Page 1

Version 1.0

July 2008

DocuColor 5000AP

Administrator

Guide

Page 2

©

Copyright 2008 by Xerox Corporation. All Rights Reserved.

Copyright protection claimed includes all forms and matters of copyrighted material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation, material generated from the software programs that are displayed on

the screen such as styles, templates, icons, screen displays, looks, etc.

®

Xerox

and all Xerox product names and product numbers mentioned in this publication are trademarks of XEROX CORPORATION.

Other company brands and product names may be trademarks or registered trademarks of the respective companies and are also

acknowledged.

This product includes software developed by the Apache Software Foundation (http://www.apache.org/

http://www.apache.org/).

Page 3

Table of contents

1. Administrator overview 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Logging on as Administrator. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Finishing System Profiles overview . . . . . . . . . . . . . . . . . . . . . 1-3

2. System Settings 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Fault Details window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Change Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting the Date & Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Productivity Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Productivity charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

All Weights Rated Speed . . . . . . . . . . . . . . . . . . . 2-11

Mixed Paper Weight . . . . . . . . . . . . . . . . . . . . . . . 2-12

Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Exit Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Auto Resume After . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Fault Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Pause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Job Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Auto Logoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

NVM Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Tray Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Auto Tray Switching, Auto Paper Selection, and Do Not

Include . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Paper Tray Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Tray Priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

DocuColor 5000AP Administrator Guide

i

Page 4

Table of contents

3. Profiles 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Alignment Adjustment Profile procedure. . . . . . . . . . . . . . . 3-2

Selecting the Registration options . . . . . . . . . . . . . . . . 3-5

Selecting the Perpendicularity options . . . . . . . . . . . . . 3-6

Selecting the Skew options . . . . . . . . . . . . . . . . . . . . . . 3-7

Selecting the Magnification options . . . . . . . . . . . . . . . 3-8

Running test prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Custom Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Custom Paper procedure . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Selecting the desired paper type . . . . . . . . . . . . . . . . 3-13

Selecting the desired paper weight. . . . . . . . . . . . . . . 3-14

Second Bias Transfer Belt . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Aligner Roll Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Paper Tray Air Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Decurler Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Decurler paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Decurler A-D Profile settings . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Decurler A-D Profile procedure. . . . . . . . . . . . . . . . . . . . . 3-28

Custom Decurler Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Entering values in the Custom Decurler Profile fields. . . . 3-34

Creating a Custom Decurler Profile . . . . . . . . . . . . . . . . . 3-36

ii

DocuColor 5000AP Administrator Guide

Page 5

1. Administrator overview

Overview

The Administrator mode allows you to set the default settings for

your digital press in order to fit your individual requirements. You

can change the settings for a variety of features, such as the

language to display on the UI, timers, changing the Administrator

password, creating custom paper and alignment profiles, and

more.

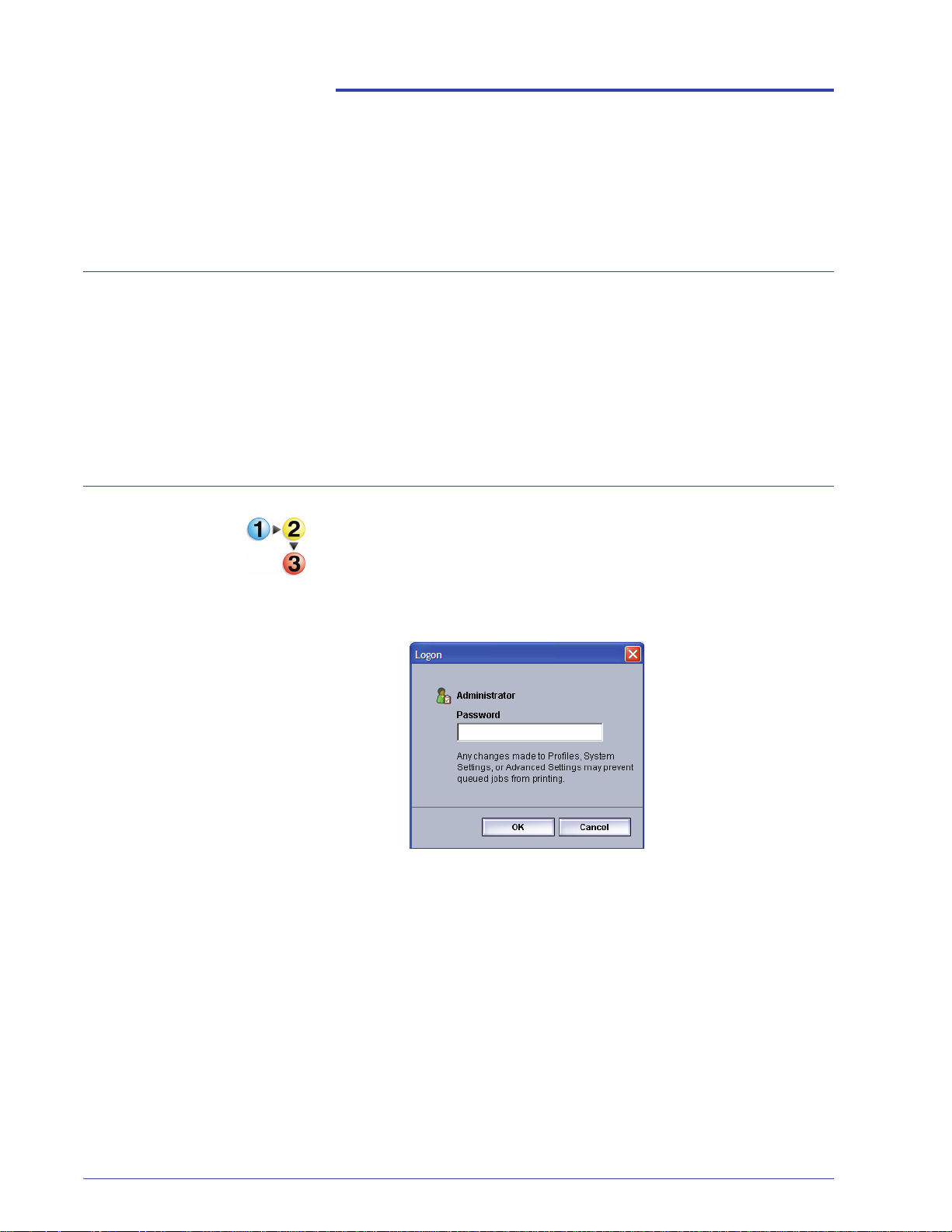

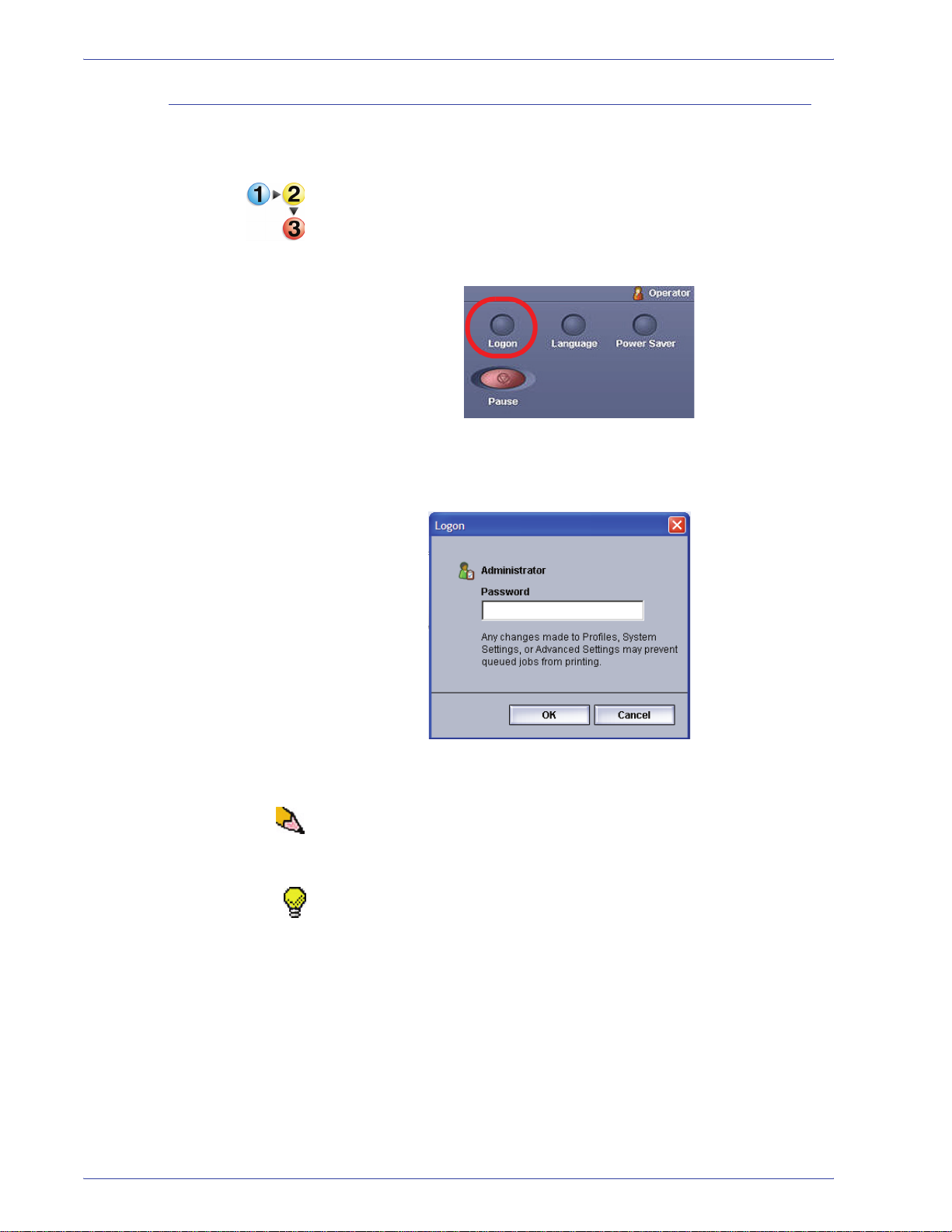

Logging on as Administrator

Use the following procedure to enter and exit the Administrator

mode:

1. Select the Logon button from the main UI window. The

Logon screen appears.

2. Use the keyboard to enter the Administrator password.

The default password is five ones (11111).

For security reasons, only asterisks are displayed on the

screen.

DocuColor 5000AP Administrator Guide

1-1

Page 6

1. Administrator overview

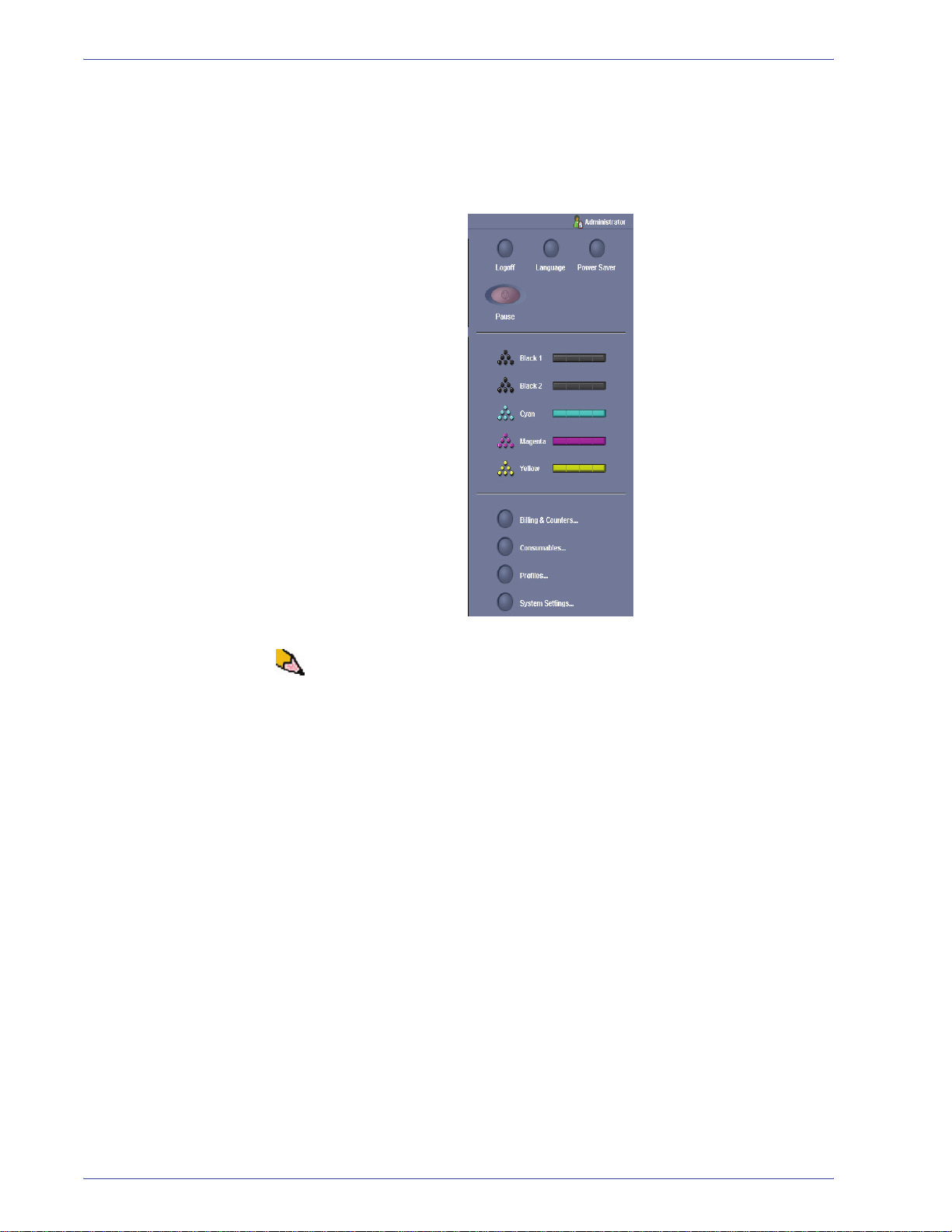

3. Select the OK button.

The main UI screen now displays additional options and

indicates in the upper right that you are in the Administrator

mode.

NOTE: It is recommended that you change the Administrator

password as soon as possible after installing the digital press in

order to prevent unauthorized access to the Administrator mode.

The procedure for changing the password is on page 2-5 of this

book.

4. To exit the Administrator mode, select the Logoff button.

1-2

DocuColor 5000AP Administrator Guide

Page 7

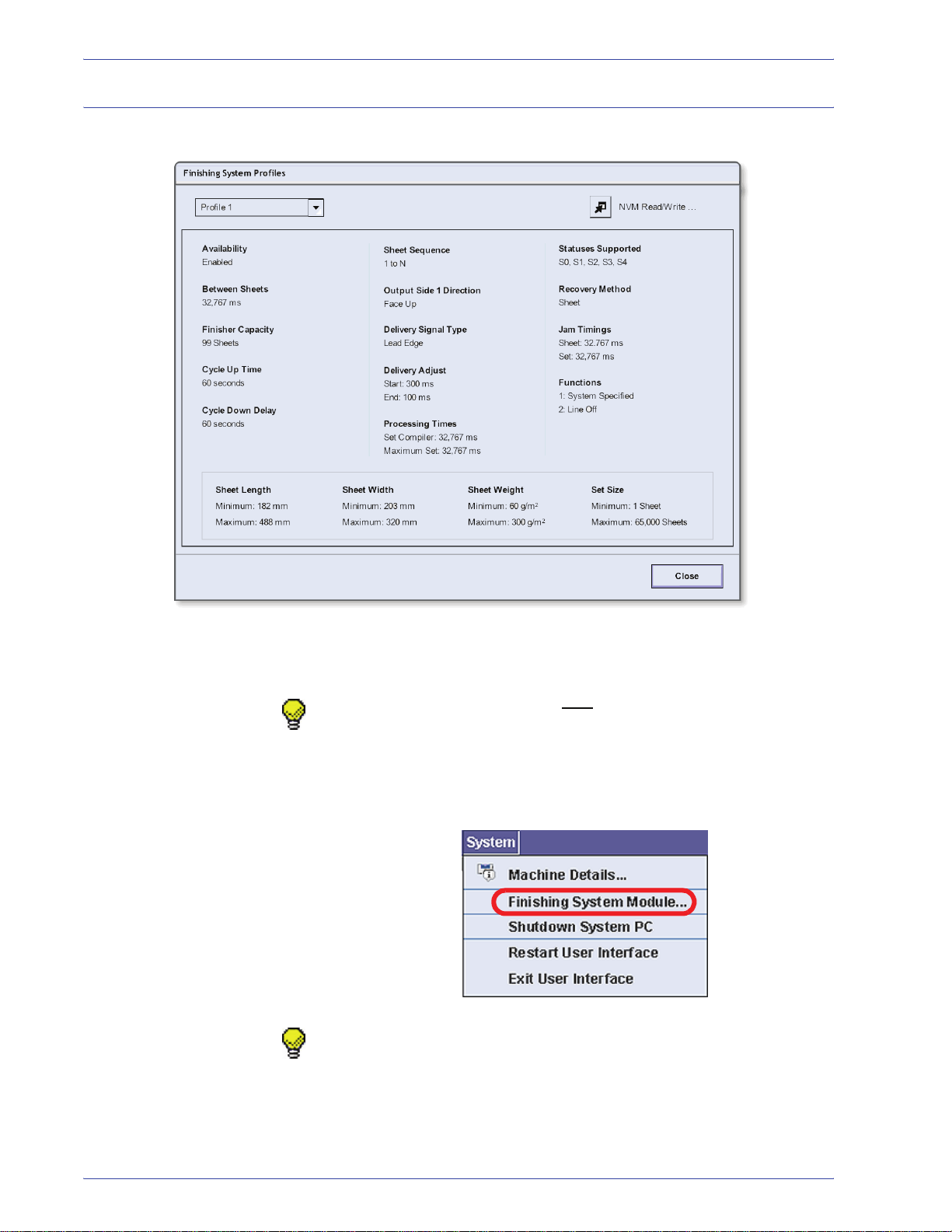

Finishing System Profiles overview

1. Administrator overview

If your digital press has an optional, third-party, Digital Finishing

Architecture (DFA) device finishing, then the Finishing System

Profiles option is available to you.

TIP: This feature is available only if you are logged on as the

Administrator.

Once your system is configured for the optional finishing

accessory, the Finishing System Profiles option is accessed from

the System pull-down menu on the main UI screen.

TIP: This window is ready-only; you cannot change the

information shown on this screen. If you have more than one

finishing device connected to your digital press, you can select the

desired profile from the pull-down menu at the upper-left portion of

the Finishing System Profiles window.

DocuColor 5000AP Administrator Guide

1-3

Page 8

1. Administrator overview

1-4

DocuColor 5000AP Administrator Guide

Page 9

Overview

2. System Settings

The System Settings feature allows you to make changes to the

following features:

• User Interface

• Date and Time

•System

• Tray Options

DocuColor 5000AP Administrator Guide

2-1

Page 10

2. System Settings

User Interface

The User Interface feature allows you to make changes to the

following:

• Fault Detail Window

• Changing the Administrator password

2-2

DocuColor 5000AP Administrator Guide

Page 11

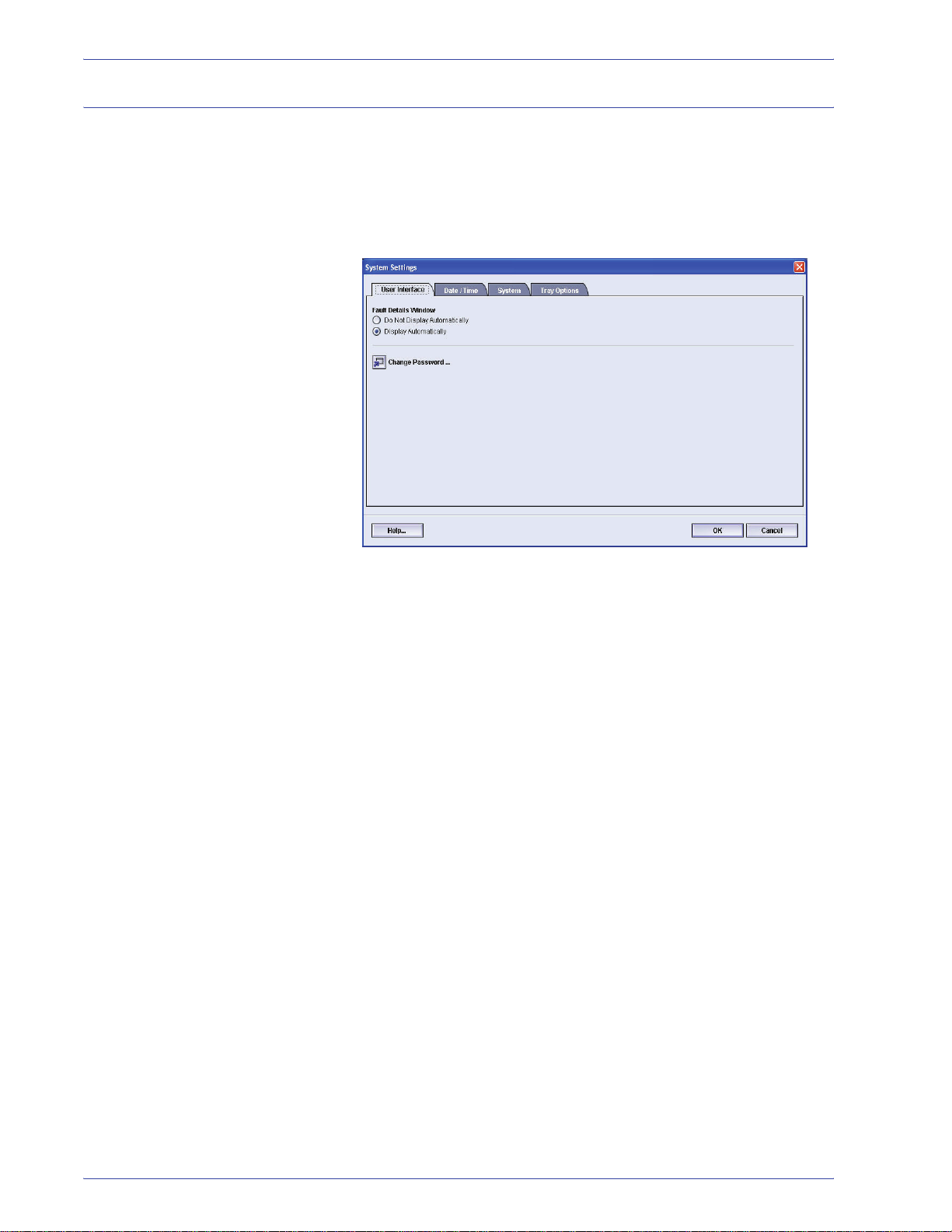

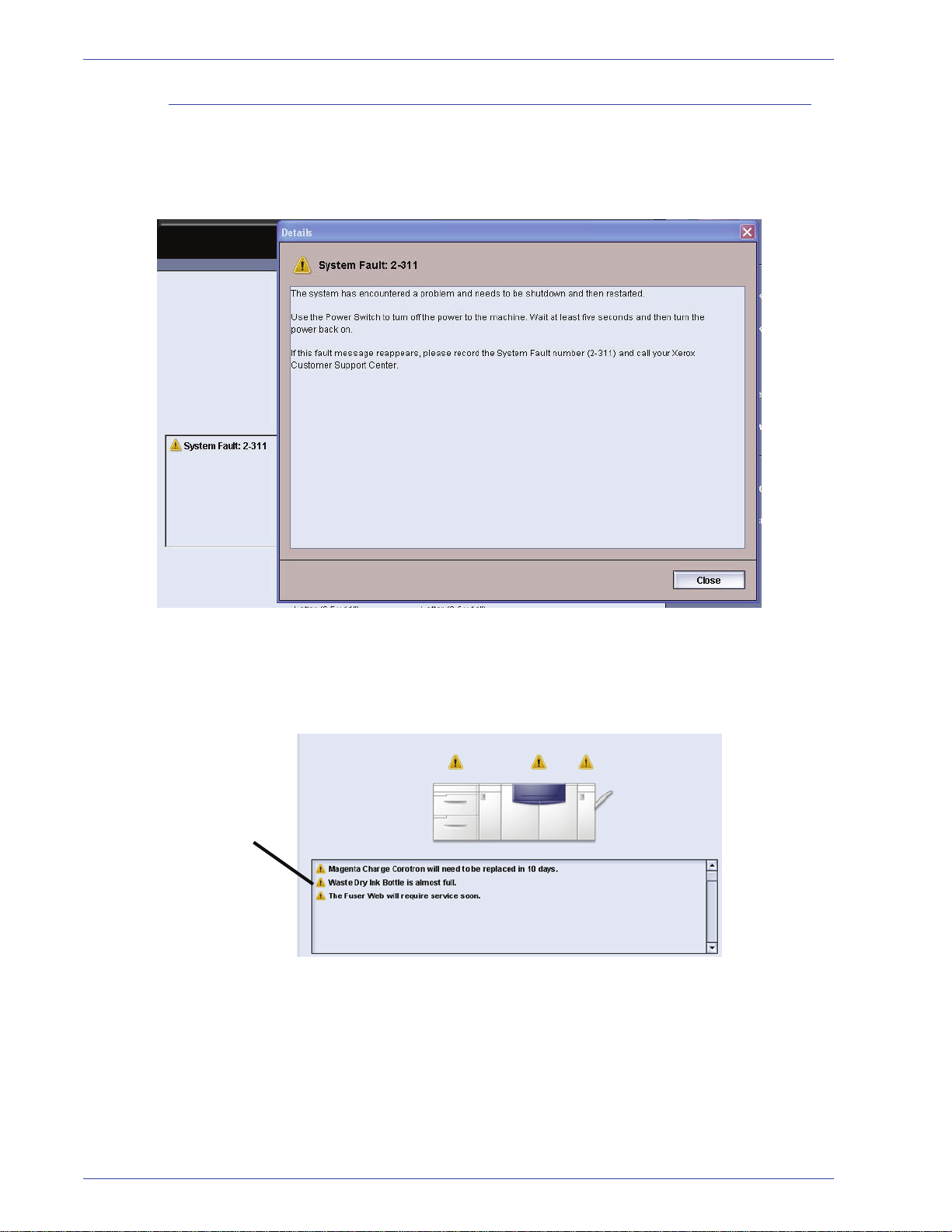

Fault Details window

By default, the UI automatically opens a Details window which

provides additional information about the alert, warning, or fault

(as shown in the following illustration).

2. System Settings

Machine

mimic and

Message

area

However, you can select whether or not you want this window

open automatically or to open only when the user clicks on the

alert, warning, or fault message in the machine mimic and

message area of the UI.

DocuColor 5000AP Administrator Guide

2-3

Page 12

2. System Settings

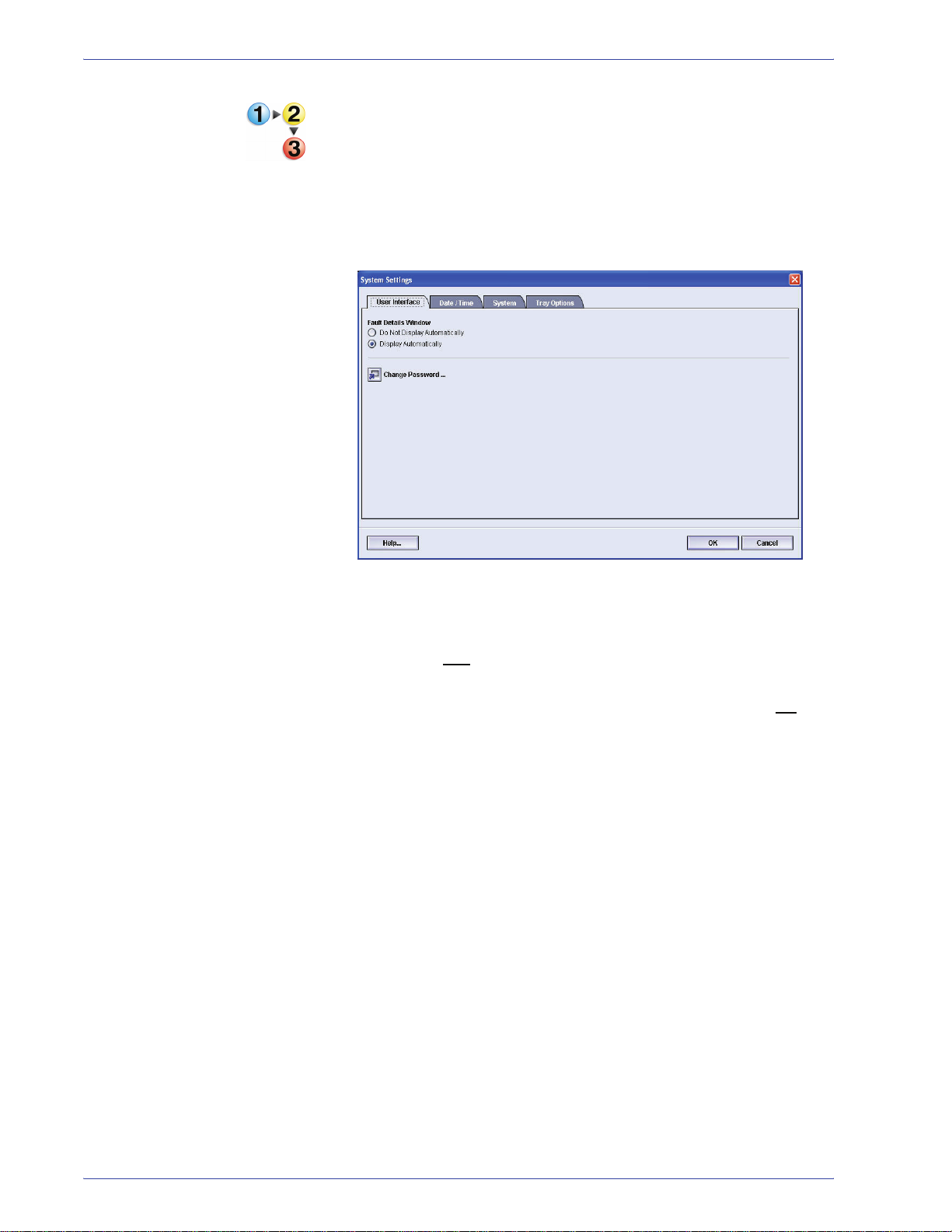

Use the following procedure to choose the default setting for this

feature.

1. Select the Logon button from the UI and logon as the

Administrator.

2. Select the System Settings button; the System Settings

window opens.

3. Select whether or not you want any machine faults to

automatically display on the UI when they occur.

• Do Not Display Automatically: Select this option if you

do not

automatically when an alert, warning, or fault occurs.

• Display Automatically: Select this option if you do

want the fault Details window to open automatically

when an alert, warning, or fault occurs.

want the fault Details window to open

4. Select OK to save the change and close the System

Settings window.

2-4

DocuColor 5000AP Administrator Guide

Page 13

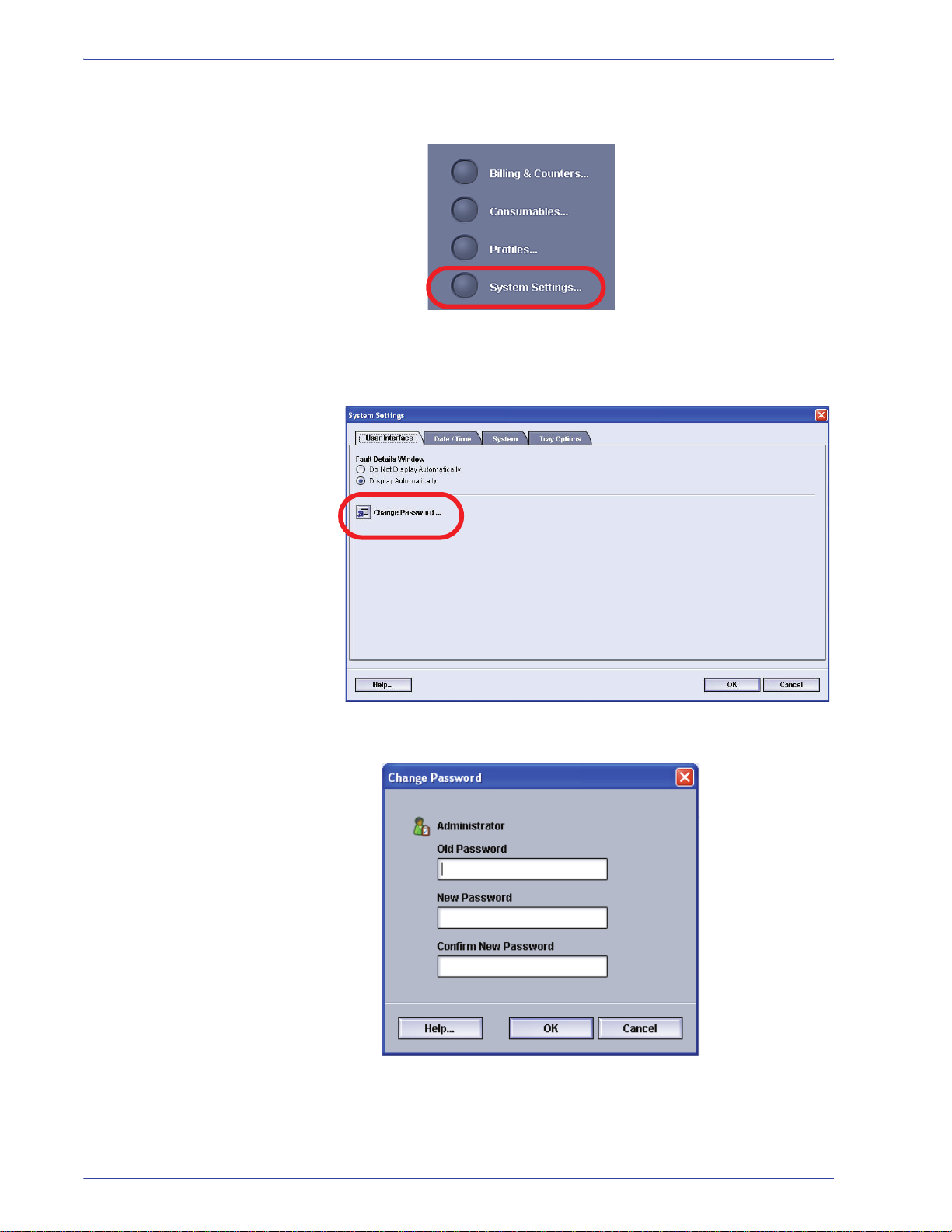

Change Password

2. System Settings

Select the Change Password button if you want to change the

Administrator password.

Use the following procedure to change the Administrator

password.

1. Select the Logon button from the main UI window.

2. From the Logon window, enter the Administrator password

and select OK.

For security reasons, only asterisks are displayed on the

screen.

NOTE: The digital press arrives from the fac tory with a default

Administrator password of five ones ( 11111). Use this default

password to logon.

TIP: For security reasons, you should change the Administrator

password from its default password to a new one.

DocuColor 5000AP Administrator Guide

2-5

Page 14

2. System Settings

3. Select the System Settings button.

4. From the System Settings window, select the Change

Password button from the User Interface tab.

The Change Password window opens.

2-6

DocuColor 5000AP Administrator Guide

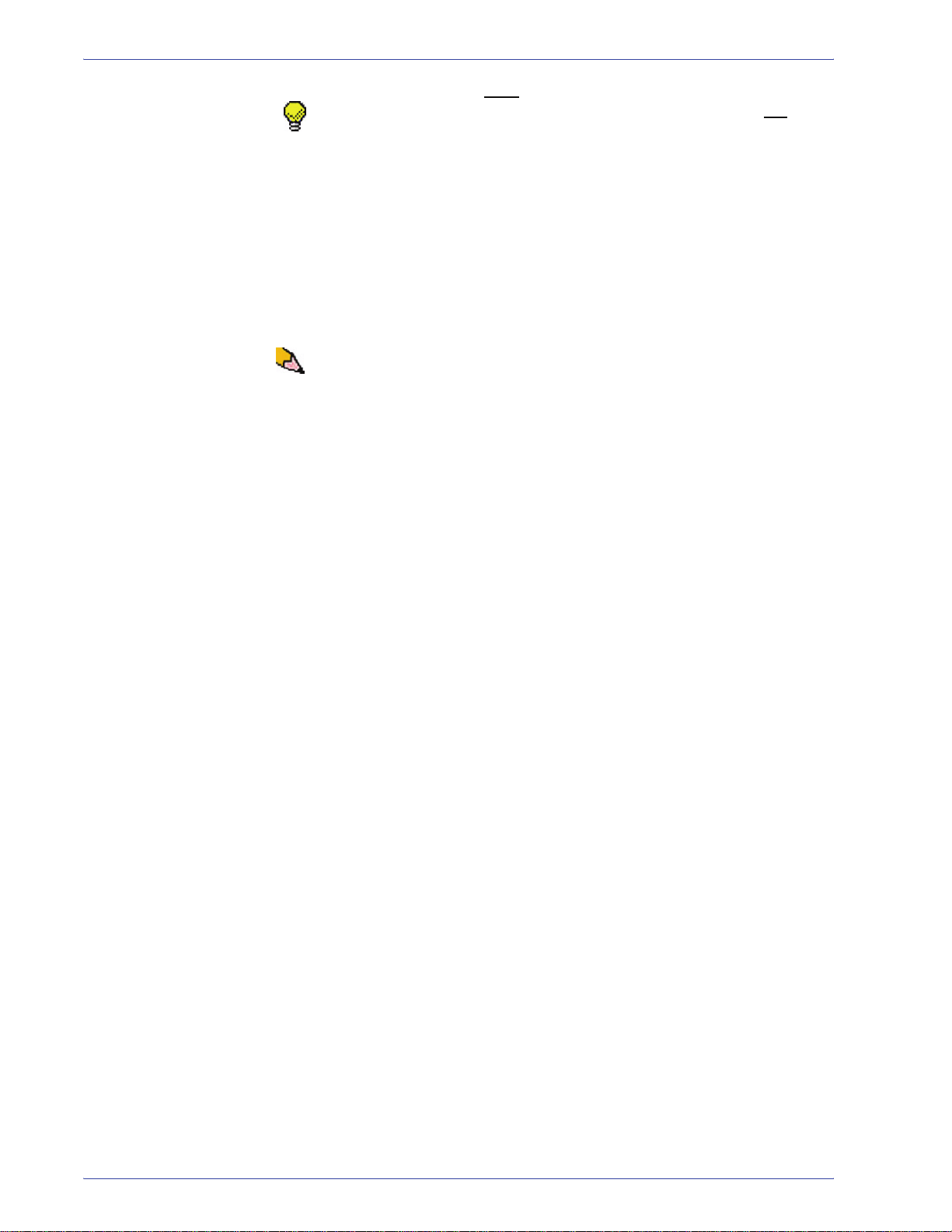

Page 15

2. System Settings

TIP: Use numbers only for creating your new password. Alpha

characters (letters and other characters, such as !*& are not

allowed). A maximum of twelve numbers can be entered for your

password.

5. From the Change Password window, enter:

a. The old (current) password

b. The new password

c. Reenter the new password in the Confirm New

Password area

d. Select OK

NOTE: For security reasons, only asterisks are displayed on the

screen.

6. Select OK from the System Settings window to return to the

main UI window.

DocuColor 5000AP Administrator Guide

2-7

Page 16

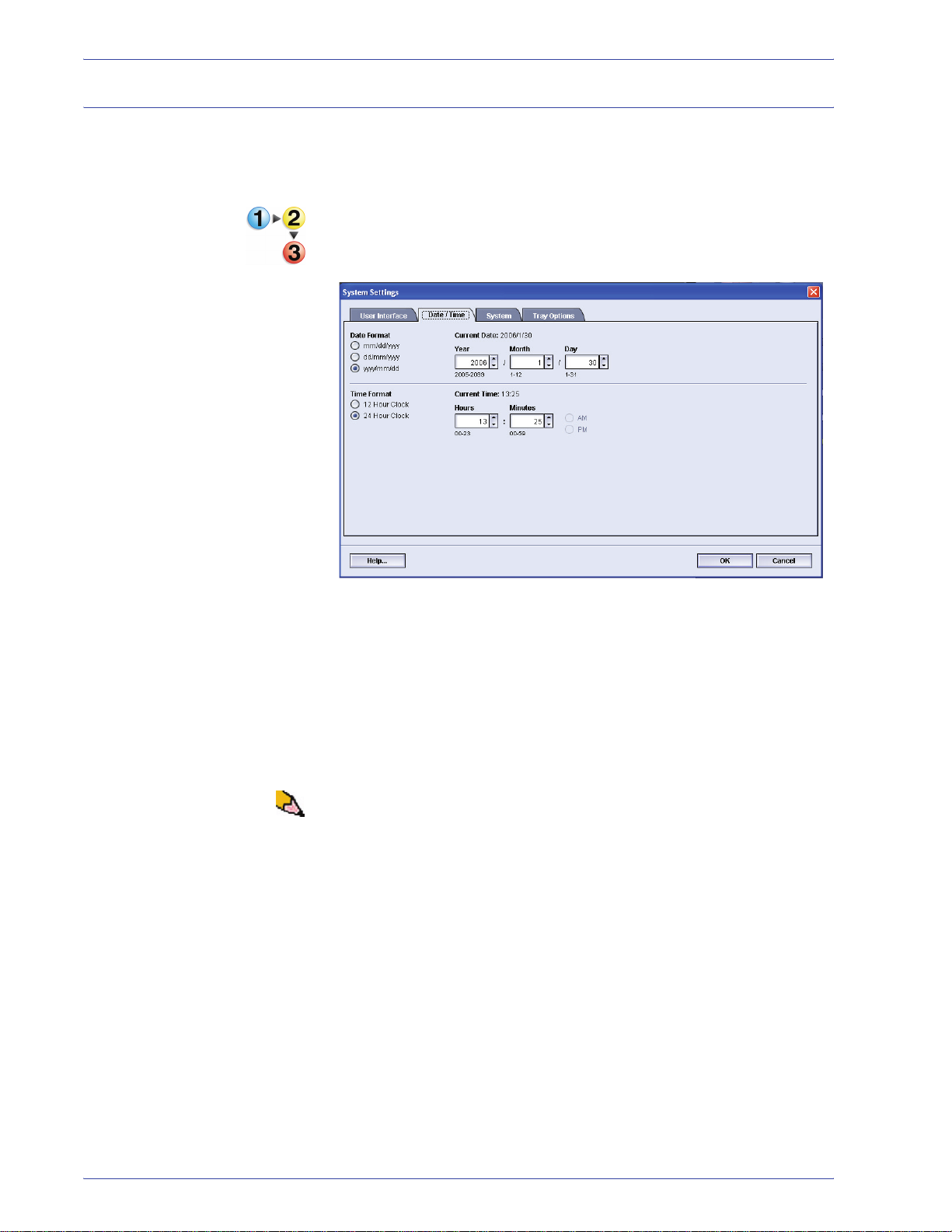

2. System Settings

Setting the Date & Time

Use this feature to set the date and time for the system. The date

and time is displayed on the Machine Details screen on both the

Installed Soft ware and Error Log screens.

1. From the System Settings window, select the Date/Time

tab.

2. Select the Date Format you wish to use.

3. Use the up or down arrow buttons to enter the correct year,

month, and day.

4. Select the Time Format you wish to use.

5. Use the up or down arrow buttons to set the correct hour

and minutes.

NOTE: If you selected the 12 Hour Clock, touch the AM or PM

button.

6. Select OK to save your changes and close the System

Settings window.

2-8

DocuColor 5000AP Administrator Guide

Page 17

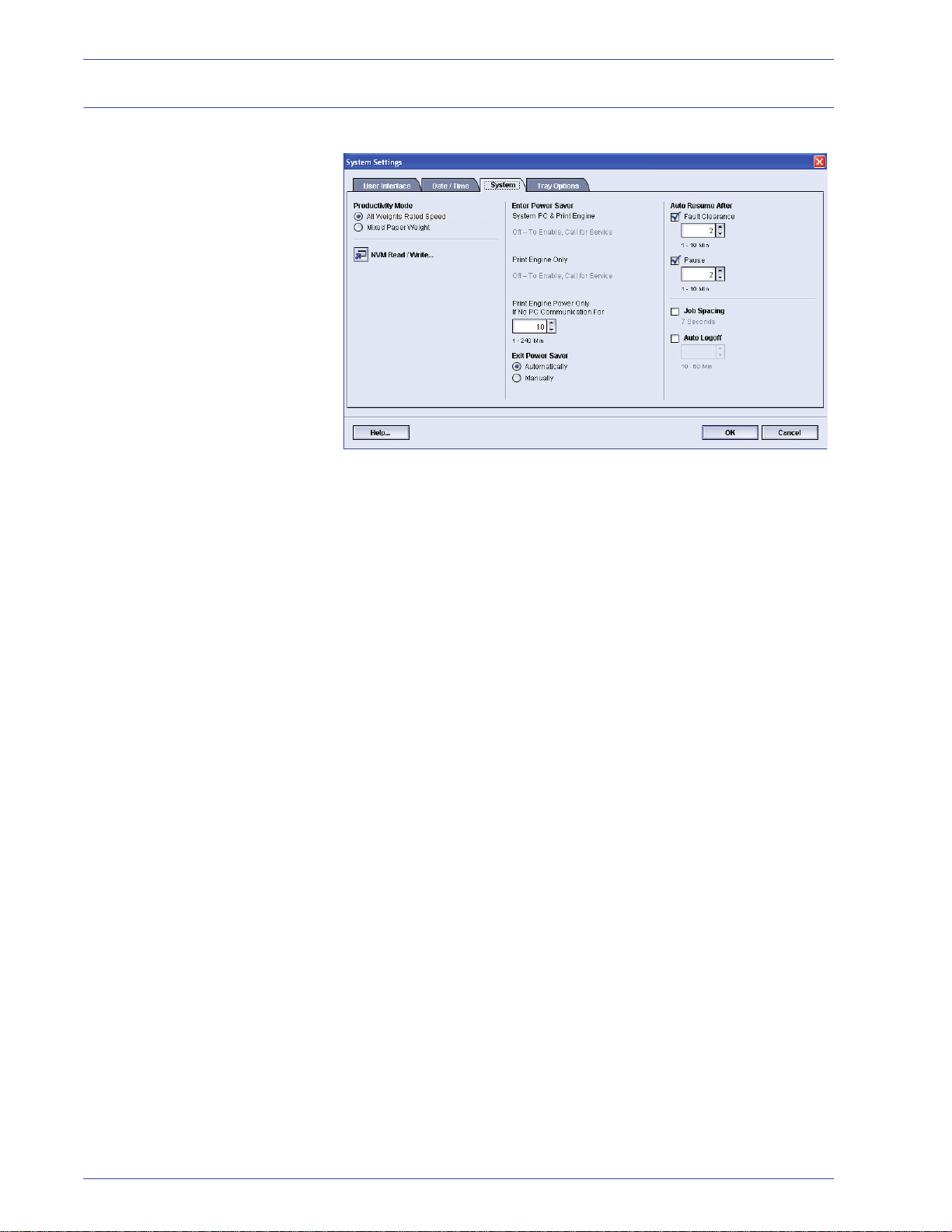

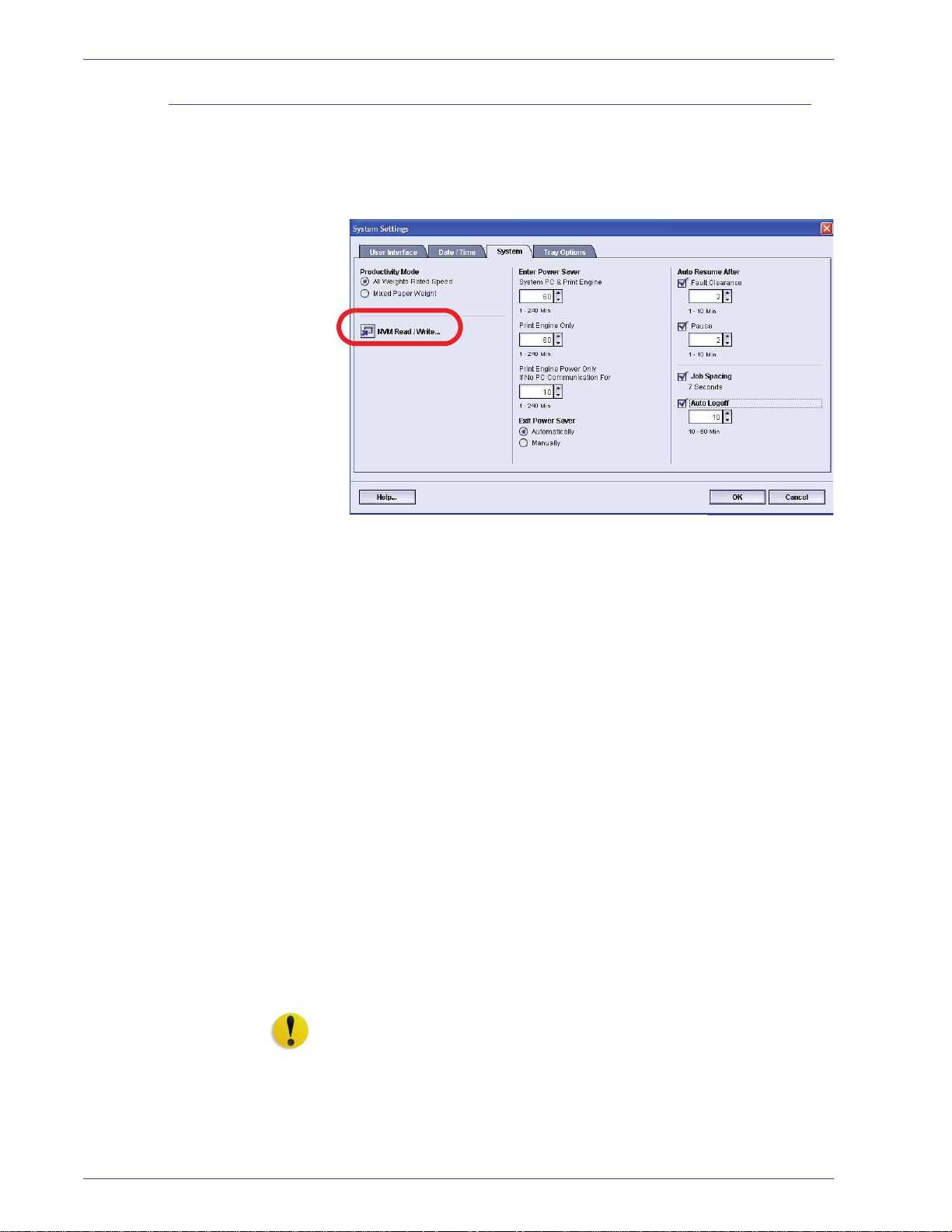

System

2. System Settings

Use this feature to change the factory default settings for the

following:

• Productivity Mode

• Power Saver (Enter and Exit options)

• Auto Resume

• Job Spacing

• Auto Logoff

The System feature also allows you to enter NVM Read/Write

values when using specialized media. This is discussed in more

detail on page 2-19.

DocuColor 5000AP Administrator Guide

2-9

Page 18

2. System Settings

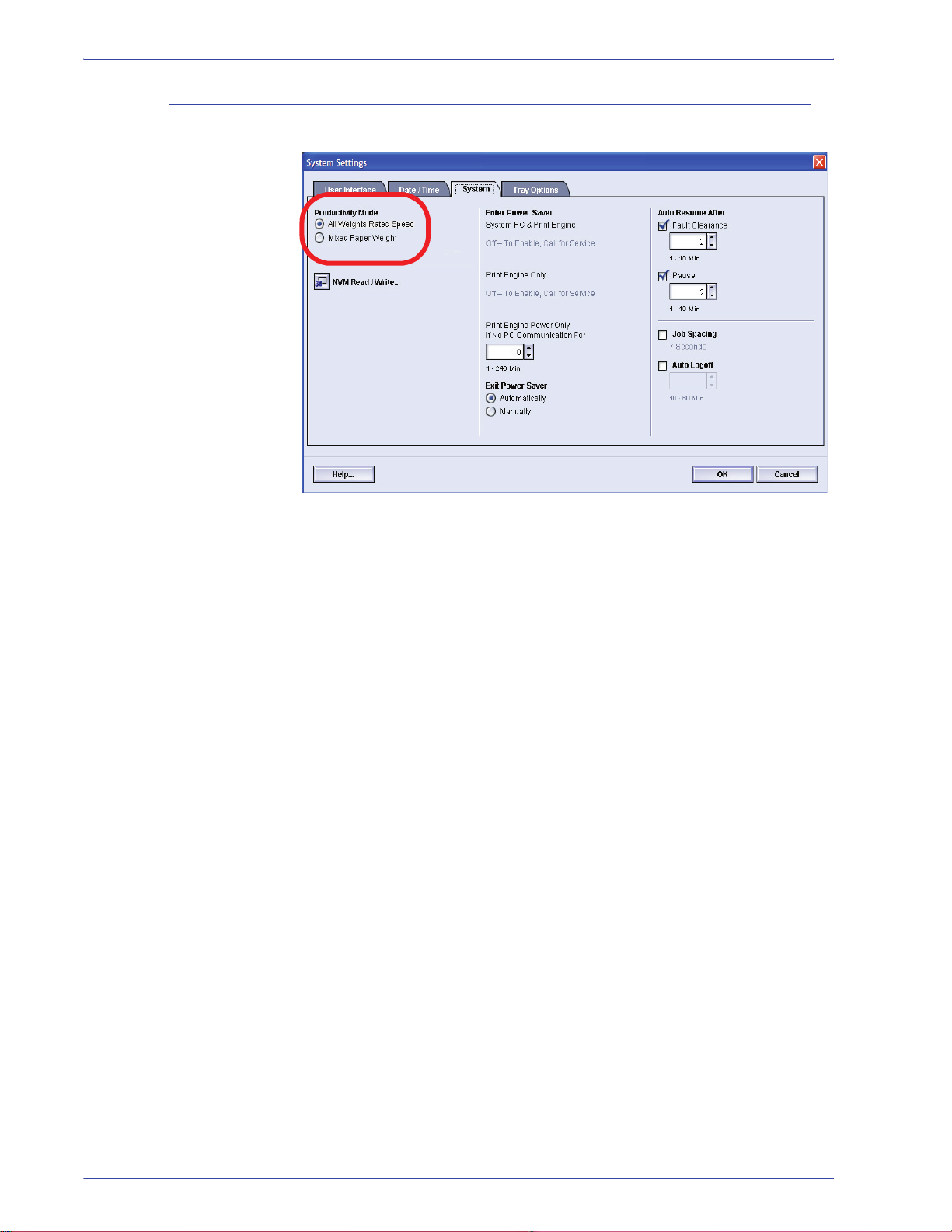

Productivity Setting

The productivity of the digital press relates to the continuous

speed of the media output as measured in prints per minute

(ppm). The continuous speed is dependent on paper size, paper

weight, and fuser temperature.

Use this setting to optimize the throughput speed for the type of

paper you run most frequently. Productivity Setting options

include:

• All Weight s Rated Speed: This setting runs all jobs at the

same speed regardless of the paper weight. Gloss levels may

appear lower on heavier weight media.

• Mixed Paper Weight: This setting optimizes the throughput

speed of print jobs that contain mixed media weights from

different paper trays.

Select the setting that best fits your printing environment and that

you use most frequently.

2-10

DocuColor 5000AP Administrator Guide

Page 19

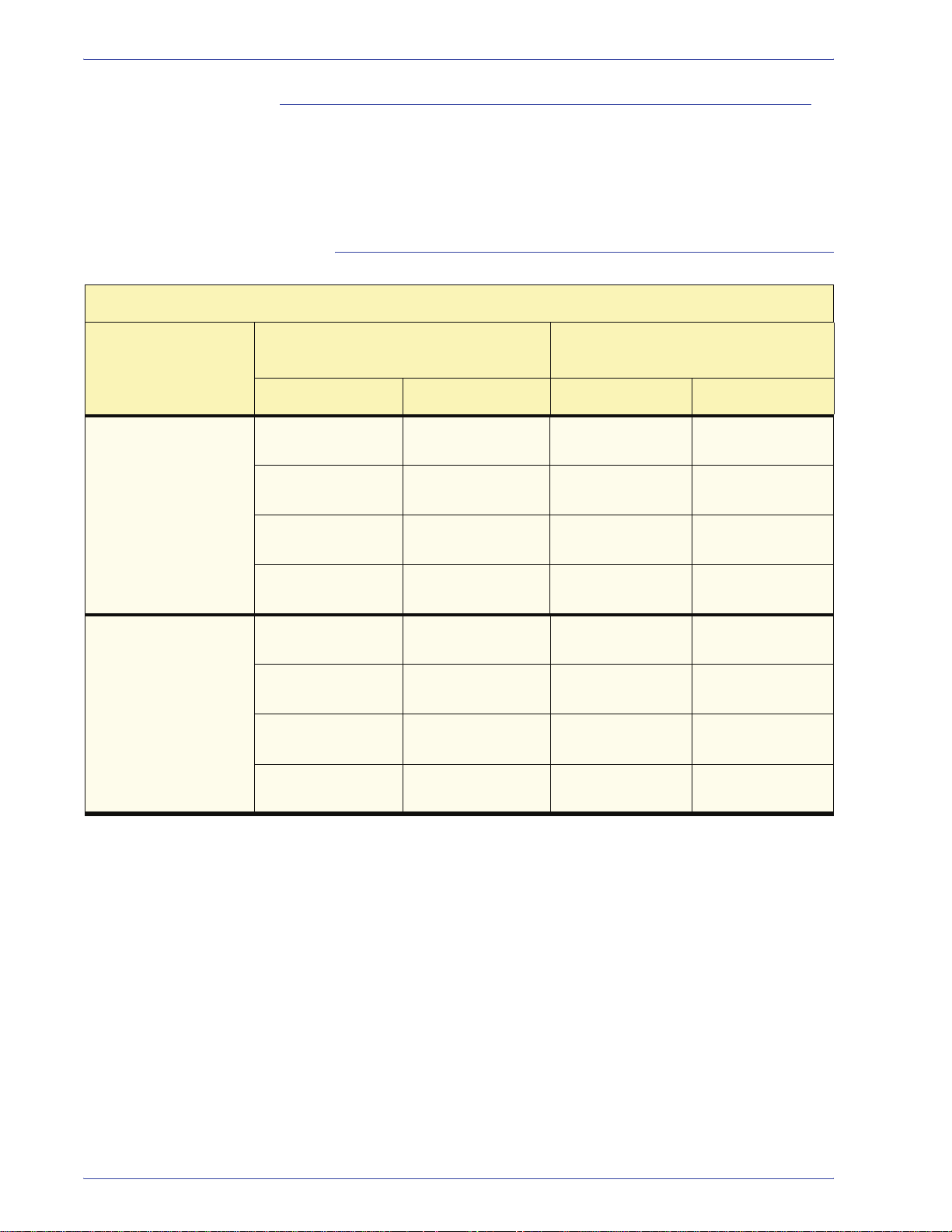

Productivity charts

The following productivity charts lists the various paper weights

and sizes and their related print speeds for 1 Sided and 2 Sided

output. Each chart outlines the print speed parameters for the

productivity settings.

All Weights Rated Speed

All Weights Rated Speed Mode

2. System Settings

Paper Weight

36 - 135 lb (60 - 220

2)

g/m

136 - 184 lb (221 300 g/m

2)

Paper Size (Feed direction length)

[inches/mm]

Min. Max 1 Sided 2 Sided

7.16 in. (182.0

mm)

8.51 in. (216.1

mm)

11.7 in. (297.1

mm)

18.1 in. (458.1

mm)

7.16 in. (182.0

mm)

8.51 in. (216.1

mm)

11.7 in. (297.1

mm)

18.1 in. (458.1

mm)

8.5 in. (216.0 mm) 50 25

11.69 in. (297.0

mm)

18 in. (458.0 mm) 50 25

19.2 in. (488.0

mm)

8.5 in. (216.0 mm) 50 25

11.69 in. (297.0

mm)

18 in. (458.0 mm) 50 25

19.2 in. (488.0

mm)

(prints per minute = ppm)

Print Speed

50 25

50 25

50 25

50 25

DocuColor 5000AP Administrator Guide

2-11

Page 20

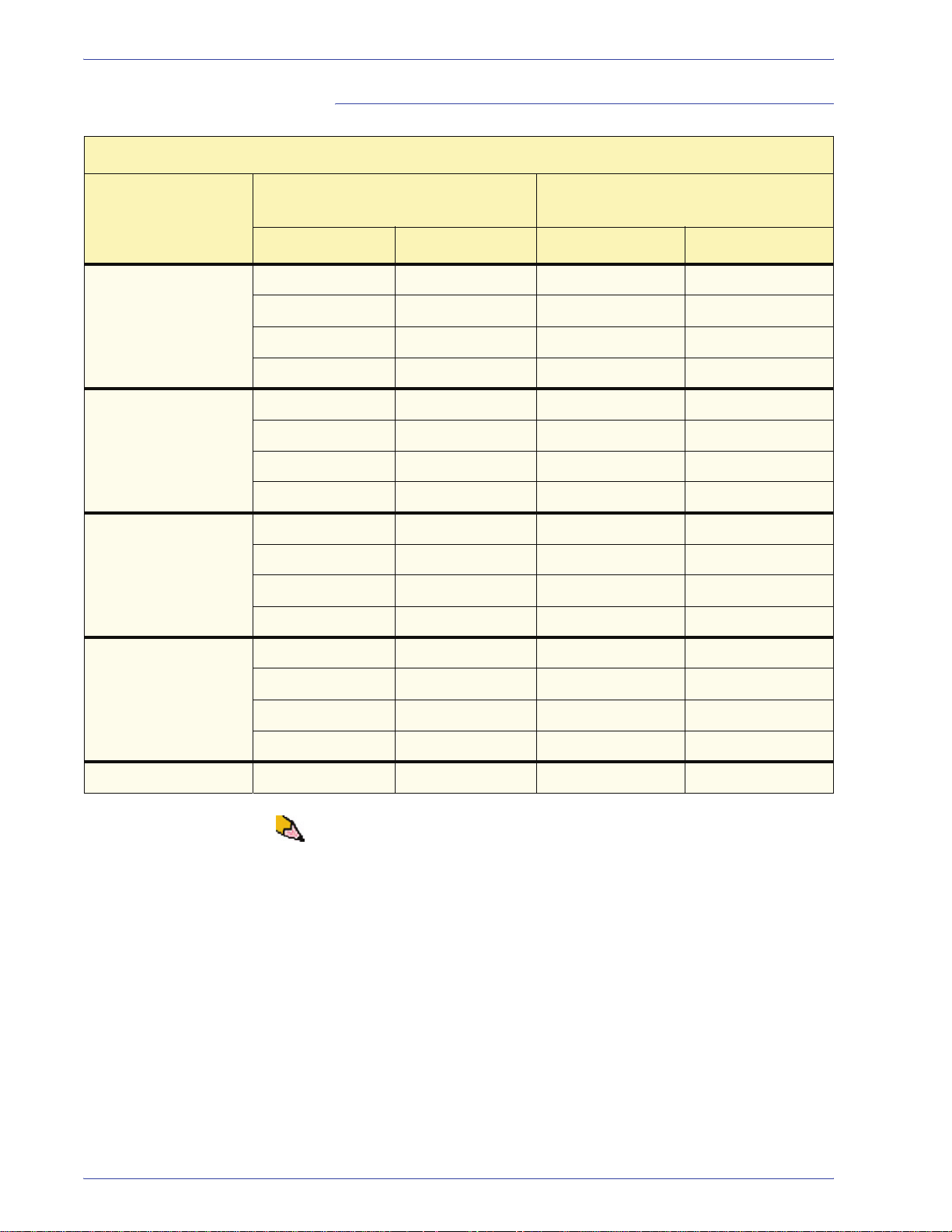

2. System Settings

Mixed Paper Weight

Mixed Paper Weight Mode

Paper Weight

60 - 135 g/m

136 - 186 g/m

187 - 220 g/m

Paper Size (Feed direction length)

[mm]

Print Speed

Min. Max 1 Sided 2 Sided

2

182.0 216.0 50 25

216.1 297.0 33.3 16.7

297.1 458.0 25 12.5

458.1 488.0 20 10

2

182.0 216.0 33.3 16.7

216.1 297.0 25 12.5

297.1 458.0 16.7 8.3

458.1 488.0 12.5 6.3

2

182.0 216.0 33.3 16.7

216.1 280.0 20 10

280.1 432.0 16.7 8.3

432.1 488.0 12.5 6.3

221 - 300 g/m

2

182.0 216.0 25* --

216.1 280.0 16.7* --

280.1 458.0 12.5* --

458.1 488.0 10* --

Transparency 210.0 216.0 25 --

NOTE: *Print speeds may decrease due to printer setup

operations, which are based on environment al conditions and

specific interval volume of continuous printing.

2-12

DocuColor 5000AP Administrator Guide

Page 21

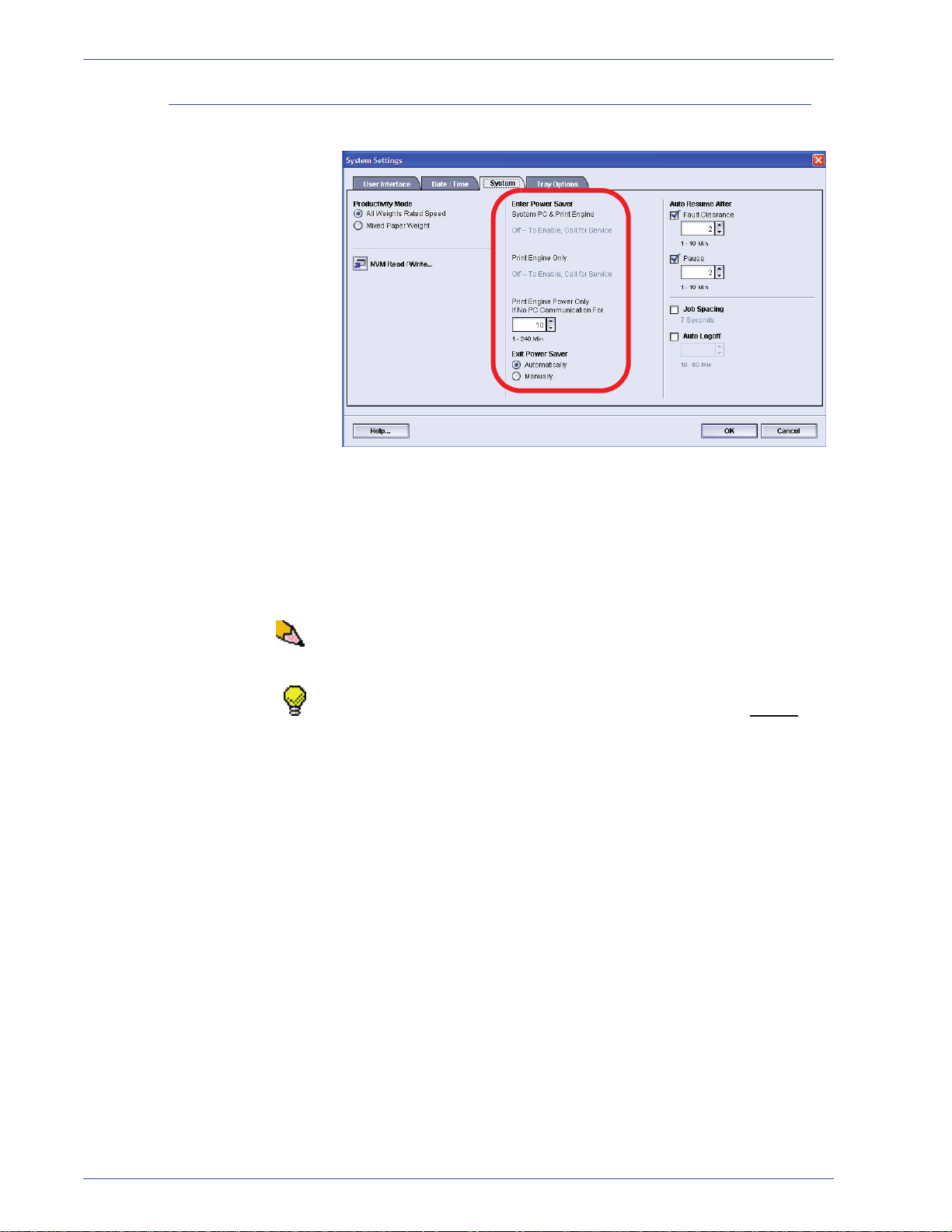

Power Save r

2. System Settings

Use this feature to set the time that elapses until the digital press

and System PC enter a reduced power consumption mode. The

timers are activated when all print jobs have been completed and

there are no jobs in the job queue.

The digital press and/or System PC exits the Power Saver mode

when a job is sent to be printed or the UI on the System PC is

activated.

NOTE: To manually exit Power Saver mode, quickly press the

power button on the System PC.

l

TIP: The System PC & Print Engine and Print Engine Only

features must be enabled by your Xerox representative before

can use them. If these features are not enabled, call your Xerox

representative for more information.

you

DocuColor 5000AP Administrator Guide

2-13

Page 22

2. System Settings

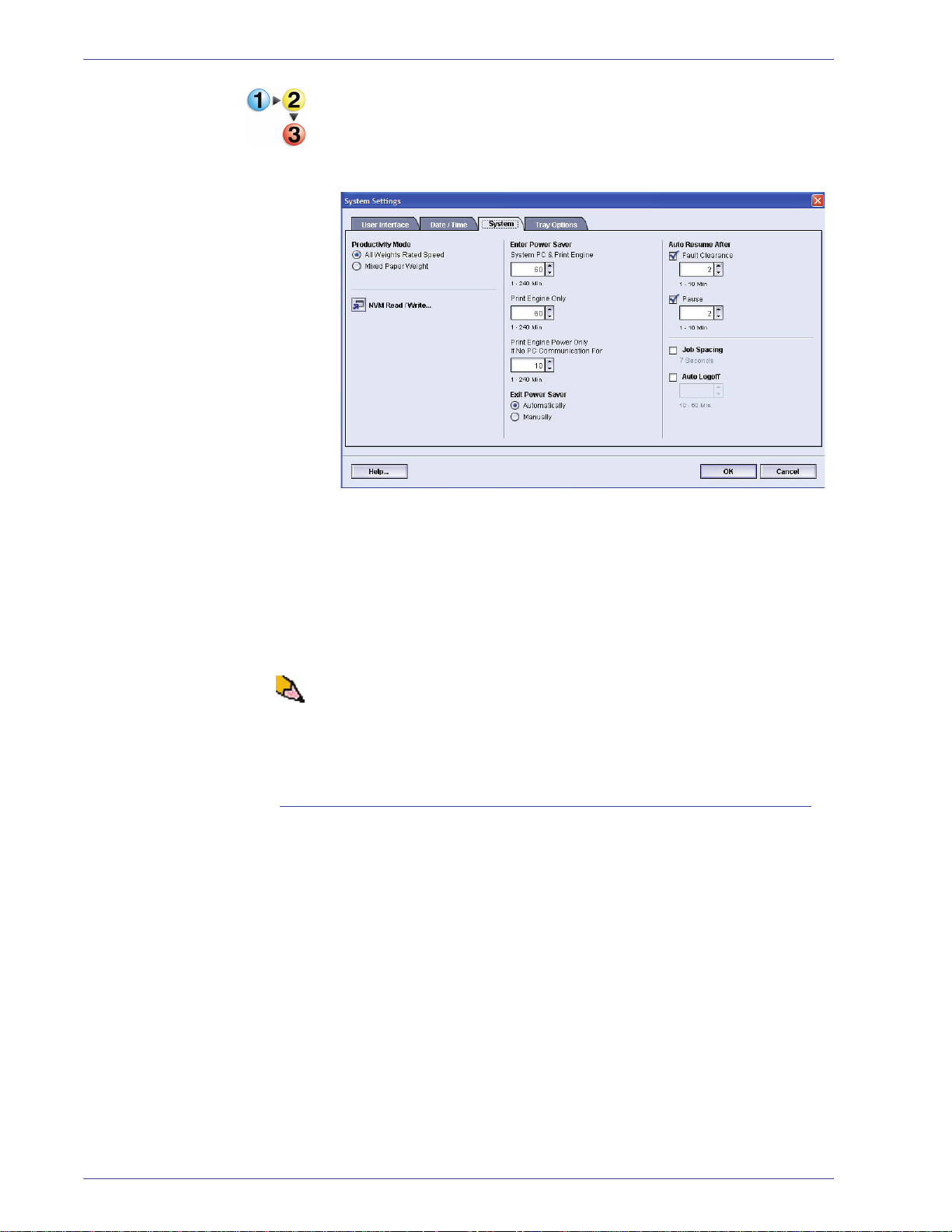

To change the time for each power saver feature, use the following

procedure.

1. From the System Settings window, select the System tab.

2. Use the up or down arrow buttons to change the time for

each of the power saver features:

• System PC & Print Engine

• Print Engine Only

• Print Engine Power Only If No PC Communication For

The range available is 1-240 minutes.

NOTE: The system default time is sixty minutes.

3. Select OK to save your changes and close the System

Settings window.

Exit Power Saver

Select one of two options:

• Automatically: Select this option if you want the system to

automatically exit from power saver mode whenever the

mouse, keyboard, or PC Power Switch is activated.

• Manually: Select this option if you want to manually exit the

system from power saver mode when the Power Saver button

on the main UI screen is selected.

2-14

DocuColor 5000AP Administrator Guide

Page 23

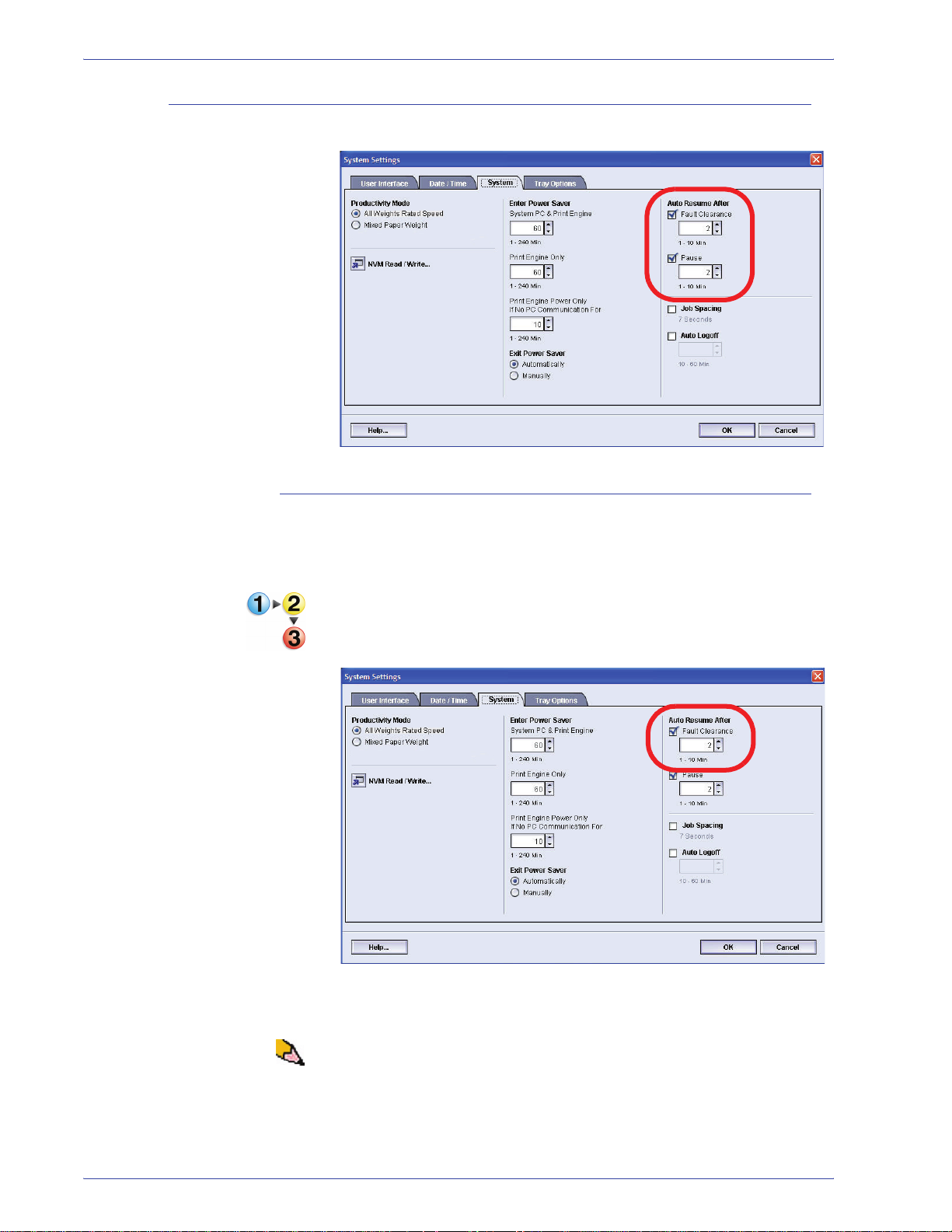

Auto Resume After

Fault Clearance

2. System Settings

Use the Auto Resume After Fault Clearance feature to restart a

job automatically after a fault is cleared and a job received over

the network is waiting for user instruction.

1. From the System tab of the System Settings window, select

the checkbox to the left of Fault Clearance.

2. Use the up or down arrow buttons to change the time. The

range available is 1-10 minutes.

NOTE: The system default time is two minutes.

3. Select OK to save your changes and close the System

Settings window.

DocuColor 5000AP Administrator Guide

2-15

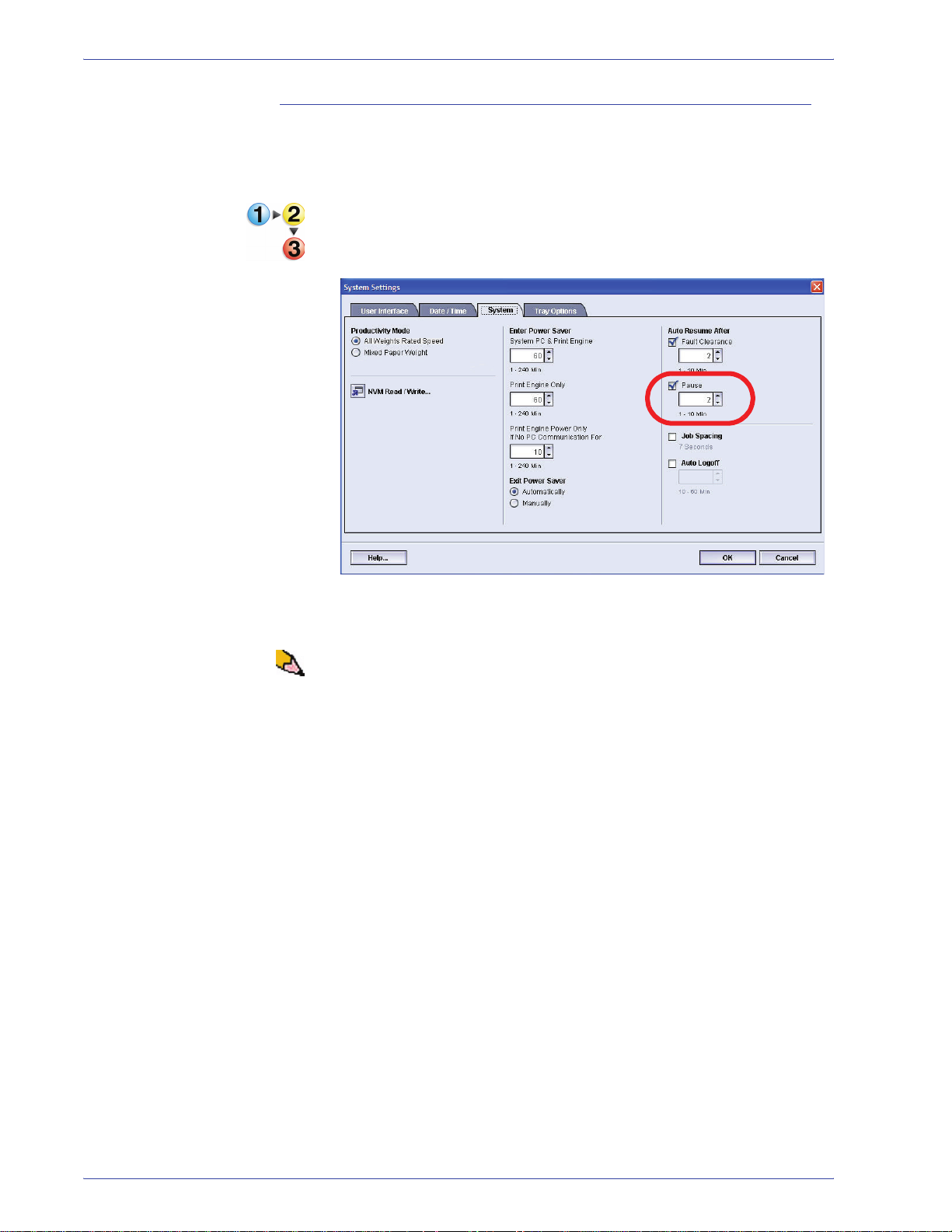

Page 24

2. System Settings

Pause

Use the Auto Resume After Pause feature to restart a job

automatically after the Pause button is selected on the UI and the

job is waiting for user instruction.

1. From the System tab of the System Settings window, select

the checkbox to the left of Pause.

2. Use the up or down arrow buttons to change the time. The

range available is 1-10 minutes.

NOTE: The system default time is two minutes.

3. Select OK to save your changes and close the System

Settings window.

2-16

DocuColor 5000AP Administrator Guide

Page 25

Job Spacing

2. System Settings

Use the Job Spacing feature when there are multiple jobs queued

and you would like to allow seven seconds to unload prints from a

finishing device before the next job starts printing.

1. From the System tab of the System Settings window, select

the checkbox to the left of Job Spacing.

Seven seconds is the standard and only time for this option.

2. Select OK to save your changes and close the System

Settings window.

DocuColor 5000AP Administrator Guide

2-17

Page 26

2. System Settings

Auto Logoff

Use the Auto Logoff feature to have the digital press automatically

return to the printing mode when no action is taken from any of the

Administrator functions after the set amount of time.

1. From the System tab of the System Settings window, select

the checkbox to the left of Auto Logoff.

2. Use the up or down arrow buttons to change the time. The

range available is 10-60 minutes.

NOTE: The system default time is ten minutes.

3. Select OK to save your changes and close the System

Settings window.

2-18

DocuColor 5000AP Administrator Guide

Page 27

NVM Read/Write

2. System Settings

Your Xerox service representative uses this feature to change

certain system settings. It also may occasionally be used by

system administrators.

Special Media Setting for

Drilled Papers

Special Media Setting for

LEF Tab Stock

Carbonless Media

Enablement

Under most conditions, this feature is not used by system

administrators; however, there are limited circumstances under

which this feature is used. These circumstances include:

If you use 3-hole, predrilled paper on a regular basis and

continually encounter an inordinate amount of paper jams, and/or

If you regularly run tab stock and continually encounter paper

jams.

• Carbonless papers are coated with several functional coatings

which promote the image transfer through the form set and

enable the form sets to separate appropriately after padding

with a special adhesive. Each supplier of xerographic

carbonless paper has developed their own unique chemistry,

which is why the following procedure enabling this application,

works best with Xerox Premium Digital Carbonless Paper.

• In order to avoid problems when running carbonless media,

you may use the NVM Read/Write feature to switch on the

carbonless media feature.

If any of the above conditions exist in your environment, you may

use the NVM Read/Write feature to switch on a feature.

CAUTION: Do not enter any numbers on this screen other than

the ones described in this procedure. Entering and saving

numbers, other than the ones described, changes the system

settings which may result in a service call to restore the system to

the correct settings.

DocuColor 5000AP Administrator Guide

2-19

Page 28

2. System Settings

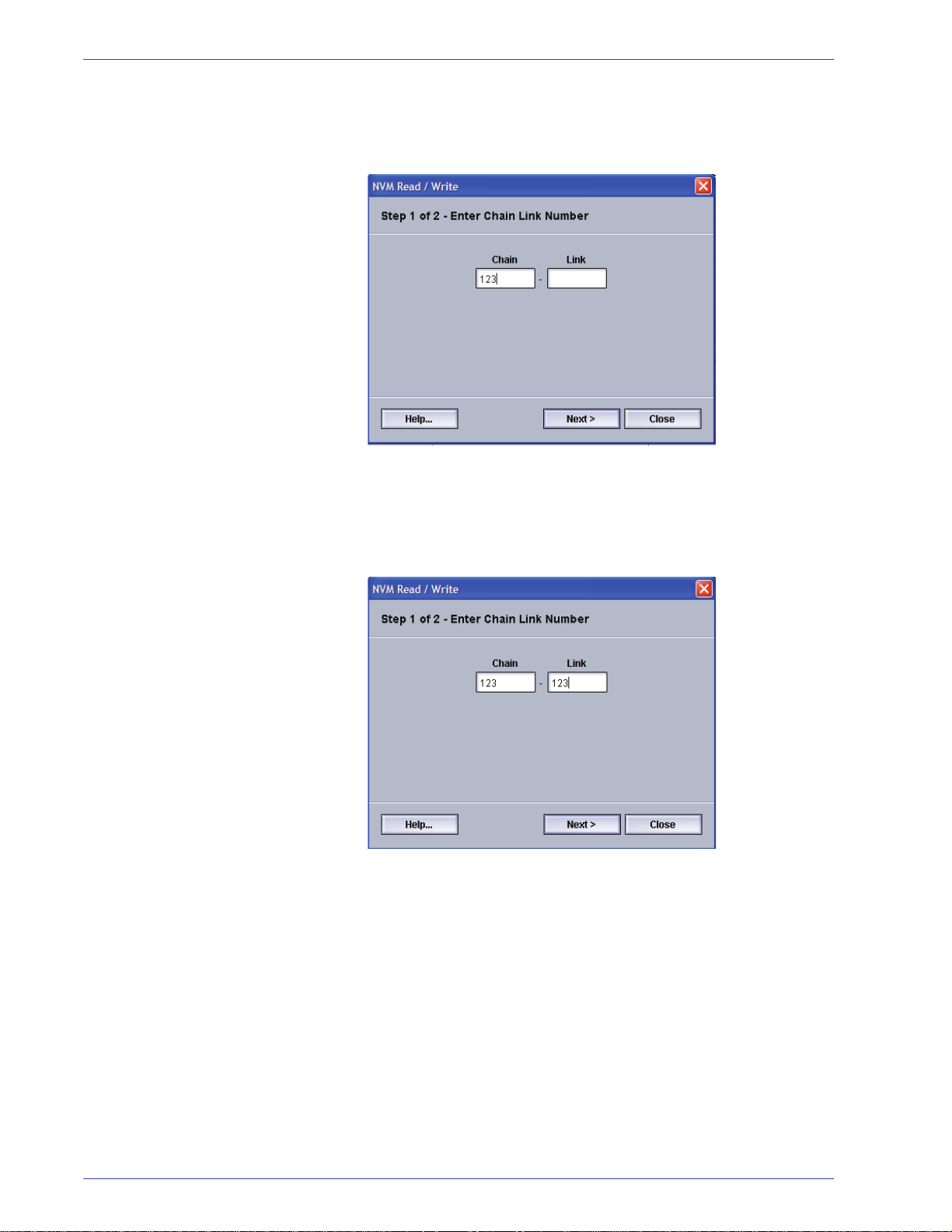

To s w it c h on a feature, perform the following:

1. From the System tab on the System Setting window, select

the NVM Read/Write button.

The NVM Read/Write window opens.

2. Enter the desired Chain Link Number:

• The Chain Link Number for Special Media Setting for

Drilled Papers is 700 545.

• The Chain Link Number for Special Media Setting for

LEF Tab Stock is 700 546.

2-20

• The Chain Link Number for Carbonless Media

Enablement is 700-920.

NOTE: For the purpose of this procedure, the following screens

show an example

New Value; this exampl e does not represent an actual Chain Link

Number. The Current Value and New Value numbers will vary

depending on the Chain Link Number entered.

of a Chain Link Number, Current Value, and

DocuColor 5000AP Administrator Guide

Page 29

2. System Settings

a. Using the numbers on the keyboard, enter the Chain

Number (the following example uses 123 as the Chain

number).

b. Press the Tab button on the keyboard to advance to

the Link field.

c. Enter the Link number (the following example uses 123

as the Link number).

d. Select the Next button.

DocuColor 5000AP Administrator Guide

2-21

Page 30

2. System Settings

3. Using the keyboard, enter the New Value (the following

example uses 234 as the New Value number).

TIP: To s w it c h on a feature, enter the appropriate value from the

keyboard:

• For Special Media Setting for Drilled Papers

the New Value.

• For Special Media Setting for LEF Tab Stock

the New Value.

• For Carbonless Media

, enter 1 for the New Value.

, enter 0 for

, enter 1 for

4. Select the Apply button. The NVM Read/Write window

displays the entered value as the Current Value.

2-22

5. Select Close to save and close your new setting.

6. Select OK to close the System Settings window.

DocuColor 5000AP Administrator Guide

Page 31

2. System Settings

TIP: After running your print job, reenter Administrator mode,

System Settings, NVM Read/Write, and switch off

that is currently on. Follow the steps outlined in this procedure

and use these settings for the New Value number:

the feature

Tray Options

• To switch off the Special Media Setting for Drilled Papers

enter 1000.

• To switch off the Special Media Setting for LEF Tab Stock

enter 0.

• To switch off the Carbonless Media

TIP: To prevent paper jams from occurring with stock types other

than the ones mentioned in this procedure, you must switch off

the NVM Read/Write feature before running other print jobs.

Use this feature to change the factory default settings for the

following:

• Auto Tray Switching

• Auto Paper Selection

• Do Not Include

• Paper Tray Air Assist

•Tray Priority

, enter 0.

,

,

DocuColor 5000AP Administrator Guide

2-23

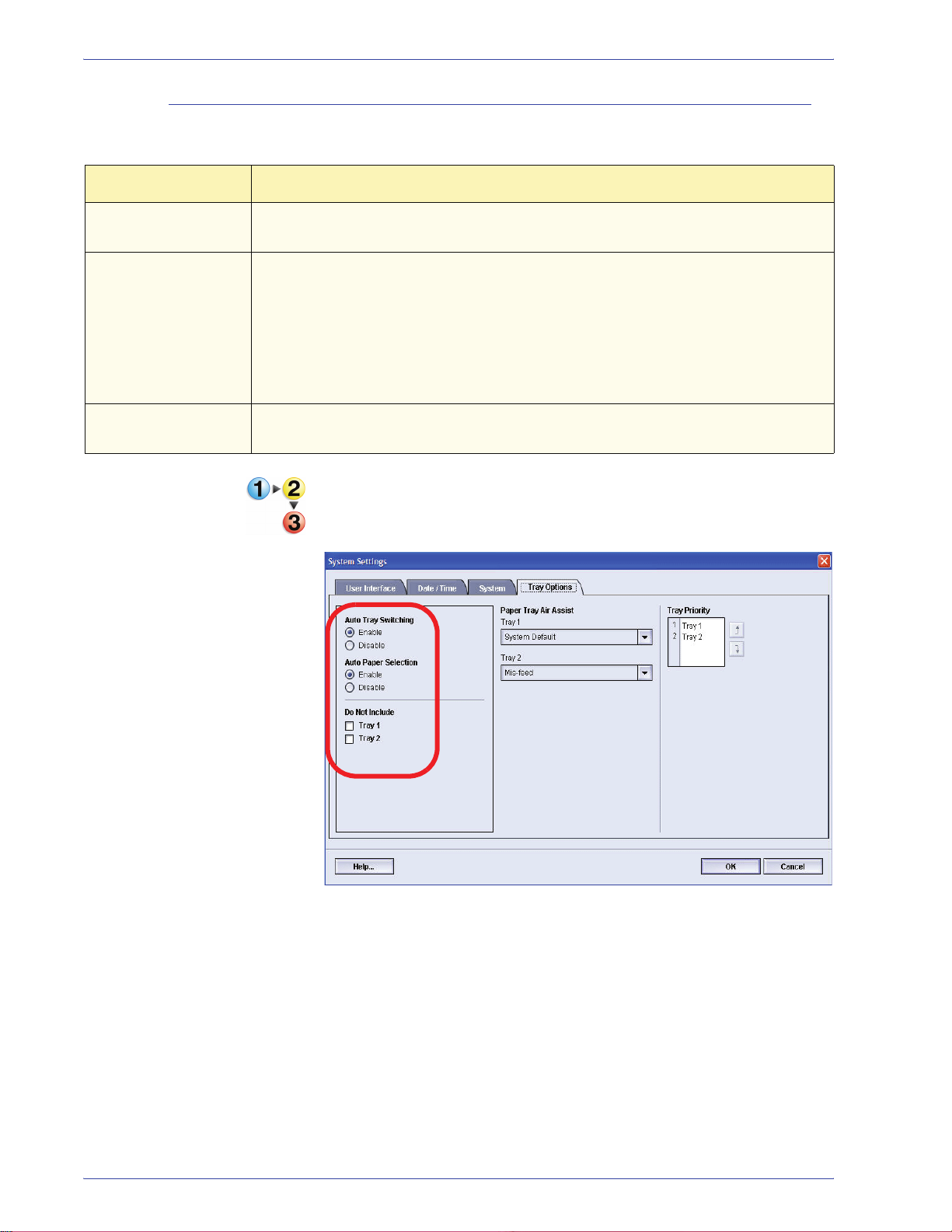

Page 32

2. System Settings

Auto Tray Switching, Auto Paper Selection, and Do Not Include

Choose the default settings for the following options:

Default Setting What the Default Does

Auto Tray Switching

(ATS)

Auto Paper Selection

(APS)

Do Not Include Selecting a tray or trays in this option tells the machine to ignore any selections

Allows the digital press to automatically select another paper tray, containing the

appropriate paper, if the selected paper tray becomes unusable.

Allows the digital press to automatically select the appropriate paper size for the

job being processed, without a specific paper tray being selected.

When Single Paper Weight is selected as the default setting, Auto Paper selects

only 81-105 g/m

Productivity Setting is enabled, Auto Paper selects only 106-135 g/m

correct size.

that were made in the Auto Tray Switching or the Auto Paper Selection options.

2

paper in the correct size. When the Mixed Paper Weight

2

paper in the

1. From the System Setting window, select the Tray Options

tab.

2-24

2. Select either the Enable or Disable button for the Auto Tray

Switching option.

3. Select either the Enable or Disable button for the Auto

Paper Selection option.

4. To instruct the digital press to bypass (ignore) one or more

of the paper trays, select the checkbox to the left of the

desired paper pray in the Do Not Include area.

5. Select OK to close the System Settings window.

DocuColor 5000AP Administrator Guide

Page 33

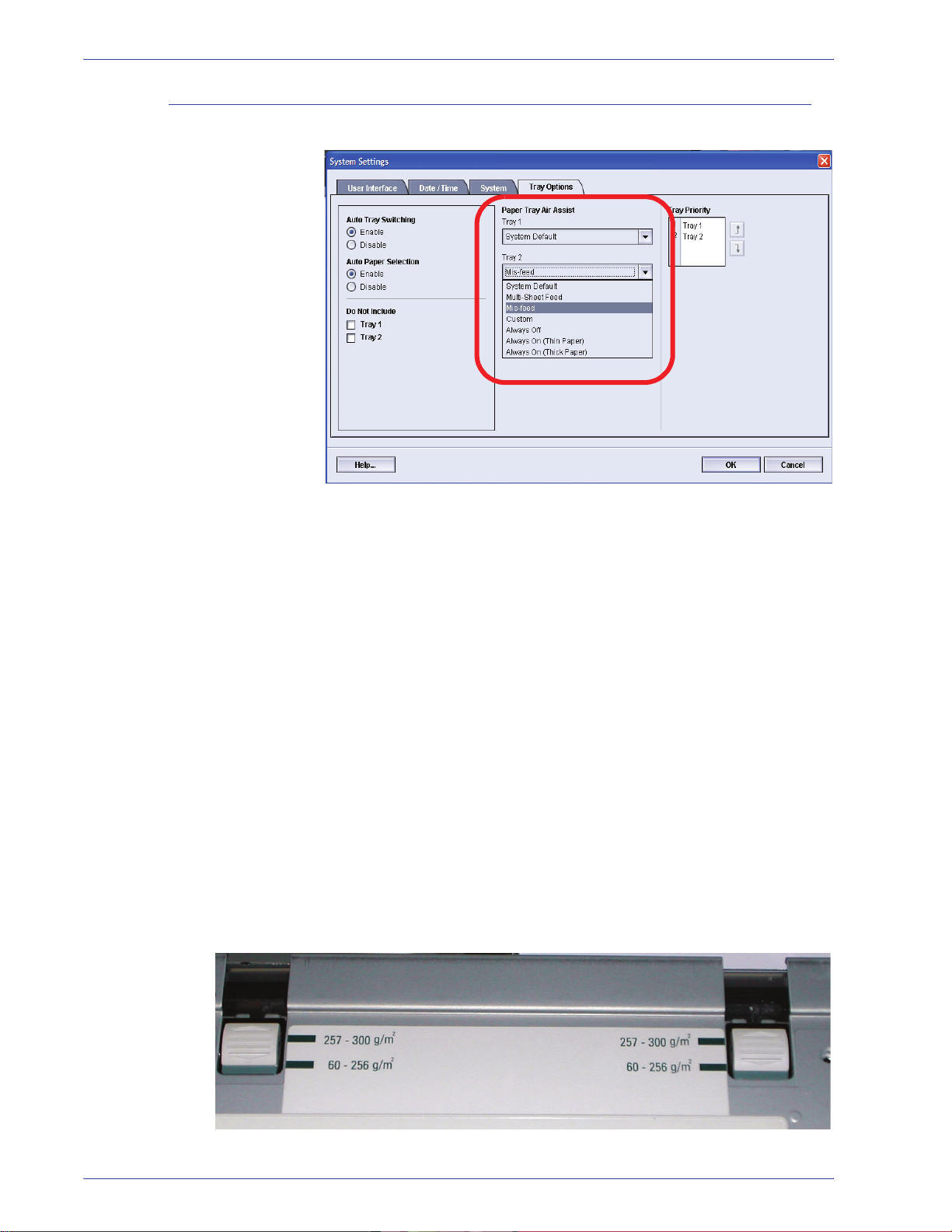

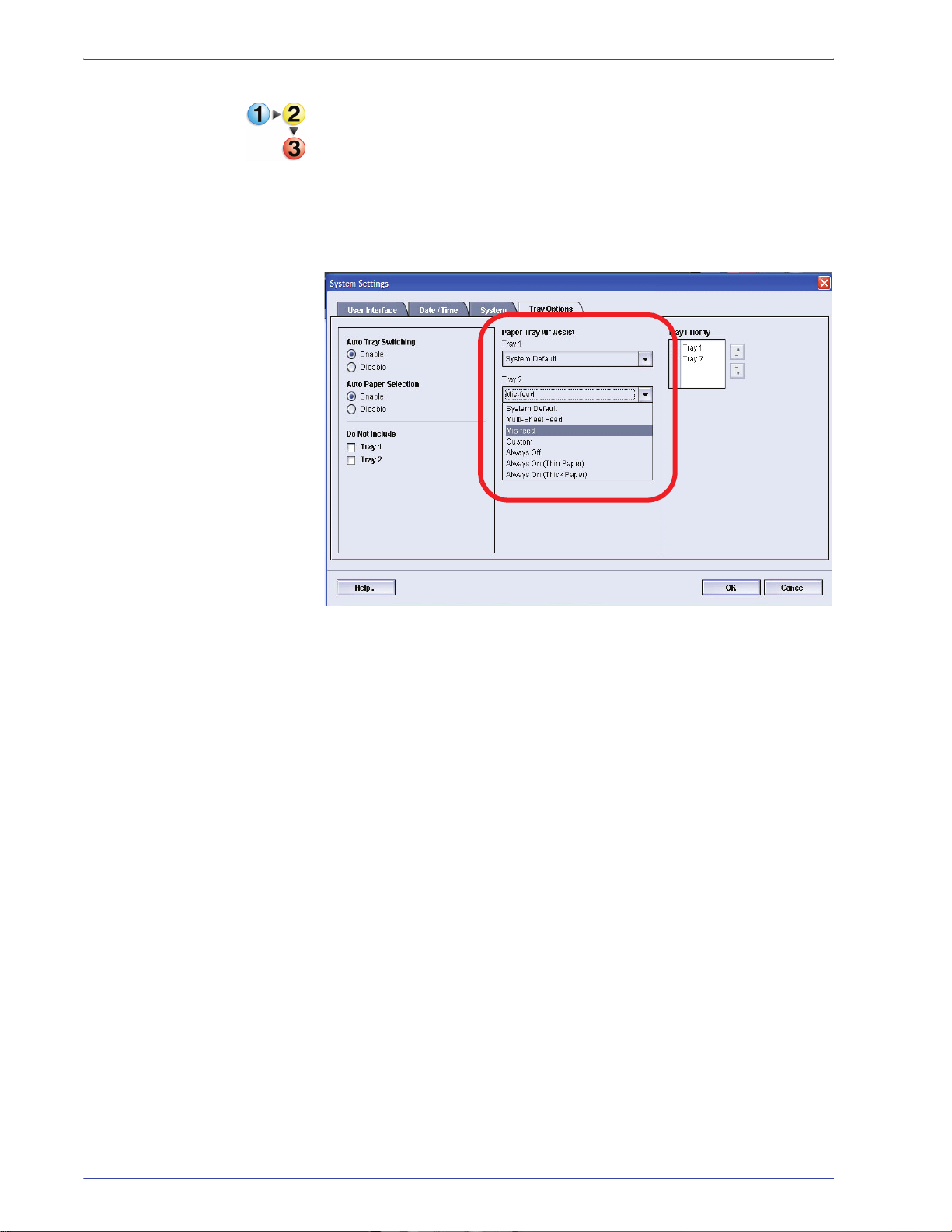

Paper Tray Assist

2. System Settings

Blowers help control the environmental conditions in the paper

trays to ensure optimum print capability:

• Each paper tray has two blowers and two fans. The

blowers are located in the front of each tray, while the two

fans are located on the right-side of the tray.

• The lead edge blower is on at all times and produces

heated air if one of the following selections are

made: Coated paper, Transparencies, or Plain paper 106

2

g/m

or heavier. The trail edge blower is on at all times and

does not produce heated air.

• The paper trays also have air adjustment levers on the

drawer to regulate the direction of the air:

2

– If the paper weight is between 60 and 256 g/m

, the

position of the air adjustment levers should be toward

the front of the tray.

– If the paper weight is between 257 and 300 g/m

2

, the

position of the air adjustment levers should be

positioned toward the rear of the tray.

DocuColor 5000AP Administrator Guide

2-25

Page 34

2. System Settings

If you adjust the blowers on the tray to accommodate a particular

type of paper (for example, thin or thick), you want to make

adjustments on the Tray Options window from the Administrator

mode. This will provide optimal output quality of your prints. To

make these adjustments, use the following procedure:

1. From the System Setting window, select the Tray Options

tab.

2. Select either the desired tray.

3. From the pull-down menu, select the option which best

correlates with the selected paper for that tray and the

adjustments made to the tray air adjustment levers.

The options include the following:

• System Default: This option is the default setting. With

this option the paper tray blowers automatically adjust

using settings that are optimized for Xerox papers.

• Multi-Sheet Feed: Select this option if you want the

paper tray blower automatic settings to incrementally

adjust in order to reduce multifeeds.

• Mis-feed: Select this option if you want the paper tray

blower automatic settings to incrementally adjust in

order to reduce misfeeds.

• Custom: With this option, the paper tray blowers are

controlled by parameters that are set by your Service

Representative.

• Always Off: Select this option if you want the paper

tray blowers always switched off; in this mode, the

blowers are not automatically controlled. This mode is

reserved for special media.

2-26

DocuColor 5000AP Administrator Guide

Page 35

2. System Settings

• Always On (Thin Paper): With this option, the paper

tray blowers are not automatically controlled, but the

are always switched on. This mode is also reserved

for special media.

• Always On (Thick Paper): With this option, the paper

tray blowers are not automatically controlled, but they

are always switched on. This mode is reserved for

special media.

4. Select OK to close the System Settings window.

DocuColor 5000AP Administrator Guide

2-27

Page 36

2. System Settings

Tray Priority

Select the priority order for each paper tray. If the Auto Tray

Switching feature is enabled and each paper tray contains the

same paper size and weight, the digital press feeds paper from

the tray set at Priority 1. If there is no paper in the Priority 1 tray,

the Priority 2 tray is automatically selected and so on.

Use the following procedure to set the priority for each paper tray.

1. From the System Setting window, select the Tray Options

tab.

2. Click once on a desired paper tray.

3. Click the up or down arrow button to the right of it in order to

move it up or down in the priority list.

4. Repeat this procedure for each Priority. You cannot set the

same paper tray for more than one Priority at a time.

5. Select OK to save your settings and close the System

Settings window.

2-28

DocuColor 5000AP Administrator Guide

Page 37

Overview

Alignment

3. Profiles

Profiles allows you to create and customize profiles for Custom

Paper, Alignment, and Decurler. These profiles are used at the

point of need for specialized print jobs which may require different

types of media, such as lightweight or heavy stock. Using a

customized profile can provide optimum image and output quality.

NOTE: The Profiles features can only be accessed from the

Administrator mode.

When printing duplex jobs and using different media types

(including paper type, weight, and coating/uncoating), the output

may require specific handling by the digital press as it is moving

through the paper path. With certain media types and duplex jobs,

the images on Side 1 and/or Side 2 may be misregistered,

skewed, perpendicularly misaligned, or stretched.

The Alignment Adjustment feature allows you to create and store

a maximum of twenty different Alignment Adjustment

Profiles. These profiles allow you to accommodate different

media types and how the image is registered, aligned, or

magnified for Side 1 and Side 2 output. These profiles may be

used at point of need in order to ensure optimum output quality of

your print.

NOTE: You can create Alignment Profiles without associating

them to a specific Cust om Paper Profile. The reverse is also

true: You can create an Alignment Profile and associate it to a

specific Custom Paper Profile. For example, Custom Paper

Profile 2 may be affiliated with Alignment Profile 2, so that when

Custom Paper Profile 2 is in use, Alignment Profile 2 is also in

use.

DocuColor 5000AP Administrator Guide

3-1

Page 38

3. Profiles

When creating Alignment Profiles for Side 1 and/or Side 2 prints,

be aware of the following:

• Side 1/Side 2 images may be misregistered because the

paper is not the exact same size. It may vary slightly, with

differences of plus or minus 1mm, causing the image to be

misregistered. To reduce the possibility of size differences, it is

recommended that you use paper from the same lot when

running duplex jobs.

• During the fusing process, the heat and pressure applied to

the paper causes the paper to stretch. If the images on Sides 1

and 2 are the same size, the stretching of the paper may

cause the image on Side 1 to be slightly larger than the image

on Side 2.

• Creating an Alignment Profile for these types of jobs allows

you to reduce or eliminate the images being larger on Side1

than on Side 2 prints.

NOTE 1:Your Alignment Profile may or may not be af filiated with a

Custom Paper Profile.

NOTE 2:Once an Alignment Profile is set and in use, your color

server will not reflect that profil e in the print options for print jobs.

NOTE 3:After an Alignment Profile is set, it remains active until

you reenter Administrator mode and switch it off. If an active

Alignment Profile is not associat ed with a Custom Paper Profil e, it

is used for each paper tray to which it is assigned.

Alignment Adjustment Profile procedure

Use the following procedure to create/modify an Alignment Profile

for adjusting Side 1/Side 2 image output.

NOTE: If you require a Custom Paper Profile associated with this

Alignment Profile, you can set the Custom Paper Profi le

information either now or af ter you create the Alignment Profile.

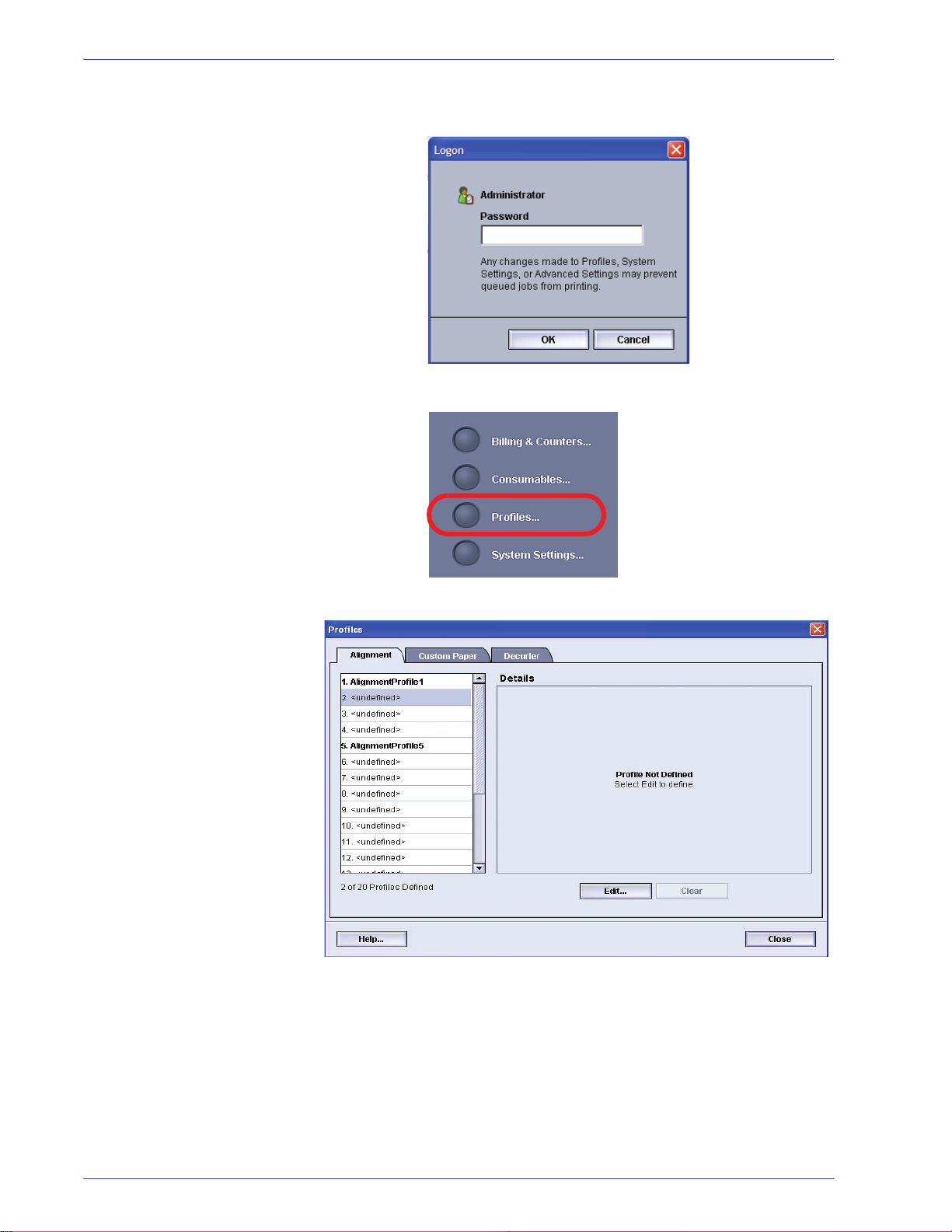

1. Select the Logon button from the main UI window.

3-2

DocuColor 5000AP Administrator Guide

Page 39

3. Profiles

2. From the Logon window, enter the Administrator password

and select OK.

3. Select the Profiles button.

4. From the Profiles window, select the Alignment tab.

DocuColor 5000AP Administrator Guide

3-3

Page 40

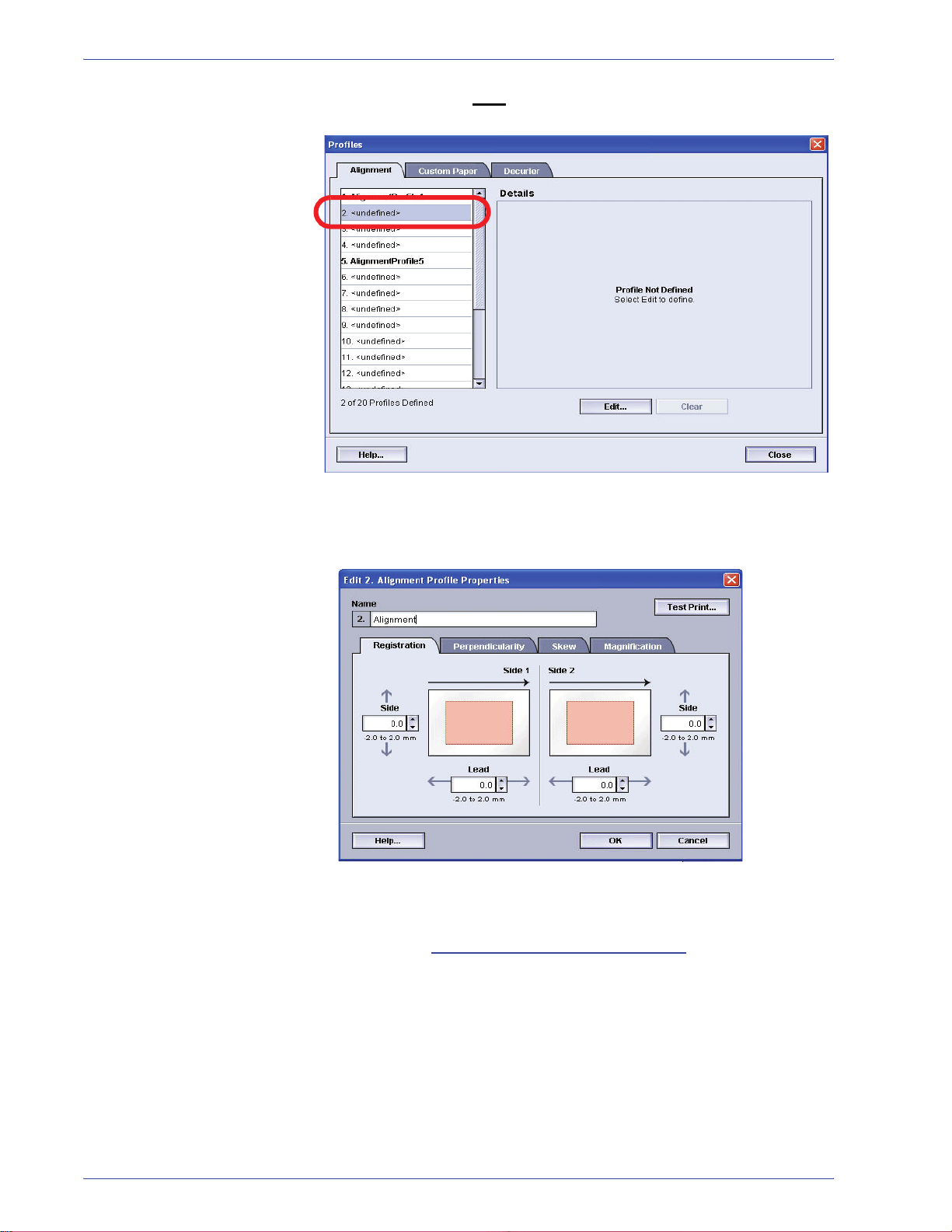

3. Profiles

5. To create a new alignment procedure, select a undefined

profile.

If you are editing an existing profile, go to Step 6.

6. Click the Edit button; the Alignment Profile Properties

window opens.

7. Type a name for this profile (the example in this procedure

uses the name “AlignmentProfile2”).

8. Next: Selecting the Registration options.

3-4

DocuColor 5000AP Administrator Guide

Page 41

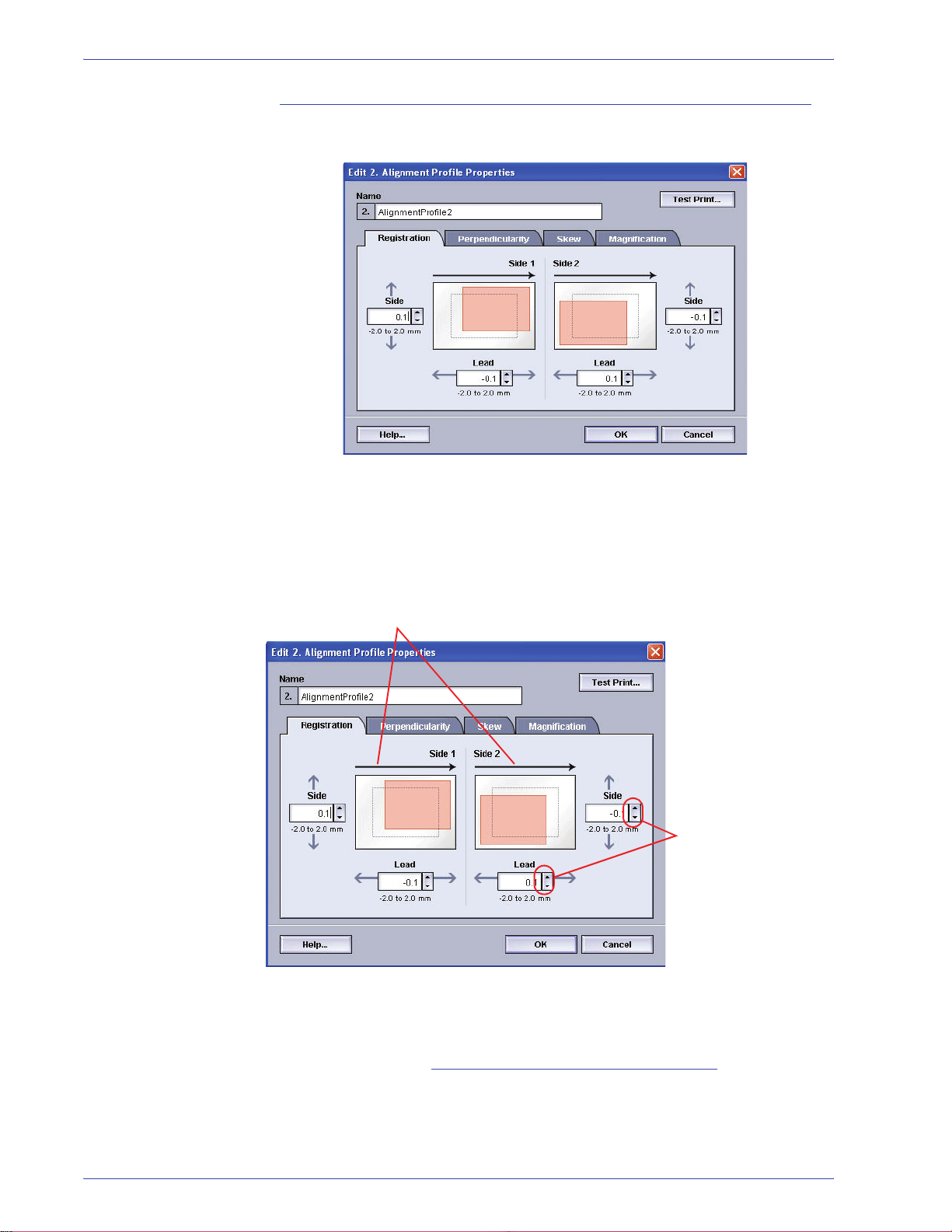

Selecting the Registration options

9. Make the desired selections to the Registration option.

• Lead Registration: Use this feature to adjust the lead

edge of the image for Side 1 and/or Side 2 registration.

3. Profiles

• Side Registration: Use this feature to adjust the side

edge of the image for Side 1 and/or Side 2 registration.

The factory default setting is zero (0).

These arrows indicate the

paper feed direction

Use the up/down

arrow buttons to

make the desired

selections.

10. Next: Selecting the Perpendicularity options.

DocuColor 5000AP Administrator Guide

As you click the up/down arrow buttons, the illustration

moves indicating the direction that the image will move

on the paper.

3-5

Page 42

3. Profiles

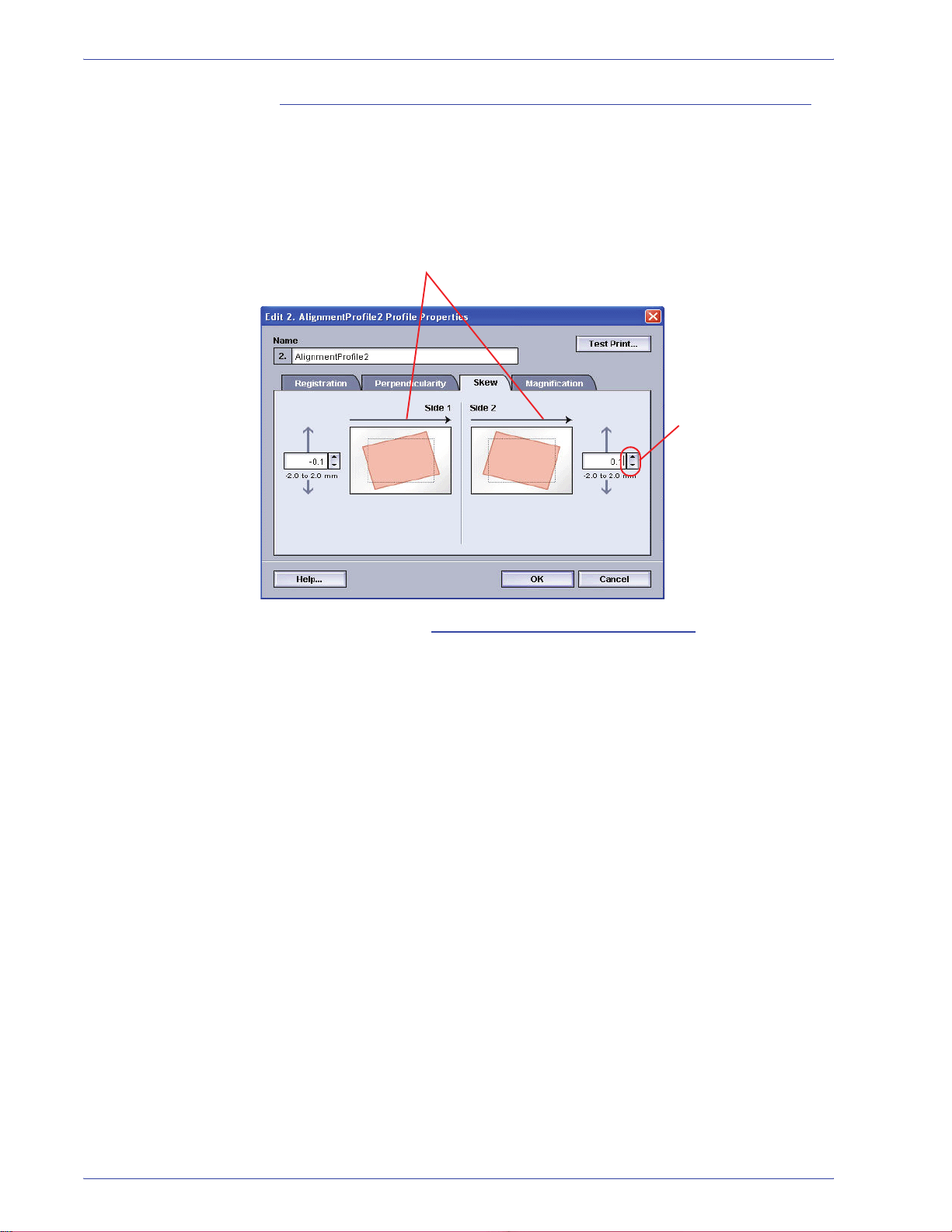

Selecting the Perpendicularity options

11. Make the desired selections to the Perpendicularity

option. Use this feature to adjust the image digitally on the

drum so that it will align with the paper for both Side 1 and

Side 2.

The factory default is zero (0).

These arrows indicate the

paper feed direction

Use these to make

the desired

selections. As you

click on the up or

down arrows, the

illustration moves

indicating the

direction that the

image will move on

the paper.

12. Next: Selecting the Skew options.

3-6

DocuColor 5000AP Administrator Guide

Page 43

Selecting the Skew options

13. Make the desired selections to the Skew option. Use this

feature to adjust the paper so that the image for Side 1 and/

or Side 2 are not skewed but aligned with each other.

The factory default is zero (0).

These arrows indicate the

paper feed direction

3. Profiles

Use these to make

the desired

selections. As you

click on the up or

down arrows, the

illustration moves

indicating the

direction that the

image will move on

the paper.

14. Next: Selecting the Magnification options.

DocuColor 5000AP Administrator Guide

3-7

Page 44

3. Profiles

Selecting the Magnification options

15. Make the desired selection to the Magnification option. Use

this feature to correct for image stretch from Side 1 to Side

2. The image may be enlarged or reduced as necessary.

The factory default is zero (0).

These arrows indicate the

paper feed direction

Use these to make

the desired

selections. As you

click on the up or

down arrows, the

illustration moves

indicating the

direction that the

image will move on

the paper.

TIP: It is recommended that you choose only one Alignment

Profile feature (such as Registration), and then run a set of Test

Prints to evaluate the registration on that output. If you want

multiple Alignment Profile features selected, individually select

each feature, run Test Prints for that feature, and evaluate the

output. After you determine that the output for the selected

feature is acceptable, then you can select another Alignment

Profile feature to adjust.

16. Next: Running test prints.

3-8

DocuColor 5000AP Administrator Guide

Page 45

Running test prints

17. Select the T est Print button; a new window opens.

3. Profiles

a. Select the 2 Sided button.

NOTE:If you want to check the registration for 1 Sided

prints only, select the 1 Sided button.

b. Select 10 test prints by clicking the Up arrow button to

change the number of test prints generated.

c. Select the desired paper tray from the pull-down list.

d. If necessary, select the Tray Properties button and

make any desired settings.

e. Select Start. The UI displays this message after the

test prints are printed:

f. Retrieve your prints.

g. Discard the first few prints, as inconsistency tends to

DocuColor 5000AP Administrator Guide

be greater with these images.

3-9

Page 46

3. Profiles

18. Evaluate the test prints by holding your 2 Sided output at

eye level near a light source. This will allow you to see the

registration marks for both Side 1 and Side 2 of the output.

a. If you determine that the registration between Side 1

and Side 2 is unacceptable and needs adjusting,

repeat this procedure starting at Selecting the

Registration options.

TIP: You may need to repeat this procedure numerous times until

you achieve acceptable output prints.

b. If the printed output for both Sides 1 and 2 is

acceptable, select OK to save and close the Profiles

window.

NOTE: Once you have selected OK to save and close the Pr ofiles

window, the new profile procedure (for example,

AlignmentProfile2) can be sele cted from the Tray Properties

window whenever you want to run a job using this profile.

19. If you are editing an existing Alignment profile:

a. From the Profiles window, Alignment tab, select the

desired profile.

b. Click the Edit button.

c. Repeat this procedure starting at Selecting the

Registration options.

3-10

DocuColor 5000AP Administrator Guide

Page 47

Custom Paper

3. Profiles

Different media (including paper type, weight, and coating/

uncoating) may require specific handling by the digital press as it

is moving through the paper path. For example, some media

types may skew or curl as they progress through the printing path

of the digital press. This may occur on frequently-run jobs and/or

jobs with a high volume output.

The Custom Paper feature allows you set custom paper profiles

for different types of media and jobs, such as outlined in the above

paragraph. These profiles may be used at point of need in order

to ensure optimum output quality of your prints/jobs.

By setting custom paper profiles for specific media types, you can

avoid output prints that are skewed, curled, have too much toner

or not enough toner in areas, or images that are not registered

properly on the output print, such as Side 1 and/or Side 2 images

that are misregistered.

NOTE 1:Once a Custom Paper Profile is created, the digital press

passes this information on to your color server. The color server

in turn reflects this information in the print options for print jobs.

NOTE 2:Adjusting registration for Side 1 and/or Side 2 images is

discussed in detail in the Alignment feature. Refer to the

Alignment feature.

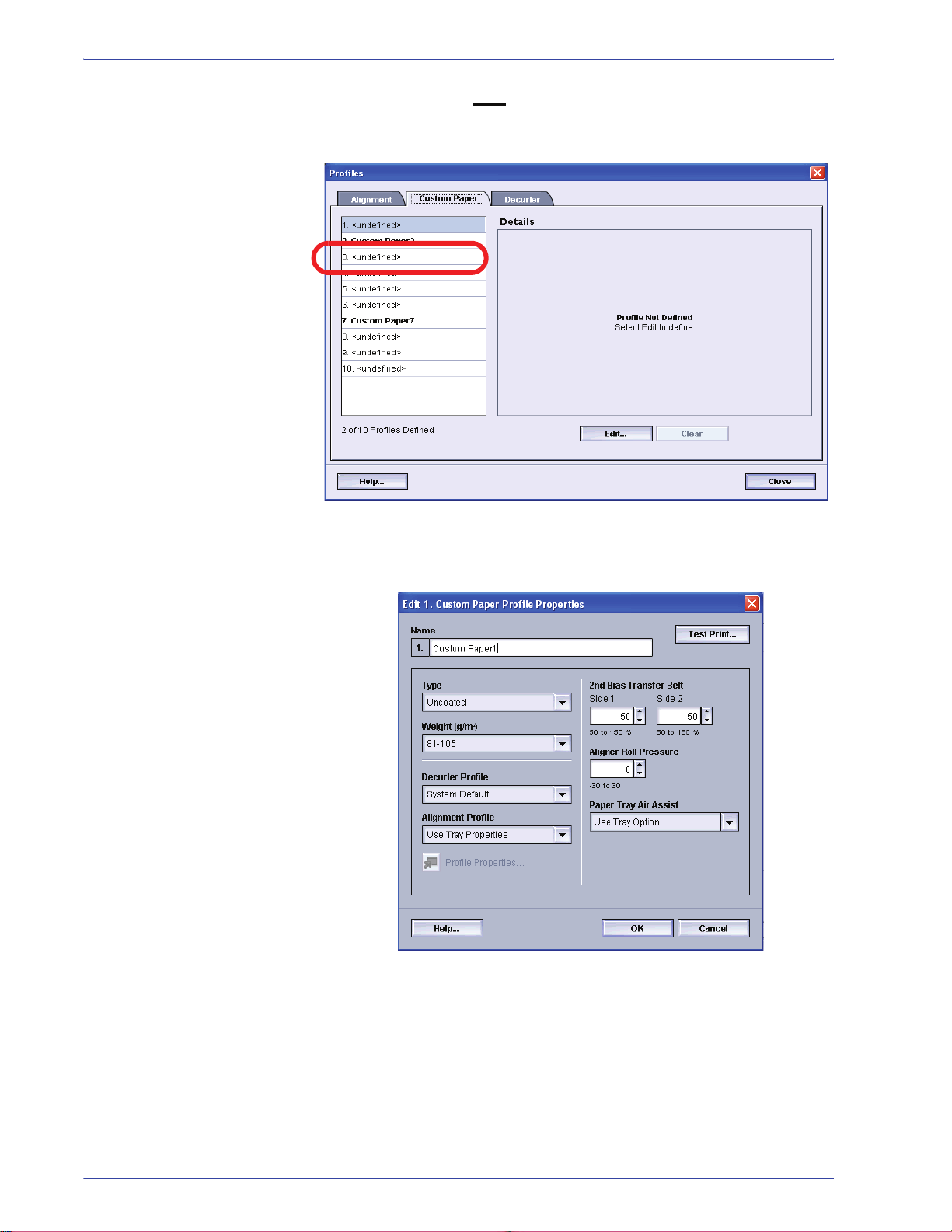

Custom Paper procedure

Use the following procedure for creating/modifying a Custom

Paper Profile.

1. From the Profiles window, select the Custom Paper tab.

DocuColor 5000AP Administrator Guide

3-11

Page 48

3. Profiles

2. To create a new custom paper procedure, select a

undefined profile.

If you are editing an existing profile, go to Step 4.

3. Click the Edit button; the Custom Paper Profile Properties

window opens.

3-12

4. Type a name for this profile (the example in this procedure

uses the name “Custom Paper1”).

5. Next: Selecting the desired paper type.

DocuColor 5000AP Administrator Guide

Page 49

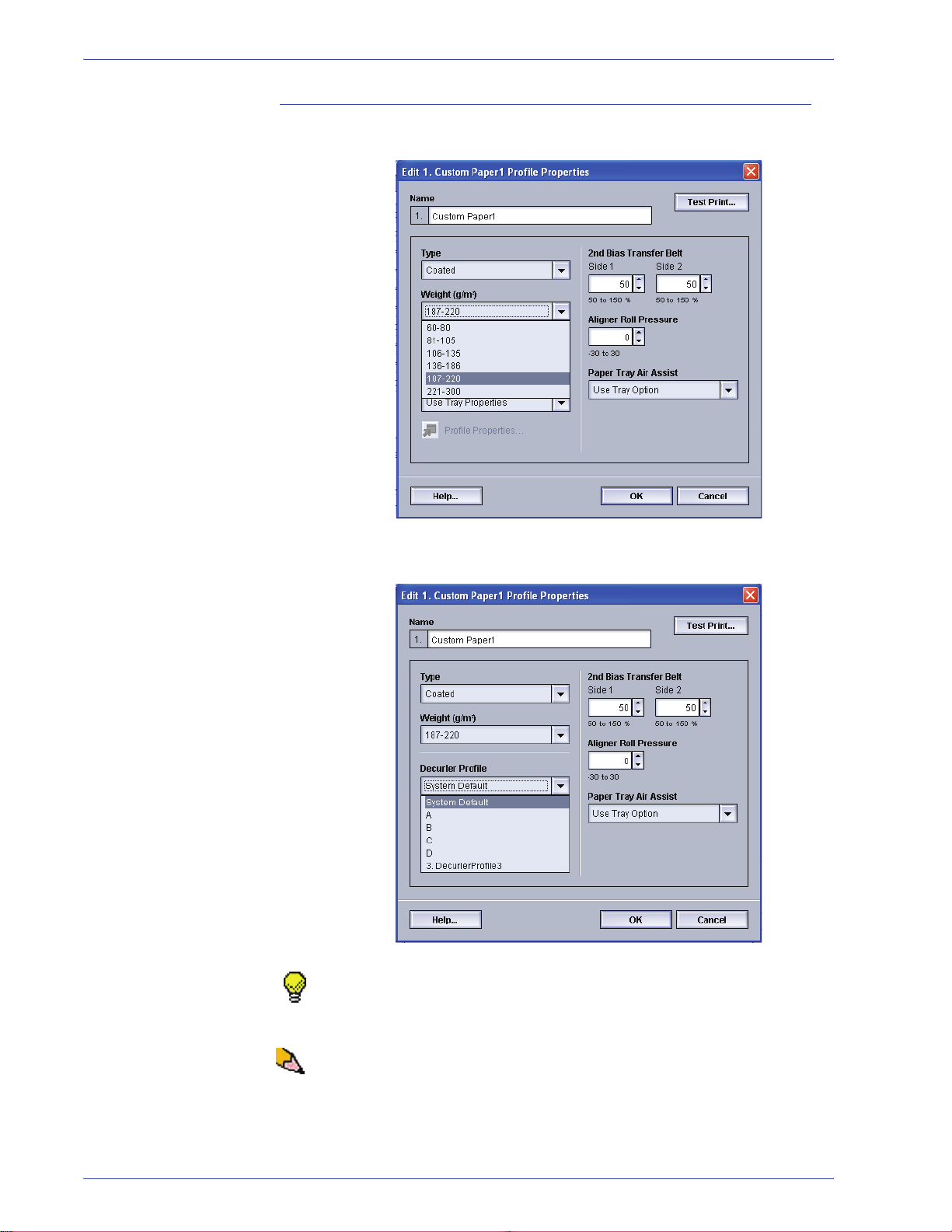

Selecting the desired paper type

6. Select the desired paper Type from the pull-down menu.

3. Profiles

TIP: The paper type does not have to match the actual type of

paper you are loading in the tray. When creating a Custom Paper

Profile, select a paper type that is rarely or never

standard paper types. This ensures that when running commonly

used paper types, the digital press does not load a Custom Paper

Profile for those types.

used as your

7. Next: Selecting the desired paper weight.

DocuColor 5000AP Administrator Guide

3-13

Page 50

3. Profiles

Selecting the desired pa per weight

8. Select the desired paper Weight from the pull-down menu.

9. If required, select a Decurler Profile from the pull-down

menu.

TIP: The default setting is System Default. It is recommended

that you leave this option at its default setting until you run test

prints and evaluate the output of the prints. Test Print is discussed

in more detail in Step 16.

3-14

NOTE: Use the Decurler feature in order to compens ate f or p aper

curl in your output prints. For Decurler information, refer to

page 3-26.

DocuColor 5000AP Administrator Guide

Page 51

3. Profiles

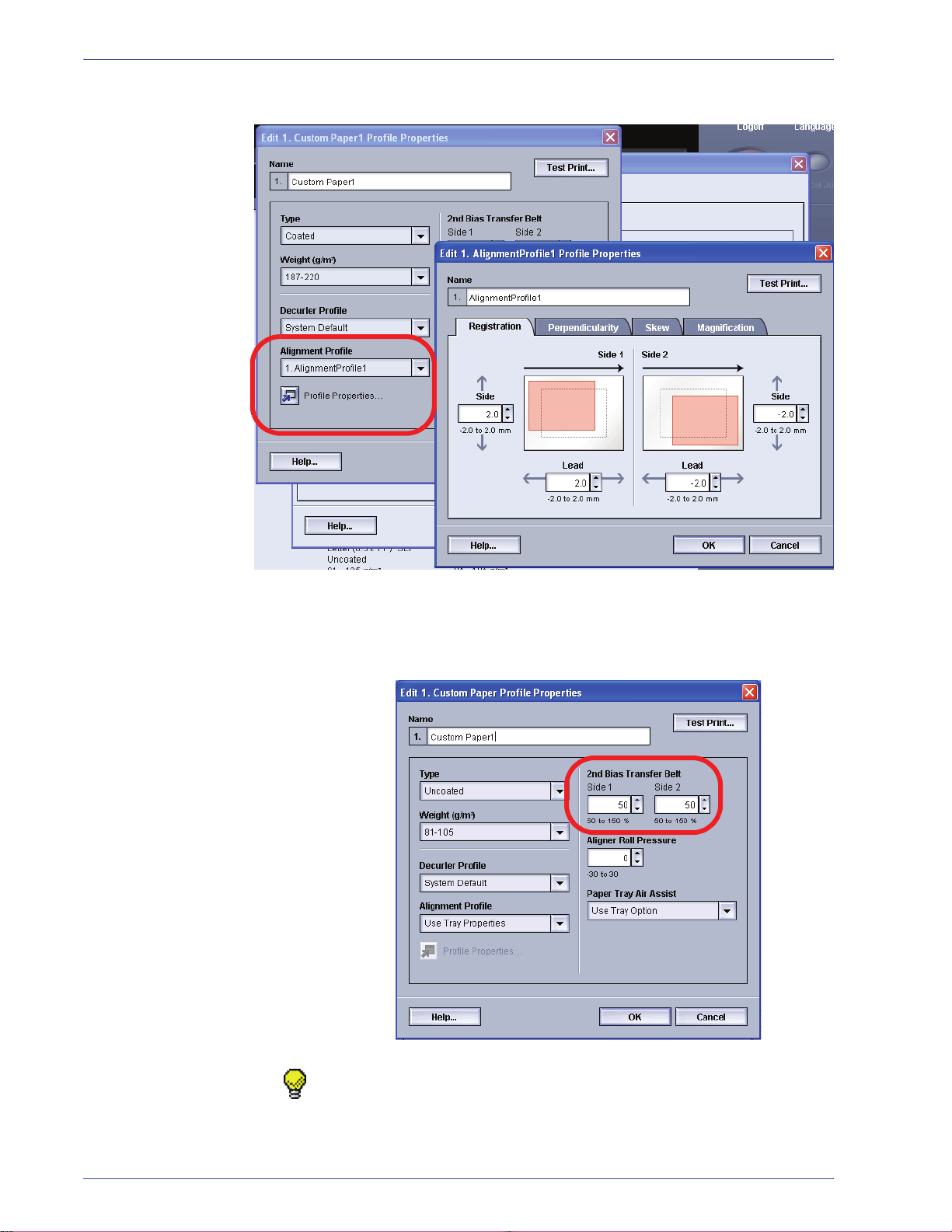

10. If required, select an Alignment Profile from the pull-down

menu.

TIP: The default setting is Use Tray Properties. It is

recommended that you leave this option at its default setting until

you run test prints and evaluate the output of the prints. Test Print

is discussed in more detail in Step 16.

NOTE: If you select a specific Alignment Profile, the Profiles

Properties button becomes accessible. By clicking on this button,

the UI opens the Alignment Profile wi ndow for the sel ected pro file,

and you can edit that Alignment Profile if necessar y.

DocuColor 5000AP Administrator Guide

3-15

Page 52

3. Profiles

NOTE: For Alignment information, refer to page 3-1.

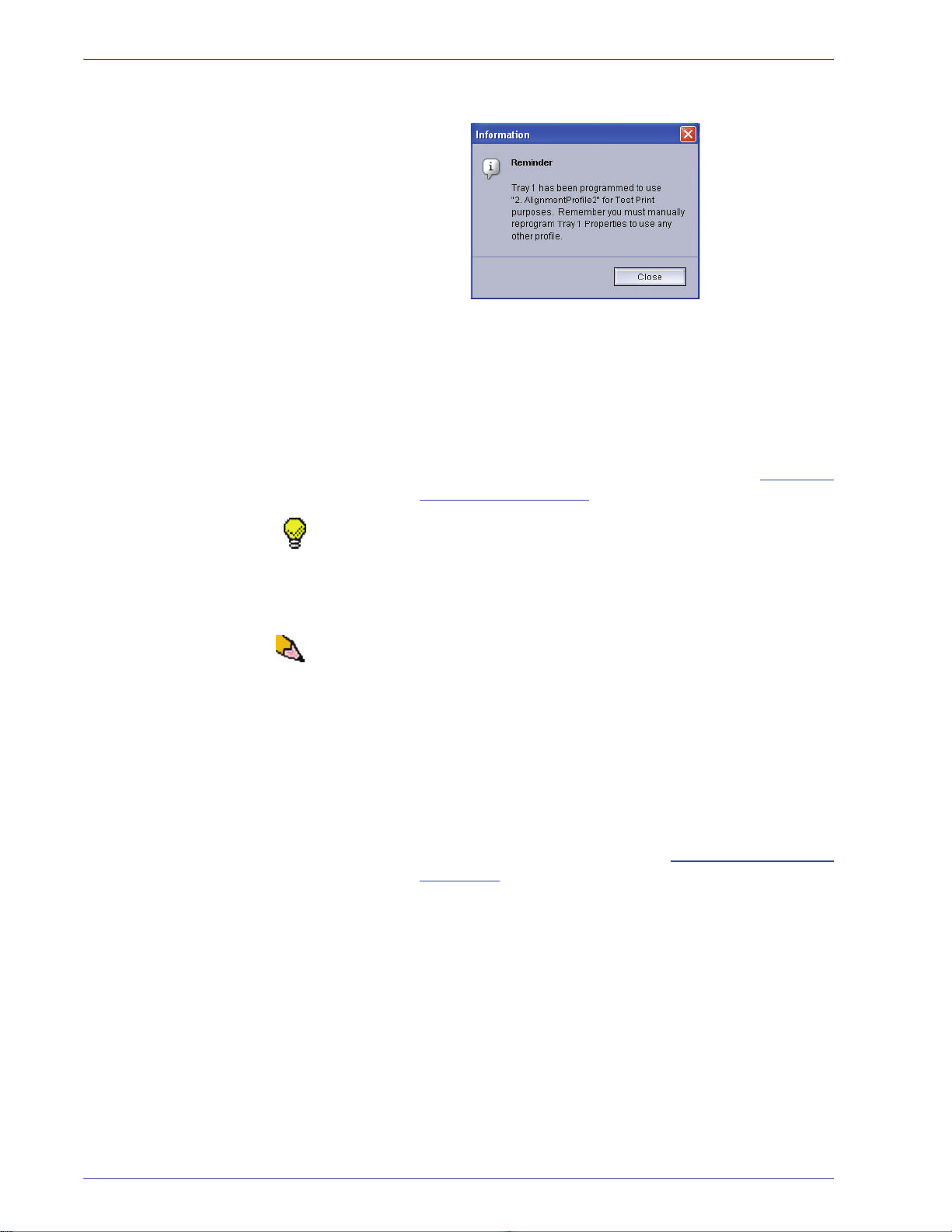

11. If required, choose 2nd Bias Transfer Roll settings for Sides

1 and 2.

TIP: The default setting for both Sides 1 and 2 is 100%. It is

recommended that you leave this option at its default setting until

you run test prints and evaluate the output of the prints. Test Print

is discussed in more detail in Step 16.

3-16

DocuColor 5000AP Administrator Guide

Page 53

3. Profiles

NOTE: Refer to page 3-20 for information on the 2nd Bias

Transfer Belt.

12. If required, choose an Aligner Roll Pressure setting.

TIP: The default setting is 0. It is recommended that you leave

this option at its default setting until you run test prints and

evaluate the output of the prints. Test Print is discussed in more

detail in Step 16.

NOTE: Refer to page 3-24 for information on the Aligner Roll

Pressure.

13. If required, choose a Paper Tray Air Assist option from the

pull-down menu.

DocuColor 5000AP Administrator Guide

3-17

Page 54

3. Profiles

TIP: The default setting Use Tray Option. It is recommended that

you leave this option at its default setting until you run test prints

and evaluate the output of the prints. Test Print is discussed in

more detail in Step 16.

NOTE: Refer to page 3-25 for information on the Paper Tray Air

Assist.

14. Load your custom paper in the desired paper tray.

15. Ensure that you select the correct paper information in the

Tray Properties window (size, weight, type). From the Type

pull-down menu, select the correct Custom Paper Profile.

16. Select the T est Print button; a new window opens.

3-18

a. Select the 2 Sided button.

NOTE:If you want to check the registration for 1 Sided

prints only, select the 1 Sided button.

b. Select 10 test prints by clicking the Up arrow button to

change the number of test prints generated.

c. Select the desired paper tray from the pull-down list.

d. If necessary, select the Tray Properties button and

make any desired settings.

DocuColor 5000AP Administrator Guide

Page 55

3. Profiles

e. Select Start. The UI displays this message after the

test prints are printed:

f. Retrieve your prints.

g. Discard the first few prints, as inconsistency tends to

be greater with these images.

17. Evaluate the test prints by holding your 2 Sided output at

eye level near a light source.

a. If you determine that further custom paper adjustments

are required, repeat this procedure starting at Selecting

the desired paper type.

TIP: You may need to repeat this procedure numerous times until

you achieve acceptable output prints.

b. If the printed output for both Sides 1 and 2 is

acceptable, select OK to save and close the Profiles

window.

NOTE: Once you have selected OK to save and close the Pr ofiles

window , the new profile procedure (for example, Cust om Paper1)

can be selected from the Tray Properties window, the Type

feature, whenever you want to run a job using this profile.

18. If you are editing an existing Custom Paper profile:

a. From the Profiles window, Custom Paper tab, select

the desired profile.

b. Click the Edit button.

c. Repeat this procedure starting at Selecting the desired

paper type.

DocuColor 5000AP Administrator Guide

3-19

Page 56

3. Profiles

Second Bias Transfer Belt

The Second Bias Transfer Belt is where the image is transferred

from the belt to the paper. The Second Bias Transfer Belt feature

is normally used with heavier weight paper, such as 220 g/m

greater, 10 pt, or 12 pt, which are just three examples; however

there are times when it is also used with lighter weight paper as

well.

When using either heavier or lighter weight paper, you may want

or need to adjust Side 1 for all 1-sided jobs. If defects continually

occur in a printed job when using heavier weight paper, perform

the following steps to determine if a Custom Paper Profile with

Side 1 or Side 2 (2nd Bias Transfer Belt) adjustments are

appropriate.

2

and

1. If the job is printed face down or 1-N, check Side 1 for

defects on the topside (upper portion) of the stacked sheets,

and check Side 2 for defects on the downside (lower

portion) of the stacked sheets.

2. If the job is printed face up or N-1, check Side 2 for defects

on the topside (upper portion) of the stacked sheets, and

check Side 1 for the downside (lower portion) of the stacked

sheets.

3-20

DocuColor 5000AP Administrator Guide

Page 57

3. Profiles

No Mottle

Mottle

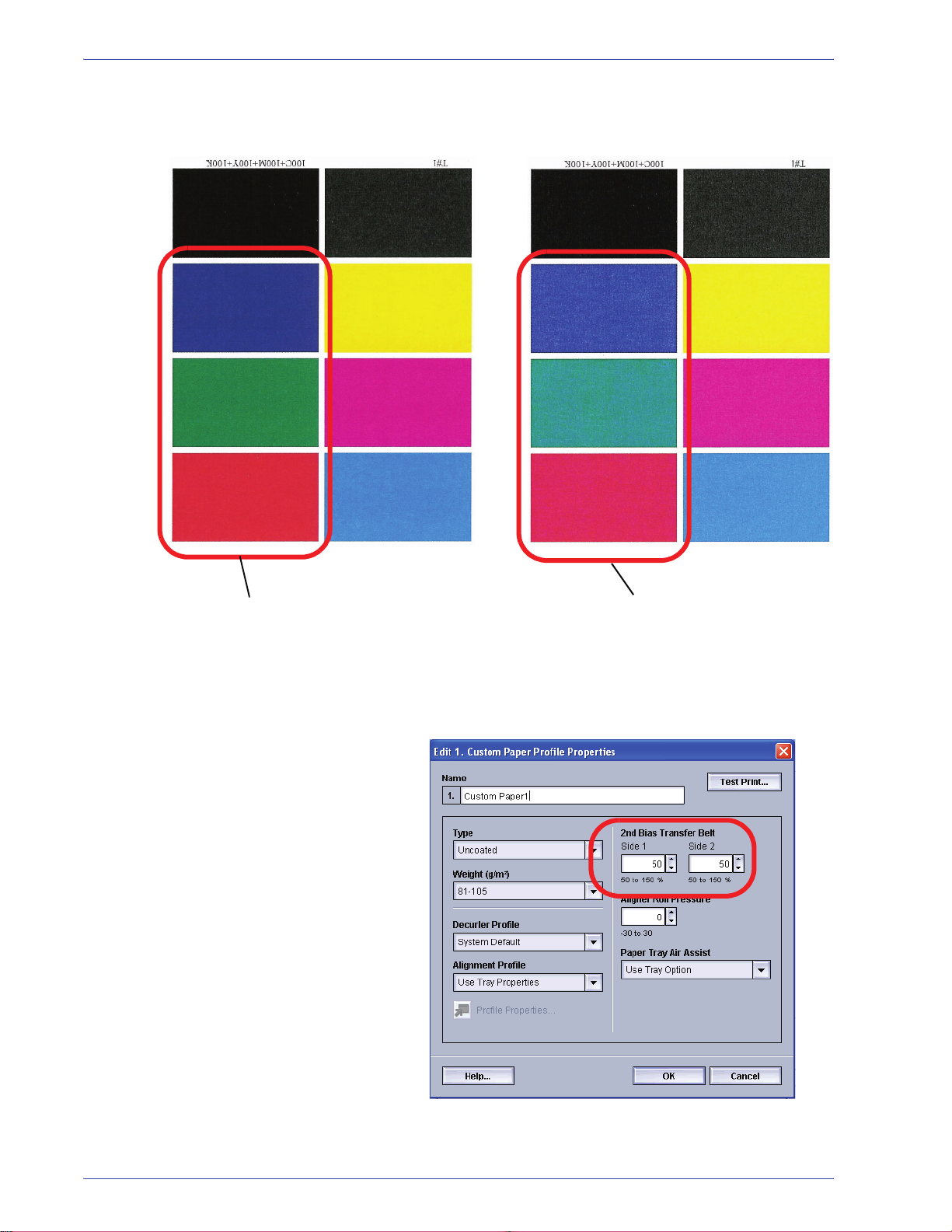

3. Use the 2nd Bias Transfer Belt feature when your:

a. Prints may have mottle

coverage that occurs when printing large, solid areas

of flat color.

, which is uneven spotty toner

DocuColor 5000AP Administrator Guide

3-21

Page 58

3. Profiles

If mottle exists and it is heavy weight paper, increase

one or both of the 2nd BTB values.

If mottle exists and it is light

weight paper, increase

one or both of the 2nd BTB values. Evaluate the

image quality. If the image quality is equal to or worse

than the 100% default setting, decrease one or both of

the 2nd BTB values until a satisfactory image quality is

obtained.

3-22

DocuColor 5000AP Administrator Guide

Page 59

3. Profiles

b. Prints have a color shift where the colors are much

different than what you desire.

This test pattern represents an

output with the desired colors.

This test pattern represents an output

with a shift in colors, and thereby an

undesired output.

If mottle color shift exists, increase one or both of the

2nd BTB values.

DocuColor 5000AP Administrator Guide

3-23

Page 60

3. Profiles

Aligner Roll Pressure

Use this feature with paper types that slip and skew or have

damaged edges.

Examples:

• Some coated paper types slip and skew, thereby

misregistering the image on the output prints. In this case, you

may want to increase

the roll pressure in order to compensate

for the slippage and skewing.

• Some light-weight papers may have too much roll pressure

applied to them, thereby causing edge damage to the output

prints. In this case, you may to decrease

the roll pressure.

• If you are experiencing numerous 8-154 faults, increase the

roll pressure and continue to run the digital press.

TIP: Increasing the roll pressure for numerous 8-154 faults,

allows you to postpone a service call. However, call your service

representative as soon as possible in order to restore the digital

press to its full feeding capabilities.

3-24

DocuColor 5000AP Administrator Guide

Page 61

Paper T ra y Air Assi st

Use this feature to switch on or switch off the fans in a paper tray

in order to eliminate misfeeds, paper jams, or other possible tray

feeding problems. You can also select System Default or Use

Tray Option if you want the digital press to decide whether or not

to switch on or off the fans for a paper tray.

3. Profiles

NOTE:The default setting is Use Tray Option.

Refer to page 2-26 of this book for information on each one of the

Paper Tray Air Assist settings.

DocuColor 5000AP Administrator Guide

3-25

Page 62

3. Profiles

Decurler Overview

TIP: Please read all the Decurler information before using the

Custom Decurler Profile procedure.

When paper is exposed to heat, the paper loses moisture and

curls toward the heat source. High toner coverage jobs tend to

curl more due to the toner plastification effect on the paper

surface. The system tries to reduce this by using mechanical

devices within the paper path called Decurlers.

Paper curl is caused by many variables, including:

• The weight of the paper and whether it is coated or uncoated.

• The amount of dry ink/toner and the area being covered on a

sheet: the heavier the coverage, the greater the tendency to

curl.

• How the paper is loaded in the tray. Make sure you load the

paper as instructed on the ream wrapper.

• The atmospheric conditions of the room where the paper is

stored, especially those related to humidity and temperature.

• The atmospheric conditions of the room where the printer is

located, especially those related to humidity and temperature.

• The heat generated during the fusing processes.

Your system is designed with several automated settings to

control curl. When using these settings the machine automatically

sends paper through the proper Decurler:

• System Default: Automatically determines the amount of

pressure needed at the different decurlers in order to reduce

the output curl of the paper.

• A, B, C, and D settings: Preset Decurler settings.

With some print jobs, the output prints still may be curled more

than you desire even after using the Decurler A-D Settings. In

those cases, use the Custom Decurler Profile feature to

compensate for paper curl in your prints. Custom Decurler Profile

settings are based on job type and image density ratio. These

settings are manually entered.

NOTE: If a decurler profile is changed, it remains at that setting

until changed again manually. As an example, if you decide to use

the B decurler setting, t he setting will remain at B unt il you change

it to another setting.

3-26

NOTE: It is important to remember that a successful decurler

setting used today may not be the same setting that you would

use on another day . This is especially relevant if the room in which

printer is located experiences changes in temperature and

humidity.

DocuColor 5000AP Administrator Guide

Page 63

Decurler paper path

3. Profiles

The Decurler has both upper and lower adjustment arms that

apply pressure to the paper based on system defaults, selections

made on the Tray Properties screen (A-D settings), or based on

entries made on the Decurler Profile screen. The degree of

pressure is applied independently to the upward and downward

Decurler arms.

DocuColor 5000AP Administrator Guide

3-27

Page 64

3. Profiles

Decurler A-D Profile settings

If paper curl is a problem, using one of the preset Decurler A-D

Profile settings usually eliminates the problem. However, due to

the broad range of paper variables, image coverage, and

environmental factors, these default settings may not result in

satisfactory performance.

Visit the www.xerox.com

Recommended Materials List (RML) for your digital press:

• To determine if Xerox has tested your paper type and weight

• View the recommended Decurler A - D Profile settings for

particular paper types.

NOTE: The settings recommended in the in the “Recommended

Materials List for DocuColor 5000” were developed from testing a

wide range of paper samples, toner area coverages, and

environments. The outcome of this testing is the preset

parameters shown in the list, and these parameters refer to how

particular papers interact with the digit al press decurling system.

Decurler A-D Profile procedure

If after using the System Default setting paper curl is still

unacceptable, select an alternate Decurler Type A - D Profile

setting:

1. At the controller, logon as Administrator.

a. Select the Logon button.

web site and refer to the latest

b. Select Administrator and enter a password.

c. Select [OK].

3-28

DocuColor 5000AP Administrator Guide

Page 65

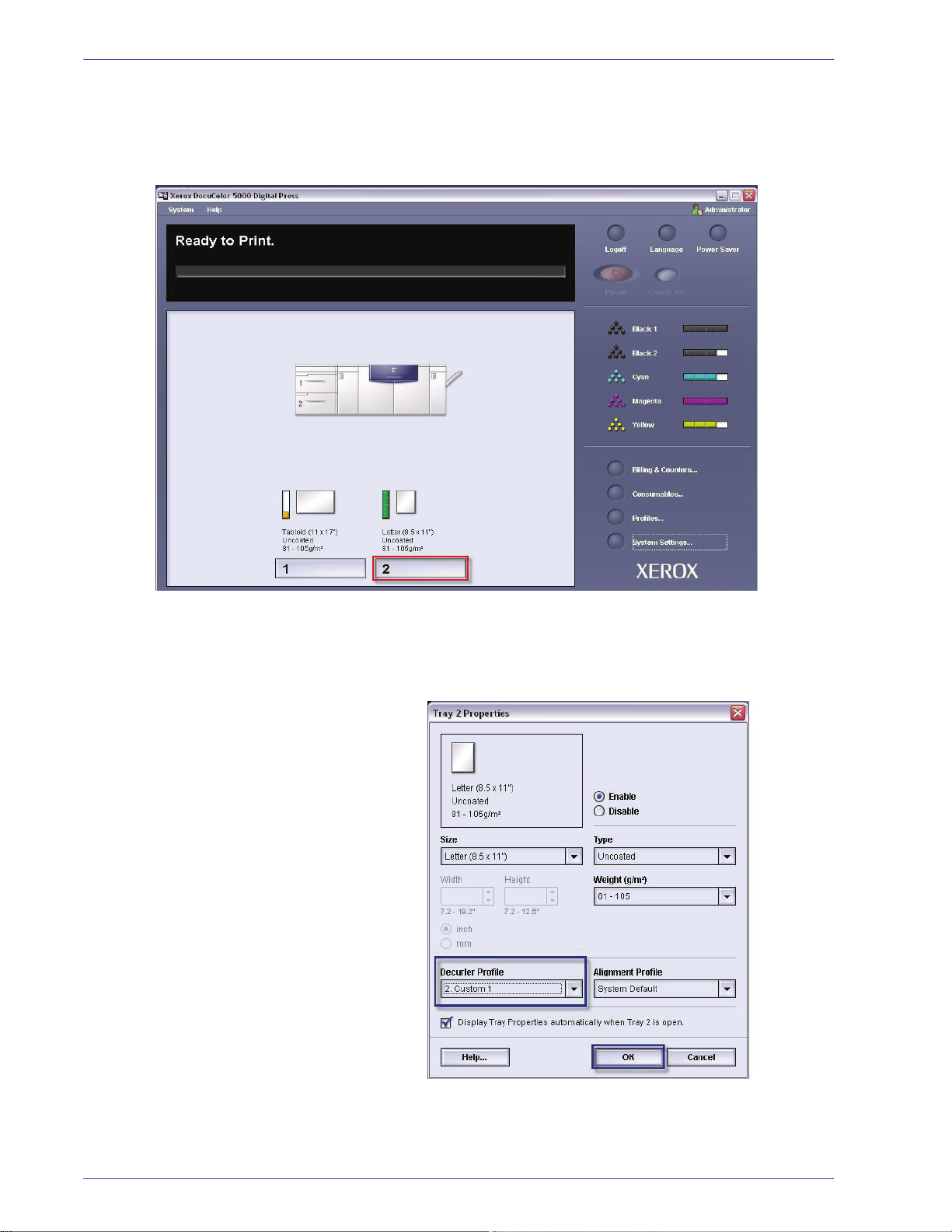

3. Profiles

2. To use an A-D Profile, select the Tray button that contains

the stock that you are using for your job. In this exercise,

select Tray 2. The Tray Properties window opens.

3. From the Decurler Profile menu, select one of the Decurler

A-D settings.

4. Select [OK].

5. Run the same print job again, and retrieve the output from

the exit area of the digital press.

DocuColor 5000AP Administrator Guide

3-29

Page 66

3. Profiles

6. Check the output for curl.

a. If the curl is eliminated, you are finished. Continue

running your prints using the specific Decurler A-D

setting.

b. If the curl is still persistent, try another Decurler Paper

Type (A-D).

Custom Decurler Profiles

c. If the curl continues after using each

Type A-D setting, continue to the Custom Decurler

Profile procedure.

NOTE: If a decurler profile is changed, it remains at that setting

until changed again manually. As an example, if you decide to use

the B decurler setting, t he setting will remain at B unt il you change

it to another setting.

While the system is programmed to correct for curl under most

conditions, there may be instances where the pre programmed

settings (System Default and A-D) may not meet your curl

requirements. Using Custom Decurler Profiles allows you to enter

an image density ratio range to help eliminate curl.

NOTE: The examples that follow are designed to give you an

understanding of programming the Custom Decurl er Profile option

to obtain optimal results, but due to various job stock and

environmental conditions the manner in which you achieve the

best results may vary.

Decurler Paper

The most important aspect for creating a Custom Decurler Profile

is determining the image density ratio on the curled paper. A

sampling of image density ratio on some typical customer

documents follows.

3-30

DocuColor 5000AP Administrator Guide

Page 67

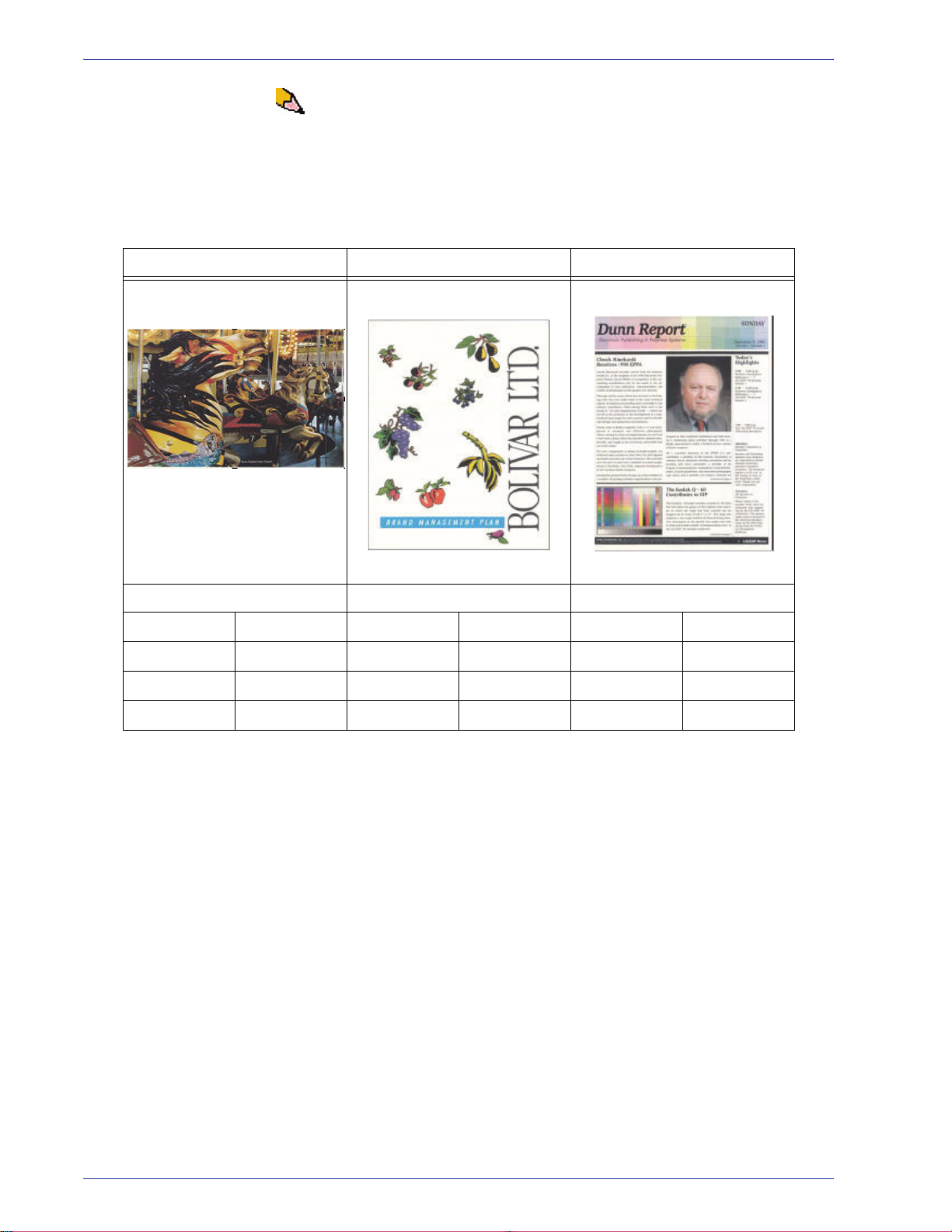

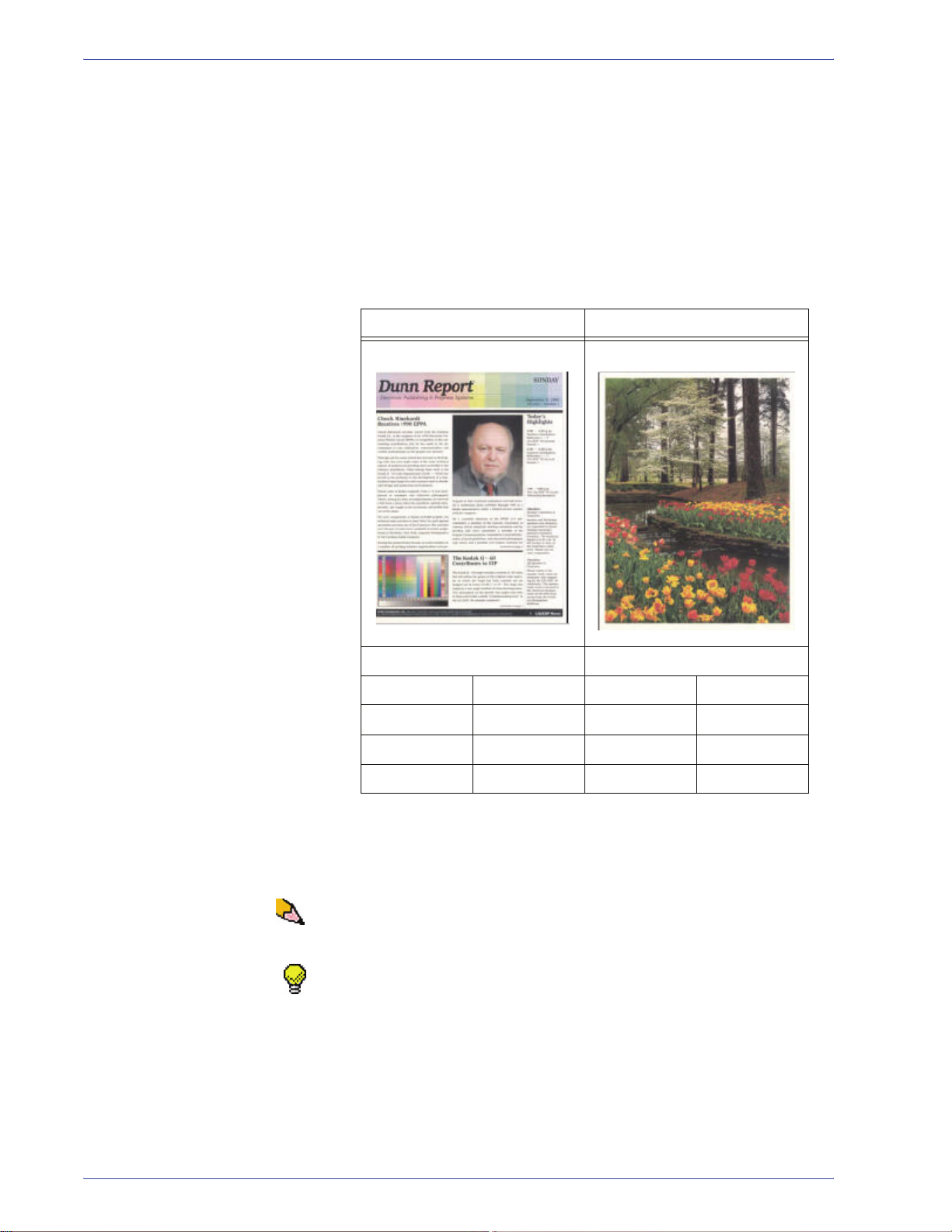

NOTE: The following image density ratios have been measured

using appropriate devices. If you do not have acces s to devi ces

that measure image density ratios, make your estimate using the

following examples as a guide. Your estimates will be used when

entering Custom Decurler Profile values, which is explained later

in this section.

Image Density Ratio examples

Carousel Horses Bolivar Ltd. Dunn Report

3. Profiles

Image Density Ratio per Color Image Density Ratio per Color Image Density Ratio per Color

Black 30.5% Black 5.4% Black 10.8%

Magenta 28.1% Magenta 4.3% Magenta 8.5%

Cyan 23.8% Cyan 6.0% Cyan 8.5%

Yellow 29.5% Yellow 6.7% Yellow 7.2%

DocuColor 5000AP Administrator Guide

3-31

Page 68

3. Profiles

Image Density Ratio examples (continued)

Upholstery by Morris Alpine Nursery Tulips

Image Density Ratio per Color Image Density Ratio per Color Image Density Ratio per Color

Black 11.6% Black 4.5% Black 27.8%

Magenta 11.9% Magenta 5.1% Magenta 24.7%

Cyan 11.1% Cyan 4.3% Cyan 23.8%

Yellow 11.4% Yellow 6.0% Yellow 28.8%

Determine if curl is upward (“cupped”) or curled downward

(“bridged”).

3-32

DocuColor 5000AP Administrator Guide

Page 69

3. Profiles

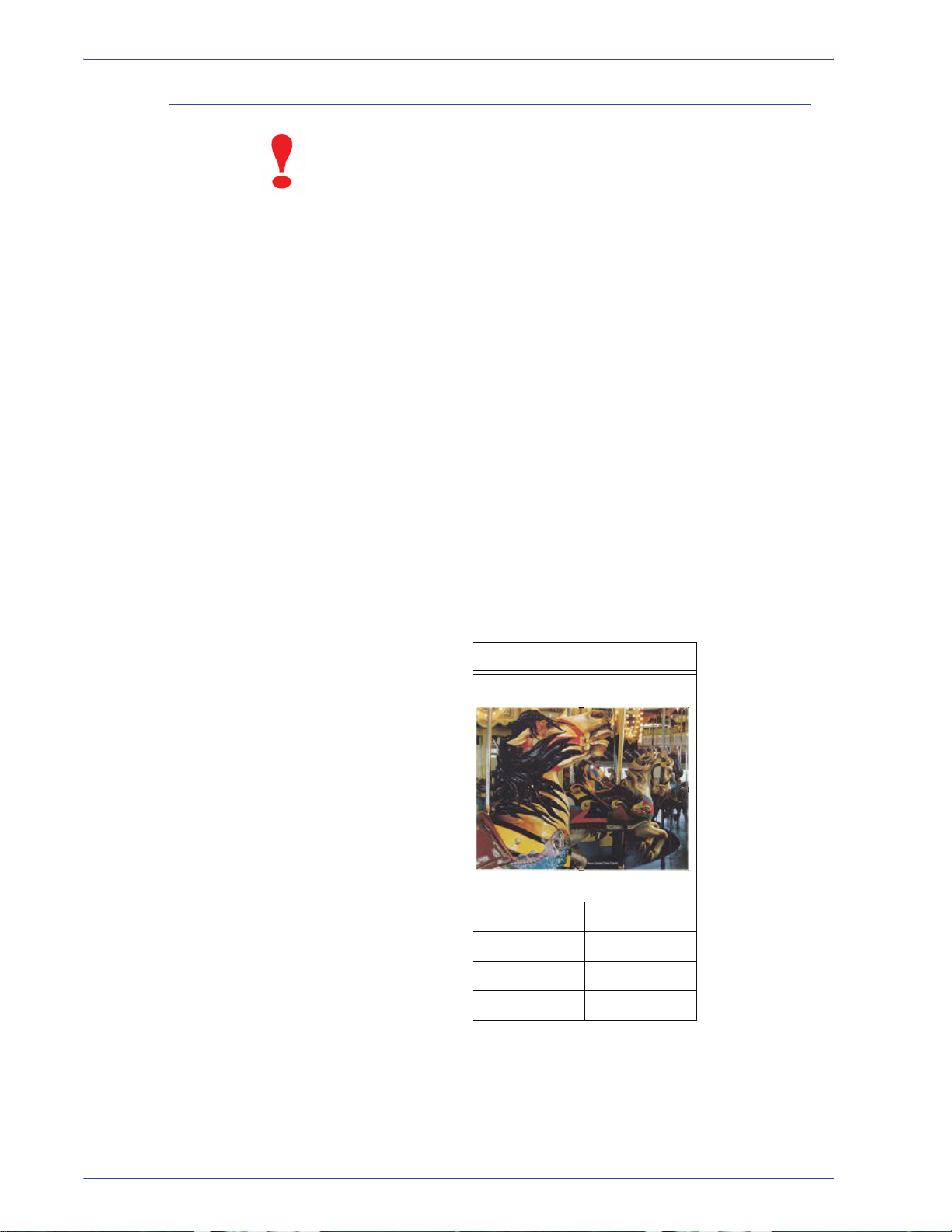

Light, Medium and Heavy curl refer to the 2 mm (Light), 6 mm

(Medium) and 10 mm (Heavy) curl selections in the Downward

and Upward fields of the Custom Decurler Profile window.

Use the following example as a guide when determining if your

curl is Light, Medium, or Heavy.

DocuColor 5000AP Administrator Guide

3-33

Page 70

3. Profiles

Entering values in the Custom Decurler Profile fields

IMPORTANT! It is important to understand that when entering

image density ratio values within the Decurler Profile Properties

window that the maximum allowed entry is 100%.

When determining what values to enter, do not total all CMYK

image density ratios, but instead determine the largest CMYK

image density ratio value. Take a look at the following examples

for further explanation:

• If your job contains image density ratios of 100% cyan, 100%

magenta, 100% yellow, and 100% black, the maximum image

density ratio value is 100%. If your job contains 100% cyan,

20% magenta, 20% yellow, and 20% black, the maximum

value is still 100%.

• If your job contains image density ratios of 50% cyan, 50%

magenta, 50% yellow, and 50% black, the maximum image

density ratio value is 50%. If your job contains 50% cyan, 10%

magenta, 10% yellow, and 10% black, the maximum value is

still 50%.

• Consider the Carousel Horses image density ratios shown

below. When entering image density ratio values to control

curl, you will use the black 30.5% value, not the combined total

of all CMYK values.

Image Density Ratios

Carousel Horses

Black 30.5%

Magenta 28.1%

3-34

Cyan 23.8%

Yellow 29.5%

DocuColor 5000AP Administrator Guide

Page 71

3. Profiles

Within the Decurler Profile Properties window, you must enter

Decurler values in ascending or descending order. If you do not

enter values in ascending or descending order, the following

screens display, which informs you to reenter the values correctly.

In the following example, 100% was followed by 80% and 90%,

respectively. The correct sequence would need to be 100%,

followed by 90% and then 80%. The conflicting values are

highlighted in red.

The exercise on the following pages will show you an example of

how to enter Decurler values correctly.

DocuColor 5000AP Administrator Guide

3-35

Page 72

3. Profiles

Creating a Custom Decurler Profile

To program a Custom Decurler Profile, perform the following:

1. At the controller, logon as Administrator.

a. Select the Logon button.

b. Select Administrator and enter a password.

a. Select [OK].

2. Select the [Profiles…] button.

3-36

NOTE: You can create up to six different Custom Decurler

Profiles.

DocuColor 5000AP Administrator Guide

Page 73

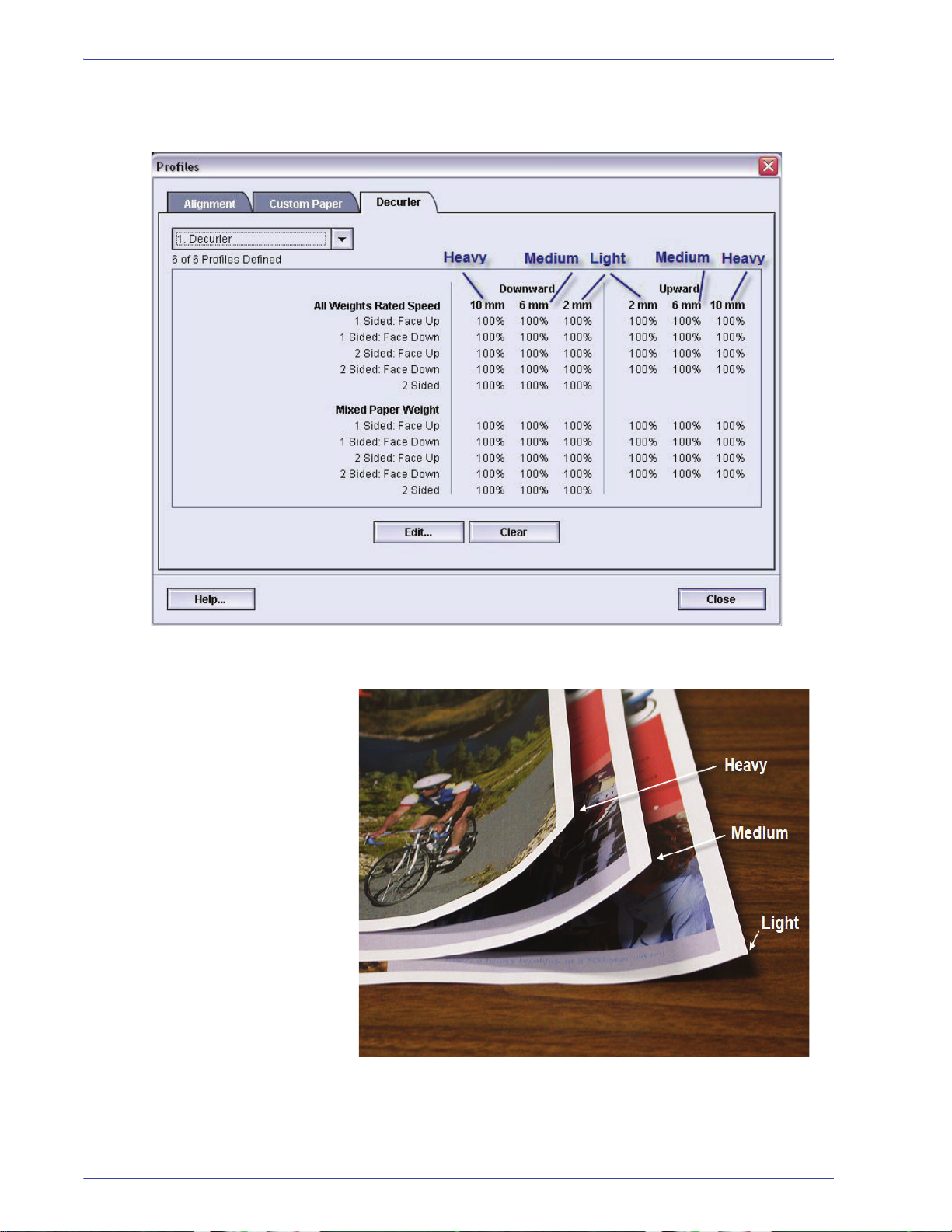

3. From the Profiles window, select the Decurler tab.

3. Profiles

4. You can edit an existing Custom Decurler Profile or create a

new one. For the following exercise you will create a new

profile.

a. From the Decurler drop-down menu, select <undefined>.

b. Select [Edit…] to define a new profile. The Decurler Profile

Properties window opens.

DocuColor 5000AP Administrator Guide

3-37

Page 74

3. Profiles

5. In this example, you are running a 10-page, 1 Sided: Face

Up job, which shows downward (bridged) curl. The job

contains:

• Six pages with maximum image density ratio of 10.8%

(Dunn Report) show light downward curl.

• Four pages with maximum image density ratio of 28.8%

(Tulips) show medium downward curl.

Image Density Ratios

Dunn Report Tulips

Image Density Ratio per Color Image Density Ratio per Color

Black 10.8% Black 27.8%

Magenta 8.5% Magenta 24.7%

Cyan 8.5% Cyan 23.8%

Yellow 7.2% Yellow 28.8%

You have tried the System Default and the A through D settings,

but curl remains. As a result, you need to program the Decurler to

use the downward Decurler path to remove the downward

(bridged) curl.

NOTE: Conversely, you would program the Decurler to use the

upward Decurler path to remove upward (cup ped) curl.

TIP: Paper that is curled upwards is adjusted using the Upward

category values. Paper that is curled downwards is adjusted

using the Downward category values.

3-38

DocuColor 5000AP Administrator Guide

Page 75

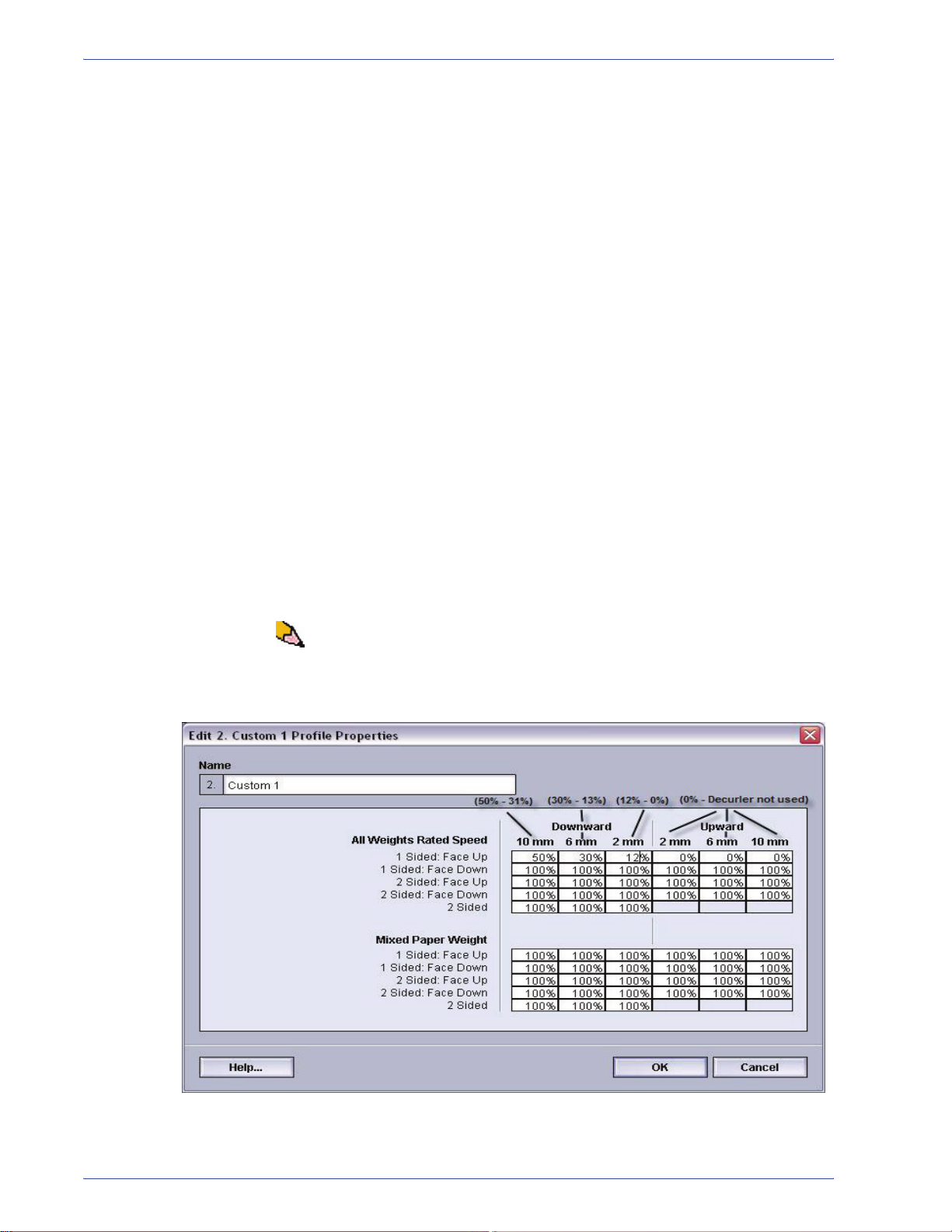

3. Profiles

6. In the Decurler Profile Properties window, you can give the

Custom Decurler Profile a new name. In this example we

rename the Custom Decurler Profile to Custom 1.

7. In the Decurler Profile Properties window, enter the

following values in the All Weights Rated Speed, 1 Sided:

Face Up fields:

• Since your job shows downward curl, you do not want to

use the Upward Decurler. As a result, in the Upward

fields you must enter values in descending order, or in

equal values less than 12% (the next value you will

enter). For this exercise we will use 0%, 0% and 0%.

• In the Downward 2 mm (Light curl) field enter 12%. This

means that all pages with a 0% through 12% image

density ratio, which includes the Dunn Report maximum

of 10.8%, will be sent to the 2 mm downward Decurler

path.

• In the Downward 6 mm (Medium curl) field, enter 30%.

This means that all pages with 13% to 30% image

density ratio, which includes the Tulips 28.8%, will be

sent to the 6 mm downward Decurler path.

• In the Downward 10 mm (Heavy curl) field, enter 50%.

Since none of your job pages have 31% through 50%

image density ratio, this Decurler will not be used.

NOTE:Remember, all fields have to be considered

(Downward and Upward) when entering Custom Decurler

Profile values.

The following screen shows how the values would be entered:

DocuColor 5000AP Administrator Guide

3-39

Page 76

3. Profiles

8. To save your Custom Decurler Profile, select [OK] after you

have entered all required values. The Custom Profiles

Properties window closes and the Profiles window displays.

9. Confirm that the values that you entered are correct in the

Profiles window. Select [Close] to exit the window and save

your profile.

3-40

DocuColor 5000AP Administrator Guide

Page 77

3. Profiles

10. To use the newly created Custom Decurler Profile, select

the Tray button that contains the stock that you are using on

your job. For this exercise, select Tray 2. The Tray

Properties window opens.

11. From the Decurler Profiles menu, select the Custom 1

profile you created.

12. Select [OK] to activate the Custom 1 profile.

DocuColor 5000AP Administrator Guide

3-41

Page 78

3. Profiles

13. Print your job and determine if the curl has been eliminated.

a. If the curl is eliminated in the new output stack, continue

printing the job and you are finished

b. If the curl remains, you may have to repeat this procedure

and adjust the image density ratios entered in the Custom

Decurler Profile window until you achieve acceptable

output prints.

.

14. If curl remains after trying various value entries in the

Custom Decurler Profile window, call your Xerox service

representative.

NOTE: If a decurler profile is changed, it remains at that setting

until changed again manually. As an example, if you decide to use

the Decurler Profile named Custom 1, the setting will remain at

Custom 1 until you change it to another setting.

3-42

DocuColor 5000AP Administrator Guide

Page 79

Page 80

Loading...

Loading...