Wolf TYG60C Installation Manual

©ITW Food Equipment Group, LLC

An Illinois Tool Works Company

3600 North Point Blvd. Baltimore,MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-36960 (9-15)

MODELS

TYG48

TYG60

TYG48

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

INSTALLATION & OPERATION MANUAL

TEPPAN-YAKI GRIDDLES

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

Improper installation,

adjustment alteration, service or maintenance

can cause property damage, injury or death.

Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

- 2 -

INSTALLATION, OPERATION AND CARE OF

Model

Number of Burners

BTU/hr Input Rating

TYG48C / TYG60C

1

30,000

HEAVY DUTY GAS GRIDDLES

GENERAL

Teppan-Yaki Griddles are produced with quality workmanship and materials. Proper

installation, usage and maintenance of your griddle will result in many years of

satisfactory performance.

Thoroughly read this entire manual and carefully follow all of the instructions provided

INSTALLATION

Before installing, verify that the type of gas supply (natural gas or propane) agree with

the specifications on the rating plate riveted behind the chassis panel on the right side of

the unit. If the supply and equipment requirements do not agree, do not proceed with the

installation. Contact your dealer immediately. It is recommended that a trained gas

service technician with the necessary tools, instruments, skills and experience with this

type of restaurant operation perform the installation of the griddle.

UNPACKING

This griddle was inspected before leaving the factory. The carrier assumes full responsibility for the

safe delivery upon acceptance of the shipment. Check for possible shipping damage immediately after

receipt.

If the griddle is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The griddle cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

Carefully unpack your griddle and make sure that no parts are discarded with packaging

material. A pressure regulator designed to operate with the griddle has been supplied and

must be installed before the griddle is placed into service (Refer to GAS PRESSURE

REGULATOR INSTALLATION in this manual).

LOCATION

Do not permit air to blow directly at the griddle. Avoid open windows next to the griddle

wherever possible. Avoid wall-type fans which create air cross-currents within the room.

This griddle is Design Certified for installation on a non-comb u s tible counter with 4 ” le gs,

or combustible floor with 20” h ig h stand.

- 3 -

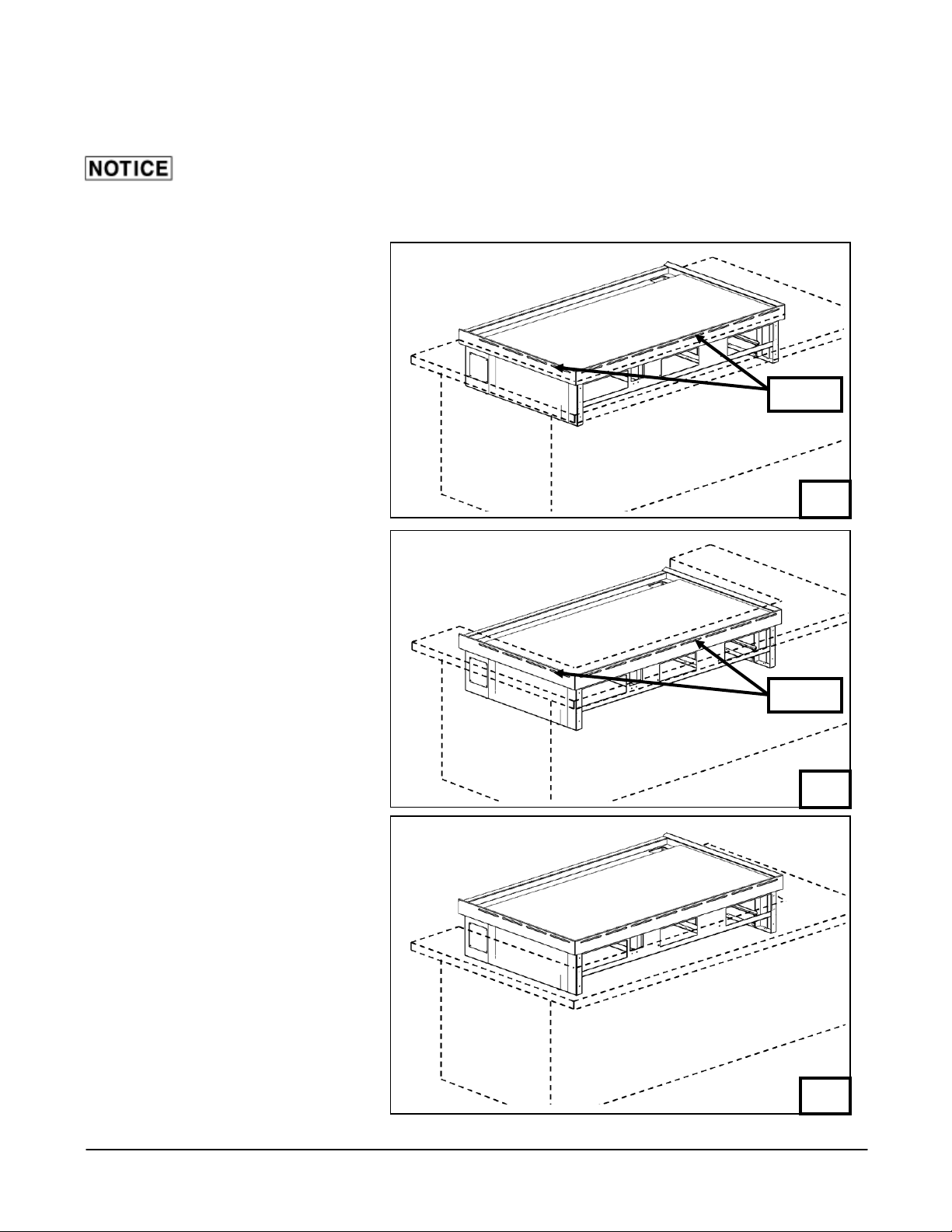

The Teppan-Yaki Griddle is designed for installation in conjunction with a dining counter

CORRECT INSTALLATION

Griddle is correctly installed in table

with flue slots exposed a minimum of

¼” above table surface. Fig. 1

INCORRECT INSTALLATION

Griddle is incorrectly installed in table

with flue slots covered by table edge.

Fig. 2

INCORRECT INSTALLATION

Griddle is incorrectly installed in table

too high with entire flue slot trim

exposed. Fig. 3

Flue Slots

Fig. 1

Fig. 2

Fig. 3

Flue Slots

or table. The design of the counter and installation should only be done by those

experienced with this type of restaurant operation.

Do not obstruct the flue slots located around the edge of the griddle. The

griddle should be installed with the flue slots ¼” above the counter or table surface.

- 4 -

INSTALLATION CLEARANCES

COMBUSTIBLE CONSTRUCTION

NON-COMBUSTIBLE

CONSTRUCTION

Back:

0”

0”

Sides:

0”

0”

INSTALLATION CODES AND STANDARDS

The griddle must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be

resistant to the action of propane gases.

Us e a ¾” NPT g as supply line for the griddle inlet, located at the rear of the griddle. All of

flexible and semi-rigid gas supply lines must comply with the applicable ANSI standard.

To ensure maximum operating efficiency this appliance must be connected with a gas

supply line of solid pipe or a commercial type Flexible Connector with the net inside

diameter (I.D.) as large as or larger than the gas pipe inlet on this appliance. Codes

require that a gas shutoff valve must be installed in the gas line upstream of the griddle.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

After checking for leaks all lines receiving gas should be fully purged to remove air.

- 5 -

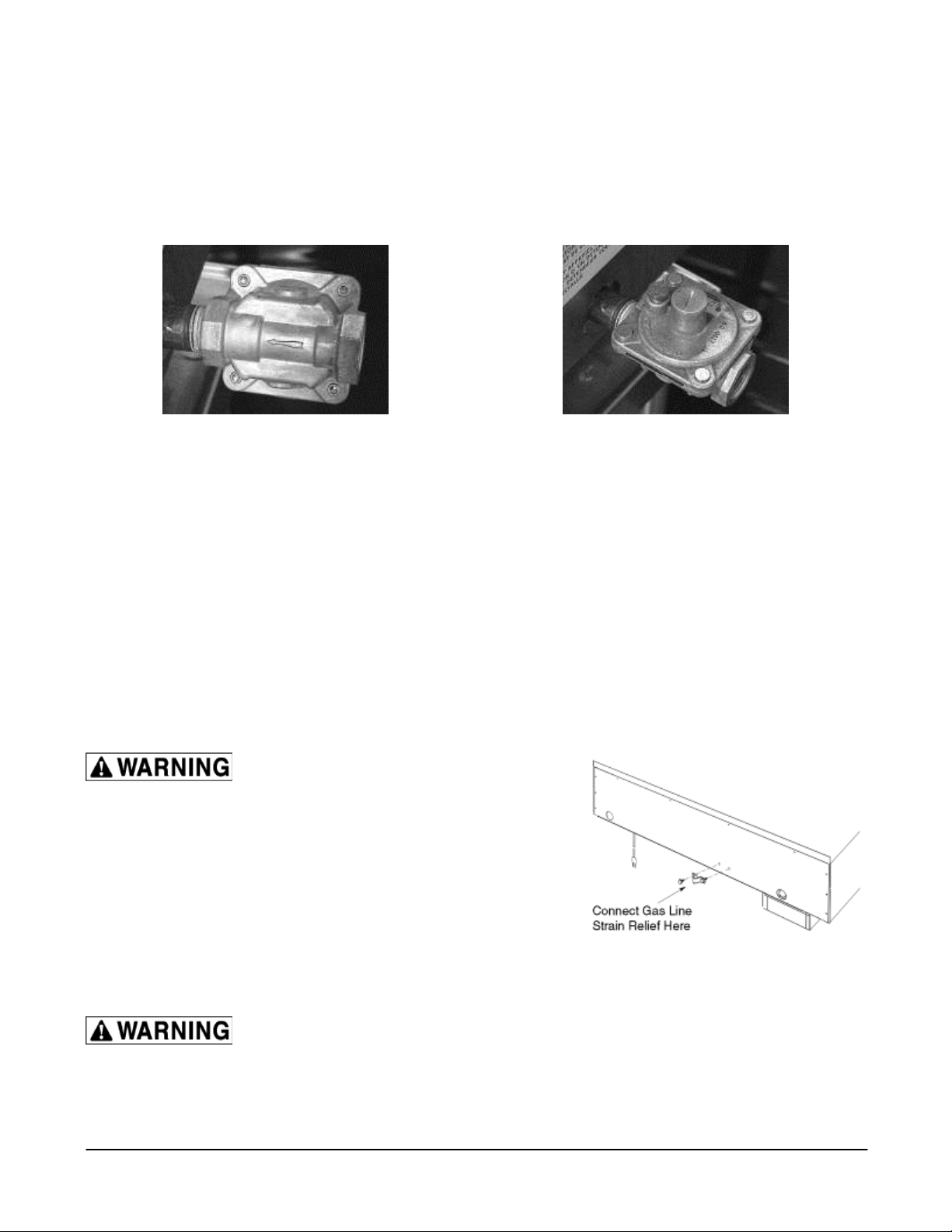

GAS PRESSURE REGULATOR INSTALLATION

Fig. 4

Fig. 5

Griddles mounted on stands with

casters must use a flexible connector (not

supplied) that complies with the Standard for

Connectors for Movable Gas Appliances ANSI

Z21 . 69•CSA6 .16, and a quick -disconnect device that

com plies with Gas Fuel, ANSI Z21.3•CS A6.9. I n

addition, adequate means must be provided to limit

movement of the appliance without depending on

the connector and the quick-disconnect device (or

its associated piping) to limit appliance movement.

Attach the restraining device at the rear of the

griddle as shown in Fig. 6.

Fig. 6

Gas regulator pressure is preset at 5” Water Column (W .C.) for natural gas, and 10” W.C.

for propane gas. No further adjustment should be required.

Make sure that the arrow on the underside of the regulator is oriented in the direction of

gas flow to the griddle (Fig. 4) and the regulator is positioned with the vent plug and

adjustment screw upright (Fig. 5).

The supply pressure (upstream of the regulator) should be 7-9 ” W .C. for natural gas and

11-12” W .C. for propane gas. At no time should the griddle be connected to s upply

pressure greater than ½ psig (3.45 kPa) or 14” W. C.

TESTING THE GAS SUPPLY SYSTEM

When the gas supply pressure exceeds ½ psig (3.45 kPa), the griddle and its individual

shutoff valve must be disconnected from the gas supply piping system.

When the gas supply pressure is ½ psig (3.45 kPa) or less, the griddle should be isolated

from the gas supply system by closing its individual manual shutoff valve.

GRIDDLES MOUNTED ON STANDS WITH CASTERS

supply before disconnecting. Reconnect the restraint prior to turning the gas

supply on and returning the griddle to its installation position.

Casters are only supplied on a griddle stand. If the griddle is moved for any reason the

griddle should be re-leveled (see LEVELING in this manual).

If disconnection of the restraint is necessary, turn off the gas

- 6 -

FLUE CONNECTIONS

Do not obstruct the flow of flue gases from the flue slots, located around the outside

perimeter of the griddle. It is recommended that flue gases be ventilated to the outside of

the building through a ventilation system installed by qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum

cle a r a n ce of 18” must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for “Vapor Removal f rom Cooking Equipment”, NFPA N o . 96 (latest edition),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

OPERATION

The griddle and its parts are hot. Use care when operating,

cleaning or servicing the griddle

BEFORE FIRST USE

Remove all packing material and protective plastic from the surfaces of the unit. Before

leaving the factory the griddle is coated with vegetable oil as a rust inhibitor. Remove this

film when the griddle plate is being cleaned prior to its first cooking use. Heat the griddle

to 200-300°F to loosen and melt the coating, then clean the surface by adding water or

a non-corrosive, grease dissolving commercial c l ean e r , follo wing the m a nuf acturer’s

directions. Scrape the oil residue from the plate with a griddle scraper. Rinse thoroughly

and wipe dry with a soft clean cloth.

SEASONING THE GRIDDLE

Season the griddle to avoid possible surface corrosion before first use, and after every

cleaning. This will also help reduce the sticking of cooked food product. Heat griddle to a

low temperature (300-350°F) and apply a small amount of cooking oil – about one ounce

per square foot of surface. Use a soft lint-free cloth to spread the oil over the entire

griddle surface to create a thin film. Wipe off any excess oil with a cloth. Repeat the

procedure until the griddle has a slick, mirror-like finish.

CONTROLS

This model features a standing pilot that must be manually lit with an outside ignition

source (such as a lit taper, etc). The pilot is monitored by a thermocouple and pilot

safety valve. If the pilot goes out, the safety valve will shut-off the gas supply to the pilot

and main burner.

The griddle burner is controlled by an infinite heat control valve. Once the pilot is lit,

turning the burner control knob to the full ON position will light the burner. The burner

will be in the full ON position when the burner control knob is turned all the way to the

left. The burner will be in the OFF position when the burner control knob is turned all the

- 7 -

way to the right. The height of the burner flame and cooking plate temperature can be

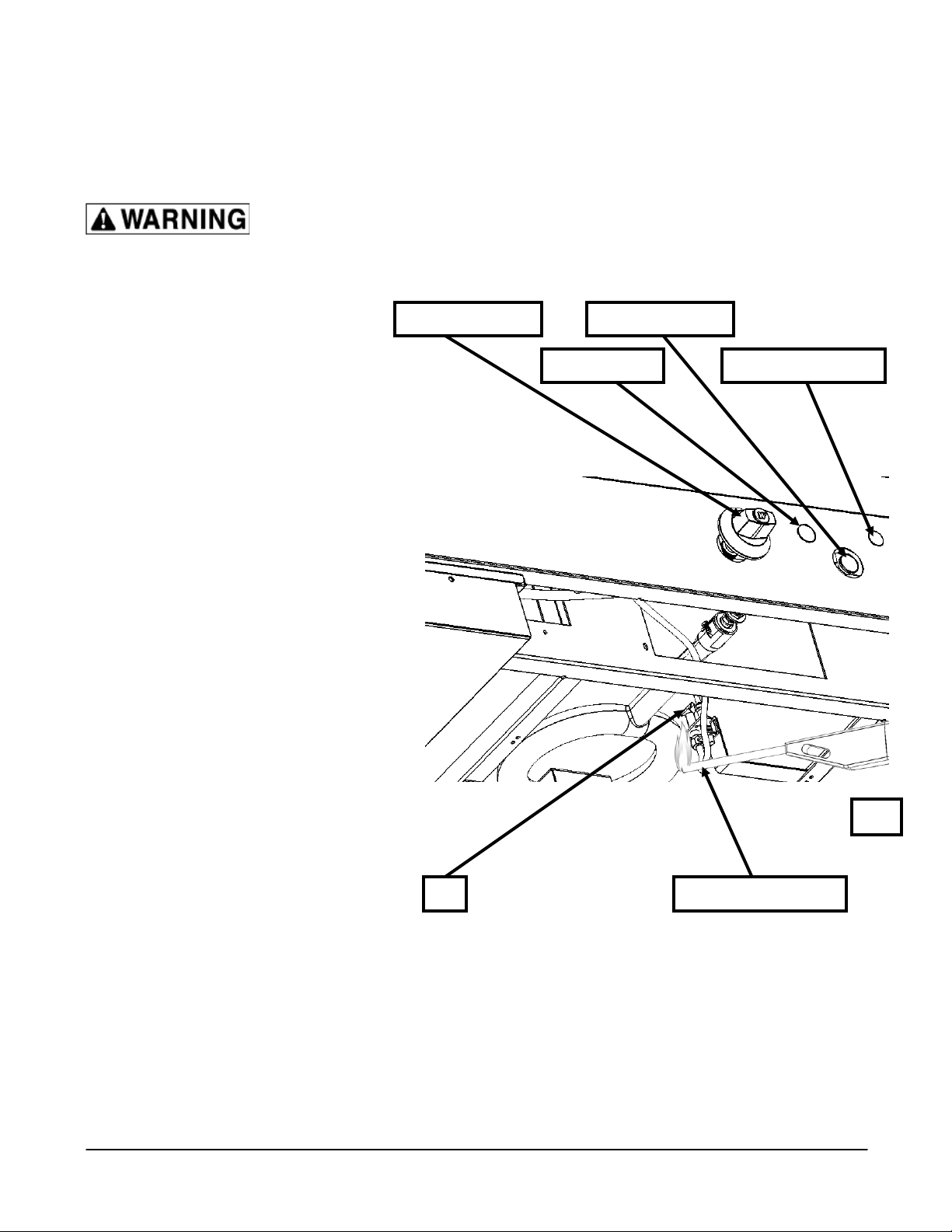

1. Turn the main gas shut-off valve and

burner control knob to the OFF position.

Wait 5 minutes to allow any gas that

may have accumulated in the burner

compartment to escape.

2. Turn the main gas shut-off valve ON.

3. Depress and hold the safety valve

button while lighting the pilot. You will

have to reach under the front of the unit

to light with an outside ignition source

(such as a lit taper, etc.) while viewing

thru the pilot sight hole.

4. When the gas at the pilot has been

burning for about 45 seconds, release

the safety valve button. If the pilot does

not remain lit, repeat the operation

allowing more time before releasing

the button. The amount of time

necessary to hold the safety valve

button will increase at the initial

installation of the unit and if the main

gas supply has been turned off for a

long period of time. It may be

necessary to adjust the pilot valve to

increase gas to the pilot.

6. If after completing steps 1-4 pilot does

not light, turn off the main gas shut-off

valve and contact an authorized

service contractor.

Fig. 7

Safety Valve Button

Pilot Adjustment Valve

Burner Control Knob

Pilot Sight Hole

Pilot

Outside Ignition Source

adjusted by turning the burner control knob while viewing burner through the burner sight

holes.

The griddle and its parts are hot. Use care when operating,

cleaning or servicing the griddle

PILOT LIGHTING PROCEDURE

- 8 -

Loading...

Loading...