Page 1

DR Series

Inverter/Charger

Installation &

Operators Manual

Page 2

Page 3

DR Series

Inverter/Charger

Table of Contents

Section Description Page

1.0 INTRODUCTION ..........................................................................1

Unpacking and Inspection................................................... 2

Model Identification and Numbering Conventions ............ 3

Certification .......................................................................... 4

2.0 INSTALLATION............................................................................ 5

Features ............................................................................ 5

Modified Sine Wave Power ........................................... 5

Battery Charger/AC Transfer Relay .............................. 5

Simplicity ........................................................................ 5

High Efficiency ............................................................... 5

Low Power Consumption ............................................. 5

Options ............................................................................ 5

RC4/RC8 ......................................................................... 5

DRI ............................................................................ 5

DRCB ............................................................................ 5

Pre-installation ..................................................................... 6

Location .......................................................................... 6

Mounting......................................................................... 6

Ventilation....................................................................... 6

Tools Required ............................................................... 7

Hardware/Materials Required ....................................... 7

Wiring ............................................................................ 7

AC Connections ............................................................. 7

DC Connections ............................................................. 7

Grounding ...................................................................... 7

AC Grounding .......................................................... 7

DC Grounding .......................................................... 7

Batteries ............................................................................ 8

Battery Location ............................................................ 8

Battery Temperature ...................................................... 8

Main Service Panel ............................................................... 10

Sub-Panel ............................................................................ 10

AC Circuit Breakers ............................................................. 10

DC Disconnect ...................................................................... 10

Wire Routing ......................................................................... 10

Inverter Mounting ................................................................. 11

Wiring ............................................................................ 13

DC Wiring (Batteries) ..................................................... 13

Battery Cable Sizing ...................................................... 13

DC Disconnect and Over-current Protection .............. 14

Battery Cable Connections ...........................................15

Battery Bank Sizing ....................................................... 16

Battery Types ................................................................. 16

Battery Configuration .................................................... 16

SERIES ..................................................................... 16

PARALLEL ............................................................... 16

SERIES-PARALLEL ................................................. 16

©2000 Xantrex Technology Inc.

i

Page 4

Continued

Section Description Page

2.0 INSTALLATION (continued)

Wiring the Batteries in Series ............................................. 17

Wiring the Batteries in Parallel ..................................... 18

Wiring the Batteries in Series-parallel ......................... 18

Series/Parallel Configurations and Cross-Tying .........20

Installation Guidelines ......................................................... 22

DC Circuit Grounding .......................................................... 23

General DC Grounding Requirements ......................... 23

Installing the Battery Temperature Sensor ........................ 24

Installing the Sensor...................................................... 24

AC Wiring ............................................................................ 25

Sub-panel and Conduit Installation .............................. 25

Input to the Inverter .......................................................25

AC Input Wiring to the Inverter ..................................... 27

AC Output Wiring to the Sub-panel .............................. 28

AC Input Wiring to the Utility Breaker Box ..................29

Generators ............................................................................ 30

Generator Requirements ............................................... 30

Basic 120 VAC Generator Hookup

(non-utility applications only) ................................ 31

Basic 120 VAC Utility/Generator Hookup..................... 32

Generator Connections

(to manual bypass switch) ............................... 32

Utility Connections (to manual bypass switch) .... 32

Inverter Connections

(to manual bypass switch) ............................... 32

Sub-panel Connections .......................................... 32

Series Stacking..................................................................... 34

3.0 OPERATION ............................................................................ 36

Front Panel Controls and Indicators .................................. 36

Power ON/OFF Switch ................................................... 36

Ports ............................................................................36

COM Port ........................................................................ 36

Remote Controls ..................................................... 36

Stacking Interface ................................................... 36

Battery Sense Port ......................................................... 37

Controls .......................................................................... 38

DC Controls ............................................................. 38

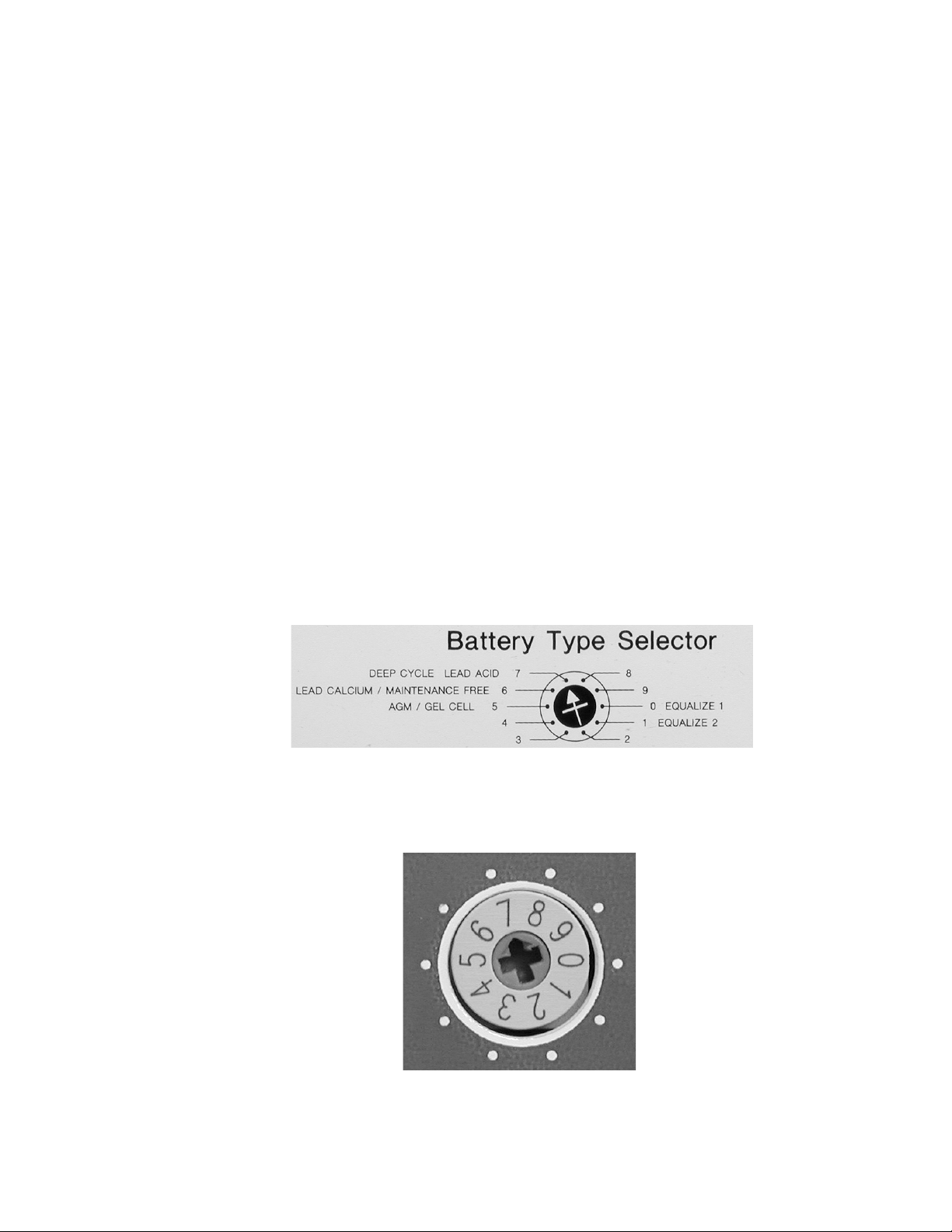

Battery Type Selector ....................................... 38

Switch Positions ............................................... 38

0 and 1Equalize 1 and 2.................................. 38

2Deep Cycle Lead Acid 2................................ 38

3Not Specified ................................................. 38

4GEL Cell 2 ...................................................... 39

5GEL Cell 1 ...................................................... 39

6PbCa - Lead Calcium .................................... 39

7Deep Cycle Lead Acid................................... 39

8NiCad 1 .......................................................... 39

NiCad 2 .............................................................. 39

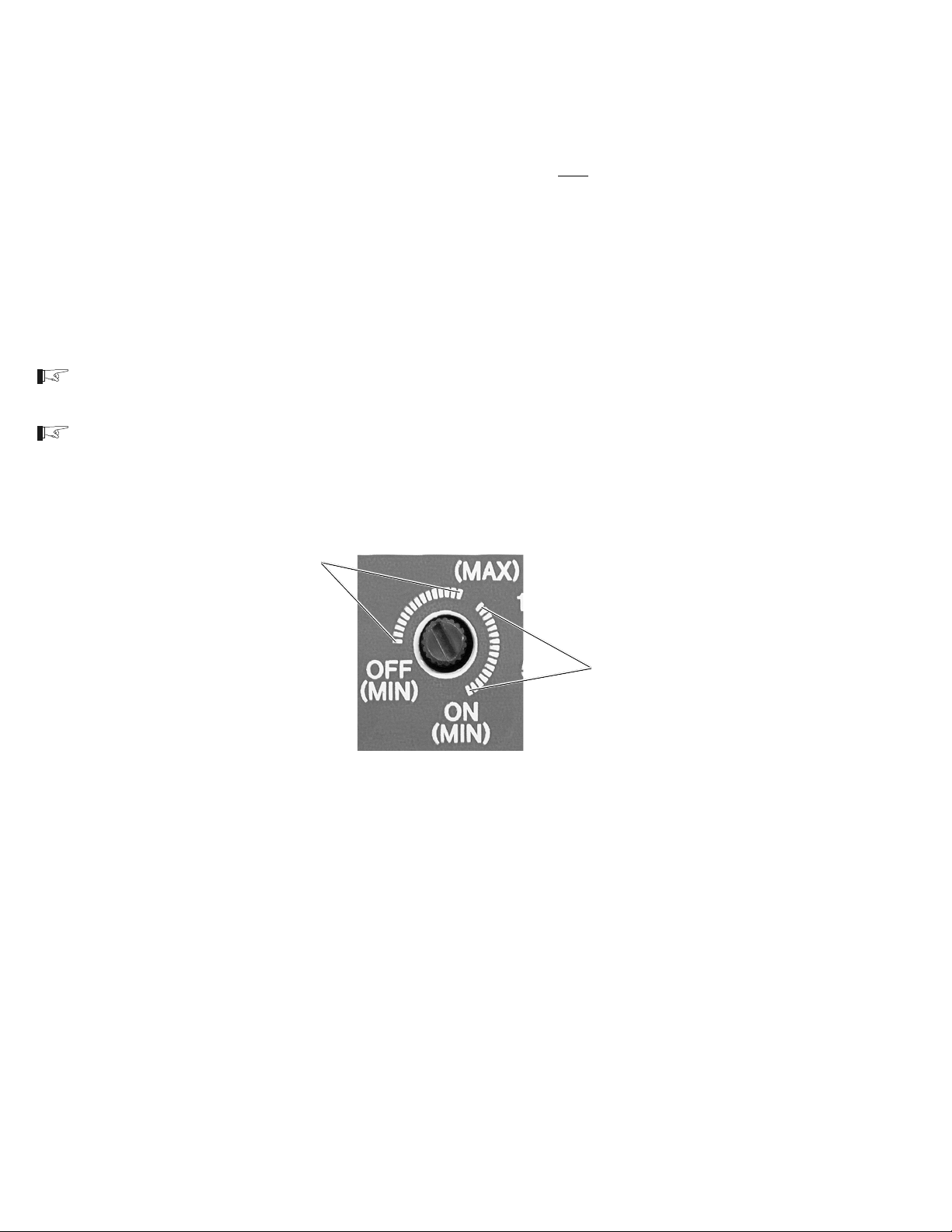

SEARCH MODE WATTS Potentiometer ....................... 40

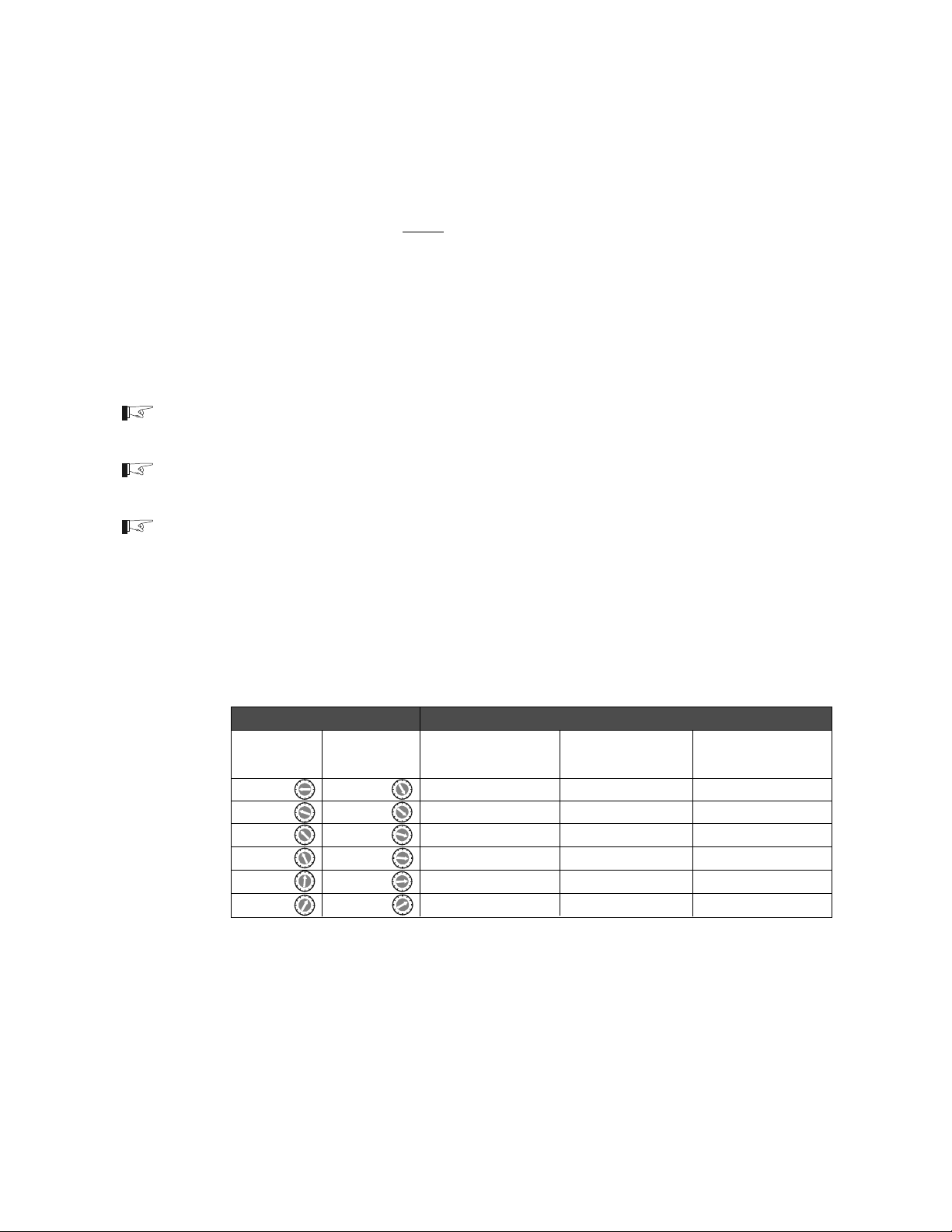

Battery Charger Rate ..................................................... 41

Over Discharge Protection/AC Transfer Voltage......... 42

Over Discharge Protection (ODP) ..........................42

AC Transfer Voltage ................................................ 43

©2000 Xantrex Technology Inc.ii

Page 5

Continued

Section Description Page

3.0 OPERATION (continued)

Battery Capacity............................................................. 45

LED Indicators ............................................................... 46

Inverter Mode LED - Green ..................................... 46

Over Temp LED - Red/Green .................................. 46

Battery Hi/Battery Low LED - Red/Green .............. 47

Charger LED - Orange/Green ................................. 47

Audible Indicator ........................................................... 47

Circuit Breakers .............................................................48

Start-up ............................................................................ 49

Charger Mode .......................................................................50

3-Stage Charging Process ............................................ 50

Bulk Charge ............................................................. 50

Absorption Charge .................................................. 50

Float Charge ............................................................ 50

Equalize Charging ......................................................... 51

Setting the Equalize Charge ................................... 51

4.0 TROUBLESHOOTING ................................................................. 53

5.0 APPENDIX ............................................................................ 55

Batteries ............................................................................ 55

Selection of a Battery Type ................................................. 55

Flooded Lead Acid (FLA) .............................................. 55

RV and Marine ......................................................... 55

Golf Cart ................................................................... 55

Industrial (electric forklift) ......................................55

Sealed Batteries ............................................................. 55

Gel Cell ..................................................................... 55

Absorbed Glass Mat ................................................ 55

NiCad and NiFe Batteries .............................................. 56

Battery Bank Sizing ............................................................. 57

Estimating Battery Requirements ................................ 57

Example ................................................................... 58

Typical Appliance Wattages ................................................ 60

Battery Care and Maintenance ............................................ 61

Charge Rate ................................................................... 61

Bulk Charge ................................................................... 61

Float Voltage................................................................... 61

Temperature Compensation ......................................... 61

Equalization Charging ................................................... 61

Replenish Water Levels................................................. 62

Clean Battery Cables and Posts ................................... 62

Torque Battery Connections ......................................... 62

Check Battery State of Charge ..................................... 63

Problem Loads ..................................................................... 64

Multiwire Branch Circuits .................................................... 66

Identifying Multiwire Branch Circuits .......................... 67

Correcting Multiwire Branch Circuit Wiring ................ 68

6.0 LIMITED WARRANTY ................................................................. 69

7.0 SERVICE INFORMATION ............................................................71

8.0 SPECIFICATIONS ........................................................................ 72

©2000 Xantrex Technology Inc.

iii

Page 6

Disclaimer of Liability

Since the use of this manual and the conditions or methods of installation, operation, use and

maintenance of the unit are beyond the control of Xantrex Technology Inc., the company does not

assume responsibility and expressly disclaims liability for loss, damage, or expense arising out of or

any way connected with such installation, operation, use or maintenance.

©2000 Xantrex Technology Inc.IV

Page 7

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation

and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation and operation of this

product, the following safety symbols have been placed throughout this manual to indicate dangerous conditions and important safety instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

AVERTISSEMENT - Une tension ou condition dangereuse existe dans cette zone.

Faire preuve dextrême prudence lors de la réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or operation of the unit. Follow these

instructions closely.

ATTENTION - Cette procédure est essentielle à linstallation ou lutilisation

de lunité en toute sécurité. Suivre ces instructions de près.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions de près.

·

All electrical work must be done in accordance with local, national and/or international electrical

codes.

·

Before installing or using this device, read all instructions and cautionary markings located in (or

on) the manual, the inverter, the controller, the batteries and the PV array.

·

Do not expose this unit to rain, snow or liquids of any type. This product is designed only for

indoor installation.

·

To reduce the chance of short-circuits when installing or working with the inverter, the batteries

or the PV array, use insulated tools.

·

Remove all jewelry such as rings, bracelets, necklaces, etc., prior to installing this system. This

will greatly reduce the chance of accidental exposure to live circuits.

·

The inverter contains more than one live circuit (batteries and AC line). Power may be present

at more than one source.

·

This product contains no user serviceable parts. Do not attempt to repair this unit.

·

Do not install 120 volt AC stand-alone inverters onto 120/240 volt AC multi-branch circuit wiring.

This could pose a fire hazard due to an overloaded neutral return wire in this configuration.

©2000 Xantrex Technology Inc.

SAVE THESE INSTRUCTIONS

V

Page 8

BATTERY SAFETY INFORMATION

·

Always wear eye protection, such as safety glasses, when working with batteries.

·

Remove all loose jewelry before working with batteries.

·

Never work alone. Have someone assist you with the installation or be close enough to come to

your aid when working with batteries.

·

Always use proper lifting techniques when handling batteries.

·

Always use identical types of batteries.

·

Never install old or untested batteries. Check each batterys date code or label to ensure age

and type.

·

Batteries are temperature sensitive. For optimum performance, they should be installed in a

stable temperature environment.

·

Batteries should be installed in a well vented area to prevent the possible buildup of explosive

gasses. If the batteries are installed inside an enclosure, vent its highest point to the outdoors.

·

When installing batteries, allow at least 1 inch of air space between batteries to promote cooling

and ventilation.

·

NEVER smoke in the vicinity of a battery or generator.

·

Always connect the batteries first, then connect the cables to the inverter or controller. This will

greatly reduce the chance of spark in the vicinity of the batteries.

·

Use insulated tools when working with batteries.

·

When connecting batteries, always verify proper voltage and polarity.

·

Do not short-circuit battery cables. Fire or explosion can occur.

·

In the event of exposure to battery electrolyte, wash the area with soap and water. If acid enters

the eyes, flood them with running cold water for at least 15 minutes and get immediate medical

attention.

·

Always recycle old batteries. Contact your local recycling center for proper disposal information.

©2000 Xantrex Technology Inc.VI

Page 9

1.0 INTRODUCTION

Thank you for purchasing the DR Series inverter/charger from Xantrex Technology Inc. The

DR Series is one of the finest inverter/chargers on the market today, incorporating state-of-the-art

technology and high reliability. The inverter features an AC pass-through circuit, powering your

home appliances from utility or generator power while charging the batteries. When utility power

fails, the battery backup system keeps your appliances powered until utility power is restored.

Internal protection circuits prevent over-discharge of the batteries by shutting down the inverter

when a low battery condition occurs. When utility or generator power is restored, the inverter

transfers to the AC source and recharges the batteries.

The front panel features LEDs for reading system status, and controls to customize the inverter

settings for your battery bank.

©2000 Xantrex Technology Inc.

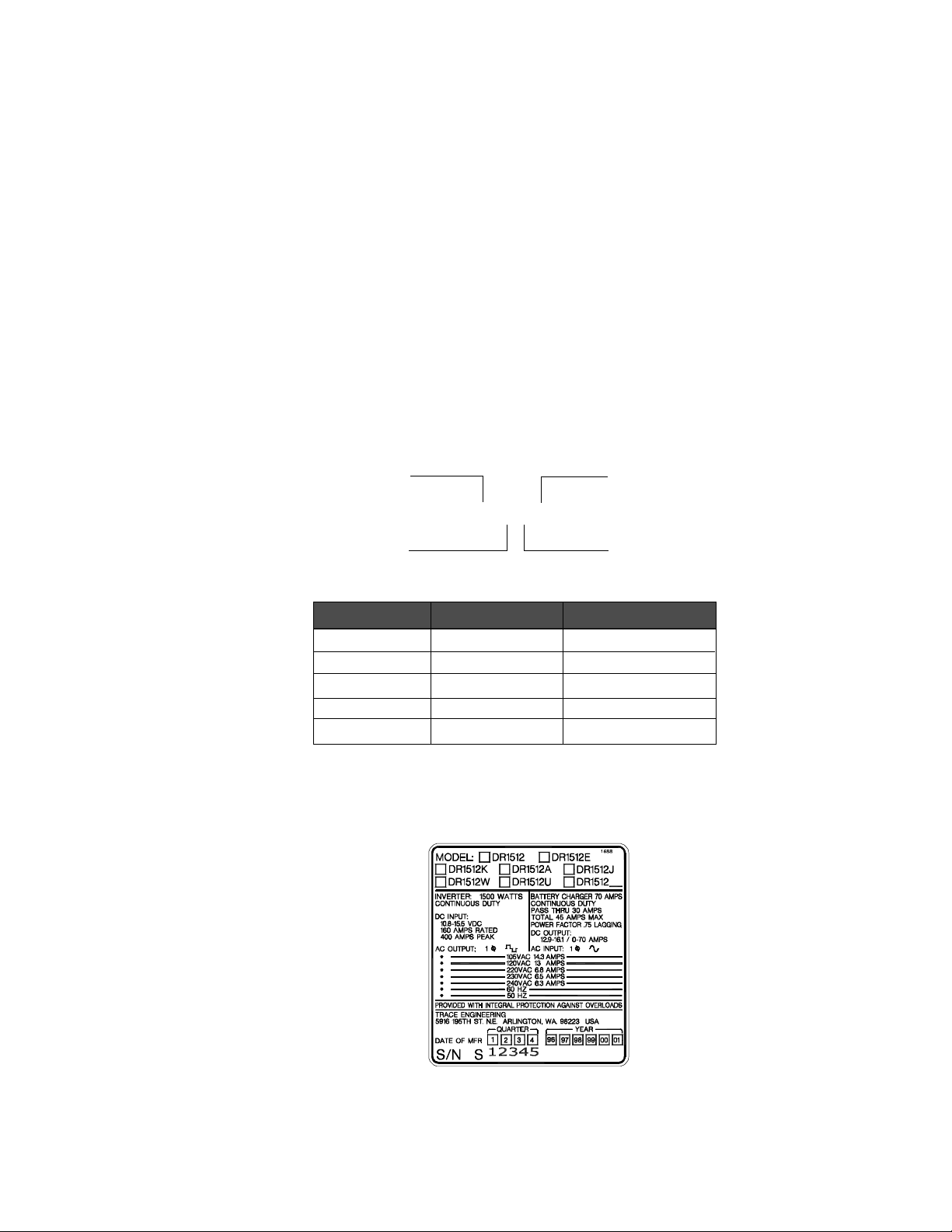

Figure 1

The DR Series Inverter/Charger

1

Page 10

1.0 INTRODUCTION

Unpacking and Inspection

Carefully unpack the inverter/charger from its shipping carton.

NOTE: The unit weighs 3545 lb/15.920.4 kg (depending on model). Have additional help available

if necessary, to assist in lifting the unit during installation.

Verify all of the items listed on the packing material sheet are present. Please call Xantrex

Customer Service at (360) 435-8826 if any items are missing.

Save your proof-of-purchase. This is required if the unit should require warranty service.

Save the original shipping carton and packing materials! If the inverter ever needs to be returned

for service, it should be shipped in the original carton. This is also a good way to protect the

inverter if it ever needs to be moved.

Record the units model, serial number and date of purchase in the appropriate fields in section

10.0 SERVICE INFORMATION.

NOTE: Due to continual improvement through product updates, photographs and/or illustrations

used in this manual may not exactly match your unit. Xantrex Technology Inc. reserves the right to

update this product without notice or releasing an updated manual when fit, form or function are not

affected.

2

©2000 Xantrex Technology Inc.

Page 11

1.0 INTRODUCTION

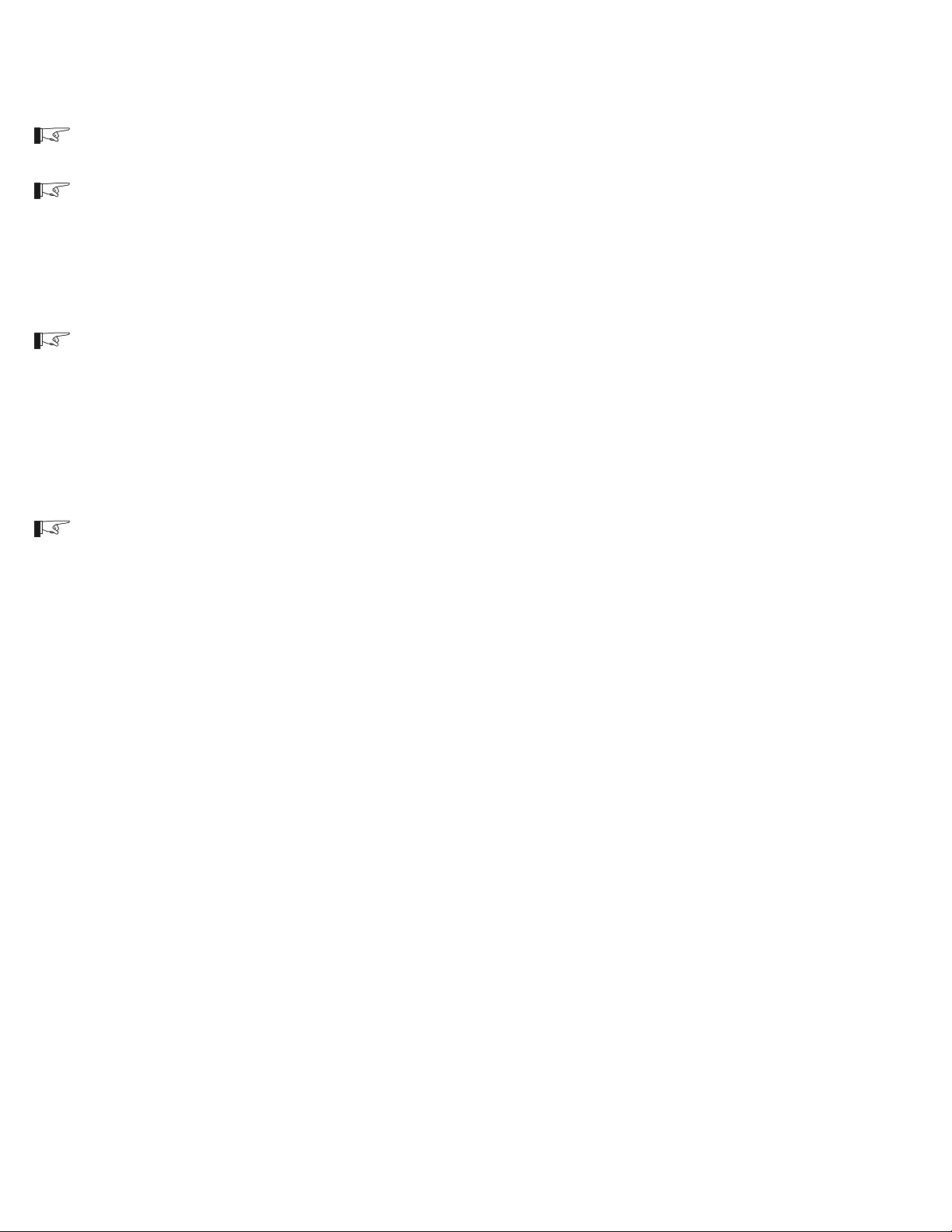

Model Identification and Numbering Conventions

The DR Series inverter/charger is identified by the model/serial number label located next to the

AC access cover. All the necessary information is provided on the label such as AC output voltage,

power and frequency (punch holes).

The inverter also has a letter designator followed by 4 or 5 digits (depending on revision). The

model number describes the type of inverter, the output specifications, the required battery voltage

and the output voltage and frequency.

DR indicates the type of inverter/charger - DR Series.

15 the first two digits of the numerical designator indicate the inverters output power - 1500

Watts.

12 the second two digits indicate the required nominal battery bank voltage - 12 VDC.

E the letter suffix code indicates the output voltage and frequency of the inverter - 230

VAC/50 Hz.

Product Family

Example: DR 1512 E

Output Power

Letter Suffix Output Voltage Output Frequency

(no letter) 120 VAC 60 Hz

E 230 VAC 50 Hz

J 105 VAC 50 Hz

K 105 VAC 60 Hz

W 220 VAC 60 Hz

Figure 2

Product Identification

Country Code

Battery Voltage

©2000 Xantrex Technology Inc.

Figure 3

Model/Serial Number Sticker

3

Page 12

1.0 INTRODUCTION

Certification

120 VAC/60 Hz models of the DR Series inverter/charger models are listed to UL Standard 1741,

Power Conditioning Units for use in Residential and Commercial Photovoltaic Power Systems. These

units are also ETL listed to CAN/CSA-22.2, No. 107.1-M91, the Canadian safety standard. These

standards guarantee that the inverter/charger has been tested to nationally recognized safety

standards (UL for the US and CSA for Canada) and have been found to be free from reasonably

foreseeable risk of fire, electric shock and related hazards.

The inverter/charger is intended to be used for residential or commercial applications. Do NOT

use this unit for applications for which it is not listed (i.e., land vehicles or marine craft). It may not

comply with the safety code requirements, or could possibly present other operational or safety

hazards.

Figure 4

UL/CSA Certification Sticker

Certification Sticker

4

©2000 Xantrex Technology Inc.

Page 13

2.0 INSTALLATION

The DR Series inverter/charger is an economical product designed to provide a reliable supply of

electricity to all the essential circuits in the home or business during a power outage. The critical

loads can be powered for hours or days, depending on the size of the system battery bank. When

utility grid power returns, the batteries are quickly recharged to ensure they will be ready to supply

backup power during the next outage.

Accessories allow the DR Series to also serve as a central hub of a renewable energy system.

Features

Modified Sine Wave Power

The DR Series inverters provide a modified sine wave output which operates most AC appliances

and equipment.

Battery Charger/AC Transfer Relay

The inverter/charger includes a 3-stage battery charger designed to recharge any type of battery

in the shortest possible time. The built-in, fully automatic AC transfer relay automatically transfers

power from the utility to the inverter and handles a full 60 amps of current at 120 VAC (30 amps

for pass-through plus 30 amps for charging).

Simplicity

The DR Series is simple to operate. All inverter and battery charger controls are located on the

front panel.

High Efficiency

The inverter/charger operates at over 90% efficiency through most of its power range.

Low Power Consumption

DR Series inverters use extremely low current while in the search mode, consuming little more

than one watt of power. In the ON mode, the inverter/charger uses less than 20 watts of power.

Options

The following options are available for the DR Series inverter/chargers:

RC4/RC8

The RC4/RC8 allows the inverter to be switched ON or OFF remotely and includes an LED status

indicator.

DRI

The DRI stacking interface provides 3-wire 120/240 VAC at twice the power using dual DR Series

inverters (120 VAC/60 Hz units only).

DRCB

The DRCB conduit box connects to the DC side of the inverter and accepts a DC conduit run.

©2000 Xantrex Technology Inc.

5

Page 14

2.0 INSTALLATION

Pre-installation

NOTE: Before installing the inverter/charger, read all instructions and cautionary markings located in

this manual.

NOTE: The inverter/charger can weigh up to 45 lb. (20.4 kg) depending upon configuration. Always

use proper lifting techniques during installation to prevent personal injury.

Location

Inverters contain sophisticated electronic components and should be located in a well

protected, dry environment away from sources of fluctuating or extreme temperatures and

moisture. Exposure to saltwater is particularly destructive and potentially hazardous.

NOTE: If the inverter is installed in a location where it is exposed to a corrosive or condensing

environment, and fails due to corrosion, it will not be covered under warranty.

Locate the inverter as close to the batteries as possible in order to keep the battery cable

length short. However, do not locate the inverter above the batteries or in the same

compartment as vented batteries. Batteries generate hydrogen sulfide gas which is corrosive

to electronic equipment. They also generate hydrogen and oxygen. If accumulated, an arc

caused by connecting the battery cables or switching a relay could ignite this mixture.

Mounting the inverter in a ventilated enclosure with sealed batteries is acceptable.

NOTE: Inverters can generate RFI (Radio Frequency Interference). Locate any sensitive electronic

equipment susceptible to RFI as far away from the inverter as possible. This includes radios and

TVs.

Mounting

UL Standard 1741 requires the inverter be mounted on a vertical surface (or wall). The

keyhole slots must not be used as the only method of mounting. The purpose of the wall

mounting requirement is to orient the inverter so that its bottom cover, which has no holes,

will not allow burning material to be ejected in the event of an internal fire. Use 0.25 inch

diameter bolts for mounting. The mounting surface must be capable of supporting twice the

weight of the inverter to comply with UL 1741.

Ventilation

Install the inverter in a well ventilated area/enclosure for proper operation. The inverters

thermal shutdown point will be reached sooner than normal in a poorly ventilated

environment, resulting in reduced peak power output and surge capability, as well as shorter

inverter life.

The inverter contains an internal fan. Ensure the air vents and intakes are not obstructed in

any way. Provide a minimum clearance of 1-1/2 inches around the top and sides of the

inverter for ventilation.

6

©2000 Xantrex Technology Inc.

Page 15

2.0 INSTALLATION

Pre-Installation (continued)

Tools required:

#2 Phillips screw driver Level

Slotted screw driver Wire strippers

Assorted open-end wrenches Torque wrench

Socket wrench and fittings Electrical tape

Multimeter (True rms) Pencil

Hole saw Utility knife

Hardware / Materials required:

4 ft. x 4 ft. sheet of 3/4" plywood or 2 x 4s studding material

#12 wood screws (or 1/2" x 1-1/4" lag bolts)

Conduit and appropriate fittings

Wire nuts

Wiring:

All wiring and installation methods should conform to applicable electrical and building codes.

Pre-plan the wire and conduit runs. The AC circuits accept cable sizes up to #6 AWG. The DC

circuits accept cable sizes up to #4/0 AWG.

For maximum safety, run both AC and DC cables in conduit.

Refer to the Figure 25 (page 29) for an example of AC wiring to the sub-panel for 120 VAC

circuits.

AC Connections:

Use #6 AWG THHN wire for all AC wiring.

DC Connections:

Battery to inverter cabling should be only as long as required. If #4/0 AWG cables are used

for example, do not exceed 5 feet (one way) in 12 VDC systems; do not exceed 10 feet (one

way) in 24 VDC systems. For optimum performance, use pre-assembled battery cables

designed specifically for this application (available from Xantrex).

Grounding:

AC Grounding

The inverter/charger should be connected to a grounded, permanent wiring system. Neutral

and ground conductors should only be bonded at the main utility service panel.

DC Grounding

The negative battery conductor should be bonded to the grounding system at only one point

in the system. The size for the conductor is usually based on the size of the largest conductor

in the DC system.

©2000 Xantrex Technology Inc.

7

Page 16

2.0 INSTALLATION

Pre-Installation (continued)

Batteries:

The battery voltage MUST match the voltage requirements of the inverter. To determine the

correct voltage for the system, check the last two digits on the inverters model number. For

example, the DR1512 is a 12 volt inverter and requires a 12 VDC battery system. The

DR2424 is a 24 volt inverter and requires a 24 VDC battery system.

Battery Location:

Locate the batteries in an accessible location. Two feet clearance above the batteries is

recommended for access to the battery caps. They should be located as close to the inverter

as possible without limiting access to the inverters disconnects. Install the batteries to the left

of a wall mounted inverter for easy access to the DC side of the inverter and shorter cable

runs.

For safety and to limit access to the batteries, a lockable, ventilated, battery enclosure or

dedicated room should be used. If an enclosure is used, it should be vented to the outside

via a one inch vent pipe located at the top of the enclosure. Install an intake vent at the

bottom of the enclosure to promote air circulation. These vents exhaust explosive hydrogen

gases and must not be overlooked when designing an enclosure.

The enclosure should be made of an acid resistant material or have a finish that resists acid

to prevent corrosion. It should be capable of holding the electrolyte from at least one battery

should a leak occur.

Place a layer of baking soda on the shelves to neutralize any acid that may be spilled in the

future (lead-acid batteries only).

Enclosures located outside must be rainproof and screened to prevent access by rodents or

insects.

Battery Temperature

The battery enclosure should provide a fairly stable temperature for the batteries. If it is installed

in a cold environment, insulation should be used to protect the batteries from the cold. The insulation

also provides a more consistent temperature and better system performance.

The battery enclosure should not be installed in direct sunlight where the summer sun can

overheat the batteries. Locate the enclosure where it will be protected from the afternoon sun and

provide vents in the top and bottom of the enclosure to provide air flow. High battery

temperatures greatly shortens the life of the batteries.

8

©2000 Xantrex Technology Inc.

Page 17

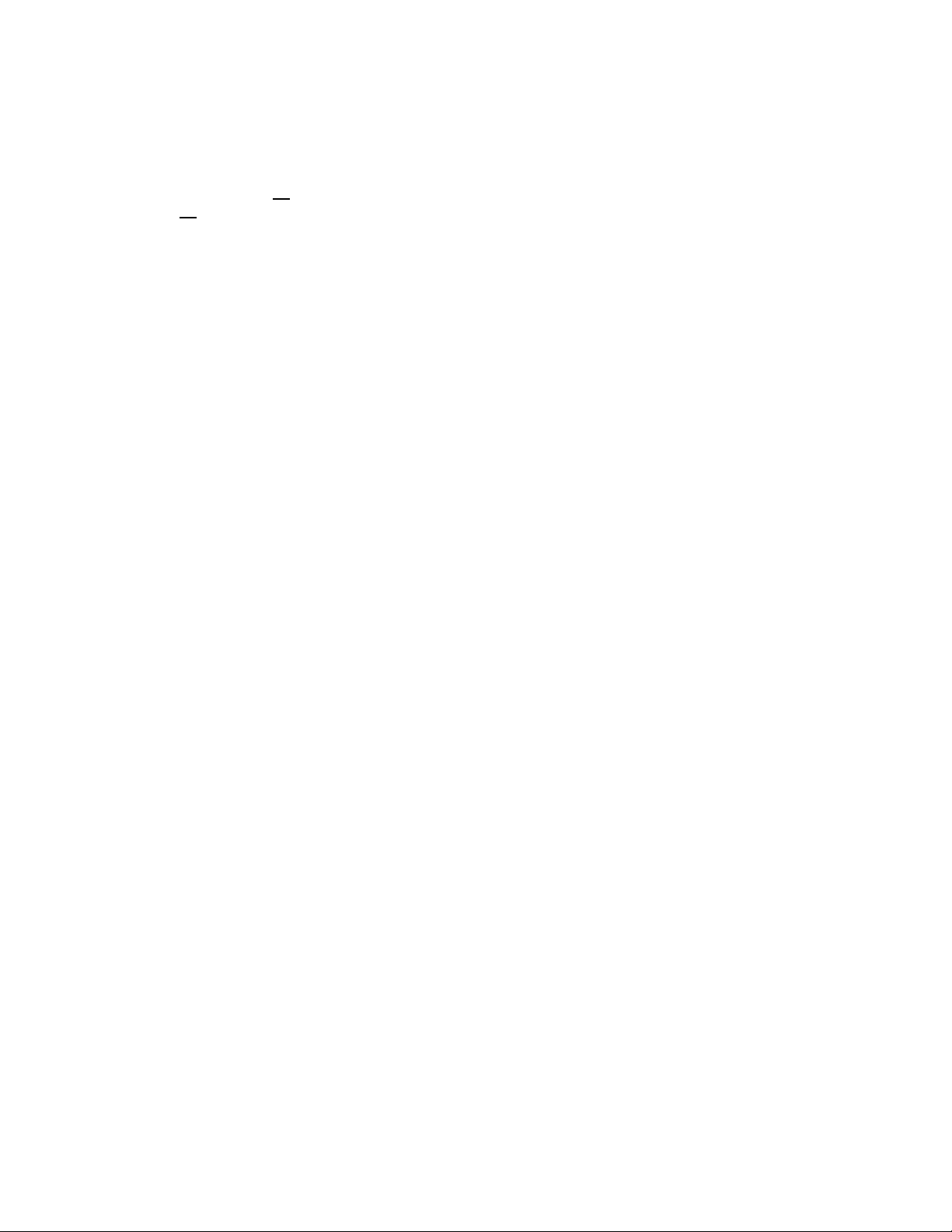

Pre-Installation (continued)

DISCONNECT

DC CONDUIT

(if used)

BATTERIES

BATTERY

ENCLOSURE

(if used)

2.0 INSTALLATION

CONDUIT

VENT

(outlet)

BOX

(if used)

INVERTER/CHARGER

MAIN PANEL

AC CONDUIT

FROM MAIN

PANEL

AC CONDUIT TO SUB-PANEL

SUB-PANEL

DC

VENT

(inlet)

DC

DISCONNECT

AND PVGFP

DC CHARGE

CONTROLLER

SOLAR

ALTERNATE DC ENERGY SOURCES

DC CONDUIT

(if used)

Figure 5

Planning Example Layout

Basic Setup

WIND

CONDUIT

VENT

(outlet)

BOX

(if used)

INVERTER/CHARGER

BATTERY

ENCLOSURE

(if used)

DC CONDUIT

(if used)

BATTERI ES

DC

DISCONNECT

MANUAL AC

TRANSFER

SWITCH

N.C.

COM.

N.O.

AC CONDUIT

AC CONDUIT TO SUB-PANEL

FROM GENERATOR

MAIN PANEL

975-0012-001

AC CONDUIT

UTILITY

SUB-PANEL

AC GENERATOR

(externally located)

DC GROUND

WIRE

©2000 Xantrex Technology Inc.

VENT

(inlet)

GROUND

DC

975-0012-002

Figure 6

Planning Example Layout

RE Setup

9

Page 18

2.0 INSTALLATION

Main Service Panel:

The input to the inverter requires a minimum 60 amp breaker (for each inverter if stacked). This

circuit breaker must be located in the utility service panel.

Sub-Panel:

Loads backed up by the inverter will need to be rerouted from the main service panel to a sub-

panel. This can be done several different ways, depending upon the installation. Always refer to

electrical codes for safe wiring practices.

AC Circuit Breakers:

Always use a properly rated circuit breaker. Depending upon the application, circuit breakers

used to protect the load can be removed from the main service panel and put into the sub-panel

ONLY if the two panels are from the same manufacturer.

DC Disconnect:

Install a DC disconnect breaker or fuse in the positive battery line. This breaker protects the DC

wiring in the event of an accidental short. Size the breaker in accordance with the battery cables.

Switch this breaker OFF whenever servicing the batteries.

Wire Routing:

Determine all wire routes both to and from the inverter and which knockouts are best suited for

connecting the AC conduits. Possible routing scenarios include:

AC Input wiring from the main utility service panel to the inverter/charger

AC Input wiring from the generator to the inverter/charger (if used)

DC Input wiring from the PV array (wind, hydro, etc.) to the inverter/charger (if used)

DC Input wiring from the batteries to the inverter/charger

AC Output wiring from the inverter/charger to the sub-panel

Battery Temperature Sensor cable from the batteries to the inverter/charger (if used)

Remote Control cable to the inverter/charger (if used)

DC Ground from the batteries to an external ground rod

Load circuit wiring rerouted from the main service panel to the sub-panel

Check for existing electrical or plumbing prior to making cuts in the walls. Cut holes in the walls

at appropriate locations for routing wiring/cables.

10

©2000 Xantrex Technology Inc.

Page 19

Inverter Mounting (continued)

Ceiling

Wall studs 16 inches on

center

2.0 INSTALLATION

7–5/8" c-c

Approximately

4–5 ft

975-0012-003

2 x 4 mounting

supports

Wallboard

Floor

Figure 7

Suggested Mounting Method

Inverter Mounting

The DR Series inverter can weigh as much as 45 lb. (20.4 kg). Wallboard is not strong enough

to support its weight so additional support must be added. The easiest method for securing it to an

existing wall is to place two 2 x 4s horizontally on the wall (spanning at least three studs) and

securing the inverter to the 2 x 4s.

WARNING: USE APPROPRIATE LIFTING TECHNIQUES. HAVE EXTRA PEOPLE ON HAND TO

ASSIST IN LIFTING THE INVERTER INTO POSITION WHILE IT IS BEING SECURED.

Procedure

Locate the studs and mark their location on the wall.

Measure the desired height from the floor for the inverter to be mounted.

Using a level, run a horizontal line. The length of the line must span at least 3 studs.

Place a pre-cut 2 x 4 on the marked location and drill pilot holes through the 2 x 4s and

studs.

Secure the 2 x 4 with #10 wood screws (length to penetrate 1-1/2 inches into the studs).

Repeat the procedure for the remaining 2 x 4.

©2000 Xantrex Technology Inc.

11

Page 20

2.0 INSTALLATION

s

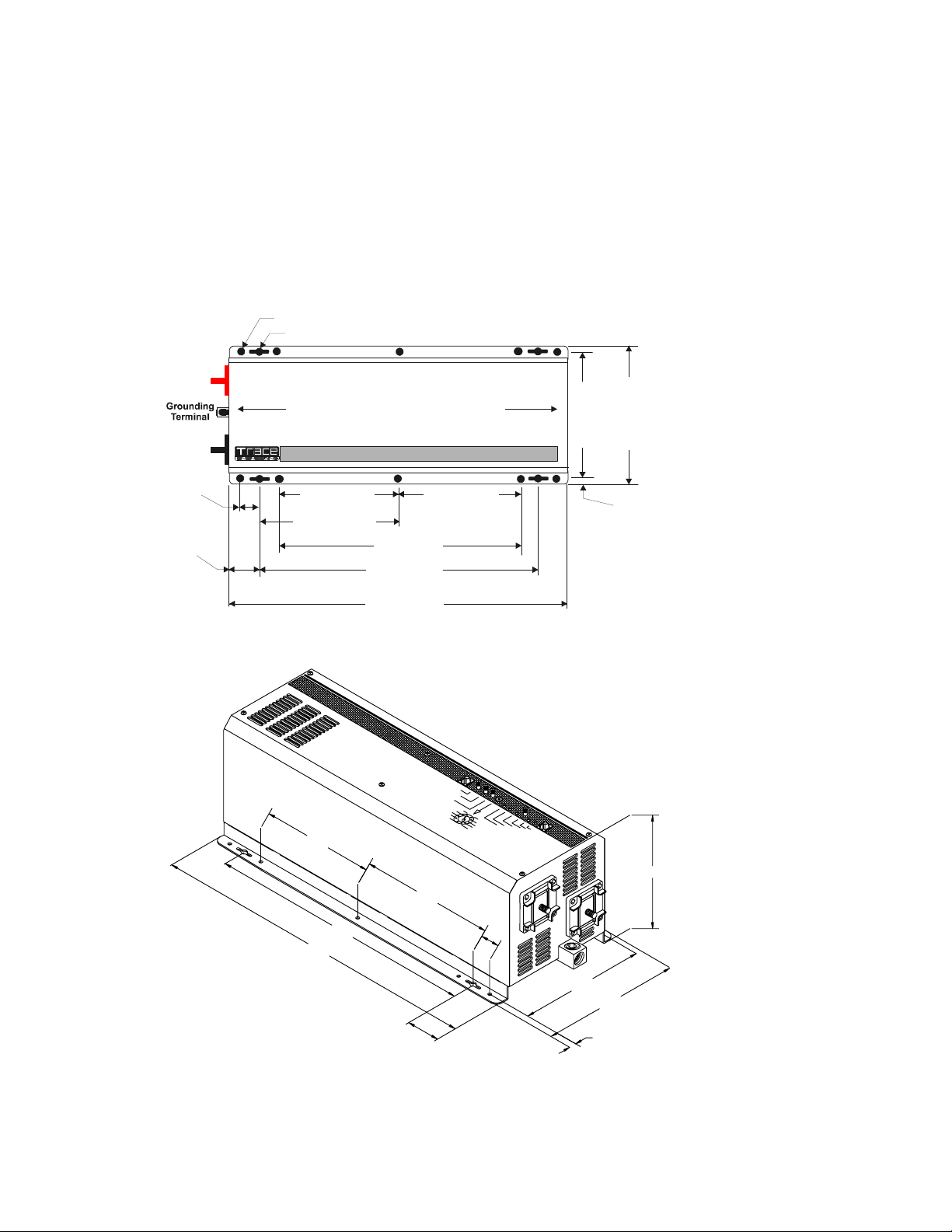

Referring to Figure 8, drill out the mounting hole locations for the inverter.

With assistance, lift the inverter into position and install it onto the 2 x 4s using 1/4 x 1-1/2

inch lag bolts and washers.

Alternatively, a half or quarter sheet of 3/4 inch plywood can also be used as a backing, with the

inverter mounted directly to the plywood using 1/4 inch diameter lag bolts and washers. The plywood

must span three studs for adequate support.

0.281 DIA 10 PLACES

0.375 DIA 4 PLACES

+

TERMINAL

–

TERMINAL

DC SIDE

AC SID E

21.25 cm

19.40 cm

8.370 inches

7.640 inches

1.00 inches

2.54 cm

1.90 inches

4.83 cm

7.00 inches

17.8 cm

8.00 inches

20.32 cm

7.00

16.00

20.175

14.00 inches

35.56 cm

16.00 inches

40.64 cm

20.175 inches

51.244 cm

8.00

7.00 inches

17.8 cm

1.00

0.365 inche

0.93 cm

975-0012-D-011

G

N

I

R

E

E

N

I

G

N

E

E

C

A

R

T

R

E

E

N

I

G

N

E

E

C

A

R

T

6.970

G

N

I

12

7.640

.281 DIA. 5 PLACES

8.370

.375 DIA. 2 PLACES

1.900

0.365

975-0012-D-012

Figure 8

Dimensional Drawings for Screw Hole Placement

©2000 Xantrex Technology Inc.

Page 21

2.0 INSTALLATION

Wiring

DC Wiring (Batteries)

Battery Cable Sizing

Proper cable sizing (diameter and length) is critical to the safe and efficient operation of an

inverter system. Larger diameter cables (smaller AWG number) have less voltage drop and are,

therefore, more efficient when transferring power to and from the batteries. If a cable is undersized

(diameter too small), it could potentially overheat, creating a fire hazard.

Cable length is another important factor. Runs should be kept as short as practical. Longer

cable runs increase resistance, thus lowering the overall efficiency of the system. This is especially

true in lower voltage systems (i.e., 12 VDC) where, depending upon the length of the cable run, it

may be necessary to oversize the diameter of the wire, or parallel (double) the cables.

Always use a properly sized cable and length rated for the amperage of the inverter and

batteries.

WARNING: UNDERSIZED CABLES CAN OVERHEAT AND MELT, CREATING A FIRE HAZARD

WHEN SUBJECTED TO HEAVY (PEAK) LOADS.

NOTE: If the system will be operated at the inverters peak power rating exceeding one hour, larger

cables and disconnects MUST be used (see Tables 1 and 2).

NOTE: If the system includes a large battery bank or large DC source (such as a micro-hydroelectric

plant or wind generator), increasing the size of the cables and disconnects will greatly reduce the

number of nuisance outages associated with breaker tripping and open fuses.

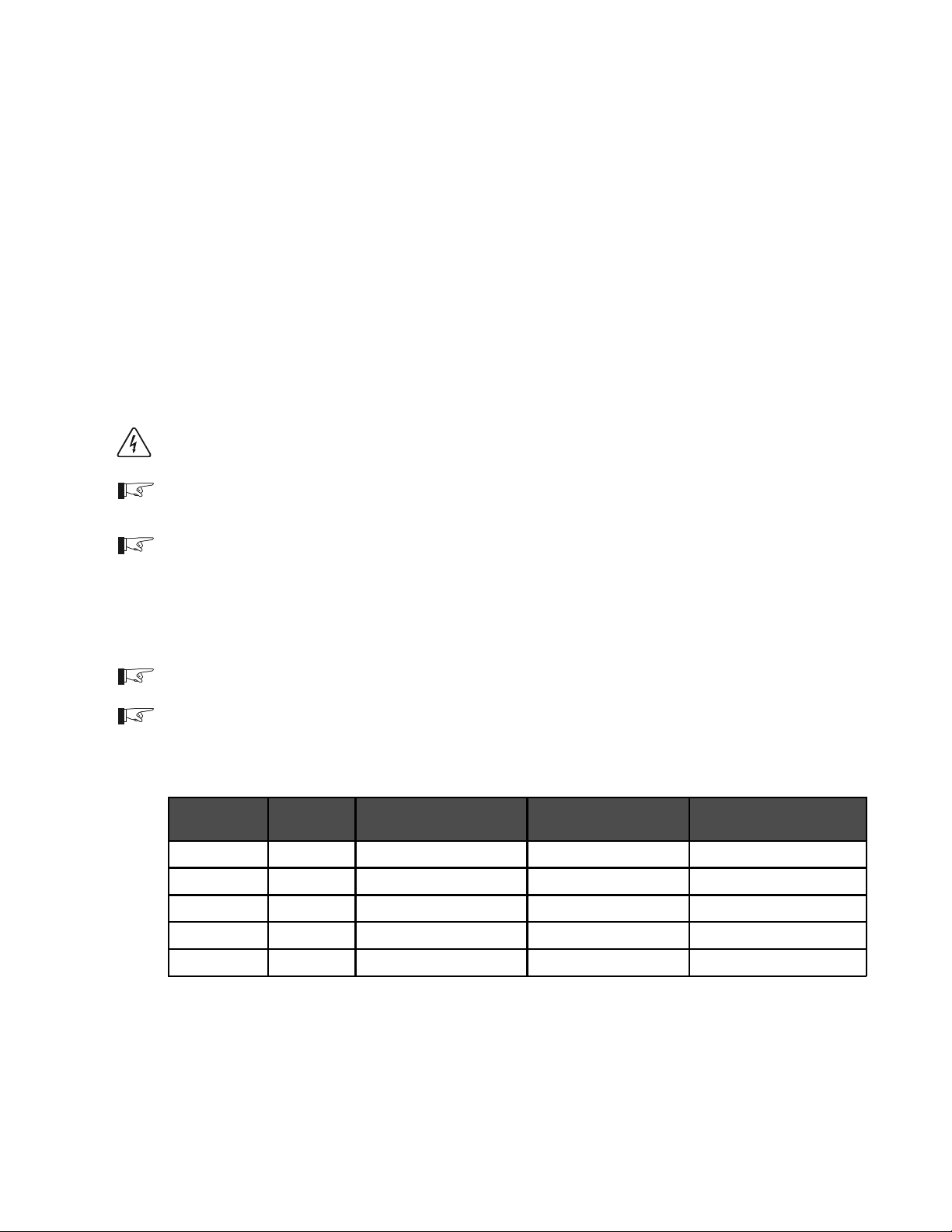

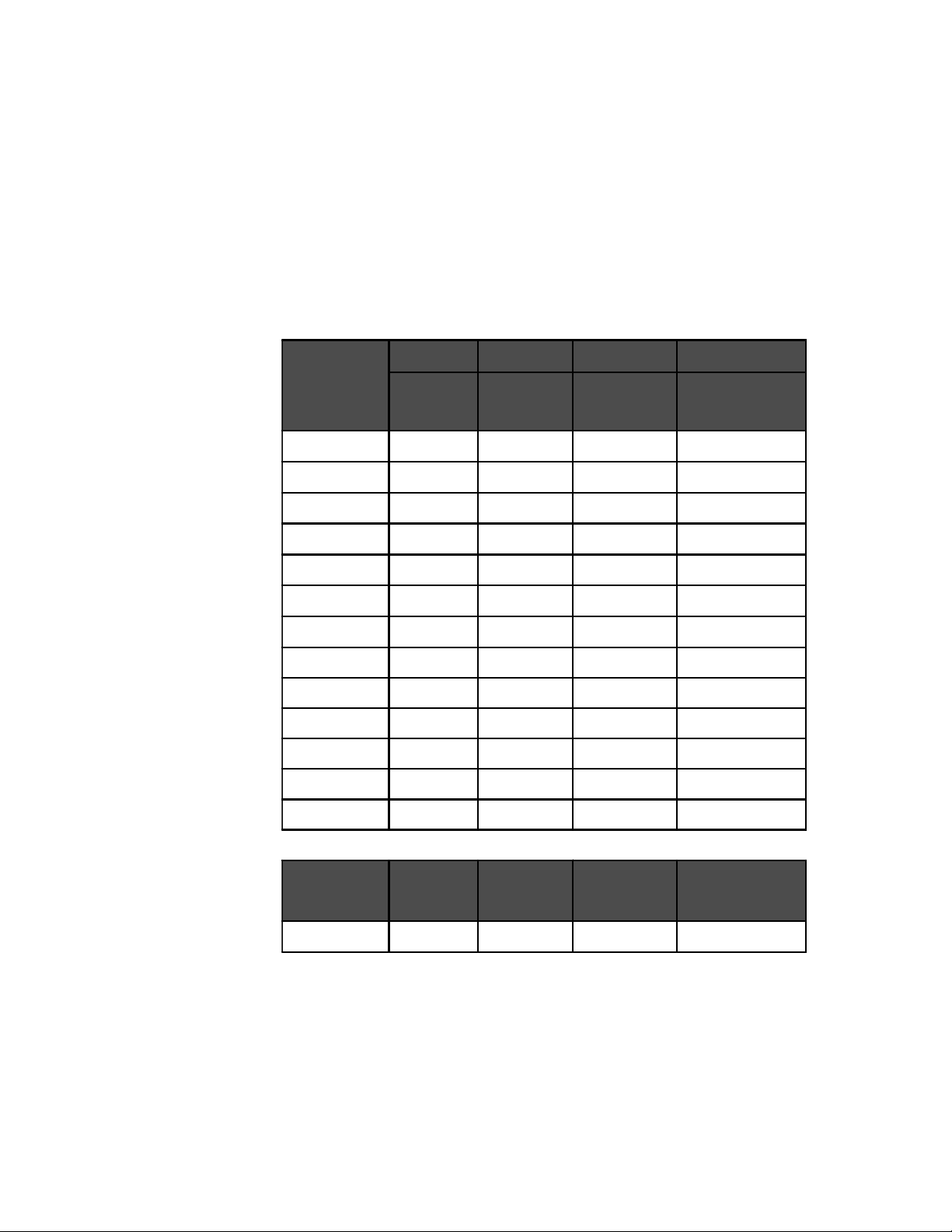

Table 1 provides recommended minimum cable sizes for various cable lengths and inverter

amperages. These recommendations may not meet all local or NEC requirements.

NOTE: Use only copper cables.

NOTE: Run the positive and negative battery cables as close to each other as possible by taping

them together. This reduces the effects of inductance and produces a better waveform thus

increasing efficiency.

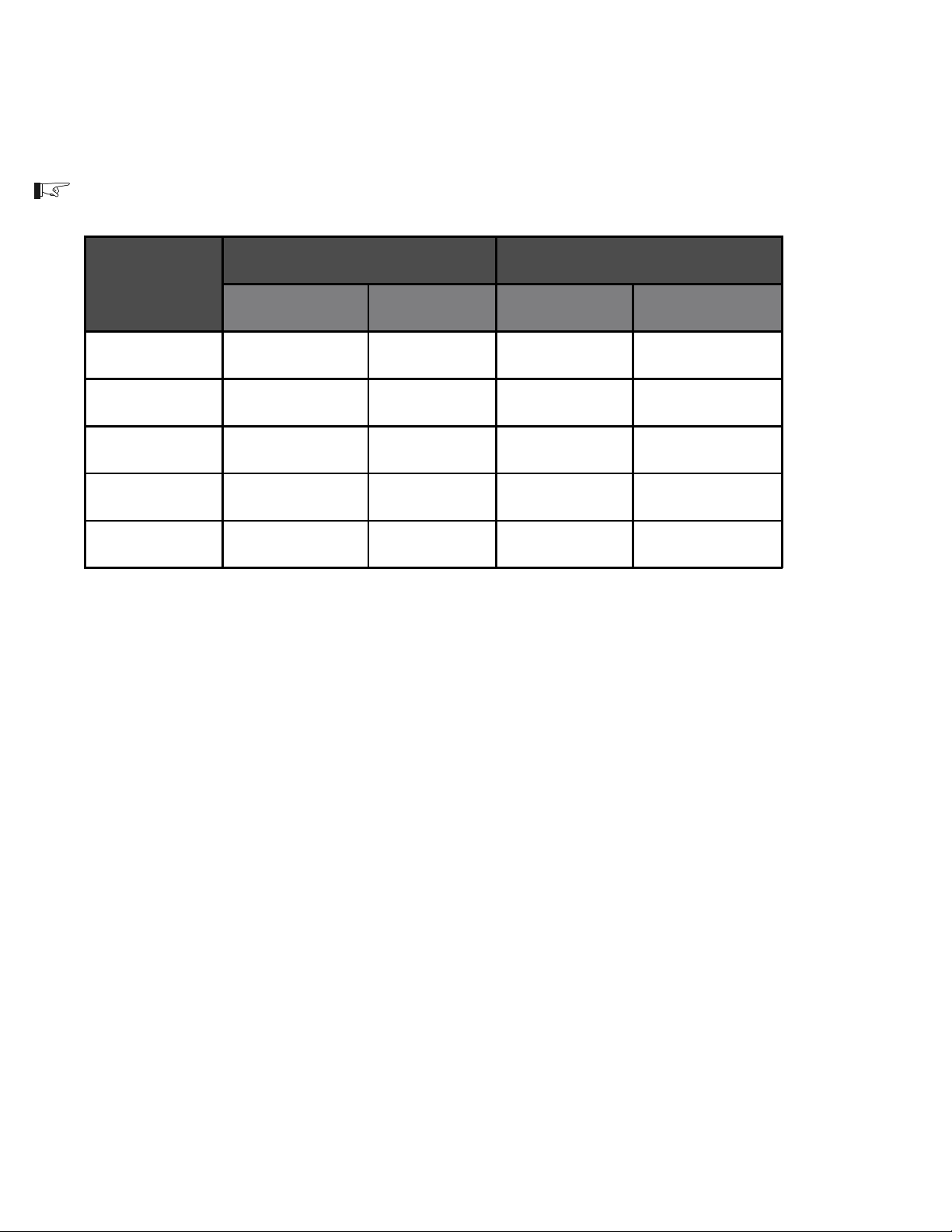

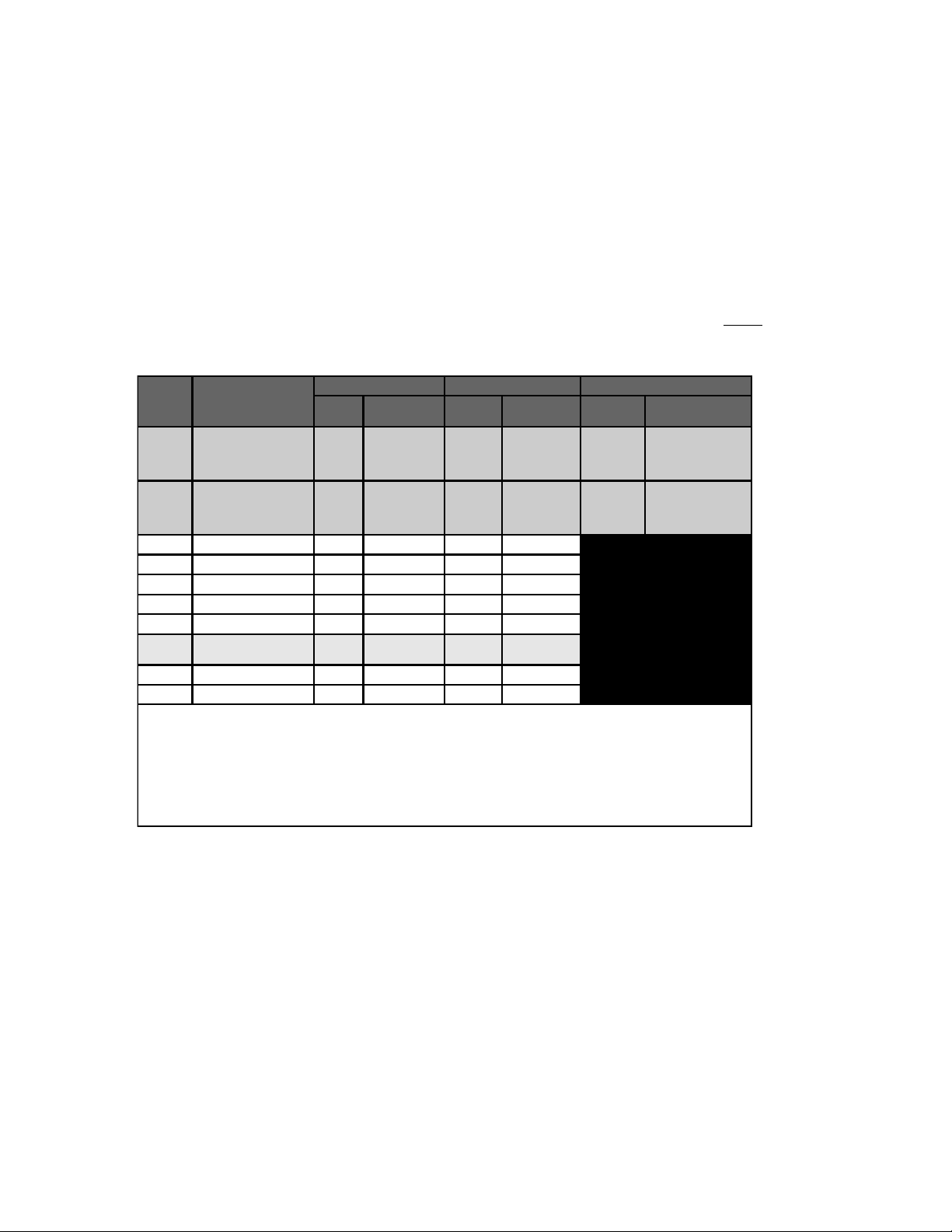

Inverter

Model

DR1512

DR2412

DR1524

DR2424

DR3624

Typical

Amperage

150 A #2/0 AWG (67.4 mm

240 A #4/0 AWG (107 mm

75 A #2/0 AWG (67.4 mm

120 A #2/0 AWG (67.4 mm

180 A #4/0 AWG (107 mm

1 to 3 Feet (one-way) 3 to 5 Feet (one-way) 5 to 10 Feet (one-way)

2

) #2/0 AWG (67.4 mm2) #4/0 AWG (107 mm2)

2

) #4/0 AWG (107 mm2) NOT RECOMMENDED

2

) #2/0 AWG (67.4 mm2) #4/0 AWG (107 mm2)

2

) #4/0 AWG (107 mm2) #4/0 AWG (107 mm2)

2

) #4/0 AWG (107 mm2) #4/0 AWG (107 mm2)

975-0012-004

Minimum Recommended Battery Cable Size VS. Length

©2000 Xantrex Technology Inc.

Table 1

13

Page 22

2.0 INSTALLATION

Wiring (continued)

DC Disconnect and Over-current Protection

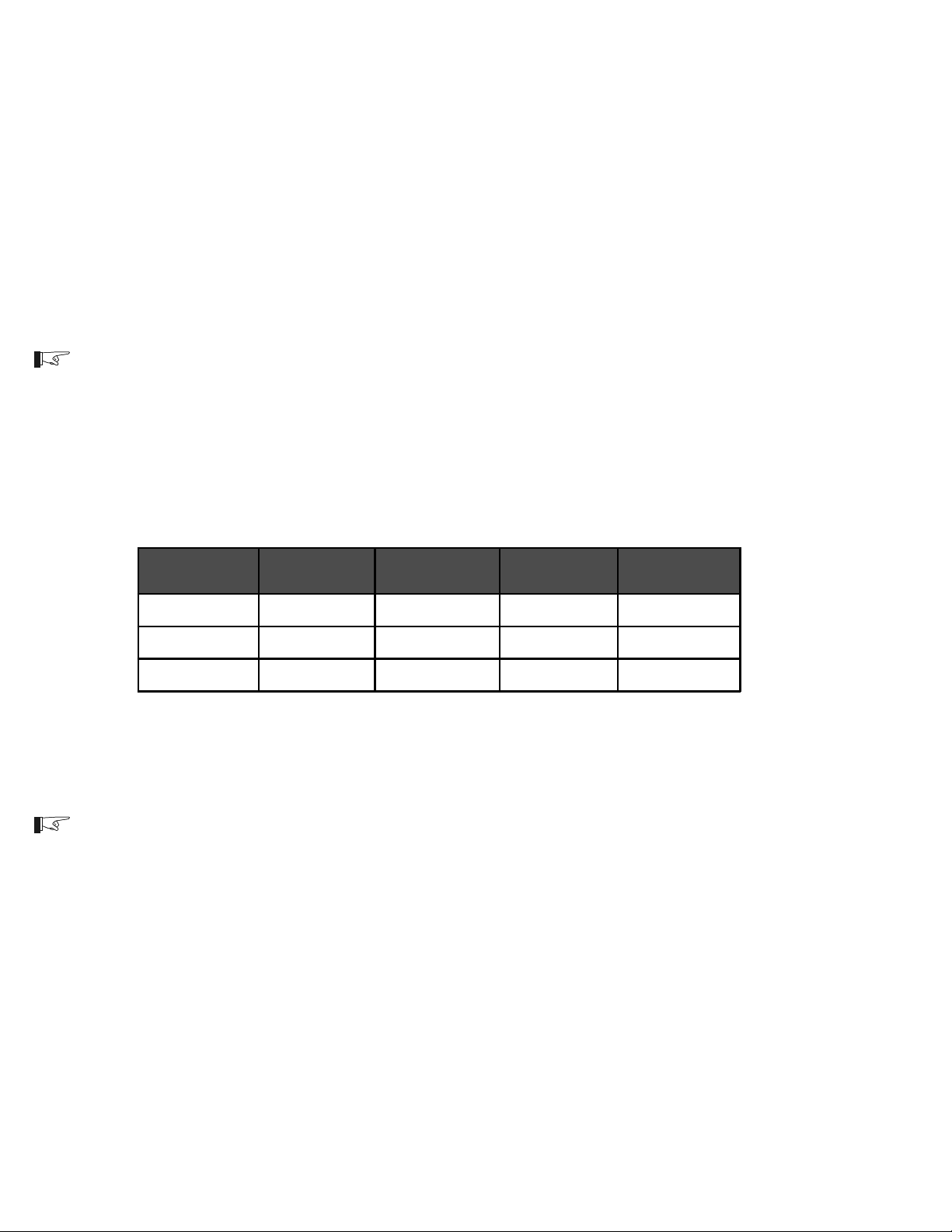

For safety and to comply with regulations, battery over-current protection is required. Fuses and

disconnects must be sized to protect the wiring in the system and are required to open before the

wire reaches its maximum current carrying capability.

The National Electrical Code (NEC) requires both over-current protection and a disconnect

switch for residential and commercial electrical systems. These items are not supplied as part of the

inverter. However, Xantrex offers a DC rated, DC250/175 ETL listed, circuit breaker disconnect

module specifically designed for use with Trace inverters to meet NEC compliance. Two amperage

ratings are available: a DC250 (250 amps) and a DC175 (175 amps) in either single or dual breaker

configurations for single or dual inverter installations.

NOTE: Trace DC disconnects are not designed to accept doubled (paralleled) cables which may

be required for long cable runs. Also, the plastic red and black covers on the DC inverter inputs are

not designed to accommodate dual cables. If dual cables are used, the optional conduit box (DRCB)

must be used.

Some installations may not require conduit or a disconnect device, although over-current

protection is still required. Xantrex offers a fuse block (TFB) providing the code required inverter

over-current protection for these applications. Refer to the table below for the proper size disconnect

device for specific cable diameters.

Cable Size

Required

#2 AWG 115 amps max N/A 170 amps max TFB200

#2/0 AWG 175 amps max DC175 265 amps max TFB300

#4/0 AWG 250 amps max DC250 360 amps max TFB400

Rating in

Conduit

Maximum

Breaker Size

Rating in "Free

Air"

Maximum Fuse

Size

975-0012-005

Table 2

Battery Cable to Maximum Breaker/Fuse Size

NOTE: The NEC allows rounding to the next standard fuse size from the cable rating (i.e., 150 amp

cable size rounds up to a standard 175 amp size). The term free air is defined by the NEC as

cabling that is not enclosed in a conduit or a raceway. Cables enclosed in conduit or raceways have

substantially lower continuous current carrying ability due to heating factors.

14

©2000 Xantrex Technology Inc.

Page 23

2.0 INSTALLATION

Wiring (continued)

Battery Cable Connections

Battery cables must have crimped (or preferably, soldered and crimped) copper compression

lugs unless aluminum mechanical lugs are used. Soldered connections alone are not acceptable.

High quality, UL-listed battery cables are available from Trace Engineering in an assortment of

lengths: 1-1/2 to 10 feet, and in #2/0 AWG or #4/0 AWG sizes. These cables are color-coded with

pressure crimped, sealed ring terminals.

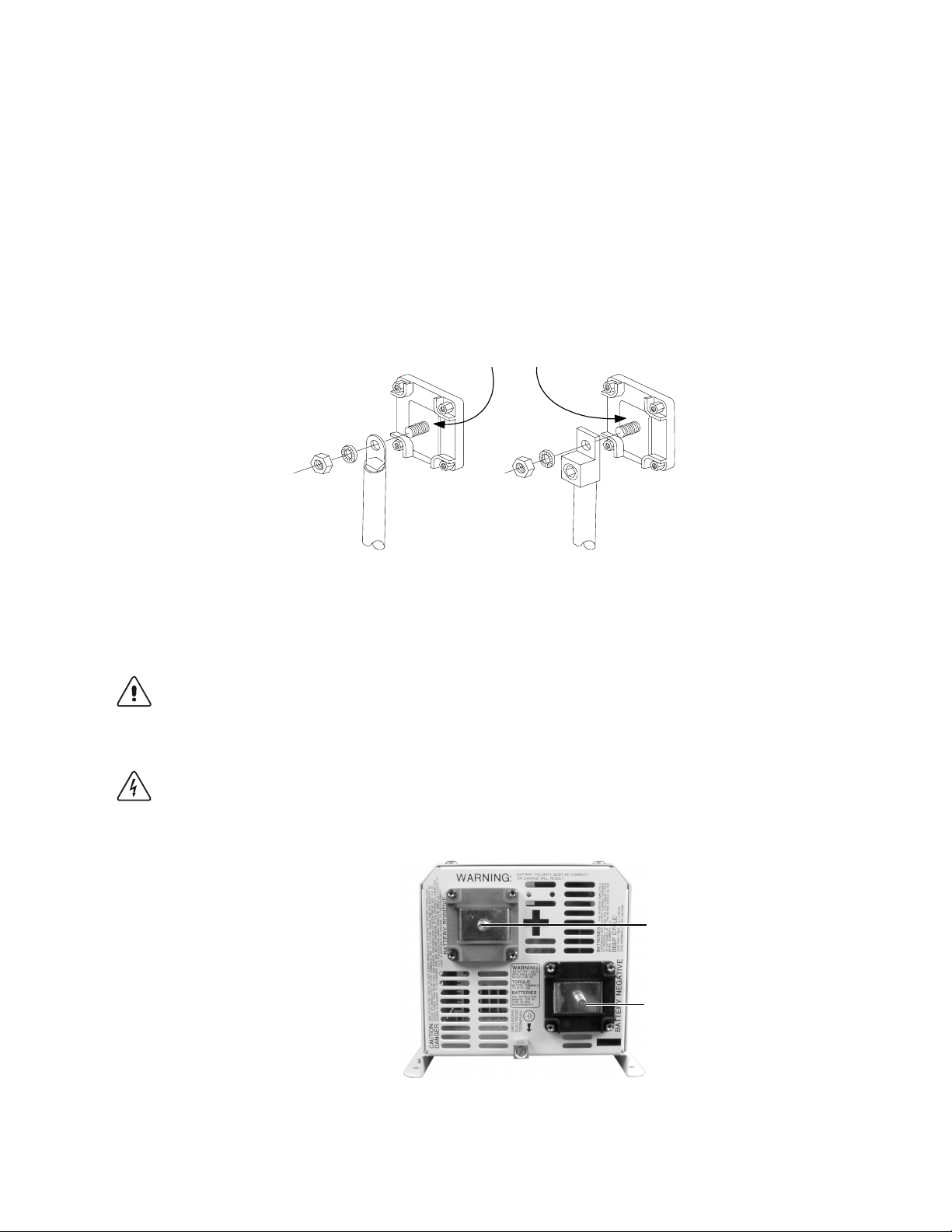

Figure 9 illustrates the proper method to connect the battery cables to the DR Series inverter/

charger terminals.

Do not place anything

between battery cable lug

and terminal surface.

Assemble exactly as shown.

2/0 Copper Compression Lug 2/0 Aluminum Mechanical Lug

Figure 9

Battery Cable Connections to Inverter

CAUTION: THE INVERTER IS NOT REVERSE POLARITY PROTECTED. REVERSING THE

BATTERY POLARITY ON THE DC INPUT CONNECTIONS WILL CAUSE PERMANENT DAMAGE

TO THE INVERTER WHICH IS NOT COVERED UNDER WARRANTY. ALWAYS CHECK

POLARITY BEFORE MAKING CONNECTIONS TO THE INVERTER.

WARNING: ENSURE THE INVERTER IS OFF BEFORE CONNECTING OR DISCONNECTING

THE BATTERY CABLES, AND THAT AC POWER IS DISCONNECTED FROM THE INVERTER

INPUT.

POSITIVE (+) RED TERMINAL

NEGATIVE (-) BLACK TERMINAL

©2000 Xantrex Technology Inc.

Figure 10

Battery Cable Connections

15

Page 24

2.0 INSTALLATION

Wiring (continued)

Battery Bank Sizing

The size of the battery bank determines how long the AC loads will operate in a backup mode

without utility power. The larger the battery bank, the longer the run time. Size the battery bank to the

systems AC load requirements and length of time required to run from the batteries. In general, the

battery bank should not be discharged more than 50%. Additional DC charging devices such as

solar, wind, hydro, etc., can provide longer run times by recharging the batteries in the absence of

AC utility or generator power.

Additional details on estimating battery bank size and capacity can be found in the Appendix

section of this manual.

Battery Types

Batteries are available in different sizes, amp-hour ratings, voltage, liquid or gel, vented or nonvented, chemistries, etc. They are also available for starting applications (such as an automobile

starting battery) and deep discharge applications. Only the deep discharge types are recommended

for inverter applications. Choose the batteries best suited for the inverter installation and cost. Use

only the same battery type for all batteries in the bank. For best performance, all batteries should be

from the same lot and date. This information is usually printed on a label located on the battery.

Additional information regarding batteries can be found in the Appendix section of this manual.

Battery Configuration

The battery bank must be wired to match the inverters DC input voltage specifications (12, 24 or

48 VDC). In addition, the batteries can be wired to provide additional run time. The various wiring

configurations are:

SERIES

Wiring batteries in series increases the total bank output voltage (to match the inverters DC

requirements).

PARALLEL

Wiring the batteries in parallel increases the total run time the batteries can operate the AC loads.

SERIES-PARALLEL

Series-parallel configurations increase both the battery voltage (to match the inverters DC

requirements) and run-time for operating the AC loads.

16

©2000 Xantrex Technology Inc.

Page 25

2.0 INSTALLATION

Wiring (continued)

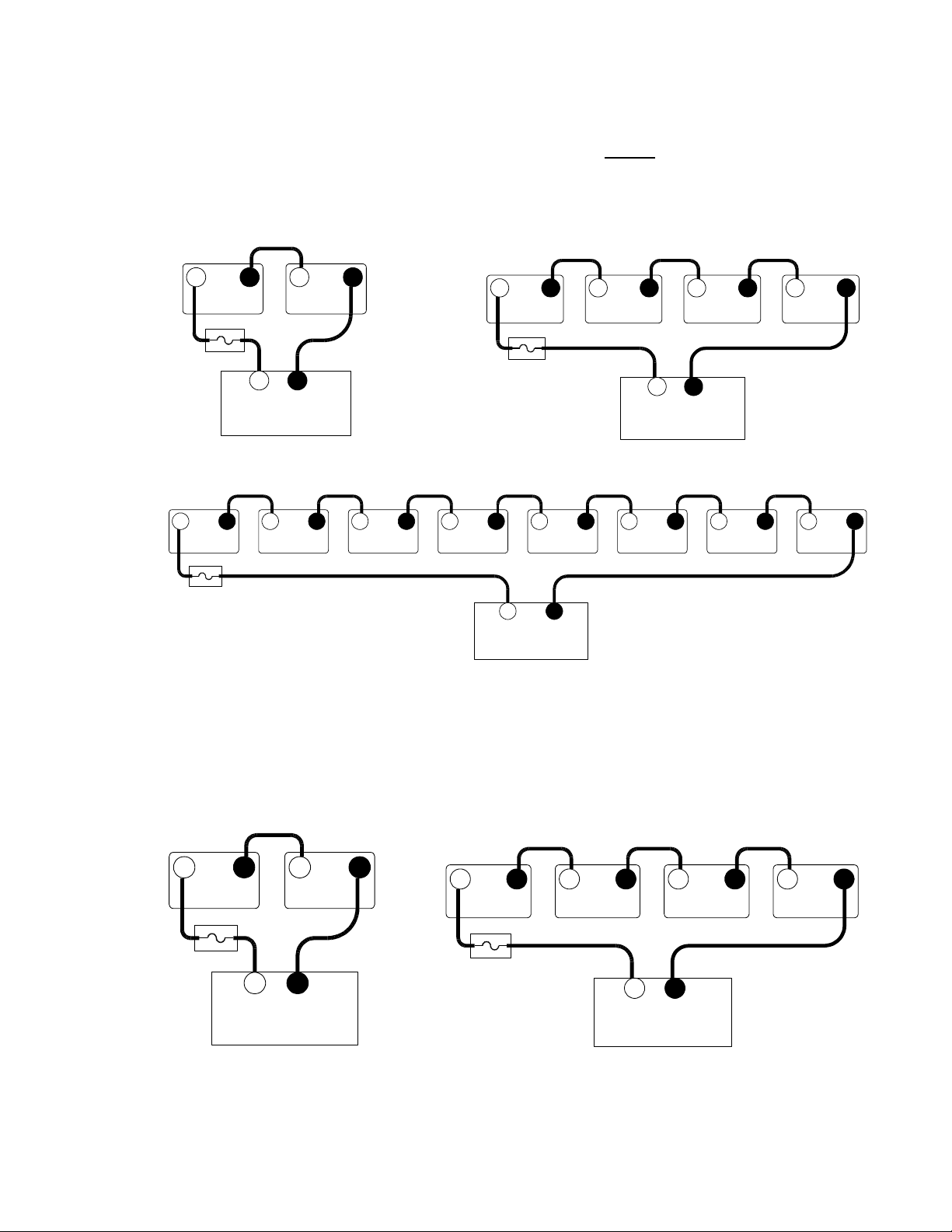

Wiring Batteries in Series

Wiring the batteries in a series configuration increases the voltage of the battery string. 6 volt

batteries can be combined to form 12 V, 24 V, or 48 V battery banks. In the same way, 12 volt

batteries connected in series form 24 V or 48 V battery banks. The total current capacity of the bank

does not increase and it retains the same amp-hour rating as a single battery.

+ - + -

6 V 6 V

+ -

12 V INVERTER

(Total battery capacity = 100 Ah)

+ - + -

6 V 6 V

+ - + -

6 V 6 V

Each batterys amp-

hour rating is 100 Ah

3597-F00-D21

+ - + -

6 V 6 V

+ - + -

6 V 6 V

+ -

48 V INVERTER

(Total battery capacity = 100 Ah)

Figure 11

6 Volt Battery WiringSeries Configuration

+ - +

6 V 6 V

+ -

24 V INVERTER

(Total battery capacity = 100 Ah)

+ - + -

-

3597-F00-D22

6 V 6 V

3597-F00-D23

+ - + -

12 V 12 V

+ -

24 V INVERTER

(Total battery capacity = 50 Ah)

©2000 Xantrex Technology Inc.

+ - + -

12 V 12 V

(Total battery capacity = 50 Ah)

3597-F00-D24

Each batterys amp-hour

rating is 50 Ah

Figure 12

12 Volt Battery WiringSeries Configuration

+ - + -

12 V 12 V

+ -

48 V INVERTER

3597-F00-D25

17

Page 26

2.0 INSTALLATION

Wiring (continued)

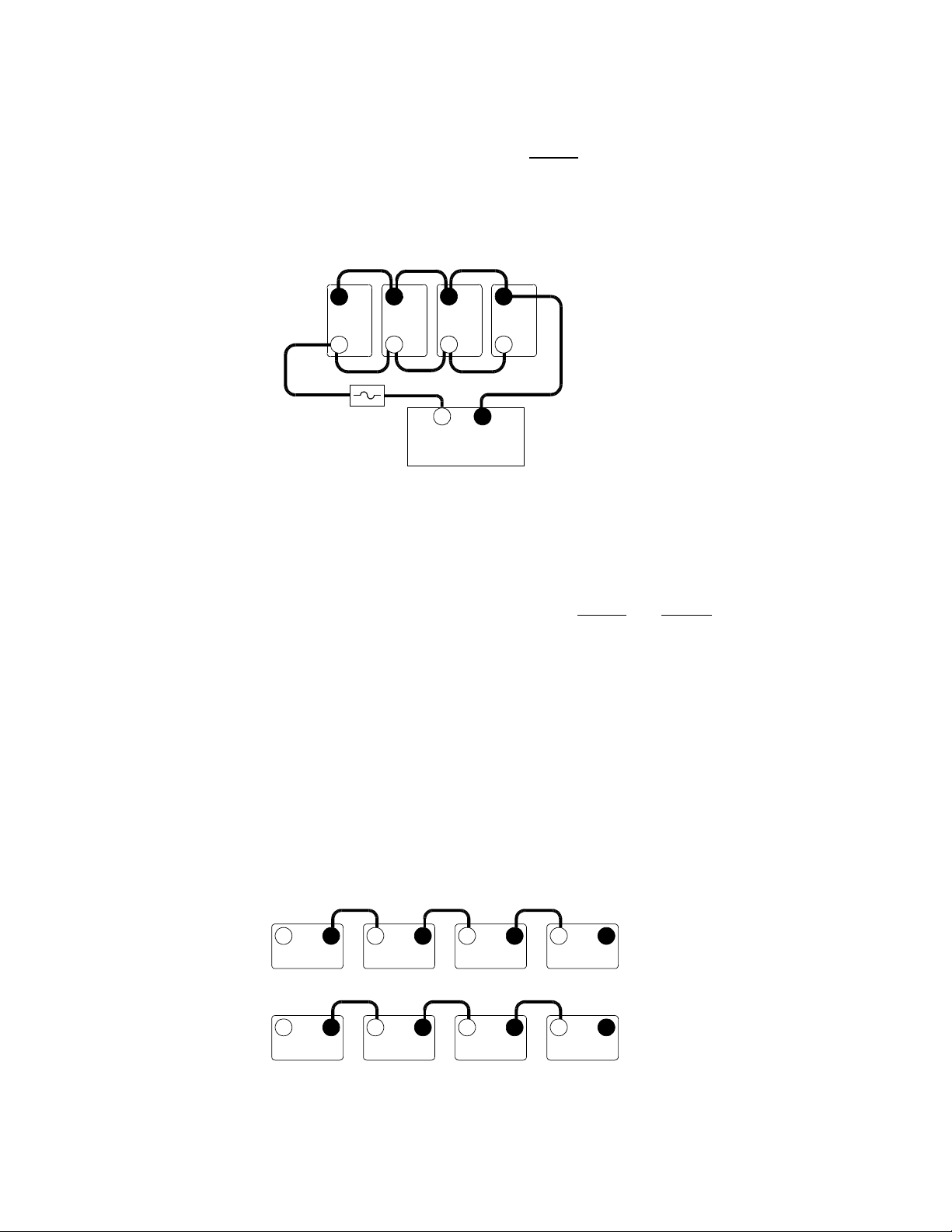

Wiring Batteries in Parallel

Wiring the batteries in a parallel configuration increases the current of the battery string. This is

commonly used in 12 volt configurations. The voltage of the battery bank remains the same as an

individual battery. Parallel configurations extend the run times of the AC loads by providing

increased current for the inverter to draw from. In a parallel configuration, all of the negative battery

terminals are connected together and all of the positive battery terminals are connected together.

–

+

–

12 V

+

–

12 V

+

–

12 V

12 V

+

Each batterys amp-hour

rating is 50 Ah

+ –

12 V INVERTER

(Total battery capacity = 200 Ah)

3597-F00-D26

Figure 13

12 Volt Battery WiringParallel Configuration

Wiring Batteries in Series-Parallel

Wiring the batteries in a series-parallel configuration increases the

current and voltage of the

battery bank. Series-parallel wiring is more complicated and care should be taken when wiring these

banks.

To construct a series-parallel battery bank follow these instructions:

Step 1

First wire the batteries in series (voltage adds) with the positive terminal of one battery

connected to the negative terminal of the next battery to meet the inverters DC input

requirements.

18

Repeat this step for the next battery string.

Two identical strings of batteries are now wired in series.

+ – + –

12 V 12 V

+ – + –

12 V 12 V

+ – + –

12 V 12 V

+ – + –

12 V 12 V

Figure 14

Step 1Wire Batteries in Series

Series String 1

Series String 2

3597-F00-D27

©2000 Xantrex Technology Inc.

Page 27

2.0 INSTALLATION

Wiring (continued)

Wiring Batteries in Parallel (continued)

Step 2

Connect the POSITIVE terminal of the first battery string to the POSITIVE terminal of the

second battery string.

Connect the NEGATIVE terminal of the first battery string to the NEGATIVE terminal of the

second battery string.

–

Parallel

Connection

+

12 V 12 V

+ –

+ – + –

12 V 12 V

Series String 1

Parallel

Connection

+ – + –

12 V 12 V

+ – + –

12 V 12 V

3597-F00-D28

Series String 2

Figure 15

Step 2Two Series Strings Wired in Parallel

Step 3

Connect a wire from the POSITIVE terminal of the first battery string to the inverters

POSITIVE DC terminal (via a fused device).

Connect the NEGATIVE terminal of the second battery string to the inverters NEGATIVE DC

terminal.

NOTE: Connecting the positive and negative wires to the inverter from different strings ensures a

balanced charge/discharge through the batteries, resulting in longer run times and improved battery

life.

Connection from

bank 1 to inverter

positive (+)

terminal

+

– + –

12 V 12 V

+ – + –

12 V 12 V

Step 3Series-Parallel Configuration Wired to the Inverter

©2000 Xantrex Technology Inc.

+

– + – + – +

12 V 12 V

+ –

48 V INVERTER

(Total batt ery capacity = 100 Ah)

Figure 16

–

12 V 12 V

Connection from

bank 2 to inverter

negative ()

terminal

3597-F00-D29

19

Page 28

2.0 INSTALLATION

Wiring (continued)

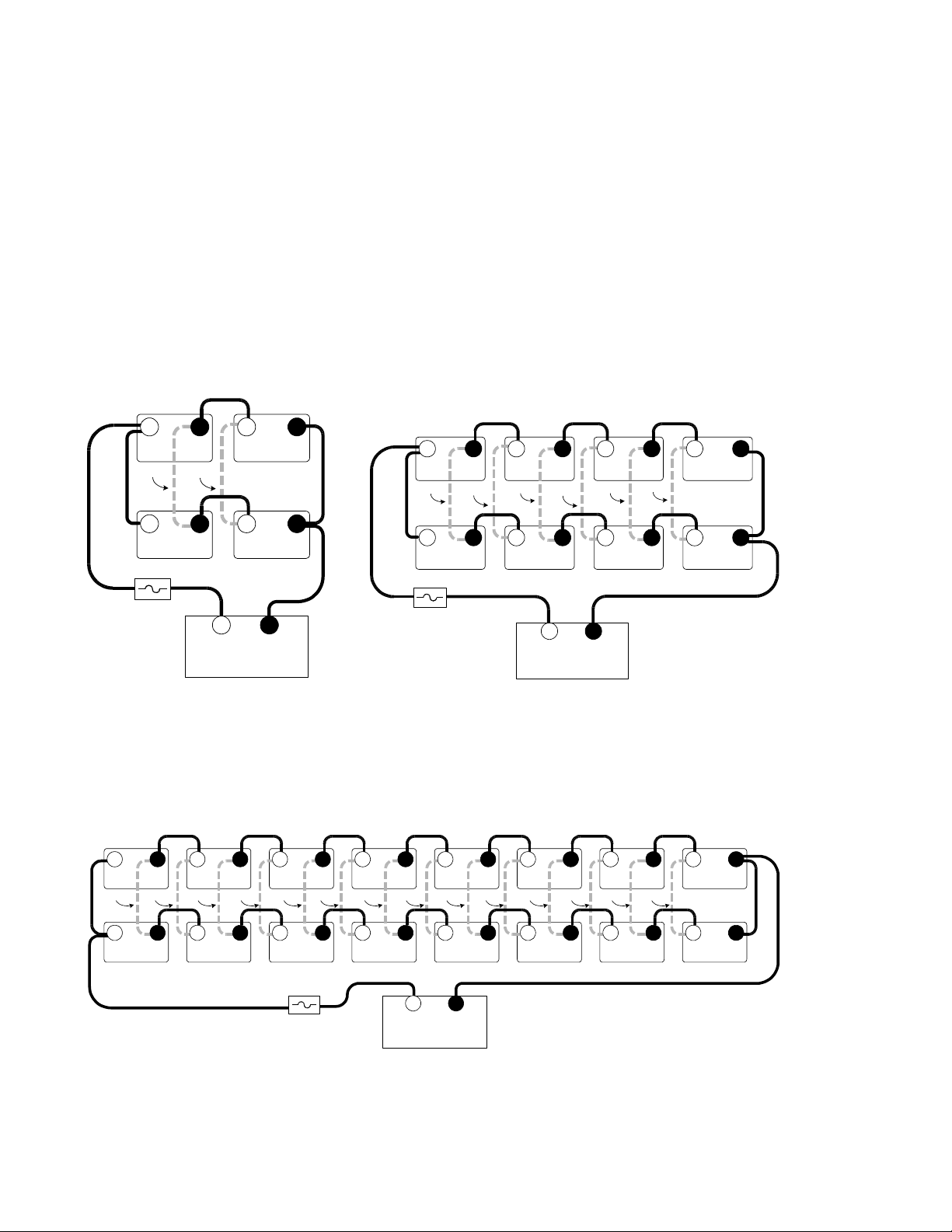

Series/Parallel Configurations and Cross-Tying

To reduce the imbalances between the batteries in a series/parallel bank and improve the

overall battery bank performance, the batteries can be cross-tied. In this arrangement, the batteries

wired in the series part of one string are also wired in parallel with the batteries in the second string

making each battery in the bank a (parallel) pair. This technique is not a requirement, but can

improve the overall performance of the batteries and further increase the battery life as each battery

receives a more even charge/discharge cycle. However, cross-tying the batteries involves additional

expense of the extra battery cables and labor to wire them.

Cross-tying is shown in the following series/parallel configurations and is indicated by a light,

dashed line. If cross-tying is not desired, ignore these dashed lines.

+ – + –

6 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

6 V

+ – + – + – + –

6 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

6 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

6 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

6 V

+ +–

6 V 6 V

Fuse Block

Disconnect

+

6 V 6 V

Cross-tie cable

Cross-tie cable

(not required)

(not required)

+

6 V 6 V 6 V 6 V 6 V 6 V 6 V 6 V

+ –

12 V INVERTER

(Total battery capacity = 200 Ah)

– + – + – + – + – +++ ––

Cross-tie cable

Cross-tie cable

(not required)

(not required)

– + – + – + – + – +++ ––

–

+ + – + – + ––

6 V 6 V 6 V 6 V

Fuse Block

Disconnec t

3597-F00-D33

6 V 6 V 6 V 6 V 6 V

Cross-tie cable

Cross-tie cable

Cross-tie cable

Cross-tie cable

Cross-tie cable

(not required)

(not required)

(not required)

(not required)

(not required)

Cross-tie cable

(not required)

+ –

24 V INVERTER

(Total battery capacity = 200 Ah)

Cross-tie cable

Cross-tie cable

(not required)

(not required)

Cross-tie cable

(not required)

Cross-tie cable

(not required)

3597-F00-D31

–

6 V

–

20

+ –

Fuse Block

Disconnect

48 V INVERTER

(Total battery capacity = 200 Ah)

Figure 17

6 Volt Battery WiringSeries/Parallel Configuration

(with optional cross-tie wiring)

3597-F00-D32

©2000 Xantrex Technology Inc.

Page 29

Wiring (continued)

Cross-Tying Series/Parallel Configurations (continued)

+ – + –

12 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

12 V

2.0 INSTALLATION

+ +–

–

12 V 12 V

Fuse Block

Disconnect

+ –

24 V INVERTER

(Total battery capacity = 100 Ah)

3597-F00-D34

+ – + – + – + –

12 V

Cross-tie cable

Cross-tie cable

(not required)

(not required)

+ + – + – + –

–

12 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

12 V

Cross-tie cable

(not required)

Cross-tie cable

(not required)

12 V 12 V 12 V 12 V

12 V

12 Volt Battery WiringSeries/Parallel Configuration

©2000 Xantrex Technology Inc.

Fuse Block

Disconnect

+ –

48 V INVERTER

(Total battery capacity = 100 Ah)

Figure 18

(with optional cross-tie wiring)

3597-F00-D30

21

Page 30

2.0 INSTALLATION

Installation Guidelines

WARNING: ENSURE THE INVERTER IS OFF BEFORE CONNECTING OR DISCONNECTING

THE BATTERY CABLES AND THAT ALL AC POWER IS DISCONNECTED FROM THE

INVERTERS INPUTS.

Determine the correct size battery cable to use for installation from Table 1.

Determine the correct size disconnect/fuse for installation from Table 2.

Color code the cables with tape or heat shrink tubing. The standard colors are red for positive (+)

and black for negative (-).

Connect the negative cable to the batterys negative terminal (torque to manufacturers

recommendations).

Install the over-current device (fuse or circuit breaker) between the batterys positive terminal and

the inverters positive terminal (as close to the batteries as possible).

Connect the (short) positive cable to the batterys positive terminal (torque to manufacturers

recommendations).

Ensure the correct polarity of the cables with a DC voltmeter (DVM).

Observing battery polarity, connect the positive battery cable (from the over-current device) to

the inverters positive terminal.

NOTE: The next step may cause a small spark and snapping sound when connecting the cable to

the inverter. This is normal, and is caused by the inverters capacitors charging up.

Observing battery polarity, connect the negative battery cable to the inverters negative terminal.

Use an insulated 1/2 inch wrench or socket to tighten the 5/16 SAE nuts to 10-15 foot/lb for each

inverter input terminal.

CAUTION: DO NOT PUT ANYTHING BETWEEN THE CABLE RING TERMINAL AND THE FLAT

METAL PART OF THE TERMINAL. OVERHEATING OF THE TERMINAL MAY OCCUR. DO NOT

APPLY ANY TYPE OF ANTIOXIDANT PASTE UNTIL AFTER THE BATTERY CABLE WIRING IS

TIGHTENED.

Apply antioxidant paste to the battery and inverter terminals.

Install the battery terminal connection covers (red for positive, black for negative) over the

inverters DC terminals and secure with the screws and washers provided.

22

©2000 Xantrex Technology Inc.

Page 31

2.0 INSTALLATION

DC Circuit Grounding

Grounding is an important part of the system installation and must be performed correctly to

ensure safe operation of the equipment. Grounding requirements vary by country and application.

Consult the NEC for specific requirements.

The ground conductor should be sized appropriately for the over-current protection device

being used and according to NEC 250-95 (see table below for a portion of the NEC code).

Size of Over-current

Device Protecting the

Conductor

Minimum Size of

Copper Ground Wire

30 or 60 amp #10 AWG

100 amp #8 AWG

200 amp #6 AWG

300 amp #4 AWG

400 amp #3 AWG

3597-000-018

Table 3

Safety Ground Wire Size

General DC Grounding Requirements

Connect the negative (-) terminal of the battery bank to an appropriately sized conductor and

connect it to a solid earth ground, such as a grounding rod, driven 68 feet into the earth.

This procedure will properly ground the DC circuits.

©2000 Xantrex Technology Inc.

+

&LUFXLW%UHDNHU

+

-

+

-

7

1

+

$

;

Figure 19

DC Grounding

5

$

;

;

(

-

-

;

(

5

7

1

&KDVVL V*URXQG

+

;

(

5

7

1

$

;

-

*URXQG

5RG

23

Page 32

2.0 INSTALLATION

Installing a Battery Temperature Sensor

A battery temperature sensor (BTS) option can easily be installed in the system to ensure

proper charging of the batteries based on temperature. Installing a BTS extends battery life by

preventing overcharging in warm temperatures and undercharging in cold temperatures.

Installing the sensor:

Run the battery temperature sensor wire in the DC conduit (if used) and route the RJ11

connector end to the BATTERY SENSE jack located on the front of the inverter.

Secure the sensor to one of the batteries located in the center the battery pack.

BATTERY SENSE

(RJ11) Jack

Figure 20

BTS (RJ11) Jack Location

To BATTERY SENSE

jack

BTS connected to

battery

Figure 21

BTS Installed on Battery

)

24

©2000 Xantrex Technology Inc.

Page 33

2.0 INSTALLATION

AC Wiring

Sub-panel Mounting and Conduit Installation

NOTE: The installation of sub-panels and wiring should be performed by a qualified person or a

licensed electrician following all local and NEC codes.

Determine the location of the sub-panel and install it according to the manufacturers

directions.

Install the AC conduit between the sub-panel (output) and inverter.

WARNING: DISCONNECT THE POWER FROM THE UTILITYS MAIN BREAKER BOX BEFORE

PROCEEDING.

Install conduit between the inverter (input) and the main breaker box.

Determine which circuits require backup. Install the appropriate circuit breakers into the

sub-panel.

Install a 60 amp (disconnect) circuit breaker in the sub-panel. This will later be wired to the

inverters output. If two inverters are being used in a stacked configuration, install two 60

amp circuit breakers for 240 VAC service (one in each leg of the circuit for L1 and L2).

Input to the Inverter

CAUTION: THE INVERTERS AC OUTPUT MUST NEVER BE WIRED TO THE UTILITY OR

GENERATOR OUTPUT. THIS WILL CAUSE SEVERE DAMAGE TO THE INVERTER WHICH IS

NOT COVERED UNDER WARRANTY.

All AC wiring connects to the terminal block located on the right-hand side of the inverter.

To access the terminal block, remove the side cover panels (if installed) by removing the

two (or three) Phillips screws. Units are shipped without the covers installed (packed in a

small plastic bag with additional hardware).

Locate the AC input and output terminals on the block. Refer to Figure 23.

NOTE: The lower AC cover varies depending on the systems power level. Higher power units are

equipped with a conduit box and not a plate. The conduit box is required for the larger diameter

wire providing ample bending radius.

Screws

Standard Cover Plate

©2000 Xantrex Technology Inc.

High Power Conduit Box

Figure 22

AC Wiring Access Cover Plates

25

Page 34

2.0 INSTALLATION

AC Wiring

Before wiring the input of the inverter, refer to the table below for the minimum recommended

wire size.

NOTE: Refer to the NEC for actual wire sizes for specific installations.

AC Input AC Output

Inverter Model

120 VAC 220-240 VAC 120 VAC 220-240 VAC

DR1512

DR2412

DR1524

DR2424

DR3624

#8 or 6 AWG #10 AWG #12 AWG #16 AWG

#6 AWG #10 AWG #10 AWG #14 AWG

#8 or 6 AWG #10 AWG #12 AWG #16 AWG

#8 AWG #10 AWG #10 AWG #14 AWG

#6 AWG Not Available #8 AWG Not Available

975-0012-007

Table 4

Minimum Recommended Wire Size (Input and Output)

26

©2000 Xantrex Technology Inc.

Page 35

2.0 INSTALLATION

AC Wiring (continued)

NOTE: The U.S. requires conduit be used in this type of installation. Refer to the NEC and local

codes. Conduit fittings can be replaced with strain reliefs where code permits.

Refer to the table on the previous page for minimum recommended wire sizes.

Procedure

AC Input Wiring to Inverter

WARNING: DISCONNECT THE BATTERY CONNECTIONS FROM THE INVERTER IF THEY ARE

ALREADY CONNECTED.

ALL WIRING SHOULD BE PERFORMED BY A QUALIFIED OR LICENSED ELECTRICIAN.

DISCONNECT THE MAIN BREAKER AT THE MAIN UTILITY BREAKER BOX.

Install a 60 amp circuit breaker in the utility service panel. This will serve as both an AC

disconnect and over-current protection.

Feed the HOT, NEUTRAL and GROUND wires (via conduit) from the inverter to the main

utility box. Leave several inches of extra wire at each end.

Make the connections to the inverter first. Wiring to the utility breaker box is performed after

all connections have been made in the inverter.

Connect the GROUND (green) wire to the inverters AC GROUND terminal.

Connect the NEUTRAL (white) wire from the main utility panel to the inverters NEUTRAL

INPUT terminal.

Connect the HOT (black) wire from the main utility panel to the inverters AC HOT INPUT

terminal.

Torque all connections to 16 inch-pounds.

AC CHASSIS

GROUND

HOT

IN

NEUTRAL

IN

©2000 Xantrex Technology Inc.

Figure 23

AC Input Wiring

27

Page 36

2.0 INSTALLATION

AC Wiring (continued)

AC Output Wiring to the Sub-panel

WARNING: ENSURE THE SUB-PANEL DOES NOT HAVE A NEUTRAL TO GROUND BOND. IF IT

DOES, REMOVE IT. ALL AC NEUTRAL-GROUND BONDING IS DONE AT THE MAIN UTILITY

BREAKER BOX (SERVICE ENTRANCE).

Connect the GROUND wire to the inverters AC GROUND chassis terminal. Connect the

other end of this wire to the GROUND bus in the sub-panel.

Connect the NEUTRAL (white) wire to the inverters NEUTRAL OUTPUT terminal. Connect

the other end of this wire to the NEUTRAL bus in the sub-panel.

Connect the HOT (black) wire to the inverters terminal labeled AC HOT OUTPUT. Connect

the other end of this wire to the sub-panels input circuit breaker.

Torque all inverter terminal block connections to 16 inch-pounds. Refer to the sub-panel

manufacturers specifications for wire torques.

AC CHASSIS

GROUND

NEUTRAL

OUT

HOT

OUT

Figure 24

AC Output Wiring

NOTE: The two neutral connections (input and output) are common to one another and may be used

in any combination.

28

©2000 Xantrex Technology Inc.

Page 37

2.0 INSTALLATION

AC Wiring (continued)

AC Input Wiring to the Main Utility Breaker Box (single inverter installations)

WARNING: MAKE CERTAIN THE POWER TO THE MAIN UTILITY BOX IS DISCONNECTED!

NEVER WORK ON LIVE CIRCUITS.

Remove the MAIN UTILITY BOXs cover plate.

Connect the ground (green) wire to the GROUND bus in the main utility box.

Connect the neutral (white) wire to the NEUTRAL bus.

Connect the hot (black) wire to the 60 amp circuit breaker (installed for the inverter).

Torque all wires to the manufacturers specifications.

CAUTION: INSPECT ALL WIRING FOR PROPER INSTALLATION BEFORE REINSTALLING THE

COVER PLATE.

UTILITY FEED

FROM METER

LINE

NEUTRAL

1

MAIN PANEL

120 VAC

120 VAC

240 VAC

NEUTRAL BONDED TO GROUND

EARTH GROUND

NOTE: FOR ILLUSTRATIVE PURPOSES ONLY.

BREAKER BOXES VARY DEPENDING ON APPLICATION.

MAIN PANEL WIRING TO NON-CRITICAL LOADS

IS NOT ILLUSTRATED.

MAIN

BREAKER

CAUTION:

IN MAIN PANEL ONLY!

EXISTING HOUSE WIRING

FROM

UTILITY

120 VAC FROM

LINE OUT

LINE OUT

120 VAC BACKUP POWER

NEUTRAL

GROUND

INVERTER/CHARGER

GROUND

120 VAC LINE IN

NEUTRAL

LINE OUT

120 VAC INVERTER OUT

INVERTER

DISCONNECT

TO LOAD

NEUTRAL

GROUND

SUB PANEL

120 VAC BACKUP POWER

TO LOAD

(NEW WIRING)

120 VAC LINE OUT

NEUTRAL

GROUND

©2000 Xantrex Technology Inc.

NEUTRAL

GROUND

3597-W00-C06

Figure 25

Single Inverter 120 VAC Wiring Diagram

29

Page 38

2.0 INSTALLATION

Generators

An AC generator can be used as an input source instead of the utility power, or can be

connected (via additional hardware) to power the loads when utility is not present (utility outage),

and to charge the batteries. The generator must be of the permanently installed type and not a

portable type unit used for emergency power. Small emergency type generators may not have a

stable enough voltage or frequency output for the inverter to synchronize to, or provide enough

current to fully charge the batteries.

Generator Requirements

The maximum charge rate the battery charger can deliver is dependant upon the peak AC

voltage available. Since the battery charger uses only the top portion of the input sine wave,

small variations in peak voltage result in large variations in the amount of energy to the charger.

The chargers rated output is based on a utility voltage of 120 VAC

169 VACp (230 VAC

has a peak voltage of 325 VACp).

rms

Low power generators may not produce enough voltage under heavy load conditions to fully

charge the batteries as the voltage peaks may be clipped, limiting the maximum charge rate. Size

the generator appropriately for the system, including battery charge and load current.

The following table demonstrates how the peak voltage available affects the charging current:

which has a peak voltage of

rms

Peak Voltage

Av ai la b le

170 VAC

DR1512 DR2412 DR1524 DR2424 DR3624

70 amps 120 amps 35 amps 70 amps 70 amps

P

Table 5

Peak Input Voltage vs Charging Current

Generator Type Inverter Type

Typical MAX charge

Rate amps

Honda 800 DR1512 43 amps

Honda 2200 DR1512 57 amps

Homelite 2500 DR1512 11 amps

Honda 3500 DR1512 39 amps

Honda 6000 DR1512 70 amps

Honda 1600 DR1524 25 amps

Westerbeke 7.0 kW DR1512 Approx. 45 amps

975-0012-012

30

Westerbeke 12.5 kW DR1512 Approx. 65 amps

975-0012-013

Table 6

Generator Types

©2000 Xantrex Technology Inc.

Page 39

2.0 INSTALLATION

Generators (continued)

Because generator hookups can vary widely, only basic hookup information is given. Complex

hookups, involving both the utility and generator, require additional hardware such as a manual AC

transfer switch and possibly an autotransformer for load balancing.

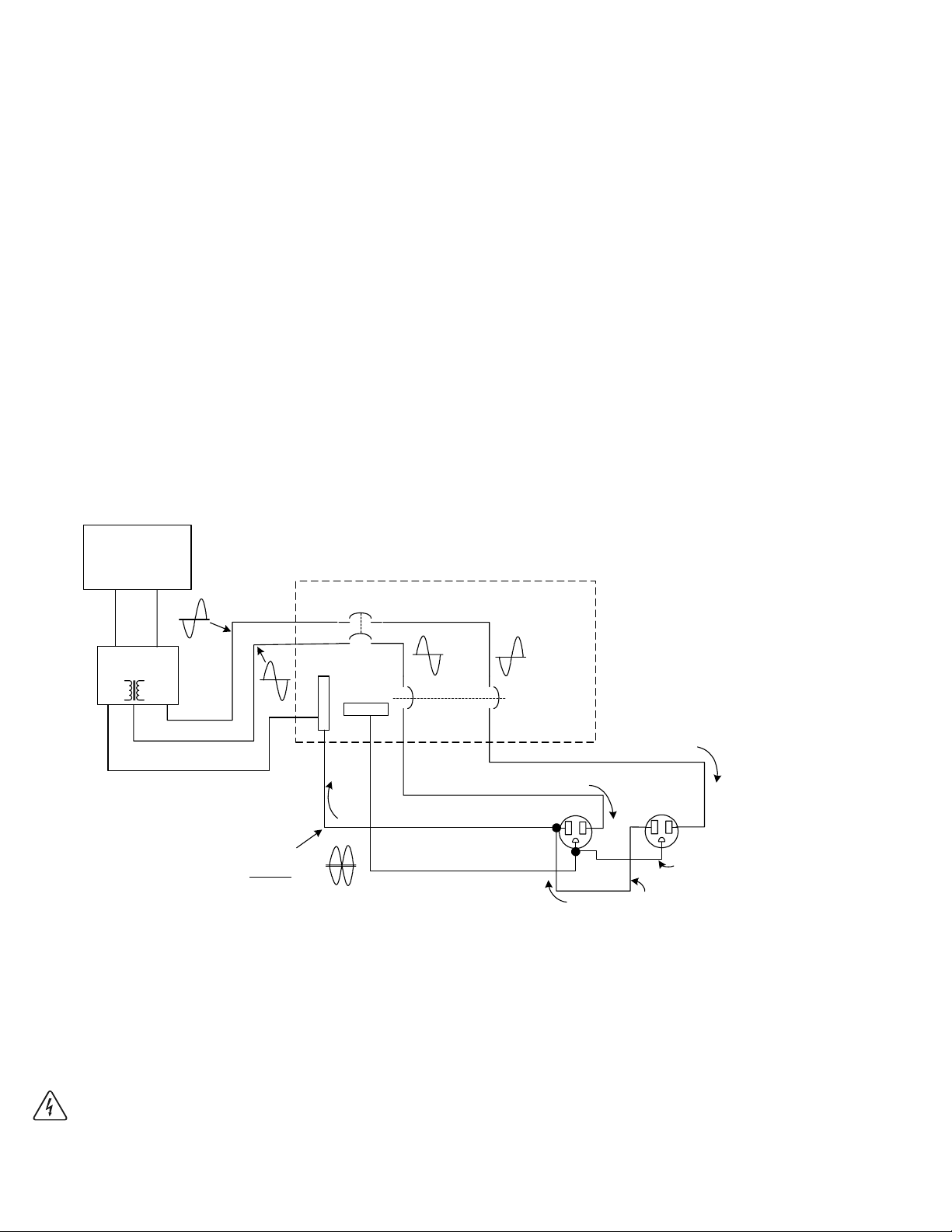

Basic 120 VAC Generator Hookup (non-utility applications only)

Connect the ground wire on the generator to the GROUND terminal on the inverter.

Connect the generator neutral wire to the NEUTRAL terminal on the inverter.

Connect the generator HOT wire to the HOT input on the inverter.

Bond the neutral to the ground on the output of the generator (only if used in non-utility

installations) or in the MAIN SERVICE PANEL (not both).

Drive a ground rod 68 feet into the ground and connect the generators ground to the

ground rod.

NOTE: The ground and neutral must be bonded at one place, and only one place, in the system. If

the generator is the main source of power, (i.e., no utility grid power) then the neutral and ground

connections are bonded at the generator. If the generator is acting as a backup for the utility grid,

then the bond should be at the main utility service entrance box. In this case, ensure that no bond

exists at the generator output.

Manually start the generator and check for proper operation of the inverter (i.e., the inverter

transfers from battery to generator power).

120 VAC

GENERATOR

Neutral/

Ground bond

HOT

Neutral

Ground

HOT

Neutral

Ground

Distribution

120 VAC

LOADS

INVERTER/

CHARGER

HOT

Neutral

Ground

Panel

3597-A00-016

Basic 120 VAC Generator Block Diagram (for non-utility applications)

©2000 Xantrex Technology Inc.

Figure 26

31

Page 40

2.0 INSTALLATION

Generators (continued)

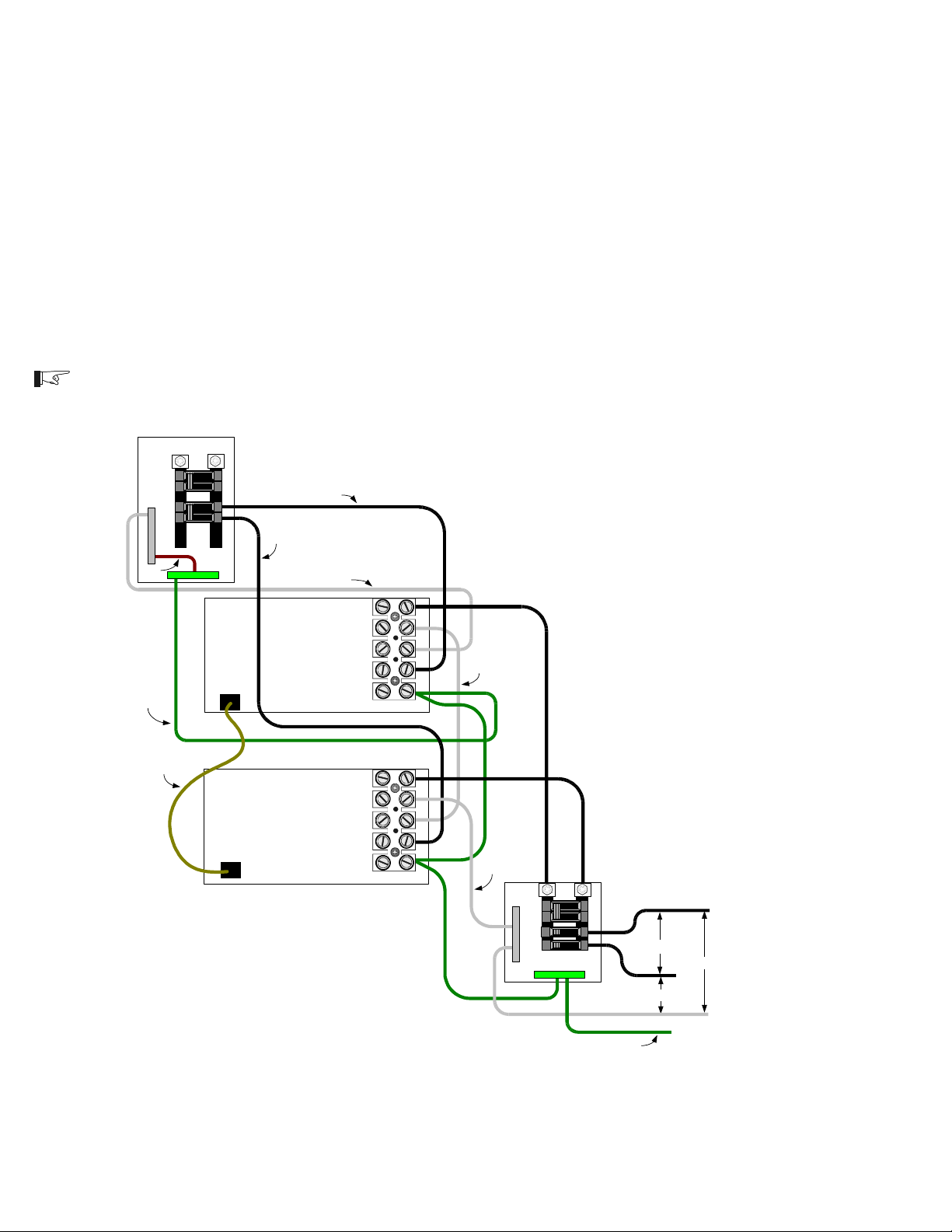

Basic 120 VAC Utility/Generator Hookup

If a generator is used as a backup for the utility, then a manual transfer switch must be added

to provide a means to switch the generator power to the inverters inputs. The generator can be

used during extended outages to recharge the batteries and provide pass through power for the

loads. Start and stop the generator manually using the generators pull-cord, ON/OFF switch, etc.

Generator Connections (to manual bypass switch)

Connect a (green) ground wire between the generators GROUND terminal and the

GROUND terminal in the manual bypass switch.

Connect a (white) neutral wire between the generators NEUTRAL terminal and the

NEUTRAL bus in the manual bypass switch.

Connect a (black - HOT) wire between the generators HOT OUT terminal and the

GENERATOR (HOT) contact in the manual bypass switch.

NOTE: Refer to the bypass switch installation manual for contact details, torque specifications, etc.

Utility Connections (to manual bypass switch)

Connect a (green) wire between the GROUND terminal in the MAIN UTILITY PANEL and the

GROUND terminal in the manual bypass switch.

Connect a (white) wire between the NEUTRAL bus in the MAIN UTILITY PANEL and the

NEUTRAL bus in the manual bypass switch.

Connect a (black) wire between the inverter circuit breaker in the MAIN UTILITY PANEL and

the UTILITY HOT contact in the manual bypass switch.

Inverter Connections (to manual bypass switch)

Connect a (green) wire between the GROUND terminal in the manual bypass switch and the

inverters AC GROUND terminal.

Connect a (white) wire between the NEUTRAL terminal in the manual bypass switch and the

inverters NEUTRAL IN terminal.

Connect a (black) wire between the COMMON terminal in the manual bypass switch and the

inverters HOT IN terminal.

Torque all wires 16 in/lb.

Sub-panel Connections

Connect a (green) wire between the inverters AC GROUND terminal and the GROUND

terminal in the sub-panel.

Connect a (white) wire between the inverters NEUTRAL OUTPUT terminal and the

NEUTRAL bus in the sub-panel.

Connect a (black) wire between the inverters terminal labeled AC HOT OUTPUT and the

SUB-PANELs INPUT circuit breaker.

32

Torque all inverter terminal block connections to 16 inch-pounds. Refer to the sub-panel

manufacturers specifications for wire torques.

Recheck all connections.

Refer to the illustration on the next page.

©2000 Xantrex Technology Inc.

Page 41

Generators (continued)

Utility Power

120 VAC

2.0 INSTALLATION

Bonded Neutral/

Ground Bus

House

Ground

Generator

Power

Main Utility

G

Circuit

R

O

Breaker

U

N

D

Bond

Wire

Manual

Start

Generator

HOT

Inverter Circuit

Breaker

Utility Service

Panel

GENERATOR

HOT CONT ACT

HOT

NEUTRAL

NEUTRAL

N

E

U

T

R

A

L

NEUTRAL

HOT

UTILITY HOT

CONTACT

U

G

AC Input

COMMOMN

CONTACT

(to inverter)

Inverter

Manual Transfer

Switch

C

Isolated

Neutral Bus

Isolated

Neutral Bus

©2000 Xantrex Technology Inc.

AC Output

Main Input

Breaker

Neutral Bus

Sub-panel

Figure 27

Basic 120 VAC Utility/Generator Block Diagram

Isolat ed

NEUTRAL

HOT

GROUND

To AC Load

975-0012-008

33

Page 42

2.0 INSTALLATION

Series Stacking

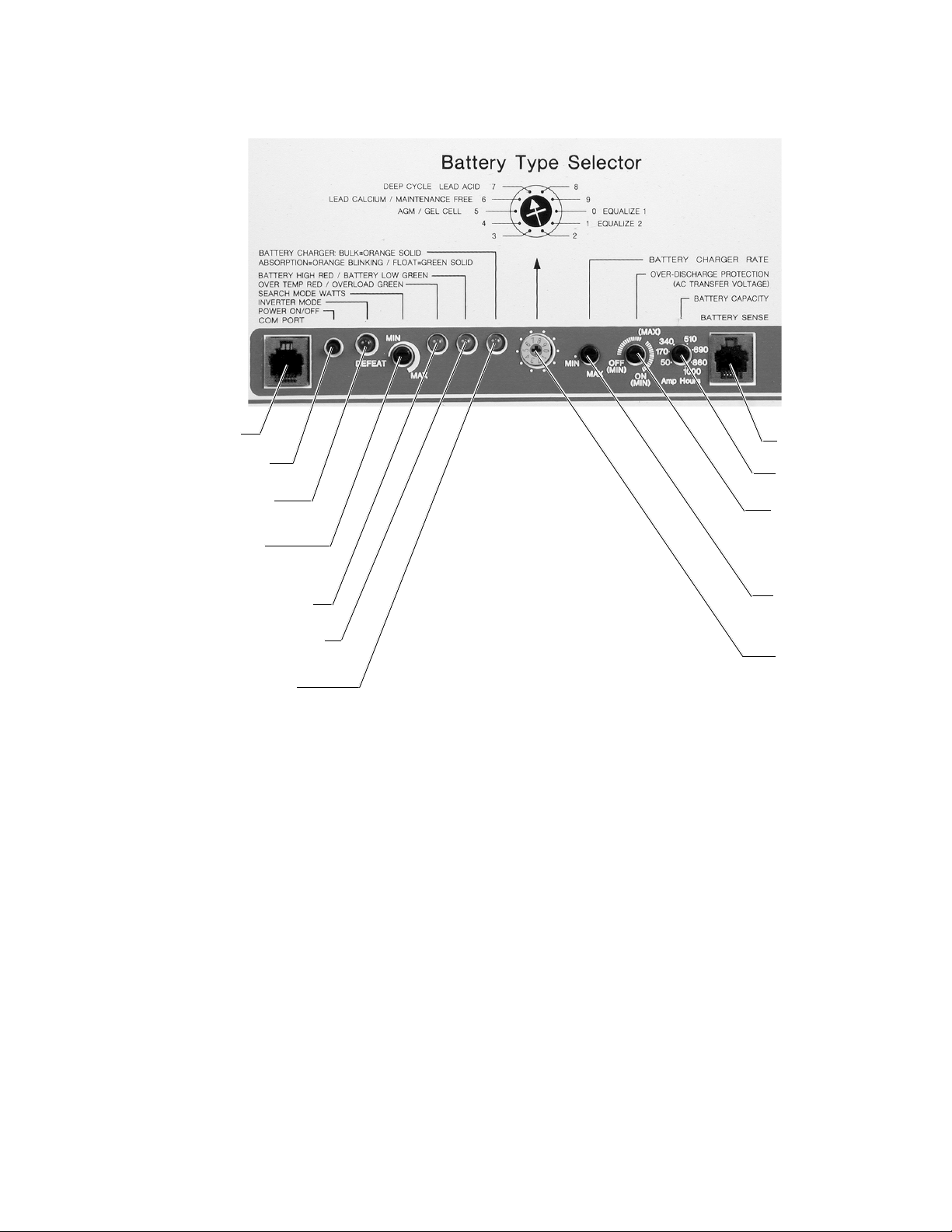

This COM port allows two DR Series inverter/chargers to be used in the same system in a

SERIES configuration to operate 240 VAC loads. Series stacking can also be used to connect to

240 VAC only power systems providing both 120 and 240 VAC outputs. A series stacking interface

cable (DRI) is required to connect the series stacking port of the inverters. In this mode, one of the

inverters will function as the primary and the other inverter becomes the secondary. The first unit

switched ON becomes the primary and ensures the secondarys output is 180 degrees out of phase

for 240 VAC operation. Both units can charge the batteries or provide battery backup power during a

utility outage.

The following illustrations provide a general overview of AC and DC wiring configurations and

output voltages supplied by stacked inverters. Detailed wiring and operating instructions are

provided with the DRI interface kit available from Xantrex Technology Inc.

NOTE: Only 120 VAC/60 Hz models can be stacked.

MAIN PANEL

L2

L1

N

E

U

T

R

A

L

BOND

GROUND

WIRE

GROUND

SERIES STACKING

CABLE (DRI)

DRI

COM PORT

DRI

COM PORT

L1

L2

HOT L2

HOT L1

NEUTRAL I N

HOT OUT

NEUTRAL OUT

NEUTRAL IN

HOT IN

GROUND

INVERTER 1 (L1)

HOT OUT

NEUTRAL OUT

NEUTRAL IN

HOT IN

GROUND

INVERTER 2 (L2)

NEUTRAL OUT

NEUTRAL OUT

N

E

U

T

R

A

L

L1

SUB-PANEL

GROUND

L2

L1

240 VAC

L2

120 VAC

120 VAC

34

GROUND

975-0012-D-014

Figure 28

Series Stacking AC Wiring

(120 VAC/60 Hz models only)

©2000 Xantrex Technology Inc.

Page 43

Series Stacking (continued)

Positive

Tie

Negative

Tie

2.0 INSTALLATION

Inverter 1

(L1)

Series Stacking

Cable (DRI)

DC

Disconnect

–

+

–

+

–

+

–

+

Figure 29

Stacking Port and Battery Wiring with One Disconnect

(120 VAC/60 Hz models only)

Inverter 2

(L2)

975-0012-009

Inverter 1

(L1)

DC

Disconnect

Stacking Port and Battery Wiring with Two Disconnects

©2000 Xantrex Technology Inc.

+

+

DC

Disconnect

–

–

Negative

Tie

–

+

–

+

Figure 30

(120 VAC/60 Hz models only)

Series Stacking

Cable (DRI)

Inverter 2

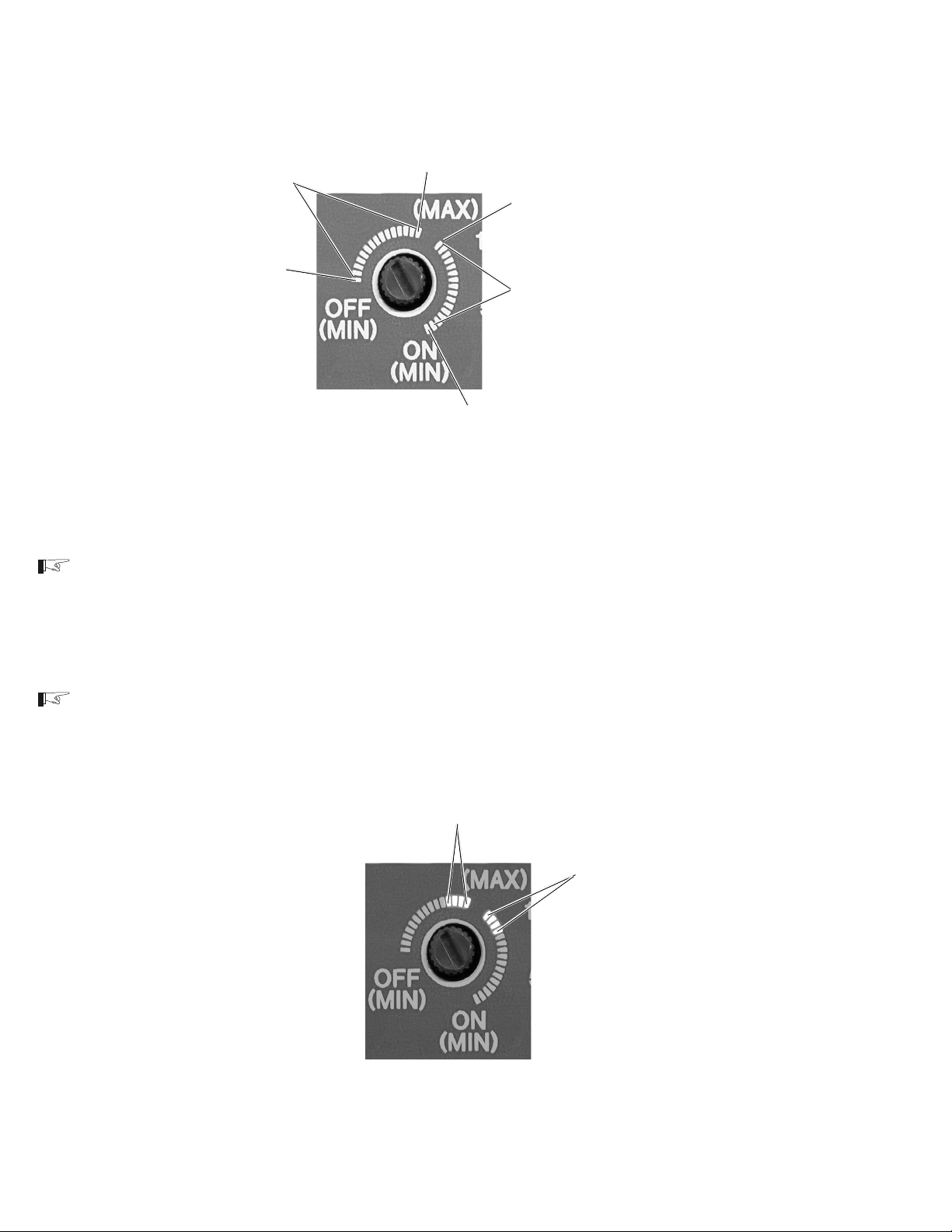

(L2)