Page 1

Xerox DocuPrint 92C IPS

Troubleshooting Guide

Version 7.1

August 2000

721P89160

Page 2

Xerox Corporation

Printing Systems Documentation and Education

701 South Aviation Boulevard, ESM1-058

El Segundo, CA 90245

© 1997, 1998, 1999, 2000 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America

Publication number: 721P89160

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of other

companies are also acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographical errors will be corrected in

subsequent editions.

Page 3

Laser safety

Warning: Adjustments, use of controls, or performance of

!

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance standards of the U.S. Department of Health, Education,

and Welfare for Class 1 laser products. Class 1 laser products do not

emit hazardous radiation. The DocuPrint printers do not emit

hazardous radiation because the laser beam is completely enclosed

during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must be

removed with a tool. DO NOT REMOVE LABELED PANELS OR

PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

Ozone information

This product produces ozone during normal operation. The amount

of ozone produced depends on copy volume. Ozone is heavier than

air. The environmental parameters specified in the Xerox installation

instructions ensure that concentration levels are within safe limits. If

you need additional information concerning ozone, call 1-800-8286571 to request the Xerox publication 600P83222, OZONE.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE iii

Page 4

Operation safety

Your Xerox equipment and supplies have been designed and tested

to meet strict safety requirements. They have been approved by

safety agencies, and they comply with environmental standards.

Please observe the following precautions to ensure your continued

safety.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

Warning: Improper connection of the equipment grounding

!

conductor may result in risk of electrical shock.

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result in

poor performance and may create a hazardous situation.

• Never move either the printer or the Printer Controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety at

the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your local Xerox

representative or operating company.

iv XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 5

Table of contents

Laser safety iii

Ozone information iii

Operation safety iv

Introduction vii

About this guide vii

Contents vii

Conventions viii

Related publications ix

1. Calling for service 1-1

Information to have on hand when calling for service 1-1

Enabling and disabling the modem for remote service 1-2

Preparing your system for remote service 1-2

Enabling your modem 1-3

Disabling your modem 1-3

2. Clearing paper misfeeds and jams 2-1

Clearing a feeder tray fault 2-2

Frequent misfeeds 2-4

Clearing paper jams 2-6

Job recovery 2-9

Printer jam clearance areas 2-9

Clearing paper jams from areas 1 and 1A 2-10

Clearing paper jams from areas 2 and 2A 2-12

Clearing paper jams from area 3 2-14

Clearing paper jams from area 4 2-15

Clearing paper jams from area 5 2-17

Clearing paper jams from areas 6 and 6A 2-19

Clearing paper jams from area 7 2-20

Clearing paper jams from area 8 2-21

Clearing paper jams from area 9 2-22

Clearing stacker tray paper jams (dual stacker) 2-23

Clearing stitcher/stacker paper jams (areas A and B) 2-24

Clearing bypass transport paper jams 2-25

Adjusting dual stacker tray scuffer arms 2-26

3. Correcting stacker problems 3-1

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE v

Page 6

TABLE OF CONTENTS

4. System unresponsive 4-1

Index INDEX-1

vi XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 7

About this guide

Introduction

This Xerox DocuPrint 92C IPS Troubleshooting Guide describes how

to solve some specific problems that may occur when you are using

the printing system.

This guide is designed for Xerox DocuPrint 92C IPS operators whose

job consists of the routine operation of one of these systems.

Users should have an understanding of Printer Controller operations.

Before using this guide, become familiar with its contents and

conventions.

Contents

This section lists the contents of this guide:

• Chapter 1, “Calling for service,” describes the information to

have on hand when calling for support service, and provides

information on using the Sixth Sense Technology.

• Chapter 2, “Clearing paper misfeeds and jams,” illustrates how

to clear paper misfeeds and jams from various parts of the

paper path.

• Chapter 3, “Correcting stacker problems,” provides solutions to

common stitcher/stacker and dual stacker problems.

• Chapter 4, “System unresponsive,” provides solutions to

specific printer problems.

An index is provided at the back of the guide.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE vii

Page 8

INTRODUCTION

Conventions

This guide uses the following conventions:

• All caps and angle brackets—Within procedures, the names of

keys are shown in all caps within angle brackets (for example,

press <ENTER>).

• <Angle brackets> — Variable information, or the position of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold — Within procedures, text and numbers that you enter are

shown in bold.

• “Enter” — Within procedures, the two-step process of keying in

data and pressing <ENTER> (for example, enter y).

• Italics — Document and library names are shown in italics (for

example, the Xerox DocuPrint 92C IPS Troubleshooting Guide).

• Capitalization of graphical user interface (GUI) window titles

matches the titles as they appear on the screen. In cases where

a window does not have a title, it is referenced using all lower

case. For example:

— At the graphical user interface, use the Output

Configuration window to group the trays.

— The main window displays the current system status.

Note: Notes are hints that help you perform a task or understand

the text.

Caution: Cautions alert you to an action that could damage

hardware or software.

Warning: Warnings alert you to conditions that could affect the

!

safety of people.

viii XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 9

Related publications

Xerox documents Following is a list of all Xerox DocuPrint IPS documents. For a

INTRODUCTION

This document is part of the Xerox DocuPrint IPS publication set.

complete list and description of available Xerox documentation, refer

to the Xerox Customer Documentation Catalog (publication number

610P17517), or call your service representative.

Application Programmer/System Administrator Quick Reference

Card

Customer Information Quick Reference Card

Generic MICR Fundamentals Guide

Glossary

Guide to Configuring and Managing the System

Guide to Performing Routine Maintenance

Helpful Facts About Paper

Installation Planning Guide

Master Index

Messages Guide

Solutions Guide

System Overview Guide

Troubleshooting Guide

Xerox Standard Font Library Font User Guide

The documentation set also includes an electronic version, the

DocuPrint IPS Interactive Customer Documentation CD.

IBM documents Following are related IBM documents. Contact your local IBM

representative for ordering instructions for IBM AFP/PSF manuals

that might be useful for your specific installation.

IBM 3825 Page Printer Product Description

IBM Intelligent Printer Data Stream Reference

IBM Advanced Function Presentation Printer Summary

IBM ITSC Distributing AFP Printing from a Host System

IBM Advanced Function Printing Data Stream Reference

IBM Data Stream and Object Architectures: Mixed Object Document

Content Architecture Reference

Guide to Advanced Function Presentation

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE ix

Page 10

INTRODUCTION

x XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 11

1. 1Calling for service

Before calling your customer service support center, make sure you

have read this chapter and have tried the corrective actions

described here. If the problem persists, gather the necessary

information and call the customer support center.

Information to have on hand when calling for service

To report DocuPrint hardware or software problems in the United

States, call the following number:

1-800-822-2979

For customers outside the United States, call your local service

representative.

Note: A model-specific phone number is attached to your printer at

installation time.

Before calling, make note of the following:

• Status code numbers and messages that appear on the

controller screen and the printer console

• Indicator lights that are lit

• Name of your printer: DocuPrint 92C IPS

• Serial number for your printing system (a 9-digit alphanumeric

code located on the frame inside the printer, behind the narrow

door to the far left, on the front of the printer).

• Problems you are having with the system.

Additional information you may wish to note prior to calling includes:

• An explanation of how output differs from what was expected.

• An assessment of whether the symptoms follow a pattern or

occur randomly.

• A list of special conditions that may be related to the problems:

— New applications

— Changes made to the software

— Recent service performed

— Previous conditions under which the application has

printed properly.

Give this information to a customer service representative, who will

discuss the information and give you an estimated time of arrival or

assist you over the phone to resolve the problem.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 1-1

Page 12

CALLING FOR SERVICE

Enabling and disabling the modem for remote service

Your system may be set up to use Sixth Sense Technology—a

remote communication capability. Sixth Sense Technology is a userfriendly suite of tools that allow service personnel to connect with a

customer system and evaluate its performance while the system is

being used. The Customer Service Engineer (CSE) can troubleshoot

problems remotely, transfer, apply, and remove patches remotely,

and, if an on-site call is required, arrive with the solution to fix the

problem.

An external modem allows your system to be accessed by remote

service technicians.

Caution: Depending on the commands used by the technician, the

printer may start up during the remote service session. You should

not attempt to operate the system or perform any tasks at the printer

during the remote service session.

Preparing your system for remote service

When making a service call, your Service Representative may ask

you to prepare your system for a remote service. If so, follow these

steps:

1. Upon request, provide the service representative with your

modem telephone number.

2. At the graphical user interface, place the system offline. This

will prohibit the printer from running a job while the service

representative is analyzing your IPS system.

3. Enable the modem (see “Enabling your modem” section later in

this chapter).

4. Answer the service representative’s questions as appropriate,

and make sure that no operators, users, or administrators use

the system while the service takes place.

5. When the service is complete, disable the modem (see

“Disabling your modem” section later in this chapter).

6. Place the system back online.

1-2 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 13

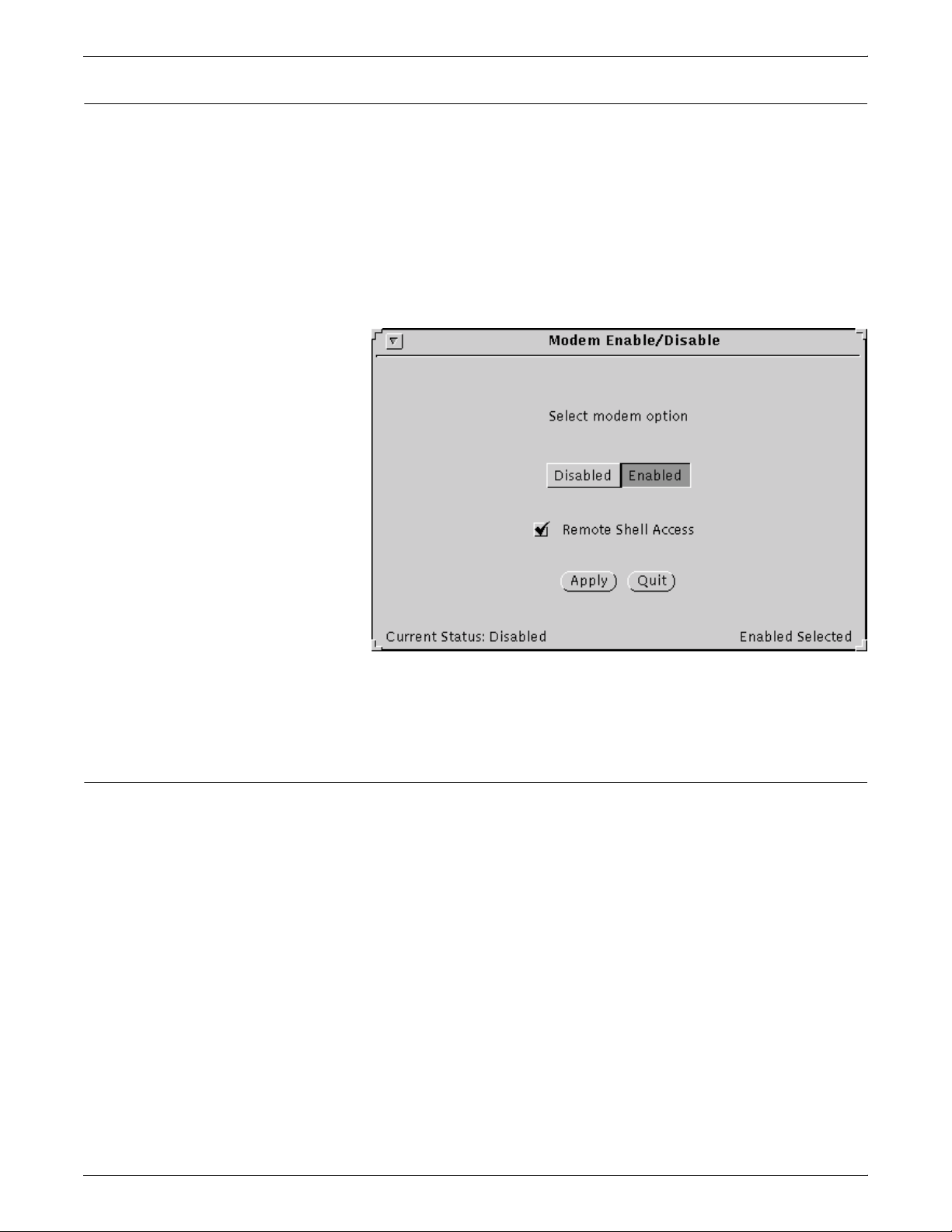

Enabling your modem

CALLING FOR SERVICE

Enable your modem at the graphical user interface following these

steps:

1. Select the Configuration pull-down menu of the IPS main

window.

2. Select the Modem Enable/Disable menu item.

3. At the Modem Enable/Disable window, select Enabled, then

click Apply.

Figure 1-1. Modem Enable/Disable window

Disabling your modem

4. At the Password window, enter the root password, then confirm

your entry.

Disable your modem at the graphical user interface following these

steps:

1. Select the Configuration pull-down menu of the IPS main

window.

2. Select the Modem Enable/Disable menu item.

3. At the Modem Enable/Disable window, select Disabled, then

click Apply.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 1-3

Page 14

CALLING FOR SERVICE

1-4 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 15

2. 2Clearing paper misfeeds and

jams

Paper jams and misfeeds can be greatly reduced or eliminated if you

use the correct type of paper under the right conditions. Refer to

Helpful Facts About Paper for information on paper selection and

care.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-1

Page 16

CLEARING PAPER MISFEEDS AND JAMS

Clearing a feeder tray fault

When paper is misfed from the paper trays, complete the following

steps:

1. Go to the paper tray indicated by the message and graphic

displays of the printer control console.

2. Press the Tray Unlock button on the front left of the paper tray.

3. When the Ready To Open indicator is lit, pull the bar up and out

to open the tray. Pull the tray all the way out for best results.

2-2 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 17

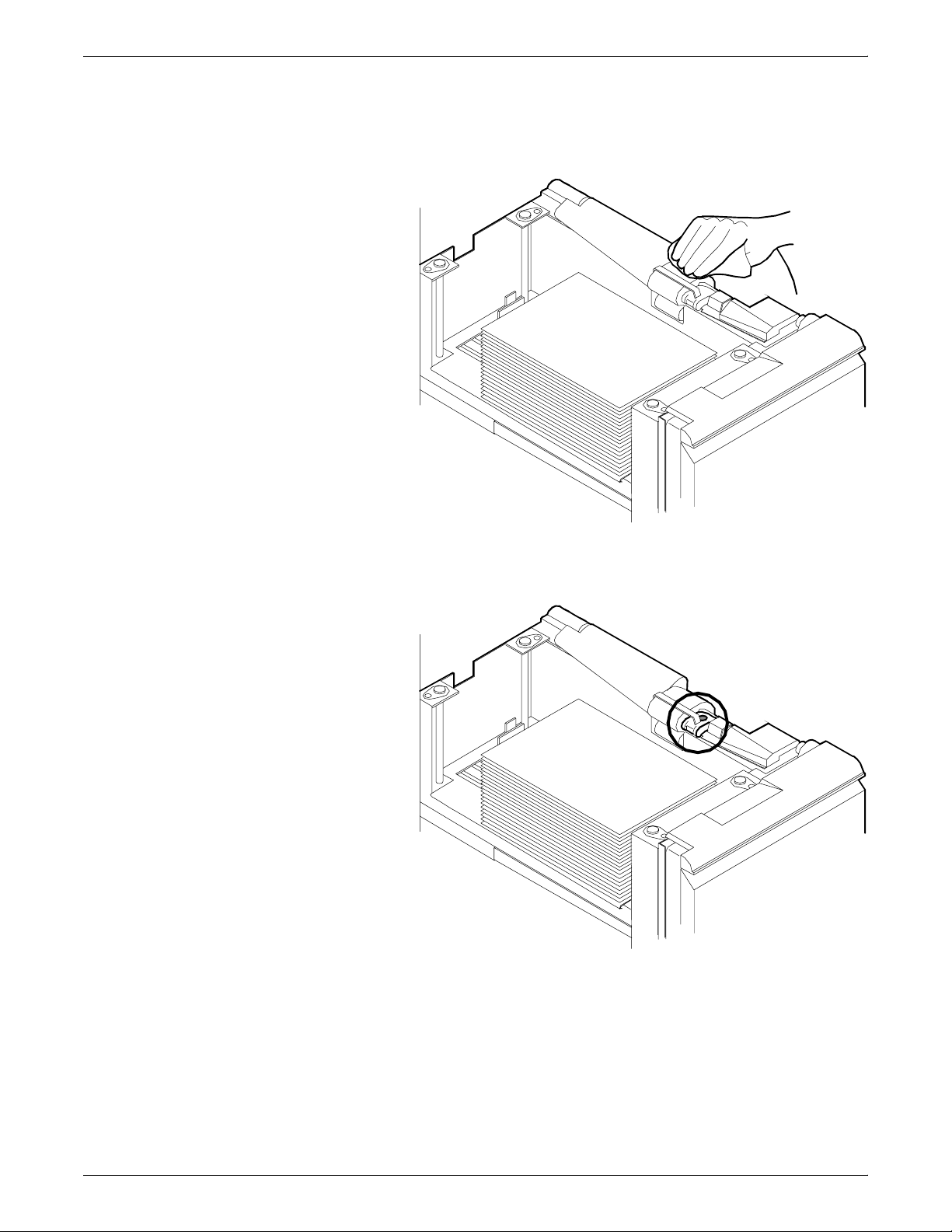

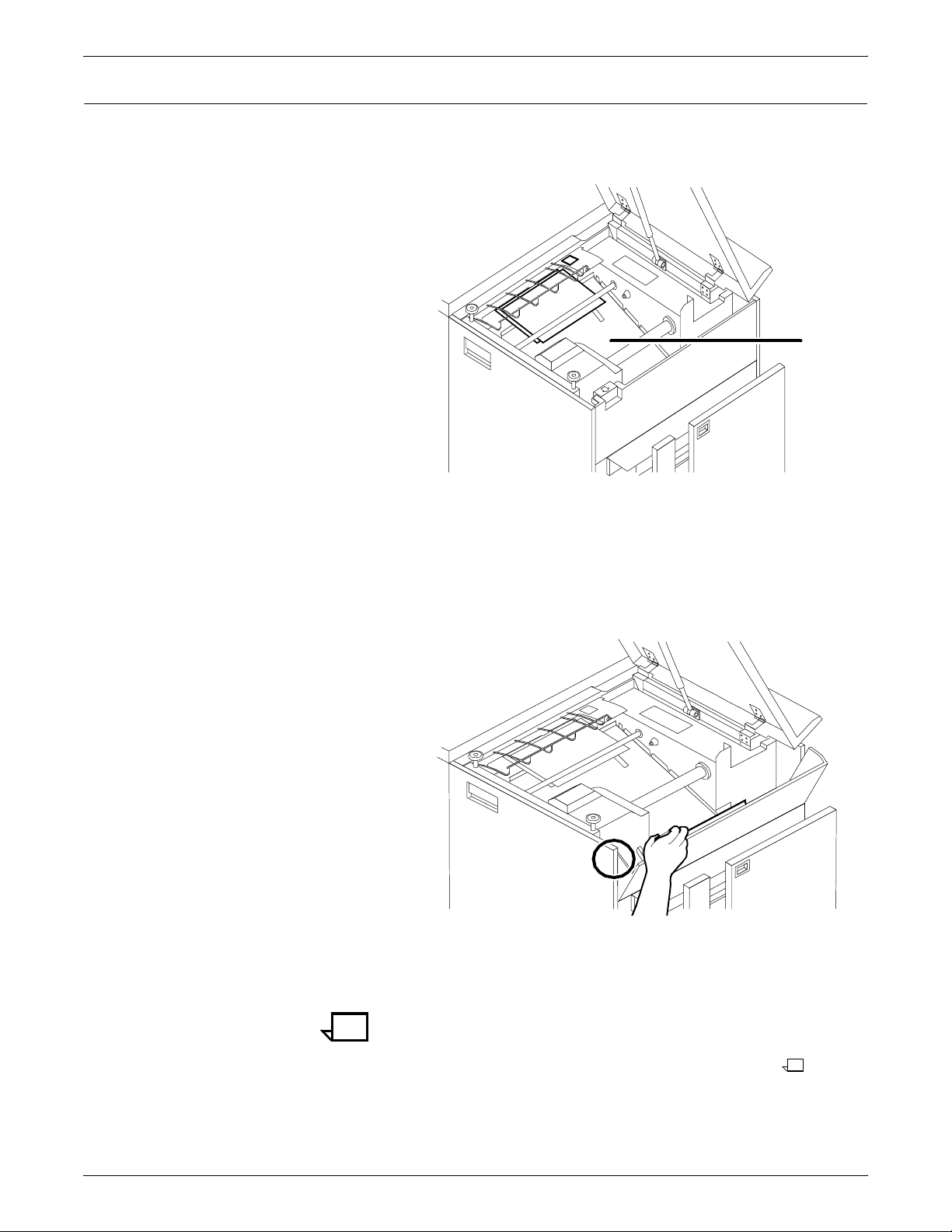

CLEARING PAPER MISFEEDS AND JAMS

4. Press the green lever to unlatch the paper feeder assembly.

5. Remove and discard any partially fed paper. Make sure the

paper supply is neatly stacked and the stack is not higher than

the MAX line on the length guide. Make sure the length guide

is firmly touching the back edge of the stack.

6. Latch the paper feeder assembly by pressing the green dot until

the assembly clicks into place.

7. Slide the tray back into the printer until the tray latches and

press the Continue button to resume printing.

8. Discard any pages sent to the sample tray or unused stacker

tray when the paper jam was detected.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-3

Page 18

CLEARING PAPER MISFEEDS AND JAMS

Frequent misfeeds

Frequent misfeeds may be caused by a glazed feed belt, especially

if one tray feeds the same kind of paper better than another tray

does. (Glazing is caused by a buildup of the chemicals found on most

papers.)

If you suspect that the belt is glazed, try cleaning it with film remover

obtained from your service representative.

Caution: Clean the feed belt only to correct misfeeds, not as

routine maintenance. Because the belt is rubber, frequent cleaning

dries it out and makes it fail prematurely.

1. Clear any misfeeds that have occurred, but do not latch the

paper feeder assembly. If necessary, unlatch it by pressing

down on the bright green lever on the right side of the paper

tray.

2-4 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 19

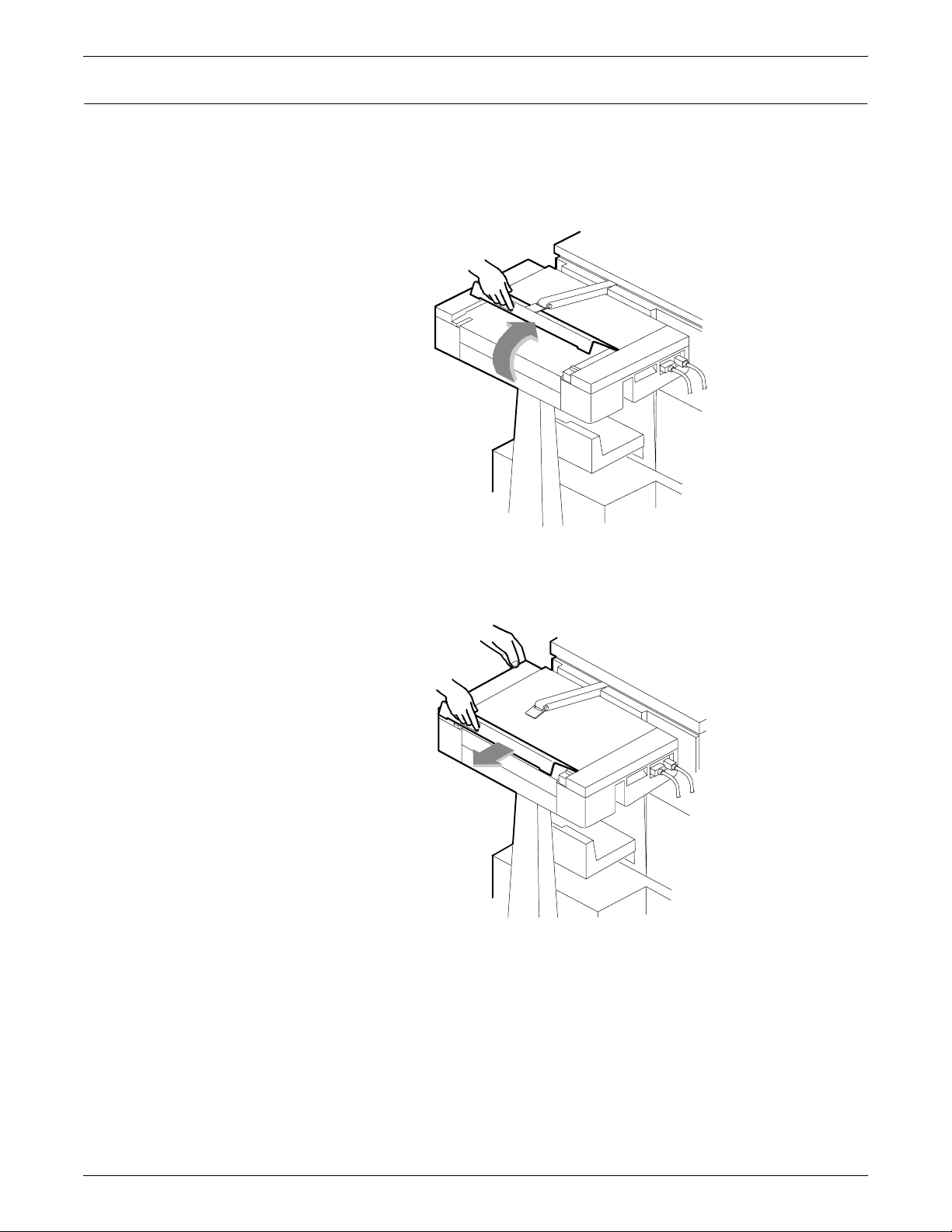

CLEARING PAPER MISFEEDS AND JAMS

2. Lightly moisten a lint-free towel with film remover and

thoroughly wipe the outside surface of the feed belt in the same

direction as the ribs on the belt. (Wiping from side to side might

pull the belt off its track.) Allow a few seconds for the film

remover to evaporate.

3. Latch the paper feeder assembly by pressing down on the

bright green dot. Slide the paper tray completely back into the

printer.

Operate the system as usual. If you continue to experience misfeeds,

place a service call.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-5

Page 20

CLEARING PAPER MISFEEDS AND JAMS

Clearing paper jams

Paper sometimes jams as it leaves the feeder trays or moves through

the paper path. You must clear the paper jam before you can

continue to print. The two illustrations below show the areas along

the paper path in which jams may occur.

Figure 2-1. Areas along the simplex paper path

Figure 2-2. Areas along the duplex paper path

2-6 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 21

CLEARING PAPER MISFEEDS AND JAMS

Jam displays on printer control console In the event of a jam, the printer control console displays the following

information:

• The message display describes the areas of the printer you

must check and clear.

• The graphic display shows the location of the jams and the

doors you must open to access them.

Figure 2-3. Message and graphic displays on printer control

console

121

2

1 Message display

2 Graphic display

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-7

Page 22

CLEARING PAPER MISFEEDS AND JAMS

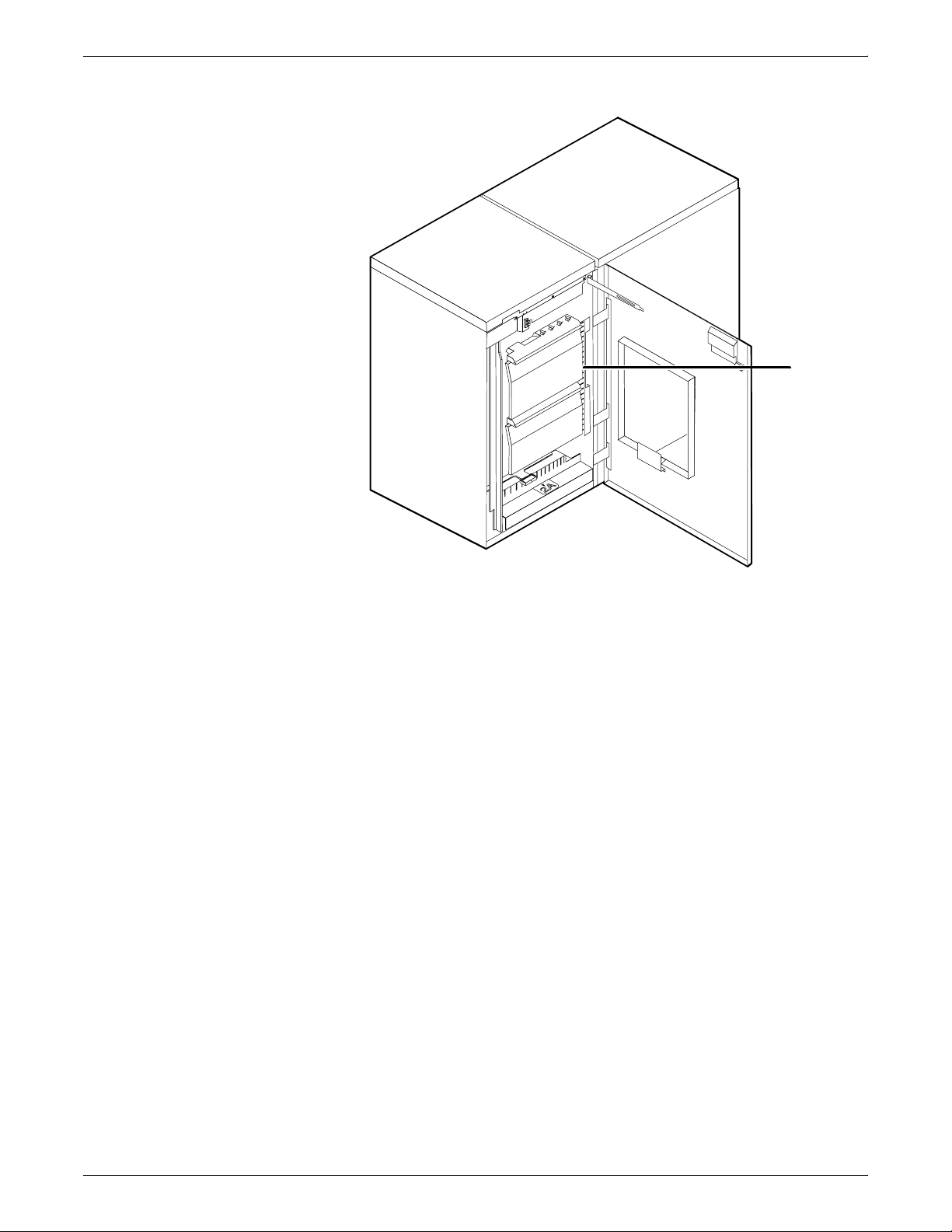

Interior labels Message labels are located inside the printer at the point of need.

Figure 2-4. Message labels inside the printer

Each handle, lever, or knob you use to clear a paper jam is bright

green and marked with an arrow indicating the direction it moves.

When a paper jam occurs in the printer, clear only the area or areas

indicated by the message and graphic displays.

2-8 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 23

Job recovery

CLEARING PAPER MISFEEDS AND JAMS

When a jam occurs, the system controller and printer send damaged

or lost pages to the print queue. For severe jams, the Printer

Controller performs the recovery while the printer reinitiates a system

status check.

The next level of recovery is for Host Channel Unit (HCU) errors, on

channel-attached systems only. If these occur, reboot the Sun

workstation and the HCU. Job recovery restarts and resumes at the

last checkpoint held by the host.

Checking job integrity following a

paper jam

Printer jam clearance areas

When printing resumes following a paper jam, there is a slight

possibility that duplicate sheets may be printed or sheets may be

missing from a job. For that reason, you should check job integrity

once the job has been printed.

Follow this procedure:

1. The printer offsets the first sheet printed following a paper jam.

Locate that sheet.

2. Check the sheets immediately before and after the offset sheet

to see if there are any missing or duplicate sheets in the job.

3. Check the output for data missing from the pages.

The following figure shows all areas in which printer jams can occur.

Note: This diagram contains the jam clearance areas for both the

dual stacker (areas 8, 8A, and 9) and the stitcher/stacker (areas A

and B). The purpose of the diagram is to give you an overall

perspective of the locations of all the printer areas relative to each

other. Note that an actual printer cannot have both a dual stacker and

a stitcher/stacker.

Figure 2-5. Overview of all printer jam areas

6

5

4

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-9

77

1

3

2

22

6A

3

4

2A2A

1A91A

8

A

B

Page 24

CLEARING PAPER MISFEEDS AND JAMS

Clearing paper jams from areas 1 and 1A

To clear paper jams from areas 1 and 1A:

1. Open the middle door and locate area 1.

Area 1

2. Remove and discard any paper you find in the areas indicated.

Area 1

3. Close the door.

2-10 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 25

CLEARING PAPER MISFEEDS AND JAMS

4. Open the high-capacity feeder front door and locate area 1A.

Area 1A

5. Remove and discard any paper you find in the area 1A.

6. Close the door and press Continue to resume printing.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-11

Page 26

CLEARING PAPER MISFEEDS AND JAMS

Clearing paper jams from areas 2 and 2A

To clear paper jams from areas 2 and 2A:

1. Open the middle door and locate area 2.

2. Lift the three green handles one by one. Each time you lift a

handle, remove and discard any paper you find beneath the

open section.

3. Lower the handles and close the door.

2-12 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 27

CLEARING PAPER MISFEEDS AND JAMS

4. Open the high-capacity feeder front door and locate area 2A.

5. Lift the green handle. Remove and discard any paper you find in

this area.

6. Lower the handle, close the door, and press the Continue

button to resume printing.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-13

Page 28

CLEARING PAPER MISFEEDS AND JAMS

Clearing paper jams from area 3

Follow these steps to clear jams in area 3.

1. Open the middle door and locate area 3.

2. Push and hold the green handle to the right (in the direction of

the arrow marked on it).

3. Remove and discard any paper you find in this area.

4. Release the handle, close the door, and press the Continue

button to resume printing.

Note: When paper jams occur in areas 3 through 5, three extra

blank sheets are sent through the printer to ensure that the fuser

is clean. These sheets are sent to the top tray and should be

discarded. You are not charged for these sheets.

2-14 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 29

Clearing paper jams from area 4

CLEARING PAPER MISFEEDS AND JAMS

Follow these steps to clear jams from area 4.

1. Open the middle and left doors and locate area 4. Remember to

clear the jam in area 5 first, if you are directed to clear both

areas.

Warning: The laser safety label located on the inside left front

!

door of the printer advises you that the panel below it must not

be removed, except by a service representative.

2. With your left hand, move and hold the green latch to the right

(the direction of the arrow marked on it). With your right hand,

pull out the large green handle until the fuser unit latches in the

fully open position.

Warning: Take care not to touch any parts in this area. They

!

may be hot enough to cause burns.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-15

Page 30

CLEARING PAPER MISFEEDS AND JAMS

3. Raise the small green handle at the front of the fuser assembly.

4. Remove and discard any paper you find in this area.

Warning: Take care not to touch any parts in this area. They

!

may be hot enough to cause burns.

Caution: Do not use a sharp object to remove paper wrapped

around the fuser rolls. Attempting to do so could damage the

roller and require its replacement.

5. Return the small green handle to its original position.

6. Push down on the green release latch, and slide the fuser unit

back into the printer until it latches into the closed position.

7. Close the doors (left one first) and press the Continue button to

resume printing.

2-16 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 31

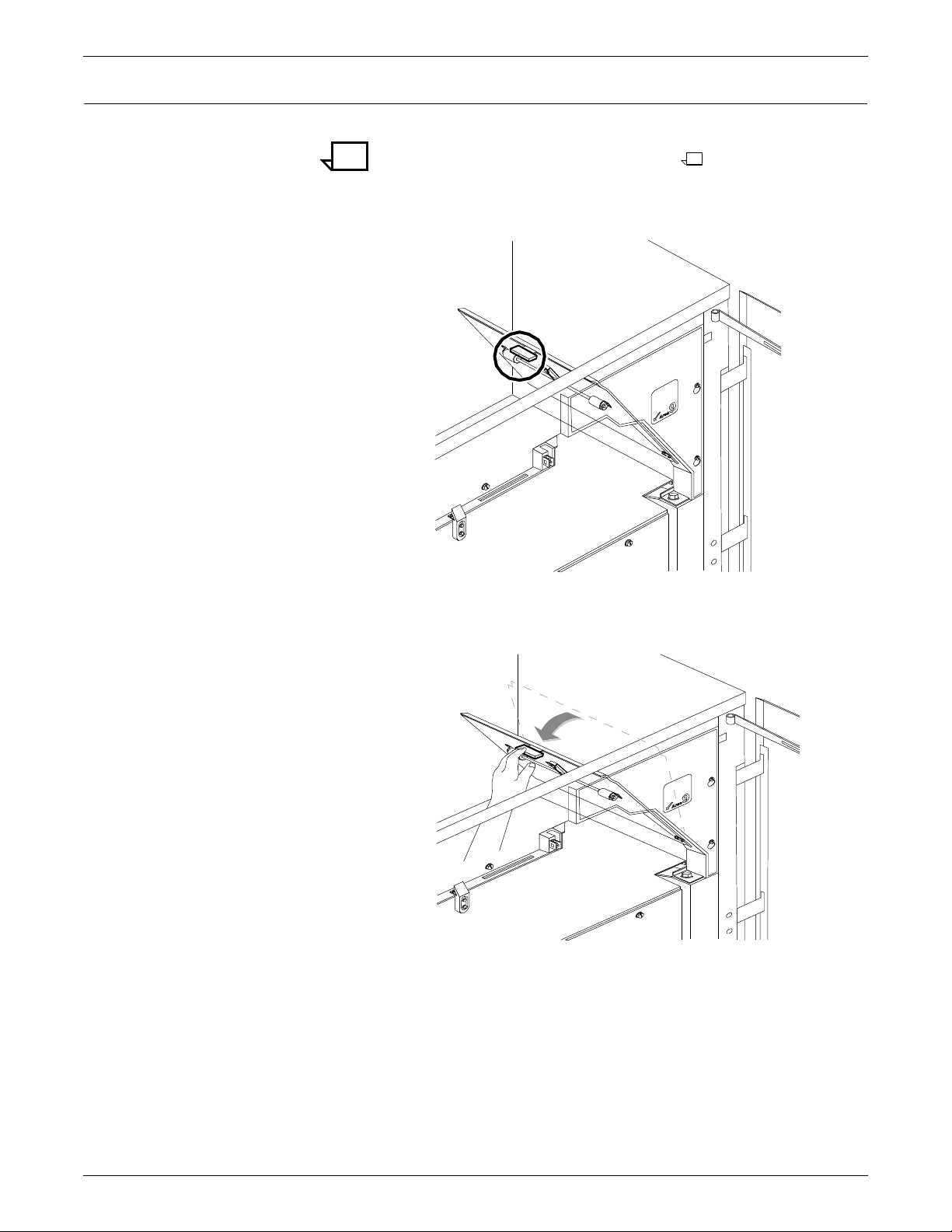

Clearing paper jams from area 5

CLEARING PAPER MISFEEDS AND JAMS

Follow these steps to clear jams in area 5.

1. Open the middle door and locate area 5.

2. If paper is caught in the rollers between areas 4 and 5, first turn

the green knob in the direction of the arrow marked on it. This

ensures that the paper has completely moved into area 5,

where you can remove it without tearing it.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-17

Page 32

CLEARING PAPER MISFEEDS AND JAMS

3. Push and hold the green handle to the left (in the direction of

the arrow marked on it). Remove and discard any paper you

find there.

4. Release the green handle.

5. Close the door and press the Continue button to resume

printing.

2-18 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 33

Clearing paper jams from areas 6 and 6A

Follow these steps to clear jams in areas 6 and 6A.

1. Open the printer left-most top cover. Remove and discard any

paper you find in this area.

2. Close the top cover.

CLEARING PAPER MISFEEDS AND JAMS

3. Open the top cover of the high-capacity feeder. (Open the top

cover of the stacker, too, if the printer control console message

display indicates it needs to be opened.)

4. Remove and discard any sheets under the high-capacity feeder

cover. If the printer control console message display also

indicates a problem in the output module, remove and discard

those sheets as well.

5. Close the top covers and press the Continue button to resume

printing.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-19

Page 34

CLEARING PAPER MISFEEDS AND JAMS

Clearing paper jams from area 7

Area 7 of the paper path is used only during two-sided (duplex)

printing.

1. Open the middle door and locate area 7.

2. Pull the block-shaped set separator toward you and hold it in

that position.

3. Remove and discard any paper in the duplex tray.

4. Return the set separator to its upright position.

5. Close the door and press the Continue button to resume

printing.

2-20 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 35

Clearing paper jams from area 8

CLEARING PAPER MISFEEDS AND JAMS

Note: If your printer has a stitcher/stacker, see the “Correcting

stacker problems” chapter.

1. Open the top cover of the output module, as indicated on the

graphic display of the printer control console.

2. Remove and discard any paper you find in this area.

3. Lower the lid and press the Continue button to resume printing.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-21

Page 36

CLEARING PAPER MISFEEDS AND JAMS

Clearing paper jams from area 9

Note: If your printer has a stitcher/stacker, see the “Correcting

stacker problems” chapter in this guide.

1. Open the right door and locate the green handle on the upper

right side of area 9.

2. Pull the green handle down and to the left (in the direction of the

arrow marked on it) to hold the assembly open while you

remove and discard any paper you find in this area.

3. Return the handle to its original position and close the door.

4. Press the Continue button to resume printing.

2-22 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 37

Clearing stitcher/stacker paper jams (areas A and B)

Follow these steps to clear stitcher/stacker jams in areas A and B.

1. Open the top cover of the stitcher/stacker and locate area A in

the center.

CLEARING PAPER MISFEEDS AND JAMS

Area A

2. Remove and discard the paper under the paper guide. The

paper guide is a spring-loaded, heavy wire form guide that pops

up when you open the cover.

3. Locate the side cover of area B on the right.

4. Push the cover to the right (in the direction of the large green

arrow at the front of the cover) to open it.

5. Remove only the set of pages leaving the stitcher/stacker at the

right, and place it on the output in the stacker tray. Do not

remove any other pages from this area.

Note: The pages were compiled by the stitcher/stacker into a

set (stapled or not), but something prevented the set from being

delivered to the stacker. You put the set in the stacker tray

because the system has counted it as completed.

6. Close the side and top covers.

7. Press the Continue button to resume printing.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-23

Page 38

CLEARING PAPER MISFEEDS AND JAMS

Clearing bypass transport paper jams

To clear bypass transport paper jams:

1. Verify that a sheet is caught between the bypass transport and

the finishing device. If a sheet is there, remove it and discard it.

2. Open the top cover of the bypass transport by lifting upward on

the recessed handle.

3. Remove and discard any paper you now see in the bypass

transport.

4. Grasp the handle again and slide the top cover to the right. This

exposes the remainder of the bypass transport paper path.

5. Remove and discard any paper you see.

6. Push the cover back to the left and close it tightly. The cover

snaps shut.

7. Press the Continue button on the printer control console to

resume printing.

8. Discard any sheets sent to the sample tray when the jam was

detected.

2-24 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 39

Adjusting dual stacker tray scuffer arms

Paper jams can occur when the paper does not stack smoothly in the

dual stacker trays. If some papers stack well while others do not, the

weights under the scuffer arms may need to be adjusted.

Note: The scuffer arm weights on some printers are bolted in place.

These must be adjusted by a service representative.

The adjustable weights are located on the underside of the scuffer

arms, on a track down the center. To adjust them:

1. Slide the weight right or left along its track under the scuffer

arm.

• If the paper is driven too far up the outside edge of the tray,

• If the paper is not driven far enough into the tray, move the

CLEARING PAPER MISFEEDS AND JAMS

move the weight toward the machine.

weight away from the machine.

Note: For lightweight paper, move the weight toward the

machine; for heavyweight paper move the weight away

from the machine.

Figure 2-6. Adjusting scuffer arm weights

1

1 Scuffer arm

2. Clear all paper jams, following the jam clearance instructions

provided by the message and graphic displays on the printer

control console.

3. Discard any pages sent to the sample tray or to a stacker tray

when the jam was detected.

4. Press the Continue button on the printer control console to

resume printing.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 2-25

Page 40

CLEARING PAPER MISFEEDS AND JAMS

2-26 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 41

3. 3Correcting stacker problems

This chapter describes problems with the stitcher/stacker and the

dual stacker, other than paper jams. It suggests corrective actions

when printed sets are not stitched. (See “Clearing paper misfeeds

and jams” for stacker paper jams.)

Symptom Probable cause Action

Printed sets are not stitched. Stitcher/stacker is out of wire

(fault code L152), or is

jammed (fault code L172), or

stitching head has

malfunctioned (various fault

codes).

Printing stops and the printer

console displays a message

indicating that an incorrect

paper size is loaded in a

feeder tray.

The number displayed in the

Wire Percentage indicator of

the printer console begins to

flash, and the message

STITCHER LOW ON WIRE

appears when you start a new

print job.

Printer console displays the

message

OFFSET FAILED, SET IN

OUTPUT BIN NOT OFFSET,

Incorrect paper size or a

damaged sheet.

Stitching wire has decreased

to the percentage that was

preset by the service

representative.

Faulty component in the

offsetting mechanism of the

stitcher.

If you have completed Advanced Customer

Training (ACT), follow the recommended

procedures to correct the problem. If not,

contact your supervisor or your service

representative. Until the problem is fixed, you

can continue printing without stitching the

output.

1. Check the paper in the indicated tray.

2. If the paper is not the correct size, load

the correct size paper or select another

feeder tray containing the correct paper

size.

If the paper size is correct, press the

Continue button to resume printing.

If you have completed Advanced Customer

Training (ACT), follow the recommended

procedures to correct the problem. If not,

contact your supervisor or your service

representative. You can continue printing, but

the stitcher may run out of wire.

One percent of the wire will stitch about 300

sets (maximum).

1. Clear the message by pressing the

Continue button on the printer console.

2. Call customer service for further

assistance.

but the printed sheets in the

stitcher/stacker tray are offset

normally.

Paper does not stack evenly in

the dual stacker trays.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 3-1

Scuffer arm weights are out of

adjustment.

If printer has adjustable weights under the

scuffer arms, slide them to the right or the left.

(Refer to “Clearing paper misfeeds and jams”

chapter in this guide.)

If the weights are bolted in place, ask your

service representative to adjust them.

Page 42

CORRECTING STACKER PROBLEMS

3-2 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 43

4. 4System unresponsive

This chapter describes problems in which your monitor shows no

image, the printer does not respond when you press the Continue

button, or the IPS main window does not respond.

Symptom Probable cause Action

Blank display: pressing a key

fails to restore image.

You have cleared all faults that

are listed on the printer control

console, but the Attention light

is still on and the following

message is displayed:

Output is stopped. See

message at the System

Display

Printer main window does not

respond (lockout).

Printer console displays the

message:

Press continue to

resume printing,

but the printer does not

respond to the Continue

button.

Monitor is switched off;

brightness and contrast

controls are misadjusted; or

there is a more serious

problem.

There is an uncleared output

fault.

Someone accessed the

System Meter Readings

display from the System

Options menu while the printer

cable was disconnected.

An internal error has occurred. 1. Be sure you have pressed the Continue

1. Make sure that the monitor is switched

on.

2. Make sure that the brightness and

contrast controls (if available) are turned

far enough to the left to brighten the

screen.

3. If switch is on and controls are turned to

the left, call the service representative.

Follow the instructions in the output message

and press the Continue button.

Call for service. Tell the representative if the

printer cable is connected to the printer and the

Printer Controller.

Caution: Do not attempt to reconnect the

cable yourself.

button on the printer, instead of clicking

the button on the screen.

2. Power the printer off and on to reset the

printer.

3. Reboot the Sun workstation.

Caution: Do not power off the Sun workstation

to reboot it. Use the rebooting procedure

described in the Xerox DocuPrint 92C IPS

Guide to Configuring and Managing the

System.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 4-1

Page 44

SYSTEM UNRESPONSIVE

Symptom Probable cause Action

Printer console displays the

messages

Black housing is not

ready

and

Color housing is not

ready,

and printing does not start.

When the system is being

started up, the IPS main

window does not open.

Instead, the Input

Configuration window is

displayed, along with an error

message window displaying:

Loading of the Input

Configuration failed.

Please verify each tray

contains the proper

media and that media is

loaded correctly in the

tray.

The system requires a PQA

(print quality adjustment).

The printer has not warmed

up; therefore, the controller

has not received information

on what paper is loaded in the

trays.

Perform a manual PQA from the Printing

Samples screen. See Xerox DocuPrint 92C

IPS Guide to Configuring and Managing the

System for more information.

1. Click OK on the message window to close

it.

2. Wait until the printer control console

displays READY TO PRINT.

3. Click Quit on the Input Configuration

window. The IPS main window should

appear.

4. If the Input Configuration window does

not close, check the printer trays against

the displayed configuration for a possible

mismatch.

5. If there is a feeder tray mismatch, either

change the input configuration or load

paper in the trays to match what the

configuration specifies. (Refer to “Setting

up the system configuration” in your

Xerox DocuPrint 92C IPS Guide to

Configuring and Managing the System.)

IPS main window temporarily

freezes after entering a new

date on the SUN.

The following message

appears on the User Interface

of a dual mode system:

Media Definition

Conflict

This behavior occurs when a

new date with a year is

entered right after opening a

command tool.

System does not recognize

the NPS mode.

Reboot the system after the date change.

Start your system and set trays in NPS mode.

4-2 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 45

SYSTEM UNRESPONSIVE

Restarting the IPS

after an error condition

To restart the IPS after you have cleared an error condition:

1. Drain the printer at the host. (Follow procedures for your host

system.)

2. In an MVS environment, cancel the FSS (Functional

Subsystem), which automatically drains the printer.

3. Reboot the Printer Controller using the following procedure:

a. Move the pointer to the background on the IPS screen,

ensuring that it is not on any window or icon.

b. Hold down the right mouse button to display the workspace

pull-down menu.

c. Select Restart. A confirmation prompt window appears.

d. Select Restart again from the confirmation prompt window.

4. Restart the printer at the host.

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE 4-3

Page 46

SYSTEM UNRESPONSIVE

4-4 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 47

Index

A

area 3, clearing paper jams, 2-14

area 4, clearing paper jams, 2-15–2-16

area 5, clearing paper jams, 2-17–2-18

area 7, clearing paper jams, 2-20

area 8, clearing paper jams, 2-21

area 9, clearing paper jams, 2-22

areas 1 and 1A, clearing paper jams, 2-10–2-11

areas 2 and 2A, clearing paper jams, 2-12–2-13

areas 6 and 6A, clearing paper jams, 2-19

areas A and B, clearing stitcher/stacker tray paper

jams, 2-23

B

bypass transport, clearing paper jams, 2-24

C

clearing

bypass transport paper jams, 2-24

feeder trays, 2-2–2-3

paper jams

area 3, 2-14

area 4, 2-15–2-16

area 5, 2-17–2-18

area 7, 2-20

area 8, 2-21

area 9, 2-22

areas 1 and 1A, 2-10–2-11

areas 2 and 2A, 2-12–2-13

areas 6 and 6A, 2-19

stacker tray paper jams, 2-25

stitcher/stacker tray paper jams (areas A and B),

2-23

Continue button, no response, 4-1

D

F

feed belt, cleaning, 2-4–2-5

feeder trays, clearing faults, 2-2–2-3

G

glazing, 2-4

H

HCU errors, 2-9

hotlines

ozone information, iii

safety, iv

J

job integrity, checking after paper jam, 2-9

L

labels, danger, iii

laser safety, iii

M

messages

labels, 2-8

paper jams, 2-7

misfeeds, frequent, 2-4–2-5

modem

enable and disable, 1-2

monitor, blank display, 4-1

O

operation safety, iv

ozone, iii

danger labels, iii

documentation

other, ix

E

error condition, restarting printer, 4-3

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE INDEX-1

P

paper

clearing jams

area 3, 2-14

area 4, 2-15–2-16

area 5, 2-17–2-18

area 7, 2-20

area 8, 2-21

Page 48

INDEX

area 9, 2-22

areas 1 and 1A, 2-10–2-11

areas 2 and 2A, 2-12–2-13

areas 6 and 6A, 2-19

bypass transport, 2-24

stacker tray, 2-25

stitcher/stacker tray (areas A and B), 2-23

jams

graphic display, 2-7

message display, 2-7

jams, clearing

checking job integrity, 2-9

types, 2-1

print jobs, automatic recovery, 2-9

printers

restarting, 4-3

procedures

feed belt, cleaning, 2-4–2-5

paper trays, clearing misfeeds, 2-2–2-3

printers, restarting, 4-3

publications, related, ix

R

Ready To Open indicator, 2-2

remote service, 1-2

S

safety

hotline, iv

laser, iii

precautions, iv

standards, iii

scuffer arms

adjusting, 2-25

service call, required information, 1-1

Sixth Sense Technology, 1-2

disabling a modem, 1-3

enabling a modem, 1-3

remote service, 1-2

stacker tray, clearing paper jams, 2-25

stitcher/stacker

problems, 3-1

tray, clearing paper jams (areas A and B), 2-23

system unresponsive, 4-1

T

Tray Unlock button, 2-2

W

Wire Percentage indicator, 3-1

INDEX-2 XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE

Page 49

../../../IPS & LPS Graphics/DPC0010A.CGM iii

../../../IPS & LPS Graphics/70 -- modem.TIF @ 83 dpi 1-3

../../../IPS & LPS Graphics/dpc0087a.cgm 2-2

../../../IPS & LPS Graphics/DPC0088A.CGM 2-3

../../../IPS & LPS Graphics/DPC0089A.CGM 2-3

../../../IPS & LPS Graphics/DPC0090A.CGM 2-4

../../../IPS & LPS Graphics/DPC0091A.CGM 2-5

../../../IPS & LPS Graphics/DPC0089A.CGM 2-5

../../../IPS & LPS Graphics/Dpc0485b.eps 2-6

../../../IPS & LPS Graphics/dpc0486b.eps 2-6

../../../IPS & LPS Graphics/dpc0534a.eps 2-7

../../../IPS & LPS Graphics/DPC0085A.EPS 2-8

../../../IPS & LPS Graphics/DPC0488A.EPS 2-9

../../../IPS & LPS Graphics/DPC0093A.EPS 2-10

../../../IPS & LPS Graphics/DPC0094A.EPS 2-10

../../../IPS & LPS Graphics/DPC0095A.EPS 2-11

../../../IPS & LPS Graphics/DPC0096A.CGM 2-12

../../../IPS & LPS Graphics/DPC0097A.CGM 2-12

../../../IPS & LPS Graphics/DPC0097A.CGM 2-12

../../../IPS & LPS Graphics/DPC0098A.CGM 2-13

../../../IPS & LPS Graphics/DPC0099A.CGM 2-13

../../../IPS & LPS Graphics/DPC0100A.EPS 2-14

../../../IPS & LPS Graphics/DPC0086A.CGM 2-14

../../../IPS & LPS Graphics/DPC0101A.CGM 2-15

../../../IPS & LPS Graphics/DPC0010A.CGM 2-15

../../../IPS & LPS Graphics/DPC0103A.CGM 2-16

../../../IPS & LPS Graphics/DPC0104B.cgm 2-16

../../../IPS & LPS Graphics/DPC0105A.CGM 2-17

../../../IPS & LPS Graphics/DPC0106A.CGM 2-17

../../../IPS & LPS Graphics/DPC0107A.CGM 2-18

../../../IPS & LPS Graphics/DPC0108A.CGM 2-19

../../../IPS & LPS Graphics/DPC0109A.CGM 2-19

../../../IPS & LPS Graphics/DPC0110A.CGM 2-20

../../../IPS & LPS Graphics/DPC0111A.CGM 2-20

../../../IPS & LPS Graphics/DPC0111A.CGM 2-20

../../../IPS & LPS Graphics/Dpc0479a.cgm 2-21

../../../IPS & LPS Graphics/DPC0113A.CGM 2-22

../../../IPS & LPS Graphics/DPC0114A.CGM 2-22

../../../IPS & LPS Graphics/DPC0092A.EPS 2-23

../../../IPS & LPS Graphics/DPC0115A.CGM 2-24

../../../IPS & LPS Graphics/DPC0116A.CGM 2-24

../../../IPS & LPS Graphics/DPC0117A.CGM 2-25

../../../IPS & LPS Graphics/DPC0118A.CGM 2-25

../../../IPS & LPS Graphics/DPC0118A.CGM 2-25

../../../IPS & LPS Graphics/DPC0092A.EPS 2-26

DOUBLE-CLICK ON THIS TEXT FROM ANY MASTER PAGE AND EDIT THE DEFINITION -1

Loading...

Loading...