Page 1

™

AirMax

Recessed

ADA Compliant High Speed Hand Dryer

Secamanos Empotrado de Alta Velocidad AirMax™ Compatible con ADA

Sèche-mains AirMax™ à grande vitesse et montage encastré conforme ADA

All XRM, RM Series

Todos los Modelos de las Series XRM y RM

Toutes les modèles de série XRM et RM

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or service

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage. Retain instructions for future reference.

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto aquí

descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. No seguir las instrucciones puede ocasionar daños,

tanto personales como materiales. Guarde estas instrucciones para referencia en el futuro.

Lire et conserver ces instructions. Les lire attentivement avant de commencer à assembler, installer, faire fonctionner, réparer ou entretenir l’appareil

décrit. Pour se protéger et protéger autrui, observer toutes les consignes de sécurité. Le fait de négliger d’appliquer ces instructions peut entraîner

des blessures et/ou des dommages matériels. Conserver ces instructions pour consultation ultérieure.

World Dryer Corporation

5700 McDermott Drive

Berkeley, IL 60163 U.S.A.

800-323-0701

www.worlddryer.com

Page 2

Description

World Dryer high performance recess mounted, ADA compliant warm air hand dryer, powered by a high speed universal motor,

delivering 2300 Watts of drying power. This hand dryer runs on 115 Volts AC or 208/220-240 Volts AC electrical supply, depending on

model. Automatic and push-button models are represented in this product group. This appliance is intended for use in hand drying,

contributing to fast, hygienic and cost effective hand sanitation. This hand dryer may be used in commercial, industrial, ofce and

public facility environments.

General Specications

Models Nozzle Drying Cycle Dimensions (WxDxH) Weight Cover Material

XRM Fixed Automatic 13.1” x 13.8” x 4” 333 mm x 351 mm x 102 mm 26.5 lbs / 12 kgs Stainless Steel

XRM Fixed Automatic 13.1” x 13.8” x 4” 333 mm x 351 mm x 102 mm 35 lbs / 15.9 kgs Cast Iron

RM Fixed 20 Seconds 13.1” x 13.8” x 4” 333 mm x 351 mm x 102 mm 35 lbs / 15.9 kgs Cast Iron

Electrical Specications

Models Type Electrical Input Amperage Watts

XRM5 Automatic 115 VAC, 60 Hz 20 2300

RM5 Push-button 115 VAC, 60 Hz 20 2300

XRM54 Automatic 208-230 VAC, 60 Hz 10 2300

RM54 Push-button 208-230 VAC, 60 Hz 10 2300

XRM548 Automatic 220-240 VAC, 50 Hz 10 2300

RM548 Push-button 220-240 VAC, 50 Hz 10 2300

(cULus Listed, E19860, CE TUV-GS)

General Safety Information

DANGER

• Always disconnect the power source before servicing or installing the hand dryer.

DANGER

• This hand dryer must be properly grounded (Earthed) for safe operation. An identied ground connection point is supplied on the

hand dryer’s wall base.

• We recommend GFCI protection in wet or damp locations or as required by local code.

WARNING

• Use only the electrical power (voltage and frequency) specied for the model hand dryer being installed.

• Connect the hand dryer to the nearest suitable distribution panel.

• To limit a voltage drop, and insure efcient operation, use wire gauge as required by local or National Electrical Code.

• Do not connect to a branch circuit with CB or fuse protection over 20 Amps. This is in compliance with The National Electrical Code.

• All automatic model hand dryers must have a dedicated 20 Amp circuit as required by Underwriters Laboratories, Inc. (UL).

• Route all eld wiring away from any moving parts within the hand dryer.

Failure to disconnect the power source before installation or servicing can

result in serious injury or death from electric shock.

Failure to properly ground this unit could result in severe electrical shock

and/or death.

Risk of re, personal injury or property damage are possible if local codes,

NEC codes or safety recommendations are not followed.

CAUTION Improper mounting could result in personal injury or property damage.

Unpacking

1. Remove all packing material. Recycling is recommended.

2. Carefully remove the hand dryer from the shipping carton, using care not to drop the appliance.

3. Inspect carefully for any damage that may have occurred during transit. Check for any loose, missing or damaged parts. If the

hand dryer is damaged, promptly inform the shipper or dealer where you purchased it.

English

2

Page 3

0

A

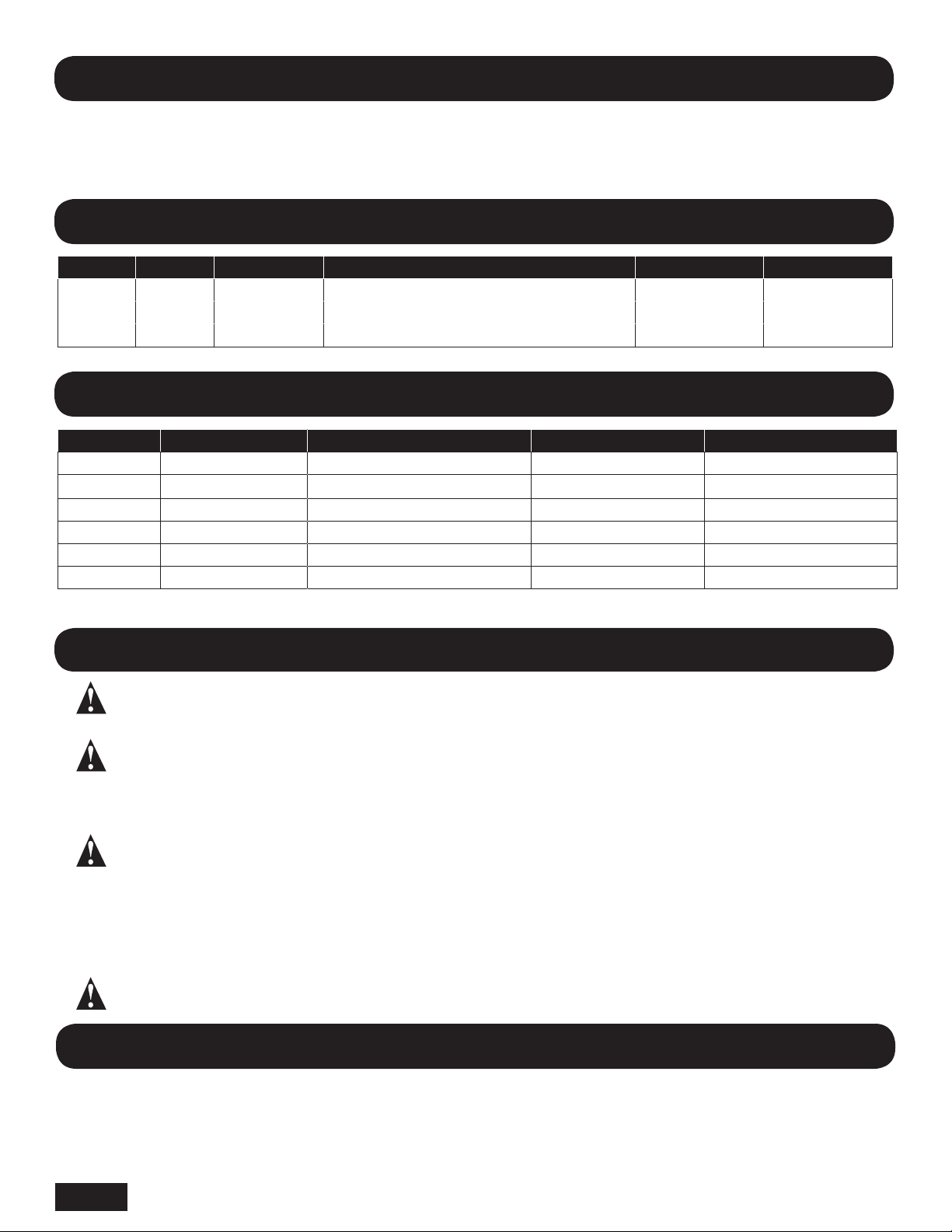

Installation

IMPORTANT: Consult local and general regulations before performing dryer installation. Make certain that the electrical

network is not overloaded. Do not connect to a branch circuit with a circuit breaker or fuse rated over 20 Amps. This is a UL

recommendation and complies with NEC.

A) DISCONNECT THE POWER SOURCE.

B) Fit and Finish Precautions;

1) Mount the hand dryer wall box at the recommended height per Table #1.

2) Mount the wall box ush - to a maximum of 1/8” (3.2mm) below the

nished wall surface for a proper recessed t.

3) Caulking is recommended AFTER installation of the aluminum base

assembly for a nished look and to help keep water out of the appliance.

(Caulking before installation may create a t problem.)

C) Mounting the Steel Wall Box;

CAUTION: Proper installation requires that the base be installed into the

steel wall box supplied.

1) Locate the steel wall box in the wall at the desired position, having the lower

edge of the box at the selected height specied in Table #1.

2) When two or more dryers are installed, they should be spaced 24” (61cm) minimum from center to center.

3) To mount the wall box, frame the opening in the wall per Figure #1.

4) Allow an opening in the framing to correspond with the preferred wall box knock-out for easy access of electrical conduit.

5) Mount the wall box in the opening. Fasten with No.10 (M5) wood screws or appropriate fasteners as required.

6) Using the nearest suitable distribution panel, run conduit.

7) To limit voltage drop for efcient operation, use No. 12 wire or larger as required by local electrical code or NEC.

8) Automatic hand dryers require dedicated 20 amp circuits to avoid unattended starting due to voltage uctuations. This includes

avoiding switched lighting circuits or other circuits where equipment may be switched on / off.

9) Provide a minimum length of 24” (61cm) of wire in the wall box to allow easy connection to the dryer terminals.

Table 1

Recommended Mounting Heights

from Floor to Dryer Bottom Edge

Men’s washrooms 42 (107)

Women’s washrooms 40 (102)

Children’s washrooms, ages 4-7 28 (71)

Children’s washrooms, ages 7-10 32 (81)

Children’s washrooms, ages 10-13 36 (91)

Children’s washrooms, ages 13-17 40 (102)

Handicap Mounting Height 34 (86)

in. (cm.)

D) Mounting the Dryer in the Wall Box;

1) Remove all shipping / packing material including the protective rubber corner squares if present on the dryer cover.

2) Use the security allen wrench supplied, to remove the (2) cover mounting screws. Remove the cover from the dryer base

assembly.

CAUTION: should be exercised when handling porcelain enameled cast iron covers. Do not drop or hit against hard

surfaces to avoid damaging the porcelain enamel.

3) Insert the base assembly in the pre-mounted wall box.

4) Facing the dryer, the blower housing will be on the left side as installed.

5) Fasten the base to the wall box with (4) 1/4-20 screws supplied.

Figure 1

6) Route the wires through

the openings in the base

assembly.

7) Connect eld wires to the

terminal block identied as

(L / N, L1 / L2).

8) Securely connect a

conrmed ground wire to the

1 1/4"

EDGE FLUSH

TO RECESS

1/8" MAX.

3"

3"

3"

1 1/4"

ground screw point.

DANGER: This hand dryer

must be properly earth

connected (grounded).

CAUTION: Route eld wires

away from any moving

parts or sharp edges.

9) Install the Hand Dryer

Cover with the (2) mounting

screws. To avoid chipping

the porcelain enamel, do not

3 1/2"

SECTION "A"

#16 GA.

STEEL BOX

12 1/2"

OPENING

8 KNOCKOUTS

DIMENSION "A"

SEE TABLE

7/8" + 1 1/8"

3"

1 1/4"

1 1/4"

3"

11 3/4"

OPENING

3"

A

over-tighten.

INSTALLATION MUST BE PERFORMED BY QUALIFIED ELECTRICAL PERSONNEL.

1 1/4"

3"

3"

8 HOLES FOR #1

WOOD SCREWS

3

English

Page 4

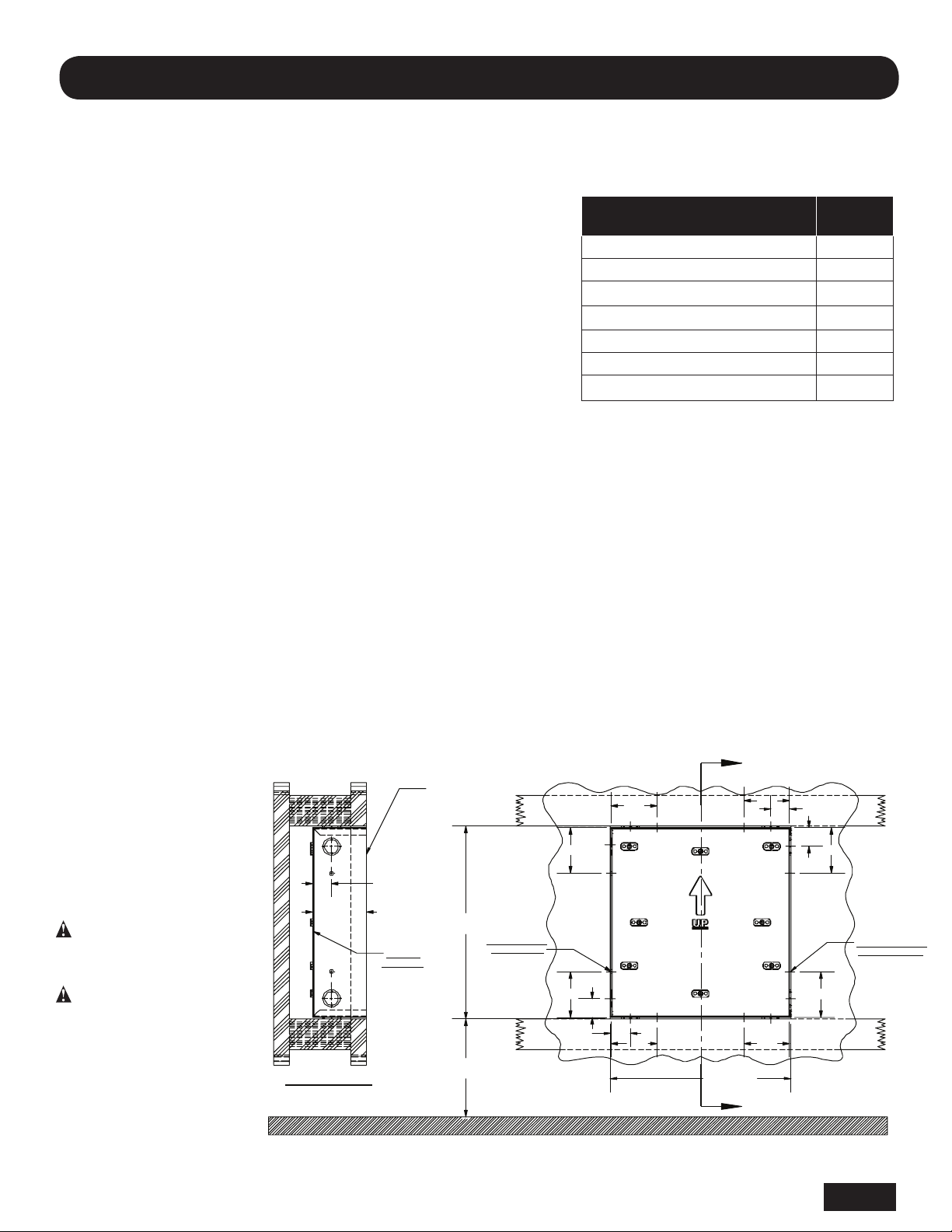

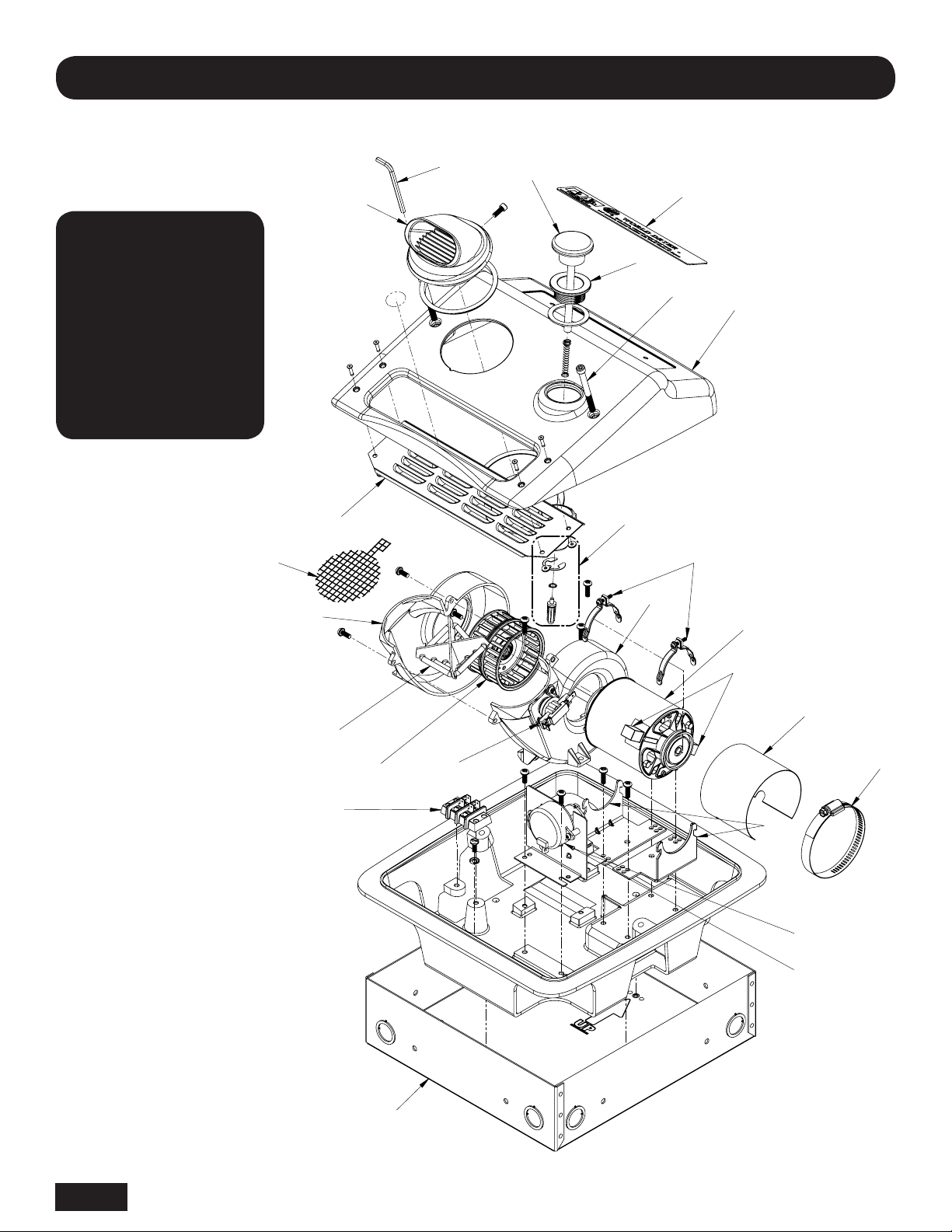

Parts List

Figure 2 - Repair Parts List For Hand Dryers

For Repair Parts, visit

www.WorldDryer.com.

Please provide following

information:

Model number

Serial number

Part description and

number shown in parts list

25

20

13

15

12

16

22

10

14

9

11

5

18

3

21

24

19

23

17

4

2

1

6

7

8

English

4

Page 5

Description Part Number Qty.

#

1 Clamp, Motor Bafe 23-100 1

2 Bafe, Motor 127HS 1

3 Motor XRM5, RM5 32-120K 1

3 Motor XRM54, RM54, XRM548, RM548 32-230K 1

4 Motor Brush 206NL 2

5 Motor Mounting Strap 110-4A 2 sets

6 Motor Mounting Brackets 110-4 2

7 Micro Switch Only RM (All) 143F 1

8 Switch Timer Unit RM5 125XMK 1

8 Switch Timer Unit RM54 125AMK 1

8 Switch Timer Unit RM548 125MCEK 1

9 Cover Complete, Cast Iron, Automatic, White XRM (All)* 703XM5-974AK 1

9 Cover Complete, Cast Iron, Push-button, White RM (All)* 703M5-974AK 1

9 Cover Complete, Stainless Steel , Automatic, Brushed XRM (All)* 713DXM5-Q973AK 1

10 Push-button Adapter, Gasket and Bushing Unit RM (All) 190K 1

11 Push-button Retaining Ring, Insulated Push Rod Tip, and Spring Kit RM (All) 193K 1

12 Security Allen Wrench, Cast Iron Cover 204TP 1

12 Security Allen Wrench, Steel Covers 56-006565 1

13 Inlet Grill, Cast Iron, Push-button, with Mtg. Hardware RM(All) 194-3K 1

r13 Inlet Grill, Cast Iron, Automatic, with Mtg. Hardware XRM(All) 194-3XRAK 1

14 Tamper Proof Cover Screw, Cast Iron Covers XRM, RM (All) 100B3 1

14 Tamper Proof Cover Screw, Steel Covers XRM (All) 46-005023 1

15 Nozzle Assembly Kit 34-173K 1

16 Push-button Assembly Kit (Knob, Rod, Ring, Spring and Tip) RM (All) 185K 1

17 Thermostat Only 3/4” 1111-0 3 1

18 Blower Scroll Half with Base Mount and Thermostat 211PA 1

19 Fan Metal 101i 1

20 Blower Scroll Half - Left Side 112P 1

21 Heating Element XRM5, RM5 213XM 1

21 Heating Element XRM54, RM54, XRM548, RM548 213AM 1

22 Nameplate, Push-button RM (All) * 38-225 1

22 Nameplate, Automatic XRM (All) * 38-226 1

Wall Box (All) 17-034 1

23

24 Terminal Block (All) 156-3 1

25 Grid, Ground Assy (All) 12-001 1

r

Automatic Sensor Control - 115V, XRM5 16-230-120 RAK 1

r

Automatic Sensor Control - 208-230V, XRM54 16-240-208 RAK 1

r

Automatic Sensor Control - 220-240V, 50 Hz CE Only XRM548 16-230-240 CEK 1

r

Filter, Electrnic, 50 Hz CE Only XRM548, RM548 110-2 1

* Specify model when ordering.

r Not shown.

5

English

Page 6

Maintenance

NOTE: Disconnect The Power Before Performing Any Of The Following

CLEANING INSTRUCTIONS:

Read complete Instructions before proceeding. Under normal use, cleaning the Dryer once a year will keep it in good operating

condition. If the washroom trafc is heavier than normal, the cleaning should be done every 6 months. Lint and dust build up inside the

dryer can result in damage to motor and heating element as well as hot emissions that could injure the user.

1. Remove two cover mounting screws from dryer cover using security Allen wrench provided. Support cover while removing screws.

2. Remove three (3) side screws holding blower housing together. Note position of heating element and protective screen. The lead

wires are directed through the clearance hole in the blower housing halves. Carefully remove the heating element however, do not

disconnect the wires.

3. Clean blower wheel halves using a 1/2“ diameter radial bristle brush. Insert brush through space between individual blades and

dislodge dirt. Do not bend or damage blades.

4. Vacuum out dirt from blower and housing, reposition heating element, protective screen and housing half and replace three (3) side

screws. Tighten gently making sure that mica heating element pieces are positioned in housing slots with connecting wires passing

through blower housing hole.

5. Use soft-medium bristle 1/2“ paint brush to clean dust and dirt from motor and switch timer. Do not bend switch blade when

cleaning.

6. Use a stiff brush to clean dirt from inside of nozzle grill and inlet grill. Water may be necessary to ush dirt from inlet grill. Dry inside

of cover before replacing if water is used.

7. Inspect motor brushes. To inspect brushes insert tooth pick in hole in end of brush assembly. If tooth pick is inserted more than one

inch, replace brushes. (See replacement instructions.)

8. Replace cover. Place cover squarely over base and push ush to wall. Insert 2 cover mounting screws and tighten until snug. Do

not over-tighten.

REPLACEMENT OF MOTOR BRUSHES

1. Remove locking spring clip securing brush holder.

2. Draw brush cap out of motor slowly until wire connector appears.

3. Detach wire connector and remove brush and holder assembly.

NOTE: When unpacking brush assembly from carton it is important to hold carbon brush in brush holder securely. P/N

206NL

4. Insert new assembly to point where wire quick connect connection can be made.

5. Push brush quick-connects on motor and brush sleeve together.

6. Push brush assembly back in place and insert locking spring clip.

REPLACEMENT OF HEATING ELEMENT

1. Remove three screws holding blower housing (#211P and #112P) together, and remove #112P side of housing.

2. Disconnect the white wires of the heating element at the terminal block and switch terminal. Replace with the new heating element

of proper voltage and wattage, being careful to connect it identically to the old one.

3. Hold element in position on stationary side of blower housing and slip removable side in place, making sure element frames t into

grooves in blower housing and both wires run through notch at top of air outlet. Reinstall the protective screen and replace three

screws fastening blower housing together.

4. Reconnect wires to terminal block and switch. Make certain all wires are properly reconnected and match the wiring diagram.

REPLACEMENT OF SWITCH TIMER MODELS RM

1. Remove screws from each of the two terminals on switch timer, marking wires for correct reconnection to switch terminals.

2. Replace defective timer with new one. (Specify Dryer Model when ordering Timer.)

3. Reconnect wires to terminals.

4. Replace cover (be sure cover ts squarely over base unit) and push in until cover is ush with wall and insert two cover mounting

screws. Do not over-tighten the mounting screws.

5. Turn on power to dryer.

English

6

Page 7

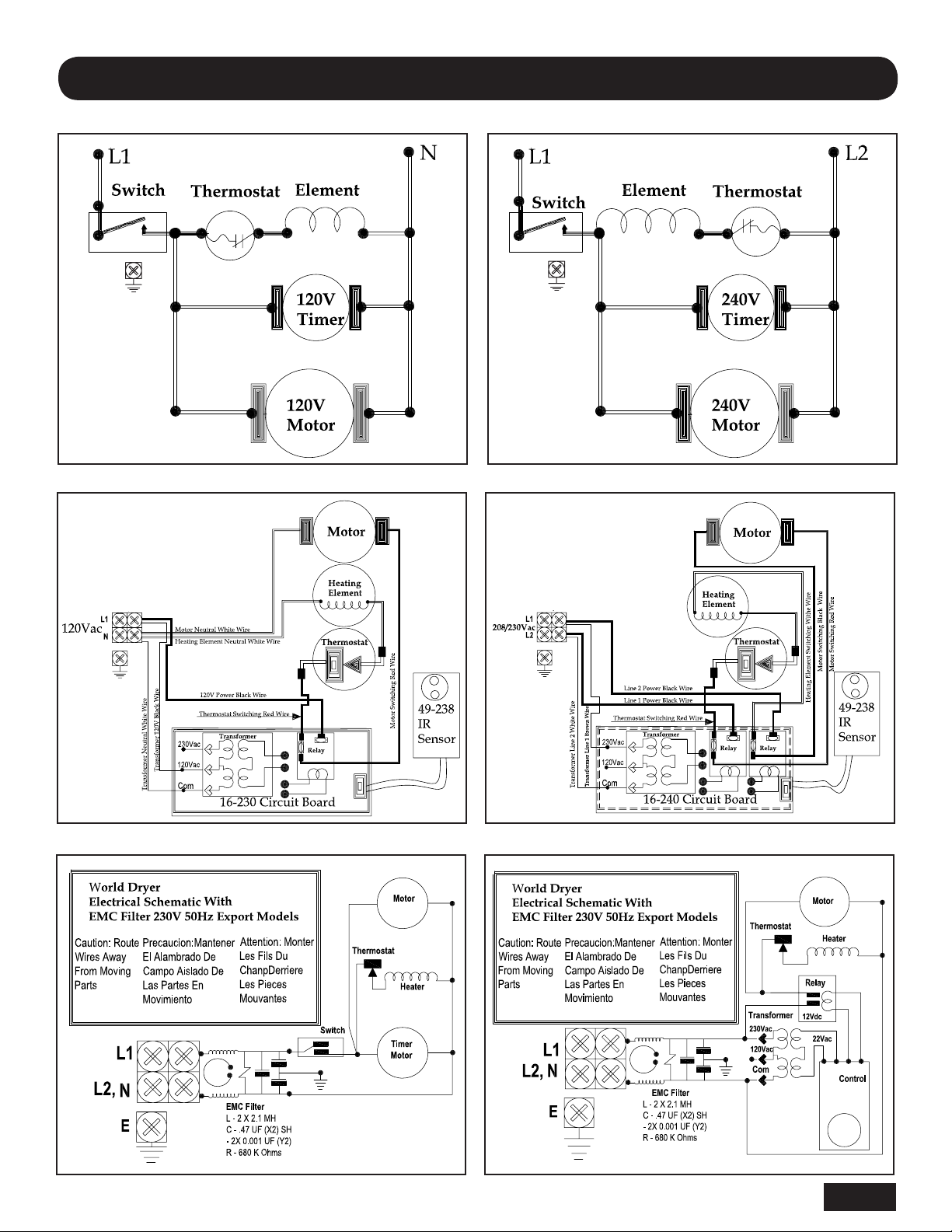

Wiring Diagram

Wiring Diagram - Model RM5

Wiring Diagram - Model XRM5

Wiring Diagram - Model RM54

Wiring Diagram - Model XRM54

Wiring Diagram - Model RM548 Wiring Diagram - Model XRM548

7

English

Page 8

Troubleshooting Chart

Symptom Model Possible Cause(s) Corrective Action

Dryer fails to start XRM Sensor obstruction 1. Check Sensor Lens for foreign material or dirt. Clean Lens with soft damp cloth

All No power to the unit Check if power is “ON”

XRM Faulty Circuit Board (PCB)

XRM Faulty Motor If Relay “Click” is heard, heating element glows for 1-2 seconds, but unit does not

RM Faulty Timer / Switch

Dryer runs for approx.

100 seconds, then will

not re-start

Dryer runs continuous

and will not shut-off.

Dryer “Ghosts”

starts with no hands

present.

Dryer blows cold air. All Defective Heating Element

Dryer air too hot. All Machine is dirty 1. Inspect for foreign material. Using a soft brush and vacuum, clean fan and motor.

Dryer noisy or vibrates. All Fan not centered in housing

XRM Sensor obstruction 1. Check Sensor Lens for foreign material or dirt. Clean Lens with soft damp cloth

RM Faulty Timer With Dryer Cover Removed, depress the Timer Switch Blade;

XRM Sensor receiving false

and Sensor

Faulty Motor

signal or reection

Or

Fluctuating power supply

Or Defective Thermostat

■ Foreign object in Fan.

■ Broken or bent Fan.

■ Bent Motor shaft.

and mild cleaning agent.

2. If Lens is damaged or scratched, replace it.

Check electrical connections.

Place hands under Sensor. Listen for PCB .

Relay “Click.” If no “Click” is heard, replace the PCB and Sensor.

start, replace the Motor.

With Dryer Cover Removed, depress the Timer Switch Blade;

a. Timer Motor should turn.

b. With an Ohm Meter, check for continuity across the Switch Terminals.

“No” in either test, replace Timer Assembly;

“Yes” in both tests, replace Motor.

and mild cleaning agent.

2. If Lens is damaged or scratched, replace the sensor.

Timer Motor should turn. “No” replace Timer Assembly.

1. Hand Dryer should be mounted a minimum of 18” above a reective surface.

2. Check if other Infrared operated appliance in the vacinity may be triggering the Dryer.

3. Multiple Hand Dryers on one circuit or Dryers sharing a lighting circuit. Automatic

Hand Dryers must be on dedicated circuits.

4. Building wiring may be insufcient gauge or too long of a run from the supply.

5. Replace the PCB and Sensor.

1. Check for break in Element Wire.

2. Check Heating Element and Thermostat for continuity. If open, replace as necessary.

2. Replace motor if running slow or erratic.

1. Fan may be rubbing against edge of Fan Housing. To center Fan;

a. On plastic fan unit, carefully “tap” the Fan Hub with a screw driver & small hammer

to center it until the Fan turns freely.

b. On metal fans, loosen the set screw and adjust the fan until it turns freely.

1. Inspect for foreign material. Using a soft brush and vacuum, clean fan and motor.

1. Replace Fan.

1. Replace Motor.

Limited Warranty

WORLD DRYER LIMITED TEN – YEAR WARRANTY. World Warm Air Hand Dryer, Model covered in this manual, is warranted by World Dryer Corporation to the

original user against defects in workmanship or materials under normal use for 10 years, the motor and electronics are warrantied for 5 years after date of purchase. Any part

which is determined to be defective in material or workmanship and returned to an authorized service location, as World designates, shipping costs prepaid, will be, as the

exclusive remedy, repaired or replaced at World’s option. For limited warranty claim procedures, see PROMPT DISPOSITION below. This limited warranty gives purchasers

specic rights from jurisdiction to jurisdiction.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, World’s liability for consequential and incidental damages is expressly disclaimed. World’s

liability in all events is limited to and shall not exceed the purchase price paid.

WARRANTY DISCLAIMER. World has made a diligent effort to provide product information and illustrate the products in this literature accurately; however, such infor-

mation and illustrations are for the sole purpose of identication, and do not express or imply a warranty that the products are MERCHANTABLE, or FIT FOR A PARTICULAR

PURPOSE, or that the products will necessary conform to the illustrations or descriptions. Except as provided below, no warranty or afrmation on fact, expressed or implied,

other than as stated in the “LIMITED WARRANTY” above is made or authorized by World.

PRODUCT SUITABILITY. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of products for certain purposes, which

may vary from those in neighboring areas. While World attempts to assure that the products comply with such codes, it cannot guarantee compliance, and cannot be respon-

sible for how the product is installed or used. Before purchase and use of a product, review the product application, and all applicable national and local codes and regulations,

and be sure that the product, installation, and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer products; e.g., (a) some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you; (b) also, some jurisdictions do not allow a limitation on how long an implied warranty lasts, consequentially

the above limitation may not apply to you; and (c) by law, during the period of this Limited Warranty, and implied warranties of implied merchantability or tness for particular

purpose applicable to consumer products purchased by consumers, may not be excluded or otherwise disclaimed.

Manufactured by World Dryer Corporation, Berkeley, Illinois 60163 U.S.A.

PROMPT DISPOSITION. World will make a good faith effort for prompt correction or other adjustment with respect to any product which proves to be defective within

limited warranty. For any product believed to be defective within limited warranty, rst write or call dealer from whom the product was purchased. Dealer will give additional

directions. If unable to resolve satisfactorily, write to World, giving dealer’s name, address, date, and number of dealer’s invoice, and describing the nature of defect. Title and

risk of loss pass to buyer on delivery to common carrier. If product was damaged in transit to you, le claim with carrier.

English

8

Page 9

Descripción

El secamanos por aire caliente de alto rendimiento World Dryer, empotrado y compatible con ADA, es accionado por un motor universal de

alta velocidad y suministra 2300 vatios de potencia de secado. Este secamanos funciona con un suministro eléctrico de 115 voltios de CA

o 208/220-240 voltios de CA, dependiendo del modelo. Este grupo de productos incluye modelos automáticos y de activación por botón

pulsador. Este aparato ha sido diseñado para uso como un secador de manos, lo cual contribuye a una limpieza rápida, higiénica y costo-

efectiva de las manos. Este secamanos se puede usar en entornos comerciales, industriales, de ocinas e instalaciones públicas.

Especicaciones Generales

Modelos Boquilla Tiempo de secado Dimensiones (A x P x Al) Peso Material de la cubierta

XRM Fija Automático 333 mm x 351 mm x 102 mm 13,1 x 13,8 x 4 pulg. 12 kg / 26,5 lb. Acero inoxidable

XRM Fija Automático 333 mm x 351 mm x 102 mm 13,1 x 13,8 x 4 pulg. 15,9 kg / 35 lb. Hierro fundido

RM Fija 20 segundos 333 mm x 351 mm x 102 mm 13,1 x 13,8 x 4 pulg. 15,9 kg / 35 lb. Hierro fundido

Especicaciones del Sistema Eléctrico

Modelos Tipo Entrada eléctrica Amperaje Vatios

XRM5 Automático 115 VCA, 60 Hz 20 2300

RM5 Botón pulsador 115 VCA, 60 Hz 20 2300

XRM54 Automático 208-230 VCA, 60 Hz 10 2300

RM54 Botón pulsador 208-230 VCA, 60 Hz 10 2300

XRM548 Automático 220-240 VCA, 50 Hz 10 2300

RM548 Botón pulsador 220-240 VCA, 50 Hz 10 2300

(Clasicación cULus, E19860, CE TUV-GS)

Información de Seguridad General

No desconectar la fuente de alimentación eléctrica antes de realizar la instalación o el

PELIGRO

• Siempre desconecte la fuente de alimentación antes de instalar el secamanos o darle mantenimiento.

PELIGRO

• Para utilizar este secamanos sin peligro, debe conectarse a tierra correctamente. En la base mural del secamanos se identica un punto de

conexión a tierra.

• Recomendamos utilizar un protector GFCI (interruptor de circuito de fallo a tierra) en emplazamientos mojados o húmedos, o donde lo exija

el código local.

ADVERTENCIA

• Utilice únicamente la energía eléctrica (voltaje y frecuencia) especicada para el modelo de secamanos que se esté instalando.

• Conecte el secamanos en el panel de distribución adecuado más cercano.

• Para limitar las caídas de voltaje, y garantizar un funcionamiento eciente, utilice el tamaño adecuado de conductor de acuerdo con los

requisitos de su localidad o del código eléctrico nacional.

• No conecte la unidad en un circuito ramal con protección de un cortacircuito o fusible de más de 20 amperios. Esto es de acuerdo con la

norma del Código Eléctrico Nacional.

• Todos los modelos automáticos de secamanos deben tener un circuito dedicado de 20 amperios para satisfacer los requisitos de

Underwriters Laboratories, Inc. (UL).

• Encamine todo el cableado realizado durante la instalación lejos de todas las partes móviles dentro del secamanos.

ATENCIÓN

mantenimiento puede resultar en lesiones graves o la muerte debido a un choque eléctrico.

No conectar correctamente a tierra esta unidad puede resultar en un choque eléctrico grave

y/o la muerte.

Los siguientes: riesgo de incendio, lesiones personales o daño a la propiedad son

posibles si no se cumple con los códigos locales, el código eléctrico nacional

(NEC) estadounidense o las recomendaciones de seguridad.

El montaje incorrecto puede ocasionar lesiones personales o daños materiales.

Desembalaje

1. Retire todos los materiales de embalaje. Se recomienda reciclar los materiales.

2. Extraiga cuidadosamente el secamanos de la caja de envío, sin dejar caer el aparato.

3. Inspeccione el producto cuidadosamente para vericar si se han producido daños durante el transporte. Revise para vericar si hay partes

sueltas, que faltan o que están dañadas. Si el secamanos está dañado, infórmele prontamente sobre dicho daño al consignador o al

concesionario de quien compró el secamanos.

9

Español

Page 10

Instalación

IMPORTANTE: Consulte los reglamentos locales y generales antes de realizar la instalación del secador. Verique que la red eléctrica

no esté sobrecargada. No conecte la unidad a un circuito derivado cuyo cortacircuito o fusible sobrepase los 20 amperios. Ésta es

una recomendación de UL y cumple con la norma del NEC.

A) DESCONECTE LA FUENTE DE ALIMENTACIÓN.

B) Precauciones de Montaje y Acabado:

1) Monte la caja de embutir del secamanos a la altura que se recomienda en la

Tabla n.º 1.

2) Monte la caja a ras de la cavidad, no más de 3,2 mm por detrás de la supercie

acabada de la pared, para que quede correctamente empotrada.

3) Se recomienda calafatear DESPUÉS de instalar el conjunto de la base de aluminio,

para dar un aspecto acabado y evitar que le entre agua al aparato (si se calafatea

antes de instalar, puede entorpecerse el montaje).

C) Montaje de la Caja de Embutir de Acero:

ATENCIÓN: Para que el aparato quede instalado correctamente, es necesario

instalar la base en la caja de embutir de acero que se proporciona.

1) Sitúe la caja de embutir de acero en el lugar de la pared que interese, de manera

que el borde inferior quede a la altura que se especica en la Tabla n.º 1.

2) Si se instalan más de un secador, deben separarse al menos 61 cm de centro a centro.

3) Para montar la caja de embutir, encuadre la abertura en la pared de acuerdo con la Figura n.º 1.

4) Haga que una abertura del encuadre corresponda con el agujero ciego de la caja de embutir que usted preera, para facilitar el acceso

del conducto portacables.

5) Monte la caja de embutir en la abertura. Fije con tornillos para madera n.º 10 (M5) o con los aanzadores que corresponda, según sea necesario.

6) Valiéndose del tablero de distribución correspondiente más próximo, pase el conducto portacables.

7) Según lo exija el código eléctrico regional o el NEC, utilice un conductor de calibre n.º 12 o mayor para limitar la caída de voltaje y

garantizar un funcionamiento eciente.

8) Para evitar que se enciendan accidentalmente como consecuencia de uctuaciones del voltaje, los secamanos automáticos deben

instalarse en circuitos dedicados de 20 A, es decir, no deben utilizarse circuitos conmutados de luces ni ningún otro circuito al que estén

conectados artefactos con interruptor.

9) El conductor debe tener al menos 61 cm de longitud en la caja de embutir para facilitar la conexión de los terminales del secamanos.

Tabla 1

Alturas de montaje recomendadas

desde el suelo hasta la parte

inferior del secamanos

Baños de hombres 107 (42)

Baños de mujeres 102 (40)

Baños de niños, 4 a 7 años de edad 71 (28)

Baños de niños, 7 a 10 años de edad 81 (32)

Baños de niños, 10 a 13 años de edad 91 (36)

Baños de niños, 13 a 17 años de edad 102 (40)

Altura de montaje para discapacitados 86 (34)

cm

(pulg)

D) Montaje del secamanos en la caja de embutir:

1) Elimine todo el embalaje, incluidos los protectores de caucho de las esquinas de la cubierta del secamanos, si los trajera.

2) Utilice la llave Allen de seguridad suministrada para extraer los (2) tornillos de montaje de la cubierta. Retire la cubierta del conjunto de la

base del secamanos.

ATENCIÓN: Las cubiertas de fundición con esmalte de porcelana deben manipularse con cuidado. No se deben dejar caer

ni golpear contra supercies duras, para evitar dañar el esmalte de porcelana.

3) Introduzca el conjunto de base en la caja de embutir que se ha montado previamente.

4) Frente al secamanos, la carcasa del soplador debe quedar instalada en el costado izquierdo.

5) Fije la base a la caja de embutir con los cuatro (4) tornillos 1/4-20 que se proporcionan.

6) Pase los conductores por las

aberturas del conjunto de la base.

7) Conecte el cableado de campo al

bloque de terminales identicado

como (L / N, L1 / L2).

8) Conecte rmemente un cable

de tierra conrmado al tornillo

de conexión a tierra.

PELIGRO: Este secamanos

debe conectarse a tierra

(ponerse a tierra) correctamente.

ATENCIÓN: Dirija el cableado

de campo de manera de evitar

todas las piezas móviles y

los bordes cortantes.

9) Instale la cubierta del secamanos

con los dos (2) tornillos de

montaje. Para evitar que se

pique el esmalte de porcelana,

no apriete demasiado.

8,9 cm

SECCIÓN “A”

BORDE A RAS

DE LA CAVIDAD

3,2 mm MÁX.

3,2 cm

CAJA DE ACERO

CALIBRE 16

ABERTURA

DE 31,75 cm

8 AGUJEROS

DIMENSIÓN “A”

VER TABLA

CIEGOS

7/8 pulg. +

1 1/8 pulg.

Figura 1

7,6 cm

7,6 cm

3,2 cm

3,2 cm

7,6 cm

7,6 cm

A

ABERTURA

DE 29,85 cm

A

7,6 cm

7,6 cm

3,2 cm

3,2 cm

7,6 cm

7,6 cm

8 AGUJEROS PARA

TORNILLOS PARA

MADERA n.º 10

Español

LA INSTALACIÓN DEBE SER REALIZADA POR PERSONAL ELÉCTRICO CALIFICADO.

10

Page 11

Lista de Piezas

Figura 2 – Lista de Piezas para Secamanos

Para información sobre

repuestos, visite

www.WorldDryer.com

Por favor proporcione la

siguiente información:

Número de modelo

Número de serie

Descripción de la pieza

y número indicados

en la lista de partes

25

20

13

15

12

16

22

10

14

9

11

5

18

3

21

24

19

23

17

4

2

1

6

7

8

11

Español

Page 12

Descripción Número de Parte Cant.

#

1 Abrazadera del deector del motor 23-100 1

2 Deector del motor 127HS 1

3 Motor XRM5, RM5 32-120K 1

3 Motor XRM54, RM54, XRM548, RM548 32-230K 1

4 Escobilla de motor 206NL 2

5 Abrazadera de montaje del motor 110-4A 2 juegos

6 Soportes de montaje del motor 110-4 2

7 Microinterruptor solamente RM (todos) 143F 1

8 Unidad de temporización del interruptor RM5 125XMK 1

8 Unidad de temporización del interruptor RM54 125AMK 1

8 Unidad de temporización del interruptor RM548 125MCEK 1

9 Cubierta completa, fundición, funcionamiento automático, color blanco XRM (todos)* 703XM5-974AK 1

9 Cubierta completa, fundición, de pulsador, color blanco RM (todos)* 703M5-974AK 1

9 Cubierta completa, acero inoxidable, funcionamiento automático, acabado cepillado XRM (todos)* 713DXM5-Q973AK 1

10 Unidad de adaptador de pulsador, empaquetadura y buje RM (todos) 190K 1

11 Juego de anillo de retención, punta de varilla de empuje aislada y resorte para pulsador RM

(todos)

12 Llave Allen de seguridad, cubierta de fundición 204TP 1

12 Llave Allen de seguridad, cubiertas de acero 56-006565 1

13 Rejilla de entrada, fundición, de pulsador, con tornillería de montaje RM (todos) 194-3K 1

Rejilla de entrada, fundición, funcionamiento automático, con tornillería de montaje XRM (todos) 194-3XRAK 1

r13

14 Tornillo resistente a manipulaciones para la cubierta, cubiertas de fundición XRM, RM (todos) 100B3 1

14 Tornillo resistente a manipulaciones para la cubierta, cubiertas de fundición XRM (todos) 46-005023 1

15 Juego del conjunto de la boquilla 34-173K 1

16 Juego del conjunto del pulsador (perilla, varilla, anillo, resorte y punta) RM (todos) 185K 1

17 Termostato solamente 19 mm (3/4 pulg) 1111- 0 3 1

18 Mitad de la voluta del soplador con montaje en la base y termostato 211 PA 1

19 Pieza de metal del ventilador 101i 1

20 Mitad de la voluta del soplador, lado izquierdo 112P 1

21 Elemento calentador XRM5, RM5 213XM 1

21 Elemento calentador XRM54, RM54, XRM548, RM548 213AM 1

22 Placa de identicación, de pulsador RM (todos)* 38-225 1

22 Placa de identicación, funcionamiento automático XRM (todos)* 38-226 1

23 Caja de embutir (todos) 17-034 1

24 Bloque de terminales (todos) 156-3 1

193K 1

25 Rejilla, montaje de tierra (todos) 12-001 1

Control de sensor automático, 115V, XRM5 16-230-120 RAK 1

r

Control de sensor automático, 208-230 V, XRM54 16-240-208 RAK 1

r

Control de sensor automático, 220-240 V, 50 Hz CE solamente XRM548 16-230-240 CEK 1

r

Filtro electrónico, 50 Hz CE solamente XRM548, RM548 110-2 1

r

* Especique el modelo en su pedido.

r No se muestra.

Español

12

Page 13

Mantenimiento

AVISO: Desconecte la alimentación eléctrica antes de efectuar cualquier de estos procedimientos

INSTRUCCIONES DE LIMPIEZA:

Lea todas las instrucciones antes de proceder. Bajo uso normal, la limpieza del Secador una vez al año lo mantendrá en buena condición

de funcionamiento. Si el tráco en el baño es más pesado que lo normal, la limpieza debe realizarse cada 6 meses. Las acumulaciones de

pelusas y polvo dentro del secador pueden dañar el motor y el elemento calentador, y también pueden producir emisiones calientes que

podrían lesionar a los usuarios.

1. Extraiga dos tornillos de montaje de la cubierta del secador usando la llave Allen de seguridad suministrada. Sujete la cubierta mientras

extrae los tornillos.

2. Extraiga tres (3) tornillos laterales que sujetan la carcasa del soplador. Observe la posición del elemento calentador y de la pantalla

protectora. Los conductores principales atraviesan el agujero pasante en las mitades de la carcasa del soplador. Retire cuidadosamente

el elemento calentador, pero sin desconectar los conductores.

3. Limpie las mitades de la rueda del soplador usando un cepillo cilíndrico de cerdas radiales de 12,7 mm (1/2 pulg.) de diámetro. Inserte

el cepillo en los espacios entre las paletas individuales y desaloje la suciedad. No doble ni dañe las aspas.

4. Aspire la suciedad del secador y de la carcasa, vuelva a colocar el elemento calentador, la pantalla protectora y la mitad de la carcasa,

y reinstale los tres (3) tornillos laterales. Apriete ligeramente y asegúrese que las piezas del elemento calentador de mica estén situadas

en las ranuras de la carcasa y los conductores de conexión pasen a través del agujero en la carcasa del soplador.

5. Use una brocha para pintar de cerdas medio-suave de 12,7 mm (1/2 pulg.) para limpiar el polvo y la suciedad del motor y del temporizador

interruptor. No doble las paletas del interruptor cuando limpie el mismo.

6. Utilice un cepillo de cerdas rmes para limpiar la suciedad del interior de la rejilla de la boquilla y de la rejilla de entrada. Quizá se necesite

agua para purgar la suciedad de la rejilla de entrada. Si se utiliza agua, seque el interior de la cubierta antes de volverla a montar.

7. Inspeccione las escobillas del motor. Para inspeccionar las escobillas, inserte un palillo de dientes en el agujero en el extremo del

conjunto de la escobillas. Si puede insertar el palillo de dientes más de 2,5 cm, reemplace las escobillas. (Consulte las instrucciones

de reemplazo).

8. Vuelva a instalar la cubierta. Coloque la cubierta encuadrada sobre la base y presiónela hasta que esté al ras contra la pared. Inserte

dos (2) tornillos de montaje de la cubierta y apriételos hasta que estén ajustados. No los apriete demasiado.

REEMPLAZO DE LAS ESCOBILLAS DEL MOTOR

1. Retire la presilla de resorte de jación que sujeta el portaescobillas.

2. Saque lentamente la tapa de la escobilla fuera del motor hasta que aparezca el conector del conductor.

3. Desconecte el conector del conductor y retire el conjunto del portaescobilla y la escobilla.

AVISO: Cuando desembale el conjunto de las escobillas de la caja de envío, es importante mantener rmemente sujetada la

escobilla de carbón en el portaescobillas. P/N 206NL

4. Inserte el conjunto nuevo en el punto donde se pueda hacer la conexión rápida del conductor.

5. Conecte a presión los manguitos de las escobillas en los conectores rápidos para escobillas en el motor.

6. Vuelva a colocar el conjunto de las escobillas en su lugar e inserte la presilla de resorte de jación.

REEMPLAZO DEL ELEMENTO CALENTADOR

1. Extraiga los tres tornillos que unen las partes de la carcasa del soplador (n.os 211P y 112P), y retire el lado n.º 112P de la carcasa.

2. Desconecte los conductores blancos del elemento calentador en el bloque de terminales y de las terminales del interruptor. Instale

el nuevo elemento calentador con tensión y vataje correctos, observando la misma conexión que se utilizó con el elemento

calentador antiguo.

3. Inmovilice el elemento en el lado jo de la carcasa del soplador y deslice el lado desmontable a su lugar, vericando que las estructuras

del elemento encajen en las ranuras de la carcasa del soplador y que ambos conductores pasen a través de la muesca en la parte

superior de la salida de aire. Reinstale la pantalla protectora y los tres tornillos que unen las partes de la carcasa del soplador.

4. Vuelva a conectar los conductores al bloque de terminales y al interruptor. Verique que todos los conductores queden debidamente

reconectados, prestando atención al diagrama de cableado.

REEMPLAZO DEL TEMPORIZADOR DEL INTERRUPTOR (MODELOS RM)

1. Extraiga los tornillos de cada una de las dos terminales en el temporizador interruptor, y marque los conductores para poder volverlos

a conectar correctamente en las terminales del interruptor.

2. Reemplace el temporizador defectuoso con uno nuevo. (Especique el Modelo de Secador cuando pida el Temporizador).

3. Vuelva a conectar los conductores en las terminales.

4. Vuelva a instalar la cubierta (asegurándose que la cubierta encaje perfectamente sobre la unidad base) y presiónela hacia adentro hasta

que la cubierta esté al ras con la pared e inserte los dos tornillos de montaje de la cubierta. No apriete demasiado los tornillos de montaje.

5. Conecte la alimentación eléctrica para el secador.

13

Español

Page 14

Diagrama de Cableado

L1

L2

Interruptor

Termostato

Elemento

calefactor

Temporizador

240 V

Motor

240 V

Conductor blanco-Elemento calefactor

L1 L1

L2

N

L1

L2

Interruptor

Interruptor

Termostato

Termostato

Termostato

Elemento

calefactor

Elemento

calefactor

Elemento

calefactor

Temporizador

120 V

Motor

120 V

Temporizador

240 V

Motor

240 V

Motor

208/230

VCA

Sensor de

IR 49-238

Placa de circuitos impresos 16-240

Relé Relé

Transformador

230 VCA

120 VCA

Com

Bloque de

terminales

alojamiento

soplador

Conductor rojo - Termostato

Conductor negro alimentación línea 1

Conductor blanco transformador línea 2

Conductor negro-Motor

Conductor rojo-Motor

Conductor marrón

transformador línea 1

Conductor negro

alimentación línea 2

L2

Interruptor

Termostato

Elemento

calefactor

Temporizador

240 V

Motor

240 V

Conductor blanco-Elemento calefactor

L1 L1

L2

N

L1

L2

L1

N

Interruptor

Interruptor

Termostato

Termostato

Termostato

Termostato

Termostato

Elemento

calefactor

Elemento

calefactor

Elemento

calefactor Elemento

calefactor

Elemento

calefactor

Temporizador

120 V

Motor

120 V

Temporizador

240 V

Motor

240 V

Motor

Motor

120 VCA

208/230

VCA

Sensor de

IR 49-238

Sensor de

IR 49-238

Placa de circuitos impresos 16-230

Placa de circuitos impresos 16-240

Relé Relé

Relé

Transformador

Transformador

Bloque de

terminales

alojamiento

soplador

230 VCA

120 VCA

Com

230 VCA

120 VCA

Com

Motor

Relé

Control

Transformador

230 VCA

120 VCA

Com

12 VCC

22 VCA

Filtro EMC

L - 2 X 2,1 MH

C - 0,47 UF (X2) SH

-2X 0,001 UF (Y2)

R - 680 K Ohmios

Conductor blanco neutro motor

Conductor blanco neutro elemento calefactor

Bloque de

terminales

alojamiento

soplador

Conductor negro alimentación 120 V

Conductor rojo - Termostato

Conductor blanco neutro transformador

Conductor negro transformador 120 V

Conductor rojo-Motor

Conductor rojo - Termostato

Conductor negro alimentación línea 1

Conductor blanco transformador línea 2

Conductor negro-Motor

Conductor rojo-Motor

Conductor marrón

transformador línea 1

Conductor negro

alimentación línea 2

Esquemas Eléctricos World Dryer

con Filtro EMC 230 V 50 Hz

para Modelos de Exportación

Caution: Route

Wires Away

From Moving

Parts

Atención: Dirija

el cableado

de manera

de evitar las

piezas móviles

Attention :

Acheminer

les fils à l’écart

des pièces

mobiles

L1

L2, N

E

Conductor blanco-Elemento calefactor

L2

L1

L2

Interruptor

Termostato

Termostato

Elemento

calefactor

calefactor

Temporizador

240 V

Motor

240 V

Motor

208/230

VCA

Sensor de

IR 49-238

Placa de circuitos impresos 16-240

Relé Relé

Transformador

230 VCA

120 VCA

Com

Bloque de

terminales

alojamiento

soplador

Conductor rojo - Termostato

Conductor negro alimentación línea 1

Conductor blanco transformador línea 2

Conductor negro-Motor

Conductor rojo-Motor

Conductor marrón

transformador línea 1

Conductor negro

alimentación línea 2

Diagrama de Cableado - Modelo RM5

L1

Elemento

Interruptor

Diagrama de Cableado - Modelo XRM5

Bloque de

terminales

alojamiento

soplador

L1

120 VCA

N

Diagrama de Cableado - Modelo RM548

Conductor negro transformador 120 V

Conductor blanco neutro transformador

Termostato

Conductor blanco neutro motor

Conductor blanco neutro elemento calefactor

Conductor negro alimentación 120 V

Conductor rojo - Termostato

230 VCA

120 VCA

Com

Placa de circuitos impresos 16-230

Transformador

calefactor

Temporizador

120 V

Motor

120 V

Motor

Elemento

calefactor

Termostato

Relé

Conductor rojo-Motor

N

Sensor de

IR 49-238

Diagrama de Cableado - Modelo RM54

L1

Elemento

Interruptor

Diagrama de Cableado - Modelo XRM54

Bloque de

terminales

alojamiento

soplador

208/230

VCA

Diagrama de Cableado - Modelo XRM548

L1

L2

Conductor blanco transformador línea 2

calefactor

Conductor negro

alimentación línea 2

Conductor negro alimentación línea 1

Conductor rojo - Termostato

230 VCA

120 VCA

Conductor marrón

transformador línea 1

Com

Placa de circuitos impresos 16-240

Transformador

Termostato

Temporizador

240 V

Motor

240 V

Motor

Elemento

calefactor

Termostato

Relé Relé

Conductor blanco-Elemento calefactor

Conductor negro-Motor

Conductor rojo-Motor

Sensor de

IR 49-238

L2

Esquemas Eléctricos World Dryer

con Filtro EMC 230 V 50 Hz

para Modelos de Exportación

Caution: Route

Wires Away

From Moving

Parts

Atención: Dirija

el cableado

de manera

de evitar las

piezas móviles

L1

L2, N

Filtro EMC

L - 2 X 2,1 MH

E

Español

C - 0,47 UF (X2) SH

-2X 0,001 UF (Y2)

R - 680 K Ohmios

Attention :

Acheminer

les fils à l’écart

des pièces

mobiles

Interruptor

Termostato

temporizador

Motor

Elemento

calefactor

Motor

Esquemas Eléctricos World Dryer

con Filtro EMC 230 V 50 Hz

para Modelos de Exportación

L1

Atención: Dirija

el cableado

de manera

de evitar las

piezas móviles

Caution: Route

Wires Away

From Moving

Parts

L2, N

14

E

Filtro EMC

L - 2 X 2,1 MH

C - 0,47 UF (X2) SH

-2X 0,001 UF (Y2)

R - 680 K Ohmios

Attention :

Acheminer

les fils à l’écart

des pièces

mobiles

Termostato

Transformador

230 VCA

120 VCA

Com

Motor

Elemento

calefactor

Relé

12 VCC

22 VCA

Control

Page 15

Tabla de Identicación de Problemas

Síntoma Modelo Causa(s) Posible(s) Medida Correctiva

El secador no arranca. XRM Sensor obstruido 1. Compruebe que la lente del sensor no esté sucia ni tenga materias extrañas. Limpie la

El secador funciona aprox.

100 segundos y ya no

vuelve a encenderse.

El secamanos funciona de

forma continua y no se apaga.

El secamanos arranca

espontáneamente, sin que se

coloquen las manos debajo.

El aire que expulsa el

secamanos es frío.

El aire que expulsa el

secamanos es demasiado

caliente.

El secamanos produce

ruido o vibra.

Todos La unidad no recibe

XRM Placa de circuitos impresos

XRM Motor averiado Si la unidad no arranca, a pesar de producirse el chasquido del relé y encenderse el

RM Temporizador o interruptor

XRM Sensor obstruido 1. Compruebe que la lente del sensor no esté sucia ni tenga materias extrañas. Limpie la

RM Temporizador averiado Quite la cubierta del secamanos y oprima la paleta del interruptor con temporizador;

XRM El sensor está recibiendo

Todos Elemento calentador o

Todos La máquina está sucia 1. Examine para vericar la presencia de materias extrañas. Con un cepillo suave y una

Todos Ventilador descentrado en

alimentación eléctrica

y sensor averiados

averiados

Motor averiado

una señal falsa o el reejo

de alguna supercie

O

La alimentación eléctrica

uctúa

termostato defectuosos

la carcasa

■ Presencia de objeto extraño

en el ventilador.

■ Ventilador roto o doblado.

■ Eje del motor doblado.

lente con un trapo suave y húmedo, y un producto de limpieza suave.

2. Si la lente está dañada o rayada, reemplácela.

Compruebe que la unidad esté encendida.

Revise las conexiones eléctricas.

Ponga las manos debajo del sensor. Preste atención al chasquido del relé de la placa de

circuitos impresos. Si no se escucha, reemplace la placa de circuitos impresos y el sensor.

elemento calentador 1 ó 2 segundos, reemplace el motor.

Quite la cubierta del secamanos y oprima la paleta del interruptor con temporizador;

a. El motor del temporizador debe arrancar.

b. Con un ohmímetro, verique la continuidad entre los terminales del interruptor.

Si la respuesta es negativa en alguna de las pruebas, reemplace el conjunto del temporizador;

Si la respuesta es armativa en ambas pruebas, reemplace el motor.

lente con un trapo suave y húmedo, y un producto de limpieza suave.

2. Si la lente está dañada o rayada, reemplace el sensor.

El motor del temporizador debe arrancar. Si la respuesta es negativa, reemplace

el conjunto del temporizador.

1. El secamanos debe montarse al menos 45,7 cm por encima de las supercies

reectantes.

2. Verique si hay algún otro artefacto accionado por infrarrojos cerca del secamanos que

pueda estar activándolo.

3. Hay varios secamanos en un mismo circuito, o los secamanos comparten un circuito de

luces. Los secamanos automáticos deben instalarse en circuitos dedicados.

4. El cableado de la edicación tiene un calibre insuciente o se extiende demasiado desde

la alimentación eléctrica.

5. Reemplace la placa de circuitos impresos y el sensor.

1. Verique si está roto el conductor del elemento.

2. Verique la continuidad en el elemento calentador y el termostato. Si no hay continuidad,

reemplace según sea necesario.

aspiradora, limpie el ventilador y el motor.

2. Reemplace el motor, si el funcionamiento es lento o irregular.

1. Es posible que el ventilador esté rozando con el borde de la carcasa del ventilador.

Para centrar el ventilador:

a. En ventiladores de plástico, golpee con cuidado el cubo del ventilador con un

destornillador y un martillo pequeño para centrarlo, hasta que el ventilador gire libremente.

b. En ventiladores de metal, aoje el tornillo prisionero y ajuste el ventilador hasta que gire

libremente.

1. Examine para vericar la presencia de materias extrañas. Con un cepillo suave y una

aspiradora, limpie el ventilador y el motor.

1. Reemplace el ventilador.

1. Reemplace el motor.

Garantía Limitada

GARANTÍA LIMITADA DE DIEZ AÑOS DE WORLD DRYER. World Dryer Corporation le garantiza al usuario original que el modelo del secamanos de aire caliente World

Dryer tratado en este manual estará libre de defectos de fabricación y materiales si se somete a un uso normal por diez años, el motor y la electrónica tienen una garantía de cinco años

a partir de la fecha de compra. Cualquier pieza que se halle defectuosa, ya sea por materiales o construcción, y se devuelva a un centro de reparación autorizado, según lo indique

World Dryer, con los costos de envío pagados por adelantado, se reparará o reemplazará, como remedio exclusivo, a la discreción de World Dryer. Para información relacionada con

los procedimientos de reclamación provistos por la garantía limitada, consulte más adelante la sección ATENCIÓN OPORTUNA. Esta garantía limitada conere al comprador derechos

especícos que varían de una jurisdicción a otra.

LÍMITES DE RESPONSABILIDAD. En la medida en que las leyes aplicables lo permitan, se excluye expresamente la responsabilidad de World Dryer por daños indirectos o

menores. La responsabilidad de World Dryer se limita al precio de compra pagado, al cual no sobrepasará.

EXCLUSIÓN DE RESPONSABILIDAD DE LA GARANTÍA. World Dryer se ha esforzado diligentemente en proporcionar a través de este manual información e

ilustraciones concernientes al producto; sin embargo, esta información y estas ilustraciones tienen como único n la identicación del producto, y no expresan ni implican garantía de que

los productos sean VENDIBLES o ADECUADOS A UN PROPÓSITO EN PARTICULAR, ni que se ajusten necesariamente a las ilustraciones o descripciones. Con excepción de lo que

se establece a continuación, World Dryer no hace ni autoriza ninguna garantía o armación de hecho, expresa o implícita, que no se estipule en la “GARANTÍA LIMITADA” anterior.

ADECUACIÓN DEL PRODUCTO. Muchas jurisdicciones tienen códigos o regulaciones sobre la venta, el diseño, la instalación y/o el uso de productos para ciertas aplicaciones;

dichas leyes pueden variar de un área a otra. Si bien World Dryer trata de que los productos cumplan con estos códigos, no puede garantizar su cumplimiento ni puede hacerse

responsable de la forma en que se instale o utilice el producto. Antes de comprar y utilizar el producto, revise su aplicación y todos los códigos y reglamentos nacionales y locales

aplicables, y asegúrese de que el producto, la instalación y el uso los cumplan.

Ciertos aspectos de las limitaciones de responsabilidad no se aplican a los productos de consumo; es decir (a) algunas jurisdicciones no permiten la exclusión o limitación de daños

menores o indirectos, por lo cual la limitación o exclusión anterior quizás no se aplique en su caso; (b) asimismo, algunas jurisdicciones no permiten limitar el plazo de las garantías

implícitas, por lo cual la limitación anterior quizás no se aplique en su caso; y (c) por ley, mientras estén vigentes, no pueden excluirse ni de ninguna otra manera denegarse la

Garantía Limitada y las garantías implícitas de comerciabilidad o idoneidad para un propósito en particular implícitas que corresponden a los productos de consumo adquiridos por los

consumidores. Fabricado por World Dryer Corporation, Berkeley, Illinois 60163 U.S.A.

ATENCIÓN OPORTUNA. World Dryer hará un esfuerzo de buena fe para corregir oportunamente o hacer otros ajustes relacionados con cualquier producto que resulte defectuoso

dentro de los términos de esta garantía limitada. En el caso de que encuentre un producto defectuoso y que esté cubierto dentro de los límites de esta garantía haga el favor de escribir

primero, o llame, al distribuidor a quien le compró el producto. El distribuidor le dará las instrucciones adicionales. Si no logra resolver el problema de forma satisfactoria, escriba a World

Dryer, y proporcione el nombre y la dirección del distribuidor, así como la fecha y el número de su factura, y describa la naturaleza del defecto. La propiedad del artículo y el riesgo de

pérdida pasan al comprador en el momento de la entrega del artículo a la compañía de transporte. Si el producto se daña durante el transporte, debe presentar su reclamo a la

compañía transportista.

15

Español

Page 16

Description

Le sèche-mains à air chaud à moteur rapide universel et haute performance, conforme ADA et à montage encastré de World Dryer offre une

puissance de séchage de 2 300 watts. Ce sèche-mains fonctionne sur une alimentation électrique alternative de 115 volts ou de 208/220-240

volts, selon le modèle. Des modèles automatiques et à bouton-poussoir sont représentés dans cette gamme. Cet appareil est conçu pour

sécher les mains de façon sanitaire d’une manière rapide, hygiénique et économique. Ce sèche-mains est conçu pour être utilisé dans les

magasins, usines, bureaux et bâtiments publics.

Caractéristiques générales

Modèles Buse Cycle de séchage Dimensions (Lar. x P x H) Poids Matériau du carter

XRM Fixe Automatique 333 mm x 351 mm x 102 mm 13,1 po x 13,8 po x 4 po 12 kg / 26,5 lb Acier inoxydable

XRM Fixe Automatique 333 mm x 351 mm x 102 mm 13,1 po x 13,8 po x 4 po 15,9 kg / 35 lb Fonte

RM Fixe 20 secondes 333 mm x 351 mm x 102 mm 13,1 po x 13,8 po x 4 po 15,9 kg / 35 lb Fonte

Caractéristiques électriques

Modèles Type Consommation électrique Intensité Watts

XRM5 Automatique 115 V c.a., 60 Hz 20 2 300

RM5 Bouton-poussoir 115 V c.a., 60 Hz 20 2 300

XRM54 Automatique 208-230 V c.a., 60 Hz 10 2 300

RM54 Bouton-poussoir 208-230 V c.a., 60 Hz 10 2 300

XRM548 Automatique 220-240 V c.a., 50 Hz 10 2 300

RM548 Bouton-poussoir 220-240 V c.a., 50 Hz 10 2 300

(Homologation cULus, E19860, CE TUV-GS)

Consignes générales de sécurité

Le fait de ne pas débrancher la source d’alimentation avant de procéder à l’installation, à la

réparation ou à l’entretien peut entraîner des blessures graves ou mortelles résultant d’un

DANGER

• Toujours débrancher la source d’alimentation avant de réparer, d’entretenir ou d’installer le sèche-mains.

DANGER

• Ce sèche-mains doit être mis à la terre correctement pour fonctionner en toute sécurité. Un point de raccordement à la terre est identié

sur la base de xation murale du sèche-mains.

• Nous recommandons une protection par disjoncteur de fuite à la terre dans les endroits mouillés ou humides, ou si les normes locales

l’exigent.

AVERTISSEMENT

• N’utiliser que le type d’alimentation électrique (en matière de tension et fréquence) spécié pour le modèle de sèche-mains en cours

d’installation.

• Raccorder le sèche-mains au tableau de distribution adapté le plus proche.

• Pour limiter les chutes de tension et garantir un fonctionnement efcace, utiliser du l correspondant au calibre exigé par le code local ou

le code national de l’électricité.

• Ne pas raccorder l’appareil à un circuit de dérivation protégé par un disjoncteur ou un fusible de plus de 20 ampères. Cette exigence est

stipulée par du code national de l’électricité.

• Pour se conformer à l’homologation Underwriters Laboratories, Inc. (UL), tous les modèles automatiques de sèche-mains doivent être

installés sur un circuit dédié de 20 ampères.

• Faire passer l’ensemble du câblage sur site à l’écart des pièces mobiles qui sont à l’intérieur du sèche-mains.

ATTENTION

choc électrique.

Veiller à mettre cet appareil à la terre correctement an d’éviter un risque de choc électrique

grave, voire mortel.

Un risque d’incendie, de blessures ou de dommages matériels est possible en

cas d’inobservation des codes locaux, du code national de l’électricité ou des

recommandations de sécurité.

Un montage incorrect peut provoquer des accidents corporels et des dommages

matériels.

Déballage

1. Enlever tous les produits d’emballage. Il est recommandé de les recycler.

2. Sortir le sèche-mains du carton avec précaution, en veillant à ne pas le faire tomber.

3. Vérier soigneusement qu’aucun dommage n’est survenu durant le transport. Examiner les pièces pour vérier si certaines sont desserrées,

manquantes ou endommagées. Si le sèche-mains est endommagé, informer immédiatement l’expéditeur ou le concessionnaire qui l’a vendu.

français

16

Page 17

Installation

IMPORTANT : Consulter les réglementations locale et générale avant d’installer le sèche-mains. S’assurer que le réseau électrique

n’est pas surchargé. Ne pas raccorder l’appareil à un circuit de dérivation protégé par un disjoncteur ou un fusible de plus de 20 A.

Il s’agit d’une recommandation UL conforme à du code national de l’électricité.

A) COUPER LA SOURCE D’ALIMENTATION.

B) Précautions pour l’adaptation et la nition

1) Monter la boîte d’applique du sèche-mains à la hauteur recommandée au Tableau n°1.

2) Monter la boîte d’applique sans saillie à un maximum de 3,2 mm en-dessous de la

surface nie du mur pour un bon encastrement.

3) Il est recommandé de calfeutrer APRÈS l’installation de la base en aluminium pour

parfaire la nition et pour aider à protéger l’appareil de l’eau. (Le calfeutrage avant

l’installation peut créer un problème d’adaptation.)

C) Monter la boîte d’applique en acier

ATTENTION : L’installation correcte nécessite l’installation de la base dans la

boîte d’applique en acier fournie.

1) Placer la boîte d’applique en acier sur le mur à la position souhaitée, en prenant soin de

placer le bord inférieur de la boîte à la hauteur sélectionnée indiquée au Tableau n°1.

2) Lorsqu’on installe plusieurs sèche-mains, on doit observer une distance minimale de

séparation entre eux de 61 cm de centre à centre.

3) Pour monter la boîte d’applique, cadrer l’ouverture dans le mur selon la Figure n°1.

4) Laisser une ouverture dans l’ossature correspondant au placement préféré du branchement électrique pour la boîte d’applique an d’avoir

un accès facile à la conduite électrique.

5) Monter la boîte d’applique dans l’ouverture. Fixer avec les vis à bois n°10 (M5) ou les xations appropriées, le cas échéant.

6) En utilisant le tableau de distribution adapté le plus proche, poser la conduite électrique.

7) Pour limiter les chutes de tension et garantir un fonctionnement efcace, utiliser du l de calibre 12 ou plus gros si le code local ou national

de l’électricité l’exige.

8) Les sèche-mains automatiques nécessitent des circuits dédiés de 20 A pour éviter un démarrage automatique en raison des uctuations

de tension. Il faut donc également éviter les circuits d’éclairage à interrupteurs ou d’autres circuits où les équipements peuvent être

allumés ou éteints.

9) Laisser dépasser une longueur de câble minimale de 61 cm de la boîte d’applique pour permettre un branchement facile aux bornes

du sèche-mains.

Tableau 1

Hauteurs de montage recommandées

entre le sol et le bord inférieur du

sèche-mains

Toilettes pour hommes 107 (42)

Toilettes pour femmes 102 (40)

Toilettes pour enfants de 4 à 7 71 (28)

Toilettes pour enfants de 7 à 10 ans 81 (32)

Toilettes pour enfants de 10 à 13 ans 91 (36)

Toilettes pour enfants de 13 à 17 ans 102 (40)

Hauteur de montage pour personnes

handicapées

cm (po)

86 (34)

D) Monter le sèche-mains dans la boîte d’applique

1) Éliminer tout matériel d’expédition ou d’emballage, notamment les coins de protection en caoutchouc si présents sur le capot du sèche-mains.

2) Utiliser la clé mâle à six pans de sécurité fournie pour enlever les deux (2) vis de montage du capot. Enlever le capot de la base du

sèche-mains.

ATTENTION : Faire bien attention lors de la manipulation de capots en fonte à porcelaine émaillée. Ne pas laisser tomber ni

cogner contre des surfaces dures an d’éviter d’endommager la porcelaine émaillée.

3) Insérer la base dans la boîte d’applique prémontée.

4) Lorsqu’en face du sèche-mains, le carter de la soufante doit se trouver à gauche lors de l’installation.

5) Visser la base sur la boîte

d’applique avec les 4 vis

1/4-20 fournies.

6) Faire passer les câbles par

les ouvertures de la base.

7) Brancher les câbles de la

conduite électrique au bornier

identié (L / N, L1 / L2).

BORD À NIVEAU AVEC

L’ENCASTREMENT

À 3,2 mm MAX.

Figure 1

7,6 cm

7,6 cm

A

7,6 cm

3,2 cm

3,2 cm

7,6 cm

8) Bien serrer un l de mise à la

terre vérié à la vis de la borne

de terre.

DANGER : Ce sèche-mains doit

être correctement mis à la terre.

ATTENTION : Acheminer les

ls de la conduite électrique

à l’écart de toute pièce mobile

ou bords coupants.

9) Installer le capot du sèche-mains

avec les (2) vis de montage. Pour

éviter d’écailler la porcelaine

8,9 cm

SECTION « A »

3,2 cm

BOÎTE EN ACIER

DE CALIBRE 16

OUVERTURE

DE 31,75 cm

8 ORIFICES

7/8 PO + 1 1/8 PO

DIMENSION « A »

VOIR TABLEAU

7,6 cm

3,2 cm

3,2 cm

7,6 cm

OUVERTURE

DE 29,85 cm

A

7,6 cm

7,6 cm

8 ORIFICES POUR

VIS À BOIS N°10

émaillée, ne pas trop serrer.

TOUTE INSTALLATION DOIT ÊTRE EFFECTUÉE PAR UN ÉLECTRICIEN AGRÉE.

17

français

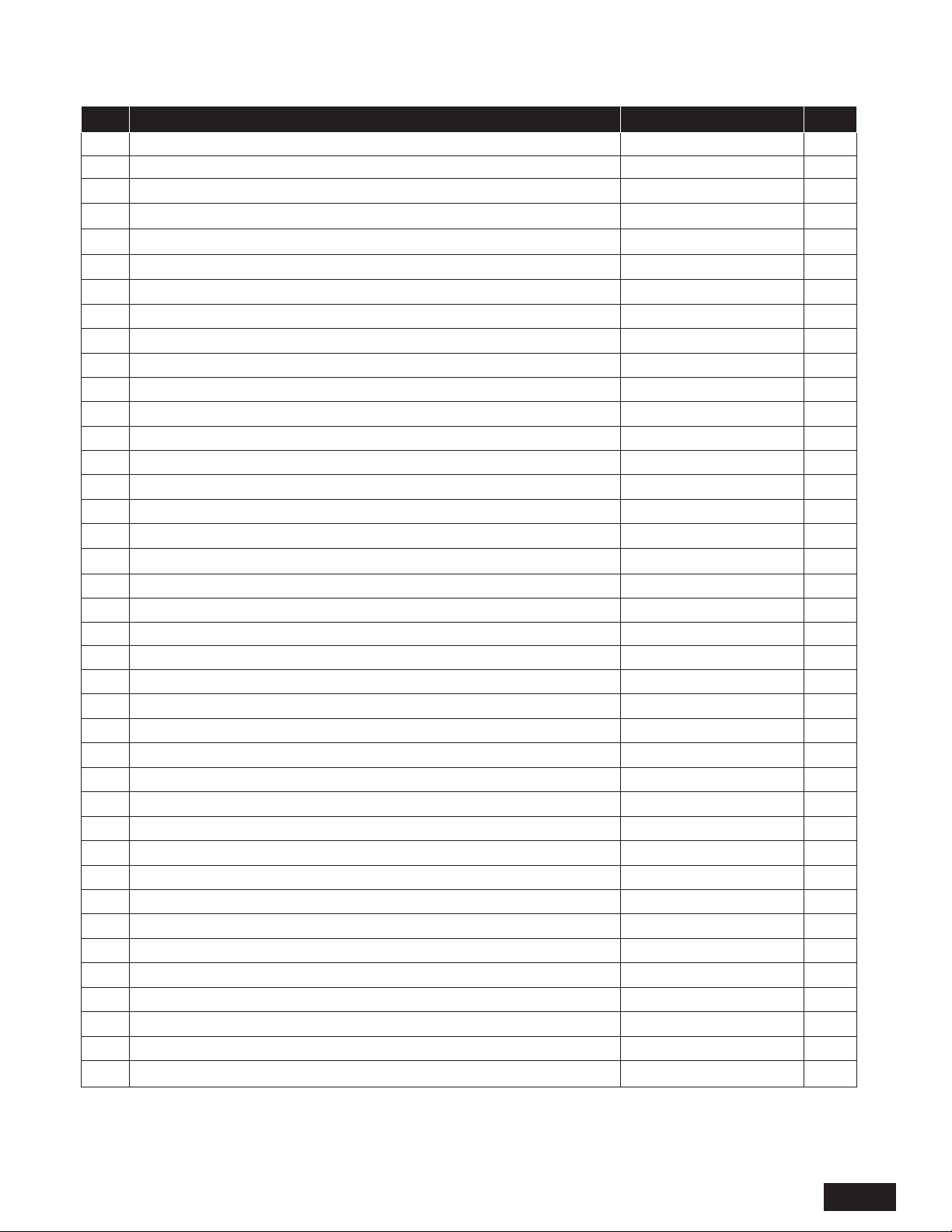

Page 18

Liste des pièces

Figure 2 – Liste des pièces détachées des sèche-mains

Pour les pièces détachées,

consulter

www.WorldDryer.com

Fournir les renseignements

suivants :

Numéro de modèle

Numéro de série

Description et numéro

de la pièce gurant sur

la liste des pièces

25

20

13

15

12

16

22

10

14

9

11

5

18

3

21

24

19

23

17

4

2

1

6

7

8

français

18

Page 19

Description Numéro de pièce Qté.

#

1 Collier du déecteur du moteur 23-100 1

2 Déecteur du moteur 127HS 1

3 Moteur XRM5, RM5 32-120K 1

3 Moteur XRM54, RM54, XRM548, RM548 32-230K 1

4 Balais du moteur 206NL 2

5 Bride de montage du moteur 110-4A 2 ensembles

6 Supports de montage du moteur 110-4 2

7 Microcommutateur seulement RM (tous) 143F 1

8 Minuteur RM5 125XMK 1

8 Minuteur RM54 125AMK 1

8 Minuteur RM548 125MCEK 1

9 Capot complet, fonte, automatique, blanc XRM (tous)* 703XM5-974AK 1

9 Capot complet, fonte, bouton-poussoir, blanc RM (tous)* 703M5-974AK 1

9 Capot complet, acier inoxydable, automatique, brossé XRM (tous)* 713DXM5-Q973AK 1

10 Adaptateur de bouton-poussoir, joint d’étanchéité et douille RM (tous) 190K 1

11 Kit de bague de retenue, embout de tige-poussoir isolé et anneau de retenue du bouton-

193K 1

poussoir RM (tous)

12 Clé mâle à six pans, capot en fonte 204TP 1

12 Clé mâle à six pans, capots en acier 56-006565 1

13 Grille d’entrée, fonte, bouton-poussoir, avec matériel correspondant RM (tous) 194-3K 1

Grille d’entrée, fonte, automatique, avec matériel correspondant XRM (tous) 194-3XRAK 1

r13

14 Vis de capot inviolable, capots en fonte XRM, RM (tous) 100B3 1

14 Vis de capot inviolable, capots en acier XRM (tous) 46-005023 1

15 Kit de montage de buse 34-173K 1

16 Kit de montage de bouton-poussoir (bouton, tige, bague, ressort et embout) RM (tous) 185K 1

17 Thermostat seul 19 mm (3/4 po) 1111- 0 3 1

18 Demi-volute de soufante avec base de montage et thermostat 211 PA 1

19 Ventilateur métal 101i 1

20 Demi-volute de soufante - Côté gauche 112P 1

21 Élément de chauffage XRM5, RM5 213XM 1

21 Élément de chauffage XRM54, RM54, XRM548, RM548 213AM 1

22 Plaque signalétique, bouton-poussoir RM (tous)* 38-225 1

22 Plaque signalétique, automatique XRM (tous)* 38-226 1

23 Boîte d'applique (tous) 17-034 1

24 Bornier (tous) 156-3 1

25 Grille, Assy moulu (tous) 12-001 1

Commande de capteur automatique - 115V, XRM5 16-230-120 RAK 1

r

Commande de capteur automatique - 208-230V, XRM54 16-240-208 RAK 1

r

Commande de capteur automatique - 220-240V, 50 Hz CE seulement XRM548 16-230-240 CEK 1

r

Filtre, électronique, 50 Hz CE seulement XRM548, RM548 110-2 1

r

* Spécier le modèle lors de la commande.

r Non représenté.

19

français

Page 20

Entretien

REMARQUE : Débrancher le courant avant d’effectuer une des procédures suivantes

INSTRUCTIONS DE NETTOYAGE :

Lire toutes les instructions avant de procéder au nettoyage. Dans des conditions d’utilisation normales, le nettoyage du sèche-mains une

fois par an le maintiendra en bon état de marche. Si la fréquentation des toilettes est supérieure à la normale, effectuer le nettoyage tous les

6 mois. L’accumulation de peluches et de poussières à l’intérieur du sèche-mains peut endommager le moteur et l’élément de chauffage et

produire des émissions chaudes susceptibles de blesser l’utilisateur.

1. À l’aide de la clé mâle à six pans de sécurité fournie avec le sèche-mains, dévisser les deux vis de montage retenant le capot. Soutenir le

capot pendant l’enlèvement des vis.

2. Enlever les trois (3) vis latérales retenant l’ensemble du carter de la soufante. Noter la position de l’élément de chauffage et de l’écran de

protection. Les ls conducteurs sont dirigés vers l’orice de dégagement dans les moitiés du carter de la soufante. Sans déconnecter les

ls, enlever avec précaution l’élément de chauffage de son logement.

3. Nettoyer les moitiés de la roue de la soufante en utilisant une brosse à soies radiales de 12,7 millimètres de diamètre. En veillant à ne pas

tordre ni endommager les ailettes, brosser entre les ailettes pour déloger les salissures.

4. Avec un aspirateur, éliminer la poussière de la soufante et de son carter, remettre en place l’élément de chauffage, l’écran de protection

et sa moitié de carter, et revisser les trois (3) vis latérales. Serrer avec modération en veillant à ce que les pièces en mica de l’élément de

chauffage soient positionnées dans leur logement et que les ls d’alimentation passent par l’orice du carter de la soufante.

5. En veillant à ne pas tordre la lame du minuteur, utiliser un pinceau à soies souples de 12,7 mm pour dépoussiérer et décrasser le moteur

et le minuteur.

6. Utiliser une brosse dure pour nettoyer les salissures à l’intérieur des grilles de sortie et d’entrée d’air. Il peut être nécessaire d’utiliser

de l’eau pour évacuer les salissures de la grille d’entrée. En cas d’utilisation d’eau, sécher l’intérieur du capot avant de le remonter.

7. Inspecter les balais du moteur. Pour cela, insérer un cure-dents dans l’orice à l’extrémité de l’ensemble des balais. Si le cure-dents

s’enfonce de plus de 2,5 cm, remplacer les balais. (Voir la rubrique Remplacement des balais du moteur.)

8. Remonter le capot en le plaçant droit sur la base et en le poussant contre le mur. Insérer les deux vis de montage du capot et les serrer

jusqu’à ce qu’elles soient bien ajustées, sans toutefois les serrer excessivement.

REMPLACEMENT DES BALAIS DU MOTEUR

1. Enlever la pince à ressort de verrouillage retenant le porte-balais.

2. Sortir lentement du moteur le capuchon des balais jusqu’à apparition du connecteur électrique.

3. Détacher le connecteur et enlever l’ensemble des balais et du porte-balais.

REMARQUE : Pendant le déballage hors du carton d’expédition de l’ensemble des balais, il est important de maintenir solidement

les balais en carbone dans le porte-balais. N° de pièce 206NL

4. Introduire le nouvel ensemble jusqu’à la position où le raccordement des ls par raccord rapide peut être effectué.

5. Pousser l’un contre l’autre les raccords rapides sur le moteur et le manchon des balais.

6. Remettre l’ensemble des balais dans sa position de fonctionnement et insérer la pince à ressort de verrouillage.

REMPLACEMENT DE L’ÉLÉMENT DE CHAUFFAGE

1. Enlever les trois vis retenant ensemble les éléments du carter de la soufante (nos de pièce 211P et 112P) et enlever l’élément 112P.

2. Déconnecter les ls blancs de l’élément de chauffage sur le bornier et le commutateur. Remplacer l’élément de chauffage en s’assurant

que la tension et l’ampérage sont corrects, et en veillant à le connecter d’une manière identique à l’ancien élément.

3. Maintenir l’élément en position sur côté stationnaire du carter de la soufante et glisser le côté amovible du carter en position, en veillant

à ce que les armatures de l’élément se placent dans les logements du carter de la soufante et que les deux ls se trouvent dans le

passage à la partie supérieure de la sortie d’air. Remonter l’écran de protection et les trois vis retenant ensemble les éléments du

carter de la soufante.

4. Reconnecter les ls au bornier et au commutateur. S’assurer que tous les ls sont correctement reconnectés et que le câblage correspond

au schéma de câblage.

REMPLACEMENT DU MINUTEUR POUR LES MODÈLES RM

1. Enlever les vis de chacune des deux bornes du minuteur, en marquant les ls an de permettre une reconnexion correcte au moment

du remontage.

2. Remplacer le minuteur défectueux. (Pour la commande du minuteur, spécier le modèle du sèche-mains.)

3. Reconnecter les ls aux bornes du minuteur.

4. Remettre le capot en place (en s’assurant qu’il est bien ajusté sur la base) et le pousser contre le mur, puis visser les deux vis de

montage sans les serrer excessivement.

5. Mettre le sèche-mains sous tension.

français

20

Page 21

Schémas de câblage

L1

L2

Interrupteur

Thermostat

Élément de

chauffage

Minuteur

240 V

Moteur

240 V

Fil blanc-Élément de chauffage

L1 L1

L2

N

L1

L2

Interrupteur

Interrupteur

Thermostat

Thermostat

Thermostat

Élément de

chauffage

Élément de

chauffage

Élément de

chauffage

Minuteur

120 V

Moteur

120 V

Minuteur

240 V

Moteur

240 V

Moteur

208/230

V c.a.

Capteur

IR 49-238

Carte de circuits imprimés 16-240

Relais Relais

Transformateur

230 V c.a.

120 V c.a.

Com

Bornier

carter de

soufflante

Fil rouge-Thermostat

Fil noir alimentation ligne 1

Fil blanc transformateur ligne 2

Fil noir-Moteur

Fil rouge-Moteur

Fil marron

transformateur ligne 1

Fil noir alimentation ligne 2

L2

Interrupteur

Thermostat

Élément de

chauffage

Minuteur

240 V

Moteur

240 V

Fil blanc-Élément de chauffage

L1 L1

L2

N

L1

L2

L1

N

Interrupteur

Interrupteur

Thermostat

Thermostat

Thermostat

Thermostat

Thermostat

Élément de

chauffage

Élément de

chauffage

Élément de

chauffage Élément de

chauffage

Élément de

chauffage

Minuteur

120 V

Moteur

120 V

Minuteur

240 V

Moteur

240 V

Moteur

Moteur

120 V c.a.

208/230

V c.a.

Capteur

IR 49-238

Capteur

IR 49-238

Carte de circuits imprimés 16-230

Carte de circuits imprimés 16-240

Relais Relais

Relais

Transformateur

Transformateur

Bornier

carter de

soufflante

230 V c.a.

120 V c.a.

Com

230 V c.a.

120 V c.a.

Com

Moteur

Relais

Contrôle

Transformateur

230 V c.a.

120 V c.a.

Com

12 V c.c.

22 VCA

Filtre EMC

L - 2 X 2,1 MH

C - 0,47 UF (X2) SH

-2X 0,001 UF (Y2)

R - 680 K Ohms

Fil blanc neutre moteur

Fil blanc neutre élément de chauffage

Bornier

carter de

soufflante

Fil noir alimentation 120 V

Fil rouge-Thermostat

Fil blanc neutre transformateur

Fil noir transformateur 120 V

Fil rouge-Moteur

Fil rouge-Thermostat

Fil noir alimentation ligne 1

Fil blanc transformateur ligne 2

Fil noir-Moteur

Fil rouge-Moteur

Fil marron

transformateur ligne 1

Fil noir alimentation ligne 2

Schémas électriques World Dryer

avec filtre EMC 230 V 50 Hz

pour modèle d’exportation

Caution: Route

Wires Away

From Moving

Parts

Atención: Dirija

el cableado

de manera

de evitar las

piezas móviles

Attention :

Acheminer

les fils à l’écart

des pièces

mobiles

L1