative.

Caution: Clean the feed belt only to correct misfeeds, not as

routine maintenance. Because the belt is rubber, frequent cleaning

dries it out and makes it fail prematurely.are or software.

1. Clear any misfeeds that have occurred, but do not latch the

paper feeder assembly. If necessary, unlatch it by pressing

down on the bright green lever on the right side of the paper

tray.

2. Lightly moisten a lint-free towel with film remover and

thoroughly wipe the outside surface of the feed belt in the same

direction as the ribs on the belt. (Wiping from side to side might

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-3

Page 24

CLEARING PAPER MISFEEDS AND JAMS

pull the belt off its track.) Allow a few seconds for the film

remover to evaporate.

3. Latch the paper feeder assembly by pressing down on the

bright green dot. Slide the paper tray completely back into the

printer

2SHUDWHWKHV\VWHPDVXVXDO,I\RXVWLOOH[SHULHQFHPLVIHHGVSODFH

DVHUYLFHFDOO

Clearing paper jams

Each area of the printer where jams can occur has detailed message

labels that tell you how to clear the jam.

Each handle, lever, or knob that must be moved to clear a jam is

bright green and marked with an arrow indicating the direction it

moves.

Follow these steps to clear a paper jam:

5-4 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 25

CLEARING PAPER MISFEEDS AND JAMS

1. Go to the area of the printer indicated by the messages and

display on the printer control console.

NOT READY

Fault Instructions

Clear any paper in areas 8, 15, 16, 17, and 18

Follow the instructions on the labels 8,15,16,17,and 18 to clear paper from theses areas.

Clear any paper in areas 8, 15, 16, 17, and 18

Clear

2. Open any printer doors necessary to access the area.

3. Clear the jammed paper from the area, following the

instructions on the Printer Controller message labels and the

messages on the printer control console. Refer to the section

“Printer areas” for more information.

Note: You may find that the printer has already cleared the

paper jam area to the sample or purge trays.

4. Close any printer doors that were opened.

5. Press the Continue button to resume printing.

6. Discard any damaged sheets sent to the sample tray or purge

tray.

Note: You may find that the printer has already cleared the paper

jam area to the sample or purge trays.

Checking job integrity following a paper jam

When printing resumes following a paper jam, there is a slight

possibility that duplicate sheets may be printed or sheets may be

missing from a job. For that reason, you should check job integrity

once the job has been printed.

Follow this procedure:

1. The printer offsets the rest of the job following a paper jam.

Locate that section.

2. Check this section and the sheets immediately before the first

offset sheet to see if there are any missing or duplicate sheets

in the job.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-5

Page 26

CLEARING PAPER MISFEEDS AND JAMS

e

,

Printer areas

This section provides illustrations of the various areas of the printer

where jams may occur.

The following illustration shows all the jam clearance areas for the

96/4635/180 printer.

Areas 17, 18

Area 8

Ar

19

Area6Areas 2,

3,4,5,7,

9,10

The following illustrations show the individual jam clearance areas of

the 96/4635/180 printer.

Area 2

Areas

14,15,

16

Area13Areas

11,12

Area13Areas

11,12

5-6 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 27

Area 3

Area 4

CLEARING PAPER MISFEEDS AND JAMS

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-7

Page 28

CLEARING PAPER MISFEEDS AND JAMS

Area 5

Area 6

5-8 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 29

Area 7

CLEARING PAPER MISFEEDS AND JAMS

Area 8

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-9

Page 30

CLEARING PAPER MISFEEDS AND JAMS

Note: If jammed paper rips as you are removing it from area 8, you

may have to use the pinch lever in area 9 to remove the paper. Refer

to the “Notes” section following the figure illustrating area 9.

Area 9

Note: Pull the area 9 green lever toward you to unlatch it. Make

sure you relatch the lever once you have cleared any paper in this

area. You may also want to pull out tray 1 and hold the green lever

down in order to remove paper wedged in this area more easily.

Area 9 also has a green knob (located to the right of the lever), which

can be turned to help you clear paper.

Using the pinch lever to access area 9: If paper rips as you are

removing it from area 9, or if you have difficulty removing paper from

this area, you may have to use the pinch lever located further inside

area 9. Follow this procedure:

1. Locate the green pinch lever directly behind area 9.

2. Carefully reaching your hand into the area, press the edges of

the pinch lever and lift it up.

Warning: This area of the printer may be hot. Be careful when

!

5-10 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

inserting your hand.

Page 31

CLEARING PAPER MISFEEDS AND JAMS

3. Remove any paper caught in this area.

4. Replace the green pinch lever to its original position.

5. Discard any paper you removed.

Area 10

Area 11

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-11

Page 32

CLEARING PAPER MISFEEDS AND JAMS

Area 12

Note: For 180 printers, when clearing area 12, you are required to

clear areas 12 and 13.

Area 13

5-12 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 33

CLEARING PAPER MISFEEDS AND JAMS

Area 14

Note: You may sometimes find paper lying on top of area 14, even

though there is no message indicating a jam in this area. Discard the

paper.

Area 15

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-13

Page 34

CLEARING PAPER MISFEEDS AND JAMS

Area 16

Note: For 180 printers, when clearing area 16, you are required to

clear areas 16 and 17.

Area 17

5-14 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 35

Area 18

CLEARING PAPER MISFEEDS AND JAMS

Note: Sometimes the printer control console messages direct you

to discard the last sheet delivered to the stack following a jam in area

18. Check for this message when clearing an area 18 paper jam.

If your printer has frequent jams in this area, you may need to clean

the Q1107A sensor. Refer to the “Cleaning the sensors and the

reflecting surfaces” section of the Guide to Performing Routine

Maintenance.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-15

Page 36

CLEARING PAPER MISFEEDS AND JAMS

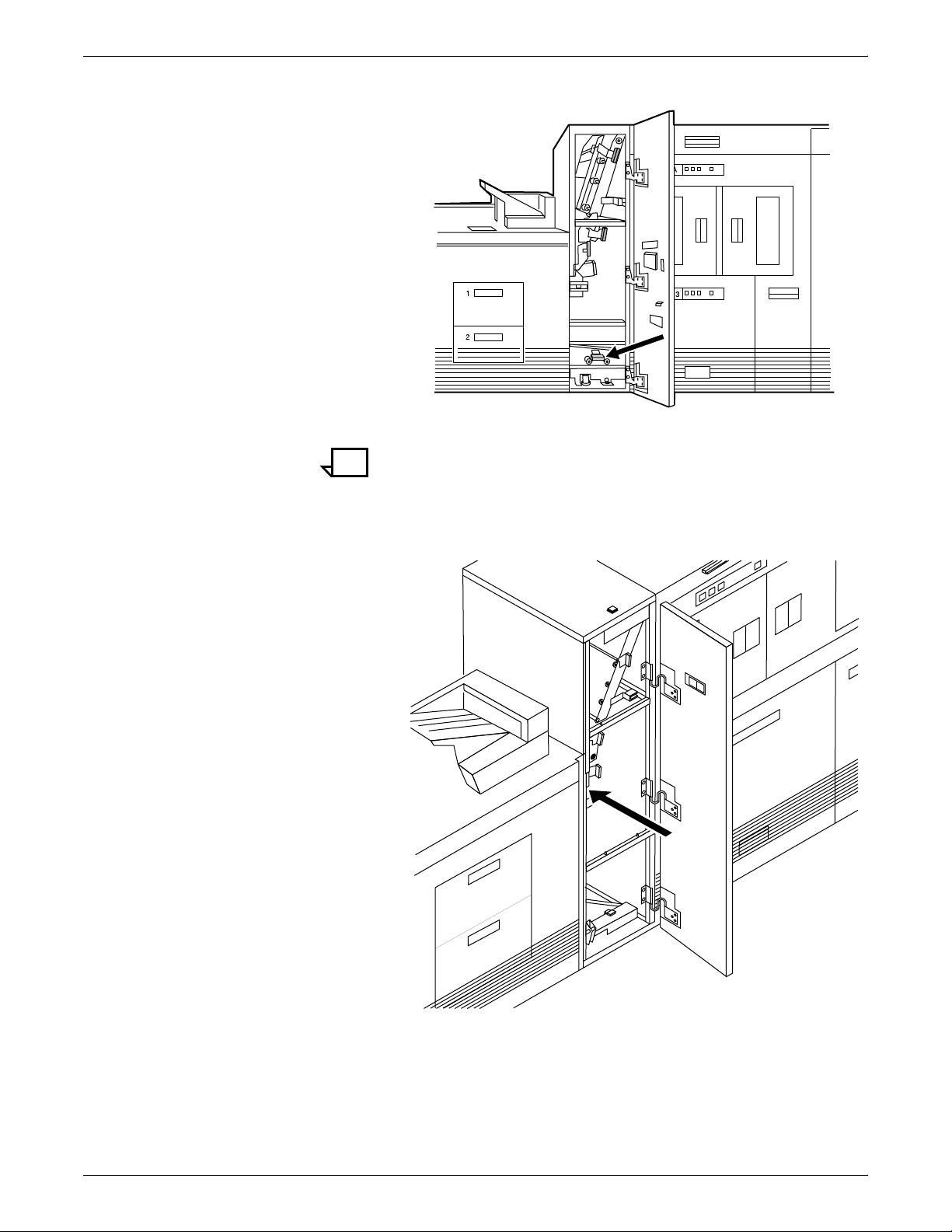

Clearing bypass transport paper jams

If your printer is configured with a bypass transport module, you

should check for paper jams in areas 19 and 20 after clearing an area

18 paper jam.

To clear bypass transport jams:

Area 19

1. Open the bypass transport module door.

2. Press the area 19 green lever in the direction of the arrow

printed on it.

3. Remove any paper in the exposed area.

4. Press the green lever to the left until the latch catches.

5. Press the area 20 green lever in the direction of the arrow

printed on it.

5-16 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 37

Area 20

CLEARING PAPER MISFEEDS AND JAMS

6. Remove any paper in the exposed area.

7. Press the green lever down and to the left until the latch

catches.

8. Close the bypass transport

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-17

Page 38

CLEARING PAPER MISFEEDS AND JAMS

Paper curl and paper jams

Measuring the paper curl

Too much curl in the paper stock can cause paper jams. You can

adjust the decurler lever to eliminate most of these problems. Refer

to the paper curl chart at the end of this chapter to determine the

amount of curl in the paper stock.

To measure the paper curl:

1. Print five one-sided (simplex) 8.5 by 11 inch or A4 sheets.

2. Measure the amount of curl in the prints by holding the five

prints in the top center of the short edge.

Keep the image toward you.

Figure 5-1. Measuring the paper curl

3. Place the bottom edge of the prints over the paper curl

measurement chart located at the end of this chapter.

• If the print curl on the printed paper stock measures

between +2 and -2, do not change the decurler setting.

• If the curl is between +2 and +3, or -3 and -4, use the

following procedure to adjust the decurler lever.

5-18 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 39

Adjusting the decurler lever

CLEARING PAPER MISFEEDS AND JAMS

To adjust the decurler lever:

1. Open the right door of the printer and locate the decurler lever.

Figure 5-2. Decurler lever

2. If the print curl is +2 or more, move the green decurler lever to

the right.

3. If the print is -3 or more, move the green decurler lever to the

left.

4. If the decurler adjustment does not eliminate the paper curl

problem, turn the paper stack over in the feeder tray.

5. If there is still a paper curl problem, perform steps 1 to 4 again.

6. If all else fails, insert paper from a new ream.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 5-19

Page 40

CLEARING PAPER MISFEEDS AND JAMS

Figure 5-3. Paper curl chart

5-20 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 41

6. 6Using sample documents

You can use sample documents to test the print quality of your

DocuPrint printer.

Listing and printing sample documents

The List Sample Documents command shows what sample

documents are available.

DocuPrintFAQ One sample document, DocuPrintFAQ, provides a list of frequently

asked questions (FAQ) and answers about DocuPrint NPS. This

document may contain information that can help you resolve some

problems.

List Sample Documents

Use the List Sample Documents command to list the available

sample documents.

Access level Administrator or operator

Syntax List Sample Documents

Arguments None

Note: The Sample button on the printer control panel is not

supported.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 6-1

Page 42

USING SAMPLE DOCUMENTS

Example Listing sample documents:

PS-op>list sample documents

Available Sample Documents are:

100 pages

2pages

4pages

50pages

dfaq0397

dpps

FontDir

HC

iso8859-1

maze

mesh50

mesh100

pclfont

shapes

StdPCLFonts

StdPSFonts

testgray

testxerox

worm

XeroxSpiral

XGFGoldenJob

XGFLicenseRequestForm

XRXGPJ1

XRXGPJ2

Print Sample Document

Use the Print Sample Document command to print the sample

document you select from the list. If you do not enter arguments with

the command, the system prompts you for them.

Access level Administrator or operator

Syntax Print Sample Document <Document> <Copies> <Plex> <Staple>

<Resolution> <Media> <Stacker group>

Arguments <Document>

Indicates the name of the sample document you want to print.

The name is case-sensitive.

<Copies>

Indicates the number of copies of the sample document you

want to print.

<Plex>

Indicates whether the sample document prints on one side of

each page or on both sides of each page. Specify “simplex,”

“duplex,” or “tumbleduplex.”

<Staple>

Indicates whether the sample document is stapled after it prints.

Specify “Staple” or “DontStaple”

<Resolution>

Indicates the printing resolution.

6-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 43

USING SAMPLE DOCUMENTS

<Media>

Indicates the media you want to use for printing the sample

document. Use the syntax <size:type:color:weight> to specify

media. Specify “USLetter,” “USLegal,” “A4” or “nxn” for the size.

Use a text string to indicate the media type and color. Specify

weight in grams per square meter (gsm).

<Stacker group>

Indicates you want the sample document to output to a

specified stacker. You can specify “Top,” “1,” or “2.”

Example Printing one duplex unstapled copy of the sample document

“shapes” at 300 dpi resolution on USLetter, white paper, output to

stacker 1:

PS–op>print sample document shapes 1 duplex dontstaple 300 USLetter::white 1

Note: When Print Sample Document is invoked with output to the

top Tray with stitching finish, the stitching is ignored.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 6-3

Page 44

USING SAMPLE DOCUMENTS

6-4 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 45

7. 7Adjusting print quality and

This chapter considers means for checking and optimizing print

quality and speed.

Installing the custom transfer assist blade

If you use nonstandard paper sizes, you should install the custom

transfer assist blade to ensure good print quality.

Caution: The custom transfer assist blade comes as a kit with

detailed instructions. Be sure to follow the instructions carefully.

To prevent damage to the printer, have your service representative

show you how to customize and install a custom transfer assist blade

for the first time.

speed

You must use the standard transfer assist blade with standard paper

of the following sizes:

• In U.S. markets

— 11.1—11.4 inches (282—290 mm)

— 11.8—12.1 inches (300—307 mm)

— 13—13.5 inches (330—343 mm)

• In non-U.S. markets

— 11.1—11.4 inches (282—290 mm)

— 11.8—12.1 inches (300—307 mm)

Note: With these paper sizes, transfer efficiency may be reduced.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 7-1

Page 46

ADJUSTING PRINT QUALITY AND SPEED

Correcting skewed printing

If the printed output is repeatedly delivered with the image skewed

(crooked on the page), or the pages themselves are damaged on

arrival at the output bin, you may need to adjust the registration

transport roll (heavy paper) levers. This may occur with heavy weight

papers. Follow this procedure:

1. Open the right and left doors of the printer and locate the heavy

paper levers, behind areas 2 and 4.

2. Pull the levers forward (toward you) on the silver latch release.

3. Turn both levers to the left (counter-clockwise), as illustrated in

the following figur

Figure 7-1. Adjusting the registration transport roll levers

Note: If your system is equipped with the optional 7 by 10-inch

paper enablement kit, it has three levers, as illustrated below.

(This kit is not available for the Model 96 NPS.)

Turn the left-most lever to the left (counter-clockwise) and the

other two levers to the right (clockwise).

7-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 47

ADJUSTING PRINT QUALITY AND SPEED

Figure 7-2. Three registration transport roll levers on system

with 7 by 10-inch enablement kit

1 Lever 1: Left - Maximum Pressure setting

2 Lever 2: Right - Maximum Pressure setting

3 Lever 3: Right - Maximum Pressure setting

4. When the print job is complete, return the levers to their normal

position.

5. Close the doors.

Note: Here are a few things to keep in mind when adjusting the

registration transport roll lever:

• Position all levers for the same (either minimum or maximum)

pressure setting. Do not intermix the positions of the levers.

• Paper greater than 14 inches / 352 mm in any dimension is

considered oversized.

• Paper heaver than 24 pounds / 90 gsm is considered heavy

weight.

• The following factors may affect the positioning of the paper

levers:

— Machine tolerance

— Paper supplier

— Job type (e.g., duplex).(clockwise).

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 7-3

Page 48

ADJUSTING PRINT QUALITY AND SPEED

Measuring performance

You can use the DocuPrint sequencer log file to calculate print

speeds. Although a stopwatch is the recommended method for

obtaining sustained throughput print speeds, the sequencer log can

be used to calculate speeds which include the start-up latency

associated with the printer. This section describes how to calculate

speeds using the sequencer log and how to minimize the start-up

latency in your calculations.

Note: The sustained throughput using a stopwatch is a better

measurement of the speed of the job since the several seconds of

start-up time do not need to be measured.

Refer to the following example when reading “Calculating

throughput.” The Show Log command in this example displays a

menu of logs with the current sequencer log named DocuPrint

sequencer:

7-4 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 49

PS-admin> Show Log

1 Quit

2 /var/log/DocuPrint

3 /var/log/DocuPrint.sequencer

4 /var/log/DocuPrint.Wed

5 /var/log/DocuPrint.Tue

6 /var/log/DocuPrint.Mon

7 /var/log/DocuPrint.sequencer.Mon

8 /var/log/DocuPrint.Sun

9 /var/log/DocuPrint.Sat

10 /var/log/DocuPrint.Fri

11 /var/log/DocuPrint.sequencer.Fri

12 /var/log/DocuPrint.Thu

13 /var/log/DocuPrint.sequencer.Wed

14 /var/log/DocuPrint.sequencer.Tue

15 /var/log/DocuPrint.sequencer.Thu

16 /var/log/syslog

17 /var/adm/messages

18 /var/adm/messages.0

19 /var/adm/messages.1

20 /var/adm/messages.2

21 /usr/spool/xerox/log/nps.log

22 /usr/spool/xerox/log/nps.log.Wed

23 /usr/spool/xerox/log/nps.log.Tue

ADJUSTING PRINT QUALITY AND SPEED

Enter choice number: 3

Enter number of lines from the end to show (or "All"): 16

Job #216 start, ftpadmin, 99995163.ps, November 19, 1996 1:16:57 pm PST

Printing duplex, 300 spi, 216 x 279 mm, 139 buf

Job #217 start, ftpadmin, 99995163.ps, November 19, 1996 1:18:38 pm PST

Job #216 stop, ftpadmin, 99995163.ps, November 19, 1996 1:19:05 pm PST

pages: 217, decomp: 84.91, elapsed: 128.49

Job #218 start, ftpadmin, 99995163.ps, November 19, 1996 1:20:14 pm PST

Job #217 stop, ftpadmin, 99995163.ps, November 19, 1996 1:20:43 pm PST

pages: 217, decomp: 83.69, elapsed: 124.94

Job #219 start, ftpadmin, 99995163.ps, November 19, 1996 1:21:46 pm PST

Job #218 stop, ftpadmin, 99995163.ps, November 19, 1996 1:22:20 pm PST

pages: 217, decomp: 84.04, elapsed: 126.62

Job #220 start, ftpadmin, 99995163.ps, November 19, 1996 1:23:19 pm PST

Job #219 stop, ftpadmin, 99995163.ps, November 19, 1996 1:23:58 pm PST

pages: 217, decomp: 84.73, elapsed: 132.42

Job #220 stop, ftpadmin, 99995163.ps, November 19, 1996 1:25:35 pm PST

pages: 217, decomp: 85.03, elapsed: 136.10

Calculating throughput

For measuring performance, note the start time, stop time,

decomposition time, elapsed time, and pages of the job being

measured:

• The start time is the time that the sequencer began to

decompose the job (translate the PostScript).

• The stop time is the time the last page was printed.

• The decomposition time is the time (in seconds) spent working

on the job. The decomposition time can be increased by factors

such as use of highlight color, images that compress poorly,

duplexing, and job size. See the Guide to Using Page

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 7-5

Page 50

ADJUSTING PRINT QUALITY AND SPEED

Description Languages for more details about factors affecting

performance.

• The elapsed time, equal to the stop time minus the start time, is

the total amount of time DocuPrint spent printing the job. The

elapsed time includes delays for warm-up time, paper loading,

jam clearing, print quality adjustments and the start-up latency

associated with the first job in a set of jobs.

• The “pages” number represents the number of images printed,

(not the number of sheets printed when running a duplex job).

To make a meaningful measurement of performance, obtain the

measurements while the printer is running a block of jobs. Since start

and stop times tend to overlap between jobs in a block, the only way

to obtain a measurement using the start and stop times is to use the

start time when the printer first powers up to print a block of jobs, then

subtract that start time from the stop time when the printer powers

down as shown in this procedure:

1. Enter Stop Printing at the Printer Controller.

2. Enter Set Option ForceReport False and Set Option

UseTitlePage False. This to avoids extra pages in the output

that are not included in the pages reported in the sequencer

log.

3. Send a series of jobs to the DocuPrint.

4. Use the List Documents command to determine that the jobs

have passed the prescanner and have a Pending status.

5. Enter Start Printing.

Note: If you experience delays due to empty paper trays or

paper jams, repeat steps 1-5 until the jobs complete without

delays.

6. Calculate the elapsed time by subtracting the stop time of the

last job from the start time of the first job.

7. Add up the total number of pages for all jobs.

8. Calculate throughput using the formula:

PPM = 60 x pages/elapsed time in seconds

Here is the calculation for the example of the sequencer log above:

The start time was: 1:16:57 pm

The stop time was: 1:25:35 pm

(This gives an elapsed time of 8 minutes and 38 seconds, or 518

seconds)

PPM = 60 x 1085/518 = 125.7 pages per minute

This example illustrates the problem with calculating the elapsed

time from the first job, since this job was actually printing at the

maximum rate of the DocuPrint Model 4635 printer (135 ppm). The

start-up latency made the printer appear to be printing at a rate 6.2

ppm lower than the maximum rate.

To verify the assumption that the sustained throughput of the job

prints at the rated speed of the printer, a calculation of the rate based

on the decomposition time is recommended. The decomposition time

gives the theoretical maximum that the DocuPrint can print this job.

7-6 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 51

Job #213 start, ftpadmin, 99995163.ps, November 19, 1996 1:05:04 pm PST

Printing duplex, 300 spi, 216 x 279 mm, 139 buf

Job #213 stop, ftpadmin, 99995163.ps, November 19, 1996 1:07:17 pm PST

pages: 217, decomp: 83.51, elapsed: 134.70

Minimizing the start-up latency

ADJUSTING PRINT QUALITY AND SPEED

Since the DocuPrint usually decomposes more than one job at a

time, the jobs are time-shared on the one processor and this will

cause the decomposition time to be larger than if the DocuPrint

decomposed once by itself. In the sample log, there are always 3 jobs

printing at the same time and the decomposition times reported vary

from 83.69 to 85.02. After submitting this job by itself, the

decomposition time reported is:

PPM=60x217/83.51 = 155.9 pages per minute

This is considerably higher than the maximum speed of the printer,

so it is very likely that this job prints at rated speed.

There are two ways to get a measurement that minimizes the impact

of the start-up latency of the printer.

• Use a stopwatch to measure the elapsed time from when the

first sheet is delivered to when the last sheet is delivered to the

output tray.

• Take the start time and stop time from the sequencer for a

larger block of jobs.

Using the second method, the same job as in the first example was

submitted 10 times to measure the throughput for 2170 pages. Here

is part of the log:

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 7-7

Page 52

ADJUSTING PRINT QUALITY AND SPEED

Sequencer restart at November 19, 1996 3:50:20 pm PST

Job #236 start, ftpadmin, 99995163.ps, November 19, 1996 3:52:22 pm PST

Printing duplex, 300 spi, 216 x 279 mm, 139 buf

Job #237 start, ftpadmin, 99995163.ps, November 19, 1996 3:53:58 pm PST

Job #236 stop, ftpadmin, 99995163.ps, November 19, 1996 3:54:34 pm PST

pages: 217, decomp: 88.31, elapsed: 131.98

Job #238 start, ftpadmin, 99995163.ps, November 19, 1996 3:55:28 pm PST

Job #237 stop, ftpadmin, 99995163.ps, November 19, 1996 3:56:11 pm PST

pages: 217, decomp: 84.58, elapsed: 132.81

Job #239 start, ftpadmin, 99995163.ps, November 19, 1996 3:56:58 pm PST

Job #238 stop, ftpadmin, 99995163.ps, November 19, 1996 3:57:48 pm PST

pages: 217, decomp: 85.04, elapsed: 139.87

Job #240 start, ftpadmin, 99995163.ps, November 19, 1996 3:58:27 pm PST

Job #239 stop, ftpadmin, 99995163.ps, November 19, 1996 3:59:27 pm PST

pages: 217, decomp: 84.39, elapsed: 148.88, compress: 3.88x, min free:

102400K

compress pages: 3, expand pages: 0

Job #241 start, ftpadmin, 99995163.ps, November 19, 1996 4:00:04 pm PST

Job #240 stop, ftpadmin, 99995163.ps, November 19, 1996 4:01:04 pm PST

pages: 217, decomp: 91.60, elapsed: 156.97, compress: 4.23x, min free:

101586K

compress pages: 21, expand pages: 0

Job #242 start, ftpadmin, 99995163.ps, November 19, 1996 4:01:41 pm PST

Job #241 stop, ftpadmin, 99995163.ps, November 19, 1996 4:02:43 pm PST

pages: 217, decomp: 90.62, elapsed: 158.70, compress: 4.05x, min free:

101849K

compress pages: 22, expand pages: 0

(More)

Job #243 start, ftpadmin, 99995163.ps, November 19, 1996 4:03:21 pm PST

Job #242 stop, ftpadmin, 99995163.ps, November 19, 1996 4:04:20 pm PST

pages: 217, decomp: 94.55, elapsed: 159.71, compress: 4.23x, min free:

101586K

compress pages: 26, expand pages: 0

Job #244 start, ftpadmin, 99995163.ps, November 19, 1996 4:04:57 pm PST

Job #243 stop, ftpadmin, 99995163.ps, November 19, 1996 4:05:57 pm PST

pages: 217, decomp: 88.65, elapsed: 156.45, compress: 3.91x, min free:

101784K

compress pages: 14, expand pages: 0

7-8 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 53

ADJUSTING PRINT QUALITY AND SPEED

Job #245 start, ftpadmin, 99995163.ps, November 19, 1996 4:06:34 pm PST

Job #244 stop, ftpadmin, 99995163.ps, November 19, 1996 4:07:31 pm PST

pages: 217, decomp: 90.09, elapsed: 154.39, compress: 4.39x, min free:

101877K

compress pages: 13, expand pages: 0

Job #245 stop, ftpadmin, 99995163.ps, November 19, 1996 4:09:08 pm PST

pages: 217, decomp: 87.61, elapsed: 154.50, compress: 5.48x, min free:

101893K

compress pages: 7, expand pages: 0

In the example shown in this log, here is the calculation:

The start time was: 4:09:08 pm

The stop time was: 10:23:31 pm

(This gives an elapsed time of 16 minutes and 30 seconds, or

990 seconds)

PPM = 60 x 2170/990 = 131.5 pages per minute

As you can see for the same job, the calculated throughput

approaches the maximum speed of the printer as the start-up latency

becomes less important and the calculation is closer to the actual

sustained throughput of the job.

300 dpi versus 600 dpi performance

There is one additional issue to consider when running performance

tests with the Model 96, 4635, or 180 systems. The above examples

were run at 300 spots per inch resolution. When a block of jobs starts,

the DocuPrint will report the printing resolution, the page size of the

document, and the number of page buffers available in the software

for the job. At 300 dpi, on 216 x 279 mm paper (UsLetter), 139 page

buffers are reported allocated. This is consistent with a DocuPrint

Printer Controller with 192 MB of memory installed.

When running jobs at 600 dpi, the amount of available page buffers

available is 4 times smaller. This leads to a corresponding decrease

in the overall performance of a job. Here is the sequencer log entry

when the above job is run at 600 dpi:

Job #214 start, ftpadmin, 99995163.ps, November 19, 1996 1:10:37 pm PST

Printing duplex, 600 spi, 216 x 279 mm, 35 buf

Job #214 stop, ftpadmin, 99995163.ps, November 19, 1996 1:13:38 pm PST

pages: 217, decomp: 147.92, elapsed: 181.47, compress: 15.08x, min

free: 101670K

compress pages: 5, expand pages: 0

As shown above, only 35 page buffers are allocated at 600 dpi. The

decomposition rate of this job at 600 dpi is:

PPM = 60 x 217/147.92 = 88.0 pages per minute,

which represents the maximum rate that this job can be printed at

600 dpi.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 7-9

Page 54

ADJUSTING PRINT QUALITY AND SPEED

Setting page order

DocuPrint delivers documents with the pages face down in the order

presented in the Page Description Language. The order can be

changed by setting the PageOrder attribute.

If the Staple attribute is set, DocuPrint must deliver the document

face up. In order to deliver the stapled document in the correct order,

it must image the document in reverse page order. In order to image

a document in reverse page order, the entire document must be

processed before printing starts.

For the best print speed, ensure that each PostScript program has

the pages in the correct order for the finishing requirement for the

document:

• No finishing is required: PDL should be in ascending page

order. PageOrder attribute should be set to ascend.

• Stapling is required: PDL should be in descending page order.

• Duplex printing is required: there should be an even number of

pages. Page order should be set to descend.

Note: If you are using a third-party finishing device connected

to DocuPrint by a bypass transport, the page delivery order is

determined by the requirements of the third-party device (face

up or face down). To maximize performance, place the pages in

the PostScript master in the order in which they are required by

the finishing device.

Product features that affect print quality

You can improve the appearance of your documents by being aware

of potential problems created through the use of proprietary

PostScript extensions and device-dependent operators.

Proprietary PostScript extensions

When PostScript masters that use proprietary PostScript extensions

to enable printer-specific features are printed on different PostScript

printers, there may be appearance inconsistencies. For example,

some versions of the Apple Macintosh PostScript driver download

encrypted proprietary image “smoothing” operators to Apple

LaserWriters. The downloaded PostScript code uses the product

operator to determine if it is being used on a LaserWriter. If not, the

proprietary code is bypassed by doing a flushfile. This allows the

PostScript master to print on non–LaserWriter products. As a result,

PostScript masters generated on a Macintosh with Apple proprietary

features may produce output that varies between LaserWriter and

non–LaserWriter PostScript printers.

7-10 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 55

Device-dependent operators

Gray shading—setscreen and setcolorscreen

ADJUSTING PRINT QUALITY AND SPEED

Some PostScript operators result in device-dependent PostScript

files. “Device dependence” means that devices having different

output characteristics may produce different-looking output even

though they use the same software. This section documents the

most serious examples of device dependence. The PostScript

Language Reference Manual, second edition, lists all of the graphics

state operators that are considered device-dependent.

Note: Depending on the emitter used, color-related operators may

be used even for monochrome jobs. On DocuPrint NPS, color jobs

undergo a color to monochrome mapping process. Therefore, if

these operators are included in the PostScript jobs, they can affect

the output.

The PostScript operators setscreen and setcolorscreen control the

PostScript halftone software that simulates various intensity levels of

gray and color inks. Since each PostScript product may have a

different default halftone definition, the halftone patterns and gray

scale range may differ also. Because setscreen is inherently device

dependent (especially when used for pattern fills), PostScript

masters look different on almost every different model of PostScript

printer.

The operators are also used to perform pattern fills, since PostScript

Level 1 does not have a pattern fill operator. (PostScript Level 2 has

pattern fill operators.) As stated in the PostScript Language

Reference Manual, first edition, “Remember that everything

pertaining to halftones is, by definition, device-dependent. In general,

when an application provides its own halftone specifications, it

sacrifices portability. Associated with every device is a default

halftone definition that is appropriate for most applications.”

In addition to the device-dependent nature of halftoning, a spot

function is used by setscreen and setcolorscreen to determine the

order of pixel darkening in the halftone cell. When two pixels have the

same spot function value, their ordering values are determined

arbitrarily. Duplicate spot function values are very common. In fact,

almost all the various default spot functions generate duplicate

values. Therefore, different PostScript implementations yield

different halftone patterns, resulting in visual differences in the

output.

Gray shading—settransfer and transfer function

The PostScript operators settransfer and setcolortransfer are

used to change the procedure for mapping perceived color values in

the output of the print device into specified color values in the

PostScript master. PostScript devices use an internal transfer array

or procedure that takes into account the printing characteristics of

their marking engines in order to produce levels of color.

Transfer functions are called by the setcmykcolor, setbsbcolor,

setrgbcolor, and setgray operator before processing of the desired

color level that is specified in the master. The transfer function takes

a value from the stack and leaves another value on the stack for each

color component (red, green, blue, and gray).

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 7-11

Page 56

ADJUSTING PRINT QUALITY AND SPEED

The PostScript language provides a scheme for overwriting the

internal transfer function of a printing device by providing the

settransfer and setcolortransfer operators. However, some Xerox

PostScript devices do not allow you to overwrite their internal transfer

function.

Typically, a master tries to replace the internal transfer function with

a null transfer function such as:

{} settransfer, or

{} {} {} {} setcolortransfer

If either of the above procedures is successful, the transfer functions

return the same color levels that are passed to them without

modifying or mapping the level. On printers which do not allow the

overwriting of the transfer function, the settransfer operator does not

affect the mapping of gray values between the output of the print

device and specified levels of color.

Note: Settransfer actually sets the transfer functions for all four

color components (red, green, blue, and gray) to the same value. The

setcolortransfer operator sets the transfer functions

individually.

Smooth curves—setflat

PostScript masters that use the PostScript operator setflat produce

inconsistent output across different PostScript printers. setflat

controls curve rendering smoothness. PostScript curve operators

use cubic Bezier control points to define the curve shape. These

curves can be rendered from straight line segments. Normally the

line segments are so short that the curve appears smooth. The

setflat operator indirectly controls the length of the straight line

segments. As stated in the PostScript Language Reference Manual,

second edition, “If the flatness parameter is large enough to cause

visible straight line segments to appear, the result is unpredictable.

setflat sets a graphics state parameter whose effect is devicedependent. It should not be used in a page description that is

intended to be device-independent.”

Invisible strokes—0 setlinewidth

PostScript masters that use the PostScript operator setlinewidth are

not consistent across different PostScript printers. setlinewidth

controls the width of a stroked line. When setlinewidth is executed

with an input of zero, it produces a line that is one pixel wide. On

devices whose dot size is small, single-pixel-width lines may be

invisible.

Scan conversion—fill, eofill, and stroke

Scan conversion algorithms are implementation-dependent, so

different PostScript printers paint (“turn on”) different dots, resulting

in output differences. For filled circles, PostScript printers differ in the

dots they paint at the edge of the circle; thus, some printers produce

slightly larger circles than others. For large circles this is not

noticeable, but for small circles, it is.

Sections 2.2 and 6.5 of the PostScript Language Reference Manual,

second edition, discuss scan conversion. Section 6.5 states that

scan conversion details are not part of the PostScript standard.

7-12 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 57

8. 8Correcting stacking problems

This chapter describes stacker problems other than paper jams. It

suggests corrective actions when printed sets are thrown around the

stacker or the bin. (See “Clearing paper misfeeds and jams” for

stacker paper jams.)

Symptom Probable cause Action

Papers are thrown around the

stacker.

Paper stack falls over or slides

around the bin

Printing stops and the printer

console displays a message

indicating that an incorrect

paper size is loaded in a

feeder tray.

Someone unloaded paper by

opening the top cover of the

stacker bin.

Excessive paper curl Try adjusting for paper curl (See “Paper curl

Incorrect paper size or a

damaged sheet.

Unload the bin following the normal procedure.

See “Unloading Stacker bin” in Guide to

Performing Routine Maintenance.).

and paper jams” in Guide to Performing

Routine Maintenance

1. Check the paper in the indicated tray.

2. If the paper is not the correct size, load

the correct size paper or select another

feeder tray containing the correct paper

size.

If the paper size is correct, press the

Continue button to resume printing.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 8-1

Page 58

CORRECTING STACKING PROBLEMS

8-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 59

9. 9System unresponsive

This chapter describes problems in which your monitor shows no

image, the printer does not respond when you press the Continue

button, or the printer main window does not respond.

Symptom Probable cause Action

Blank display: pressing a key

fails to restore image.

You have cleared all faults that

are listed on the printer control

console, but the Attention light

is still on and the following

message is displayed:

Output is stopped. See

message at the System

Display

Printer is totally unresponsive

even after pressing the

Continue button.

The first job to print after a

reboot or a diagnostics

session takes 30 to 60

seconds longer than usual.

Monitor is switched off;

brightness and contrast

controls are misadjusted; or

there is a more serious

problem.

There is an uncleared output

fault.

Unknown Enter Restart Sequencer. If that fails to

This is normal operation. No action is needed. Subsequent jobs should

1. Make sure that the monitor is switched

on.

2. Make sure that the brightness and

contrast controls (if available) are turned

far enough to the left to brighten the

screen.

3. If switch is on and controls are turned to

the left, call the service representative.

Follow the instructions in the output message

and press the Continue button.

correct the problem, enter Restart System. If

the printer is still unresponsive, call your

service representative. Refer to Guide to

Configuring and Managing the System for

more information on Restart Sequencer.

print without a delay.

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE 9-1

Page 60

SYSTEM UNRESPONSIVE

9-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Page 61

Index

Numerics

300 dpi, 7-9

600 dpi, 7-9

A

Attention light, 2-1

C

calculating throughput, 7-5

Class 1 laser device, iii

clearing

feeder trays, 5-1–5-4

Continue button, no response, 9-1

Correcting stacking problems, 8-1

curl, paper, 5-18

custom transfer assist blade, installing, 7-1

D

danger labels, iii

decurler lever, adjusting, 5-19

device-dependent operators, 7-11

DocuPrintFAQ, 6-1

settransfer function, 7-11

transfer function, 7-11

H

hard disk, Xerox Client Software requirements, 3-1

Hint icon, 2-1

hotlines

ozone information, iii

safety, iv

I

installing, custom transfer assist blade, 7-1

invisible strokes, setlinewidth, 7-12

J

job integrity, checking after paper jam, 5-5

L

labels, danger, iii

laser safety, iii

List Sample Documents command, 6-1

listing, sample documents, 6-1

E

eofill, 7-12

error messages, Client Software installation, 3-2

F

FAQ

DocuPrintFAQ, 6-1

Fault List

screen, 2-1

faults, masking, 2-1–2-2

feeder trays, clearing faults, 5-1–5-4

fill, 7-12

flushfile, 7-10

G

glazing, 5-3

gray shading

setcolorscreen, 7-11

setscreen, 7-11

XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE INDEX-1

M

masking faults, 2-1–2-2

measuring, 7-4

measuring performance, 7-4

measuring, paper curl, 5-18

messages

Client Software installation, 3-2

modem

enable, 1-2

monitor, blank display, 9-1

N

Novell implementation, troubleshooting, 4-1–4-3

O

operation safety, iii, iii–iv

ozone, iii

ozone information, iii

Page 62

INDEX

P

page order, setting, 7-10

paper

curl

adjusting, 5-19

measuring, 5-18

jams, checking job integrity, 5-5

misfeeds, frequent, 5-3

paper curl, measuring, 5-18

performance, 7-4

300 dpi vs. 600 dpi, 7-9

PostScript, proprietary extensions, 7-10

print quality, adjusting, 7-1

Print Sample Document command, 6-2

printers

paper jam areas, 5-6–5-15

start-up latency, 7-4, 7-7

printing

correcting skewed, 7-2

quality

features affecting, 7-10

sample documents, 6-1

speed, optimizing, 7-1

procedures, 7-2

see also paper, clearing jams

calculating throughput, 7-6

feed belt, cleaning, 5-3–5-4

paper trays, clearing misfeeds, 5-1–5-3

product operator, 7-10

PServer problems, 4-1

Q

Q1107A sensor, 5-15

service call, required information, 1-1

setbscolor, 7-11

setcmykcolor, 7-11

setcolorscreen, 7-11

setflat, 7-12

setgray, 7-11

setlinewidth, 7-12

setrgbcolor, 7-11

setscreen, 7-11

settransfer, 7-11

skewed printing, correcting, 7-2

smooth curves, 7-12

start-up latency

minimizing, 7-7

printers, 7-4

stroke, 7-12

System unresponsive, 9-1

T

third-party finishing device, 7-10

throughput, calculating, 7-5

transfer, 7-11

transfer functions, 7-11

Tray Unlock button, 5-1

troubleshooting

Novell implementation, 4-1–4-3

Xerox Client Software installation, 3-1

X

Xerox Client print command, 3-1

Xerox Client Software, troubleshooting installation,

3-1

R

Ready To Open indicator, 5-1

remote service, 1-2

requirements, hard disk, 3-1

RPrinter problems, 4-3

S

safety

hotline, iv

laser, iii

operation, iii–iv

precautions, iii

standards, iii

sample documents,DocuPrintFAQ, 6-1

SAP packets, 4-1

scanconversion, 7-12

sequencer log file, 7-4

server override switch, Xerox Client print command,

3-1

INDEX-2 XEROX DOCUPRINT 96/4635/180 NPS TROUBLESHOOTING GUIDE

Loading...

Loading...