Page 1

Installation Guide

Grid Tie Interface (GTI)

SW Series

SW4024, SW4048, SW5548

Page 2

ii

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

About Xantrex

Xantrex Technology Inc., is a world-leading supplier of advanced power

electronics and controls with products from 50 watt mobile units to 1 MW utilityscale systems for wind, solar, batteries, fuel cells, microturbines, and backup power

applications in both grid-connected and stand-alone systems. Xantrex products

include inverters, battery chargers, programmable power supplies, and variable

speed drives that convert, supply, control, clean, and distribute electrical power.

Trademarks

Trace and Xantrex are registered trademarks of Xantrex International.

Notice of Copyright

Grid Tie Interface (GTI) Installation Guide ©March 2002 Xantrex Technology

Inc. All rights reserved.

Disclaimer

While every precaution has been taken to ensure the accuracy of the contents

of this guide, Xantrex International assumes no responsibility for errors or

omissions. Note as well that specifications and product functionality may change

without notice.

Since the use of this manual and the conditions or methods of installation,

operation, use and maintenance of the unit are beyond the control of Xantrex

Technology Inc., the company does not assume responsibility and expressly

disclaims liability for loss, damage, or expense arising out of or any way connected

with such installation, operation, use, or maintenance.

Due to continual improvement through product updates, photographs and/or

illustrations used in this manual may not

exactly

match your unit. Xantrex

Technology Inc., reserves the right to update this product without notice or releasing

an updated manual when

fit, form or function

are not affected.

Date and Revision

March 2002, Revision A

Part Number

975-0041-01-02

Contact Information

Web: www.xantrex.com

Email: dpm@xantrex.com

Phone: 360/435.8826

Fax: 360/435.2229

Page 3

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

iii

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed

during the installation and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation and

operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING WARNING

WARNING WARNING

WARNING - A DANGEROUS VOLTAGE OR

CONDITION EXISTS IN THIS AREA. USE EXTREME

CAUTION WHEN PERFORMING THESE TASKS.

AA

AA

A

VERTISSEMENT VERTISSEMENT

VERTISSEMENT VERTISSEMENT

VERTISSEMENT - UNE TENSION OU CONDITION

DANGEREUSE EXISTE DANS CETTE ZONE. FAIRE

PREUVE D’EXTRÊME PRUDENCE LORS DE LA

RÉALISATION DE CES TÂCHES.

CAUTION CAUTION

CAUTION CAUTION

CAUTION - This procedure is critical to the safe

installation or operation of the unit. Follow these

instructions closely.

AA

AA

A

TTENTION TTENTION

TTENTION TTENTION

TTENTION - Cette procédure est essentielle à

l’installation ou l’utilisation de l’unité en toute

sécurité. Suivre ces instructions de près.

NOTE NOTE

NOTE NOTE

NOTE - This statement is important. Follow instructions

closely.

NOTE NOTE

NOTE NOTE

NOTE - Cette déclaration est importante. Suivre les

instructions de près.

• All electrical work must be done in accordance with local, national, and/or

international electrical codes.

• Before installing or using this device, read all instructions and cautionary

markings located in the manual, and on the inverter, the batteries, and the PV

array.

• Do not expose this unit to rain, snow, or liquids of any type. This product is

designed only for indoor mounting.

• To reduce the chance of short-circuits use instulated tools when installing or

working with the inverter, the batteries, or the PV array.

• Remove all jewelry while installing this system. This will greatly reduce the

chance of accidental exposure to live circuits.

Page 4

iv

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

SAVE THESE INSTRUCTIONS

• The unit contains more than one live circuit (inverter and utility grid). Power

may be present at more than one source.

• This product contains no user-serviceable parts. Do not attempt to repair this

unit.

• To reduce risk of electric shock, disconnect all wiring before attempting any

maintenance or cleaning.

• Do not mount this device in unventilated enclosures.

• To reduce risk of electric shock, disconnect all wiring before attempting any

maintenance or cleaning.

• Additional AC disconnects may be required as part of the system installation.

Consult local and national electrical code requirements.

• This unit is designed to be horizontally wall mounted.

• The AC input and output neutral conductors are not connected (bonded) to

the chassis.

• The AC input and output HOT conductor are not isolated from each other.

• The chassis housing of the GTI must be connected to a permanent grounding

system as required by the National Electric Code, ANSI/NFPA 70-1996. This is

the responsibility of the system installer. A grounding terminal lug is provided

for connection of an equipment grounding conductor.

• CSA certified for sale in the U.S. under Photovoltaic Power Systems (UL1741).

IMPORTANT SAFETY INSTRUCTIONS (Continued)

Page 5

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

v

CC

CC

C

ontentsontents

ontentsontents

ontents

IMPORTANT SAFETY INSTRUCTIONS ............................................................. iii

1.0 INTRODUCTION1.0 INTRODUCTION

1.0 INTRODUCTION1.0 INTRODUCTION

1.0 INTRODUCTION

............................................................................................................................

............................................................................................................................

..............................................................

11

11

1

Introduction .......................................................................................................... 1

Standard Features .................................................................................................4

Utility Interactive Mode ....................................................................................4

Bypass Mode .................................................................................................... 4

2.0 INST2.0 INST

2.0 INST2.0 INST

2.0 INST

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

..................................................................................................................................

..................................................................................................................................

.................................................................

55

55

5

Pre-Installation ......................................................................................................5

Required Tools and Materials .......................................................................... 5

Removing the Top Cover .................................................................................. 5

Mounting ...............................................................................................................6

Procedure ..........................................................................................................6

Wiring .................................................................................................................... 8

AC Wiring for Single-Inverter Installations ......................................................8

Ground Wiring ........................................................................................... 10

Utility Grid AC Wiring to the GTI .............................................................. 12

Inverter AC Input Wiring to the GTI ..........................................................14

Inverter AC Output Wiring to the GTI .......................................................16

GTI Wiring to the Sub-Panel ......................................................................18

Communications Cable ............................................................................. 20

AC Wiring for Dual-Inverter Installations ...................................................... 22

Ground Wiring ........................................................................................... 24

Utility Grid AC Wiring to Dual GTIs ..........................................................26

Inverter AC Input and Output Wiring to the GTIs ...................................28

GTI Wiring to the Sub-Panel ......................................................................30

Connecting the Communications Cables for Dual Inverter Installations 30

AC Rewiring for Dual-Inverter Power Panel Installations ............................. 32

AC Rewiring for Power Module Installations ................................................ 34

AC Rewiring for Power Module Installations (continued) ............................36

Wiring Check ....................................................................................................... 37

Operating Stacked Inverters ...............................................................................37

Start-up and Test .................................................................................................37

3.0 TROUBLESHOOTING3.0 TROUBLESHOOTING

3.0 TROUBLESHOOTING3.0 TROUBLESHOOTING

3.0 TROUBLESHOOTING

..........................................................................................................

..........................................................................................................

.....................................................

3939

3939

39

APPENDIX A – SPECIFICAAPPENDIX A – SPECIFICA

APPENDIX A – SPECIFICAAPPENDIX A – SPECIFICA

APPENDIX A – SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

..................................................................................

..................................................................................

.........................................

A-1A-1

A-1A-1

A-1

Electrical Specifications1 .................................................................................. A-1

Mechanical Specifications ................................................................................ A-1

APPENDIX B – PRODUCT AND SYSTEM INFORMAAPPENDIX B – PRODUCT AND SYSTEM INFORMA

APPENDIX B – PRODUCT AND SYSTEM INFORMAAPPENDIX B – PRODUCT AND SYSTEM INFORMA

APPENDIX B – PRODUCT AND SYSTEM INFORMA

TIONTION

TIONTION

TION

........

........

....

B-1B-1

B-1B-1

B-1

Warranty ............................................................................................................ B-1

Return Material Authorization Policy ............................................................... B-2

Return Material Procedure ........................................................................... B-2

Service Information .......................................................................................... B-3

Page 6

vi

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

List of FiguresList of Figures

List of FiguresList of Figures

List of Figures

Figure 1-1 Grid Tie Interface Flow Diangram .......................................................... 2

Figure 1-2 Grid Tie Interface Flow Diagram

with External Manual Bypass Switch ................................................. 3

Figure 1-3 Grid Tie Interface Unit .............................................................................4

Figure 2-1 Removing the Top Cover ......................................................................... 5

Figure 2-2 Mounting Holes ...................................................................................... 6

Figure 2-3 Dimensional Drawing (Not to scale) ..................................................... 7

Figure 2-4 GTI Circuit Board Enlargement ...............................................................8

Figure 2-5 AC Input and Output Wiring for Single-Inverter Installations .............. 9

Figure 2-5a Ground Wiring for a Single-Inverter Installations ................................ 11

Figure 2-5b Utility Grid AC Wiring to the GTI ..........................................................13

Figure 2-5c Inverter AC Input Wiring to the GTI ..................................................... 15

Figure 2-5d Inverter AC Output Wiring to the GTI .................................................. 17

Figure 2-5e GTI Wiring to the Sub-Panel ................................................................. 19

Figure 2-6 GTI Communications Cable Location .................................................. 20

Figure 2-7 Connecting the Communications Cable to the Circuit Board ............. 21

Figure 2-8 Wiring Diagram for Dual-Inverter Installations ................................... 23

Figure 2-8a Ground Wiring for Dual-Inverter Installations ..................................... 25

Figure 2-8b Utility Grid AC Wiring to Dual GTIs ..................................................... 27

Figure 2-8c Inverter AC Input and Output Wiring to Dual GTIs ............................ 29

Figure 2-8d GTI Wiring to the Sub-Panel ................................................................. 31

Figure 2-9 Re-wiring Power Panel Installations to include dual GTIs ................... 33

Figure 2-10 Original Power Module Wiring ............................................................. 35

Figure 2-10a Power Module Rewiring for dual GTI Installations ..............................36

Page 7

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

1

1.0 INTRODUCTION

INTRODUCTION

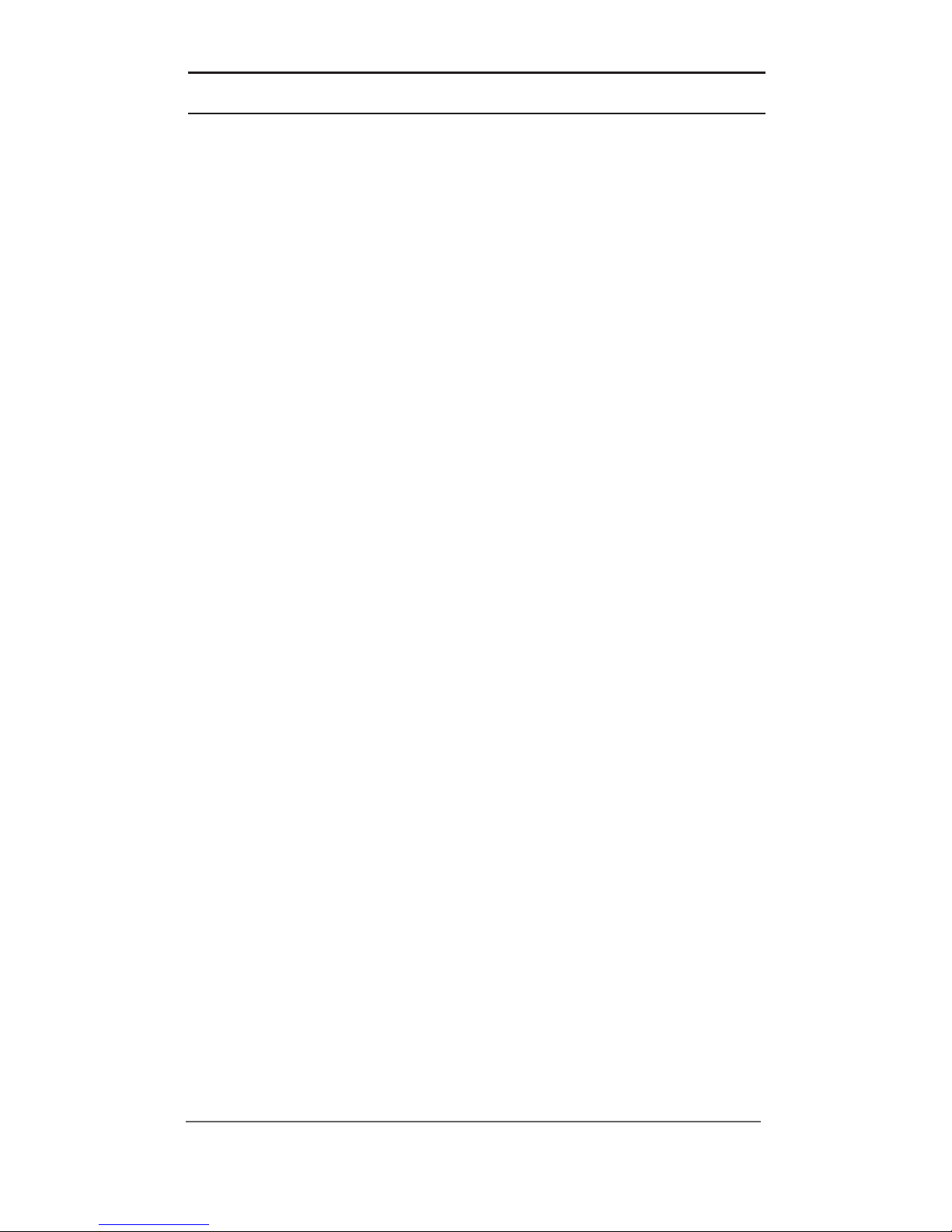

The Grid Tie Interface (GTI) is an integrated assembly used with the Trace™

SW Series II inverter/charger with Revision 4.2 (or higher) software. This new device

provides active anti-islanding protection and reduces current Total Harmonic

Distortion (THD) as required in UL-1741-2000.

The Grid Tie Interface is an accessory, which is connected between the grid, the

AC loads, and the SW Series II inverter to optimize the “SELL” feature. While there

is a small inductor in the GTI, this device is not a “filter”; rather it contains an

additional control microprocessor, which connects to the SW Series II with a

communications cable.

When the GTI is connected and the Inverter “SELL” mode is selected, the

microprocessor of the GTI takes control of the SW Series II and operates the inverter

“SELL” feature. The GTI affords a dedicated microprocessor and new, sophisticated

control algorithms that are able to optimize the sell function.

The SW Series II with the GTI meets all power quality requirements of UL1741,

including harmonic distortion, power factor, and anti-islanding requirements. In

addition, it has increased the SW Series II’s efficiency in SELL mode to within 1% of

the impressive off-grid efficiency of the SW.

The GTI also contains an automatic transfer/shorting relay, which the SW

Series II uses to disconnect the GTI from the circuit when it is not needed, for

example when the SW Series II is charging batteries from the grid. This is also used

to disconnect the GTI so that it does

NOTNOT

NOTNOT

NOT

represent a phantom load or parasitic

loss to the system.

All new SW Series II units (manufactured since December of 2001) are

equipped to allow the GTI to be installed in the field. The SW Series II inverter is

Certified to UL1741 for off grid and backup power applications. The SW can be

connected to the grid as a battery charger; however, it is

NOTNOT

NOTNOT

NOT

approved to use the

SELL feature (net meter) without the GTI accessory. The GTI carries all necessary

approvals and markings to allow a safety inspector to approve the installation for net

metering.

Page 8

1.0 INTRODUCTION

2

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Figure 1-1

Grid Tie Interface Flow Diagram

Page 9

1.0 INTRODUCTION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

3

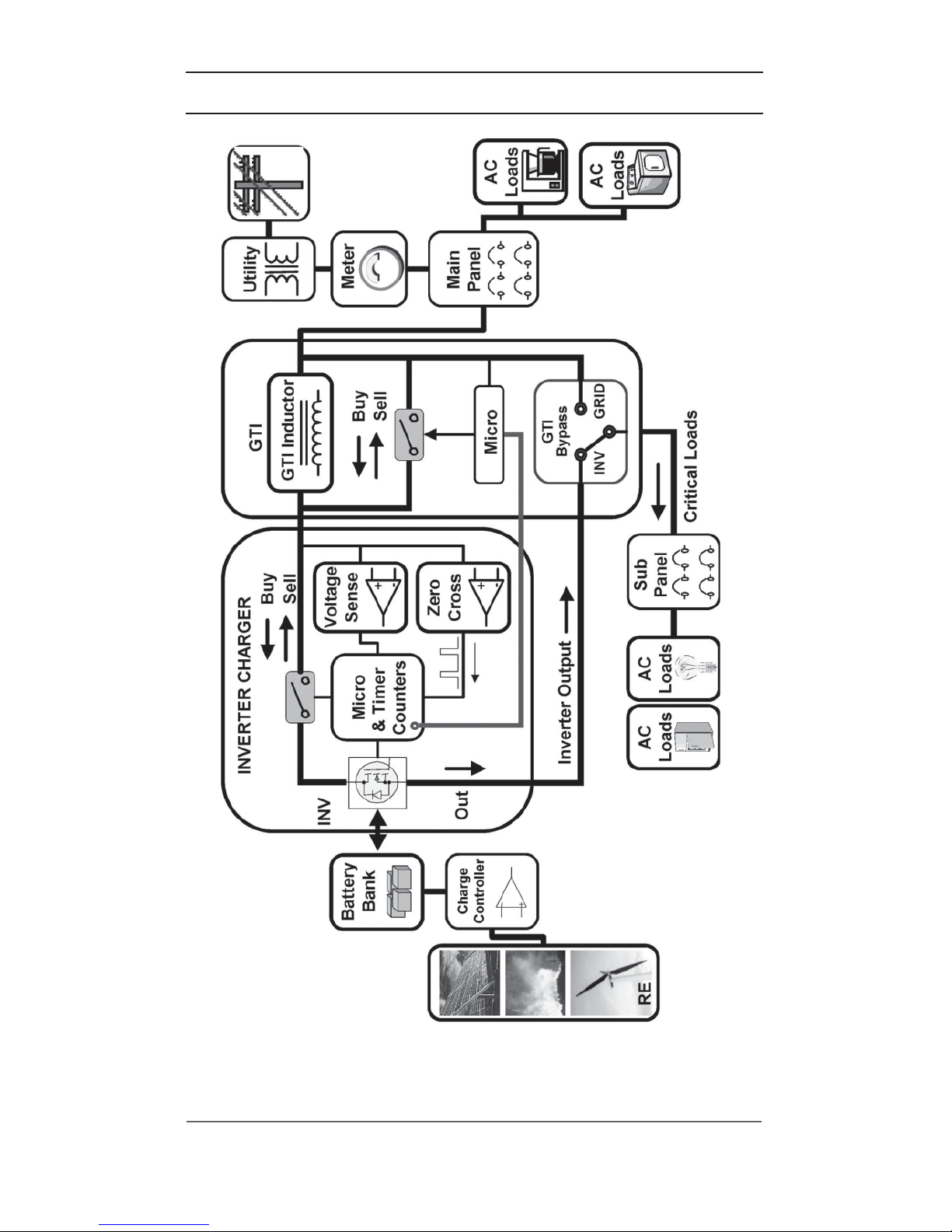

Figure 1-2

Grid Tie Interface Flow Diagram with External Manual Bypass Switch

Page 10

1.0 INTRODUCTION

4

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

STANDARD FEATURES

The Grid Tie Interface (GTI) is an external unit that is required for use with the

Xantrex SW Series Inverters, models SW4024, SW4048, and SW5548 with Rev. 4.2

firmware or higher, being used in Utility Interactive “Sell” mode. This device ensures

compliance with regulatory standards for utility interface applications.

The GTI utilizes a highly-efficient inductor constructed of high temperature

materials and M-6 grade steel laminations, meeting UL Class-H standards.

The unit is housed in a powder-coated, steel enclosure, suitable for indoor

installations and contains dual knockouts for ¾" - 1" and ½" - ¾" conduit

connections. The unit includes a control board with one 10-pin, polarized, connector

that connects to the SW inverter.

The GTI has two functions: 1) Utility Interactive Mode, and 2) Bypass Mode.

Utility Interactive Mode

Utility Interactive Mode is only engaged when the SW inverter begins selling

power in the “Sell” mode. When in this mode, the GTI engages an inductor

through an internal relay that filters out current harmonics and ensures that the

power transferred to the grid has Total Harmonic Distortion (THD) levels that are

within acceptable ranges and ensures the power factor is high. The GTI also

provides anti-islanding protection in the event of a utility grid failure.

Bypass Mode

The GTI includes a bypass relay that is controlled by the current direction and

levels in the GTI and allows the critical loads to be connected to the grid or to the

output of the SW inverter. When a low level “sell” current begins, the GTI will

engage the bypass relay to allow the loads to be connected to the grid. In this

operation (grid-connected), the inverter’s AC1 relay and the bypass relay work

together to ensure fast transfer of the critical loads in a backup situation.

The critical loads are effectively connected directly to the grid – through the GTI

– rather than passing through the inverter, resulting in the “LOAD AMPS AC” menu

item displayed on the SW inverter to read zero. This zero reading will continue until

the inverter batteries require a “buy” current of 10-15 amps AC or if a loss of grid

power is detected. If either one of these conditions is detected, the bypass relay will

engage to allow the critical loads to be directly powered by the inverter (inverterconnected). The inverter will continue to power the critical loads until another “sell”

current begins, which again switches to the grid-connected operation.

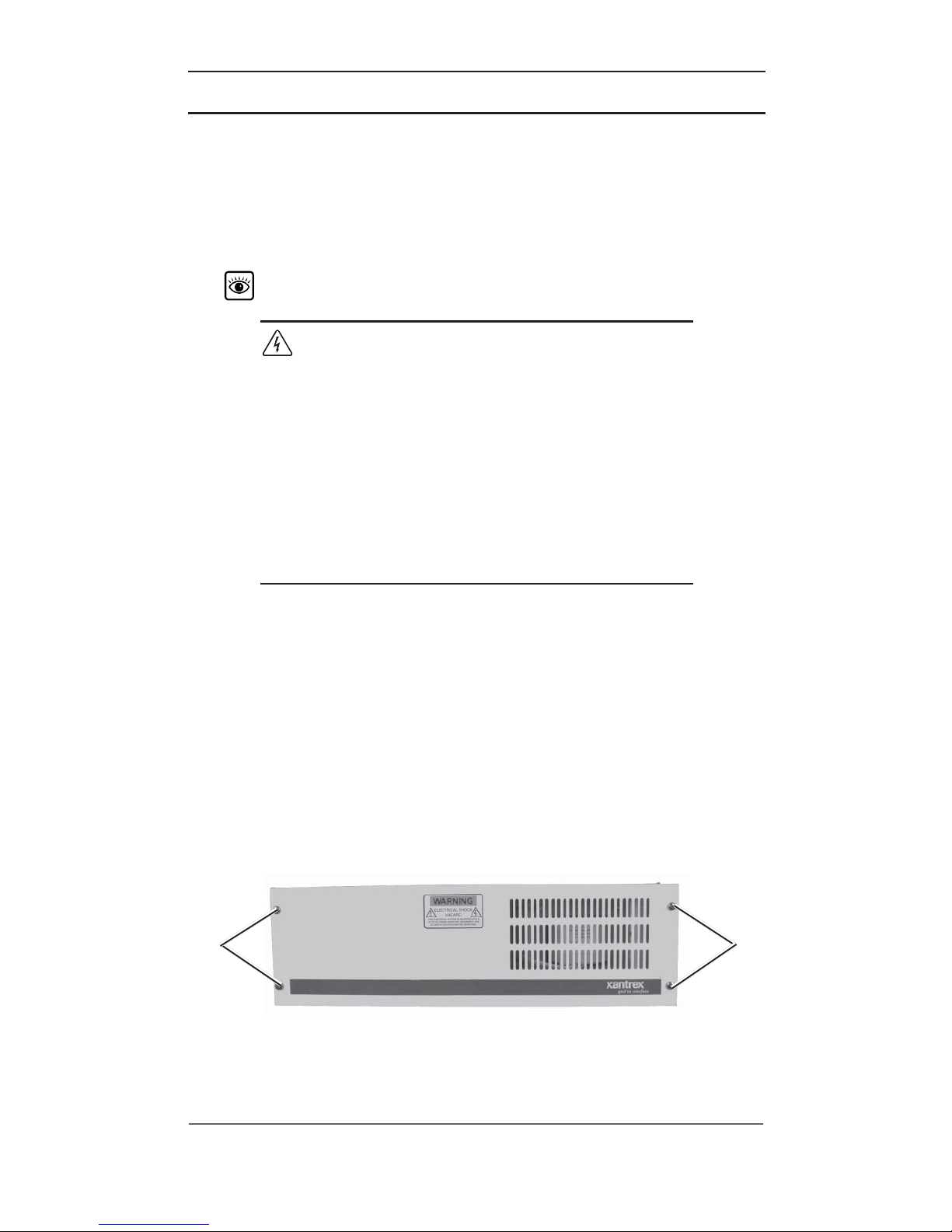

Figure 1-3

Grid Tie Interface Unit

Page 11

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

5

2.0 INSTALLATION

PRE-INSTALLATION

The GTI is only designed to work with the SW4024, SW4048 and SW5548

models that have revision 4.2 (or higher) software. Prior to installing the GTI,

ensure that you have the appropriate model, the proper level of software and the

inverter has the communication cable located within.

See Figure 2-6 for the location of this cable.

WARNING: THE CRITICAL LOADS ARE NOW

POWERED THROUGH THE GTI; THESE LOADS

WILL NOT BE POWERED IF THE SW INVERTER OR

THE GTI ARE OFF OR DISCONNECTED. IT IS

RECOMMENDED THAT AN EXTERNAL BYPASS

SWITCH/BREAKER BE INSTALLED BETWEEN THE

GRID AND THE CRITICAL LOAD-PANEL. THIS

SWITCH, WHEN ENGAGED, WILL ALLOW THE

GRID TO DIRECTLY POWER THE LOADS WHILE

THE GTI OR SW INVERTER IS OFF OR

DISCONNECTED. SEE FIGURE 2-9 FOR AN

EXAMPLE OF THIS RELAY IN A XANTREX POWER

PANEL.

Required Tools and Materials

• Wire strippers

• Phillips screw driver

• Slotted screw driver

• Torque wrench

• 3/16" Hex-Head wrench

• #6 AWG Wire

Removing the Top Cover

1. Remove the four Phillips screws and starwashers and set aside. Be sure to

put these screws and washers somewhere where they can’t get lost.

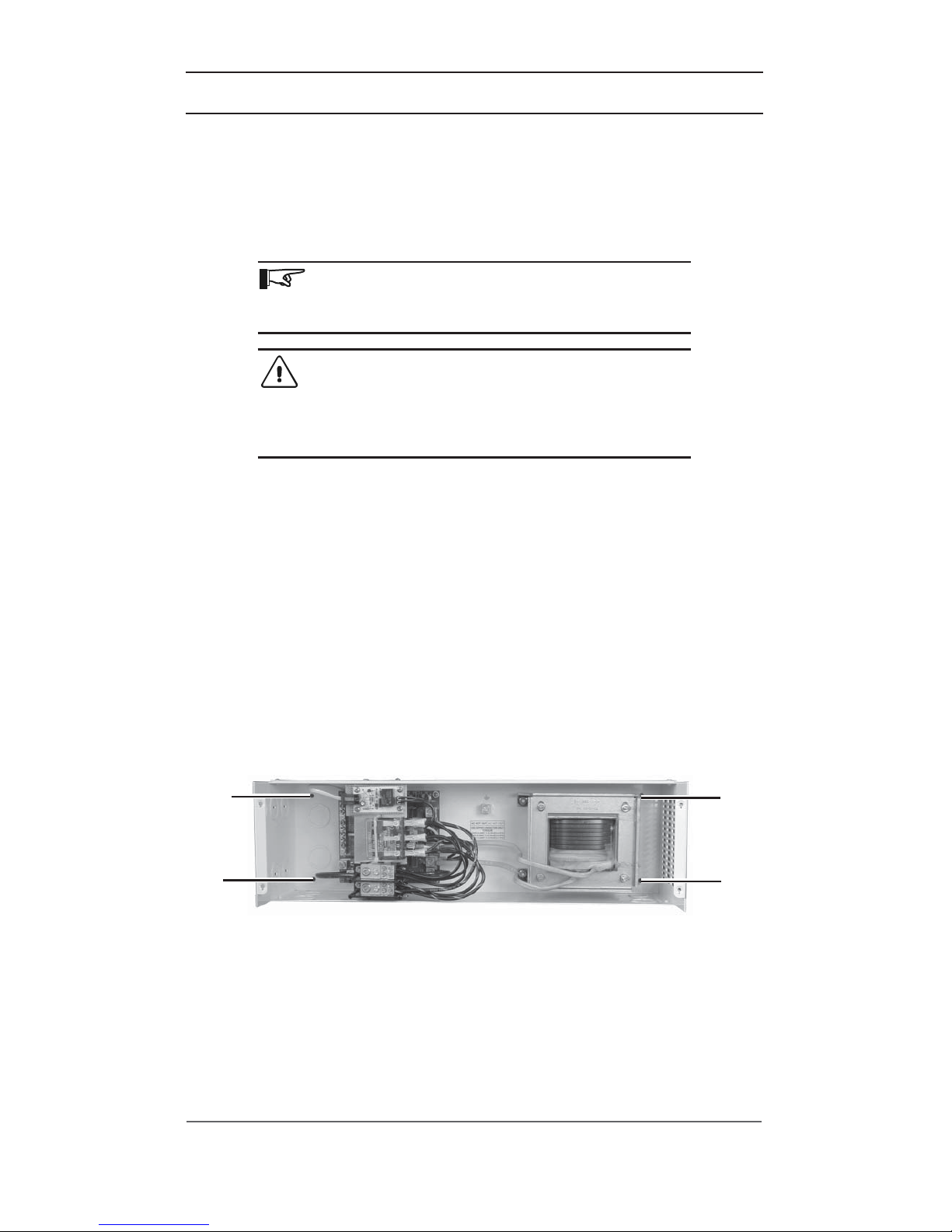

Figure 2-1

Removing the Top Cover

Remove

these

phillips

screws to

remove

top cover

Remove

these

phillips

screws to

remove

top cover

Page 12

2.0 INSTALLATION

6

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Figure 2-2

Mounting Holes

Mounting

Hole

Mounting

Hole

Mounting

Hole

Mounting

Hole

MOUNTING

Place the GTI in a convenient location, close to the inverter. The GTI must

be mounted horizontally on a flat surface (such as a wall) in a clean, dry

environment. Do not mount the GTI where it will be exposed to the weather or in

a damp location.

NOTE: The GTI weighs approximately 25 pounds. Use

appropriate wall anchors or backing material (plywood,

2 x 4’s, etc.) that will support its weight.

CAUTION: Do not mount vertically as water may

enter the enclosure and damage the internal

circuitry. Damage caused by mounting the unit

vertically is NOT covered under the limited

warranty.

Procedure

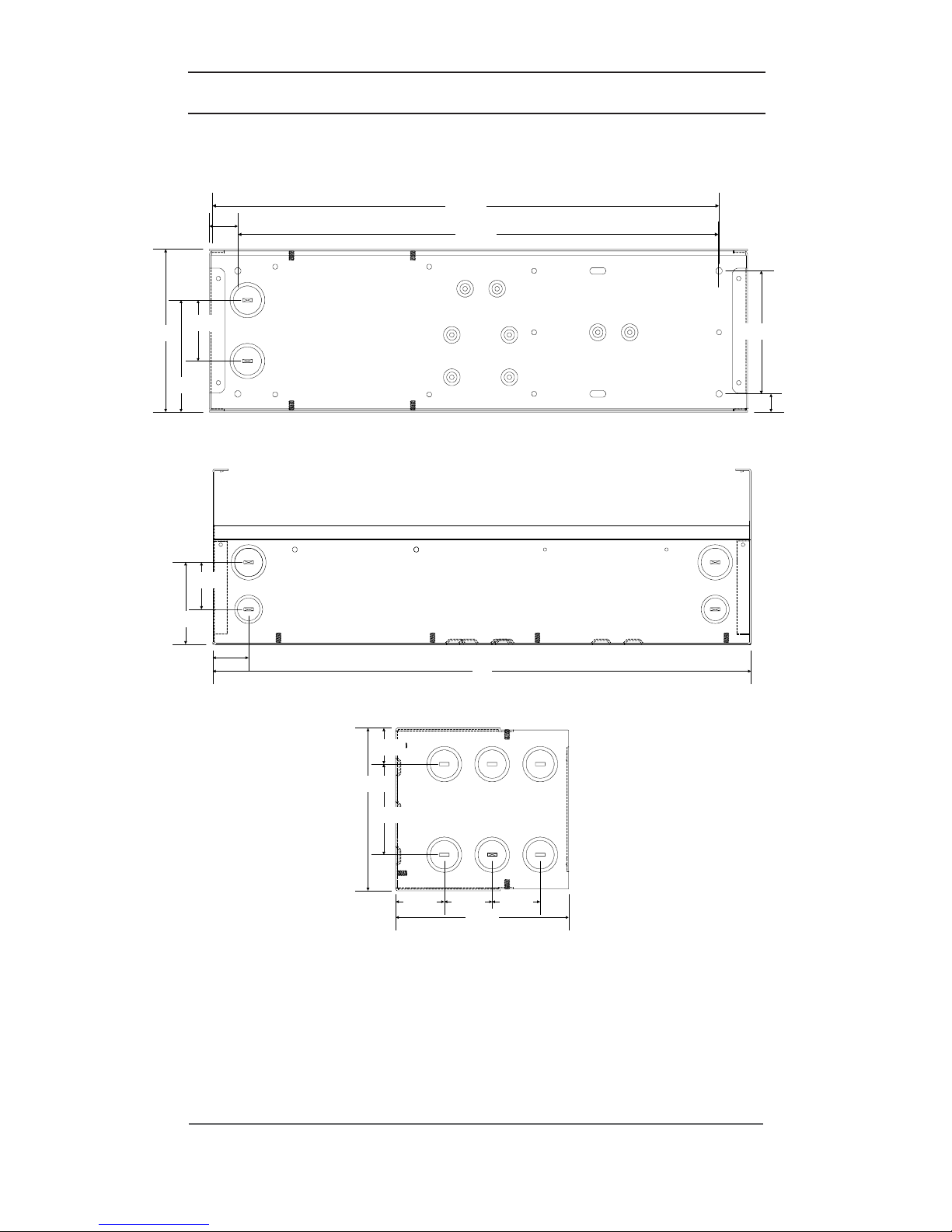

1. Use a level and mark the location for mounting the unit on the wall.

2. Measure out the four mounting screw holes according to Figure 2-3.

3. Use a #10 x 3/8 (or 1/2) inch long screw and washer (and appropriate

anchors if necessary) and mount the GTI securely to the wall or backing

material (plywood, 2 x 4’s, etc.).

4. Remove the appropriate knockouts for the conduit. Install the conduit

between the GTI and the inverter. Use separate conduit for the AC wiring

and the communications cable.

Page 13

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

7

Figure 2-3

Dimensional Drawing (Not to scale)

Front Internal view of unit

Side of unit

Ends of unit (both ends)

2 3/8"

4 3/8"

1 1/8"

19 7/8"

4 3/4"

3/4"

6 1/8"

1 3/4"

3 1/8"

1 3/8"

21"

1 7/8" 1 7/8" 1 7/8"

3 1/5"

1 3/8"

6 1/4"

6 3/4"

18 3/4"

Page 14

2.0 INSTALLATION

8

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

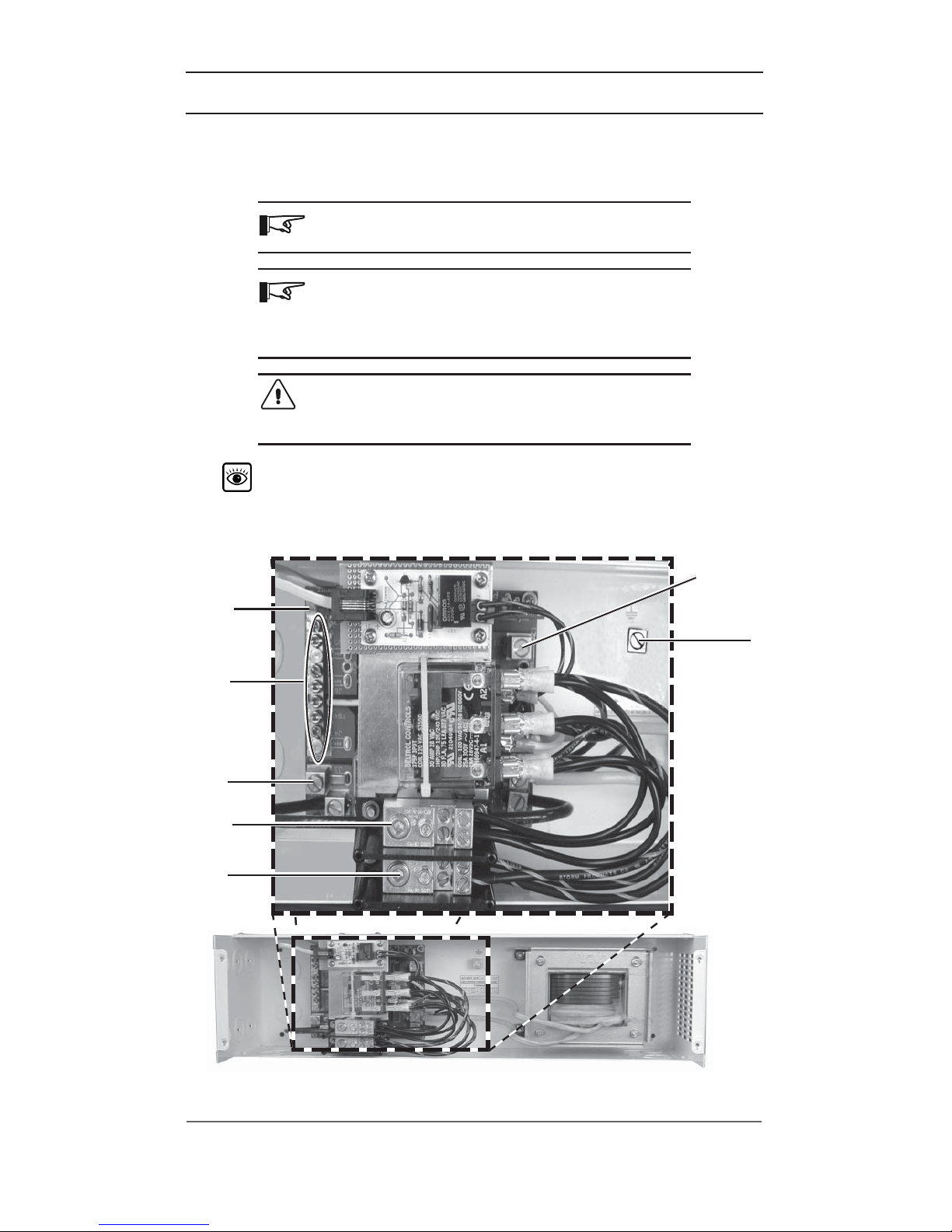

Figure 2-4

GTI Circuit Board Enlargement

WIRING

AC Wiring for Single-Inverter Installations

NOTE: All wiring should be performed by a qualified

person or a licensed electrician.

NOTE: Ensure that wire size and conduit sizes are

appropriate for this installation. AC wiring should be

routed in separate conduits from the communications

cable.

CAUTION: AC pass-through ability through the GTI

is 60 amps. It is recommended to use minimum

#6 AWG (THHN) wiring.

See Figure 2-7 for an enlargement of this circuit board showing the

location of the communications cable port.

NEUTRAL

Bar

AC IN

from the

inverter output

AC OUT

to the

subpanel

AC OUT

to the

inverter’s

AC HOT IN1

Communications

Cable Port

(behind this cable)

AC IN

from the grid

GROUND

LUG

Page 15

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

9

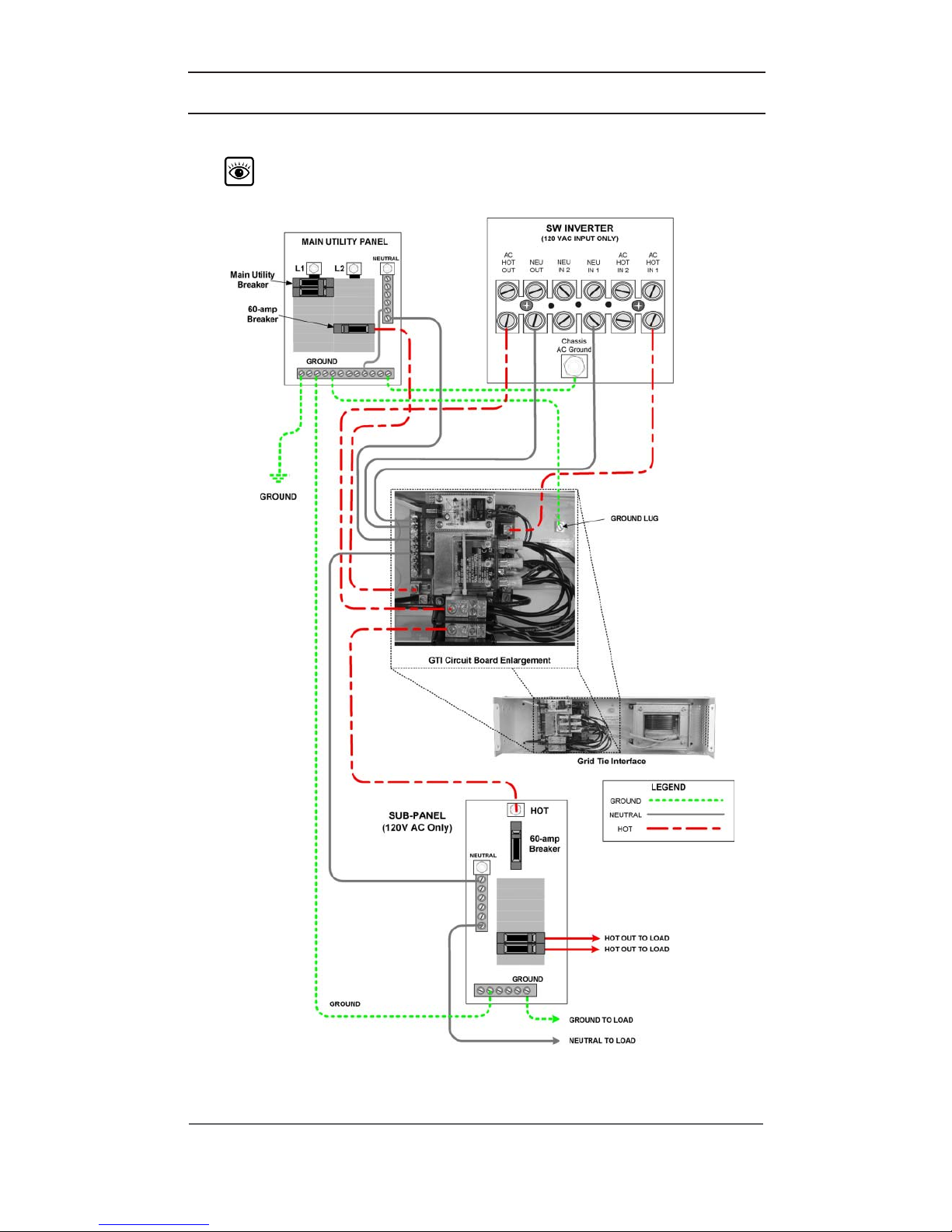

Figure 2-5

AC Input and Output Wiring for Single-Inverter Installations

AC Wiring for Single-Inverter Installations (continued)

See pages 10 through 21 for detailed instructions for AC Input and AC

output wiring for single-inverter/GTI installations.

Page 16

2.0 INSTALLATION

10

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Single-Inverter Installations (continued)

Ground Wiring

Note: Ground wiring must be established at each unit.

Ground wiring can also be accomplished in a variety of

ways. The following instructions describe only one

method. Please consult your local electrician for specific

wiring details pertaining to your installation.

1. Connect a wire from the ground bus in the main service panel to the

ground lug in the GTI.

2. Connect a wire from the ground bus in the main service panel to the

ground terminal in the inverter.

3. Connect a wire from the ground bus in the main service panel to the

ground terminal in the sub-panel.

See Figure 2-5a for an illustration of ground wiring for a single-inverter

installation with the GTI.

Page 17

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

11

Figure 2-5a

Ground Wiring for a Single-Inverter Installations

AC Wiring for Single-Inverter Installations (continued)

Page 18

2.0 INSTALLATION

12

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Single-Inverter Installations (continued)

Utility Grid AC Wiring to the GTI

WARNING: DISCONNECT THE BATTERIES FROM

THE INVERTER IF THEY ARE ALREADY CONNECTED.

1. Ensure the breaker that feeds the GTI is OFF (i.e., no power out). Feed the

HOT and NEUTRAL input wires from the GTI to the main utility panel.

Leave a sufficient amount of extra wire at each end.

2. Confirm a GROUND (green) wire exists from the main utility panel to the

GTI’s AC GROUND lug.

3. Connect the NEUTRAL (white) wire from the main utility panel to the GTI’s

NEUTRAL bar.

4. Connect the HOT (BLACK) wire from a single-pole breaker (60 amps) in

the main utility panel to the GTI’s AC1 HOT IN terminal.

5. Torque all connections to 10 to 15 inch-pounds.

See Figure 2-5b for an illustration of Utility Grid AC Wiring to the GTI.

Page 19

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

13

Figure 2-5b

Utility Grid AC Wiring to the GTI

AC Wiring for Single-Inverter Installations (continued)

Page 20

2.0 INSTALLATION

14

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Inverter AC Input Wiring to the GTI

1. Feed the HOT and NEUTRAL input wires from the inverter to the GTI.

Leave three to six inches of extra wire at each end.

2. Connect the NEUTRAL (white) wire from the GTI’s NEU OUT terminal to

the inverter’s NEUTRAL IN 1 terminal.

3. Connect the AC1 HOT OUT (BLACK) wire from the GTI to the inverter’s

AC1 HOT IN terminal.

4. Torque all connections to 10 to 15 inch-pounds.

See Figure 2-5c for an illustration of the inverter AC input wiring to the

GTI.

Wiring (continued)

AC Wiring for Single-Inverter Installations (continued)

Page 21

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

15

AC Wiring for Single-Inverter Installations (continued)

Figure 2-5c

Inverter AC Input Wiring to the GTI

Page 22

2.0 INSTALLATION

16

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Inverter AC Output Wiring to the GTI

WARNING: ENSURE THE SUB-PANEL DOES NOT

HAVE A NEUTRAL-TO-GROUND BOND. IF IT

DOES, REMOVE IT. ALL AC NEUTRAL-GROUND

BONDING IS DONE AT THE MAIN UTILITY PANEL.

1. Connect a NEUTRAL (white) wire to the inverters’s NEUTRAL OUT

terminal.

2. Connect the other end of this same NEUTRAL wire to the NEUTRAL bar in

the GTI.

3. Connect a HOT (Black) wire to the inverter’s terminal labeled AC HOT

OUTPUT.

4. Connect the other end of the HOT (black) wire from the inverer’s AC HOT

OUT terminal to the GTI’s HOT IN terminal.

5. Torque all connections to 10 to 15 inch-pounds.

See Figure 2-5d for an illustration of the inverter AC output wiring to

the GTI.

Wiring (continued)

AC Wiring for Single-Inverter Installations (continued)

Page 23

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

17

Figure 2-5d

Inverter AC Output Wiring to the GTI

AC Wiring for Single-Inverter Installations (continued)

Page 24

2.0 INSTALLATION

18

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Single-Inverter Installations (continued)

GTI Wiring to the Sub-Panel

WARNING: ENSURE THE SUB-PANEL DOES NOT

HAVE A NEUTRAL-TO-GROUND BOND. IF IT

DOES, REMOVE IT. ALL AC NEUTRAL-GROUND

BONDING IS DONE AT THE MAIN UTILITY PANEL.

1. Connect a NEUTRAL (white) wire to the GTI’s NEUTRAL bar.

2. Connect the other end of this NEUTRAL wire to the NEUTRAL bar in the

sub-panel.

3. Connect the HOT (black) wire to the GTI’s AC HOT OUT terminal.

4. Connect the other end of this HOT (black) wire to the sub-panels HOT IN

terminal.

5. Torque all the inverter’s connections to 10 to 15 inch-pounds.

NOTE: Consult the sub-panel manufacturer’s

specifications for wire torques on the sub-panel

connections. Use those torque requirements if different.

Page 25

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

19

AC Wiring for Single-Inverter Installations (continued)

Figure 2-5e

GTI Wiring to the Sub-Panel

Page 26

2.0 INSTALLATION

20

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

Communications Cable

Figure 2-6

GTI Communications Cable Location

1. Remove the access panel on the bottom of the inverter.

2. Clip the cable binding and gently remove the loose end of the

communications cable from inside of the inverter. It will be located directly

behind the AC Terminal Block. This cable extends approximately 2.5 feet

out of the inverter.

3. Connect the loose end of the communications cable to the communications

cable port on the GTI circuit board.

See Figure 2-7 for the location of the communications port inside the

GTI.

Communications

Cable

Remove this

screw to remove

the access panel.

Remove this screw

to remove the

access panel.

Cable binding

Page 27

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

21

Wiring (continued)

Communications Cable (continued)

Figure 2-7

Connecting the Communications Cable to the Circuit Board

NOTE: An additional 8-foot 10-conductor extension cable

is available at Xantrex (P/N 130-0118-01-01) for

installations where the inverter is more than 2 feet away

from the GTI.

Page 28

2.0 INSTALLATION

22

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

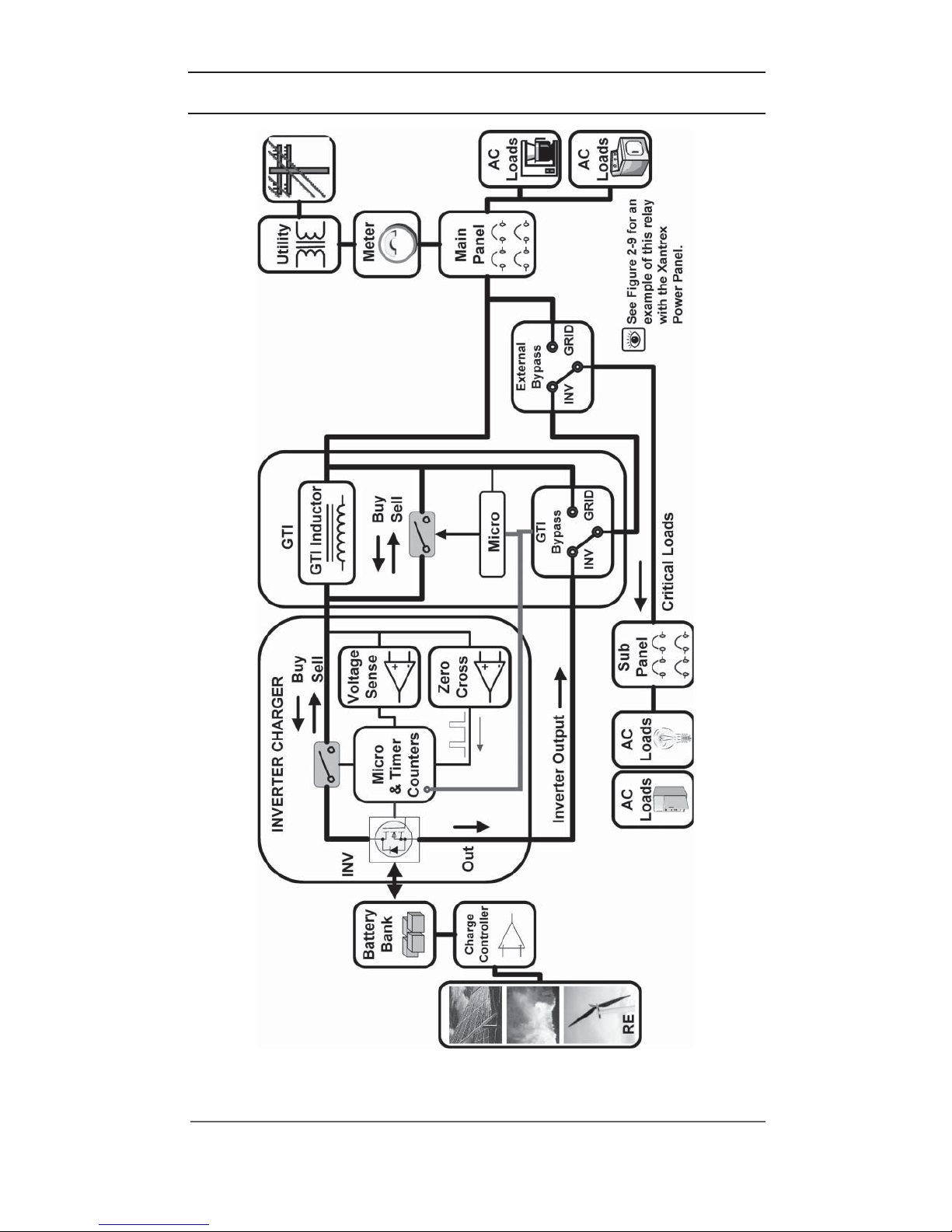

AC Wiring for Dual-Inverter Installations

Series stacking is used in applications where either 240-volt loads (or a

combination of both 240- and 120-volt loads) need to be powered from the inverters.

One inverter, connected to the utility’s L1 line, provides one 120 volt AC output and

a second inverter connected to the utility’s L2 line provides the second 120 volt AC

output (180 degrees out-of-phase from the first inverter). The combined out-ofphase voltages can power 240 volt AC loads as well as 120 volt loads, up to the

power rating of the inverters.

NOTE: For full pass-through capability of the inverter,

#6 AWG (90°C) minimum is recommended. Protect the

wire with an appropriately sized breaker.

See Figure 2-8 for a an illustration of input and output wiring for dualinverters with dual GTI installations.

See pages 24 through31 for detailed instructions for AC Input and AC

output wiring for dual-inverter/GTI installations.

Page 29

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

23

Figure 2-8

Wiring Diagram for Dual Inverter Installations

AC Wiring for Dual-Inverter Installations (continued)

Page 30

2.0 INSTALLATION

24

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Dual-Inverter Installations (continued)

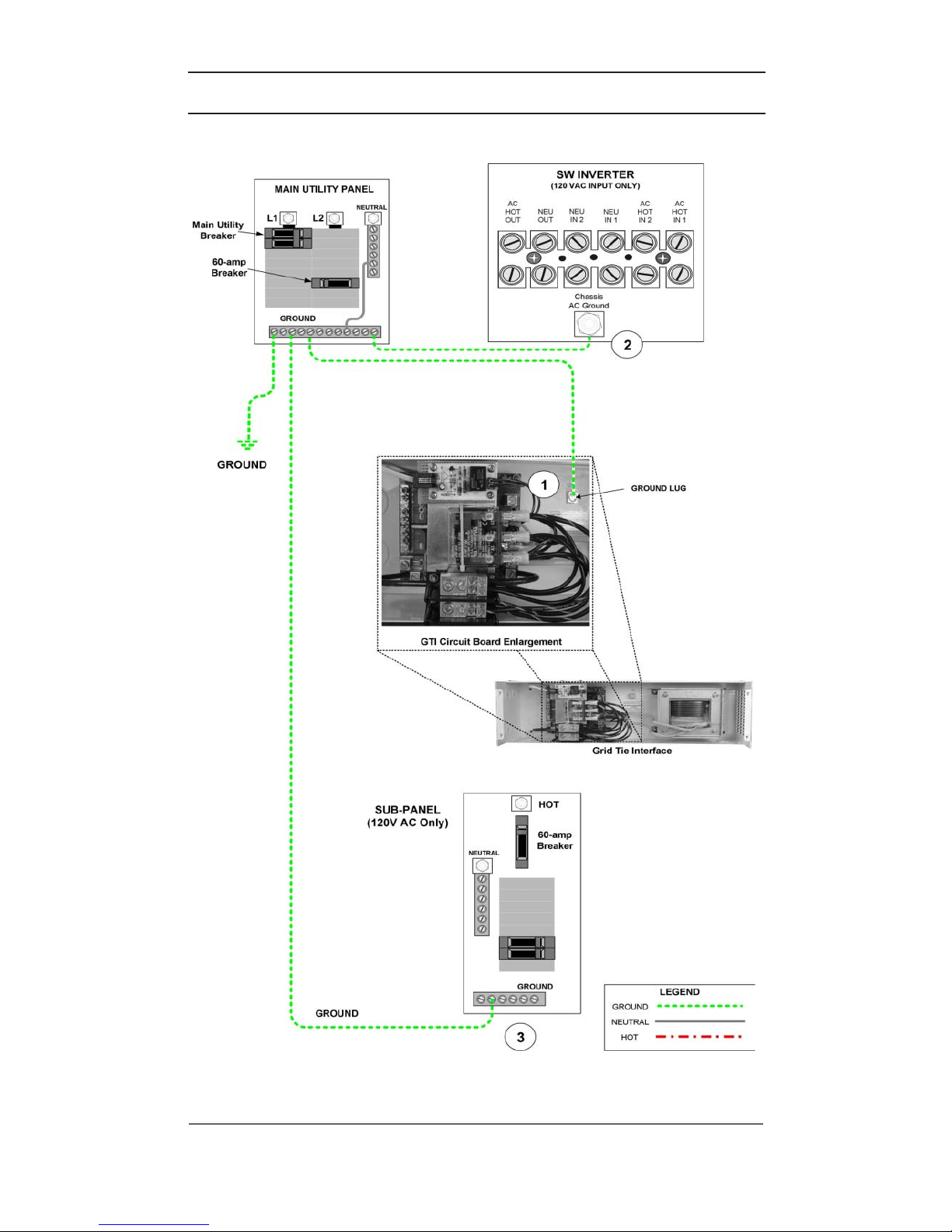

Ground Wiring

1. Ensure there is a ground wire from inverter-1 to the main service panel.

2. Ensure there is a ground wire from inverter-2 to the main service panel.

3. Connect a wire from the ground bus in the main service panel to the

GROUND terminal in the GTI-1.

4. Connect a wire from the ground bus in the main service panel to the

GROUND terminal in the GTI-2.

5. Connect a wire from the ground bus in the main service panel to the

GROUND terminal in the sub-panel.

See Figure 2-8a for an illustration of the ground wiring for dual-inverter/

dual-GTI installations.

Page 31

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

25

Figure 2-8a

Ground Wiring for Dual-Inverter Installations

AC Wiring for Dual-Inverter Installations (continued)

Page 32

2.0 INSTALLATION

26

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Dual-Inverter Installations (continued)

Utility Grid AC Wiring to Dual GTIs

1. Connect a wire from the neutral bus in the main service panel to the

NEUTRAL bar in the GTI-1.

2. Connect a wire to the NEUTRAL bar on the GTI-1 and route this wire to the

GTI-2’s NEUTRAL bar. Keep this wire as short as possible.

3. Select a dual-pole breaker in the main service panel. Connect a wire from

the L1-pole of the selected breaker to the GTI-1’s AC HOT IN terminal.

4. Connect a wire from the L2 pole of the same dual-pole breaker to the GTI2’s AC HOT IN terminal.

See Figure 2-8b for an illustration of AC wiring from the utility grid to

the GTIs.

Page 33

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

27

Figure 2-8b

Utility Grid AC Wiring to Dual GTIs

Wiring (continued)

AC Wiring for Dual-Inverter Installations (continued)

Page 34

2.0 INSTALLATION

28

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Dual-Inverter Installations (continued)

Inverter AC Input and Output Wiring to the GTIs

The output of each inverter provides 120 Vac. The voltage between the HOT

outputs from the L1 and L2 inverter is 240 Vac.

NOTE: Both inverter AC IN and inverter AC OUT will

be wired to the GTIs.

1. Connect a wire from the GTI-1’s AC HOT OUT to the L1 inverter’s

AC HOT IN 1 terminal.

2. Connect a wire from the GTI-2’s AC HOT OUT to the L2 inverter’s

AC HOT IN 1 terminal.

3. Connect the AC HOT OUTPUT (120 Vac) from the L1 inverter to the AC IN

terminal in the GTI-1.

4. Connect the NEUTRAL wire from the L1 inverter’s NEUTRAL OUT terminal

to the neutral bar in the GTI-1.

5. Connect the AC HOT OUTPUT (120 Vac) from the L2 inverter to the AC IN

terminal in the GTI-2.

6. Connect the NEUTRAL wire from the L2 inverter’s NEUTRAL OUT terminal

to the neutral bar in the GTI-2.

7. Connect a wire from the NEUTRAL bar in GTI-1 to the NEUTRAL bar in

GTI-2.

8. Ensure a NEUTRAL wire exists from the L1 inverter NEUTRAL IN 1 terminal

to the L2 inverter NEUTRAL IN 1 terminal.

See Figure 2-8c for an illustration of AC wiring from the inverters to the

GTIs.

Page 35

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

29

Figure 2-8c

Inverter AC Input and Output Wiring to the GTIs

AC Wiring for Dual-Inverter Installations (continued)

Page 36

2.0 INSTALLATION

30

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Wiring for Dual-Inverter Installations (continued)

GTI Wiring to the Sub-Panel

1. Connect a NEUTRAL wire from GTI-2’s NEUTRAL bar to the NEUTRAL

bar in the sub-panel.

2. Connect the AC OUTPUT (120 Vac) from GTI-1 to the L1 terminal in the

sub-panel.

3. Connect the AC OUTPUT (120 Vac) from the GTI-2 to the L2 terminal in

the sub-panel.

WARNING: ENSURE THE ONLY NEUTRAL-TOGROUND BOND IS IN THE MAIN UTILITY PANEL.

REMOVE ANY BONDING FROM THE SUB-PANEL IF

IT IS PRESENT.

See Figure 2-8d for an illustration of GTI Wiring to the Sub-Panel.

Connecting the Communications Cables for Dual Inverter Installations

See Figure 2-6 for the location of the communications cable inside the

SW inverters.

See Figure 2-7 for the location of the communications port on the GTI

circuit board.

NOTE: The communications cables are not

interchangeable. Make sure that you connect the

communications cable from the inverter to the GTI that

has that inverter’s AC HOT IN 1 connection.

1. Connect the communications cable from inverter 1 to the

communications port on GTI-1.

2. Connect the communications cable from inverter 2 to the

communications port on GTI-2.

Page 37

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

31

Figure 2-8d

GTI Wiring to the Sub-Panel

AC Wiring for Dual-Inverter Installations (continued)

Page 38

2.0 INSTALLATION

32

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Rewiring for Dual-Inverter Power Panel Installations

NOTE: The following procedure is for a dual-inverter

power panel system. If your system is only a singleinverter power panel system, disregard the steps that

refer to components that are not present.

NOTE: Use appropriate sized wire and circuit breakers

(if needed) for all wiring added to the installation.

THHN #6 AWG wire is recommended.

1. Inside the power panel, locate and label wires 1A and 1C from inverter-1

and wires 2A and 2C from inverter-2 as labeled in Figure 2-9.

2. Inside the power panel, locate and label terminals 1B, 1D, 2B and 2D as

labeled in Figure 2-9.

3. Inside each GTI, locate and label the terminals 1B, 1D, 2B, and 2D as

labeled in Figure 2-9.

4. Remove wire 1A from terminal 1B in the power panel.

a. Use a wire nut to add a sufficient length of wire to wire 1A to reach

terminal 1A in GTI-1.

b. Connect the extended wire 1A to terminal 1A in GTI-1.

5. Remove wire 1C from terminal 1D in the power panel.

a. Use a wire nut to add a sufficient length of wire to wire 1C to reach

terminal 1C in GTI-1.

b. Connect the extended wire 1C to terminal 1C in GTI-1.

6. Remove wire 2A from terminal 2B in the power panel.

a. Use a wire nut to add a sufficient length of wire to wire 2A to reach

terminal 2A in GTI-1.

b. Connect the extended wire 2A to terminal 2A in GTI-2.

7. Remove wire 2C from terminal 2D in the power panel.

a. Use a wire nut to add a sufficient length of wire to wire 2C to reach

terminal 2C in GTI-1.

b. Connect the extended wire 2C to terminal 2C in GTI-2.

8. Add a neutral wire (NEU) to the NEUTRAL BAR in GTI-1 and connect it to

the NEUTRAL BAR in GTI-2.

9. Add a neutral wire (NEU) to the NEUTRAL BAR (NEU) in the power panel

and connect it to either GTI-1 or GTI-2.

10. Add a wire to terminal 1B in the power panel and connect it to terminal 1B

in GTI-1.

11. Add a wire to terminal 1D in the power panel and connect it to terminal

1D in GTI-1.

12. Add a wire to terminal 2B in the power panel and connect it to terminal

2B in GTI-2.

13. Add a wire to terminal 2D in the power panel and connect it to terminal

2D in GTI-2.

Page 39

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

33

Figure 2-9

Rewiring Power Panel Installations to include dual GTIs

AC Re-Wiring for Power Panel Installations (continued)

Page 40

2.0 INSTALLATION

34

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Wiring (continued)

AC Rewiring for Power Module Installations

NOTE: The following procedure is for a dual-inverter

power module system. If your system is only a singleinverter power module system, disregard the steps that

refer to components that are not present.

See Figure 2-10 for an illustration of the original power module wiring.

See Figure 2-10a for an illustration of the power module re-wiring.

NOTE: Use appropriate sized wire and circuit breakers

(if needed) for all wiring added to the installation.

THHN #6 AWG wire is recommended.

1. Inside the power module, locate and label wires 1A and 1C from inverter-1

and wires 2A and 2C from inverter 2 as labeled in Figure 2-10.

2. Inside the power module, locate and label terminals 1B, 1D, 2B and 2D as

labeled in Figure 2-10.

3. Inside each GTI, locate and label the terminals 1B, 1D, 2B, and 2D as

labeled in Figure 2-10a.

4. Remove wire 1A from terminal 1B in the power module.

a. Use a wire nut to add a sufficient length of wire to wire 1A to reach

terminal 1A in GTI-1.

b. Connect the extended wire 1A to terminal 1A in GTI-1.

5. Remove wire 1C from terminal 1D in the power module.

a. Use a wire nut to add a sufficient length of wire to wire 1C to reach

terminal 1C in GTI-1.

b. Connect the extended wire 1C to terminal 1C in GTI-1.

6. Remove wire 2A from terminal 2B in the power module.

a. Use a wire nut to add a sufficient length of wire to wire 2A to reach

terminal 2A in GTI-2.

b. Connect the extended wire 2A to terminal 2A in GTI-2.

7. Remove wire 2C from terminal 2D in the power module.

a. Use a wire nut to add a sufficient length of wire to wire 2C to reach

terminal 2C in GTI-2.

b. Connect the extended wire 2C to terminal 2C in GTI-2.

8. Add a neutral wire (NEU) to the NEUTRAL BAR in GTI-1 and connect it to

the NEUTRAL BAR in GTI-2.

9. Add a neutral wire (NEU) to the NEUTRAL BAR (NEU) in the power

module and connect it to either GTI-1 or GTI-2.

Page 41

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

35

Figure 2-10

Original Power Module Wiring

AC Rewiring for Power Module Installations (continued)

10. Add a wire to terminal 1B in the power panel and connect it to terminal 1B

in GTI-1.

11. Add a wire to terminal 1D in the power panel and connect it to terminal 1D

in GTI-1.

12. Add a wire to terminal 2B in the power panel and connect it to terminal 2B

in GTI-2.

13. Add a wire to terminal 2D in the power panel and connect it to terminal

2D in GTI-2.

Page 42

2.0 INSTALLATION

36

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Figure 2-10a

Power Module Re-wiring for dual GTI Installations

Wiring (continued)

AC Rewiring for Power Module Installations (continued)

Page 43

2.0 INSTALLATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

37

WIRING CHECK

Before powering on the GTI, recheck all wiring and ensure it is connected to

the proper terminals. Check that the ground and neutral connections are

properly wired and tight.

After all the wiring has been checked, install the front cover and secure it

with the four phillips screws removed in the beginning of the installation.

OPERATING STACKED INVERTERS

Stacked inverters must operate together in order to provide the 120/240 Vac

to the loads. The Series Stacking Interface cable ensures the output from each

inverter is 180 degrees out-of-phase for operating 240 Vac loads.

NOTE: Until the units are tested, do not connect loads

to the inverters 120 or 240 Vac output.

START-UP AND TEST

1. Ensure the main service panel’s circuit breakers feeding the inverters are

OFF.

2. Switch ON both inverters. The inverter should be providing 120/240 Vac

to the sub-panel.

3. Use an AC voltmeter and measure the voltage between the L1 terminal and

neutral bus in the sub-panel. This voltage should be 120 Vac (± 3%).

4. Measure the voltage between the L2 terminal and neutral bus in the subpanel. This voltage should be 120 Vac (± 3%).

5. Measure the voltage between the L1 and L2 terminals in the sub-panel.

This voltage should be 240 Vac (± 3%).

6. Switch ON the main service panel’s circuit breakers feeding the inverters.

7. Verify the inverters are charging the batteries and powering the sub-panel

(refer to the operator’s manual).

8. Switch both inverters OFF.

9. Replace all covers and panels on the inverters and sub-panel.

The stacked inverter system is now ready for use.

NOTE: If the inverters are not operating properly, please

refer to the operator’s manual for setup and

troubleshooting information.

Page 44

2.0 INSTALLATION

38

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

Notes:

Page 45

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-01 Rev A 01/02

39

3.0 TROUBLESHOOTING

Table 3-1

Troubleshooting Guidelines for the Grid Tie Interface

motpmyS noitcAdednemmoceR noituloseR

tonsimetsysehT

ehtotrewopgnilles

retrevniehtdnadirg

.gnihsalfsiDEL1CA

.nosiretrevniehterusnE.noretrevniehtnruT

tonsimetsysehT

ehtotrewopgnilles

retrevniehtdnadirg

.ffosiDEL1CA

ITGdnaretrevniehtotgniriwkcehC

.tupni

.gniriwCAehttcerroC

CAehtgnikcehcretfA

:gniriw

tonllitssimetsysehT

ehtotrewopgnilles

retrevniehtdnadirg

.ffosiDEL1CA

ehtkcehcdnarevocITGehtevomeR

.draobtiucriclacitrevehtnoDEL

fonoitacolehtrof7-2erugiFeeS

.DELeht

dnaegatloveht,NOsiDELITGehtfI

.tneserperaycneuqerf

.tinuehthtiwmelborponsierehT

dnaegatloveht,gnihsalfsiDELITGehtfI

nihtiwtontub,tneserperaycneuqerf

.stimilLUelbatpecca

DELeht,yaledetunim-5aretfA

sahrewopdirgehtfinonrutlliw

.stimilelbatpeccanihtiwdenruter

dnaegatloveht,ffosiDELITGehtfI

ITGehttatneserptoneraycneuqerf

.tupni

CAdnarekaerbtupniehtkcehC

.gniriw

Page 46

3.0 TROUBLESHOOTING

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-01 Rev A 01/02

40

Notes:

Page 47

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

A-1

APPENDIX A – SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

1

Utility Interactive Protection Over/under AC voltage and frequency

detection plus active islanding detection

AC Voltage (Nomimal) 120 VAC

AC Voltage (Allowed)

Utility Interactive Mode 106 - 132 VAC

Bypass mode/”Buy” Current 80-149 VAC

Input Frequency (Allowed)

Utility Interactive Mode 59.3 - 60.5 Hz

Bypass Mode/”Buy” Current 53.0 - 67.0 Hz

AC Current (Allowed) (@ 25°C)

Utility Interactive Mode 40 amps continuous

Bypass Mode/”Buy” Current 60 amps continuous

Total Output Harmonic Distortion

Rated <5% at rated power

Typical 2.5% at rated power

MECHANICAL SPECIFICATIONS

Enclosure Type Indoor, ventilated, steel chassis with

white, powder-coat finish

Unit Weight 26 lb (15.9 kg)

Dimensions (H x W x D) 6.3" x 21" x 7"

(16 cm x 53.3 cm x 17.8 cm)

Mounting wall mount in a horizontal position only

AC Input/Output Terminals Sized for #2-#14 AWG wires

Neutral Bar Sized for #6 AWG wires

Conduit Sizes Dual ¾" - 1" and ½" - ¾" knockouts

Specifications @ 25 °C

Specifications subject to change without notice.

1

All electrical specifications are based on the unit operating

in the Utility Interactive Mode (SELL Mode selected)

unless otherwise specified.

Page 48

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-02 Rev A 03/02

A-2

Page 49

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-01 Rev A 01/02

B-1

APPENDIX B – PRODUCT AND SYSTEM INFORMATION

WARRANTY

Xantrex Technology Inc., warrants its power products against defects in

materials and workmanship for a period of two (2) years from the date of purchase,

established by proof of purchase or formal warranty registration, and extends this

warranty to all purchasers or owners of the product during the warranty period.

Xantrex does not warrant its products from any and all defects:

• arising out of material or workmanship not provided by Xantrex or its

Authorized Service Centers;

! when the product is installed or exposed to an unsuitable environment as

evidenced by generalized corrosion or biological infestation;

! resulting from abnormal use of the product, alteration, or use in violation of

the instructions;

• in components, parts, or products expressly warranted by another manufacturer.

Xantrex Technology Inc., agrees to supply all parts and labor to repair or replace

defects covered by this warranty with parts or products of original or improved

design, at the company's option. Xantrex Technology Inc., also reserves the right to

improve the design of its products without obligation to modify or upgrade those

previously manufactured. Defective products must be returned to Xantrex

Technology Inc., or its Authorized Service Center in the original packaging or

equivalent. The cost of transportation and insurance on items returned for service is

the responsibility of the customer. Return transportation (UPS Ground or

equivalent) as well as insurance on all repaired items is paid by Xantrex Technology

Inc.

All remedies and the measure of damages are limited to the above. Xantrex

Technology Inc., shall in no event be liable for consequential, incidental, contingent,

or special damages, even if Xantrex Technology Inc., has been advised of the

possibility of such damages. Any and all other warranties, expressed or implied,

arising by law, course of dealing, course of performance, usage of trade or otherwise,

including, but not limited to, implied warranties of merchantability and fitness for a

particular purpose, are limited in duration for a period of two (2) years from the

original date of purchase.

Some states or countries do not allow limitations on the term of an implied

warranty, or the exclusion or limitation of incidental or consequential damage, which

means the limitations and exclusions of this warranty may not apply to you. Even

though this warranty gives you specific legal rights, you may also have other rights

which vary from state to state.

Page 50

APPENDIX B – PRODUCT & SYSTEM INFORMATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-01 Rev A 01/02

B-2

RETURN MATERIAL AUTHORIZATION POLICY

You must obtain a Return Material Authorization (RMA) number from Xantrex

before returning a product directly to Xantrex. Products returned without an RMA

number or shipped collect will be refused. When you contact Xantrex to obtain

servcie, be prepared to supply the serial number of your product and its date of

purchase as well as information about the installation and use of the unit.

Return Material Procedure

If you are returning a product, follow this procedure:

1. Obtain an RMA number and a shipping address from Xantrex.

2. Package the unit safely, preferably using the original box and packing

materials. Include the following:

• The RMA number

• A copy of your dated proof of purchase

• A return address where the repaired unit can be shipped

• A contact telephone number

• A brief description of the problem

3. Ship the unit freight prepaid to the address provided in step 1.

Page 51

APPENDIX B – PRODUCT & SYSTEM INFORMATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-01 Rev A 01/02

B-3

SERVICE INFORMATION

Xantrex Technology Inc., takes great pride in its products and makes every

effort to ensure your unit fully meets your independent powering needs.

If your product needs repair, contact our Customer Service department at:

(360) 435.8826 to obtain an RMA# and shipping information.

Please provide:

Model Number: _____________________________________

Serial Number: _____________________________________

Purchase Date: _____________________________________

Problem: ___________________________________________

Include a telephone number where you can be reached during business hours

and a complete return shipping address (P.O. Box numbers are not acceptable).

Name: _______________________________________________

Address: _____________________________________________

City: ________________________________________________

State / Province: _______________________________________

Zip / Postal Code: _____________________________________

Country: _____________________________________________

Phone: (____) _________________________________________

FAX: (____) __________________________________________

E-mail Address: _______________________________________

Page 52

APPENDIX B – PRODUCT & SYSTEM INFORMATION

© 2002 Xantrex Technology Inc.

P/N 975-0041-01-01 Rev A 01/02

B-4

Page 53

Page 54

Page 55

Page 56

tt

tt

t 1 360 435 8826

ff

ff

f 1 360 435 2229

dpm@xantrex.com

www.xantrex.com

P/N 975-0041-01-02 Rev A Printed in USA

Loading...

Loading...