Page 1

7

J

W

S

ork Center 5016, 5020

ervice Documentation

CAUTION

Certain components in the Work Center 5016/ 5020

are susceptible to damage from electrostatic dis-

01P48365

une 2008

charge. Observe all ESD procedures to avoid component damage.

Page 2

A

P

8

W

I

©

X

a

P

While Xerox has tried to make this documentation accurate, Xerox will have

no liability arising out of any inaccuracies or ommissions. Changes are pe

rio-

r-

y

s

d

r

y

odically made to this document. Changes, technical inaccuracies, and typ

graphical errors will be corrected in subsequent editions.

All service documentation is supplied to Xerox external customers for info

mational purposes only. Xerox service documentation is intended for use b

certified product trained service personal only. Xerox does not warrant or

represent that such documentation is complete, nor does Xerox represent

or warrant that it will notify or provide to such customer any future change

to this documentation. Customer performed service of equipment, or modules, components or parts of such equipment may affect the warranty

offered by Xerox with respect to such equipment. You should consult the

applicable warranty for its terms regarding customer or third party provide

service. If the customer services such equipment, modules, components o

parts thereof, the customer releases Xerox from any and all liability for the

customer actions, and the customer agrees to indemnify, defend and hold

Xerox harmless from any third party claims which arise directly or indirectl

from such servic e.

cknowledgements

repared by Global Knowledge & Llanguage Services - North America

00 Phillips Road - Building 0218-01A

ebster, New York 14580-9791

SO9001 AND ISO27001 Certified

Copyright 2007-2008 by Xerox Corporation. All rights reserved.

erox® and all product names and number names

re trademarks of Xerox Corporation.

rinted in the USA

Page 3

WorkCentre 5016, 5020

Printed in the United States of America.

Service Documentation

WorkCentre 5016, 5020 Service Documentation

701P48365

Reissue

June, 2008

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes

only. Xerox service documentation is intended for use by certified, product-trained service per

sonnel only. Xerox does not warrant or represent that it will notify or provide to such customer

any future change to this documentation. Customer performed service of equipment, or m od

ules, components, or parts of such equipment may affect whether Xerox is responsible to fix

machine defects under the warranty offered by Xerox with respect to such equipment. You

should consult the applicable warranty for its terms regarding customer or third-party provided

service.

If the customer services such equipment, modules, components or parts thereof, the customer

releases Xerox from any and all liability for the customer actions, and the custom er agrees to

indemnify, defend and hold xerox harmless from any third party claims which arise directly or

indirectly for such service.

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising

out of any inaccuracies or omissions. Changes are periodically made to this document.

Changes, technical inaccuracies, and typographical errors will be corrected in subsequent edi

tions.

XEROX® and all Xerox product names mentioned in this publication are trademarks of

XEROX CORPORATION. Other company trademarks are also acknowledged.

PANTONE is a registered trademark of Pantone, Inc.

Changes are periodically made to this document. Changes, technical inacc uracies, and typographic errors will be corrected in subsequent editions.

CAUTION

This equipment generates, uses and can radiate radio frequency energy, and if not installed

and used in accordance with the instructions documentation, may cause interference to radio

communications. It has been tested and f ound to comply with t he limits for a Clas s A comput

ing device pursuant to subpart B of part 15 of FCC rules, which are designed to provide rea-

-

sonable protection against such interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to cause interference in which case

-

the user, at his own expense, will be required to correct the interference.

-

-

Prepared by:

Xerox Corporation

Global Knowledge and Language Services

800 Phillips Road, Bldg. 0218-01A

Webster, New York 14580-9791

USA

©2007 - 2008 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable material and information now allowed by statutory judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed on the s creen such as

icons, screen displays, looks, etc.

Front Matter

June, 2008

Reissue

i WorkCentre 5016, 5020

Page 4

Front Matter

June, 2008

ii WorkCentre 5016, 5020

Reissue

Page 5

How To Use This Manual................................................................................................ iii

Introduction

Reissue

WorkCentre 5016, 5020

June, 2008

i

Introduction

Page 6

Introduction

June, 2008

ii

Reissue

WorkCentre 5016, 5020

Page 7

How To Use This Manual

This manual is used as the standard service manual for the WorkCentre 5016, 5020.

Enter any comments and/or corrections regarding the WorkCentre 5 016, 5020 Service Documentationl on the Publication Comment Sheet, and send it to the Technical Support Center

SDEG.

This manual describes the standard procedures for servicing the WorkCentre 5016, 5020.

Refer to Section 1 Service Call Procedure f or efficient and effective servicing during mainte

nance calls.

Chain 1 Standby Power

Chain 2 Mode Selection

Chain 3 Machine Run Control

Chain 4 Start Print Power

Chain 6 Imaging

Chain 7 Paper Supplying

Chain 8 Paper Transportation

Chain 9 Marking

-

Chain 10 Fusing and Copy Transportation

Contents of Manual

This manual is divided into nine sections as described below.

Section 1 Service Call Procedures

This section describes the structured process for determining the type and sequence of actions

that are performed during a service call.

Section 2 Status Indicator RAPs

This section contains the Repair Analysis Pr ocedures (RAPs) necessary to repair all faults

other than image quality faults.

Section 3 Image Quality RAPs

This section contains the Repair Analysis Procedures (RAPs) that are used to diagnose image

quality defect problems.

Section 4 Removal/Replacement and Adjustment Procedures

This section contains the removal, replacement, and adjustment procedures for components of

WorkCentre 5016, 5020.

Section 5 Parts List

This section contains a list of spare parts list for the WorkCentre 5016, 5020.

Section 6 General Procedures/Information

Description of Terminology and Symbols

The terminology and symbols used throughout this service manual are described as follows:

WARNING

A Warning statement indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in personal injury or loss of life.

CAUTION

A Caution statement indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of, equipment.

NOTE: A Note statement indicates an operating or maintenance procedure, practice, or condition that is necessary to accomplish a task efficiently.

Reference:

Used when other explanations are given.

Purpose:

Used to describe the purposes of adjustment and troubleshooting.

REP:

Indicates the removal/replacement procedure for reference.

ADJ:

Indicates the adjustment procedure for reference.

PL:

Indicates the parts list for reference.

This section contains frequently used procedures that relate to the diagnosis, setup, or operation of the machine. It also contains pertinent information that will not be found in any other part

of the service documentation.

Section 7 Wiring Data

This section contains the wiring information for the WorkCentre 5016, 5020. It contains a connector list/locator, wirenet diagrams, and Block Schematic Diagrams (BSDs) for the following

chains:

Reissue

WorkCentre 5016, 5020

June, 2008

ASSY:

Means Assembly.

Safety Critical Components (SCC):

These are components, such as electrostatic-sensitive IC chips, which could be damaged if not

handled properly. Follow the regulations regarding Safety Critical Components set by XEROX

Corp.

Introduction

iii

Page 8

Introduction

June, 2008

iv

Reissue

WorkCentre 5016, 5020

Page 9

1.1 Before Starting Service............................................................................................. 1-3

1.2 Service Call Procedure . ............................................................................................ 1-4

1.3 Service Call Details................................................................................................... 1-4

1.4 TRIM Checklist.......................................................................................................... 1-5

1.5 Periodic Replaceme n t Pa rts/Consumables List................................................. ....... 1-5

1 Service Call Proced ur es

Reissue

WorkCentre 5016, 5020

June, 2008

1-1

Service Call Procedures

Page 10

Service Call Procedures

June, 2008

1-2

Reissue

WorkCentre 5016, 5020

Page 11

1.1 Before Starting Service

1.1.1Safety

To prevent any accident that may occur during maintenance service, any warning or any caution regarding the service must be strictly observed. Do not perform any hazardous operation.

1. Power Supply

To prevent electrical shocks, burns, or injury, etc., be sure to switch OFF the machine and

disconnect the plug before starting the maintenance service. If the machine has to be

switched ON, such as when measuring a voltage, take extra care to avoid an electrical

shock.

2. Drive Area

Never inspect, clear or lubricate the drive components, such as chain belts, chain wheels

or gears, when the machine is in operation.

3. Heavy Parts

When removing or installing heavy parts, keep your back straight and lift with your legs.

Some parts should not be lifted by one person:

IOT (Platen): 31.5kg (requires 3 persons)

2 Tray Modules: 8.6kg (requires 2 persons)

Take extra care of your working posture to prevent backache.

4. Safety Devices

See that safety devices for preventing accidents, such as fuses, circuit breakers, interlock

switches, etc., and those for protecting customers from injury, such as panels and covers,

function properly. Modifications that hinder the function of any safety devices are strictly

prohibited.

5. Installing and Removing Parts

The edges of parts and covers may be sharp, so take care not to touch them. Be careful

not to touch those parts, and wipe off any oil that may have adhered to your fingers or

hands before servicing. When pulling out parts, cables, etc., do it gently. Do not use

excessive force.

6. Specified Tools

Follow the instructions when a particular tool is specified.

7. Cleaning Up Toner Spills

Since toner can be explosive, sweep or brush any spilled toner into a container to collect

it. To clean away the remaining toner using a vacuum cleaner, always use an FX standard

vacuum cleaner that is toner-tolerant. Never use the customer's vacuum cleaner.

8. Earthquake Preparedness Measures

If the customer requests earthquake proofing, an earthquake preparedness kit is avail-

able.

Check the Service Guide for more information on the earthquake preparedness kit.

9. Modifications to the Machine

Before altering the machine, submit an irregular use license application.

10. Other Safety Precautions

Follow the recommendations in WORKING PRACTICES FOR ENGINEERS issued by

FXAP EH&S (Environmental Health and Safety).

1.1.2Things to Note When Handling Customer Data

1. Handling of copied/printed customer data.

Before you bring back any sample for the purpose of investigation/analysis, always obtain

permission from the customer. Make sure you assure them that the data will not be used

for any other purpose.

2. Security-related NVM values that were changed during diagnostics.

If any security-related NVM values, such as polling, were set for test purposes, make sure

you restore them to their original values after the test.

3. Other things to note when handling customer data.

Follow the safety guidelines established within the OpCo and ensure that customer data

do not get compromised during service.

1.1.3 Other Precautions

To avoid performing wrong or unnecessary service, observe the following:

1. Reference Materials

Read all relevant service documentation, so that you can take a systematic approach.

2. Disassembling

Make sure to note the assembled condition of the machine before removing parts or dis-

assembling it.

3. Installation and Adjustment

After the installation or adjustment is complete, check that no parts or tools are left inside

the machine.

4. Handling of replaced parts and consumables

Make sure that any replaced parts or consumables, as well as t he packaging materials,

are taken back to the Service Center.

WARNING

Never discard the Drum/Toner Cartridges into a fire. Always keep them away from

open flames to prevent them from igniting and causing a fire.

NOTE: For separation and processing methods for replaced parts or consumables, refer

to Common Technical Information No. 2-138 for all machines.

• If you have replaced the following consumables, affix the "U-TAG" so that the recy-

clable parts will be handled appropriately.

a. Drum Cartridge

b. Toner Cartridge

• For recyclable parts, fill in the necessary items on the "U-TAG."

5. General Precautions

• Take care not to disturb the customer's daily work.

• Place any service-related trash into a trash bag and bring it to the service office.

• Clearly record the following information in the Machine Service Log:

– Details of the service call

– Parts and consumables replaced

Reissue

WorkCentre 5016, 5020

June, 2008

1-3

Service Call Procedures

1.1

Page 12

1.2 Service Call Procedure

1.2.1 Initial Actions

1. Ask the operator(s) about the machine’s condition.

2. Record the billing meter readings.

3. Inspect any faulty copies, then check the machine.

4. Check the Service Log.

1.2.2 Actions to Take During UM (Unscheduled Maintenance)

1. Perform the service flow in Section 2 Status Indicator RAPs.

2. Perform the applicable RAP in Section 2 Status Indicator RAPs.

If there are no applicable RAPs, troubleshoot by referring to the BSD in Section 7 Wiring

Data.

3. Check the copy quality.

Make several copies using the Test Pattern (499T247), then check the quality.

4. Look at the last 20 error codes in order to understand the machine status.

• Enter Diagnostic Mode. Enter [40-01] (Display Error History How to Enter the Diag -

nostic Mode).

• When the last error code is displayed, press t he [Start] key to return to the Function

input screen.

• Pressing the [Stop] key during the display will stop it and return you to the Function

input screen.

5. Repair all the secondary problems.

6. Perform TRIM servicing.

1.2.3 Actions to Take During SM (Scheduled Maintenance)

1. Check the copy quality.

Make several copies using the Test Pattern (499T247), then check the quality.

2. Look at the last 20 error codes in order to understand the machine status.

• Enter Diagnostic Mode. Enter [40-01] (Display Error History How to Enter the Diag -

nostic Mode).

• When the last error code is displayed, press t he [Start] key to return to the Function

input screen.

• Pressing the [Stop] key during the display will stop it and return you to the Function

input screen.

3. Perform TRIM servicing.

1.2.4 Final Actions

1. Check overall machine operation/features.

2. Check the machine exterior and consumables.

3. Train the operator as required.

4. Complete the Service Log and Service Report.

5. Keep the copy samples with the Service Log.

1.3 Service Call Details

1.3.1 Initial Actions

1. Ask the operator(s) about the machine’s condition.

• Frequency and location of recent paper jams

• Copy quality

2. Record the billing meter readings.

3. Inspect any faulty copies, then check the machine.

4. Check the copy sample and the Service Log from the last call.

1.3.2 Checking Reproducibility of Problem

1. Perform the service flow in Section 2 Status Indicator RAPs.

2. Perform the applicable RAP in Section 2 Status Indicator RAPs.

3. If there are no applicable RAPs, troubleshoot by referring to the B SD in Se ction 7 Wiring

Data.

1.3.3 Checking Copy Quality

1. Make several copies using the Test Pattern (499T247), then check the quality.

2. If there is a problem in copy quality, perform the applicable RAP in Section 3 Image Quality.

1.3.4 TRIM Servicing

Perform TRIM servicing during the maintenance call.

1. Perform the necessary TRIM items using the TRIM Checklist.

2. Check for parts that require periodic cleaning/replacement by referring to the TRIM

Checklist and the Periodic Replacement Parts/Consumables List. Clean them if neces

sary. If replaced, always clear the counters of the corresponding items in the Chain Function.

-

Service Call Procedures

1.2, 1.3

June, 2008

1-4

Reissue

WorkCentre 5016, 5020

Page 13

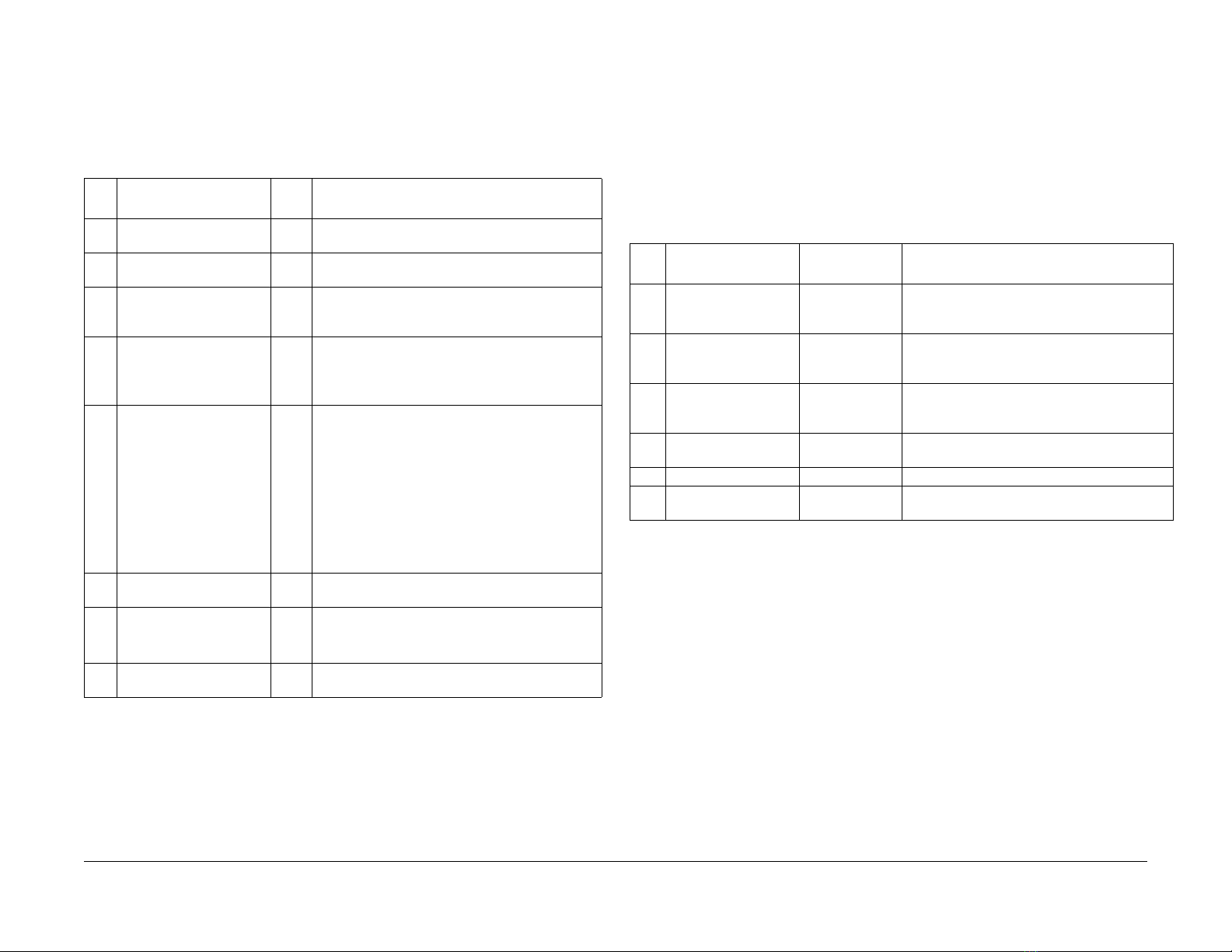

1.4 TRIM Checklist

A: Check. Clean, replace, or replenish if necessary.

B: Always check and clean.

*: Always replace at the specified interval.

Table 1

Every

No. Service Items

1.1 Check before servicing

(check machine operation)

1.2 Check before Servicing

(copy the Test Pattern)

2 Clean the interior of the

machine (paper transport

system)

3 Clean the IIT A • Clean the Platen Glass surface and the Platen

5 Safety Precautions B • Make sure that the power cord is plugged in

6.1 Check after servicing

(copy quality check)

6.2 Check after servicing

(check machine operation)

time

Service Details

A Turn on the machine, and make sure that there are

no abnormal sounds.

A Make several copies using the Test Pattern

(499T247), then check the image quality.

A Clean the paper dust and toner residue in the paper

path and on the jam sensor.

Cushion with the optical cleaning cloth.

• Clean the Reflector, back of the Platen Glass,

mirrors and lens with the optical cleaning cloth.

properly.

• Make sure that there are no cracks in the

power plug and no holes or cuts in the power

cord insulation.

• If an extension cord or power strip is used,

make sure it is of sufficient capacity to handle

the power requirements of the machine.

• Make sure that no more than one power plug

is connected to a single socket.

A Make several copies using the Test Pattern

(499T247), then check the image quality.

A • Check the paper feed.

• Make sure that there are no abnormal sounds.

1.5 Periodic Replacement Parts/Consumables List

When servicing the machine, check the number of copies and the replacement interval for the

consumables and parts that require periodical cleaning/replacement. Clean or replace them if

necessary. The IOT history can be checked at Chain-Function > NVRAM R/W, while the IIT

history can be checked in the Counters (r efer to Diagnost ic M ode in S ect ion 2 Status Indicator

RAPs). For items that cannot be checked in the Diagnostic Mode, clean or replace them

according to the replacement intervals (standard PV).

CAUTION

Do not keep toner and drum cartridges in your car for long periods of time.

Table 1

Parts/Consumables

Name/PL No.

No

1 Tray 1 Feed Roll/

Retard Pad

2 Tray 2 Feed Roll/

Retard Roll

3 MSI Feed Roll/

Retard Pad

4 Fuser Unit 100,000 [21/39] [21/29] [21/19] [21/9]

5 Toner Cartridge 6,000

6 Drum Cartridge 36,000 31,000 (Warning)

Replacement

Interval (copies)

50,000 [29/34] [29/24] [29/14] [29/4]

100,000 [29/25] [29/15] [29/5]

50,000 [29/39] [29/29] [29/19] [29/9]

Counters Check

Count up 1 for every feed. Replace both at the

same time .

Count up 1 for every feed. Replace both at the

same time .

Count up 1 for every feed. Replace both at the

same time.

Count up 1 for every feed.

36,000 (Machine Stops)

6.3 Check after servicing

(check the meter)

Do not touch the Drum of the Drum Cartridge.

Reissue

WorkCentre 5016, 5020

A Create the Service Log and Service Report.

CAUTION

June, 2008

1-5

Service Call Procedures

1.4, 1.5

Page 14

Service Call Procedures

1.4, 1.5

June, 2008

1-6

Reissue

WorkCentre 5016, 5020

Page 15

Error Codes

Fault Repair Overview and List of Error Codes............................................................... 2-3

RAPs

U0-1 Main Motor Stop Error............................................................................................ 2-25

U1-1 Main Motor Rotation Error...................................................................................... 2-25

U2-1 Carriage Module Fail.............................................................................................. 2-26

U3-5 Laser Power Or ROS Motor Fail.............. ................... ................................... ....... 2-26

U4-1 Fuser On Time Fail............................ ................... ................... .............................. 2-27

U4-2 Over Heat Temp Fail............................................................................................. 2-27

U4-3 FS1 Thermistor Defect.......................................................................................... 2-28

U4-9 Fuser Fan Defect........................... ................... ..................................................... 2-28

U6-2 RAM Read/Write Check Error ............................................................................... 2-29

U6-3 NVM Data Defect .................................................................................................. 2-29

U6-4 NVM Read/Write Cannot Be Executed ................................................................. 2-30

U6-5 CPU Power To Access NVM Is Not Enough......................................................... 2-30

U7-0 UI Communication TimeOut....................... ...................................................... ..... 2-31

U7-1 UI Communication Error................................. ................... ................... ................. 2-31

U8-1 Billing Counter Defect............................................................................................ 2-32

U9-0 HVPS Fail........................................ .................................... ................... ............... 2-32

062-300 Platen Interlock Open ....................................................................................... 2-33

062-345 IISS EEPROM Failure....................................................................................... 2-33

062-360 Carriage Position Fail........................................................................................ 2-34

062-371 Lamp Illumination Fail....................................................................................... 2-34

062-380 AGC Failure ...................................................................................................... 2-35

062-386 AOC Failure ...................................................................................................... 2-35

062-392 IPS PWB Memory Fail ...................................................................................... 2-36

062-393 IPS PWB Fail .................................................................................................... 2-36

005-170 DADF Feed Failure........................................................................................... 2-37

005-171 DADF Regi / Exit Failure.................................................................................. 2-38

005-172 DADF Inverted Document Jam......................................................................... 2-39

005-198 Short Scan Jam ................................................................................................ 2-40

005-199 Long Scan Jam................................................................................................. 2-40

005-305 Feeder Top Cover Open................................................................................... 2-41

005-920 Static Jam......................................................................................................... 2-41

2 Status Indicator RAPS

Reissue

WorkCentre 5016, 5020

June, 2008

2-1

Status Indicator RAPS

Page 16

Status Indicator RAPS

June, 2008

2-2

Reissue

WorkCentre 5016, 5020

Page 17

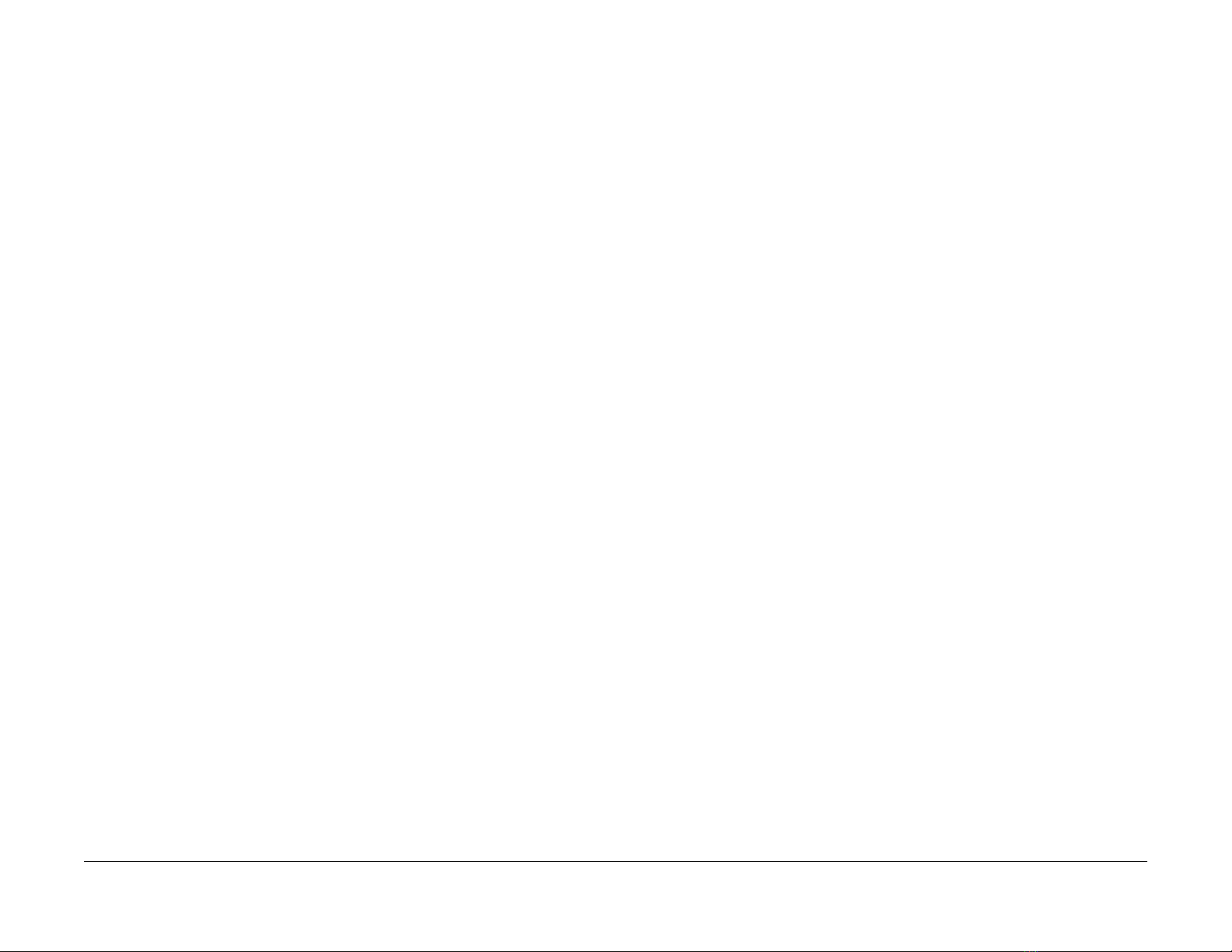

Fault Repair Overvie w and List of Error Codes

Fault Repair Overview

The fault repair operation proceeds in the following flow. After performing the pre-check, verify

the symptoms and refer to the Error Code List and Section 7 Wiring Data to effectively repair

the fault:

Check the status of Installation

Check the problem status

Perform RAP

.

Diagnostic Mode

Operating Principles

Wiring Data

Reissue

WorkCentre 5016, 5020

Check if the fault is repaired

Completed

Figure 1 Tr oubleshooting Procedure

June, 2008

2-3

Reference

Information

Status Indicator RAPS

Page 18

Check the Status of Installation

Before starting to troubleshoot, always check the following items:

• The voltage of the power supply (measure the voltage at the power outlet to see if it is

within specification).

• The power cord for damage, short circuits, open circuits, and wrong internal connections.

• The machine for proper grounding.

• The machine is not installed in a place with high temperature, high humidity, low temperature, low humidity, or a place with drastic changes in temperature.

• The machine is not installed near a water outlet, humidifier, heater or fire source, dusty

areas, or under the direct draft of an air conditioner.

• The machine is not installed in a place where volatile or flammable gas is generated.

• The machine is not installed in a place exposed to direct sunlight.

• The machine is installed in a well-ventilated place.

• The machine is installed on a stable level surface.

• The paper is within specification (standard paper is recommended).

• The machine for any improper handling.

• The Periodic Replacement Parts are replaced at the proper intervals.

Safety Considerations

• Before servicing, always unplug the power cord unless required otherwise. When the

power is turned ON, never touch a current-carrying part unless required otherwise. Also,

since current is carried in the LVPS power switch/inlet even when the power is turned

OFF, never touch this area.

• When turning the power ON to perform a check while the Interlock Switch or Security

Switch is also turned ON and the covers are removed, always disconnect the connector

( P/J140) that is connected to the ROS, unless required otherwise, because a laser beam

might be emitted from the ROS.

• When connecting the connector ( P/J520) on the HVPS according to the instructions in

the RAP, never touch the HVPS and high-voltage output parts.

• When performing a high voltage output check using the Input Diagnostics or Output Diagnostics in Diagnostic Mode, make sure that all covers are installed unless specified otherwise. Also, never touch any high voltage output section when performing the high voltage

output check.

• When operating the Drive Section using the Input Diagnostics or Output D iagnostics in

Diagnostic Mode, make sure that all covers are installed unless specified otherwise. Also,

never touch the Drive Section while operating it.

• Be careful not to burn yourself when touching parts that can get very hot.

• When servicing, use a grounded wrist band to remove static electricity from your body.

Things to Note When Using RAPs

• When troubleshooting using RAPs, prepare normally working parts such as the AIOC

PWB, LVPS, HVPS and Fuser in advance because they might be required to identify a

failure. In addition, if the fault cannot be repaired, replace the "parts considered to be the

cause" and related parts in sequence and check the operation.

• When servicing, always disconnect the power cord unless required otherwise. When the

power cord is connected, never touch any current-carrying part unless absolutely neces

sary.

• Descriptions related to connectors are expressed as follows: “P/J12" -> The connector (P/

J12) is in the connected state. "P12" -> The plug side when the connector (P/J12) is in the

disconnected state (except when it is directly connected to a board). "J12" -> The jack

side when the connector (P/J12) is in the disconnected state (except when it is directly

connected to a board).

• In a RAP, "P/J1 <=> P/J2" means that all the opposing pins between "P/J1" and "P/J12"

(refer to Section 7, Wiring Data) should be measured.

• The voltages on small connectors are measured using a special tool. Handle the tool

carefully because it has a sharp tip.

• The numerical values described in the RAPs are for re ference only. Approximate values

are considered to be the same.

• Note that for the checks specified in the RAP, you must check the references for the parts

that must be removed and their procedures.

• "Replacement" in the RAPs indicates the parts that are considered to be the cause of the

problem. Check by replacing the parts and, if necessary, the assembly that contains those

parts.

• In the RAPs, the highest level paper supply is called "Tray 1," and the one below it is

called "Tray 2."

• In the RAPs, some procedures are described separately for each specification. Follow the

instructions for your model to repair the faults.

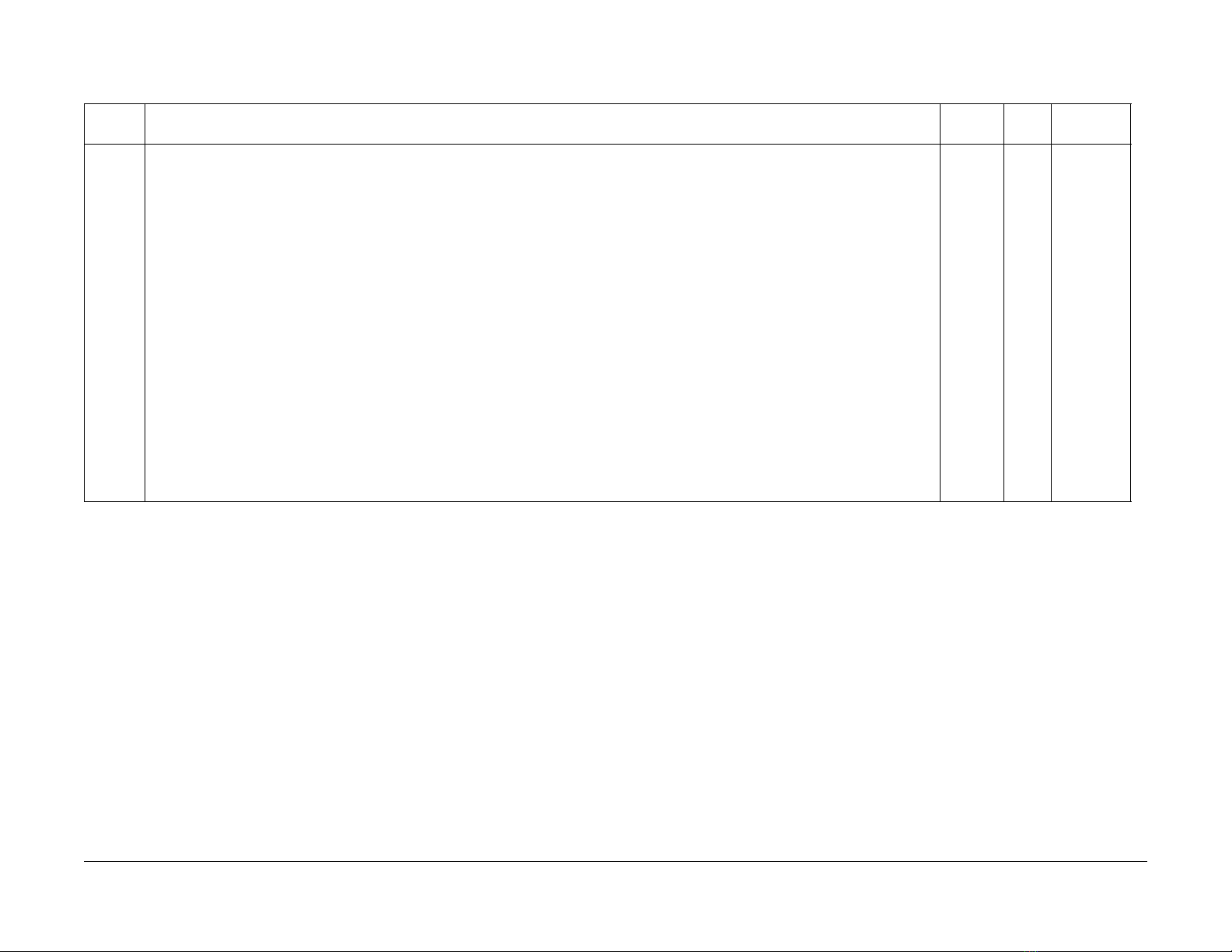

RAP Flow

RAPs are a good place to start in diagnosing a failure. RAPs guide you through the troubleshooting process by checking for th e presence of error codes and other types of problematic

symptoms. To troubleshoot problems related to image quality, refer to Section 3 Image Qu ality

Troubleshooting.

-

Status Indicator RAPS

June, 2008

2-4

Reissue

WorkCentre 5016, 5020

Page 19

Ask the operator about the problem

Did the operator operate the machine correctly?

Yes

No

Turn the Power Switch OFF then ON

Does the error recur when operating the

machine in the same way as before (when

the problem originally occurred)?

Yes

Does the Control Panel display an Error

Code?

No

Yes

Figure 2 RAP Flow

Explain how to operate the

machine

Procedure is complete

Refer to the Error Code List and perform the

relevant troubleshooting

Reissue

WorkCentre 5016, 5020

June, 2008

2-5

Status Indicator RAPS

Page 20

Error Code List

NOTE: In the “Record in Error Log” column, “O” = yes and “X” = no.

Error

Code

C1-1

Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Tray1 F/O#1 SNR on JAM

Explanation

Timeout between Tray1 Feed Clutch ON and Tray1 Feed Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-07] Tray1 Feed Sensor

• [08-12] Tray1 Feed Clutch

Check Items

• Feed Roll or Retard Pad dirty, contaminated with paper dust, worn, or faulty

• Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• Tray1 Feed Clutch faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor

(PL 2.5)(REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7

– Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8

• Replace the Tray1 Feed Clutch (PL 2 . 2) (REP 2.2.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Record in

Error Log

O -

RAP BSD

CH8.1

Figure 1

Status Indicator RAPS

June, 2008

2-6

Reissue

WorkCentre 5016, 5020

Page 21

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Tray1 Regi SNR on JAM

Explanation

Timeout between Tray1 Feed Sensor ON and IOT Registration Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-07] Tray1 Feed Sensor

• [08-05] IOT Registration Sensor

• [08-10] IOT Registration Clutch

Check Items

• Take Away Roll 1 dirty, contaminated with paper dust, worn, or faulty

• Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

C1-2

• Drive gear worn or damaged

• IOT Registration Clutch faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor

(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7

– Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9).

- Wire between IOT Registration Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

- Wire between IOT Registration Sensor J156-2 and LVPS J503-2

- Wire between IOT Registration Sensor J156-1 and LVPS J503-3

• Replace the IOT Registration Clutch (PL 2.9) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Record in

Error Log RAP BSD

CH8.1

O -

Figure 1

CH8.4

Figure 4

Reissue

WorkCentre 5016, 5020

June, 2008

2-7

Status Indicator RAPS

Page 22

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

STM F/O#2 SNR on JAM

Explanation

Timeout between STM Feed Motor ON and STM Feed Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-06] STM Feed Sensor

• [08-11] STM Feed Clutch

• [08-13] STM Feed Motor

Check Items

• Tray2 Feed Roll or Tray2 Retard Roll dirty, contaminated with paper dust, worn, or faulty

• STM Feed Sensor dirty and Sensor Actuator deformed or damaged

C2-1

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• STM Feed Clutch faulty

• STM Feed Motor faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed Sensor (PL

11.5) (REP 11.5.1 ).

– - Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542)

– - Wire between STM Feed Sensor J172-2 and STM PWB J542-7

– - Wire between STM Feed Sensor J172-1 and STM PWB J542-8

• Replace the STM Feed Clutch (PL 11.6) (REP 11.6.1), the STM Feed Motor (PL 11.6) (REP 11.6.2), and the STM PWB (PL 11.5) (REP

11.5.2 ) in that order.

Record in

Error Log RAP BSD

O -

CH8.2

Figure 2

Status Indicator RAPS

June, 2008

2-8

Reissue

WorkCentre 5016, 5020

Page 23

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Tray1 F/O#1 SNR on JAM from STM feed

Explanation

Timeout between STM Feed Out Sensor ON and Tray 1 Feed Out Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-06] STM Feed Sensor

• [08-07] Tray1 Feed Sensor

• [08-11] STM Feed Clutch

• [08-13] STM Feed Motor

Check Items

• Take Away Roll 2 dirty, contaminated with paper dust, worn, or faulty

• STM Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

C2-2

• Drive gear worn or damaged

• STM Feed Clutch faulty

• STM Feed Motor faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed Sensor (PL

11.5) (REP 11.5.1).

– Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542)

– Wire between STM Feed Sensor J172-2 and STM PWB J542-7

– Wire between STM Feed Sensor J172-1 and STM PWB J542-8

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor

(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and STM PWB J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and STM PWB J501-7

– Wire between Tray 1 Feed Sensor J158-1 and STM PWB J501-8

• Replace the STM Feed Clutch (PL 11.6) (REP 11.6.1), the STM Feed Motor (PL 11.6) (REP 11.6.2), and the STM PWB (PL 11.5) (REP

11.5.2) in that order.

Record in

Error Log RAP BSD

CH8.1

O -

Figure 1

CH8.2

Figure 2

Reissue

WorkCentre 5016, 5020

June, 2008

2-9

Status Indicator RAPS

Page 24

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

STM Regi SNR on JAM

Explanation

• When feeding paper from the STM, timeout between Tray1 Feed Sensor ON and IOT Registration Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-05] IOT Registration Sensor

• [08-10] IOT Registration Clutch

Check Items

• Take Away Roll 1 dirty, contaminated with paper dust, worn, or faulty

• IOT Registration Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

C2-3

• Drive gear worn or damaged

• IOT Registration Clutch faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor

(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J502)

– Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7

– Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9).

– Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

– Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2

– Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3

• Replace the IOT Registration Clutch (PL 2.9) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Error Name

No paper in the selected paper tray (Tray1)

Explanation

• No paper is detected in Tray1 when ATS function is disabled and Tray1 is selected during a copy job.

• No paper is detected in Tray1 when Tray1 is selected during a print job (the paper size setting matches the one specified for the job).

I/O Diagnostic Codes

[07-07] Tray1 No Paper Sensor

Check Items

C5-0

• Press the [Stop] button on the Control Panel.

• Check the tray to see if it is empty; if it is, add paper specified by the job.

• Tray1 No Paper Sensor dirty and Sensor Actuator deformed or damaged

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 No Paper Sensor (PL 2.7) (REP 2.7.1).

– Wire between Tray1 No Paper Sensor J157-3 ( P/J157) and LVPS J501-3 ( P/J501)

– Wire between Tray1 No Paper Sensor J157-2 and LVPS J501-4

– Wire between Tray1 No Paper Sensor J157-1 and LVPS J501-5

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Record in

Error Log RAP BSD

CH8.1

O -

Figure 1

CH8.4

Figure 4

X -

CH7.1

Figure 1

Status Indicator RAPS

June, 2008

2-10

Reissue

WorkCentre 5016, 5020

Page 25

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Tray1 Paper Size Mismatch

Explanation

C5-1

• Paper that is different from the one in the Tray Settings is detected when feeding.

• Or, paper size setting in Tray1 is different from the paper size specification of the job when Tray1 is selected during a print job.

Check Items

• Press the [Stop] button on the Control Panel.

• Change the paper size of Tray 1 to the one specified by the job.

Error Name

No paper in the selected paper tray (Tray2)

Explanation

• No paper is detected in the STM when ATS function is disabled and STM is selected during a copy job.

• No paper is detected in the STM when STM is selected during a print job (the paper size setting matches the one specified for the job).

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[07-08] STM No Paper Sensor

Check Items

C6-0

• Press the [Stop] button on the Control Panel.

• Load the correct paper into the STM.

• STM No Paper Sensor dirty and Sensor Actuator deformed or damaged.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM No Paper Sensor (PL 11.7) (REP 11.7.1).

– Wire between STM No Paper Sensor J171-3 ( P/J171) and STM PWB J542-3 ( P/J542)

– Wire between STM No Paper Sensor J171-2 and STM PWB J542-4

– Wire between STM No Paper Sensor J171-1 and STM PWB J542-5

• Replace the STM PWB (PL 11.5) (REP 11.5.2) and the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Name

Tray2 Paper Size Mismatch

Explanation

C6-1

• Paper that is different from the one in the Tray Settings is detected when feeding.

• Or, paper size setting in the STM is different from the paper size specification of the job when STM is selected during a print job.

Check Items

• Press the [Stop] button on the Control Panel.

• Change the paper size of STM to the one specified by the job.

Error Name

MSI Paper Size Mismatch

Explanation

C7-1

• Paper that is different from the one in the Tray Settings is detected when feeding.

• Or, paper size setting in the MSI is different from the paper size specification of the job when MSI is selected during a print job.

Check Items

• Press the [Stop] button on the Control Panel.

• Change the paper size of Bypass to the one specified by the job.

Record in

Error Log RAP BSD

X - -

X -

CH7.2

Figure 2

X - -

X - -

Reissue

WorkCentre 5016, 5020

June, 2008

2-11

Status Indicator RAPS

Page 26

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

APS NG Unselected

Explanation

• Either Tray 1 or STM is in one of the "paper settings is of a size that causes missing image" states when APS is selected during a copy job.

C0-1

• Or, either T r ay 1 or STM is "set with paper size that is different from the one specified for the job" when Auto Tray is selected during a print

job.

Check Items

• Press the [Stop] button on the Control Panel.

• Change the paper size of Tray 1 or STM to the one specified by the job.

Error Name

MSI Regi SNR on JAM

Explanation

Timeout between Bypass Solenoid ON and IOT Registration Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-05] IOT Registration Sensor

• [08-17] Bypass Solenoid

Check Items

• Bypass Feed Roll, Retard Pad, or Bypass Take Away Roll dirty , contaminated with paper dust, worn, or faulty

• IOT Registration Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

C9-3

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• Bypass Solenoid faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9).

– Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

– Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2

– Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3

• Check that the Bypass Solenoid and the LVPS J502-1/3 ( P/J502) pins are connected securely with good electrical contact. If there is no

problem, replace the Bypass Solenoid (PL 7.5).

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Record in

Error Log RAP BSD

X -

CH3.2

Figure 2

CH8.3

O -

Figure 3

CH8.4

Figure 4

Status Indicator RAPS

June, 2008

2-12

Reissue

WorkCentre 5016, 5020

Page 27

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

F/O#1 SNR Static JAM

Explanation

Tray1 Feed Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[08-07] Tray1 Feed Sensor

Check Items

C8-1

• Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor

(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and STM PWB J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and STM PWB J501-7

– Wire between Tray 1 Feed Sensor J158-1 and STM PWB J501-8

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Name

F/O#2 SNR Static JAM

Explanation

STM Feed Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[08-06] STM Feed Sensor

Check Items

C8-2

• STM Feed Sensor dirty and Sensor Actuator deformed or damaged

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed Sensor (PL

11.5) (REP 11.5.1).

– Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542)

– Wire between STM Feed Sensor J172-2 and STM PWB J542-7

– Wire between STM Feed Sensor J172-1 and STM PWB J542-8

• Replace the STM PWB (PL 11.5) (REP 11.5.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Error Name

CPM Image Lost

E0-1

Explanation

During a copy job in CMP Priority Mode, it is detected that the paper containing an image cannot be output after the image is deleted.

Check Items

Press the [Stop] button on the Control Panel.

Record in

Error Log RAP BSD

O -

O -

CH8.1

Figure 1

CH8.2

Figure 2

O - -

Reissue

WorkCentre 5016, 5020

June, 2008

2-13

Status Indicator RAPS

Page 28

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Regi SNR Static JAM

Explanation

IOT Registration Sensor ON is detected during standby .

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[08-05] IOT Registration Sensor

Check Items

E1-6

• Sensor dirty

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9).

– Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

– Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2

– Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3

• Replace the AIOC PWB (PL 8.1)(REP 8.1.1).

Error Name

Exit SNR JAM

Explanation

Fuser Exit Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[10-23] Fuser Exit Sensor

Check Items

E3-6

• Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exit Sensor (PL

6.2).

– Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505)

– Wire between Fuser Exit Sensor J153-2 and LVPS J505-2

– Wire between Fuser Exit Sensor J153-1 and LVPS J505-3

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Record in

Error Log RAP BSD

O -

O -

CH8.4

Figure 4

CH10.2

Figure 2

Status Indicator RAPS

June, 2008

2-14

Reissue

WorkCentre 5016, 5020

Page 29

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

IOT L/H Cover open

Explanation

The Left Hand Cover is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[01-01] LH Cover Interlock Switch

E5-1

Check Items

• Check that the Left Hand Cover closes correctly.

• Check that the LH Cover Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the LH Cover Interlock

Switch (PL 8.2).

– Wire between LH Cover Interlock Switch FS151 ( FS151) and LVPS J506-4 ( P/J506)

– Wire between LH Cover Interlock Switch FS152 ( FS152) and LVPS J506-3

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1 ) (REP 8.1.1) in that order.

Error Name

IOT Front Cover open

Explanation

The Front Cover is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[01-12] Front Cover Interlock Switch

E5-2

Check Items

• Check that the Front Cover closes correctly.

• Check that the Front Cover Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Front Cover Interlock

Switch (PL 8.2).

– Wire between Front Cover Interlock Switch FS153 ( FS153) and LVPS J506-2 ( P/J506)

– Wire between Front Cover Interlock Switch FS154 ( FS154) and LVPS J506-1

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1 ) (REP 8.1.1) in that order.

Error Name

L/H Low Cover open

Explanation

Access Cover 1 is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[01-11] Tray1 Interlock Switch

E6-1

Check Items

• Check that Access Cover 1 closes correctly.

• Check that the Tray 1 Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Interlock

Switch (PL 2.5).

– Wire between Tray 1 Interlock Switch J161-2 ( P/J161) and LVPS J501-9 ( P/J501)

– Wire between Tray 1 Interlock Switch J161-1 and LVPS J501-10

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1 ) (REP 8.1.1) in that order.

Record in

Error Log RAP BSD

X -

X -

X -

CH1.2

Figure 2

CH1.2

Figure 2

CH7.1

Figure 1

Reissue

WorkCentre 5016, 5020

June, 2008

2-15

Status Indicator RAPS

Page 30

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

STM L/H Cover open

Explanation

Access Cover 2 is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[01-10] STM Interlock Switch

E6-2

Check Items

• Check that Access Cover 2 closes correctly.

• Check that the STM Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Inte r lo ck Sw it ch

(PL 11.5).

– Wire between STM Interlock Switch J173-2 ( P/J173) and STM PWB J542-9 ( P/J542)

– Wire between STM Interlock Switch J173-1 and STM PWB J542-10

• Replace the STM PWB (PL 11.5) (REP 11.5.2), the LVPS (PL 8.1) (REP 8.1.2), and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Error Name

Nup NG Out Of Range

Explanation

The magnification is not within the range of 50 to 200% during Nup.

E8-1

Check Items

• Press the [Stop] button on the Control Panel.

• Press the [Paper Supply] button on the Control Panel.

• Press the [Special Copy] button on the Control Panel.

• Press the [Original Size Input] button on the Control Panel.

• Press the [Clear All] button on the Control Panel.

Error Name

Nup Paper direction mismatch

Explanation

The paper orientation of the document and the tray are not aligned during Nup.

E8-2

Check Items

• Press the [Stop] button on the Control Panel.

• Press the [Paper Supply] button on the Control Panel.

• Press the [Special Copy] button on the Control Panel.

• Press the [Original Size Input] button on the Control Panel.

• Press the [Clear All] button on the Control Panel.

Record in

Error Log RAP BSD

X -

X -

X -

CH7.2

Figure 2

CH3.2

Figure 2

CH3.2

Figure 2

Status Indicator RAPS

June, 2008

2-16

Reissue

WorkCentre 5016, 5020

Page 31

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Exit SNR on JAM

Explanation

Timeout between IOT Registration Clutch ON and Fuser Exit Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [08-10] IOT Registration Clutch

• [10-23] Fuser Exit Sensor

Check Items

• Registration Roll dirty, contaminated with paper dust, worn, or faulty

• Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged or not within specification

E1-2

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• IOT Registration Clutch faulty

• Check that the IOT Registration Clutch and the LVPS J503-4/5 ( P/J503) pins are connected securely with good electrical contact. If there is

no problem, replace the IOT Registration Clutch (PL 2.9).

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exit Sensor (PL

6.2).

– Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505)

– Wire between Fuser Exit Sensor J153-2 and LVPS J505-2

– Wire between Fuser Exit Sensor J153-1 and LVPS J505-3

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Name

Exit SNR off JAM

Explanation

Timeout between Fuser Exit Sensor ON and Fuser Exit Sensor OFF.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[10-23] Fuser Exit Sensor

Check Items

• Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged

E3-1

• Paper damaged or not within specification

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exit Sensor (PL

6.2).

– Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505)

– Wire between Fuser Exit Sensor J153-2 and LVPS J505-2

– Wire between Fuser Exit Sensor J153-1 and LVPS J505-3

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1 ) (REP 8.1.1) in that order.

Record in

Error Log RAP BSD

O -

O -

CH10.2

Figure 2

CH10.2

Figure 2

Reissue

WorkCentre 5016, 5020

June, 2008

2-17

Status Indicator RAPS

Page 32

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

• MCU-STM comm. error

Explanation

H9-7

A communication failure has occurred between the MCU and the Tray Module.

Check Items

• Turn the power OFF then ON.

• Check for any open circuit or short circuit between the STM connectors.

• Replace the STM PWB (PL 11.5) (REP 11.5.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Error Name

Copy Counter Full

L9-0

Explanation

The user that is logged in has reached the allotted copy limit in the Account Mode.

Check Items

Press the [Stop] button on the Control Panel.

Error Name

Toner Cartridge was PRENEAR empty

Explanation

The toner cartridge is low.

J1-0

Check Items

• Refill the toner.

• Foreign matter on the sensor.

• Check that the T oner Empty Sensor and the L VPS J509-1-4 ( P/J509) pins are connected securely with good electrical contact. If there is no

problem, replace the Toner Empty Sensor (PL 4.2).

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Name

Toner Empty

Explanation

The Toner Cartridge is empty.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

J1-2

[09-07] Toner Empty Sensor

Check Items

• Refill the toner.

• Foreign matter on the sensor.

• Check that the Toner Empty Sensor and the LVPS J509 ( P/J509) 1-4 pins are connected securely with good electrical contact. If there is

no problem, replace the Toner Empty Sensor (PL 4.2).

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Record in

Error Log RAP BSD

O -

X -

CH3.1

Figure 1

CH3.2

Figure 2

X - -

O -

CH9.2

Figure 2

Status Indicator RAPS

June, 2008

2-18

Reissue

WorkCentre 5016, 5020

Page 33

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

No Drum Cartridge

Explanation

Unable to detect the Drum Cartridge.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

[09-02] Drum Cartridge

Check Items

• Turn the power OFF then ON.

J3-1

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Drum Cartridge (PL

4.1) (REP 4.1.1).

– Wire between Drum Cartridge P610-7 ( P610) and AIOC PWB J402-1 ( P/J402)

– Wire between Drum Cartridge P610-3 and AIOC PWB J402-4

– Wire between Drum Cartridge P610-2 and AIOC PWB J402-5

– Wire between Drum Cartridge P610-5 and AIOC PWB J402-2

– Wire between Drum Cartridge P610-4 and AIOC PWB J402-3

– Wire between Drum Cartridge P610-1 and AIOC PWB J402-6

• Replace the Drum Cartridge (PL 4.1) (REP 4.1.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Error Name

Drum near end of life

J6-0

Explanation

The Drum Cartridge is near the end of its life.

Check Items

Replace the Drum Cartridge (PL 4.1) (REP 4.1.1).

Error Name

Drum cartridge life end

J6-1

Explanation

The Drum Cartridge has reached the end of its life.

Check Items

Replace the Drum Cartridge (PL 4.1) (REP 4.1.1).

Record in

Error Log RAP BSD

O -

CH9.2

Figure 2

X - -

O - -

Reissue

WorkCentre 5016, 5020

June, 2008

2-19

Status Indicator RAPS

Page 34

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Drum CRUM comm. Error

Explanation

The AIOC PWB is unable to communicate with the Drum Cartridge.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)

• [09-02] Drum Cartridge

Check Items

• Turn the power OFF then ON.

J7-1

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Drum Cartridge (PL

4.1) (REP 4.1.1).

– Wire between Drum Cartridge P610-7 ( P610) and AIOC PWB J402-1 ( P/J402)

– Wire between Drum Cartridge P610-3 and AIOC PWB J402-4

– Wire between Drum Cartridge P610-2 and AIOC PWB J402-5

– Wire between Drum Cartridge P610-5 and AIOC PWB J402-2

– Wire between Drum Cartridge P610-4 and AIOC PWB J402-3

– Wire between Drum Cartridge P610-1 and AIOC PWB J402-6

• Replace the Drum Cartridge (PL 4.1) (REP 4.1.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Error Name

Drum CRUM Market Identity Mismatch

Explanation

J7-2

The AIOC PWB has detected that the Drum CRUM destination does not match.

Check Items

• Turn the power OFF then ON.

• Replace the Drum Cartridge (PL 4.1) (REP 4.1.1).

Error Name

Drum CRUM ID error

Explanation

J7-3

• The AIOC PWB has detected that the Drum CRUM ID is incorrect.

Check Items

• Turn the power OFF then ON.

• Replace the Drum Cartridge (PL 4.1) (REP 4.1.1).

Error Name

EPC Memory F ull

Explanation

N1-1

• During a copy job in Collate Mode, the EPC memory is full.

• Or, the machine has reached a state where it is unable to scan in any more documents.

Check Items

Press the [Stop] button on the Control Panel.

Record in

Error Log RAP BSD

O -

O -

O -

CH9.2

Figure 2

CH9.2

Figure 2

CH9.2

Figure 2

O - -

Status Indicator RAPS

June, 2008

2-20

Reissue

WorkCentre 5016, 5020

Page 35

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

No Response from USB-Host

Explanation

N4-0

• Either "USB disconnected" or "Communication timed-out" is detected during a print job.

• Or, either "USB disconnected" or "Communication timed-out" is detected during a scan job.

Check Items

• Cancel the print job.

• Reconnect the USB cable correctly.

Error Name

HBPL or XPJL Syntax Error

Explanation

N4-1

An abnormal command that cannot be ignored is received from the USB-Host during a print job.

Check Items

• Cancel the print job.

• Reconnect the USB cable correctly.

Error Name

Download File Error

N4-2

Explanation

There is an abnormal Product ID or there is a checksum error in the download file.

Check Items

Press the [Stop] button on the Control Panel.

Error Name

Download Flash Write Error

N4-3

Explanation

Unable to write the downloaded file into flash memory.

Check Items

Press the [Stop] button on the Control Panel.

Error Name

CPM Image Lost

E0-1

Explanation

During a copy job in CPM Priority Mode, the paper containing an image cannot be output after the image is deleted.

Check Items

Press the [Stop] button on the Control Panel.

Error Name

Push Scan TimeOut

Explanation

N5-0

• Push scan notification failed during a scan job.

• Or, there is no scan job request from the PC after a push scan notification.

Check Items

The error will clear itself after a set amount of time has passed.

Record in

Error Log RAP BSD

O -

O -

CH3.2

Figure 2

CH3.2

Figure 2

-

-

O - -

O - -

Reissue

WorkCentre 5016, 5020

June, 2008

2-21

Status Indicator RAPS

Page 36

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

Controller Logic fail

N9-0

Explanation

A software defect that cannot be ignored is found in the Controller software.

Check Items

Turn the power OFF then ON.

Error Name

IOT Communication Error

N9-1

Explanation

The AIOC PWB has detected a Type-Di communication error.

Check Items

Turn the power OFF then ON.

Error Name

U0-1

Main Motor stop error

Explanation

The motor runs for over 120 seconds without any paper being fed.

Error Name

U1-1

Main Motor rotation error

Explanation

500ms after the IOT has started, the Main Motor Lock signal is "Low."

Error Name

U2-1

Carriage Module Fail

Explanation

An abnormality was detected in the Carriage Module.

Error Name

Laser Power or ROS Motor Fail

U3-5

Explanation

• The ROS Motor is unable to rotate.

• Or, the laser output is not normal.

Error Name

Fuser On Time Fai l

U4-1

Explanation

• The lamp did not turn OFF within the specified time after turning ON.

• Or, Warm Up was not completed within the specified time after power ON.

Error Name

U4-2

Over Heat Temp Fail

Explanation

A temperature above 250°C is continuously detected for 480ms .

Error Name

U4-3

FS1 thermistor defect

Explanation

FS1 cannot be monitored any more.

Record in

Error Log RAP BSD

O -

O -

O U0-1

O U1-1

O U2-1

O U3-5

O U4-1

O U4-2

O U4-3

CH3.2

Figure 2

CH3.2

Figure 2

CH4.1

Figure 1

CH4.1

Figure 1

CH6.2

Figure 2

CH6.3

Figure 3

CH10.1

Figure 1

CH10.1

Figure 1

CH10.1

Figure 1

Status Indicator RAPS

June, 2008

2-22

Reissue

WorkCentre 5016, 5020

Page 37

Error

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Error Name

U4-9

Fuser Fan defect

Explanation

After the start of Fan Fail Signal monitoring, the signal level was Low not more than 30 times.

Error Name

U6-2

RAM read/write check error

Explanation

When the MCU runs the overall Read/Write check for RAM during startup, the Read Data and Write Data do not match.

Error Name

NVM data defect

U6-3

Explanation

• The NVM Header data ERROR and NVM 3 page data do not match.

• Or, unable to find the NVM Write & Read area.

• The NVM or Counter areas are full.

Error Name

NVM read/write cannot be executed

U6-4

Explanation

• An NVM Ack NG is detected during NVM Read.

• An NVM Write Error is detected 5 times during NVM Recovery.

Error Name

U6-5

CPU Power to access NVM is not enough

Explanation

NVM queue full is detected during NVM Write.

Error Name

U7-0

UI Communication TimeOut

Explanation

At the Power On Sequence, the AIOC PWB did not communicate with the User Interface PWB.

Error Name

U7-1

UI Communication Error

Explanation

The User Interface PWB has detected a communication failure.

Error Name

Billing Counter Defect

U8-1

Explanation

• It is detected that the Billing Counter Value is incorrect.

• Or, the AOIC PWB has failed to read the Billing Counter.

Error Name

U9-0

HVPS fail

Explanation

A 500 msec cycle of the signal HVPS#ERR=High was detected twice in a row.

Record in

Error Log RAP BSD

O U4-9

O U6-2

O U6-3

O U6-4

O U6-5

X U7-0

X U7-1

O U8-1

O U9-0

CH10.3

Figure 3

CH3.2

Figure 2

CH3.2

Figure 2

CH3.2

Figure 2

CH3.2

Figure 2

CH2.1

Figure 1

CH2.1

Figure 1

CH3.2

Figure 2

CH9.1

Figure 1

Reissue

WorkCentre 5016, 5020

June, 2008

2-23

Status Indicator RAPS

Page 38

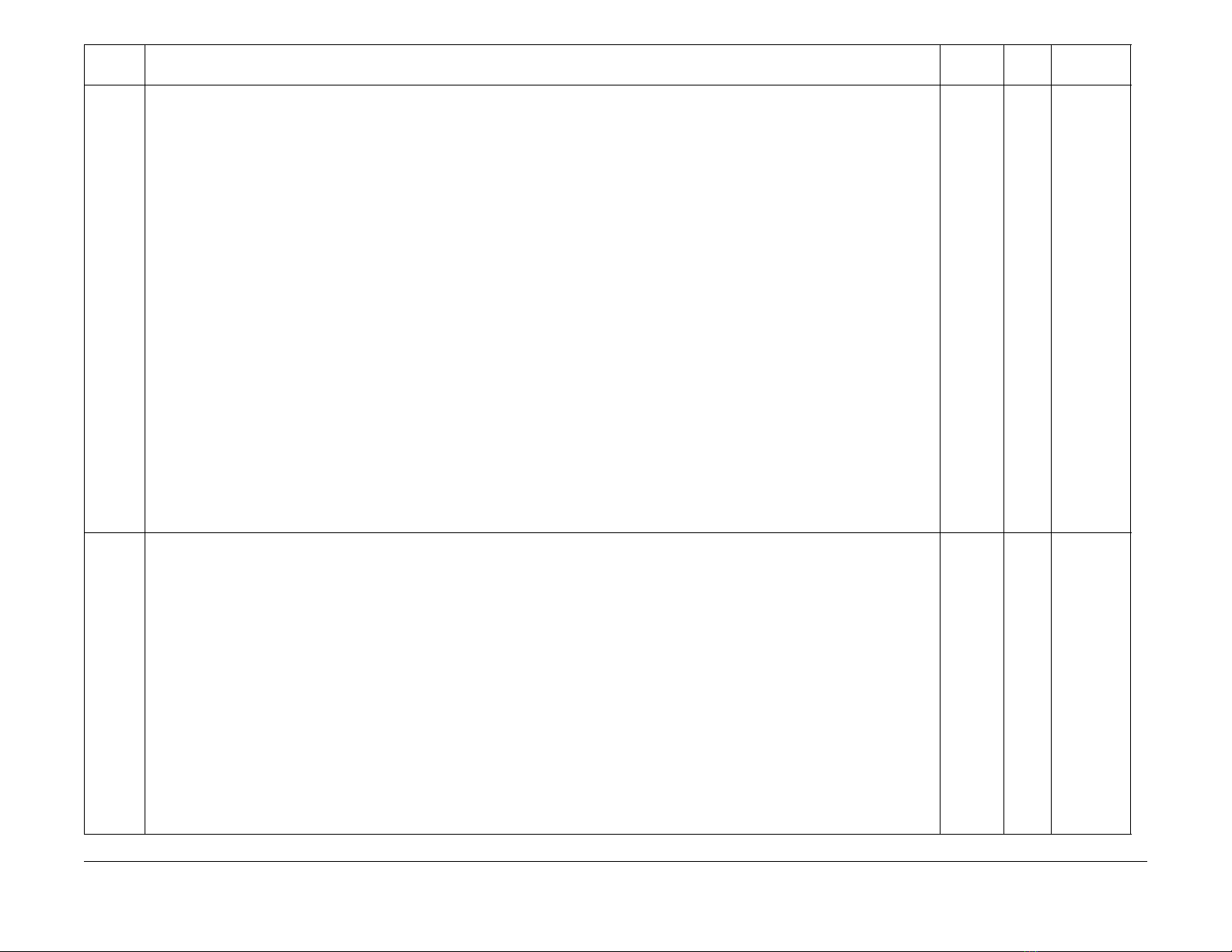

Display Priority in Case of Multiple Errors

When multiple errors occur simultaneously, they will be shown on the Control Panel display in

the following priority order. Always begin troubleshooting with the highest-priority error.

Priority

Order

1

(Highest)

2 U7-1 UI Communication Error

3 H9-7 MCU-STM comm. error

4 N9-1 IOT Communication Error

5 N9-0 Controller Logic fail

6 U0-1 Main Motor stop error

7 U1-1 Main Motor rota t ion error

8 U2-1 Carriage Module Fail

9 U3-5 Laser Power or ROS Motor Fail

10 U4-1 Fuser On Time Fail

11 U4-2 Over Heat Temp Fail

12 U4-3 FS1 thermistor defect

13 U4-9 Fuser Fan defect

14 U6-2 RAM read/write check error

15 U6-3 NVM data defect

16 U6-4 NVM read/write cannot be executed

17 U6-5 RAM read/write check error

18 U8-1 Billing Counter Defect

19 U9-0 HVPS fail

20 E9-1 AMS NG Out Of Range

21 E9-2 Paper direction mismatch

22 E8-1 Nup NG Out Of Range

23 E8-2 Nup Paper direction mismatch

24 L9-0 Copy Counter Full

25 N4-0 No Response from USB-Host

26 N4-1 HBPL or XPJL Syntax Error

27 N4-2 Download File Error

27 N4-3 Download Flash Write Error

29 N5-0 Push Scan TimeOut

30 A5-1 Platen Cover Open Document Cover

32 E5-1 IOT L/H Cover open

33 E5-2 IOT Front Cover open

34 E6-1 L/H Low Cover open

35 E6-2 STM L/H Cover open

Error

Code

U7-0 UI Communication TimeOut

Error Name Error Characteristic

Unable to control the

display at the Control

ler

Fatal Error

Dynamic Error

(Job Cancel)

Open

Paper Cover Open

-

Priority

Order

36 A1-1 Doc Misfeed Jam

37 A2-2 No Supported Doc Size

38 A4-1 Short Length Detect

39 A4-2 Long Length Detect

40 C1-1 Tray1 F/O#1 SNR on JAM

41 C1-2 Tray1 Regi SNR on JAM

42 C2-1 STM F/O#2 SNR on JAM

43 C2-2 Tray1 F/O#1 SNR on JAM from STM feed

44 C2-3 STM Regi SNR on JAM

46 C9-3 MSI Regi SNR on JAM

47 E1-2 Exit SNR on JAM

48 E3-1 Exit SNR off JAM

49 C8-1 F/O#1 SNR Static JAM

50 C8-2 F/O#2 SNR Static JAM

51 E1-6 Regi SNR Static JAM

52 E3-6 Exit SNR JAM

53 E0-1 CPM Image Lost

54 C0-1 APS NG Unselected

56 C5-1 Tray1 Paper Size Mismatch

57 C6-1 Tray2 Paper Size Mismatch

58 C7-1 MSI Paper Size Mismatch

59 C5-0 No paper in the select paper tray (Tray1)

60 C6-0 No paper in the select paper tray (Tray2)

61 J1-2 Toner Empty

62 J3-1 No Drum cartridge

63 J6-1 Drum cartridge life end

64 J7-1 Drum CRUM comm. Error

65 J7-2 Drum CRUM Market Identity Mismatch

66 J7-3 Drum CRUM ID error

67 N1-1 EPC Memory Full An error that only

Error

Code Error Name Error Characteristic

Document Jam

Paper Jam

Tray-related errors

Resolvable by replac-

ing parts

stops scanning

Status Indicator RAPS

June, 2008

2-24

Reissue

WorkCentre 5016, 5020

Page 39

U0-1 Main Motor Stop Error

BSD-Reference: CH4.1 (Figure 1)

U1-1 Main Motor Rotation Error

BSD-Reference: CH4.1 (Figure 1)

Explanation

The motor runs for over 120 seconds without any paper being fed.

Procedure

The problem can be solved according to RAP U1- 1 Main Motor Rotation Error (U1-1).

YN

Execute diagnostics [29-49] (How to Enter the Diagnostic Mode) to check the ROM ve rsion. The ROM is the latest version.

YN

Upgrade the ROM to the latest version.

Replace the IOT Motor (PL 1.1) (REP 1.1.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in

that order.

Completed

Explanation

500 ms after the IOT Motor starts, the IOT Motor Lock signal is Low.

Procedure

Close the Left Hand Cover and the Front Cover. Execute diagnostics [04--01 Main Motor On].

(How to Enter the Diagnostic Mode)

YN

Check P/J504 and P/J201. Both P/J504 and P/J201 are connected securely.

YN

Connect P/J504 and P/J201 securely.

Measure the voltage between LVPS PWB P504-1 ( P/J504) (+) and GND (-). The volt-

age is approximately +24VDC.

YN

Replace the LVPS (PL 8.1) (REP 8.1.2).

Check the wire between J504-3 ( P/J504) and J201-3 ( P/J201). The wire is not

shorted or o pe n .

YN

Repair the wire.

Replace the IOT Motor (PL 1.1) (REP 1.1.1) a nd the AIOC PWB (PL 8.1) (REP 8.1.1) in

that order.

Check the installation of the IOT Motor (PL 1.1 ) (REP 1.1.1). The IOT Motor is installed

properly.

YN

Install the IOT Motor (PL 1.1 ) (REP 1.1.1) properly.

The IOT Motor can be heard rotating.

Reissue

WorkCentre 5016, 5020

Turn the rotor of the IOT Motor (PL 1.1 ) counterclockwise by hand. It rotates smoothly,

without any abnormal loa d.

YN

Check for any foreign substances that obstruct the drive and for any incorrectly installed

There are foreign substances or incorrectly installed parts.

parts.

YN

Replace the IOT Motor (PL 1.1) (REP 1.1.1).

Remove any foreign substances and fix any installation errors.

Check the wire between J504-3 ( P/J504) and J201-3 ( P/J201). The wire is not shorted

or open.

YN

Repair the wire.

Replace the IOT Motor (PL 1.1) (REP 1.1.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that

order.

June, 2008

2-25

Status Indicator RAPS

U0-1, U1-1

Page 40

U2-1 Carriage Module Fail

BSD-Reference: CH6.2 (Figure 2)

U3-5 Laser Power Or ROS Motor Fail

BSD-Reference: CH6.3 (Figure 3)

Explanation

A carriage fault was detected.

Procedure

Execute diagnostics [05-22 Move scanner to home position] and [05-23 Move scanner to maintenance position]. (How to Enter the Diagnostic Mode) The carriage moves.

YN

Check each IIT Carriage connector. Each connector is connected securely.

YN

Connect each connector securely.

Check for foreign substances and deformed parts in the carriage. None is found.

YN

Remove the foreign substances and repair the deformed parts.

Replace the IIT Carriage (PL 10.3)(REP 10.3.1).

Execute diagnostics [05-23 Move scanner to maintenance position]. When the IIT Carriage

has moved to the leftmost position, press the [Stop] button to put the Carriage Sensor into the

blocked state.

YN

Check each IIT Carriage and Carriage Sensor connector. Each connector is connected securely.

YN