Page 1

GSM

Generator Start Module

Installation and Operation Guide

ã2001 Xantrex Technology Inc. P/N 975-0008-01-02 Rev. A 01/01

Page 2

Page 3

GSMGenerator Start Module

Table of Contents

1.0 INTRODUCTION ................................................................. 1

Unpacking and Inspection ............................................................................. 1

Controls and Indicators ................................................................................. 2

Indicator LEDs ....................................................................................... 2

GENERATOR RUN/GLOWSTOP RELAY 7 LED ......................... 2

GENERATOR START RELAY 8 LED ........................................... 2

INVERTER OPERATIONAL LED ................................................. 2

Switches ................................................................................................ 3

GENERATOR START Switch ....................................................... 3

Internal Components ..................................................................................... 4

INVERTER ERROR Switch .......................................................... 3

Relays .................................................................................................... 4

Relay Terminal Block ............................................................................. 4

Ground Stud .......................................................................................... 4

Fuses ..................................................................................................... 4

2.0 INSTALLATION ................................................................... 6

Tools Required............................................................................................... 6

Pre-Installation .............................................................................................. 6

Mounting Procedure ...................................................................................... 6

Generator Wiring ........................................................................................... 9

To connect the generator wires to the terminal block ........................... 9

Two-Wire Start Circuits ....................................................................... 10

Wiring Honda-Type Generators .......................................................... 11

Wiring Onan-Type Generators ............................................................ 12

Error Indicator Wiring .................................................................................. 13

Communication Cable ................................................................................. 14

3.0 OPERATION ...................................................................... 15

Operation and Test ...................................................................................... 15

Internal Sticker .................................................................................... 16

Danger Label ....................................................................................... 16

4.0 TROUBLESHOOTING ...................................................... 17

5.0 SERVICE INFORMATION .................................................. 18

6.0 WARRANTY ...................................................................... 19

7.0 SPECIFICATIONS.............................................................. 20

©2001 Xantrex Technology Inc. i

Page 4

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed

during the installation and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation

and operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

AVERTISSEMENT - Une tension ou condition dangereuse existe

dans cette zone. Faire preuve dextrême prudence lors de la

réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or

operation of the unit. Follow these instructions closely.

ATTENTION - Cette procédure est essentielle à linstallation ou

lutilisation de lunité en toute sécurité. Suivre ces instructions

deprès.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions

deprès.

All electrical work must be done in accordance with local, national,

and/or international electrical codes.

Before installing or using this device, read all instructions and cautionary

markings located in the manual and on the generator.

Do not expose this unit to rain, snow or liquids of any type. This product is

designed only for indoor mounting.

To reduce the chance of short-circuits, use insulated tools when installing

or working with this product, the inverter, the batteries or generator.

Remove all jewelry such as rings, bracelets, necklaces, etc., while installing

the GSM. This will greatly reduce the chance of accidental exposure to live

circuits.

The inverter contains more than one live circuit (batteries, PV array, AC

line, etc.). Power may be present at more than one source.

To reduce risk of electric shock, disconnect all wiring before attempting any

maintenance or cleaning. Turning off the device may not reduce this risk.

Disable the generators starting circuit by disconnecting the starter battery,

spark plug, etc., before wiring this device.

SAVE THESE INSTRUCTIONS

ii ©2001 Xantrex Technology Inc.

Page 5

Disclaimer of Liability

Since the use of this manual and the conditions or methods of installation,

operation, use and maintenance of the unit are beyond the control of Xantrex

Technology Inc., the company does not assume responsibility and expressly

disclaims liability for loss, damage, or expense arising out of or any way

connected with such installation, operation, use, or maintenance.

©2001 Xantrex Technology Inc. iii

Page 6

NOTE: Due to continual improvement through product updates,

photographs and/or illustrations used in this manual may not exactly

match your unit. Xantrex Technology Inc., reserves the right to

update this product without notice or releasing an updated manual

when fit, form or function are not affected.

iv ©2001 Xantrex Technology Inc.

Page 7

1.0 INTRODUCTION

The GSM (Generator Start Module) is an accessory for selected Trace

inverter/charger models allowing automatic generator control and inverter error

indication when using the optional SWRC remote control. The unit contains

three relays providing normally open (N.O.), normally closed (N.C.) and

common (COM) contacts. Relays RY7 and RY8 are used for generator

control. Relay RY11 is used to indicate an error condition (via an external

indicator) whenever the inverters output is shutdown. This could be a bell,

buzzer, light, etc.

The unit interfaces the inverter (via a phone type cable) to an auto-start/

stop generator. Commands from the inverter control the generator when

defined parameters (programmed via the SWRC or SWCA for PS Series

models) are met. Refer to the inverter operators manual for setting the

various parameters for generator operation.

Front panel LEDs provide a visual display of relay activity whenever a

relay contact receives an engage command from the inverter. A highly visible

blue LED indicates the inverter is operational.

Unpacking and Inspection

Carefully inspect the contents of the shipping carton for damages. Report

any damages to the carrier immediately.

The following items are packed with the GSM:

Generator Start Module unit (GSM)

25-foot cable

Operators manual

Generator Danger Label

Report any missing items to Xantrex Technology Inc., immediately.

Generator Start Module (GSM)

©2001 Xantrex Technology Inc. 1

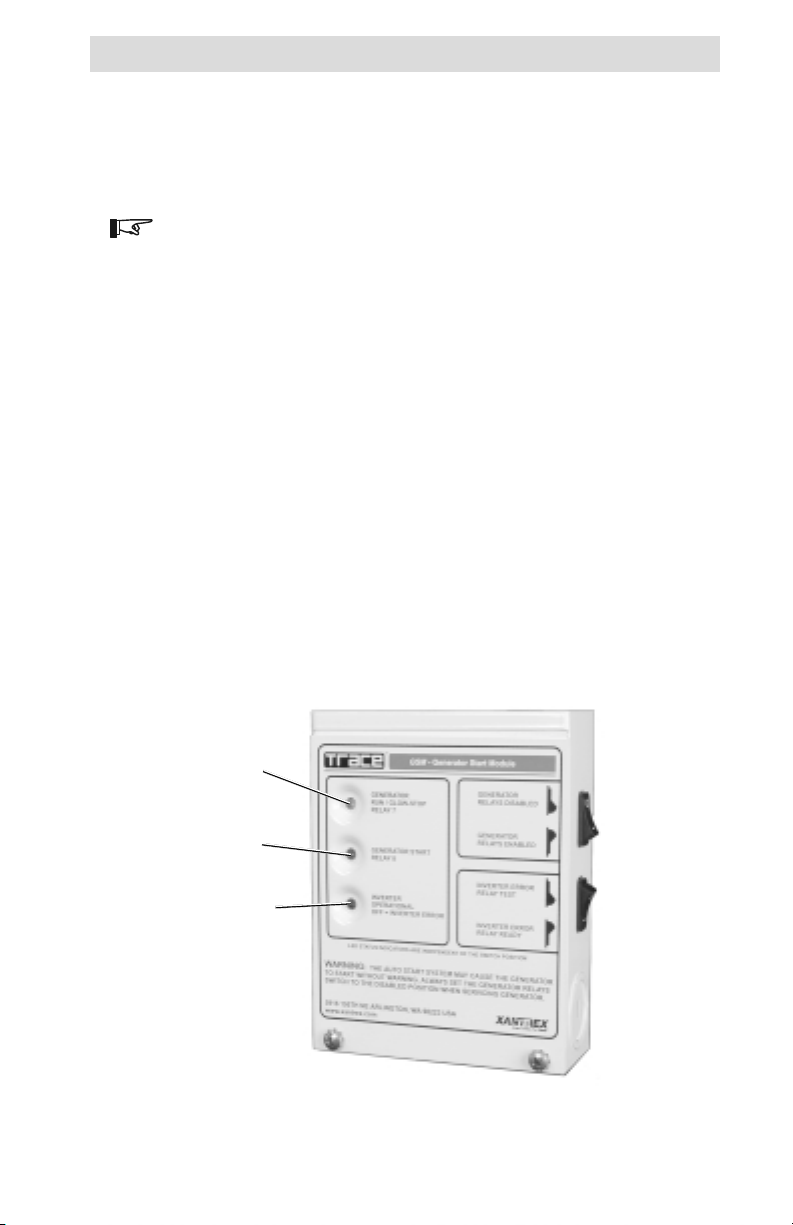

Figure 1

Page 8

1.0 INTRODUCTION

Controls and Indicators

Indicator LEDs

Three LEDs located on the front panel of the GSM indicate the relay

control signal status from the inverter.

NOTE: The LEDs are unaffected by the GSMs switch positions or

fuse condition.

GENERATOR RUN/GLOWSTOP RELAY 7 LED

The yellow LED indicates relay RY7 is receiving a control signal to

engage the relay and RUN the generator or provide a GLOWSTOP signal

(for diesel generators). The LED turns ON when the relays COM and N.O.

contacts engage. The function of this relay is dependent on the selection

made (using the SWRC) as to whether it is used to RUN the generator or

provide GLOWSTOP control.

GENERATOR START RELAY 8 LED

The green LED indicates relay RY8 is receiving a START signal from the

inverter. The LED turns ON when the relays COM and N.O. contacts

engage.

INVERTER OPERATIONAL LED

The blue LED indicates the inverters operational status. If the inverter is

powered and ready for operation, the blue SYSTEM OPERATIONAL LED

turns ON as soon as the phone-type cable is plugged into the inverter. If

the blue LED does not turn ON, the inverter is either not powered, is set to

the CHG only mode without any utility pass-through, or has no AC output

which may be caused by an error condition.

Yellow LED

RUN/GLOWSTOP

RELAY 7

Green LED

GENERATOR START

RELAY 8

Blue LED

INVERTER OPERATIONAL

OFF = INVERTER ERROR

Figure 2

Indicator LEDs

2 ©2001 Xantrex Technology Inc.

Page 9

1.0 INTRODUCTION

Controls and Indicators (continued)

Switches

Two switches are provided on the right side of the GSM to effectively

disconnect the relay coils from the inverters supply voltage (11 VDC), thus

preventing the relays from engaging if a control signal is sent out from the

inverter. This is a safety feature which allows the generator to be serviced

without it unexpectedly starting due to an inverter GEN-START command.

GENERATOR START Switch

The GENERATOR START switch enables the relays by providing the

operating voltage to the relay coils RY7 and RY8. When the relays are

enabled, they will respond to the control signals provided by the inverter.

When the switch is in the RELAYS DISABLED position, the inverter control

signals have no effect on relay operation (i.e., the COM and N.C. contacts

engage). This switch does not affect the operation of the LEDs which

continue to light whenever the inverter sends a CLOSE CONTACT

command to therelays.

INVERTER ERROR Switch

The INVERTER ERROR switch provides a simple way to test an

externally connected alarm. Once the alarm is tested, this switch should be

switched to the RELAY READY position.

GENERATOR

Switch

(RY7 and RY8)

INVERTER ERROR

Switch (RY 11)

Figure 3

Switches

©2001 Xantrex Technology Inc. 3

Page 10

1.0 INTRODUCTION

Internal Components

The Generator Start Module (GSM) is designed to control generators

equipped with two- or three-wire, electronic, automatic start operation (not all

generators are supported) and provides the following features.

Relays

There are three 12 VDC relays, rated at 10 amps/250 VAC; 8 amps/

30VDC (forresistive loads), with gold contacts increasing the low-end

signalrange.

Relay RY7 is used for generator RUN/GLOWSTOP functions.

Relay RY8 is used for the generator START function.

Relay RY11 can be connected to an external indicator device to display

or sound an alarm whenever the inverter AC output is lost.

The normally open (N.O.) and normally closed (N.C.) contacts are

available to accommodate the various generator auto-start circuits.

Relay Terminal Block

Connections to the GSM are accomplished by the nine position, spring

clamp, terminal block with quick connect levers. All relay contacts (N.O.,

COM and N.C.) are available at this connector, which accepts wire sizes

from #28 AWG to #14 AWG. No tools are required to secure the wires as

the spring clamp holds the wires securely in place.

Ground Stud

A ground screw is provided in the GSM to provide a safety ground path

when hazardous voltages are connected to the relays. Connect this screw

to a grounded conductor whenever high voltages (i.e., above 90 volts) are

connected to the relays.

NOTE: No hazardous voltages are supplied from the inverter to

power or control the relays; however, some generator control circuits

may use a high voltage in their starting/control circuits or 120 V

could be used for an external error indicator.

Fuses

Each relays common (COM) contact is protected with a 6.3 amp (5 mm

x 20 mm) 250 VAC fuse which will open if excess current is drawn through

the relay contacts. Always replace this fuse with the same type and rating.

Type GDC (Bussman) or 218 (Littlefuse) is recommended.

NOTE: These fuses can be replaced with lower amperage fuses to

also protect the connected circuitry, if desired. Refer to the

generators specifications for the correct size fuse. In no case,

should this fuse be replaced with one of a higher amperage.

4 ©2001 Xantrex Technology Inc.

Page 11

Internal Components (continued)

1.0 INTRODUCTION

Communication

jack J1

GROUNDING

screw

F1 protects

relay RY 7

F2 protects

relay RY 8

Figure 4

Internal Components

F3 protects

relay RY 11

Terminal

Block

©2001 Xantrex Technology Inc. 5

Page 12

2.0 INSTALLATION

The GSM should be mounted close to the generator in a location where it

is easily accessible. Knockouts, 3/4 and 1 inch, are provided for cable routing

and conduit connections. Mount the GSM to a flat, vertical surface, such as

awall.

Tools Required

screwdrivers (Phillips and flat blade)

wood screws (#10)

anchors (if required)

drill and assorted bits

wire strippers

WARNING: before making any connections to the generator or

inverter, ensure that all inverter power is disconnected and the

generator starter isdisabled.

Pre-Installation

Before installing the GSM, read all instructions and cautionary markings

located in this manual. The unit should be mounted in a clean, dry, protected

environment.

Determine the wire route (or conduit runs) to the GSM, generator, inverter

and error indicator (if used).

NOTE: Check for existing electrical, plumbing, or other potential

areas of accidental damage prior to making cuts in structural

surfaces.

Mounting Procedure

Remove the two Phillips screws from the units front panel and remove the

cover.

Open the inverters access panel and locate the GEN connector if

necessary. Refer to the inverter operators manual for the location of the

connector.

Hold the GSM against the surface to be mounted and use the unit as a

template to mark the four hole locations.

NOTE: Six holes are provided in the back panel of the GSM.

Use the two top and two bottom screw holes.

Drill holes for mounting and insert appropriate anchors if necessary.

Use four #10 wood screws to mount the unit to the wall or other vertical

surface.

Install conduit runs if necessary for the generator control wires, error

indicator (if used), and communication cable (between the inverter and

GSM).

6 ©2001 Xantrex Technology Inc.

Page 13

Mounting Procedure (continued)

2.0 INSTALLATION

SW1

6-9/64

4-27/32

1-13/64

19/32

J1

19/32

Dimensional Drawing

SW2

3-11/16

4-7/8

975-0008-002

Figure 5

©2001 Xantrex Technology Inc. 7

Page 14

2.0 INSTALLATION

Mounting Procedure (continued)

Mounting Holes Mounting Holes

Figure 6

Mounting Holes

8 ©2001 Xantrex Technology Inc.

Page 15

2.0 INSTALLATION

Generator Wiring

Connect the generator auto-start wires to RY7 for the RUN/GLOWSTOP

functions and RY8 (if used) for the START circuit.

To connect the generator wires to the terminal block

Lift the appropriate lever for the relay contact.

Insert the wire (stripped back 1/4 inch) into the terminal block.

Snap the lever down to secure the wire.

Please refer to the generator section of the inverters operation manual

for additional information.

NOTE: Due to the various wiring schemes used by different

manufacturers, detailed wiring instructions can not be given in this

manual. Please refer to the generator manufacturers documentation

for wiring details.

CAUTION: DO NOT WIRE THE RELAYS DIRECTLY TO A HIGHAMPERAGE DEVICE, SUCH AS A STARTER MOTOR. THESE

RELAYS ARE DESIGNED TO INTERFACE WITH THE

GENERATORS AUTO-START CIRCUIT (LOW-CURRENT SIGNALS) ONLY. CONNECTION TO A HIGH-CURRENT DEVICE WILL

OPEN THE FUSE IN THE COMMON LINE AND Possibly DAMAGE

THE RELAY.

NOTE: All wiring described in this manual must be performed by a

qualified, licensed electrician and meet local and national codes,

such as NEC.

RELAY 7

Connections

Terminal Block Connections

©2001 Xantrex Technology Inc. 9

RELAY 8

Connections

Figure 7

RELAY 11

Connections

Page 16

2.0 INSTALLATION

Generator Wiring (continued)

Two-Wire Start Circuits

Two-wire starting generators are the easiest to control and are highly

recommended for this type of application. A contact closure starts the

generator, while an open contact stops the generator.

Connect the two wires from the generators remote, auto-start, control

circuit to the RY7, N.O. and COM terminals.

Select RUN from the SWRCs SET RY7 FUNCTION menu item (found

under the GEN STARTING DETAILS (13) menu heading).

To Inverter’s

GEN Connector

2-WIRE START TYPE

GEN START MODULE

RY7

N.O.

COM

N.C.

INTERNAL

FUSE

GENERATOR

REMOTE START/

STOP

TERMINALS

2-Wire Start Connections

Figure 8

10 ©2001 Xantrex Technology Inc.

Page 17

2.0 INSTALLATION

Generator Wiring (continued)

Wiring Honda-Type Generators

In this starting configuration, relay RY7 duplicates the RUN position and

RY8 duplicates the START position, cranking the starter motor.

Connect the COM contact of RY7 to one of the RUN/STOP switch contacts

of the generator.

Connect the N.O. contact of RY7 to the other RUN/STOP switch contact of

the generator.

Connect the COM contact of RY8 to one of the START switch contacts of

the generator.

Connect the N.O. contact of RY8 to the other START switch contact of the

generator.

Select RUN from the SWRCs SET RY7 FUNCTION menu item (found

under the GEN STARTING DETAILS (13) menu heading).

To Inverter’s

GEN Connector

GEN START MODULE

RY7

RY8

COM

COM

N.O.

N.C.

N.O.

N.C.

INTERNAL

FUSE

INTERNAL

FUSE

HONDA 3-WIRE TYPE GENERATOR

RUN/STOP

SWITCH

CONTACTS

START

SWITCH

CONTACTS

3597-B00-D29

Figure 9

Honda-Type Connections

©2001 Xantrex Technology Inc. 11

Page 18

2.0 INSTALLATION

Generator Wiring (continued)

Wiring Onan-Type Generators

In this system, RY8 duplicates the START position and relay RY7

duplicates the STOP position. Some generators use a similar system with

two push-button switches, one to start and one to stop the generator.

Connect the COM contact of RY7 to one of the STOP switch contacts of

the generator.

Connect the COM contact of RY7 to the COM contact of RY8.

Connect the N.O. contact of RY7 to the other STOP switch contact of

thegenerator.

Connect the N.O. terminal of RY8 to the START switch contact.

Select GLOWSTOP from the SWRCs SET RY7 FUNCTION menu item

(found under the GEN STARTING DETAILS (13) menu heading).

To Inverter’s

GEN Connector

GEN START MODULE

RY7

RY8

COM

COM

N.O.

N.C.

N.O.

N.C.

INTERNAL

FUSE

INTERNAL

FUSE

ONAN 3-WIRE TYPE GENERATOR

STOP SWITCH

CONTACTS

START

SWITCH

CONTACTS

Figure 10

Onan-Type Start Connections

12 ©2001 Xantrex Technology Inc.

Page 19

2.0 INSTALLATION

Error Indicator Wiring

If an error indicator is used (light, buzzer, bell, etc.), connect the wires to

the RY11 relay contacts. Depending on the error indicator used, either the

N.O. or N.C. contacts can be used. Typically, the N.C. and COM contacts are

used to complete a circuit, turning on a light, buzzer, etc. The N.C. contacts

are held open until an error condition is detected (or the AC output is OFF);

at which time the N.C. contact will close completing the circuit and activating

the external device.

NO SIGNAL FROM

INVERTER

(relay dise ngaged)

COM

N.O.

Fuse

EXTERNAL

INDICATOR

POWER SOURCE

External Error

Indicator

N.C.

975-0008-001

External Alarm

OFF Switch

CONTROL SIGNAL

FROM INVERTER

(relay engaged)

Fuse

N.C.

N.O.

EXTERNAL

INDICATOR

POWER SOURCE

COM

975-0008-001A

External Error

Indicator

External Alarm

OFF Switch

Figure 11

External Error Indicator Connections

For convenience, add an external OFF switch in line with the alarm

device. This allows turning off the alarm until the inverters output is restored.

NOTE: The diagrams shown here are intended as an example of

how the relays operate an external alarm device. Actual alarm types

may operate differently from these diagrams. Refer to the owners

manual for specific alarm wiring. Do not exceed the voltage or

amperage ratings of the relay and fuse.

CONTROL SIGNAL

FROM INVERTER

(relay engaged)

External Error

Indicator

COM

Fuse

N.C.

N.O.

EXTERNAL

INDICATOR

POWER SOURCE

975-0008-001B

External Alarm

OFF Switch

Figure 12

External Alarm OFF Switch

©2001 Xantrex Technology Inc. 13

Page 20

2.0 INSTALLATION

Communication Cable

The GSM is supplied with a 25-foot, telephone-type, cable with RJ11

connectors on each end.

NOTE: Longer cable lengths are available from Xantrex: part

Numbers TC/50 for 50 feet (15.24 m) and TC/100 for 100 feet (30.48

m).

Route the telephone-type cable through one of the knockouts fitted with a

strain relief (or conduit).

Connect one end of the cable to the jack labeled J1 on the GSM

circuitboard.

Connect the other end of the cable to the jack labeled GEN inside the

inverter (refer to the inverter/chargers operators manual for location).

Reinstall the cover on the GSM using the two Phillips screws.

Reinstall the inverters cover.

NOTE: Recheck all wiring before proceeding to the OPERATION

section.

J1 Connector

Communication

cable to inverter

J1 Control Signal Connection

Figure 13

14 ©2001 Xantrex Technology Inc.

Page 21

3.0 OPERATION

Operation and Test

NOTE: Refer to the inverters operators manual for setting the RY7

relay for either RUN or GLOWSTOP (whichever is appropriate for

the generator).

NOTE: Ensure the inverters MAXIMUM AC AMPS IN switch is in

the AC2 position otherwise generator auto-start will not operate

properly.

Immediately after installation, the GSM should be tested for proper

operation of the generator and error indicator.

Ensure the GENERATOR RELAY switch on the GSM is in the ON

(ENABLED) position and the INVERTER ERROR relay is in the RELAY

READY position.

Reconnect all power to the inverter and generator start circuits. Turn ON

the inverter. The blue INVERTER OPERATIONAL LED should immediately

turn ON.

Using the SWRC remote, press the green GEN MENU button to access the

generator menu. Select ON from the display. The generator should begin

to operate and the appropriate relay LEDs should be illuminated on

theGSM.

NOTE: The LEDs will turn ON differently, depending upon the

function selected in the SWRCs RY7 menu. On two-wire configurations, the RY8 relay is not used.

If the test passes, select OFF from the SWRCs GEN MENU display.

When the generator stops, select AUTO from the GEN MENU display (if

desired) for automatic generator operation.

If an external alarm is connected to the GSM, turn the INVERTER ERROR

switch to the RELAY TEST position. The external device should activate.

Place the INVERTER ERROR switch in the RELAY READY position.

NOTE: If the tests did not pass (i.e., the generator did not start or

stop), recheck the wiring to the generator auto-start circuits and

GSM for proper relay contact selection (N.O. or N.C.). Also check

the settings for the RY7 relay (using the SWRC) and ensure they are

correct.

©2001 Xantrex Technology Inc. 15

Page 22

3.0 OPERATION

Internal Sticker

Please refer to the component layout sticker located inside the front

cover. This label can be used as a quick reference for component location and

fuse sizing information.

™

GSM - GENERATOR START MODULE

SUPPLIED FUSE RATING: 6.3 AMP 250VAC

FUSE TYPE: 5mm X 20mm

MAXIMUM RELAY CONTACT RATINGS: (RESISTIVE LOAD)

10 AMPS @ 250VAC

8 AMPS @ 30VDC

FUSE SHOULD BE SELECTED FOR PROPER

PROTECTION OF CONNECTED DEVICES.

(DO NOT EXCEED RELAY CONTACT RATING)

PN 110-0035 - -

LED1

LED2

R4

D1

LED3

J1

Interconnect cable (J1):

WARNING:

RELAY RELAY

RY7

SW1 SW1 SW2

R1R2R3

RELAY

RY8

RY11

F2F1

F3

TB1

91

NCCCNONO

NOCNC

DO NOT OPERATE WITH COVER REMOVED.

HAZARDOUS VOLTAGES MAY BE PRESENT.

NC

Terminal Block w ire size: 14-28 AWG

Wire strip length: .25" (6mm)

Connect to Gen Port of

Trace Inverter

SW1

SW2

PN: 270-0023-01-02

Internal Component Identification Sticker

Figure 14

Danger Label

A danger label is included with the GSM to warn service personnel that

the generator may suddenly start without warning (due to an inverter command). Place this label close to the generator where it can easily be seen.

GENERATOR

AUTO START SYSTEM

GENERATOR HAS AN AUTO START SYSTEM WHICH

MAY CAUSE THE GENERATOR TO START WITHOUT

WARNING

DISABLE GENERATOR AUTO START BEFORE SERVICING

270-0025-01-01

Figure 15

Danger Label

16 ©2001 Xantrex Technology Inc.

Page 23

4.0 TROUBLESHOOTING

Troubleshooting

The GSM contains no serviceable parts other than the three fuses in the

common contact circuit of the relays. If the module requires servicing, return it

to Xantrex Technology Inc., or contact a Xantrex representative for assistance.

motpmyS esuaCelbissoP ydemeR

.thgiltonseodDELeulB.NOdenruttonretrevnI

.retrevniNOnruT

tonelbacnoitacinummoC

.kcajgnorweht

.edom)ylno

neerg,sthgilDELeulB

.thgil

.tratstonseod

tonodsDELwolleydna

sDELwolleydnaneerG

rotarenegehttubthgil

.noitisop

.nepo)s(esuF

.launams'rotarepos'retrevni

nisiroretrevniotdetcennoc

.detcetedrorreretrevnI

egrahc(GHCnisiretrevnI

.yltcerrocputestonsiretrevnIehtfoputesehtkcehC

FFOehtnisihctiwS

.noitisopNOeht

.yltcerrocnideriwrotareneG

tierusnE.noitcennockcehC

reporpehtotdetcennocsi

.retrevniehtnikcaj

reporprofretrevniehtkcehC

ehttoohselbuorT.noitarepo

ehtgnisurorreehtfoesuac

.ediugasaCRWS

CAylpparoedomegnahC

otrewop)rotarenegro(ytilitu

.tupnis'retrevnieht

refeR.CRWSgnisuretrevni

.launams'rotareporetrevniot

nisihctiwsreppuehterusnE

toohselbuort,esufecalpeR

.tnerrucrevofoesuac

-otuarotarenegkcehceR

.tcerrocdnagniriwtrats

ehtninoitcesgnitoohselbuortehtehtotrefer,noitamrofnilanoitiddaroF:ETON

300-8000-579

©2001 Xantrex Technology Inc. 17

Page 24

5.0 SERVICE INFORMATION

Xantrex Technology Inc., takes great pride in its products and makes

every effort to ensure your unit fully meets your independent powering needs.

If your product needs repair, contact our Customer Service department at:

(360) 435-8826 to obtain an RMA# and shipping information; or, fax this page

with the following information to: (360) 474-0616.

Please provide:

Model Number: _________________________________

Serial Number: _________________________________

Purchase Date: _________________________________

Problem: ______________________________________

Include a telephone number where you can be reached during business

hours and a complete return shipping address (P.O. Box numbers are not

acceptable).

Name: __________________________________________

Address: ________________________________________

City: ___________________________________________

State / Province: __________________________________

Zip / Postal Code: _________________________________

Country: ________________________________________

Phone: (____) ____________________________________

FAX: (____)______________________________________

E-mail Address: __________________________________

visit our website at: www.traceengineering.com

or e-mail us at: traceengineering.com

18 ©2001 Xantrex Technology Inc.

Page 25

6.0 WARRANTY

Limited Warranty

Xantrex Technology Inc., warrants its power products against defects in materials

and workmanship for a period of two (2) years from the date of purchase, established by

proof of purchase or formal warranty registration, and extends this warranty to all

purchasers or owners of the product during the warranty period. Xantrex Technology

Inc., does not warrant its products from any and all defects:

arising out of material or workmanship not provided by Xantrex or

its Authorized Service Centers;

when the product is installed or exposed to an unsuitable environment as

evidenced by generalized corrosion or biological infestation;

resulting from abnormal use of the product, alteration, or use in violation of the

instructions;

in components, parts, or products expressly warranted by another manufacturer.

Xantrex Technology Inc., agrees to supply all parts and labor to repair or replace

defects covered by this warranty with parts or products of original or improved design, at

the company's option. Xantrex Technology Inc., also reserves the right to improve the

design of its products without obligation to modify or upgrade those previously

manufactured. Defective products must be returned to Xantrex Technology Inc., or its

Authorized Service Center in the original packaging or equivalent. The cost of

transportation and insurance on items returned for service is the responsibility of the

customer. Return transportation (UPS Ground or equivalent) as well as insurance on all

repaired items is paid by Xantrex Technology Inc.

All remedies and the measure of damages are limited to the above. Xantrex

Technology Inc., shall in no event be liable for consequential, incidental, contingent, or

special damages, even if Xantrex Technology Inc., has been advised of the possibility of

such damages. Any and all other warranties, expressed or implied, arising by law,

course of dealing, course of performance, usage of trade or otherwise, including, but

not limited to, implied warranties of merchantability and fitness for a particular purpose,

are limited in duration for a period of two (2) years from the original date of purchase.

Some states or counties do not allow limitations on the term of an implied

warranty, or the exclusion or limitation of incidental or consequential damage, which

means the limitations and exclusions of this warranty may not apply to you. Even

though this warranty gives you specific legal rights, you may also have other rights

which vary from state to state.

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

visit our website at: www.traceengineering.com

©2001 Xantrex Technology Inc. 19

Page 26

7.0 SPECIFICATIONS

Specifications

ELECTRICAL:

Operating Voltage 11 VDC (provided by inverter)

Operating Current < 10 ma

Relay Contact Rating 250 VAC, 10 amps max. (resistive load only)

Wire Size Accepted 28 AWG to 14 AWG

Switches 2 DPDT switches

Protection 3Fuses, 6.3 amps max. (5 mm x 20 mm), time delay

Indicator LEDs 3LEDs, green, yellow and blue

Interface Cable 25 ft. Telephone-type cable with RJ11 plugs

Interface Connection Telephone-type RJ11 jack

Terminal Block Snap lock type connection

MECHANICAL:

Material Powder coated, steel enclosure

Dimensions 6.8" H x 4.8" W x 2.0" D

30 VDC, 8 amps max. (resistive load only)

BussmanGDC, Littlefuse218 series

(15.6 cm H x 12.4 cm W x 5.0 cm D)

20 ©2001 Xantrex Technology Inc.

Page 27

©2001 Xantrex Technology Inc. 21

Page 28

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

22 ©2001 Xantrex Technology Inc.

visit our website at: www.traceengineering.com

Loading...

Loading...