Page 1

Xerox DocuPrint 96/4635/180 IPS

System Overview Guide

Version 7.1

August 2000

721P88150

Page 2

Xerox Corporation

Printing Systems Documentation and Education

701 South Aviation Boulevard, ESM1-058

El Segundo, CA 90245

©1998, 1999, 2000 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 721P88150

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of other

companies are also acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent

editions.

Page 3

Laser safety

Warning: Adjustments, use of controls, or performance of

!

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance standards of the U.S. Department of Health, Education,

and Welfare for Class 1 laser products. Class 1 laser products do not

emit hazardous radiation. The DocuPrint printers do not emit

hazardous radiation because the laser beam is completely enclosed

during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must be

removed with a tool. DO NOT REMOVE LABELED PANELS OR

PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

Ozone information

This product produces ozone during normal operation. The amount

of ozone produced depends on copy volume. Ozone is heavier than

air. The environmental parameters specified in the Xerox installation

instructions ensure that concentration levels are within safe limits. If

you need additional information concerning ozone, call 1-800-8286571 to request the Xerox publication 600P83222, OZONE.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE iii

Page 4

Operation safety

Your Xerox equipment and supplies have been designed and tested

to meet strict safety requirements. They have been approved by

safety agencies, and they comply with environmental standards.

Please observe the following precautions to ensure your continued

safety.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

Warning: Improper connection of the equipment grounding

!

conductor may result in risk of electrical shock.

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result in

poor performance and may create a hazardous situation.

• Never move either the printer or the Printer Controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety at

the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States contact your local Xerox

representative or operating company.

iv XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 5

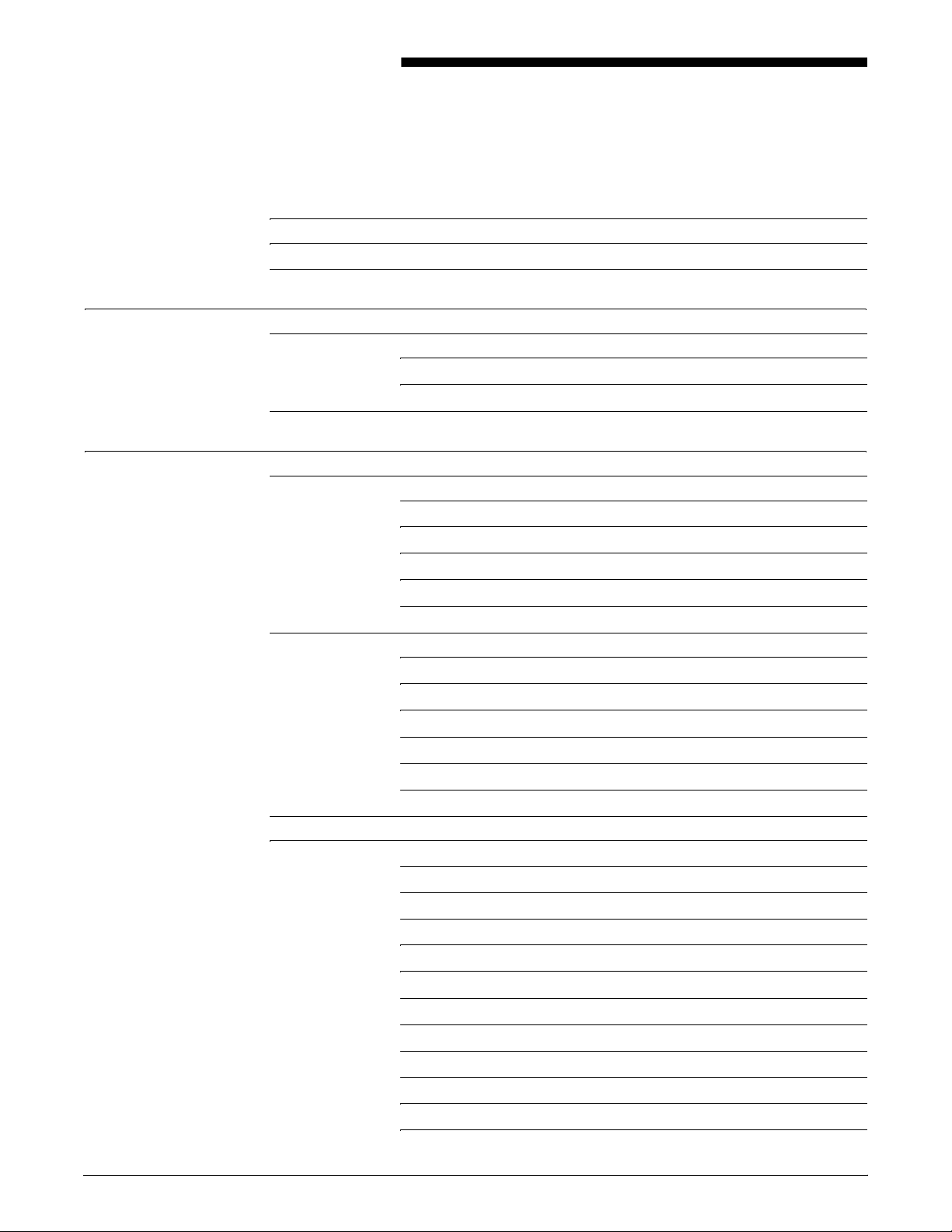

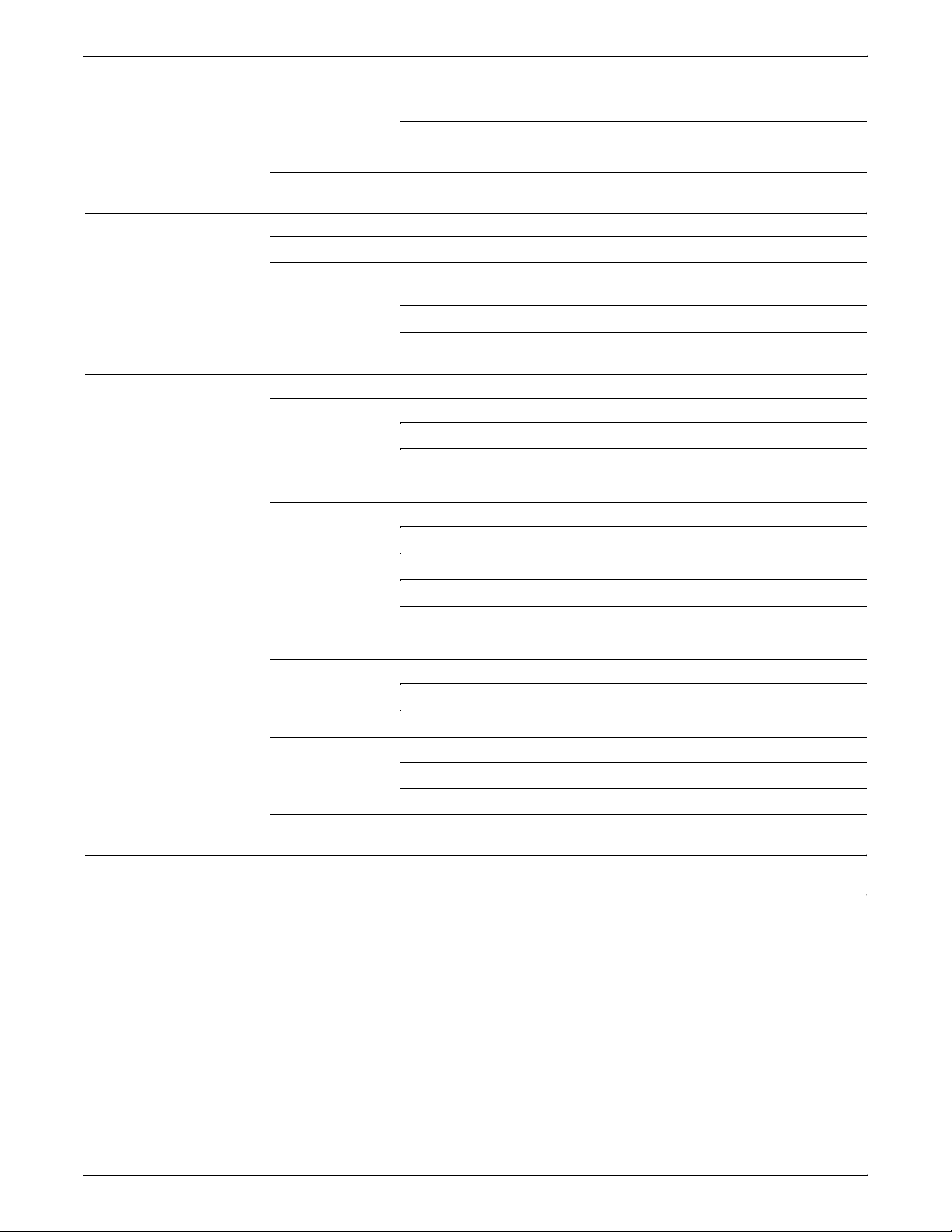

Table of contents

Laser safety iii

Ozone information iii

Operation safety iv

Introduction ix

About this guide ix

Contents ix

Conventions x

Related publications xi

1. System overview 1-1

Functional overview of the DocuPrint IPS 1-1

Major system components 1-2

Throughput speed 1-3

Host connectivity options 1-4

IPDS data stream 1-5

Dual Mode 1-5

96/4635/180 IPS hardware features 1-6

Multiple input trays 1-6

Roll feeder support 1-7

Advanced paper handling 1-7

600 dpi resolution 1-8

Multiple high-capacity output bins 1-8

Bypass transport option 1-9

User interface 1-10

Software features 1-11

Mixed paper sizes within a job 1-11

Tray selection capabilities 1-11

IOCA Replicate and Trim 1-12

Mixed plex 1-12

Enhanced N-Up 1-13

Trace facility 1-13

Overstrike, underscore, subscript, and superscript 1-13

Background color for OCA colors 1-13

Full-page 600 dpi images 1-14

Document Feeding and Finishing Architecture (DFA) 1-14

Page origin rotation for continuous form jobs 1-14

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE v

Page 6

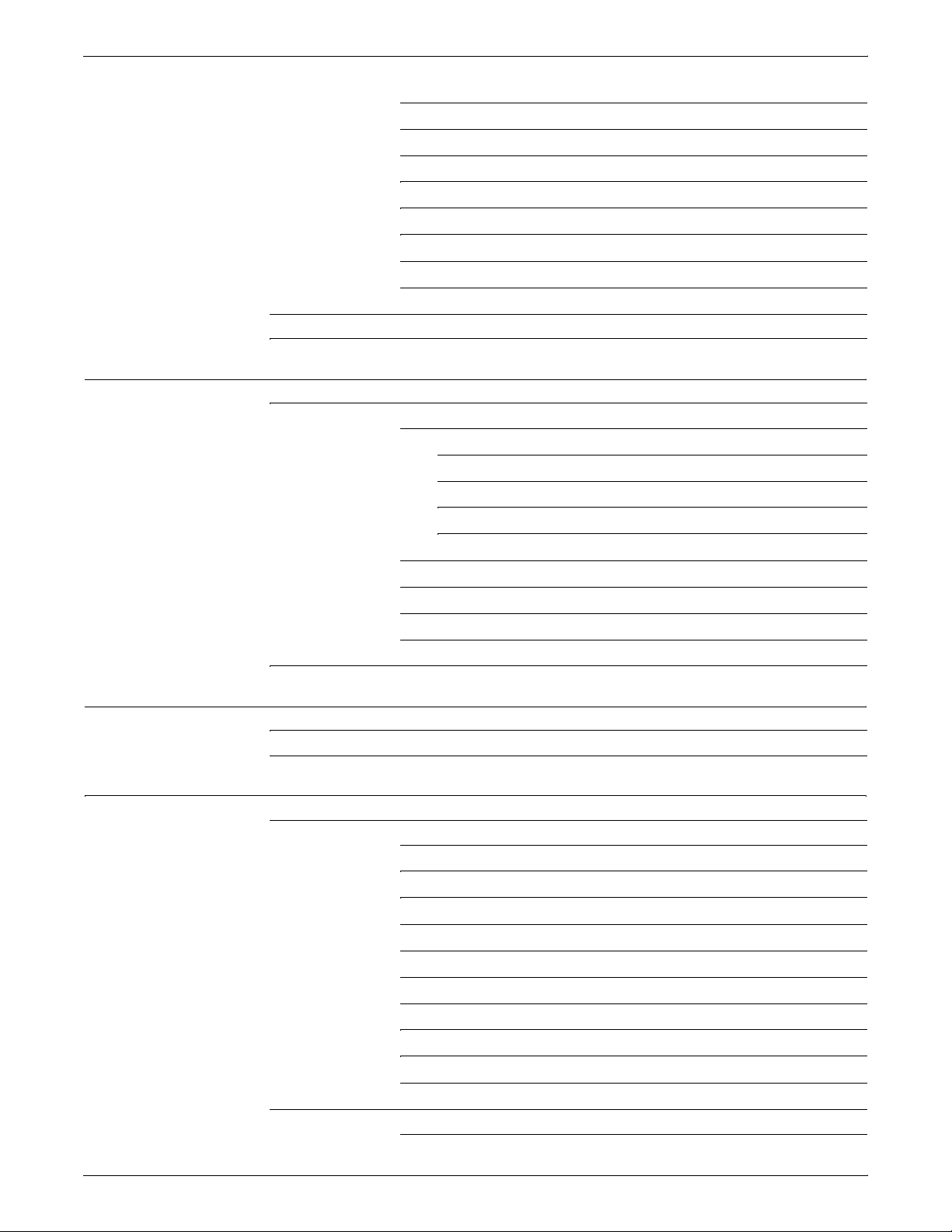

TABLE OF CONTENTS

Double-byte fonts 1-14

Outline font support 1-15

Printer resident font support 1-15

Processing options 1-15

Message translation 1-15

Configuration file processing 1-15

PCI Bus support 1-16

Access control by privilege mode 1-16

Software license 1-17

Remote service (Sixth Sense Technology) 1-17

2. Printer Controller 2-1

Components of the Printer Controller 2-1

Processor 2-3

Hard disk 2-3

Diskette drive 2-4

CD-ROM drive 2-4

Cartridge tape drive 2-4

Monitor 2-4

Keyboard 2-4

Mouse 2-4

Host Channel Unit (HCU) — channel-attached systems only 2-5

Placement of the processor 2-5

3. User interface 3-1

Graphical user interface screen 3-2

IPS main window 3-4

4. Printers 4-1

Printer components 4-2

Components overview 4-2

Printer control console 4-3

Sample tray 4-6

Attention light 4-6

Purge tray 4-6

Inverter 4-7

Feeder/stacker modules 4-7

Processor feeder trays 4-7

Feeder trays 4-8

High-capacity stackers 4-10

Printer configurations 4-12

Options enabling third-party feeding and finishing 4-14

vi XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 7

TABLE OF CONTENTS

Configurations supporting bypass transport and Input

Enablement kit 4-15

Additional IPS printer features 4-15

Printer paper paths 4-16

5. MICR IPS 5-1

96/4635/180 MICR IPS printing features 5-1

MICR output 5-3

Verifying MICR output with the MICR Position and

Dimension Gauge 5-4

Verifying MICR output with the MICR comparator 5-4

A. Paper and other supplies A-1

Paper and other throughput stocks A-1

Selecting paper A-1

Paper width and printer performance A-3

Paper care A-9

Other supplies A-12

Dry ink A-12

Fuser agent A-12

Developer A-12

Diskettes A-13

Cartridge tapes A-13

MICR tools A-14

MICR Positioning and Dimension Gauge A-14

MICR comparator A-14

Consumable supplies tables A-15

Paper and special stocks tables A-15

Complete supplies list—96/4635/180 printers A-22

Ordering supplies A-23

B. Paper performance guidelines B-1

Index INDEX-1

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE vii

Page 8

TABLE OF CONTENTS

viii XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 9

About this guide

Introduction

This Xerox DocuPrint 96/4635/180 IPS System Overview Guide

provides an overview of the individual components of the DocuPrint

IPDS Printer System (IPS) and how they work together. This

reference is designed to provide you with background information

that can be used to make informed decisions regarding printer use

and performance.

The Xerox DocuPrint 96/4635/180 IPS System Overview Guide

provides information to help you quickly determine hardware,

software, and connectivity requirements for printing from various

clients to DocuPrint IPS.

This reference is useful for workstation users, printer operators, and

system administrators who want to understand the overall DocuPrint

IPS. Managers can use the reference information to assist them in

making planning decisions.

Contents

Before using this guide, become familiar with its contents and

conventions.

This section lists the contents of this guide:

• Chapter 1, “System overview,” identifies and describes the

function of the major components of the DocuPrint 96/4635/180

IPS.

• Chapter 2, “Printer Controller,” provides the information on the

Printer Controller components, software, and fonts.

• Chapter 3, “User interface,” describes the features of the IPS

graphical user interface.

• Chapter 4, “Printer,” details the base printer components and

optional printer components.

• Chapter 5, “MICR IPS,” discusses the special features of the

96, 4635, and 180 MICR IPS systems, and the requirements for

MICR printing on the IPS.

• Appendix A, “Paper and other supplies,” provides information

and specifications on paper and other media used with the IPS

or MICR IPS, as well as instructions for ordering supplies.

• Appendix B, “Paper performance guidelines,” summarizes the

capabilities of the paper trays, duplex printing considerations,

and paper stock considerations.

An index is provided at the back of the guide.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE ix

Page 10

INTRODUCTION

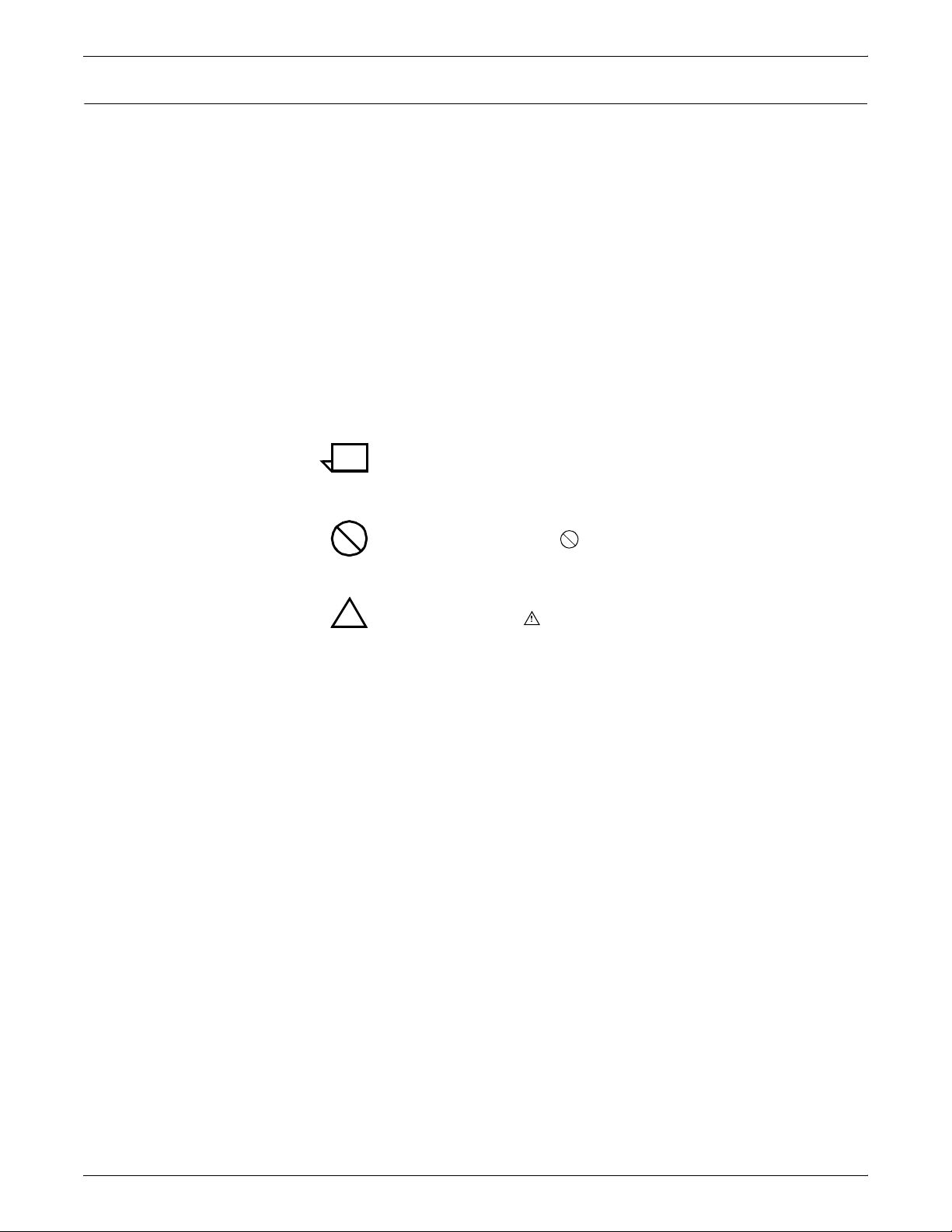

Conventions

This guide uses the following conventions:

• All caps and angle brackets — Within procedures, the names of

keys are shown in all caps within angle brackets (for example,

press <RETURN>).

• Italics — Document and library names are shown in italics (for

example, the Xerox DocuPrint 96/4635/180 IPS System

Overview Guide).

• Capitalization of graphical user interface (GUI) window titles

matches the titles as they appear on the screen. In cases where

a window does not have a title, it is referenced using all lower

case. For example:

— At the graphical user interface, use the Output

Configuration window to group the trays.

— The main window displays the current system status.

Note: Notes are hints that help you perform a task or understand

the text.

Caution: Cautions alert you to an action that could damage

hardware or software.

Warning: Warnings alert you to conditions that could affect the

!

safety of people.

x XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 11

Related publications

Xerox documents Following is a list of all Xerox DocuPrint IPS documents. For a

INTRODUCTION

This document is part of the Xerox DocuPrint IPS publication set.

complete list and description of available Xerox documentation, refer

to the Xerox Customer Documentation Catalog (publication number

610P17517), or call your service representative.

Application Programmer/System Administrator Quick Reference

Card

Customer Information Quick Reference Card

Generic MICR Fundamentals Guide

Glossary

Guide to Configuring and Managing the System

Guide to Performing Routine Maintenance

Helpful Facts About Paper

Installation Planning Guide

Master Index

Messages Guide

Solutions Guide

System Overview Guide

Troubleshooting Guide

Xerox Standard Font Library Font User Guide

The documentation set also includes an electronic version, the

DocuPrint IPS Interactive Customer Documentation CD.

IBM documents Following are related IBM documents. Contact your local IBM

representative for ordering instructions for IBM AFP/PSF manuals

that might be useful for your specific installation.

IBM 3825 Page Printer Product Description

IBM Intelligent Printer Data Stream Reference

IBM Advanced Function Presentation Printer Summary

IBM ITSC Distributing AFP Printing from a Host System

IBM Advanced Function Printing Data Stream Reference

IBM Data Stream and Object Architectures: Mixed Object Document

Content Architecture Reference

Guide to Advanced Function Presentation

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE xi

Page 12

INTRODUCTION

xii XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 13

1. 1System overview

This chapter introduces the DocuPrint 96 and 96 MICR IPS, the 4635

and 4635 MICR IPS, and the DocuPrint 180 and 180 MICR IPS

printing systems. It describes the systems’ hardware and software

components, features, functions, and modes of operation.

Functional overview of the DocuPrint IPS

The 96 IPS, 96 MICR IPS, 4635 IPS, 4635 MICR IPS, 180 IPS, and

the 180 MICR IPS print high quality documents in simplex or duplex

mode at high speeds.

DocuPrint IPS printers support:

• Duplex printing

• Media handling of multiple weights, sizes, and types

• Optional modules for enhanced finishing and output to third-

party finishing devices

• Optional enabling of third-party roll feeders

• Optional high-capacity feeder which provides additional feeder

trays.

The IPS emulates an IBM AFP Group 3 page printer with the

Advanced Function Image and Graphics (AFIG) option and can print

in all the following PSF environments:

• MVS

• VM (channel-attached only)

• VSE (channel-attached only)

• OS/2

• OS/400 (with TCP/IP only)

• AIX

Note: Although PSF/VSE does not support TCP/IP directly, a

printing system with PSF/2, PSF/6000, or IBM InfoPrint Manager can

attach to a PSF/VSE system and the PSF/2, PSF/6000, or IBM

InfoPrint Manager can furnish the TCP/IP support for the IPS printer.

For information on the minimum PSF levels needed to support the

IPS, refer to your Xerox DocuPrint 96/4635/180 IPS Installation

Planning Guide.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-1

Page 14

SYSTEM OVERVIEW

Major system components

Printer Controller The Printer Controller accepts IPDS data from the host, processes

Graphical user interface The full-color graphical user interface (GUI) provides an easy-to-use,

The IPS has the following main components, each of which is

described in greater detail in later chapters of this guide:

the data, and sends it to the printer using the IPS operating system

for IPDS or the NPS operating system for PostScript or PCL.

The Printer Controller provides the printer with print data and

commands and receives status information from the printer.

Host Channel Unit: On channel-attached systems, the Printer

Controller has an additional component called the Host Channel Unit,

or HCU. The HCU contains the channel communications board, and

handles communication between PSF and the controller when data

is received over a bus and tag connection.

mouse-driven interface to the IPS. Using the windows on the GUI

screen, you can configure your system; perform diagnostic and

administrative tasks; and set up, change, and implement system

options, and run print jobs.

The IPS main window displays the current system status, as well as

the current printer settings, including the current input and output tray

configurations. From the IPS main window you access the various

menus and windows you use to configure and operate the system.

Refer to the chapter “User interface” in this guide, for more detailed

information on the IPS graphical user interface components.

Printer The printer accepts data from the Printer Controller and prints the

document according to the print options specified by the user. The

printer also provides paper stacking, collating, and optional finishing.

The 96, 4635, and 180 IPS are monochrome printers. Print jobs that

contain color commands are printed in black.

1-2 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 15

Throughput speed

With small paper sizes Using the smaller papers, such as 7 by 10-inch / 178 by 254 mm or

Monthly print volume The monthly print volumes for these systems are:

SYSTEM OVERVIEW

The 96 IPS, 4635 IPS and 180 IPS can print at the following speeds,

using stocks 8 by 10 inches / 203 by 254 mm or larger:

• 96 IPS and 96 MICR IPS: Up to 96 impressions per minute

• 4635 IPS and 4635 MICR IPS: Up to 135 impressions per

minute

• 180 IPS and 180 MICR IPS: Up to 180 impressions per minute.

B4, with the 7 by 10-inch paper option kit, the throughput rates

increase:

• 4635 IPS/4635 MICR IPS: Up to 154 impressions per minute

• 180 IPS/180 MICR IPS: Up to 206 impressions per minute.

Note: The 7 by 10-inch kit is not available on the 96 IPS.

• 96 IPS: Up to 3 million impressions

• 4635 IPS: Up to 4 million impressions

• 180 IPS: Up to 6 million impressions

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-3

Page 16

SYSTEM OVERVIEW

1

Host connectivity options

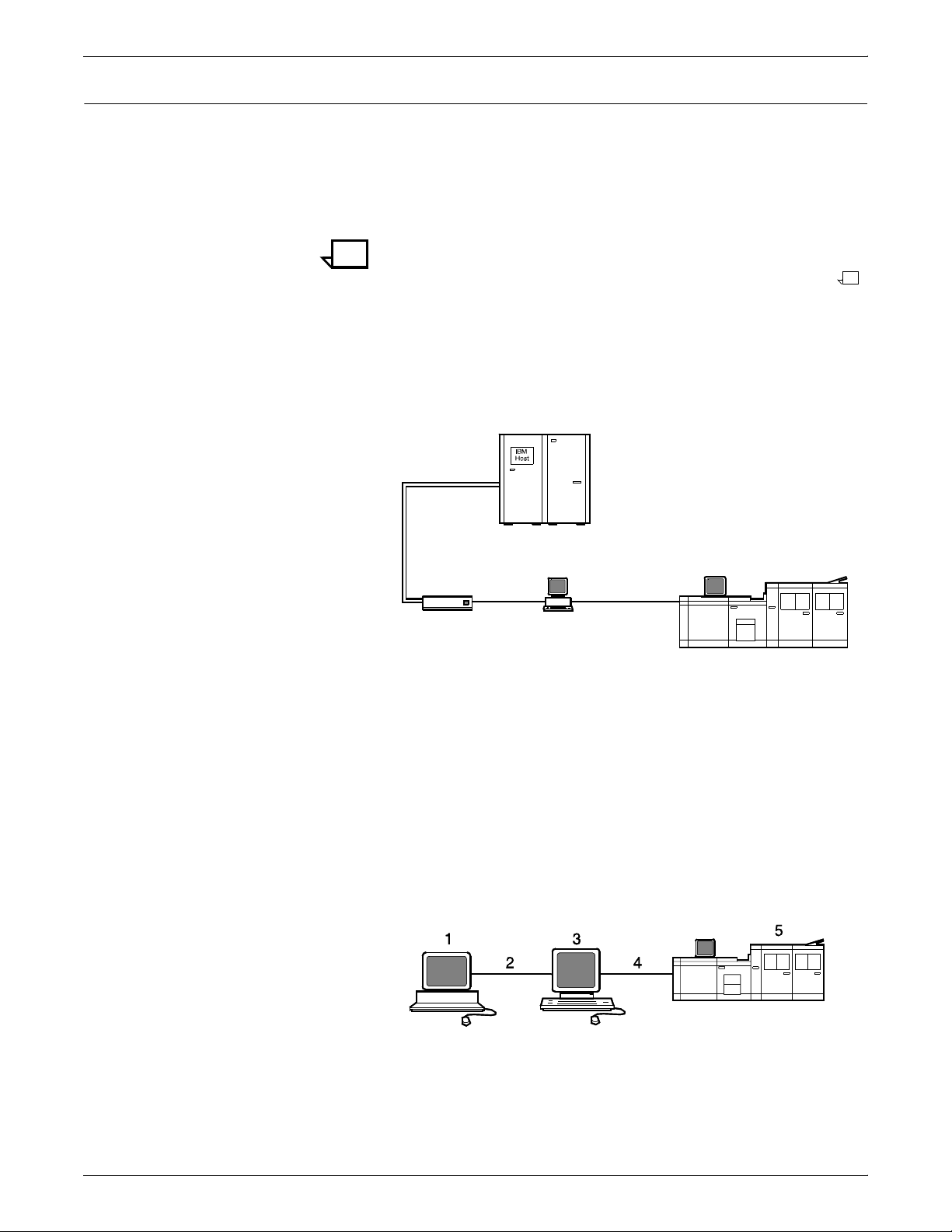

Channel-attached configuration Figure 1-1 illustrates the components of a channel-attached IPS.

The IPS can be set up to receive data from a host in one of two ways:

• Over a channel with bus and tag cable connection, via the Host

Channel Unit (HCU)

• Through a Token Ring or Ethernet interface, using TCP/IP

protocol (not available in a VM or VSE host environment)

Note: A transmission rate of at least 16 megabits per second

should be used with a Token Ring interface on the IPS. (Overall

performance depends on network traffic and job density.)

This configuration requires a Host Channel Unit (HCU) to interface

between the host channel and the IPS controller.

Figure 1-1. 96/4635/180 IPS: channel-attached configuration

7

4

6

1 Host system (PC or mainframe)

2 96, 4635, or 180 IPS printer

3 Printer interface cable

4 Printer Controller

5 SCSI interface

6 Host Channel Unit (HCU)

7 Bus and tag cables

TCP/IP configuration If you are using Token Ring or Ethernet with TCP/IP, as shown in

figure 1-2, the bus and tag cables and the HCU are not required.

Figure 1-2. 96/4635/180 IPS: TCP/IP configuration

5

3

2

1 Host system (PC or mainframe)

2 Token Ring or Ethernet network connection

3 Printer Controller

4 Printer interface cable

5 96, 4635, or 180 IPS printer

1-4 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 17

IPDS data stream

SYSTEM OVERVIEW

All IPDS resources (print data sets, page definitions, form definitions,

page segments, fonts, and overlays) supported by the IBM 3825 and

3827 printers are supported by the Xerox IPS software. Additionally,

there are several data towers supported within the AFP environment

which are fully supported by the IPS software, to a level supported by

the IBM 3825 and IBM 3827 printer capabilities:

• IM Image IMD1

• FOCA: Font Object Content Architecture

• MO:DCA-P: Mixed Object Document Content Architecture for

Presentation

• PTOCA PT1, PT2, and PT3: Presentation Text Object Content

Architecture

• IOCA: Image Object Content Architecture

• GOCA: Graphics Object Content Architecture

• BCOCA: Bar code Object Content Architecture

• OL1: Overlay One

• PS1: Page Segment One

Dual Mode

• Line mode data streams

Each of the data objects follow the same object rule of containing

delimiting fields with structured fields describing each object.

Xerox DocuPrint Dual Mode option enables both DocuPrint NPS and

IPS systems to coexist on the same Printer Controller (Sun

workstation). This allows the DocuPrint system to receive data

streams supported by NPS and IPS, including IPDS, PostScript

Levels 1 and 2, HP PCL5c, HP PCL5e, and ASCII.

Either of the following types of configurations may be used:

• The same Token Ring or Ethernet connection can be used for

both IPDS (IPS) and Postscript/PCL (NPS).

• Both a Token Ring card and an Ethernet card can reside in the

Sun workstation controller, with one being used for IPDS and

the other for PostScript/PCL.

• Bus and tag attachment through the HCU can be used for

IPDS, and Token Ring or Ethernet connection for the NPS.

When the DocuPrint system is in IPS mode, it can accept PostScript

and PCL data streams in the background; however, it can print these

jobs only after it is switched to NPS mode. However, when the

system is in NPS mode, it cannot accept IPDS data streams in the

background.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-5

Page 18

SYSTEM OVERVIEW

96/4635/180 IPS hardware features

The 96, 4635, and 180 IPS provide numerous features that can be

enabled or configured using the graphical user interface on the

printer controller.

Multiple input trays

Multiple feeder trays can be configured to feed paper for jobs in the

most effective manner. For example, the trays can provide nonstop

printing of a complex job that requires many paper stocks, or only a

few stocks, by using the trays’ continuous loading capability. A

different input tray can also be selected for each copy of a specific

page in a print job, for example, to provide different paper colors for

specific pages.

• 96 IPS: Three addressable input trays are standard with the

• 4635 and 180 IPS: Four addressable input trays are standard

system, and one additional tray is available as an option.

with the system, and two additional trays are available as

options.

Feeder tray capacities, based on 20-pound or 80 gsm (grams per

square meter) bond, are:

• Tray 1: 1100 sheets

• Tray 2: 600 sheets

• Trays 3, 4, 5, and 6: 2600 sheets

Note: The equivalent grams per square meter of 20-pound bond is

actually 75 gsm. However, there is no standard 75 gsm paper — the

available stock that is closest in weight to 20-pound bond is 80

gsm.

1-6 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 19

Roll feeder support

SYSTEM OVERVIEW

The 96, 4635, and 180 IPS can each accommodate a third-party roll

feeder as an optional input tray.

• The 96 and 4635 IPS have an optional configuration in which

the roll feeder interfaces with the last feeder/stacker module.

With this configuration the 4635 IPS may have up to six feeder

trays with the sixth being the roll feeder. The 96 IPS may have

up to five input trays, with the roll feeder as the fifth.

Note: To be able to use this roll feeder option on the 96/4635

IPS, you must have the Input Enablement kit installed. (Refer to

“Options enabling feeding and finishing,” later in this

chapter.)

• The roll feeder option for the 180 IPS is installed in the inverter

feeder/stacker module, replacing the feeder tray. It does not

require the Input Enablement kit or DFA software. The

maximum number of feeder/stacker modules supported for this

configuration is four, including the inverter module with the roll

feeder. With the two processor feeder trays, this makes a total

of six input trays possible.

Advanced paper handling

The 96/4635/180 IPS can handle paper stock ranging in size from 8

by 10 inches / 203 by 254 mm to 14.33 by 17 inches / 364 by 432

mm, including sizes A3 and A4. They process paper weights from 16to 110-pound / 60 to 200 gsm.

Note: The 4635 and 180 IPS can also print on paper as small as 7

by 10 inches / 178 by 254 mm, with the optional 7 by 10-inch kit.

Jobs can also be printed on label stock, transparencies, precollated

stock, tab stock, carbonless paper, and other specialized stocks. The

printer engine monitors the print job so that, should a paper jam

occur, the job resumes on the correct page, at the correct tab, using

the same color, and so forth, providing complete document integrity.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-7

Page 20

SYSTEM OVERVIEW

600 dpi resolution

The 96, 4635, and 180 IPS all print at high resolution. The printers

can receive data at 240, 300, and 600 dpi (dots per inch). All 240 or

300 dpi data is interpolated to 600 dpi for higher print quality.

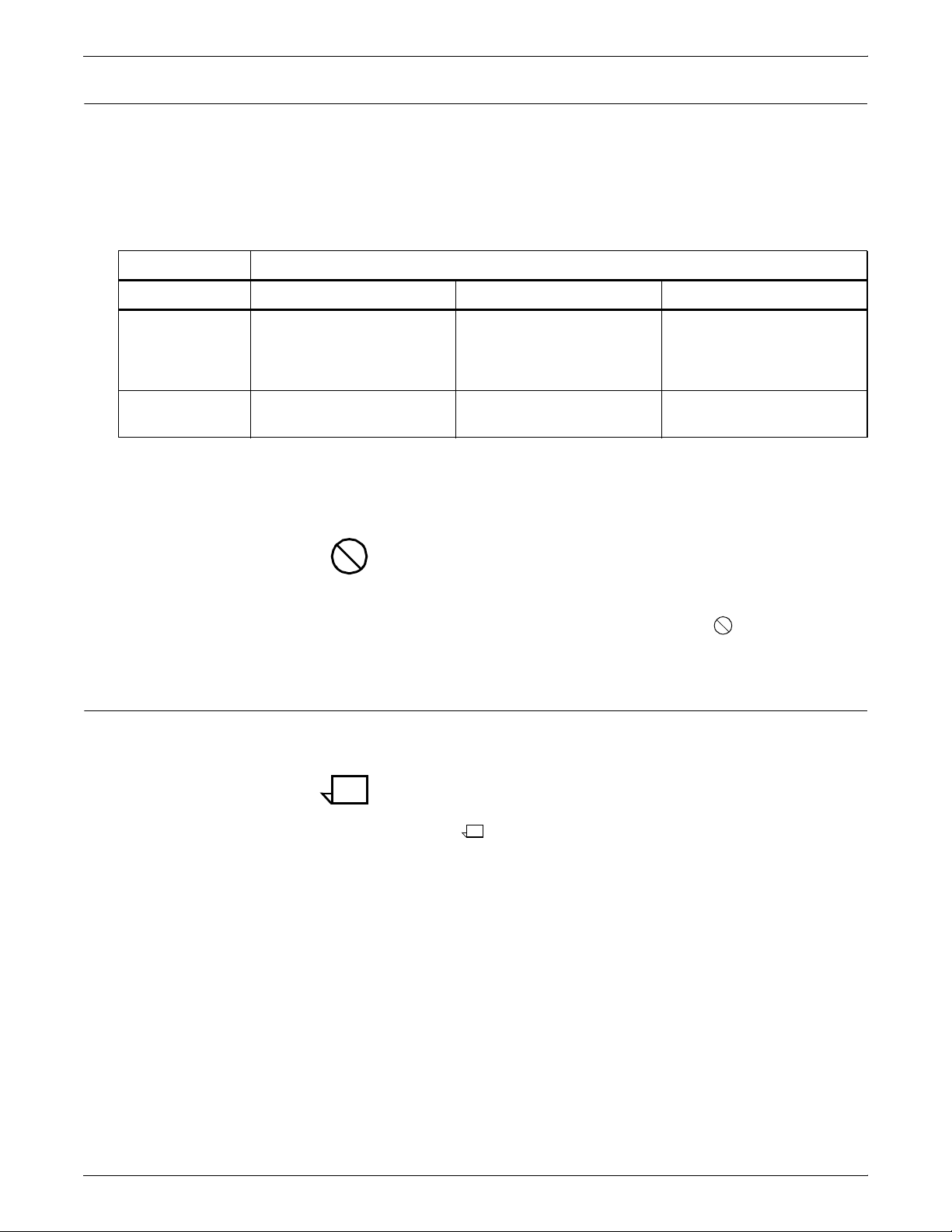

Table 1-1 shows how data streams of different resolutions are

interpolated.

Table 1-1.Data stream conversion to 600 dpi

Incoming input resolution of document

Printer 240 dpi data 300 dpi data 600 dpi data

180 IPS Interpolated by printer to

600 x 2400 dpi

(when 240 board is installed

in the printer)

96/4635 IPS Converted by controller to

600 dpi

Multiple high-capacity output bins

Interpolated by printer to

600 x 2400 dpi

Interpolated by printer to

600 x 600 dpi

For the 96 IPS, the 4635 IPS, and the 96/4635 MICR IPS, it is

recommended that all fonts and other resources that are at 240 dpi

be converted to 300 dpi before printing, rather than leaving the

conversion for the controller to do. This ensures better print quality.

Caution: The 96/4635/180 IPS must have the same font resolution

specified as the host input data stream (refer to your 96/4635/180

IPS Guide to Configuring and Managing the System for instructions

on specifying the input resolution). Conflicts between the input font

resolution and the IPS specification could result in inability to print the

job, or in missing variable data in the output.

Each output bin has offsetting capability and a capacity of 2500

sheets of 20-pound or 80 gsm bond.

Print at 600 x 2400 dpi

Print at 600 x 600 dpi

Note: This capacity does not apply to 11 by 17-inch and A3 papers.

Because of the additional weight these large sheets add to the bins,

each bin can hold only up to 1500 sheets of A3 or 11 by 17-inch

papers.

• 96 IPS: One output bin is standard for the system, with one

additional bin available as an option (providing up to two bins

total).

• 4635 and 180 IPS: Two output bins are standard, with up to two

additional bins available as options (providing up to four bins

total).

1-8 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 21

Bypass transport option

SYSTEM OVERVIEW

The programmable bypass transport moves paper from the stacker

to a third-party finishing device (for example, a stitcher). When

installed, the bypass transport is attached to the last feeder stacker

module.

Note: With the bypass transport installed, the 4635 and 180 IPS

can support up to three feeder/stacker modules, including the

inverter feeder/stacker. The 96 IPS can have no more than two

feeder/stackers.

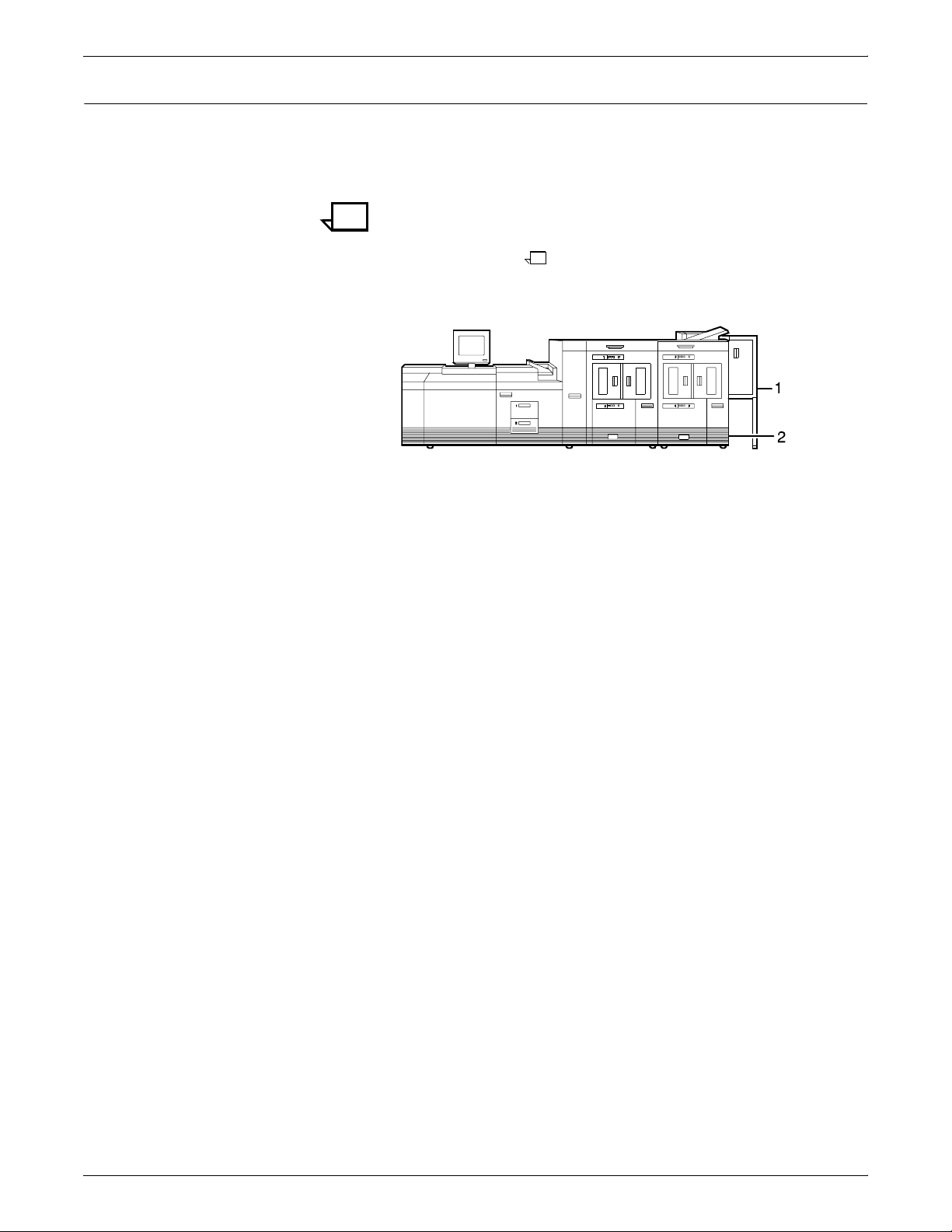

Figure 1-3. 96/4635/180 IPS with bypass transport

1 Bypass transport paper output location

2 Input enablement device paper input location

The illustration above shows a 96/4635/180 IPS with two feeder/

stacker modules and a bypass transport. For complete information

on printer configurations available with the bypass transport, refer to

the chapter “Printers.”

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-9

Page 22

SYSTEM OVERVIEW

User interface

The IPS full-color graphical user interface provides an easy-to-use,

mouse-driven interface to the IPS. Using the graphical screens, you

can configure your system; perform diagnostic and administrative

tasks; and set up, change, and implement system options.

The IPS main window displays the current system status, as well as

the current printer settings, including the current input and output tray

configurations. From the IPS main window you access the various

menus and windows you use to change the system settings and

perform diagnostic and administrative tasks. Refer the “User

interface” chapter in this guide for further information on the IPS

graphical user interface.

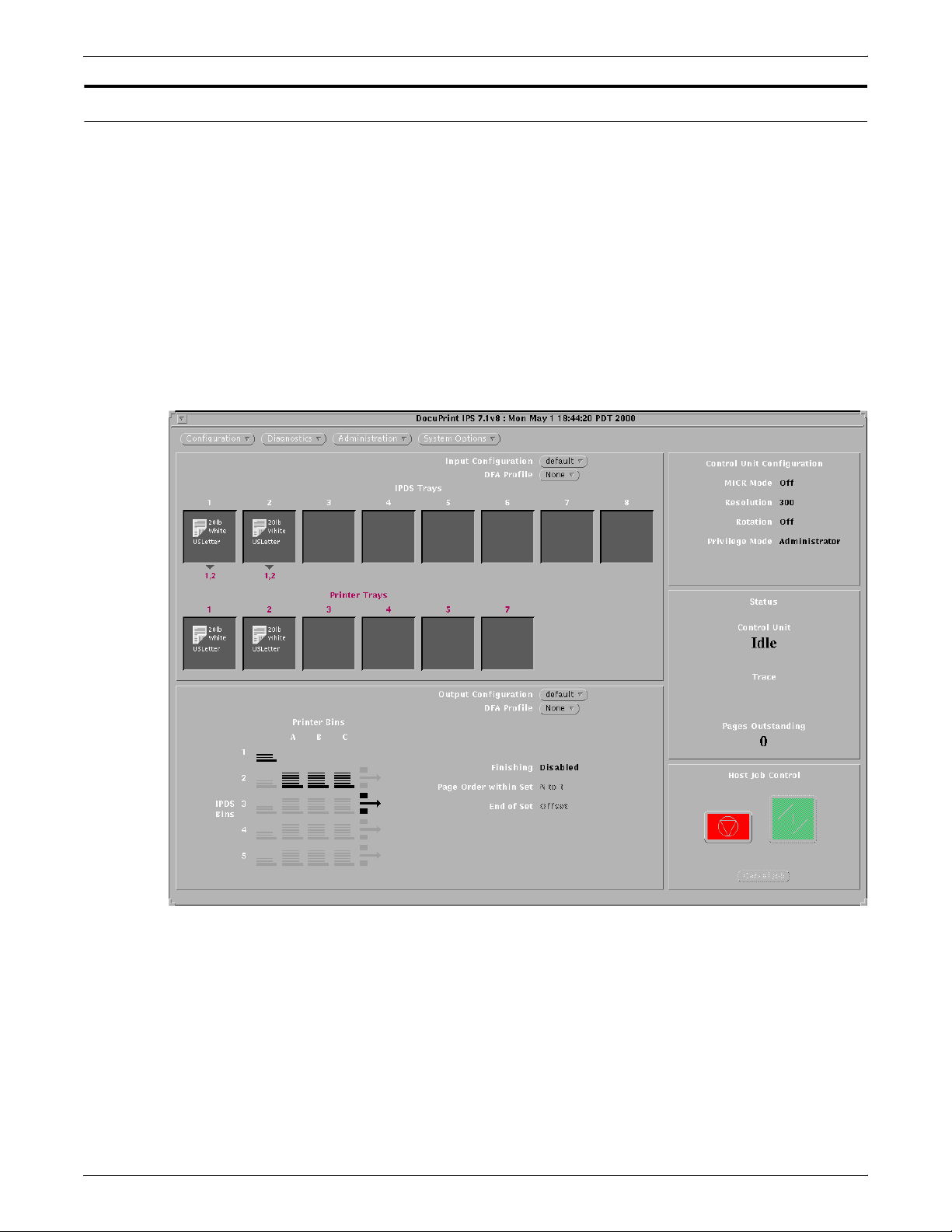

Figure 1-4. DocuPrint 96/4635/180 IPS main window (system

with DFA)

1-10 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 23

Software features

Mixed paper sizes within a job

SYSTEM OVERVIEW

The following special IPS software features provide system flexibility.

The IPS can print jobs that call for a mix of paper sizes, without

needing to interrupt or slow down printing.

An example of such an application would be a multi-page billing

statement consisting of:

• One or more 8 1/2 by 11-inch sheets itemizing charges, and

• A final 8 1/2 by 14-inch page containing the rest of the billing

items, the total amount due, and a tear-off section to mail back

with payment.

Note: When a print job calls for paper sizes that span over different

pitch modes, the software will either cycle down or run at a lower

pitch mode, based on the different pitch modes required, the paper

sizes called for, the speed of the printer, and the time it takes to shut

down the printer.

Tray selection capabilities

Output tray With the output bin selection capability you can select a different

Note: Paper size and printer trays cannot be changed while the job

is running.

You can select a different input tray or output bin for each job. You

can also select a different input tray for each page of a job.

Input tray With the input tray selection capability at the Copy Subgroup level,

you can select a different input tray for each copy of a page of a job.

You can use this capability to print each page of a multiple-part form

on a different color paper stock, or to print the cover of a job on a card

stock and to print specific pages within the job on a different color

stock.

To specify a different input tray for each job, use the BIN command

in the SUBGROUP level of the COPYGROUP in the FORMDEF.

output bin group for each print job. This selection requires two steps:

1. At the host, set the JCL keyword OUTBIN in the OUTPUT

statement to specify a bin number from 1 to 65535, or use the

OUTBIN command in the FORMDEF to specify a bin number

from 1 to 255.

2. At the graphical user interface, use the Output Configuration

window to group the trays. You must also select Allow Host

Control from the Bin Selection Mode pull-down menu.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-11

Page 24

SYSTEM OVERVIEW

IOCA Replicate and Trim

Mixed plex

The IPS also supports Replicate and Trim, which improves the

processing of IM and IO images that contain large areas of shaded

graphics. (IM images are resolution-dependent images that cannot

be compressed or scaled; IO images are resolution-independent.)

The IOCA Replicate and Trim capability allows for faster

transmission to the printer of AFP applications with IM images that

have large or widespread shaded areas. It also reduces the storage

area required on the host and on the printer.

The IPS allows switching between plex modes (simplex to duplex

and vice versa) within and between jobs without shutting down the

printer.

Switching of plex modes occurs as follows:

• From simplex to duplex: The switch is done without a printer

shutdown or dead cycles.

• From duplex to simplex: The switch is done without a printer

shutdown. However, the printer may, if necessary, dead cycle to

clear the paper path of all duplex sheets before feeding the first

simplex sheet.

Users can avoid switching from duplex to simplex mode (and thus,

avoid the dead cycles) by using the Maximum Simplex GUI panel to

perform simulated simplex. For more details, refer to the “Setting the

system configuration” chapter in the Xerox DocuPrint 96/4635/180

IPS Guide to Configuring and Managing the System.

Note: When you print simplex pages in duplex mode, the

throughput speed is halved. The blank back pages of the simulated

simplex sheets are counted as billable pages by the system’s

meter.

1-12 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 25

Enhanced N-Up

SYSTEM OVERVIEW

Enhanced N-Up provides the following capabilities:

Sheets On a given sheet, users can place individual pages:

• At any position on either side of the sheet

• In any orientation

• In any size that fits on the sheet

Each side of the sheet of paper can have up to four pages.

Overlays Users can place overlays relative to any partition origin, with or

without variable page data from the application program.

Users can specify different overlays for each page.

Offsets Users can specify different offsets for each page.

Rotations Users can specify different rotations for each page.

Form ejection Users can specify form ejection to a new partition or a new sheet.

Trace facility

To help diagnose problems, the system provides a trace mechanism.

Trace files store system configuration information, maintain TCP/IP

protocol headers, and time-stamp all records.

For detailed information on this feature, refer to the “Setting the

system configuration” chapter in the Xerox DocuPrint 96/4635/180

IPS Guide to Configuring and Managing the System.

Overstrike, underscore, subscript, and superscript

Support for the PT2 Subset of PTOCA enables the IPS to print

overstrikes, underscores, subscripts, and superscripts where

specified in jobs.

Background color for OCA colors

Users can specify COLOR on DRAWBOX (i.e., background color) as

long as the color is restricted to colors defined with the OCA or the

Highlight Color model.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-13

Page 26

SYSTEM OVERVIEW

Full-page 600 dpi images

This feature allows for 600 dpi full-page images to be printed on the

IPS. To invoke this feature, you must have the resolution set at the

controller to 600 dpi.

Note: 600 dpi images can be generated only in the PSF/6000

environment. However, they can be transported to other

environments for printing.

Document Feeding and Finishing Architecture (DFA)

The Document Feeding and Finishing Architecture (DFA) on the

4635 and 180 IPS supports all third-party finishing devices currently

validated for the LCDS (J11) printers. The bypass transport option is

required for in-line finishing devices and support of ENDOFSET and

ENDOFJOB (using the PSF MARKFORM or FORMDEF JOG

command). DFA also supports personality profiles, which identify the

unique characteristics (for example, the sheet timing and the status

feedback profiles) of the attached finishing devices.

DFA also enables use of certain third-party roll feed-to-cut sheet

feeders. An Input Enablement kit is required for some of these

devices.

Page origin rotation for continuous form jobs

The 90-degree page origin rotation feature enables the IPS to print

jobs designed for continuous form printing, without the need to

rework an existing application. At the user interface, you can set a

job’s page origin to be rotated 90

continuous form jobs on cut-sheet paper.

Double-byte fonts

Double-byte fonts consist of characters that are larger and more

complex than the single-byte characters making up the Roman

alphabet. Therefore, each character of a double-byte font requires

two bytes to represent it. Some languages requiring double-byte

fonts include Chinese, Korean, and Japanese.

The IPS supports printing with certain double-byte fonts, which can

be used in combination with single-byte fonts.

The following double-byte character sets are supported:

• Simplified Chinese

• Traditional Chinese

• Japanese

• Korean

• Thai.

o

to accommodate printing

Note: When using double-byte fonts, the font loading time will

increase if a font change occurs between reports.

1-14 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 27

Outline font support

Printer resident font support

SYSTEM OVERVIEW

The IPS supports the use of IBM outline fonts for both single- and

double-byte applications. These fonts may be downloaded during the

jobs or may be loaded into the system and made resident through the

use of a user interface option on the Configuration menu.

These outline fonts allow users to specify a single font that can be

rasterized in a variety of point sizes by the IPS. The IBM outline fonts

are based on Adobe type 1 and type 0 fonts that are in PostScript

format.

Note: The IPS supports printer resident outline fonts. It does not

support printer resident raster fonts.

The IPS stores both single-byte and double-byte fonts locally on the

Printer Controller and does not require you to download the fonts

from the host. This can lead to significant performance gains,

especially when the printer is attached remotely.

Processing options

Message translation

Users can also set the default font for text or barcode Human

Readable Interpretation (HRI) to one of the installed fonts to replace

a font that is distributed with the system.

Fonts can be installed from an IBM supplied font CD or via FTP to the

Controller workstation.

Note: The IPS supports printer resident outline fonts. It does not

support printer resident raster fonts.

The IPS allows users to specify processing options using the GUI.

For example, changing the model number reported to the host. Refer

to the Xerox DocuPrint 96/4635/180 IPS Guide to Configuring and

Managing the System for details on these options.

The IPS provides some message translatability for the GUI and

printer monitor. Users can select the language of their choice from a

GUI menu option.

Configuration file processing

The IPS adds a version identifier to the configuration files. The

identifier allows for migration of configuration data from one release

to a subsequent release at upgrade time. The IPS allows users to

save, upgrade, and restore configuration data such as input and

output tray mappings and DFA configurations.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-15

Page 28

SYSTEM OVERVIEW

PCI Bus support

Access control by privilege mode

The IPS supports the SUN Peripheral Component Interconnect (PCI)

Bus architecture, in addition to the S-Bus platform. PCI support

provides the following advantages:

• Migration of Printer Controller components to newer technology

• Higher performance on the Printer Controller

• Wider selection of system peripherals

• Adherence to industry standards.

The IPS controls access to various functions based on four privilege

modes:

1. User

2. Operator

3. Administrator

4. Service.

Depending on the privilege mode set by the Customer Service

Engineer, users will have access to certain graphical user interface

(GUI) functions, while other functions will be grayed out. Refer to the

Xerox DocuPrint 96/4635/180 IPS Guide to Configuring and

Managing the System for details on this functionality.

1-16 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 29

Software license

SYSTEM OVERVIEW

When an IPS is purchased, the owner needs a license to use the

operating system software. After a user calls in with a host ID (Sun

SPARC/Ultra host ID), the user will receive a license string.

The user license is enabled by entering the 20-character

authorization text string at the Printer Controller keyboard. Your

Xerox service representative can obtain the license text string for you

and enter it when your IPS is installed, or when you receive your IPS

software upgrade. For details on how to obtain the license string from

Xerox, refer to the Xerox DocuPrint 96/4635/180 IPS Guide to

Configuring and Managing the System, in the chapter “Setting up the

printer controller.”

Until the license string is entered, your IPS cannot receive data from

the host to print. You can power on and boot the system, and perform

all offline tasks such as setting up input and output configurations,

but the IPS remains in Disabled mode and cannot print.

Although your service representative usually does this for you, you

are able to enter your license string yourself from the IPS main

window. The procedures are outlined in the chapter “Setting up the

printer controller” in your Xerox DocuPrint 96/4635/180 IPS Guide to

Configuring and Managing the System.

Note: If your system will be operating in Dual Mode, it requires two

license strings: one for IPS and one for NPS.

Remote service (Sixth Sense Technology)

Sixth Sense Technology is a user-friendly suite of tools that allow

service personnel to connect with a customer system and evaluate

its performance while the system is being used. The Customer

Service Engineer (CSE) can troubleshoot problems remotely,

transfer, apply, and remove patches remotely, and, if an on-site call

is required, arrive with the solution to fix the problem.

Customer benefits of using this technology include:

• Diagnostic help and identification of required parts before the

service visit

• Planned visits based on known problems and/or replacement of

wear-out items

• Customer self-maintenance to provide faxed replacement

change reminder to trained operators.

Using the Sixth Sense Technology, CSEs can access your system’s

diagnostic data remotely using a regular telephone line almost as if

they were at the Printer Controller (SPARCstation).

For security reasons, the customer maintains control of the modem

connection, and may leave the modem disconnected. Also, the

customer provides a password for access to the Sixth Sense

Technology via the modem.

For information on enabling and disabling of the Sixth Sense

Technology, refer to the chapter “Calling for Service” in your Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 1-17

Page 30

SYSTEM OVERVIEW

1-18 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 31

2. 2Printer Controller

This chapter describes the DocuPrint IPS Printer Controller (also

called the system controller). It includes a list of component

hardware, software, and fonts, and discusses the key elements of

software operation.

Components of the Printer Controller

The Printer Controller enables you to use proprietary Xerox IPS

hardware, firmware, and software to control the printer. It has the

following major hardware components:

• Sun UltraSPARC workstation. The Sun workstation has a

high-performance RISC processor chipset, based on the

industry-standard Scalable Processor Architecture (SPARC)

and a high-capacity hard disk drive. It contains the following

components:

— Processor

– Hard disk

– Diskette drive

– CD-ROM drive

– Connectivity boards for Ethernet and, optionally, Token

Ring

— Monitor

— Keyboard

— Mouse

• Host Channel Unit (HCU) (Channel-attached systems only).

The HCU contains the channel communications board. This is

used only when printing data received over a channel via a bus

and tag connection.

Note: Some elements and components of the Printer Controller are

accessible only by a service representative; for example, the

diagnostics for the Sun workstation processor.

Note: Printer controller hardware configurations are subject to

upgrade.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 2-1

Page 32

PRINTER CONTROLLER

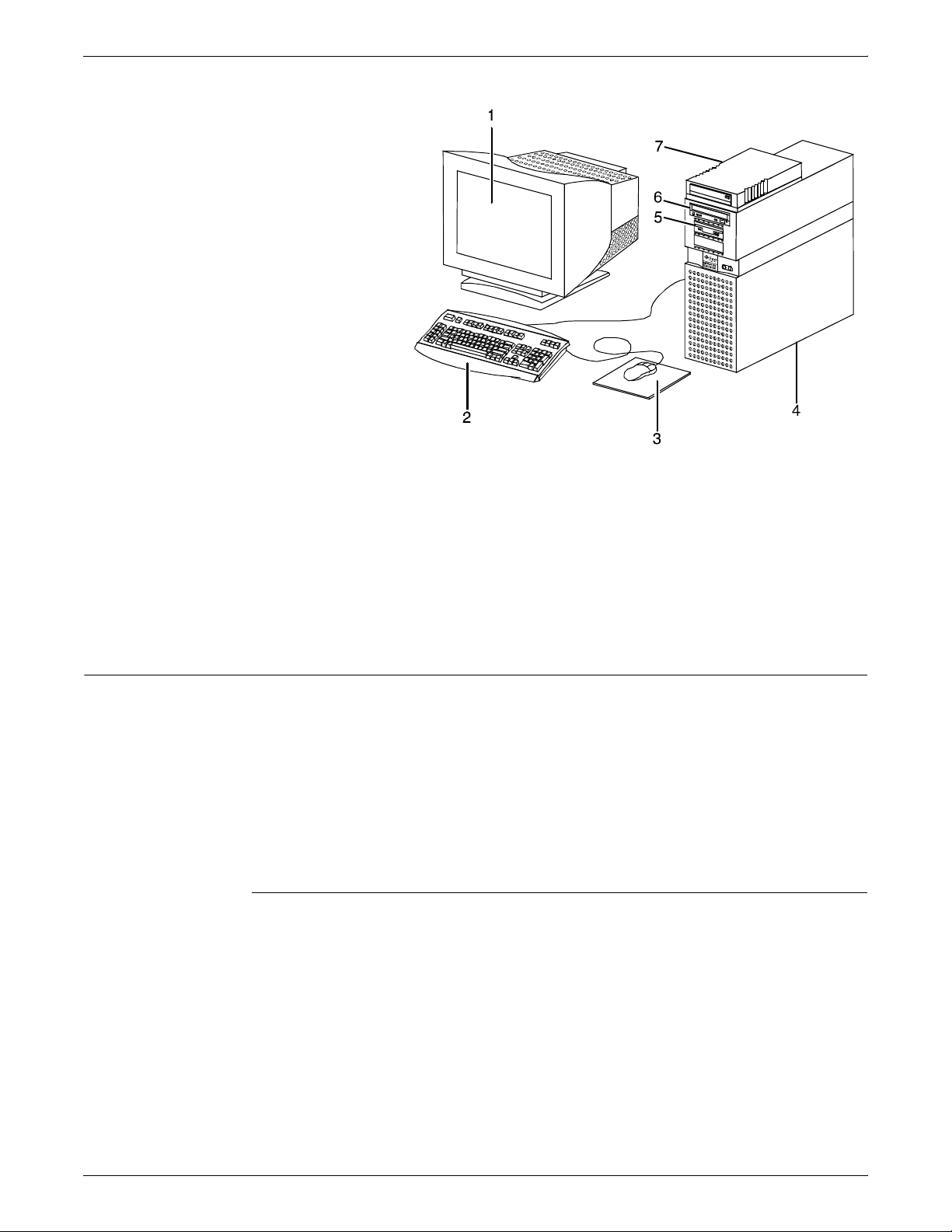

The Sun Ultra workstation consists of the processor, monitor,

keyboard and mouse. Both Sun Ultra 2 and Sun Ultra 60

workstations are available.

Figure 2-1. Components of the Sun Ultra 2

1 Processor

2 Monitor

3 Mouse and mouse pad

4 Keyboard

5 Diskette drive

6 CD-ROM drive

2-2 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 33

Figure 2-2. Components of the Sun Ultra 60

1 Monitor

2 Keyboard

3 Mouse

4 Processor

5 Diskette drive

6 CD-ROM drive

7 Cartridge tape drive

PRINTER CONTROLLER

Processor

The processor is the central processing unit (CPU) of the Sun

workstation. It contains a power switch, a hard drive, a diskette drive,

a CD-ROM drive, a power receptacle and outlet, connectors, and

ports.

A Data Control Interface Module (DCIM2) card for the Sun Ultra 2, or

a PCIM2 card for the Sun Ultra 60 is installed in the processor, to

which the printer cable is connected. In addition, the processor

contains the connectivity boards for Ethernet and, optionally, Token

Ring.

Hard disk

One addressable, high-speed, high-capacity hard disk is provided.

The hard disk stores the operating system, the IPS application, and

any buffered pages. Do not use the hard disk to store other

applications or data except as directed by your service

representative.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 2-3

Page 34

PRINTER CONTROLLER

Diskette drive

The floppy disk drive is located in the processor, on the front section

of the UltraSPARC. It uses industry standard 3.5 inch, 1.44-MB,

double-sided, high-density floppy disks. This disk drive is not an input

source for print jobs or for any other data or application. It is reserved

exclusively for use by a service representative to update software

and to store files.

CD-ROM drive

The CD-ROM drive, located in the processor above the diskette

drive, is a high-density, read-only, optical laser storage device used

for loading the IPS operating system, online documentation, and

other files.

Cartridge tape drive

An optional 8 GB, 4 mm external SCSI cartridge tape drive also is

available for the IPS. Like the diskette and CD drives, this tape drive

is not an input source for print jobs or for any other data or

application. It provides the service representative with another

means of loading system maintenance files or saving diagnostic

information.

Monitor

Keyboard

Mouse

The monitor has a high-resolution color screen, which displays the

IPS graphical user interface screen.

The type 4 or 5 keyboard has 107 alphanumeric keys, symbol and

special character keys, an extended character set, and function keys.

The mouse has three buttons. The left and right buttons are used to

select IPS functions. The center button provides additional functions

that you will not be required to use.

If your workstation has an optical mouse, it must remain on its

designated metallic pad to be active. If the mouse has a roller ball

instead of an optical sensor underneath, it requires a non-metallic

pad.

2-4 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 35

Host Channel Unit (HCU) — channel-attached systems only

The HCU handles all of the IPDS communications and handshaking

with PSF on the host when receiving data over a channel. (It is not

used when the IPS is printing data using TCP/IP.)

• The front panel of the HCU has a single-digit LED display,

which enables you to monitor power-up and offline status, and

alerts you to error conditions. (Refer to your IPS Messages

Guide for an explanation of the HCU codes displayed here.)

• The back panel of the HCU has a power switch and outlet, bus

and tag cable input and bypass connectors, and a dual serial

port. The standard switching power supply is capable of 10 amp

on the 5-volt output.

Note: You are responsible for obtaining, stringing, and maintaining

fully-populated bus and tag cables.

Figure 2-3. Host channel unit (HCU)

PRINTER CONTROLLER

Placement of the processor

When you place your Printer Controller processor on a desktop,

make sure to allow at least 6 inches / 152 mm of unobstructed space

at the rear and both sides of the processor. Do not allow any piece of

equipment to blow warm air into the air-intake vents of the processor.

Caution: Do not place a monitor with a base larger than the

processor on top of the unit. Do not block any fan or vents on the

sides or rear of the processor.

Caution: If you plan to move the Printer Controller, make sure to

consult with your service representative.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 2-5

Page 36

PRINTER CONTROLLER

2-6 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 37

3. 3User interface

The IPS graphical user interface on the Printer Controller enables

you to interact with the IPS. It contains windows and pull-down

menus through which you can perform operator and system

administrator tasks.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 3-1

Page 38

USER INTERFACE

Graphical user interface screen

After you power on the HCU (if appropriate) and the Sun workstation,

the Printer Controller monitor displays three windows:

• IPS main window

• IPS Console window

• IPS Print Engine Monitor window.

The IPS main window is the largest window on the screen. The main

window displays the current system setup, the current system status,

and any jobs that are running. This window also provides access to

menus and subwindows from which you can configure and operate

your system.

The IPS Console window displays messages that warn you of

Printer Controller problems. (This window initially displays below the

IPS main window on the left, but it can be moved where desired.)

Note: High frequency service indicator (HFSI) messages may

appear occasionally in this window. These messages do not indicate

any problem, merely that you should advise your service

representative to check the indicated areas during the next service

call.

The IPS Print Engine Monitor window shows printer error

messages, indicates the printer status and displays printer and DFA

messages. (This window initially displays below the IPS main window

on the right, but it can be moved where desired.)

The following figure shows these windows on the screen of the

Printer Controller monitor.

3-2 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 39

USER INTERFACE

Figure 3-1. Printer Controller monitor with IPS main window,

IPS Console window, and IPS Print Engine Monitor

window

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 3-3

Page 40

USER INTERFACE

IPS main window

Use the IPS main window to access other windows for configuring,

setting up, and operating the system, for monitoring the current setup

and status of the system, for performing various administration tasks,

and for interrupting and resuming printing.

Figure 3-2. IPS main window (system with DFA)

The IPS main window consists of the following:

• Menus:

— Configuration

— Diagnostics

— Administration

— System Options

• Input Configuration section, which provides access to the

windows that enable you to configure input trays to feed

required paper stocks, and to set up margin values. It also

displays the current configuration of the feeder trays.

3-4 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 41

USER INTERFACE

• Output Configuration section, which provides access to the

direct windows that enable you to direct printed output to the

desired output tray or bin. It also displays the current

configuration of the stacker trays.

• Setup and status information, which consists of the following

sections:

— Control Unit Configuration section, which displays the

current configuration of the system

— Status section, which indicates what the printer is doing

— Host Job Control section, which allows you to stop or

continue job processing.

For detailed information on the main window and its various

functions, refer to the chapter “Introduction to the graphical user

interface” in the Xerox DocuPrint 96/4635/180 IPS Guide to

Configuring and Managing the System.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 3-5

Page 42

USER INTERFACE

3-6 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 43

4. 4Printers

The IPS printer (sometimes referred to as the image output terminal

or IOT) is where the actual printing takes place. This chapter

discusses the components and possible configurations of the

96/4635/180 IPS printer.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-1

Page 44

PRINTERS

Printer components

Components overview

The 96 IPS, the 4635 IPS, and the 180 IPS printers have almost the

same appearance, print engine, and base components. All printers

contain a xerographic engine, one or more high-capacity feeder/

stacker modules, sample and purge trays, and a printer control

console.

The components of the base printer for the 4635 and 180 IPS are

shown in figure 4-1.

Note: The 96 IPS base printer configuration contains only the

inverter feeder/stacker module. An additional feeder/stacker (giving

the 96 IPS the configuration shown below) is an option.

Figure 4-1. Base printer components (4635/180 IPS)

1 Printer control console

2 Sample tray

3 Attention light

4 Purge tray

5 Feeder/stacker module

6 Inverter feeder/stacker module

7 Processor feeder trays

These components are described in more detail in the following

sections.

4-2 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 45

Printer control console

PRINTERS

The printer control console is the color monitor located on top of the

printer. It contains message areas and graphic displays that alert you

to paper jams and other fault conditions, such as low dry ink. The

printer control console also contains buttons that allow you to control

certain functions of the printer—such as stopping printing and

continuing an interrupted job—without returning to the Printer

Controller.

The printer control console has the following features:

• Local controls and displays for jam clearance, paper loading/

unloading, and diagnostics/service (used by the service

representative). Two types of messages are displayed on the

printer control console: fault messages, which relate to printer

malfunctions, and information messages, which relate to printer

conditions such as low dry ink.

• Touch-sensitive areas that allow you to select options by

touching the printer control console screen. A tone sounds

when you touch one of these areas.

• A printer alarm which gives three beeps, repeated for ten

seconds. The alarm is generated by any event that stops the

printer.

The alarm stops after three cycles or as soon as you start to

clear the fault condition (for example, when you open printer

doors or covers specified in the clearance instructions). You can

stop the alarm by pressing one of the printer control console

buttons or by selecting a function through the touch screen.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-3

Page 46

PRINTERS

Figure 4-2. Printer control console

1 Language icon

2 Printer icon

3 Fault List icon

4 Tools icon

5 Guarded Tools icon

6 Clear button

7 Continue button

8 Stop button

9 Sample button

10 Brightness control thumbwheel

11 Icon area

12 Message area

1. Language icon

If two languages are available for your printer control console,

selecting this icon allows you to choose the language for the

printer control console messages.

2. Printer icon

Select this icon to display the printer mimic. This is the default

display on the printer control console.

3. Fault List icon

Select this icon to display the Fault List screen.

4-4 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 47

4. Tools ico n

Select this icon to display call for service information and to

adjust display features of the printer control console (for

example, alarm loudness).

5. Guarded Tools icon

This icon is reserved for the service representative and

operators who have completed Advanced Customer Training

(ACT).

6. Clear button

Select this button to clear fault messages.

7. Continue button

Press this button to resume printing.

8. Stop button

Press this button to stop printing.

9. Sample button

Press this button to print a sample to the sample tray.

PRINTERS

Note: The following software levels are required for the

sample button to function:

• 96 IPS: 21.50 or higher

• 4635 IPS: 11.51 or higher

• 180 IPS: 70.10 or higher

Note: Once pressing the Sample button, the message

Sample is being delivered is displayed on the printer

console, and remains there until another message overwrites

it.

Note: The sample button is disabled during MICR print

jobs.

10. Brightness control thumbwheel

Use this thumbwheel to adjust the brightness of the printer

control console display.

11. Icons

Area where the following icons appear:

Fault icon — Appears when a fault exists in the system that

stops the printer or prevents it from printing. If you click this

button, the Clear button is displayed on the screen.

Hint icon — Appears when a masked fault or condition exists in

the printer. See the chapter “Fault masking” in the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-5

Page 48

PRINTERS

Sample tray

ACT icon — Appears when a maintenance task requiring an

ACT trained operator must be done. If you have successfully

completed ACT, either check the Printer Controller for

messages concerning the maintenance task or touch the

Guarded Tools icon to display the Guarded Tools screen. If you

are not an ACT trained operator, notify your lead operator or an

ACT trained operator at your site.

12. Message area

The message area is used as follows:

• Lines 1 and 2. These lines display the current status of the

printer; for example, READY.

• Line 3. This line displays messages concerning masked

conditions, such as low dry ink. These messages are

preceded by an asterisk.

• Line 4. This line displays messages that originate at the

System Controller.

Attention light

The sample tray located on top of the printer receives output such as

transparencies, sample prints or system files, and waste sheets that

cannot be sent to the purge tray. The sample tray should be

monitored and emptied when it contains 100 sheets, although no

notification is given when the tray is full.

An Attention light is mounted on top of the inverter module. This light

either blinks or modulates (alternately brightens and dims) when the

printer requires operator attention. The light has three states:

• Off — No printer problems exist that require attention.

• Steady light — A situation exists that needs attention soon

(such as a low dry ink condition).

• Flashing — The printer has stopped and requires your

attention immediately.

Note: When the Attention light starts flashing, an explanatory

message appears on the printer control console display. A similar

message appears in the IPS Print Engine Monitor window on the

Printer Controller screen.

Purge tray

The purge tray is located on top of the feeder/stacker module.

Aborted sheets (for example, damaged sheets or sheets cleared

after a paper jam) are sent to this tray. The purge tray should be

emptied when it has received 100 sheets of paper, although the

printer does not notify you when the tray is full.

4-6 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 49

Inverter

Feeder/stacker modules

High-capacity feeder (HCF) tray This tray is located in the bottom half of the feeder/stacker module.

High-capacity stacker (HCS) This bin is located in the top half of the feeder/stacker module. Each

PRINTERS

The inverter is part of the inverter feeder/stacker module. It allows for

proper collation of the print job. It also directs printed output to the

sample tray, when required.

Each feeder/stacker module contains a high-capacity feeder tray and

a high-capacity stacker.

Each HCF tray can hold up to 2600 sheets of 20 pound or 80 gsm

paper.

The high-capacity feeder trays can handle paper sized from 8 by 10

inches/ 203 by 254 mm to 14 by 17 inches / 364 by 432 mm.

HCS can hold 2500 sheets of 20 pound or 80 gsm paper.

Processor feeder trays

The 4635 and 180 printers may have up to four feeder/stacker

modules (including the inverter feeder/stacker), containing feeder

trays 3, 4, 5, and 6, and stacker bins A, B, C, and D. The 96 IPS can

have up to two feeder/stacker modules, containing feeder trays 3 and

4, and stacker bins A and B.

Two processor feeder trays are located in the main part of the printer

and are not part of a feeder/stacker module.

• The main tray (tray 1) holds up to 1100 sheets of 20 pound or

80 gsm paper.

• The auxiliary tray (tray 2) holds up to 600 sheets of 20 pound or

80 gsm paper.

• Trays 1 and 2 can handle paper sized from 8 by 10 inches / 203

by 254 mm to 9.02 by 14.02 inches / 230 by 356 mm.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-7

Page 50

PRINTERS

Feeder trays

The 4635 IPS and the 180 IPS may have up to six feeder trays: the

two processor trays and two to four high-capacity trays. The 96 IPS

can have up to four input trays: the two processor trays and one to

two high-capacity feeder trays.

The total input and output page quantities for each high-capacity

feeder tray are shown in table 4-1.

Table 4-1. Total input and output capacity for printer with

each added feeder/stacker module

Configuration — 2

processor feeder

trays plus:

First (inverter) F/S 4300 2500

Second F/S 6900 5000

Third F/S 9500 7500

Fourth F/S 12100 10000

Total input

(pages)

Total output

(pages)

• The 4635 and 180 IPS can feed papers as small as 7 inches /

178 mm in width if the optional 7 by 10-inch enablement kit is

installed. The 7 by 10-inch paper option is not available on the

96 IPS.

• Paper that is 17 inches / 432 mm long can be fed only short

edge first.

An elevator moves the tray up or down when it is in use. The HCF

trays have Paper Level switches which detect the position of the

elevator to determine the fullness of the tray. Paper Size switches

detect the size of the paper loaded in the trays.

4-8 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 51

PRINTERS

Feeder tray control panels Each processor feeder tray and HCF tray has a control panel

consisting of a button, indicators, and paper level displays.

Figure 4-3. Feeder tray control panel

Ready

Please

wait

Tray

unload

to open

1

34

2

1 Ready to Open indicator

2 Please Wait indicator

3 Tray Unlock button

4 Paper Level indicators

1. Ready to Open indicator

This indicator glows when paper can be added to the tray.

2. Please Wait indicator

This indicator shows that the tray is in motion. It is lit when the

Tray Unlock button is pressed, when the tray is being lowered,

or when the tray is being raised. The indicator goes off when

the tray elevator reaches its destination.

3. Tray Unlock button

You can use this button any time the Please Wait indicator is off.

• If the tray is in use when this button is pressed, the feed

selection changes to the backup tray if one exists.

Otherwise, printing stops.

• If the tray is in use and selected as a backup tray, pressing

this button causes the tray elevator to lower and the tray is

no longer available for auto switching.

• If the tray elevator is in the raised position and the tray is not

in use or selected as a backup tray, pressing this button

causes the elevator to lower with no effect on printing

operations.

4. Paper Level indicators

These indicators display the approximate quantity of paper

within the tray. The display shows paper by quarter reams up to

one ream, and then by full reams. The green indicator light

appears above the Paper Level indicator which shows the

amount of paper in the tray.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-9

Page 52

PRINTERS

High-capacity stackers

The 4635 IPS and 180 IPS can have from two to four high-capacity

stacker bins, and the 96 IPS can have from one to two. Each bin

holds up to 2500 sheets.

Figure 4-4. High-capacity stackers (HCS)

The printed output is stacked onto the bin platform. The stacking

capacity is approximately 100 to 150 sheets less when stacking into

a container.

It is also possible to select the level to which paper will be stacked in

the HCS.

A stacking elevator maintains the paper at the proper level for

stacking and lowers the stack for unloading. There is an offset

mechanism that offsets printed sets toward the front or back of the

HCS bin. Each HCS bin has unlinked double doors to provide you

with easy, yet safe, access for unloading paper from the printer.

4-10 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 53

Bin control panels Each HCS bin has a control panel consisting of buttons and

indicators.

Figure 4-5. HCS bin control panel

1 Ready to Unload indicator

2 Please Wait indicator

3 Bin Unload button

4 In Use indicator

1. Ready to Unload indicator

When this indicator glows, you can remove printed sheets from

the stacker bin.

PRINTERS

2. Please Wait indicator

When this indicator glows, the elevator is in motion. This

indicator goes off when the platform reaches its destination.

3. Bin Unload button

Pressing this button causes the bin elevator to lower. If the bin

is in use and part of a SELECT AUTO combination, the printed

pages begin stacking in the other stacker bin. If the bin is not in

use, there is no effect on printing operations.

4. In Use indicator

When this indicator glows, the bin is selected to receive the next

printed sheet.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-11

Page 54

PRINTERS

Printer configurations

The DocuPrint 96, 4635, and 180 IPS are available in the following

configurations, some of which may include the bypass transport and/

or Input Enablement kit.

Figure 4-6. 96 IPS printer with inverter feeder/stacker only

Figure 4-7. 96 IPS printer with inverter feeder/stacker + bypass

transport

Figure 4-8. 96/4635/180 IPS printer with inverter feeder/stacker

+ feeder/stacker

Figure 4-9. 4635/180 IPS printer with inverter feeder/stacker +

feeder/stacker + bypass transport

4-12 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 55

PRINTERS

Figure 4-10. 4635/180 IPS printer with inverter feeder/stacker +

feeder/stacker + feeder/stacker

Figure 4-11. 4635/180 IPS printer with inverter feeder/stacker +

feeder/stacker + feeder/stacker + bypass transport

Figure 4-12. 4635/180 IPS printer with inverter feeder/stacker +

feeder/stacker + feeder/stacker + feeder/stacker

Note: The bypass transport device is not available for this

configuration four feeder/stacker modules). The Input Enablement

kit is available for this configuration on the 180 IPS only.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-13

Page 56

PRINTERS

Options enabling third-party feeding and finishing

The Input Enablement and bypass transport devices are offered as

optional components. These options allow you to customize your

printer for increased efficiency and specialized applications, such as

roll feed and finishing devices.

Programmable bypass transport The ability to add a third-party finisher to your 96/4635/180 IPS is

made possible by the programmable bypass transport option.

Finishers increase your production capabilities by providing a wide

variety of finishing choices (for example, slitting, booklet making,

binding, and so forth).

Connected to the printer’s last feeder/stacker module, the

programmable bypass transport allows finishers to interface directly

with your 96/4635/180 IPS. It accepts all paper stocks within the 96/

4635/180 range and accommodates simplex and duplex printing.

The programmable bypass transport meets the Xerox Document

Feeding and Finishing Architecture (DFA) specifications.

Input Enablement kit Adding a third-party feeder to your 96, 4635, or 180 IPS is made

possible by the Input Enablement option. The 96/4635/180 IPS

accepts cut sheets from the feeding device through an entry slot at

the lower right of the last feeder/stacker module.

The input enablement option provides extended paper feed

capability from third party feeder devices. Sheets are received from

a third party feeder device through an entry slot located in the last

feeder/stacker module of the system. The 96/4635/180 IPS controls

the input sheet feeding in accordance with DFA specifications.

Note: The 180 IPS has the option of a roll feeder that does not

require the Input Enablement kit and is not enabled by DFA. This

feeder is installed in the inverter feeder/stacker module in the place

of the feeder tray.

4-14 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 57

Configurations supporting bypass transport and Input Enablement kit

The Input Enablement kit and/or bypass transport are supported on

the 96/4635/180 IPS configurations as follows:

PRINTERS

96 IPS configurations Input Enablement Kit and/or

4635 IPS configurations Input Enablement kit and/or

180 IPS configurations Input Enablement kit and/or

Additional IPS printer features

bypass transport:

• Inverter feeder/stacker only

• Inverter feeder/stacker + feeder/stacker

bypass transport:

• Inverter feeder/stacker + feeder/stacker

• Inverter feeder/stacker + feeder/stacker + feeder/stacker

bypass transport:

• Inverter feeder/stacker + feeder/stacker

• Inverter feeder/stacker + feeder/stacker + feeder/stacker

Input Enablement kit only (no bypass transport):

Inverter feeder/stacker + feeder/stacker + feeder/stacker + feeder/

stacker + feeder/stacker.

Additional features of the DocuPrint 96/4635/180 IPS printers

include:

Instruction labels Located throughout the printer to assist you with jam clearance and

other tasks.

Power saver To conserve energy, the printer has a power saver in the fuser. After

a predetermined period, it times itself out and shuts down. The timeout period can be adjusted by a service representative to meet your

needs. The Printer Controller automatically brings the printer out of

power saver mode when there is a document to be printed.

The power saver times itself out after about four hours and requires

four to seven minutes to warm up.

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-15

Page 58

PRINTERS

Printer paper paths

The paper path is the route materials (paper, transparencies, labels,

etc.) follow through the printer from the feeder trays to the output bins

or finisher receptacle.

Paper path through the IPS printer The following figure illustrates the entire IPS printer paper path.

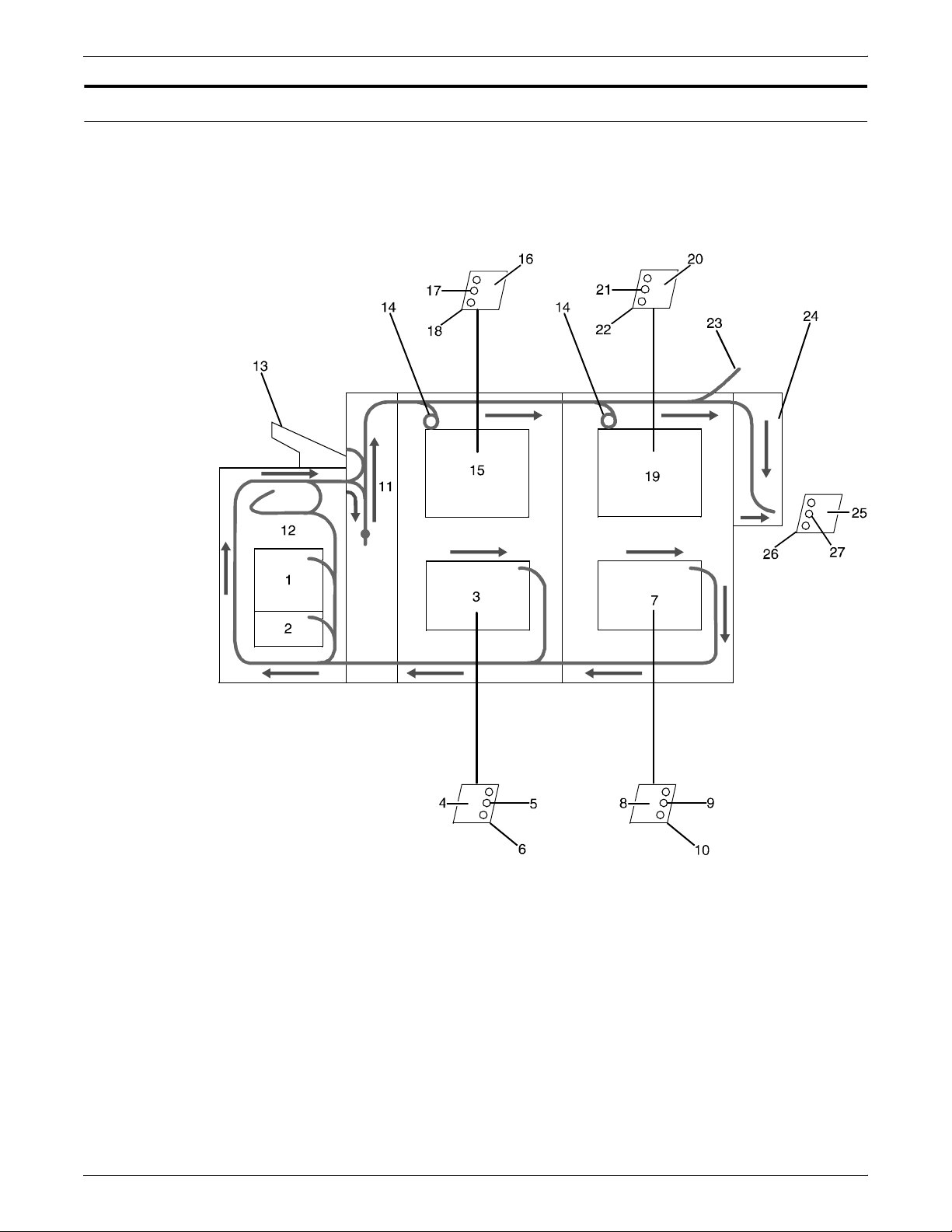

Figure 4-13. Route of paper through 96/4635/180 IPS

1 Processor feeder tray 1

2 Processor feeder tray 2

3 High-capacity feeder tray 3

4 Side 1 of sheet leaving feeder tray

5 Drilled holes (on right edge)

6 Origin 0,0: portrait feeder tray 4

7 High-capacity feeder tray 4

8 Side 1 of sheet leaving feeder tray

9 Drilled holes (on right edge)

10 Origin 0,0: portrait feeder tray 4

11 Inverter

12 Duplex inverter

13 Sample tray

14 Disk inversion

4-16 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 59

PRINTERS

15 High-capacity stacker bin A

16 Side 2 of sheet stacked in bin

17 Drilled holes (on left edge)

18 Origin 0,0: portrait orientation

19 High-capacity stacker bin B

20 Side 2 of sheet stacked in bin

21 Drilled holes (on left edge)

22 Origin 0,0: portrait orientation

23 Purge tray

24 Bypass transport

25 Side 2 of sheet passing through bypass transport

26 Drilled holes (on left edge)

27 Origin 0,0: portrait orientation

Input enablement paper path The following figure shows the paper path and the dimensions of the

input enablement area from a printer front view. The input

enablement kit option supports third-party feeding devices.

Figure 4-14. Input enablement paper path and dimensions

XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE 4-17

Page 60

PRINTERS

Bypass transport paper path The following figure shows the paper path through the bypass

transport from a printer front view.

Figure 4-15. Bypass transport paper path

1 Sheet path

2 Exit rollers

3 Floor

4-18 XEROX DOCUPRINT 96/4635/180 IPS SYSTEM OVERVIEW GUIDE

Page 61

5. 5MICR IPS

The 96 MICR IPS, 4635 MICR IPS, and 180 MICR IPS produce a

magnetic ink character recognition (MICR) line on negotiable and

turnaround documents such as checks and bills. The 96/4635/180

MICR IPS prints documents using magnetic ink and special fonts to

create machine-readable information that allows for quick document

processing.

In general, MICR is used to print accounting and routing information

on blank checks and other negotiable documents, the magnetic

encoding capabilities can be used for any printed output.

For more information on creating MICR documents and using MICR

tools, refer to the Generic MICR Fundamentals Guide, publication

number 721P14083, provided with your IPS.

96/4635/180 MICR IPS printing features

The 96, 4635, and 180 MICR IPS meet ABA standards and ANSI and

ISO specifications for automatic check handling. These printing