Page 1

XW Power System

XW4024-120/240-60

XW4548-120/240-60

XW6048-120/240-60

Installation Guide

XW Power Distribution Panel

XW System Control Panel

XW Solar Charge Controller

XW Automatic Generator Start

Page 2

Page 3

XW Power System

Installation Guide

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to 2.5 MW utility-scale systems for wind, solar, batteries, fuel cells, micro turbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery chargers,

programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute electrical

power.

Trademarks

XW Power System is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

XW Power System Installation Guide © May 2007 Xantrex International. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL

OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES,

WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT

OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE

USER’S RISK; AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH

STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY

CANNOT BE GUARANTEED. APPROVED XANTREX CONTENT IS CONTAINED WITH THE ENGLISH

LANGUAGE VERSION WHICH IS POSTED AT WWW.XANTREX.COM.

Due to continuous quality improvement and product updates, the illustrations shown in this manual may not exactly match

the unit purchased.

Date and Revision

May 2007, Revision A

Part Number

975-0239-01-01

Product Numbers

865-1000 (XW 6048-120/240-60)

865-1005 (XW4548-120/240-60)

865-1010 (XW4024-120/240-60)

Contact Information

Telephone: 1-800-670-0707 (toll free in North America)

Telephone: 1-360-925-5097 (direct)

Fax: 1-800-994-7828 (toll free in North America)

Fax: 1-360-925-5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Guide

Purpose

The purpose of this Installation Guide is to provide explanations and procedures for

installing the XW Power System.

Scope

The Guide provides safety guidelines, detailed planning and procedures for installing

the XW Inverter/Charger and related system components (the “XW Power System”).

It does not provide details about configuration, operation, maintenance or

troubleshooting. See the Operation Guide or Owner’s Manual of each device for this

information. This Guide also does not provide details about particular brands of

batteries. You need to consult individual battery manufacturers for this information.

Audience

The Guide is intended for anyone who needs to install the XW Power System.

Installers should be certified technicians or electricians.

Organization

This guide is organized into four chapters and three appendices.

Chapter 1, “Introduction” lists and describes the components and basic features of the

XW Power System.

Chapter 2, “Inverter/Charger Installation” describes how to mount and install the XW

Inverter/Charger, and the XW Power Distribution Panel and XW Conduit Box.

Chapter 3, “Xanbus Network Installation” provides detailed information for planning

and installing the components necessary for network communication on a Xanbus

system.

Chapter 4, “XW Solar Charge Controller Installation” describes how to mount and

connect the XW Charge Controller as part of the XW System.

Chapter 5, “XW System Accessories Installation” describes how to mount and install

the XW System Control Panel and the Automatic Generator Start.

Appendix A, “Specifications” provides the electrical and environmental specifications

for the XW Series.

Appendix B, “Wiring Diagrams” illustrate the most basic configurations and are for

reference only. Specific installations may require additional equipment to meet

national or local electric codes. Ensure all safety requirements are strictly followed.

Appendix C, “Alternate System Configurations” provides wiring diagrams for

inverter/charger installations that do not require use of the power distribution panel

and the XW Conduit Box.

975-0239-01-01 iii

Page 6

About This Guide

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions or practices that could result in personal

injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to

the XW Power System components or other equipment.

Related Information

Additional information about operating the XW Inverter/Charger, see the XW

Inverter/Charger Operation Guide (975-0240-01-01).

For more information about related components, refer to:

• XW Power System Intallation Overview (975-0238-01-01)

• XW System Control Panel Owner’s Guide (975-0298-01-01)

• XW Solar Charge Controller Owner’s Guide (975-0283-01-01)

• XW Automatic Generator Start Owner’s Guide (975-0307-01-01)

These guides are available at www.xantrex.com. Printed copies should be included

with the components.

For more information about Xantrex Technology, Inc. as well as its products and

services visit www.xantrex.com.

iv 975-0239-01-01

Page 7

Important Safety Instructions

WARNING

This chapter contains important safety and operating instructions as required by UL and

CSA standards for inverters used in residential applications. Read and keep this

Installation Guide for future reference.

1. Before using the inverter, read all instructions and cautionary markings on the

unit, the batteries, and all appropriate sections of this manual.

2. Use of accessories not recommended or sold by Xantrex Technology Inc. may result in

a risk of fire, electric shock, or injury to persons.

3. The inverter is designed to be permanently connected to your AC and DC electrical

systems. Xantrex recommends that all wiring be done by a certified technician or

electrician to ensure adherence to the local and national electrical codes applicable in

your jurisdiction.

4. To avoid a risk of fire and electric shock, make sure that existing wiring is in good

condition and that wire is not undersized. Do not operate the inverter with damaged or

substandard wiring.

5. Do not operate the inverter if it has been damaged in any way. If the unit is damaged,

see the Warranty and Product Information section at the end of this manual.

6. This unit does not have any user-serviceable parts. Do not disassemble the inverter

except where noted for connecting wiring and cabling. See the Warranty Section in the

XW Inverter/Charger Operation Guide and other component manuals for instructions

on obtaining service. Attempting to service the unit yourself may result in a risk of

electrical shock or fire. Internal capacitors remain charged after all power is

disconnected.

7. To reduce the risk of electrical shock, disconnect both AC and DC power from the

inverter before attempting any maintenance or cleaning or working on any

components connected to the inverter. Turning off controls will not reduce this risk.

8. The inverter must be provided with an equipment-grounding conductor connected to

the AC input ground.

9. Do not expose this unit to rain, snow, or liquids of any type. This product is designed

for indoor use only. Damp environments will significantly shorten the life of this

product and corrosion caused by dampness will not be covered by the product

warranty.

10. To reduce the chance of short-circuits, always use insulated tools when installing or

working with this equipment.

11. Remove personal metal items such as rings, bracelets, necklaces, and watches when

working with batteries.

975-0239-01-01 v

Page 8

Important Safety Instructions

Limitations on Use

WARNING: Limitations on Use

The XW Power System is not intended for use in connection with life support

systems or other medical equipment or devices.

Explosive Gas Precautions

1. Working in the vicinity of lead acid batteries is dangerous. Batteries generate

explosive gases during normal operation. Therefore, you must read this guide and

follow the instructions exactly before installing or using your inverter/charger.

2. To reduce the risk of battery explosion, follow these instructions and those published

by the battery manufacturer and the manufacturer of the equipment in which the

battery is installed.

FCC Information to the User

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

vi 975-0239-01-01

Page 9

Contents

Important Safety Instructions

Limitations on Use - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Explosive Gas Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

1

Introduction

System Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

System Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

System Components and Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

XW Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

XW Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

XW Power Distribution Panel Panel and XW Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

XW Connection Kit for INV2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

XW Solar Charge Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

XW System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

XW Automatic Generator Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–7

2

Inverter/Charger Installation

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Knockout Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Clearance Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Step 1: Installing the Mounting Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Step 2: Mounting the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Step 3: Mounting the XW Power Distribution Panel and XW Conduit Box- - - - - - - - - - - - - - - - - - - - - 2–7

Step 4: Wiring the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Battery Bank Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Battery Cable Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Torque Values for the XW Series Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Torque Values for the XW Power Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Inverter Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Backfeed Protection Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Wiring the Inverter to the XW Power Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Grounding the DC System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Installing the Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Making DC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Making AC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

AC Connections and Communication Ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -v

975-0239-01-01 vii

Page 10

Contents

Accessing the AC Terminal Block and AC Ground Bar - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Grounding the AC System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

AC Wiring to the Inverter AC Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

AC Wiring to the XW Power Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Wiring the XW Inverter/Charger to a XW Power Distribution Panel - - - - - - - - - - - - - - - - - - - 2–21

Generator Wiring to the XW Inverter/Charger using a XW Power Distribution Panel - - - - - - - 2–22

AUX Port - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

AUX+12V Voltage Supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

AUX-RPO: User Remote Power Off (RPO) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

User Line Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

AUX Port Terminal Assignments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Basic Functional Test - Single Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Confirm All Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Applying DC Power to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Enable the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–26

AC Voltage Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Confirming Battery Charger Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Step 5: Installing Additional Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–29

Installation Steps - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–29

Parts List for Dual-Inverter Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–30

Converting a Single-Inverter Power Distribution Panel to a Dual-Inverter Power Distribution Panel 2–30

DC Wiring for a Dual-Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–30

AC Wiring for a Dual-Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–32

Parts List for a Triple-Inverter Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–34

Converting a Single-Inverter Power Distribution Panel to a Triple-Inverter Power Distribution Panel 2–34

DC Wiring for a Triple-Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–34

AC Wiring for a Triple-Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–36

Xanbus and AC Sync Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–38

Basic Functional Test - Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–39

3

Xanbus Network Installation

Xanbus-enabled Devices- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

The Xanbus System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Network Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–3

Ordering Network Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Network Layouts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Multi-Drop Backbone Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Daisy Chain Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

Installing the Network - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Before You Begin the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Installation Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Guidelines for Routing the Xanbus Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Mounting a Network Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Installing Xanbus-Enabled Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–9

Completing the Multi-Drop Backbone Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–9

Completing the Daisy Chain Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

viii 975-0239-01-01

Page 11

4

XW Solar Charge Controller Installation

Installing the Charge Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

PV Array Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Array Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Array Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Array Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

MPPT Voltage Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Choosing a Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

Removing the Wiring Terminals Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

Removing Knockouts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Mounting the Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–6

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–8

Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–9

DC Terminal Connector Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–9

Wire Size and Over-current Protection Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–9

Connecting the XW Solar Charge Controller to the Distribution Panel - - - - - - - - - - - - - - - - - - - - 4–12

Commissioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–14

Configuration Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–14

Commissioning Units Using a XW System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–14

Contents

5

XW System Accessories Installation

The XW System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–2

Materials and Tools Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Choosing a Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–3

Mounting the XW System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–3

Verifying the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–7

The XW Automatic Generator Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Preparing an Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Materials and Tools Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–7

Choosing a Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Routing the Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Installing the XW Automatic Generator Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Mounting the Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Wiring to the 20-contact Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Connecting the Generator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Connecting the Thermostats (optional) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–13

Connecting an External Shutdown (optional) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–13

Connecting an External Manual ON/OFF Switch (optional) - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–14

Connecting an External ON/OFF LED - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–15

Connecting the Wiring Harness to the XW Automatic Generator Start - - - - - - - - - - - - - - - - - 5–16

Connecting the XW Automatic Generator Start to the Xanbus Network - - - - - - - - - - - - - - - - 5–17

Verifying Power Is Available - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

975-0239-01-01 ix

Page 12

Contents

Appendix A

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

XW Series Overload Capability - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Output Power Versus Ambient Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

XW Series Efficiency - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Mechanical Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Accessories- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

Appendix B

Single-Inverter System (Backup only)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Single-Inverter System Renewable Energy (Solar) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

Single-Inverter System Renewable Energy (Wind or Hydro) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Dual-Inverter System Renewable Energy (Solar) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Dual-Inverter System Renewable Energy (Wind or Hydro) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–7

Appendix C

DC Grounding for Single-Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Battery Connections for Single Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

AC Grounding for Single-Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

AC Output Wiring to the Inverter AC Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–5

Generator Wiring to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–6

Utility Wiring to the Inverter Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–7

Wind or Hydro DC Sources- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Specifications

Inverting Efficiency (Typical) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Charging Efficiency (Typical) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Sell Mode Efficiency (Typical) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Wiring Diagrams

Alternate System Configurations

x 975-0239-01-01

Page 13

Figures

Figure 1-1 XW Power System Installation Diagram Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Figure 1-2 XW Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-3 XW Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-4 Power Distribution Panel and XW Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-5 XW Connection Kit for INV2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

Figure 1-6 XW Solar Charge Controller- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Figure 1-7 XW System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Figure 1-8 Automatic Generator Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–7

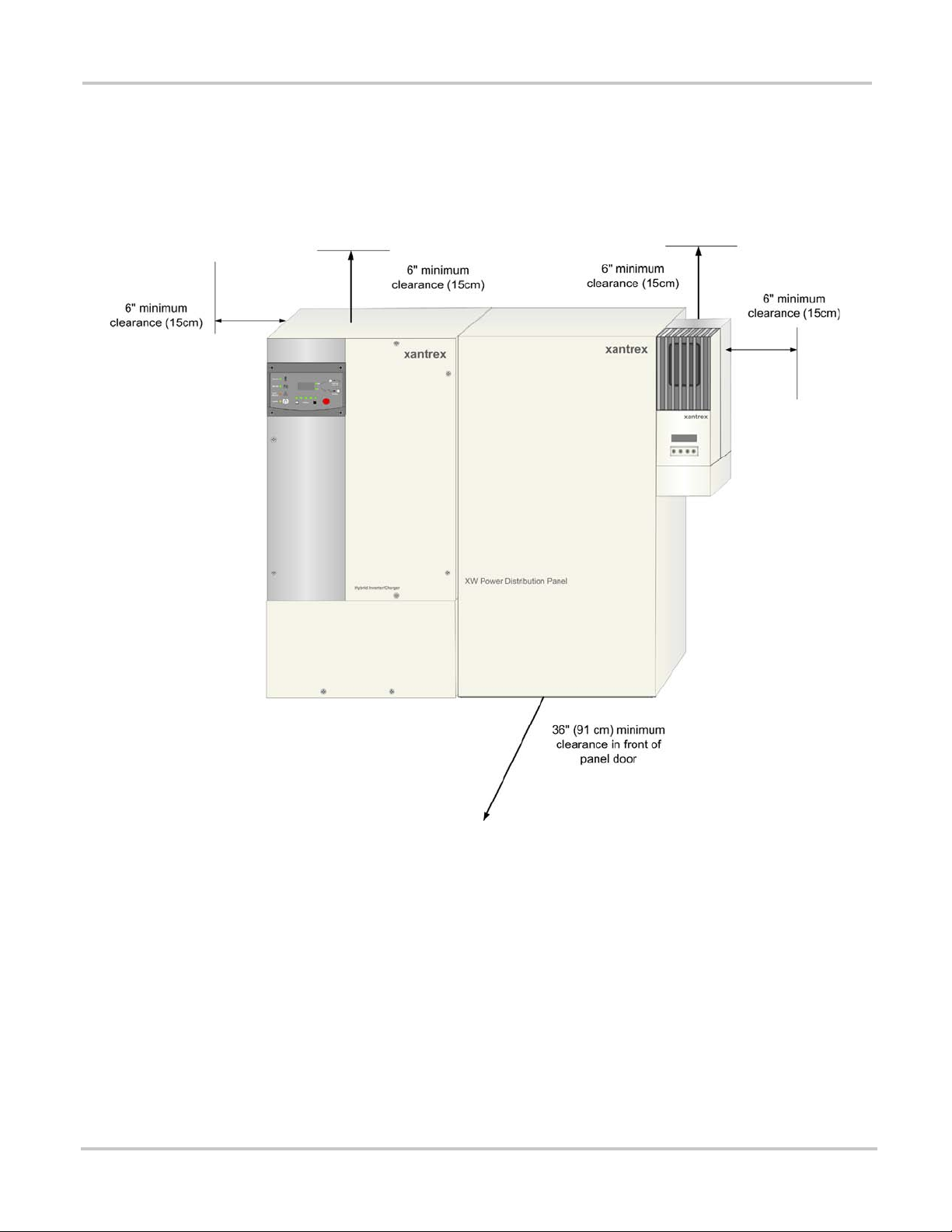

Figure 2-1 Clearance Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

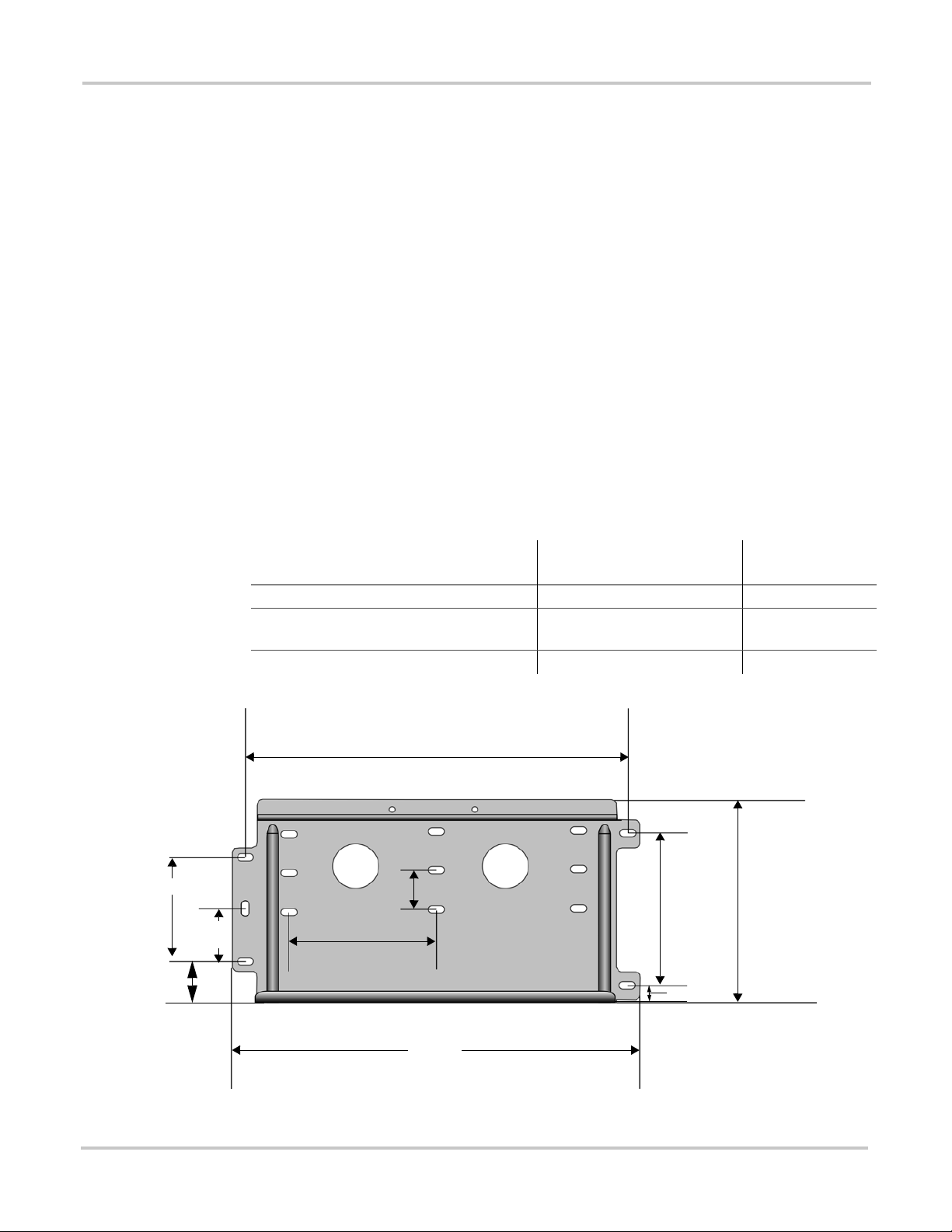

Figure 2-2 Mounting Plate Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

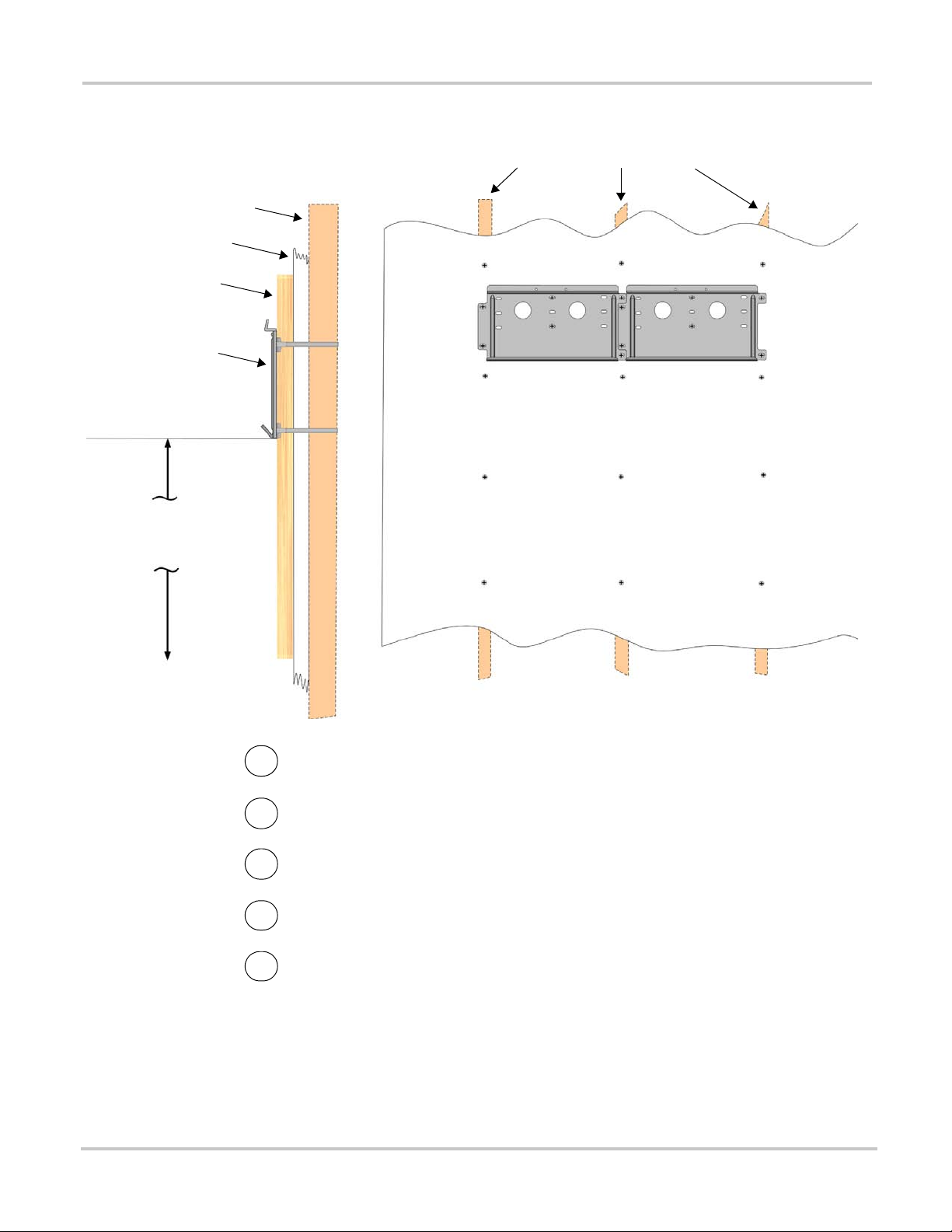

Figure 2-3 Mounting the Bracket for the XW Inverter/Charger or Distribution Panel- - - - - - - - - - - - - - 2–5

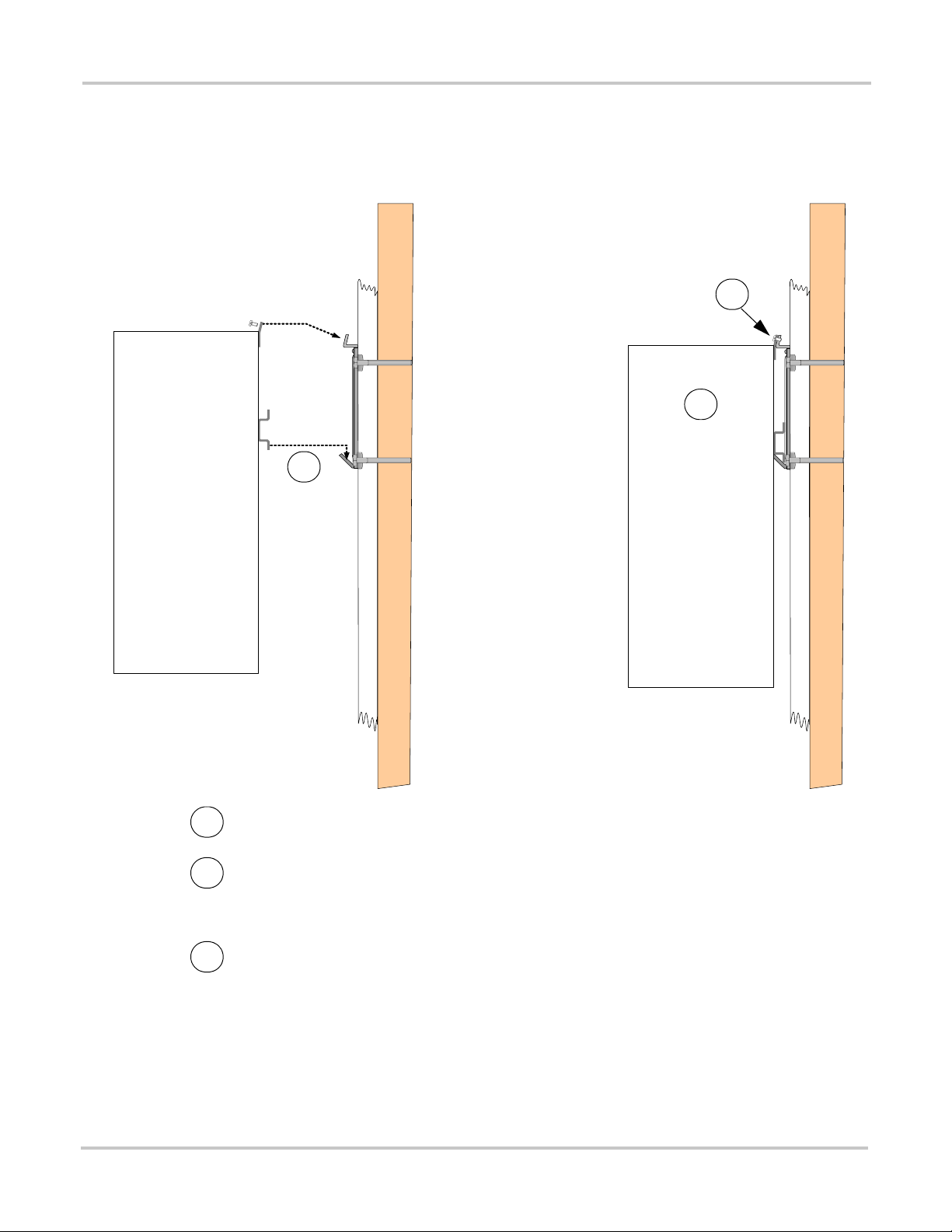

Figure 2-4 Mounting the XW Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Figure 2-5 Installing the XW Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-6 Routing Communications Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-7 DC Grounding Using a Power Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Figure 2-8 Battery Temperature Sensor (RJ11) Port Location and Installation - - - - - - - - - - - - - - - - - 2–13

Figure 2-9 XW Inverter/Charger DC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Figure 2-10 Battery Cable Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Figure 2-11 DC Connections to a Single Inverter Using a XW Power Distribution Panel- - - - - - - - - - - 2–15

Figure 2-12 XW Inverter/Charger AC Connections and Communications Ports - - - - - - - - - - - - - - - - - 2–16

Figure 2-13 AC Terminal Block - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Figure 2-14 Grounding the AC System using the Distribution Panel- - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Figure 2-15 Wiring the XW Power Distribution Panel to the Sub-panel or Utility Grid - - - - - - - - - - - - 2–20

Figure 2-16 Wiring the Inverter to the XW Power Distribution Panel- - - - - - - - - - - - - - - - - - - - - - - - 2–21

Figure 2-17 Generator Wiring Using a XW Power Distribution Panel- - - - - - - - - - - - - - - - - - - - - - - - 2–22

Figure 2-18 AUX Port Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Figure 2-19 Power-up Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Figure 2-20 Enable the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–26

Figure 2-21 Checking AC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-22 Checking Charging Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-23 Functional Test for Single Inverter Systems- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Figure 2-24 DC Connections to Dual Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–31

Figure 2-25 Dual Inverter AC Breaker Arrangement and Wiring Enlargement with

Multiple AC Input Sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–32

Figure 2-26 AC Wiring for Dual-Inverter Systems- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–33

Figure 2-27 DC Connections for a Triple-Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–35

Figure 2-28 Triple-Inverter AC Breaker Arrangement and Wiring Enlargement with

Multiple AC Input Sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–36

Figure 2-29 Triple-Inverter AC Breaker Arrangement and Wiring Enlargement with a

Single AC Input Source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–37

Figure 2-30 Wiring an External Bypass Switch for a Triple-Inverter Configuration- - - - - - - - - - - - - - - 2–37

Figure 2-31 Installing the AC Sync Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–38

Figure 2-32 Functional Test for Multiple Inverters - Page 1 of 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–41

975-0239-01-01 xi

Page 14

Figures

Figure 2-33 Functional Test for Multiple Inverters - Page 2 of 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–42

Figure 3-1 Network-Managed Power System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Figure 3-2 Xanbus Cable and RJ45 Connector Pin Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-3 Network Terminators- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-4 3-Way Network Connector (sample configuration)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-5 Multi-Drop Backbone Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Figure 3-6 Daisy Chain Network Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Figure 3-7 Recommended Mounting Orientation for Network Connector - - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-8 Options for Completing a Multi-Drop Backbone Layout - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-9 Completing a Daisy-Chain Layout- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Figure 4-1 Minimum Clearance Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Figure 4-2 Removing the Wiring Terminals Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Figure 4-3 Dimensions and Knockout Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Figure 4-4 Knockout Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

Figure 4-5 Mounting the XW Solar Charge Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Figure 4-6 XW Solar Charge Controller Safety Ground Connector- - - - - - - - - - - - - - - - - - - - - - - - - - 4–8

Figure 4-7 DC Connection Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–9

Figure 4-8 Connecting Solar DC Sources in the Power Distribution Panel - - - - - - - - - - - - - - - - - - - - 4–13

Figure 5-1 XW System Control Panel Xanbus Port Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–2

Figure 5-2 Inserting the Mounting Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Figure 5-3 Securing the Mounting Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Figure 5-4 Connecting the Network Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Figure 5-5 Securing the XW System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Figure 5-6 Surface Mounting the XW System Control Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Figure 5-7 Connecting the AGS Communications Cable to the XW Series - - - - - - - - - - - - - - - - - - - - 5–7

Figure 5-8 XW Automatic Generator Start External Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Figure 5-9 XW Automatic Generator Start Wiring Harness- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

Figure 5-10 External On/Off Switch and LED Wiring Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–15

Figure 5-11 XW Automatic Generator Start External Connections - - - - - - - - - - - - - - - - - - - - - - - - - - 5–16

Figure 5-12 Connecting the SCP- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–17

Figure 5-13 Verifying Power is Available - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Figure A-1 XW Series AC Overload Capability - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Figure A-2 Output Power Versus Ambient Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Figure B-1 Single-Inverter System (Backup only) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Figure B-2 Single-Inverter System Renewable Energy (Solar) - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

Figure B-3 Single-Inverter System Renewable Energy (Wind or Hydro) - - - - - - - - - - - - - - - - - - - - - B–5

Figure B-4 Dual-Inverter System Renewable Energy (Solar) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Figure B-5 Dual-Inverter System Renewable Energy (Wind or Hydro) - - - - - - - - - - - - - - - - - - - - - - B–7

Figure C-1 DC Grounding for an Inverter only - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Figure C-2 DC Connections to a Single Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

Figure C-3 Grounding the AC System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Figure C-4 AC Output Wiring to the Inverter AC Distribution Panel- - - - - - - - - - - - - - - - - - - - - - - - C–5

Figure C-5 Generator Wiring directly to the Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–6

Figure C-6 Utility Wiring to the Inverter Input- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–7

Figure C-7 Connecting Wind or Hydro DC Sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

xii 975-0239-01-01

Page 15

Tables

Table 2-1 Mounting Plate Fastener Recommendations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Table 2-2 Recommended Battery Cable Size Versus Length- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Table 2-3 Battery Cable (in conduit) to Maximum Breaker/Fuse Size - - - - - - - - - - - - - - - - - - - - - 2–10

Table 2-4 Torque Values for AC Wiring (AC Terminals and Ground Bar) - - - - - - - - - - - - - - - - - - 2–10

Table 2-5 Torque Values for the Chassis Ground Lug - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Table 2-6 Torque Values for the Inverter Battery Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Table 2-7 Torque Values for AC Disconnects and AC Breakers - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Table 2-8 Torque Values for the Ground Bus, AC Neutral Bus, DC Negative Bus, and

DC Positive Bus in the XW Power Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Table 2-9 Torque Values for the Power Distribution Bars in the XW Power Distribution Panel - - - - 2–11

Table 2-10 Torque Values for the Battery Cables to the DC Negative Bus, and

DC Positive Bus in the XW Power Distribution Panel - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Table 2-11 User Connector Terminals and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Table 3-1 T568A Standard Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Table 3-2 Xanbus Network Components and Part Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Table 3-3 Minimum and Maximum Cable Length- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Table 4-1 MPPT Operational Window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Table 4-2 Minimum Clearance Requirements- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Table 4-3 Recommended Circuit Breakers for the XW Solar Charge Controller- - - - - - - - - - - - - - - 4–10

Table 4-4 One-Way Wire Distance and Wire Size for a 24 Vdc System - - - - - - - - - - - - - - - - - - - - 4–11

Table 4-5 One-Way Wire Distance and Wire Size for a 48 Vdc System - - - - - - - - - - - - - - - - - - - - 4–11

Table 5-1 Circuit Limitations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Table 5-2 Required Wiring Size Based on Length of Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

Table 5-3 Contact Numbers and Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

Table 5-4 Wiring for Connecting Thermostats - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–13

Table 5-5 Wiring for Connecting an External Shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–13

Table 5-6 Wiring for Connecting an External Manual ON/OFF Switch - - - - - - - - - - - - - - - - - - - - 5–14

Table A-1 XW Power System Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Table A-2 XW Power System Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

975-0239-01-01 xiii

Page 16

xiv

Page 17

1

Introduction

Chapter 1, “Introduction” lists and describes the components and basic

features of the XW Power System.

For this Topic See....

“System Overview” page 1–2

“System Components and Accessories” page 1–3

Page 18

Introduction

System Overview

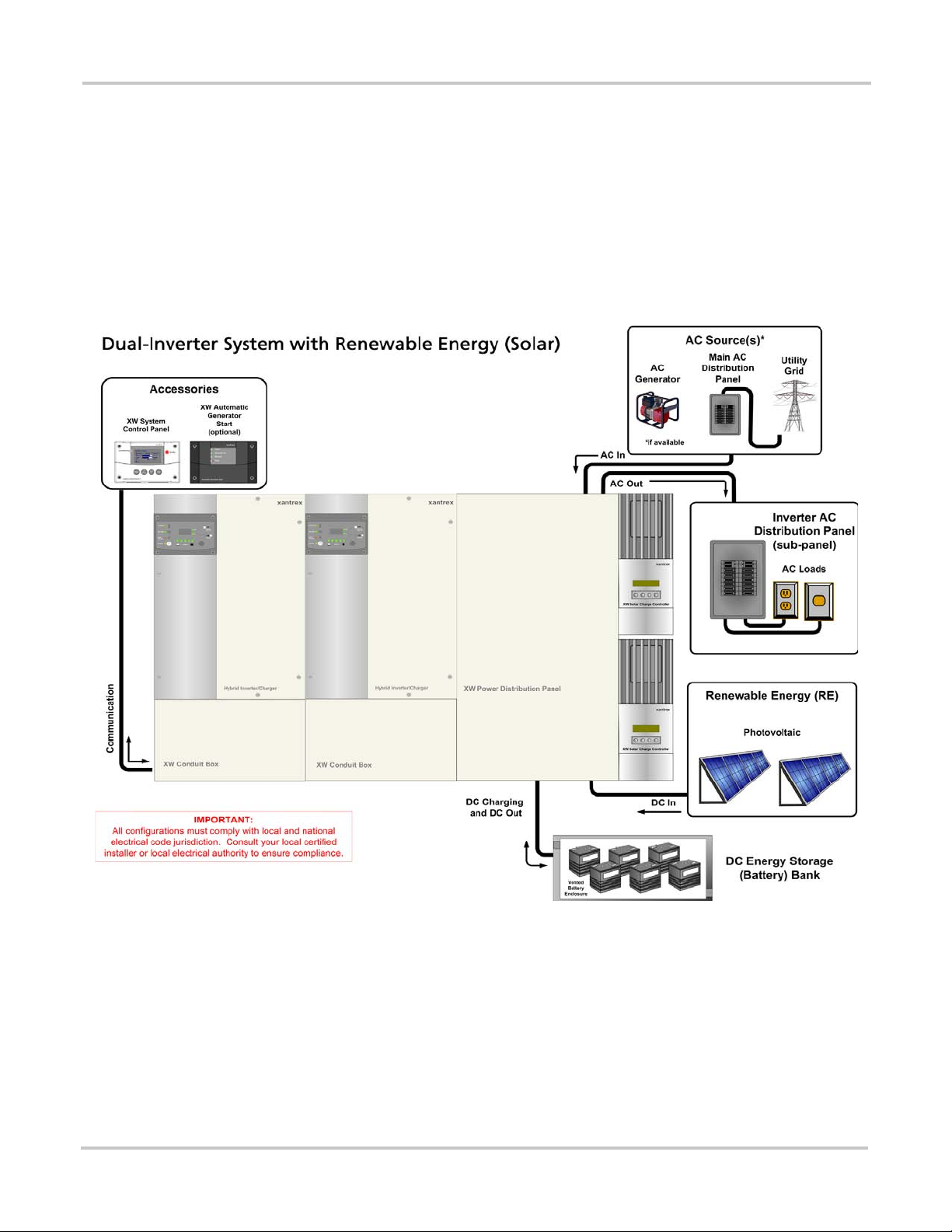

The XW Power System consists of several devices, components, and optional accessories

that, when installed together, create a renewable energy power system that can be

customized to suit nearly any application—off grid, grid tied, or backup. Up to three

inverters can be installed in parallel to create larger 120/240 V 3-wire, single-phase

systems allowing for increased capacity.

System Diagram

Figure 1-1

1–2 975-0239-01-01

XW Power System Installation Diagram Example

Page 19

System Components and Accessories

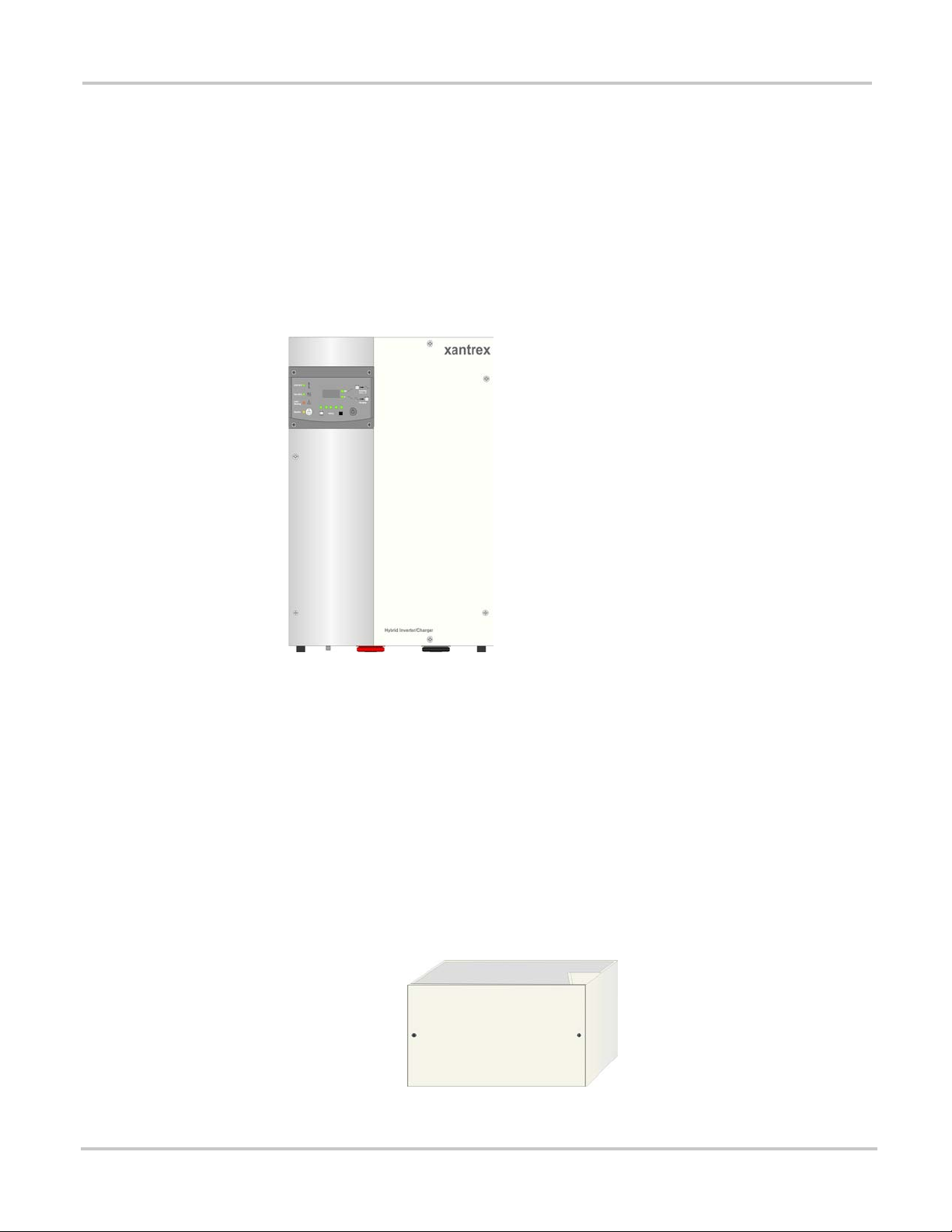

XW Inverter/Charger

The XW Inverter/Charger is a modular “building block” sine-wave inverter/charger that

can be used for both residential and commercial stand-alone, grid-backup, and grid-tie

applications with battery energy storage. The XW Series is a self-contained DC to AC

inverter, battery charger, and AC transfer switch. Up to three inverters can be installed in

parallel to create larger 120-240-volt, 3-wire, single-phase systems allowing for increased

capacity.

System Components and Accessories

XW Conduit Box

Figure 1-2

A Battery Temperature Sensor (FGA # 808-0232-02) is also included with the XW

Inverter/Charger. The Battery Temperature Sensor monitors the temperature of the battery

bank and adjusts the charging accordingly. See page 2–13 for installation instructions for

this accessory.

A conduit box (FGA # 865-1025) is available to enclose the bottom of the XW

Inverter/Charger and protect the cabling. Use of the conduit box may be required

depending on the local electrical code. Be sure to consult with the local electrical authority

to ensure the installation is code-compliant.

Figure 1-3

XW Inverter/Charger

XW Conduit Box

975-0239-01-01 1–3

Page 20

Introduction

The XW Conduit Box comes in two pieces and mounts directly to the bottom of the

inverter/charger with keyhole slots and screws. It is secured to the inverter by two

#10-32 screws and is secured to the wall by two screws (not provided).

Internal wire barriers (or raceways) are included to keep communications wires separate

from AC and DC power wires. The XW Conduit Box also includes multiple cable strap

points.

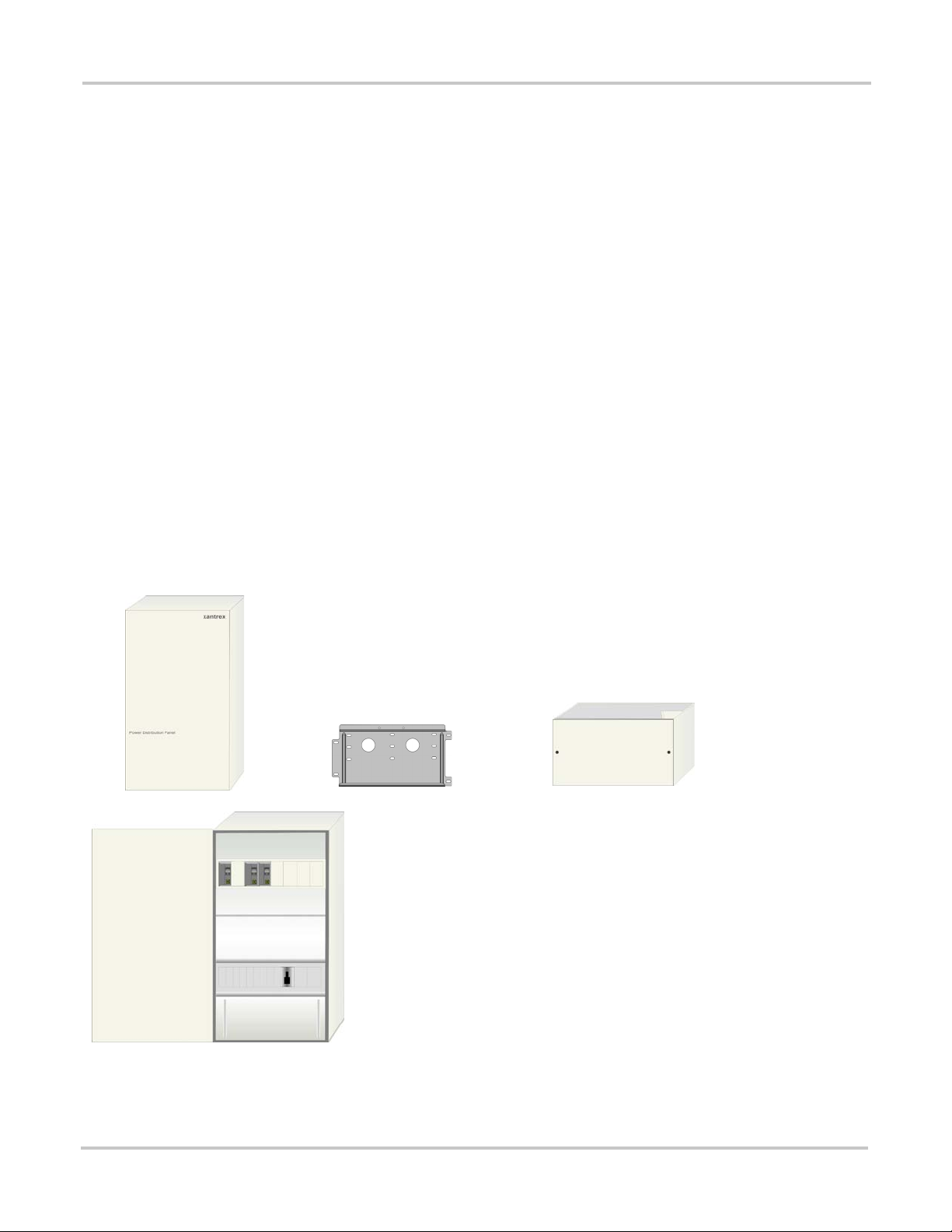

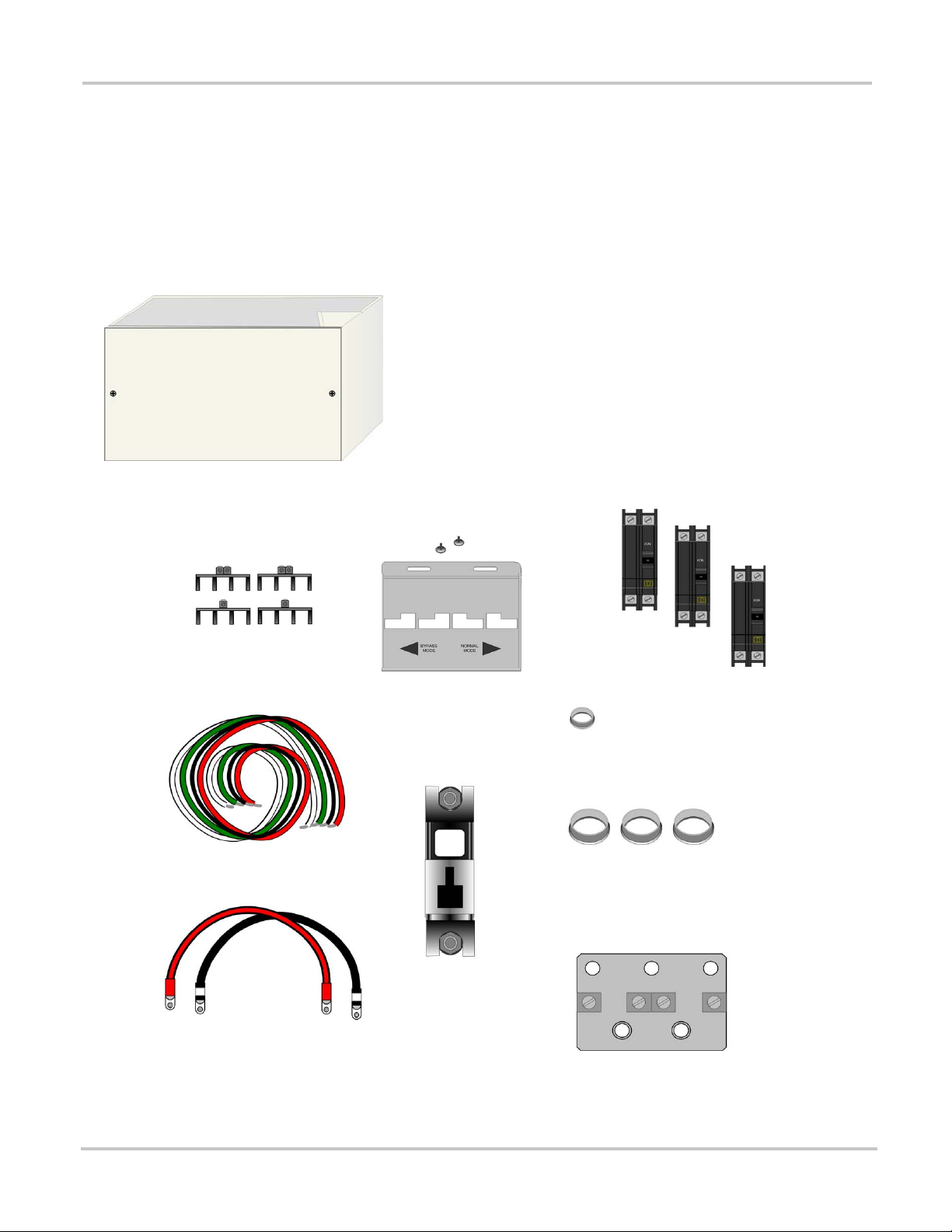

XW Power Distribution Panel Panel and XW Conduit Box

The XW Power Distribution Panel (FGA: 865-1015) includes a mounting plate and XW

Conduit Box. It is factory wired and labelled with everything to support a code-compliant

single-inverter installation. It is designed to mount on the right side of the inverter/charger,

but it can also be configured to mount on the left side. Internal wiring and breakers can be

added to expand the XW Power System with up to three inverters, four charge controllers,

or other equipment to support 120/240-volt, 3-wire, single-phase systems.

The XW Power Distribution Panel and XW Conduit Box interface with:

• XW4024, XW4548, and XW6048 inverter/chargers

• XW Solar Charge Controllers (requires customer supplied breakers and wiring)

• C-Series Charge Controllers (requires customer supplied breakers and wiring).

Internal wire barriers (or raceways) are included to keep communications wires separate

from AC and DC power wires.

XW Power Distribution Panel

XW PDP Dimensions:

30" (761mm) H x 16" (406mm) W x 8 ¼" (210mm) D

Depth from the wall = 8 ¾" (223 mm)

XW Power Distribution Panel includes:

• Power Distribution Panel enclosure with a field-reversible panel door

• Mounting Plate

• XW Conduit Box

Mounting Plate

The enclosure comes pre-wired with:

• 3x 60A, 120/240 Vac, 2-pole, Square-D, Type QOU, DIN-rail mounted

• 1x GJ250A 160 Vdc, 3/8" stud DC breaker

• 1x Ground terminal bus bar

• 1x Neutral terminal bus bar

• 1 pair #4/0 AWG Battery Cables

The panel door can be mounted on the right or left side of the XW Power

Distribution Panel.

AC Knockout slots = 8 (for dual 60A Square D, type QOU breakers)*

DC Knockout slots = 8 small (for 60A DC breakers) and 3 large (for GJ breakers)

XW Conduit Box

AC breakers (pre-wired to connect to one XW inverter)

*AC Breakers cannot exceed 60A.

Figure 1-4

1–4 975-0239-01-01

Power Distribution Panel and XW Conduit Box

Page 21

XW Connection Kit for INV2

The XW Connection Kit for Inv2 (FGA # 865-1020) is the extension kit required for

connecting a second or third XW Inverter/Charger in the same system.

XW Conduit Box

System Components and Accessories

XW Connection Kit includes:

• XW Conduit Box with raceway barriers and cable strap

connections points,

• 3x 60 A, 120/240 Vac, 2-pole, Square-D, Type QOU, Din-Rail

mountable, AC breakers (includes bypass plate)

• #6 AWG AC wiring to connect the inverter to the AC breakers

(includes 4 conduit bushings)

• 4x Power Distribution Bars (replaces factory-installed bars)

• 1x GJ250A 160 Vdc, 3/8" stud DC breaker

• 1x Bus Bar for DC positive

• 1 pair #4/0 AWG battery cables

• AC Sync and Xanbus cables (not shown)

60A, 120/240Vac AC

Breakers

AC Bypass Plate

Power Distribution Bars

#6 AWG AC Wiring

#4/0 AWG battery cables

15/16" bushing for AC sync

and Xanbus knockouts

GJ250A DC breaker

1-3/8" bushings for AC

Wiring knockouts

DC Positive Bus Bar

Figure 1-5

XW Connection Kit for INV2

975-0239-01-01 1–5

Page 22

Introduction

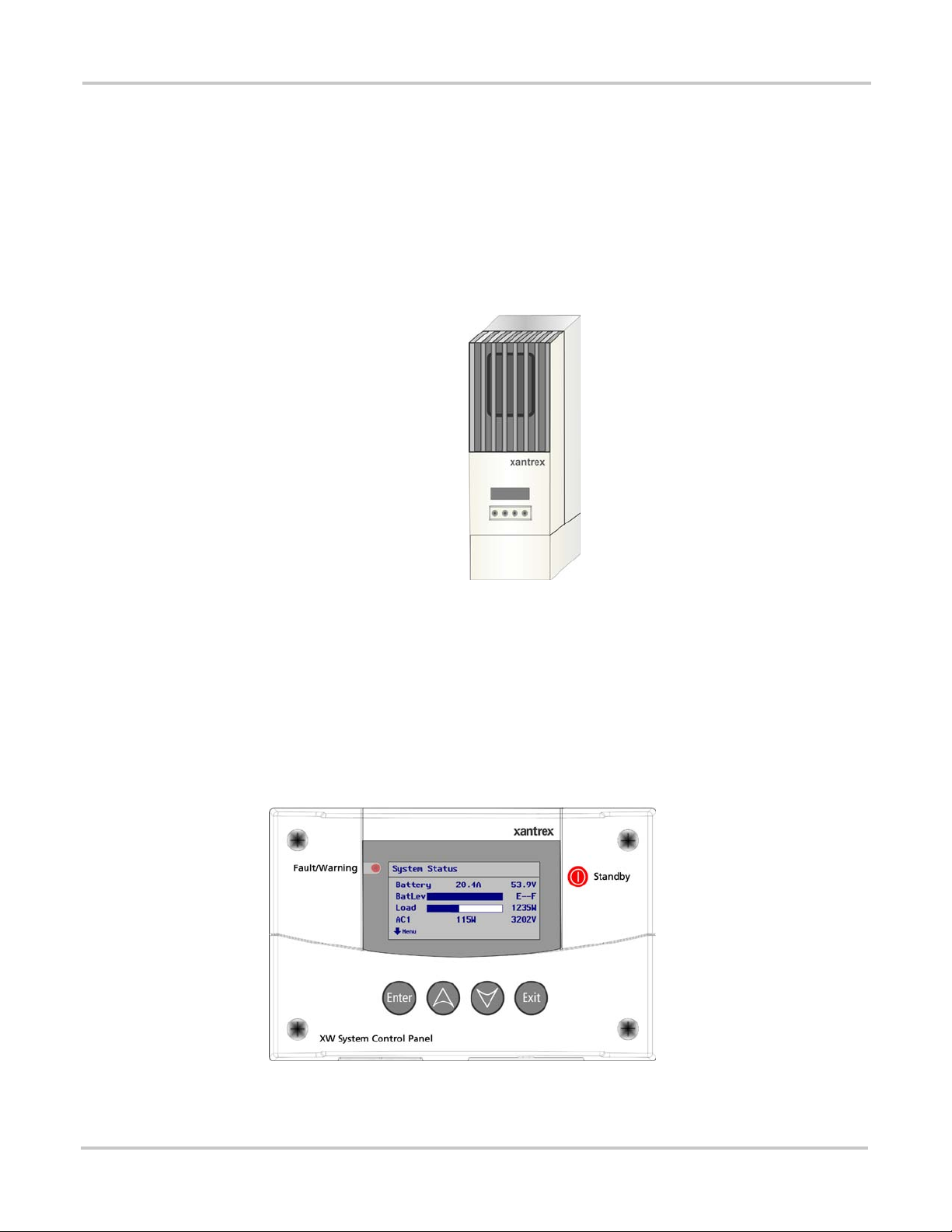

XW Solar Charge Controller

The XW Solar Charge Controller (FGA # 865-1030) is a 60 amp charge controller with

integrated PVGFP and separate Battery Temperature Sensor. The XW Solar Charge

Controller can be used with 12-, 24-, 36-, 48-, and 60-volt DC battery systems. However,

the XW Inverter/Charger can only work at 24 or 48 volts depending on the model. When

the XW Solar Charge Controller is used with the XW Inverter/Charger, it is limited to 24or 48-volt battery banks. The XW Solar Charge Controller will automatically detect the

24- or 48-volt settings.

Figure 1-6

XW System Control Panel

The XW System Control Panel features a graphical, backlit liquid crystal display that

displays system configuration and diagnostic information for all devices connected to the

network. When installed as an XW Power System accessory, the XW System Control

Panel eliminates the need for separate control panels for each device and gives a single

point of control to set up and monitor an entire XW Power System.

XW Solar Charge Controller

FGA Number:

865-1050

Figure 1-7

1–6 975-0239-01-01

XW System Control Panel

Page 23

XW Automatic Generator Start

The XW Automatic Generator Start can automatically activate a generator to provide an

XW Series Inverter/Charger with power to recharge depleted batteries or assist with heavy

loads. The XW Automatic Generator Start adds intelligence to power management and

eliminates time spent monitoring batteries and inverter loads.

The XW Automatic Generator Start is compatible with popular generators, and can be

configured to start the generator in response to low battery voltage, thermostat operation,

or load size on the inverter battery. A quiet time setting prevents the generator from

starting at inconvenient times. LEDs display the status of the XW Automatic Generator

Start, while all user-defined settings are programmed through the XW System Control

Panel.

System Components and Accessories

FGA Number:

865-1060

Figure 1-8

Automatic Generator Start

Generator The generator should be a 120/240V, 2-wire or 3-wire generator with Auto Start capability.

Important:

power from a generator of this kind.

Do not use a 120-volt only generator. The inverter will not accept

The generator should also supply a Generator Run signal. This signal is used by the XW

Automatic Generator Start to detect whether the generator is running. Some generator

manufacturers refer to this signal as the Hour Meter Signal or Switched B+.

Generator

Compatibility

The XW Automatic Generator Start supports most two and three-wire generator starters.

Some manufacturers include, but are not limited to, Onan (Quiet Diesel, gasoline, and LP),

Power Tech, Generac, Northern Lights, Fisher Panda, Westerbeke, Kohler, Honda, and

Yamaha. Check with the generator manufacturer to ensure the generator in question

includes automatic starting capabilities.

XW System Control

Panel

A XW System Control Panel is required to configure the XW Automatic Generator Start

and monitor generator starting and stopping activity.

The XW System Control Panel also provides real-time clock information for the XW

Automatic Generator Start Quiet Time and Exercise Time features.

975-0239-01-01 1–7

Page 24

1–8

Page 25

Inverter/Charger

2

Installation

Chapter 2, “Inverter/Charger Installation” describes how to mount and install

the XW Inverter/Charger, and the XW Power Distribution Panel and XW

Conduit Box.

For this Topic See....

“Pre-Installation” page 2–2

“Step 1: Installing the Mounting Plate” page 2–4

“Step 2: Mounting the Inverter” page 2–6

“Step 3: Mounting the XW Power Distribution Panel and XW

Conduit Box”

“Step 4: Wiring the Inverter” page 2–8

page 2–7

“Step 5: Installing Additional Inverters” page 2–29

Page 26

Inverter/Charger Installation

Pre-Installation

Before installing the XW Inverter/Charger, read all instructions and cautionary markings

located in this manual.

Important:

starting this installation. Installations must meet all local codes and standards.

Installations of this equipment should only be performed by skilled personnel

such as qualified electricians and Certified Renewable Energy (RE) System

installers.

Be sure to obtain the appropriate permits, if necessary, prior to

WARNING: Personal Injury

The XW Inverter/Charger weighs approximately 120 pounds (54 kg). To prevent personal injury,

always use proper lifting techniques and have someone available to assist with lifting during

installation.

Location

The XW Inverter/Charger is certified for indoor (heated or unheated) installations only.

Close to battery

bank

Locate the inverter as close to the batteries as possible in order to keep the battery cable

length short. The maximum recommended battery cable length is 10 feet (3 m).

WARNING: Explosion and Corrosion Hazard

Do not locate the inverter directly above the batteries or in the same compartment as vented

batteries.

Locate any electronic equipment susceptible to radio frequency and electromagnetic

interference as far away from the inverter as possible.

Fire safety Do not locate the inverter near readily flammable materials such as cloth, paper, straw, or

plastic sheeting. Flammable materials should be kept a minimum distance of 24 inches

(60 cm) from the top surface and 12 inches (30 cm) from either side surface and the front

of the XW Inverter/Charger.

Knockout Preparation

Remove your choice of knockouts from the chassis to facilitate conduit installation for

wire runs. Ensure no debris from this procedure remains inside the inverter enclosure.

Important:

Panel. Use only the knockouts provided for conduit entry.

2–2 975-0239-01-01

Do not drill, cut, or punch holes into the XW power distribution

Page 27

Clearance Requirements

Provide a minimum clearance of 6 inches (15 cm)—12 inches is preferred—around the top

and 6 inches (15 cm) at the bottom of the inverter for ventilation. There must be at least

three feet of clearance in front of the inverter. Ensure that the vents are not obstructed with

foreign objects and that the minimum clearances are met.

Pre-Installation

Figure 2-1

Clearance Requirements

Mounting

The XW Power System is designed to be mounted on a vertical surface. The supporting

surface must be strong enough to support a minimum of 500 pounds (227 kg). To facilitate

installation, a wall mounting plate (Xantrex p/n 210-0462-01-01) is provided for each XW

Inverter/Charger and XW Power Distribution Panel. The mounting plate and hardware on

the XW Inverter/Charger and XW Power Distribution Panel are designed to meet

standards for structural and seismic stability. When properly installed, the system also

meets Section 59 of UL 1741 for Static Loads.

975-0239-01-01 2–3

Page 28

Inverter/Charger Installation

Step 1: Installing the Mounting Plate

Each XW Inverter/Charger and XW Power Distribution Panel requires a separate

mounting plate. This bracket is first attached to the wall, then the inverter/charger or

distribution panel is attached to the wall bracket.

The wall bracket is attached to the wall with lag bolts or other fasteners, provided by the

installer. A minimum of four ¼-inch diameter fasteners are required. The fasteners must

be sufficiently strong to support 500 pounds.

The wall bracket has mounting holes spaced 16 inches (40 cm) apart and is designed to

span two wall studs spaced 16 inches on-center. Additional mounting holes are also

provided for flexibility in mounting options. If the wall does not have 16-inch on-center

studs, the installer will need to provide adequate supports for the brackets. For example, a

sheet of plywood can be attached to the wall, and the wall brackets can then be attached to

plywood.

Both the XW Inverter/Charger and XW Power Distribution Panel use the same wall

bracket. The brackets are designed to interlock (as shown in Figure 2-3), so that additional

mounting plates are easily installed without additional measuring or levelling.

The type of fastener required to secure the mounting plate varies according to the vertical

surface and wall structure of your installation location.

4 1/2 (115)

2 1/4

(57)

Table 2-1

Structure Required Fastener

Wood studs at 16" (on center - O.C.) 1/4" Ø × 3 1/2" long lag screw Four

Wood studs not at 16" O.C. (3/4" minimum

plywood panel required)

Steel studs at 16" O.C. (minimum 18 gauge) 1/4" Ø self-drilling screw Four

Mounting Plate Fastener Recommendations

1/4" Ø × 1" long wood screw Six

16 (406)

1 3/4 (45)

6 (153)

6 7/8

(175)

Number of Screws

Per Bracket

9 3/16

(233)

2 (49)

17 (432)

Figure 2-2

2–4 975-0239-01-01

Mounting Plate Dimensions

3/4 (19)

all measurements in inches

(millimeters)

Page 29

2 × 4 wall stud

Wallboard

Plywood

(optional)

mounting plate

Step 1: Installing the Mounting Plate

Wall studs 16" on center behind

wallboard

Side View

Multiple mounting plates should fit together

as shown.

60" (152.4 cm) from floor

puts the inverter display

panel at approx. 65"

high.

Add ¾" plywood if additional support is

needed.

Locate the wall studs.

1

If necessary, enhance the support surface with a ¾" plywood panel

2

secured to the wall studs. Plywood should span at least three wall studs.

Use hardware sized to support a minimum of 500 lbs (not provided) to

3

secure the plywood to the wall.

Using a level, secure the first mounting bracket to the wall. Use

4

recommended anchoring hardware to secure the plate (see Table 2-1).

Mount the next bracket adjacent to the first one. The brackets are designed

5

to interlock, so additional mounting brackets are easily installed without

additional measuring or levelling.

Figure 2-3

Mounting the Bracket for the XW Inverter/Charger or Distribution Panel

975-0239-01-01 2–5

Page 30

Inverter/Charger Installation

Step 2: Mounting the Inverter

1

3

2

1

Align the flange on the back of the XW Inverter/Charger with the bottom edge of the

mounting plate.

Lower the flange on the inverter onto the mounting plate.

2

CAUTION: Before releasing the full weight of the unit, ensure the inverter is seated

properly on the mounting plate.

3

Secure the top of inverter with two #10 self-tapping screws (supplied).

Figure 2-4

2–6 975-0239-01-01

Mounting the XW Inverter/Charger

Page 31

Step 3: Mounting the XW Power Distribution Panel and XW Conduit Box

Step 3: Mounting the XW Power Distribution Panel and XW Conduit

Box

Mount the XW Distribution Panel on the mounting bracket following the same procedure

in Step 2.

When mounting the XW Conduit Box as shown in Figure 2-5, it is not necessary to attach

the front panel until all wiring is complete.

Attach the back panel of the

1

XW Conduit Box to the bottom

of the inverter with two screws

through the keyhole slots under

the back panel top and the

corresponding holes in the

bottom of the inverter (A).

Secure the bottom edge of the

back panel to the wall using two

screws (B).

Grid (AC1)

Gen (AC2)

Fault /

Warning

Equalize

AC

OU

PVGFP

T

Inverting

Flashing = sell

Charging

Battery

UG

AC

OU

IN

Power Di stribution

P

T

P

V

V

O

A

U

N

T

Mounting

Plate

Hybrid In vert er /Ch arger

UG

IN

Block?

I

NEUTRALS ?

GE

GE

N

OU

T

N

IN

xantrex

DC

OU

T

AC

GND?

AC

OU

T

PVGFP

Power Distribution Panel

DC

IN

UG

AC

OU

IN

T

P

V

O

U

T

NEUTRALS ?

Mounting

GE

Plate

UG

N

IN

OU

T

Power Di stribution

Block?

P

V

I

N

DC

GND

?

xantrex

GE

N

IN

DC

DC

OU

IN

T

Grid (AC1)

Gen (AC2)

Fault /

Warning

Equalize

AC

OU

T

PVGFP

Battery

UG

AC

OU

IN

P

T

V

O

U

T

B

Inverting

Flashing = sell

Charging

Mounting

Plate

Hybrid Inverter /Charg er

NEUTRALS ?

GE

N

UG

OU

IN

Power Distribution

P

T

Block?

V

I

N

GE

N

IN

xantrex

DC

OU

T

AC

GND?

AC

OU

T

PVGFP

Power Distribution Panel

DC

IN

UG

AC

OU

IN

T

P

V

O

U

T

NEUTRALS ?

Mounting

GE

Plate

UG

N

IN

OU

T

Power Distribution

Block?

P

V

I

N

DC

GND

?

xantrex

GE

N

IN

Attach the front panel of the XW

2

Conduit Box by sliding the

bottom lip of the front panel over

DC

DC

OU

IN

T

the lower edge of the back

panel. Align the two holes in the

front panel with the two holes in

the back panel. Use the two

#10-32 screws provided to

secure the front panel to the

back panel.

Figure 2-5

Installing the XW Conduit Box

975-0239-01-01 2–7

Page 32

Inverter/Charger Installation

Step 4: Wiring the Inverter

This section provides procedures for making AC and DC connections between the XW

Inverter/Charger and the power distribution panel using the cables that are pre-installed in

the distribution panel. This section also assumes that the XW Conduit Box was installed in

the previous section.

For diagrams and information about installing the inverter/charger without the XW

Conduit Box and XW Power Distribution Panel, see Appendix C.

Important:

Communication and signal cables must be segregated from all DC and

AC wiring. Therefore, a small raceway has been included in the design of both the

XW Power Distribution Panel and the XW Conduit Box to separate the

communications cables from the power cables. This is a small raceway run built into

the bottom of both the XW Power Distribution Panel and the XW Conduit Box and is

held in place by a single screw at the top of the raceway.

Installation Tip Before making the AC or DC cable connections, route the communications cables through

the raceway, but do not connect them to their components until after all the inverter

connections are made. Once the AC and DC connections are made the run becomes

difficult to access. Use different colors for the communications cables (or cable tags) to

help make them easier to identify.

Route the communications cables for any

accessories being installed BEFORE

making AC or DC Connections.

Do not connect to the

XW Automatic

Generator Start until

all other connections

have been made.

XW Automatic

Generator Start

IMPORTANT: When routing communications cables through the XW

Power Distribution Panel, the raceway conduit must be used to keep the

communications cables separate from the power cables.

XW System

Control Panel

Do not connect to

the XW System

Control Panel until

all other

connections have

been made.

Raceway for Shunt

Sense cable*.

Raceway exits the

panel through the

back.

Do not connect to

the BTS to the

batteries until the

battery bank has

been prepared and

See Figure 2-12 on

page 2–16 for an

illustration showing

the Communications

Ports and where the

accessories connect.

Figure 2-6

Routing Communications Cables

Raceway for Communications

Cables*

*To remove, remove the screws at

the top (Or side) of the raceway.

Raceway for Communications

Cables*

is ready to connect

to the inverter.

BTS

2–8 975-0239-01-01

Page 33

Batteries

See the FAQs section of the Xantrex Web site for information on determining battery bank

requirements.

Consider the following recommendations for battery use.

• Use only the deep discharge types for inverter applications.

• Use the same battery type for all batteries in the bank.

• Use only batteries from the same lot and date in your battery bank. This information is

usually printed on a label located on the battery.

CAUTION: Damage to Equipment

The XW Inverter/Charger is intended to operate with batteries as its source of DC power. Do not

connect DC power sources, such as PV arrays, wind turbines, or micro-hydro turbines, directly to

the XW Inverter/Charger without a battery. Connect DC power sources to a charge controller such

as the XW Solar Charge Controller instead. If DC power sources are connected directly to the

inverter, the DC rating of the inverter can be exceeded and the inverter can be damaged.

Battery Bank Requirements

Step 4: Wiring the Inverter

The DC voltage of the inverter must match the nominal voltage of the system and all

battery-connected devices. If the inverter is a 24-volt inverter, then the battery bank and all

battery-connected devices in the system need to be configured for 24 volts.

Important: The minimum recommended battery bank is 100 Ah. The inverter is designed to

operate with batteries and should not be operated without them. Also, do not allow the battery

bank to become completely discharged. If the voltage of the battery bank falls below 10 volts, the

XW Power System will not operate.

Battery Cable Requirements

WARNING: Fire Hazard

Undersized cables can overheat and melt, creating a fire hazard when subjected to heavy (peak)

loads. Always use a cable of proper size and length, rated for the amperage of the inverter and

batteries.

Important:

not use coarse-stranded wire, as the lack of flexibility may damage battery and inverter terminals.

Battery cable length Runs should be kept as short as practical. Length should not exceed 10 feet (3 m). For best

performance, the positive and negative cables should run alongside each other. Avoid

cable loops.

Battery cable lugs Battery cables must have crimped copper compression lugs or crimped and soldered

copper compression lugs. Soldered connections alone are not acceptable. Lugs must be

rated for use with fine-stranded cable.

Use only fine-stranded copper cables for battery and inverter DC connections. Do

Overcurrent

protection

For safety and compliance with regulations, battery overcurrent protection is required.

Fuses and disconnects must be sized to protect the wiring in the system and are required to

open before the wire reaches its maximum current carrying capability.

975-0239-01-01 2–9

Page 34

Inverter/Charger Installation

Terminal covers Color-coded snap-on DC terminal covers are provided to prevent accidental contact with

the terminals. Terminal covers are required for all installations, even if a XW Conduit Box

is used. It is also recommended that the shank of the ring terminals (cable lugs) be covered

with heat shrink or some other form of insulation.

Table 2-2

Inverter Model Up to 5 Feet (1.5 m) (90°C wire) Up to 10 Feet (3 m) (90°C wire)

XW4024

XW4548

XW6048

Important:

residential and commercial electrical systems. These items are not supplied as part of the inverter,

but are included in the XW Power Distribution Panel.

Table 2-3

Cable Size

Required

#2/0 (00) AWG 175 amps

#4/0 (0000) AWG 250 amps

Recommended Battery Cable Size Versus Length

#4/0 AWG (120 mm

#2/0 AWG (70 mm

#4/0 AWG (120 mm

The NEC/CEC requires both overcurrent protection and a disconnect switch for

Battery Cable (in conduit) to Maximum Breaker/Fuse Size

Maximum Breaker/Fuse

Size

Torque Values for the XW Series Inverter/Charger

Table 2-4

Wire Size Torque Value

AWG In-lb N-m

14–10 35 4

8404.5

6–4 45 5

Torque Values for AC Wiring (AC Terminals and Ground Bar)

2

) #4/0 AWG (120 mm2)

2

) #4/0 AWG (120 mm2)

2

) #4/0 AWG (120 mm2)

Table 2-5

Wire Size Torque Value

AWG In-lbs N-m

6-4 45 5.1

3-2 50 5.6

Table 2-6

Ft-lbs N-m

15 20.4

2–10 975-0239-01-01

Torque Values for the Chassis Ground Lug

Torque Values for the Inverter Battery Terminals

Torque Valu e

Page 35

Torque Values for the XW Power Distribution Panel

Step 4: Wiring the Inverter

Table 2-7

Wire Size Torque Value

AWG In-lb N-m

16–10 45 5

8455

6–4 45 5

Table 2-8

Torque Values for AC Disconnects and AC Breakers

Torque Values for the Ground Bus, AC Neutral Bus, DC Negative Bus, and DC

Positive Bus in the XW Power Distribution Panel

Wire Size Torque Value

AWG In-lbs N-m

14 - 10 35 4.0

8404.5

6 - 4 45 5.1

3 - 2/0 50 5.6

Table 2-9

Torque Values for the Power Distribution Bars in the XW Power Distribution

Panel

Wire Size Torque Value

AWG In-lbs N-m

14 - 10 35 4.0

8404.5

6 - 4 45 5.1

3 - 2/0 50 5.6

Table 2-10

Torque Values for the Battery Cables to the DC Negative Bus, and DC

Positive Bus in the XW Power Distribution Panel

Torque Value

Ft-lbs N-m

15 20.4

Inverter Grounding

Important:

must comply with national and local codes. Consult local and national codes for specific grounding

and bonding requirements for the desired installation.

The grounding requirements vary by country and by application. All installations

Backfeed Protection Requirements

Important:

be fed into a distribution panel and the means and location for feed-in, in

accordance with NEC 2005 article 690.64 or similar requirements of the local

electrical code.

975-0239-01-01 2–11

Installers must make allowance for the amount of power that can

Page 36

Inverter/Charger Installation

Wiring the Inverter to the XW Power Distribution Panel

Important:

cables must run through the raceway at the rear of the XW Conduit Box. Before making AC and

DC connections, route all communication and Battery Temperature Sensor cables through the

raceways. The raceways becomes more difficult to access after all AC and DC wiring is completed.

Grounding the DC System

The inverter’s chassis ground bar (see Figure 2-7) is used to connect the chassis of the

inverter to the DC grounding system. The terminal accepts wires from #14 AWG to

#2 AWG.

A

See Table 2-5 on page 2–10

for torque values for the AC

Chassis Ground.

If a XW Conduit Box is installed, communication and Battery Temperature Sensor

Actual ground requirements may vary.

Figure 2-7

DC Grounding Using a Power Distribution Panel

B

A

B

See Table 2-6 on page 2–10

for torque values for the

Ground bar in the XW Power

Distribution Panel.

2–12 975-0239-01-01

Page 37

Installing the Battery Temperature Sensor

The Battery Temperature Sensor (BTS) port is for connecting to the Battery Temperature

Sensor, which regulates battery charging based on battery temperature. Installing a sensor

extends battery life by preventing overcharging in warm temperatures and undercharging

in cold temperatures. This port is also considered part of the DC interface (see Figure 2-9).

To install the Battery Temperature Sensor:

1. Pass the end of the Battery Temperature Sensor cable through a conduit hole and insert

the Battery Temperature Sensor plug into the Battery Temperature Sensor port.

2. Route the cable to the battery enclosure and connect the ring terminal on the Battery

Temperature Sensor directly to a battery terminal (recommended), or use the adhesive

backing on the sensor back to attach the sensor to any side of the battery to be

monitored.

If using the adhesive backing, install the Battery Temperature Sensor on the side of the

battery below the electrolyte level. It is best to place the sensor between batteries and

place the batteries in an insulated box to reduce the influence of the ambient

temperature outside the battery enclosure.

Battery Temperature

Sensor Port (RJ11)

Step 4: Wiring the Inverter

1

RJ11 jack

Note: If other Xanbus

connected components

supply a BTS or are BTS

enabled, it is not necessary

to install all of them at once.

Only one BTS needs to be

installed.

However, if multiple

battery-banks are being

used, multiple sensors can

be installed. In which case,

the system will use the

highest temperature from

all the input as it’s

operational parameter.

Figure 2-8

Battery Temperature Sensor (RJ11) Port Location and Installation

If using the adhesive backing, install

the Battery Temperature Sensor on

the side of the battery below the

electrolyte level.

2

975-0239-01-01 2–13

Page 38

Inverter/Charger Installation

Making DC Connections

This section describes how to make DC connections between the inverter/charger and the

power distribution panel (using the pre-installed DC cables in the distribution panel),

between the distribution panel to the batteries (using battery cables provided by the

installer—see Table 2-2 on page 2–10). This section also provides procedures for

installing the battery temperature sensor. See Appendix C, “Alternate System

Configurations” if the installation will not be including an XW Power Distribution Panel.

WARNING: Shock Hazard

Ensure that all AC and DC breakers are switched OFF before connecting or disconnecting the

battery cables and that all sources of power (both AC and DC) are disconnected from the inverter.

Chassis Ground

Lug

Figure 2-9

Positive (+, red)

battery terminal

Bottom View

XW Inverter/Charger DC Connections

To connect the XW Power Distribution Panel to the inverter:

1. Connect the pre-installed DC cables from the XW Power Distribution Panel to the

inverter DC terminals. Figure 2-10 shows the proper stacking order of hardware. Be