Page 1

Xantrex Datacom

Inverter

XDI2048

2kVA/1.5kW

Operating Manual

Page 2

Page 3

Xantrex Datacom Inverter

XDI2048 2kVA/1.5kW

Operating Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products

from 50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines,

and backup power applications in both grid-connected and stand-alone systems. Xantrex products include

inverters, battery chargers, programmable power supplies, and variable speed drives that convert, supply, control,

clean, and distribute electrical power.

Trademarks

Xantrex Datacom Inverter is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex

International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are

used herein for identification purposes only.

Notice of Copyright

Xantrex Datacom Inverter Operating Manual © December 2003 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WI LL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

December 2003 Revision C

Part Number

TM-DIOP-01XN-01

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 800 994 7828 (toll free North America)

Email: customerservice@xantrex.com

Web: www.xantrex.com

1 360 925 5097 (direct)

1 360 925 5143 (direct)

Page 5

About This Manual

Purpose

The purpose of this Operating Manual is to provide explanations and

procedures for installing, operating, maintaining, and troubleshooting the

Xantrex Datacom Inverter.

Scope

The Manual provides safety guidelines, detailed planning and setup

information, procedures for installing the inverter, as well as information

about operating and troubleshooting the unit.

Audience

The Manual is intended for anyone who needs to install and operate the

Xantrex Datacom Inverter. Installers should be certified technicians or

electricians.

Organization

This Manual is organized into five chapters and an appendix:

Chapter 1, “Introduction”, Chapter 1 contains an introduction to the XDI

Inverter and the Ethernet card. This chapter provides a list of the major

features, protections and options included with both the XDI Inverter and

the Ethernet card.

Chapter 2, “Rack Mount Frame Assembly and Installation”, Chapter 2

contains information and procedures to assemble and install the rack mount,

and install the inverter.

TM-DIOP-01XN-01 iii

Page 6

About This Manual

Chapter 3, “Inverter Module Installation and Operation”, Chapter 3

contains information and procedures for installing and using the XDI

Inverter.

Chapter 4, “Remote Communication & Monitoring”, Chapter 4 contains

information and procedures for using the Ethernet to provide remote

communication and monitoring.

Chapter 5, “Troubleshooting”, Chapter 5 contains information and

procedures for troubleshooting your XDI Inverter and Ethernet card.

Appendix A, “Specifications”, Appendix A supplies information about

specifications for the XDI Inverter and the Ethernet.

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit

or other equipment.

Important:

but not as serious as a caution or warning.

These notes describe things which are important for you to know,

Related Information

You can find more information about Xantrex Technology Inc. as well as

its products and services at www.xantrex.com

iv TM-DIOP-01XN-01

Page 7

Important Safety Instructions

WARNING

Operate the Inverter in an environment free of flammable gases or fumes. To

ensure that the Inverter’s safety features are not compromised, use the Inverter as

specified in this manual and do not substitute parts or make any unauthorized

modifications. Contact the service technician for service and repair help. Repairs

must be made by experienced service technicians only.

WARNING

The XDI is intended for installation in a restricted access location. This is an area

intended for qualified or trained personnel only, access to which is controlled by

a locking mechanism (for example, a key lock or an access card system).

WARNING

Appropriate care and attention must be exercised when connecting any

equipment to a DC supply system due to the short circuit energy hazard that

exists.

CAUTION

The inverter will operate from a DC source in the range of -40 V to -60 V. The

maximum voltage without damage to the unit is -80 V. The source and cabling

shall be capable of supplying 45 A continuously for a worst case operating

voltage of -40 V. Under overload conditions (maximum 3 kW) the source

requirement will be 90 A at -40 V

TM-DIOP-01XN-01 v

Page 8

vi

Page 9

Contents

Important Safety Instructions

1

Introduction

Inverter Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Features and Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Ethernet Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Features and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Part Number and Ordering Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

2

Rack Mount Frame Assembly and Installation

Initial Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Packaging for Shipping or Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Location, Mounting and Ventilation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Installation Into Cabinet Style Equipment Racks - - - - - - - - - - - - - - - - - - - - - -2–5

Installation into Relay Racks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

DC Input Power- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

Input Connector and Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

DC Input Wire Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

AC Load and Signal Line Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

AC Output Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Load Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Load Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–10

User Line Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

User Line Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–12

User Line Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–12

User Line Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–12

TM-DIOP-01XN-01 vii

Page 10

Contents

CAN/SYNC Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Specifications: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

CAN/SYNC Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

CAN/SYNC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Connection Schemes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Stand-Alone Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Parallel Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Split Phase Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Three Phase Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

3-Phase Synchronization and Signal Wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

3-Phase, 3-Wire Delta Output Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–20

3-Phase, 3-Wire Y-Connection Output Wiring - - - - - - - - - - - - - - - - - - - - - - 2–20

3-Phase, 4-Wire Y-Connection Output Wiring - - - - - - - - - - - - - - - - - - - - - - 2–21

Ethernet Port- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–21

3

Inverter Module Installation and Operation

Installation into Rack Mount Frame - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Operation of Inverter Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

System Startup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Standby Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Cooling Fans - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

User Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

User Lines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

Protections and Alarms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Input Voltage Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Output Voltage Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Overload Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Over Temperature Protection (OTP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Short-circuit Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Over-Current protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–9

Internal Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

viii TM-DIOP-01XN-01

Page 11

Fuses and Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

Incorrect Connection Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

Output (AC) Alarm - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

To Clear an Alarm - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–11

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–11

4

Remote Communication & Monitoring

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Web-enabled User Interface- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Initial Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

How to Setup For the First Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Hardware Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Ethernet Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

Resetting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–6

Operating Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–9

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–9

Network Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–9

Using DHCP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–11

What Power On Does - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–11

Password - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–12

Automatic Power-On Email - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–13

How to Use the Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–13

Manage Page - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–14

Setup Page - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–15

Monitor page - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–17

Automatic Shutdown Email - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–19

Contents

5

Troubleshooting

User Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–2

Emergency Shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–2

Unusual or Erratic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–2

Diagnostic Guide - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–3

TM-DIOP-01XN-01 ix

Page 12

Contents

A

Specifications

Inverter Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Regulatory Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Ethernet Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–7

Warranty and Product Information

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–1

Return Material Authorization Policy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–3

Return Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

Out of Warranty Service- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

Information About Your System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

xTM-DIOP-01XN-01

Page 13

Figures

Figure 2-1 Packing List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Figure 2-2 Shipping or Storage Carton Label- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Figure 2-3 Rack Mount Frame Rear View- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Figure 2-4 Installing into Cabinet Style Racks- - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Figure 2-5 Installing into Relay Racks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-6 Connecting the Input Wires- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-7 User Lines Schematic- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Figure 2-8 Parallel Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Figure 2-9 Split-Phase Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Figure 2-10 3-Phase Sync Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Figure 3-1 Installing an Inverter into a Rack - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Figure 3-2 Inverter Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Figure 3-3 Overload curve - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-4 Replacing the Fan Filters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Figure 4-1 Ethernet Interface PCB- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Figure 4-2 First Time Setup Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Figure 4-3 Removing Unit’s Top Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Figure 4-4 Ethernet Reset Jumper - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–8

Figure 4-5 Network Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–10

Figure 4-6 Password Confirmation Boxes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–12

Figure 4-7 Manage Page of Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–14

Figure 4-8 Setup Page of Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–15

Figure 4-9 Monitor Page of Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–17

Figure A-1 Inverter and Rack Mount Frame Dimensions - - - - - - - - - - - - - - - - - - - - A–6

TM-DIOP-01XN-01 xi

Page 14

xii

Page 15

Tables

Table 2-1 User Line Connection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Table 2-2 CAN/SYNC Pin-out- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Table 2-3 3-Phase Configurations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Table 3-1 Front Panel LED Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Table 3-2 User Line Pins- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Table 4-1 Default Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Table 4-2 User Configured Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

Table 4-3 Reset Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Table 4-4 Manage Page of Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–14

Table 4-5 Setup Page of Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–16

Table 4-6 Monitor Page of Web Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–18

Table 4-7 Shutdown Code- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–19

Table 5-1 Inverter Diagnostics- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Table 5-2 Ethernet Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

TM-DIOP-01XN-01 xiii

Page 16

xiv

Page 17

1

Introduction

Chapter 1 contains an introduction to the XDI Inverter and the

Ethernet card. This chapter provides a list of the major features,

protections and options included with both the XDI Inverter and

the Ethernet card.

Page 18

Introduction

Inverter Information

Description

The Xantrex Datacom Inverter (patent pending) is the most versatile

modular rack mounted Inverter system for telecom and industrial

applications requiring constant AC power from standard –48 V battery

systems. The XDI consists of a 1 U (1.7 in, 73 mm) thin, true sinewave

2000 VA/1500 W inverter module rated for continuous duty, and a

compatible 19-inch wide equipment rack mount frame with back-plane

mounted connectors. The system is easily scalable by adding parallelconnected modules and can be configured in N+1 single or three-phase

arrays for maximum reliability. No single unit is a “master”, and an array

of units will tolerate the failure of one or more parallel-connected

inverters.

Features and Options

Product

Features

Protection

Features

Options • Optional TCP/IP enabled Ethernet port card

• Compact size (1 U) designed to fit standard 19 in (483 mm)

equipment racks

• Easily paralleled for N+1 redundant systems

• High efficiency and reliability

• Power share in parallel system for up to 20 kVA (10 units) of AC

power

• 3 kW, 4 kVA (5 s) surge capability

• Short circuit proof

• Rack mounted back plane accommodates DC input and AC output

connectors

• High performance noise filters on both input and output

• 3-year warranty

• cCSAus, CE, NEBS LEVEL 3, FCC Class B approvals

• Input under/over voltage protection

• Output under/over voltage protection

• Incorrect connection protection

• Temperature limit shutdown

• Output overload protection

• Optional static transfer switch for added system reliability

1-2 TM-DIOP-01XN-01

Page 19

Ethernet Information

Ethernet Information

Description

The internal XDI Ethernet interface allows you to monitor and operate

your inverter from a local or remote computer equipped with an Ethernet

card.

The Ethernet interface allows monitoring and configuration of the XDI

Inverter as well as network settings for the interface card itself. The

interaction is done through an HTTP server and a custom Web page

served by the Ethernet interface.

A proactive emailing system uses SMTP to inform you that the unit has

turned on or a fault condition has occurred.

This section describes the features and specifications of the XDI Ethernet

interface card.

Features and Functions

Features • No special software required to monitor/control XDI Inverter (Simple

Web browser will work)

• Easy to use Web page interface

• Automatically sends email when XDI is powered on

• Automatically sends email when XDI shuts down

• Allows remote monitor from any PC with Internet access

• Possible re-use of network cable infrastructure for connections

• Password protected for added security

Programmable

Functions

• Output Standby Mode

• Password

• Default IP address

• Gateway IP address

• Sub-Net Mask

• Domain Name Server #1

• Domain Name Server #2

• SMTP Server

• Email Alert Address

TM-DIOP-01XN-01 1-3

Page 20

Introduction

Monitor

Functions

• DSP Firmware Version

• Manufacturer

•Model

• Serial Number

• Front Panel LED status

• Output Voltage

• Output Current

• Percent Load

• Startup State

• Current Fault Status

• Faults Since Power On

Part Number and Ordering Information

XDI2048-RM Includes Inverter Module and Rack Mount Frame.

Ready to install into 19 in. (483 mm) standard

equipment rack.

XDI2048HV-RM (“HV” for 230 V/50 Hz output)

XDI2048 Includes Inverter Module only . Ready to insert into

a pre-wired Rack Mount Frame.

XDI2048HV (“HV” for 230 V/50 Hz output)

ENET -XDI Optional factory-installed TCP/IP enabled Ethernet

communications card.

RM-XDI Includes Rack Mount Frame Assembly. Ready to

be installed in a 19 in. (483 mm) standard

equipment rack.

RM-1U23 Optional Rack Mount Adapter Kit to mount

equipment into a 23 in. (585 mm) standard

equipment rack.

1-4 TM-DIOP-01XN-01

Page 21

Rack Mount Frame

2

Assembly and

Installation

Chapter 2 contains information and procedures to assemble and

install the rack mount, and install the inverter.

This chapter describes the following:

• rack mounting the Inverter

• connecting the DC input power

• connecting the AC load and signal line

• setting up a variety of operating formats

Page 22

Rack Mount Frame Assembly and Installation

Initial Inspection

When you first receive your unit, perform a quick physical check.

1. Inspect the unit for scratches and cracks, broken switches, connectors,

terminals, and missing accessories.

2. Have a service technician check the unit if you suspect internal

damage.

If the unit is damaged, save all packing materials and notify the carrier

immediately. See instructions in “Packaging for Shipping or Storage” on

page 2–3 and “Return Procedure” on page B–4.

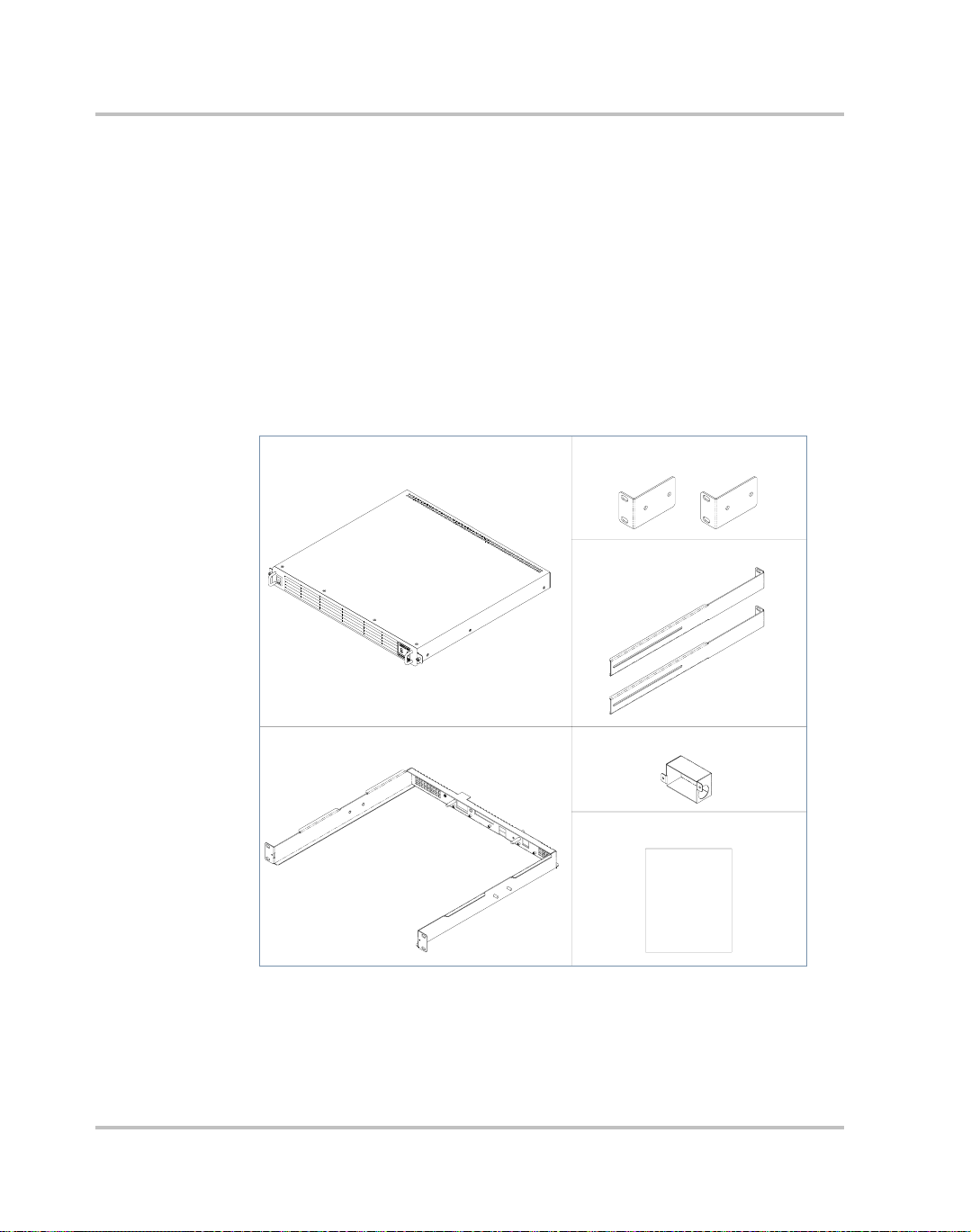

Your purchase should ship with the following items:

INVERTER MODULE

RACK MOUNT BACKPLANE

RELAY RACK MOUNTING BRACKETS

SLIDING RAILS

OUTPUT STRAIN RELIEF COVER

USER MANUAL

MANUAL

Figure 2-1

2-2 TM-DIOP-01XN-01

Packing List

Page 23

Packaging for Shipping or Storage

Follow these instructions to prepare the unit for shipping or storage.

1. When returning the unit or sending it to the service center, attach a tag

to the unit stating its model number (available from the front panel

label) and its serial number (available from the rear panel label). Give

the date of purchase and an invoice number, if you have it, as well as

a brief description of the problem. You will need an RMA number to

return the unit. See “Return Material Authorization Policy” and

“Return Procedure” on page B–4.

2. For storage or shipping, repack the inverter in its original container. If

the original container is not available, seal the unit in a plastic bag and

then pack it in a 200 lb. (90 kg) test, corrugated cardboard carton

large enough to allow 2 in (50 mm) of cushioning material to

surround the unit. Use a material such as foam slabs or chips.

3. Label the carton as shown in Figure 2-2.

4. If shipping, mark the address of the service center and your return

address on the carton.

5. If storing, stack no more than eight cartons high. Check the storage

temperature range and storage altitude specification in

“Environmental Specifications” on page A–4.

Initial Inspection

INVERTER

Model Number: _______________________

Serial Number: _______________________

FRAGILE — ELECTRONIC EQUIPMENT

Figure 2-2

TM-DIOP-01XN-01 2-3

Shipping or Storage Carton Label

Page 24

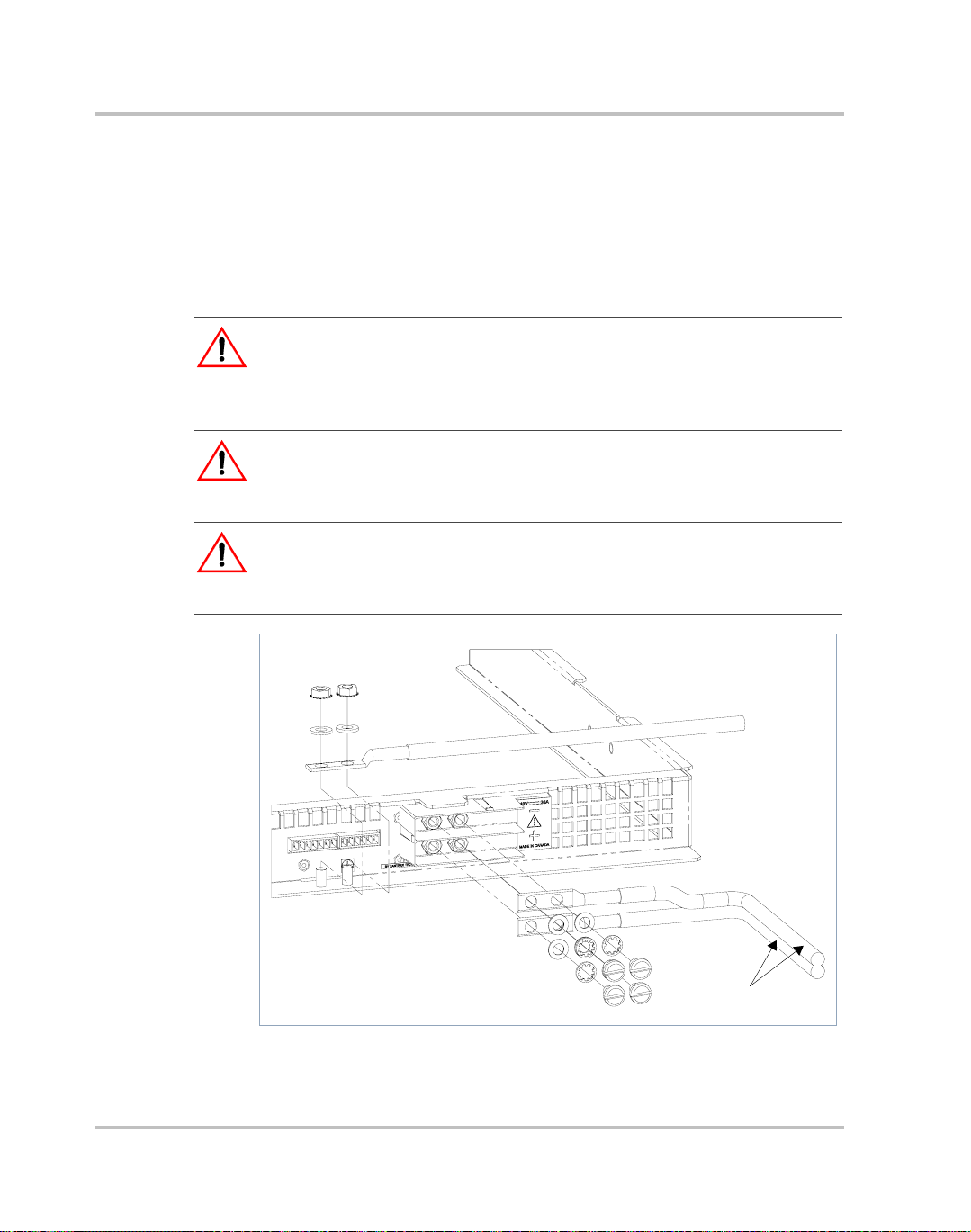

Rack Mount Frame Assembly and Installation

Introduction

You can use the Inverter in rack-mounted applications. Alternate

configurations can be created for custom applications.

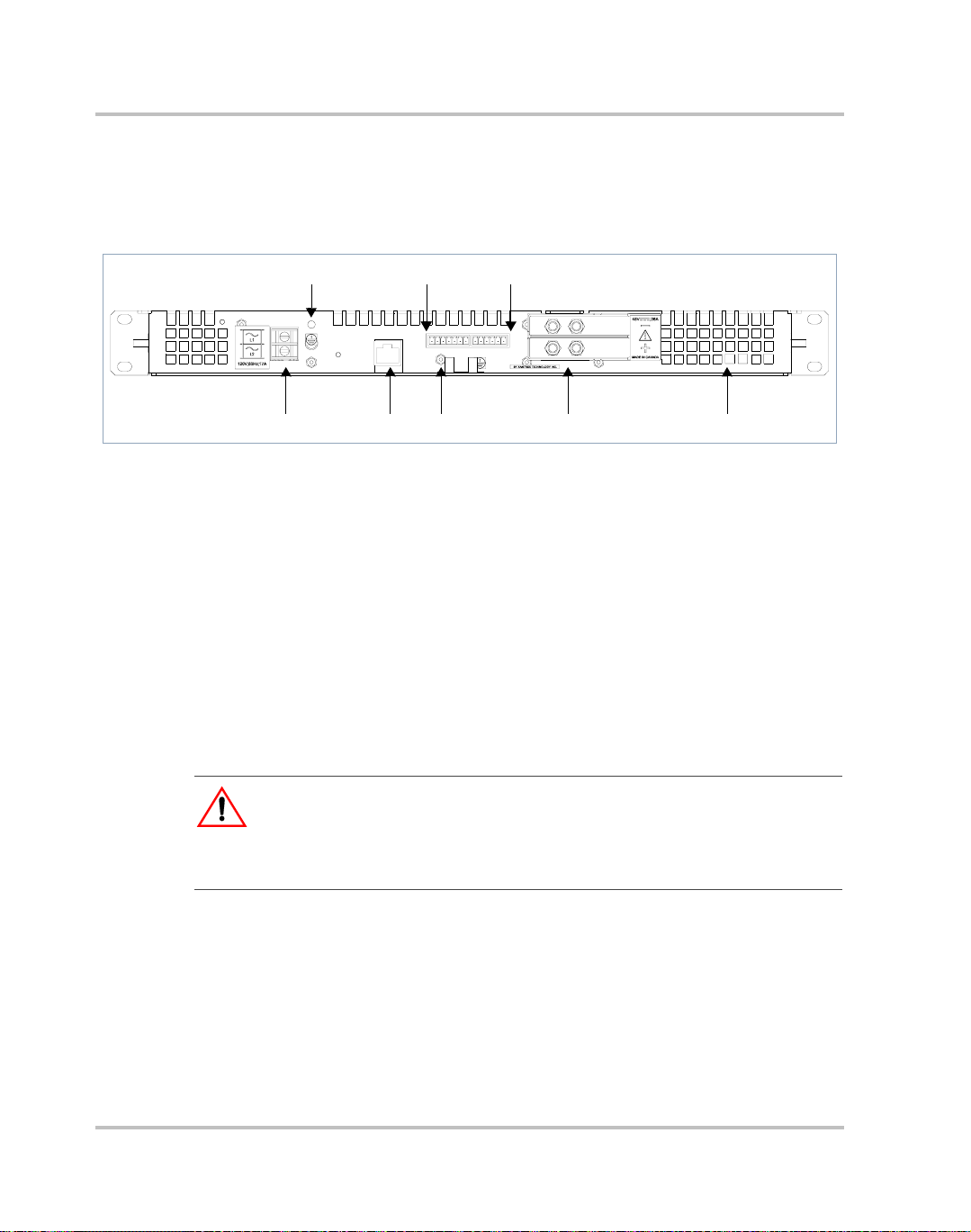

246

Figure 2-3

ETHERNET

135 7 8

Rack Mount Frame Rear View

1. AC Output Terminal Block

2. AC Output Ground Stud

3. Ethernet card (optional)

4. Can/Sync Connector

5. DC Input Ground Stud

6. User Lines Connector

7. DC Input Terminal Block

8. Air Vents

WARNING

The XDI is intended for installation in a restricted access location. This is an area

intended for qualified or trained personnel only, access to which is controlled by

a locking mechanism (for example, a key lock or an access card system).

CAN/SYNC USER LINES

1234567 123456

2-4 TM-DIOP-01XN-01

Page 25

Location, Mounting and Ventilation

Location, Mounting and Ventilation

When you install the Inverter into a rack, allow cooling air to reach the

ventilation inlets. At the same time, do not block the air exhaust. See

“Electrical Specifications” on page A–2 for the operating altitude

specification and the operating ambient temperature range measured at

the unit case.

The inverter is designed to fit into a standard 19 in. (483 mm) equipment

rack. Mounting brackets are included which allow the unit to be mounted

in either cabinet style racks or relay racks.

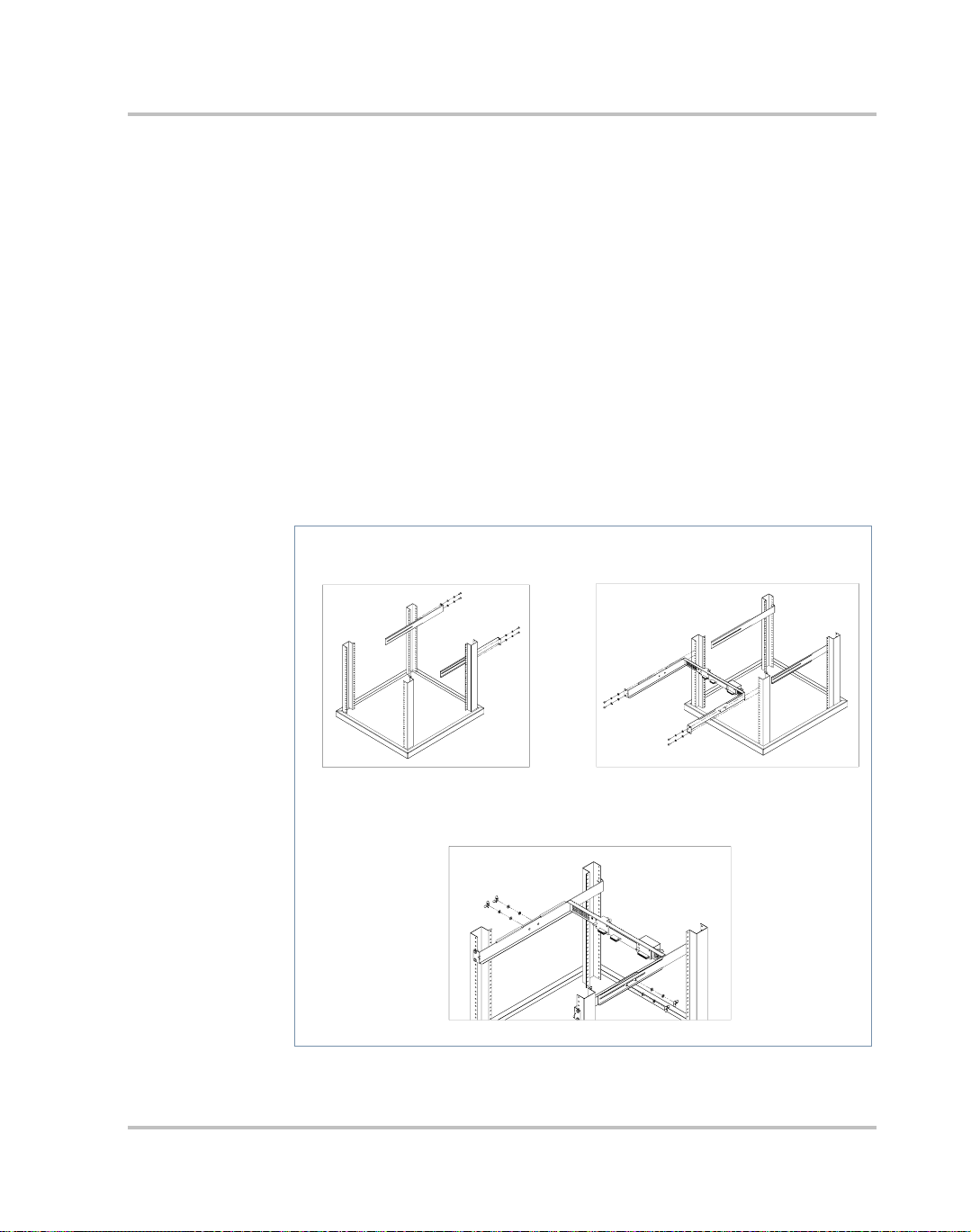

Installation Into Cabinet Style Equipment Racks

For installation into a cabinet style equipment rack, the backplane is

secured using two sliding rails as shown below.

2. Assemble the Backplane1. Assemble the Sliding Rails

3. Secure the Backplane

Figure 2-4

TM-DIOP-01XN-01 2-5

Installing into Cabinet Style Racks

Page 26

Rack Mount Frame Assembly and Installation

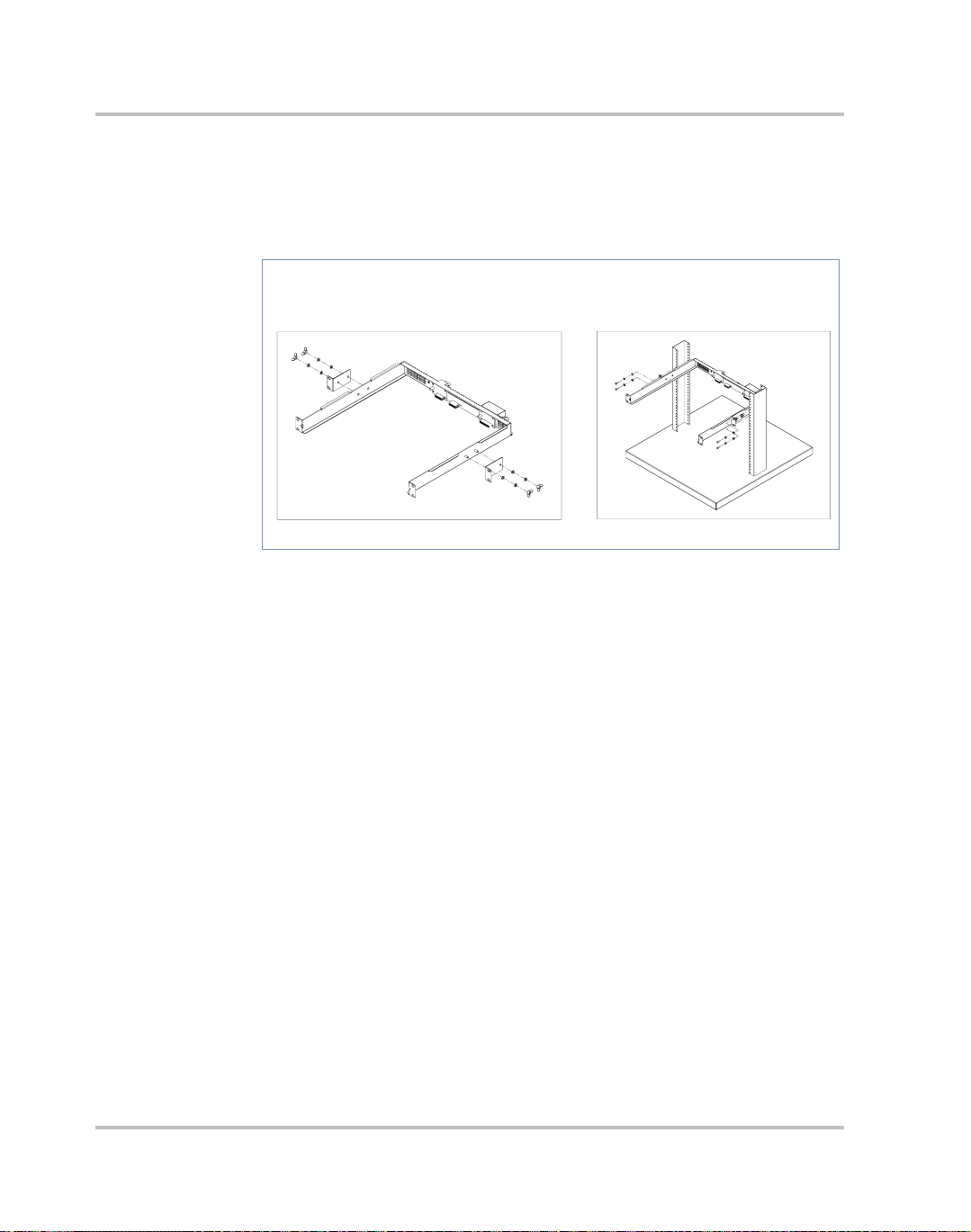

Installation into Relay Racks

Use the supplied mounting brackets to secure the backplane in a relay

rack.

2. Assemble in Relay Rack1. Attach the Mounting Brackets

Figure 2-5

Installing into Relay Racks

2-6 TM-DIOP-01XN-01

Page 27

DC Input Power

CAUTION

The inverter will operate from a DC source in the range of -40 V to -60 V. The

maximum voltage without damage to the unit is -80 V. The source and cabling

shall be capable of supplying 45 A continuously for a worst case operating

voltage of -40 V. Under overload conditions (maximum 3 kW) the source

requirement will be 90 A at -40 V

Input Connector and Cables

The XDI input connector is a 2-pole, double lug terminal block with

separate double studs for the ground connection. A minimum of 6 AWG

copper conductor (rated 85°C minimum) is the recommended wire gauge

for all three input cables.

DC Input Wire Connection

DC Input Power

Important:

that the installation complies with the specific wiring rules applicable to your

country or area of jurisdiction.

The DC input wiring should be routed through a 60 A circuit breaker for

each inverter used. This provides additional disconnect options and adds

to safety. A 2-pole breaker is recommended, but should a single pole be

used, it should be mounted in the negative side of the input wiring.

To connect DC input wires from the breaker:

1. Ensure DC breaker is de-energized.

2. Strip 7/16 in. (11 mm) off the positive, negative and ground cables

and install a standard two hole compression lug (hole diameter:

0.25 in. (6 mm)) on each cable.

• Burndy part #: YA6CL2TC14

• T&B part #: 54205

• Hendry part #: 06117-01

3. Remove the supplied nut and washer on the ground studs and install

and secure the ground connection.

The following procedure should be used as a guide only. Ensure

TM-DIOP-01XN-01 2-7

Page 28

Rack Mount Frame Assembly and Installation

4. Note the polarity on the input connector as indicated and fasten the

positive and negative cable ends onto the terminal block using the

brass screws and washers provided. Tighten both securely . See Figure

2-6.

5. The DC input wiring should be appropriately restrained to the

equipment rack to provide strain relief.

WARNING

Appropriate care and attention must be exercised when connecting any

equipment to a DC supply system due to the short circuit energy hazard that

exists.

WARNING

It is critical that the wires be stripped the right length so that the insulator enters

the connector.

WARNING

T o avoid the risk of a short-circuit hazard, bare wire must NOT protrude past the

connector.

DC Input

Figure 2-6

2-8 TM-DIOP-01XN-01

Connecting the Input Wires

Page 29

AC Load and Signal Line Connection

AC Load and Signal Line Connection

Important:

that the installation complies with the specific wiring rules applicable to your

country or area of jurisdiction.

AC Output Connector

This is a two terminal barrier strip for use with up to #12 AWG wire. The

two terminals, L1 & L2 are floating outputs, L1 or L2 can be grounded to

simulate a neutral conductor. The barrier strip will accept a maximum lug

width of 0.32 in. (8.1 mm). The recommended torque on the screw is 9 inlbs.

Load Wiring

When selecting load wiring, consider the following factors:

• Current carrying capacity of the wire

• Maximum wire length

• Maximum ambient temperature

• Noise effects on signal lines

Use the table below as a guide to help identify wiring requirements for

permanent connection to an AC distribution box. The distribution box

shall include a 2 pole appropriately rated circuit breaker in series with

each inverter used in an array of units. The guide below applies for up to

2.5m long load terminations. Consider other means such as bus bar

distribution for longer runs.

The following procedure should be used as a guide only. Ensure

AC Output Voltage Wire

120 Minimum 3 x 16 AWG (2 wire plus safety ground),

stranded copper 105°C, 300 V

220-230 Minimum 3 x 16 AWG (2 wire plus safety ground),

stranded copper 105°C, 300 V

TM-DIOP-01XN-01 2-9

Page 30

Rack Mount Frame Assembly and Installation

Load Connection

WARNING

Exercise caution when making connections to a rack in an existing installation.

Ensure all input and output breakers are de-energized and that adjacent racks are

also powered down.

1. If necessary, remove the output cover by loosening the two securing

nuts. Release the clamp on the strain relief and insert one end of the

load wire

2. Strip and install appropriately sized spade or ring terminals on the two

load lines. Only use a ring type terminal for the safety ground

connection.

[70 mm]

1.97"

[50 mm]

2.76

"

GROUND

LINE 1

LINE 2

3. Loosen or remove the two screws on the barrier strip and insert the

load connections noting polarity if neutral is chosen. Tighten screws

to secure.

4. Connect the safety ground wire to the ground stud provided. The

ground stud accepts a 0.2 in. (5 mm) #10 diameter ring terminal.

5. Route the load wires inside the cover to prevent pinching but with a

sufficient service loop. Replace cover and secure. Tighten clamping

screw on strain relief to secure wire in place.

2-10 TM-DIOP-01XN-01

Page 31

User Line Connection

Overview

The User-line interface provides basic remote control and monitoring on

the Inverter using TTL logic signals. The available signals are an Inverter

on/off input, fault and Inverter-on flags as well as a configurable auxiliary

line. The aux output can only be configured when the Ethernet option

card is installed. The user lines are optically isolated with typical source/

sink capability of 10 mA. To prevent damage to this interface, do not

exceed 40 mA of source/sink current.

CAUTION

Do not bias this port more than 50 V DC to chassis.

AC Load and Signal Line Connection

Figure 2-7

TM-DIOP-01XN-01 2-11

User Lines Schematic

Page 32

Rack Mount Frame Assembly and Installation

User Line Connector

The user-line is a 6-position wire clamp connector adjacent to the DC

input connector. Table 2-1 lists user functions and associated terminal

numbers.

User Line Wiring

Use twisted pairs of 22-24 AWG for connections. Before making any

connections, ensure power to the rack has been disconnected. Carefully

route the wires away from high power load cables to minimize noise

effects on signal integrity .

User Line Connection

Use this table to wire appropriate signals.

Table 2-1

Terminal Label I/O Logic Level Function

1 User line return GND GND GND reference

2 User shutdown Input Active high Shuts down

3 Fault Flags Output Active high Inverter faults

4 AUX flag Output N/A User configurable

5 Inverter flag Output Active high Inverter on-line

6 Not used N/A N/A N/A

User Line Connection

inverter

User line voltages are below:

Inputs

High

Low

Outputs

High

Low

1.25 V to 5 V

0.0 V to 1.25 V

5V

1.5 V max.

2-12 TM-DIOP-01XN-01

Page 33

CAN/SYNC Connector

Overview

The CAN/SYNC connector provides access to functions necessary for

operation of multiple units in parallel, series or three phase. The

connector is a 7-position wire clamp adjacent to the user-line. T w o sets of

signals are provided on this connector:

• Can-bus: Paralleled units relay data necessary to achieve load sharing

between units using this arbitration bus. The protocol used is

proprietary hence cannot be and should not be interfaced to different

products.

• Sync-lines: Used to configure and synchronize units in parallel, series

or 3 phase.

Specifications:

Maximum number of units 10

Bus Speed 1 Mb/sec

Termination 120 Ω 1/4 W

AC Load and Signal Line Connection

Addresses 1 to 10

CAN/SYNC Connection

Table 2-2 outlines the pinout of the terminal. See connection schemes for

wiring method applicable to your requirements.

TM-DIOP-01XN-01 2-13

Page 34

Rack Mount Frame Assembly and Installation

CAN/SYNC Wiring

Due to high bus speed, use shielded twisted pairs of 22-24 AWG for

improved noise immunity . Before ma king any connections, ensure power

to the rack has been disconnected. Carefully route the wires away from

high power load cables to minimize noise effects on signal integrity.

Table 2-2

Terminals Function

1 Return/GND

2 CAN-LO

3 CAN-HI

4 Return/GND

5 SYCN-OUT 240 degrees

6 SYCN-OUT 120 degrees

7 SYCN-OUT 0 degrees

CAN/SYNC Pin-out

2-14 TM-DIOP-01XN-01

Page 35

Connection Schemes

CAUTION

Before attempting any connections, ensure power to rack is off by de-energizing

input and output circuit breakers.

This section covers the realization of different output configurations available

with this product line.

Stand-Alone Operation

A 120 Ohm resistor should be connected across the CAN-hi and CAN-lo

terminals to properly terminate the bus. No other connections to this port

are necessary for single unit operation.

Parallel Operation

When operated in this mode, up to ten XDI inverters can operate on a

single bus by daisy chaining the canbus lines. Any additional units above

this will still operate autonomously and not participate in load sharing

arbitration. At power-up, the first ten units to access the bus acquire a

unique I.D. each, beyond which no more I.D.s are made available. No

unique master exists in a parallel system. All units continuously execute a

complex algorithm to determine the load current based on the number of

units online and the highest individual current. This ensures no

interruption to the load should any unit in the system fail or is turned off.

Connection Schemes

Connection

• Make connections to the CAN/SYNC connector using its screw-type

wire clamps. It may be necessary to remove the mating connector to

facilitate connections to the terminal. Daisy chain the CAN-bus lines

across all units in parallel (i.e. all CAN-hi terminals are connected

together and likewise for CAN-lo). 120 Ohm terminating resistors

must be connected across the CAN terminals of the first and last units

in the chain.

• Also daisy chain the “SYNC-OUT 0” and “return” terminals on the

connector. This provides phase lock between paralleled units. See

Figure 2-8.

TM-DIOP-01XN-01 2-15

Page 36

Rack Mount Frame Assembly and Installation

Figure 2-8

Parallel Operation

L1

1

L2

L1

L2

1

L1

L2

1

7

5

3

26

4

7

5

36

2

4

75

36

4

2

• The AC output load wires are also connected in parallel ensuring only

like terminals L1 and L2 are connected together at the distribution

bus or load. Each inverter output should be in series with a suitably

rated two pole circuit breaker before being terminated at the load.

2-16 TM-DIOP-01XN-01

Page 37

Split Phase Operation

Use this scheme to extend the output voltage. No more than two units

should be connected in series though more can be added in parallel with

either series unit.

To connect two units for split voltage, proceed as follows:

• First ensure power to the rack has been disconnected. make

connections to the CAN/SYNC connector using its screw-type wire

clamps. It may be necessary to remove the mating connector to

facilitate connections to the terminal

• Start with the phase synchronizing lines on the CAN/SYNC

connector. W ire the “SYNC_OUT 0” and “RETURN” of the first unit

in the top phase to those of the first unit in the bottom phase.

• To add units in parallel on either top or bottom phase, see “Parallel

Operation” on page 2–15 for wiring details.

• To create the Split-voltage between the top phase and bottom phase,

connect the L2 terminals of the first group to L1 terminals of the

second group. This node must also be connected to safety ground.

• This leaves L1 of top phase and L2 of bottom phase as the output

terminals. These should be connected to the load or distribution bus

using a suitably rated circuit breaker.

Connection Schemes

Load Terminal Voltage Output Voltage

120 V model 230 V model

T erminal - Terminal (L1-L2) 240 460

Terminal - Chassis (L1-GND or L2-GND) 120 230

TO TOP PARALLEL UNITS

L1

2-POLE BREAKER

L2

Figure 2-9

Split-Phase Operation

L1

L2

L1

L2

5

7

36

4

21

357

26

4

1

TO BOTTOM PARALLEL UNITS

UNIT 1

UNIT 2

TM-DIOP-01XN-01 2-17

Page 38

Rack Mount Frame Assembly and Installation

Three Phase Operation

Overview

XDI inverters can be configured for 3-phase operation where necessary.

Synchronizing signals are used to achieve this functionality, precisely

phase locking the units at 120 phase displacement. For single units this

results in a 6kVA 3-phase source but up to 2 more units can be added to

each phase to increase capacity. (See “Parallel Operation” on page 2–15

for wiring details.) The units can be configured for 3-phase, 4-wire or 3phase,3-wire depending on the load setup.

Table 2-3

Wiring

Configuration Circuit

3-Phase Configurations

Output

Terminals Model Voltage

120 V 230 V

3-phase, 3-wire

(DELTA)

L1

L2

L3

GND

3-phase, 3-wire (Y) Line Voltage 208 230

3-phase, 4-wire (Y) Phase Voltage

L1

L2

L3

GND

L1

N

L2

L3

GND

Line/Phase

Volta ge

Line Voltage

120 230

120

208

230

398

2-18 TM-DIOP-01XN-01

Page 39

3-Phase Synchronization and Signal Wiring

3-Phase Synchronization and Signal Wiring

Figure 2-10

L1

L2

L1

L2

L1

L2

3-Phase Sync Connection

5

3

4

6

21

5

3

26

41

5

1

36

4

2

7

7

7

Refer to Table 2-2 for the signal pinouts.

To achieve proper three-phase output, units configured for each phase

need to be wired to the appropriate phase. Extra care should be exercised

when multiple paralleled units are also wired for 3-phase operation. In

this case it is advisable to group all parallel inverters belonging to the

same phase together in a rack.

• First ensure power to the rack has been disconnected. Make

connections to the CAN/SYNC connector using its screw-type wire

clamps. It may be necessary to remove the mating connector to

facilitate connections to the terminal.

• T wisted bundles of four multi-colored wires should be used for easier

identification.

• Start with unit in Phase-1, wire from “SYNC-OUT 0” in this phase to

“SYNC-OUT 120” of Phase-2 and “SYNC-OUT 240” of Phase-3.

• Next, Connect a different color wire from “SYNC-OUT 120” of

Phase-1 to “SYNC-OUT 240” of phase-2 and “SYNC-OUT 0” of

Phase-3.

• Connect a different color wire from “SYNC-OUT 240” of Phase-1 to

“SYNC-OUT 0” of phase-2 and “SYNC-OUT 120” of Phase-3.

• Lastly , connect all “R ETURN” lines together.

• See section on “Parallel Operation” on page 2–15 to connect

additional units to each phase.

TM-DIOP-01XN-01 2-19

Page 40

Rack Mount Frame Assembly and Installation

3-Phase, 3-Wire Delta Output Wiring

L1

L2

L1

L2

L1

L2

• All outputs should be wired through an appropriately rated circuit

breaker.

• On Phase-1, Connect terminal L1 to phase-3 Terminal L2.

• On phase-1, connect terminal L2 to phase-2 terminal L1.

• On phase-2, connect terminal L2 to phase-3 terminal L1.

3-Phase, 3-Wire Y-Connection Output Wiring

L1

L2

L1

L2

L1

L2

• All outputs should be wired through an appropriately rated circuit

breaker.

• Connect L2 terminals of the three phases to a common bus.

• Wire L1 of phase-1 to Line-1 output.

• Wire L1 of phase-2 to Line-2 output.

• Wire L1 of phase-3 to Line-3 output.

2-20 TM-DIOP-01XN-01

Page 41

3-Phase, 4-Wire Y-Connection Output Wiring

This scheme is the same as the preceding with the addition of a neutral

connection.

L1

L2

L1

L2

L1

L2

• All outputs should be wired through an appropriately rated circuit

breaker.

• Connect L2 terminals of the three phases to the neutral bus.

• Connect L1 of phase-1 to Line-1 output.

• Connect L1 of phase-2 to Line-2 output.

• Connect L1 of phase-3 to Line-3 output.

Ethernet Port

Ethernet Port

Network connection to each inverter module is made through a standard

RJ-45 connector mounted on the rack mount frame assembly.

TM-DIOP-01XN-01 2-21

Page 42

2-22

Page 43

Inverter Module

3

Installation and

Operation

Chapter 3 contains information and procedures for installing

and using the

This chapter describes the following:

• installing the

• setting up the inverter

• protections and alarms

• maintaining the

XDI Inverter.

inverter

inverter

Page 44

Inverter Module Installation and Operation

Installation into Rack Mount Frame

WARNING

During the installation or removal of the inverter, ensure that the power switch

(see Figure 3-2) is in the off position.

Installing To install an inverter module, slide it into a pre-wired rack mount frame

until the mounting ears are flush with the front of the rack. In order to

prevent the inverter from being accidentally displaced from its proper

position, apply the captive screws.

The mating of the inverter with the rack mount frame should be

established without excessive force. If the unit does not slide into the rack

mount frame completely, please verify that the rack mount frame was

assembled and installed into the equipment rack according to “Installation

Into Cabinet Style Equipment Racks” on page 2–5 or “Installation into

Relay Racks” on page 2–6.

The inverter is a forced air cooled device. Please observe that the air

intake and exhaust are not blocked (refer to “Initial Inspection” on

page 2–2).

Please refer to Figure 3-1.

3-2 TM-DIOP-01XN-01

Page 45

Installation into Rack Mount Frame

Figure 3-1

1

1

Figure 3-2

Installing an Inverter into a Rack

2

3

2

3

4

4

Inverter Front Panel

5

5

1. Captive Screw

2. Handle

3. Power Switch

4. Air Intake Vents

5. “Fault” and “ON” LED’s

Uninstalling To uninstall the inverter module, release the captive screws and slide the

module out.

TM-DIOP-01XN-01 3-3

Page 46

Inverter Module Installation and Operation

Operation of Inverter Module

Theory of Operation

The XDI is a digitally controlled power converter. It provides galvanic

isolation from the DC input to the AC output. The isolation stage is a

resonant full-bridge converter and the inversion stage is a highly efficient

class D amplifier (patent pending).

Depending on the rack wiring, inverters can operate in stand-alone,

parallel, 3-phase or split-phase mode. Details on rack wiring are in

Chapter 2.

When paralleled there is no master unit and each unit adjusts its own

power level for best power sharing.

The user interface lines and the optional Ethernet provide a convenient

way to remotely control and monitor the status of each Inverter in the

rack.

All user lines (see Figure 2-3) as well as communication lines between the

units (CANbus and synchro lines - see Figure 2-3) are isolated from the

input DC and output AC power potential.

System Startup

Turn the front panel switch (see Figure 3-2) to the ON position to enable

the inverter.

At power-on, the unit enters into a self-diagnostic mode to check that the

inverter is functioning correctly and no alarm conditions exist. During

this short delay (about 10 seconds), the “Standby/ON” Indicator (see

Figure 3-2) will flash green. Once the unit has completed its selfdiagnosis and everything is functioning correctly, by default the inverter

output will turn on. The “Standby/ON” indicator will remain solid green

and he power will be delivered to the output AC terminals (see Figure 2-

3).

3-4 TM-DIOP-01XN-01

Page 47

Standby Mode

Cooling Fans

Operation of Inverter Module

This low power state allows your inverter to recommence operation

quickly but conserves power in the meantime. In this mode the output to

your inverter remains OFF and the green “S tandby/ON” LED (see Figure

3-2) on the front panel flashes. The “Standby” mode can be initiated via

the user interface lines (see Figure 2-3) or via an optional Ethernet

connection.

Please note that during the self diagnostic mode, the flashing of the green

LED is with approximately 50% duty cycle. During the standby mode the

flashing is significantly slower (with approximately 10% duty cycle, this

is referred to as “short flash”.)

To improve operating efficiency and extend fan lifespan, fan speed is

controlled by the XDI’s microprocessor. When the XDI’s internal

temperatures are below a safe threshold the fans will remain off. As the

internal temperatures rises, fan speed will smoothly increase to the

maximum.

TM-DIOP-01XN-01 3-5

Page 48

Inverter Module Installation and Operation

User Interface

Front Panel

User Lines

Table 3-1

Red LED Green LED Function

ON OFF A con tinuously incompatible operating condition

OFF ON Regular operating conditions. Output is on and

OFF fast flashing Self-Diagnostic mode. Prior to enabling the

OFF slow-short flash Stand-by mode.

Front Panel LED Functions

exists and an alarm has tripped. See “Protections

and Alarms” on page 3–7). The inverter is

automatically turned off until the fault/alarm has

been cleared.

delivering power.

inverter the unit always performs a self-check and

diagnostics.

The port with user lines is located at the rear panel of the rack mount

frame (Figure 2-3). See Figure 2-7. The following table lists the signals:

Table 3-2

Pin Name Function

1 User_Ground All user lines are referenced to user_gnd. User_gnd is

2 Shut_Down This is an input pin. The input impedance is 100 Ω in

3 Fault_Flag This is an output pin. A logic high (5 V) indicates that an

4 Auxiliary_Line This is an output pin. The functionality of this user line is

5 Inverter_On This is an output pin. A logic high (5 V) indicates that the

User Line Pins

isolated from both the input DC power and the output AC

power.

parallel with 20 pF . A logic high (1.25 V to 5 V) would set

the inverter into Standby Mode (see page 3–5). If pin 2 is

floating, the internal pull_down resistor of 100 Ω will

force a logic “0” and this pin becomes inactive.

alarm has tripped. The output of the inverter is, therefore,

disabled.

factory preset. It can be user configured if the Ethernet

option is installed.

inverter is in an “on” state and delivering AC power to the

AC output power terminal.

3-6 TM-DIOP-01XN-01

Page 49

Protections and Alarms

Overview

The Digital Signal Processor (DSP) in the inverter continuously monitors

a number of parameters for purposes of protecting the power source, load,

inverter and user from hazardous conditions. Fuses on the DC input and

AC output provide additional hardware fault protection. An alarm is

triggered whenever a fault is detected. The protective action in the case of

a fault is to turn the inverter off. The inverter then enters a self-diagnosis

loop until the fault causing the alarm clears. This also clears the alarm in

the fault register and allows the inverter to resume normal operation. If an

alarm is tripped the fault flag on the user port as well as the red front panel

indicator will be active.When equipped with the Ethernet option, the

actual fault condition causing the alarm can be queried.

Input Voltage Protection

The inverter will continuously operate from an input source in the range

of -35 to -75 Vdc. Should the input voltage fall outside this range for

more than 4 seconds, the inverter output is disabled and internal relays

open to isolate the load and source. In this condition, the red LED on the

front panel is lit and fault flag on the user port is set high. The inverter

resumes normal operation as soon as the input is within acceptable limits

for 2 seconds.

Protections and Alarms

Output Voltage Protection

The output is monitored for conditions potentially damaging to the

inverter or load. A voltage exceeding 140 Vac (263 Vac for the 230 V

model) at the inverter output for over 1 second, or a voltage below 80 V

(154 Vac for the 230 V model) for more than 5 seconds will cause the

inverter to shut down and open the internal load relay. This fault condition

is reported by setting the fault flag on the user port and fault LED on the

front panel. The DSP continues to check for compatible output conditions

before enabling the inverter and switching to “on-line” status.

TM-DIOP-01XN-01 3-7

Page 50

Inverter Module Installation and Operation

Overload Protection

The inverter will deliver the rated load power continuously at the rated

ambient temperature. It will also reliably operate up to 1600 Watts

without further restriction on the maximum ambient temperature. The

internal temperatures of critical components monitored by the DSP will

determine operating time at this overload range. Beyond 1600 Watts, the

DSP computes the power and extrapolates the operating time at that

power level before shutting down. The maximum overload rating is

3000 Watts for 5 seconds. After each overload trip event, the inverter

re-starts after a 10-second pause. Should three such events occur within a

2-minute interval, the inverter shuts down permanently . Normal operation

can be restored by clearing the alarm (see “To Clear an Alarm” on

page 3–11) or using the front panel switch.

3500

3000

OVERL OAD OP ERATION

2500

2000

1500

1000

Output Power (W)

500

0

0 5 10 15 20

Time (s)

Figure 3-3

3-8 TM-DIOP-01XN-01

Overload curve

Page 51

Over Temperature Protection (OTP)

This feature protects critical components from failure due to temperature

stress should a fan fail or the ambient temperature or internal temperature

exceed acceptable levels. This module also controls the fans, turning them

on when internal temperatures exceed 35°C and increasing fan speed in

proportion to increase in temperature. When an OTP event occurs, the

Inverter shuts down and the fault flag is set on the front panel and userline port. Fans maintain operation at maximum speed until internal heatsink temperatures drop below 70°C at which point the inverter re-starts.

Short-circuit Protection

The inverter output is short-circuit proof. The DSP detects a sustained

short-circuit (greater than 2 seconds) and shuts down the inverter to

protect the load. The inverter will attempt to power the load a total of

three times in a 4-second window before permanently shutting down.

After clearing the load fault, normal operation can be restored (see “To

Clear an Alarm” on page 3–11).

Over-Current protection

Protections and Alarms

The inverter can reliably deliver up to 50 A of peak current without

tripping any protections. Two levels of protections are provided. The first

level of protection is hardware based, providing peak current clipping at

50 A. Should the current exceed this (e.g. in the event of severe backfeed) the DSP forces the inverter to skip a line cycle. Three consecutive

line cycle skips will force a reset of the inverter where the output is

temporarily disabled for about 4 seconds or until the back-feed falls away .

Internal Diagnostics

Upon power-up or fault event, the inverter executes a sequence of internal

diagnostics checking for compatible conditions at the DC input, output

and selected internal modules. Different alarms cause execution of

differing diagnostic sequences. All preceding fault conditions are

continuously monitored as part of the internal diagnostics routine. In

addition, the internal bus voltage, which is the inverter voltage source is

also monitored. The diagnostic module checks to ensure this is within

limits at start-up and continuously during normal operation. A failure of

this bus sets the fault flag on the front panel and user-line port and

disables the inverter. Normal operation resumes when within limits.

TM-DIOP-01XN-01 3-9

Page 52

Inverter Module Installation and Operation

Fuses and Grounding

The inverter is equipped with non-user replaceable, internal fuses for fault

protection. The input fuse (fuse F1) is rated at 60 A, 170 Vdc, 100 kA 1R

and positioned in the return path. Both L1 and L2 output ports are

protected with slow acting fuses (fuses F2 and F3). The fuse ratings are

model dependant and as follows:

XDI2048 120 V output: 20 A 250 V

XDI2048 230 V output: 12 A 250 V

Grounding studs are provided adjacent to the DC input and AC output

ports. The equipment must be grounded at these locations as required by

end applications and local regulations. See Chapter 2, “Rack Mount

Frame Assembly and Installation” for connection details.

Incorrect Connection Protection

• Input contactor will not close for normal startup with reverse polarity

input connection.

• The output contactor will not close if AC back feed is detected on

power up or if a unit is unable to synchronize to the AC bus.

• The output fuse will open for output faults not covered by internal

protection circuitry.

Output (AC) Alarm

The following conditions will cause an output alarm:

• Output overload

• Output short circuit

• Output Over-voltage

•Over-temperature

• Module failure

When such a condition exists,

1. The red FAULT indicator located on the front panel is turned on,

2. The open collector “Fault” alarm output is energized,

3. The output contactor is opened and the inverter output is disabled.

Except in the case of an Output Overload when the module will

continue to run for a short period, depending on the overload power,

prior to shutdown.

3-10 TM-DIOP-01XN-01

Page 53

To Clear an Alarm

Depending on the cause of the alarm, the alarm may be cleared

automatically as soon as the fault condition has elapsed. In some cases,

the alarm is cleared by:

• cycling the ON/OFF switch on the rear panel,

• toggling the Shut_Down user line,

• or toggling between Standby and Active buttons on the Web Browser

Maintenance

Maintenance

interface (if Ethernet Option is being used).

Periodic

Cleaning

Fan Filter

Replacement

Whenever a unit is removed from operation, clean the outside surfaces

with a weak solution of soap and water. If required, use low-pressure

compressed air to blow dust from in and around components on the

printed circuit boards.

The XDI is fitted with disposable fan filters which prevent the entry of

dust and debris into the unit. These filters should be inspected every six

months. When the filters become dirty they can be replaced as shown in

Figure 3-4.

TM-DIOP-01XN-01 3-11

Page 54

3. Remove the Fan Bracket

2. Remove the Cover1. Unscrew the Cover

5. Remove the Fan and Fan Filters4. Remove the Front Panel

Figure 3-4

3-12

Replacing the Fan Filters

Page 55

Remote

4

Communication &

Monitoring

Chapter 4 contains information and procedures for using the

Ethernet to provide remote communication and monitoring.

This chapter describes the following:

• setting up the computer and inverter for the first time

• using the Ethernet to remotely communicate with the

inverter

• setting up and using the Web interface

Page 56

Remote Communication & Monitoring

Introduction

When installed, the optional TCP/IP enabled Ethernet communications

card and user interface provides remote monitoring and ON/STBY

control of a Xantrex Datacom Inverter module.

Web-enabled User Interface

• Provides monitoring capability: Pout, Vout, Iout, On/Stby Status,

Inverter model/version, and Fault Condition (if exists)

• Provides control capability: Remote On/Stby control of inverter

• Provides pro-active Fault Alarm: Emails SRQ to user-specified email

address

• Output Current, Iout

• On/Stby Status

• Inverter model/version

• Fault Condition Query

Initial Setup

Introduction

To use the XDI Inverter Ethernet Interface Card, you must have the

following equipment:

• A compatible model of inverter

• CAT5/CAT5e patch cable if you want to connect over the network

• Computer with Ethernet installed

• Web browser program

The Ethernet interface is usually installed in the inverter at the factory.

Your local distributor or service center can also install the interface,

especially for use in a previously-purchased inverter already on site. The

Ethernet interface card will be configured with default settings (Table 4-

1).

4-2 TM-DIOP-01XN-01

Page 57

Initial Setup

[96 mm]

Figure 4-1

Important:

The only way to configure the interface card is through the

Ethernet port using TCP/IP protocol. Therefore, the Ethernet interface must be

set up properly the first time. Once it is setup, the parameters (such as, password

and IP address) should be saved in a safe place. Table 4-2 is provided to record

your settings after they have changed.

3.45 " [88 mm]

Ethernet Board Top View Ethernet Board Bottom View

Ethernet Interface PCB

TM-DIOP-01XN-01 4-3

Page 58

Remote Communication & Monitoring

How to Setup For the First Time

Hardware Setup

In order to communicate to the XDI Ethernet for the first time, you will

need a CAT5/CAT5e cable and a computer with an Ethernet adapter

installed.

Setting up to configure for the first time:

1. Wire up the rack mount assembly as stated in Chapter 2.

2. Connect to the unit as shown in Figure 4-2, “First Time Setup

Connections” on page 4–4.

3. Turn on the inverter.

4. Configure the computer’s Ethernet adapter settings (contact Network

Administrator).

5. Open your Web browser and go to the default IP address (Table 4-1).

Special cross-over cable required

PC

Network Setup (PC to

Inverter)

Inverter

OR

PC

Network Setup (PC to Hub to

Figure 4-2

4-4 TM-DIOP-01XN-01

First Time Setup Connections

Hub

Inverter)

Inverter

Page 59

Ethernet Setup

Initial Setup

You must run a Web browser to communicate and configure the XDI

Ethernet. Microsoft Internet Explorer or Netscape Communicator are

such examples.

Important:

Ensure the computer’s IP address and sub-net mask are compatible with the

unit’s. (contact network administrator for details).

Ensure that the unit’s IP address is unique on the network.

Configure Ethernet settings:

1. Run your Web browser program.

2. In the address box type in the “Default IP” (Table 4-1).

3. Select the “Setup” link located on the upper left hand side.

4. Configure the Ethernet settings to your unique setup (see “Setup

Page” on page 4–15).

Table 4-1

Setting Default Value

Default IP 192.168.1.1

Gateway IP 0.0.0.0

Sub-Net Mask 255.255.255.0

Domain Name Server 1 0.0.0.0

Domain Name Server 2 0.0.0.0

SMTP (email) Server none

Email Alert Address none

Password 12345

Default Settings

Important:

changed to a value where communication can not be established any more, a hard

reset must be done (see “Resetting” on page 4–6).

TM-DIOP-01XN-01 4-5

Be careful when you change the network settings. If they are

Page 60

Remote Communication & Monitoring

You can use Table 4-2 to record your own settings.

Resetting

Table 4-2

Setting V alue

Default IP

Gateway IP

Sub-Net Mask

Domain Name Server 1

Domain Name Server 2

SMTP (email) Server

Email Alert Address

Password

User Configured Settings

To reset the Ethernet settings the cover will have to be removed to put a

jumper onto the control card. When the Ethernet is reset, its settings will

be changed to the default values as shown in Table 4-3.

To reset the Ethernet:

1. Remove the XDI unit from it’s rack mount.

2. Remove the top cover (Figure 4-3, “Removing Unit’s Top Cover” on

page 4–7).

3. Place a jumper on SW2 (Figure 4-4, “Ethernet Reset Jumper” on page

4–8).

4. Replace top cover.

5. Apply power to the XDI by putting it back into the rack mount and

turning the unit on.

6. Wait 10 seconds.

7. Remove the XDI from the rack mount.

8. Remove the top cover.

9. Remove the jumper on SW2.

10. Replace the top cover.

4-6 TM-DIOP-01XN-01

Page 61

Initial Setup

Table 4-3

Setting Reset Value

Default IP 192.168.1.1

Gateway IP 0.0.0.0

Sub-Net Mask 255.255.255.0

Domain Name Server 1 0.0.0.0

Domain Name Server 2 0.0.0.0

SMTP (email) Server not changed

Email Alert Address not changed

Password 12345

Reset Settings

Figure 4-3

TM-DIOP-01XN-01 4-7

Removing Unit’s Top Cover

Page 62

Remote Communication & Monitoring

Ethernet configuration

reset jumper (SW2)

Figure 4-4

Ethernet Reset Jumper

4-8 TM-DIOP-01XN-01

Page 63

Operating Instructions

Introduction

The Ethernet interface card allows you to monitor/configure settings

using a Web page. It also adds email functionality to the XDI. The unit

will automatically send an email when it is powered up or when there is a

fault condition.

This section describes how the Web page and email works.

Network Connection

This configuration is used when you want to communicate to one or more

XDI inverters over a network. In order to use network connection the

network settings on the XDI’s Ethernet interface card must be configured

properly. Chapter 2 describes how to configure the network settings for

the first time.

Setting up to communicate using network connection:

1. Wire up the rack mount assembly as stated in the XDI manual.

Operating Instructions

2. Connect the XDI to a network.

3. Turn on the inverter.

4. Wait for an email that will be sent to the configured “Email Alert

Address”.

5. Run a Web browser program on the computer.

6. In the address box of your browser, type in the configured IP address

sent in the email.

Important:

browser to access its Web page at any one time.

TM-DIOP-01XN-01 4-9

Each XDI Ethernet on the network will allow only one Web

Page 64

Remote Communication & Monitoring

Special cross-over cable required

PC

PC

PC

Inverter

Network Setup (PC to Inverter)

InverterHub

Network Setup (PC to Hub to Inverter)

DHCP Server

Inverter

Inverter

Inverter

Figure 4-5

Hub

PC

Network Setup (Full Network)

Network Setup

4-10 TM-DIOP-01XN-01

Page 65

Using DHCP

Operating Instructions

A DHCP server is used to obtain a dynamic IP that is unique on the

network. To enable DHCP, set the default IP to “0.0.0.0”. On power up

the Ethernet interface card will request a unique IP address from the

DHCP server which it will set as its active IP address.

If the “SMTP (email) Server” and “Email Alert Address” is setup

properly the Ethernet interface card will send an email with the obtained

IP address to be used on your Web browser.

On power up, if the default IP address is set to “0.0.0.0” the “Gateway IP”

will be reset to “0.0.0.0” as well so that it could obtain a valid gateway IP.

This is done to facilitate the use of the XDI on different networks when

using DHCP. If the default IP is static, the gateway IP is left unchanged.

Important:

directly to the inverter (without a DHCP server), the unit’s active IP will also be

“0.0.0.0”and communication to the inverter will not be possible.

To correct the problem, connect the inverter back onto the network using DHCP

or reset the Ethernet (see “Resetting” on page 4–6).

What Power On Does

During power on the Ethernet interface card takes approximately 8

seconds to initialize. If a DHCP server is used, the card resets the gateway

IP and attempts to get a new active IP and gateway. Once initialization is

completed, the card will attempt to enable its Web server. It will do so for

the next minute. If successful, it attempts to send an email to the

configured “Email Alert Address” using the configured “SMTP Server”

(see “Network Connection” on page 4–9).

If you set the default IP to “0.0.0.0” and you connect a computer

TM-DIOP-01XN-01 4-11

Page 66

Remote Communication & Monitoring

Password

The Web page interface is password protected. See “Password” on

page 4–12 for the default password. The Web page uses the industry

standard MD5 algorithm to authenticate the remote user.

Network configurations (Default IP, SMTP Server etc.) are protected with

one password (at+iRPG) and all other settings (for example, Monitor

Refresh Rate and Standby) are protected by another (at+iWPWD). For

simplicity, the Web interface will set both passwords to the same value.

Therefore, when you try to change a parameter, a password prompt may

appear twice. After submitting a password you can freely change

parameters for 10 minutes.

Figure 4-6, “Password Confirmation Boxes” on page 4–12 shows the

screen that will appear when both passwords are needed. There may be

only one box at other times. Enter the previously saved password into

both boxes and select “Submit”.

Passwords must be 4 to 10 characters long. To disable the password enter

a new password with blanks in the Setup Page (see page 4–15).

Important:

following the procedure described in “Resetting” on page 4–6.

Figure 4-6

If you forget the password, you can reset all the parameters by

Password Confirmation Boxes

4-12 TM-DIOP-01XN-01

Page 67

Automatic Power-On Email

When the inverter is turned on, it will attempt to send an email to the

configured “Email Alert Address” using the configured “SMTP Server”.

Contents of the email:

From: XDI <serial number>

To: <Email Alert Address>

Subject: Unit powered on

Body:

IP address: <IP_address>

How to Use the Web Interface

To communicate to the Web interface the active IP must be entered into

the “Address” box of your Web browser. i .e. “192.168 .1.1”. The “Man age

page” will be displayed and it will contain links to monitor and setup the

inverter. You will have access to the “Manage page”, described on

page 4–14, the “Setup page”, described on page 4–15, and the “Monitor

page”, described on page 4–17 .

Operating Instructions

TM-DIOP-01XN-01 4-13

Page 68

Remote Communication & Monitoring

Manage Page

The “Manage page” is the first page of the Web page. It contains

information about the inverter as well as buttons to put the unit into or out

of standby mode.

Figure 4-7

4-14 TM-DIOP-01XN-01

Manage Page of Web Interface

Table 4-4

Object Description

Active Button Puts the unit into active mode. The inverter’s output

Standby Button Puts the unit into standby mode. The inverter’s output

DSP Firmware Version Current version of the inverter’s control DSP

Manufacturer inverter manufacturer

Serial Number Programmed inverter serial number

Manage Link Link to same page

Monitor Link Link to Monitor Page

Setup Link Link to Setup Page

Manage Page of Web Interface

is enabled.

is disabled.

firmware.

Page 69

Setup Page

Operating Instructions

The “Setup page” allows the user to set the Ethernet interface card’s

network setting, email settings and refresh rate. It is important that the

network settings are correct to ensure proper communication.

Important:

Contact Network Administrator for more information.

Figure 4-8

TM-DIOP-01XN-01 4-15

Setup Page of Web Interface

Page 70

Remote Communication & Monitoring

Table 4-5