PRO WALL HOOD

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

PRO WALL HOOD

Contents

3 Pro Wall Hood

4 Safety Precautions

5 Specications

9 Installation

14 Blower Specications

15 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

2 | Wolf Customer Care 800.222.7820

PRO WALL HOOD

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

Product Information

Important product information, including the model and

serial number, are listed on the product rating plate. The

rating plate is located inside the left wall of the hood shell.

Refer to the illustration below.

If service is necessary, contact Wolf Factory Certied

Service with the model and serial number. For the name of

the nearest Wolf Factory Certied Service or for questions

regarding the installation, visit the contact and support

section of our website, wolfappliance.com, or call Wolf

Customer Care at 800-222-7820.

RATING PLATE

Rating plate location

wolfappliance.com | 3

SAFETY PRECAUTIONS

IMPORTANT INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY, OBSERVE THE FOLLOWING:

• Installation work and electrical wiring must be

done by qualied person(s) in accordance with all

applicable codes and standards, including rerated construction.

• Two installers are recommended due to the size

and weight of the pro hood.

• Install the pro hood only with a blower manufac-

tured by Wolf.

• When cutting or drilling into the wall or ceiling,

do not damage electrical wiring and other hidden

utilities.

CAUTION

To reduce the risk of re and properly exhaust air,

be certain to duct air outside. Do not vent exhaust

air into spaces within walls or ceilings or into

attics, crawl spaces, or garages.

• Ducted fans must always be vented to the

outdoors.

4 | Wolf Customer Care 800.222.7820

SPECIFICATIONS

Installation Requirements

Installation of the hood should be 30" (762) to 36" (914) from

the bottom of the hood to the countertop.

BLOWER ASSEMBLIES

Pro Wall Hoods require an internal, in-line, or remote blower

assembly, avail able through an authorized Wolf dealer. For

local dealer information, visit the nd a showroom section of

our website, wolfappliance.com. Refer to specic installation instructions provided with each blower assembly.

For internal blowers, install the blower prior to mounting the

hood.

HORIZONTAL DISCHARGE

Pro Low-Prole Wall Hoods have an adjustable discharge.

Pro Wall Hoods that are 24"

(610) and 27" (686) deep have

a vertical discharge. A horizontal discharge kit is avail able

through your authorized Wolf dealer. For local dealer information, visit the nd a showroom section of our website,

wolfappliance.com.

DUCT COVER

RECIRCULATING APPLICATION

Pro Wall Hoods in 30" and 36" widths with an internal

blower (600 CFM or less), can be used in a non-ducted

application with a recirculating lter. A recirculation kit, available through an authorized Wolf dealer, is required. For local

dealer information, visit the nd a showroom section of our

website, wolfappliance.com.

Optional stainless steel duct covers, in multiple heights, are

available through your authorized Wolf dealer. Duct covers

must be attached to the hood prior to hood installation. For

local dealer information, visit the nd a showroom section of

our website, wolfappliance.com.

wolfappliance.com | 5

SPECIFICATIONS

Ducting

WARNING

To reduce the risk of re, use only metal ducting.

IMPORTANT NOTE: Consult a qualied HVAC professional

for specic installation and ducting applications.

Pro Wall Hoods accommodate a 10"

(254) round duct. Use

only rigid metal ducting.

A straight, short duct run allows the hood to perform most

efciently. If the duct run exceeds 50'

(15 m), a higher CFM

blower may be required to maintain proper air ow.

Internal and in-line blowers require a roof or wall cap.

Connect ducting to the cap or to the remote blower and

work back towards the hood. Use sheet metal screws and

high-temperature duct tape to seal joints between ducting

sections.

Pro Wall Hoods include a backdraft damper. Local codes

may require the use of an additional backdraft and/or makeup air damper. Contact your local HVAC professional for

specic requirements.

A make-up air damper is available through an authorized

Wolf dealer. For local dealer information, visit the nd a

showroom section of our website, wolfappliance.com.

6 | Wolf Customer Care 800.222.7820

SPECIFICATIONS

Discharge

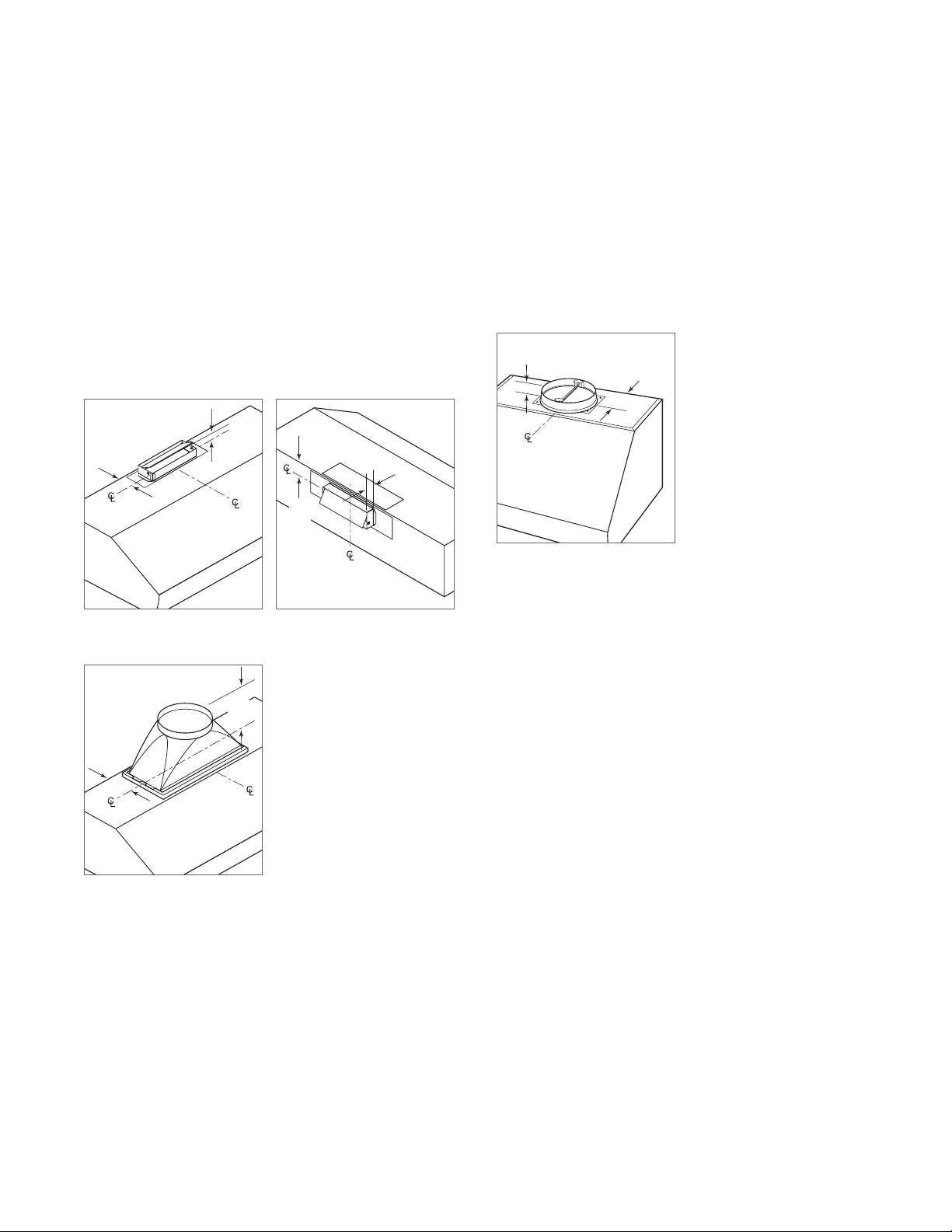

LOW-PROFILE WALL HOOD

Pro Low-Prole Wall Hoods with an internal blower can have

a vertical or horizontal discharge. Refer to the illustrations

below.

For Pro Low-Prole Wall Hoods with an in-line or remote

blower, a transition is required.

25/8"

(60)

Vertical discharge

11/2"

(38)

2"

(51)

Horizontal discharge

11/2" (38)

24"/27" DEEP WALL HOOD

Pro Wall Hoods that are 24" (610) and 27" (686) deep have a

vertical discharge. Refer to the illustration below.

2" (54)

Vertical discharge

55/8" (143)

TO CENTER

OF TRANSITION

55/8"

(143)

Accessory round transition

9"

(229)

wolfappliance.com | 7

SPECIFICATIONS

Electrical Requirements

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustration

below. A separate circuit servicing only this appliance is

required.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

6"

E

(152)

5"

(127)

30" (762) TO 36" (914) BOTTOM EDGE TO COUNTERTOP

Hood Preparation

Remove the lters prior to installation. To remove, press

the lter upward and rotate the bottom. Remove the grease

cups from the bottom edge of the hood. Refer to the illustration below.

FILTER

GREASE

Filters

CUP

SPRING

SIDE VIEW

Electrical location

RATING PLATE

Rating plate location

8 | Wolf Customer Care 800.222.7820

INSTALLATION

Low-Prole Wall Hood

INSTALLATION

WARNING

Wall framing must be able to support the weight of the

hood and internal blower, if applicable.

1 Refer to the illustration for typical wall framing. Additional

framing or blocking is required in the mounting bracket

location.

2 Position the mounting brackets on the wall as shown

in the illustration below. Secure the brackets to the wall

framing and blocking with the provided screws and

washers.

261/4" (667)

MOUNTING BRACKET

CENTERS

71/4" (189)

TO BOTTOM

OF HOOD

BLOCKING

3 Install the transition. For an internal blower, the transi-

tion is included with the blower. For in-line and remote

blowers, a transition is required (not provided). Refer to

the illustration below.

4 Place the hood on the mounting brackets. Secure with

the provided screws through the mounting holes on the

back panel. Verify the screws engage the wall framing or

blocking. If additional support is required, drill supplementary holes through the back panel and secure with

screws and washers.

5 Insert Romex

®

wire(s) into the electrical box knockout

and secure with a UL or C/UL approved connector (not

provided).

6 Connect the ducting to the transition and secure with

duct sealing tape.

TRANSITION

Mounting bracket location

C

L

Transition (internal blower)

ELECTRICAL

BOX

(INSIDE HOOD)

Electrical box location

wolfappliance.com | 9

INSTALLATION

24"/27" Deep Wall Hood

INSTALLATION

WARNING

Wall framing must be able to support the weight of the

hood and internal blower, if applicable.

1 Refer to the illustration for typical wall framing. Additional

framing or blocking is required in the mounting bracket

location.

2 A wood mounting strip and hardware are provided with

the hood. Secure the mounting strip to the wall framing

and blocking with the provided screws and washers.

3 Position the mounting brackets on the mounting strip

as shown in the illustration below. Secure the brackets

to the mounting strip with the provided screws and

washers.

MOUNTING BRACKET LOCATION

30" (762) Hood 231/2" (597)

36" (914) Hood 241/2" (622)

42" (1067) Hood 301/2" (775)

48" (1219) Hood 361/2" (927)

54" (1372) Hood 421/2" (1080)

60" (1524) Hood 481/2" (1232)

66" (1675) Hood 541/2" (1384)

A

MOUNTING

STRIP

1

/2" (13)

151/8" (384)

TO BOTTOM

OF HOOD

MOUNTING BRACKET CENTERS

BLOCKING

A

Mounting bracket location

C

L

10 | Wolf Customer Care 800.222.7820

INSTALLATION

24"/27" Deep Wall Hood

INSTALLATION

4 The hood is shipped with the transition attached upside

down inside the top of the hood. Refer to the illustration

below.

5 Separate the transition from the hood by removing the

hold-down brackets. Remove the shipping material from

the transition.

6 Mount the transition and hold-down brackets to the top

of the hood using the existing screws. Refer to the illustration below.

7 For internal blowers, install the blower prior to mounting

the hood. Refer to the instructions provided with the

blower.

TRANSITION

HOLD-DOWN

BRACKET

8 Place the hood on the mounting brackets. Secure with

the provided screws through the mounting holes on the

back panel. If additional support is required, drill supplementary holes through the back panel and secure with

screws and washers.

9 Insert Romex

®

wire(s) into the electrical box knockout

and secure with a UL or C/UL approved connector (not

provided).

10 Connect the ducting to the transition and secure with

duct sealing tape.

MOUNTING STRIP

ELECTRICAL

BOX

(INSIDE HOOD)

TRANSITION

Transition position (shipping) Transition mounting

Hood installation

Electrical box location

wolfappliance.com

wolfappliance.com | 11

|

11

INSTALLATION

Electrical Connections

WARNING

Before making electrical connections, verify power is

turned off at the service panel.

IMPORTANT NOTE: Refer to installation instructions pro-

vided with the blower assembly.

INTERNAL BLOWER

1 Remove the hood’s electrical box cover.

2 Connect black to black and white to white with the

provided connectors, and connect the green/bare wire

to the ground screw.

3 Place all wiring connections inside the electrical box.

Verify all wires are secure and not pinched, and reinstall

the cover.

4 Insert the blower power cord into the receptacle inside

the hood. Refer to the illustration below. Turn the power

on and check operation.

IN-LINE/REMOTE BLOWER

1 Remove the hood’s electrical box cover.

2 Connect the home supply. Connect black to black and

white to white with the provided connectors, and connect the green/bare wire to the ground screw.

3 Connect the blower supply to the power cord provided

with the blower. Connect black to black, white to white,

and the green/bare wire to the ground screw.

4 Place all wiring connections inside the electrical box.

Verify all wires are secure and not pinched, and reinstall

the cover.

5 Insert the blower power cord into the receptacle inside

the hood. Refer to the illustration below. Turn the power

on and check operation.

RECEPTACLE

RECEPTACLE

ELECTRICAL

BOX

Blower receptacle

12 | Wolf Customer Care 800.222.7820

ELECTRICAL

Blower receptacle

BOX

INSTALLATION

Complete the Installation

FILTERS

Install the grease cups at the bottom rear edge of the hood.

Orient the lters with the lines running vertically. To install,

place the top edge of the lter against the spring, press

upward and rotate the bottom. Refer to the illustration

below.

LIGHT BULBS

A suction-cup-style light bulb changer is provided with

the hood. To install, use the changer to push the bulb into

the receptacle and rotate counterclockwise one-quarter

turn. Refer to the illustration below.

(686) deep wall hoods, install the heat lamp bulbs

For 27"

(not included). Use R40, 250W bulbs.

FILTER

GREASE

CUP

SPRING

WOLF LOGO

To attach the Wolf logo, clean the mounting area with rubbing alcohol. Remove the paper backing, position the logo

parallel with the bottom of the hood, then press into place.

Filters

SIDE VIEW

LIGHT BULB

CHANGER

Light bulb installation

wolfappliance.com | 13

BLOWER SPECIFICATIONS

28

29

29

11

Blower Dimensions

IN-LINE BLOWERS

243/8"

(619)

3

/4"

(298)

181/2"

(470)

41/2"

(114)

211/2"

(546)

121/4"

(311)

18"

(457)

12"

(305)

22"

(559)

8"

(203)

24

(632)

18"

(457)

7

/8

"

600 CFM in-line blower

REMOTE BLOWERS

3

/4

20

"

24

(629)

(527)

3

/4

"

1

(718)

/4

15

(394)

"

10" (254)

DIAMETER

1

/2

"

14"

(356)

600/900 CFM remote blower

24

(622)

1

/2

3

4

(121)

1100 CFM in-line blower

18" (457)

10"

1

/2

"

(749)

14

"

/4

"

(375)

10" (254)

DIAMETER

3

/4

"

1

/8

10

"

(257)

22"

(559)

1200 CFM remote blower

(254)

29

(749)

7

(184)

1

/2

"

(749)

1

/2

"

1

/4

"

14

(375)

10" (254)

DIAMETER

3

/4

"

3

/8

10

"

(264)

1500 CFM remote blower

25"

(635)

21" (533)

10"

(254)

29

(749)

7

(184)

1

/2

"

1

/4

"

14 | Wolf Customer Care 800.222.7820

TROUBLESHOOTING

Troubleshooting

IMPORTANT NOTE: If the hood does not operate properly,

follow these troubleshooting steps:

• Verify electrical power is supplied to the hood.

• Verify proper wiring connections.

• If the hood does not operate properly, contact Wolf

Factory Certied Service. Do not attempt to repair the

hood. Wolf is not responsible for service required to

correct a faulty installation.

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

wolfappliance.com | 15

WOLF APPLIANCE, INC. P.O. BOX 44848 MADISON, WI 53744 WOLFAPPLIANCE.COM 800.222.7820

10/2018

Loading...

Loading...