Sorensen XFR Series

2.8 kW

DC Power Supply with Zero Voltage “Soft Switching”

• Analog programming

• Zero voltage “soft switching”

• Constant voltage or constant current operation

with automatic crossover and mode indication

• Standby/Remote/Local modes

• Front panel button preview of voltage, current, OVP

• Remote sense, 5 V line loss compensation

• LabVIEW® and LabWindows® drivers

The Sorensen XFR Series provides 2.8 kilowatts

of power for research, product development,

and production test applications such as magnet

control, ATE, process control, electroplating and

burn-in. The XFR Series is ideal for applications

where high power and a wide adjustment of

output voltage or current is required.

The XFR Series is designed for excellent thermal

management so each unit can be conveniently

stacked in rack mounts without leaving ventilation

space between each unit.

The XFR Series features zero voltage “soft

switching” which virtually eliminates switching

transients, resulting in lower noise performance

that is closer to linear levels. Soft switching also

increases efciency, decreases heat generation,

and reduces stress on the switching transistors –

resulting in higher reliability.

7.5–600 V

4–300 A

19

0 208 230

208 230

858.458.0223

sales.ppd@ametek.com

AMETEK

Programmable Power

9250 Brown Deer Road

San Diego, CA 92121-2267

USA

10252013

47

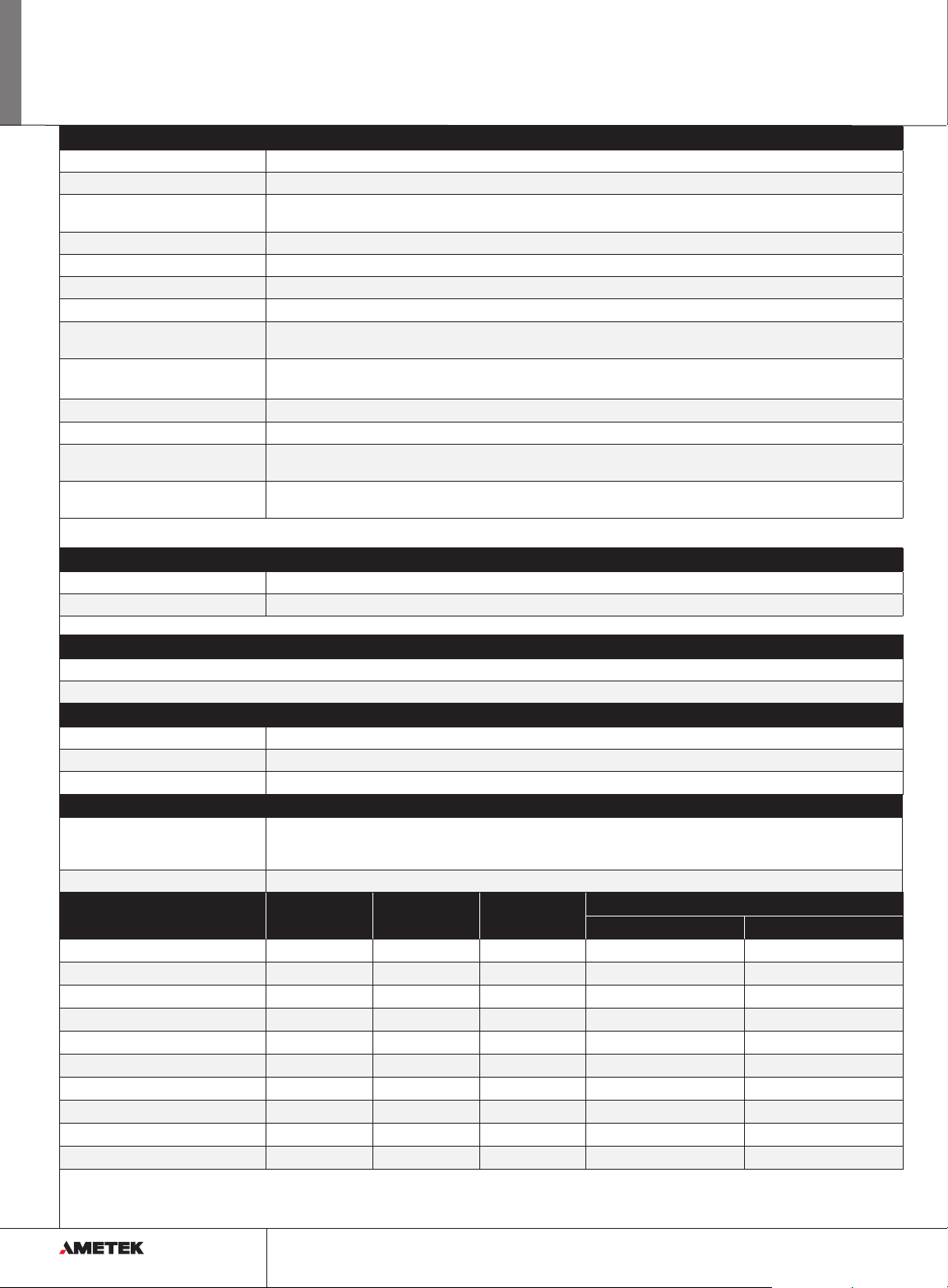

XFR Series : Product Specications

Common

Switching Frequency XFR 2.8 kW: Nominal 31 kHz (62 kHz output ripple) 60 V to 600 V models: nominal 62.5 kHz (125 kHz output ripple).

Time Delay 7 sec maximum from power on until output stable

Voltage Mode Transient Response Time < 3 ms for output voltage to recover within 0.5% of its rated voltage after a step change in load current of up

Maximum Voltage Differential ±600 Vdc from output to safety ground

Remote Start/Stop and Interlock 2.5-15 V signal or TTL-compatible input, selectable logic

Remote Analog Programming Voltage and current programming inputs (source must be isolated): 0-5 k, 0-10 k resistances; 0-5 V, 0-10 V (default) voltage sources

Remote Analog Monitoring Voltage and current monitor outputs 0-5 V, 0-10 V (default) ranges for 0-100% of output

Remote Programming &

Monitoring Accuracy

Maximum Remote Sense

Line Drop Compensation

Front Panel Voltage and Current Control 10-turn voltage and current potentiometers

Front Panel Voltage Control Resolution 0.02% of maximum voltage

Main Output Connector XFR 2.8 kW: 7.5 - 100 V models: nickel-plated copper bus bars with bus bar cover and strain relief; 150V to 600 V models: 4-terminal,

Approvals NRTL approved and CE-marked to UL Std. No. 61010-1, CAN/CSA-C22.2 No. 61010-1-04, EN 610101-1 (Equipment Class I, Pollution

Input

Input Voltage Ranges XFR 2.8 kW: 190-264 Vac, 1φ (24.3 A @ 208 Vac; 20.5 A @ 230 Vac typical), 47-63 Hz; Option: M2 3φ 208 Vac input

AC Input Connector Type 3-terminal, 34 A, 250 V, wire clamp connector with strain relief cover

to 10% to 90% of rated output

1% zero to full scale output for the default range

5 V / line (Line drop is subtracted from total voltage available at supply output.)

wire clamp connector with cover and strain relief

Degree 2, Installation Category II) Meets USA EMC standard: FCC, part 15B, Class A; Meets Canadian EMC standard: ICES-001, Class A.

Protection Features

Over-voltage protection

Over-temperature protection

Environmental

Operating Temperature XFR 2.8 kW: 0 to 50°C

Storage Temperature -20°C to 70°C

Humidity (Non-condensing) Up to 90% RH, non-condensing

Physical XFR 2.8 kW

Dimensions Width: 19” (429.4 mm)

Weight 33 lb (15 kg)

Height: 3.5” (88.9 mm)

Depth: 21” (533.5 mm)

Model Output Voltage Output Current Output Power Line Regulation

Voltage Current

XFR 7.5-300

XFR 12-220

XFR 20-130

XFR 33-85

XFR 40-70

XFR 60-46

XFR 100-28

XFR 150-18

XFR 300-9

XFR 600-4

0-7.5 V 0-300 A 2250 W 2.75 mV 32 mA

0-12 V 0-220 A 2640 W 3.2 mV 24 mA

0-20 V 0-130 A 2600 W 4 mV 15 mA

0-33 V 0-85 A 2805 W 5.3 mV 10.5 mA

0-40 V 0-70 A 2800 W 6 mV 9 mA

0-60 V 0-46 A 2760 W 8 mV 6.6 mA

0-100 V 0-28 A 2800 W 12 mV 4.8 mA

0-150 V 0-18 A 2700 W 17 mV 3.8 mA

0-300 V 0-9 A 2700 W 32 mV 2.9 mA

0-600 V 0-4 A 2400 W 62 mV 2.4 mA

2

48

www.ProgrammablePower.com

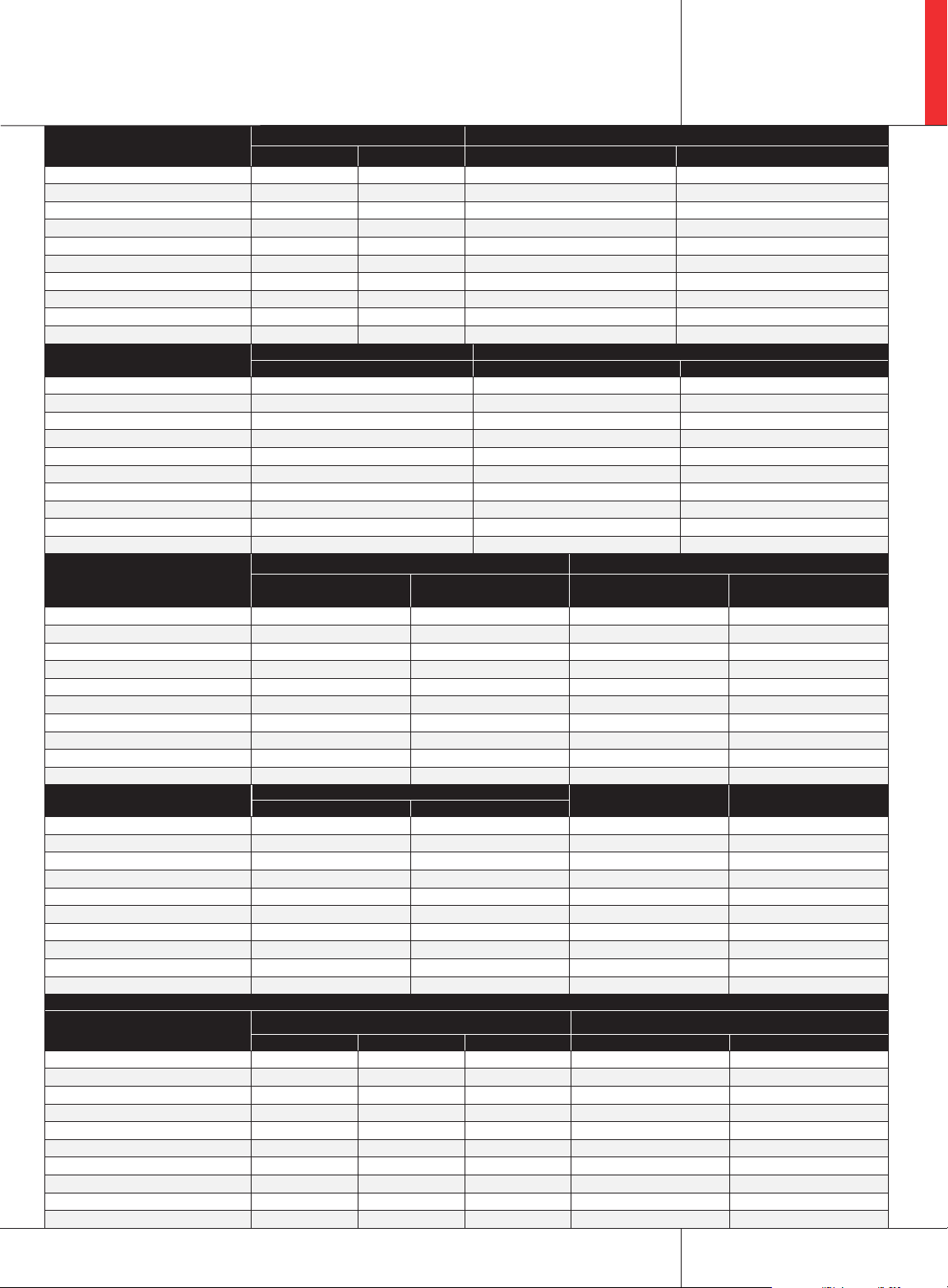

XFR Series : Product Specications

2.8 kW

Model Load Regulation

3

Meter Accuracy

Voltage Current Voltage (1% of Vmax + 1 count) Current (1% of lmax + 1 count)

XFR 7.5-300

XFR 12-220

XFR 20-130

XFR 33-85

XFR 40-70

XFR 60-46

XFR 100-28

XFR 150-18

XFR 300-9

XFR 600-4

6.5 mV 65 mA 0.09 V 4 A

7.4 mV 49 mA 0.13 V 2.3 A

9 mV 31 mA 0.3 V 1.4 A

11.6 mV 22 mA 0.43 V 0.95 A

13 mV 19 mA 0.5 V 0.8 A

17 mV 14.2 mA 0.7 V 0.56 A

27 mV 10.6 mA 1.1 V 0.38 A

35 mV 8.6 mA 1.6 V 0.19 A

65 mV 6.8 mA 4 V 0.1 A

125 mV 5.8 mA 7 V 0.05 A

Model Output Noise (0-20MHz) Output Ripple (rms)

Voltage (p-p) Voltage Current

XFR 7.5-300

XFR 12-220

XFR 20-130

XFR 33-85

XFR 40-70

XFR 60-46

XFR 100-28

XFR 150-18

XFR 300-9

XFR 600-4

100 mV 10 mV 1600 mA

100 mV 10 mV 1200 mA

100 mV 10 mV 400 mA

100 mV 15 mV 300 mA

150 mV 15 mV 200 mA

150 mV 15 mV 100 mA

175 mV 25 mV 80 mA

200 mV 25 mV 40 mA

400 mV 40 mV 20 mA

500 mV 100 mV 10 mA

Model Drift (8 hours)4 Temp Coeffcient

Voltage

(0.05% of Vmax)

XFR 7.5-300

XFR 12-220

XFR 20-130

XFR 33-85

XFR 40-70

XFR 60-46

XFR 100-28

XFR 150-18

XFR 300-9

XFR 600-4

3.75 mV 150 mA 1.5 mV 90 mA

6 mV 110 mA 2.4 mV 66 mA

10 mV 65 mA 4 mV 39 mA

16.5 mA 42.5 mA 6.6 mV 25.5 mA

20 mV 35 mA 8 mV 21 mA

30 mV 23 mA 12 mV 13.8 mA

50 mV 14 mA 20 mV 8.4 mA

75 mV 9 mA 30 mV 5.4 mA

150 mV 4.5 mA 60 mV 2.7 mA

300 mV 2 mA 120 mV 1.2 mA

Model Program Slew Rate

Rise time Fall time

XFR 7.5-300

XFR 12-220

XFR 20-130

XFR 33-85

XFR 40-70

XFR 60-46

XFR 100-28

XFR 150-18

XFR 300-9

XFR 600-4

100 ms 100 ms 0.375-8.25 V 80%

100 ms 100 ms 0.6-13.2 V 82%

100 ms 100 ms 1-22 V 85%

100 ms 100 ms 1.65 - 36.6 V 85%

100 ms 100 ms 2-44 V 87%

100 ms 100 ms 3-66 V 90%

170 ms 170 ms 5-110 V 90%

170 ms 170 ms 7.5-165 V 90%

170 ms 170 ms 15-330 V 91%

170 ms 100 ms 30-660 V 91%

Current

(0.05% of lmax)

6

Voltage

(0.02% of Vmax ºC)

OVP Adjustment Range

(5% to 110% of Vmax)

(0.03% of Vmax ºC)

Interface Specications with RS-232 or GPIB Interface Installed*

Model Program Accuracy Readback Accuracy

Voltage (mV) Current (mA) OVP (mV) Voltage (mV) Current (mA)

XFR 7.5-300

XFR 12-220

XFR 20-130

XFR 33-85

XFR 40-70

XFR 60-46

XFR 100-28

XFR 150-18

XFR 300-9

XFR 600-4

10 +0.12% 900 +0.15% 40 30 +0.12% 900 +0.1%

75 +0.12% 750 +0.15% 75 75 +0.12% 750 +0.1%

75 +0.12% 500 +0.15% 100 75 +0.2% 500 +0.1%

75 +0.3% 425 +0.1% 175 75 +0.3% 425 +0.1%

75 +0.3% 350 +0.15% 200 75 +0.3% 350 +0.1%

150 +0.3% 250 +0.1% 300 150 +0.35% 250 +0.1%

150 +0.35% 140 +0.15% 500 150 +0.35% 140 0.1%

225 +0.35% 120 +0.1% 750 225 +0.35% 120 +0.1%

225 +0.35% 80 +0.1% 1500 225 +0.35% 80 +0.1%

300 +0.35% 80 +0.1% 3000 250 +0.35% 80 +0.1%

5

Current

Efciency

7

858.458.0223

sales.ppd@ametek.com

49

XFR Series : Diagram

16.9 [429.3]

21.2 [538.1]

TOP VIEW

17.5 [443.9]

3.5 [87.6]

50

19.0 [482.6]

FRONT VIEW

XFR 2.8

www.ProgrammablePower.com

XFR 40

Series

Voltage

70

Current

(XXX)

Options

XFR Series

Model Number Description

XFR 2.8 Options and Accessories

MGA / MGB* GPIB / IEEE 488.1

MGP Multi-channel GPIB / IEEE 488.2

MCA CANbus interface for hardware linking multiple units (used with GPIB-M)

MRA / MRB* RS-232 interface

MIA ISOL interface card provides isolated analog control and readback

M2 3-phase 208 Vac input

Specications subject to change without notice.

1. Specications indicate typical performance at 25°C ±5°C, nominal line input of 208 Vac.

2. For input voltage variation over the AC input voltage range, with constant rated load.

3. For 0-100% load variation, with constant nominal line voltage.

4. Maximum drift over 8 hours with constant line, load and temperature, after 30 minute warm-up.

5. Change in output per °C change in ambient temperature, with constant line and load.

6. Measured with stepped 0-10 V analog programming source and a resistive load.

7. Typical efciency at nominal input voltage and rated output power.

8. Apply accuracy specications according to the following voltage program accuracy example:

Set a model 20-130 power supply to 10 V. The expected result will be within the range of 10 V ± 75 mV ± 0.12% of the set voltage of 10 V.

* MGB/MRB 600V output only. MGA/MRA for output less than 600V GB 600V output only. MGA for output less than 600V

2.8 kW

© 2013 AMETEK Programmable Power All rights reserved. AMETEK Programmable Power is the trademark of AMETEK Inc., registered in the U.S. and other countries.

Elgar, Sorensen, California Instruments, and Power Ten are trademarks of AMETEK Inc., registered in the U.S.

sales.ppd@ametek.com

858.458.0223

51

Notes

52

www.ProgrammablePower.com

Loading...

Loading...