Page 1

Version 3.1

March 2007

DocuColor 8000/7000

Operator

Manual

Page 2

Prepared by:

Xerox Corporation

Global Knowledge & Language Services

800 Phillips Road

Building 845

Webster, New York 14580

©

Copyright 2007 by Xerox Corporation. All Rights Reserved.

Copyright protection claimed includes all forms and matters of copyrighted material and information now allowed by statutory or judicial law or

hereinafter granted, including without limitation, material generated from the software programs that are displayed on the screen such as styles,

templates, icons, screen displays, looks, etc.

®

Xerox

, Xerox Canada Ltd®, Xerox Limited®, and all Xerox product names and product numbers mentioned in this publication are trademarks

of XEROX CORPORATION. Copyright protection claimed includes all forms and matters of copyrightable material and information now allowed

by statutory or judicial law or hereinafter granted, including without limitations, material generated from the software programs which are

displayed on the screen such as styles, templates, icons, screen displays looks, etc. Other company brands and product names may be

trademarks or registered trademarks of the respective companies and are also acknowledged.

While every care has been taken in the preparation of this material, no liability will be accepted by Xerox Corporation arising out of any

inaccuracies or omissions.

Changes are periodically made to this document. Changes, technical innacuracies, and typographic errors will be corrected in subsequent

editions.

Page 3

Table of contents

Conventions vii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety notices ix

Electrical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Disconnect device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Europe (EU) and other markets . . . . . . . . . . . . . . . . . . . . . . xii

Safety standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Europe (EU) and other markets . . . . . . . . . . . . . . . . . . . . . . xii

Maintenance safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Operational safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Ozone safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Notices xv

Radio frequency emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

FCC in the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

In Canada (ICES-003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Regulatory information for RFID. . . . . . . . . . . . . . . . . . . . . .xvi

Safety extra low voltage approval. . . . . . . . . . . . . . . . . . . . . . . .xvi

Certifications in Europe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

It’s illegal in the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

It’s illegal in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Environmental notices for Canada . . . . . . . . . . . . . . . . . . . . . . .xxi

Product recycling and disposal . . . . . . . . . . . . . . . . . . . . . . . . . xxii

North America. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

European union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Other countries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

DocuColor 8000/7000 Operator Manual

i

Page 4

Table of contents

Overview 1-1

Identifying the external components . . . . . . . . . . . . . . . . . . . . . 1-2

Ecology Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrical Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Dry Ink/Toner Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Ground Fault Indicator (GFI) circuit breakers . . . . . . . . . . . 1-8

User Interface (UI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Job Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Machine Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Machine Details tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Maintenance tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Audio tones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Alert screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Identifying the internal components . . . . . . . . . . . . . . . . . . . . 1-26

Serial number label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Paper Transport drawer . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Transport Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Paper path in the digital press . . . . . . . . . . . . . . . . . . . . . 1-28

Exit Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Relocating the digital press. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Customer documentation updates . . . . . . . . . . . . . . . . . . . . . 1-30

Paper and paper trays 2-1

Recommended Materials List (RML) . . . . . . . . . . . . . . . . . . . . 2-1

Paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Paper trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Paper guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Paper specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Tray capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Duplexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Transparency guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Tabbed inserts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Drilled paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Simplex Print Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Duplex Print Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

ii

DocuColor 8000/7000 Operator Manual

Page 5

Table of contents

Letterhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Nonstandard size paper . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Auto Tray Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Auto Paper Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Loading paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Paper weight conversion tables . . . . . . . . . . . . . . . . . . . . . . . 2-16

Specific weight conversion . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Weight conversion ranges . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Accessories 3-1

Trays 3 and 4 (Second Feeder Module) . . . . . . . . . . . . . . . . . . 3-1

Identifying the parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Loading paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Paper trays air adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Jam clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Physical characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Floor space requirements . . . . . . . . . . . . . . . . . . . . . . . 3-8

High Capacity Stacker 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Identifying the parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Top Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Stacker Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Paper guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Recommended baseline/centerline. . . . . . . . . . . . . . . 3-16

Paper specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Unloading the Stacker Tray. . . . . . . . . . . . . . . . . . . . . . . . 3-18

Selecting Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

How to Enable Automatic Output Switching . . . . . . . . 3-19

Using a DFA Finishing Device . . . . . . . . . . . . . . . . . . . . . 3-20

Jam clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Clear Bypass area jam . . . . . . . . . . . . . . . . . . . . . . . . 3-21

. . . . . . . Clear Top Tray and Stacker Tray paper jams3-22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Problem Solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

DocuColor 8000/7000 Operator Manual

iii

Page 6

Table of contents

Loss of Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

High Capacity Stacker Stapler 80 (HCSS80) . . . . . . . . . . . . . 3-25

Identifying HCSS80 Parts . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Electrical/environmental requirements . . . . . . . . . . . . . . . 3-27

Paper stock specifications . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Using the HCSS80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Stapling Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Paper specifications for stapling . . . . . . . . . . . . . . . . . 3-31

Staple Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Stapling capacity for different paper types and weights . . 3-34

Unloading the HCSS80. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Jam Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Ordering and Loading Staples . . . . . . . . . . . . . . . . . . . . . 3-36

HCSS80 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Cleaning the HCSS80. . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Problem Solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Loss of Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Common Stacker/Stapler (CSS) . . . . . . . . . . . . . . . . . . . . . . . 3-41

Identifying CSS Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Electrical/environmental requirements . . . . . . . . . . . . . . . 3-43

Paper stock specifications . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Using the stacker/stapler . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Stapling Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Paper specifications for stapling . . . . . . . . . . . . . . . . . 3-47

Staple Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Stapling capacity for different paper types and weights . . 3-50

Unloading the stacker/stapler . . . . . . . . . . . . . . . . . . . . . . 3-50

Jam Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Ordering and Loading Staples . . . . . . . . . . . . . . . . . . . . . 3-52

Stacker/stapler Maintenance. . . . . . . . . . . . . . . . . . . . . . . 3-53

Cleaning the stacker/stapler . . . . . . . . . . . . . . . . . . . . 3-53

Problem Solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Loss of Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

iv

Problem solving 4-1

General problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

DocuColor 8000/7000 Operator Manual

Page 7

Table of contents

Jam clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Paper tray jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Upper Transport Area jam . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Transport Module jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Exit Module jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Right/left door paper path jams. . . . . . . . . . . . . . . . . . . . . 4-12

Jam clearance with 2-sided printing . . . . . . . . . . . . . . 4-14

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Technical Data 5-1

Digital Press Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Warm-up Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

First Print Out Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . 5-2

Ambient Temperature and Humidity . . . . . . . . . . . . . . . 5-2

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Noise Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Ozone Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Dust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Tray Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Print Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Digital Press Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Digital Press Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Floor Space Requirements . . . . . . . . . . . . . . . . . . . . . . 5-6

Metric Conversion Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Maintenance 6-1

Cleaning procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cleaning the digital press . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cleaning the UI Touch Screen . . . . . . . . . . . . . . . . . . . . . . 6-2

Cleaning the Charge Corotrons . . . . . . . . . . . . . . . . . . . . . 6-2

Cleaning the Second Transport and Fusing areas . . . . . . 6-10

Cleaning the paper path . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Replacing Consumable Supplies . . . . . . . . . . . . . . . . . . . . . . 6-19

DocuColor 8000/7000 Operator Manual

v

Page 8

Table of contents

Replacing a Dry Ink/Toner Cartridge. . . . . . . . . . . . . . . . . 6-20

Adding Fuser Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Changing the Waste Dry Ink/Toner Bottle. . . . . . . . . . . . . 6-25

Replacing a Charge Corotron . . . . . . . . . . . . . . . . . . . . . . 6-27

When to replace a charge corotron. . . . . . . . . . . . . . . 6-27

Which charge corotron to replace. . . . . . . . . . . . . . . . 6-27

Banding samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Replacing the Fuser Web . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Calling for Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Consumable Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

vi

DocuColor 8000/7000 Operator Manual

Page 9

Symbols

Conventions

Standardized conventions have been used in this manual to assist

you in visually locating and identifying information quickly.

CAUTION: This symbol alerts you to an action that may cause

damage to hardware, software, or result in the loss of data.

WARNING: Warnings mark alert users to areas of the machine

where there is a possibility of personal injury.

WARNING: This symbol identifies an area on the machine that is

HOT and should not be touched.

WARNING: This symbol indicates a laser is being used in the

machine and alerts you to refer to the appropriate safety

information.

TIP: This symbol identifies information that is being emphasized

and is important for you to remember.

DocuColor 8000/7000 Operator Manual

vii

Page 10

Conventions

The 1 2 3... symbol indicates the beginning of a task or work

process you should use to complete a procedure and is followed

by the first step of a numbered procedure, task, or work process.

NOTE: This symbol calls your attention to information that is

helpful, but not essential to compl e te a procedure or task.

viii

DocuColor 8000/7000 Operator Manual

Page 11

Electrical safety

Safety notices

This Xerox product and the recommended supplies are designed

and tested to meet strict safety requirements. These include

safety agency approval and compliance to established

environmental standards. Please read the following instructions

carefully before operating the product, and refer to them as

needed to ensure the continued safe operation of your product.

TIP: The safety testing and performance of this product have

been verified using Xerox materials only.

WARNING: Any unauthorized alteration, which may include the

addition of new functions or connection of external devices, may

impact the product certification. Please contact your authorized

local dealer for more information.

• Use only the power cord supplied with this equipment.

• Plug the power cord directly into a correctly grounded

electrical outlet. Do not use an extension cord. If you do not

know whether or not an outlet is grounded, consult a qualified

electrician.

• Do not use a ground adapter plug to connect this equipment to

an electrical outlet that lacks a ground connection terminal.

WARNING: You may incur a severe electrical shock if the outlet is

not grounded correctly.

• Do not place the machine where people may step or trip on the

power cord. Do not place objects on the power cord.

• Do not override or disable electrical or mechanical interlocks.

• Do not obstruct the ventilation openings. These openings

prevent overheating of the machine.

DocuColor 8000/7000 Operator Manual

ix

Page 12

Safety notices

Disconnect device

WARNING: Never push objects of any kind into slots or openings

on this equipment. Making a contact with a voltage point or

shorting out a part may result in fire or electrical shock.

If any of the following conditions occur, immediately switch off the

power to the machine and disconnect the power cord from the

electrical outlet. Call an authorized Xerox service representative

to correct the problem.

• The machine emits unusual noises or odors.

• The power cord is damaged or frayed.

• A wall panel circuit breaker, fuse, or other safety device is

tripped.

• Liquid is spilled into the press.

• The machine is exposed to water.

• Any part of the machine is damaged.

The power cable is the disconnect device for this equipment and is

attached to the back of the machine as a plug-in device. To

remove all electrical power from the machine, disconnect the

power cable from the electrical outlet.

WARNING: This product must be connected to a protective earth

current.

x

DocuColor 8000/7000 Operator Manual

Page 13

Laser safety

North America

Safety notices

This product complies with safety standards and is certified as a

Class 1 Laser product under the Center for Devices and

Radiological Health (CDRH) of the United States Food and Drug

Administration (FDA) implemented regulations for laser

products. This product complies with FDA 21 CFR 1940.10 and

1040.11 except for deviations pursuant to Laser Notice No. 50,

dated July 26, 2001. These regulations apply to laser products

marketed in the United States. The label on the machine indicates

compliance with CDRH regulations and must be attached to laser

products marketed in the United States. This product does not

emit hazardous laser radiation.

CAUTION: Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous exposure of laser light.

Since radiation emitted inside this product is completely confined

within the protective housing and external covers, the laser beam

cannot escape from the machine during any phase of the user

operation.

This product contains laser warning labels. These labels are

intended for use by the Xerox Service Representative and are

placed on or near panels or shields that require special tools for

removal. Do not remove any of the panels. There are no operator

serviceable areas in these covers.

DocuColor 8000/7000 Operator Manual

xi

Page 14

Safety notices

Europe (EU) and other markets

This product complies with IEC’s safety standard 60825-1 (Edition

1.2) issued August 2001.

The equipment complies with laser product performance

standards set by governmental, national, and international

agencies as a Class 1 Laser Product. It does not emit hazardous

radiation as the beam is totally enclosed during all phases of

customer operation and maintenance.

CAUTION: Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

This product contains laser warning labels. These labels are

intended for use by the Xerox Service Representative and are

placed on or near panels or shields that require special tools for

removal. Do not remove any of the panels. There are no operator

serviceable areas inside these covers.

If you need additional safety information concerning the product or

Xerox supplied materials, you may call the following number:

Safety standards

North America

Europe (EU) and other markets

+44 (0) 1707 353434

This Xerox product is safety certified by Underwriters Laboratories

Incorporated to Standards UL60950-1 (first edition), and CSA

International CAN/CSA C22.2 No. 60950-1-03 (First Edition).

This Xerox product is Safety Certified by NEMKO to publication

IEC60950-1 (2001) First Edition.

xii

DocuColor 8000/7000 Operator Manual

Page 15

Maintenance safety

Safety notices

• Do not attempt any maintenance procedure that is not

specifically described in the documentation supplied with your

product.

• Do not use aerosol cleaners. The use of supplies that are not

approved may cause poor performance of the press and could

create a dangerous condition.

• Use the supplies and cleaning materials only as directed in

this manual. Keep all materials out of the reach of children.

• Do not remove the covers or guards that are fastened with

screws. There are no parts behind these covers that you can

maintain or service.

Do not perform any maintenance procedures unless you have

been trained to do them by a Xerox representative, or unless a

procedure is specifically described in one of the manuals included

with your press.

Operational safety

Your Xerox equipment and supplies were designed and tested to

meet strict safety requirements. These include safety agency

examination, approval, and compliance with established

environmental standards.

Your attention to the following safety guidelines will help ensure

the continued safe operation of your product:

• Use the materials and supplies specifically designed for your

product. The use of unsuitable materials may result in poor

performance of the machine and possibly a hazardous

situation.

• Follow all warnings and instructions that are marked on or

supplied with the machine.

• Place the machine in a room that provides adequate space for

ventilation and servicing.

• Place the machine on a level, solid surface (not on a thick pile

carpet) that has adequate strength to support the weight of the

machine.

• Do not attempt to move the machine. A leveling device that

was lowered when your machine was installed may damage

the carpet or floor.

• Do not set up the machine near a heat source.

• Do not set up the machine in direct sunlight.

DocuColor 8000/7000 Operator Manual

xiii

Page 16

Safety notices

Ozone safety

• Do not set up the machine in line with the cold air flow from an

air conditioning system.

• Do not place containers of coffee or other liquid on the

machine.

• Do not block or cover the slots and openings on the machine.

• Do not attempt to override any electrical or mechanical

interlock devices.

WARNING: Be careful when working in areas identified with this

warning symbol. These areas may be very hot and should not be

touched.

If you need any additional safety information concerning the

machine or materials, contact your Xerox representative.

This product produces ozone during normal operation. The ozone

is heavier than air, and the quantity is dependent on print volume.

Providing the correct environmental parameters, as specified in

the Xerox installation procedures, ensures that concentration

levels meet safe limits.

If you need additional information about ozone, request the Xerox

publication, OZONE by calling 1-800-828-6571 in the USA. For a

French language version, call 1-800-828-6571 in the USA, then

press 2.

xiv

DocuColor 8000/7000 Operator Manual

Page 17

Notices

Radio frequency emiss i ons

FCC in the USA

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

Federal Communications Commission (FCC) Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his/her

own expense.

Changes or modifications to this equipment not specifically

approved by the Xerox Corporation may void the user’s authority

to operate this equipment.

WARNING: Shielded cables must be used with this equipment to

maintain compliance with FCC regulations.

In Canada (ICES-003)

This Class “A” digital apparatus complies with Canadian ICES-

003.

Cet appareil numérique de la classe “A” est conforme á la norme

NMB-003 du Canada.

DocuColor 8000/7000 Operator Manual

xv

Page 18

Notices

Regulatory information for RFID

This product generates 13.56 MHz using an Inductive Loop

System as a Radio Frequency IDentification system device

(RFID). This system is certified in compliance with European

Council Directive 99/5/EC and applicable local laws or regulations

as applicable.

Safety extra low volt age approval

This Xerox product is in compliance with various governmental

agencies and national safety regulations. All system ports meet

the Safety Extra Low Voltage (SELV) circuits for connection to

customer-owned devices and networks. Additions of customerowned or third-party accessories that are attached to the press

must meet or exceed the requirements previously listed. All

modules that require external connection must be installed per the

installation procedure.

Certifications in Europe

January 1, 1995: Council Directive 73/23/EEC amended by Council Directive 93/68/

January 1, 1996: Council Directive 89/336/EEC, approximation of the laws of the

March 9, 1999 Council Directive 99/5/EC on radio equipment and

The CE marking that is applied to this product symbolizes Xerox

Declaration of Conformity with the following applicable Directives

of the European Union as of the dates indicated:

EEC, approximation of the laws of the member states related to

low voltage equipment.

member states related to electromagnetic compatibility.

telecommunications terminal equipment and the mutual

recognition of their conformity.

xvi

DocuColor 8000/7000 Operator Manual

Page 19

Notices

A full declaration, defining the relevant directives and referenced

standards, can be obtained from your Xerox Limited

representative or by contacting:

Environment, Health and Safety

The Document Company Xerox

Bessemer Road

Welwyn Garden City

Herts

AL7 1HE

England

Tel Number +44 (0) 1707 353434

WARNING: This system is certified manufactured and tested in

compliance with strict safety and radio frequency interference

regulations. Any unauthorized alteration which includes the

addition of new functions or the connection of external devices

may impact this certification. Please contact your local Xerox

Limited representative for a list of approved accessories.

WARNING: In order to allow this equipment to operate in

proximity to Industrial, Scientific, and Medical (ISM) equipment,

the external radiation from the ISM equipment may have limited or

special mitigation measures taken.

WARNING: This is a Class A product in a domestic

environment. This product may cause radio frequency

interference in which case the user may be required to take

adequate measures.

WARNING: Shielded cables must be used with this equipment to

maintain compliance with Council Directive 89/336/EEC.

DocuColor 8000/7000 Operator Manual

xvii

Page 20

Notices

It’s illegal in the USA

Congress, by statute, has forbidden the reproduction of the

following subjects under certain circumstances. Penalties of fine

or imprisonment may be imposed on those guilty of making such

reproductions.

1. Obligations or Securities of the United States Government,

such as:

Certificates of Indebtedness National Bank Currency

Coupons from Bonds Federal Reserve Bank Notes

Silver Certificates Gold Certificates

United States Bonds Treasury Notes

Federal Reserve Notes Fractional Notes

Certificates of Deposit Paper Money

Bonds and Obligations of certain agencies of the

government, such as FHA, etc.

Bonds. (U.S. Savings Bonds may be photographed only for

publicity purposes in connection with the campaign for the

sale of such bonds.)

Internal Revenue Stamps. (If it is necessary to reproduce a

legal document on which there is a canceled revenue stamp,

this may be done provided the reproduction of the document

is performed for lawful purposes.)

Postage Stamps, canceled or uncanceled. (For philatelic

purposes, Postage Stamps may be photographed, provided

the reproduction is in black and white and is less than 75%

or more than 150% of the linear dimensions of the original.)

Postal Money Orders.

Bills, Checks, or Drafts of money drawn by or upon

authorized officers of the United States.

Stamps and other representatives of value, of whatever

denomination, which have been or may be issued under any

Act of Congress.

xviii

DocuColor 8000/7000 Operator Manual

Page 21

Notices

2. Adjusted Compensation Certificates for Veterans of the

World Wars.

3. Obligations or Securities of any Foreign Government, Bank,

or Corporation.

4. Copyrighted material, unless permission of the copyright

owner has been obtained or the reproduction falls within the

“fair use” or library reproduction rights provisions of the

copyright law. Further information of these provisions may be

obtained from the Copyright Office, Library of Congress,

Washington, D.C. 20559. Ask for Circular R21.

5. Certificates of Citizenship or Naturalization. (Foreign

Naturalization Certificates may be photographed.)

6. Passports. (Foreign Passports may be photographed.)

7. Immigration Papers.

8. Draft Registration Cards.

9. Selective Service Induction Papers that bear any of the

following Registrant’s information:

Earnings or IncomeDependency Status

Court RecordPrevious military service

Physical or mental condition

Exception: United States military discharge certificates may

be photographed.

10. Badges, Identification Cards, Passes, or Insignia carried by

military personnel, or by members of the various Federal

Departments, such as FBI, Treasury, etc. (unless photograph

is ordered by the head of such department or bureau.)

Reproducing the following is also prohibited in certain states:

Automobile Licenses - Drivers’ Licenses - Automobile

Certificates of Title.

The above list is not all inclusive, and no liability is assumed for its

completeness or accuracy. In case of doubt, consult your attorney.

DocuColor 8000/7000 Operator Manual

xix

Page 22

Notices

It’s illegal in Canada

Parliament, by statute, has forbidden the reproduction of the

following subjects under certain circumstances. Penalties of fines

or imprisonment may be imposed on those guilty of making such

copies.

1. Current bank notes or current paper money.

2. Obligations or securities of a government or bank.

3. Exchequer bill paper or revenue paper.

4. The public seal of Canada or of a province, or the seal of a

public body or authority in Canada, or of a court of law.

5. Proclamations, orders, regulations or appointments, or

notices thereof (with intent to falsely cause same to purport

to have been printed by the Queen’s Printer for Canada, or

the equivalent printer for a province).

6. Marks, brands, seals, wrappers or designs used by or on

behalf of the Government of Canada or of a province, the

government of a state other than Canada or a department,

board, Commission or agency established by the

Government of Canada or of a province or of a government

of a state other than Canada.

7. Impressed or adhesive stamps used for the purpose of

revenue by the Government of Canada or of a province or

by the government of a state other than Canada.

8. Documents, registers or records kept by public officials

charged with the duty of making or issuing certified copies

thereof, where the reproduction falsely purports to be a

certified copy thereof.

9. Copyrighted material or trademarks of any manner or kind

without the consent of the copyright or trademark owner.

The above list is provided for your convenience and assistance,

but it is not all inclusive, and no liability is assumed for its

completeness or accuracy. In case of doubt, consult your solicitor.

xx

DocuColor 8000/7000 Operator Manual

Page 23

Environmental notices for Canada

Terra Choice Environmental Services, Inc. of Canada has verified

that this Xerox product conforms to all applicable Environmental

Choice EcoLogo requirements for minimized impact to the

environment.

As a participant in the Environmental Choice program, Xerox

Corporation has determined that this product model meets the

Environmental Choice guidelines for energy efficiency.

Environment Canada established the Environmental Choice

program in 1988 to help consumers identify environmentally

responsible products and services. Copier, printer, digital press,

scanners, and fax products must meet energy efficiency and

emissions criteria, and exhibit compatibility with recycled supplies.

Currently, Environmental Choice has more than 1600 approved

products and 140 licensees. Xerox has been a leader in offering

EcoLogo approved products. In 1996, Xerox became the first

company licensed to use the Environmental Choice EcoLogo for

its copiers, printers, and fax machines.

Notices

DocuColor 8000/7000 Operator Manual

xxi

Page 24

Notices

Product recycling and disposal

If you are managing the disposal of your Xerox product, please

note that the product contains lead and other materials whose

disposal may be regulated due to environmental

considerations. The presence of lead is fully consistent with

global regulations applicable at the time that the product was

placed on the market.

North America

Xerox operates a worldwide equipment take-back and reuse/

recycle program. Contact your Xerox sales representative (1-800ASK-XEROX) to determine whether this Xerox product is part of

the program. For more information about Xerox environmental

programs, visit www.xerox.com/environment

For recycling and disposal information, contact your local

authorities. In the United States, you may also refer to the

Electronic Industries Alliance web site: www.eiae.org

.

.

Perchlorate Material This product may contain one or more Perchlorate-containing

devices, such as batteries. Special handling may apply, please

see www.dtsc.ca.gov/hazardouswaste/perchlorate

If your product is not part of the Xerox program and you are

managing its disposal, please follow the instructions provided in

the above paragraph.

.

xxii

DocuColor 8000/7000 Operator Manual

Page 25

European union

Other countries

Notices

Application of this symbol on your equipment is confirmation that

you must dispose of this equipment in compliance with agreed

national procedures.

In accordance with European legislation end-of-life electrical and

electronic equipment subject to disposal must be managed within

agreed procedures.

Prior to disposal, contact your local dealer or Xerox representative

for end-of-life take-back information.

Please contact your local waste authorities and request disposal

guidance.

DocuColor 8000/7000 Operator Manual

xxiii

Page 26

Notices

xxiv

DocuColor 8000/7000 Operator Manual

Page 27

1. Overview

The DocuColor 8000/7000 is a full color/black and white digital

press operating at a speed of either eighty prints per minute

(DocuColor 8000) or seventy prints per minute (DocuColor 7000).

This chapter provides the location, name, and function of the

various digital press components including:

• External components

• The User Interface

• The Control Panel

• Internal components

DocuColor 8000/7000 Operator Manual

1-1

Page 28

1. Overview

t

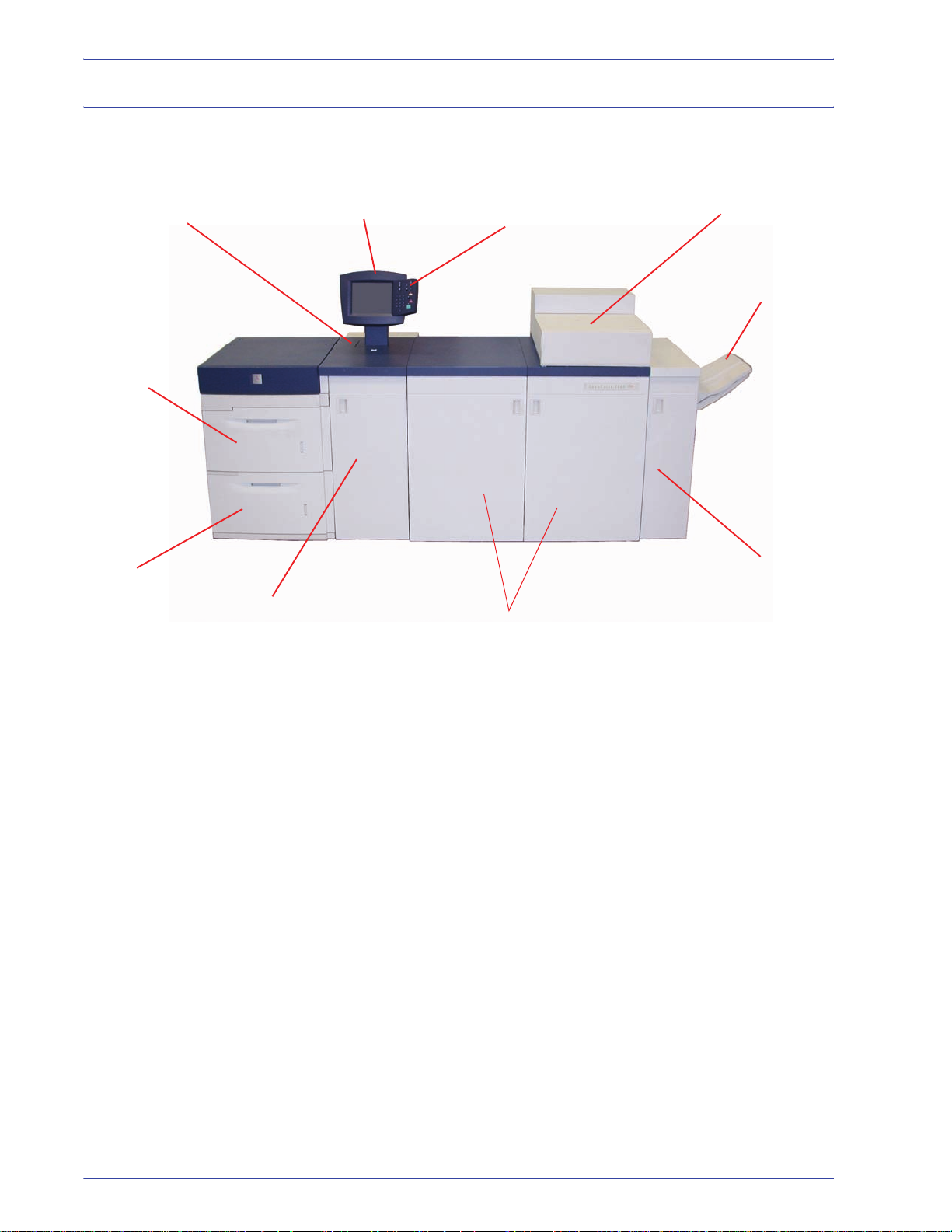

Identifying the external components

Use the illustration below to identify external components listed in

the table on the next page.

Power on/off switch

Tray 1

Tray 2

Transport Module

User Interface

Control Panel

Front Doors

Dry Ink/Toner compartmen

Offset Catch T ray

Exit Module

1-2

DocuColor 8000/7000 Operator Manual

Page 29

1. Overview

Part Description

Paper Tray 1

Paper Tray 2

Transport Module The Transport Module carries the paper from the paper trays to the upper

On/Off

On

Off

User Inte rface The User Interface contains two components: the Control Panel and the

Holds 2000 sheets of 24 lb. (90 g/m2) paper.

Holds 2000 sheets of 24 lb. (90 g/m2) paper.

paper path of the digital press. It also routes the paper from the lower paper

path of the digital press to the upper paper path of the digital press when

duplexing.

Press the Power Switch to the On position to power on the digital press.

A screen message advises of a short wait while the Fuser warms up and

the digital press runs a system check.

Press the Power Switch to the Off position to power off the digital press.

Allow the digital press to remain off for a minimum of twenty seconds

before switching the power on again.

Touch Screen.

The Touch Screen allows selections to be made by simply touching a

button on the screen.

DocuColor 8000/7000 Operator Manual

1-3

Page 30

1. Overview

Part Description

Control Panel Allows keypad selection of features. Refer to the Control Panel

section in this chapter.

Dry Ink/Toner Compartment Contains the Dry Ink/Toner cartridges. The cartridge colors from left to

right, are black, cyan, magenta, and yellow. Refer to the Maintenance

Chapter of this manual for instructions on changing the cartridges.

Offset Catch T ray (OCT) Receives completed print job. Sets are offset for easy separation.

2

Maximum capacity is 500 sheets of 24 lb. (90 g/m

) paper.

Right/Left Front Doors Houses the image transfer system for simplex and duplex printing.

Open to clear jams in the paper path in the Printing Module and at the

Fuser. Follow the instructions precisely for clearing a jam in the Fuser.

WARNING: The Fuser is extremely hot and will cause injury if

jam clearing instructions are not followed.

Exit Module Contains the decurler and the inverter. The decurler removes any curl

from the printed page. The inverter is used when duplexing or face

down output is selected.

1-4

DocuColor 8000/7000 Operator Manual

Page 31

Ecology Module

1. Overview

The Ecology Module connected to the back of the DocuColor

8000/7000 contains the environmental components (ozone and

dust filters). The Ecology Module is maintained by the Xerox

service representative.

DocuColor 8000/7000 Operator Manual

1-5

Page 32

1. Overview

Electrical Module

The Electrical Module houses software, printed wiring boards, and

power supplies. The Xerox service representative connects a

laptop to the twenty-five pin connector on the Electrical Module to

load software or run diagnostics. This connector is for the Xerox

service representative only; do not connect a computer cable to it.

CAUTION: Do not block the vents of the Electrical Module.

WARNING: Do not remove the covers or guards that are fastened

with screws. There are no parts behind these covers that you can

maintain or service.

1-6

DocuColor 8000/7000 Operator Manual

Page 33

Dry Ink/Toner Waste Bottle

The Dry Ink/Toner Waste Bottle collects the waste dry ink/toner in

the printing process. The Dry Ink/Toner Waste Bottle is customer

replaceable and located in the rear of the Exit Module.

Refer to the Maintenance Chapter of this manual for instructions

on changing the Dry Ink/Toner Waste Bottle.

Dry Ink/Toner

Waste Bottle

1. Overview

DocuColor 8000/7000 Operator Manual

1-7

Page 34

1. Overview

Ground Fault Indicator (GFI) circuit breakers

The digital press is equipped with two safety circuit breakers

called a Ground Fault Indicators (GFI). These devices trip if the

power to the digital press is interrupted.

Ecology Module

Fuser GFI

Digital Press and

SFM GFI

Fuser GFI The Fuser receives power through the Fuser GFI.

Digital Press GFI The digital press receives power through the Digital Press GFI. If

an optional Second Feeder Module is connected to the Digital

Press, then it too receives power from this GFI.

After a power outage

occurs:

Power on the digital press as soon as possible after the power is

restored, and print a job to ensure that there is no damage to the

digital press.

1-8

DocuColor 8000/7000 Operator Manual

Page 35

1. Overview

If power to the digital press is interrupted,

• Locate the circuit breakers on the Ecology Module on the back

of the digital press next to the toner waste bottle.

• If either device is tripped, the switch is in the Off position

(down). Flip the switch up.

NOTE: I f the device trips again or if power is not restored by the

above procedure, call your Xerox service representative.

CAUTION: The Pressure Pad in the Fuser remains in an up

position if power to the digital press is interrupted while the digital

press is in use. The Pressure Pad is not released from this

position until the power is restored, the Power Switch is in the On

position, and the Start button is pressed.

KEY POINT: If the Pressure Pad remains in the up position for a

prolonged period of time, print quality defects will occur.

DocuColor 8000/7000 Operator Manual

1-9

Page 36

1. Overview

User Interface (UI)

The User Interface (UI) displays messages that indicate the status

of the digital press during idle, run, or fault conditions. The UI also

displays the default screen selected in the Tools Mode by your

System Administrator.

The default screen can be either the Job Status or the Machine

Status screen.

1-10

DocuColor 8000/7000 Operator Manual

Page 37

1. Overview

Message Area

Tabs

Message Area The message area at the top of the UI displays messages

concerning the digital press status, programming conflicts, or

errors. Messages may also provide instructions for the operator.

Tabs and Functions Some UI screens display tabs which contain various selectable

options. Options are initially set to the factory default settings.

These settings can be changed by your System Administrator in

Tools Mode.

Ask your System Administrator for more informa tion regarding

these selections,

or refer to the System Administration Guide.

DocuColor 8000/7000 Operator Manual

1-11

Page 38

1. Overview

Control Panel

Your digital press has one of two Control Panels: a Control Panel

with words or one with international symbols. The function of each

button is described in the table on the following pages.

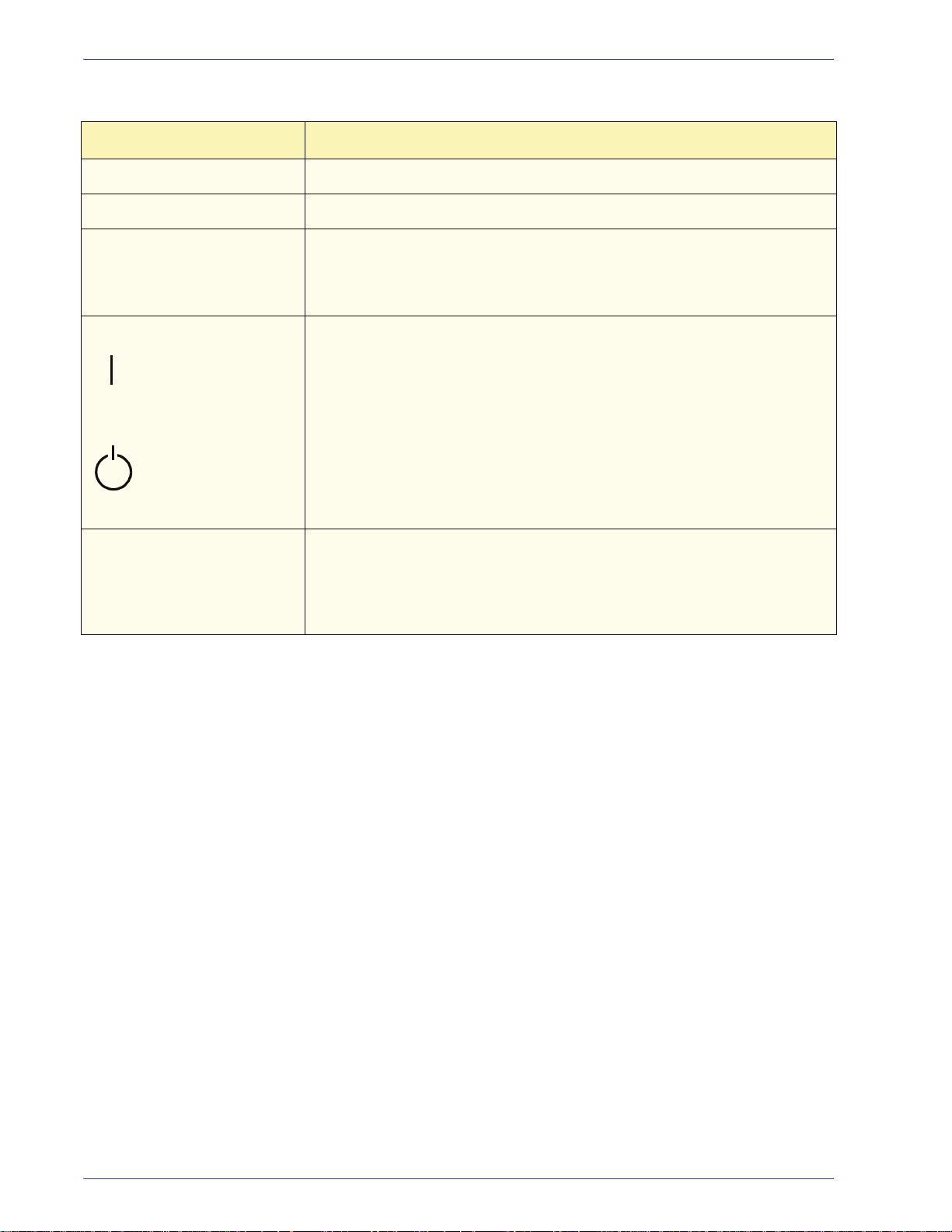

Name Function

Power Saver Lights up when the digital press is in Sleep

Mode, which lowers the Fuser temperature.

Press to return to Standby Mode.

Job Status Displays a list on the UI of the current jobs and

their status. You can hold, release, promote,

delete, and see the options selected for each job.

Language Allows you to select one of two languages to be

displayed on the UI.

Access Allows access to the password-protected Tools

Mode and the Auditron Mode.

Machine

Status

Accesses the Paper Tray, Machine Details, Error

Log, and Maintenance screens. Machine Status

is where you find the serial number for the digital

press, along with the customer support phone

numbers, and the meters that show the count for

color, black and white, color large size, and total

output.

1-12

DocuColor 8000/7000 Operator Manual

Page 39

1. Overview

Name Function

Help Displays additional information useful in

completing a task.

Clear All The Clear All button is used in the Tools

Mode for clearing certain selections or

settings. It is also used by the service

representative in the diagnostics mode.

Pause Press the Pause button to pause the

printing process in order to perform certain

maintenance procedures such as changing

the fuser oil or the dry ink/toner cartridge.

You must press Pause again to resume the

printing process.

Start The Start button is used in the Tools Mode

for certain settings. It is also used by the

service representative in the diagnostics

mode.

Keypad Use the keypad to enter your password for

access to Tools Mode. Use the keypad for

certain Tools Mode features. The keypad is

also used by the service representative in

the diagnostics mode.

DocuColor 8000/7000 Operator Manual

1-13

Page 40

1. Overview

Job Status

When you press the Job Status button, the Job Status screen is

displayed.

The Job St atus screen can be set as the initial screen default by

your System Administrator. Information about the job includes Job

Type, Current Status, Paper Size, Output Quantity (refers to the

output in sheets for a single page job and in sets or stacks for a

multiple page job), and total Number of Pages.

Jobs are numbered in the order they are received for processing.

Job order in the queue may be modified by an automatic Hold

(something has to be done to the digital press before continuing),

a Manual Hold (at user request), Promotion of one or more jobs,

or Delete a job.

1-14

DocuColor 8000/7000 Operator Manual

Page 41

1. Overview

To perform one of the following functions, you must first touch the

desired job to select it, then touch one of the buttons below.

•Touch Hold Job for a manual hold. When a job is in Hold Job

status in the queue, it does not print when it reaches the top of

the job queue. It is skipped until it is released or deleted.

•Touch Release Job to reactivate a job that is on hold in the

queue. If the job is being held due to a resource (paper, dry

ink/toner, etc.) problem, the job is not released until the

resource is provided. A job that is held due to user request can

be released by touching the Release button.

•Touch Promote Job to advance a selected job in the queue to

be processed after the job that is currently printing. Jobs are

processed on a first-in/first-out basis when multiple jobs are

promoted. Once a job has been promoted, it cannot be

skipped by jobs promoted after it.

•Touch Delete Job to delete a selected job from the queue. You

must answer “Yes” when confirmation of the delete is

requested.

•Touch Job Details for detailed information about a selected

job such as Number of Images processed, Color Mode, Paper

Tray in use, Paper Type, and Finishing.

DocuColor 8000/7000 Operator Manual

1-15

Page 42

1. Overview

Job names are truncated to sixteen characters on the Job Status

screen, which may be fewer characters than are displayed on your

color server screen.

Indicates total number

of pages for the Job List

The Up and Down arrow buttons are

selectable when the total number of jobs

exceeds one page

Name Function

Job List Shows all jobs submitted to the digital press.

Hold Job Holds a job in the print queue until released.

Release Job Releases a Hold Job to be printed.

Promote Job Enables a job to be moved in front of other jobs in

the queue.

Delete Job Deletes a selected job.

Job Details Shows the programmed options for a selected job.

Up/Down Arrows Enables scrolling through job list.

1-16

DocuColor 8000/7000 Operator Manual

Page 43

Power Save r

Language

1. Overview

Pressing the Power Saver button puts the digital press in a

reduced power consumption mode during which the Fuser

temperature is lowered. The digital press automatically goes into

this mode after no activity occurs for the factory default time of

fifteen minutes. This time can be changed in Tools to reflect a

value of 1-240 minutes

.

Refer to the System Administration Guide for further information.

The Language button toggles the UI text between two preset

languages.

DocuColor 8000/7000 Operator Manual

1-17

Page 44

1. Overview

Access

Machine Status

The Access button brings up a screen that requires a password to

enter the Tools or Auditron screens.

Refer to the System Administration Guide for further information

on Tools and Auditron features.

When the Machine Status button on the Control Panel is pressed,

the Paper Trays tab screen is displayed by default. The Machine

Status screen can be set as the initial screen default by your

System Administrator.

1-18

DocuColor 8000/7000 Operator Manual

Page 45

1. Overview

If an optional Second Feeder Module is connected to the digital

press, Trays 3 and 4 will appear in the Paper Supply column.

Screen Name Function

Paper Trays Shows the trays available, and the size, type,

weight and level of the paper in the trays.

Machine Details Displays the customer support phone number,

the serial number of the machine, and access to

the Meters screen.

Error Log Shows all error codes to assist your Xerox

service representative in solving problems with

the digital press.

Maintenance Touch the Customer Replaceable Unit button to

display the status of the Dry Ink/Toner

Cartridges, Dry Ink/Toner Waste Bottle, Charge

Corotrons and Fuser Web. A green check mark

indicates that the status is Okay. A yellow check

mark indicates a Warning. A red circle indicates

a Fault.

DocuColor 8000/7000 Operator Manual

1-19

Page 46

1. Overview

Machine Details t a b

This screen provides the telephone number to call for support, the

machine serial number and access to the meter counts.

Meters keep track of print counts. To view the print count, touch

the Meters button on the Machine Details screen. The Billing

Meters screen is displayed.

1-20

DocuColor 8000/7000 Operator Manual

Page 47

Maintenance tab

1. Overview

To reset the meters to zero, touch the Resettable Meters button.

On the following screen touch the Reset button.

Touch the Customer Replaceable Unit button on the Maintenance

screen to display a list of replaceable items and their status.

DocuColor 8000/7000 Operator Manual

1-21

Page 48

1. Overview

The Customer Replaceable Unit screen displays a gauge or a

check mark indicating the level at which the consumable is.

For example, the gauges for the dry ink/toner cartridges indicate

the amount of toner in each cartridge:

• The cartridge is full when all four bars are red.

3

• The cartridge is

• The cartridge is

• The cartridge

/4 full when three bars are red.

1

/2 full when two bars are red.

1

/4 full when one bar is red.

For the other consumables, such as the Waste Dry Ink Bottle,

each Corotron, and the Fuser Web, the following applies:

• A green check mark indicates that the level of the consumable

is adequate

• A yellow triangle alerts you that the level is low, and

• A red circle indicates that the consumable is depleted

When a consumable item is depleted, the digital press

automatically interrupts the current job and does not restart until

the consumable is replaced.

1-22

DocuColor 8000/7000 Operator Manual

Page 49

1. Overview

Your Xerox service representative uses the Service Engineer

Replaceable Unit function to check on the status items that are

replaced only by the service engineer.

These items include the fuser oil and the second bias transfer belt.

DocuColor 8000/7000 Operator Manual

1-23

Page 50

1. Overview

Help

Audio tones

Press Help for an overview of the different options displayed in the

various tabs on the UI.

There are three audio tones:

• Attention:

The Attention Tone sounds six seconds after a scan job has

been completed to remind you to remove the document from

the Scanner glass.

• Button Selection:

A single tone indicates that the button you pressed can be

selected. A double tone indicates that the button is not

available.

• Fault:

The Fault Tone indicates that the digital press is in a fault

condition and does not operate until the fault is cleared.

The Audio Tones can be deactivated or made louder or softer

through the Tools Mode.

For more information, refer to the System Administration Guide.

1-24

DocuColor 8000/7000 Operator Manual

Page 51

Alert screens

1. Overview

An Alert screen has a red bar across the screen when a

consumable product, such as Dry Ink/Toner, needs to be replaced.

An Alert screen also indicates that the digital press is unable to

make prints because of a fault condition. Follow the instructions

on the UI to resolve the problem and resume printing.

DocuColor 8000/7000 Operator Manual

1-25

Page 52

1. Overview

Identifying the internal components

Charge Corotron Assemblies

Paper Transport Drawer

Serial number label

If the digital press loses power and it is impossible to access the

Machine Details tab for the serial number, open the two main front

doors. The serial number label is in the center of the bottom frame

of the digital press.

Paper T ransport drawer

This area is where paper is aligned, the image is applied and

fused, and the paper is flipped over if duplexing is required.

Serial Number Label

1-26

DocuColor 8000/7000 Operator Manual

Page 53

Transport Module

1. Overview

Paper from all trays moves through the Transport Module to the

upper paper path in the digital press. The lower paper path

carries duplexed sheets through the Transport Module to the

digital press upper paper path.

Tray 1

Upper paper path

Tray 2

Lower paper path

DocuColor 8000/7000 Operator Manual

1-27

Page 54

1. Overview

rt

Paper path in the digital press

The paper path transfers an image to the paper and fuses it for

both the simplex and duplex selections. It has two areas, the

upper paper path and the lower paper path. The upper path is

used for both simplexing and duplexing. The lower path is used

for duplexing only. The Horizontal Transport 1 decurls the paper

when printing duplex.

Inverter

Gate

From Transport Module

To Transport Module

Alignment

Transport

Horizontal Transport 2

Vacuum

Transport

Inverter Transport

Fuser Transport

Horizontal Transport 1

To the Exit Module

From the Duplex

Inverter Transpo

1-28

DocuColor 8000/7000 Operator Manual

Page 55

Exit Module

1. Overview

A completed print passes through the Exit Module to the Offset

Catch Tray or other finishing device. The Exit Module contains a

Decurler that removes paper curl caused by the fusing

process. The Exit Module also contains an Inverter which turns

the paper over to image side two when duplexing, or when face

down output is selected.

To the

output

device

Decurler

From Digital Press

T o Inverter Transport

To Digital Press

Duplex Inverter

Transport

DocuColor 8000/7000 Operator Manual

1-29

Page 56

1. Overview

Relocating the digital press

If you need to relocate the digital press, call your Xerox customer

representative. The Installation Planning procedure must be

conducted for every new site.

Customer documentation updates

You can get the latest customer documentation updates for your

digital press by going to www.xerox.com

check this website for the latest information for your digital press.

. Be sure to periodically

1-30

DocuColor 8000/7000 Operator Manual

Page 57

2. Paper and paper trays

Recommended Materials List (RML)

Refer to the Color Materials Usage Guide, the Recommended

Materials List, and the Speciality Media Guide: Hints and Tips for

paper guidelines. The Recommended Materials List and the

Speciality Media Guide: Hi nts and T ips documents are updated on

an on-going basis to include new papers and other media. PDF

files are available at www.xerox.com

DocuColor 8000/7000 and follow the path until you reach the files

to download.

Paper handling

. Use the search parameter

x

o

r

e

X

Label on ream

instructs you to

“Print arrow side

first”

For the best performance, load paper with the seam side up in all

the paper trays. The seam side is where the ream of paper is

sealed. Refer to the label on the paper ream.

NOTE: Many suppl iers use arrows on the product labels to

indicate the preferred side to image first. Use this side (as

signaled by the arrow) as equivalent to the seam side when

loading the paper.

DocuColor 8000/7000 Operator Manual

2-1

Page 58

2. Paper and paper trays

Stored paper: • On a flat surface. Do not store paper directly on the floor, since

Many factors affect the performance of paper, including room

temperature, humidity, paper quality, dust, and the size of the

image area. If jams or paper curl problems occur, remove the

paper from the paper tray, turn it over, place it back in the paper

tray, and resume printing. If the problem is rectified, continue to

load your paper in the same manner.

If the problem is not rectified, load a new ream of paper and try the

process again. If the problem persists, your System Administrator

may go into the Tools Mode and try the different decurler

settings. If, after trying all the previous suggestions, the problem

still persists, call your Xerox representative.

For reliable digital press operation and good print quality, Xerox

recommends the following:

this increases the possibility of moisture absorption. Paper

should be stored on pallets, shelves, or in cabinets in an area

protected from extremes of temperature and humidity.

• In a low dust area.

• In a low humidity area. Humidity is one of the most important

steps to promote proper paper characteristics. Optimum paper

storage conditions include a relative humidity of 35-55%. An

increase in humidity may cause paper to develop wavy edges.

This occurs because the edges absorb moisture while the rest

of the ream remains unaffected. Wavy edges causes jams and

misfeeds.

• In an air-tight, moisture-proof container.

2-2

DocuColor 8000/7000 Operator Manual

Page 59

2. Paper and paper trays

• In a controlled temperature. The temperature in the room

where paper is stored has a significant effect on how that

paper performs in the machine. Optimum paper storage

temperature is 68-76

° F (20-24.4° C).

For additional paper handling information, refer to the Color

Materials Usage Guide.

Cutting and trimming paper Proper cutting of the paper is important. Mills that offer paper in

“cut sizes” crop their papers using state-of-the-art rotary slitters on

high performance systems. Slitting and edge trimming by circular

knives with dust removal at every cutting point prevents

contamination of the paper.

Trimming papers from parent sheets to get the desired output size

may generate dust if dull knives are used. The recommendation is

to delay trimming until printing has been finalized to prevent paper

dust generation and contamination.

If pre-printing is imperative, an in-house maintenance program,

including knife sharpness maintenance and dust removal with a

vacuum or air system, are key to achieving good results.

DocuColor 8000/7000 Operator Manual

2-3

Page 60

2. Paper and paper trays

Paper trays

Paper Trays 1 and 2 are the standard paper trays for the basic

configuration of the digital press. The following figure shows the

paper path from trays 1 and 2 through the Transport Module.

Transport

Module

Tray 1

To the digital

press

Tray 2

From the

Horizontal

(Duplex)

Transport

2-4

DocuColor 8000/7000 Operator Manual

Page 61

Paper guidelines

SEF

LEF

2. Paper and paper trays

For the best results, remember the following:

• Do not load paper or other materials above the MAX line on

the rear paper guide.

• Do not store extra reams of paper in the paper trays.

• Do not use wrinkled, torn, curled, or folded paper.

• Use the paper sizes and weights shown in the Recommended

Materials List.

• Follow the suggestions in the Specialty Media Guide: Hints

and Tips.

• Do not mix sizes or weights of paper in a paper tray.

• Ensure that the tray indicator LEDs are set for the correct

paper size, weight range, and paper type.

Copy paper is fed into the digital press in one of two positions:

long edge feed (LEF) or short edge feed (SEF). Long edge refers

to the long edge of the paper. When you see LEF, position the

paper so the long edge is fed first. Short edge refers to the short

edge of the paper. When you see SEF, position the paper so the

short edge is fed first.

NOTE: It is imperative that you load paper with the paper guides

adjusted properly. If the paper is NOT loaded properly, it skews

and jams occur.

DocuColor 8000/7000 Operator Manual

2-5

Page 62

2. Paper and paper trays

Curl

When paper is exposed to heat, the paper loses moisture and

curls toward the heat source. High coverage jobs tend to curl more

due to the toner plastification effect on the paper surface. The

system tries to reduce this by using mechanical devices within the

paper path called decurlers.

Your system has been designed with an automatic curl control

system that uses information such as: the amount of coverage on

the page, paper weight, whether the paper is coated or uncoated,

and the current humidity and temperature to determine the

amount of pressure needed at the different decurlers to reduce

output curl.

If you are experiencing excessive curl, remove the paper from the

tray, turn it over and replace it in the tray. If the curl is still

excessive, refer to the System Administration Guide, Tools Mode

chapter, to change the decurler settings to accommodate the

environmental and pape r conditions.

2-6

DocuColor 8000/7000 Operator Manual

Page 63

2. Paper and paper trays

Paper specifications

Paper All Paper Trays

Minimum Paper Size 182mm x 182mm

(7.16 x 7.16”)

Maximum Paper Size 320mm x 488mm

(12.6 x 19.2”)

Standard Sizes B5 LEF/SEF A4 LEF/SEF

B4 SEF A3 SEF

8 x 10” LEF 8.5 x 11” LEF/SEF

8.5 x 13” SEF 8.5 x 14” SEF

11 x 17” SEF 12 x 18” SEF

Kai8 SEF Kai16 LEF

12.6 x 17.7” SEF

X

12.6 x 19.2” SEF

X

Paper Weight Range

Transparencies

H

60 - 300 g/m

Yes

2

(A4 LEF or 8.5 x 11” LEF)

LabelsH Yes

Transfer Paper

Coated Paper

Tabbed Inserts

H

u b

D

No

Yes

Yes

Drilled Yes: 2, 3, 4 hole

X

Refer to the Non-Standard Size Paper section in this chapter.

D

Refer to the Tabbed Inserts section in this chapter.

H

Refer to the Recommended Materials List and the Speciality

Media Guide for guidelines.

u

Duplex is limited to paper that is 220 g/m2 or less.

b

L80 g/m2 cannot duplex in high humidity. L85 g/m2 coated media

is not allowed.

DocuColor 8000/7000 Operator Manual

2-7

Page 64

2. Paper and paper trays

Tray capacity

Duplexing

Transparency guidelines

All paper trays have a capacity of 2000 sheets of 24 lb. (90 g/m2)

paper.

The DocuColor 8000/7000 duplexes prints from all paper trays up

to 220 g/m

2

. The system does not duplex media larger than 12.6 x

18 inch (321.1 x 458.1 mm).

Transparencies can be run from all the paper trays.

Use only the transparencies recommended:

• Xerox Removable Paper Stripe: USA and Canada, 3R5765;

Xerox Europe, 3R93179.

• Load transparencies into a tray with the paper stripe side

facing DOWN and with the stripe as the leading edge. (The

leading edge is the edge that feeds into the digital press first.)

• Do not mix paper and transparencies in a tray. Jams may

occur.

• Ensure that Transparency is selected in the Paper Weight

section at the top/front of the paper tray.

2-8

DocuColor 8000/7000 Operator Manual

Page 65

Tabbed inserts

2. Paper and paper trays

Tabbed Inserts can be loaded into the paper trays as NonStandard paper.

• When loading, the non-tabbed, short edge of the tabbed insert

should be the lead edge to the digital press.

• If a jam occurs while running tabbed sets, there is no recovery

procedure.

• You have to manually reassemble your originals and

prints, determine where the job left off, and resume printing

or cancel the job and start again.

• The size of the tabbed insert should be 9 x 11 inch (229 x 279

mm) for letter size tabs (223.5 x 296 mm for A4 equivalent

tabs).

• The correct weight of the insert should be selected on the

tray.

• Select Non-Standard size on the paper tray and on the UI,

Tools Mode, input 11 inches or 296 mm for A4 as the X axis

and 9 inches or 223.5 mm for A4 as the Y axis dimensions for

SEF.

Refer to the System Administration Guide for the procedure to

program non-standard size paper.

DocuColor 8000/7000 Operator Manual

2-9

Page 66

2. Paper and paper trays

Drilled paper

Three-hole drilled paper can be run from all the trays either LEF or

SEF with the holes facing any direction.

NOTE: If you are stapling 3-hole drilled paper with the optional

High Capacity Stacker Stapler 80 (HCSS80), refer to the

Accessories chapter for paper loading instructions, based on the

position of the staple.

Drilled paper should be run in the Simplex (1-sided) and Duplex

(2-sided) orientations shown below to avoid paper jams caused by

the holes not aligning correctly with the paper sensor in the press.

Simplex Print Jobs

Load the drilled paper into any tray in the Long Edge Feed (LEF)

direction. Refer to the following illustration:

Rear of paper tray

Duplex Print Jobs

Load drilled paper into any tray in either the Long Edge Feed

(LEF) or Short Edge Feed (SEF) direction. Refer to the following

illustration:

LEF direction

Rear of paper tray

Paper

tray

guides

Front of paper tray

Paper

tray

guides

Front of paper tray

Right

side

Right

side

SEF direction

Rear of paper tray

Paper

tray

guides

Front of paper tray

2-10

NOTE: If you are stapling 3-hole drilled paper with the optional

High Capacity Stacker Stapler 80 (HCSS80), refer to the

Accessories chapter

(see page 3-27 and page 3-43) for paper

loading instructions, based on the positi on of the staple.

DocuColor 8000/7000 Operator Manual

Page 67

Letterhead

Different inks and dry inks/toners are used to produce preprinted

letterhead that may not pass through the digital press intact.

Refer to the Specialty Medi a Guide: Hint s a nd T ip s fo r inf ormati on

on using preprinted letterhead p aper.

Nonstandard size paper

Nonstandard size paper is identified as any paper for which there

is no paper guide setting within the minimum and maximum sizes

for the trays: 7.16 to 12.6 inch LEF or 7.16 to 19.2 inch SEF (182 320 mm LEF or 182 x 488 mm SEF)

Non-Standard size paper can be loaded into all the trays. The

Non-Standard setting must be selected on the top/front of the

paper tray.

2. Paper and paper trays

Refer to the System Administration Guide for the procedure to

program a Non-Standard size paper to be the default setting for a

particular tray .

DocuColor 8000/7000 Operator Manual

2-11

Page 68

2. Paper and paper trays

Auto Tray Switching

Auto Paper Selection

When Auto Tray Switching (ATS) is activated in the Tools Mode,

the digital press automatically switches to another tray containing

paper of the identical size, weight, type, and feeding orientation

(SEF or LEF) when the tray being used is empty.

Refer to the System Administration Guide for the instruction on

enabling ATS.

Auto Paper Selection (APS) can be enabled in the Tools

Mode. When enabled, the digital press automatically selects the

paper tray containing the correct size paper without a specific

paper tray being selected.

Refer to the System Administration Guide for information on how

to enable Auto Paper Selection or t o sel ect a particular tray as the

default setting.

When the Single Paper Weight setting in Tools Mode is selected