Woods Equipment DUAL 199758, DUAL 111307, DUAL 118460 User Manual

INSTALLATION INSTRUCTIONS

AND

REPAIR PARTS INFORMATION

#111307 LOADER MOUNTING KIT

for mounting DuAl Model 195 Loader to

John Deere 5500 2WD Tractors

#118460 LOADER MOUNTING KIT

for mounting DuAl Model 215 Loader to

John Deere 5500 FWA Tractors

#199758 HYDRAULIC HOSE KIT

for mounting DuAl Model 195 & 215 Loaders to

John Deere 5500 Tractors

PN-53661 (Rev. 12/96)

TO THE DEALER:

The loader mounting kit and/or hydraulic hose kit assembly and proper installation to the tractor is

the responsibility of the DuAl dealer.Readmanualinstructionsandsafetyrules.Makesure all items

on the Pre-Delivery and Delivery Check Lists in the loader manual are completed before releasing

equipment to the owner.

TO THE OWNER:

Read thesemountinginstructionsbefore installing loadermounting kit and/or hydraulichose kit. The

information presented will prepare you to do a better and safer job. Keep this document handy for

ready reference. Require all operators to read the loader manual carefully and become acquainted

with all the adjustment and operating procedures before attempting to operate. Replacement

manuals canbe obtained from your dealer or by calling 1-800-319-6637, in the USA or Canada only.

The loader mounting kit and/or hydrulic hose kit you have purchased has been carefully engineered

and manufactured to provide dependable and satisfactory use. Like all mechanical products, it will

require cleaning and upkeep. Observe all safety information in this document, the loader and tractor

manuals, and all safety decals on the loader and tractor.

Forservice, yourauthorized DuAldealer hastrained mechanics,genuine DuAlservice parts, andthe

necessary tools and equipment to handle all your needs.

Use only genuine DuAl service parts. Substitute parts will void the warranty and may not meet

standards required for safe and satisfactory operation. Record the model number of your loader

mounting kit and/or hydraulic hose kit below and provide it to your dealer when requesting repair

parts.

Loader Mounting Kit Model:

Hydraulic Hose Kit Model:

Provide this information to your dealer to obtain correct rep

air parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause

damage to equipment. The termsCAUTION, WARNINGand DANGER are used in conjunction with

the Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for

items of personal safety.

The Safety-AlertSymbol means ATTENTION!BECOMEALERT!

YOUR SAFETY IS INVOLVED!

Denotes a reminder of safety practices or directs attention to

CAUTION

WARNING

unsafe practices which could result in personal injury if proper

precautions are not taken.

Denotes a hazard exists which can result in injury or death if

proper precautions are not taken.

DANGER

Denotes an extreme intrinsic hazard exists which would result in

highprobabilityof death orirreparable injury if proper precautions

are not taken.

PN-53661 (Rev. 12/96)ii

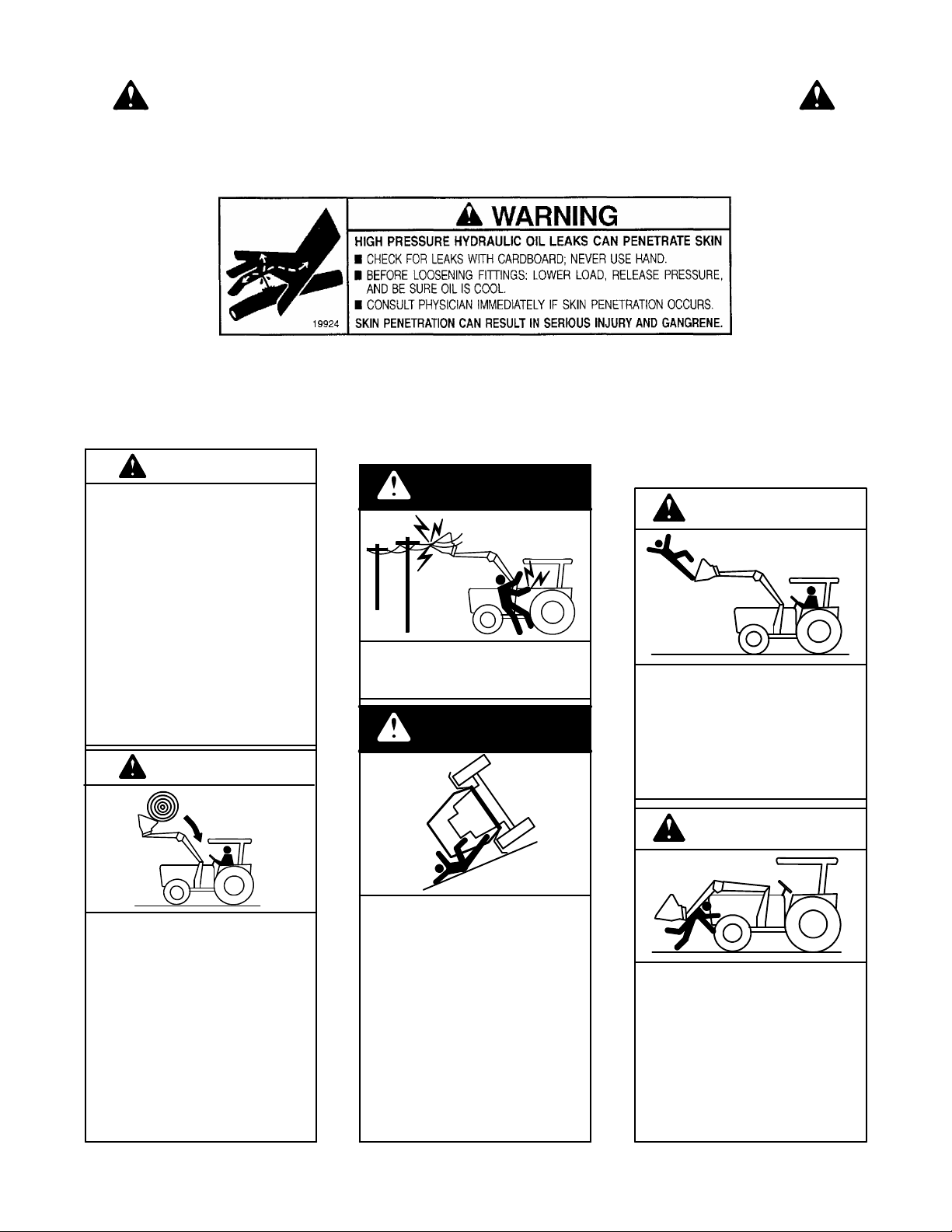

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

WARNING

D Read and understand

Operator’s Manual before

operating (available from

dealer or call 1-800-319-6637).

D Keep others away when

operating loader.

D Do not allow children or

untrained persons to operate

equipment.

D Lower loader to ground, stop

engine, set park brake and

remove key before leaving

tractor seat.

D Failure to follow safety rules

can result in serious injury or

death.

WARNING

SAFETY RULES

DANGER

SERIOUS INJURY OR DEATH

CAN RESULT FROM CONTACT

WITH ELECTRICAL LINES.

DANGER

WARNING

FALLING HAZARD

TO AVOID INJURY

OR DEATH:

D DO NOT WORK FROM OR

ALLOW RIDERS ON LOADER

OR ITS ATTACHMENTS.

FALLING LOAD HAZARD

TO AVOID INJURY

OR DEATH:

D Do not handle round bale or

other shiftable load unless

loader is equipped with

approved attachments. (Read

Operator’s Manual.)

D Lift and carry only one bale

at a time.

D Handle raised load with

caution.

D Carry load low.

26-0352

ROLLOVERS CAN

RESULT IN INJURY

OR DEATH

D ALWAYS USE ROPS AND

SEAT BELT.

D ADD REAR TRACTOR

BALLAST

D MOVE WHEELS TO WIDEST

SETTING.

D AVOID SLOPE OPERATION.

D OPERATE AT LOW SPEEDS.

D CARRY LOAD LOW.

26-0351

1PN-53661 (Rev. 12/96)

WARNING

CRUSHING HAZARD

TO AVOID INJURY

OR DEATH:

D DO NOT WALK OR WORK

UNDERNEATH A RAISED

LOADER.

D LOWER LOADER TO

GROUND BEFORE LEAVING

TRACTOR SEAT.

26-0350

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by a single careless act of an operator.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel

involved in the operation, transport,maintenance

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be

that kind of an operator.

The designed and tested safety of this equipment

depends on it being operated within the limitations as

explained in this manual.

INSTALLATION

J Duri ng installation, the tractor engine

should be off, the key removed and the

brakeslocked.Donotdisconnecthydraulic

lines until attachments are removed or

loweredtothegroundandsystempressure

isreleasedbyoperatingvalve levers.Never

operateany hydraulic cylinders during any

phase of the installation process.

TRAINING

J Safety instructionsare impor tant!Read

this manual and the DuAl Loader manual

and follow all safety rules and safety

decals. (Replacement manuals are available from dealer or call 1-800-319-6637.)

Failureto followinstructionsorsafetyrules

can result in serious injury or death.

J If you do not understand any part of

this manual and need assistance, see your

dealer.

J Keep hands and body away from pr essurized lines. Use paper or cardboard, not

body parts to check for leaks. Wear safety

goggles.Hydraulic fluid(oil)underpressure

willeasilypenetrateskinandcancauseserious injury or death.

J Make sure that all operating and

service personnel know that in the event

hydraulic fluid penetrates skin, it must be

surgically removed within a few hours by

a doctor familiar with this form of injury,or

gangrene, serious injury or death can

result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID ENTERS SKIN OR EYES.

J Do not allow children or untrained

persons to operate equipment.

PREPARATION

J Air in hydraulic systems can cause

erraticoperationandallowsloadsor equipment components to drop unexpectedly.

Before operating or allowing anyone to

approach the equipment, purge any air in

the system by operating all hydraulic

functions several times after connecting

equipment, connecting hoses, or doing

any hydraulic maintenance.

J After connecting hoses, check that all

control lever positions function as

instructed in the Operator’s Manual. Do not

operate until control lever and equipment

movements are correct.

J Protectivesleevesmustbe over hydraulic hosesand securelyfastenedonto metal

hose fittings as shown in this manual. Replace if damaged or if protective sleeve is

not properly positioned or secured.

J Make sure all hydraulic hoses, fittings

and valves are in good condition and not

leaking beforestarting power unit or using

equipment. Check and route hoses carefully to prevent damage. Hoses must not

be twisted, bent sharply, kinked, frayed,

pinched, or come into contact with any

moving parts. Operate moveable components through full operational range to

check clearances. Replace any damaged

hoses immediately.

J Your dealer can supply original equipment hydraulic accessories and repair

parts. Substitute parts may not meet original equipment specifications and may be

dangerous.

J Always wear relatively tight and belted

clothing to avoid entanglement in moving

parts. Wear sturdy, rough-soled work

shoes and protective equipment for eyes,

hair, hands, hearing and head.

J Tractor must be equipped with ROPS

or ROPS CAB and seat belt. Keep seat belt

securely fastened. Falling off tractor can

result in death from being run over or

crushed. Keep foldable ROPS systems in

“locked up” position at all times.

J Whenever 3-point implements are attached to tractor, always check full range

of operation for mechanical or hydraulic

hose interference.

(Safety Rules continued on next page)

2 PN-53661 (Rev. 12/96)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

(Safety Rules continued from previous page)

J Ensure shields and guards are properly installed and in good condition.Replace

if damaged.

OPERATIONAL SAFETY

J Protectivesleevesmustbeoverhydraulic hoses and securely fastened onto metal

hose fittings as shown in this manual. Replace if damaged or if protective sleeve is

not properly positioned or secured.

J Keep bystanders away from equipment while it is in operation.

J Donot modifyoralter orpermit anyone

else to modify or alter the loader, loader

mountingkit, any of its componentsor any

loader function.

J Tractor must be equipped with ROPS

or ROPS CAB and seat belt. Keep seat belt

securely fastened. Falling off tractor can

result in death from being run over or

crushed. Keep foldable ROPS systems in

“locked up” position at all times.

J Always sit in tractor seat when operating controls or starting engine. Securely

fastenseatbelt, placetransmission in park

or neutral, engage brake and ensure all

other controls are disengaged before

starting tractor engine.

J Before dismounting tractor or performing any service or maintenance, disengage

powertoimplement,lowerthe3-pointhitch

and all raised components to the ground,

operatevalve levers to release any hydraulicpressure,stopengine,setparkingbrake,

remove key, and unfasten seat belt.

MAINTENANCE SAFETY

J Before dismounting tractor or performing any service or maintenance, disengage

powertoimplement,lowerthe3-pointhitch

and all raised components to the ground,

operatevalve levers to release any hydraulicpressure,stopengine,setparkingbrake,

remove key, and unfasten seat belt.

J Your dealer can supply original equipment hydraulic accessories and repair

parts. Substitute parts may not meet original equipment specifications and may be

dangerous.

J Always wear relatively tight and belted

clothing to avoid entanglement in moving

parts. Wear sturdy, rough-soled work

shoes and protective equipment for eyes,

hair, hands, hearing and head.

J Keep all persons away from operator

control area while performing adjustments, service or maintenance.

J Tighten all bolts, nuts and screws, and

check that all cotter pins are installed

securely to ensure equipment is in a safe

condition before operating.

J Ensure shields and guards are properly installedand ingood condition. Replace

if damaged.

NOTES

3PN-53661 (Rev. 12/96)

Loading...

Loading...