Page 1

OWNER’S MANUAL

INSTALLATION & OPERATION

WKE SERIES

ELECTRIC

CONVECTION OVENS

MODELS

WKE ML-126755

WKED ML-126756

WKEC ML-126757

WKEX ML-126758

WKEDX ML-126759

WKECX ML-126760

FORM 31162 (Apr. 2000)

THE WOLF RANGE COMPANY LLC

19600 S. Alameda St., Compton, California 90221-6291

P. O. Box 7050, Compton, California 90240-7050

(310) 637-3737 • FAX (310) 637-7931 • (800) 366-WOLF

®

Page 2

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing Basic Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembling the Legs to the Single Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembling the Stand to the Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling Stacked Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Connections (Stacked Ovens). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before First Use (All Models). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls — Models Models WKE / WKEX / WKED / WKEDX . . . . . . . . . . . . . . . . . . . . . 7

Using Models Models WKE / WKEX / WKED / WKEDX . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Optional Stainless Steel Oven Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controls — Models WKEC / WKECX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Manually Setting the Temperature and Cook Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Program Menu Item and Rack # Cook Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Change the Time Setting for any Menu Item (1 – 6). . . . . . . . . . . . . . . . . . . . . . . . . 10

To Program Individual Rack # Cook Times for a Menu Item . . . . . . . . . . . . . . . . . . . . . 10

Always Set the Temperature before Setting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Starting a Timed Cycle on All Racks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Starting a Timed Cycle Using Programmed Individual Menu / Rack # Cook Time(s) . 11

To Display the Actual Oven Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

To End a Cooking Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Door and Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting the Oven for Roast & Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Roast and Hold Operation — Models WKEC / WKECX. . . . . . . . . . . . . . . . . . . . . . . . . 12

Proper Utensils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating Hints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cooking Guidelines (Holding Feature) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Standard Cooking Time Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Outage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

© THE WOLF RANGE COMPANY LLC, 2000

– 2 –

Page 3

Installation, Operation, and Care of

WKE SERIES

ELECTRIC CONVECTION OVENS

SAVE THESE INSTRUCTIONS

GENERAL

The WKE Series Electric Convection Ovens feature a 500°F thermostat, timer, porcelain interior, and

1

a two-speed,

⁄2 HP blower motor as standard equipment. Ovens equipped with standard voltages are

208 or 240 Volt, 60 Hertz, single- or three-phase. Ovens equipped for 480 volt, 60 Hertz, single- or

three-phase electrical specifications are optional.

The WKE Series Oven is a single cavity oven furnished with five racks. Independently opening doors

are standard; simultaneously opening doors with chain mechanism underneath are optional. Oven

lights with on-off switch are standard on all models.

An open stand with lower storage rack is available as an option.

Stacked ovens are furnished with either Stacking Kit 426983G3 (8" LEGS) or Stacking Kit 426984G3

CASTERS) for mounting one oven on top of the other.

(

Additional racks are available as accessories.

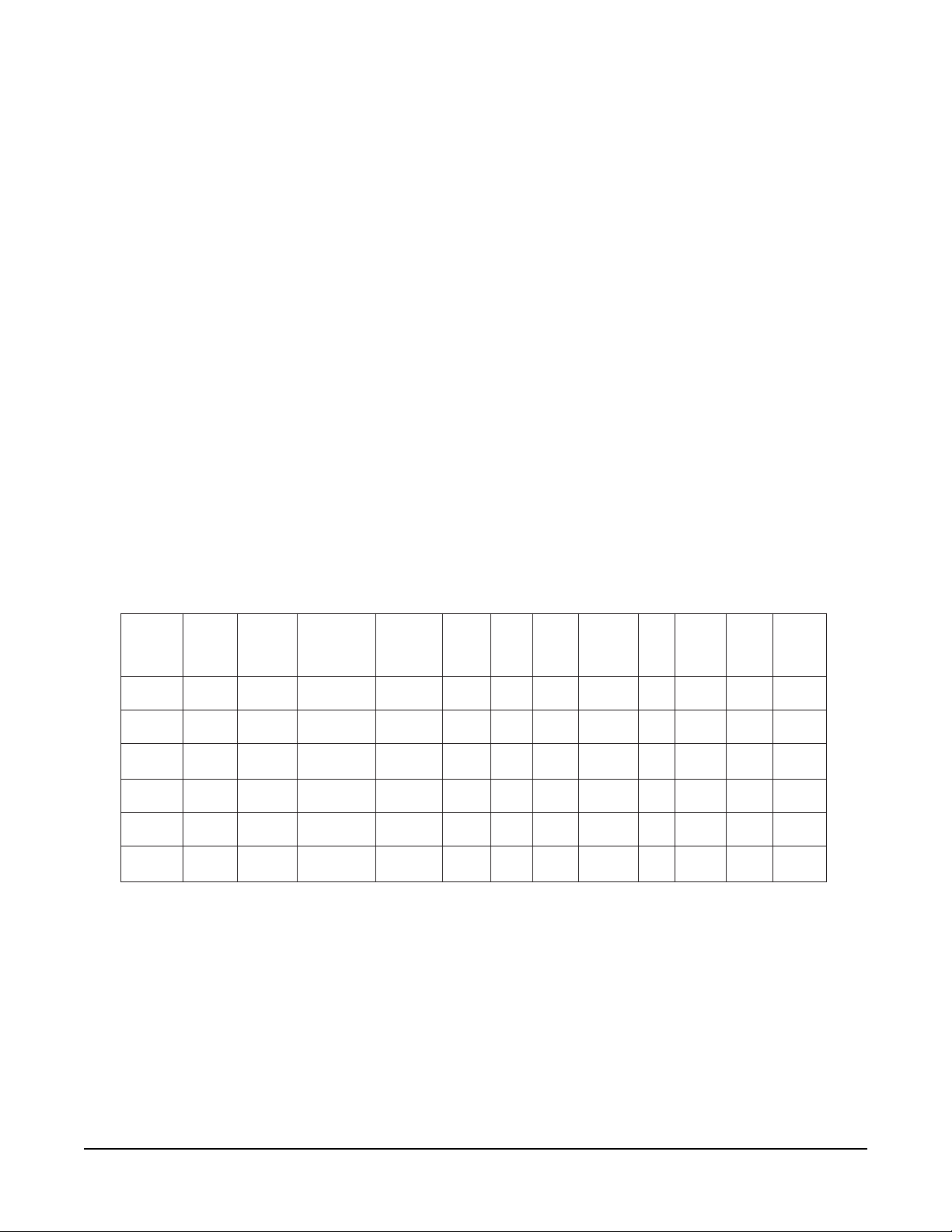

Features of the models are shown below:

SNOITPO&SERUTAEFSNOITPO&SERUTAEF

SNOITPO&SERUTAEFSNOITPO&SERUTAEF

SNOITPO&SERUTAEF

kcatSkcatS

kcatSkcatS

nevOnevO

nevOnevO

621/2"

1

/2"

62

1

62

/2"

1

03

/2"

1

/2"

03

1

03

/2"

nevO

roiretnIroiretnI

roiretnIroiretnI

roiretnI

htpeDhtpeD

htpeDhtpeD

htpeD

ledoMledoM

ledoMledoM

ledoM

EKW

DEKW

CEKW

XEKW

XDEKW

XCEKW

nevOnevO

nevOnevO

nevO

roiretxEroiretxE

roiretxEroiretxE

roiretxE

htpeDhtpeD

htpeDhtpeD

htpeD

141/2"

)mc3.76(

)mc4.501(

141/2"

)mc3.76(

)mc4.501(

141/2"

)mc3.76(

)mc4.501(

541/2"

)mc5.77(

)mc6.511(

541/2"

)mc5.77(

)mc6.511(

541/2"

)mc5.77(

)mc6.511(

.ylnOsnevOdekcatSowThtiW*

tatsomrehTtatsomrehT

tatsomrehTtatsomrehTremiTremiT

tatsomrehT

remiTremiT

remiT

lacinahceMlaiD.rH1AN.tpO.tpO.tpO.dtS.tpO.tpO.tpO

etatSdiloSlaiD.rH1AN.tpO.tpO.tpO.dtS.tpO.tpO.tpO

retupmoC

.rH42

latigiD

lacinahceMlaiD.rH1AN.tpO.tpO.tpO.dtS.tpO.tpO.tpO

etatSdiloSlaiD.rH1AN.tpO.tpO.tpO.dtS.tpO.tpO.tpO

retupmoC

.rH42

latigiD

tsaoRtsaoR

tsaoRtsaoR

tsaoR

dloH&dloH&

dloH&dloH&

dloH&

.dtSAN.tpO.tpO.dtS.tpO.tpO.tpO

.dtSAN.tpO.tpO.dtS.tpO.tpO.tpO

kcatS

.rH5.rH5

.rH5.rH5

tiKtiK

tiKtiK

.rH5

tiK

remiTremiT

remiTremiT

htiwhtiw

htiwhtiw

remiT

htiw

*sgeL*sgeL

*sgeL*sgeL

*sgeL

tiKkcatStiKkcatS

tiKkcatStiKkcatS

sgeLsgeL

sgeLsgeL

sgeLsgeL

tiKkcatS

htiwhtiw

htiwhtiw

htiw

htiwhtiw

htiwhtiw

htiw

*sretsaC*sretsaC

*sretsaC*sretsaC

*sretsaC

sgeLsgeL

sgeL

sgeL

htiwhtiw

htiwhtiw

htiw

teeFteeF

teeFteeF

teeF

dnatSdnatS

dnatSdnatS

dnatS

htiwhtiw

htiwhtiw

htiw

kcaRkcaR

kcaRkcaR

kcaR

sretsaCsretsaC

sretsaCsretsaC

sretsaC

dnatSdnatS

dnatSdnatS

dnatS

htiwhtiw

htiwhtiw

htiw

&kcaR&kcaR

&kcaR&kcaR

teeF&teeF&

teeF&teeF&

teeF&

&kcaR

sretsaCsretsaC

sretsaCsretsaC

sretsaC

INSTALLATION

UNPACKING

Immediately after unpacking the oven, check for possible shipping damage. If the oven is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees with the specifications on the oven data

plate, located on the inside of the top front cover.

Do not use the doors or their handles to lift the oven.

– 3 –

Page 4

LOCATION

The installation location must allow adequate clearances for servicing and proper operation.

INSTALLATION CODES AND STANDARDS

In the United States, install the oven in accordance with: 1) State and local codes; 2) National Electrical

Code, NFPA-70 (latest edition); and 3) NFPA Standard #96,

Vapor Removal from Cooking Equipment

(latest edition), available from National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

In Canada, install the oven in accordance with: 1) Local codes; 2) Canadian Electrical Code, CSA

Standard C22.2 No.1 (latest edition), and 3) Canadian Standard for Commercial Cooking Equipment

CSA Standard C22.2 No.109 (latest edition).

INSTALLING BASIC OVEN

The basic oven must be installed on legs or be mounted on a modular stand. Installations on concrete

bases or other supports restricting air circulation underneath the oven is not advisable and may void

the warranty. If using the modular stand, set the oven on the stand after unpacking.

ASSEMBLING THE LEGS TO THE SINGLE OVEN

The legs must be installed on the bottom of the oven. Gently position the oven on its left side, taking

care not to cause scratches or damage.

Attach each of the four leg assemblies to the bottom of the oven with the 24 bolts and lockwashers

(6 bolts and lockwashers per leg). Carefully raise the oven to its normal position.

LEVELING

Adjust the legs to ensure that the oven racks are level in the

BACK

final installed position.

CASTERS

If the oven is to be installed on casters, assemble the

casters to the legs provided. Then attach the caster-leg

units to the oven at each corner using the 24 bolts and

lockwashers (6 bolts and lockwashers per leg). Place the

locking casters on the front legs and non-locking casters

on the rear legs.

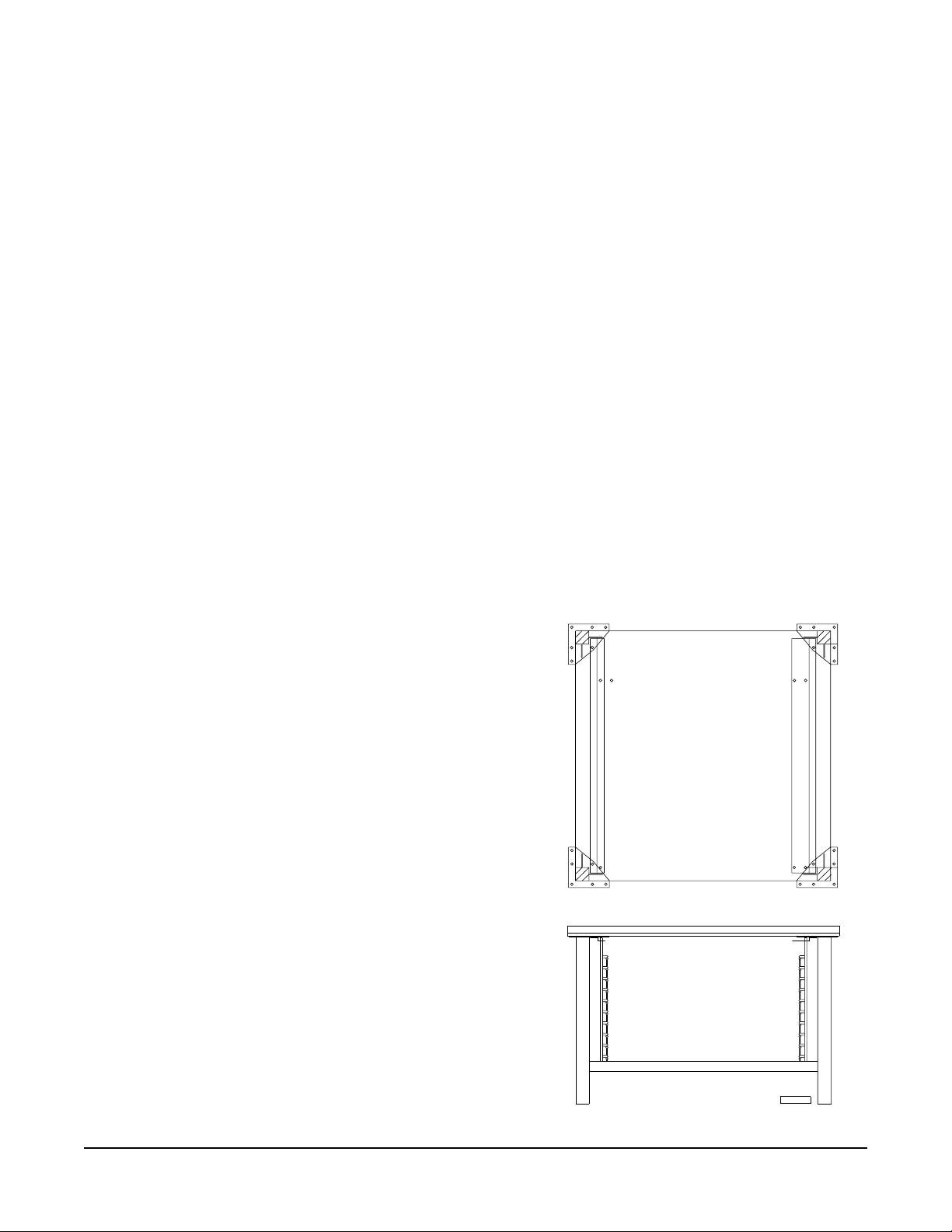

ASSEMBLING THE STAND TO THE OVEN

FRONT

Attach each of the four leg assemblies to the bottom of the

oven with the 24 bolts and lockwashers (6 per leg). Carefully

raise the oven to the normal position.

Attach the undershelf to the legs with 8 bolts and

lockwashers (2 per leg).

Install the rack guides into the shelf at the desired locations

(for pan or flat rack), then attach the rack supports to the

top end of the rack guides. Attach rack supports to the leg

assembly by removing one middle bolt and reattaching the

back through the end holes in the rack support (Fig. 2).

– 4 –

PL-53274

Fig. 2

Page 5

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Remove the wiring compartment cover on the front of the oven. Remove the appropriate knockout on

the bottom of the oven and attach the power supply conduit to the bottom of the oven.

Comply with the wiring diagram (located inside the right side panel) when making connections to the

electrical supply lines.

Replace the wiring compartment cover and turn on the power supply.

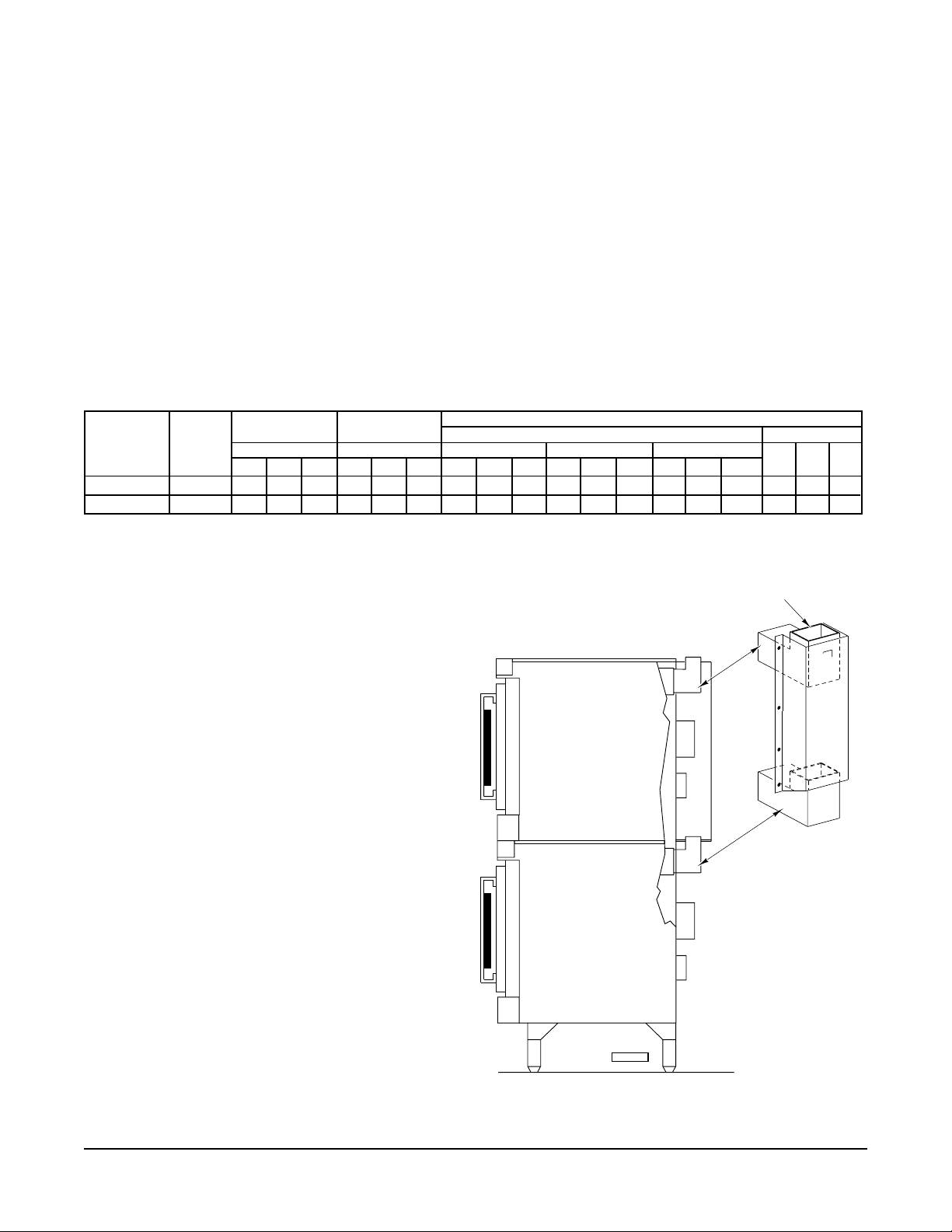

ELECTRICAL DATA

208-240V 480V

TOTAL

Single Oven 12.5 4 4 4.5 4 4 4.5 35 33 35 33 29 33 14.4 15.3 15.3 60 52 26

Stacked Oven 25 8 8 9 8 8 9 70 66 70 66 58 66 28.8 30.6 30.6 120 104 52

3-PHASE LOADING 3-PHASE LOADING

KW KW PER PHASE KW PER PHASE 208V 240V 480V

L1-L2 L2-L3 L1-L3 L1-L2 L2-L3 L1-L3

L1 L2 L3 L1 L2 L3 L1 L2 L3

NOMINAL AMPERES PER LINE WIRE

3-PHASE 1-PHASE

208V 240V 480V

STACKING FLUE

ASSEMBLING STACKED OVENS

Unpack the ovens and the stack kit. Position

the oven to be used as the bottom oven on

its left side for access to the oven bottom,

taking care not to scratch or damage it.

Attach the four leg assemblies with the 24

bolts and lockwashers (6 per leg).

Place the lower oven (with legs) on the floor

and remove two

7

⁄16" (11 mm) diameter

knockouts on each side of the top cover.

Install two locating studs to the bottom of the

top oven per stacking kit instructions.

Move the oven with legs to the installed

position. Place the upper oven on top of the

lower oven using the locating studs.

Remove the optional rear panel, if provided,

from the TOP oven. Install the Stacking Flue

(Fig. 3) with the four screws provided.

Replace the top oven rear panel, if provided.

PL-53463

Fig. 3

– 5 –

Page 6

ELECTRICAL CONNECTIONS (Stacked Ovens)

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Make sure that the electrical power supply agrees with the specifications on the oven data plate, the

wiring diagram on the oven, and with Electrical Data, page 5.

1. Wires to connect both ovens are provided with each oven. Carefully route these leads from the

top oven through the bushing (supplied with the stacking kit) through the electrical access

knockout holes common to both ovens.

2. Connect wires X, Y, and Z from the upper oven to the lower oven per the wiring diagram using

wire nuts provided. Attach the power supply conduit to the bottom of the lower oven. Connect the

power supply leads to the line side of the terminal block on the bottom oven.

3. Finally, inspect and check all wiring and terminal connections for tightness and proper routing

away from any moving parts (relay solenoid core), or pinch points (cover on oven frame).

4. Refer to reference drawing 426986 supplied with the stacking kit for electrical connection

instructions.

5. Refer to instructions supplied with the stacking kit for marking the combined electrical load

information to the electrical data plate of the bottom oven.

BEFORE FIRST USE (All Models)

Before using the oven for the first time, it must be burned off to release any odors that might result from

heating the new surfaces in the chamber.

1. Using a clean damp cloth, wipe the inside of the oven, including the racks.

2. Close the oven doors, turn the Master Switch ON, turn the Thermostat to 300°F (149°C) and allow

the oven to cycle for 6 to 8 hours before turning the Master Switch OFF.

– 6 –

Page 7

OPERATION

WARNING: THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR PERFORMING ANY MAINTENANCE.

CONTROLS — MODELS WKE / WKEX / WKED / WKEDX

MOVE TO VENT

MASTER SWITCH

ON

OFF

OVEN COOL

HEAT

TEMPERATURE

F

500

C

250

450

400

200

Models WKE / WKEX Models WKED / WKEDX

60

55

50

45

FAN SPEED

HI

LOW

200

100

250

300

350

150

TIMER

0

5

OFF

10

15

20

25

30

40

35

LIGHTS

ON

OFF

PL-53495

MOVE TO VENT

150

300

275

250

225

C

100

60

55

50

45

FAN SPEED

HI

LOW

MASTER SWITCH

ON

OVEN COOL

HEAT

350

325

F

150

TEMPERATURE

TIMER

0

OFF

40

35

OFF

200

375

400

425

450

475

500

250

5

10

15

20

25

30

LIGHTS

ON

OFF

PL-53494

MOISTURE VENT DAMPER – Open the damper to exhaust excess moisture. Close the damper

when cooking dry products. Select settings between OPEN and

CLOSED for optimum performance.

MASTER SWITCH – ON -Turns oven control circuits on.

– OFF - Turns oven control circuits off.

– OVEN COOL - Allows the fan motor to run with the doors ajar to

speed oven cooling.

ON LIGHT (Amber) – Lit when MASTER SWITCH is turned to ON.

HEAT LIGHT (White) – Comes on and goes off when the heating elements cycle on and off.

TEMPERATURE – Controls oven temperature.

TIMER – Use to set the cooking time. Alarm sounds continuously when time

has elapsed to 0. Turn the timer OFF to silence the alarm. The timer

does not turn the oven off. Keep timer set to OFF when the oven is

not in use.

FAN SPEED – Adjust air velocity in the oven cavity.

HI - Normal operating speed.

LOW - Use this setting when cooking a delicate product like

meringue, which could blow around in the oven.

LIGHTS – ON - turns the interior lights on.

– OFF - turns the interior lights off.

– 7 –

Page 8

USING MODELS WKE / WKEX / WKED / WKEDX

Preheating

1. Turn Master Switch ON. Amber ON light will come on, indicating that power to oven is on.

2. Set Thermostat as desired. Refer to COOKING GUIDELINES for suggested temperatures and

times for various products.

3. Prepare product and place in suitable pans. When white HEAT light goes off, oven has reached

desired preheat temperature.

Cooking

1. Open doors and load the product into the oven. Place pans in the center of the racks. Close doors.

2. Set the Timer. After the preset time lapses, turn timer to OFF position to stop alarm.

3. When product is done, open doors and carefully remove cooked product from the oven. Wipe up

any spills.

End of Day

1. Turn thermostat to OFF.

2. Turn Master Switch to OVEN COOL. Leave doors open while the fan is on to cool the oven.

3. When oven has cooled sufficiently, turn Master Switch OFF and clean the oven.

CLEANING (all models)

WARNING: DISCONNECT ELECTRICAL SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THAT YOU ARE WORKING ON THE OVEN BEFORE CLEANING.

Clean outside of the oven daily by wiping with a clean damp cloth.

Clean porcelain oven interior daily with soap or detergent and water. Rinse thoroughly and wipe dry

with a soft clean cloth.

Optional Stainless Steel Oven Interior

Soap or detergent and water usually handle routine cleaning. Rinse thoroughly, dry with a soft clean

cloth.

For burned-on foods and grease which resist simple soap and water cleaning, an abrasive cleanser

(scouring powder) mixed into a paste may be used. Apply with stainless steel wool or sponge, always

rubbing with the grain.

This treatment is equally effective for "heat tint" (slightly darkened areas caused by oxidation). Again,

remember to rub in the direction of the polish lines. Rinse with clear water and dry with a soft cloth.

– 8 –

Page 9

CONTROLS — MODELS WKEC / WKECX

MOVE TO VENT

R & H

MODE

OVEN

READY

MENU SELECT

PRIMARY

SECONDARY

SET

1/2

OVEN

HEATING

1

2

3

R & H

MODE

OVEN

READY

OVEN

HEATING

PRIMARY

SECONDARY

Always displays [HR:Min] when setting the Time.

Displays [HR:Min] if the countdown Time is more than 1 Hour.

Displays [Min:Sec] if the countdown Time is less than 1 Hour.

Displays Temperature in °F.

Indicates the oven is in the Roast and Hold Mode.

Indicates the oven is preheated and ready for cooking.

Indicates the oven is preheating.

Primary indicates Menu Items 1, 3, or 5.

Secondary indicates Menu Items 2, 4, or 6.

Up arrow increases; Down arrow decreases — a displayed

Time or Temperature value (if arrow keys are lit).

TEMPERATURE: Use with SET to set the oven temperature.

ROAST

3/4

5/6

&

HOLD

START

STOP

4

5

MENU RACK

POWER LIGHTS

ON

ON

OFF

OVEN

COOL

OFF

PL-53499

SET

ROAST

&

HOLD

START

STOP

1/2

1

3/4

5/6

2 3 4

SET: Use with Time or Temperature.

TIME: Use with SET to manually set the time.

Selects Roast and Hold mode; also selects Low Fan Speed.

Press once to start; press a second time to stop.

Press once for Primary Menu Items (1, 3,or 5).

Press a second time for Secondary Menu Items (2, 4,or 6).

Rack Buttons select individual Menu / Rack # Cook

5

Times — once programmed.

– 9 –

Page 10

MANUALLY SETTING THE TEMPERATURE AND COOK TIME

To Set the Temperature

• Press the SET button. Press the TEMPERATURE button;

StPt

displays to indicate Setpoint.

• Use the Up and Down Arrow keys to increase or decrease the displayed Temperature value.

• Press the SET button again to save the Temperature setpoint in the computer.

To Set the Cook Time

Tine

• Press the SET button. Press the TIME button.

displays to indicate TIME.

• Use the Up and Down Arrow keys to increase or decrease the displayed Cook Time (HR:min).

• Press the SET button again to save the Time setting in the computer.

To Start Cooking

• Press the START / STOP button.

• The manual Cook Time counts down to 00:00. Displays [HR:Min] above 1 hour; [min: sec] below.

• The buzzer will sound. To silence the buzzer, press the START / STOP button again.

* The control retains the manual settings for Temperature and Time.

TO PROGRAM MENU ITEM and RACK # Cook Times

Factory Preset and Programmable Cook Times are shown in the table, below:

NOITCELESUNEM

yramirP2/11.nim01

yradnoceS2/12.nim51

yramirP4/33.nim02

yradnoceS4/34.nim52

yramirP6/55.nim03

yradnoceS6/56.nim53

UNEM

METIMETI

METIMETI

METI

TESERPYROTCAF

METIUNEMMETIUNEM

METIUNEMMETIUNEM

METIUNEM

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

METIUNEM

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

1KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

2KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

SEULAVELBAMMARGORP

3KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

4KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

5KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

The Primary indicator light with Menu 1 / 2 selects Menu Item 1 (Factory Preset Cook Time = 10

minutes). The Secondary indicator light with Menu 1 / 2 selects Menu Item 2 (Factory Preset Cook Time

= 15 minutes). Similarly, for Menu Buttons 3 / 4 or 5 / 6. Any Menu Item Cook Time can be changed

using the procedure below. Rack # Cook Times may be programmed if desired but are not required.

To Change the Time Setting for any Menu Item (1 – 6)

• To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

✤ Select the Menu Item to be programmed (1 – 6).

Tine

displays to indicate TIME. Use the Up and

Down arrow buttons to increase or decrease the Menu Item's COOK TIME. Repeat this step for

any other Menu Items.

• Press the START / STOP button; LOC displays. Press the START / STOP button a second time

to save the Menu Item(s)' COOK TIME(s).

• Press the START / STOP button once to begin cooking (with the Menu Item's Cook Time). To

exit, press the START / STOP button a second time.

To Program Individual Rack # Cook Times for a Menu Item

• To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

Tine

• Select the Menu Item to be programmed (1 – 6);

✤ Then select the Rack # (1 – 5). [

t 1

] indicates Rack #1; [

displays to indicate TIME.

t 2

] indicates Rack #2; ... [

t 5

] indicates

Rack #5. Use the Up and Down arrows to increase or decrease the COOK TIME for any Rack #.

LOC

• Press the START / STOP button;

displays. Press the START / STOP button a second time

to save the Menu / Rack #'s COOK TIME(s).

• To exit program mode, press START / STOP twice.

– 10 –

Page 11

Always Set the Temperature Before Setting the Time

StPt

• Press the SET button. Press the TEMPERATURE button;

displays. Use the Up and Down

Arrow keys to increase or decrease the Temperature. To save, press the SET button again.

At startup, the display will initially show a

GROWING BAR

. When the oven temperature reaches the Set

Point, the set temperature displays. The READY light is lit, the HEAT light goes out, and the oven is

ready for you to select the Cook Time, Menu Item Cook Time, or Menu / Rack # Cook Time.

Starting a Timed Cycle On All Racks

door

• Open the door,

will display.

• Place the desired product on any of the five racks.

• Close the door. The display should return to the set temperature or the

GROWING BAR

.

• Press the Menu Key once for Primary or twice for Secondary to select a Menu Item Cook Time.

• Press the START / STOP button *.

• The timer will count down the time remaining for the Menu Item Cook Time.

• When the time has counted down to 00:00, the buzzer will sound and all Rack Buttons will flash.

• To silence the buzzer, press the START / STOP button.

Pressing the START / STOP button after making a menu selection will time all racks for the

*

selected menu time.

Starting a Timed Cycle Using Programmed Individual Menu / Rack # Cook Time(s)

door

• After the set Temperature is reached, open the door;

• Close the door. The display returns to the set Temperature or the

displays. Place product(s) in oven.

GROWING BAR

.

• Select the Menu Item (once for Primary or twice for Secondary) and the Rack # to select the

Menu / Rack # Cook Time. If using simultaneous cook times, select the other Menu / Rack #'s.

• The timer selects the Rack # with the shortest Cook Time and counts down to 00:00.

• The buzzer sounds and the Rack # flashes. To silence the buzzer, press the flashing Rack #.

door

• Open the door;

displays; remove the finished product; close the door.

✣ The next shortest Cook Time displays, its Rack # flashes and the time counts down to 00:00.

• The buzzer sounds. Press the flashing Rack #. Open the door,

door

displays. Remove the

product, close the door. Repeat from ✣ until all Rack #'s are done.

To Display the Actual Oven Temperature

• Press and hold the Temperature button for 3 seconds to display Actual Oven Temp until released.

To End a Cooking Cycle

At the end of a cooking cycle, the alarm will sound. To silence the alarm and end a Menu Item cooking

cycle, press START / STOP. To silence the alarm and end a Rack # cooking cycle, press the Rack #.

To cancel a cooking cycle which might have been started in error, press and hold the Rack button to

be terminated and press START / STOP at the same time.

Door and Timing

Opening the door while loading additional product will interrupt all timing functions until the door is

closed and the timer resumes. For example, if a product time had diminished to 1 minute and the door

was opened for 30 seconds and then closed, the timer would still show 1 minute.

SETTING THE OVEN FOR ROAST & HOLD

• Press the Roast & Hold button to select Roast & Hold.

• Set the first stage Temperature and the Cook Time as described in: M

ANUALLY SETTING THE

TEMPERATURE AND COOK TIME. Press START / STOP to begin cooking.

The HOLD Temperature is preset by the computer control at 150°F (66°C).

*

*

The LOW FAN SPEED is present during Roast & Hold. Use R&H to select LOW FAN SPEED.

– 11 –

Page 12

ROAST AND HOLD OPERATION — Models WKEC and WKECX

Roast and Hold cooks the product in two stages. During First Stage Cooking, the oven temperature is

regulated by the Temperature setpoint and the Time setting. After the time counts down to 00:00,

Second Stage Cooking begins. During Second Stage Cooking, the heating elements are off as the

temperature in the oven declines to the Hold Temperature. The doors should remain closed during

Second Stage Cooking.

When the Hold temperature is reached, the display flashes

HOLD

maintained at the Hold temperature until the oven is turned off.

ROAST AND HOLD DIAGRAM - Time vs. Temperature

400ºF

300ºF

200ºF

100ºF

TEMP.

TIME

PREHEAT FIRST STAGE COOKING SECOND STAGE

OVEN TEMPERATURE

TIMER DISPLAY COUNTS DOWN.

COOKING FROM

STORED HEAT

LOAD PRODUCT

INTO OVEN

PRODUCT TEMPERATURE

COOKING

(DO NOT OPEN

DOORS)

. Temperature in the oven will be

SHORT BEEP.

TIMER DISPLAYS "HOLD."

ROAST THERMOSTAT OFF.

HEATERS OFF UNTIL HOLD

TEMPERATURE IS REACHED.

HEATERS MAINTAIN

HOLD TEMPERATURE.

TIMER DISPLAY FLASHES

"HOLD."

HOLDING

PL-53493

PROPER UTENSILS

The use of proper utensils can enhance oven operation. Medium and light weight pans allow the

product to warm faster. Roast meats in shallow pans deep enough to hold all juices yet allow free air

circulation.

OPERATING HINTS

When using the convection oven for the first time with a particular food, check the degree of doneness

periodically before the suggested time has elapsed, to make sure the desired doneness is achieved.

Record your temperature and time settings for various products. The convection oven can provide

consistent, repeatable results.

The convection oven is faster than conventional deck-type ovens; temperature settings are lower and

cook times are shorter. Since recipes and foods are subject to many variations and tastes, the

guidelines regarding Times and Temperatures in this manual are SUGGESTIONS ONLY. Experiment

with your food products to determine the cooking temperatures and times that give you the best results.

– 12 –

Page 13

COOKING GUIDELINES

The information in the Cooking Guidelines chart is suggested only. Cooking times for various products

may be different depending on the brand, consistency and the chef’s preferences for taste and

presentation. The times below may require adjustments. Note the times and temperatures of your

preferred results for future use. The preheating time for all of the following is 15 minutes. The computer

control's Holding Temperature is preset at 150°F (66°C) and cannot be changed.

COOKING GUIDELINES (HOLDING FEATURE)

Cooking Cooking Min. Hold Max. Internal Internal

Amount Temp. Time Time Cook Temp. Hold Temp.

Product lbs. / kg

Prime Rib 20 / 9.06 225 / 107 5 4 140 / 60

Rib Eye Boneless 12 / 5.43 225 / 107 3 4 140 / 60

Top Round 20 / 9.06 225 / 107 5 4 140 / 60

Steamship Round 20 / 9.06 225 / 107 7 2 140 / 60

Bottom Round 20 / 9.06 225 / 107 5 8 140 / 60

Boneless Strip Loin 12 / 5.43 225 / 107 3 4 140 / 60

Whole Tenderloin 6 / 2.71 225 / 107 2 2 140 / 60

Top Sirloin Butt 14 / 6.34 225 / 107 3 4 140 / 60

Beef Short Ribs 10 / 4.53 225 / 107 4 4 165 / 74

Cube Steaks 10 / 5.43 225 / 107 3 3 180 / 82

Beef Back Ribs 30 / 13.6 225 / 107 5 4 175 / 79

Beef Stew 10 / 5.43 225 / 107 4 6 175 / 79 150 / 66

Corned Beef 12 / 5.43 250 / 121 4 4 165 / 74 150 / 66

Fresh Ham 12 / 5.43 250 / 121 6 4 165 / 74

Cooked Cured Ham 12 / 5.43 250 / 121 4 4 135 / 57

Pork Back Ribs 10 / 4.53 250 / 121 5 3 175 / 79 150 / 66

Pork Spare Ribs 30 / 13.6 250 / 121 5 4 175 / 79 150 / 66

Fresh Sausages 10 / 4.53 225 / 107 2 5 (Max) 175 / 79

Pre-Cooked Sausage 10 / 4.53 250 / 121 13/4 51/2 (Max) 160 / 71

Roast Suckling Pig 30 / 13.6 250 / 121 6 3 170 / 77 155 / 68

Bacon 350 / 177 40 min. N/A

Roasted Chicken 10 / 4.56 350 / 177 45 min. N/A 165 / 74

Chicken Pieces (per tray) 10 / 4.56 250 / 121 21/2

Whole Chickens

(per chicken) 3.25 / 1.47 250 / 121 21/2 41/2 (Max) 170 / 77 140 / 60

Whole Turkeys 20 / 9.06 230 / 110 61/2 12 (Max) 170 / 77 160 / 71

Bone In Turkey Breast 10 / 4.53 250 / 121 5 1 160 / 71 150 / 66

Roast Duckling (per duck) 4 / 1.81 350 / 177 11/2 3 (Max) 170 / 77 150 / 66

Rack of Lamb 15 racks 250 / 121 3

per tray

Lamb Shanks, Braised 250 / 121 4 4 180 / 82 150 / 66

Fish Filets 4-6 oz./ 23g 225 / 107 40 min. 4 160 / 71

1/1 Gastronome

Clear Soups or 12x20x4" 225 / 107 3 Overnight 175 / 79 150 / 66

Steam Pan

Frozen Pizza (2) 18” Pies 350 / 177 15 min. 2 175 / 79 160 / 71

Rice 1 Qt. dry 250 / 121 2 18 160 / 171 N/A

Baked Potatos 90 CT. 350 / 177 1 1

°F / °C Hours Hours °F / °C °F / °C

1

/2 (Max) 170 / 77 150 / 66

1

/2 21/2 160 / 71

1

/2 200 / 93 170 / 77

– 13 –

Page 14

STANDARD COOKING TIME CHART

Product Amount Temp. Time

Frozen Croissant Dough 1.75 oz. 350°F/177°C 25 Min

Cinnamon Croissant 1.75 oz. 350°F/177°C 35 Min.

Small Bread Loaves 1 Tray 350°F/177°C 30 Min.

Large Bread Loaves 1.5 lbs. 350°F/177°C 60 Min.

Sheet Cake (1) 18x26" Tray 300°F/149°C 25 Min.

Scone Mix 1 Tray 350°F/177°C 30 Min.

Muffin Mix 1 Tray 350°F/177°C 30 Min.

Kaiser Rolls 1 Tray 350°F/177°C 16 Min.

Italian Bread 1 Tray 350°F/177°C 40 Min.

Danish Rounds* 1 Tray 350°F/177°C 30 Min.

Cream Cake* 1 Tray 350°F/177°C 60 Min.

Cookies 1 Tray 325°F/163°C 16 Min.

*The maximum internal cooking temperature should be 190°F/88°C.

POWER OUTAGE

In case of a power outage, the oven will automatically shut down. When power is restored to the lines,

the oven will resume its normal operation. However, if the oven is to be left unattended during a power

outage, push the master switch to the OFF position. When power is restored to the lines, push master

switch to the ON position, wait for the oven to preheat, then resume normal cooking operations.

MAINTENANCE

WARNING: THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR PERFORMING ANY MAINTENANCE.

WARNING: DISCONNECT ELECTICAL SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THAT YOU ARE WORKING ON THE OVEN BEFORE PERFORMING ANY

MAINTENANCE.

The fan motor comes with sealed bearings and requires no lubrication.

Annually check the vent, when cool, to be sure it is free of obstructions.

Replacing Lamps

• Allow oven to cool.

• Remove all racks by pulling forward, lifting up and out.

• Unscrew glass dome(s) from light body.

• Replace the bulb(s).

• Reassemble glass dome(s), and racks by reversing the disassembly procedure.

SERVICE

Contact your local Wolf-authorized service office for any repairs or adjustments needed on this

equipment.

– 14 –

Page 15

IMPORTANT INFORMATION

When requesting information, Owner’s Guides, replacement parts or service, always

refer to the model and serial number of your unit. The serial number of your appliance

is located on the rating plate. For your convenience, space is provided below to

record this information for future reference.

SERIAL NO.

MODEL NO.

DEALER:

INSTALLATION DATE:

IMPORTANT

This equipment is design certified by a Nationally

Recognized Testing Laboratory, to the appropriate

National Standards as indicated on the Equipment

Rating Plate. Any modification without written

permission of The Wolf Range Company LLC voids

the certification and the warranty of this unit.

NOTICE: When this appliance is installed with casters, it must be installed with the casters supplied, a connector

complying with either the standard for Connectors of Movable Gas Appliances, ANSI Z21.69 or CAN/CGA-

6.16, and a quick disconnect device which complies with either Quick Disconnect Devices for Use with Gas

Fuel, ANSI Z21.41 or CAN1-6.9. It must also be installed with restraining means to guard against transmission

of strain to the connector, as specified in the appliance manufacturer’s instructions.

If an appliance is equipped with casters and is connected to the supply piping by means of a connector for

movable appliances, the user and maintenance personnel must be aware that there is a restraint on the appliance

and if disconnection of the restraint must be reconnected after the appliance is returned to its original installed

position.

FOR SAFE OPERATION AND PROPER VENTILATION, KEEP SPACE BETWEEN

COOKING EQUIPMENT AND HOOD FREE FROM ANY OBSTRUCTIONS.

Your selection of Wolf equipment is your assurance of quality and dependability that reflects over 65 years of

experience in manufacturing the finest commercial gas cooking equipment. You can always rely on your Wolf

dealer and The Wolf Range Company LLC to stand behind every Wolf product anywhere in the world. For

additional equipment, service and information, contact your Wolf dealer.

THE WOLF RANGE COMPANY LLC

19600 S. Alameda St., Compton, California 90221-6291

P. O. Box 7050, Compton, California 90240-7050

(310) 637-3737 • FAX (310) 637-7931 • (800) 366-WOLF

– 15 –

Page 16

THE WOLF RANGE COMPANY LLC

LIMITED COMMERCIAL EQUIPMENT WARRANTY

EFFECTIVE APRIL 1, 1995

The W olf Range Company LLC (Company) warrants to the original owner that the product is free from defect in material and

workmanship. This warranty shall be in effect for one (1) year from the date of installation, but shall not exceed eighteen (18)

months from the date of shipment. The warranty is limited, at the option of the company, to the replacement or repair of any

part found by the company to be defective. The warranty covers normal labor charges for products or parts installed in the

United States and Canada. Labor charges shall be covered to the extent the performance is effected within 50 miles from an

authorized servicer.

THE WARRANTY DOES NOT COVER: THE OWNER SHALL BE

RESPONSIBLE FOR:

• Misused, abused or improperly installed.

• Proper installation and compliance with

• Exposure to harsh chemicals. local codes.

• Altered or modified by persons other than authorized • Supplying proper gas type and pressure.

W olf servicers.

• Making product reasonably accessible for

• Where serial numbers have been altered or removed. service.

• Damaged during transit or handling. • Electrical connections, ventilation

requirements and scheduled maintenance.

• Damaged by other than genuine Wolf replacement

parts. • Observation of instructions in owner’s manual.

• Damaged by flood, fire or other acts of God. • Use of authorized servicers only.

• Cleaning, Adjustments or Calibrations.

The product is intended to be used for commercial purposes. The warranty is void if the product is used for other than

commercial purposes. Replacement parts must be supplied by W olf authorized servicers and defective parts returned intact to

the same. Documents verifying ownership and installation date are required. Stainless steel fry tanks are warranted for five (5)

years from the date of installation. Labor shall be covered for one (1) year. No warranty applies to range light bulb.

Warranty applies only to products manufactured on or after April 1, 1995 according to the manufacture/date code. The

company shall not be liable for any incidental or consequential damages, direct or special damages, claims of loss of use,

claims of loss of profit, or any other loss, cost or expense.

THIS WARRANTY CONSTITUTES THE EXCLUSIVE REMEDY OF THE COMPANY.

THE WARRANTY SET FORTH HEREIN, IS EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE.

Some areas do not allow limitations on whether, or how long, an implied warranty lasts, so the limitation may not apply to

you. Some areas do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specific rights, you may also have other rights that vary from location to location.

THE WOLF RANGE COMPANY LLC

19600 South Alameda Street, Compton, California 90221

(310) 637-3737 • FAX (310) 637-7931 • (800) 366-WOLF

FORM 31162 (Apr. 2000) PRINTED IN U.S.A.

– 16 –

®

Loading...

Loading...