Page 1

Xerox DocuPrint EPS

Using LCDS Print Description Language

701P21091

Version 3.7

May 2003

Page 2

Xerox Corporation

Global Knowledge and Language Services

West Coast Operations

701 South Aviation Boulevard, ESM1-058

El Segundo, CA 90245

©2003 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrighted

material and information now allowed by statutory or judicial law or hereinafter

granted including without limitation, material generated from the software

programs that are displayed on the screen such as styles, templates, icons,

screen displays, looks, etc.

Printed in the U.S.A., U.K., and France.

XEROX, XEROX Europe, and XEROX Canada Limited, The Document

Company, the stylized X, and all names and identifying numbers used in

connection with Xerox products mentioned in this publication are trademarks

of XEROX CORPORATION. All non-Xerox brands and product names are

trademarks or registered trademarks of their respective companies. Other

company trademarks are also acknowledged.

While the information in this guide is correct at the time of this publication,

Xerox reserves the right at any time to change the information without notice.

Changes are made periodically to this document. Changes and technical

updates will be added in subsequent editions.

Page 3

Table of contents

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

DocuPrint 100/115/135/155/180 EPS documentation . . . . . . . . xxv

DocuPrint 75/90 EPS documentation . . . . . . . . . . . . . . . . . . . . .xxvi

1. PDL principles and procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Enabling PDL features and functions . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

PDL command structure and components . . . . . . . . . . . . . . . . . . . . . . 1-3

Command lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Components of a command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Command syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Syntax rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Command syntax conventions . . . . . . . . . . . . . . . . . . . . 1-14

Sample PDL commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

PDL command categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

The Job Source Library (JSL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

What does a JSL specify? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

JSL command levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

JDL name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

JDL or system level commands . . . . . . . . . . . . . . . . . . . 1-21

Coding system level commands with identifiers . 1-21

Coding other system level commands . . . . . . . . 1-24

Catalog level commands . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Using LCDS Print Description Language iii

Page 4

Table of contents

Dynamic job descriptor entries (DJDEs) . . . . . . . . . . . . . . . . . . . . . . . 1-72

Dumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-73

Compatibility with other Xerox laser printing systems that use PDL . . 1-76

Job or JDE level commands . . . . . . . . . . . . . . . . . . . . . 1-26

Coding job or JDE level commands . . . . . . . . . . 1-27

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Ending a JSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Sample completed JSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Before creating a JSL: considerations and decisions . . . . . . . . 1-31

Input data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Output specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Interactions between JSLs, catalogs, and jobs . . . . . . . 1-34

Paper sizes and page frames . . . . . . . . . . . . . . . . . . . . 1-34

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Overriding PDL commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Coding a JSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Short JSL coding procedure . . . . . . . . . . . . . . . . . . . . . 1-50

Full JSL coding procedure . . . . . . . . . . . . . . . . . . . . . . . 1-55

Sample online JSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

Sample offline JSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

Compiling a JSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

Compiling procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

Files produced by the compilation procedure . . . . . . . . 1-68

Correcting errors in a JSL . . . . . . . . . . . . . . . . . . . . . . . 1-69

Benefits of using DJDEs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-72

Online dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-73

Starting and ending online dump sessions . . . . . . . . . . 1-73

Online dump format and content . . . . . . . . . . . . . . . . . . 1-73

Offline dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

Starting and ending tape dump sessions . . . . . . . . . . . . 1-75

Offline dump format and content . . . . . . . . . . . . . . . . . . 1-75

Printing highlight color applications on DP EPS . . . . . . . . . . . . 1-78

Other Xerox monochrome LPS jobs . . . . . . . . . . . . . . . . . . . . . 1-80

2. Specifying input parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Input data streams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Input processing functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Input processing online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Forms control buffer (FCB) and vertical format control

processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Example of an online JSL . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Input processing offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

iv Using LCDS Print Description Language

Page 5

Table of conte nts

Host computer tape formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Tape codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Packed data formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Record formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Record structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Multivolume processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Input processing command descriptions . . . . . . . . . . . . . . . . . . . . . . . 2-11

BLOCK command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

BLOCK command parameters . . . . . . . . . . . . . . . . . . . . 2-12

BLOCK ADJUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

BLOCK CONSTANT . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

BLOCK FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

BLOCK LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

BLOCK LMULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

BLOCK LTHFLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

BLOCK OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

BLOCK POSTAMBLE . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

BLOCK PREAMBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

BLOCK ZERO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

BLOCK command: points to note . . . . . . . . . . . . . . . . . 2-18

Block command example . . . . . . . . . . . . . . . . . . . . . . . . 2-18

CODE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

CODE command parameters . . . . . . . . . . . . . . . . . . . . 2-19

CODE ASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

CODE DEFAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

CODE SPACECODE . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

DBCODE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

DBCODE command parameters . . . . . . . . . . . . . . . . . . 2-23

DBCODE ASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

DBCODE DEFAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

DBCODE command: point to note . . . . . . . . . . . . . . . . . 2-24

IDEN command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

IDEN command parameters . . . . . . . . . . . . . . . . . . . . . 2-25

IDEN DJPCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

IDEN OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

IDEN OPRINFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

IDEN PREFIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

IDEN SKIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

IDEN command example . . . . . . . . . . . . . . . . . . . . . . . . 2-28

KCODE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

KCODE command parameters . . . . . . . . . . . . . . . . . . . 2-28

KCODE ASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

KCODE DEFAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

KCODE command: point to note . . . . . . . . . . . . . . . . . . 2-30

PCC command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

PCC command parameters . . . . . . . . . . . . . . . . . . . . . . 2-30

Using LCDS Print Description Language v

Page 6

Table of contents

PCC ADVTAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

PCC ASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

PCC DEFAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

PCC INITIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

PCC MASK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

PCC command: points to note . . . . . . . . . . . . . . . . . . . . 2-35

PCC command example . . . . . . . . . . . . . . . . . . . . . . . . 2-35

RECORD command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Record command parameters . . . . . . . . . . . . . . . . . . . . 2-36

RECORD ADJUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

RECORD CONSTANT . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

RECORD FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

RECORD LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

RECORD LMULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

RECORD LTHFLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

RECORD OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

RECORD POSTAMBLE . . . . . . . . . . . . . . . . . . . . . . . . 2-40

RECORD PREAMBLE . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

RECORD STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . 2-41

RECORD command: Points to note . . . . . . . . . . . . . . . 2-41

RECORD command example . . . . . . . . . . . . . . . . . . . . 2-42

SEFFNT command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

SEFFNT command parameters . . . . . . . . . . . . . . . . . . . 2-45

SEFFNT SEFMAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

SEFFNT MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

SEFFNT command: points to note . . . . . . . . . . . . . . . . 2-47

SEFFNT command examples . . . . . . . . . . . . . . . . . . . . 2-48

TCODE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

TCODE command parameters . . . . . . . . . . . . . . . . . . . 2-50

TCODE DEFAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

TCODE TASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

TCODE TRESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

TCODE command examples . . . . . . . . . . . . . . . . . . . . . 2-53

VOLUME command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

VOLUME command parameters . . . . . . . . . . . . . . . . . . 2-54

VOLUME BMULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

VOLUME CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

VOLUME DBCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

VOLUME DBCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

VOLUME EMTYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

VOLUME EOV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

VOLUME EXPAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

VOLUME HOST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

VOLUME KANJI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

VOLUME KCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

VOLUME LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

vi Using LCDS Print Description Language

Page 7

Table of conte nts

VOLUME LCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

VOLUME LPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

VOLUME MAXLAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

VOLUME MINLAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

VOLUME OPTIMIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

VOLUME OSCHN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

VOLUME OSHDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

VOLUME OSTLP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

VOLUME RMULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

VOLUME TCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

VOLUME UNPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

VOLUME VCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

VOLUME command examples . . . . . . . . . . . . . . . . . . . 2-71

3. Using logical processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Types of commands for logical processing . . . . . . . . . . . . . . . . . . . . . . 3-1

Test expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Coding a test expression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Logical processing commands that have TEST parameters . . . 3-4

Commands that define criteria and constants . . . . . . . . . . . . . . . . . . . . 3-4

TABLE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

TABLE command parameters . . . . . . . . . . . . . . . . . . . . . 3-5

TABLE CONSTANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

TABLE MASK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

TABLE command: points to note . . . . . . . . . . . . . . . . . . . 3-7

TABLE command examples . . . . . . . . . . . . . . . . . . . . . . 3-7

CRITERIA command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

CRITERIA command modes . . . . . . . . . . . . . . . . . . . . . . 3-9

Using the CRITERIA command . . . . . . . . . . . . . . . . . . . 3-10

String comparisons . . . . . . . . . . . . . . . . . . . . . . . 3-11

CRITERIA command parameters . . . . . . . . . . . . . . . . . 3-14

CRITERIA CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

CRITERIA CONSTANT . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

CRITERIA LINENUM . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

CRITERIA VALUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Logical processing command descriptions . . . . . . . . . . . . . . . . . . . . . 3-22

BANNER command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

BANNER command parameters . . . . . . . . . . . . . . . . . . 3-23

BANNER HCOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

BANNER HJOBNO . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

BANNER HRPTNA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

BANNER TCOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

BANNER TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

BANNER TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

BANNER command: points to note . . . . . . . . . . . . . . . . 3-27

BANNER command examples . . . . . . . . . . . . . . . . . . . . 3-27

Using LCDS Print Description Language vii

Page 8

Table of contents

BSELECT and BDELETE commands . . . . . . . . . . . . . . . . . . . 3-28

BSELECT and BDELETE TEST parameter . . . . . . . . . 3-28

BSELECT and BDELETE commands: points to note . . 3-29

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

LMODIFY command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

LMODIFY command parameters . . . . . . . . . . . . . . . . . . 3-31

LMODIFY INK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

LMODIFY SELECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

LMODIFY TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Points to note: LMODIFY command . . . . . . . . . . . . . . . 3-33

RAUX command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

RAUX TEST parameter . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

RAUX command: points to note . . . . . . . . . . . . . . . . . . 3-34

RAUX command example . . . . . . . . . . . . . . . . . . . . . . . 3-34

RDELETE and RSELECT commands . . . . . . . . . . . . . . . . . . . 3-35

RSELECT and RDELETE TEST parameter . . . . . . . . . 3-35

RDELETE and RSELEC T commands: point to note . . 3-36

RDELETE command example . . . . . . . . . . . . . . . . . . . . 3-36

RFEED command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

RFEED TEST parameter . . . . . . . . . . . . . . . . . . . . . . . . 3-37

RFEED command: points to note . . . . . . . . . . . . . . . . . 3-38

ROFFSET command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

ROFFSET command parameters . . . . . . . . . . . . . . . . . 3-40

ROFFSET PASSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

ROFFSET TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

ROFFSET command: points to note . . . . . . . . . . . . . . . 3-41

ROFFSET command example . . . . . . . . . . . . . . . . . . . . 3-42

RPAGE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

RPAGE command parameters . . . . . . . . . . . . . . . . . . . 3-43

RPAGE SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

RPAGE TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

RPAGE WHEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

RPAGE command: points to note . . . . . . . . . . . . . . . . . 3-46

RPAGE command examples . . . . . . . . . . . . . . . . . . . . . 3-46

RRESUME and RSUSPEND commands . . . . . . . . . . . . . . . . . 3-49

RSUSPEND and RRESUME command parameters . . . 3-49

RSUSPEND and RRESUME BEGIN . . . . . . . . . . . . . . . 3-49

RSUSPEND and RRESUME TEST . . . . . . . . . . . . . . . . 3-50

RRESUME and RSUSPEND commands: points to

note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

RSUSPEND and RRESUME example . . . . . . . . . . . . . 3-52

RSTACK command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

RSTACK delimiter modes . . . . . . . . . . . . . . . . . . . . . . . 3-53

Delimiter on accounting page . . . . . . . . . . . . . . . . . . . . 3-54

viii Using LCDS Print Description Language

Page 9

Table of conte nts

Status display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

RSTACK command parameters . . . . . . . . . . . . . . . . . . 3-55

RSTACK ACCTINFO . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

RSTACK DELIMITER . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

RSTACK HRPTNA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

RSTACK PRINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

RSTACK TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

RSTACK command: points to note . . . . . . . . . . . . . . . . 3-58

RSTACK command example . . . . . . . . . . . . . . . . . . . . . 3-59

4. Specifying pr int format parameters. . . . . . . . . . . . . . . . . . . . . . . .4-1

Print format command descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

ABNORMAL command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

ABNORMAL command parameters . . . . . . . . . . . . . . . . . 4-2

ABNORMAL ACCTFEED . . . . . . . . . . . . . . . . . . . . . . . . 4-2

ABNORMAL CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

ABNORMAL ERROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

ABNORMAL IMISMATCH . . . . . . . . . . . . . . . . . . . . . . . . 4-5

ABNORMAL ISUBSTITUTE . . . . . . . . . . . . . . . . . . . . . . 4-6

ABNORMAL OTEXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ABNORMAL REP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

ABNORMAL SECURITY . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

ACCT command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

ACCT command parameters . . . . . . . . . . . . . . . . . . . . . . 4-9

ACCT DEPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

ACCT USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

ACCT command: points to note . . . . . . . . . . . . . . . . . . . 4-10

ACCT command example . . . . . . . . . . . . . . . . . . . . . . . 4-10

CME command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

CME command parameters . . . . . . . . . . . . . . . . . . . . . . 4-12

CME CONSTANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

CME FONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

CME INK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

CME LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

CME POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

CME command: points to note . . . . . . . . . . . . . . . . . . . 4-16

CME command examples . . . . . . . . . . . . . . . . . . . . . . . 4-18

IDR command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

IDR command parameters . . . . . . . . . . . . . . . . . . . . . . . 4-20

IDR ICATALOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

IDR ILIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

IDR PALETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

LINE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

LINE command parameters . . . . . . . . . . . . . . . . . . . . . . 4-22

LINE BASELINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

LINE BLANKTYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Using LCDS Print Description Language ix

Page 10

Table of contents

LINE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

LINE FCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

LINE FDATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

LINE FONTINDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

LINE GDATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

LINE INKINDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

LINE LPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

LINE MARGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

LINE OVERPRINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

LINE PCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

LINE PCCTYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

LINE VFU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

LINE command: points to note . . . . . . . . . . . . . . . . . . . 4-36

LINE command examples . . . . . . . . . . . . . . . . . . . . . . . 4-37

MESSAGE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

MESSAGE command parameters . . . . . . . . . . . . . . . . . 4-39

MESSAGE ITEXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

MESSAGE OTEXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

MESSAGE command: points to note . . . . . . . . . . . . . . . 4-41

MESSAGE command example . . . . . . . . . . . . . . . . . . . 4-41

OUTPUT command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

OUTPUT command parameters . . . . . . . . . . . . . . . . . . 4-42

OUTPUT BFORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

OUTPUT BINDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

OUTPUT COLLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

OUTPUT COPIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

OUTPUT COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

OUTPUT CYCLEFORMS . . . . . . . . . . . . . . . . . . . . . . . 4-49

OUTPUT DENSITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

OUTPUT DESTINATION . . . . . . . . . . . . . . . . . . . . . . . . 4-51

OUTPUT DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

OUTPUT FACEUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

OUTPUT FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

OUTPUT FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

OUTPUT FORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

OUTPUT GRAPHICS . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

OUTPUT IDFAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

OUTPUT IDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

OUTPUT IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

OUTPUT INVERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

OUTPUT IRESULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

OUTPUT LOGO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

OUTPUT MODIFY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

OUTPUT NTO1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

OUTPUT NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

OUTPUT OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

x Using LCDS Print Description Language

Page 11

Table of conte nts

OUTPUT OSTK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

OUTPUT PAPERSIZE . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

OUTPUT PURGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

OUTPUT SF1FUNCTION . . . . . . . . . . . . . . . . . . . . . . . 4-75

OUTPUT SF2FUNCTION . . . . . . . . . . . . . . . . . . . . . . . 4-76

OUTPUT SHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

OUTPUT SIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

OUTPUT STAPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

OUTPUT STOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

OUTPUT SYSPPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-81

OUTPUT TMODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

OUTPUT TRANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

OUTPUT UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

OUTPUT XSHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

OUTPUT command: point to note . . . . . . . . . . . . . . . . . 4-89

OUTPUT command examples . . . . . . . . . . . . . . . . . . . . 4-89

PDE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Standard PDEs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

PDE command parameters . . . . . . . . . . . . . . . . . . . . . . 4-93

PDE BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-93

PDE FONTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

PDE PMODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

PDE command: points to note . . . . . . . . . . . . . . . . . . . . 4-98

PDE command examples . . . . . . . . . . . . . . . . . . . . . . . 4-98

ROUTE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-99

ROUTE command parameters . . . . . . . . . . . . . . . . . . . 4-99

ROUTE RFORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-100

ROUTE RTEXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-100

ROUTE command example . . . . . . . . . . . . . . . . . . . . . 4-103

STOCKSET command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

STOCKSET command parameters . . . . . . . . . . . . . . . 4-104

STOCKSET ASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . 4-104

STOCKSET INIFEED . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

STOCKSET SYSPAGE . . . . . . . . . . . . . . . . . . . . . . . . 4-105

STOCKSET command example . . . . . . . . . . . . . . . . . 4-107

VFU command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

VFU command parameters . . . . . . . . . . . . . . . . . . . . . 4-108

VFU ASSIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

VFU BOF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-109

VFU TOF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-109

VFU command: points to note . . . . . . . . . . . . . . . . . . . 4-110

VFU command example . . . . . . . . . . . . . . . . . . . . . . . 4-111

5. Using Dynamic Job Descriptor Entries (DJDEs) . . . . . . . . . . . . .5-1

Using the IDEN command to enable DJDEs . . . . . . . . . . . . . . . . . . . . . 5-1

Specifying DJDE records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Using LCDS Print Description Language xi

Page 12

Table of contents

Application of DJDEs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

DJDE operator information pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Restrictions on job parameter modification . . . . . . . . . . . . . . . . . . . . . . 5-6

Considerations and cautions for using DJDEs . . . . . . . . . . . . . . . . . . . 5-8

Types of DJDEs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

DJDE descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

ALTER DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

ALTER DJDE: point to note . . . . . . . . . . . . . . . . . . . . . . 5-15

Examples of ALTER DJDE . . . . . . . . . . . . . . . . . . . . . . 5-15

ASSIGN DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

ASSIGN DJDE: points to note . . . . . . . . . . . . . . . . . . . . 5-16

BATCH DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

BATCH DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-17

BEGIN DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

BEGIN DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-18

BFORM DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

BFORM DJDE: points to note . . . . . . . . . . . . . . . . . . . . 5-19

BOF DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

BOF DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . . 5-20

C (text) DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

C (text) DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-21

CANCEL DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

COLLATE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

COLLATE DJDE: point to note . . . . . . . . . . . . . . . . . . . 5-22

COPIES DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

COPIES DJDE: points to note . . . . . . . . . . . . . . . . . . . . 5-23

DATA DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

DATA DJDE: point to note . . . . . . . . . . . . . . . . . . . . . . . 5-23

DEPT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

DEPT DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . 5-24

DESTINATION DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

DESTINATION DJDE: points to note . . . . . . . . . . . . . . . 5-25

DUPLEX DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

END DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

END DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . . 5-26

EOF DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

EOF DJDE: point to note . . . . . . . . . . . . . . . . . . . . . . . . 5-26

FEED DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

FDATA DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

FILE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

FILE DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . . 5-29

FILE DJDE processing . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

FONTINDEX DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

FONTINDEX DJDE: points to note . . . . . . . . . . . . . . . . 5-34

FONTS DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

FONTS DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-36

xii Using LCDS Print Description Language

Page 13

Table of conte nts

FORMAT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

FORMAT DJDE: points to note . . . . . . . . . . . . . . . . . . . 5-37

FORM[S] DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

FORM[S] DJDE: point to note . . . . . . . . . . . . . . . . . . . . 5-38

GDATA DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

GRAPHIC DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

GRAPHIC DJDE: points to note . . . . . . . . . . . . . . . . . . 5-41

ICATALOG DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

ICATALOG DJDE example . . . . . . . . . . . . . . . . . . . . . . 5-42

IDFAULT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

IDFAULT DJDE: point to note . . . . . . . . . . . . . . . . . . . . 5-43

IDR DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

ILIST DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

ILIST DJDE example . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

IMAGE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

INKINDEX DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

INVERT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

IRESULT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

IRESULT DJDE: points to note . . . . . . . . . . . . . . . . . . . 5-47

ITEXT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

ITEXT DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . 5-48

JDE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

JDE DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . . 5-49

JDL DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

JDL DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . . 5-50

LOGO DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

LOGO DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-52

LPI DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

LPI DJDE: point to note . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

MAP DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

MARGIN DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

MARGIN DJDE: points to note . . . . . . . . . . . . . . . . . . . 5-54

MODIFY DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

MODIFY DJDE: points to note . . . . . . . . . . . . . . . . . . . . 5-55

NUMBER DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

NUMBER DJDE: point to note . . . . . . . . . . . . . . . . . . . . 5-56

NUMBER DJDE example . . . . . . . . . . . . . . . . . . . . . . . 5-58

OTEXT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

OTEXT DJDE: point to note . . . . . . . . . . . . . . . . . . . . . . 5-59

OVERPRINT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

OVERPRINT DJDE: points to note . . . . . . . . . . . . . . . . 5-60

PALETTE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

PALETTE DJDE example . . . . . . . . . . . . . . . . . . . . . . . 5-61

PMODE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

PMODE DJDE: point to note . . . . . . . . . . . . . . . . . . . . . 5-61

RFORM DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

Using LCDS Print Description Language xiii

Page 14

Table of contents

RFORM DJDE: points to note . . . . . . . . . . . . . . . . . . . . 5-62

RTEXT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

RTEXT DJDE example . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

SAVE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

SAVE DJDE: point to note . . . . . . . . . . . . . . . . . . . . . . . 5-64

SEFMAP DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

SEFMAP DJDE: points to note . . . . . . . . . . . . . . . . . . . 5-65

SEFMAP DJDE examples . . . . . . . . . . . . . . . . . . . . . . . 5-65

SF1FUNCTION DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

SF2FUNCTION DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

SHIFT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

SHIFT DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-68

SIDE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

SIDE DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . 5-69

STOCKS DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

STOCKS DJDE: point to note . . . . . . . . . . . . . . . . . . . . 5-70

TMODE DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

TOF DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

TOF DJDE: points to note . . . . . . . . . . . . . . . . . . . . . . . 5-71

TRANS DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

TRANS DJDE: points to note . . . . . . . . . . . . . . . . . . . . . 5-72

XMP DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

XSHIFT DJDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

6. Using PDL commands for graphics. . . . . . . . . . . . . . . . . . . . . . . .6-1

Input for graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Error handling for graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Graphic processing modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Formats for graphic data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Impact of graphics on system performance . . . . . . . . . . . . . . . . . . . . . 6-6

Graphics features restricti ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

A. PDL command and DJDE summary. . . . . . . . . . . . . . . . . . . . . . . .A-1

Summary table of PDL commands and DJDEs . . . . . . . . . . . . . . . . . . A-2

B. PDL command quick referenc e . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

PDL command Quick Reference table . . . . . . . . . . . . . . . . . . . . . . . . . B-2

C. Character code assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

IBM BCD code set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Honeywell/Bull 200 and 2000 BCD code set . . . . . . . . . . . . . . . . . . . . . C-2

Honeywell/Bull 6000 BCD code set . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Fieldata translation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

UNIVAC ASCII character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Standard ASCII character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Standard EBCDIC character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

xiv Using LCDS Print Description Language

Page 15

Table of conte nts

Xerox EBCDIC to extended ASCII hexadecimal translation values . . . C-7

D. Offline specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Input unpacking examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Valid host computer and label specifications . . . . . . . . . . . . . . . . . . . . D-2

Host system JDLs on system software CD . . . . . . . . . . . . . . . . . . . . . . D-3

LPS tape label format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glossary-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

Using LCDS Print Description Language xv

Page 16

Table of contents

xvi Using LCDS Print Description Language

Page 17

Laser safety

WARNING

Adjustments, use of controls, or performance of procedures

other than those specified herein may result in hazardous

light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance stan dards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuPrint printers

do not emit hazardous radiation, because the laser beam is

completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must

be removed with a tool. DO NOT REMOVE LABELED PANELS

OR PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

Ozone information: U. S. only

This product produces ozone during normal operation. The

amount of ozone produced depends on print volume. Ozone is

heavier than air. The environmental parameters specified in the

Xerox installation instructions ensure that concentration levels

are within safe limits. If you need additional information

concerning ozone, call 1-800-828-6571 to request the Xerox

publicat ion 600P83222, OZONE.

Using LCDS Print Description Language xvii

Page 18

Laser safety

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with

environmental standards. Please observe the following

precautions to ensure your continued safety.

Improper connection of the equipment grounding conductor

may result in risk of electrical shock.

• Always connect equipment to a properly grounded electrical

• Never use a ground adapter pl ug t o con nect equipment to an

WARNING

outlet. If in doubt, have the outlet checked by a qualified

electrician.

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the printer controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. Th ere are no oper ator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning mater ials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusu al noises or

odors. Disconnect the power cord from the electrical outlet

and call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Produc t

Safety at the following toll-free number in the United States:

1-800-828-6571

xviii Using LCDS Print Description Language

Page 19

For customers outside the United St ates, contact your local

Xerox representative or operating company.

Operation safety: Eur o pe

This Xerox product and supplies ar e manufactured, tested and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorized alteration, which may include the addition of

new functions or conn ection of externa l devices, may impact the

product certification.

Please contact your Xerox representative for more information.

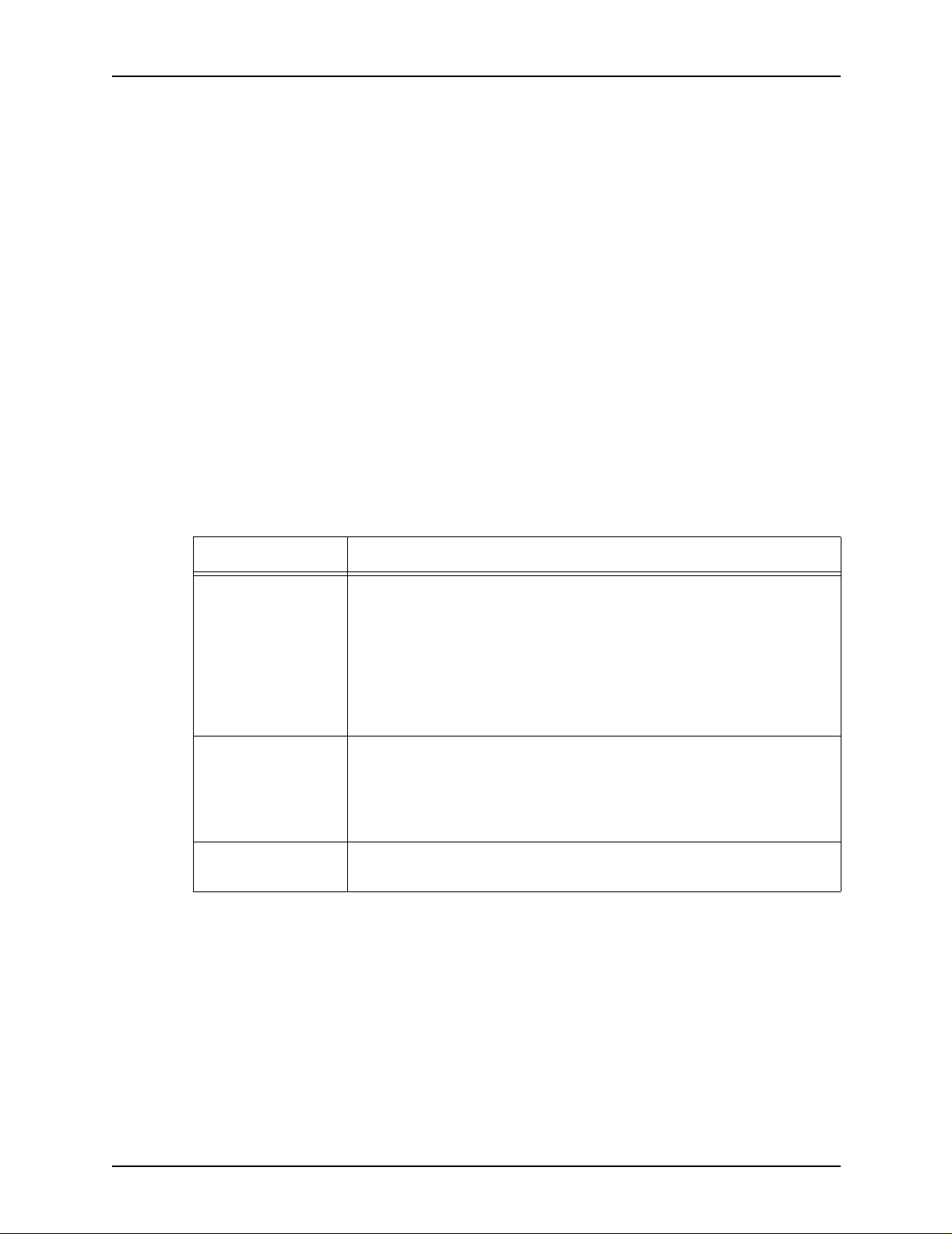

Warning markings

Laser safety

All warning ins tructions marked on or supplie d with the product

should be followed.

This WARNING alerts users to areas of the product where there

is the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surf ace s, which should not be touched.

Electrical supply

This product shall be operated from the type of electrical supply

indicated on the data plate label of the produc t. If you are not

sure that your electrical supply meets the requirements, please

consult your local power co mpany for advice.

Using LCDS Print Description Language xix

Page 20

Laser safety

WARNING

This product must be connected to a protective earth

circuit.

This product is supplied with a plug that has a protect ive earth

pin. This plug fits only into an earthed electrical outlet. This is a

safety f eature . Always co nnect equipment to a properly gr ounded

electrical outlet. If in doubt, ha ve the ou tlet check ed b y a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Ventilation

Slots and openings in the enclosure of the product are provided

for ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheating.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to restrict operator access to

safe areas only. Operator access to hazardous areas is

restricted with covers or guards, which would require a tool to

remove. Never remove these covers or guards.

xx Using LCDS Print Description Language

Page 21

Maintenance

Any operator product maintenance procedures will be described

in the user docume ntation supplied with the product . Do not

carry out any maintenance on the product, which is not

described in the customer documentation.

Before cleaning your product

Before cleaning this product, unplug the product from the

electrical outlet. Always use materials specifically designated for

this product, the use of other materials may result in poor

performance and may create a hazardous situation. Do not use

aerosol cleaners , they may be flammable under certain

circumstances.

Laser safety

CE mark: Europe only

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipm ent.

January 1, 1996: Council Directive 89/336/EEC, approximation

of the laws of the member states related to electromagnetic

compatibility.

March 9, 1999: Council Directive 99/5/EC, on radio equipment

and telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives

and referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

Using LCDS Print Description Language xxi

Page 22

Laser safety

This is a Class A product. In a domestic environment this product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this product to

maintain compliance with Council Directive 89/36/EEC.

For further information

For more information on Enviro nment, Health and Safety in

relation to this Xerox product and supplies, please contac t the

following customer help lines:

Europe: +44 1707 353434

USA: 1-800-828-6571

Canada: 1-800-82 8- 65 71

xxii Using LCDS Print Description Language

Page 23

Contents

Introduction

Using LCDS Print Description Language provides information on

how to use PDL to pr ogra m LCDS job descriptions that can be

used on the Xerox DocuPrint 75/90 and 100/115/135/155/180

Enterprise Printing Systems, the DocuPrint 75 MX, and other

Xerox laser printing systems.

Before using this documentation, become familiar with its

contents and conventions.

The topics discussed in this guide include:

• Explanation of a Job Source Library (JSL), including required

and optional commands and components

Focus of this

guide

• Rules and guidelines for coding LCDS PDL commands

• Procedures for creating and compiling a JSL

• Syntax and explanation of each LCDS PDL command,

parameter, and DJDE

• Explanation of Dynamic Job Descriptor Entries (DJDEs) and

the process for inserting them into the data stream

• Reference list of all PDL and DJDE commands, including

online and offline usage, parameters, and the Xerox printing

systems that support them

A glossary and index are also provided.

This documentation de scribes LCDS Print Description Language

as it applies to the DocuPrint 100/115/135/155/180 and 75/90

EPS, and DocuPrint 75 MX. Except where otherwise noted, the

PDL information contained in this documentation also applies to

the following families of Xerox Laser Printing Systems that print

LCDS data:

Xerox 180, 180MX, 96, and 96MX Laser Printing Systems

Using LCDS Print Description Language xxiii

Page 24

Introduction

The following f amilies of printing systems support subsets of the

PDL commands that can be used on the DP EPS.

• Xerox 4635 and 4635 MX Laser Printing Systems

• Xerox 4850 and 4890 HighLight Color Laser Printing

Systems

• Xerox DocuPrint 92C HighLight Color Laser Printing System

• Xerox 4050, 4090, and 4650 Laser Printing Systems

• Xerox 9790 and 8790 Laser Printing Systems

Refer to appendix A, “PDL command and DJDE summary,” for

information on which laser printer families support the different

commands.

NOTE: Forms Description Language (FDL) commands cannot

be used on the DP EPS, because these systems do not have

forms compiling capability. You can, however, create forms by

using FDL on another laser printing system or by using a forms

creation software package on a PC or other type of workstation.

Form files that are created externally can be transferred or

imported to the system disk of your DP EPS, and can be

specified for jobs that are printed on the system.

Conventions

This guide uses the following conventions:

• Alerts: Alerts include notes, cautions, and warnings.

– Notes are hints that help you perform a task or

understand the text.

– Cautions alert you to an action that could damage

hardware, software, or your print job.

– Warnings alert you to conditions that may cause injury to

people.

Alerts appear as follows:

– Notes: Printed in italics

–CAUTIONS: Printed in red

– WARNINGS: Printed in bold red

• Angle brackets: Angle brackets surrounding a word indicate

the word is the name of a k ey on the controller ke yboar d. K e y

names start with a capital letter. (Example: Press <Enter>.)

xxiv Using LCDS Print Description Language

Page 25

Introduction

• Square brackets: Placed around words or phras es that are

names of buttons that you click or menu options that you

select on a screen, and names of fields and text boxes on

screens. (Example: In the [Folders] field, select [resources].

• Bold type: Used for emphasis. It is also used for keywords

that introduce items in a list.

• Entering: Within procedures , the t wo-step process of k e ying

in text and pressing <Enter>. (Example: Enter y in the box).

• Fixed pitch font: Used to indicate text that you enter in a

text field on a window, such as examples of PDL commands.

It also indicates text that the system displays on the screen,

such as messages. Example:

LINE DATA=(1,132), FONTINDEX=133;

• Italics: Indicate variables (types of items that va ry from one

command to anoth er), or th e position of a spec ified a rgument

in the command syntax. (Example: IDEN SKIP = value).

Related publications

Using LCDS Print Description Language is part of the Xerox

DocuPrint 100/115/135/155/180, 75/90, and 75 MX publication

sets.

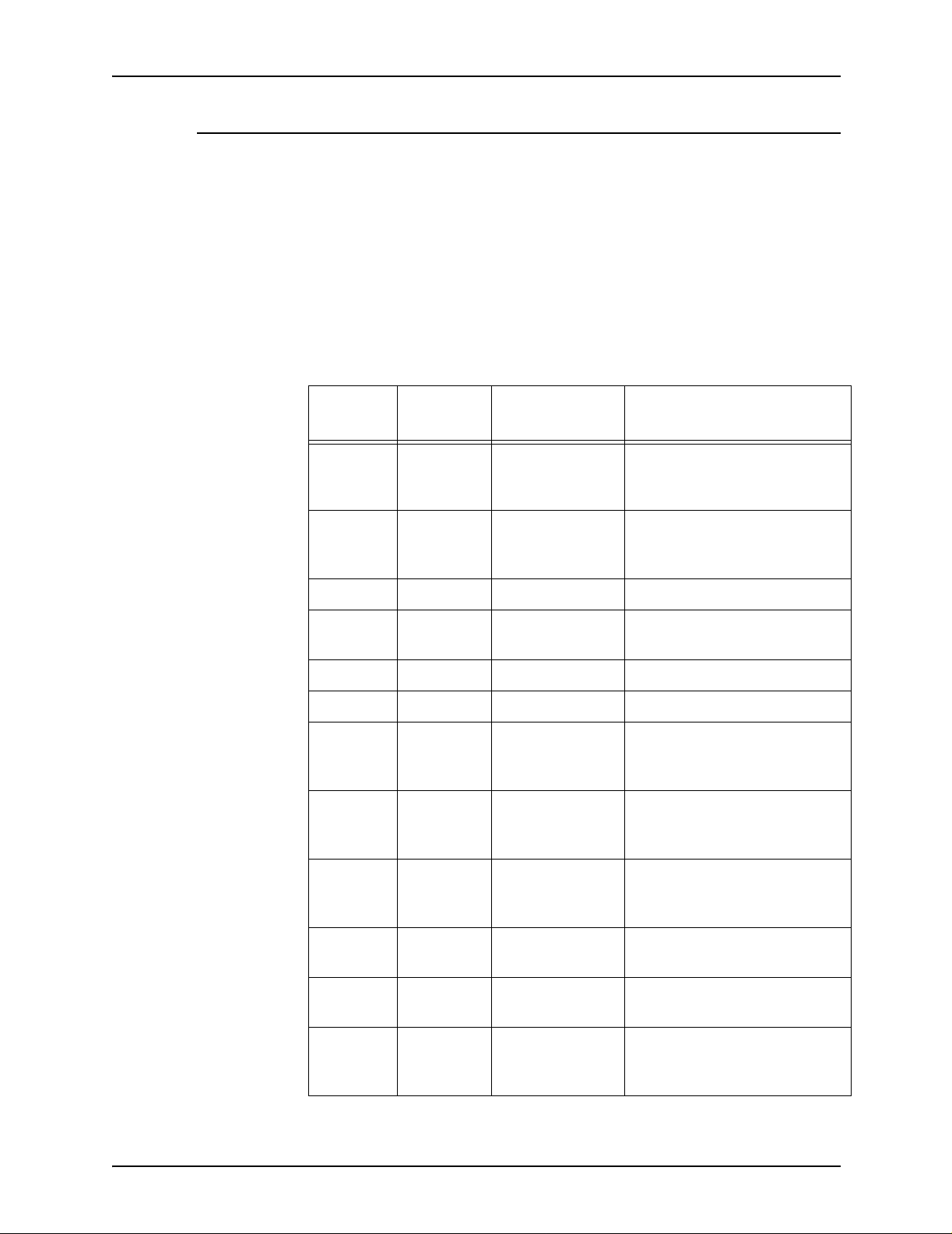

DocuPrint 100/115/135/155/180 EPS documentation

Following are related Xerox documen ts that pertain to the

DocuPrint 100/115/135/155/180 EPS.

Table 1. DP 100/115/135/155/180 EPS documents

DocuPrint 100/115/135/155/180 EPS Customer Information Quick Reference Card

DocuPrint 100/115/135/155/180 EPS Font Reference Manual

Italics are also used f or document ti tles and library names (f or

example, Using LCDS Print Description Language).

DocuPrint 100/115/135/155/180 EPS Installation Planning Guide

DocuPrint 100/115/135/155/180 EPS Operator Guide

DocuPrint 100/115/135/155/180 EPS Operator Quick Reference Card

DocuPrint 100/115/135/155/180 EPS User Job Submission Quick Reference Card

DocuPrint EPS Tape Client Job Submission Guide

Using LCDS Print Description Language xxv

Page 26

Introduction

DocuPrint EPS Using LCDS Print Description Language

DocuSP Common Controller System Guide

Getting Ready for the DocuSP Installation

Getting Started

Generic MICR Fundamentals Guide

Helpful Facts About Paper

MICR User Guide

NPS/IPS Extensions Operations Guide

Tape Formats Manual

Using the lp Utilities for Solaris

Using the lpr Utilities for DOS and Unix

Using the Xerox Cli ent Software for Solaris

Table 1. DP 100/115/135/155/180 EPS documents (Continued)

DocuPrint 75/90 EPS documentation

The following Xerox documents pertain to the DP 75/90 EPS and

the DP 75 MX.

Table 2. DP 75/90 EPS and 75 MX documents

DocuPrint 75/90 EPS Installation Planning Guide

DocuPrint 75/90 EPS Operator Guide

DocuPrint 75/90 EPS Operator Quick Reference Card

DocuPrint EPS Tape Client Job Submission Guide

DocuPrint EPS Using LCDS Print Description Language

Generic MICR Fundamentals Guide

DocuSP Common Controller System Guide

Getting Ready for the DocuSP Installation

Getting Star ted

Helpful Facts About Paper

MICR User Guide

Tape Formats Manual

Useful Resources

xxvi Using LCDS Print Description Language

Page 27

Table 2. DP 75/90 EPS and 75 MX documents

Using the lp Utilities for Solaris

Using the lpr Utilities for DOS and Unix

Using the Xerox Cli ent Software for Solaris

Introduction

Using LCDS Print Description Language xxvii

Page 28

Introduction

xxviii Using LCDS Print Description Language

Page 29

1. PDL principles and proced ures

The Xerox LCDS Print Description Language (PDL) is a set of

commands that you give to the printing system to define

properties such as the appearance, output destination, and

paper feed source for your LCDS print job.

You can use LCDS PDL to do all of the following in your print

jobs:

• Change and mix font types on a page to page, line to line, or

character to character basis. This allows you to customize

printed output for specific needs; for example, emphasizing

important headings by changing font styles and sizes.

• Change text orientation and positioning on a page to page

basis. This allows you to print characters along the width or

length of the page with equal ease. The printing system can

switch instantly, at a page boundary, between portrait (tall

and narrow) and landscape (wide) page formats, combining

the two styles within a single report.

• Print a number of previously separate logical pages on the

same physical page of a document.

• Modify documents on a page to page basis by using copy

modification entries (CMEs) to replace selected portions of

text with other data, change fonts, or label copies as

“confidential.”

• Merge variable print data with forms stored on the system

disk. This feature eliminates the need for forms overlays and

most preprinted fo rms, as well as assuring perfect

registration.

• Print two different forms back to back (dup lex) on one sheet

of paper, thereby reducing paper costs. Additionally, this

option offers potential savings in inv entory , filing, storage, and

mailing costs for computer generated material.

• Feed paper either short edge first or long edge first to

accommodate a variety of paper sizes.

Using LCDS Print Description Language 1-1

Page 30

PDL principles and procedures

Enabling PDL features and functions

To enable these fu nctio ns, y ou en ter PDL com mands th at do the

following for your print job:

• Describe the input (type, format, characteristics, and source)

• Define any logical or special processing functions to be

performed on selected text, pages, or copies

• Describe the output (type, format, font selection, accounting

options, and destination)

Each command has a set of parameters and parameter options

that are used to define the above characteristics of a print job.

PDL commands may be specified in the following ways:

• In a Job Source Library (JSL)

• As Dynamic Job Descriptor Entries (DJDEs)

Job Source

Libraries (JSLs)

Dynamic job

descriptor entries

(DJDEs)

One way to issue PDL job definition commands to your printing

system is to create a text file of these commands for your job.

The source (text, uncompiled) file of PDL commands is called a

“job source library” (JSL) file . The JSL file is th en compiled by the

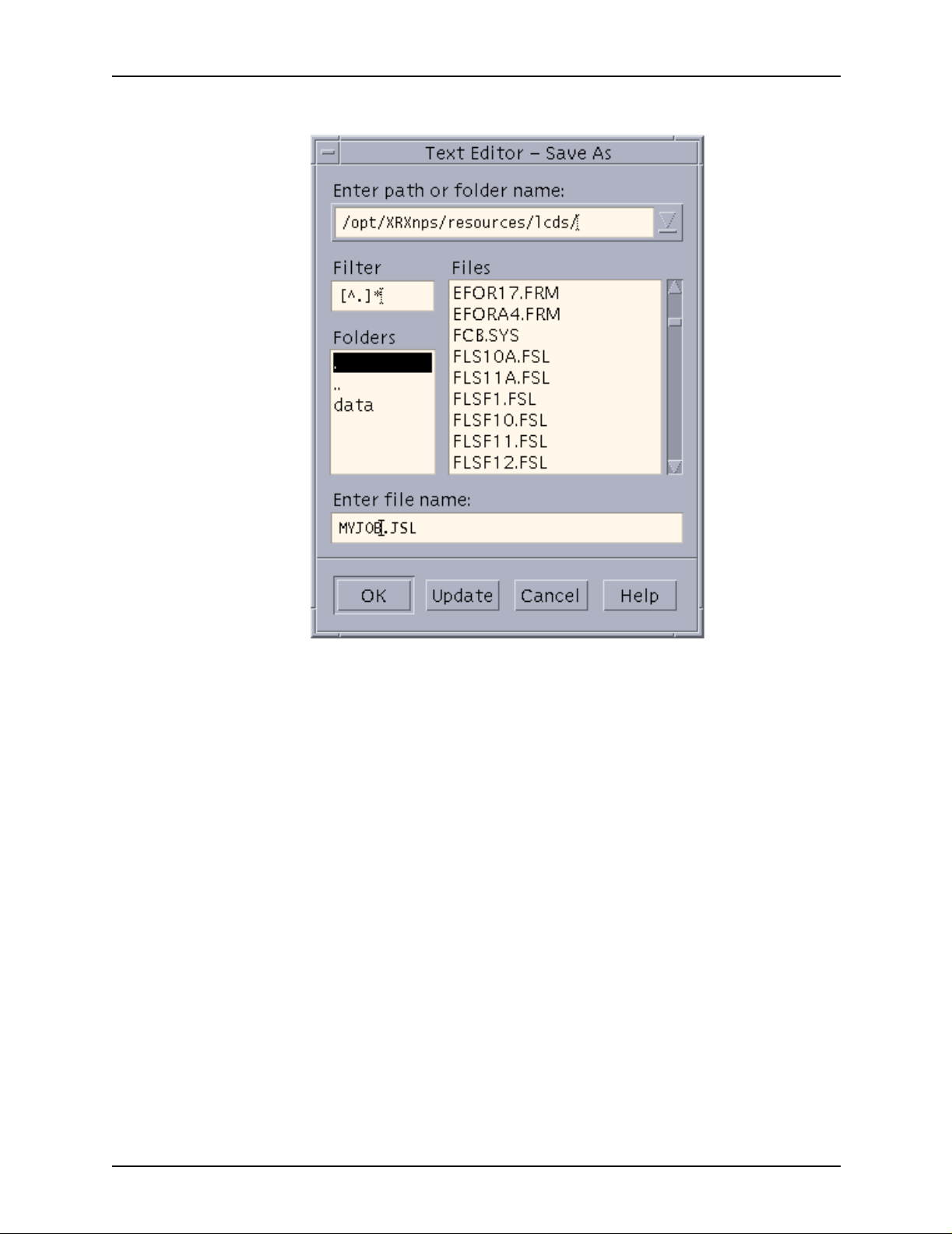

system to create an object file, called a “job descriptor library”

(JDL).

Each compiled JDL file is stored in a resource folder named

“lcds” that is located on the controller disk. The system accesses

the required JDL from the “lcds” folder when the operator

specifies it to start a job. When a job is sent from the host, the

printing system reads the specified JDL, from which it obtains

instructions on wha t f onts and f o rms to use when prin ting the job ,

where to direct the printed output, and so forth.

Dynamic Job Descriptor Entries (DJDEs) are parameters

embedded within the inpu t data stre am. Th e y mo dify t he prin ting

environment established by a job descriptor entry (JDE) within a

JDL, as the job is printing. DJDEs allow page by page or record

by record modifications to your applications.

Most PDL commands are also available as DJDEs. (Refer to

“PDL command and DJDE summary” in appendix A for

informatio n on wh i ch PD L comm a nds have DJDE counterparts.)

In order to use DJDEs, you must specify an IDE N command in

the JSL to advise the system that DJDE records are included in

the input data stream and where to look for them.

1-2 Using LCDS Print Description Language

Page 31

(Refer to “Specifying DJDE records,” later in this chapter for

information on how to include DJDEs in the data stream.)

PDL command structure and components

In order for the system to recognize and respond correctly to

your PDL commands, you must construct and enter them

correctly. Some components of PDL commands must be

specified e very time, while ot he rs are optional. Th ere are some

rules for constructing commands. You must follow these rules in

order for your system to print y our job the wa y y ou w ant it. (Refe r

to “Command syntax,” later in this chapter, for details on the JSL

syntax rules.)

Command lines

PDL principles and procedures

The JSL consists of command lines, also called records, on

which you enter PDL commands. The length of these records

can be up to 133 characters for JSLs on tape.

NOTE: If you select the [TRUNCATE] option of the xjdc

compiling command, only characters 1 through 72 may be used

for parameter information. Refer to “Compiling a JSL,” later in

this chapter.

You can continue commands on successive lin es if the

parameters are separated by commas. Multiple commands may

appear on one record line if separated by semicolons.

Components of a command

Each PDL command con sists of a com mand k eyw ord and o ne or

more parameters. Parameters are separated by commas or

spaces. A PDL command has the following parts:

• Command identifier (if required)

NOTE: DJDEs do not have identifiers.

• Command keyword

• One or more command parameters

• Parameter options

• Comments (if appropriate)

Using LCDS Print Description Language 1-3

Page 32

PDL principles and procedures

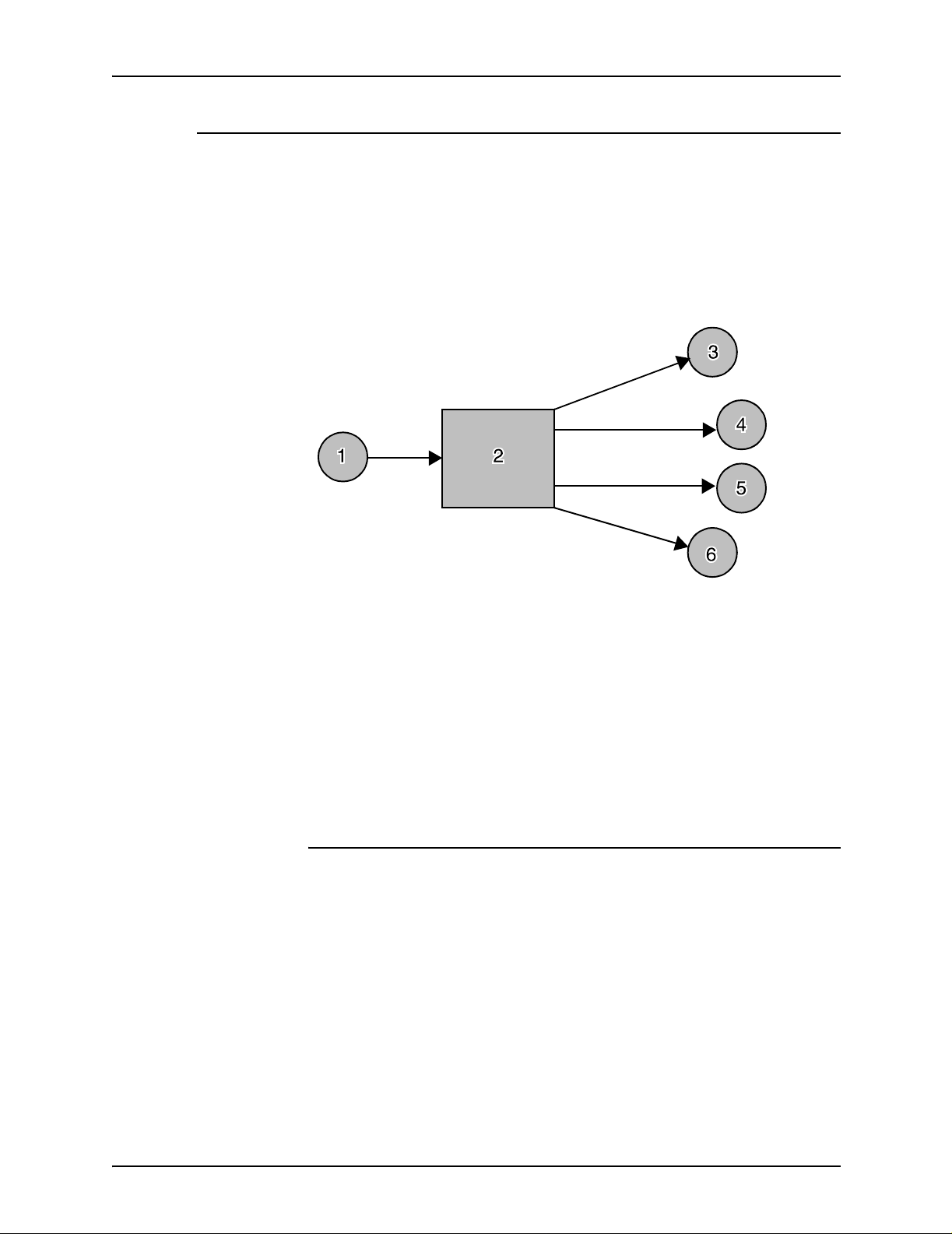

These components are shown in the following figure.

Figure 1-1. Diagram of PDL command components

1. Command statement

2. Identifier

3. Command keyword

4. Parameter keyword

5. Parameter option

6. Additional parameter keywords and options

In the example above, the identifier, parameter keyword, and

parameter options are part of the VFU command, which is

represented b y the r equired com mand k eyw ord VFU. All of these

components may be collectively referred to as a “command

statement.”

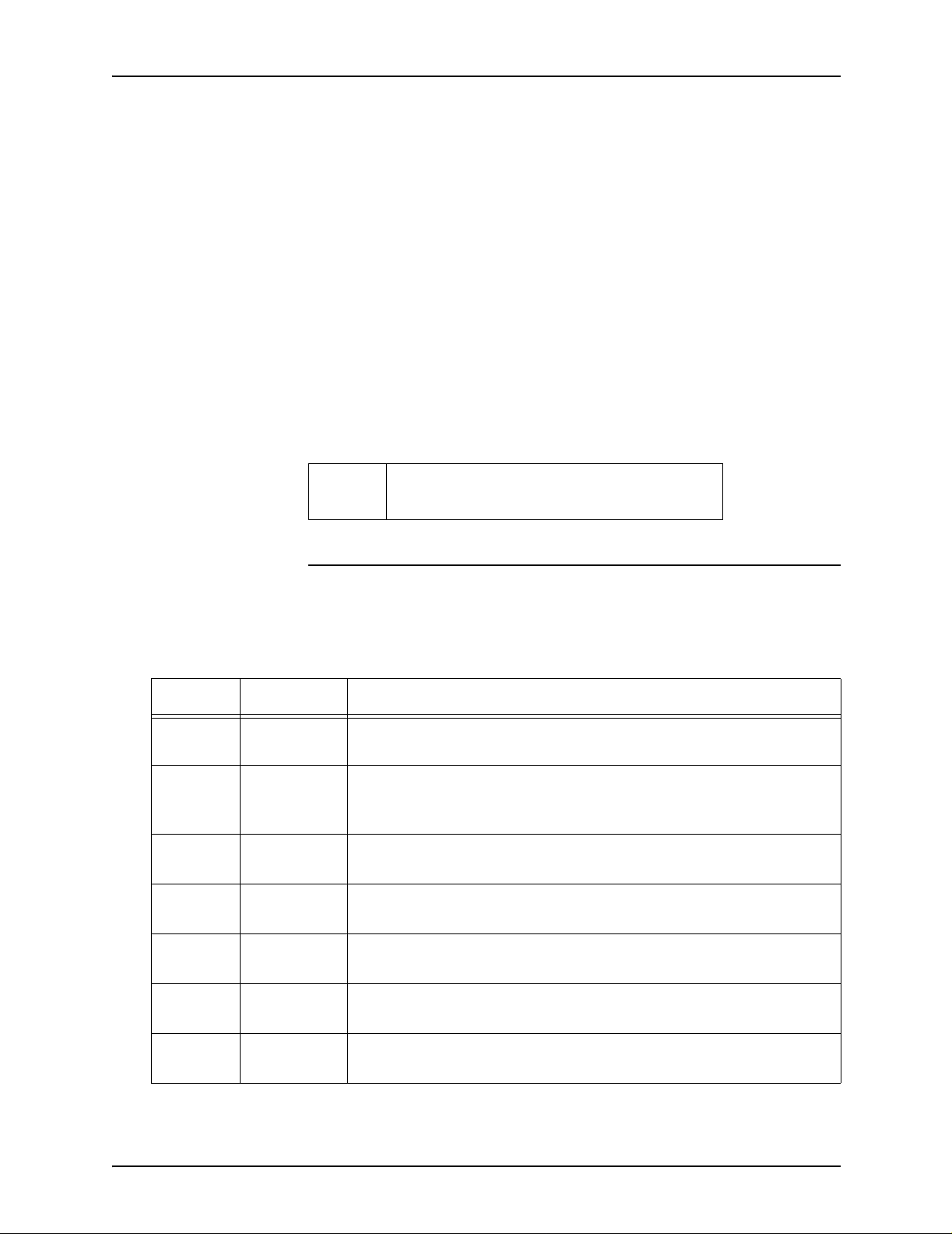

The following table shows examples of the typical components of

a PDL command statement.

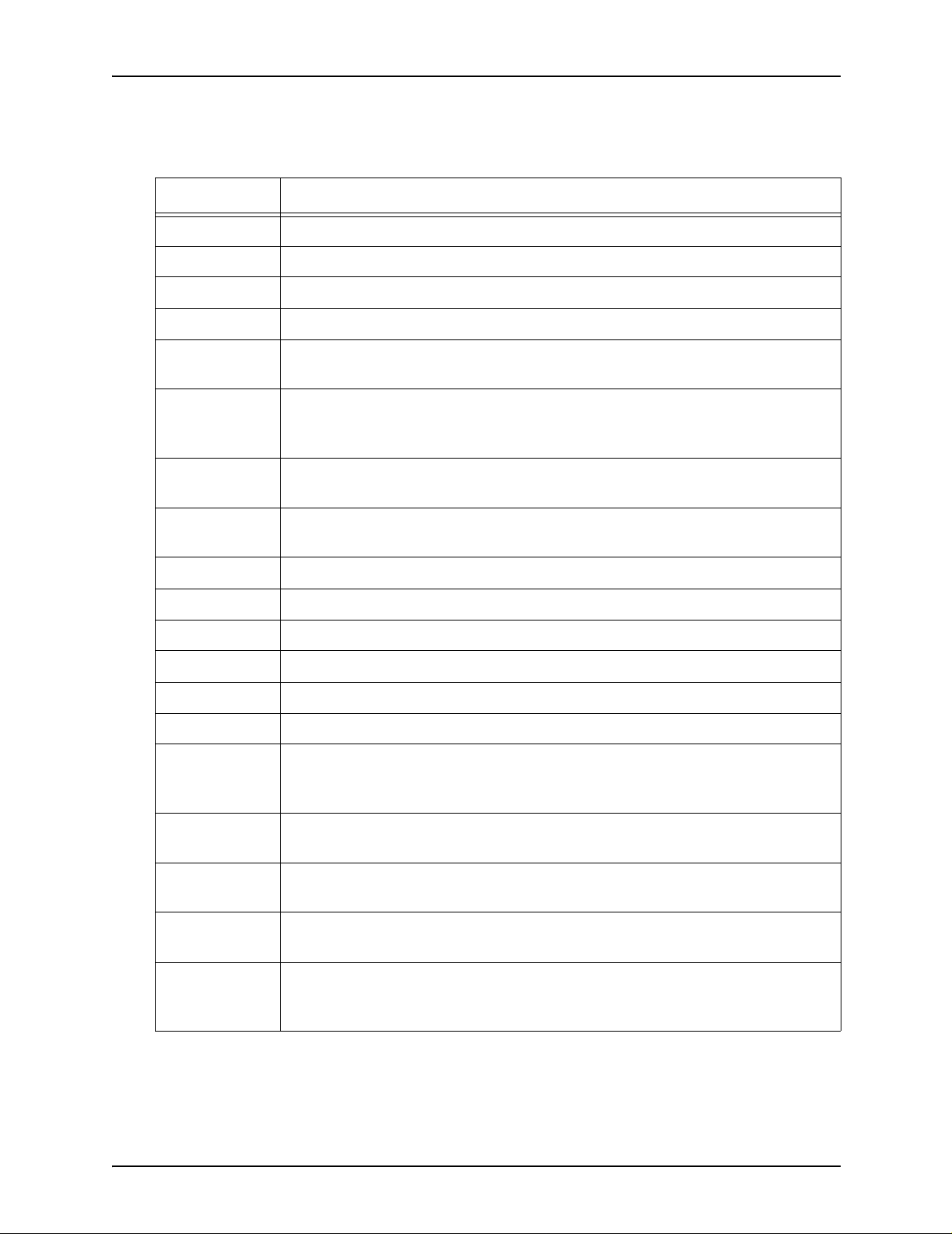

Table 1-1. Set of typical PDL commands

Command

Command

identifier

VFU1:

CME4:

keyword

(required)

VFU

CME

Parameter

keywords

ASSIGN=

TOF=

BOF=

LINE=

POSITION=

FONT=

Parameter

options

(1,1),

1,

55;

(1,60),

5,

2;

1-4 Using LCDS Print Description Language

Page 33

PDL principles and procedures

Command

identifier

Some PDL commands require identifiers to precede their

command keywords. By coding an identifier before a command,

you associate the identifier with the command. This allows the

command to be referenced (by its identifier) by other commands

within the JSL. Some identifiers also determine the names of the

files that the XJDC compiler creates.

Different syntax rules apply to identifiers, depending on the

command being coded. Each command description in this

document tells you if an identifier is required (or optional) for the

command and if so, how it must be coded.

In most cases, in a JSL, if a command will be referenced by

another command w ithi n th e JSL, an i den ti fier must precede the

keyword of the referenced command. A command identifier is

defined using a label of up to six alph an u m eric char act er s,

followed by a colon (:).

There are two typ es of identifiers that can be used:

1. ac type: Must have at least one alpha character (that is, a

letter).

2. dd type: May have all numerals, all alpha characters, or a

combination of both .

Command

keyword

The following PDL command has the command identifier VFU1.

(Its keyw or d is VFU.)

VFU1: VFU

ASSIGN=(1,1), TOF=1, BOF=55;

END;

The identifier in this command may have any number of blanks

following the VFU1 characters; however , no blanks are permitted

within the identifier name.

NOTE: A command that requires an identifier must always be

defined before any other command that references it.

Every command must have a keyword, which is the “name” of

the command for which various parameters may be select ed.

In the following example, CME is the command keyword (CME4

is the identifier).

CME4: CME LINE=(1,60), POSITION=5, FONT=2;

In the next example, the command keyword OUTPUT ca n be

followed by any number of parameters, such as:

OUTPUT GRAPHICS=YES, DU PLEX=NO, FORMAT=PDFLT,

FORM=BAR;

Using LCDS Print Description Language 1-5

Page 34

PDL principles and procedures

Refer to the “Summary table of PDL commands and DJDEs” in

appendix A for a list of all available command keywords.

Parameters Each command keyword is followed by parameters. Parameters

give precise specifications for the print job or applicatio n.

• In commands that comprise a JSL, each parameter consists

of a left part and a right part, separated by an equal (=) sign.

(Spaces bef ore and after the equal sign are optio nal.) The left

part is the parameter name; the right part indicates the

parameter options or values.

• In DJDEs, the left part is the DJDE command name. The

DJDE options are right part components, following the equal

sign.

Parameter options

and right part

components

The right part of a parameter contains the options, which may

consist of keywords, variable references, and value or string

constants.

Each parameter has one or more options. For example, the

OFFSET parameter of th e OUTPUT command (which can be

shortened to OUTPUT OFFSET parameter) has three options:

ALL, FIRST, and NONE.

Some parameter options have multiple components. Some of

these components must have values specified; others are

optional. Parentheses are used to enclose mu lti ple com po nen ts

of a right part, as shown in the following example.

In the example below, the VFU command has three parameters:

ASSIGN, TOF (top of form), and BOF (bottom of form).

VFU1: VFU ASSIGN=(1,1), TOF=1, BOF=55;

END;

In this example, the ASSIGN parameter option has two

components. M ultiple compone nts of an option must be code d in

the order shown in the command description syntax diagram.

• Keywords

Ke ywords are terms that direct the system to perf orm specific

activities. Keywords always consist of the same characters

and do not vary.

1-6 Using LCDS Print Description Language

Page 35

PDL principles and procedures

Example:

ABNORMAL ERROR=CONTINUE, OTEXT=(... WAIT);

ACCT USER=BOTH;

• Variable references

In creating your JSLs, you will often include variable

references, which may be either file names of resources

stored on the system disk (forms, CMEs, PDEs, stocksets,

and so on); or they may be identifiers for commands that

were coded previously in the J SL.

Example:

OUTPUT FORM=FORM1, MODIFY=CME12;

NOTE: In some cases, such as in the MODIFY= command

shown in the example above, the variable (CME12) co uld be

either a file name or an identifier for a CME coded earlier in

the JSL. In other cases, such as in the FORM= command,

the variable (FORM1) can only be a file name.

• Value constants

Value constants have arithmetic values. Value constant s

should be e xpr esse d as d ecim al n umb er s. They may also be

expressed as hexadecimal values, octal values, or ch aracter

values, but these expressions are not recommended.

Decimal numbers may be signed and may have fractional

digits.

Example:

PDE BEGIN=(1.1,.37);

RECORD LENGTH=132;

OUTPUT IMAGE=(1.30 CM,0.85 IN);

To express value constants as hex, octal, or characters, you

use string constants to define one or two bytes of data.

• String con s t ants

String constants are used to specify a sequence of

characters. The length of string constants is important.

– Ways to express string constants

String constants may be expressed as any of the

following:

• Hexadecimal

•ASCII

Using LCDS Print Description Language 1-7

Page 36

PDL principles and procedures

– Using the # character (case toggle)

– Using a repeat count

T1: TABLE CONSTANT=(3)'*';

• EBCDIC

•Octal

•Kanji

Within a text string, the # character may be used as a

case toggle. In other words, when a text str ing is

encountered, it is assumed that characters are inserted

into the print line as they appear in the text string (usually

in uppercase). If the system encounters a #, it interprets

the characters as lowercase mode. All letters after the #

are considered lowerca se until another # is encountered,

which toggles back to uppercase.

The sequence ## indicates that the actual # character

should be inserted and should not be treated as a toggle

for lowercase mode.

String constants may be preceded by an optional repeat

count. A repeat count is enclosed in parentheses and

must be in the range of 1 to 255. For example:

is equivalent to: