Installation instructions for contractors

Gas condensing boilers

MGK-2-390

MGK-2-470

MGK-2-550

MGK-2-630

Wolf GmbH • Postfach 1380 • D -84048 Mainburg • Tel. +49 (0)8751/74-0 • Fax +49 (0)8751/74-1600 • Internet: www.wolf-heiztechnik.de

Document no.: 3063772_201507 Subjecttotechnicalmodications

GB

(dt.)

2 3063772_201507

Table of contents

1. Information about this document ......................................................................... 3

2. Safety instructions .......................................................................................... 4 - 5

3. Dimensions ......................................................................................................... 6

4. Specification ........................................................................................................ 8

5. Boiler layout ........................................................................................................ 9

6. Casing ............................................................................................................... 10

7. Standards and regulations ......................................................................... 11 - 12

Installation

8. Handling / Installation instructions ..................................................... 13 - 15

9. Safety equipment...................................................................................... 16

10. Information about water treatment............................................................ 17

11. Boiler system pipework............................................................................. 18

12. Selection of circulation pumps .................................................................. 19

13. Gas connection......................................................................................... 20

14. Fitting the siphons .................................................................................... 21

15. Neutralising system (accessory)............................................................... 22

16. Neutralising system / Condensate pump (accessories) ........................... 23

17. Air/flue gas routing.............................................................................24 - 25

Control unit

18. Electrical connection..........................................................................26 - 31

19. Display/programming module / Installation............................................... 32

20. AM display module ................................................................................... 32

21. AM display module menu structure .......................................................... 34

22. Operating mode / Heating appliance burner status .................................. 35

23. BM2 programming module ....................................................................... 36

24. HG control parameters ............................................................................. 37

25. Parameter description .......................................................................38 - 47

26. Flue gas damper power supply ................................................................ 48

Cascade operation

27. Cascade operation ............................................................................49 - 51

Commissioning

28. Filling / draining the heating system ......................................................... 52

29. Commissioning ......................................................................................... 53

30. Checking the gas supply pressure ........................................................... 54

31. Changing the gas type / CO

2

settings ................................................55 - 56

Specification

32. Commissioning report............................................................................... 57

33. Design information – air/flue gas routing .................................................. 58

34. Wiring diagram HCM2 /GBC-P ..........................................................59 - 60

35. Troubleshooting .................................................................................61 - 64

36. Troubleshooting warning messages ......................................................... 65

37. Sensor resistance table ............................................................................ 66

38. Technical parameters according to EU regulation no. 813/2013 .............. 67

Declaration of conformity .................................................................................. 68

3063772_201507 3

1. Information about this document

1.1 Other applicable documents

MGK-2 user operating instructions

MGK-2 maintenance instructions

System and operator's log

The instructions for all accessory modules and other accessories may also apply.

1.2 Safekeeping of these documents

The system user or operator should ensure the safekeeping of all instruction manuals

and documents.

f Please pass these installation instructions and all other applicable instruction

manuals on to the operator and/or system user.

1.3 Obligations of the operator

System operators must take active steps to full their responsibilities regarding safe

gas use. This applies to the commissioning of specialist companies to maintain the

appliance. The system operator is obliged to provide documentation.

1.4 Applicability of these instructions

These installation instructions apply to the MGK-2 gas condensing boiler

1.5 Acceptance

Within four weeks of commissioning of the burner the operator must notify the local

ue gas inspector accordingly.

1.6 Information about disposal

We are happy to accept the return of your old Wolf boiler free of charge at one of our

delivery depots.

1 x MGK-2 gas condensing boiler, fully encased, assembled and wired

2 x siphons with 3 condensate hoses and 1 tee

1 x condensate trap

1 x MGK-2 installation instructions for contractors

1 x MGK-2 user operating instructions

1 x MGK-2 maintenance instructions

1 x system and operator's log

MGK-2 standard delivery

4 3063772_201507

2. Safety instructions

The following symbols are used in these instructions. This

important information concerns personal as well as

operational safety.

"Safety instructions" are instructions with

which you must comply exactly, to prevent risks

and injuries to individuals and damage to the

boiler.

Danger due to live electrical components.

Please note: Turn OFF the ON/OFF switch before

removing the casing.

Never touch electrical components or contacts

when the ON/OFF switch is in the ON position.

This can result in a risk of electrocution that

could lead to injury or death.

The terminals are live even when the ON/OFF

switch is in the OFF position.

"Caution" indicates technical instructions that

you must observe to prevent boiler damage and

malfunctions.

Caution

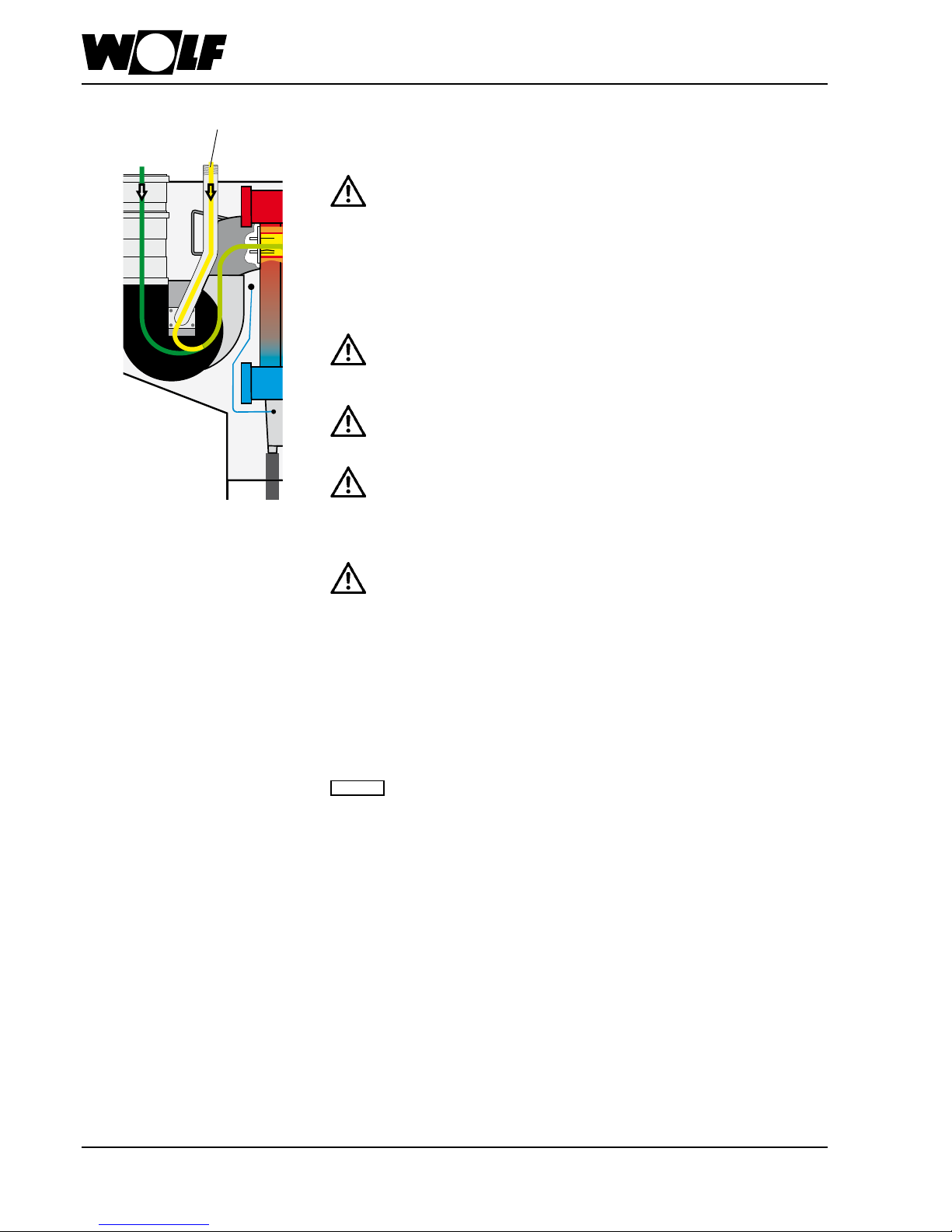

Fig: Ignition transformer, high voltage ignition electrode, gas

combination valve, gas pressure switch, fan, combustion

chamber.

Danger from electrical voltage, escaping gas may cause

poisoning or an explosion, risk of burning through hot

components.

Danger if you smell gas

- Close the gas shut-off valve.

- Open the windows.

- Do not operate electrical switches.

- Extinguish naked flames.

- Phone the gas supply utility company and approved

contractor from an external location.

Authorised personnel should read these instructions before any installation, commissioning or maintenance work. Observe

the instructions given in this document. Failure to observe these installation instructions voids any WOLF warranty. In

some countries, the installation of a gas boiler must be notified to and approved by the relevant gas supply company.

Please note that regional permits may be required for the flue system and the condensate drain into the public sewer.

Before installation work begins, the local flue gas inspector and water authority must be informed. The boiler must be

installed, commissioned and maintained by qualified and trained personnel only. In accordance with VDE 0105 Part 1,

work on electrical components (e.g. control unit) must only be carried out by qualified electricians. VDE/ÖVE regulations

and those of your local power supply utility company are applicable to electrical installation work. Only operate the boiler

within its output range, which is stated in the technical documentation supplied by WOLF. Intended use of the boiler refers

to the exclusive use for hot water heating systems in accordance with DIN EN 12828. Never remove, bypass or otherwise

disable any safety and monitoring equipment. The boiler must only be operated if it is in perfect technical condition. Any

faults and damage with potential impact on safety and which might limit the safe use of the equipment must be remedied

immediately by a qualified contractor. Only replace faulty components and equipment with original WOLF spare parts.

Working on the system

- Gas systems: close the gas shut-off valve and ensure that

unauthorised reopening is prevented.

- Isolate the system from the power supply (e.g. by removing

a separate mains fuse or by means of a mains electrical

isolator, heating emergency stop switch) and check to

ensure that there is no voltage.

- Safeguard the system against restarting.

Fig: Control box

Danger from electrical voltage

3063772_201507 5

2. Safety instructions

Danger if you smell flue gas

- Switch OFF the boiler.

- Open windows and doors.

- Notify an approved contractor.

Inspection and maintenance

- Recommendation for the customer: Take out an inspection

and maintenance contract with an approved contractor,

including an annual inspection and demand-dependent

servicing.

- The operator is responsible for the safety, environmental

compatibility and energy quality of the heating system

(German Immission Control Act / Energy Saving Ordinance).

- Only use genuine spare parts!

This appliance is not designed to be operated by persons

(including children) with restricted physical, sensory or

mental capacities or who lack the necessary experience

and/or knowledge, unless they are supervised by a person

responsible for their safety or have received instructions

on how to use the appliance from this person.

We accept no liability for damage caused by

technical modifications made to the control unit

or the control system components.

These installation instructions must be kept in

a safe place and read before installing the boiler.

Please also observe the design information in

the appendix.

Note

Information about disposal:

We are happy to accept the return of your old Wolf boiler free

of charge at one of our delivery depots.

6 3063772_201507

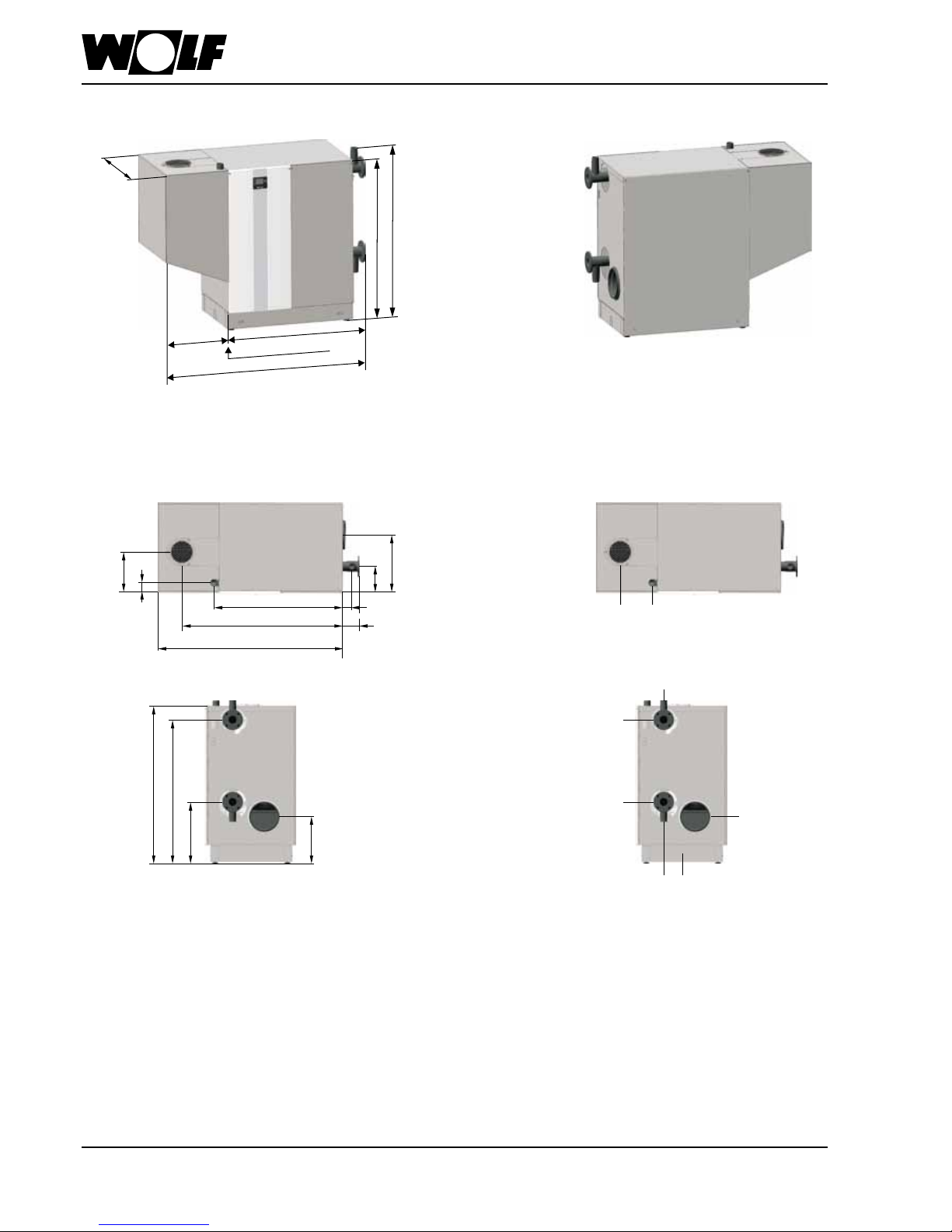

3. Dimensions

A = ventilation air pipe DN 200

B = gas pipe 2"

C = safety assembly connection 2"

D = flow pipe DN 80

E = return pipe DN 80

F = BDF valve connection

G = flue pipe DN 250

H = condensate drain

850

(790 without

casing)

Can be split for transportation

1295

1860

565

1460

1420

365

240

525

1290

1420

535

410

160

1180

1480

1700

85

85

C

D

E

G

F H

A B

3063772_201507 7

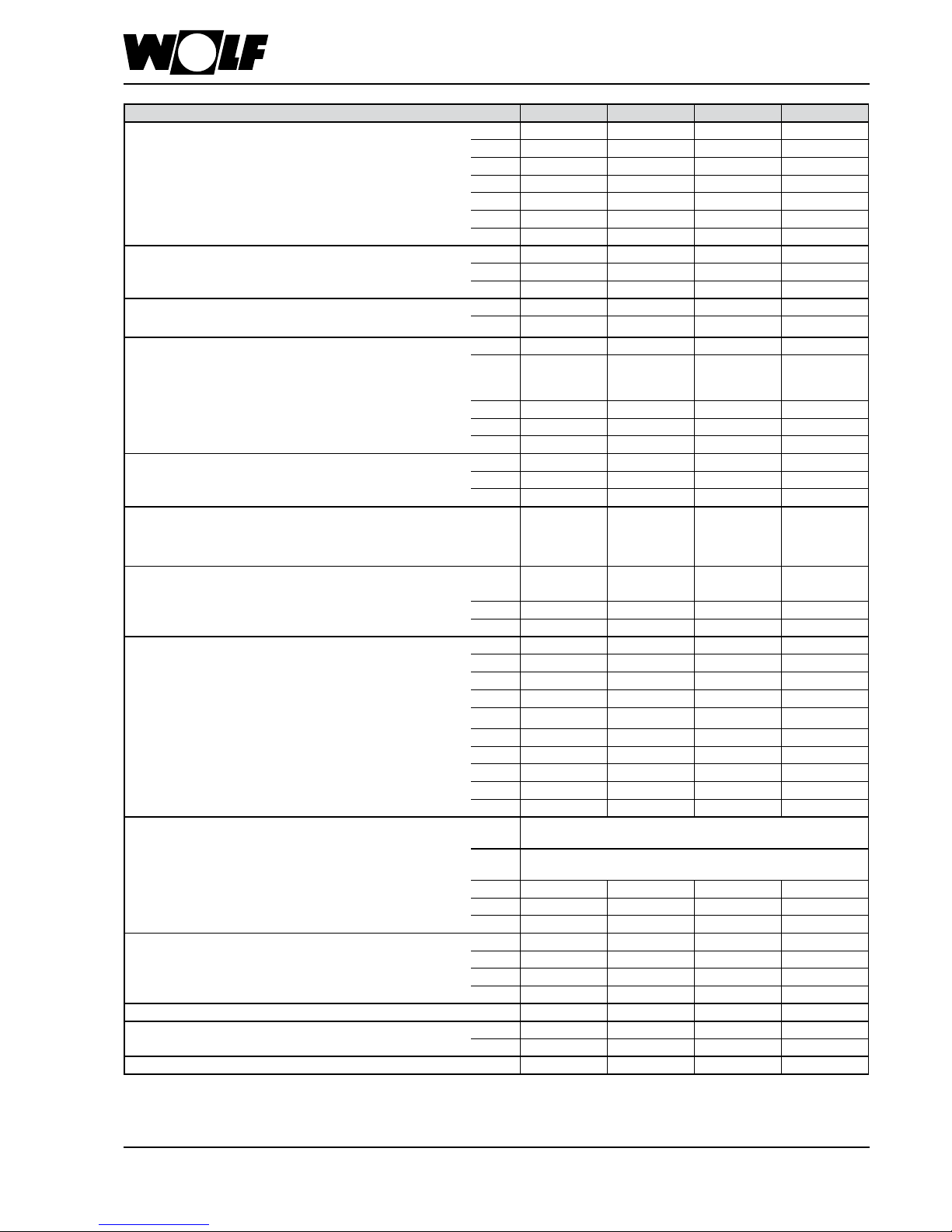

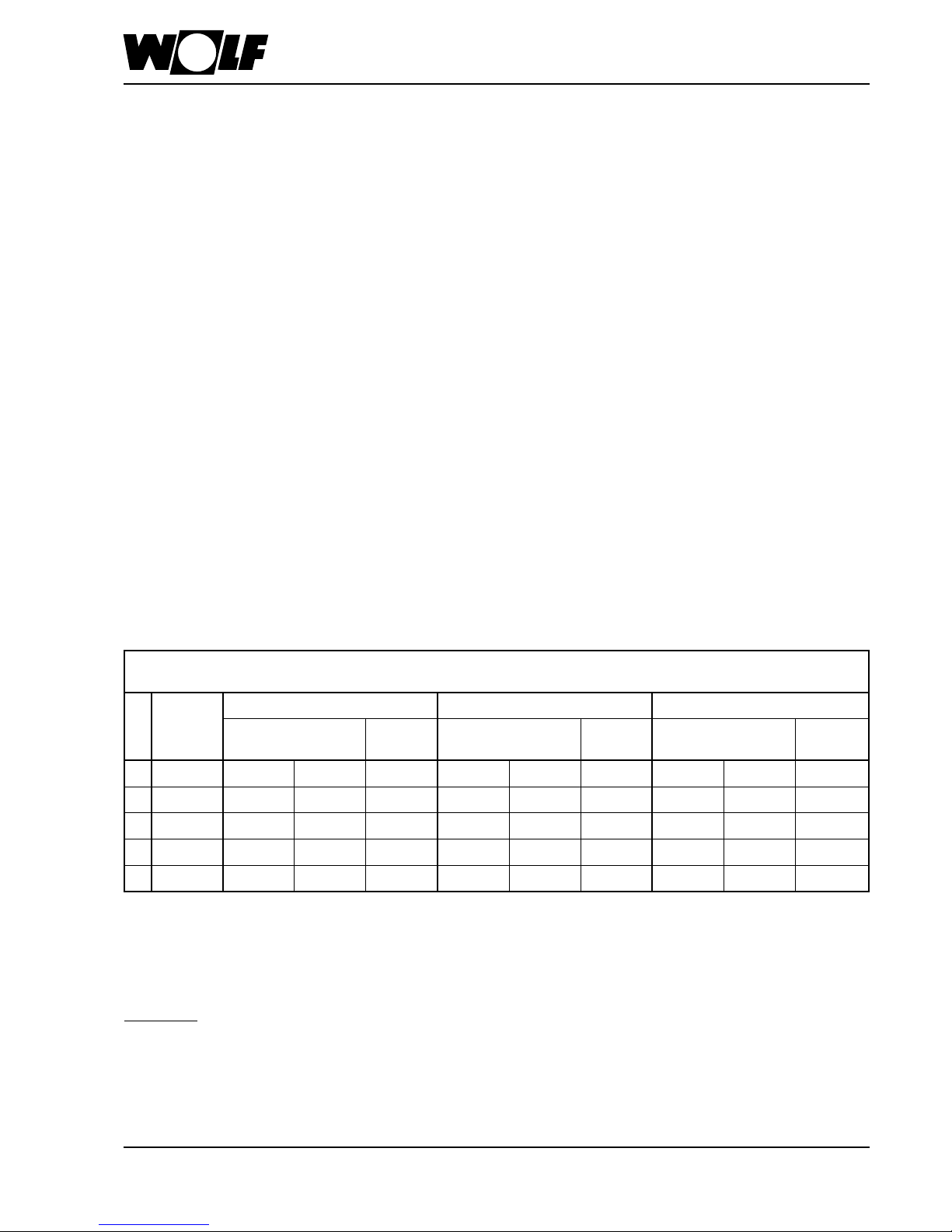

4. Specication

Type MGK-2 390 470 550 630

Rated heating output at 80/60 °C kW 366.7 434.7 511.6 584.4

Rated heating output at 50/30 °C kW 392.0 467.1 549.3 626.6

Rated heat input kW 371.2 443.6 521.0 593.9

Low boiler output (modul.) at 80/60 °C kW 58.5 70.7 84.5 96.7

Low boiler output (modul.) at 50/30 °C kW 64.2 78.7 94.0 106.8

Low heat input (modulating) kW 59.5 73.2 86.8 98.5

Heat input modulation range % 17-100 17-100 17-100 17-100

Efciency η 80/60 at Qmax % 98.8 98.0 98.2 98.4

η 50/30 at Qmax % 105.6 105.3 105.4 105.5

η TR30 at 30 % % 107.8 108.9 108.6 107.6

Standard seasonal efciency at 40/30 °C % 109.9 110.1 110.3 110.4

at 75/60 °C

% 106.4 106.4 106.3 106.3

Overall height mm 1460 1460 1460 1460

Overall width mm

1860

(1295 in

sections)

1860

(1295 in

sections)

1860

(1295 in

sections)

1860

(1295 in

sections)

Overall depth / depth without casing mm 850 / 790 850 / 790 850 / 790 850 / 790

Flue diameter mm 250 250 250 250

Combustion air supply mm 200 200 200 200

Heating ow DN 80 PN6 80 PN6 80 PN6 80 PN6

Heating return DN 80 PN6 80 PN6 80 PN6 80 PN6

Gas connection R 2" 2" 2" 2"

Air/ue gas routing Type B23, B23P,

C33, C43,

C53, C63,

C83, C93

B23, B23P,

C33, C43,

C53, C63,

C83, C93

B23, B23P,

C33, C43,

C53, C63,

C83, C93

B23, B23P,

C33, C43,

C53, C63,

C83, C93

Gas supply details:

Natural gas E/H (H

i

= 9.5 kWh/m³ = 34.2 MJ/m³) m³/h 39.1 46.7 54.8 62.5

Natural gas LL (H

i

= 8.6 kWh/m³ = 31.0 MJ/m³) m³/h 43.2 51.6 60.6 69.1

Gas supply pressure: Natural gas E/H/LL mbar 20 20 20 20

Water content, heating water heat exchanger l 50 56 62 68

Max. permissible boiler pressure bar 6 6 6 6

Max. permissible ow temperature °C 85 85 85 85

Available gas fan draught Pa 150 150 150 150

Standby losses excess temperature

30 / 50 K

% 0.11 / 0.18 0.10 / 0.17 0.09 / 0.15 0.09 / 0.14

Flue gas temperature 80/60-50/30 at Qmax °C 65-35 65-35 65-35 65-35

Flue gas temperature 80/60-50/30 at Qmin °C 60-30 60-30 60-30 60-30

Max. ue gas volume ow

g/s 156.3 185.2 225.3 247.4

Flue gas category to DVGW G 635 G 52 G 52 G 52 G 52

Heating water pressure drop at 20 K spread mbar 120 113 126 118

Electrical connection of MCB protection V~/Hz

1~ NPE / 230 V AC / 50 Hz / 10 A/B

Alternative: 3~ PE / 400 V AC / 50 Hz / 10 A/B

Output heating circuit pump / ZHP fuse/MCB protection V~/Hz

1~ NPE / 230VAC / 50Hz / 4A

Alternative: 3~ PE / 400 V AC / 50 Hz / 4 A

Power consumption (partial load / full load) W 42 - 410 45 - 490 48 - 580 50 - 660

Standby power consumption W 11 11 11 11

IP rating IP20 IP20 IP20 IP20

Sound power to DIN EN 15036 Part 1, balanced ue dB(A) 61 66 68 68

Sound pressure level 1 m upstream of MGK-2, balanced ue

1)

dB(A) 44 49 50 50

Sound power to DIN EN 15036 Part 1, open ue dB(A) 78 82 84 84

Sound pressure level 1 m upstream of MGK-2, open ue

1)

dB(A) 60 64 65 65

Total weight (dry) kg 390 420 450 480

Amount of condensate at 40/30 °C l/h 39 46 52 59

Condensate pH value approx. 4.0 approx. 4.0 approx. 4.0 approx. 4.0

CE ID 0085CN0326 0085CN0326 0085CN0326 0085CN0326

1)

depending on the general system conditions, such as: type/version of the flue system, size and nature of the installation room

8 3063772_201507

4. Specication

Max. spread A cast section protection function is integrated in the MGK-2. This prevents stresses in

the material by limiting the maximum temperature differential between the flow and

return. As of 28 K, the output is reduced. If 40 K is nevertheless reached, the burner

shuts down briefly without a fault message. This characteristic must be taken into account

when selecting the components (e.g. pumps, heat exchanger and cylinder).

Flow rate Excessive flow velocities may lead to erosion.

Maximum flow rate (volume flow) at Q

max

:

MGK-2-390: 28.5 m³/h

MGK-2-470: 34.4 m³/h

MGK-2-550: 39.8 m³/h

MGK-2-630: 45.5 m³/h

MGK-2 heating water pressure drop:

Heating water pressure drop [mbar]

Throughput [m³/h]

MGK-2-550

MGK-2-630

MGK-2-470

MGK-2-390

3063772_201507 9

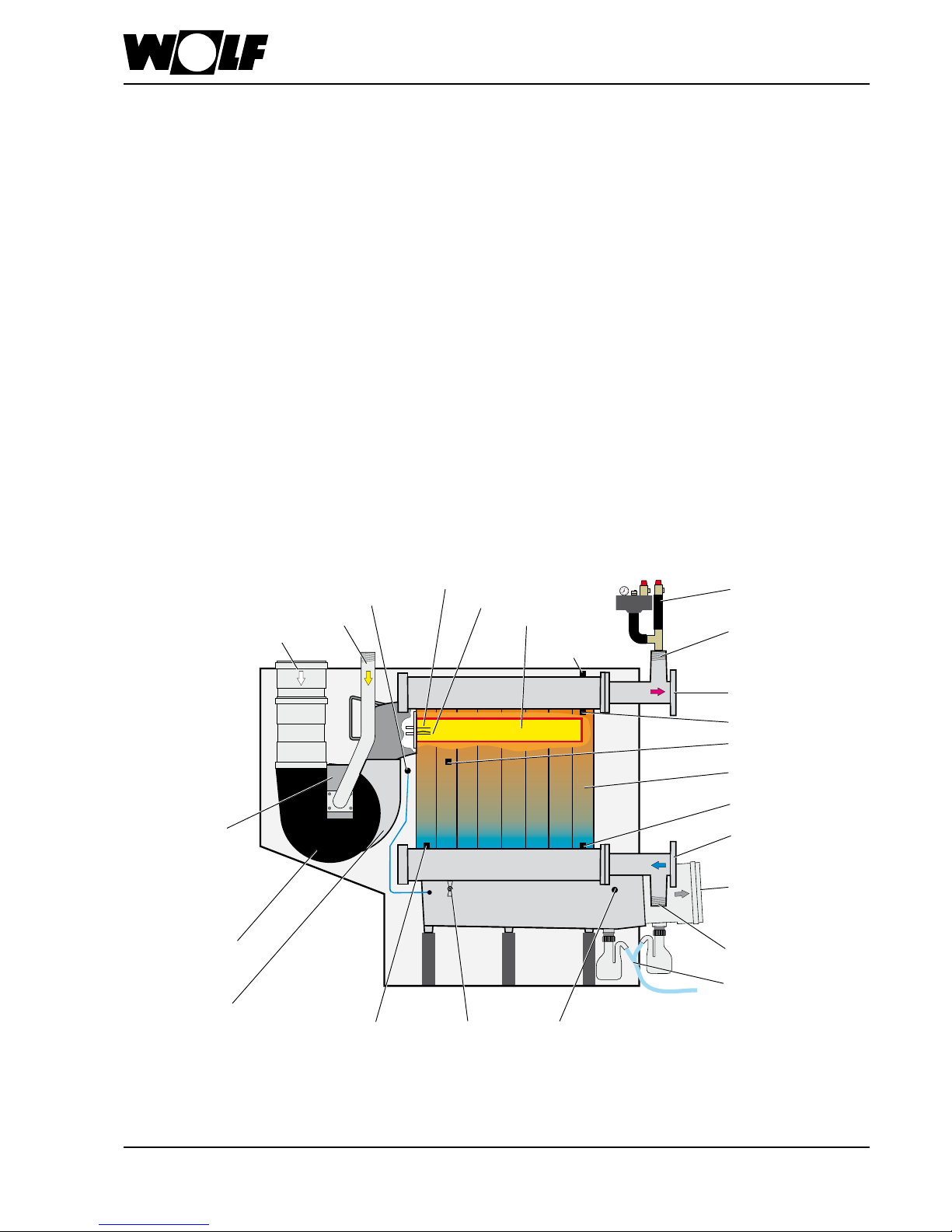

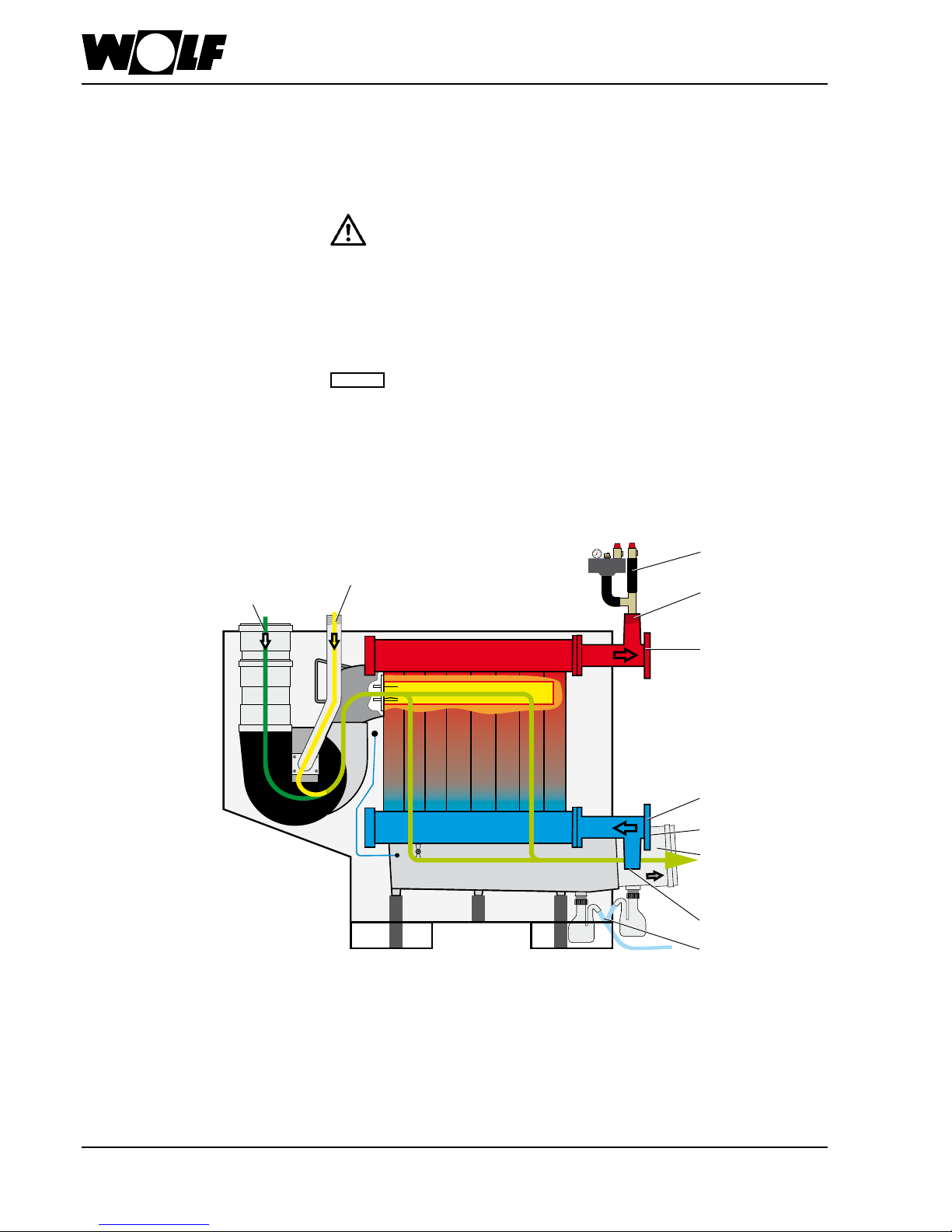

5. Boiler layout

Wolf MGK-2-390/470/550/630 gas condensing boilers are adjusted at the factory for

natural gas E and LL. The high performance heat exchanger is made from robust

aluminium-silicon alloy with a high resistance to corrosion. The gas premix burner with

gas-air mixture for modulating combustion from 17-100 % ensures extremely clean

combustion with a standard seasonal efficiency [to DIN] of up to 110 % for highly efficient

energy utilisation. The connections for the combustion air supply – for room sealed

operation – and gas are on the top of the boiler. The flue gas, heating flow and heating

return connections are on the side of the boiler. The removable burner hood guarantees

easy access for servicing the gas-air mixing unit.

Compact, space-saving installation right up against the wall with no clearance needed.

Quick and easy installation thanks to pre-installed thermal insulation and casing,

hydraulically and electrically ready to connect.

Direct access to all components from the front, simple operation and maintenance.

Integral attenuation minimises sound emissions, ideal for apartment buildings.

• Control unit fully wired; may be used for a wide range of heating system applications

• Cascades with up to four gas condensing boilers provide an output range of up to

2.5 MW

• No return temperature raising facility or minimum water circulation volume required

• Additional 2nd HLSC already integrated in the device

The boiler is fully assembled and encased.

The standard control unit includes a burner control unit, electronic ignition, ionisation

flame monitor and output-dependent fan speed regulation.

Flue gas pressure

switch

Ignition electrode

Monitoring electrode

Round gauze burner

Additional

HLSC

Safety assembly 2"

(accessory)

Gas combination

valve with gas

pressure limiter

Flue gas temperature sensorBDF valveWater pressure sensor

Gas fan

Mixing chamber

Ventilation air

pipe DN200

Gas connection R2"

Flue outlet DN250

Connection R2" for

safety assembly

Heat exchanger as a

sectional design

Connection R2" for

BDF set (accessory)

Siphons with

condensate drain

Flow connection

DN80 / PN6

Boiler water temperature sensor

Return temperature

sensor

Return connection

DN80 / PN6

Temperature sensors

eHLSC1 and eHLSC2

Layout MGK-2

10 3063772_201507

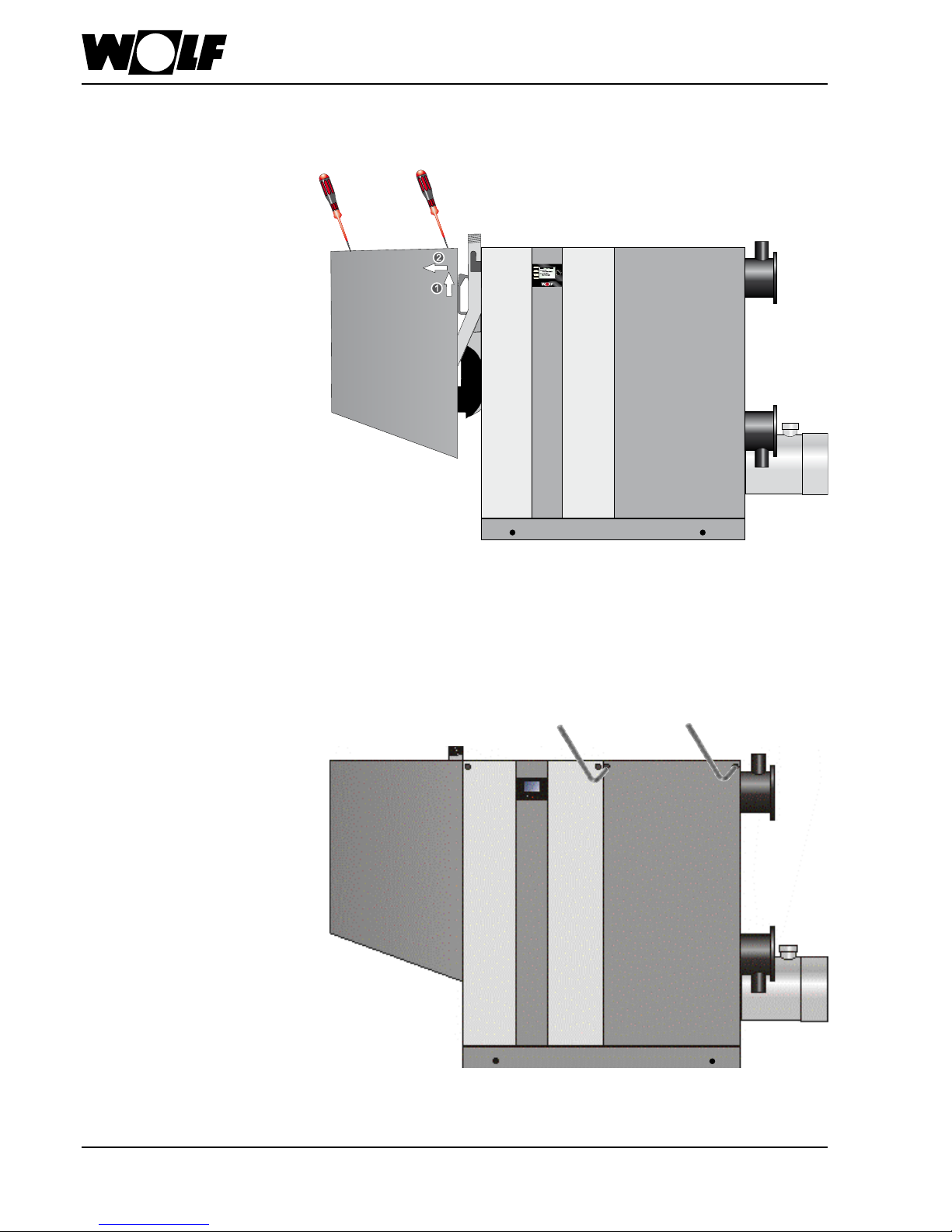

6. Casing

- Remove 3 screws on the top of the boiler.

- Lift burner hood slightly and remove from boiler.

- Remove 2 screws on the right side casing of the boiler.

- Tip right side casing forward and lift off.

Re-assemble in reverse order.

Re-assemble in reverse order.

Remove burner hood

(e.g. for servicing the gas-air mixing unit)

Open side casing

(e.g. to connect boiler to power

supply):

3063772_201507 11

7. Standards and regulations

Observe all standards and guidelines applicable to the installation and

operation of this heating system in your country.

Observe the information on the boiler type plate.

The following local regulations must be complied with for installation and

operation:

• Regulations on installation conditions

• Regulations on the ventilation air and exhaust air and the connection to a chimney

• Electrical connection to the power supply

• The technical regulations of the gas supply utility company regarding the

connection of the gas appliance to the local gas mains

• The regulations and standards regarding the safety equipment of the water

heating system

• DHW installation

The following general regulations, rules and guidelines must be observed for

installation in particular:

• (DIN) EN 1717 Protection of DHW against contamination in DHW installations

• (DIN) EN 12831 Heating systems in buildings – procedure for calculating the

standard heat load

• (DIN) EN 12828 Heating systems in buildings – designing hot water heating

systems

• (DIN) EN 13384 Flue systems – heat and flow rate calculations

• (DIN) EN 50156-1 (VDE 0116 Part 1) Electrical equipment in combustion systems

• VDE 0470/(DIN) EN 60529 Protection through casings

• VDI 2035 Prevention of damage in hot water heating systems

- Scaling (sheet 1)

- Corrosion in the primary system (sheet 2)

- Corrosion in the flue system (sheet 3)

The following also apply to installation and operation in Germany:

• Technical Regulations for Gas Installations DVGW-TRGI 1986/1996 (DVGW Code

of Practice G600 and TRF)

• DIN 1988 Technical regulations for DHW installations

• DIN 18160 Flue systems

• DWA-A 251 Condensate from condensing boilers

• ATV-DVWK-M115-3 Indirect discharge of non-domestic waste water

Part 3: Indirect discharge practice

• VDE 0100 Regulations regarding the installation of high voltage systems with

rated voltages up to 1000 V

• VDE 0105 Operation of high voltage systems, general stipulations

• KÜO German Federal Sweeping and Inspection Act

• Energy Savings Act (EnEG) and related ordinances

• EnEV Energy Saving Ordinance (currently applicable version)

• DVGW Code of Practice G637

12 3063772_201507

7. Standards and regulations

For installation and operation in Austria, the following apply:

• ÖVE regulations

• Provisions of the ÖVGW and the corresponding Austrian standards

• ÖVGV TR-Gas (G1), ÖVGW-RTF (G2)

• Provisions of ÖVGW guideline G41 for condensate drainage

• Local regulations of building and industry regulatory agencies (usually represented

by the flue gas inspector)

• Local regulations of the gas supply utility company

• Regulations and requirements of the local power supply utility company

• Provisions of regionally applicable building regulations

• Minimum heating water requirements in accordance with ÖNORM H5195-1 must be

observed

For installation in Switzerland, the following apply:

• SVGW regulations

• VKF regulations

• BUWAL and local regulations must be observed

• G1 gas guidelines

• EKAS form 1942; LPG guideline Part 2

3063772_201507 13

8. Handling / Installation instructions

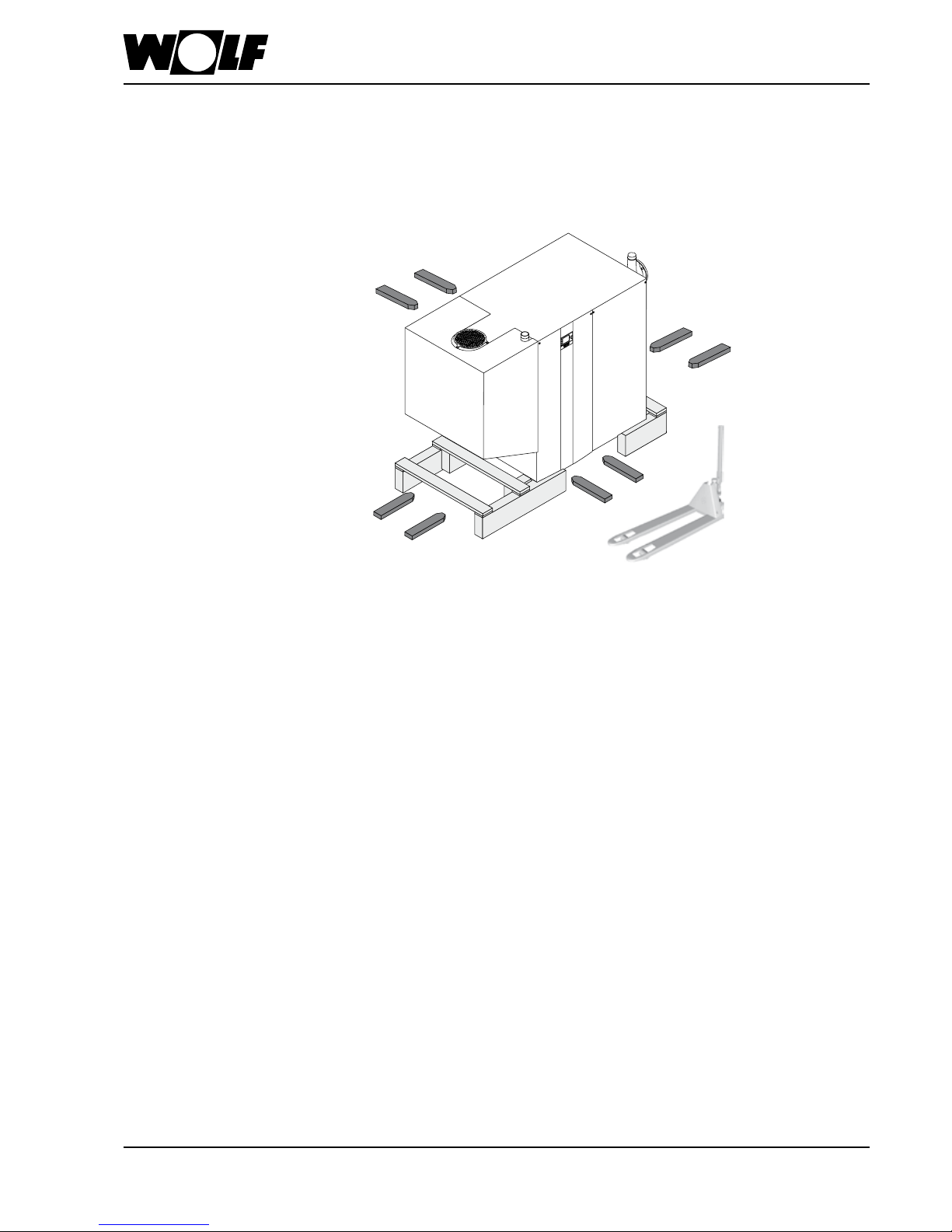

Handling • With ground conveyor vehicle:

With or without a pallet, the boiler can be handled easily using a pallet truck or

forklift, as it can be lifted from any side.

Example:

14 3063772_201507

8. Handling / Installation instructions

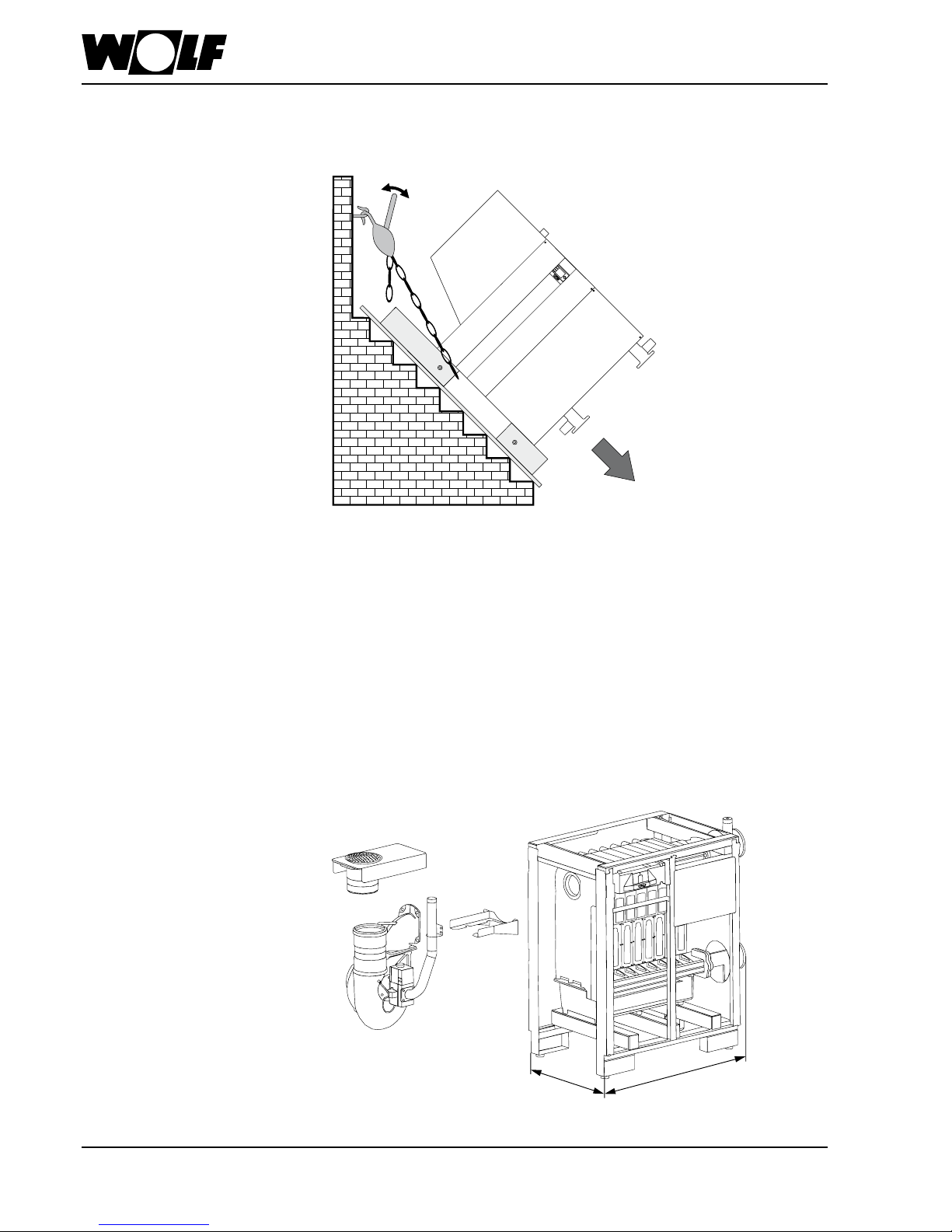

Dimensions after separating:

• Can be lowered into the basement with a cable winch or chain hoist, secured to

prevent it from sliding down on its own.

The gas condensing boiler can be separated into a gas-air mixing unit and heat

exchanger unit measuring 790 mm x 1295 mm for easier handling.

- Remove the burner hood

- Remove the gas-air mixing unit

- Remove the retainer for the gas-air mixing unit

Example:

1295 mm

790 mm

3063772_201507 15

• The boiler should be installed on a level surface which is substantial enough to carry

its weight.

• The boiler must be level (level with adjustable feet).

The boiler must only be installed in a room that is protected from frost.

If there is a risk of frost while the system is shut down, drain the boiler and

the system components that are at risk to prevent pipes from bursting.

Boilers should not be installed in areas subject to aggressive vapours, very

dusty or highly humid conditions (workshops, wash rooms, hobby rooms etc.).

This prevents the optimum burner function from being achieved.

The installation room and the combustion air supplied to the boiler must be

free from halogenated hydrocarbons (e.g. as contained in sprays, solvents,

cleaning uids, paints and adhesives). At worst these can lead to pitting of

the boiler and even the ue system.

Never store or use combustible material or liquids near the boiler.

The ventilation air supply must be ensured and must comply with local

regulations or those relating to gas installations. An insufcient fresh air supply

can lead to ue gas escaping, which represents a risk to life (poisoning/

suffocation).

A neutralising system for the condensate is a basic requirement and is

available as an accessory.

Caution

Caution

8. Installation instructions

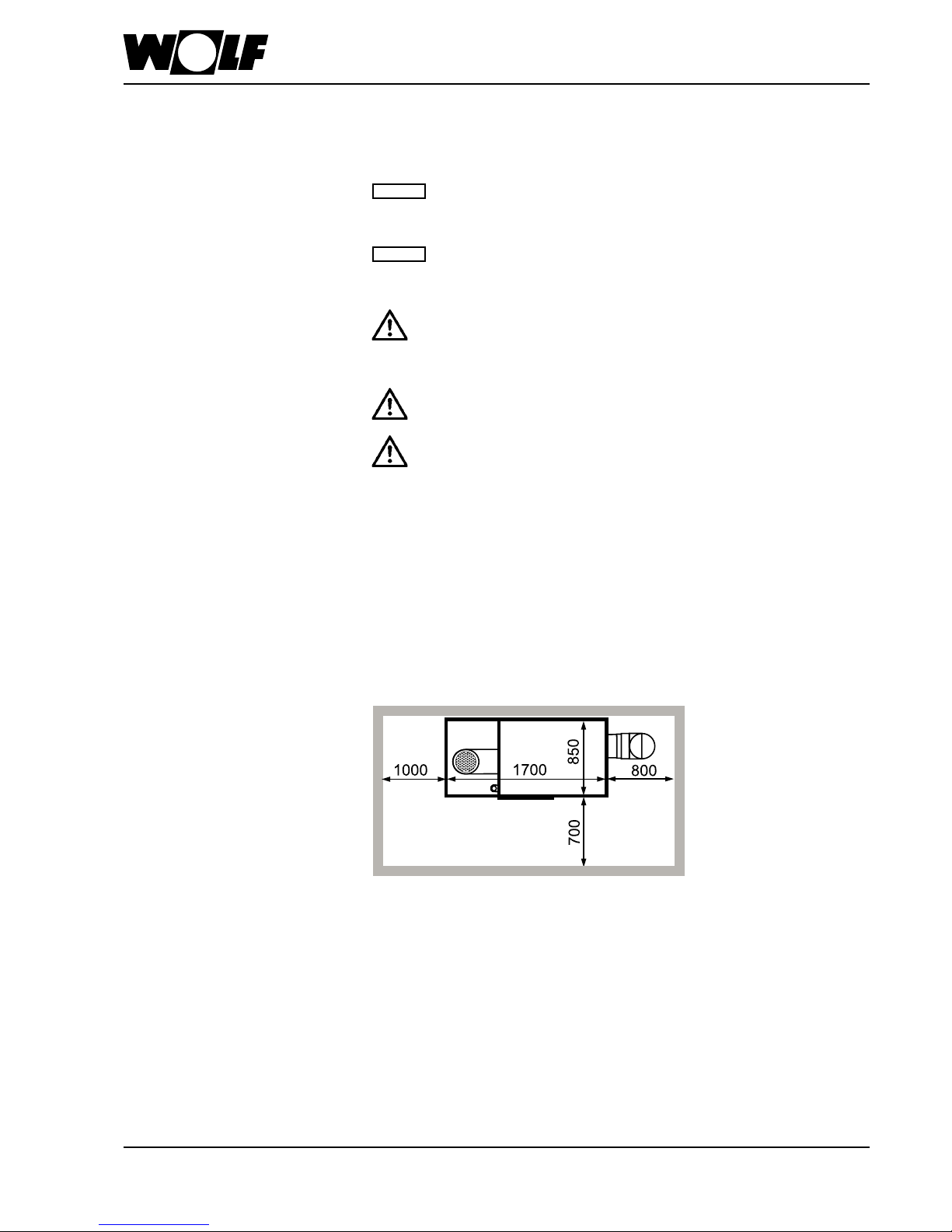

Fig: Boiler in the installation room

Different minimum clearances must be observed when installing the boiler in the

installation room.

Minimum clearances:

Installation instructions

16 3063772_201507

9. Safety equipment

The safety equipment for central heating systems must comply with DIN EN 12828.

This standard applies to all hot water heating systems and heat generation systems

with a maximum operating temperature of 105 °C and a maximum output of 1 MW.

Note: Provide a drain and fill valve at the lowest system point.

The minimum system pressure is 0.8 bar. The gas condensing boilers are approved exclusively for sealed unvented systems up

to 6 bar (safety assembly accessories 3 bar). The maximum flow temperature is factory-set to 85 °C on the MGK-2 and may be

adjusted to 90 °C if required.

There is no need for a minimum throughput at maximum flow temperatures below 85 °C.

Equipment level to DIN EN 12828

for MGK-2

Task Function MGK-2 installation location Comments

Temperature indicator

(°C)

Display Integrated in boiler

High limit safety cut-out

(HLSC)

Device to prevent ow

temperature being exceeded

Integrated in the boiler,

2nd HLSC integrated in boiler

(eHLSC)

Second electronic high

limit safety cut-out already

integrated in boiler

Temperature controller Device to prevent ow

temperature being exceeded

Integrated in boiler and set to

85 °C

Max. setting 90 °C

Low water indicator Low water indicator Device to

prevent incorrect heating when

water level or volume ow are

insufcient

In ow line near MGK-2 Can be substituted by

minimum pressure limiter.

Flow limiter Functions like low water

indicator

Not required Replaced by

maximum pressure limiter

Water level limiter Functions like low water

indicator

Not required Replaced by

minimum pressure limiter

Pressure measuring

device (bar)

Display Integrated in boiler Integrated in safety assembly

as accessory

Safety valve Facility to prevent permissible

operating pressure being

exceeded

Flow line near heat source Integrated as accessory (up to

3 bar) in the safety assembly

Maximum pressure limiter Devices for preventing the

permissible operating pressure

being exceeded

In ow line near MGK-2

2nd maximum pressure limiter

that can be integrated in Wolf

safety assembly (accessory)

Two can be installed as

accessories in MGK-2 safety

assembly accessory

Flash trap Facility to prevent permissible

operating pressure being

exceeded

Near safety valve or replaced

by 2nd HLSC (already

integrated) and 2nd maximum

pressure limiter

Can be replaced by 2nd

maximum pressure limiter and

2nd high limit safety cut-out

Expansion vessel

diaphragm

Device to compensate

for changes in water

volume (external pressure

maintenance)

Return line Expansion vessels should be

able to be securely isolated

and emptied for maintenance

purposes

3063772_201507 17

10. Information about water treatment

The system must be cleaned / flushed thoroughly before

commissioning and a sludge filter/dirt trap

(e.g. Wolf accessory, <500 μm = 0.5 mm mesh width MW)

installed in the return line. This must be in close proximity to

the heating appliance and at the lowest position in the heating

system.

The fill and top-up water must only be treated with a

desalination process. The "Maximum permissible total

hardness" table shows the degree to which water treatment is

required.

The system water must not fall below a total hardness of 2°dH,

which corresponds to conductivity of ≈ 60 μS/cm. The max.

permissible total hardness and the corresponding max.

conductivity are system-specific and must be calculated (see

also "Maximum permissible total hardness" table). The

desalinated water (conductivity <= 30 μS/cm) must not be

mixed with untreated DHW.

The addition of chemicals or de-scaling using single-stage ion

exchangers is not permissible, as system damage due to water

leaks may occur.

We recommend regular emptying of the sludge filter.

The operator must ensure that the heating system is maintained

and serviced regularly to maintain its energy quality (see

EnEV).

The Wolf system and operator's log for treatment of

heating water must be kept in a safe place and made

available by the owner / operator. It is provided along with

these installation instructions.

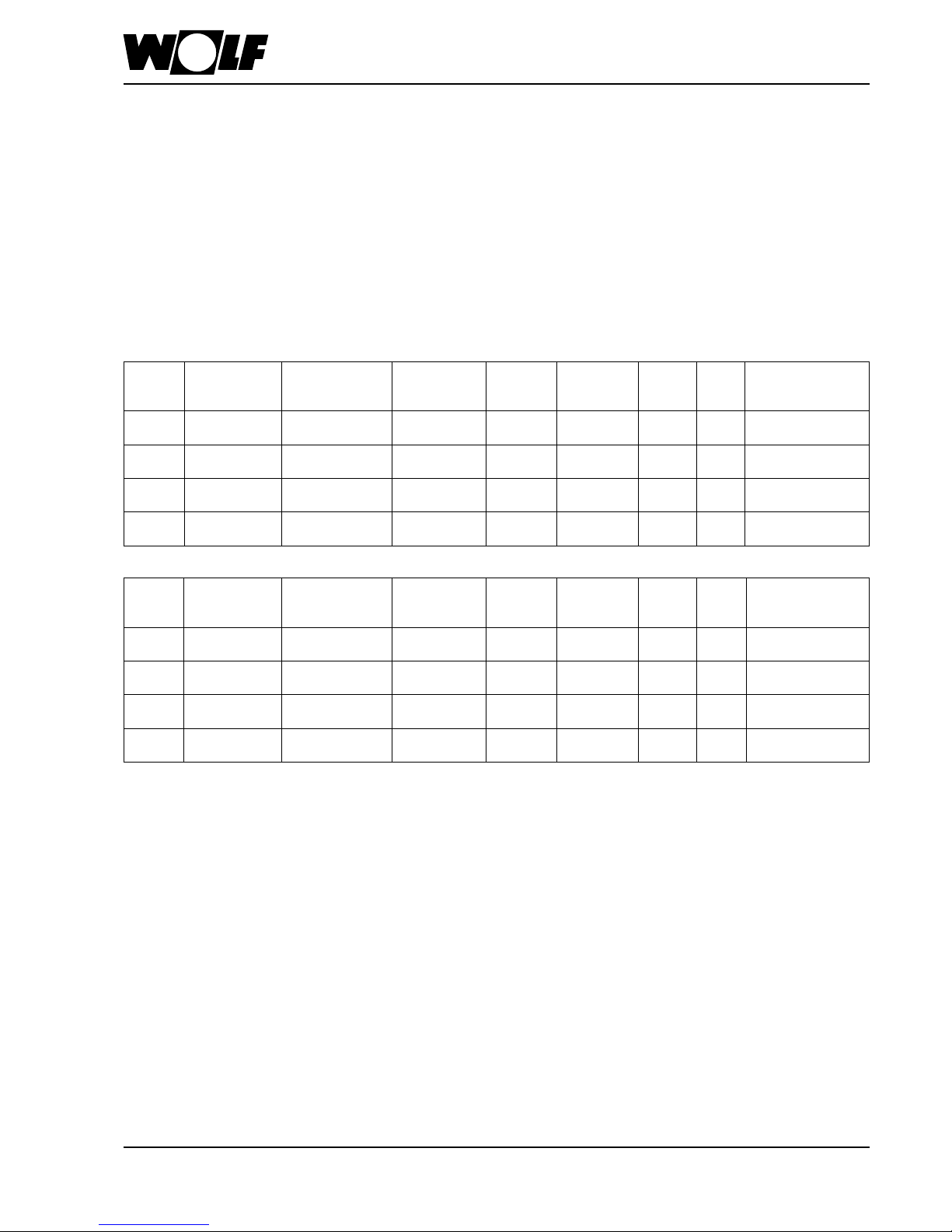

Limits depending on the spec. system volume VS (VS = system volume / lowest individual output)

Total hardness conversion: 1 mol/m³ = 5.6°dH

Total

heating

output

VS ≤ 10 l/kW VS > 10 l/kW and < 40 l/kW VS ≤ 40 l/kW

Total hardness / total

alkaline earths

Conductivity

Total hardness / total

alkaline earths

Conductivity

Total hardness / total

alkaline earths

Conductivity

[kW] [°dH] [mol/m³] C [μS/cm] [°dH] [mol/m³] C [μS/cm] [°dH] [mol/m³] C [μS/cm]

1* < 50 2 - 16.8* 0.36 - 3.0* 60 - 500 2 - 11.2 0.36 - 2.0 60 - 300 2 - 3 0.36 - 0.54 60 -100

2 50-200 2 - 11.2 0.36 - 2.0 60 - 300 2 - 8.4 0.36 - 1.5 60 - 200 2 - 3 0.36 - 0.54 60 -100

3 200-600 2 - 8.4 0.36 - 1.5 60 - 200 2 - 3 0.36 - 0.54 60 -100 2 - 3 0.36 - 0.54 60 -100

4 > 600 2 - 3 0.36 - 0.54 60 -100 2 - 3 0.36 - 0.54 60 -100 2 - 3 0.36 - 0.54 60 -100

*) for system boiler (<0.3 l/kW) and systems with electric heating elements

Gradual increase in the requirement for the spec. system volume (VS = system volume / lowest individual output) and the total

heating output.

The total amount of ll water over the life cycle of the appliance must not exceed three times the nominal volume of the heating

system.

Please note: The total hardness must not fall below 2°dH.

Treatment of heating water in accordance with VDI 2035:

We recommend a heating water pH value of between 8.2 and

8.5, also in mixed installations with various materials.

Request a water analysis from the water utility company. This

must test whether the total hardness is sufficiently low.

For a specific system volume of V

S,specific

>= 10 l/kW, the next

lowest limit from the table below must be applied,

for V

S,specific

>= 20 l/kW the next but one lowest limit, and for

V

S,specific

>= 40 l/kW the lowest limit.

For a specific system volume of >50 l/kW, the total hardness

must be adjusted to 2-3°dH using a desalination process. This

corresponds to conductivity of 60 - 100 μS/cm.

If the heating appliance is integrated in the system without a

hydraulic low loss header, the total hardness must be adjusted

to 2 - 3°dH (conductivity = 60 - 100 μS/cm).

If the water is not treated, the warranty is voided.

Maximum permissible total hardness table:

18 3063772_201507

11. Boiler system pipework

Heating ow and return are on the right-hand side of the boiler. Always provide shut-off

valves for the ow and the return.

Install a check valve downstream of the boiler circuit pump(s) to prevent incorrect

circulation.

For new systems we recommend installing a blow-down tank (or alternatively a dirt lter)

into the return. For older systems this installation is compulsory.

Install a safety assembly comprising a safety valve with a response pressure

of max. 6 bar, a pressure gauge and an automatic air vent valve.

The line between the boiler and the safety valve must not be able to be

shut off. Severely excessive boiler pressure due to excessive boiler water

temperatures can burst the boiler body or the boiler pipework, which would

lead to a sudden escape of hot water (risk of scalding).

When using pipes and climate-controlled oors that are not impermeable to

oxygen, always provide system separation by means of a heat exchanger.

This boiler is only suitable for heating systems with pumped heating circuits.

If no heating circuit pump has been installed, sufcient circulation through the

radiators cannot be ensured and the room will not be heated.

Caution

Safety assembly 2"

(accessory)

Ventilation air pipe

DN200 Connection for

room sealed operation

Gas connection R2"

Condensate trap with

DN250 flue outlet

Test nipple for flue gas

emissions test

Connection R2" for

safety assembly

Connection R2" for BDF

valve (accessory)

Siphons with

condensate drain

Flow connection DN80

/ PN6

Return connection

DN80 / PN6

3063772_201507 19

The MGK-2 is supplied without a circulation pump. The pump rate of the pump to be

supplied by the customer must be determined depending on the system and boiler

pressure drop. The fan's power supply and speed control are via the MGK-2 (see

electrical connection).

The primary and secondary circuit pumps should generally have the same flow rate.

The pumps shown below are designed for a spread of 20 K. If the spread on the

secondary side is smaller, a larger pump must be selected on the primary side. The

maximum flow rates under 4. Specification must be observed.

The following pumps are recommended for the assembly of an MGK-2 with low loss

header.

12. Selection of circulation pumps

Wilo

Nominal ow

rate at 20 K

Spread [m

3

/h]

HE pressure drop

at 20 K

Spread [mbar]

Wilo type

Delivery

head

[mbar]

Residual

head [mbar]

Output

[W]

Current

[A]

Connection

MGK-2

390

17.2 120 Stratos 50/1-2 770 650 590 2.6

1~230V

DN 50 ange tting

MGK-2

470

20.2 113 Stratos 50/1-12 680 567 590 2.6

1~230V

DN 50 ange tting

MGK-2

550

23.7 126 Stratos 65/1-12 730 604 800 3.5

1~230V

DN 65 ange tting

MGK-2

630

26.7 118 Stratos 65/1-12 655 537 800 3.5

1~230V

DN 65 ange tting

Grundfos

Nominal ow

rate at 20 K

Spread [m3/h]

HE pressure drop

at 20 K

Spread [mbar]

Grundfos

Type

Delivery

head

[mbar]

Residual

head [mbar]

Output

[W]

Current

[A]

Connection

MGK-2

390

17.2 120

Magna3

50-120F

730 610 540 2.4

1~230V

DN 50 ange tting

MGK-2

470

20.2 113

Magna3

50-120F

640 527 540 2.4

1~230V

DN 50 ange tting

MGK-2

550

23.7 126

Magna3

50-150F

650 524 630 2.8

1~230V

DN 50 ange tting

MGK-2

630

26.7 118

Magna3

50-180F

680 562 760 3.4

1~230V

DN 50 ange tting

• The maximum power consumption of the circulation pump must not exceed 4 A.

• Reductions from DN80/PN6 to DN/50 or DN65/PN6 are required for the

hydraulic connection of the pumps.

• For the speed control of the circulation pump via the 0-10 V or PWM output of

the boiler control unit, an extension module may be required from the pump

manufacturer.

20 3063772_201507

13. Gas connection

With the power supply disconnected, connect the gas supply line to gas connection

R2" at the gas connection or the expansion joint (recommended) using the approved

sealant.

Routing the gas pipe and making the gas connections must only be

carried out by a licensed gas tter.

Remove all residues from the heating pipework and the gas line prior to

connecting the condensing boiler, particularly in older systems. Prior to

commissioning, test all pipe and gas connections for leaks. Inappropriate

installation or using unsuitable components or assemblies may lead to

gas escaping, which results in a risk of poisoning and explosion.

Install a gas ball valve with re protection in the gas supply line upstream

of the Wolf condensing boiler. Otherwise explosions may occur during a

re. Size the gas supply line in accordance with DVGW-TRGI regulations.

Check the gas line for tightness without the boiler. Never release the

test pressure via the gas valve.

Gas ttings on the appliance should be pressure tested to a

maximum of 150 mbar.Higher pressure may damage the gas train,

resulting in a risk of explosion, suffocation or poisoning. Close the

gas ball valve on the gas condensing boiler to pressure test the gas

line.

Mount the gas ball valve in an easily accessible place.

• Prior to installation, ensure that the boiler is set to the available gas type.

At the factory, the boiler is set up for natural gas E/H 15.0:

Ws = 11.4 - 15.2 kWh/m3 = 40.9 - 54.7 MJ/m

3

Only commission the appliance when the rated supply pressure has been reached.

If the supply pressure for natural gas (flow pressure) lies outside the

18 to 25 mbar range, adjustments must not be carried out and the boiler

must not be put into operation.

Caution

Gas connection R2"

3063772_201507 21

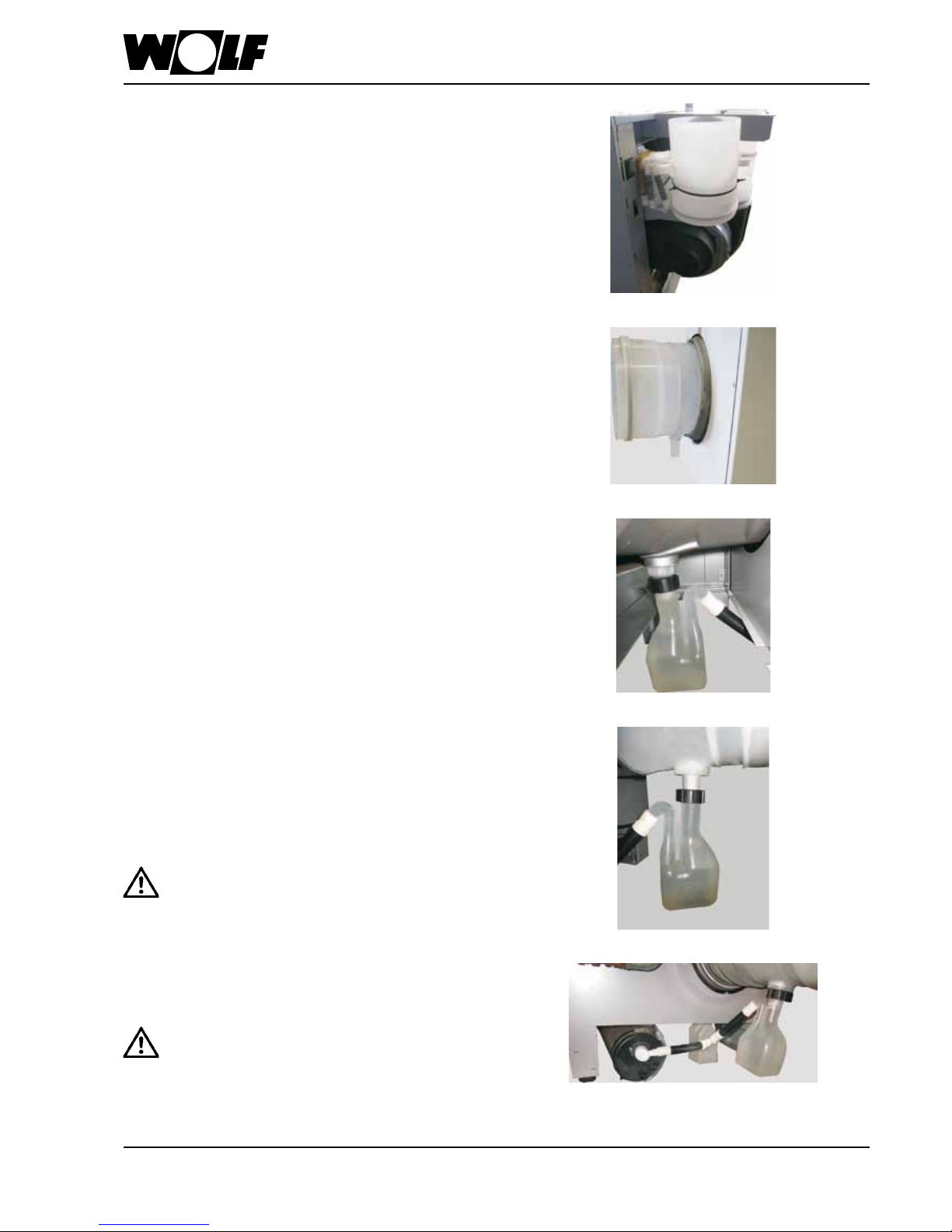

14. Fitting the siphons

Install siphons:

Install the first siphon on the connector of the condensate pan.

Install the second siphon on the connector of the condensate

trap.

Fill the siphons with water prior to

commissioning. Otherwise there is a risk of flue

gas escaping.

Connect the condensate hoses of both siphons from the

condensate pan and condensate trap with a tee and connect

to the neutralising system.

Check tightness of the connections.

The standard delivery includes:

1 x condensate trap (under the burner hood on the

ventilation air pipe)

2 x siphons with 3 condensate hoses and 1 tee (on the

condensate trap)

Condensate connection:

Install condensate trap in the flue outlet of the condensate pan.

Check tightness of the connections.

Loading...

Loading...