Page 1

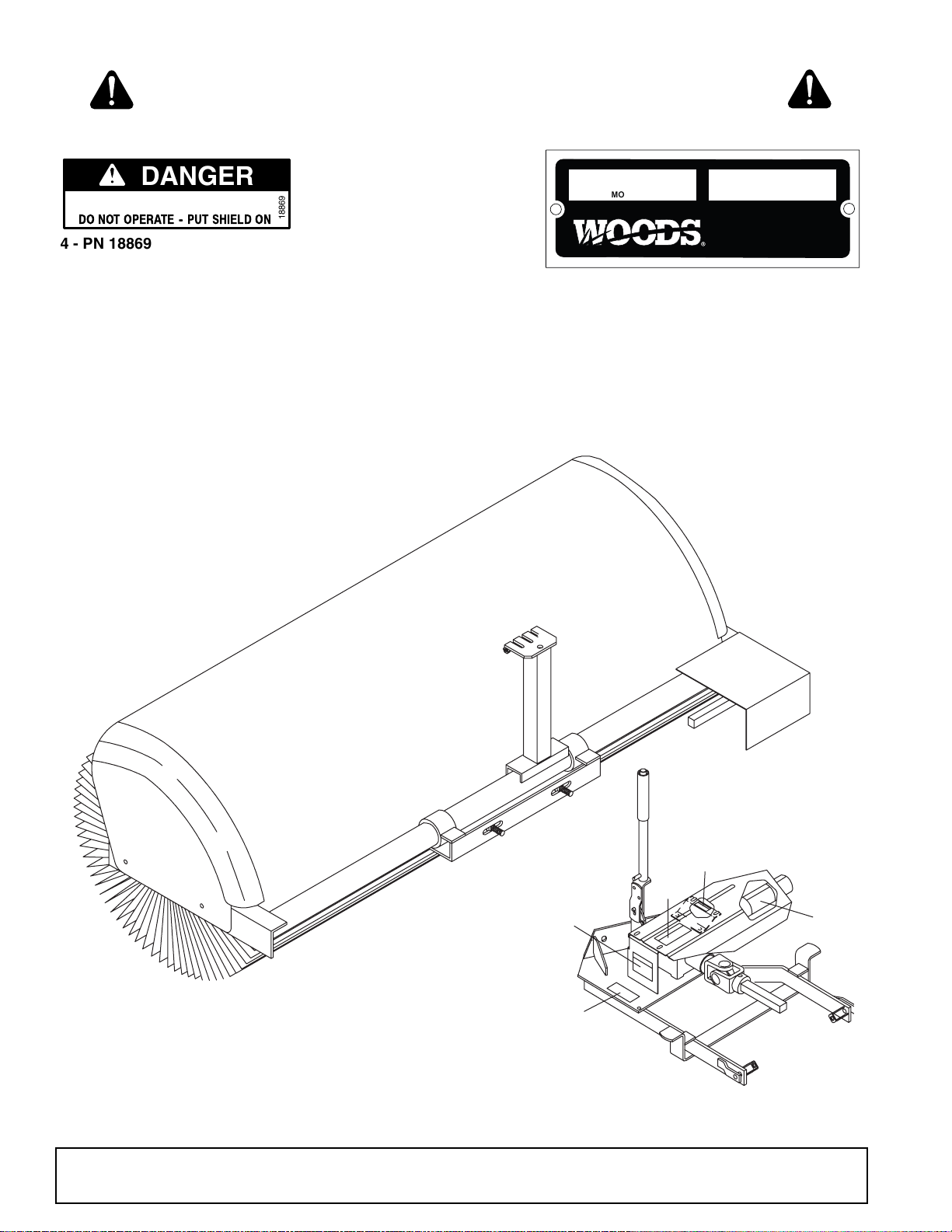

MOW’N MACHINE

SWEEPER

FSW6000F

FSW6000T

MAN0118

Rev. 12/1/2006

Tested. Proven. Unbeatable.

Page 2

TO THE DEALER:

CAUTION

IMPORTANT

WARNING

DANGER

NOTE

®

Assembly and proper installation of this product is the responsibility of the Woods

and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual

are completed before releasing equipment to the owner.

The dealer must complete the Product Registration included with the Operator’s Manual. The customer must sign the

registration which certifies that all Dealer Check List items have been completed. The dealer is to return the prepaid

postage portion to Woods, give one copy to the customer, and retain one copy. Failure to complete and return this

card does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model: _______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a

triangle with an exclamation mark) to indicate the degree of hazard for items of personal safety.

This Safety-Alert Symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

IMPORTANT

DANGER

WARNING

CAUTION

NOTE

ii Introduction

Indicates helpful information.

Gen’l (Rev. 5/23/2005)

Page 3

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DEALER CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 19

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . INSIDE BACK COVER

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your WOODS Mow'n Machine and

Sweeper. Read it carefully. It furnishes information and

instructions that will help you achieve years of dependable performance. These instructions have been compiled from extensive field experience and engineering

data. Some information may be general in nature due

to unknown and varying operating conditions. However, through experience and these instructions, you

should be able to develop procedures suitable to your

particular situation.

The illustrations and data used in this manual were current at the time of printing, but due to possible inline

production changes, your machine may vary slightly in

detail. We reserve the right to redesign and change the

machines as may be necessary without notification.

WARNING

■ Some illustrations in this manual show the

mower with safety shields removed to provide a

better view. The mower should never be operated

with any safety shielding removed.

Throughout this manual, references are made to right

and left direction These are determined by standing

behind the equipment facing the direction of forward

travel.

MAN0116 (Rev. 4/15/2004)

Introduction 1

Page 4

S

AFETY RULE

S

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

!

LEA EL INSTRUCTIVO!

Si no lee Ingles, pida ayuda a

alguien que si lo lea para que le

traduzca las medidas de seguridad.

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of

personnel involved in the operation, transport,

maintenance, and storage of equipment.

It has been said, “The best safety device is an

informed, careful operator.” We ask you to be

that kind of operator.

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Never allow children or untrained persons to

operate equipment.

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure the driveline spring-activated locking

collar slides freely and is seated firmly in power

unit PTO groove. Make sure the set screws

securely attach driveline to the attachment gearbox

shaft.

The safety interlock system was installed for

your protection. Do not disconnect, disable, override, or execute any action that would cause this

system to malfunction. If malfunction occurs, stop

all operation and contact dealer for repair.

Remove accumulated debris from this equipment, power unit, and engine to avoid fire hazard.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

When using weight transfer system, correct

counterweight must be used to maintain stability.

See counterweight chart in power unit manual or

contact dealer.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

OPERATION

Never place any part of the body underneath

implement/attachment or between its moving parts

even when the engine has been turned off. Service

work does not require going underneath unit.

Mechanical failures, electrical failures, or operating

controls can cause equipment to drop.

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Never allow riders on power unit or attachment.

Do not operate PTO during transport.

2 Safety

Mow’n Machine Vacuum (10/8/2004)

Page 5

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

Moving steering levers rapidly from forward to

reverse or reverse to forward could cause loss of

control.

Do not operate power unit with attachment

removed. Attachment is required for power unit

stability.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Never perform service or maintenance with

engine running.

Never place any part of the body underneath

implement/attachment or between its moving parts

even when the engine has been turned off. Service

work does not require going underneath unit.

Mechanical failures, electrical failures, or operating

controls can cause equipment to drop.

Do not put Mow’n Machine into service unless

clutch is working properly. When the engine is at

full throttle, PTO-driven accessories must stop

within five seconds after the PTO switch is turned

to “OFF.” See your dealer for replacement

clutches.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Tighten all bolts, nuts and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

TRANSPORTATION

Use extra care when loading or unloading the

machine onto a trailer or truck.

Never allow riders on power unit or attachment.

Do not operate or transport on steep slopes.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

MAINTENANCE

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Mow’n Machine Vacuum (10/8/2004)

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

Safety 3

Page 6

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

DANGER

SHIELD MISSING

DO NOT OPERATE -- PUT SHIELD ON

4 - PN 18869

BE CAREFUL!

Use a clean, damp cloth to clean safety decals.

Avoid spraying too close to decals when using a pressure

washer; high-pressure water can enter through very small

scratches or under edges of decals causing them to peel or

come off.

Replacement safety decals can be ordered free from your

Woods dealer. To locate your nearest dealer, check the

Dealer Locator at www.WoodsEquipment.com, or in the

United States and Canada call 1-800-319-6637.

18869

MODEL NO. SER IAL NO.

Woods Equipment Company

Oregon, Illinois, U.S.A.

1 - SERIAL NUMPER PLATE

CD4787

72803

4

2

5

1

3

4 Safety

MAN0118 (Rev. 12/23/2004)

Page 7

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

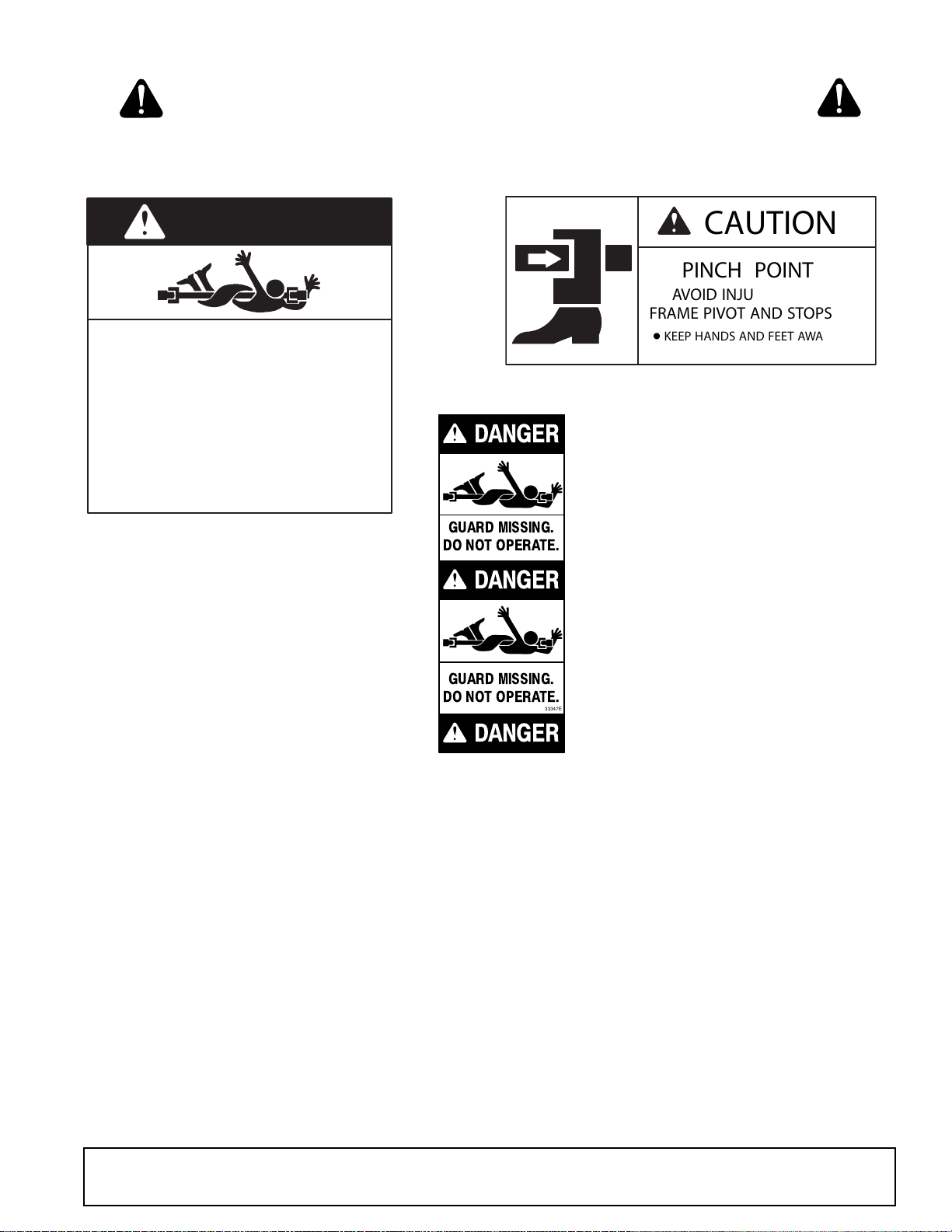

2 - PN 18864

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT -

All driveline guards, tractor and

equipment shields in place

Drivelines securely attached at both ends

Driveline guards that turn freely on

driveline

5 - PN 72803

CAUTION

PINCH POINT

AVOID INJURY FROM

FRAME PIVOT AND STOPS

D KEEP HANDS AND FEET AWAY.

50-0075-1

3 - PN 33347

DANGER

18864-C

GUARD MISSING.

DO NOT OPERATE.

DANGER

GUARD MISSING.

DO NOT OPERATE.

33347E

DANGER

MAN0118 (Rev. 12/23/2004)

Safety 5

Page 8

OPERATION

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of

personnel involved in the operation, transport,

maintenance, and storage of equipment.

It has been said, “The best safety device is an

informed, careful operator.” We ask you to be

that kind of operator.

A WARNING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

Make sure the driveline spring-activated locking

collar slides freely and is seated firmly in power

unit PTO groove. Make sure the set screws

securely attach driveline to the attachment gearbox

shaft.

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Never allow children or untrained persons to

operate equipment.

Keep bystanders away from equipment.

Do not stop, start, or change directions sud-

denly on slopes.

A CAUTION

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

REAR TRACTOR WEIGHT

REQUIREMENTS

The sweeper attachment requires additional rear tractor weight as shown in the counterweight chart below.

Contact your WOODS dealer for counterweights and

mount kit appropriate for your specific tractor.

REAR TRACTOR COUNTERWEIGHT

REQUIREMENT CHART

Sweeper

Model

60" Sweeper 100 lbs. 150 lbs.

Mow’n Machines

F-Series F-Series with

ROPS

2-WAY ANGLE MOUNT HEIGHT

ADJUSTMENT

The sweeping height of the broom should be adjusted

by the actuator motor. When using the broom for dethatching, the gauge wheels should be mounted to the

sides of the Sweeper broom and the height of the

broom should be adjusted by placing spacers on the

wheel forks above or below the fork housings.

FIXED ANGLE HEIGHT ADJUSTMENT

The sweeping height of the broom is adjusted by pushing the button on the end of the adjustment lever and

moving lever rearward to raise broom and forward to

lower broom.

SWEEPING TIPS

A WARNING

Never place any part of the body underneath

implement/attachment or between its moving parts

even when the engine has been turned off. Service

work does not require going underneath unit.

Mechanical failures, electrical failures, or operating

controls can cause equipment to drop.

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Always operate tractor engine at full governed RPM

when using the bi-directional broom for snow removal.

6 Operation

MAN0118 (Rev. 12/23/2004)

Page 9

Operate tractor engine at half throttle when de-thatching grass or sweeping dirt.

When de-thatching grass, stop tractor, disengage PTO,

turn off key and check for grass wrap around PTO shaft

and universal shaft every 30 minutes of operation.

Use the gauge wheels only when de-thatching grass.

Before de-thatching or snow removal, analyze the area

to determine the best procedure. Consider the grass

type or snow depth and the terrain type (rolling, level or

rough).

UNEVEN TERRAIN

A WARNING

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Pass diagonally through sharp dips and avoid sharp

drops to prevent hanging up the tractor and broom.

Practice will improve your skills in maneuvering on

uneven terrain.

Avoid sudden starts and stops when traveling up and

down hill. Never sweep or back up steep hills.

Move very slowly when turning or operating on slopes

to reduce the possibility of unit tipping or loss of control.

PRE-OPERATION CHECK LIST

(Owner Responsibility)

___ Review and follow safety rules and safety

decals on pages 2 through 5.

___ Make sure driveline spring-activated locking

pin or collar slides freely and securely connects driveline to tractor PTO shaft.

___ Check that equipment is properly and securely

attached to tractor.

___ Service equipment according to lubrication

table.

___ Check that all hardware and cotter pins are

properly installed and secured.

___ Check that all shields and guards are properly

installed and in good condition. Replace if

damaged.

___ Inspect area to be cleaned and remove stones,

branches or other hard objects that might be

MAN0118 (Rev. 12/23/2004)

Operation 7

Page 10

SERVICE

A CAUTION

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

A WARNING

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Never place any part of the body underneath

implement/attachment or between its moving parts

even when the engine has been turned off. Service

work does not require going underneath unit.

Mechanical failures, electrical failures, or operating

controls can cause equipment to drop.

LUBRICATION

To prevent excessive wear, do not let excess grease

collect on or around parts. Figure 1 shows the lubrication points. The accompanying chart gives the frequency of lubrication in operating hours based on

normal operating conditions. Severe or unusual conditions may require more frequent lubrication.

In addition to these lubrication points, lightly oil all roller

chains periodically.

Check the oil level in gearboxes periodically. Maintain

oil level to the bottom of fill plug hole. Use SAE 90W oil.

CHAIN ADJUSTMENT

Check periodically for proper chain tension between

gearboxes. If chain tightening is required, loosen the

four mounting bolts on the right gearbox and slide the

gearbox to the right until proper chain tension is

achieved. Do not overtighten chain.

A WARNING

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

NOTE: When performing any maintenance or making

adjustments to the Sweeper broom, refer to the

Sweepster) operator's manual.

Ref. Description Frequency

1 Guage Wheel Pivot (2 fittings) 8 Hours

2 Gauge Wheel (2 fittings) 8 Hours

3 Broom Pivot (2 fitttings) 40 Hours

4 Power Shafts (6 fittings) 8 Hours

1

2

8 Service

3

CD3882

Figure 1. Lubrication Points

4

4

MAN0118 (Rev. 12/23/2004)

Page 11

ASSEMBLY

DEALER SET-UP INSTRUCTIONS

Assembly of this sweeper is the responsibility of the

WOODS dealer. It should be delivered to the owner

completely assembled, lubricated, and adjusted for

normal cutting conditions.

FIXED ANGLE MOUNT KIT INSTALLATION

(Figure 2)

Mark Sweeper input driveshaft at 6-1/2 inches from the

center cross. Loosen the set screw retaining the rectangular shaft and remove it from the U-joint. Cut shaft

to proper length and reinstall shaft and secure with set

screws.

Position broom head in front of mount while inserting

broom head input shaft into sleeve assembly (7). Bolt

6--1/2

TRIM INPUT SHAFT

broom head to mount (1) using bolts provided with

broom head.

Attach height adjustment lever (2), and lever guide (18)

as shown. Pivot bolt (35) and nut (37) must be snug but

still allow the lever to rotate.

Secure one end of chain (17) to lug on adjustment

lever using washer (40) and cotter pin (30). Attach midpoint of chain to slots in broom head lift arm. Secure

chain to slots using pin provided with the broom head.

Attach assist spring (16) to hole in sweeper mount.

Attach other end of spring to loose end of chain.

Attach broom and mount to tractor according to instructions on page 12.

SEE SWEEPSTER®MANUAL

FOR SWEEPSTER

1. Fixed angle sweeper mount

2. Lever

7. Output shaft

16. Spring

17. 20 - Link chain

CD4649A-1

®

17

PART S .

16

30

18

37

18. Lever guide

30. Cotter pin

35. Hex head cap screw

37. Elastic stop nut

40. Standard flat washer

2

40

8

7

35

1

MAN0118 (Rev. 12/23/2004)

Assembly 9

Page 12

TRIM INPUT SHAFT

20

8--1/4

5

10

11

1. Broom mount

2. 12V Actuator

3. Universal half sheet

4. Universal half sleeve

5. Power shaft shield

6. Shield mount strap

24

8

21

9

7

23

22

2

22

CD4647A

1

7. 2-1/2" Clamp

8. Extension spring

9. Upper actuator mount

10. Caster wheel assembly right

11. Caster wheel assembly left

20. 5/16" x 3/4" NC Hex head cap screw

DRILL .343 (11/32) DIA

HOLES IN SWEEPSTER SHIELD

6

24

4

3

21. 5/16" NC Flanged hex lock nut

22. 1/2 NC x 2-1/2 Hex head cap screw

23. 1/2 NC x 3 Hex head cap screw

24. 1/2 NC Hex locknut

Figure 3. 2-Way Angle Sweeper Installation

2-WAY ANGLE MOUNT KIT

(Figure 3)

Attach upper actuator mount (9) to square upright mast

on Sweeper broom head using 1/2 x 3 bolt and 1/2

locknut.

Mark Sweeper input driveshaft at 8-1/4 inches from the

center cross. Loosen the set screw retaining the rectangular shaft and remove it from the U-joint. Cut shaft

to proper length and reinstall shaft and secure with set

screws.

Position broom head in front of mount while inserting

broom head input shaft into sleeve assembly (4). Bolt

broom head to mount (1) using bolts provided with

broom head.

Attach fixed end of upper actuator (2) to mount using

1/2 x 2-1/2 bolt and 1/2 locknut. Attach rod end of actuator to slots in upper actuator mount (9) using 1/2 x 21/2 bolts and 1/2 locknut. Slide broom head left or right

10 Assembly

until actuator lines up with upper mount. Do not over

tighten, rod must be able to float in slot. Attach wire

from actuator motor to black and white wires from the

switch box.

Attach extension spring (8) to hole in broom head mast

and to hole in main mount near rear actuator mounting

location.

Attach 2-1/2 clamp (7) and shield mount strap (6) to

round cross member of broom frame. Do not tighten

fully so shield may be adjusted. Attach power shaft

shield (5) to strap. Position shield so it can be bolted to

existing chain shield of broom head. Drill 2.343 (11/32)

dia holes in broom head shield to mount power shaft

shield. Bolt power shaft shield to broom head and

tighten all bolts and clamps.

Attach broom and mount to tractor according to instruction in the following section.

MAN0118 (Rev. 12/23/2004)

Page 13

ATTACHING SWEEPER TO TRACTOR

(Figure 4)

Replace existing step on 2-way angle mount of tractor

with shorter step supplied with sweeper. Remove cotter

pin on end of step rod and slide out. Install shorter step

and replace rod and cotter pin. Keep existing step for

use with mower decks if desired.

Attach sweeper mount (2) to the holes in tractor mounting bracket (1) that allow the broom mount assembly

to set in a level position.

Secure mount to tractor by rotating attaching pins (3)

rearward to lock pins into place.

Connect the PTO sleeve and yoke to rectangular shaft

of sweeper mount. Attach PTO to shaft on tractor.

Refer to instruction in SweepsterR manual and make

sure the broom is level prior to operation.

2-WAY ANGLE WIRING INSTRUCTIONS

(Figure 5)

Position the wiring harness along the right mounting

arm of mount, under step, and through the hole in the

tractor front panel, directly below the right steering

lever. The wiring harness may be separated at the con-

nector (A) to ease installation. Disconnect the wiring

harness from the tractor at this point when removing

the broom from the tractor. Rear section of wiring harness may remain on tractor at all times.

Secure relay and connector to tractor frame using plastic wire ties through holes near seat hinge.

Attach T-tap securely to a purple wire, directly behind

the ignition switch, inside the console. Connect the

short black pigtail to the T-tap and install a 7.5 amp

auto fuse into the slot. Route the black harness lead

into the console through the hole near the seat hinge.

Connect the pigtail to the black lead from harness.

Attach eyelet of green wire to negative post of battery.

Attach eyelet of red wire with fuse holder to positive

post of battery.

Route wires and secure them with wire ties so they are

clear of all moving parts of the tractor.

When using the broom for de-thatching, bolt the caster

wheel assemblies to each side of the broom head

using existing bolts in the broom head. The broom's

height can be adjusted by placing spacers on wheel

forks above or below the fork housings.

CD4648A

1. Tractor mount

2. Sweeper mount

3. Attaching pin

MAN0118 (Rev. 12/23/2004)

1

3

2

Figure 4. Attaching Sweeper to Tractor

Assembly 11

Page 14

7

(+)

BATTERY

(--)

FEMALE SPADE

CONNECTOR

KCA

L

B

4

15 AMP FUSE

GREEN

WHEN REMOVING

SWEEPSTER FROM

TRACTOR, DISCONNECT

WIRING HARNESS AT

THIS POINT

A

IGNITION

PURPLE

MALE SPADE

CONNECTOR

5

7.5 AMP FUSE

BLACK

5WAYFEMALE

CONNECTOR TO

RELAY. MOUNT RELAY TO SEAT

HINGE CENTER MOUNTING BOLT.

RED

GREEN

3

PURPLE

2 WAY MALE CONNECTOR

2 WAY FEMALE

CONNECTOR

PURPLE

GREEN

MALE SPADE CONNECTOR

2

SWITCH

BOX

2

WHITE

BLACK

2 WAY FEMALE CONNECTOR

TO ACTUATOR MOTOR

CD4661--var

2 WAY FEMALE CONNECTOR

TO ACTUATOR MOTOR

1. Wiring harness

2. Toggle switch

3. Relay - 12V

4. Auto fuse 15 AMP

5. Auto fuse 7.5 AMP

6. Actuator wire

7. Female spade T-tap

Figure 5. 2-Way Angle Sweeper Wire Diagram

WHITE

BLACK

12 Assembly

MAN0118 (Rev. 12/23/2004)

Page 15

DEALER CHECK LISTS

PRE-DELIVERY CHECK LIST

(Dealer Responsibility)

___ Inspect the Mow'n Machine and attachments

thoroughly after assembly to be certain it is set up

properly before delivering it to the customer.

___ The following check lists are a reminder of points

to inspect. Check off each item as it is found satisfactory or after proper adjustment is made.

___ Check that all safety shielding and decals are

properly installed and in good condition.

___ Check all bolts to be sure they are tight.

___ Check that all cotter pins are properly installed.

___ Check that all gearboxes are serviced and are

not leaking.

___ Lubricate equipment as specified in lubrication

section.

DELIVERY CHECK LIST

(Dealer Responsibility)

___ Point out safety features of cutter. Explain the

importance and meaning of all safety decals and

the potential hazards when not followed.

___ Explain to the customer that sweeper attachment

requires the use of rear counterweights, as specified in the counterweight chart, to provide necessary tractor stability.

___ Present Operator's Manual and request that cus-

tomer and all operators read it before operating

equipment.

___ Show customer how to make adjustments and

select proper PTO speed.

___ Instruct customer how to lubricate equipment and

explain importance of lubrication.

___ Show customer how to make sure driveline is

properly installed and that spring-activated locking pin or collar slides freely and is seated in

groove on tractor PTO shaft.

MAN0118 (Rev. 12/23/2004)

Dealer Check List 13

Page 16

2-WAY ANGLE SWEEPER ASSEMBLY

CD4646A

45

37

36

38

38

43

42

41

37

38

39

33

44

40

32

30

29

53

46

41

64 -- DECAL SET

32

31

54

34

9 47

48

24

12

1

2

10

57

32

30

51

52

5

13

8

22

11

58

23

4

14

62

61

15

50

17

17

4

18

18

8

21

20

55

9

7

9

10

15

59

63

6

8

8

35

16

25

28

60

26

3

13

56

9

27

48

3

14 Parts

MAN0118 (Rev. 12/1/2006)

Page 17

2-WAY ANGLE SWEEPER ASSEMBLY

REF PART DESCRIPTION

- 73967 Sweepster® mounting kit

- 71965 Sweepster® broom head

1 72737 Broom main mount

2 72118 Broom mount pivot

3 72119 12V Actuator

4 70767 Gearbox

5 72120 Sprocket 50B20

6 72121 Sprocket 50B11

7 72122 Chain

8 3886 * 1/4 x 1-1/4 Square key

9 12915 * 3/8 NC x 4-1/2 HHCS R5

10 66885 3/8 NC Flange nut

11 72123 Broom mount pin - lower

12 72124 Broom mount pin - upper

13 64462 * 5/32 x 1-1/4 Cotter pin

14 72769 DCL, Instruction switch

15 72767 Grommet .06 x .63 x .88

16 74046 Universal half shaft

18 65689 Cross and bearing

20 70768 Output shaft

22 72125 Switch box back

23 72126 Switch box cover

24 72127 Drive chain shield

25 72128 Power shaft shield

26 72129 Shield mount strap

27 72130 2-1/2" Clamp

28 70762 Extension spring

29 72131 Upper actuator mount

30 639 * 1/2 NC x 2-1/2 HHCS GR5

31 3489 * 1/2 NC x 3 HHCS GR5

32 765 * 1/2 NC Hex lock nut

33 72764 Fork housing - right

REF PART DESCRIPTION

34 35197 Spring, complete .89 x .12 x 1.0

35 72403 Pin, bent .5 x 1.96

36 1972 * Grease fitting

37 70086 3/8 Spacer

38 70004 3/4 Spacer

39 72761 Gauge wheel fork

40 31745 Semi-pneumatic wheel

41 31345 .75 x 1.38 Bearing

42 29368 1/2 x 3/4 x 3-3/8 Sleeve

43 23479 1/2 x 5 HHCS

44 11900 1/2 NC Flanged hex lock nut

45 62043 1/4 x 1-3/4 Linch pin

46 72765 Break-away mount

47 72101 Break-away pin

48 71105 External retainer

49 4115 * 3/16 x 1-4/8 Spring pin

50 21374 * No 10 x 1/2 Tap screw

51 1282 * 1/4 NC x 1/2 RD head screw

52 70065 * 1/4 NC Whiz nut

53 6698 * 3/8 Hex lock nut

54 565 * 3/8 Standard flat washer

55 4544 * 3/8 NC x 3/8 Set screw

56 3699 * 1/2 NC x 2 HHCS

57 6096 * 5/16 x 3/4 HHCS

58 14139 5/16 Hex flange lock nut

59 66510 Spring complete .66 x .06 x 2.5

60 639 * 1/2 NC x 2-1/2 HHCS

61 72793 Locking ring

62 72794 Face nut

63 73926 Step, short

64 72425 Decal set

* Standard Hardware - Obtain Locally

MAN0118 (Rev. 12/1/2006)

Parts 15

Page 18

TRIM INPUT SHAFT

FIXED ANGLE SWEEPER MOUNT KIT ASSEMBLY

6--1/2

41 -- DECAL SET

CD4649A

SEE SWEEPSTER®MANUAL

FOR SWEEPSTER

REF PART QTY DESCRIPTION

- 73959 - Fixed angle mount kit (includes 1-40)

- 71965 - Sweepster® bruck head 60"

1 72778 1 Fixed angle sweeper mount

2 70764 1 Lever includes items 3 & 4

3 07530700 1 Grip, black foam

4 70766 1 Push rod grip

5 70767 1 Gearbox

6 3886* 2 .25 x 1.25 Square key

7 70768 1 Output shaft

10 65689 2 Cross & bearing kit

11 74046 1 Input shaft assembly

13 72790 2 Pin, bent .5 x 2.06

14 66510 2 Spring compression

15 70918 1 Shield

16 70762 1 Spring, Ext. 1-3/4 x 3/16 x 11-5/8

17 33046 1 20-Link chain

18 70772 1 Lever guide

®

PART S .

17

16

31

3

15

7

20

14

10

34

37

18

30

2

40

4

36

32

19

10

33

6

39

5

35

38

1

13

8

11

REF PART QTY DESCRIPTION

19 70931 1 Shield mount bracket

20 4115* 2 3/16 x 1-1/8 Spring pin

30 3597* 1 1/8 x 1 Cotter pin

31 71206* 4 .25-20 x .5 Hex whiz bolt

32 72474 4 Spring nut 1/4020 U-tapped

33 6096* 2 5/16 NX x 3/4 HHCS

34 14139 2 5/16 NC Flange hex lock nut

35 839* 1 3/8 NC x 1 HHCS

36 12915* 4 3/8 NC x 4-1/2 HHCS

37 71635 1 3/8 NC Elastic stop nut

38 66885 4 Flange nut, 3/8 NC Spiralock

39 4544* 2 3/8 NC x 3/8 NC Socket head SS

40 565* 1 3/8 Standard flat washer

41 72425 1 Decal set

* Standard Hardware - Obtain Locally

16 Parts

MAN0118 (Rev. 12/1/2006)

Page 19

2-WAY ANGLE SWEEPER WIRE DIAGRAM

7

(+)

BATTERY

(--)

FEMALE SPADE

CONNECTOR

KCA

L

B

4

15 AMP FUSE

GREEN

WHEN REMOVING

SWEEPSTER FROM

TRACTOR, DISCONNECT

WIRING HARNESS AT

THIS POINT

A

IGNITION

PURPLE

MALE SPADE

CONNECTOR

5

7.5 AMP FUSE

BLACK

5WAYFEMALE

CONNECTOR TO

RELAY. MOUNT RELAY TO SEAT

HINGE CENTER MOUNTING BOLT.

RED

GREEN

3

PURPLE

2 WAY MALE CONNECTOR

2 WAY FEMALE

CONNECTOR

PURPLE

GREEN

MALE SPADE CONNECTOR

2

SWITCH

BOX

2

WHITE

BLACK

2 WAY FEMALE CONNECTOR

TO ACTUATOR MOTOR

REF PART QTY DESCRIPTION

1 73501 1 Wiring Harness

2 72185 2 Toggle switch

3 66069 1 Relay - 12V

4 71386 1 Auto fuse 15 AMP

5 71387 1 Auto fuse 7.5 AMP

6 72748 2 Actuator wire

7 73500 1 Female spade T-tap

CD4661--var

WHITE

BLACK

2 WAY FEMALE CONNECTOR

TO ACTUATOR MOTOR

MAN0118 (Rev. 12/1/2006)

Parts 17

Page 20

BOLT TORQUE CHART

(

)

(

)

Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific

application.

Fasteners must always be replaced with the same grade as specified in the manual parts list.

Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware.

Make sure fastener threads are clean and you start thread engagement properly.

All torque values are given to specifications used on hardware defined by SAE J1701 & J1701M JUL96.

SAE SERIES

A

A

Diameter

(Inches)

1/4" 7/16" 6 8 10 13 14 18

5/16"1/2"121719262737

3/8"9/16"233135474967

7/16"5/8"3648557578106

1/2" 3/4" 55 75 85 115 120 163

9/16" 13/16" 78 106 121 164 171 232

5/8" 15/16" 110 149 170 230 240 325

3/4" 1-1/8" 192 261 297 403 420 569

7/8" 1-5/16" 306 416 474 642 669 907

1" 1-1/2" 467 634 722 979 1020 1383

TORQUE

CHART

Wrench

Size

SAE Grade 2

(No Dashes)

SAE 2 SAE 5 SAE 8

lbs-ft N-m lbs-ft N-m lbs-ft N-m

METRIC SERIES

A

TORQUE

CHART

A

Diameter &

Thread Pitch

(Millimeters)

6 x 1.0 10 mm 8 6 11 8 8 6 11 8 6 x 1.0

8 x 1.25 13 mm 20 15 27 20 21 16 29 22 8 x 1.0

10 x 1.5 16 mm 39 29 54 40 41 30 57 42 10 x 1.25

12 x 1.75 18 mm 68 50 94 70 75 55 103 76 12 x 1.25

14 x 2.0 21 mm 109 80 151 111 118 87 163 120 14 x 1.5

16 x 2.0 24 mm 169 125 234 173 181 133 250 184 16 x 1.5

18 x 2.5 27 mm 234 172 323 239 263 194 363 268 18 x 1.5

20 x 2.5 30 mm 330 244 457 337 367 270 507 374 20 x 1.5

22 x 2.5 34 mm 451 332 623 460 495 365 684 505 22 x 1.5

24 x 3.0 36 mm 571 421 790 583 623 459 861 635 24 x 2.0

30 x 3.0 46 mm 1175 867 1626 1199 1258 928 1740 1283 30 x 2.0

Wrench

Size

N-m lbs-ft N-m lbs-ft N-m lbs-ft N-m lbs-ft

COARSE THREAD FINE THREAD

MARKING ON HEAD MARKING ON HEAD

Metric 8.8 Metric 10.9 Metric 8.8 Metric 10.9

SAE Bolt Head

Identification

8.8

Metric

Grade 8.8

SAE Grade 5

3 Radial Dashes

MARKING ON HEAD

Metric Bolt Head

Identification

SAE Grade 8

6 Radial Dashes

10.9

Metric

Grade 10.9

A

Diameter &

Thread Pitch

(Millimeters)

Typical Washer Installations

Lock Washer

Bolt

18 Appendix

Nut

Flat Washer

8/9/00

Bolt Torque & Size Charts (Rev. 8/14/2002)

Page 21

BOLT SIZE CHART

NOTE: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and metric bolts.

SAE Bolt Thread Sizes

5/16 3/8 1/2 5/8 3/4 7/8

IN 1 2 3 4 5 6

MM 25 50 75 100 125 150 175

Metric Bolt Thread Sizes

8MM 18MM14MM12MM10MM

16MM

ABBREVIATIONS

AG............................................................. Agriculture

ATF...............................Automatic Transmission Fluid

BSPP ...........................British Standard Pipe Parallel

BSPTM...............British Standard Pipe Tapered Male

CV .................................................. Constant Velocity

CCW ............................................ Counter-Clockwise

CW ............................................................. Clockwise

F..................................................................... Female

GA................................................................... Gauge

GR (5, etc.) ......................................... Grade (5, etc.)

HHCS.......................................Hex Head Cap Screw

HT ......................................................... Heat-Treated

JIC............... Joint Industry Council 37° Degree Flare

LH ...............................................................Left Hand

LT ......................................................................... Left

m ....................................................................... Meter

mm ..............................................................Millimeter

M ........................................................................ Male

MPa........................................................Mega Pascal

N .................................................................... Newton

NC.................................................... National Coarse

NF ......................................................... National Fine

NPSM................... National Pipe Straight Mechanical

NPT .........................................National Pipe Tapered

NPT SWF ........National Pipe Tapered Swivel Female

ORBM .........................................O-Ring Boss - Male

P......................................................................... Pitch

PBY ..................................................... Power-Beyond

psi ........................................Pounds per Square Inch

PTO.................................................... Power Take Off

QD.................................................. Quick Disconnect

RH............................................................ Right Hand

ROPS ......................... Roll-Over Protective Structure

RPM ...................................... Revolutions Per Minute

RT ......................................................................Right

SAE ........................ Society of Automotive Engineers

UNC ................................................... Unified Coarse

UNF.........................................................Unified Fine

UNS ................................................... Unified Special

7

Bolt Torque & Size Charts (Rev. 8/14/2002)

Appendix 19

Page 22

LIMITED WARRANTY

(Mow’n MachineTM Zero-Turn Mower and

Woods BoundaryTM Utility Vehicle Replacement Parts)

Woods Equipment Company (“WOODS”) warrants replacement parts for Mow’n MachineTM zero-turn

mowers and attachments and Woods Boundary

TM

utility vehicles, accessories and attachments to be free

from defect in material and workmanship for a period of ninety (90) days from the date of delivery of the

product to the original purchaser.

IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED IN DURATION TO A PERIOD OF NINETY (90) DAYS FROM THE

DATE OF DELIVERY OF THE PRODUCT TO THE ORIGINAL PURCHASER. Some states do not

allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

This Warranty is extended solely to the original purchaser of the product. Should the original purchaser

sell or otherwise transfer the product to a third party, this Warranty does not transfer to the third party

purchaser in any way. There are no third party beneficiaries of this Warranty.

This Warranty does not cover normal wear or tear, or normal maintenance items, or any damage, failure

or loss caused by improper operation, improper maintenance, misuse, or an accident.

WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement,

free of charge, of the product if the product is defective or in noncompliance with this Warranty. The

product must be returned to WOODS with proof of purchase within thirty (30) days after such

defect or noncompliance is discovered or should have been discovered, routed through the dealer

and distributor from whom the purchase was made, transportation charges prepaid. WOODS

shall complete such repair or replacement within a reasonable time after WOODS receives the product.

WOODS shall not be liable for any incidental or consequential losses, damages or expenses,

arising directly or indirectly from the product, whether such claim is based upon breach of

contract, breach of warranty, negligence, strict liability in tort or any other legal theory. Without

limiting the foregoing, WOODS shall not be liable for any damages relating to (i) lost profits, business,

revenues or goodwill; (ii) any expense or loss incurred for labor, supplies, substitute machinery or rental;

or (iii) any other type of damage to property or economic loss. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitations may not apply to you.

No agent, representative, dealer, distributor, service person, salesperson, or employee of any company,

including without limitation, WOODS, its authorized dealers, distributors, and service centers, is

authorized to alter, modify, or enlarge this Warranty.

This Warranty gives you specific legal rights, and you may also have other rights which may vary from

state to state.

Answers to any questions regarding warranty service and locations may be obtained by contacting:

Woods Equipment

Company

2606 South Illinois Route 2

Post Office Box 1000

Oregon, Illinois 61061

800-319-6637 tel

800-399-6637 fax

www.WoodsEquipment.com

F-8495 MM & Boundary Repair Parts (Rev. 2/15/2006)

Page 23

LIMITED WARRANTY

(Mow’n MachineTM Zero-Turn Mowers and Woods BoundaryTM Utility Vehicles)

Please Enter Information Below and Save For Future Reference.

Date Purchased: __________________________ From (Dealer): _____________________________________

Model Number: __________________________ Serial Number: _____________________________________

WHAT IS COVERED:

Woods Equipment Company (“WOODS”) warrants Mow’n Machine

vehicles, accessories and attachments to be free from defect in material and workmanship for the warranty periods listed below.

FOR HOW LONG:

Mow’n Machine Model #CZ2136B, CZ1736K, CZ1942K, CZ1948K, CZ1952K, FE21B, FZ21D, FZ23B, FZ28K, ME2052B, MZ1952K,

MZ2652G, MZ2561K, MZ2761, MZ3361G, MZ3372G, MZ2061YD & attachments are warranted for two (2) years from the date of

delivery to the original purchaser or 2000 hours of operation, whichever occurs first.

Woods Boundary utility vehicle Model #MAV350, MAV480, MAV4x4, accessories & attachments are warranted for two (2) years from the

date of delivery to the original purchaser.

IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN

DURATION TO THE DURATION OF THE WRITTEN WARRANTY PERIODS LISTED ABOVE. Some states do not allow limitations

on how long an implied warranty lasts, so the above limitation may not apply to you.

WHO IS COVERED:

This Warranty is extended solely to the original purchaser of the product. Should the original purchaser sell or otherwise transfer the

product to a third party, this Warranty does not transfer to the third party purchaser in any way. There are no third party beneficiaries of this

Warr an ty.

WHAT IS NOT COVERED:

This Warranty does not cover normal wear or tear, or normal maintenance items, or any damage, failure or loss caused by:

1. Improper operation, improper maintenance, misuse, or an accident;

2. Any modification or repair by someone other than WOODS, a WOODS authorized dealer or distributor, and/or a WOODS

authorized service center; or

3. Repairs made with parts other than those obtainable through WOODS.

WOODS makes no warranty, express or implied, with respect to engines, batteries, tires or other parts or accessories not manufactured by

WOODS. Warranties for these items, if any, are provided separately by their respective manufacturers.

WHAT WOODS WILL DO TO CORRECT PROBLEMS:

WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement, free of charge, of the product if the

product is defective or in noncompliance with this Warranty. The product must be returned to WOODS with proof of purchase within thirty

(30) days after such defect or noncompliance is discovered or should have been discovered, routed through the dealer and distributor from

whom the purchase was made, transportation charges prepaid. WOODS shall complete such repair or replacement within a reasonable time

after WOODS receives the product.

OTHER LIMITATIONS:

WOODS shall not be liable for any incidental or consequential losses, damages or expenses, arising directly or indirectly from the

product, whether such claim is based upon breach of contract, breach of warranty, negligence, strict liability in tort or any other

legal theory. Without limiting the foregoing, WOODS shall not be liable for any damages relating to (i) lost profits, business, revenues or

goodwill; (ii) any expense or loss incurred for labor, supplies, substitute machinery or rental; or (iii) any other type of damage to property

or economic loss. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations may

not apply to you.

No agent, representative, dealer, distributor, service person, salesperson, or employee of any company, including without limitation,

WOODS, its authorized dealers, distributors, and service centers, is authorized to alter, modify, or enlarge this Warranty.

HOW STATE LAW APPLIES:

This Warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.

QUESTIONS:

Answers to any questions regarding warranty service and locations may be obtained by contacting:

TM

zero-turn mowers and attachments and Woods BoundaryTM utility

F-8045 MM & Boundary (Rev. 7/14/2006)

Page 24

oods Equipment

ompany

606 South Illinois Route 2

Post Office Box 1000

regon, Illinois 61061

MAN0118

15-732-2141 tel

15-732-7580 fax

ww.WoodsEquipment.com

© 2001 WEC Company, d/b/a Woods Equipment Company. All rights reserved. WOODS, the Woods logo, and "Tested. Proven. Unbeatable." are

trademarks of Woods Equipment Company. All other trademarks, trade names, or service marks not owned by Woods Equipment Company that

appear in this manual are the property of their respective companies or mark holders. Specifications subject to change without notice.

Loading...

Loading...