Wolf KAFS-200E-C-C Installation Manual

RECOMMENDED

To

provide

equipment

person

or

proper

must

an

authorized

operation

be

maintained

MAINTENANCE

and

insure

and

service

serviced

agency

at

regular

the

safety

by a trained

intervals.

of

the

maintenance

user,

this

.1,

'{NSTALLATION

OPERATING

&

MAINTENANCE

INSTRUCTIONS

following

The

1.

All

necessary.

2.

Burners

burner

3.

Appliances

a

competent

4.

All

clean

5.

Pilots

constant

Ignition.

6.

All

with a high-temperature

7.

At

company

8.

All

polyester,

contact

Carelessness,

9.

the

by

Frequency

usage.

1.

10·12

2.

4·6

are

moving

should

throats,

places

valves

the

operators

life

the

where

at

all

are

to

combustion

and

slightest

or

wood,

with

of

the

manufacturer.

of

service

RECOMMENDED

hours

hours a day

recommendations:

parts

must

be

be

thoroughly

or

venturi,

equipped

service

011,

times.

be

kept

controls,

odor

service

are

to

etc. are

pilots,

burners,

abusive

equipment

maintenance

operation

- 5

agency.

must

with

agency

grease,

clean

and

and

prevent

at

the

grease

of

gas,

be

cautioned

highly

handling,

and

per

days

a week: - Every

checked

cleaned.

be

burner

to

assure

or

lood

adjusted

fire

first

sign

by

a trained

shut

off

that

combustible

or

heated

or

jeopardize

will

SERVICE

day:

• 7

for

wear,

and

lubricated,

Ports

are

to

free

from

safeties

01

gas

surfaces.

altering

be

days a week -Every

should

proper

can

accumulate

at

the

proper

flash-outs

sticking,

person.

valve

certain

and

equipment

the

limited

largely

FREQUENCY:

120

be

grease

materials

days.

and

be

operation.

height

caused

should

and

notify

should

warranty

dependent

cleaned

lint.

checked

must

to

by

delayed

be

lubricated

local

such

not

can

shorter.

on

30-60

if

and

by

be

kept

assure

gas

as silk,

come

in

offered

customer

days.

OWNER'S

MANUAL

~

~

·CONVECTION

DESIGNED AND ENGINEERED FOR

• INSTALLATION AND OPERATING INSTRUCTIONS

FOR

• GUIDE

COOKING TIME AND TEMPERATURES

• PARTS • WIRING DIAGRAMS

COMMERCIAL

•

~

TM

OVENS

USE ONLY

10/66/2M

3.

4.

Limited

All

equipment

Any

Wolf

of

this unit.

WOLF

19600

dally

usage:

modification

Range Company>

Every

should

of

BANGE/company

ALAMEDA ST.•

(213)

637-3737.

P.O. BOX

180

be

serviced

IMPORTANT

this

unit

voids

7050.

From

L.A. (213) 774-7565

days.

at

least

once

without

the

written

certilication

COMPTON. CALIF. 90224

a year.

permission

and

warranty

01

Printed in

U.S.A.

I

1965

WOLF

19600

WOLF~NGE

S.

ALAMEDA

BANGE/company

ST. • P.O.

(213) 637-3737 • From

BOX

7050 •

LA.

(213)

COMPTON,

774-7565

CA. 90224

lIP

Operating

and/or

All

licensed

Service

information

authorized

installation

and/or

may

Representative

QUALIFIED

Qualified

information

previous

AND/OR

or

authorized

in

experience

OPERATING.

for

operating

and

service on

authorized

be

obtained

or

Local

Service

AUTHORIZED

operating

this

manual

with

IMPORTANT

INSTALLING

this

equipment

personnel.

this

equipment

installation

by

contacting

and

are

the

operation

or

Agency.

DEFINITIONS

OPERATING

personnel

familiar

AND

SERVICE PERSONNEL

has been

is

to

be

performed

service personnel.

the

Factory

PERSONNEL

are

those

with

the

of

the

equipment's

equipment

prepared

Service

who

have

covered

for

use

by

by

qualified,

Department,

carefully

functions

in

this

or

manual.

qualified

certified,

Factory

read

the

have

had

~eE~SMe't

CONVECTION

• ~ TM

OVEN

QUALIFIED

Qualified

either

1.

The

regulator

gas

be

of

INSTALLATION

installation

in

person

installation

when the

appliance.

iamiliar

state

or

personnel

or

through a representative

of

gas

meter

Qualified

with all

precautions

local

authorities

America - National Fuel Gas

Standard CANI-B

149.1

Local Codes.

2.

The

installation

service

ance

Code

part

outlet

with

ANSljN.F.P.A.

1,

CSA-C22.1.

work, be

ments

of state

QUALIFIED

Qualified

service personnel

have been

required

mum

to

amount

NOTICE:

which

will

This

Information

In.tructlon.

of

to the

local

codes,

familiar

or

SERVICE

endorsed

be

equipped

of

parts

In.truct

mu.t

electrical

electric

No. 70-1981. In Canada,

Qualified

with all

local

PERSONNEL

by

for

mu.t

the

user

be

SHIPPING

For

your

personnel

acceptance

II

Ihlpmenl

1.

VISIBLE

making

2.

FILE

CLAIM

3.

CONCEALED

company

days

ot

We

cannot

necessary

protection,

before

documents

of

thiS

.rrtvel

LOSS

delivery

FOR

or

carner

date

delivery

assume

PLEASE

please

leaving

the

equipment

demeged:

OR

DAMAGE -Be

DAMAGES

LOSS

OR

Immediately.

IS

responSibility

to

support

note

fe-crary

DAMAGE

made

RETAIN

PERSONNEL

are

piping

from the

is

not

installation

having

individuals,

provided,

required,

jurisdiction.

Code

a firm,

are

engaged

outlet

and

personnel

and

side

of

the

connection

must

have

Referencn

corporation,

in,

the

be

experienced

complied

and

gas

are

meter,

and

with all

in

the

or

company

responsible

or

installation

in

requirements

United

ANSI Z·223.1 - 1984. In Canada - Canadian

(Nat. Gas) or CANI-B149.2 (Propane). Installation Codes

wiring

from

the

or

in

the

appliance

absence

must

of

installation

precautions

authorities

are

the

Wolf

with a complete

Wolf

equipment.

be

of

thl.

obtained

that

equIpment

The

transportation

certain

.MMEDIATELY -Regardless

-II

damage

and

file

to

you

Be

tor

damage

your

claim.

THIS

having

those

who

Range

Company.

posted

equipment

from

DAMAGE

In thiS

this

IS

IS

u~notlced

"concealed

sure

to

retain

or

lossllncurred

MANUAL

required

jurisdiction.

are

set

In a

your

CLAIM

shipment

company

nored

damage"

contamer

electric

be

local

follow

personnel

familiar

of

service

prominent

In

the

local

on

fre'ght

01

until

claim

in

transit,

FOR

meter, main

electrically

codes

with

the

Canadian

must

and have

complied

with

All

authorized

parts

manuals

place

event he

gas

company

PROCEDURE

was

carefully

assumes

full

responsibility

bIll

or

express

e.xtenl ot

damage

merchandlSe.s

with

them

ror

inspectIon

We

will,

however.

FUTURE

control

grounded

the

National

Electrical

be

experienced

with

all req'

Wolf

equipment

service personnel are

and stock a

within

the

or

be

the

gas

and

lor

sate delrvery

and

notIfy

glad

to

kitchen

smell

packed

sIgned

done

furnish

detects

Inspected

receipt

unpacked.

ThiS Should be

REFERENCE

2

which

for:

the

service

of

the

such

work,

States

and/or

box

in

or

accord-

Electrical

C.

ir

and

who

mini-

area

of ga•.

distributor.

by

skilled

upon

by

person

IransportallOn

Within (15)

you

With

of

Uses

up

to 40% Less Gas!

The revolutionary new Wolf Snorkler

Convection Oven does everything a

regular convection oven can do, but

with less gas consumption.

•

Less

gas consumption

...

because

it recirculates the heated air that

formerly

was

exhausted up the flue,

in all convection ovens.

• Faster heat-up time . . . advanced

burner system and recycled heat

brings

oven

up

to

temperature

faster, using less energy.

• Reduces gas requirements

...

uses

only 49,000 BTU's.

• High Production

is

ideal

for

...

baking,

full-size oven

roasting

and

reconstitution of frozen foods.

Three

(3)

heavy duty chrome-plated

oven racks can increase production

up to

50%.

3

with

SINGLE

KAFS-IOOE-F

KAFS-lOOE-C

AIR·FLOW

Gas

Pilots

DECK

(Cabinet Door)

(Chef Door)

OVEN

CRUSADER

with

Gas

SINGLE

KCAF-I-F (Cabinet Door)

KCAF-I-C (Chef Door)

DECK

Pilots

OVEN

~ENERAL

Upon

receipt

during

immediately.

shipment.

of

Wolf

If

damage

eqUipment,

is observed,

thoroughly

contact

inspect

the

it

for

any

delivering

damage

carrier

DOUBLE

KAFS-200E-F-F

Bottom)

KAFS-200E-C-C

Bottom)

KAFS-200E-F-C

Chef

Door

Bottom)

With Electric Ignition Pilots

KAFSX-200E-F

KAFSX-200E-F-F

and

KAFSX-200E-C-C

KAFSX-200E-F-C

SINGLE

DOUBLE

Bottom)

Bottom)

Chef

Door

(Cabinet Door)

Bottom)

THIS

INSTALLED

MANUFACTURER'S RECOMMENDATIONS

The Wolf Range

factured

manship

obligation

without

defective

date

of

Twelve

nized

responsibility

only

of

or safeties

couple

NOTE:

included

the

warranty

DECK

(Cabinet

(Chef

(Cabinet

DECK

DECK

(Cabinet

(Chef

(Cabinet

OVEN

Door

Top

Doors

Top

Doors

OVEN

OVEN

Doors

Doors

Top

Doors

LIMITED

and

Top,

Top

Top,

and

KCAF-2-F-F

KCAF-2-C-C

KCAF-2-F-C

KCAFX-I-F (Cabinet Door)

KCAFX-I-C (Chef Door)

KCAFX-2-F-F

and

KCAFX-2-C-C

KCAFX-2-F-C

WARRANTY

DOUBLE

(Cabinet Door

(Chef

(Cabinet

Bottom)

With Electric Ignition Pilots

SINGLE

DOUBLE

Bottom)

Door Bottom)

DECK

Doors

DECK

DECK

(Cabinet

(Chef

Doors

(Cabinet

Doors

Doors

Doors

Top

Top

OVEN

OVEN

Top

WARRANTY APPLIES TO ALL EQUIPMENT

IN

ACCORDANCE

Company

by it to be free

for

which

under

charge

within a period

original

THERMOSTATS, SAFETIES AND MOTORS

(12)

months

factory

the

must

labor

service

under

replacement

under

be

and

in

this

period

it

this

warranty

any

part

installation

when

agency

this

warranty,

intact.

transportation

warranty. Parts

of

the

warrants

from

defects

is

responsible

shall be

or

parts

of

ninety

except

furnished

or

warranty

part. When

capillary

appliance.

4

of said

as

limited

costs are

replaced

WITH

appliances

in

material

The

Company's

limited

(90)

follows:

from

dealer -the

returning

tube

to

furnishing

appliances

days

factory

to

the

furnishing

thermostats

and/or

not

covered

do

not

THE

manu-

and

found

from

or

recog-

factory

thermo-

extend

work·

OVEN

and

and

Top

and

Top

and

Top,

the

or

Bottom)

Bottom)

and

bottom)

Chef

~)

~(

Safe and

depends

tions

National

should

NFPA No.

In Canada,

149.1

and

Part I"

BENEFITS

TIPS

satisfactory

to a great

should

and

Equipment"

1.

2.

3

4.

5.

ON

1.

2. Use fan for. preheating and baking.

3. Open-face pies with

4.

5_

be

Gas Fuel Code

be

made

70-1981.

installations

B-149.2

and

local codes.

Speed-fast,

lower temperatures.

Capacity-increased,

in

ovens

Shrinkage-reduced,

reduces shrinkage.

Operation-its

reach racks, simple controls, easy

Results-excellent,

and all general baking.

USING

In

general, reduce temperature

a.

Bakery products, reduce temperature

less.

b.

Casserole cookery, reduce temperature about

25t050%.

c.

Meat roasting, reduce temperature to

thermometer. Cooking

to

3 minutes before

2

Check product at

Level pans bake more evenly; warped pans will give uneven

baking results.

See

operation

extent

made

upon

in

accordance

ANSI-Z223.1

in

accordance

should

-

Installation

and

CSA

Standard

baking time cut

greater capacity than conventional deck

V2

the space.

cooking less

easy, oven

does roasts, casseroles, breads, pies, cakes

WOLF

page 17 for cooking times and temperatures.

(:RMil;1!§tj{CONVECTION

thin

turning

1/

stated

2

of

your

SNORKLER Convection Oven

its

proper

with

be

C221. - Canadian

is

time

filling

time

5

installation.

with

State and Local Codes and

-1984

the

National

made

Code

in

accordance

for

Gas

~1l

to

V2

the regular time and at

time

at a lower temperature

at good working height, easy to

to

clean.

50°

from conventional recipe.

may

be

reduced up to

mixture should be in heated oven

on fan switch.

of regular recipe.

In USA,

Electrical

Electric

Burning

Electrical

OVENS

50°.

Time

50°

275°-300°.

with

installa-

installation

Code ANSI-

CGA B-

Appliances

Code

25

to

33 %

and

time

Use

meat

50%.

INSTALLATION .'jj)

FOR YOUR SAFETY

Do

not

store

or

use

gasoline

liquids

RETAIN THIS

in the

vicinity

of

MANUAL

this

NOTICE: Instructions must be posted in a

kitchen

area

which

will

event he detects the smell of gas, to shut off gas valve and notify

local Gas

company

or

Service agency.

PRESSURE TESTING INSTRUCTIONS:

1.

The

appliance

nected

testing

2. The

by

closing

appliance

testing

less than

CAUTION:

followed

Provisions

to

ensure

bustion

When

unit

with

obstruct

from

of

of

installing

and

its

individual

gas

supply

that system at test pressures in excess

must

be

isolated

its

the

Y2

psig.

The

gas

individual

supply

items

manual

piping

listed

explicitly:

shall

be

incorporated

an

adequate

and

ventilation.

the

unit

a raised

the

flow

of

curb

air

into

or

other

or

any other

flammable

appliance.

vapors

FOR FUTURE REFERENCE

instruct

piping

from the gas

system at

below

supply

never

or

other

the

prominent

the user of this

shutoff valve must

system

during

supply

shutoff

valve

test

must

be

read,

in the

design

of

fresh

air

enclose

the

construction

unit.

place within the

equipment

any

of

Y2

piping

during

any

pressures

understood

of

the kitchen,

for

proper

bottom

area

which

be

psig.

and

in the

discon-

pressure

system

pressure

equal

to

com-

of the

would

or

an

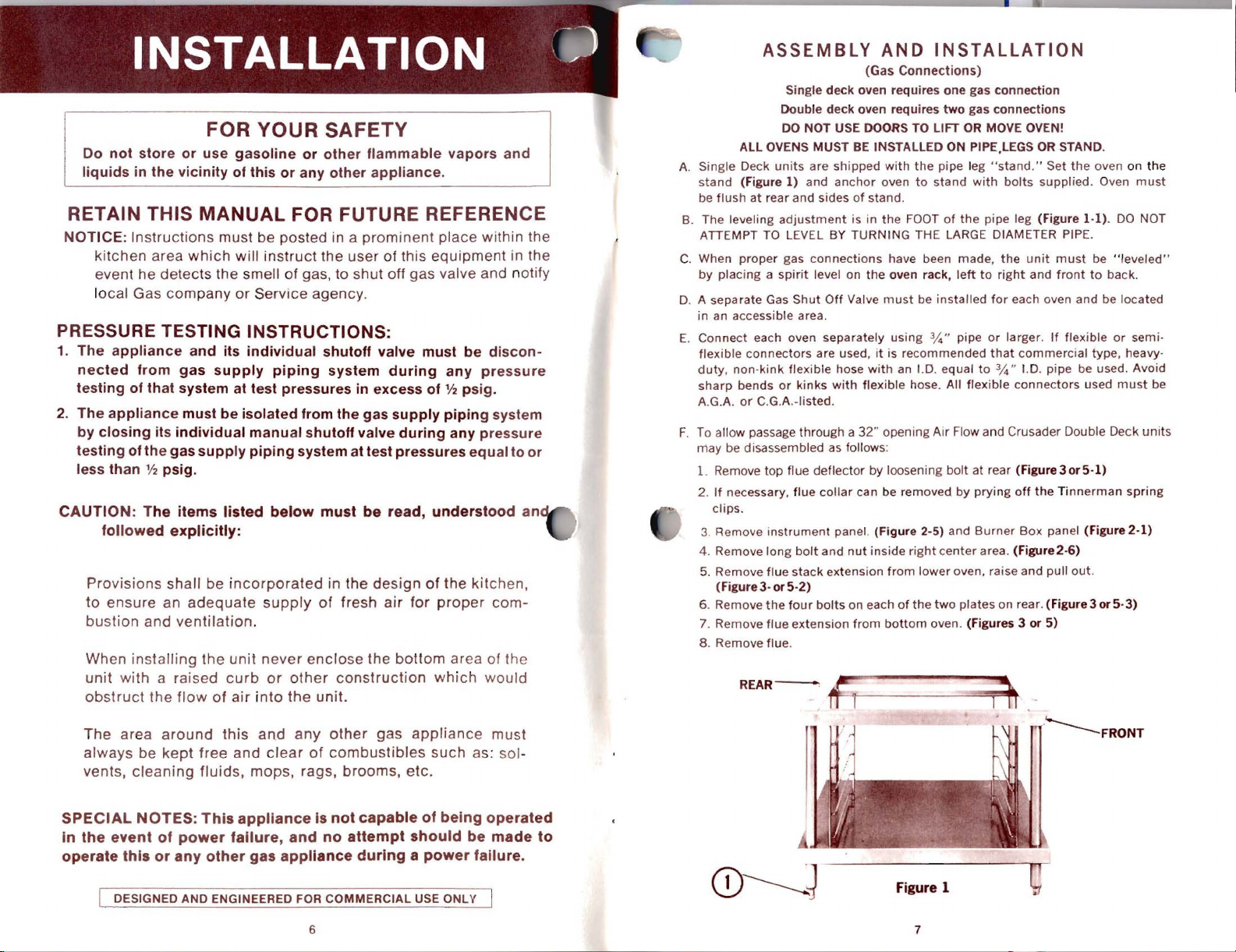

ASSEMBLY

Single

deck

Double deck oven requires

DO

NOT USE DOORS

ALL OVENS MUST

A.

Single Deck

stand

be flush

B.

The leveling

ATTEMPT

C.

When

by placing a

D.

A separate

an

in

E.

Connect each oven separately

flexible connectors are used,

duty,

sharp

A.G.A.

F.

To allow passage through a 32" opening

may be disassembled as follows:

1.

Remove top flue deflector by loosening bolt at rear (Figure 3

2.

If

necessary, flue

clips.

3.

Remove instrument panel. (Figure 2-5) and

4. Remove long

5.

Remove flue stack extension from lower oven, raise and pull out.

(Figure3·

6. Remove

7. Remove

8.

Remove flue.

units

are shipped

(Figure

1)

and

at

rear and sides

adjustment

TO

LEVEL

proper

gas

connections

spirit

level on the oven rack,

Gas

Shut

accessible area.

non·kink

bends

or

REAR---'

flexible hose

or

kinks

C.G.A.-listed.

bolt

or5·2)

the

four

bolts

flue

extension

anchor

BY

Off

with

collar

and

fit·,

AND

(Gas

oven requires

BE

INSTALLED ON PIPE,LEGS

with

oven

of

stand.

is in the

TURNING THE

Valve

must

it

is recommended

with

flexible hose. All

can be removed by

nut

inside

on each

from

bottom

INSTALLATION

Connections)

one

gas

two

gas

TO

LIFT

OR

the

pipe leg

to

stand

FOOT

of

the

LARGE

have been made, the

left

be installed

using

%"

pipe

an

1.0. equal

flexible

Air

Flow and Crusader Double Deck

right

center

of

the

two

plates on rear. (Figure 3

oven. (Figures 3 or

-

connection

connections

MOVE OVEN!

"stand."

with

bolts

pipe leg (Figure I-I).

DIAMETER PIPE.

to

right

for

each oven and be located

or

larger.

that

to

314"

connectors used

prying

off

Burner

area.

(Figure2·6)

i'"

OR

STAND.

Set

the

oven on the

supplied. Oven

unit

must

and

front

If

flexible

commercial

1.0. pipe be used. Avoid

or5·1)

the

Tinnerman

Box

panel (Figure

5)

must

DO

NOT

be

"leveled"

to

back.

or

semi·

type, heavy·

must

units

spring

2-1)

or5-3)

be

The

area

always be

vents,

SPECIAL

In

the

event

operate

around

kept

cleaning

NOTES:

of

this

or

any

free

fluids,

This

power

other

this

and

appliance

failure,

I DESIGNED AND ENGINEERED FOR

and

clear

mops,

gas

appliance

any

other

of

combustibles

rags,

Is

not

and

no

COMMERCIAL

6

gas

appliance

brooms,

capable

attempt

etc.

of

should

during a power

USE ONLY I

such

being

must

as: sol-

operated

be

made

failure.

to

CD------.j

Figure 1

7

.'------FRONT

~

J

I

,11111111111111111

'"""""11111 • r

III

.11111111111111111

1111111111111111

"

FIGURE 2 (Model KAFS-200E·F-C)

.1f6\

~~

CD

(.

FRONT

VIEW

1111111111111111111,

AIR

FLOW

111111111111111111

1I1111111t11l1ll1l

,'JI

I

~;~

=

EB

11111111

wmmm

111111111111111111

II,©

1':::1

~

lm'Mj13_m™OVEN

o

o

00

0

o

o

\

o

@

4

~~

FIGURE 3

1

---~--

3

REAR

(Model

I I

.

VIEW

KAFS-200E·F-C)

~

,1111111111111111111

IlIIJlIIIIlIII

IIU

-

.IIWIIIIIIIIIIIILI

IIIIIIIIIIIIIIUII

~-

FIGURE 4 (CAF)

MODEL KCAF·2·f·C

CRUSADER II:-UMj13_:mI™OVEN

~

~".

n

IIiI:r!mID

.

[

1I1111111111l1l1U.

IlIIWIJJIlIIJIIl

-"-II,@

.

[11111111011111111.

1IlDIIIUUIUJil

VIEW

FRONT

QD

1111111

II.

@

::;\

'b

~IIIII

i>

@lll

@

ffiD

II~JII

~

~

1

11

4

I

/"'

4

-/

/CD

I

II

119>

"-.../

0

/

n

r----t----,

::

1]

CD

cD

REAR

FIGURE 5 (CAF)

Model

---

VIEW

KCAf-200f-C

ILl

I

, ,

\"

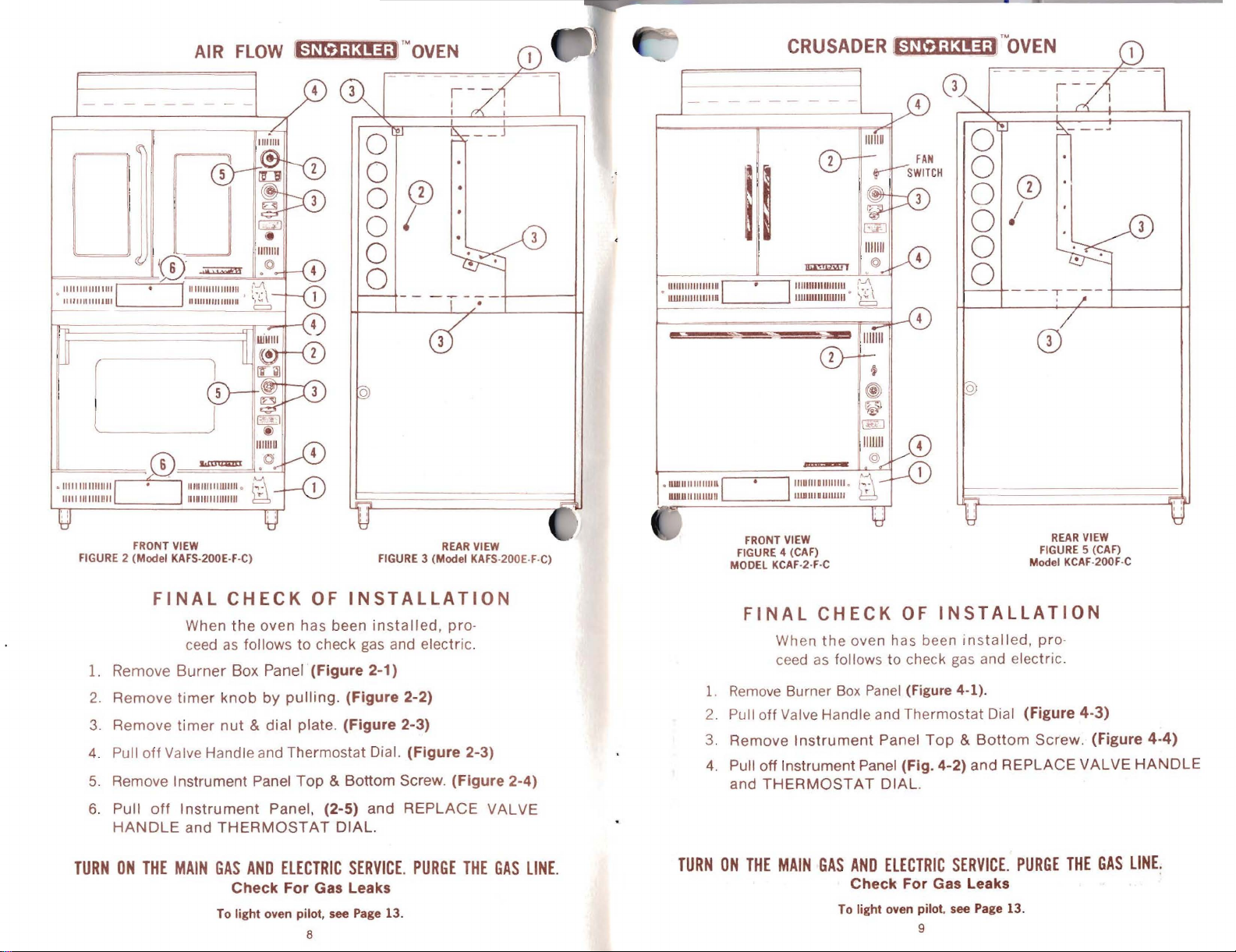

FINAL

When

ceed

1.

Remove

2.

Remove

3.

Remove

4.

Pull

5.

Remove Instrument Panel

6.

Pull

HANDLE

TURN

ON

Burner

timer

timer

off

Valve Handle and Thermostat Dial.

off

Instrument

and

THE

MAIN

CHECK

the

oven has been

as

follows to check

Box Panel

knob

by

nut

& dial plate.

THERMOSTAT

GAS

AND

Check

To

light oven pilot,

OF

(Figure

pulling.

Top

Panel,

ElECTRIC

For

Gas

8

INSTALLATION

installed,

gas

and electric.

2-1)

(Figure

(Figure

& Bottom Screw.

(2-5)

DIAL.

SERVICE.

Leaks

see

Page

2-2)

2-3)

(Figure

and REPLACE VALVE

PURGE

13.

pro-

2-3)

(Figure

THE

2-4)

GAS

LINE.

1.

2.

3.

4.

TURN

FINAL

Remove

Pull off Valve Handle and Thermostat Dial

Remove

Pull off Instrument Panel

and

THERMOSTAT

ON

THE

CHECK

When

the

as

ceed

Burner

Instrument

MAIN

GAS

OF

oven has been

follows to check

Box

Panel

(Figure 4-1).

Panel

Top & Bottom

(Fig.

DIAL.

AND

ElECTRIC

Check

To

For

Gas

light oven pilot.

9

INSTALLATION

installed,

gas

and electric_

4-2) and REPLACE VALVE

SERVICE.

Leaks

see

Page

pro-

(Figure

Screw.

PURGE

13.

4-3)

(Figure

THE

GAS

4-4)

HANDLE

LINE:

Loading...

Loading...