Page 1

INSTALLATION GUIDE

Fryer Module

Page 2

Contents

Important Note

Wolf Fryer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fryer Module Specifications . . . . . . . . . . . . . . . . . . . . . 4

Fryer Module Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Features and specifications are subject to change at any time

without notice. Visit wolfappliance.com/specs for the most

up-to-date information.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specified.

o ensure the safe and efficient use of Wolf equipment,

T

please take note of the following types of highlighted

information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION signals a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

Page 3

Wolf Fryer Module 3

wolfappliance.com/specs

Fryer Module Installation

IMPORTANT NOTE: I

nstallation of the Wolf electric fryer

module must be completed by a qualified installer.

Read this entire installation guide prior to installation and

save for the local inspector’s reference. The homeowner

should keep this installation guide for future reference.

This appliance must be installed in accordance with

National Electrical Codes, as well as all state, municipal

and local codes. The correct voltage, frequency and

amperage must be supplied to the appliance from a dedicated, grounded circuit which is protected by a properly

sized circuit breaker or time delay fuse. The proper

voltage, frequency, and amperage ratings are listed on the

product rating plate.

Record the model and serial numbers before installing

the fryer module. Both numbers are listed on the product

rating plate, located on the underside of the module. Refer

to the illustration below.

olf Fryer Module

W

Model Number IF15/S

Serial Number

RATING PLATE

Location of rating plate.

Page 4

Fryer Module Specifications 4

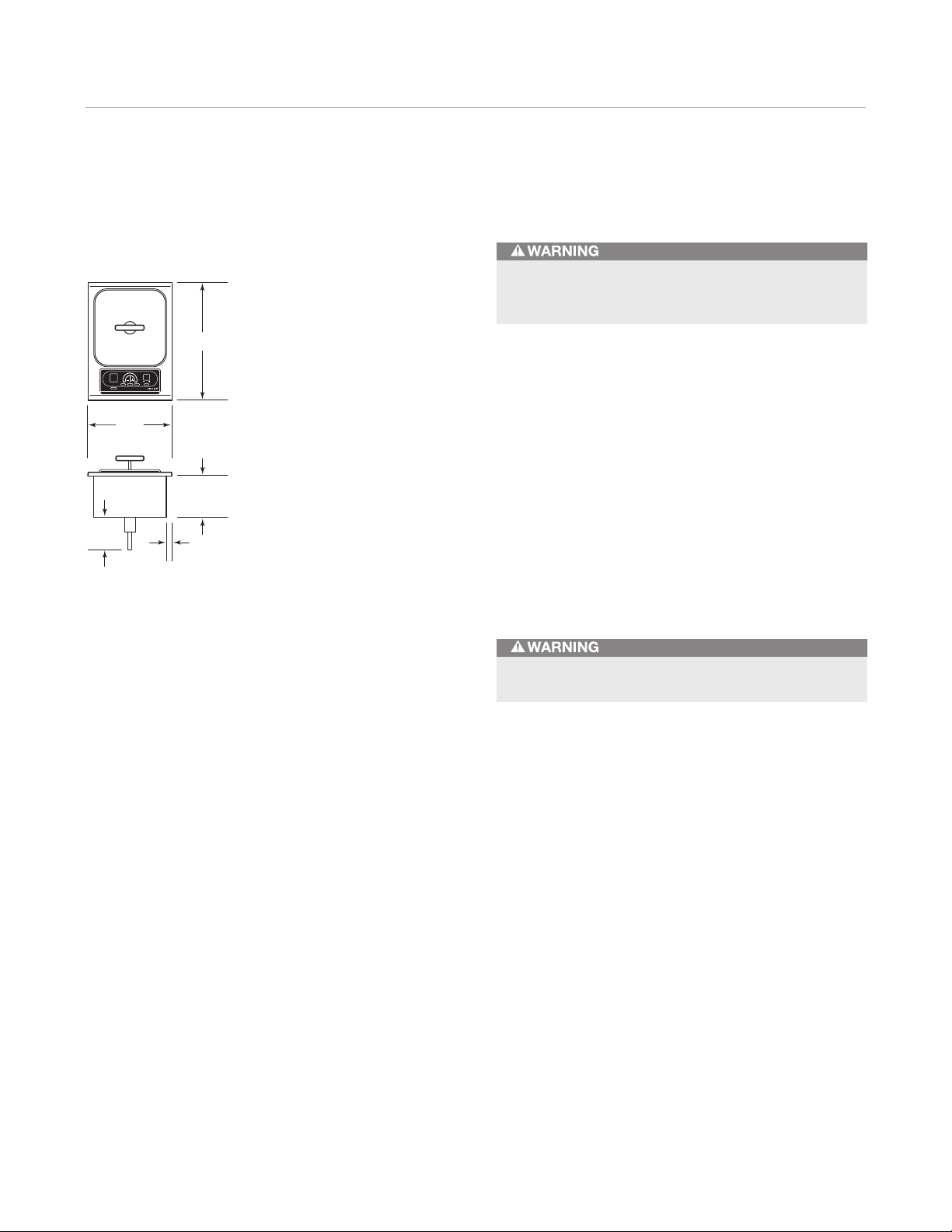

1

/2" (13)

SIDES

1" (25)

FRONT / BACK

71/2" (191)

6"

(152)

DRAIN

OUTLET

21" (533)

15"

(

381)

Overall Dimensions

FRYER MODULE

Installation Specifications

Failure to locate the fryer module without the proper

clearances will result in a fire hazard.

IMPORTANT NOTE: Installation of the Wolf electric fryer

module must meet minimum clearance requirements

shown in the installation illustration on page 6.

The fryer module is designed to fit a standard 24" (610)

deep base cabinet with 25" (635) deep countertop. Before

making the countertop cut-out, verify that the module will

clear the side walls of the base cabinet below.

It is recommended that you use a Wolf cooktop ventilation

hood, pro hood or hood liner with the fryer module. Refer

to the Wolf design guide.

IMPORTANT NOTE: Wolf does not recommend the use of

downdraft ventilation with the fryer module.

The fryer module is intended for indoor use.

MANUAL DRAIN OUTLET

IMPORTANT NOTE:

The fryer module must be installed in

a base cabinet that allows access to the manual drain

valve for draining the oil. A heat-resistant bucket must be

positioned under the drain outlet to accept the oil. The

bucket must have a minimum 2 gallon (7.6 L) capacity.

Refer to the installation illustration on page 6 for location

of the manual drain outlet.

Page 5

Fryer Module Specifications 5

wolfappliance.com/specs

Electrical Requirements

Verify that power is disconnected from the electrical

box before proceeding.

The Wolf electric fryer module requires a separate,

grounded 3-wire electrical supply with its own circuit

breaker. Locate the electrical supply within the shaded

area shown in the installation illustration on the following

page.

MODEL IF15/S

• Power supply: 240/208 V AC, 60 Hz, 15 amp service.

• Max connected load: 2.6 kW at 240 V, 1.9 kW at 208 V.

The fryer module is provided with a 4' (1.2 m) flexible

3-wire conduit that makes a connection to a junction box.

The conduit consists of two insulated hot lead conductors

and one insulated ground conductor.

IMPORTANT NOTE: You must follow all National Electrical

Code regulations. In addition, be aware of local codes and

ordinances when installing your service.

IMPORTANT NOTE: T

accordance with National Electrical Codes, as well as all

state, municipal and local codes. The correct voltage,

frequency and amperage must be supplied to the appliance from a dedicated, grounded circuit which is

protected by a properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and amperage ratings

are listed on the product rating plate located on the underside of the module. Refer to the illustration on page 3.

The complete appliance must be properly grounded at

all times when electrical power is applied.

Do not ground the appliance with the neutral (white)

house supply wire. A separate ground wire must be

utilized.

If aluminum house supply wiring is utilized, splice the

appliance copper wire to the aluminum house wiring

using special connectors designed and agency certified

for joining copper and aluminum. Follow the connector

manufacturer’s recommended procedure carefully.

Improper connection can result in a fire hazard!

his appliance must be installed in

For electrical installation, attach the conductors to the

residence wiring in accordance with National Electrical

Codes and all state, provincial, municipal and local codes.

The wiring diagram covering the control circuit is located

inside the module control box.

Page 6

Fryer Module Specifications 6

E

15" (381)

15"

(381)

123/8"

(314)

75/8"

(194)

DRAIN

OUTLET

131/2"

(343)

123/8"

(314)

6"

(152)

36" (914)

FLOOR TO

COUNTERTOP

3

0"

(762) min

COUNTERTOP

T

O COMBUSTIBLE

M

ATERIALS

S

EE COUNTERTOP

C

UT-OUT BELOW

14" (356)

CUT-OUT

WIDTH

COUNTERTOP CUT-OUT

FRONT

191/4" (489)

CUT-OUT

DEPTH

21/2" (64) min

7" (178) T

O

C

OMBUSTIBLE

*

7" (178) T

O

C

OMBUSTIBLE

*2" (51)*

S

IDE

C

ABINET

1

3"

(330)

max

*Minimum clearance from cooktop cut-out to combustible mater ials up to 18" (457) above countertop.

NOTE: Fryer module must be installed in base cabinet with access to valve at bottom of unit to drain oil into heat-resistant receptacle.

Application shown allows for installation of two 15"

(381) modules side by side.

18" (457) min

DRAIN

OUTLET

Installation Specifications

FRYER MODULE

Page 7

Fryer Module Specifications 7

wolfappliance.com/specs

Installation Specifications

MULTIPLE COOKTOP INSTALLATION

If the fryer module is to be used in combination with

additional cooktops or modules with a filler strip, refer to

the chart below for the countertop cut-out width. The

dimensions are derived by adding an additional 1

1

/4" (32)

for each additional unit, to give you the total countertop

cut-out width. Dimensions include the filler strip.

When multiple cooktops are installed side by side, each

unit must have its own separate, recommended electrical

circuit.

When two or more cooktops or modules are installed

together, an integrated module filler strip is recommended.

The filler strip and other accessories are available through

your authorized Wolf dealer. To obtain local dealer information, visit the find a showroom section of our website,

wolfappliance.com.

IMPORTANT NOTE: Review specific installation instruc-

tions for product to product capabilities.

Multiple Cooktops

COUN TERTOP CUT-OUT WIDT H

2 Modules 291/4" (743)

3 Modules 441/2" (1130)

4 Modules 593/4" (1518)

30" (762) Cooktop / Module 441/4" (1124)

30" (762) Cooktop / 2 Modules 591/2" (1511)

36" (914) Cooktop / Module 501/4" (1276)

The fryer module must be installed at least 15" (381)

from any open-flame cooking device or a Wolf steamer

module. The open flame may cause ignition of oil, and

contact between water and hot oil may cause burns.

Page 8

Fryer Module Installation 8

MODULE

FOAM

STRIP

31/2" (89)

CLAMPING

SCREW

MODULE

COUNTERTOP

BRACKET

CLIP

Install the Module

o attach the brackets to the sides of the module, insert

emove the fryer module from its shipping carton and

R

discard packing materials.

Lower the fryer module into the countertop cut-out

opening. Center the module in the opening and check that

the front edge of unit is parallel to the front edge of the

countertop. Check that all minimum clearances are met.

Using a pencil, outline the rear edge of the module frame

on the countertop. Remove the module from the opening.

IMPORTANT NOTE: When repositioning the module in the

countertop opening, lift the entire unit up from the opening

to prevent scratching the countertop.

Apply the foam strip, included in the hardware package,

to the underside of the module frame. Refer to the illustration below.

T

the clip into the rectangular punchout in the pan, and push

down. Install the clamping screw into the bracket and

tighten until the screw contacts the underside of the countertop. Do not overtighten screws. Refer to the illustration

below.

IMPORTANT NOTE: Do not seal the fryer module to the

countertop. It must be removed if service is necessary.

Reinsert the fryer module into the countertop opening.

Align the rear edge of the module frame with the pencil

line and check that it is parallel to the front edge of the

countertop. Lift the entire module to make adjustments.

Foam strip. Installation brackets.

Page 9

Fryer Module Installation 9

wolfappliance.com/specs

Before Operating

ead the entire Wolf fryer module use & care guide

R

included with the unit. It contains important safety, operation, service and warranty information.

Before operating, clean the fryer module thoroughly with

hot water and a mild detergent. Rinse and dry with a soft

cloth. This removes any residual oil and grease left on the

surface from the manufacturing process. Refer to care

recommendations in the use & care guide.

Never operate the fryer module without oil; damage to

the unit may result. Oil must be added to the fryer basin

before turning the module on.

Module Removal

The fryer module must be disconnected from power

prior to removal and service.

IMPORTANT NOTE: Removal of the fryer module should

only be performed by a Wolf authorized service center

technician.

If removing the fryer module is necessary for cleaning or

service, first disconnect the electric supply. Remove the

mounting brackets on each side of module and remove.

To reinstall, follow the steps on the previous page.

Page 10

Service Information 10

Troubleshooting

IMPORTANT NOTE: I

properly, follow these troubleshooting steps:

• Verify that electrical power is being supplied to the

module.

• Check the electrical connections to ensure that the

installation has been completed correctly.

• Follow troubleshooting procedures outlined in the

Wolf fryer module use & care guide.

• If the module still does not operate properly, contact a

Wolf authorized service center. Do not attempt to repair

the module yourself. Wolf is not responsible for service

required to correct a faulty installation.

f the fryer module does not operate

Service Information

f service is necessary, maintain the quality built into your

I

fryer module by calling a Wolf authorized service center.

To obtain the name and number of a Wolf authorized

service center, check the contact & support section of our

website, wolfappliance.com or call Wolf customer service

at 800-332-9513.

When calling for service, you will need the fryer module

model and serial numbers. Both numbers are listed on the

product rating plate located on the underside of the

module. Refer to the illustration below for the location of

the rating plate.

IMPORTANT NOTE: Installation and service must be

performed by a qualified installer or service agency.

Warranty service must be performed by a Wolf authorized

service center.

RATING PLATE

Location of rating plate.

Page 11

The information and images in this guide are the copyright property of Wolf Appliance, Inc. Neither this guide nor any information or images contained herein

may be copied or used in whole or in part without the express written permission of Wolf Appliance, Inc. ©Wolf Appliance, Inc. all rights reserved.

Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf Appliance, Inc.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care and The Living Kitchen are registered trademarks and service marks of Sub-Zero, Inc.

(collectively,the“Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

Page 12

WO LF APPLIA NCE, I NC. P. O . BOX 4 4848 MADIS ON, WI 53 744 WO LFAPPL IANCE .COM 8 00.33 2.951 3

816 177 RE V-A 5/ 2010

Loading...

Loading...