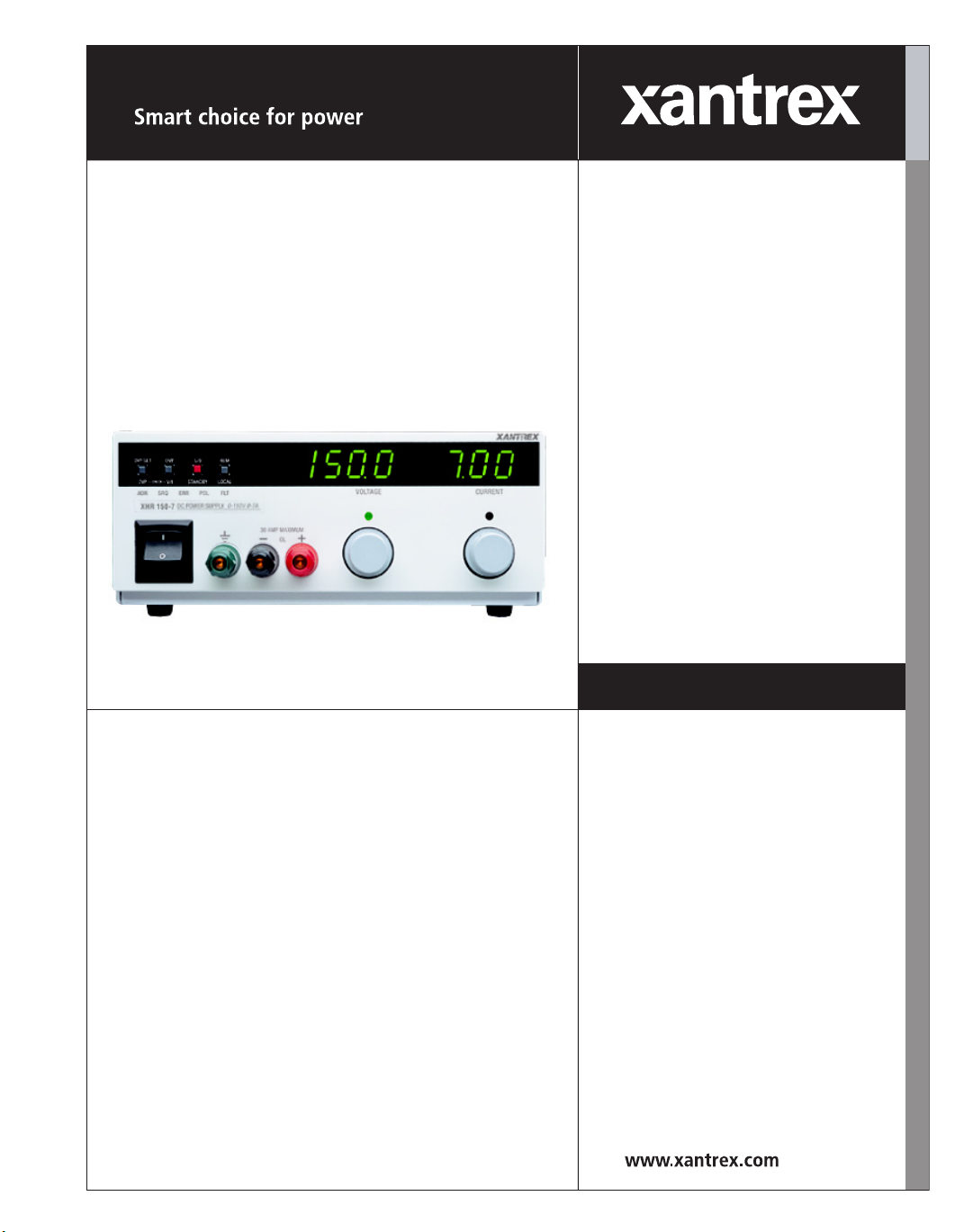

XHR 1000 Watt Series

Programmable DC

XHR 7.5-130

XHR 20-50

XHR 33-33

XHR 40-25

XHR 60-18

XHR 100-10

XHR 150-7

XHR 300-3.5

XHR 600-1.7

Operating Manual

Power Supply

Operating Manual for

XHR Series

Programmable DC

Power Supply

Limited

Warranty

What does this warranty cover and how long does it last?

This Limited Warranty is provided by Xantrex Technology, Inc. (“Xantrex”) and

covers defects in workmanship and materials in your XHR 1000 Watt Series DC

Power Supply. This warranty lasts for a Warranty Period of 5 years from the date of

purchase at point of sale to you, the original end user customer.

What will Xantrex do?

Xantrex will, at its option, repair or replace the defective product free of charge,

provided that you notify Xantrex of the product defect within the Warranty Period,

and provided that Xantrex through inspection establishes the existence of such a

defect and that it is covered by this Limited Warranty.

Xantrex will, at its option, use new and/or reconditioned parts in performing

warranty repair and building replacement products. Xantrex reserves the right to use

parts or products of original or improved design in the repair or replacement. If

Xantrex repairs or replaces a product, its warranty continues for the remaining

portion of the original Warranty Period or 90 days from the date of the return

shipment to the customer, whichever is greater. All replaced products and all parts

removed from repaired products become the property of Xantrex.

Xantrex covers both parts and labor necessary to repair the product, and return

shipment to the customer via a Xantrex-selected non-expedited surface freight

within the contiguous United States and Canada. Alaska and Hawaii are excluded.

Contact Xantrex Customer Service for details on freight policy for return shipments

outside of the contiguous United States and Canada.

How do you get service?

If your product requires troubleshooting or warranty service, contact your merchant.

If you are unable to contact your merchant, or the merchant is unable to provide

service, contact Xantrex directly at:

Phone: 604 422 8595

Toll Free North America: 1 800 667 8422

Fax: 604 421 3056

Email: info@xantrex.com

ii Operating Manual for XHR Series Power Supply

Direct returns may be performed according to the Xantrex Return Material

Authorization Policy described in your product manual. For some products, Xantrex

maintains a network of regional Authorized Service Centers. Call Xantrex or check

our website to see if your product can be repaired at one of these facilities.

In any warranty claim, dated proof of purchase must accompany the product and the

product must not have been disassembled or modified without prior written

authorization by Xantrex.

Proof of purchase may be in any one of the following forms:

• The dated purchase receipt from the original purchase of the product at point of

sale to the end user, or

• The dated dealer invoice or purchase receipt showing original equipment

manufacturer (OEM) status, or

• The dated invoice or purchase receipt showing the product exchanged under

warranty

What does this warranty not cover?

This Limited Warranty does not cover normal wear and tear of the product or costs

related to the removal, installation, or troubleshooting of the customer’s electrical

systems. This warranty does not apply to and Xantrex will not be responsible for any

defect in or damage to:

a. the product if it has been misused, neglected, improperly installed, physically

damaged or altered, either internally or externally, or damaged from improper

use or use in an unsuitable environment;

b. the product if it has been subjected to fire, water, generalized corrosion,

biological infestations, and high input voltage from lightning strikes;

c. the product if repairs have been done to it other than by Xantrex or its authorized

service centers (hereafter “ASCs”);

d. the product if it is used as a component part of a product expressly warranted by

another manufacturer;

e. the product if its original identification (trade-mark, serial number) markings

have been defaced, altered, or removed.

Revision A iii

Disclaimer Product

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED

BY XANTREX IN CONNECTION WITH YOUR XANTREX PRODUCT AND IS, WHERE

PERMITTED BY LAW, IN LIEU OF ALL OTHER WARRANTIES, CONDITIONS,

GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND LIABILITIES, EXPRESS

OR IMPLIED, STATUTORY OR OTHERWISE IN CONNECTION WITH THE PRODUCT,

HOWEVER ARISING (WHETHER BY CONTRACT, TORT, NEGLIGENCE, PRINCIPLES

OF MANUFACTURER’S LIABILITY, OPERATION OF LAW, CONDUCT, STATEMENT

OR OTHERWISE), INCLUDING WITHOUT RESTRICTION ANY IMPLIED WARRANTY

OR CONDITION OF QUALITY, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE TO THE EXTENT REQUIRED UNDER

APPLICABLE LAW TO APPLY TO THE PRODUCT SHALL BE LIMITED IN DURATION

TO THE PERIOD STIPULATED UNDER THIS LIMITED WARRANTY.

IN NO EVENT WILL XANTREX BE LIABLE FOR ANY SPECIAL, DIRECT, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSSES, COSTS OR EXPENSES

HOWEVER ARISING WHETHER IN CONTRACT OR TORT INCLUDING WITHOUT

RESTRICTION ANY ECONOMIC LOSSES OF ANY KIND, ANY LOSS OR DAMAGE TO

PROPERTY, ANY PERSONAL INJURY, ANY DAMAGE OR INJURY ARISING FROM OR

AS A RESULT OF MISUSE OR ABUSE, OR THE INCORRECT INSTALLATION,

INTEGRATION OR OPERATION OF THE PRODUCT.

Exclusions If this product is a consumer product, federal law does not allow an exclusion of

implied warranties. To the extent you are entitled to implied warranties under federal

law, to the extent permitted by applicable law they are limited to the duration of this

Limited Warranty. Some states and provinces do not allow limitations or exclusions

on implied warranties or on the duration of an implied warranty or on the limitation

or exclusion of incidental or consequential damages, so the above limitation(s) or

exclusion(s) may not apply to you. This Limited Warranty gives you specific legal

rights. You may have other rights which may vary from state to state or province to

province.

iv Operating Manual for XHR Series Power Supply

Information WITHOUT LIMITING THE GENERALITY OF THE FOREGOING, UNLESS

SPECIFICALLY AGREED TO BY IT IN WRITING, XANTREX

a. MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY

OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN MANUALS OR

OTHER DOCUMENTATION PROVIDED BY IT IN CONNECTION WITH THE

PRODUCT; AND

b. ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES,

COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF

SUCH INFORMATION.

THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

WARNING:

Limitations

on Use

Please refer to your product user manual for limitations on uses of the product.

Specifically, please note that this power supply is not intended for use in connection

with life support systems and Xantrex makes no warranty or representation in

connection with any use of the product for such purposes.

Xantrex Technology, Inc.

8999 Nelson Way

Burnaby, British Columbia

Canada V5A 4B5

Information

About Your

Power

Supply

Please record the following information when you first open your Power Supply

package:

Model Number ______________________________________________

Serial Number ______________________________________________

Purchased From ______________________________________________

Purchase Date ______________________________________________

Release Revision A (2004-03)

Copyright © 2004 Xantrex Technology Inc. All rights reserved.

Printed in Canada

Revision A v

Warnings

!

!

!

and

Cautions

Power

Supply

Safety

Warnings and cautions are defined and formatted in this manual as shown below.

WARNING

Describes a potential hazard which could result in injury or death, or, a procedure

which, if not performed correctly, could result in injury or death.

CAUTION

Describes a procedure which, if not performed correctly, could result in damage

to data, equipment, or systems.

WARNING—High Energy and High Voltage

Exercise caution when using and calibrating a power supply. High energy levels

can be stored at the output voltage terminals on a power supply in normal

operation. In addition, potentially lethal voltages exist in the power circuit and on

the output and sense connectors of a power supply with a rated output greater

than 40 V. Filter capacitors store potentially dangerous energy for some time after

power is removed.

CAUTION

Operate the power supply in an environment free of flammable gases or fumes. To

ensure that the power supply’s safety features are not compromised, use the

power supply as specified in this manual and do not substitute parts or make any

unauthorized modifications. Contact the service technician for service and repair

help. Repairs must be made by experienced service technicians only.

CAUTION

For Use as a Battery Charger

When you are using any of these power supplies for battery charging applications,

it is essential to provide an appropriately sized fuse or circuit breaker in series

between the power supply output and the battery.

Installation of a protector (fuse or DC circuit breaker) rated for about 115% of the

maximum current rating of the power supply and designed specifically to interrupt

the DC voltage of the battery, will provide adequate reverse polarity current

protection. Where several power supplies are in parallel, it is best to fuse each one,

rather than one large fuse for all.

vi Operating Manual for XHR Series Power Supply

About This Manual

This Operating Manual contains user information for the XHR Series DC output

power supply, available in several models at 1000 watts. It provides information on

features and specifications, installation procedures, and basic functions testing, as

well as procedures for operating the power supply at the front panel or from a remote

device.

Who Should Use This Manual

This manual is designed for the user who is familiar with basic electrical laws

especially as they apply to the operation of power supplies. This implies a

recognition of Constant Voltage and Constant Current operating modes and the

control of input and output power, as well as the observance of safe techniques while

making supply or pin connections and any changes in switch settings.

Main Sections

Section 1 Features and Specifications Describes the power supply, lists its

features, and provides tables of specifications.

Section 2 Installation Provides procedures for inspecting, installing, and testing

the power supply. Includes descriptions of the rear panel switch and connector, and

considerations for load wiring, load connections, and remote sensing.

Section 3 Local Operation Provides procedures for local (front panel)

operation. Includes procedures for using over voltage protection, shutdown function,

multiple supplies, and over temperature protection.

Section 4 Remote Operation Shows how to control the power supply voltage

and current limit from a remote analog source using the rear panel SW1 switch and

J2 connector. Includes both remote analog programming and readback. Discusses

the Isolated Programming Interface (ISOL) option.

Section 5 Calibration Provides procedures for calibrating programming and

readback accuracy.

Manual Revisions

The current release of this manual is listed below. Updates may be issued as an

addendum.

Revision A (2004-03)

Revision A vii

About This Manual

Power Supply Safety Markings

Alternating Current Off (Supply)

Earth (Ground) Terminal Caution (Hot Surface)

Protective Conductor Terminal Caution (Check manual for

additional information.)

On (Supply)

viii Operating Manual for XHR Series Power Supply

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Section 1.

Features and

Specifications

Section 2.

Installation

Revision A ix

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Features and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Front Panel Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rear Panel Connectors and Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Rear Panel Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SW1 Programming Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

J2 Programming Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Additional Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Input Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remote Programming and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Basic Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Inspection, Cleaning, and Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Periodic Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Returning Power Supplies to the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Return Material Authorization Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Packaging for Shipping or Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Location, Mounting, and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

AC Input Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power-on Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Voltage Mode Operation Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Current Mode Operation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Front Panel Function Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Load Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Load Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Making Load Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Inductive Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting Single Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Connecting Multiple Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Local and Remote Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sense Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Local Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Using Remote Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Section 3.

Local

Operation

Section 4.

Remote

Operation

Standard Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operating Modes and Automatic Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Shipped Configuration (Local Control Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setting Output Voltage and Current Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Using Multiple Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuring Multiple Supplies for Series Operation. . . . . . . . . . . . . . . . . . . . . . 55

Configuring Multiple Supplies for Parallel Operation. . . . . . . . . . . . . . . . . . . . . 56

Configuring Multiple Supplies for Split Supply Operation . . . . . . . . . . . . . . . . . 57

Using Over Voltage Protection (OVP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Front Panel OVP Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Resetting the OVP Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Using the Shutdown Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

STANDBY Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Controlling the Shutdown Function via the J2 Connector . . . . . . . . . . . . . . . . . 61

Over Temperature Protection (OTP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

User Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Emergency Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Unusual or Erratic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Troubleshooting for Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Remote Analog Programming of Output Voltage and Current Limit . . . . . . . . . . . . . 67

Remote Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Remote Analog Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Sample Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Remote Monitoring of Output Voltage and Current . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Readback Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Using the Isolated Programming (ISOL) Interface Option . . . . . . . . . . . . . . . . . . . . . 72

ISOL Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ISOL Setup and Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ISOL Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Section 5.

Calibration

x Operating Manual for XHR Series Power Supply

Calibration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Service Environment and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Front Panel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Additional Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Voltmeter Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Ammeter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Over Voltage Protection (OVP) Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Calibrating for Programming Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Voltage Programming Circuit Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Current Programming Circuit Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Calibrating for Readback Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Output Voltage Monitor Circuit Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Output Current Monitor Circuit Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

List of Figures

Figure 1.1 Power Supply Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 1.2 Rear Panel with Bus Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 1.3 Rear Panel with High Voltage Output Connector . . . . . . . . . . . . . . . 19

Figure 1.4 SW1 Programming Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 1.5 J2 Programming Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 1.6 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2.1 Shipping or Storage Carton Label . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 2.2 Maximum Load Wire Length for 1 V Line Drop. . . . . . . . . . . . . . . . . 40

Figure 2.3 Bus Bar Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 2.4 Typical Load Connection Hardware . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 2.5 Output Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 2.6 Single Load with Local Sensing (Default) . . . . . . . . . . . . . . . . . . . . . 45

Figure 2.7 Single Load with Remote Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 2.8 Multiple Loads with Local Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 2.9 Multiple Loads with Remote Sensing . . . . . . . . . . . . . . . . . . . . . . . . 47

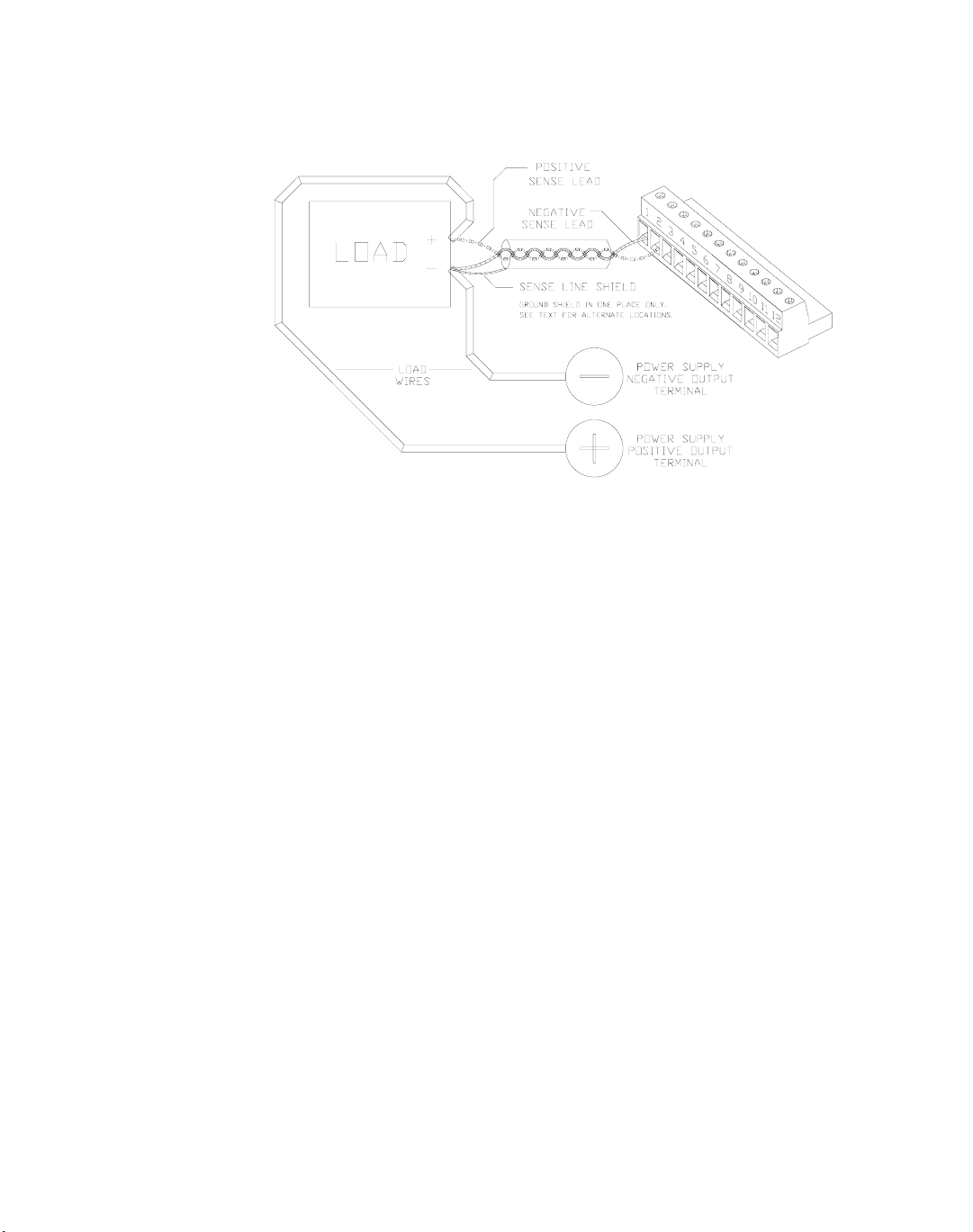

Figure 2.10 Connecting Remote Sense Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 3.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Figure 3.2 Series Operation of Multiple Supplies. . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 3.3 Parallel Operation of Multiple Supplies . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 3.4 Split Supply Operation of Multiple Supplies . . . . . . . . . . . . . . . . . . . 57

Figure 3.5 Split Supply Operation of Multiple Supplies . . . . . . . . . . . . . . . . . . . 58

Figure 3.6 Shutdown Programming with Active Low Signal . . . . . . . . . . . . . . . 62

Figure 3.7 Shutdown Programming with Active High Signal . . . . . . . . . . . . . . . 62

Figure 4.1 Connecting Programming Sources to J2 Connector . . . . . . . . . . . . 70

Figure 4.2 Sample Analog Programming Configuration . . . . . . . . . . . . . . . . . . 70

Figure 4.3 0-5 Vdc Output Voltage and Current Monitoring. . . . . . . . . . . . . . . . 71

Figure 4.4 0-10 Vdc Output Voltage and Current Monitoring. . . . . . . . . . . . . . . 72

Figure 5.1 Front Panel Calibration Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 5.2 Voltage and Current Programming Calibration Locations . . . . . . . . 78

Figure 5.3 Voltage Current and Monitor Calibration Locations . . . . . . . . . . . . . 80

Revision A xi

List of Figures

xii

Operating Manual for XHR Series Power Supply

List of Tables

Table 1.1 SW1 Switch Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 1.2 Electrical Specifications for 7.5 V to 40 V Models . . . . . . . . . . . . . . 24

Table 1.3 Electrical Specifications for 60 V to 600 V Models. . . . . . . . . . . . . . 25

Table 2.1 Basic Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2.2 Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 2.3 Current Carrying Capacity for Wiring . . . . . . . . . . . . . . . . . . . . . . . 39

Table 3.1 Shipped Configuration (Local Control Mode) . . . . . . . . . . . . . . . . . . 53

Table 3.2 Switch Settings for Shutdown Circuit Logic . . . . . . . . . . . . . . . . . . . 61

Table 3.3 Switch Settings for Over Temperature Recovery Options . . . . . . . . 63

Table 3.4 Quick Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 4.1 Power Supply Settings for Different Programming Sources . . . . . . 69

Table 4.2 Power Supply Settings for Remote Monitoring of Readback Signals71

xiii Operating Manual for XHR Series Power Supply

List of Tables

xiv

Operating Manual for XHR Series Power Supply

Section 1. Features and Specifications

Description

The 1000 watt DC output power supplies provide low noise, precisely regulated,

variable DC output. Typically they are used for bench and automated test equipment

(ATE) applications. Each unit includes over voltage protection and thermal

shutdown as standard features. Universal AC input allows you to use line voltages

globally without resetting switches or adding options. Built-in power factor

correction gives you full output power from low current/low voltage outlets, reduces

power line interference, and allows you to meet international regulations.

You can select from several remote control choices for either analog or digital

control. For analog control, choose from standard analog control or optional

4-channel isolated programming. Digital control options include RS-232 control or

GPIB programming. You can use the power supply on your benchtop or rack

mounted; each supply occupies less than 3-1/2 in. (2 U) of vertical space. Whether

you are powering batteries, development circuits, and magnet coils or running ATE

systems, the power supply provides the precision and power that you need.

Features and Options

• Models available with voltage ranges from 0-7.5 Vdc to 0-600 Vdc; current

ranges from 0-1.7 A to 0-130 A.

• Internal power factor correction allows operation from a standard 120 Vac, 15 A

outlet.

• Thermal shutdown, latching or auto reset.

• Front panel control of Over Voltage Protection (OVP).

• Simultaneous digital display of both voltage and current.

• Ten-turn front panel voltage and current controls for high resolution setting of

the output voltage and current from zero to the rated output.

• Automatic mode crossover into current or voltage mode.

• Front panel push button control of output standby mode, and preview of voltage,

current, or OVP set points. Front panel LED indicators for voltage and current

mode operation, OVP, remote programming mode, and shutdown.

• Multiple units can be connected in parallel or in series to provide increased

current or voltage.

Revision A 15

Features and Specifications

Front Panel Controls

• Remote analog voltage and current limit programming with selectable

programming ranges.

• External monitor signals for output voltage and current.

• Isolated analog remote programming control of the output voltage or current and

isolated readback of output voltage and current with the optional ISOL interface.

• Optional internal GPIB or RS-232 computer control for complete remote

programming and readback capability.

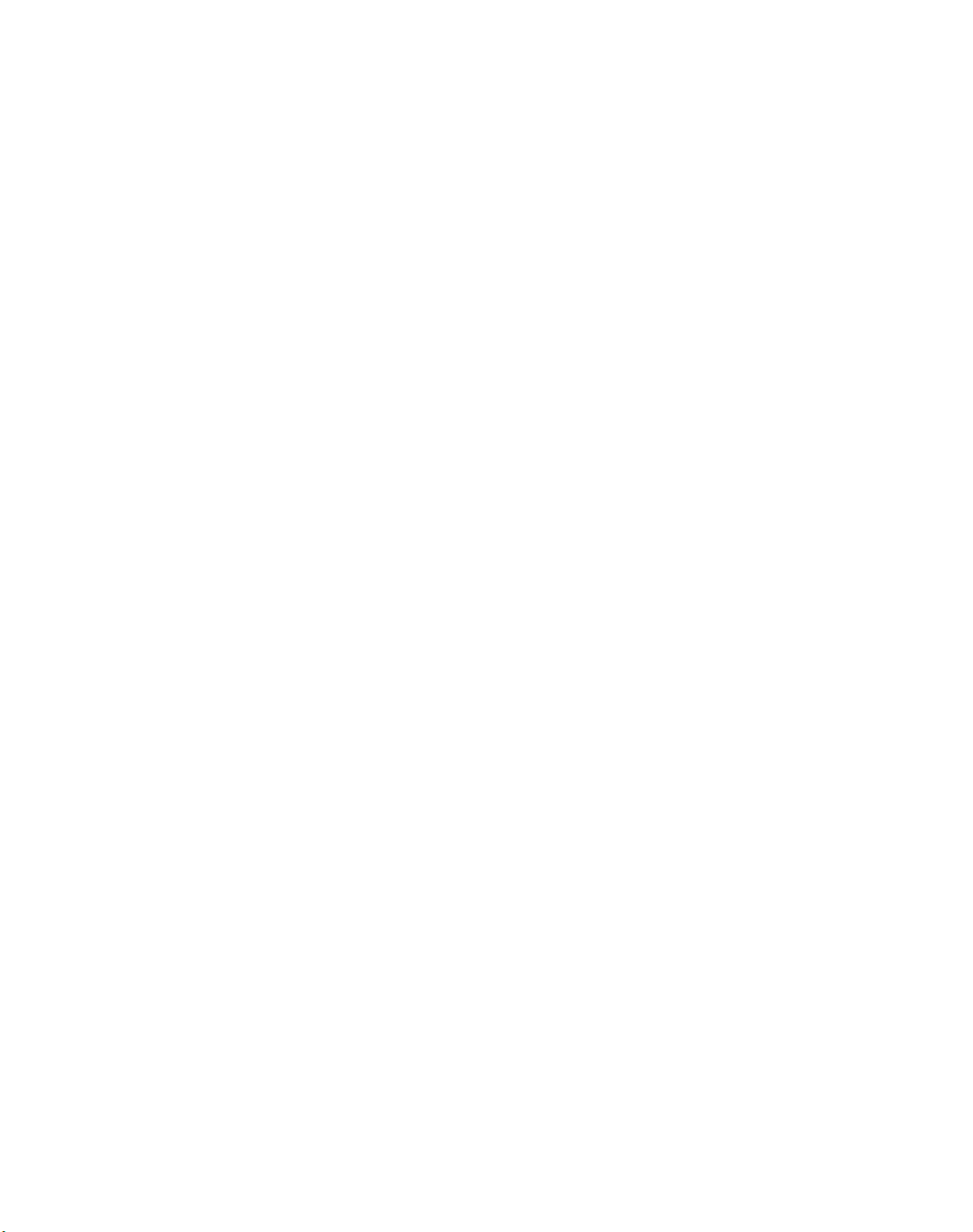

Front Panel Controls

See Figure 1.1 to review the controls, LEDs, and meters located on the power

supply’s front panel. Check the following sections for additional descriptions of front

panel controls and functions.

• “Mechanical Specifications” on page 29

• “Functional Tests” on page 37

• “Local Operation” on page 51

16 Operating Manual for XHR Series Power Supply

Features and Specifications

Front Panel Controls

Shutdown LED (S/D)

(See page 61 for more information.)

OVP Shutdown

LED (OVP)

Local Voltage and Current

Limit Setting Preview Switch

(V/I CHECK)

(See page 37.)

OVP Set Potentiometer

(OVP SET)

(See page 59.)

OVP Setting Preview Switch

(OVP CHECK)

AC Power Switch

ADR SRQ ERR POL FLT

30 AMP MAXIMUM

OL

Standby Switch (STANDBY)

(See page 61.)

Remote Programming LED (REM)

(See page 67.)

Return to Local Programming (LOCAL)

(For units with digital programming

interface installed.)

Over Temperature Protection Shutdown

LED (OTP) (See page 63.)

AC Fail LED (ACF)

Voltage Meter

Current Meter

(For units with digital programming

Option Board LEDs

Binding Posts

Output Voltage

Control Knob

Output Current

Limit Control Knob

interface installed.)

Current Mode

LED

Binding Post Overload

Voltage Mode

LED

LED (OL)

Figure 1.1 Power Supply Front Panel

(For all models.)

Revision A 17

Features and Specifications

Rear Panel Connectors and Switch

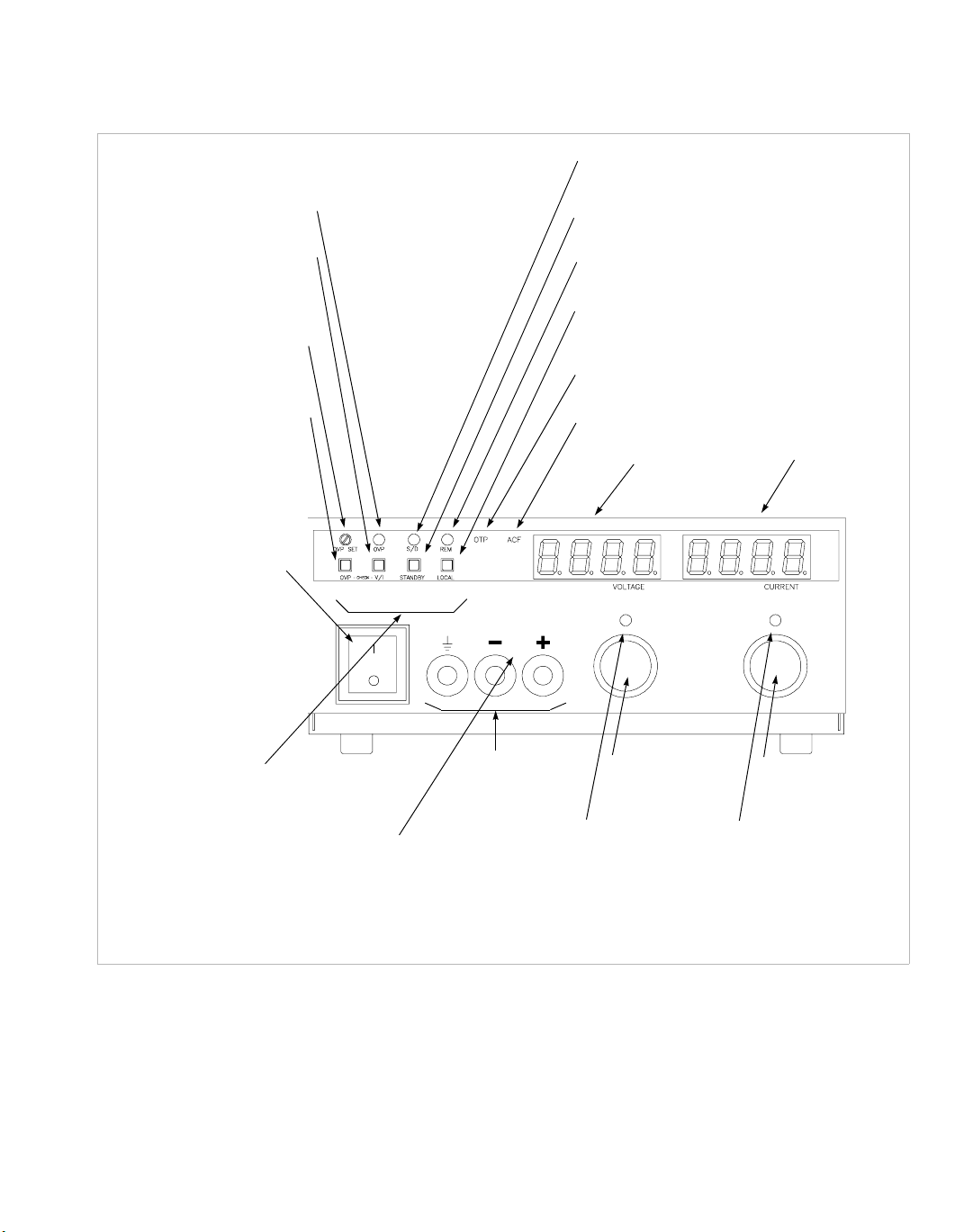

Rear Panel Connectors and Switch

The output terminals for the low voltage models (7.5 V to 40 V) are bus bars. The

high voltage models (60 V to 600 V) use a wire clamp connector. See Figure 1.2 and

Figure 1.3 to identify the switches and connectors on the rear panel.

Use the SW1 Programming, Monitoring, and Shutdown Select switch and the J2

Programming, Monitoring, and Sense connector to choose among several remote

programming and monitoring options. See the following sections for more

information about remote programming:

• “SW1 Programming Switch” on page 19

• “J2 Programming Connector” on page 20

• Section 4. Remote Operation

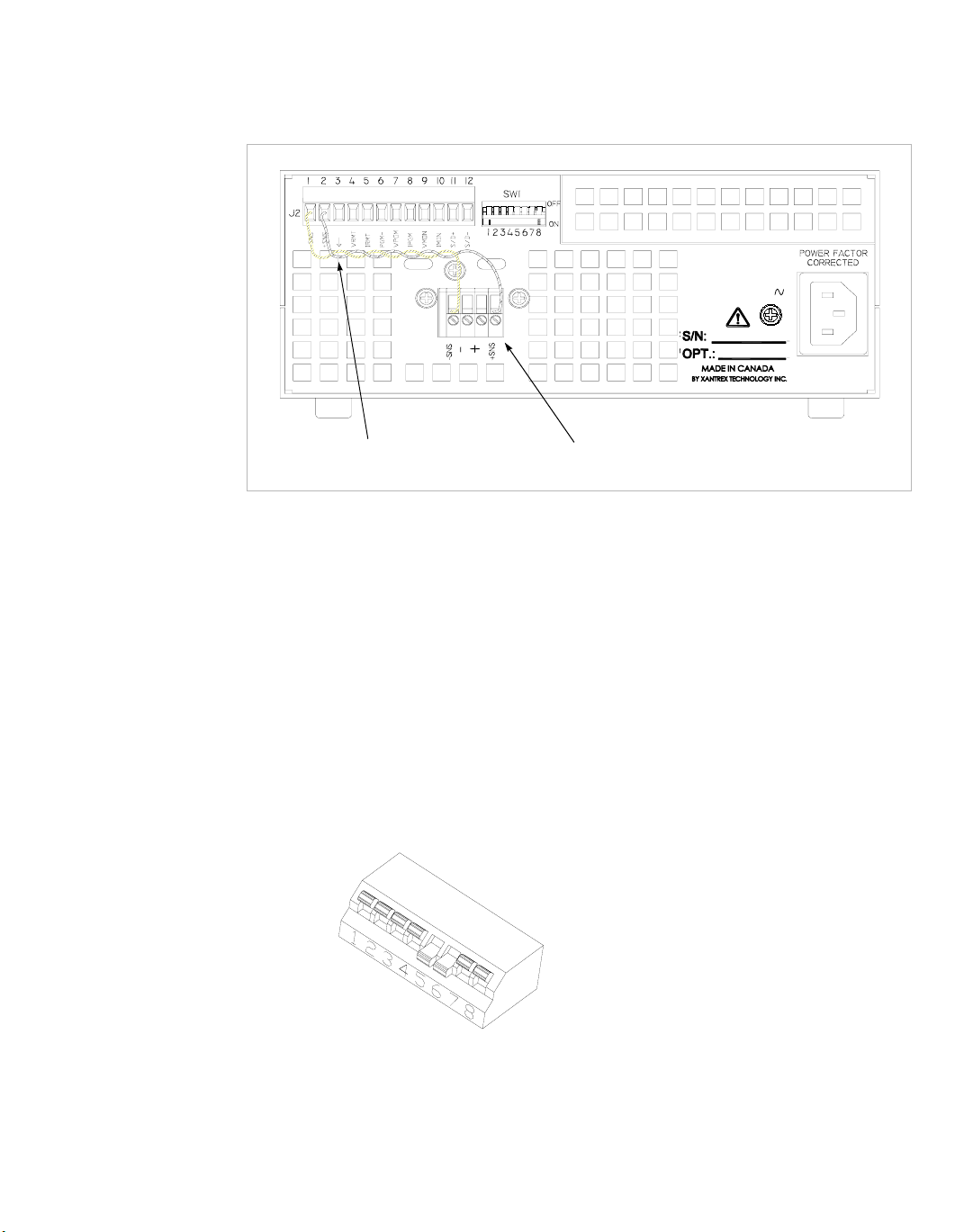

Rear Panel

Illustrations

J2 Programming, Monitoring, and

Sense Connector

(See page 20 for more

information.)

Local Sense Wires

(See page 48.)

SW1 Programming, Monitoring,

and Shutdown Select Switch

(See page 19.)

Blank Subplate

(Replaced if digital programming

interface installed.)

100/120/200/240V

50/60 HZ

1300VA

Negative Output

(Return) Bus Bar

Positive Output Bus Bar

(See page 39.)

Fan Exhaust Vents

(Do not block.)

Ground Screw

AC Input Connector

(See page 36.)

Figure 1.2 Rear Panel with Bus Bar

(For 7.5 V to 40 V models.)

18 Operating Manual for XHR Series Power Supply

Features and Specifications

Rear Panel Connectors and Switch

100/120/200/240V

50/60 HZ

1300VA

SW1

Programming

Switch

Local Sense Wires

(See page 48.)

DC Output and Local Sense Connector

(See page 39 for more information.)

Figure 1.3 Rear Panel with High Voltage Output Connector

(For 60 V to 600 V models.)

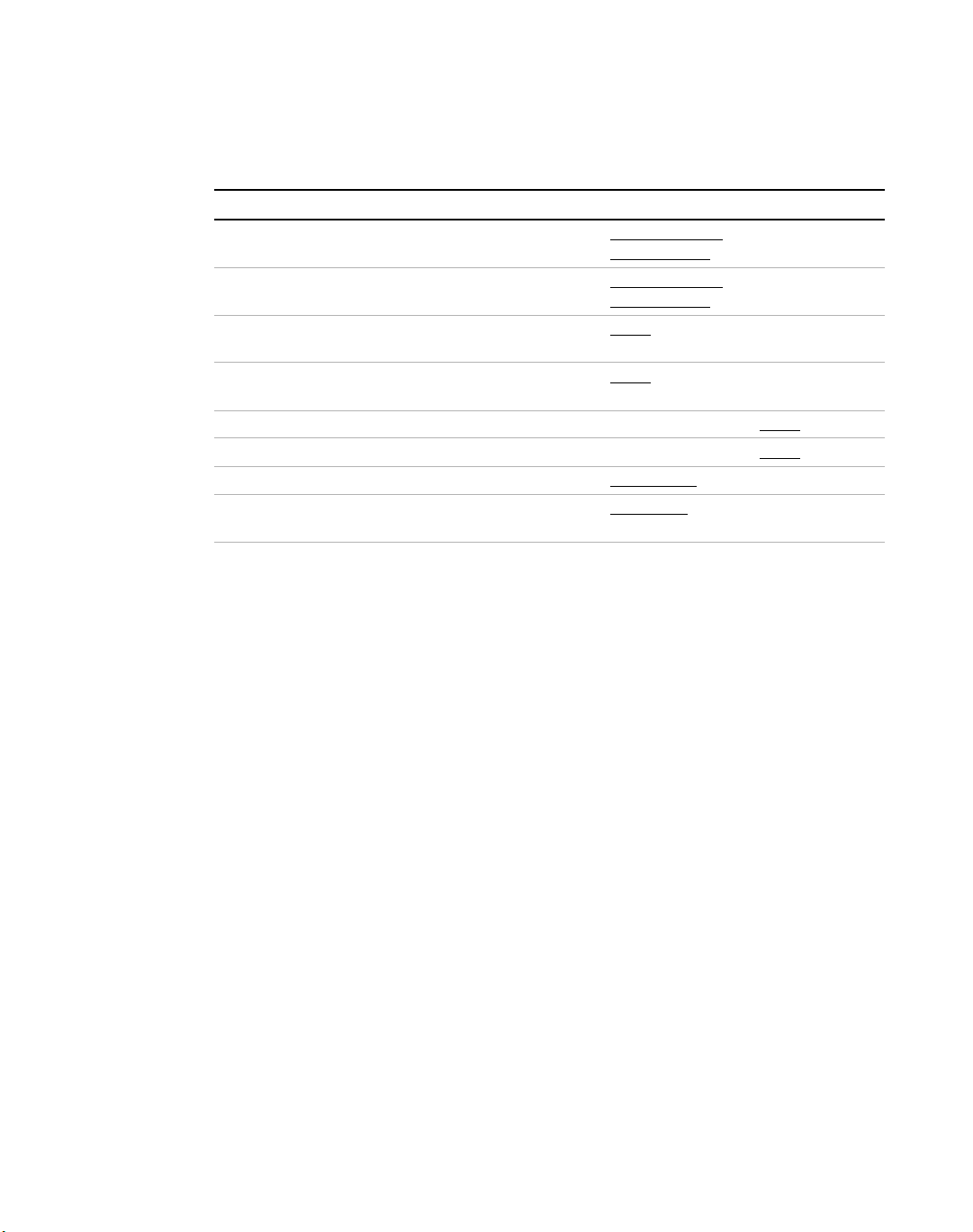

The SW1 Programming, Monitoring, and Shutdown Select switch is an 8-position

piano DIP switch located on the power supply’s rear panel. The SW1 switch enables

you to choose:

• Output voltage and current limit programming scales

• Output voltage and current monitor scales

• Remote shutdown circuit logic

• Resistive programming of output voltage or current limit

• Over temperature shutdown mode

The power supply is shipped with the SW1 switch set in the default operating

configuration, as illustrated in Figure 1.4.

Figure 1.4 SW1 Programming Switch

(Shown in its default configuration.)

Revision A 19

Features and Specifications

Rear Panel Connectors and Switch

See Table 1.1 for a list of the functions assigned to each SW1 switch.

Table 1.1 SW1 Switch Functions

Switch Function OFF (Open)

SW1-1 1 mA current source for resistive

SW1-2 1 mA current source for resistive

SW1-3 Output voltage programming source

SW1-4 Output current limit programming

SW1-5 Output voltage monitor range select. 0-10 V 0-5 V

SW1-6 Output current monitor range select. 0-10 V 0-5 V

SW1-7 Remote shutdown logic select. HIGH=OFF HIGH=ON

SW1-8 Over temperature shutdown reset

1. Factory defaults underlined.

programming of output voltage.

programming of output current limit.

range select.

source range select.

mode select.

Voltage source

programming

Voltage source

programming

0-5 V

0-5 V

Auto reset

1

ON (Closed)

Resistive

programming

Resistive

programming

0-10 V

0-10 V

Latch OFF

1

J2

Programming

Connector

Resetting the Switches The rear panel is labelled with OFF at the top of the

switch and ON at the bottom. Any of the eight switches on SW1 is OFF (OPEN)

when it has been flipped up to break contact, ON (CLOSED) when flipped down to

close contact.

Before making any changes to the switch settings, disable the power supply output.

Either turn OFF the supply, or place the supply in shutdown mode by pressing the

front panel STANDBY button to its ON position. Once output is disabled, use any

small, straight-bladed screwdriver to change the switch settings.

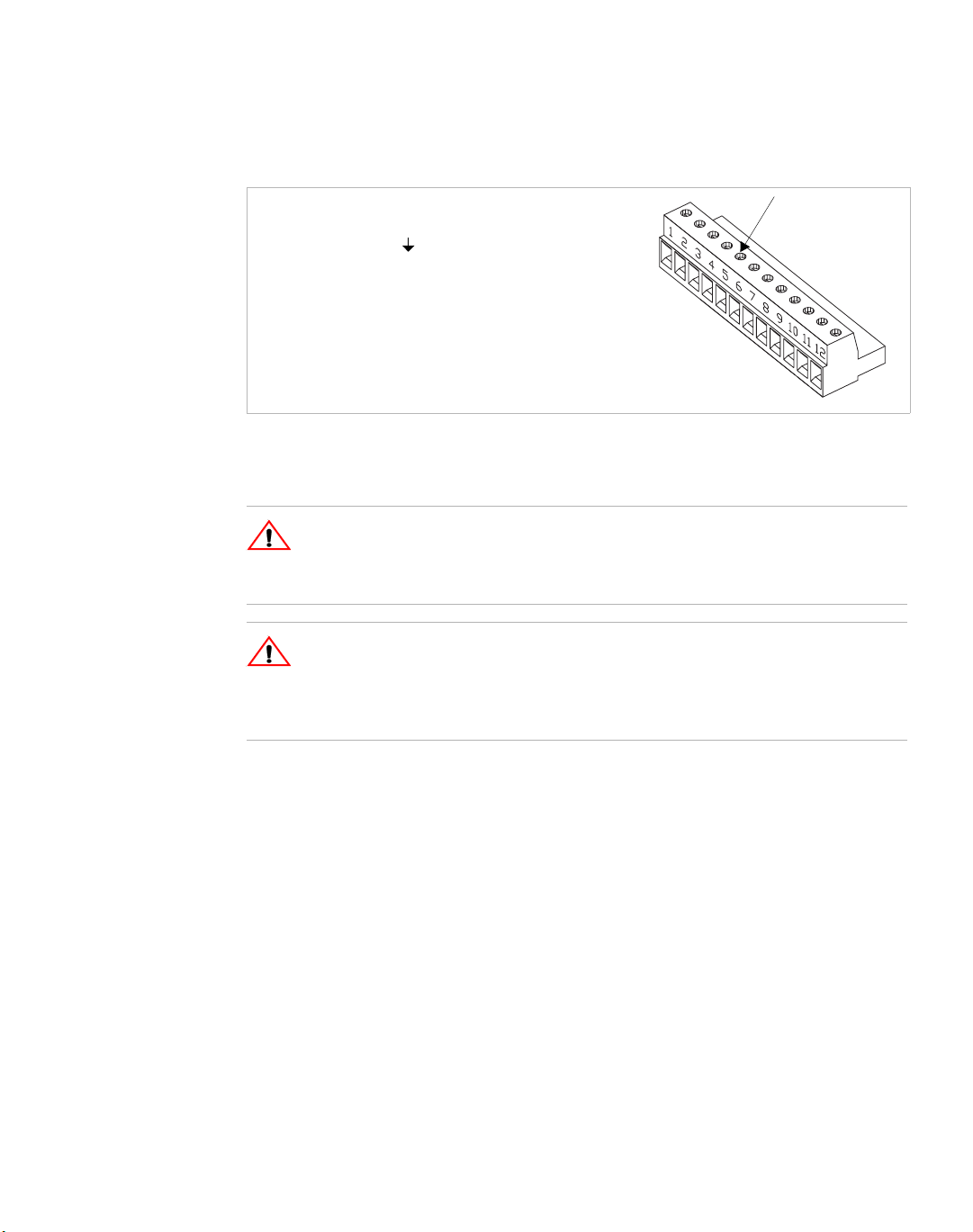

The J2 Programming, Monitoring, and Sense connector is a 12-terminal wire clamp

connector located on the power supply’s rear panel. The J2 connector provides

access to the following functions:

• remote programming of output voltage and/or current limit

• remote monitoring of calibrated readback signals for output voltage and output

current

• remote control of the shutdown function using 2.5-15 V or TTL-compatible

signals

• remote sensing of output voltage

20 Operating Manual for XHR Series Power Supply

Features and Specifications

!

!

Rear Panel Connectors and Switch

See Figure 1.5 to identify the function of each of the 12 terminals on the J2

connector.

1 Return Sense (–SNS)

2 Positive Sense (+SNS)

3 Control Ground ( )

4 Remote Output Voltage Programming Select (VRMT)

5 Remote Current Limit Programming Select (IRMT)

6 Program/Monitor Signal Return (PGM–)

7 Output Voltage Programming Input (VPGM)

8 Output Current Limit Programming Input (IPGM)

9 Output Voltage Monitor (VMON)

10 Output Current Monitor (IMON)

11 Shutdown Input (S/D+)

12 Shutdown Signal Return (S/D–)

Figure 1.5 J2 Programming Connector

Making J2 Connections

CAUTION

To maintain the isolation of the power supply output and prevent ground loops,

use an isolated (ungrounded) programming source when operating the power

supply via remote analog control at the J2 connector.

CAUTION

Do not attempt to bias the Program/monitor signal return (J2-6) relative to the

power supply output return, as they are connected internally. Use the Isolated

Programming (ISOL) option for control from programming sources at potentials

differing from the supply output return.

Wire Clamp

Connector Screw

Make connections to the J2 connector using its screw-type wire clamps. Before

making any connections, turn the power supply OFF and wait until the front panel

displays have gone out. You can unplug the connector from the back of the unit in

order to make it easier to install the required wiring.

Revision A 21

Features and Specifications

Rear Panel Connectors and Switch

Wiring

WARNING

There is a potential shock hazard at the output and J2 terminals when using a

power supply with a rated output greater than 40 V. Use load wiring with a

minimum insulation rating equivalent to the maximum output voltage of the

power supply. For example, select TEW-105, 105 °C, 600 V wiring for use with a

600 V, 1.7 A model power supply

For lowest noise performance, make connections to the J2 connector with either

2

individually or group shielded 18-22 AWG (0.3-0.8 mm

) wire. Maintain the shield

to within 1.5in. (40 mm) of the end of each wire. Strip 0.26.in (6.5 mm) of insulation,

insert into the correct terminal, and tighten the wire clamp. You must ground the

shield(s) to the power supply chassis with a connection less than 1.5.in (40 mm)

long.

22 Operating Manual for XHR Series Power Supply

Specifications

Features and Specifications

Specifications

Electrical

Specifications

Specifications are warranted over a temperature range of 0 to 40 °C with default

local sensing.

The tables on the following pages post maximum values for model-dependent

specifications.

Specifications which are different due to measurements being taken at the front panel

binding posts are identified, where they occur, in the tables.

Specifications are subject to change without notice.

Revision A 23

Features and Specifications

Specifications

Table 1. 2 Electrical Specifications for 7.5 V to 40 V Models

Models 7.5-130 20-50 33-33 40-25

Output Ratings:

Output Voltage

Output Current

Output Power

0-7.5 V

0-130 A

975 W

0-20 V

0-50 A

1000 W

0-33 V

0-33 A

1089 W

0-40 V

0-25 A

1000 W

At the front panel binding posts:

Output Current

Output Power

Line Regulation:

1

Voltage (0.01% of Vmax + 2 mV)

Current (0.01% of Imax + 1 mA)

Load Regulation:

2

Voltage (0.01% of Vmax + 2 mV)

Current (0.05% of Imax + 1 mA)

0-30 A

225 W

3mV

14 mA

3mV

66 mA

0-30 A

600 W

4mV

6mA

4mV

26 mA

0-30A

990 W

5mV

4.3 mA

5mV

18 mA

8mV

2.8 mA

6mV

14 mA

At the front panel binding posts:

Voltage

650 mV

650 mV

650 mV

500 mV

Meter Accuracy:

Voltage (1% of Vmax + 1 count)

Current (1% of Imax + 1 count)

0.09 V

1.4 A

0.3 V

0.6 A

0.43 V

0.43 A

0.5 V

0.35 A

Output Noise and Ripple (V):

rms

p-p (0-20 MHz)

10 mV

70 mV

10 mV

70 mV

7.5 mV

75 mV

7.5 mV

75 mV

At the front panel binding posts:

p-p (0-20 MHz)

Drift (8 hours):

3

Voltage (0.05% of Vmax)

Current (0.1% of Imax)

Temperature Coefficient:

Voltage (0.02% of Vmax/°C)

Current (0.03% of Imax/°C)

Maximum Remote Sense

Line Drop Compensation

4

5

250 mV

3.75 mV

130 mA

1.5 mV

39 mA

250 mV

10 mV

50 mA

4mV

15 mA

350 mV

16.5 mV

33 mA

6.6 mV

9.9 mA

350 mV

20 mV

25 mA

8mV

7.5 mA

3 V/line 5 V/line 5 V/line 5 V/line

OVP Adjustment Range:

(5% to 110% of Vmax) 0.375-8.25 V 1-22 V 1.65-36.3 V 2-44 V

Efficiency

1. For input voltage variation over the AC input voltage range, with constant rated load.

2. For 0-100% load variation, with constant nominal line voltage. Measured at the rear panel output connector unless

stated otherwise.

3. Maximum drift over 8 hours with constant line, load, and temperature, after 30-minute warm-up.

4. Change in output per °C change in ambient temperature, with constant line and load.

5. Line drop is subtracted from total voltage available at supply output.

6. Typical efficiency at 115 Vac input and rated output power.

6

81% 83% 83% 83%

24 Operating Manual for XHR Series Power Supply

Features and Specifications

Specifications

Table 1.3 Electrical Specifications for 60 V to 600 V Models

Models 60-18 100-10 150-7 300-3.5 600-1.7

Output Ratings:

Output Voltage

Output Current

Output Power

Line Regulation:

1

Voltage (0.01% of Vmax + 2 mV)

Current (0.01% of Imax + 1 mA)

Load Regulation:

2

Voltage (0.01% of Vmax + 2 mV)

Current (0.05% of Imax + 1 mA)

0-60 V

0-18 A

1080 W

8mV

2.8 mA

8mV

10 mA

0-100 V

0-10 A

1000 W

12 mV

2mA

12 mV

6mA

0-150 V

0-7 A

1050 W

17 mV

1.7 mA

17 mV

4.5 mA

0-300 V

0-3.5 A

1050 W

32 mV

1.3 mA

32 mV

3mA

0-600 V

0-1.7 A

1020 W

62 mV

1.2 mA

62 mV

2mA

At the front panel binding posts:

Voltage

400 mV

300 mV

200 mV

100 mV

62 mV

Meter Accuracy:

Voltage (1% of Vmax + 1 count)

Current (1% of Imax + 1 count)

0.7 V

0.19 A

1.1 V

0.11 A

1.6 V

0.08 A

4V

0.05 A

7V

0.03 A

Output Noise and Ripple (V):

rms

p-p (0-20MHz)

10 mV

75 mV

10 mV

100 mV

20 mV

150 mV

30 mV

250 mV

120 mV

500 mV

At the front panel binding posts:

p-p (0-20MHz)

Drift (8 hours):

3

Voltage (0.05% of Vmax)

Current (0.05% of Imax)

Temperature Coefficient:

Voltage (0.02% of Vmax/°C)

Current (0.03% of Imax/°C)

Maximum Remote Sense

Line Drop Compensation

4

5

400 mV

30 mV

18 mA

12 mV

5.4 mA

400 mV

50 mV

10 mA

20 mV

3mA

450 mV

75 mV

7mA

30 mV

2.1 mA

500 mV

150 mV

3.5 mA

60 mV

1.1 mA

700 mV

300 mV

1.7 mA

120 mV

0.48 mA

5 V/line 5 V/line 5 V/line 5 V/line 5 V/line

OVP Adjustment Range

(5% to 110% of Vmax) 3-66 V 5-110 V 7.5-165 V 15-330 V 30-660 V

Efficiency

1. For input voltage variation over the AC input voltage range, with constant rated load.

2. For 0-100% load variation, with constant nominal line voltage. Measured at the rear panel output connector unless

stated otherwise.

3. Maximum drift over 8 hours with constant line, load, and temperature, after 30-minute warm-up.

4. Change in output per °C change in ambient temperature, with constant line and load.

5. Line drop is subtracted from total voltage available at supply output.

6. Typical efficiency at 115 Vac input and rated output power.

6

84% 84% 85% 85% 85%

Revision A 25

Features and Specifications

Additional Electrical Specifications

Additional Electrical Specifications

Voltage Mode Transient Response

(Time for the output voltage to

recover within 0.5% of its

previous level after a step change

in load current of up to 50% of the

rated output.)

Time delay from power on until

output stable

Input Conditions

Rated AC Input Voltage 100/120/200/220/230/240 Vac (nominal)

Maximum AC Input Rating 1300 VA

Operational AC Input Voltage

Range

Maximum Input Current 13 A maximum at 100 Vac,

Input Frequency Range 47

Power Factor 0.99 minimum for full load and 120 Vac

1ms

4s maximum

85-250 Vac; power factor corrected.

Derate maximum output power to 900 W for

AC input less than 95 V.

11 A maximum at 120 Vac,

6 A maximum at 220 Vac.

–63 Hz

input

26 Operating Manual for XHR Series Power Supply

Electrical Characteristics

Switching Frequency 7.5 V to 300 V models:

Output Hold-up Time Greater than 10 ms with interruption of AC

Features and Specifications

Electrical Characteristics

nominal 125 kHz (250 kHz output ripple)

600 V model

nominal 62.5 kHz (125 kHz output ripple)

line, for nominal AC input and full load.

Maximum Voltage Differential

from output to safety ground

Isolation Voltage Input to output: 1350 Vac

Remote Programming and Monitoring

Remote Start/Stop and Interlock 2.5-15 V signal or TTL-compatible input,

Remote Analog Programming

(Full Scale Input)

Remote monitoring Output voltage and current: 0-5 V, 0-10 V

±600 Vdc

selectable logic.

Input impedance: 1 k (in series with one

diode drop).

Voltage and current programming inputs

(source must be isolated): 0-5 k, 0-10 k

resistances; 0-5 V (default), 0-10 V voltage

sources;

Input impedance (V and I): approximately

475 k.

(default);

Output impedance (V and I): approximately

221 Ω;

Output short circuit current: approximately

50 mA.

Remote Programming and

Monitoring Accuracy

Maximum Remote Sense Line

Drop Compensation.

must be deducted from the supply’s

maximum output voltage.)

(Line drop

Isolated Program and Readback

(V & I) (Optional)

1% zero to full scale output for the default

range.

7.5 V models: 3 V/line.

20 V to 600 V models: 5 V/line.

0-5 V (ISOL interface). Input impedance:

200 k.

Output impedance: 21 Ω

Digital Control (Optional) RS-232, GPIB or GPIB-M (multichannel)

Revision A 27

Features and Specifications

Environmental Specifications

Environmental Specifications

Operating Ambient Temperature 0 to 40 °C.

Storage Temperature Range – 40 ° to 85 °C

Humidity Range Up to 80% RH, non-condensing

Operating Altitude Up to 6,500 feet (2000 m)

Installation Category II

Pollution Degree 2

Approvals

Units marked with c(CSA)us are CSA certified to:

Canadian safety standard CAN/CSA C22.2 No. 61010.1-92 and

USA safety standard UL 61010B-1.

Units marked with CE meet:

EMC Directive (standards EN50081-2 and EN50082-1) and

Low Voltage Directive (safety standard IEC 61010:1990 +A.1:1992 +A.2:1995).

Meets FCC part 15 Class A limits for radio emissions.

Meets Canadian EMC standard ICES-001, Class A limits.

28 Operating Manual for XHR Series Power Supply

Mechanical Specifications

Features and Specifications

Mechanical Specifications

Front Panel Voltage and Current

10-turn voltage and current potentiometers

Control

Front Panel Voltage Control

0.02% of maximum voltage

Resolution

Front Panel Voltage and Current

Meters

3.5-digit numeric LED displays (for accuracy

specifications, see Table 1.2 and Table 1.3)

AC Input Connector Type IEC 320 Connector, appropriate power cord

for destination country.

Front Panel Output 5-way binding posts:

maximum current limit 30 A

OVP Control Screwdriver-set potentiometer on front panel

Input Fuses 20 A, 250 V, 5 x 20 mm slow fuses,

location: A5 PCB, F321, 325;

0.005 A, 250 V, 5 x 20 mm fast fuse,

location: A3 PCB, F1.

Main Output Connector 7.5 V to 40 V models: nickel-plated copper

bus bars;

60 V to 600 V models: 4-terminal wire clamp

connector for DC output and local sense.

Analog Programming, Monitoring,

12-terminal wire clamp connector

and Sense Connector (2-piece)

Chassis Ground Chassis ground screw located on rear panel

for bonding connections

Cooling Fan cooled. Air exhausts to rear. Over

temperature shutdown: automatic restart or

latch off (switch-selectable).

Mounting Optional rack mount pan. (RM3-XHR)

Size (one unit) 87.0 mm H x 214.6 mm W x 472.2 mm D

(3.425in. H x 8.45in. W x 18.59in. D)

Weight (one unit) Approximately 6.4 kg (14 lb.)

Revision A 29

Features and Specifications

Dimensions

Dimensions

18.78 in. (477 mm)

15.85 in. (403 mm)

16.18 in. (411 mm)

8.45 in. (215 mm)

3.43 in.

(87 mm)

Figure 1.6 Dimensional Drawings

(Dimensions given are nominal.)

3.14 in.

(79 mm)

30 Operating Manual for XHR Series Power Supply

Section 2. Installation

Basic Setup Procedure

See Tab l e 2. 1 for a summary of the basic setup procedure and an overall view of the

information in this section. Use the procedure as a quick reference if you are familiar

with the installation requirements for the power supply. If you want more

information, each step in the procedure refers to sections which contain more details.

Execute each step in the sequence given.

Table 2.1 Basic Setup Procedure

Step # Description Action Reference

1 Inspection Perform an initial physical

inspection of the supply.

2 Installation Install the supply (bench or rack

mount); ensure adequate

ventilation.

3 Input Power Connect AC input power. “AC Input Power” on

4 Test Perform functional tests for voltage

mode operation, current mode

operation, and front panel controls.

5 Load Connect the load. “Load Connection” on

6 Sensing Connect sensing lines. “Local and Remote

“Initial Inspection” on

page 32

“Location, Mounting,

and Ventilation” on

page 35

page 36

“Functional Tests” on

page 37

page 39

Sensing” on page 48

Revision A 31

Installation

Inspection, Cleaning, and Packing

Inspection, Cleaning, and Packing

Initial

Inspection

Periodic

Cleaning

When you first receive your unit, perform a quick physical check.

1. Ensure that each package contains the power supply and an AC input cord.

2. Inspect the unit for scratches and cracks, and for broken switches, connectors,

and displays.

3. If you suspect internal damage, have a service technician check the unit.

If the unit is damaged, save all packing materials and notify the carrier immediately.

See packing instructions in “Packaging for Shipping or Storage”.

No routine servicing of the power supply is required except for periodic cleaning.

Whenever a unit is removed from operation, clean the metal surfaces with naphtha

or an equivalent solvent and the front panel with a weak solution of soap and water.

Use low pressure compressed air to blow dust from in and around components on the

printed circuit boards.

32 Operating Manual for XHR Series Power Supply

Returning Power Supplies to the Manufacturer

Installation

Returning Power Supplies to the Manufacturer

Return

Material

Authorization

Policy

Before returning a product directly to Xantrex you must obtain a Return Material

Authorization (RMA) number and the correct factory “Ship To” address. Products

must also be shipped prepaid. Product shipments will be refused and returned at your

expense if they are unauthorized, returned without an RMA number clearly marked

on the outside of the shipping box, if they are shipped collect, or if they are shipped

to the wrong location.

When you contact Xantrex to obtain service, please have your operating manual

ready for reference and be prepared to supply:

• The serial number of your product

• Information about the installation and use of the unit

• Information about the failure and/or reason for the return

• A copy of your dated proof of purchase

When you ship:

1. Package the unit safely following the procedures on page 34, preferably using

the original box and packing materials. Please ensure that your product is

shipped fully insured in the original packaging or equivalent. This warranty will

not apply where the product is damaged due to improper packaging.

2. Include the following:

• The RMA number supplied by Xantrex Technology Inc clearly marked on

the outside of the box.

• A return address where the unit can be shipped. Post office boxes are not

acceptable.

• A contact telephone number where you can be reached during work hours

• A brief description of the problem

Ship the unit prepaid to the address provided by your Xantrex customer service

representative.

If you are returning a product from outside of the USA or Canada:

In addition to the above, you MUST include return freight funds and are fully

responsible for all documents, duties, tariffs, and deposits.

If you are returning a product to a Xantrex Authorized Service Center (ASC):

A Xantrex return material authorization (RMA) number is not required. However,

you must contact the ASC prior to returning the product or presenting the unit to

verify any return procedures that may apply to that particular facility.

Revision A 33

Installation

Returning Power Supplies to the Manufacturer

Packaging for

Shipping or

Storage

Follow these instructions to prepare the unit for shipping or storage.

1. When returning the unit or sending it to the service center, attach a tag to the unit

stating its model number (available from the front panel label) and its serial

number (available from the rear panel label). Give the date of purchase and an

invoice number, if you have it, as well as a brief description of the problem.

2. For storage or shipping, repack the power supply in its original container. If the

original container is not available, seal the unit in a plastic bag and then pack it

in a 200 lb. (90 kg) test, corrugated cardboard carton large enough to allow 2

inches (5 cm) of cushioning material to surround the unit. Use a material such as

foam slabs or chips.

3. Label the carton as shown in Figure 2.1.

4. If shipping, mark the address of the service center and your return address on the

carton.

5. If storing, stack no more than eight cartons high. Check the storage temperature

range and storage altitude specification in “Environmental Specifications” on

page 28.

POWER SUPPLY

Model Number: _______________________

Serial Number: _______________________

FRAGILE — ELECTRONIC EQUIPMENT

Figure 2.1 Shipping or Storage Carton Label

34 Operating Manual for XHR Series Power Supply

Location, Mounting, and Ventilation

!

Rack

Mounting

CAUTION

Ensure that any rack mounting screws do not extend more than 1/4in. (6.3 mm)

into the base of the unit.

The rack mount kit allows you to mount two units side by side in a standard 19in.

(483 mm) rack space.

1. Install commercially available rack slides, if used. Follow the manufacturer’s

instructions.

2. Remove the four (4) rubber feet from the bottom of each power supply.

3. Place the power supply (or supplies) into the rack mount pan (option

RM3-XHR).

4. Screw four (4) #6-32 x ¼in. flat head, rack mounting screws through the pan into

the threaded holes on the bottom of each power supply.

5. Install the rack mount pan in the rack.

Installation

Location, Mounting, and Ventilation

Ventilation Always ensure that cooling air reaches the ventilation inlet on the lower front of the

unit and that the fan can exhaust from the rear of the unit. Additional ventilation

space at the top and bottom of the supply will further lower internal operating

temperatures.

Check “Environmental Specifications” for the specified operating ambient

temperature range for the power supply.

Revision A 35

Installation

!

AC Input Power

AC Input Power

WARNING

There is a potential shock hazard if the power supply chassis and cover are not

connected to an electrical ground via the safety ground in the AC input

connector. Ensure that the power supply is connected to a grounded AC outlet

with the recommended AC input connector configured for the available line

voltage

CAUTION

When the power switch is turned on, the output voltage or current previously set

will be applied to loads

We warrant that the unit will perform to specification at AC input voltage range from

85 to 250 Vac. The power output derates to 900 W when the AC input voltage is

below 95 V.

AC Fail LED The AC Fail (ACF) LED turns on when the input voltage is outside

of the range specified for the power supply. The LED turns off when the input

voltage is within the range.

AC Input Cord We ship the power supply with an AC input cord rated for your

location. See Table 2 .2 for the list of power cords that we ship. Use a power cord

rated for your local voltage as long as it is within the supply’s input range as stated

in “Input Conditions” on page 26. Any cord that you use requires a standard IEC 320

termination to mate with the power supply’s AC input connector. If you need a

specific cord, call us.

Table 2.2 Power Cords

Location Power Cord Rating

North America 125 V, 13 A NA plug

Asia 125 V, 13 A NA plug

Great Britain 250 V, 10 A British plug

36 Operating Manual for XHR Series Power Supply

Functional Tests

The functional test procedures include power-on and front panel function checks as

well as voltage and current mode operation checks.

Installation

Functional Tests

Equipment

Required

Power-on

Check

Voltage Mode

Operation

Check

• Digital voltmeter (DVM) rated better than 0.5% accuracy.

• DC shunt 1 mV/A (±0.25%) with connecting wire. The recommended current

ratings for the DC shunt and the wire must be at least 10% more than the output

current of the power supply.

1. Ensure that the AC power switch is in the OFF position.

2. Ensure that the output sense lines are connected in the default configuration. On

low voltage models, local sense jumpers connect terminal J2-2 on the J2

connector to the positive bus bar, and terminal J2-1 to the negative bus bar. On

high-voltage models, terminal J2-2 connects to positive sense (+SNS) and

terminal J2-1 to return sense (–SNS) on the wire clamp connector.

3. Turn the voltage and current controls fully counter-clockwise.

4. Connect the unit to an AC outlet.

5. Turn the front panel power switch to ON.

After a short, power-on delay, the front panel digital meters light up. Both voltmeter

and ammeter displays read zero.

1. Ensure that both the voltage and current controls on the front panel are turned

fully counter-clockwise.

2. Connect the DVM to the output terminals on the rear panel, observing correct

polarity.

3. Turn the current control 1/2-turn clockwise.

4. Slowly turn the voltage control clockwise and observe both the front panel

voltmeter and the DVM. The voltage mode LED will turn on.

5. Compare the DVM reading with the front panel voltmeter reading to verify the

accuracy of the internal voltmeter. The minimum control range is from zero to

the maximum rated output for the particular power supply model.

6. Turn the front panel power switch to OFF.

Revision A 37

Installation

Functional Tests

Current Mode

Operation

Check

Front Panel

Function

Check

1. Ensure that the front panel power switch is set to OFF.

2. Turn the voltage and current controls on the front panel fully counter-clockwise.

3. Turn the voltage control one (1) or two (2) turns clockwise.

4. Connect a DC shunt across the output terminals on the rear panel.

5. Connect a DVM across the DC shunt. The DC shunt-DVM combination must be

rated better than 0.5% accuracy.

6. Turn the power switch to ON.

7. Slowly turn the current control clockwise. The current mode LED will turn on.

8. Compare the DVM reading with the front panel ammeter reading using I=V/R

where V is the DVM reading and R is the DC shunt resistance. The control range

is from zero to the maximum rated output for the power supply model.

9. Turn the power switch to OFF.

10. Disconnect the DVM and the shunt.

1. Turn the power switch to ON.

2. Set the voltage and current controls fully clockwise. Push the STANDBY switch

to its IN position and check that the voltmeter reading falls to zero and the S/D

(Shutdown) LED turns on. Push the STANDBY switch once again to reset it to

its OUT position. The S/D LED turns off.

3. Press the STANDBY switch to the IN position.

4. Press the OVP CHECK switch. Check that the voltmeter displays approximately

the model-rated output voltage plus 10%.

5. Turn the OVP SET potentiometer counter-clockwise and check that the

voltmeter reading decreases. Continued turning (up to 20 turns) will see the

reading decrease to approximately 5% of the model-rated voltage output. Turn

the OVP SET potentiometer clockwise until the voltmeter once again displays

approximately the model rated output voltage plus 10%.

6. Press the STANDBY switch to its OUT position.

7. Make sure the voltage and current controls are turned all the way in the

clockwise direction. Press the V/I CHECK switch and check that the voltmeter

and ammeter display a minimum of the power supply model output ratings.

8. Turn the power switch to OFF.

38 Operating Manual for XHR Series Power Supply

Installation

Load Connection

Load Connection

This section provides recommendations for load wires and how to connect them for

both single and multiple load configurations.

Load Wiring When connecting load wiring to the power supply, consider the following factors:

• Current capacity and voltage rating of the wire

• Maximum load wiring length for operation with sense lines

• Noise and impedance effects of the load lines

Insulation Rating

WARNING

There is a potential shock hazard at the output when using a power supply with a

rated output greater than 40 V. Use load wiring with a minimum insulation rating

equivalent to the maximum output voltage of the power supply. For example,

select TEW-105, 105 °C, 600 V wiring for use with a 600 V, 1.7 A power supply.

Current Capacity

As a minimum requirement, load wiring must have a current

capacity greater than the output current rating of the power supply. This ensures that

the wiring will not be damaged even if the load is shorted. Tabl e 2.3 shows the

maximum current rating, based on 450 A/cm

2

, for various gauges of wire rated for

105 °C operation. Operating at the maximum current rating results in an approximate

30 °C temperature rise for a wire operating in free air. Where load wiring must

operate in areas with elevated ambient temperatures or bundled with other wiring,

use larger gauges or wiring rated for higher temperatures.

Table 2.3 Current Carrying Capacity for Wiring

Wire Size

(AWG)

18 4 8 36

16 6 6 61

14 10 4 97

12 16 2 155

10 21

Maximum Current

(A)

Wire Size

(AWG)

Maximum Current

(A)

Revision A 39

Installation

Load Connection

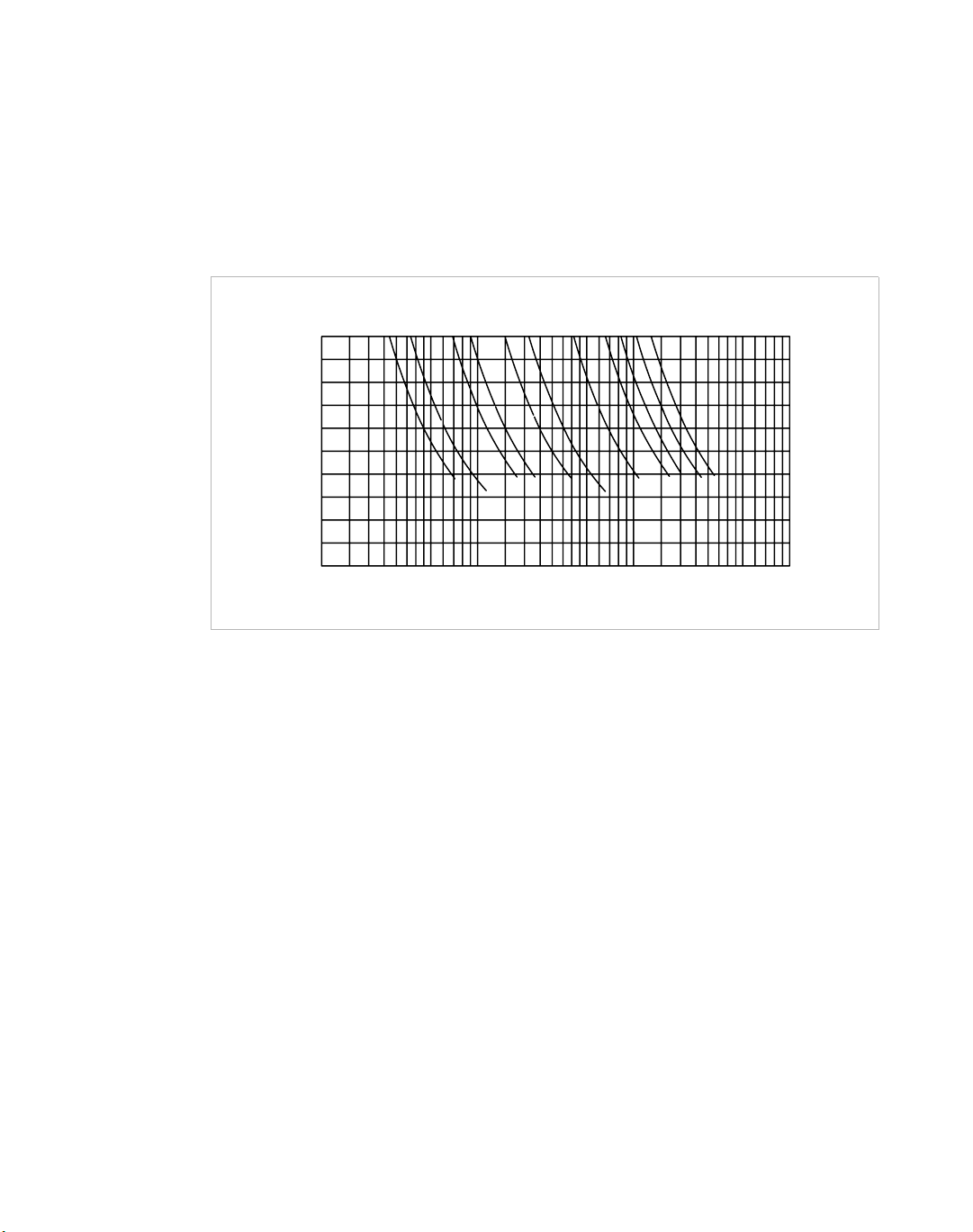

Load Wiring Length for Operation with Sense Lines For applications using

remote sensing, you must limit the voltage drop across each load line. Figure 2.2

shows some maximum allowable wire lengths for a given load current and wire size.

We recommend that you use the larger load wiring to ensure a smaller voltage drop

(1 V typical maximum), although the units (except 7.5 V models) will compensate

for up to 5 V drop in each line. See also “Local and Remote Sensing” on page 48.

WIRE GAUGE (AWG)

16

100

90

80

70

60

50

40

30

WIRE LENGTH (FEET)

20

10

1

2

12

14

3456789

10

8

10

4

6

20

30405060708090

1 2/0

2 1/0

100

200

300

400

500

1000

LOAD CURRENT (AMPS)

Figure 2.2 Maximum Load Wire Length for 1 V Line Drop

Noise and Impedance Effects To minimize noise pickup and radiation, use

shielded pair wiring of shortest possible length for load wires. Connect the shield to

the chassis using the ground screw on the rear panel. Where shielding is impossible

or impractical, simply twisting the wires together will offer some noise immunity.

When using local sense connections, use the largest practical wire size to minimize

the effects of load line impedance on the regulation of the supply.

40 Operating Manual for XHR Series Power Supply

Making Load

!

!

Connections

Installation

Load Connection

WARNING

There is a potential shock hazard at the load when using a power supply with a

rated output greater than 40 V. To protect personnel against accidental contact

with hazardous voltages, ensure that the load, including connections, has no live

parts which are accessible. Also ensure that the insulation rating of the load

wiring and circuitry is greater than or equal to the maximum output voltage of the

power supply.

Make load connections to the power supply at output connectors at the rear of the

power supply, or at the binding posts on the front panel.

Binding Posts (All Models) The binding posts on the front panel have a built-in

current limiting function which will not allow more than 30 A to be drawn from the

output on units with high output current capability. If the draw exceeds 30 A, the

Binding Post Overload (OL) LED on the front panel lights up and the current draw

is limited to 30 A. Once the load draw drops below 30 A, the OL LED goes out and

normal operation resumes. Use remote sensing to improve load regulation at the

binding posts. See “Specifications” on page 23 for any differences in specifications

when operating with the load connected at the binding posts.

7.5 V to 40 V Models

CAUTION

Do not remove the A16 EMI filter board or the bus bar capacitor from the bus

bars. Operating the power supply without the EMI filter board or the bus bar

capacitor will impair its electrical performance.

CAUTION

When making connections to the bus bars, ensure each terminal’s mounting

hardware and wiring assembly are placed to avoid touching the other terminal

and shorting the power supply output. Heavy connecting cables must have some

form of strain relief to avoid loosening the connections or bending the bus bars.

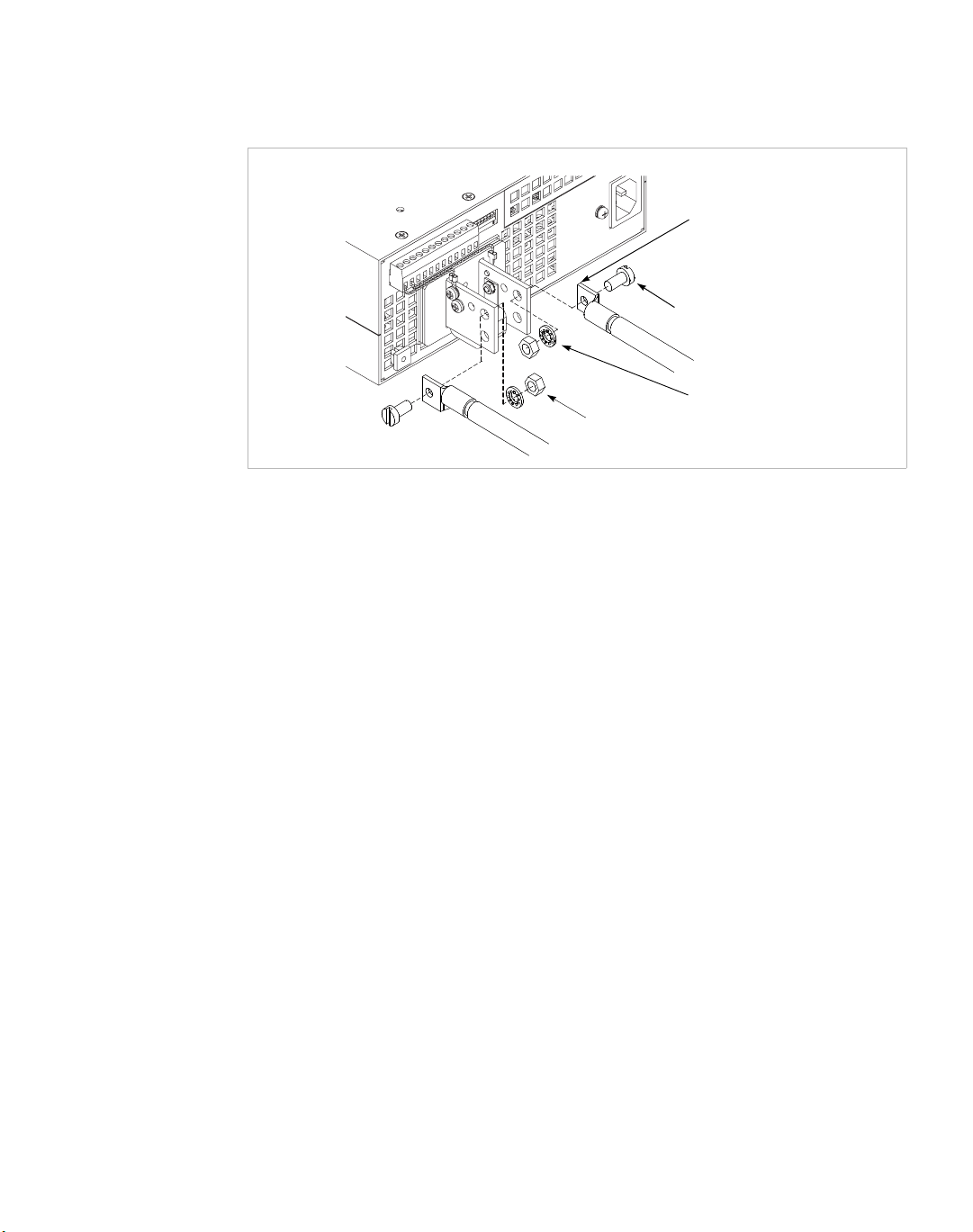

The 7.5 V to 40 V models have output bus bars on the rear panel and come with a

bus bar shield. A filter capacitor and the A16 EMI filter board are attached to the bus

bars on the rear panel. Detach only the bus bar shield before making load or remote

sense line connections. To detach the shield, remove the screws as shown in

Figure 2.3.

Revision A 41

Installation

Load Connection

A16 EMI Filter

PCB

Bus Bar

Capacitor

Figure 2.3 Bus Bar Shield

Shield

Flat Washer

(3 places)

1/4in. Screw

(2 places)

3/8in. Screw

(1 place)

Inductive

Loads

Use the following protection methods only when using local sensing.

To prevent damage to the power supply from inductive kickback, connect a diode

across the output. The diode must be rated at greater than or equal to the supply’s

output voltage and have a current surge rating greater than or equal to the supply’s

output rating. Connect the cathode to the positive output and the anode to the return.

Where positive load transients such as back EMF from a motor may occur, connect

a transorb or a varistor across the output to protect the power supply. The breakdown

voltage rating for the transorb or varistor must be approximately 10% higher than the

rated supply output.

42 Operating Manual for XHR Series Power Supply

Load Connection

Wire Terminal

Lug (2 places)

Screw (2 places)

Lock Washer

Hex Nut

(2 places)

(2 places)

Figure 2.4 Typical Load Connection Hardware

(For 7.5 V to 40 V models.)

To make load connections to a 7.5 V, 130 A power supply:

1. Install a connecting wire terminal lug to load wiring. See Figure 2.4.

Installation

2. Fasten wire terminal lugs to bus bars with 1/4in. x 1/2in. (M6 x 12 mm) screws,

1/4in. (M6) internal tooth lock washers, and hex nuts as shown.

Note:Bus bar hole sizes are: 2 of 0.257in. (6.50 mm) diameter (D); 1 of 0.191in.

(4.83 mm) D; and 2 of 0.156in. (3.95 mm) D.

Revision A 43

Installation

Load Connection

60 V to 600 V Models

WARNING

To protect personnel against accidental contact with hazardous voltages, ensure

that the load, including connections, has no live parts which are accessible. Also

ensure that the insulation rating of the load wiring and circuitry is greater than or

equal to the maximum output voltage of the power supply.

The output connector for the 60 V to 600 V models is a 4-terminal, wire clamp

connector located on the rear panel. Two of the terminals are for local sense

connections. See Figure 2.5.

To prepare and connect the load wiring:

1. Strip insulation 0.35in. (9 mm) at the end of the wires.

2. Loosen the terminal screw, insert the stripped wire into the terminal, and tighten

the screw securely.

Load Wires

Output

Connector

–

SNS

SNS +

+

Figure 2.5 Output Connector

(For 60 V to 600 V models.)

44 Operating Manual for XHR Series Power Supply

Installation

Load Connection

Connecting

Single Loads

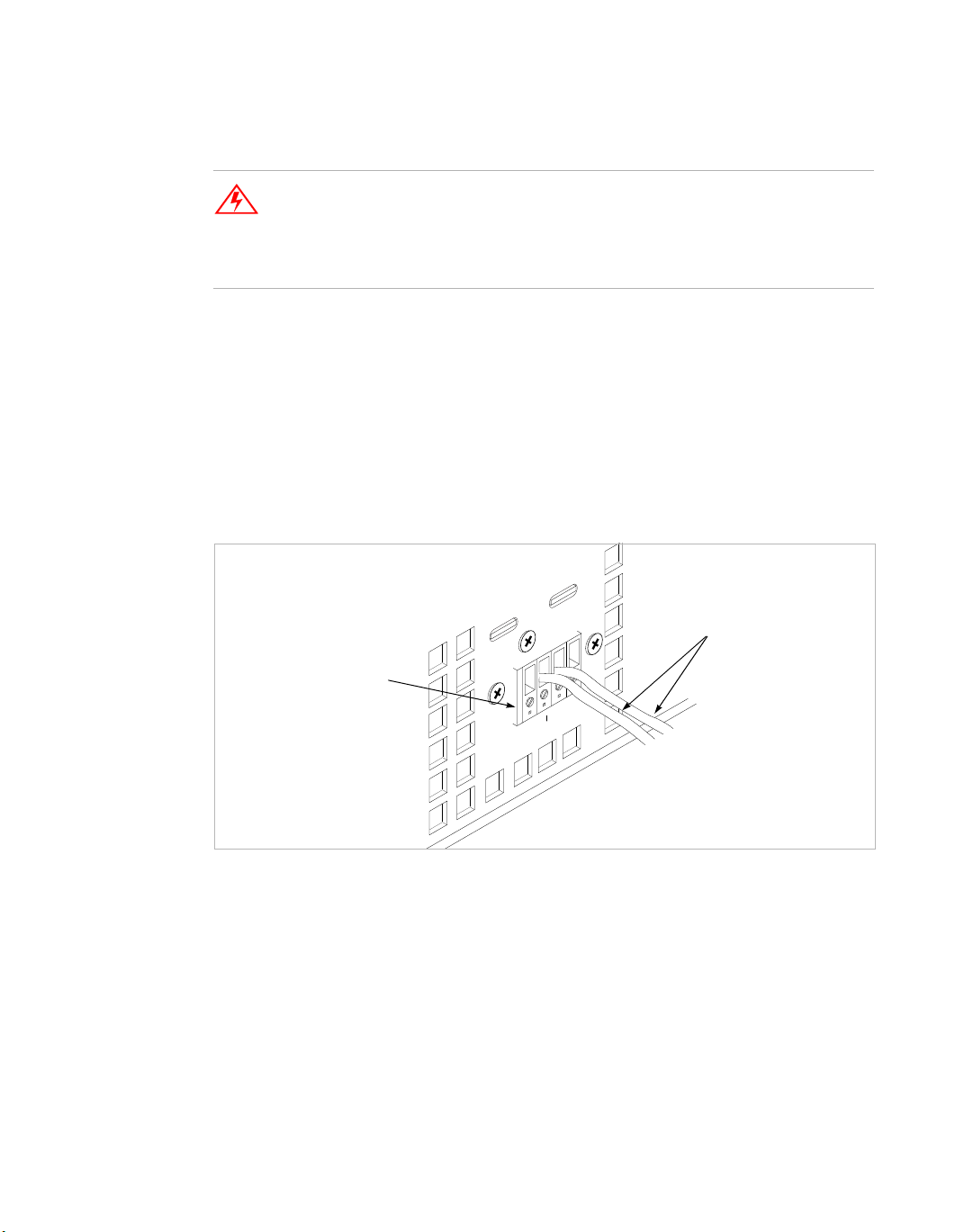

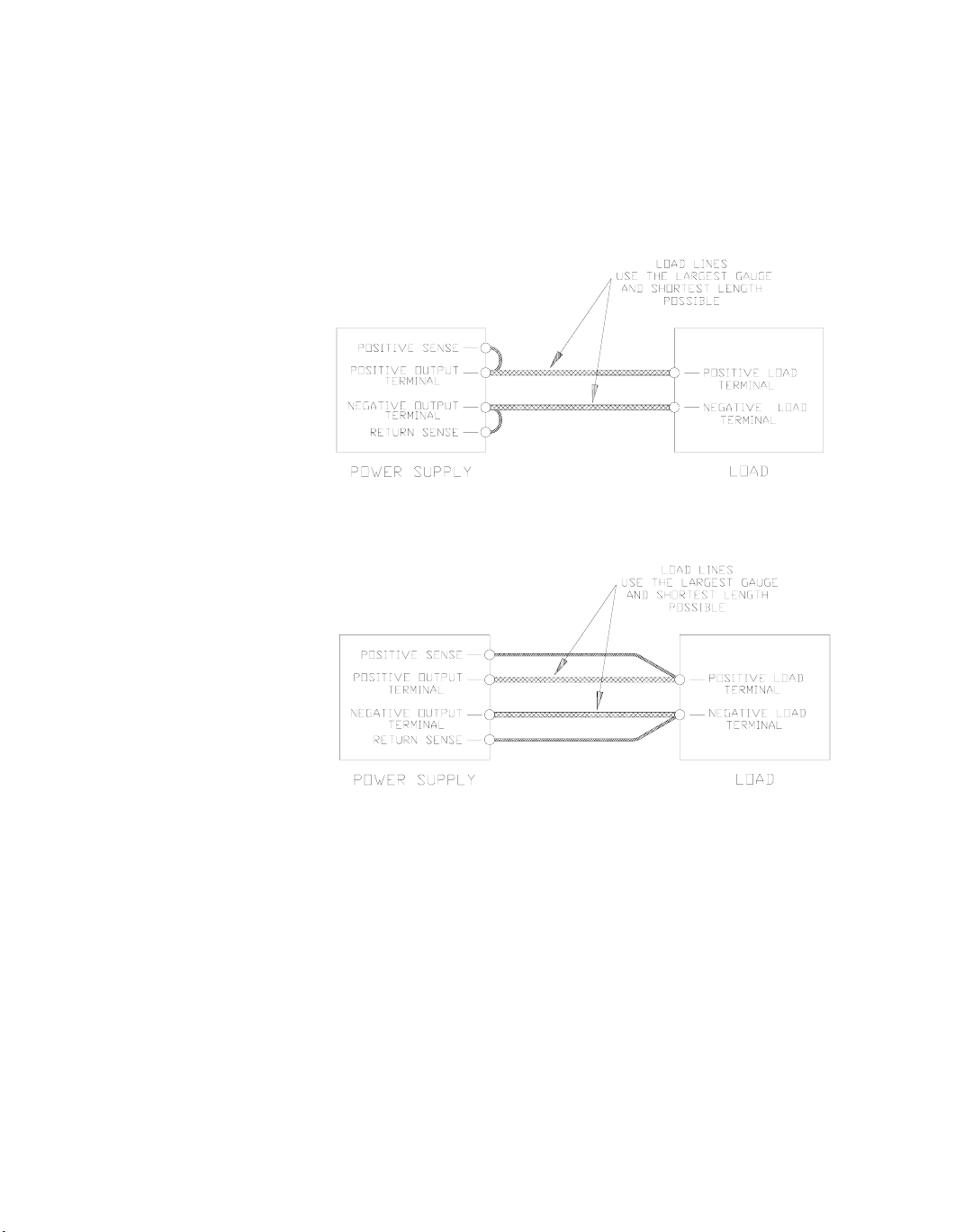

Figure 2.6 and Figure 2.7 show recommended load and sensing connections for

single loads. Local sense lines shown are default J2 connections.

You do not need remote sensing for basic operation of your supply. However, if you

wish to correct for any small drops in your load lines, then use this feature. Refer to

Using Remote Sensing for more information.

Figure 2.6 Single Load with Local Sensing (Default)

Figure 2.7 Single Load with Remote Sensing

Connecting

Multiple

Loads

Proper connection of distributed loads is an important aspect of power supply use.

Two common methods of connection are the parallel power distribution method and

the radial power distribution method.

Parallel Power Distribution This distribution method involves connecting leads

from the power supply to one load, from that load to the next load, and so on for each

load in the system. This method results in the voltage at each load depending on the

current drawn by the other loads and allows DC ground loops to develop. Except for

low current applications, we do not recommend using this method.

Revision A 45

Installation

Load Connection

Radial Power Distribution Method To connect distributed loads, we

recommend that you use radial power distribution. With this method, you connect

power to each load individually from a single pair of terminals designated as the

positive and negative distribution terminals. These terminals may be the power

supply output terminals, the terminals of one of the loads, or a distinct set of

terminals especially established for distribution use. Connect the sense leads to these

terminals to compensate for losses and minimize the effect of one load upon another.

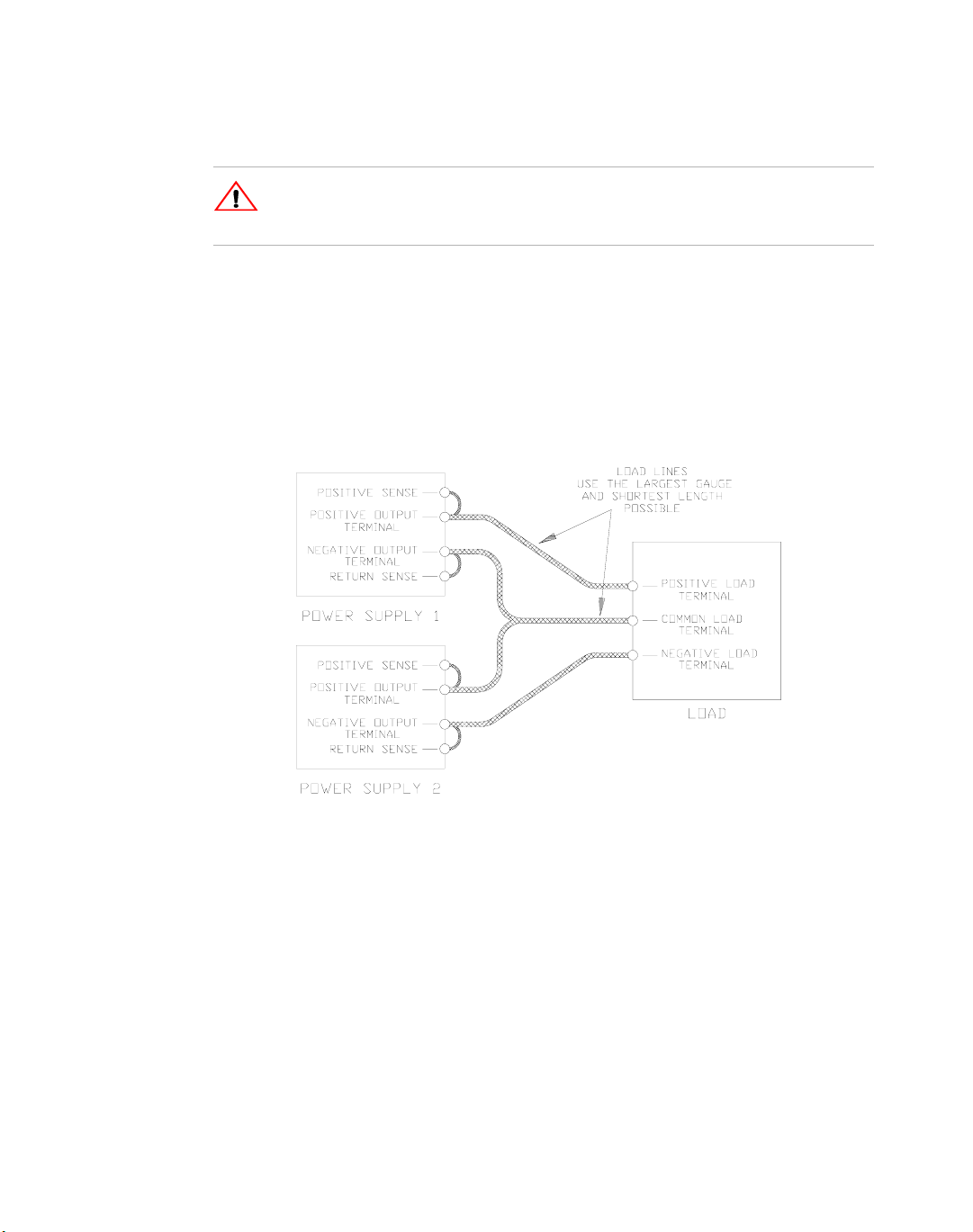

Figure 2.8 and Figure 2.9 show recommended load and sensing connections for

multiple loads. Local sense lines shown are default J2 connections. Refer to Using

Remote Sensing for how to ground the sense line shield.

Figure 2.8 Multiple Loads with Local Sensing

46 Operating Manual for XHR Series Power Supply

Figure 2.9 Multiple Loads with Remote Sensing

Installation

Load Connection

Revision A 47

Installation

!

Local and Remote Sensing

Local and Remote Sensing

Use connections on the rear panel J2 connector to set up the power supply for local

or remote sensing of output voltage.

Sense Wiring

WARNING

There is a potential shock hazard at the sense connector when using a power

supply with a rated output greater than 40 V. Select wiring with a minimum

insulation rating equivalent to the maximum output voltage of the power supply

for use as local sense jumpers or for remote sense wires. For example, select

TEW-105, 105 °C, 600 V wiring for use with a 600 V, 1.7 A power supply. Ensure

that connections at the load end are shielded to prevent contact with hazardous

voltages.

Local

Sensing

Using

Remote

Sensing

We ship the power supply with wire jumpers installed for local sensing of the output.

See “Rear Panel Illustrations” on page 18. With local sensing, the output voltage is

regulated at the output terminals. This method does not compensate for voltage

losses in the load lines, so it is recommended only for low current applications or for

applications in which load regulation is not essential.

Note: When using local sense connections, use the largest practical wire size to

minimize the effects of load line impedance on the regulation of the supply.

WARNING

There is a potential shock hazard at the sense points when using a power supply

with a rated output greater than 40 V. Ensure that connections at the load end

are shielded to prevent contact with hazardous voltages.

CAUTION

Do not use remote sensing with multiple supplies connected in series.

Note: Ground the sense line shield in one place only. Locations include: the power

supply’s return output connection at the load, the power supply’s return output at its

negative output terminal, or the power supply’s chassis.

48 Operating Manual for XHR Series Power Supply

Installation

Local and Remote Sensing

Use remote sensing during voltage mode operation to shift the power supply’s

regulation point from its output terminals to the load or distribution terminals by

using a separate pair of wires to allow the control circuitry to monitor the load