Page 1

Xerox DocuPrint Network Printer Series

Installation Planning Guide

for Model 92C NPS

Version 7.1

$XJXVW

721P87421

2000

Page 2

Xerox Corporation

701 South Aviation Boulevard

El Segundo, CA 90245

¸

2000 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 721P87421

·,

Xerox

The Document Company, the stylized X, and all Xerox

product names mentioned in this publication are trademarks of Xerox

Corporation. Products and trademarks of other companies are also

acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent

editions.

Page 3

Laser safety

Warning: Adjustments, use of controls, or performance of

!

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance standards of the U.S. Department of Health, Education,

and Welfare for Class 1 laser products. Class 1 laser products do not

emit hazardous radiation. The DocuPrint printers do not emit

hazardous radiation because the laser beam is completely enclosed

during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must be

removed with a tool. DO NOT REMOVE LABELED PANELS OR

PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

Ozone information

Operation safety

This product produces ozone during normal operation. The amount

of ozone produced depends on copy volume. Ozone is heavier than

air. The environmental parameters specified in the Xerox installation

instructions ensure that concentration levels are within safe limits. If

you need additional information concerning ozone, call 1-800-8286571 to request the Xerox publication 600P83222, OZONE.

Your Xerox equipment and supplies have been designed and tested

to meet strict safety requirements. They have been approved by

safety agencies, and they comply with environmental standards.

Please observe the following precautions to ensure your continued

safety.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

Warning: Improper connection of the equipment grounding

!

conductor may result in risk of electrical shock.

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS iii

Page 4

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result in

poor performance and may create a hazardous situation.

• Never move either the printer or the Printer Controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety at

the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your local Xerox

representative or operating company.

iv XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 5

Table of Contents

Laser safety iii

Ozone information iii

Operation safety iii

Introduction ix

About this guide ix

Contents ix

Conventions x

Notice x

1. Product overview 1-1

System overview 1-1

Client workstations and system software 1-3

Supported hardware and operating systems 1-3

Client networking software 1-4

Ethernet LAN 1-4

Token Ring 1-5

Fiber Distributed Data Interface 1-5

NPS/IPS Dual Mode 1-5

Sixth Sense 1-5

2. Controller components and options 2-1

Controller hardware 2-1

Sun Ultra 2 workstation 2-1

Sun Ultra 60 workstation 2-4

Controller software 2-9

3. Printer components and options 3-1

Printer components 3-1

Printer control console 3-3

Printer options 3-4

High-capacity feeder 3-4

Dual stacker 3-5

Stitcher/stacker 3-6

Customer-changeable unit (CCU) 3-7

Bypass transport option 3-8

Interface with third-party devices 3-9

Electrical interface 3-9

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS v

Page 6

TABLE OF CONTENTS

4. Preparing for installation 4-1

Responsibilities 4-1

Xerox responsibilities 4-1

Customer responsibilities 4-2

Installation planning checklist 4-4

NPS network installation checklist 4-7

Novell network information 4-9

DocuPrint as a print server (PSERVER) 4-9

DocuPrint NPS as a remote printer (RPRINTER) 4-10

Connectivity requirements 4-12

Ethernet specifications 4-12

Token Ring specifications 4-12

Fiber Distributed Data Interface specifications 4-12

5. Controller specifications and requirements 5-1

Power requirements 5-1

Outlet configurations 5-2

Environmental specifications 5-3

Space requirements 5-3

Printer controller placement 5-3

Controller hardware specifications and requirements summary 5-7

6. Printer specifications and requirements 6-1

Power requirements 6-1

Outlet configurations 6-2

Printer outlet voltages—60 Hz 6-2

Printer outlet voltages—50 Hz 6-3

Environmental specifications 6-4

Space requirements 6-5

Printer placement 6-5

CCU changeout cart 6-10

Space planning guidelines 6-11

Clearance space requirements 6-11

Shared space 6-11

Floor leveling 6-15

Delivery access requirements 6-15

Printer hardware specifications and requirements summary 6-18

Space planning templates 6-19

7. System connections 7-1

Cable lengths 7-1

Cable locations 7-2

vi XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 7

TABLE OF CONTENTS

8. Installation 8-1

Installation process 8-1

Your responsibilities 8-2

Software licensing 8-3

Ongoing maintenance 8-4

Routine maintenance 8-4

Meter reading and reporting 8-4

A. Supplies A-1

Paper and other throughput stocks A-1

Selecting paper A-1

Paper care A-3

Other supplies A-6

Dry ink A-6

Fuser lubricant A-6

Developer A-6

Stitcher wire A-7

Diskettes A-7

Tapes A-7

Fonts A-8

Consumable supplies tables A-9

Paper and special stocks tables A-9

Complete supplies list—Model 92C printer A-12

Ordering supplies A-14

B. Xerox support services B-1

Xerox Customer Service Support Center B-1

Xerox Printing Systems Customer Support Center B-2

Xerox Customer Documentation Catalog B-3

Xerox Documentation and Software Services (XDSS) B-3

Operator training B-3

Xerox Customer Education B-4

Xerox Font Center B-4

C. Related publications C-1

D. DocuPrint NPS on a Novell network D-1

Novell NetWare overview D-1

Print queues D-1

Queue to printer relationships D-2

PCONSOLE D-2

Print server (PSERVER) D-3

Job parameters D-3

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS vii

Page 8

TABLE OF CONTENTS

Using Novell forms to specify virtual printers D-4

Remote printer (RPRINTER) D-4

DocuPrint NPS as a print server or as a remote printer D-5

Choosing a Print Server or Remote Printer Configuration D-5

Novell configuration D-7

Configuring DocuPrint as a PSERVER D-7

Configuring DocuPrint as an RPRINTER D-9

Supporting DocuPrint NPS on the file server D-10

Glossary GLOSSARY-1

Index INDEX-1

viii XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 9

About this guide

Contents

Introduction

This guide helps you prepare for delivery and installation of your new

Xerox DocuPrint printing system.

This guide is intended for the person responsible for coordinating the

installation of the DocuPrint printer at your site. It lists the tasks you

must complete before installation can begin, as well as your

responsibilities during the installation.

Before using this guide, become familiar with its contents and

conventions.

This guide contains the following:

• Chapter 1, "Product overview," provides an overview of the

printing system.

• Chapter 2, "Controller components and options," describes

system controller hardware, software, and options of your

printing system.

• Chapter 3, "Printer components and options," describes printer

components, configurations, and options.

• Chapter 4, "Preparing for installation," provides a checklist of

tasks that must be accomplished before the installation. It also

explains connectivity requirements for transporting documents

from the host or client to the DocuPrint printing system.

• Chapter 5, "Controller specifications and requirements,"

describes power, environmental, and space requirements for

the system controller.

• Chapter 6, "Printer specifications and requirements," describes

power, environmental, and space requirements for the printer.

Space planning guidelines and diagrams are provided to help

you set up the work area.

• Chapter 7, "System connections," provides cable requirements

for your printing system.

• Chapter 8, "Installation," describes the activities that occur

during installation. It also describes ongoing maintenance

activities.

• Appendix A, "Supplies," describes how to select, store, and use

supplies for the DocuPrint printing system. It also provides a list

of consumable supplies you can order.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS ix

Page 10

INTRODUCTION

Conventions

• Appendix B, "Xerox support services," explains how to utilize

available Xerox support services.

• Appendix C, "Related publications," lists other Xerox

documents that are part of this publication set.

• Appendix D, "DocuPrint NPS on a Novell network," describes

some of the considerations to make before the installation of

DocuPrint on a Novell network.

A glossary and index are provided at the back of the guide.

This guide uses the following conventions:

• Italics—Document and library names are shown in italics (for

example, the Xerox DocuPrint IPS Series Messages Guide).

• Capitalization of graphical user interface (GUI) window titles

matches the titles as they appear on the screen. In cases where

a window does not have a title, it is referenced using all lower

case. For example:

— At the graphical user interface, use the Output

Configuration window to group the trays.

Notice

— The main window displays the current system status.

Note: Notes are hints that help you perform a task or understand

the text.

Caution: Cautions alert you to an action that could damage

hardware or software.

Warning: Warnings alert you to conditions that may affect the

!

safety of people.

This publication may contain descriptions of concepts and features

not currently available for your Xerox printing system. Consult your

Xerox sales representative or your operating system software

program description for additional information.

x XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 11

System overview

1. 1Product overview

This chapter provides an overview of the features and functions of

the Xerox DocuPrint Model 92C NPS.

The DocuPrint system enables personal computer (PC), Sun

Workstation, DEC workstation, HP/Apollo, IBM RS/6000, and Apple

Macintosh users to print PostScript level 2, HP PCL5e, or ASCII

documents on a high-speed Xerox DocuPrint Model 92C NPS

printer.

One or more of the following network communication systems may

be used to transport documents from the client workstation to the

printer:

• Ethernet local area network (LAN) running Transmission

Control Protocol/Internet Protocol (TCP/IP), AppleTalk, or

Novell NetWare network protocol software.

• Token Ring running TCP/IP, Novell, or AppleTalk network

protocol software.

• Fiber Distributed Data Interface (FDDI) running TCP/IP, Novell

3.x, or Apple Talk network protocols. The FDDI supports a

Single Connection configuration only.

Multiple network devices may be installed on the same NPS

controller. The default network device that ships with your NPS

controller is a 100 Mbit Ethernet connection. You may install other

network devices by installing additional network cards, provided each

card has a unique network to which it connects. For example, if you

use a Token Ring network connection, you have the option of using

the default Ethernet device as a secondary network.

If you choose to install multiple network devices on your NPS

controller, the following parameters apply:

• You must select a primary network device and designate any

others as secondary. The primary network device does not

have to be the default Ethernet device that ships with your

controller; it can be any of the network devices installed.

• You must run the TCP/IP protocol on the primary network

device. You may also run TCP/IP on other network devices. For

each network device running TCP/IP, you must specify a unique

IP address and IP netmask. For the primary network device,

you must specify the HostName and router IP address. The

HostName for any secondary devices is created from the name

chosen for the primary device.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 1-1

Page 12

PRODUCT OVERVIEW

Note: You may not use the NPS controller as an IP router.

Consequently, the router IP address must be on the primary

network devices network only.

• You may run the AppleTalk protocol on only one network device.

The network device on which AppleTalk is run does not have to

be the primary network device.

• You may run Novell protocols on only the primary network

device.

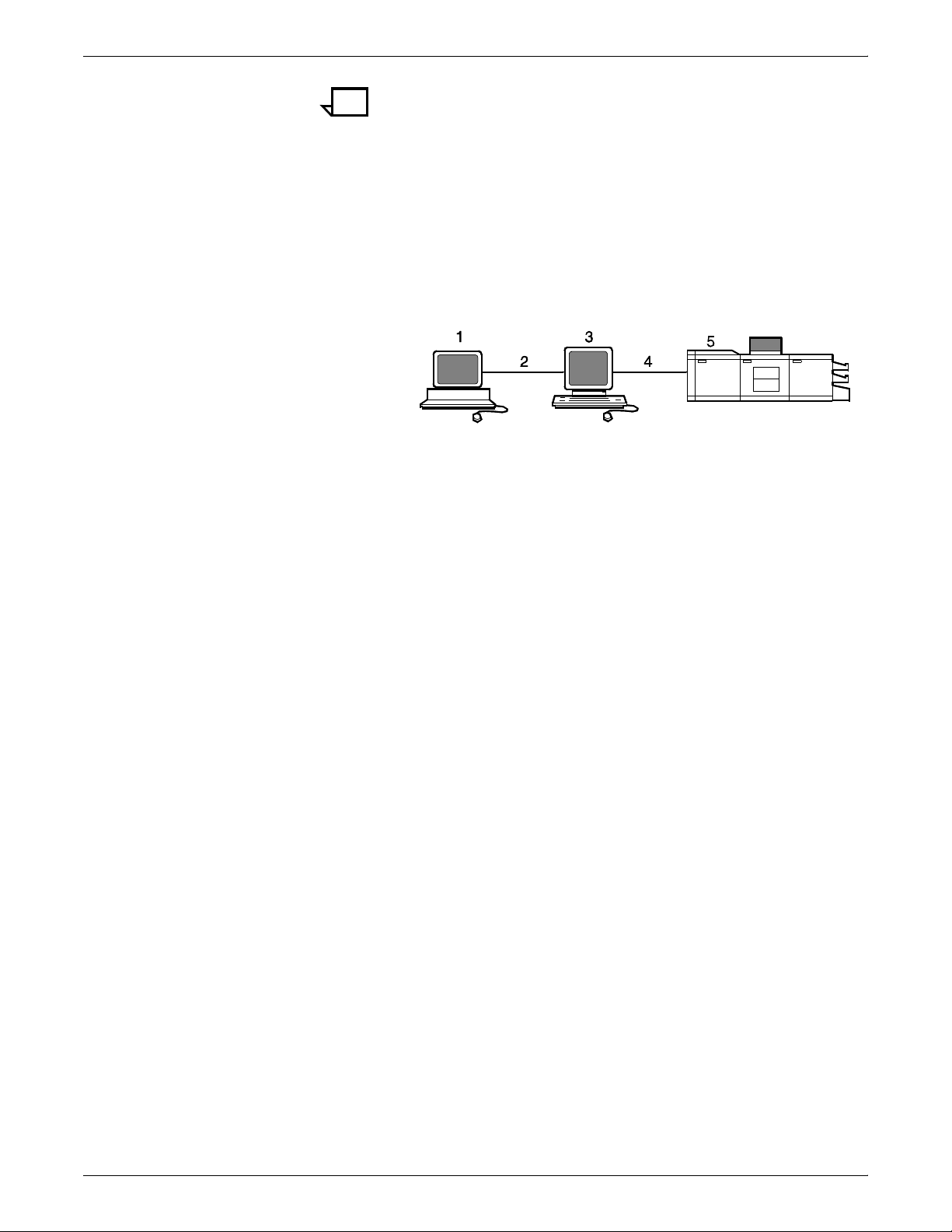

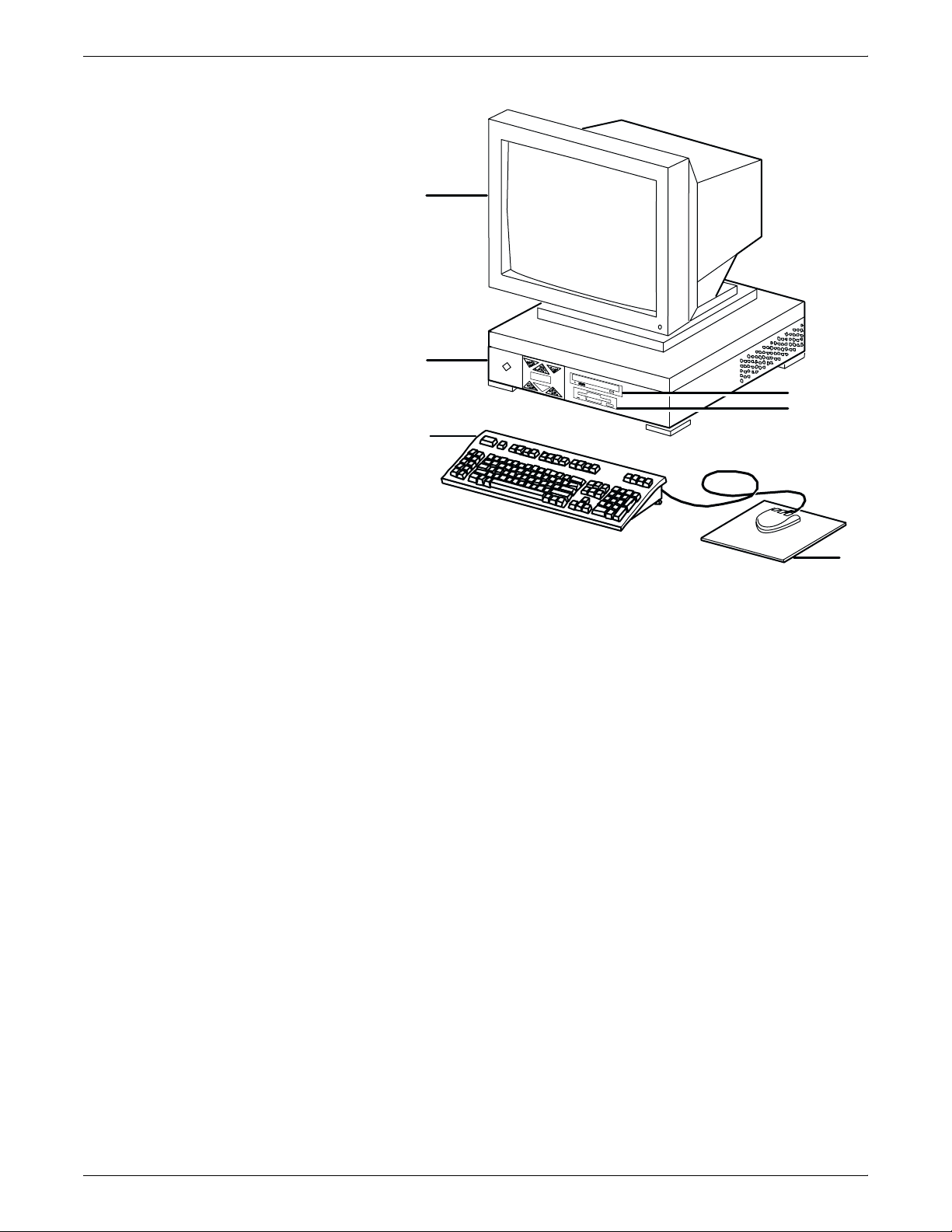

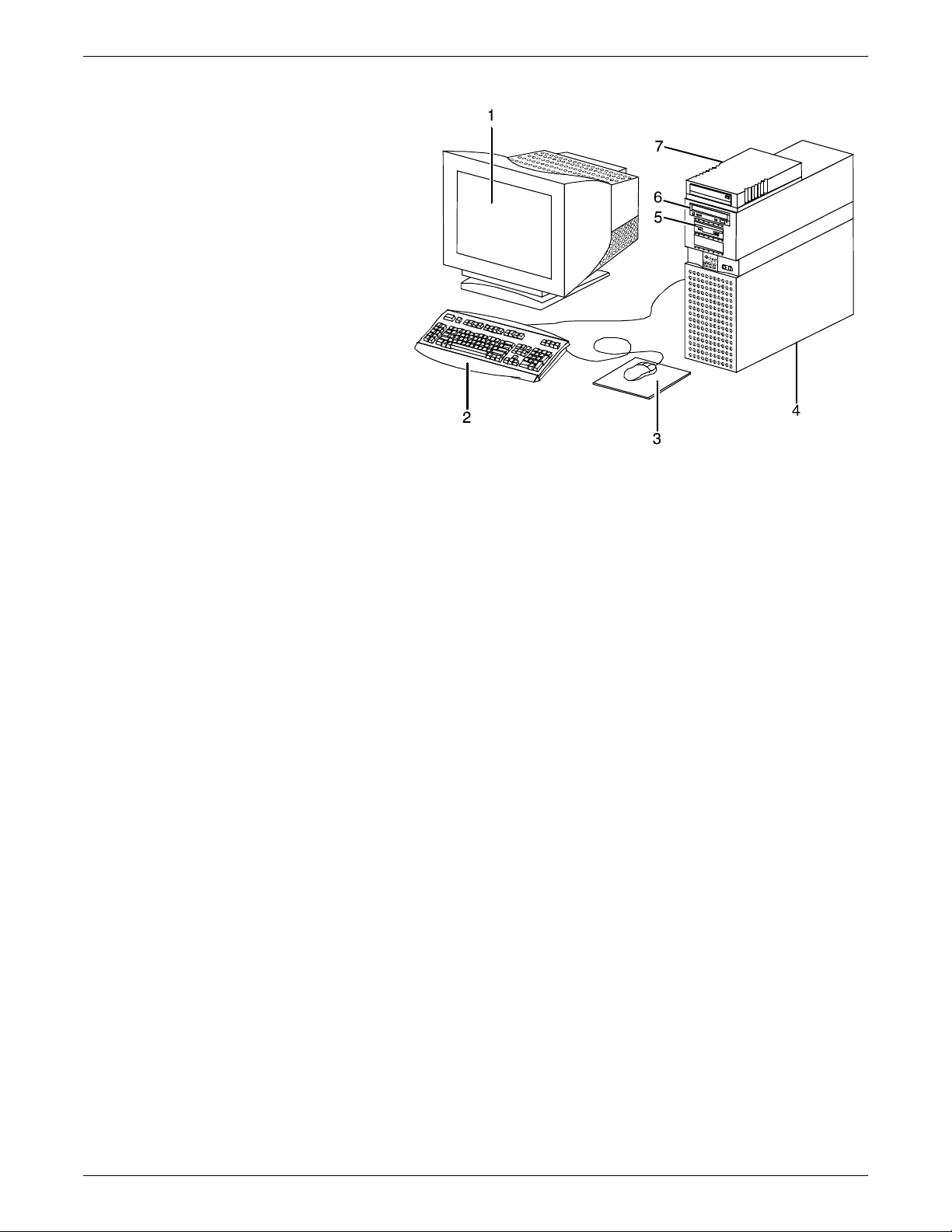

Figure 1-1. DocuPrint printer system components

1 Customer-supplied client PC or workstation

2 Customer-supplied network

3 Xerox-supplied printer controller

4 Xerox-supplied printer interface

5 DocuPrint Model 92C printer.

Briefly, the functions of the components are as follows:

Customer-supplied client PC or

workstation

Customer-supplied network The customer will need to supply one or more of the following

Users create their documents at the networked client PCs or

workstations using software applications that generate PostScript

(XGF), HP PCL5e, or ASCII output. When ready to print, users

submit the documents to the printer controller.

networks:

• Ethernet local area network (LAN) running TCP/IP, AppleTalk,

or Novell NetWare network protocol.

• Token Ring running TCP/IP, Novell, or AppleTalk network

protocol.

• Fiber Distributed Data Interface (FDDI) running TCP/IP, Novell

3.x, or Apple Talk network protocols. The FDDI supports a

Single Connection configuration only.

Xerox-supplied printer controller Printer controller (color or monochrome monitor, processor, CD-

ROM drive, keyboard, mouse, optional 1/4-inch or 4mm tape drive):

The printer controller accepts the print job from the client workstation,

converts the files into page images, and sends the page images to

the printer. The user interface at the printer controller allows you to

perform tasks such as monitoring job status, prioritizing jobs, and

configuring the system. The optional cartridge tape drive can be used

for tasks such as backing up files. The CD-ROM drive also allows you

to install the printer controller software.

1-2 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 13

PRODUCT OVERVIEW

Xerox-supplied printer interface The printer interface cable provides high-speed data transport and

communication between the printer controller and the printer.

Xerox-supplied DocuPrint printer The printer (also known as an IOT or print engine) accepts data from

the printer controller and prints the document according to the print

options specified by the user. The printer also provides paper

stacking, collating, and optional finishing.

DocuPrint Network Printing System

(NPS)

The entire DocuPrint Network Printing System includes the printer

(also known as an IOT or print engine), printer controller, printer

interface, and all appropriate software. “DocuPrint printer” or “printer”

refers to the base printer engine (IOT) only, without the printer

controller and interface.

Note: It is your responsibility to supply, install, and maintain

hardware and software on any PC, DECStation, Sun Workstation,

HP/Apollo Workstation, IBM RS/6000 Workstation, or Macintosh

system used to generate documents for printing on the DocuPrint

printers. You are also responsible for obtaining, installing, and

maintaining the required Ethernet LAN or Token Ring network,

transceivers, cables, and connectors, as well as any necessary FDDI

connectors.

Xerox is responsible for the physical installation and service of the

printer and printer controller hardware and software components.

You have the general responsibility for the site of ensuring that the

right personnel, supplies, and that network hardware and software is

available. Refer to the “Preparing for installation” chapter of this

guide for a detailed description of the shared responsibilities of the

customer and of Xerox.

Client workstations and system software

To send print jobs to the DocuPrint NPS printer, the customer needs

to provide the proper client hardware as well as operating system

and network software.

Supported hardware and operating systems

Xerox DocuPrint Model 92C NPS supports the following types of

networked client workstations and operating systems:

• Sun Workstation running Solaris 1.1.x or Solaris 2.x

• PC running MS-DOS 6.2 and Microsoft Windows 3.1, using

Ethernet with TCP/IP or Novell NetWare 3.11 and 3.12

Note: Customers using Novell 4.1 must set the “Bindery

Emulation Mode” to be backwards compatible with Novell

3.12.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 1-3

Page 14

PRODUCT OVERVIEW

• PC 386 or 486, running MS-DOS, version 6.2, with one of the

following TCP/IP packages:

— PathWay Access 3.1, Wollongong Integrated Networking/

Transmission Control Protocol (WIN/TCP) for DOS, release

6.0

— File Transfer Program (FTP) software, PC-TCP/IP, release

3.0 or higher

— Sun Personal Computer–Network File Services (PC-NFS),

version 5.1

• IBM RS/6000 running IBM AIX, version 4.1

• HP/Apollo running HP-UX, version 10.01

• DECStation 5000/200 running DEC Ultrix, version 4.3

• Apple Macintosh, System 7.x or 8.x, using AppleTalk through

EtherTalk, phase 1 or 2

• Any system that supports RFC-1179 lpr/lpd.

DocuPrint Model 92C NPS software may be compatible with

workstation models and software versions other than those listed

above.

Ethernet LAN

Client networking software

Xerox client software, a third-party TCP/IP lpr networking software,

Novell, or Apple/Macintosh Printer Access Protocol (PAP)

networking software must be installed on your client workstations or

downloaded from the printer controller. This software provides an

interface with the printer controller, which allows you to submit print

jobs and check job status.

Note: The DocuPrint printing options available to a client user vary

according to the networking software loaded on the client

workstation.

For additional information on submitting jobs from a client

workstation, refer to the Xerox DocuPrint Network Printer Series

Guide to Submitting Jobs from the Client.

Users of networked client workstations may send print jobs to the

DocuPrint NPS printer over the Ethernet LAN using TCP/IP,

AppleTalk using EtherTalk Link Access Protocol (ELAP), or Novell

NetWare 3.1x as the network protocol.

Regardless of printing or transmission protocol, the Ethernet

connection to the printer controller must be compatible with the

Institute of Electrical and Electronics Engineers (IEEE) 802.3

standard.

1-4 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 15

Tok en R ing

Fiber Distributed Data Interface

NPS/IPS Dual Mode

PRODUCT OVERVIEW

Users of network client workstations may send print jobs to the

DocuPrint NPS printer over Token Ring network using TCP/IP,

Novell 3.x, or AppleTalk network protocol.

Regardless of printing transmission protocol, the Token Ring

connection to the printer controller must be compatible with the

Institute of Electrical and Electronics Engineers (IEEE) 802.5

standard.

TCP/IP, Novell 3.x, and Apple Talk network protocols are supported

over FDDI. The FDDI supports a Single Connection configuration

only.

The Xerox DocuPrint Dual Mode option enables both DocuPrint IPS

and NPS systems to coexist on the same printer controller (Sun

workstation). This allows the DocuPrint system to receive data

streams supported by NPS and IPS, including IPDS, PostScript

Levels 1 and 2, HP PCL5c, HP PCL5e, and ASCII.

Sixth Sense

The customer may switch from one mode to the other. When your

system is operating in IPS mode, it can accept PostScript and PCL

data streams in the background; however, you can print these jobs

only when the system is in NPS mode. When in NPS mode, the

system cannot accept IPDS data streams in the background; you can

print them only when the system is in IPS mode.

Refer to the Xerox DocuPrint IPS/NPS Dual Mode Switching

Instructions and other Xerox DocuPrint IPS documentation for more

information.

Sixth Sense is a unique suite of diagnostic tools that allows Xerox

customer service engineers, analysts, and consultants to serve

customers more effectively.

Sixth Sense is intended to automate and expedite the range of

service-related support functions. Sixth Sense is a tool that enables

Xerox to provide benchmark service support. Xerox customers

benefit from the ability to bring broader support to focus more quickly.

For example, Sixth Sense can allow the Service Representative to

repeatedly "preview" the condition of the system prior to an actual

site visit. This may provide the ability to determine the correct part or

piece of information to have on hand when the site visit is made.

Sixth Sense is a no charge feature available to customers through

Xerox Service. The customer need only provide an analog phone line

for use by the Sixth Sense modem connection. For those customers

unable to dedicate a phone line to the Sixth Sense connection, three

and five port phone share devices are available for purchase.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 1-5

Page 16

PRODUCT OVERVIEW

To take advantage of Sixth Sense, the customer needs to:

• Request Sixth Sense enablement through Xerox Service

• Provide an analog phone line

• If necessary, purchase an optional phone share device.

More information about the Sixth Sense can be found in the Xerox

DocuPrint 4850/4890 NPS System Administration Guide.

1-6 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 17

Controller hardware

2. 2Controller components and

options

The printer controller provides the printer with print data and

commands, and receives status information from the printer. This

chapter describes the components and options available for the

controller.

The printer controller consists of a Sun workstation and uses

proprietary Xerox hardware, firmware, and software to run the NPS.

Your controller may be either a Sun Ultra 2 or Ultra 60 workstation.

The following sections contain information about both the Ultra 2 and

the Ultra 60.

Sun Ultra 2 workstation

The Sun workstation provides a user interface to the print engine. It

is used to operate the NPS software that controls the printer. The

workstation contains the following hardware components:

• Sun Ultra 2 workstation processor (system unit)

• Display monitor

• Keyboard and mouse

• Connectivity boards for Ethernet and, optionally, Token Ring

• A Data Control Interface Module (DCIM2) card installed in the

processor to interface with the print engine.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 2-1

Page 18

CONTROLLER COMPONENTS AND OPTIONS

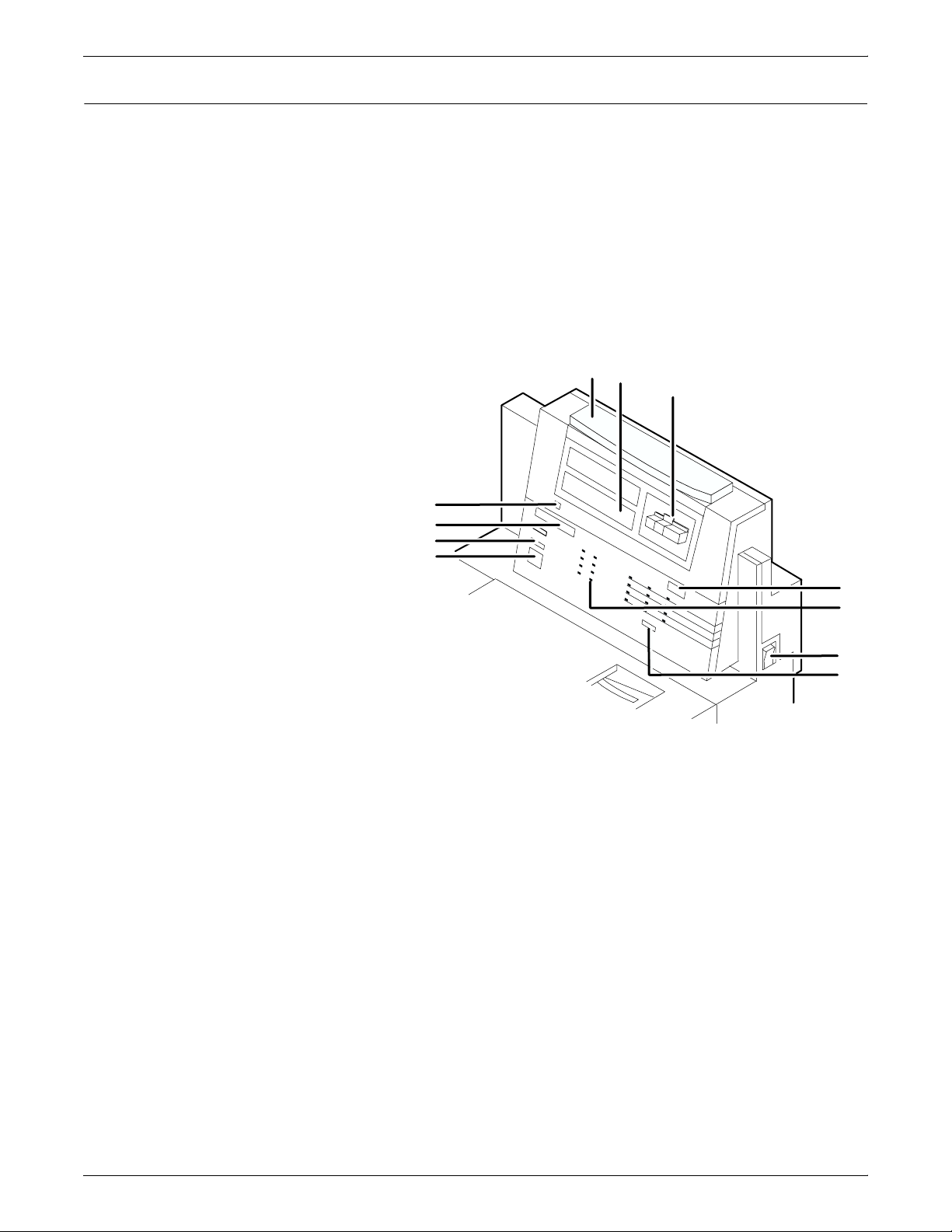

Figure 2-1. Components of the Sun Ultra 2 workstation

2

1

6

5

4

3

1 Processor

2 Monitor

3 Mouse and mouse pad

4 Keyboard

5 Diskette drive

6 CD-ROM drive

Processor The 256 MB RAM processor is the central processing unit of the Sun

workstation. It contains a power switch, an internal disk drive, a

diskette drive, a CD-ROM drive, a power receptacle and outlet,

connectors and ports.

The processor has the following components:

• Internal disk drive: One 4.2 GB internal disk drive is provided

as a standard feature of the processor. The operating system,

the NPS application, and any queued print jobs are stored on

the internal disk. This disk cannot be used to store other

applications or data except as directed by your service

representative. Up to three optional disk drives are available in

increments of 4 or 9 GB.

• Diskette drive: Diskettes inserted into a diskette drive are used

to load files to, and back up files from, the internal disk drive.

The diskette drive uses industry standard 3.5 inch, 1.44 MB,

double-sided, high-density diskettes. This diskette drive is not

an input source for print jobs nor any other data or application; it

is reserved exclusively for use by a service representative to

update software and to store files. The diskette drive is located

in the processor, on the right front section for the Ultra 2.

2-2 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 19

CONTROLLER COMPONENTS AND OPTIONS

• CD-ROM drive: The CD-ROM drive is a high density, read-only,

optical laser storage device used for loading the NPS operating

system and other files. The CD-ROM drive is located in the

processor above the diskette drive.

• Cartridge tape drive (not shown): An optional 8 GB, 4 mm

SCSI cartridge tape drive also is available for the NPS. Like the

diskette and CD drives, this tape drive is not an input source for

print jobs or for any other data or application. It provides the

service representative with another means of loading system

maintenance files or saving diagnostic information.

• Back panel: The back panel of the processor has a power

switch, a power receptacle and outlet, connectors, connector

openings, and ports. The following figure shows the back panel

of the Sun workstation that is a part of your NPS controller.

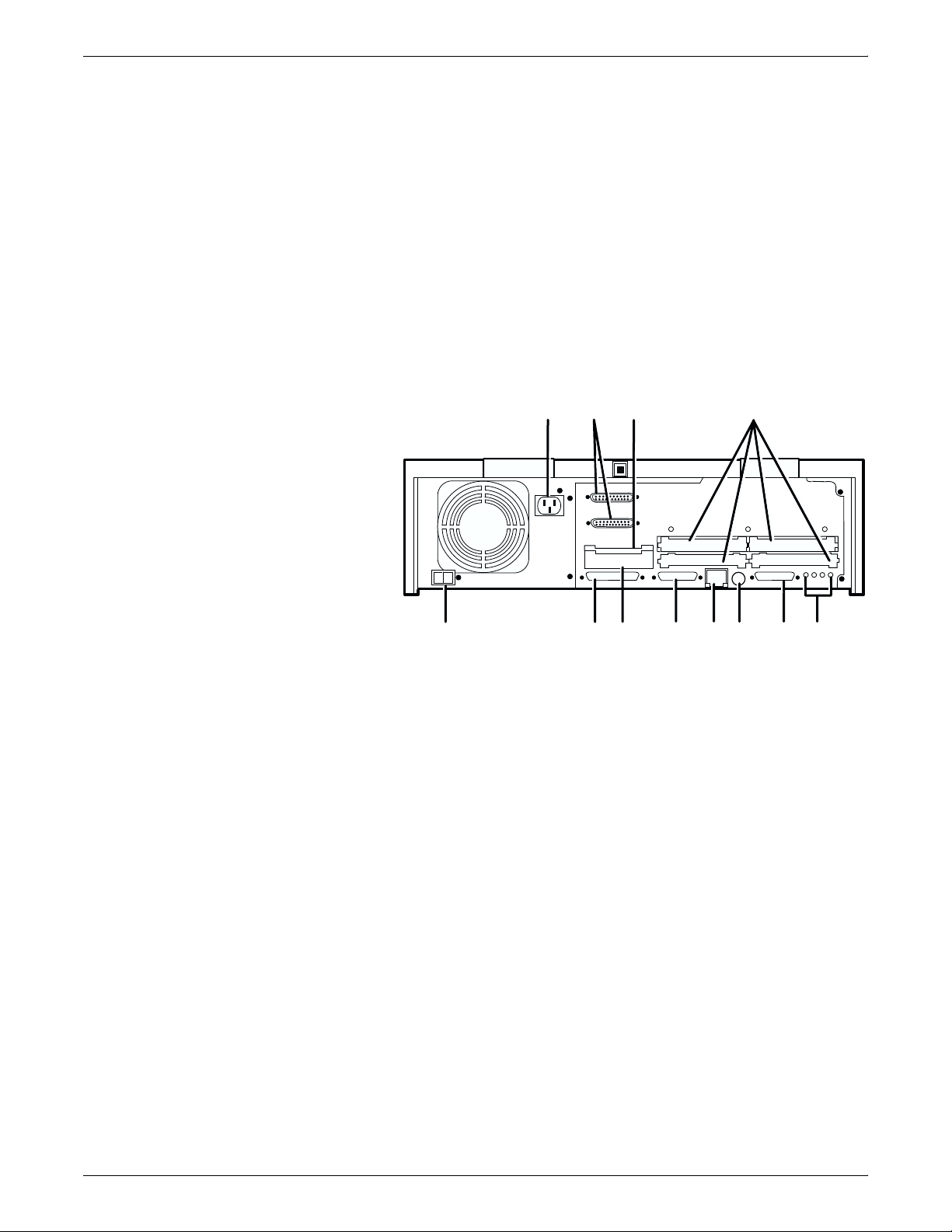

Figure 2-2. Back panel of the Sun Ultra 2 processor

11

3

2

3

2

10

9

4

1

0

8

7

5

6

1

12

1 Power inlet

2 Serial connectors (2): RS-432/RS-232

3 Graphics/video output: UPA slot

4 Sbus slots (Number of slots varies depending on the model)

5 Audio connectors (4)

6 Parallel connector

7 Keyboard/mouse connector

8 TPE connector

9 MII connector

10 UPA slot

11 SCSI connector

12 Power on/Standby switch

Display monitor The display monitor has a 1192 x 700 pixel screen which displays the

NPS graphical user interface windows.

The graphical user interface allows you to interact with the printer

and to monitor its interaction with the various components. During a

print job, printer error messages may display to notify you of any

unexpected conditions.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 2-3

Page 20

CONTROLLER COMPONENTS AND OPTIONS

Keyboard The keyboard consists of alphanumeric keys similar to a typewriter,

Mouse The mouse is another main method of communicating with the

Sun Ultra 60 workstation

symbols and special character keys, an extended character set, and

function keys. The keyboard is one of your main methods of

communicating with the printer. You can use the keyboard to make

selections, and to enter commands that control functions such as

requesting sample prints, obtaining billing meter totals, shutting down

the system, and so forth.

printer. The mouse has three buttons. The left and right buttons are

used to select NPS functions. The center button provides additional

functions that you will not be required to use. If your workstation has

an optical mouse, it must remain on its designated metallic pad to be

active. If the mouse has a roller ball instead of an optical sensor

underneath, it requires a non-metallic pad.

Note: Printer controller hardware configurations are subject to

upgrade.

The Sun Ultra 60 workstation provides a user interface to the print

engine. It has a high performance RISC processor chipset, based on

the industry standard Scalable Processor Architecture (SPARC). It is

used to operate the software that controls the printer. The

workstation contains the following hardware components:

• Sun Ultra 60 workstation processor (system unit)

• Display monitor

• Keyboard and mouse

• Diskette, CD-ROM, and cartridge tape drives

• Connectivity board for Ethernet and, optionally, Token Ring

• A Data Control Interface Module (PDCIMu) card installed in the

processor to interface with the print engine.

2-4 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 21

CONTROLLER COMPONENTS AND OPTIONS

Figure 2-3. Components of the Sun Ultra 60 workstation

1 Monitor

2 Keyboard

3 Mouse

4 Processor

5 Diskette drive

6 CD-ROM drive

7 Cartridge tape drive

Processor The 256 MB RAM processor is the central processing unit of the Sun

Ultra 60 workstation. It contains a power switch, a disk drive, a

diskette drive, a CD-ROM drive, a power receptacle and outlet,

connectors and ports.

The processor has the following components:

• Internal disk drive: Two 18.2 GB primary disk drives are

provided as a standard feature of the processor. The operating

system, the NPS application, and any queued print jobs are

stored on the internal disk. This disk cannot be used to store

other applications or data except as directed by your service

representative.

• Diskette drive: Diskettes inserted into a diskette drive are used

to load files to, and back up files from, the internal disk drive.

The diskette drive uses industry standard 3.5 inch, 1.44 MB,

double-sided, high-density diskettes. This diskette drive is not

an input source for print jobs nor any other data or application; it

is reserved exclusively for use by a service representative to

update software and to store files.

• CD-ROM drive: The CD-ROM drive is a high density, read-only,

optical laser storage device used for loading the NPS operating

system and other files. The CD-ROM drive is located in the

processor above the diskette drive.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 2-5

Page 22

CONTROLLER COMPONENTS AND OPTIONS

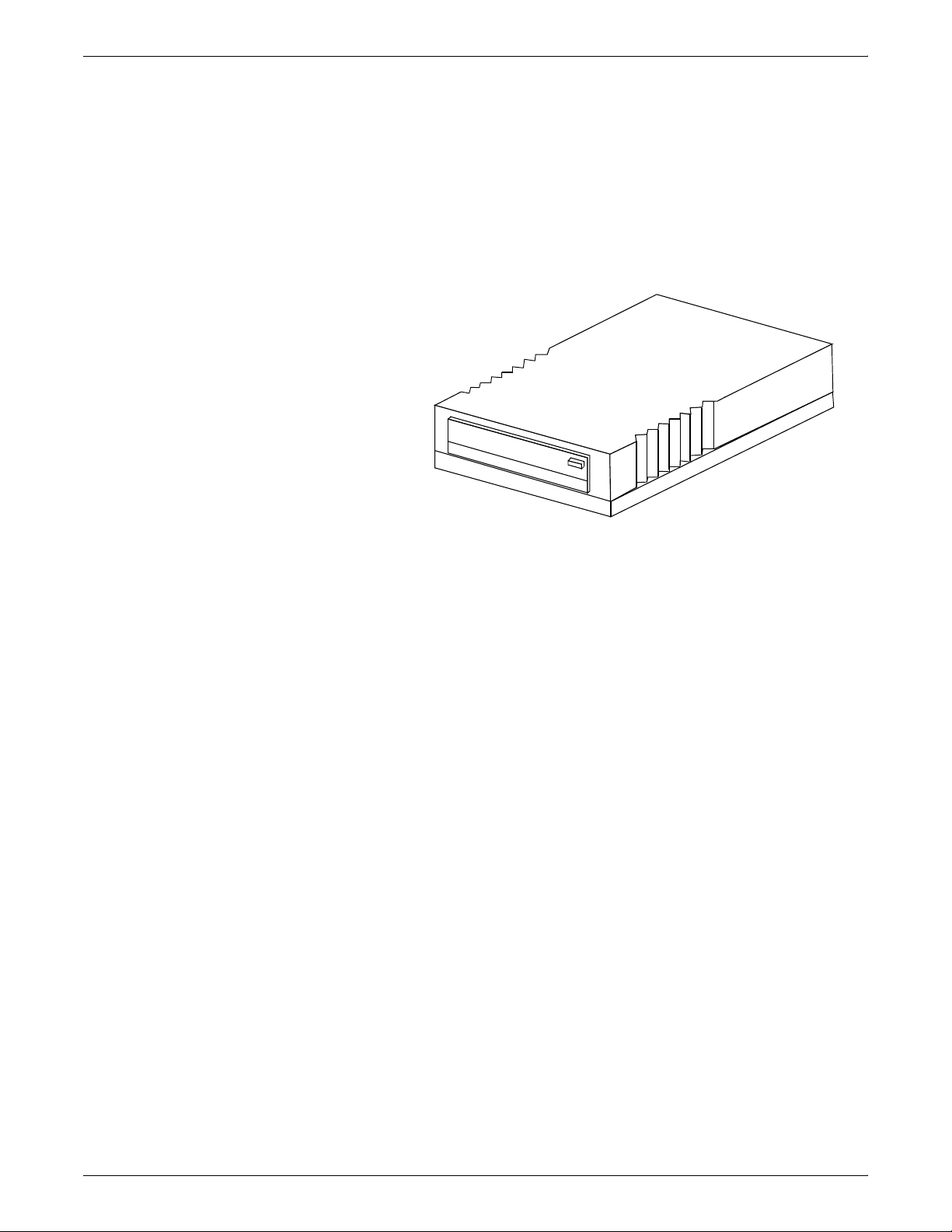

• Cartridge tape drive: A 4 GB external SCSI quarter inch

cartridge (QIC) tape drive is an external device provided with

the printing system. The cartridge tape drive connects to the

controller through the SCSI port on the processor back panel.

Like the diskette and CD drives, this tape drive is not an input

source for print jobs or for any other data or application. You

use it to load resource files, and the service representative uses

it to load system maintenance files or to save diagnostic

information.

Figure 2-4. External cartridge tape drive

• Back panel: The back panel of the processor has a power

receptacle and outlet, connectors, connector openings, and

ports. The following figure shows the back panel of the Sun

Ultra 60 workstation that is a part of your NPS controller.

2-6 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 23

CONTROLLER COMPONENTS AND OPTIONS

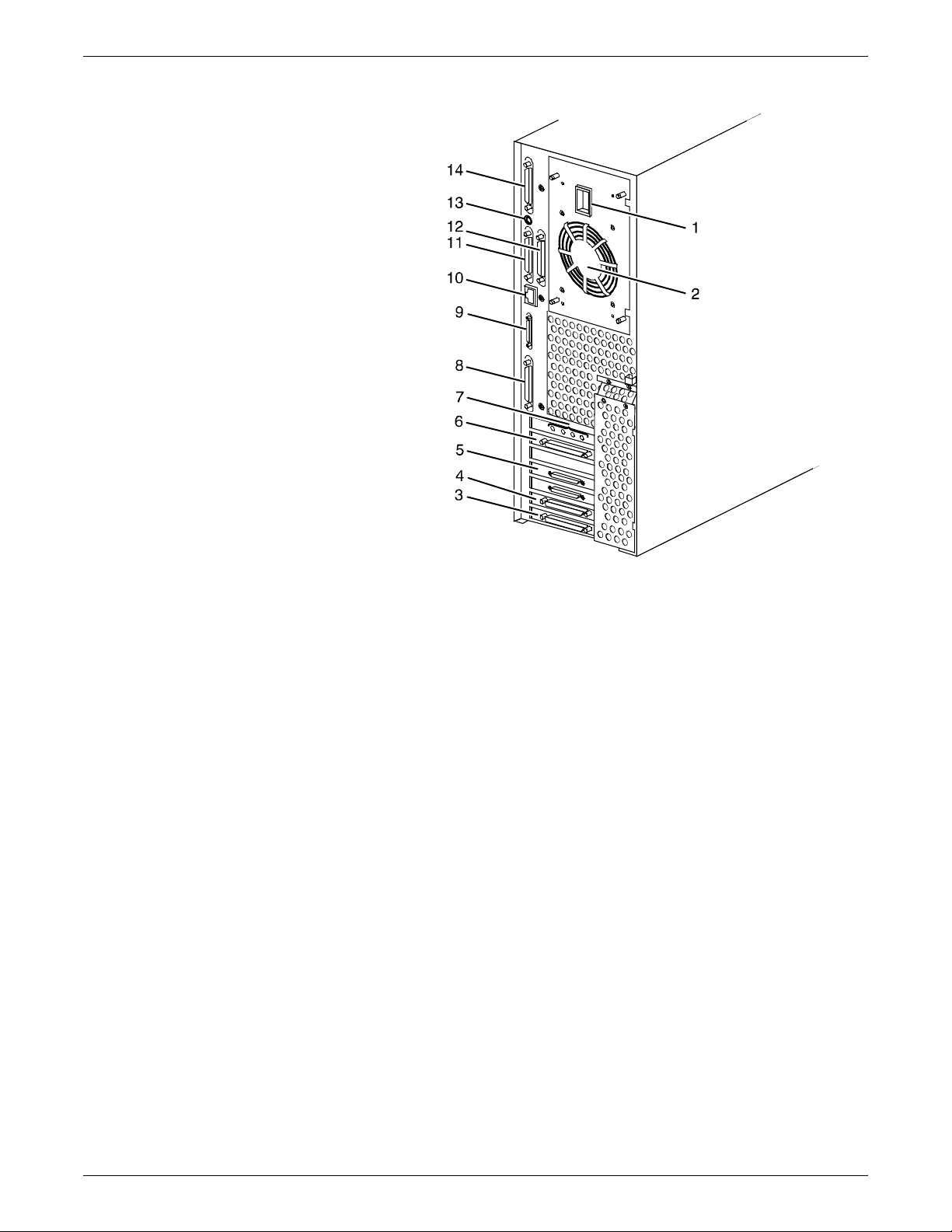

Figure 2-5. Back panel of the Sun Ultra 60 processor

1 Power inlet

2 Fan vent

3 Online interface (if configured)

4 Differential SCSI PWB (optional)

5 Printer connector (PCI66 1)

6 Monitor connector

7 Audio connectors (4)

8 Single-ended SCSI connector

9 MII connector

10 TPE (Ethernet) connector

11 Serial connector A: RS-432/RS-232

12 Serial connector B: RS-432/RS-232

13 Keyboard connector

14 Parallel connector

Display monitor The graphical user interface allows you to interact with the printer

and to monitor its interaction with the various components. During a

print job, printer error messages may display to notify you of any

unexpected conditions.

Keyboard The keyboard consists of alphanumeric keys similar to a typewriter,

symbols and special character keys, an extended character set, and

function keys. The keyboard is one of your main methods of

communicating with the printer. You can use the keyboard to make

selections, and to enter commands that control functions such as

requesting sample prints, obtaining billing meter totals, shutting down

the system, and so forth.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 2-7

Page 24

CONTROLLER COMPONENTS AND OPTIONS

Mouse The mouse is another main method of communicating with the

printer. The mouse has three buttons. The left and right buttons are

used to select NPS functions. The center button provides additional

functions that you will not be required to use. If your workstation has

an optical mouse, it must remain on its designated metallic pad to be

active. If the mouse has a roller ball instead of an optical sensor

underneath, it requires a non-metallic pad.

Note: Printer controller hardware configurations are subject to

upgrade.

2-8 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 25

Controller software

CONTROLLER COMPONENTS AND OPTIONS

The installation of printer controller software is performed by your

service representative once all the hardware components are in

place and properly connected. The following is a summary of major

software components installed on the printer controller:

• Xerox printer controller software

— UNIX Sun operating system

Note: The printer controller’s Sun operating system is

based on the standard Sun operating system; however, it

has been customized for use with the Xerox printer

controller. Therefore, not all standard Sun operating system

features are available.

— Additional software components for the user interface,

printer driver, PDL decomposer, Job Pool Manager, and

other operating system utilities.

• Xerox Client Software

— Xerox client protocol software (an alternative to lpr)

downloaded to client workstations or PCs as a means to

communicate with the printer controller

— Windows client (Windows 3.1, Windows 95, or Windows

NT 4.0)

— Xerox PostScript and PCL print drivers

— Xerox PPDs for use with third-party print drivers.

• Adobe Type 1 PostScript fonts

— ITC AvantGarde Gothic (Book, Book Oblique, Demi, Demi

Oblique)

— ITC Bookman (Demi, Demi Italic, Light, Light Italic)

— Courier (Courier, Bold, Oblique, Bold Oblique)

— ITC Garamond (Light, Light Italic, Bold, Bold Italic)

— Helvetica (Helvetica, Bold, Oblique, Bold Oblique, Light,

Light Oblique, Black, Black Oblique)

— Helvetica (Narrow, Narrow Bold, Narrow Oblique, Narrow

Bold Oblique)

— Helvetica (Condensed, Condensed Oblique, Condensed

Bold, Condensed Bold Oblique)

— ITC Korinna (Italic, Bold, Bold Italic)

— New Century Schoolbook (Roman, Bold, Italic, Bold Italic)

— Palatino (Roman, Bold, Italic, Bold Italic)

— Symbol

— Times (Roman, Bold, Italic, Bold Italic)

— ITC Zapf Chancery Medium Italic

— ITC Zapf Dingbats.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 2-9

Page 26

CONTROLLER COMPONENTS AND OPTIONS

Using font installation commands, you can load other Type

1 PostScript fonts in *.PFB file format from a MS-DOSformatted, 3.5-inch diskette or CD-ROM. Refer to the Xerox

DocuPrint Network Printer Series Guide to Configuring and

Managing the System for more information on the font

installation commands. Type 1 and Type 3 PostScript fonts

can also be downloaded with a print job.

• Adobe Type 0 fonts

Support Chinese double byte printing with third party double

byte fonts.

• PCL fonts

— 35 Intellifont typefaces

— 10 TrueType typefaces

— Bitmap typefaces.

2-10 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 27

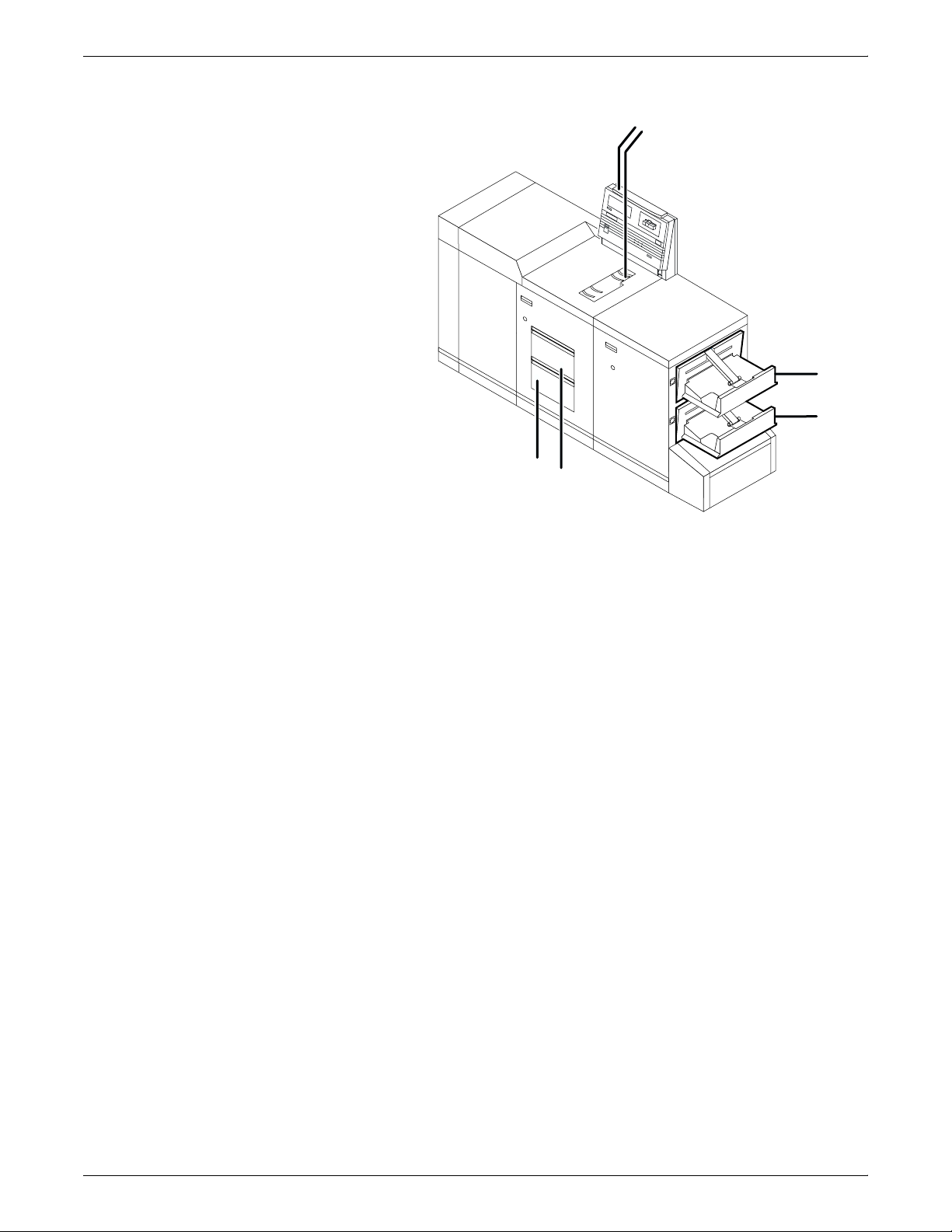

Printer components

3. 3Printer components and

options

The printer processes the electronic data and images received from

the controller and produces the printed report. This chapter

describes the components and options available for the printer.

The standard printer components are the printer control console, the

sample tray, the feeder trays, and the stacker trays. Labels are

located throughout the printer to assist you with a variety of tasks

such as clearing a paper jam. The printer also sounds an audible

tone to direct your attention to a printer problem. Your service

representative can adjust the volume of this tone.

The printer provides control buttons and displays for basic printer

functions and status information. The printer control console contains

message and graphic displays that assist you with jam clearance and

printer maintenance.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 3-1

Page 28

PRINTER COMPONENTS AND OPTIONS

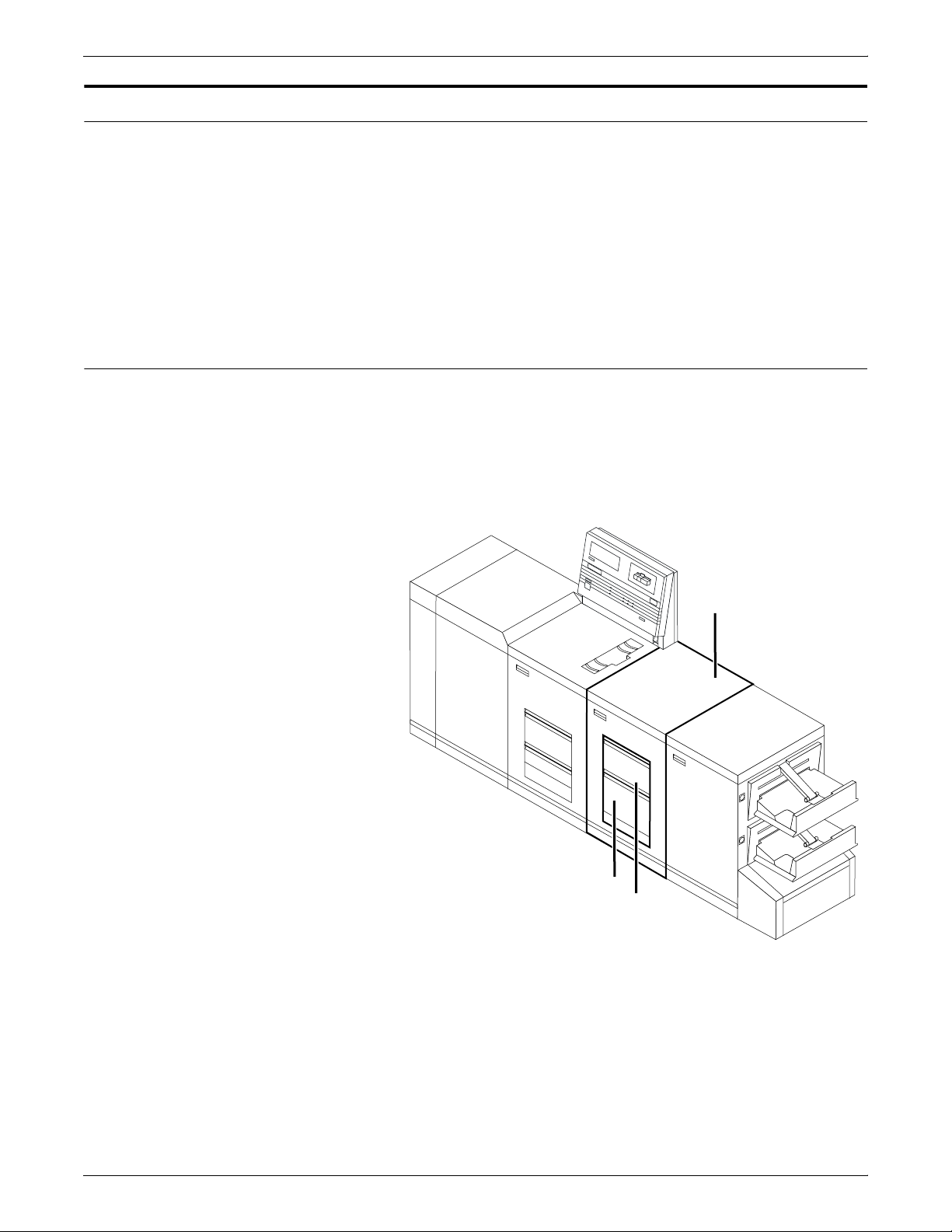

Figure 3-1. Printer components

6

5

1

2

3

4

1 Printer control console

2 Sample tray

3 Stacker tray 1

4 Stacker tray 2

5 Feeder tray 1

6 Feeder tray 2

Refer to the Product Reference manual for a detailed description of

the features and operation of the printer components.

3-2 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 29

Printer control console

PRINTER COMPONENTS AND OPTIONS

The printer control console contains message and graphic displays

as well as status indicator lights that alert you to printer conditions,

paper jams, and other fault and status conditions (such as low dry

ink). Other indicator lights show which feeder tray is active and the

paper size in use. These indicators and the Information button help

you to solve printer problems.

Also on this console are Stop and Continue buttons, which allow you

to stop printing and resume an interrupted job without returning to the

workstation controller. These buttons give you temporary control of

the printer without interrupting input processing.

Figure 3-2. Printer control console

1

2

3

11

10

9

8

1 Attention light

2 Message display

3 Graphic display

4 Wire percentage indicator

5 Feeder tray indicators

6 Power on/off switch

7 Sample button (disabled)

8 Continue button

9 Stop button

10 Fault code display

11 Information button

4

5

6

7

Refer to the Product Reference manual for a detailed description of

the features and operation of the printer control console components.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 3-3

Page 30

PRINTER COMPONENTS AND OPTIONS

Printer options

High-capacity feeder

All DocuPrint Model 92C printers are available with the following

options:

• High-capacity feeder

• Dual stacker or stitcher/stacker

• Bypass transport.

These options allow you to customize your printing system for

increased efficiency and for specialized applications.

Two feeder trays are provided as part of the printer base

configuration (feeder trays 1 and 2). For the DocuPrint Model 92C,

the high-capacity feeder option increases the versatility and

productivity of the printer with two additional feeder trays (trays 3 and

4), increasing the feeder capacity by approximately 2,000 sheets.

Figure 3-3. Xerox DocuPrint 92C with high-capacity feeder

1

3

2

1 High-capacity feeder module

2 Feeder tray 3

3 Feeder tray 4

Tray capacities Each high-capacity feeder tray holds 1,000 sheets of 20-pound or 80

gsm bond paper.

3-4 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 31

Dual stacker

PRINTER COMPONENTS AND OPTIONS

Paper sizes Both high-capacity feeder trays handle paper sizes from 8 by 10

inches / 203 by 254 mm to 8.5 by 14 inches / 216 by 356 mm. This

range includes international paper size A4 (8.27 by 11.16 inches /

210 by 283 mm).

The dual stacker contains two identical output trays in which it can

offset jobs or reports. Using the output configuration windows on the

graphical user interface, you can send output to either or both of

these trays in the desired order.

Figure 3-4. Xerox DocuPrint 92C with dual stacker

1

2

3

1 Sample tray

2 Stacker tray 1

3 Stacker tray 2

Tray capacities Stacker trays 1 and 2 each hold up to 750 sheets of 20-pound or 80

gsm bond paper.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 3-5

Page 32

PRINTER COMPONENTS AND OPTIONS

Stitcher/stacker

The stitcher/stacker can place a wire stitch (staple) in stacks of up to

50 sheets. It contains a single output tray in which it can offset jobs

and reports.

Figure 3-5. Xerox DocuPrint 92C with stitcher/stacker

1

1 Sample tray

2 Stitcher/stacker tray

Tray capacities The stitcher tray holds:

• Up to 2,000 sheets of 20-pound or 80 gsm bond, unstitched

• Up to 200 two-sheet stitched sets

Up to 50 sheets can comprise each stitched set. The wire supply

provides up to 32,000 staples.

2

3-6 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 33

Customer-changeable unit (CCU)

PRINTER COMPONENTS AND OPTIONS

The customer-changeable unit (CCU) contains the replaceable

colored dry ink dispenser bottle and the color developer housing. It is

a self-contained unit that is easily removed from the printer and

stored until needed. Each bottle is uniquely coded to the color of the

housing to ensure that a wrong color is not added to a housing.

Note: Only the color housing can be changed. The black housing

is permanently installed in the printer; only its ink and developer

bottles are changed.

A changeout cart is used to remove a CCU from the printer and to

transport a CCU to the printer or to another area. Because of the

physical weight of the CCU, the cart is required to change colored dry

ink.

The cart also serves as a storage device for CCUs that are not

currently in use. For example, if you use both the red and blue inks

in your operation, one CCU is always out of the machine in storage

on the cart while the other CCU is installed.

Figure 3-6. Changeout cart with CCU installed

Note: You should have a cart for each CCU, so that one cart is

always empty and available to remove the CCU installed in the

system. However, if your printer is used to print only one color—the

CCU will never be removed—or if there is more than one printer in

operation at your site, it may not be necessary to have one cart for

each CCU. Consult your site representative for more

information.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 3-7

Page 34

PRINTER COMPONENTS AND OPTIONS

Bypass transport option

The bypass transport enables third-party finishing equipment to

connect to and interface directly with the printer. The bypass

transport requires that your printer have a dual stacker output module

configuration. Likewise, third-party finishing devices require that your

printer have a bypass transport.

The bypass transport option enables individual printed sheets of

paper to pass through the printer’s output module to third-party

finishing equipment. The third-party devices perform a variety of

finishing tasks such as saddle-stitching, binding, folding, stapling,

trimming, and stacking. These devices are usually stand-alone units

that can be connected in any number of configurations.

Figure 3-7. Xerox DocuPrint 92C with bypass transport

1

2

1 Bypass transport

2 Bypass transport support

The bypass transport fits into tray 1 of the dual stacker. With the

bypass transport, sheets of paper flow from left to right (when viewed

from the front of the printer), leading from the long edge of each

sheet. You can configure the output module to run with or without the

bypass transport. The bypass transport support is stationary and

cannot be removed. However, the support does not interfere with the

operation of trays 1 or 2 when the bypass transport is removed.

3-8 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 35

PRINTER COMPONENTS AND OPTIONS

Figure 3-8. Third-party finishing device configuration

1

1 Paper path

2 Bypass transport

3 Third-party finishing devices

It is important to note that while the bypass transport option provides

you with an interface between your DocuPrint 92C NPS and your

finishing accessories, the finishing accessories require their own AC

and DC power sources. The power must be independent of your

DocuPrint 92C NPS.

More information on the bypass transport and document finishing

can be obtained from the Xerox Finishing web site

http://www.xerox-finishing.com/

2

3

Interface with third-party devices

Electrical interface

Included on this web site are the DFA Interface Specifications for

your printer.

Consult your Xerox sales representative, as well as the sales

representative of the company from which you purchased your

finishing equipment, for specific electrical and space requirements.

The mechanical interface between the laser printer and third-party

finishing devices can connect as follows:

• Physically aligning a finishing device with the exit slot of the

bypass transport exit slot.

• Docking the third-party finishing device to the bypass transport

and establishing a mechanical and electrical interface between

the two.

When you power up the NPS, the printer automatically detects the

presence of the bypass transport and external finishing devices. The

system also begins monitoring the interlocks (physical links) between

the bypass transport and the finishing device and starts finishing

device interface communications.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 3-9

Page 36

PRINTER COMPONENTS AND OPTIONS

Your Xerox DocuPrint 92C and third-party finishing devices interface

on several different levels:

• The NPS requires information about the finishing devices to

store in its non-volatile memory (NVM).

• The finishing device information is grouped into a personality

profile for each device.

• Your operators prepare the third-party device hardware to finish

the printed output and inform the NPS of device names and

parameters.

• The bypass transport feeds single sheets of paper to the

external finishing device.

• Communications between the bypass transport and the

external finishing device consist of command and status

signals.

3-10 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 37

4. 4Preparing for installation

This chapter assists you in preparing for the installation of your Xerox

DocuPrint Model 92C NPS.

Preparing for installation is a responsibility shared by personnel at

your site and Xerox. Your service representatives are available to

discuss installation issues and to assist you in completing the site

installation tasks.

Before installation, you must select and prepare an appropriate

location for the printing system and order supplies. This chapter

helps you accomplish these tasks by providing the following

information:

• A summary of your responsibilities and those of your Xerox

service representative

• A checklist of installation planning activities.

For information on controller power and space requirements, refer to

the “Controller specifications and requirements” chapter of this guide.

For facts about printer power and space requirements, refer to the

“Printer specifications and requirements” chapter of this guide.

Responsibilities

Xerox responsibilities

This section describes your site responsibilities and the

responsibilities of your service representatives. Included are some

joint responsibilities.

This section lists the responsibilities of the service representatives

and system analysts before, during, and after installation:

• Site selection

— Assist in site selection

— Inspect and approve the site.

• Installation

— Schedule the delivery of the hardware

— Monitor installation activities

— Assist you in ordering any supplies required

— Install the DocuPrint system.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 4-1

Page 38

PREPARING FOR INSTALLATION

Customer responsibilities

• Training

— Provide initial operator training

— Provide information and assistance in registering for Xerox

Customer Education classes or obtaining tutorials.

• Service

— Review preventive maintenance schedules and service call

procedures

— Provide ongoing maintenance

— Assist in resolving hardware and software problems.

Your responsibilities prior to, during, and after installation of the

DocuPrint NPS system are to schedule and monitor your installation

activities. Refer to the “DocuPrint Model 92C NPS installation

planning checklist” and the “Network preinstallation checklist” in this

chapter for a complete list of responsibilities.

Refer to the “Xerox support services” appendix for information on

services designed to support you prior to, during, and after your

installation.

Site personnel Identify the person (or persons) at your site who will be the primary

interface with Xerox.

After the installation of your DocuPrint Model 92C NPS, there are a

few ongoing tasks that must be performed. These tasks may include

all or some of the following:

• Meter reading and reporting

• Overseeing routine maintenance

• Placing service calls for hardware problems

• Ordering additional documentation, software, or fonts

• Arranging additional operator training

• Maintaining an adequate inventory of consumable supplies.

It is your responsibility to designate a person (or persons) to perform

these tasks.

Operator and Systems training Select personnel for Operator and Systems training and set up a

training schedule.

Site preparation Select and prepare the site for DocuPrint NPS system installation

(including proper power, air conditioning, and work space).

Network installation Install the necessary network connections required to connect client

workstations to the printer controller. Refer to the “Network

preinstallation checklist” in this chapter.

4-2 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 39

PREPARING FOR INSTALLATION

Client workstations Make sure all client workstations that will be submitting print jobs

have the proper hardware, operating system, and networking

software supported by the DocuPrint system as client platforms.

Applications Work with your Xerox systems analyst to determine requirements for

initial applications.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 4-3

Page 40

PREPARING FOR INSTALLATION

Installation planning checklist

To aid you in installation planning of the DocuPrint NPS, this section

provides a checklist, listing tasks you and your service representative

need to complete in the weeks before installation. If you have

questions about any of these activities, contact your sales or service

representative.

Use the timeframes in this checklist as guidelines. It is best to consult

your suppliers to determine the exact lead times they require.

Table 4-1.DocuPrint Model 92C NPS installation planning

checklist

Week Activity Reference Responsibility

Date

completed

-4

-3

• Select location for DocuPrint

system.

• Identify networked client

workstations to be used. Make sure

the hardware, operating systems,

and networking software are

supported by the DocuPrint NPS.

• In the United States, sign up with

Xerox Documentation and Software

Services. Order additional

documentation, if needed.

• In the United States, register for

Xerox Customer Education

classes, if needed.

• Schedule hardware delivery.

• Prepare the site:

— Install network to system location

— Establish network addresses and

logical unit names for print server

and user workstations.

— Complete preinstallation checklist.

Chapters 5 and 6

Chapter 4 and

Appendix D

Appendix B

Appendix B

Sales rep

Chapters 4 to 6

Customer

Customer

Customer

Customer and Xerox

Customer and Xerox

Customer

_________

_________

_________

_________

_________

_________

_________

_________

— Provide table with adequate space

for hardware and cables.

— Ensure and install proper electrical

receptacles.

— Ensure proper operating

environment.

4-4 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

_________

_________

_________

Page 41

PREPARING FOR INSTALLATION

Table 4-1.DocuPrint Model 92C NPS installation planning

checklist (continued)

Week Activity Reference Responsibility

Date

completed

-2 • Inspect and approve site.

• Order consumable supplies.

• Minimum supplies needed for

installation:

— Paper (2 cartons)

— Developer (1 carton, plus 1 carton

of each color desired for DocuPrint

Model 92C NPS)

— Fuser agent (2 cartons)

— Dry ink (1 carton black, plus 1

carton of each color desired for

DocuPrint Model 92C NPS)

After installation, you will need to

establish a procedure for ordering

supplies according to your ongoing

production requirements.

-1 Schedule operator training. Systems analyst Customer and Xerox _________

Install

• Ensure supplies are available.

• Ensure system administrators are

available during software

installation.

Chapter 4, Appendix

A and sales rep

Chapter 4 and

Appendix A

Xerox

Customer and Xerox

Customer

Customer

_________

_________

_________

_________

• Provide preinstallation checklist

and network address of print server

(or host file containing this

information) to Xerox personnel.

Also, designate two client

workstations if applicable, for Xerox

client software installation.

• Install DocuPrint system hardware

and software.

• Load Xerox client software on client

workstations.

• Have operators available for

training.

• Check documentation and software

kits for completeness.

• Have test jobs ready to run.

Chapter 4

Guide to Configuring

and Managing the

System

Appendix B

Customer

Xerox

Customer

Customer

Customer

Customer

_________

_________

_________

_________

_________

_________

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 4-5

Page 42

PREPARING FOR INSTALLATION

Table 4-1.DocuPrint Model 92C NPS installation planning

checklist (continued)

Week Activity Reference Responsibility

Date

completed

Postinstall

• Become familiar with support

services available.

• Establish supplies ordering

procedure.

• Provide ongoing printer controller

and DocuPrint printer maintenance.

• Adjust the IOT alignment and

magnification.

Appendix B

Appendix A

Guide to Performing

Routine Maintenance

Customer

Customer

Customer and Xerox

Xerox

_________

_________

_________

_________

4-6 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 43

NPS network installation checklist

The DocuPrint NPS system is installed and configured by your

service representative. The service representative needs certain

information about your network environment to complete the

DocuPrint printer controller software installation. Use the “Network

preinstallation checklist” table in this chapter to gather the necessary

information for the installation.

Some of the items in the checklist may not apply to your environment.

Fill in those items that you know may apply, and refer to your network

administrator for information, if necessary.

Note: If you are installing the DocuPrint NPS in a Novell NetWare

environment, refer to this chapter and your Novell network NPS

administrator to assist you in completing the checklist in the “Network

preinstallation checklist” table.

The information you may need to provide is defined as follows:

Hostname A unique name that designates a node on the network. You may use

up to 32 characters: upper and lower case alpha (a-z and A-Z),

integers (0-9), and hyphens (-). The name you choose may be the

same as the printer name.

PREPARING FOR INSTALLATION

IP address Series of four integers between 0 and 255 separated by a period,

such as 192.9.200.1, to create an IP address for the DocuPrint

system. (Do not use all zeros or designate 255 for all integers when

assigning an IP address.)

• You must assign a unique, valid IP address for each TCP/IP

network to which the NPS is attached.

Note: To avoid routing problems that will slow down the

controller, the IP addresses you assign must belong on different

TCP/IP subnets, as determined by the IP subnet netmask.

• If you are not on a TCP/IP network, use the Xerox-supplied IP

address value (192.9.200.1), or the IP address value assigned

by your network administrator.

IP netmask Series of four integers between 0 and 255 separated by a period,

such as 255.255.255.0 to create an IP netmask. (Do not use all zeros

or designate 255 for all integers when assigning an IP netmask, and

do not use the IP address value.)

• If you are on a TCP/IP network, assign a valid IP netmask.

• If you are not on a TCP/IP network and you used the Xerox-

supplied IP address value (192.9.200.1), use 255.255.255.0 for

the IP netmask.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 4-7

Page 44

PREPARING FOR INSTALLATION

IP broadcast address Series of four integers between 0 and 255 separated by a period,

such as 255.255.255.0, to create an IP broadcast address. (Do not

use the IP address value.)

• If you are on a TCP/IP network, assign a valid IP broadcast

address.

• If you are not on a TCP/IP network, use the Xerox-supplied IP

broadcast address value (255.255.252.0), which is a plus (+)

sign.

Default router Series of four integers between 0 and 255 separated by a period,

such as 188.9.234.1, to specify a default router. Most TCP/IP

networks broadcast routing information.

Caution: Specify a default router only if your network does not

specify broadcast routing information.

• If the TCP/IP network does not broadcast routing information,

specify an IP address of an existing router that is on the same

subnet as the DocuPrint.

• If you are not on a TCP/IP network, specify the default of

NONE.

Superuser password

(UNIX root password)

AppleTalk network information If the DocuPrint NPS is installed in an AppleTalk network

Select a password to prevent unauthorized access to your superuser

account. You can select a series of any ASCII characters, except

those that your UNIX system interprets in a special way. Passwords

have no limits on the number of characters, but the system uses only

the first eight characters to administer password security. The

password selection you make is case sensitive to the system.

Caution: Select a password that cannot be easily obtained by

others to avoid unauthorized access to your account. This is not the

same password used for Operator or Administrator functions.

environment, indicate whether your AppleTalk network is phase

1 or 2. Also, indicate the AppleTalk zone name you want the

DocuPrint to locate. The zone name must be the same name as the

existing zone used on the network to which the DocuPrint is

attached. In addition, you must specify the network device on which

AppleTalk runs.

Note: Do not use the ampersand (“&”) in the zone name to avoid

conflict with UNIX expressions. If the ampersand character must be

used, enter “\\&” instead.

Accounting information Indicate whether to set an interval on the system to automatically

purge accounting information. If accounting information is not purged

manually or automatically, the system disk can reach storage limits.

To keep your system running at optimum speed, you need to

periodically purge accounting data.

4-8 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 45

PREPARING FOR INSTALLATION

Xerox client software Indicate whether you have Xerox client software installed, and are

supporting Xerox clients on the network.

lpr and lpd Indicate whether to enable client use of lpr and lpd job submission

and status commands.

UNIX command tool Indicate whether to have a UNIX command tool available for use in

the background menu.

Retry count Determine whether the DocuPrint NPS system supports a print

production environment, or whether the system remains unattended.

Once you determine the environment the DocuPrint NPS supports,

you must decide the number of attempts the system makes to print a

job before a sequencer restart causes the job to be held for

intervention.

• If the DocuPrint NPS supports a print production environment,

you may want to specify a large number or zero as the number

of attempts the system makes to retry a print job. (Zero

indicates an infinite number of retries.)

• If the DocuPrint NPS is unattended, you may want to specify

only 1 or 2 retries to print a job.

Novell network information

DocuPrint as a print server (PSERVER)

The Novell network information you provide to your service

representative is based on whether you configure the DocuPrint as a

print server or a remote printer. Refer to this chapter and your Novell

network administrator for assistance, if necessary.

Provide the following information to the service representative if you

configure DocuPrint NPS as a print server on the Novell network (for

further information, refer to the “Installation process” section in the

“Installation” chapter of this guide):

• Novell file server name—indicates the name of the file server

that the DocuPrint NPS services. The file server must have the

appropriate print server definition and the queue to be serviced.

• Print server name—indicates the name used by the DocuPrint

NPS print server. A print server definition with this name must

exist on the file server that the DocuPrint NPS services. A

single printer (type Remote Other/Unknown) must be defined

for this print server and the queue (refer to the queue name

below).

• Password for the print server—refers to a password you may

have added in the print server definition (using PCONSOLE). It

is not necessary to add a password to a print server, and there

is no default password.

• Queue name to service—refers to the name of the queue from

which the DocuPrint print server accepts jobs. The queue must

be defined on the file server that the DocuPrint NPS services.

The single printer that must be defined for the print server (as

stated above) must also be defined to service the specified

queue.

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 4-9

Page 46

PREPARING FOR INSTALLATION

DocuPrint NPS as a remote printer (RPRINTER)

IPX internal network number Specify the network number for the internal IPX network in the

• Form names—distinct form names for DocuPrint NPS that map

to the DocuPrint virtual printer names.

Provide the following information to the service representative if you

configure DocuPrint NPS as a remote printer on the Novell network

(for further information, refer to the “Installation process” section in

the “Installation” chapter of this guide):

• Novell print server name—indicates the name of the print

server to which the DocuPrint NPS will connect. An advertising

print server with this name must be running on the Novell

internet.

• Printer name(s) to service—refers to the name(s) of the printers

defined for the Novell print server. Virtual printers should be

defined with these names after DocuPrint NPS installation is

complete. These printers should be defined as type Remote

Other/Unknown.

DocuPrint server. This number must be globally unique within the

NetWare internet to which the DocuPrint NPS is connected. (Do not

assign a number that is used by other machines to which the

DocuPrint NPS will be connected.)

LAN network number Specify the network number for the cabling system to which the

DocuPrint NPS is connected, for example the Ethernet or Token Ring

segment.

Network framing type Specify the network framing type used for IPX/SPX communication

by DocuPrint NPS. There are eight options:

• ETHERNET__II

• ETHERNET__802.3

• ETHERNET__802.2

• ETHERNET__SNAP

• TOKENRING

• TOKENRING__SNAP

• FDDI

• FDDI__SNAP.

Choose a framing type used by the file server that communicates

with DocuPrint NPS. If you are using print server or remote printer,

and have the DocuPrint NPS communicate with a different machine

for each, then choose a framing type that is used by both of the

machines.

If you are installing a new Novell network using Ethernet, it is

recommended that you choose the ETHERNET__II framing type for

the file server and the DocuPrint NPS. If you are using Token Ring

and the Novell server has both TOKENRING and TOKEN

RING_SNAP enabled, use TOKENRING on the DocuPrint NPS. For

FDDI networks running Novell, it is recommended that you choose

the FDDI framing type.

4-10 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 47

Table 4-2.Network preinstallation checklist

Network Information Information you supply

Hostname

IP address for primary net device

IP netmask for primary net device

IP address for secondary net device #1 (if applicable)

IP netmask for secondary net device #1 (if applicable)

IP address for secondary net device #2 (if applicable)

IP netmask for secondary net device #2 (if applicable)

IP address for secondary net device #3 (if applicable)

IP netmask for secondary net device #3 (if applicable)

Primary network device

Default router

Secondary network devices (if applicable)

PREPARING FOR INSTALLATION

Superuser password

Accounting information

Xerox client software

lpr and lpd

UNIX command tool

Retry count

Table 4-3.Novell preinstallation checklist

Novell Network Information Information you supply

Novell network information (DocuPrint NPS as a print

server)

Novell file server name

Print server name

Password for the print server

Queue name to service

Form names

Novell network information (DocuPrint NPS as a remote

printer)

Novell print server name

Printer name(s) to service

IPX internal network number

LAN network number

Ethernet framing type (ETHERNET__II, 802.3, 802.2,

or SNAP; TOKENRING or TOKENRING_SNAP)

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 4-11

Page 48

PREPARING FOR INSTALLATION

AppleTalk Network Information Information you supply

AppleTalk Phase 1 or 2

AppleTalk zone name

Network device used for the AppleTalk protocol

Connectivity requirements

Ethernet specifications

Table 4-4.AppleTalk preinstallation checklist

A Token Ring network or an Ethernet local area network (LAN)

running Transmission Control Protocol/Internet Protocol (TCP/IP),

AppleTalk, or Novell NetWare software is the network

communication system used to transport documents from the client

workstation to the printer.

The Ethernet connection to the printer controller processor must be

compatible with the Institute of Electrical and Electronics Engineers

(IEEE) 802.3 standard.

The Ethernet interface on the processor is a 10Mb/sec twisted pair

standard (10BaseT and 100BaseT). The MII (for UltraSPARC) Coax

Ethernet is enabled with an adapter cable.

The Ethernet interface on the printer controller processor is a 10Mb/

sec twisted pair standard (10BaseT and 100BaseT). Attachment Unit

Interface (AUI) Coax Ethernet is enabled with an adapter cable.

Work with your system administrator to assess what type of network

you have and what modifications need to be made to supply an

Ethernet connector to the printer controller processor.

Token Ring specifications

The Token Ring connection must be compatible with the IEEE 802.3

standard. The printer controller processor has a 4 MB/16 MB Token

Ring interface (16 MB is preferred).

Fiber Distributed Data Interface specifications

TCP/IP, Novell 3.x, and Apple Talk network protocols are supported

over FDDI. The FDDI supports a Single Connection configuration

only.

4-12 XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS

Page 49

Power requirements

5. 5Controller specifications and

requirements

This chapter provides power and space requirements for your

DocuPrint Model 92C NPS printer controller. It also provides

controller environmental specifications.

For facts about printer power and space requirements, refer to the

“Printer specifications and requirements” chapter of this guide.

Your DocuPrint Model 92C NPS controller has important power

requirements that must be accommodated. These requirements are

summarized in the table below.

For details on printer power requirements, refer to the “Printer

specifications and requirements” chapter of this guide.

Table 5-1. 92C NPS controller

60 Hz electrical requirements

Amp

Voltage

Sun Ultra 2 printer controller 100 to 240 VAC 15 amp 0.4 KVA 5-15R

Sun Ultra 60 printer controller 100 to 240 VAC 15 amp. 0.4 KVA 5-15R

Table 5-2. 92C NPS controller

50 Hz electrical requirements

Voltage

Sun Ultra 2 printer controller 100 to 240 VAC 15 amp 0.4 KVA

Sun Ultra 60 printer controller 100 to 240 VAC 15 amp 0.4 KVA

Agency certification: UL 478 and 1950, IEC 950, CSA 22.2 #220-

1986, FCC (Class A), and VDE 0871 (Class A).

service KVA rating NEMA

Amp

service KVA rating

XEROX DOCUPRINT NETWORK PRINTER SERIES INSTALLATION PLANNING GUIDE FOR MODEL 92C NPS 5-1

Page 50

CONTROLLER SPECIFICATIONS AND REQUIREMENTS

Outlet configurations

This section discusses specifications for system outlets and the

required wall outlet configurations for the USA/Canada and

internationally.

Note: All power outlets must be dedicated to this equipment. When

determining the electrical connections for your printing system, make

sure that:

• Each power cord has a separate circuit