Page 1

Version 2.0

March 2007

DocuColor 5000

Administrator

Guide

Page 2

©

Copyright 2007 by Xerox Corporation. All Rights Reserved.

Copyright protection claimed includes all forms and matters of copyrighted material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation, material generated from the software programs that are displayed on

the screen such as styles, templates, icons, screen displays, looks, etc.

®

and all Xerox product names and product numbers mentioned in this publication are trademarks of XEROX CORPORATION.

Xerox

Other company brands and product names may be trademarks or registered trademarks of the respective companies and are also

acknowledged.

This product includes software developed by the Apache Software Foundation (http://www.apache.org/

).

Page 3

Table of contents

Conventions v

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety notices vii

Electrical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Disconnect device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Europe (EU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Safety standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

North America. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Europe (EU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Maintenance safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Operational safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Ozone safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Notices xv

Radio frequency emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

FCC in the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

In Canada (ICES-003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Regulatory information for RFID. . . . . . . . . . . . . . . . . . . . . .xvi

Safety extra low voltage approval. . . . . . . . . . . . . . . . . . . . . . . .xvi

Certifications in Europe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

It’s illegal in the USA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

It’s illegal in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Environmental notices for Canada . . . . . . . . . . . . . . . . . . . . . . xxii

Product recycling and disposal . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

DocuColor 5000 Administrator Guide

i

Page 4

Table of contents

North America. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

European union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

Other countries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

1. Administrator overview 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Logging on as Administrator. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Finishing System Profiles overview . . . . . . . . . . . . . . . . . . . . . 1-3

2. System Settings 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Fault Details window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Change Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting the Date & Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Productivity Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Productivity charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Single Paper Weight . . . . . . . . . . . . . . . . . . . . . . . 2-11

Mixed Paper Weight . . . . . . . . . . . . . . . . . . . . . . . 2-12

Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Exit Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Auto Resume After . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Fault Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Pause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Job Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Auto Logoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

NVM Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Tray Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Auto Tray Switching, Auto Paper Selection, and Do Not

Include . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Paper Tray Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Tray Priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

ii

DocuColor 5000 Administrator Guide

Page 5

Table of contents

3. Profiles 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Alignment Adjustment Profile procedure. . . . . . . . . . . . . . . 3-4

Creating an Alignment profile . . . . . . . . . . . . . . . . . . . . 3-6

Selecting the Registration options . . . . . . . . . . . . . . . . 3-7

Selecting the Perpendicularity options . . . . . . . . . . . . . 3-8

Selecting the Skew options . . . . . . . . . . . . . . . . . . . . . . 3-9

Selecting the Magnification options . . . . . . . . . . . . . . 3-10

Running test prints . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Editing an existing Alignment profile. . . . . . . . . . . . . . 3-13

Custom Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Custom Paper procedure . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Creating an Custom Paper profile. . . . . . . . . . . . . . . . 3-16

Selecting the desired paper type . . . . . . . . . . . . . . . . 3-17

Selecting the desired paper weight. . . . . . . . . . . . . . . 3-18

Selecting other options for your Custom Paper profile 3-19

Running test prints . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Editing a Custom Paper profile . . . . . . . . . . . . . . . . . . 3-25

Second Bias Transfer Belt . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Aligner Roll Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Paper Tray Air Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

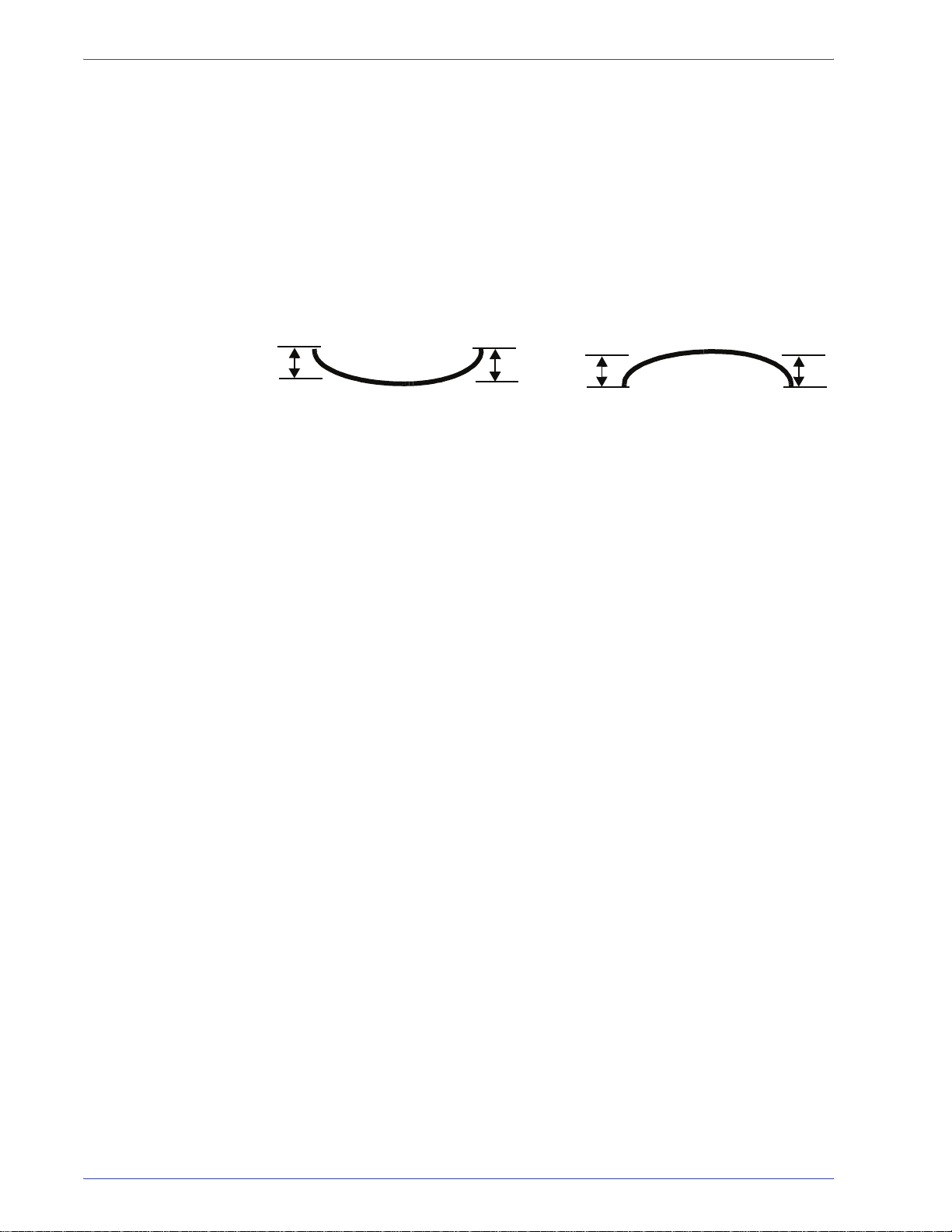

Decurler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Decurler specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Decurler settings A-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Evaluate your print output for paper curl. . . . . . . . . . . . . . 3-35

Decurler Profile options. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Downward/Upward Values . . . . . . . . . . . . . . . . . . . . . 3-39

Decurler Profile procedure . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Selecting the Decurler tab. . . . . . . . . . . . . . . . . . . . . . 3-40

Creating a Decurler profile . . . . . . . . . . . . . . . . . . . . . 3-41

Entering your curl calculations . . . . . . . . . . . . . . . . . . 3-42

Running test prints . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

DocuColor 5000 Administrator Guide

iii

Page 6

Table of contents

iv

DocuColor 5000 Administrator Guide

Page 7

Symbols

Conventions

Standardized conventions have been used in this manual to assist

you in visually locating and identifying information quickly.

CAUTION: This symbol alerts you to an action that may cause

damage to hardware, software, or result in the loss of data.

WARNING: Warnings mark alert users to areas of the machine

where there is a possibility of personal injury.

WARNING: This symbol identifies an area on the machine that is

HOT and should not be touched.

WARNING: This symbol indicates a laser is being used in the

machine and alerts you to refer to the appropriate safety

information.

TIP: This symbol identifies information that is being emphasized

and is important for you to remember.

The 1 2 3... symbol indicates the beginning of a task or work

process you should use to complete a procedure and is followed

by the first step of a numbered procedure, task, or work process.

DocuColor 5000 Administrator Guide

v

Page 8

Conventions

NOTE: This symbol calls your attention to information that is

helpful, but not essential to compl e te a procedure or task.

This symbol indicates that there is additional information from

another source, such as a web site or manual.

vi

DocuColor 5000 Administrator Guide

Page 9

Safety notices

This Xerox digital press and the recommended supplies are

designed and tested to meet strict safety requirements. These

include safety agency approval and compliance to established

environmental standards. Please read the following instructions

carefully before operating the product, and refer to them as

needed to ensure the continued safe operation of your digital

press.

TIP: The safety testing and performance of this product have

been verified using Xerox materials only.

WARNING: Any unauthorized alteration, which may include the

addition of new functions or connection of external devices, may

impact the product certification. Please contact your authorized

local dealer for more information.

Electrical safety

• Use only the power cord supplied with this equipment.

• Plug the power cord directly into a correctly grounded

electrical outlet. Do not use an extension cord. If you do not

know whether or not an outlet is grounded, consult a qualified

electrician.

• Do not use a ground adapter plug to connect this equipment to

an electrical outlet that lacks a ground connection terminal.

DocuColor 5000 Administrator Guide

vii

Page 10

Safety notices

WARNING: You may incur a severe electrical shock if the outlet is

not grounded correctly.

• Do not place the press where people may step or trip on the

power cord. Do not place objects on the power cord.

• Do not override or disable electrical or mechanical interlocks.

• Do not obstruct the ventilation openings. These openings

prevent overheating of the machine.

WARNING: Never push objects of any kind into slots or openings

on this equipment. Making a contact with a voltage point or

shorting out a part may result in fire or electrical shock.

If any of the following conditions occur, immediately switch off the

power to the machine and disconnect the power cord from the

electrical outlet. Call an authorized Xerox service representative

to correct the problem.

• The machine emits unusual noises or odors.

• The power cord is damaged or frayed.

• A wall panel circuit breaker, fuse, or other safety device is

tripped.

• Liquid is spilled into the press.

• The machine is exposed to water.

• Any part of the machine is damaged.

viii

DocuColor 5000 Administrator Guide

Page 11

Disconnect device

Safety notices

The power cable is the disconnect device for this equipment and is

attached to the back of the machine as a plug-in device. To

remove all electrical power from the machine, disconnect the

power cable from the electrical outlet.

WARNING: This product must be connected to a protective earth

current.

DocuColor 5000 Administrator Guide

ix

Page 12

Safety notices

Laser safety

North America

This product complies with safety standards and is certified as a

Class 1 Laser product under the Center for Devices and

Radiological Health (CDRH) of the United States Food and Drug

Administration (FDA) implemented regulations for laser

products. This product complies with FDA 21 CFR 1940.10 and

1040.11 except for deviations pursuant to Laser Notice No. 50,

dated July 26, 2001. These regulations apply to laser products

marketed in the United States. The label on the machine indicates

compliance with CDRH regulations and must be attached to laser

products marketed in the United States. This product does not

emit hazardous laser radiation.

CAUTION: Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous exposure of laser light.

Since radiation emitted inside this product is completely confined

within the protective housing and external covers, the laser beam

cannot escape from the machine during any phase of the user

operation.

This product contains laser warning labels. These labels are

intended for use by the Xerox Service Representative and are

placed on or near panels or shields that require special tools for

removal. Do not remove any of the panels. There are no operator

serviceable areas in these covers.

x

DocuColor 5000 Administrator Guide

Page 13

Europe (EU)

Safety notices

This product complies with IEC’s safety standard 60825-1 (Edition

1.2) issued August 2001.

The equipment complies with laser product performance

standards set by governmental, national, and international

agencies as a Class 1 Laser Product. It does not emit hazardous

radiation as the beam is totally enclosed during all phases of

customer operation and maintenance.

CAUTION: Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

This product contains laser warning labels. These labels are

intended for use by the Xerox Service Representative and are

placed on or near panels or shields that require special tools for

removal. Do not remove any of the panels. There are no operator

serviceable areas inside these covers.

If you need additional safety information concerning the product or

Xerox supplied materials, you may call the following number:

+44 (0) 1707 353434

DocuColor 5000 Administrator Guide

xi

Page 14

Safety notices

Safety standards

North America

Europe (EU)

Maintenance safety

This Xerox product is safety certified by Underwriters Laboratories

Incorporated to Standards UL60950, third edition (2000), and CSA

International CAN/CSA C22.2 No. 60950-00 third edition.

This Xerox product is Safety Certified by NEMKO to publication

IEC60950-1 (2001) First Edition.

• Do not attempt any maintenance procedure that is not

specifically described in the documentation supplied with your

digital press.

• Do not use aerosol cleaners. The use of supplies that are not

approved may cause poor performance of the press and could

create a dangerous condition.

• Use the supplies and cleaning materials only as directed in

this manual. Keep all materials out of the reach of children.

• Do not remove the covers or guards that are fastened with

screws. There are no parts behind these covers that you can

maintain or service.

Do not perform any maintenance procedures unless you have

been trained to do them by a Xerox representative, or unless a

procedure is specifically described in one of the manuals included

with your press.

xii

DocuColor 5000 Administrator Guide

Page 15

Operational safety

Safety notices

Your Xerox equipment and supplies were designed and tested to

meet strict safety requirements. These include safety agency

examination, approval, and compliance with established

environmental standards.

Your attention to the following safety guidelines will help ensure

the continued safe operation of your digital press:

• Use the materials and supplies specifically designed for your

digital press. The use of unsuitable materials may result in

poor performance of the machine and possibly a hazardous

situation.

• Follow all warnings and instructions that are marked on or

supplied with the machine.

• Place the machine in a room that provides adequate space for

ventilation and servicing.

• Place the machine on a level, solid surface (not on a thick pile

carpet) that has adequate strength to support the weight of the

machine.

• Do not attempt to move the machine. A leveling device that

was lowered when your machine was installed may damage

the carpet or floor.

• Do not set up the machine near a heat source.

• Do not set up the machine in direct sunlight.

DocuColor 5000 Administrator Guide

xiii

Page 16

Safety notices

Ozone safety

• Do not set up the machine in line with the cold air flow from an

air conditioning system.

• Do not place containers of coffee or other liquid on the

machine.

• Do not block or cover the slots and openings on the machine.

• Do not attempt to override any electrical or mechanical

interlock devices.

WARNING: Be careful when working in areas identified with this

warning symbol. These areas may be very hot and should not be

touched.

If you need any additional safety information concerning the

machine or materials, contact your Xerox representative.

This product produces ozone during normal operation. The ozone

is heavier than air, and the quantity is dependent on print volume.

Providing the correct environmental parameters, as specified in

the Xerox installation procedures, ensures that concentration

levels meet safe limits.

If you need additional information about ozone, request the Xerox

publication, OZONE, 600P83222, by calling 1-800-828-6571 in

the USA. For a French language version, call 1-800-828-6571 in

the USA, then press 2.

xiv

DocuColor 5000 Administrator Guide

Page 17

Notices

Radio frequency emis sions

FCC in the USA

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

Federal Communications Commission (FCC) Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his/her

own expense.

Changes or modifications to this equipment not specifically

approved by the Xerox Corporation may void the user’s authority

to operate this equipment.

Shielded cables must be used with this equipment to maintain

compliance with FCC regulations.

DocuColor 5000 Administrator Guide

xv

Page 18

Notices

In Canada (ICES-003)

This Class “A” digital apparatus complies with Canadian ICES-

003.

Cet appareil numérique de la classe “A” est conforme á la norme

NMB-003 du Canada.

Regulatory information for RFID

This product generates 13.56 MHz using an Inductive Loop

System as a Radio Frequency IDentification system device

(RFID). This system is certified in compliance with European

Council Directive 99/5/EC and applicable local laws or regulations

as applicable.

Safety extra low volt age approval

This Xerox digital press is in compliance with various

governmental agencies and national safety regulations. All system

ports meet the Safety Extra Low Voltage (SELV) circuits for

connection to customer-owned devices and networks. Additions of

customer-owned or third-party accessories that are attached to

the press must meet or exceed the requirements previously listed.

All modules that require external connection must be installed per

the installation procedure.

xvi

DocuColor 5000 Administrator Guide

Page 19

Certifications in Europe

January 1, 1995: Council Directive 73/23/EEC amended by Council Directive 93/68/

January 1, 1996: Council Directive 89/336/EEC, approximation of the laws of the

March 9, 1999 Council Directive 99/5/EC on radio equipment and

Notices

The CE marking that is applied to this product symbolizes Xerox

Declaration of Conformity with the following applicable Directives

of the European Union as of the dates indicated:

EEC, approximation of the laws of the member states related to

low voltage equipment.

member states related to electromagnetic compatibility.

telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration, defining the relevant directives and referenced

standards, can be obtained from your Xerox Limited

representative or by contacting:

Environment, Health and Safety

The Document Company Xerox

Bessemer Road

Welwyn Garden City

Herts

AL7 1HE

England

Tel Number +44 (0) 1707 353434

WARNING: This system is certified manufactured and tested in

compliance with strict safety and radio frequency interference

regulations. Any unauthorized alteration which includes the

addition of new functions or the connection of external devices

may impact this certification. Please contact your local Xerox

Limited representative for a list of approved accessories.

DocuColor 5000 Administrator Guide

xvii

Page 20

Notices

It’s illegal in the USA

WARNING: In order to allow this equipment to operate in

proximity to Industrial, Scientific, and Medical (ISM) equipment,

the external radiation from the ISM equipment may have limited or

special mitigation measures taken.

WARNING: This is a Class A product in a domestic

environment. This product may cause radio frequency

interference in which case the user may be required to take

adequate measures.

Shielded cables must be used with this equipment to maintain

compliance with Council Directive 89/336/EEC.

Congress, by statute, has forbidden the reproduction of the

following subjects under certain circumstances. Penalties of fine

or imprisonment may be imposed on those guilty of making such

reproductions.

1.Obligations or Securities of the United States Government,

such as:

Certificates of Indebtedness National Bank Currency

Coupons from Bonds Federal Reserve Bank Notes

Silver Certificates Gold Certificates

United States Bonds Treasury Notes

Federal Reserve Notes Fractional Notes

Certificates of Deposit Paper Money

Bonds and Obligations of certain agencies of the government,

such as FHA, etc.

Bonds. (U.S. Savings Bonds may be photographed only for

publicity purposes in connection with the campaign for the sale

of such bonds.)

Internal Revenue Stamps. (If it is necessary to reproduce a

legal document on which there is a canceled revenue stamp,

this may be done provided the reproduction of the document is

performed for lawful purposes.)

Postage Stamps, canceled or uncanceled. (For philatelic

purposes, Postage Stamps may be photographed, provided

the reproduction is in black and white and is less than 75% or

more than 150% of the linear dimensions of the original.)

xviii

Postal Money Orders.

Bills, Checks, or Drafts of money drawn by or upon authorized

officers of the United States.

Stamps and other representatives of value, of whatever

denomination, which have been or may be issued under any

Act of Congress.

DocuColor 5000 Administrator Guide

Page 21

Notices

2.Adjusted Compensation Certificates for Veterans of the World

Wars.

3.Obligations or Securities of any Foreign Government, Bank, or

Corporation.

4.Copyrighted material, unless permission of the copyright

owner has been obtained or the reproduction falls within the

“fair use” or library reproduction rights provisions of the

copyright law. Further information of these provisions may be

obtained from the Copyright Office, Library of Congress,

Washington, D.C. 20559. Ask for Circular R21.

5.Certificates of Citizenship or Naturalization. (Foreign

Naturalization Certificates may be photographed.)

6.Passports. (Foreign Passports may be photographed.)

7.Immigration Papers.

8.Draft Registration Cards.

9.Selective Service Induction Papers that bear any of the

following Registrant’s information:

Earnings or Income Dependency Status

Court Record Previous military service

Physical or mental condition

Exception: United States military discharge certificates may be

photographed.

10.Badges, Identification Cards, Passes, or Insignia carried by

military personnel, or by members of the various Federal

Departments, such as FBI, Treasury, etc. (unless photograph

is ordered by the head of such department or bureau.)

Reproducing the following is also prohibited in certain states:

Automobile Licenses - Drivers’ Licenses - Automobile

Certificates of Title.

The above list is not all inclusive, and no liability is assumed for its

completeness or accuracy. In case of doubt, consult your attorney.

DocuColor 5000 Administrator Guide

xix

Page 22

Notices

It’s illegal in Canada

Parliament, by statute, has forbidden the reproduction of the

following subjects under certain circumstances. Penalties of fines

or imprisonment may be imposed on those guilty of making such

copies.

1.Current bank notes or current paper money.

2.Obligations or securities of a government or bank.

3.Exchequer bill paper or revenue paper.

4.The public seal of Canada or of a province, or the seal of a

public body or authority in Canada, or of a court of law.

5.Proclamations, orders, regulations or appointments, or notices

thereof (with intent to falsely cause same to purport to have

been printed by the Queen’s Printer for Canada, or the

equivalent printer for a province).

6.Marks, brands, seals, wrappers or designs used by or on

behalf of the Government of Canada or of a province, the

government of a state other than Canada or a department,

board, Commission or agency established by the Government

of Canada or of a province or of a government of a state other

than Canada.

7.Impressed or adhesive stamps used for the purpose of

revenue by the Government of Canada or of a province or by

the government of a state other than Canada.

8.Documents, registers or records kept by public officials

charged with the duty of making or issuing certified copies

thereof, where the reproduction falsely purports to be a

certified copy thereof.

9.Copyrighted material or trademarks of any manner or kind

without the consent of the copyright or trademark owner.

The above list is provided for your convenience and assistance,

but it is not all inclusive, and no liability is assumed for its

completeness or accuracy. In case of doubt, consult your solicitor.

xx

DocuColor 5000 Administrator Guide

Page 23

Environmental notices for Canada

Terra Choice Environmental Services, Inc. of Canada has verified

that this Xerox product conforms to all applicable Environmental

Choice EcoLogo requirements for minimized impact to the

environment.

As a participant in the Environmental Choice program, Xerox

Corporation has determined that this digital press model meets

the Environmental Choice guidelines for energy efficiency.

Environment Canada established the Environmental Choice

program in 1988 to help consumers identify environmentally

responsible products and services. Copier, printer, digital press,

and fax products must meet energy efficiency and emissions

criteria, and exhibit compatibility with recycled supplies. Currently,

Environmental Choice has more than 1600 approved products

and 140 licensees. Xerox has been a leader in offering EcoLogo

approved products. In 1996, Xerox became the first company

licensed to use the Environmental Choice EcoLogo for its copiers,

printers, and fax machines.

Notices

DocuColor 5000 Administrator Guide

xxi

Page 24

Notices

Product recycling and disposal

If you are managing the disposal of your Xerox product, please

note that the product contains lead and other materials whose

disposal may be regulated due to environmental

considerations. The presence of lead is fully consistent with

global regulations applicable at the time that the product was

placed on the market.

North America

Xerox operates a worldwide equipment take-back and reuse/

recycle program. Contact your Xerox sales representative (1-800ASK-XEROX) to determine whether this Xerox product is part of

the program. For more information about Xerox environmental

programs, visit www.xerox.com/environment

For recycling and disposal information, contact your local

authorities. In the United States, you may also refer to the

Electronic Industries Alliance web site: www.eiae.org

.

.

Perchlorate Material This product may contain one or more Perchlorate-containing

devices, such as batteries. Special handling may apply, please

see www.dtsc.ca.gov/hazardouswaste/perchlorate

If your product is not part of the Xerox program and you are

managing its disposal, please follow the instructions provided in

the above paragraph.

.

xxii

DocuColor 5000 Administrator Guide

Page 25

European union

Other countries

Notices

Application of this symbol on your equipment is confirmation that

you must dispose of this equipment in compliance with agreed

national procedures.

In accordance with European legislation end-of-life electrical and

electronic equipment subject to disposal must be managed within

agreed procedures.

Prior to disposal, contact your local dealer or Xerox representative

for end-of-life take-back information.

Please contact your local waste authorities and request disposal

guidance.

DocuColor 5000 Administrator Guide

xxiii

Page 26

Notices

xxiv

DocuColor 5000 Administrator Guide

Page 27

1. Administrator overview

Overview

The Administrator mode allows you to set the default settings for

your digital press in order to fit your individual requirements. You

can change the settings for a variety of features, such as the

language to display on the UI, timers, changing the Administrator

password, creating custom paper and alignment profiles, and

more.

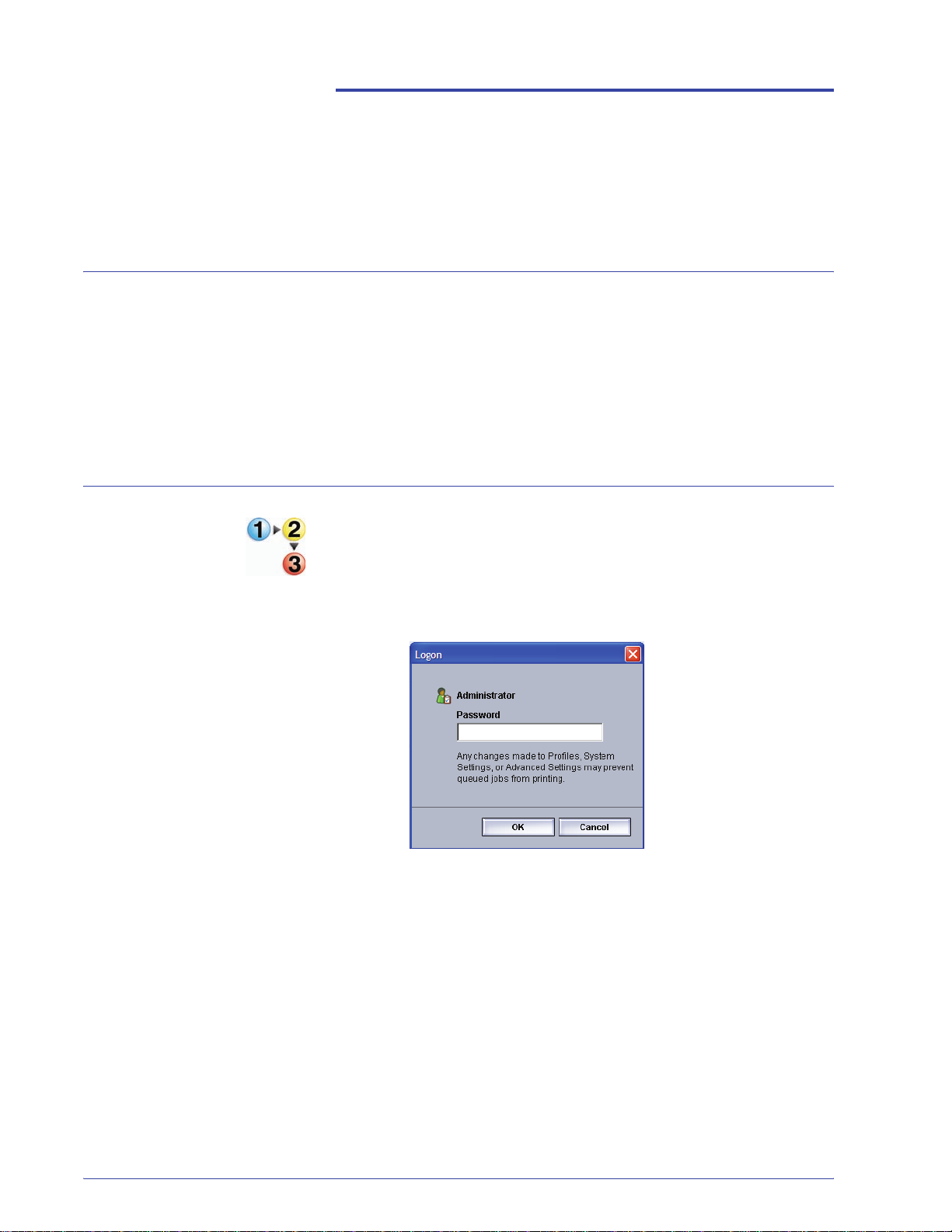

Logging on as Administrator

Use the following procedure to enter and exit the Administrator

mode:

1. Select the Logon button from the main UI window. The

Logon screen appears.

2. Use the keyboard to enter the Administrator password.

The default password is five ones (11111).

For security reasons, only asterisks are displayed on the

screen.

DocuColor 5000 Administrator Guide

1-1

Page 28

1. Administrator overview

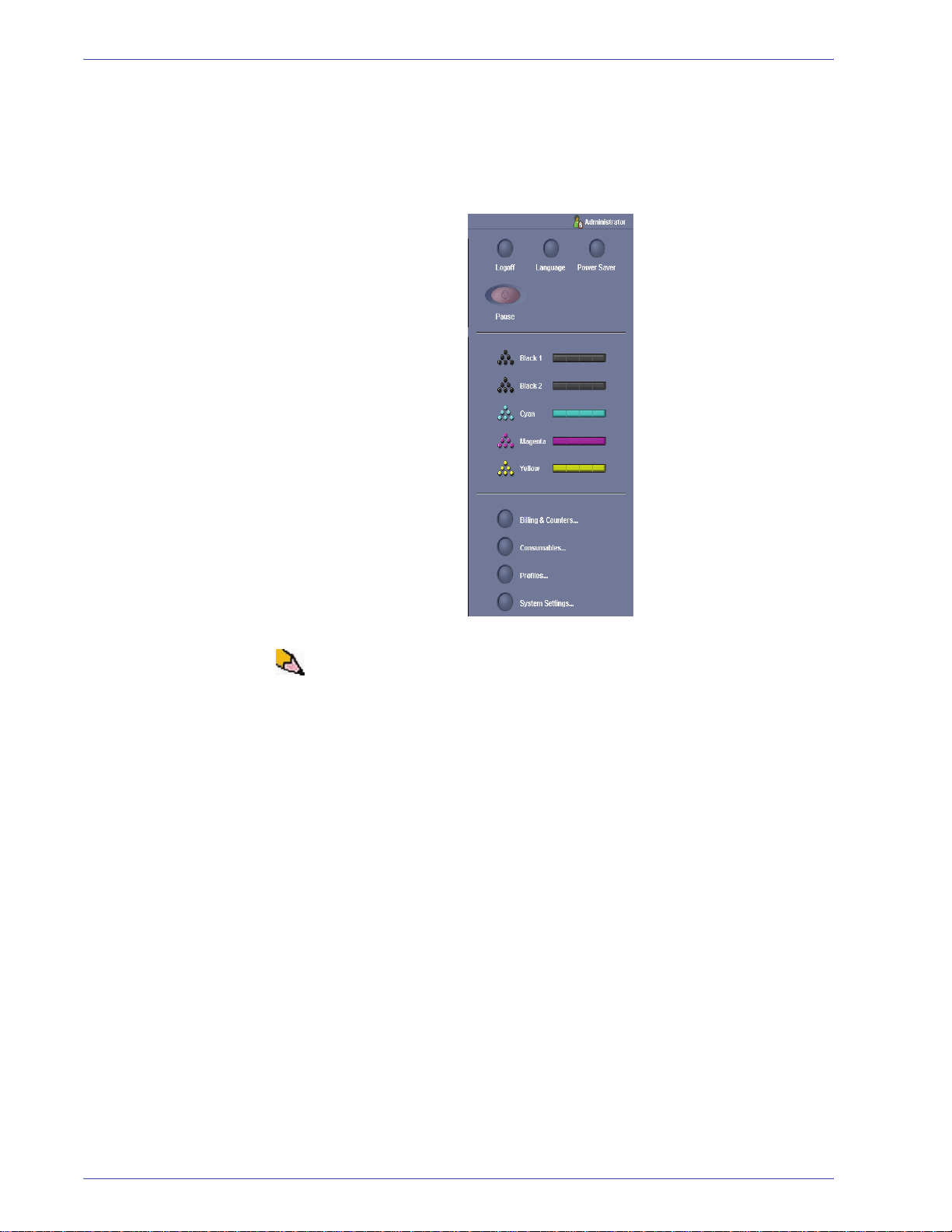

3. Select the OK button.

The main UI screen now displays additional options and

indicates in the upper right that you are in the Administrator

mode.

NOTE: It is recommended that you change the Administrator

password as soon as possible after installing the digital press in

order to prevent unauthorized access to the Administrator mode.

The procedure for changing the password is on page 2-5 of this

book.

4. To exit the Administrator mode, select the Logoff button.

1-2

DocuColor 5000 Administrator Guide

Page 29

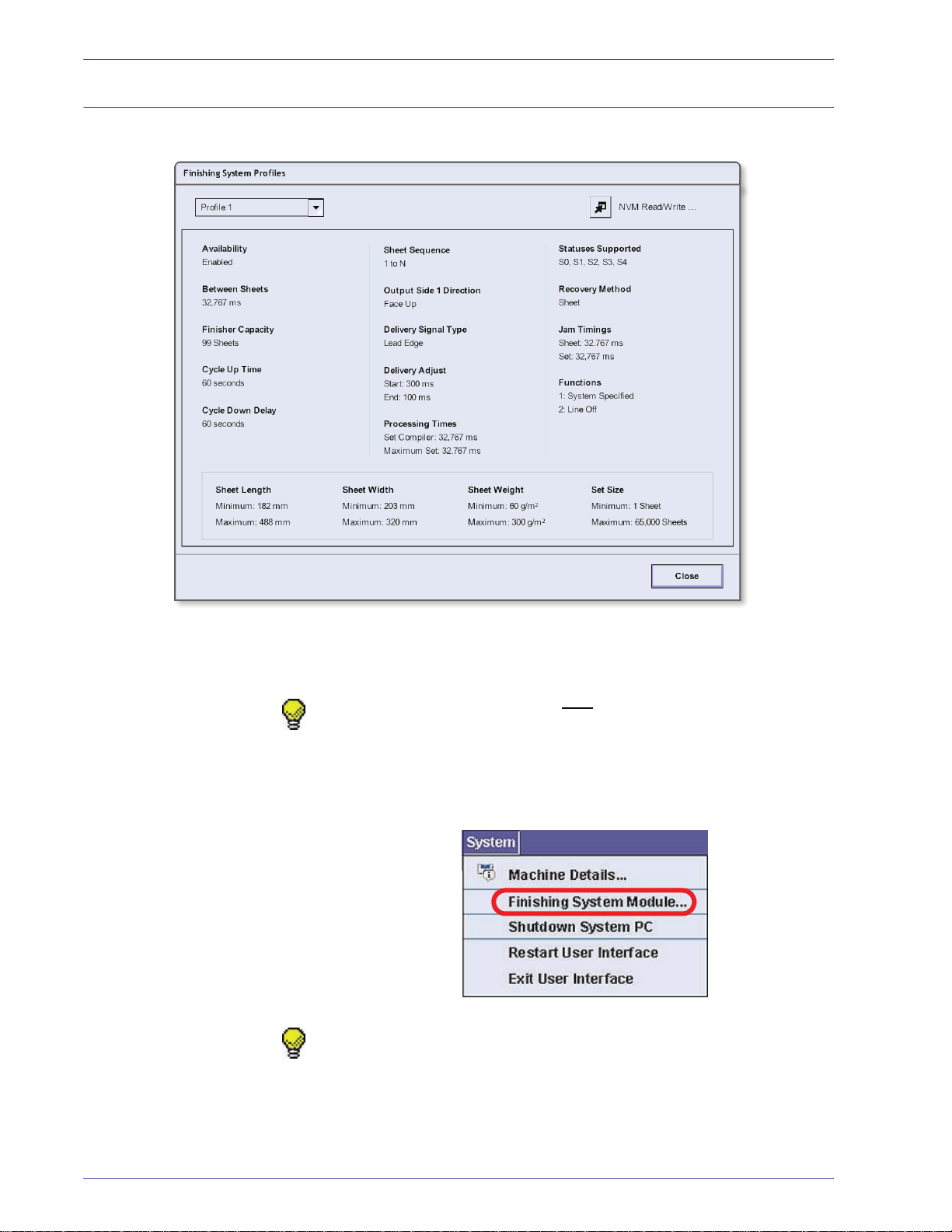

Finishing System Profiles overview

1. Administrator overview

If your digital press has an optional, third-party, Digital Finishing

Architecture (DFA) device finishing, then the Finishing System

Profiles option is available to you.

TIP: This feature is available only if you are logged on as the

Administrator.

Once your system is configured for the optional finishing

accessory, the Finishing System Profiles option is accessed from

the System pull-down menu on the main UI screen.

TIP: This window is ready-only; you cannot change the

information shown on this screen. If you have more than one

finishing device connected to your digital press, you can select the

desired profile from the pull-down menu at the upper-left portion of

the Finishing System Profiles window.

DocuColor 5000 Administrator Guide

1-3

Page 30

1. Administrator overview

1-4

DocuColor 5000 Administrator Guide

Page 31

Overview

2. System Settings

The System Settings feature allows you to make changes to the

following features:

• User Interface

• Date and Time

•System

• Tray Options

DocuColor 5000 Administrator Guide

2-1

Page 32

2. System Settings

User Interface

The User Interface feature allows you to make changes to the

following:

• Fault Detail Window

• Changing the Administrator password

2-2

DocuColor 5000 Administrator Guide

Page 33

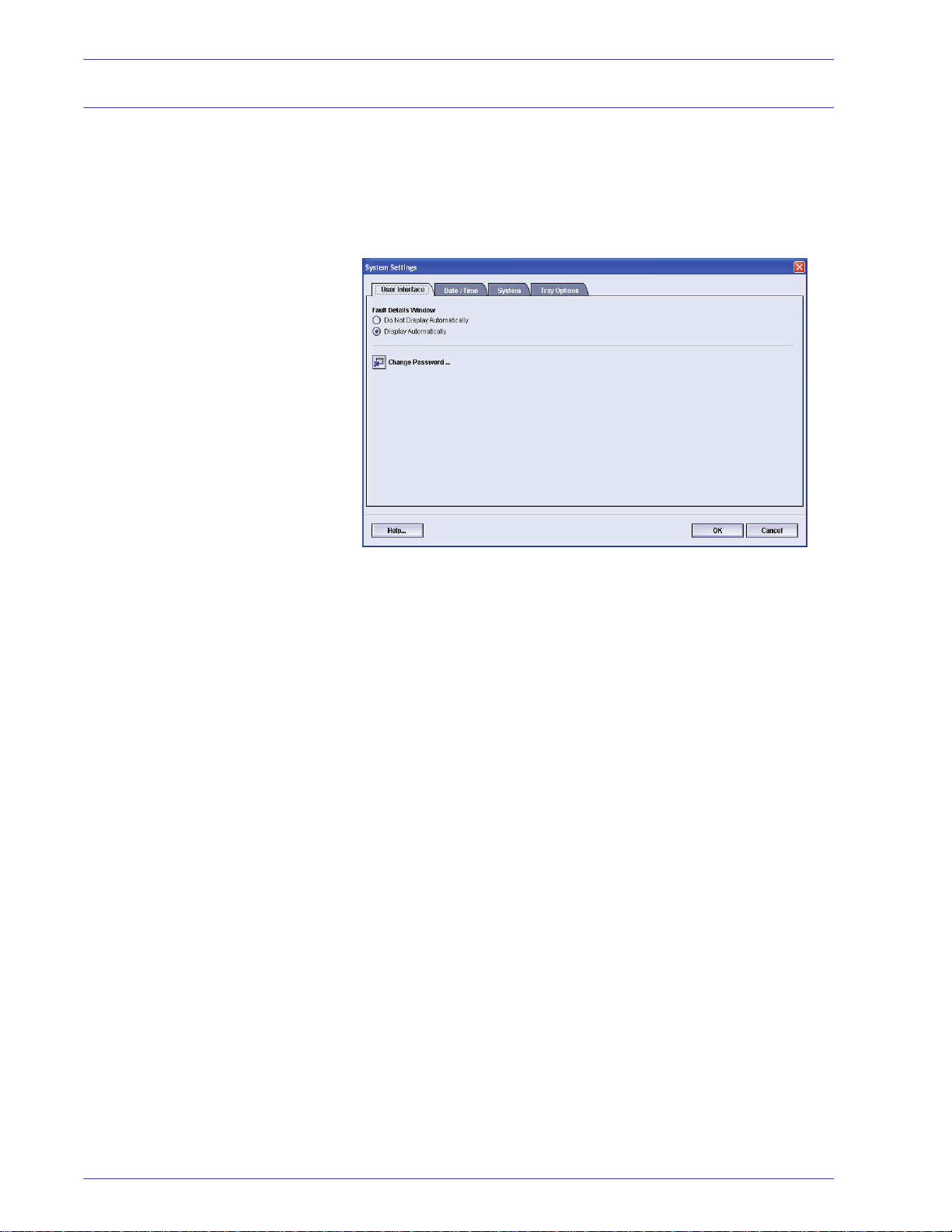

Fault Details window

By default, the UI automatically opens a Details window which

provides additional information about the alert, warning, or fault

(as shown in the following illustration).

2. System Settings

Machine

mimic and

Message

area

However, you can select whether or not you want this window

open automatically or to open only when the user clicks on the

alert, warning, or fault message in the machine mimic and

message area of the UI.

DocuColor 5000 Administrator Guide

2-3

Page 34

2. System Settings

Use the following procedure to choose the default setting for this

feature.

1. Select the Logon button from the UI and logon as the

Administrator.

2. Select the System Settings button; the System Settings

window opens.

3. Select whether or not you want any machine faults to

automatically display on the UI when they occur.

• Do Not Display Automatically: Select this option if you

do not

automatically when an alert, warning, or fault occurs.

• Display Automatically: Select this option if you do

want the fault Details window to open automatically

when an alert, warning, or fault occurs.

want the fault Details window to open

4. Select OK to save the change and close the System

Settings window.

2-4

DocuColor 5000 Administrator Guide

Page 35

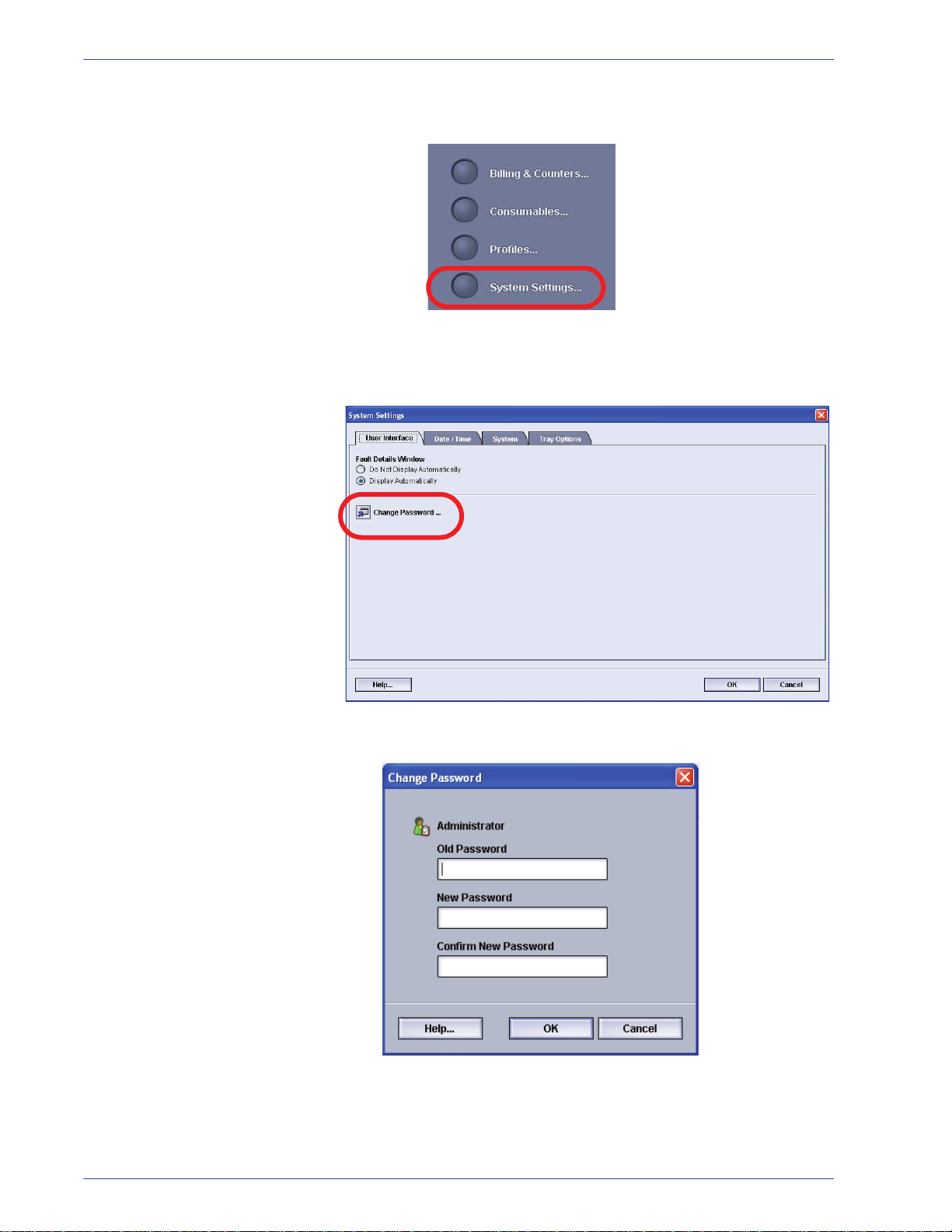

Change Password

2. System Settings

Select the Change Password button if you want to change the

Administrator password.

Use the following procedure to change the Administrator

password.

1. Select the Logon button from the main UI window.

2. From the Logon window, enter the Administrator password

and select OK.

NOTE: The digital press arrives from the fac tory with a default

Administrator password of five ones ( 11111). Use this default

password to logon.

TIP: For security reasons, you should change the Administrator

password from its default password to a new one.

DocuColor 5000 Administrator Guide

For security reasons, only asterisks are displayed on the

screen.

2-5

Page 36

2. System Settings

3. Select the System Settings button.

4. From the System Settings window, select the Change

Password button from the User Interface tab.

The Change Password window opens.

2-6

DocuColor 5000 Administrator Guide

Page 37

2. System Settings

TIP: Use numbers only for creating your new password. Alpha

characters (letters and other characters, such as !*& are not

allowed). A maximum of twelve numbers can be entered for your

password.

5. From the Change Password window, enter:

a. The old (current) password

b. The new password

c. Reenter the new password in the Confirm New

Password area

d. Select OK

NOTE: For security reasons, only asterisks are displayed on the

screen.

6. Select OK from the System Settings window to return to the

main UI window.

DocuColor 5000 Administrator Guide

2-7

Page 38

2. System Settings

Setting the Date & Time

Use this feature to set the date and time for the system. The date

and time is displayed on the Machine Details screen on both the

Installed Soft ware and Error Log screens.

1. From the System Settings window, select the Date/Time

tab.

2. Select the Date Format you wish to use.

3. Use the up or down arrow buttons to enter the correct year,

month, and day.

4. Select the Time Format you wish to use.

5. Use the up or down arrow buttons to set the correct hour

and minutes.

NOTE: If you selected the 12 Hour Clock, touch the AM or PM

button.

6. Select OK to save your changes and close the System

Settings window.

2-8

DocuColor 5000 Administrator Guide

Page 39

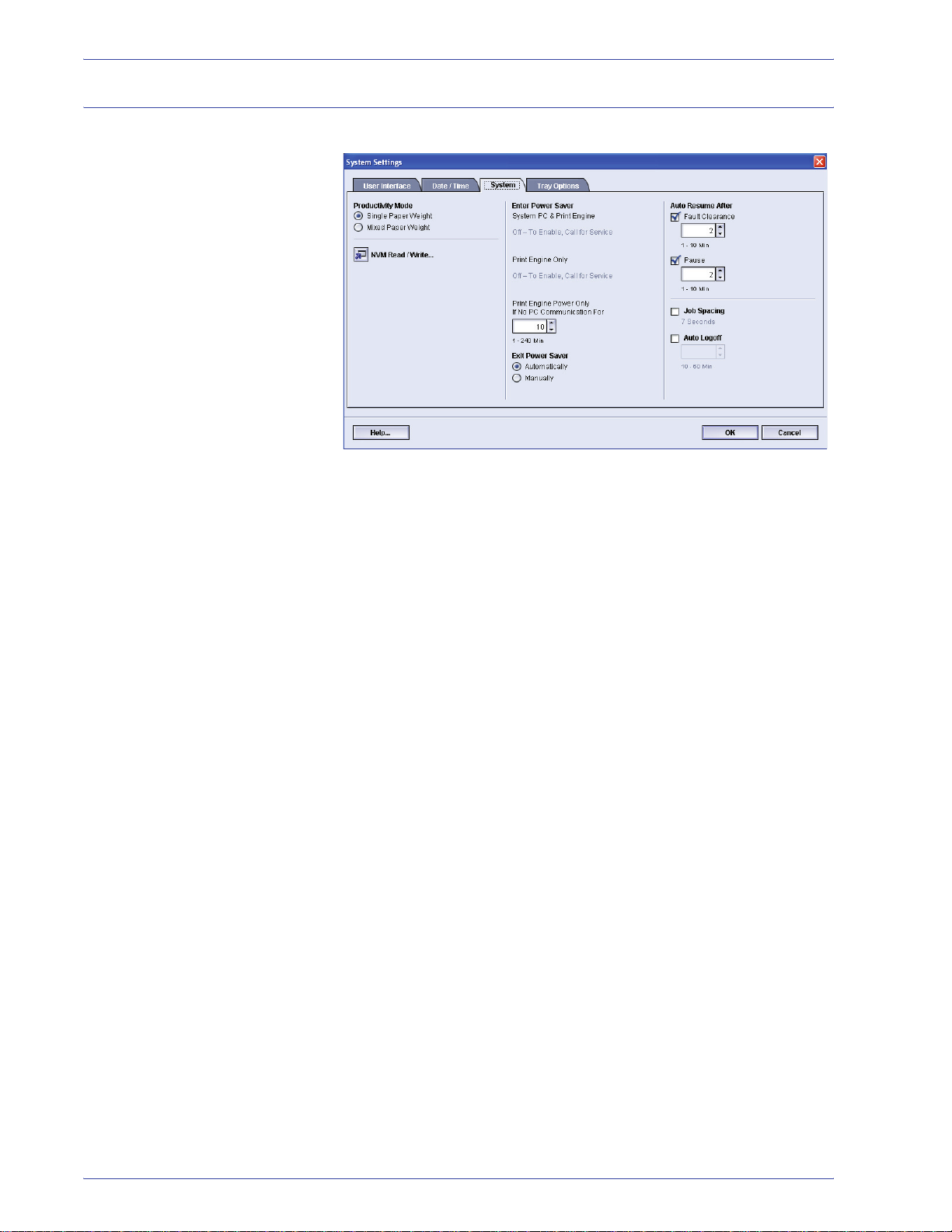

System

2. System Settings

Use this feature to change the factory default settings for the

following:

• Productivity Mode

• Power Saver (Enter and Exit options)

• Auto Resume

• Job Spacing

• Auto Logoff

The System feature also allows you to enter NVM Read/Write

values when using specialized media. This is discussed in more

detail on page 2-19.

DocuColor 5000 Administrator Guide

2-9

Page 40

2. System Settings

Productivity Setting

The productivity of the digital press relates to the continuous

speed of the media output as measured in prints per minute

(ppm). The continuous speed is dependent on paper size, paper

weight, and fuser temperature.

Use this setting to optimize the throughput speed for the type of

paper you run most frequently. Productivity Setting options

include:

• Single Paper Weight: This setting optimizes the throughput

speed for single (light or heavy) weight papers, according to

the weight range that is set in the paper tray.

• Mixed Paper Weight: This setting optimizes the throughput

speed of print jobs that contain mixed media weights from

different paper trays.

Select the setting that best fits your printing environment and that

you use most frequently.

2-10

DocuColor 5000 Administrator Guide

Page 41

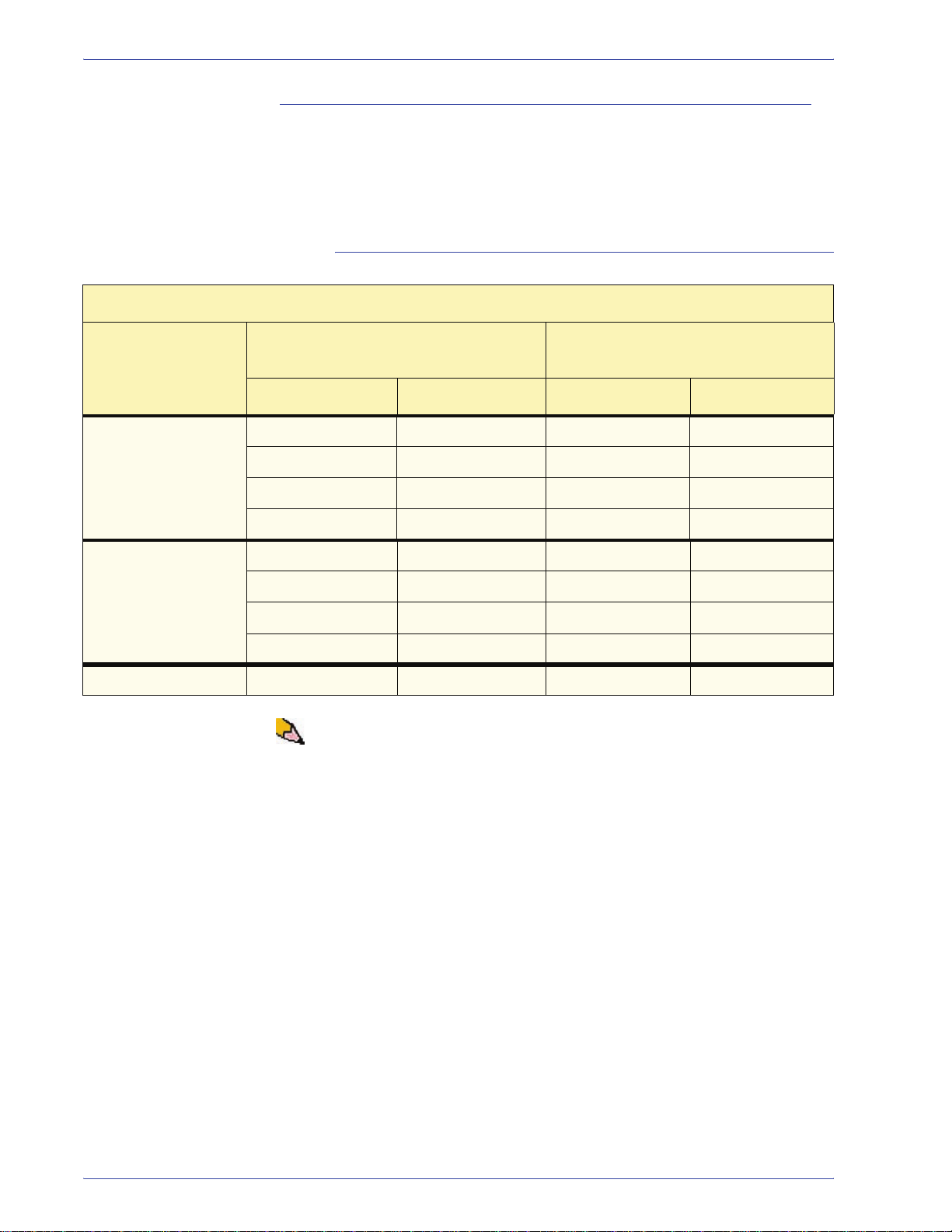

Productivity charts

The following productivity charts lists the various paper weights

and sizes and their related print speeds for 1 Sided and 2 Sided

output. Each chart outlines the print speed parameters for both

productivity settings.

Single Paper Weight

Single Paper Weight Mode

2. System Settings

Paper Size (Feed direction length)

Paper Weight

Min. Max 1 Sided 2 Sided

60 - 220 g/m

221 - 300 g/m

Transparency 210.0 216.0 25 --

2

2

182.0 216.0 50 25

216.1 297.0 33.3 16.7

297.1 458.0 25 12.5

458.1 488.0 20 10

182.0 216.0 33.3 --

216.1 280.0 25 --

280.1 458.0 16.7 --

458.1 488.0 12.5 --

[mm]

(prints per minute - ppm)

Print Speed

NOTE 1:2-Sided printing is not available for transparency and

paper that is 221 g/m

2

or greater.

NOTE 2:There is no decrease in productivity (ppm) from the

second feeder module to the first feeder module.

NOTE 3:Transparency is only available for 1 Sided, A4 or 8.5” x

11” LEF.

DocuColor 5000 Administrator Guide

2-11

Page 42

2. System Settings

Mixed Paper Weight

Mixed Paper Weight Mode

Paper Weight

60 - 135 g/m

136 - 186 g/m

187 - 220 g/m

Paper Size (Feed direction length)

[mm]

Print Speed

Min. Max 1 Sided 2 Sided

2

182.0 216.0 50 25

216.1 297.0 33.3 16.7

297.1 458.0 25 12.5

458.1 488.0 20 10

2

182.0 216.0 33.3 16.7

216.1 297.0 25 12.5

297.1 458.0 16.7 8.3

458.1 488.0 12.5 6.3

2

182.0 216.0 33.3 16.7

216.1 280.0 20 10

280.1 432.0 16.7 8.3

432.1 488.0 12.5 6.3

221 - 300 g/m

2

182.0 216.0 25* --

216.1 280.0 16.7* --

280.1 458.0 12.5* --

458.1 488.0 10* --

Transparency 210.0 216.0 25 --

NOTE: *Print speeds may decrease due to printer setup

operations, which are based on environment al conditions and

specific interval volume of continuous printing.

2-12

DocuColor 5000 Administrator Guide

Page 43

Power Save r

2. System Settings

Use this feature to set the time that elapses until the digital press

and System PC enter a reduced power consumption mode. The

timers are activated when all print jobs have been completed and

there are no jobs in the job queue.

The digital press and/or System PC exits the Power Saver mode

when a job is sent to be printed or the UI on the System PC is

activated.

l

TIP: The System PC & Print Engine and Print Engine Only

features must be enabled by your Xerox representative before

can use them. If these features are not enabled, call your Xerox

representative for more information.

To change the time for each power saver feature, use the following

procedure.

1. From the System Settings window, select the System tab.

you

DocuColor 5000 Administrator Guide

2-13

Page 44

2. System Settings

2. Use the up or down arrow buttons to change the time for

each of the power saver features:

• System PC & Print Engine

• Print Engine Only

• Print Engine Power Only If No PC Communication For

The range available is 1-240 minutes.

NOTE: The system default time is sixty minutes.

3. Select OK to save your changes and close the System

Settings window.

Exit Power Saver

Select one of two options:

• Automatically: Select this option if you want the system to

automatically exit from power saver mode whenever the

mouse, keyboard, or PC Power Switch is activated.

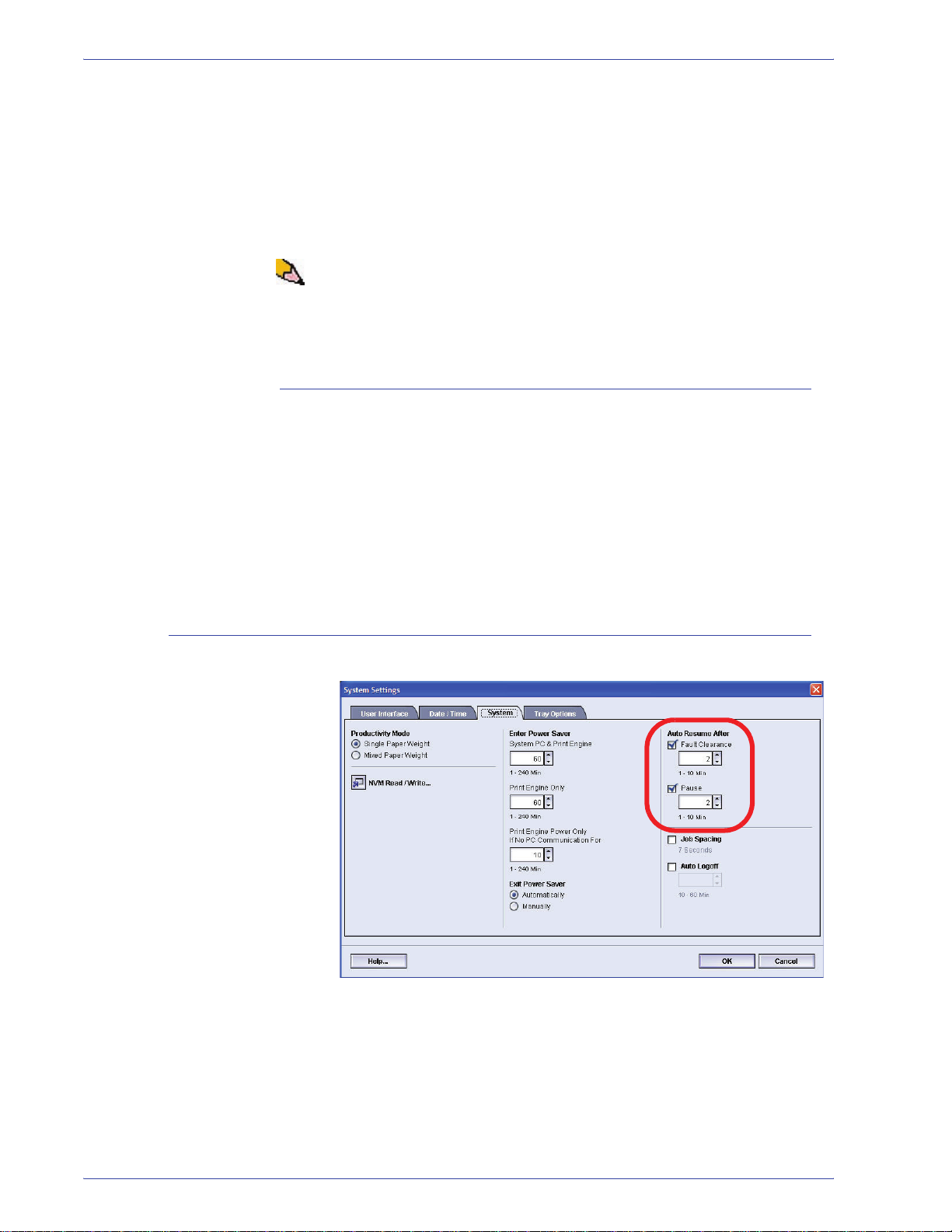

Auto Resume After

• Manually: Select this option if you want to manually exit the

system from power saver mode when the Power Saver button

on the main UI screen is selected.

2-14

DocuColor 5000 Administrator Guide

Page 45

Fault Clearance

Use the Auto Resume After Fault Clearance feature to restart a

job automatically after a fault is cleared and a job received over

the network is waiting for user instruction.

1. From the System tab of the System Settings window, select

the checkbox to the left of Fault Clearance.

2. System Settings

2. Use the up or down arrow buttons to change the time. The

range available is 1-10 minutes.

NOTE: The system default time is two minutes.

3. Select OK to save your changes and close the System

Settings window.

DocuColor 5000 Administrator Guide

2-15

Page 46

2. System Settings

Pause

Use the Auto Resume After Pause feature to restart a job

automatically after the Pause button is selected on the UI and the

job is waiting for user instruction.

1. From the System tab of the System Settings window, select

the checkbox to the left of Pause.

2. Use the up or down arrow buttons to change the time. The

range available is 1-10 minutes.

NOTE: The system default time is two minutes.

3. Select OK to save your changes and close the System

Settings window.

2-16

DocuColor 5000 Administrator Guide

Page 47

Job Spacing

2. System Settings

Use the Job Spacing feature when there are multiple jobs queued

and you would like to allow seven seconds to unload prints from a

finishing device before the next job starts printing.

1. From the System tab of the System Settings window, select

the checkbox to the left of Job Spacing.

Seven seconds is the standard and only time for this option.

2. Select OK to save your changes and close the System

Settings window.

DocuColor 5000 Administrator Guide

2-17

Page 48

2. System Settings

Auto Logoff

Use the Auto Logoff feature to have the digital press automatically

return to the printing mode when no action is taken from any of the

Administrator functions after the set amount of time.

1. From the System tab of the System Settings window, select

the checkbox to the left of Auto Logoff.

2. Use the up or down arrow buttons to change the time. The

range available is 10-60 minutes.

NOTE: The system default time is ten minutes.

3. Select OK to save your changes and close the System

Settings window.

2-18

DocuColor 5000 Administrator Guide

Page 49

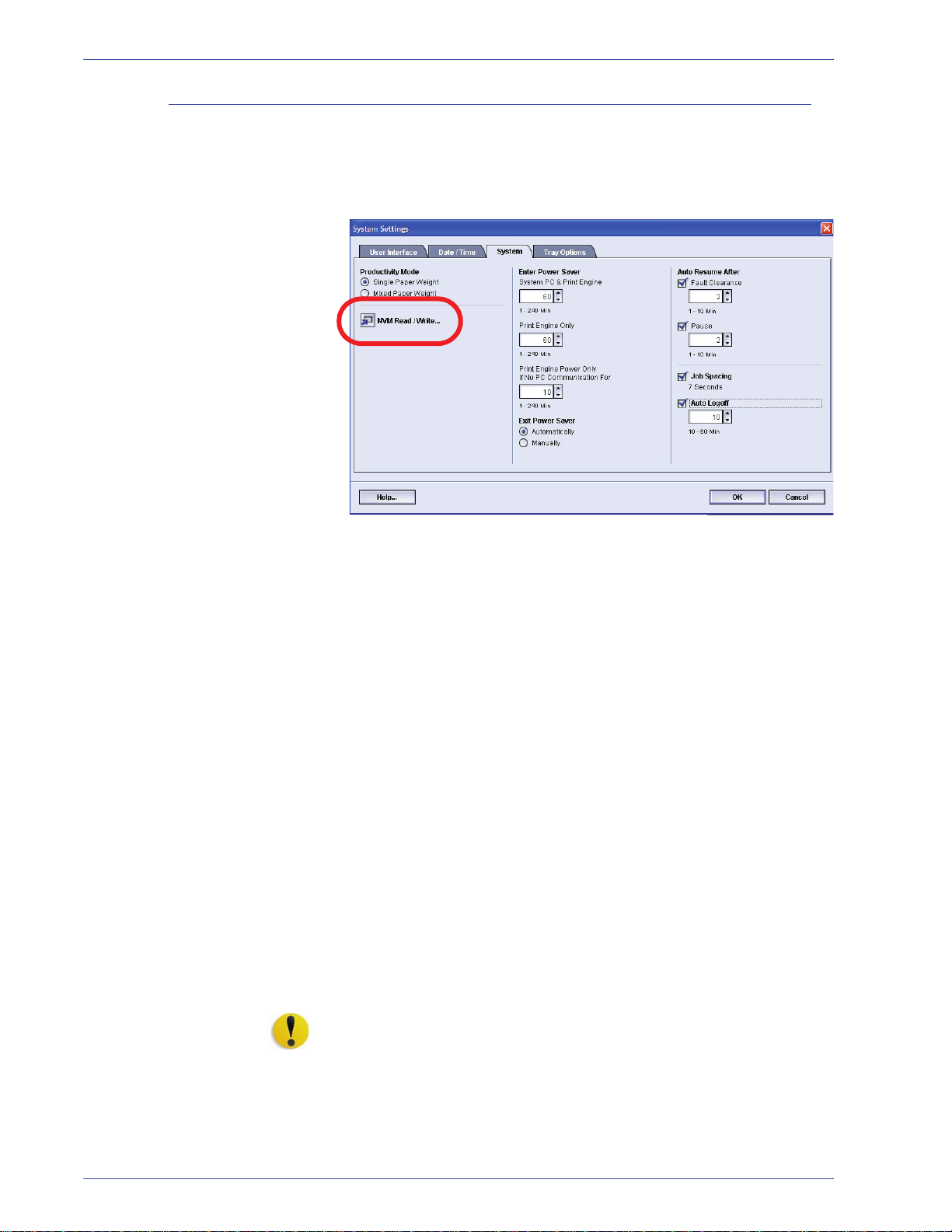

NVM Read/Write

2. System Settings

Your Xerox service representative uses this feature to change

certain system settings. It also may occasionally be used by

system administrators.

Special Media Setting for

Drilled Papers

Special Media Setting for

LEF Tab Stock

Carbonless Media

Enablement

Under most conditions, this feature is not used by system

administrators; however, there are limited circumstances under

which this feature is used. These circumstances include:

If you use 3-hole, predrilled paper on a regular basis and

continually encounter an inordinate amount of paper jams, and/or

If you regularly run tab stock and continually encounter paper

jams.

• Carbonless papers are coated with several functional coatings

which promote the image transfer through the form set and

enable the form sets to separate appropriately after padding

with a special adhesive. Each supplier of xerographic

carbonless paper has developed their own unique chemistry,

which is why the following procedure enabling this application,

works best with Xerox Premium Digital Carbonless Paper.

• In order to avoid problems when running carbonless media,

you may use the NVM Read/Write feature to switch on the

carbonless media feature.

If any of the above conditions exist in your environment, you may

use the NVM Read/Write feature to switch on a feature.

CAUTION: Do not enter any numbers on this screen other than

the ones described in this procedure. Entering and saving

numbers, other than the ones described, changes the system

settings which may result in a service call to restore the system to

the correct settings.

DocuColor 5000 Administrator Guide

2-19

Page 50

2. System Settings

To s w itc h on a feature, perform the following:

1. From the System tab on the System Setting window, select

the NVM Read/Write button.

The NVM Read/Write window opens.

2. Enter the desired Chain Link Number:

• The Chain Link Number for Special Media Setting for

Drilled Papers is 700 545.

• The Chain Link Number for Special Media Setting for

LEF Tab Stock is 700 546.

2-20

• The Chain Link Number for Carbonless Media

Enablement is 700-920.

NOTE: For the purpose of this procedure, the following screens

show an example

New Value; this exampl e does not represent an actual Chain Link

Number. The Current Value and New Value numbers will vary

depending on the Chain Link Number entered.

of a Chain Link Number, Current Value, and

DocuColor 5000 Administrator Guide

Page 51

2. System Settings

a. Using the numbers on the keyboard, enter the Chain

Number (the following example uses 123 as the Chain

number).

b. Press the Tab button on the keyboard to advance to

the Link field.

c. Enter the Link number (the following example uses 123

as the Link number).

d. Select the Next button.

DocuColor 5000 Administrator Guide

2-21

Page 52

2. System Settings

3. Using the keyboard, enter the New Value (the following

example uses 234 as the New Value number).

TIP: To s w itc h on a feature, enter the appropriate value from the

keyboard:

• For Special Media Setting for Drilled Papers

the New Value.

• For Special Media Setting for LEF Tab Stock

the New Value.

• For Carbonless Media

, enter 1 for the New Value.

, enter 0 for

, enter 1 for

4. Select the Apply button. The NVM Read/Write window

displays the entered value as the Current Value.

2-22

5. Select Close to save and close your new setting.

6. Select OK to close the System Settings window.

DocuColor 5000 Administrator Guide

Page 53

2. System Settings

TIP: After running your print job, reenter Administrator mode,

System Settings, NVM Read/Write, and switch off

the feature

that is currently on. Follow the steps outlined in this procedure

and use these settings for the New Value number:

Tray Options

• To switch off the Special Media Setting for Drilled Papers

,

enter 1000.

• To switch off the Special Media Setting for LEF Tab Stock

,

enter 0.

• To switch off the Carbonless Media

, enter 0.

TIP: To prevent paper jams from occurring with stock types other

than the ones mentioned in this procedure, you must switch off

the NVM Read/Write feature before running other print jobs.

Use this feature to change the factory default settings for the

following:

• Auto Tray Switching

• Auto Paper Selection

• Do Not Include

• Paper Tray Air Assist

•Tray Priority

Auto Tray Switching, Auto Paper Selection, and Do Not Include

Choose the default settings for the following options:

Default Setting What the Default Does

Auto Tray Switching

(ATS)

Auto Paper Selection

(APS)

Do Not Include Selecting a tray or trays in this option tells the machine to ignore any selections

Allows the digital press to automatically select another paper tray, containing the

appropriate paper, if the selected paper tray becomes unusable.

Allows the digital press to automatically select the appropriate paper size for the

job being processed, without a specific paper tray being selected.

When Single Paper Weight is selected as the default setting, Auto Paper selects

only 81-105 g/m

Productivity Setting is enabled, Auto Paper selects only 106-135 g/m

correct size.

that were made in the Auto Tray Switching or the Auto Paper Selection options.

2

paper in the correct size. When the Mixed Paper Weight

2

paper in the

DocuColor 5000 Administrator Guide

2-23

Page 54

2. System Settings

1. From the System Setting window, select the Tray Options

tab.

2. Select either the Enable or Disable button for the Auto Tray

Switching option.

3. Select either the Enable or Disable button for the Auto

Paper Selection option.

4. To instruct the digital press to bypass (ignore) one or more

of the paper trays, select the checkbox to the left of the

desired paper pray in the Do Not Include area.

5. Select OK to close the System Settings window.

2-24

DocuColor 5000 Administrator Guide

Page 55

Paper Tray Assist

2. System Settings

Blowers help control the environmental conditions in the paper

trays to ensure optimum print capability:

• Each paper tray has two blowers and two fans. The

blowers are located in the front of each tray, while the two

fans are located on the right-side of the tray.

• The lead edge blower is on at all times and produces

heated air if one of the following selections are

made: Coated paper, Transparencies, or Plain paper 106

2

g/m

or heavier. The trail edge blower is on at all times and

does not produce heated air.

• The paper trays also have air adjustment levers on the

drawer to regulate the direction of the air:

2

– If the paper weight is between 60 and 256 g/m

, the

position of the air adjustment levers should be toward

the front of the tray.

– If the paper weight is between 257 and 300 g/m

2

, the

position of the air adjustment levers should be

positioned toward the rear of the tray.

DocuColor 5000 Administrator Guide

2-25

Page 56

2. System Settings

If you adjust the blowers on the tray to accommodate a particular

type of paper (for example, thin or thick), you want to make

adjustments on the Tray Options window from the Administrator

mode. This will provide optimal output quality of your prints. To

make these adjustments, use the following procedure:

1. From the System Setting window, select the Tray Options

tab.

2. Select either the desired tray.

3. From the pull-down menu, select the option which best

correlates with the selected paper for that tray and the

adjustments made to the tray air adjustment levers.

The options include the following:

• System Default: This option is the default setting. With

this option the paper tray blowers automatically adjust

using settings that are optimized for Xerox papers.

• Multi-Sheet Feed: Select this option if you want the

paper tray blower automatic settings to incrementally

adjust in order to reduce multifeeds.

• Mis-feed: Select this option if you want the paper tray

blower automatic settings to incrementally adjust in

order to reduce misfeeds.

• Custom: With this option, the paper tray blowers are

controlled by parameters that are set by your Service

Representative.

• Always Off: Select this option if you want the paper

tray blowers always switched off; in this mode, the

blowers are not automatically controlled. This mode is

reserved for special media.

2-26

DocuColor 5000 Administrator Guide

Page 57

2. System Settings

• Always On (Thin Paper): With this option, the paper

tray blowers are not automatically controlled, but the

are always switched on. This mode is also reserved

for special media.

• Always On (Thick Paper): With this option, the paper

tray blowers are not automatically controlled, but they

are always switched on. This mode is reserved for

special media.

4. Select OK to close the System Settings window.

DocuColor 5000 Administrator Guide

2-27

Page 58

2. System Settings

Tray Priority

Select the priority order for each paper tray. If the Auto Tray

Switching feature is enabled and each paper tray contains the

same paper size and weight, the digital press feeds paper from

the tray set at Priority 1. If there is no paper in the Priority 1 tray,

the Priority 2 tray is automatically selected and so on.

Use the following procedure to set the priority for each paper tray.

1. From the System Setting window, select the Tray Options

tab.

2. Click once on a desired paper tray.

3. Click the up or down arrow button to the right of it in order to

move it up or down in the priority list.

4. Repeat this procedure for each Priority. You cannot set the

same paper tray for more than one Priority at a time.

5. Select OK to save your settings and close the System

Settings window.

2-28

DocuColor 5000 Administrator Guide

Page 59

Overview

3. Profiles

Profiles allows you to create and customize profiles for Custom

Paper, Alignment, and Decurler. These profiles are used at the

point of need for specialized print jobs which may require different

types of media, such as lightweight or heavy stock. Using a

customized profile can provide optimum image and output quality.

NOTE: The Profiles features can only be accessed from the

Administrator mode.

DocuColor 5000 Administrator Guide

3-1

Page 60

3. Profiles

Alignment

When printing duplex jobs and using different media types

(including paper type, weight, and coating/uncoating), the output

may require specific handling by the digital press as it is moving

through the paper path. With certain media types and duplex jobs,

the images on Side 1 and/or Side 2 may be misregistered,

skewed, perpendicularly misaligned, or stretched.

The Alignment Adjustment feature allows you to create and store

a maximum of twenty different Alignment Adjustment

Profiles. These profiles allow you to accommodate different

media types and how the image is registered, aligned, or

magnified for Side 1 and Side 2 output. These profiles may be

used at point of need in order to ensure optimum output quality of

your print.

NOTE: You can create Alignment Profiles without associating

them to a specific Cust om Paper Profile. The reverse is also

true: You can create an Alignment Profile and associate it to a

specific Custom Paper Profile. For example, Custom Paper

Profile 2 may be affiliated with Alignment Profile 2, so that when

Custom Paper Profile 2 is in use, Alignment Profile 2 is also in

use.

3-2

DocuColor 5000 Administrator Guide

Page 61

3. Profiles

When creating Alignment Profiles for Side 1 and/or Side 2 prints,

be aware of the following:

• Side 1/Side 2 images may be misregistered because the

paper is not the exact same size. It may vary slightly, with

differences of plus or minus 1mm, causing the image to be

misregistered. To reduce the possibility of size differences, it is

recommended that you use paper from the same lot when

running duplex jobs.

• During the fusing process, the heat and pressure applied to

the paper causes the paper to stretch. If the images on Sides 1

and 2 are the same size, the stretching of the paper may

cause the image on Side 1 to be slightly larger than the image

on Side 2.

• Creating an Alignment Profile for these types of jobs allows

you to reduce or eliminate the images being larger on Side1

than on Side 2 prints.

NOTE 1:Your Alignment Profile may or may not be af filiated with a

Custom Paper Profile.

NOTE 2:Once an Alignment Profile is set and in use, your color

server will not reflect that profil e in the print options for print jobs.

NOTE 3:After an Alignment Profile is set, it remains active until

you reenter Administrator mode and switch it off. If an active

Alignment Profile is not associat ed with a Custom Paper Profil e, it

is used for each paper tray to which it is assigned.

DocuColor 5000 Administrator Guide

3-3

Page 62

3. Profiles

Alignment Adjustment Profile procedure

Use the following procedure to create/modify an Alignment Profile

for adjusting Side 1/Side 2 image output.

NOTE: If you require a Custom Paper Profile associated with this

Alignment Profile, you can set the Custom Paper Profi le

information either now or af ter you create the Alignment Profile.

1. Select the Logon button from the main UI window.

2. From the Logon window, enter the Administrator password

and select OK.

3. Select the Profiles button.

3-4

DocuColor 5000 Administrator Guide

Page 63

3. Profiles

4. From the Profiles window, select the Alignment tab.

5. To create a new alignment procedure, select a undefined

profile.

If you are editing an existing profile, go to Editing an existing

Alignment profile.

6. Next: Creating an Alignment profile.

DocuColor 5000 Administrator Guide

3-5

Page 64

3. Profiles

Creating an Alignment profile

7. Click the Edit button; the Alignment Profile Properties

window opens.

8. Type a name for this profile (the example in this procedure

uses the name “AlignmentProfile2”).

9. Next: Selecting the Registration options.

3-6

DocuColor 5000 Administrator Guide

Page 65

Selecting the Registration options

10. Make the desired selections to the Registration option.

3. Profiles

• Lead Registration: Use this feature to adjust the lead

edge of the image for Side 1 and/or Side 2 registration.

• Side Registration: Use this feature to adjust the side

edge of the image for Side 1 and/or Side 2 registration.

The factory default setting is zero (0).

These arrows indicate the

paper feed direction

Use the up/down

arrow buttons to

make the desired

selections..

11. Next: Selecting the Perpendicularity options.

DocuColor 5000 Administrator Guide

As you click the up/down arrow buttons, the illustration

moves indicating the direction that the image will move

on the paper.

3-7

Page 66

3. Profiles

Selecting the Perpendicularity options

12. Make the desired selections to the Perpendicularity

option. Use this feature to adjust the image digitally on the

drum so that it will align with the paper for both Side 1 and

Side 2.

The factory default is zero (0).

These arrows indicate the

paper feed direction

Use these to make

the desired

selections. As you

click on the up or

down arrows, the

illustration moves

indicating the

direction that the

image will move on

the paper.

13. Next: Selecting the Skew options.

3-8

DocuColor 5000 Administrator Guide

Page 67

Selecting the Skew options

14. Make the desired selections to the Skew option. Use this

feature to adjust the paper so that the image for Side 1 and/

or Side 2 are not skewed but aligned with each other.

The factory default is zero (0).

These arrows indicate the

paper feed direction

3. Profiles

Use these to make

the desired

selections. As you

click on the up or

down arrows, the

illustration moves

indicating the

direction that the

image will move on

the paper.

15. Next: Selecting the Magnification options.

DocuColor 5000 Administrator Guide

3-9

Page 68

3. Profiles

Selecting the Magnification options

16. Make the desired selection to the Magnification option. Use

this feature to correct for image stretch from Side 1 to Side

2. The image may be enlarged or reduced as necessary.

The factory default is zero (0).

These arrows indicate the

paper feed direction

Use these to make

the desired

selections. As you

click on the up or

down arrows, the

illustration moves

indicating the

direction that the

image will move on

the paper.

TIP: It is recommended that you choose only one Alignment

Profile feature (such as Registration), and then run a set of Test

Prints to evaluate the registration on that output. If you want

multiple Alignment Profile features selected, individually select

each feature, run Test Prints for that feature, and evaluate the

output. After you determine that the output for the selected

feature is acceptable, then you can select another Alignment

Profile feature to adjust.

17. Next: Running test prints.

3-10

DocuColor 5000 Administrator Guide

Page 69

Running test prints

18. Select the Test Print button; a new window opens.

3. Profiles

a. Select the 2 Sided button.

NOTE:If you want to check the registrat ion for 1 Sided

prints only, select the 1 Sided button.

b. Select 10 test prints by clicking the Up arrow button to

change the number of test prints generated.

c. Select the desired paper tray from the pull-down list.

d. If necessary, select the Tray Properties button and

make any desired settings.

DocuColor 5000 Administrator Guide

3-11

Page 70

3. Profiles

e. Select Start. The UI displays this message after the

test prints are printed:

f. Retrieve your prints.

g. Discard the first few prints, as inconsistency tends to

be greater with these images.

19. Evaluate the test prints by holding your 2 Sided output at

eye level near a light source. This will allow you to see the

registration marks for both Side 1 and Side 2 of the output.

a. If you determine that the registration between Side 1

and Side 2 is unacceptable and needs adjusting,

repeat this procedure starting at Selecting the

Registration options.

TIP: You may need to repeat this procedure numerous times until

you achieve acceptable output prints.

b. If the printed output for both Sides 1 and 2 is

acceptable, select OK to save and close the Profiles

window.

NOTE: Once you have selected OK to save and close the Pr ofiles

window, the new profile procedure (for example,

AlignmentProfile2) can be sele cted from the Tray Properties

window whenever you want to run a job using this profile.

20. Next: Editing an existing Alignment profile.

3-12

DocuColor 5000 Administrator Guide

Page 71

Editing an existing Alignment profile

21. If you are editing an existing Alignment profile:

a. From the Profiles window, Alignment tab, select the

desired profile.

b. Click the Edit button.

c. Repeat this procedure starting at Selecting the

Registration options.

3. Profiles

DocuColor 5000 Administrator Guide

3-13

Page 72

3. Profiles

Custom Paper

Different media (including paper type, weight, and coating/

uncoating) may require specific handling by the digital press as it

is moving through the paper path. For example, some media

types may skew or curl as they progress through the printing path

of the digital press. This may occur on frequently-run jobs and/or

jobs with a high volume output.

The Custom Paper feature allows you set custom paper profiles

for different types of media and jobs, such as outlined in the above

paragraph. These profiles may be used at point of need in order

to ensure optimum output quality of your prints/jobs.

By setting custom paper profiles for specific media types, you can

avoid output prints that are skewed, curled, have too much toner

or not enough toner in areas, or images that are not registered

properly on the output print, such as Side 1 and/or Side 2 images

that are misregistered.

NOTE 1:Once a Custom Paper Profile is created, the digital press

passes this information on to your color server. The color server

in turn reflects this information in the print options for print jobs.

NOTE 2:Adjusting registration for Side 1 and/or Side 2 images is

discussed in detail in the Alignment feature. Refer to the

Alignment feature.

3-14

DocuColor 5000 Administrator Guide

Page 73

Custom Paper procedure

Use the following procedure for creating/modifying a Custom

Paper Profile.

1. From the Profiles window, select the Custom Paper tab.

3. Profiles

2. To create a new custom paper procedure, select a

undefined profile.

If you are editing an existing profile, go to Editing a Custom

Paper profile.

3. Next: Creating an Custom Paper profile.

DocuColor 5000 Administrator Guide

3-15

Page 74

3. Profiles

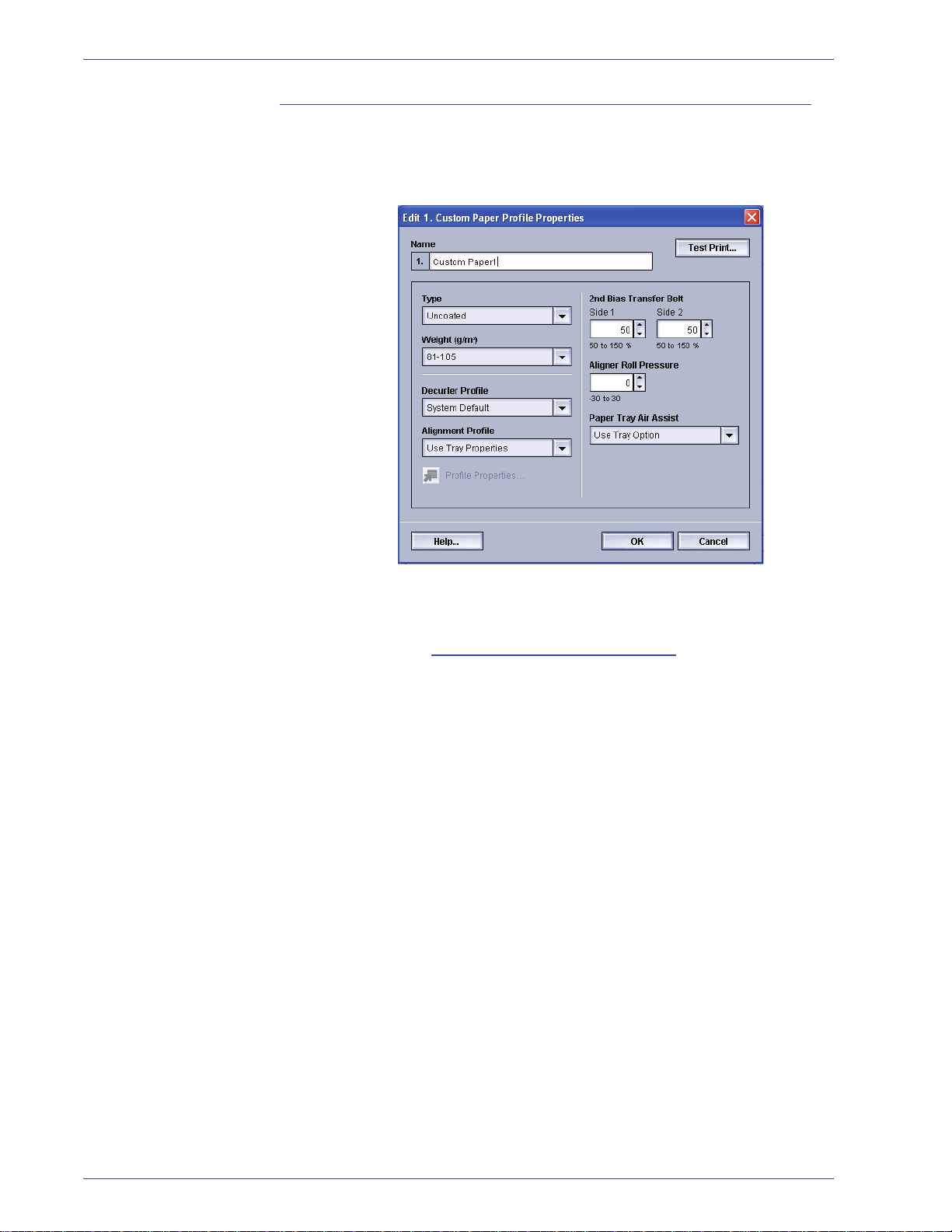

Creating an Custom Paper profile

4. Click the Edit button; the Custom Paper Profile Properties

window opens.

5. Type a name for this profile (the example in this procedure

uses the name “Custom Paper1”).

6. Next: Selecting the desired paper type.

3-16

DocuColor 5000 Administrator Guide

Page 75

Selecting the desired paper type

7. Select the desired paper Type from the pull-down menu.

3. Profiles

TIP: The paper type does not have to match the actual type of

paper you are loading in the tray. When creating a Custom Paper

Profile, select a paper type that is rarely or never

standard paper types. This ensures that when running commonly

used paper types, the digital press does not load a Custom Paper

Profile for those types.

used as your

8. Next: Selecting the desired paper weight.

DocuColor 5000 Administrator Guide

3-17

Page 76

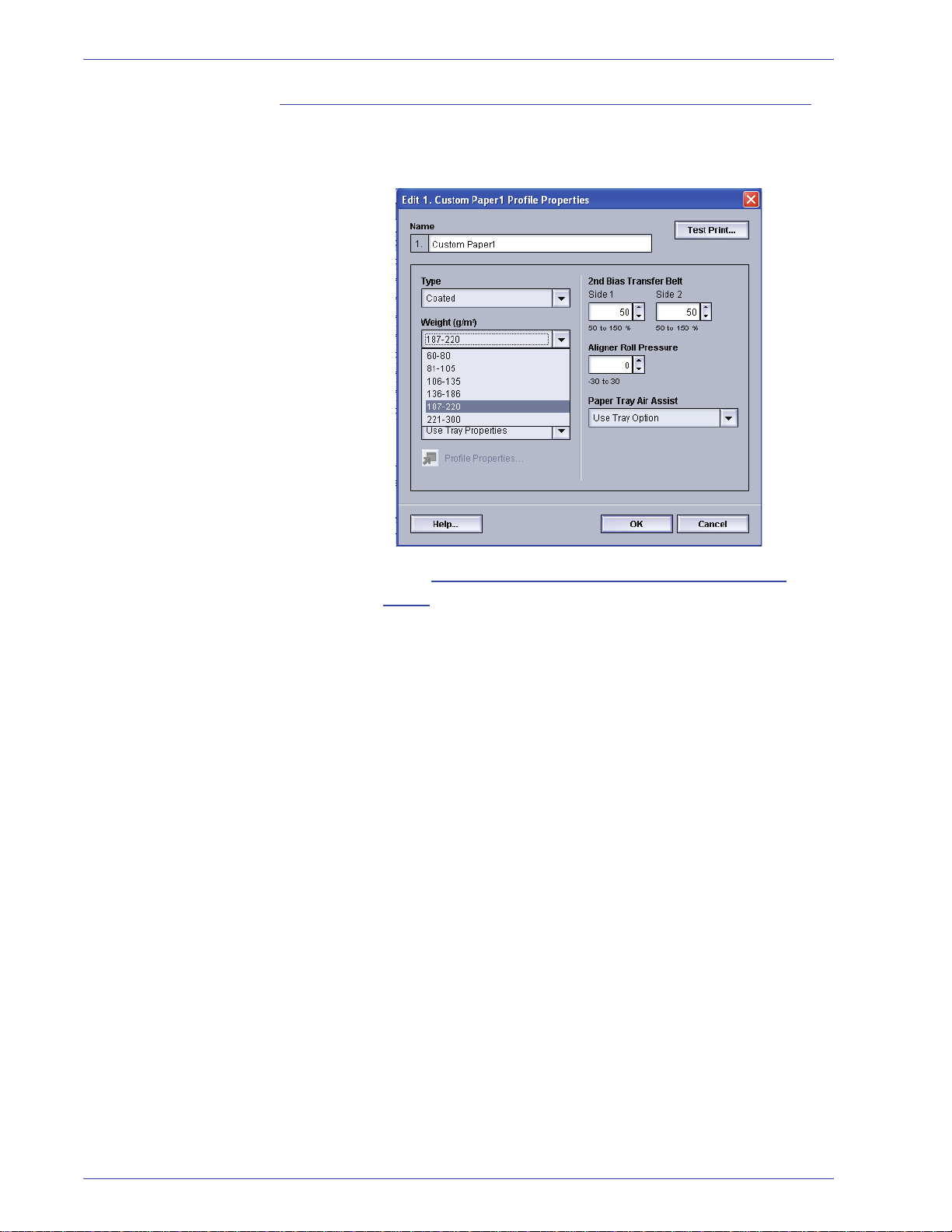

3. Profiles

Selecting the desired pa per weight

9. Select the desired paper Weight from the pull-down menu.

10. Next: Selecting other options for your Custom Paper

profile.

3-18

DocuColor 5000 Administrator Guide

Page 77

Selecting other options for your Custom Paper profile

11. If required, select a Decurler Profile from the pull-down

menu.

3. Profiles

TIP: The default setting is System Default. It is recommended

that you leave this option at its default setting until you run test

prints and evaluate the output of the prints. Test Print is discussed

in more detail in Running test print

NOTE: Use the Decurler feature in order to compens ate f or p aper

curl in your output prints. For Decurler information, refer to

page 3-32.

s.

DocuColor 5000 Administrator Guide

3-19

Page 78

3. Profiles

12. If required, select an Alignment Profile from the pull-down

menu.

TIP: The default setting is Use Tray Properties. It is

recommended that you leave this option at its default setting until

you run test prints and evaluate the output of the prints. Test Print

is discussed in more detail in Running test print

s.

3-20

DocuColor 5000 Administrator Guide

Page 79

3. Profiles

NOTE: If you select a specific Alignment Profile, the Profiles

Properties button becomes accessible. By clicking on this button,

the UI opens the Alignment Profile wi ndow for the sel ected pro file,

and you can edit that Alignment Profile if necessar y.

NOTE: For Alignment information, refer to page 3-2.

13. If required, choose 2nd Bias Transfer Roll settings for Sides

1 and 2.

DocuColor 5000 Administrator Guide

3-21

Page 80

3. Profiles

TIP: The default setting for both Sides 1 and 2 is 100%. It is

recommended that you leave this option at its default setting until

you run test prints and evaluate the output of the prints. Test Print

is discussed in more detail in Running test print

NOTE: Refer to page 3-26 for information on the 2nd Bias

Transfer Belt.

s.

14. If required, choose an Aligner Roll Pressure setting.

TIP: The default setting is 0. It is recommended that you leave

this option at its default setting until you run test prints and

evaluate the output of the prints. Test Print is discussed in more

detail in Running test print

NOTE: Refer to page 3-30 for information on the Aligner Roll

Pressure.

s.

3-22

DocuColor 5000 Administrator Guide

Page 81

3. Profiles

15. If required, choose a Paper Tray Air Assist option from the

pull-down menu.

TIP: The default setting Use Tray Option. It is recommended that

you leave this option at its default setting until you run test prints

and evaluate the output of the prints. Test Print is discussed in

more detail in Running test print

NOTE: Refer to page 3-31 for info rmation on the Paper Tray Air

Assist.

s.

16. Load your custom paper in the desired paper tray.

17. Ensure that you select the correct paper information in the

Tray Properties window (size, weight, type). From the Type

pull-down menu, select the correct Custom Paper Profile.

18. Next: Running test prints.

DocuColor 5000 Administrator Guide

3-23

Page 82

3. Profiles

Running test prints

19. Select the Test Print button; a new window opens.

a. Select the 2 Sided button.

NOTE:If you want to check the registrat ion for 1 Sided

prints only, select the 1 Sided button.

b. Select 10 test prints by clicking the Up arrow button to

change the number of test prints generated.

c. Select the desired paper tray from the pull-down list.

d. If necessary, select the Tray Properties button and

make any desired settings.

e. Select Start. The UI displays this message after the

test prints are printed:

f. Retrieve your prints.

3-24

g. Discard the first few prints, as inconsistency tends to

be greater with these images.

DocuColor 5000 Administrator Guide

Page 83

20. Evaluate the test prints by holding your 2 Sided output at

eye level near a light source.

a. If you determine that further custom paper adjustments

are required, repeat this procedure starting at Selecting

the desired paper type.

TIP: You may need to repeat this procedure numerous times until

you achieve acceptable output prints.

b. If the printed output for both Sides 1 and 2 is

acceptable, select OK to save and close the Profiles

window.

NOTE: Once you have selected OK to save and close the Pr ofiles

window , the new profile procedure (for example, Cust om Paper1)

can be selected from the Tray Properties window, the Type

feature, whenever you want to run a job using this profile.

21. Next: Editing a Custom Paper profile.

Editing a Custom Paper profile

3. Profiles

22. If you are editing an existing Custom Paper profile:

a. From the Profiles window, Custom Paper tab, select

the desired profile.

b. Click the Edit button.

c. Repeat this procedure starting at Selecting the desired

paper type.

DocuColor 5000 Administrator Guide

3-25

Page 84

3. Profiles

Second Bias Transfer Belt

The Second Bias Transfer Belt is where the image is transferred

from the belt to the paper. The Second Bias Transfer Belt feature

is normally used with heavier weight paper, such as 220 g/m

greater, 10 pt, or 12 pt, which are just three examples; however

there are times when it is also used with lighter weight paper as

well.

When using either heavier or lighter weight paper, you may want

or need to adjust Side 1 for all 1-sided jobs. If defects continually

occur in a printed job when using heavier weight paper, perform

the following steps to determine if a Custom Paper Profile with

Side 1 or Side 2 (2nd Bias Transfer Belt) adjustments are

appropriate.

2

and

1. If the job is printed face down or 1-N, check Side 1 for

defects on the topside (upper portion) of the stacked sheets,