Page 1

DSECONTROL®

DSE7000 Quick Start Guide

057-101

Author : John Ruddock

Page 2

DSE Model 7000 Series Quick Start Guide

Deep Sea Electronics Plc

Highfield House

Hunmanby

North Yorkshire

YO14 0PH

ENGLAND

Sales Tel: +44 (0) 1723 890099

Sales Fax: +44 (0) 1723 893303

E-mail: sales@deepseaplc.com

Website:

DSE Model 7000 series Control and Instrumentation System Operators Manual

© Deep Sea Electronics Plc

All rights reserved. No part of this publication may be reproduced in any material form (including photocopying or storing in any

medium by electronic means or other) without the written permission of the copyright holder except in accordance with the

provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be addressed to Deep

Sea Electronics Plc at the address above.

The DSE logo and the names DSEUltra, DSEControl, DSEPower, DSEExtra, DSEMarine and DSENet are UK registered

trademarks of Deep Sea Electronics PLC.

Any reference to trademarked product names used within this publication is owned by their respective companies.

Deep Sea Electronics Plc reserves the right to change the contents of this document without prior notice.

Amendments since last publication

Amd. No. Comments

www.deepseaplc.com

Clarification of notation used within this publication.

Highlights an essential element of a procedure to ensure correctness.

NOTE:

Indicates a procedure or practice, which, if not strictly observed, could result in damage or

CAUTION!

destruction of equipment.

Indicates a procedure or practice, which could result in injury to personnel or loss of life if not

WARNING!

followed correctly.

2

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 3

DSE Model 7000 Series Quick Start Guide

TABLE OF CONTENTS

Section Page

1 BIBLIOGRAPHY ........................................................................................... 4

2 INTRODUCTION ........................................................................................... 4

3 DESCRIPTION OF CONTROLS .................................................................... 5

3.1 DSE7210 / DSE7310 AUTOSTART CONTROL MODULE ............................................. 5

3.2 DSE7220 / DSE7320 AMF CONTROL MODULE........................................................... 7

3.3 QUICKSTART GUIDE.................................................................................................. 9

3.3.1 STARTING THE ENGINE....................................................................................... 9

3.3.2 STOPPING THE ENGINE ...................................................................................... 9

3.4 VIEWING THE INSTRUMENTS .................................................................................. 10

3.4.1 INSTRUMENT PAGE CONTENT .......................................................................... 11

3.4.2 CAN ERROR MESSAGES ................................................................................... 12

3.5 VIEWING THE EVENT LOG ...................................................................................... 13

3.6 USER CONFIGURABLE INDICATORS ....................................................................... 13

4 OPERATION............................................................................................... 14

4.1 ECU OVERRIDE........................................................................................................ 14

4.2 AUTOMATIC MODE OF OPERATION........................................................................ 15

4.2.1 WAITING IN AUTO MODE .................................................................................. 15

4.2.2 STARTING SEQUENCE ...................................................................................... 15

4.2.3 ENGINE RUNNING .............................................................................................. 16

4.2.4 STOPPING SEQUENCE ...................................................................................... 16

4.3 MANUAL OPERATION .............................................................................................. 17

4.3.1 WAITING IN MANUAL MODE .............................................................................. 17

4.3.2 STARTING SEQUENCE ...................................................................................... 17

4.3.3 ENGINE RUNNING .............................................................................................. 18

4.3.4 STOPPING SEQUENCE ...................................................................................... 18

4.4 TEST MODE OF OPERATION................................................................................... 19

4.4.1 WAITING IN TEST MODE ................................................................................... 19

4.4.2 STARTING SEQUENCE ...................................................................................... 19

4.4.3 ENGINE RUNNING .............................................................................................. 20

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 3

Page 4

DSE Model 7000 Series Quick Start Guide

1 BIBLIOGRAPHY

This document refers to and is referred to by the following DSE publications which can be obtained from the DSE

website www.deepseaplc.com

DSE PART DESCRIPTION

053-026 7210 installation instructions

053-027 7220 installation instructions

053-028 7310 installation instructions

053-029 7320 installation instructions

057-004 Electronic Engines and DSE wiring manual

057-077 DSE7000 Series configuration software manual

057-082 DSE2130 input expansion manual

057-083 DSE2157 output expansion manual

057-084 DSE2548 annunciator expansion manual

2 INTRODUCTION

This document details the installation and operation requirements of the DSE7000 Series modules, part of the

DSEControl® range of products.

The manual forms part of the product and should be kept for the entire life of the product. If the product is passed or

supplied to another party, ensure that this document is passed to them for reference purposes.

This is not a controlled document. You will not be automatically informed of updates. Any future updates of this

document will be included on the DSE website at www.deepseaplc.com

The DSE 7000 series is designed to provide differing levels of functionality across a common platform. This allows

the generator OEM greater flexibility in the choice of controller to use for a specific application.

The DSE 7000 series module has been designed to allow the operator to start and stop the generator, and if

required, transfer the load to the generator either manually (via fascia mounted push-buttons) or automatically.

Additionally, the DSE7320 automatically starts and stops the generator set depending upon the status of the mains

(utility) supply.

The user also has the facility to view the system operating parameters via the LCD display.

The DSE 7000 module monitors the engine, indicating the operational status and fault conditions, automatically

shutting down the engine and giving a true first up fault condition of an engine failure by a COMMON AUDIBLE

ALARM. The LCD display indicates the fault.

The powerful ARM microprocessor contained within the module allows for incorporation of a range of complex

features:

• Text based LCD display (supporting multiple languages).

• True RMS Voltage, Current and Power monitoring.

• Engine parameter monitoring.

• Fully configurable inputs for use as alarms or a range of different functions.

• Engine ECU interface to electronic engines.

Using a PC and the 7000 series configuration software allows alteration of selected operational sequences, timers

and alarm trips.

Additionally, the module’s integral fascia configuration editor allows adjustment of a subset of this information.

A robust plastic case designed for front panel mounting houses the module. Connections are via locking plug and

sockets.

4

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 5

DSE Model 7000 Series Quick Start Guide

buttons

LEDs

mode

mode

mode

Lamp test

instrumentation display

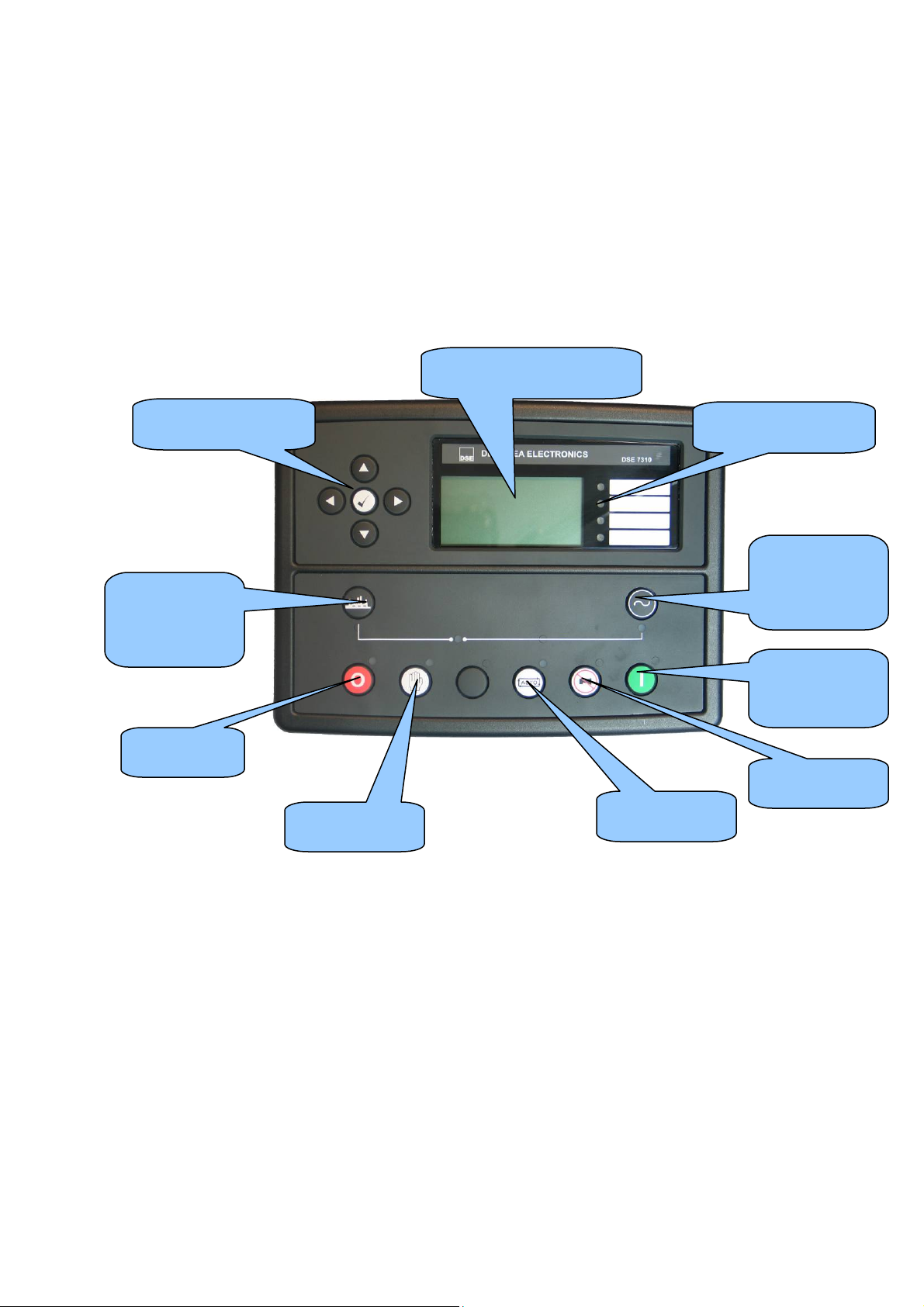

3 DESCRIPTION OF CONTROLS

The following section details the function and meaning of the various controls on the module.

3.1 DSE7210 / DSE7310 AUTOSTART CONTROL MODULE

Main status and

Menu navigation

Open generator

(manual mode

only)

Select Stop

Select Manual

Four configurable

Close

generator

(manual mode

only)

Start engine

(when in

manual mode)

Mute alarm /

Select Auto

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 5

Page 6

DSE Model 7000 Series Quick Start Guide

Close Generator LED.

On When The Generator

Is Required To Be On

Load.

Generator

Available

LED.

On when the

generator is

within limits

and able to

take load.

NOTE:- “Generator on load” LED has two modes of operation depending upon the configuration of the

controllers digital inputs.

1) Digital input configured for “Generator closed auxiliary” – The LED illuminates when the generator

closed auxiliary input is active – The LED shows the state of the auxiliary contact.

2) There is NO input configured for “Generator closed auxiliary” (factory default setting) – The LED

illuminates when the 7x20 gives the loading signal to the generator – The LED shows the state of the

7x20’s loading request.

6

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 7

DSE Model 7000 Series Quick Start Guide

buttons

mode

mode

mode

Lamp test

instrumentation display

load mode

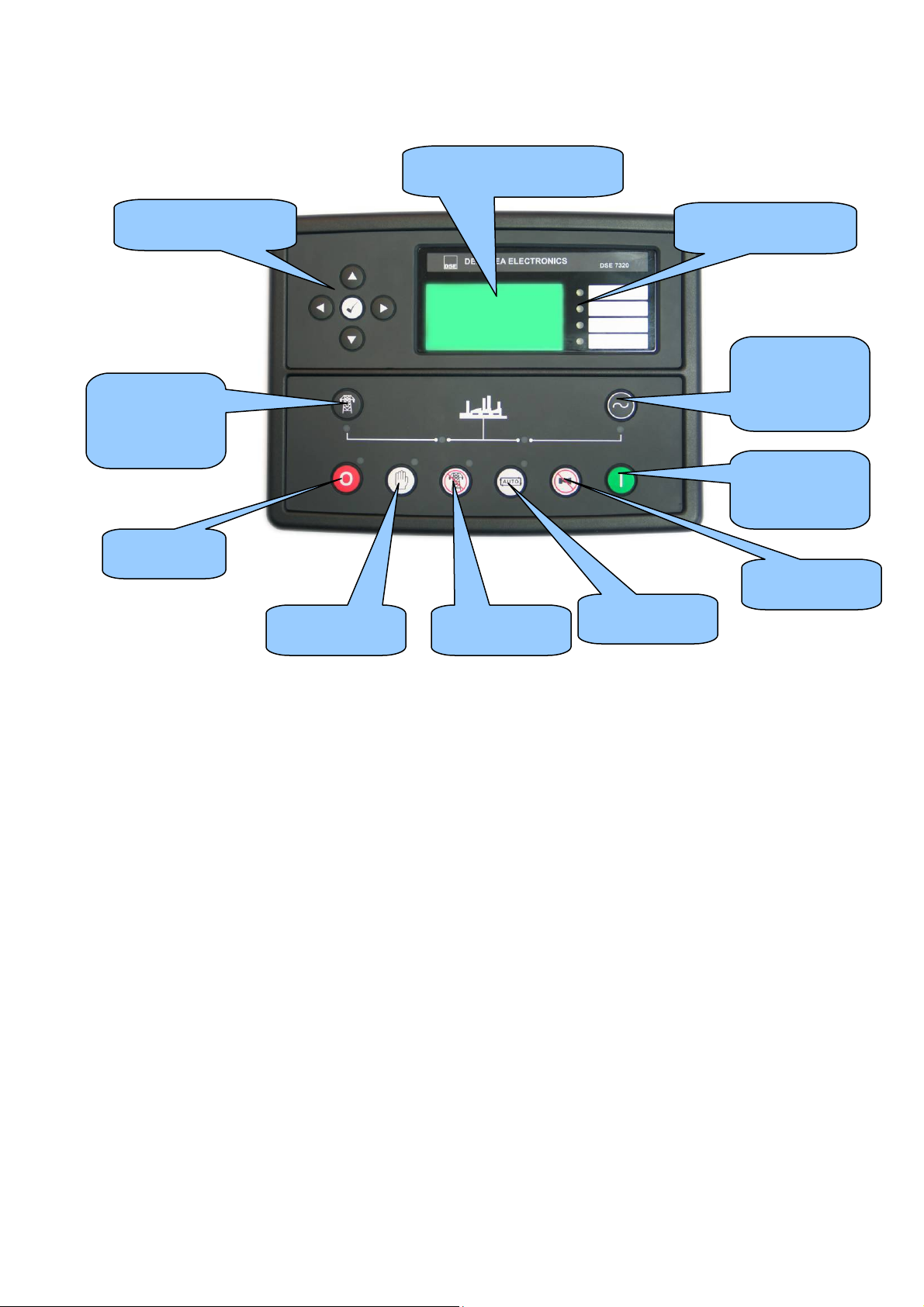

3.2 DSE7220 / DSE7320 AMF CONTROL MODULE

Menu navigation

Transfer to

mains (manual

mode only)

Main status and

Four configurable

LEDs

Transfer to

generator

(manual mode

only)

Start engine

(when in

manual mode)

Select Stop

Continued overleaf….

Select Manual

Select Test on

Mute alarm /

Select Auto

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 7

Page 8

Mains Available

LED.

On when the

mains is within

limits and able to

take load.

Close Mains LED.

On When The Generator

Is Required To Be On

Load.

DSE Model 7000 Series Quick Start Guide

Close Generator LED.

On When The Generator

Is Required To Be On

Load.

Generator

Available

LED.

On when the

generator is

within limits

and able to

take load.

NOTE:- “Generator on load” LED has two modes of operation depending upon the configuration of the

controllers digital inputs.

3) Digital input configured for “Generator closed auxiliary” – The LED illuminates when the generator

closed auxiliary input is active – The LED shows the state of the auxiliary contact.

4) There is NO input configured for “Generator closed auxiliary” (factory default setting) – The LED

illuminates when the 7x20 gives the loading signal to the generator – The LED shows the state of the

7x20’s loading request.

NOTE:- “Mains on load” LED has two modes of operation depending upon the configuration of the

controllers digital inputs.

5) Digital input configured for “Mains closed auxiliary” – The LED illuminates when the mains closed

auxiliary input is active – The LED shows the state of the auxiliary contact.

6) There is NO input configured for “Mains closed auxiliary” (factory default setting) – The LED illuminates

when the 7x20 gives the loading signal to the mains – The LED shows the state of the 7x20’s loading

request.

8

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 9

DSE Model 7000 Series Quick Start Guide

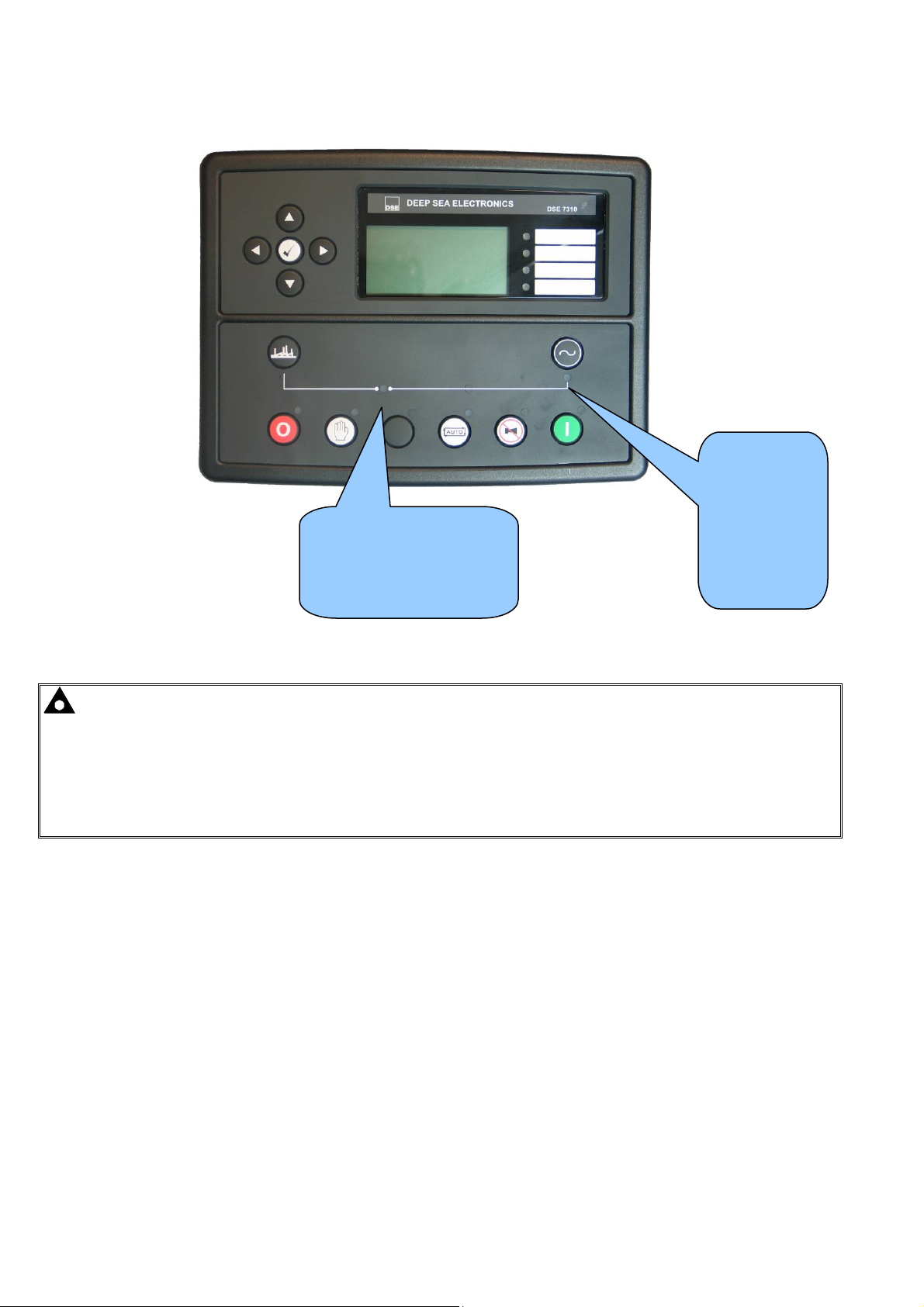

3.3 QUICKSTART GUIDE

This section provides a quick start guide to the module’s operation.

3.3.1 STARTING THE ENGINE

First, select manual

mode…

…then press the

Start button to crank

the engine.

NOTE:- For further details, see the section entitled ‘OPERATION’ elsewhere in this manual.

3.3.2 STOPPING THE ENGINE

Select Stop/Reset

mode. The generator

is stopped.

NOTE:- For further details, see the section entitled ‘OPERATION’ elsewhere in this manual.

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 9

Page 10

DSE Model 7000 Series Quick Start Guide

3.4 VIEWING THE INSTRUMENTS

It is possible to scroll to display the different pages of information by repeatedly operating the next page

button.

Once selected the page will remain on the LCD display until the user selects a different page or after an extended

period of inactivity, the module will revert to the status display.

If no buttons are pressed upon entering an instrumentation page, the instruments will be displayed automatically

subject to the setting of the Scroll Delay.

Alternatively, to scroll manually through all instruments on the currently selected page, press the scroll or

buttons. The ‘autoscroll’ is disabled.

To re-enable ‘autoscroll’ press the or buttons to scroll to the ‘title’ of the instrumentation page (ie

Engine).

When scrolling manually, the display will automatically return to the Status page if no buttons are pressed for the

duration of the configurable LCD Page Timer.

If an alarm becomes active while viewing the status page, the display shows the Alarms page to draw the operator’s

attention to the alarm condition.

Page order:-

Status, Engine, Generator, Mains, Alarms, ECU DTCs (electronic engines only), Event log, Scheduler (if enabled),

About.

First page -

Press to change to the next page -

Status

Engine

If you want to view one of the

instruments towards the end

of the list, it may be quicker to

scroll up through the

Press to change to the next page -

Generator

10

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 11

DSE Model 7000 Series Quick Start Guide

3.4.1 INSTRUMENT PAGE CONTENT

Engine

• Engine Speed

• Oil Pressure

• Coolant Temperature

• Engine Battery Volts

• Run Time

• Oil Temperature*

• Coolant Pressure*

• Inlet Temperature*

• Exhaust Temperature*

• Fuel Temperature*

• Turbo Pressure

• Fuel Pressure*

• Fuel Consumption*

• Fuel Used*

• Fuel Level*

• Auxiliary Sensors (If fitted and configured)

• Engine Maintenance Due (If configured)

• Engine ECU Link*

*When connected to suitably configured and compatible engine ECU. For details of supported engines see

‘Electronic Engines and DSE wiring’ (DSE Part number 057-004)

Generator

• Generator Voltage (ph-N)

• Generator Voltage (ph-ph)

• Generator Frequency

• Generator Current

• Generator Earth Current

• Generator Load (kW)

• Generator Load (kVA)

• Generator Power Factor

• Generator Load (kVAr)

• Generator Load (kWh, kVAh, kVArh)

• Generator Phase Sequence

Mains (DSE7220/DSE7320 only)

• Mains Voltage (ph-N)

• Mains Voltage (ph-ph)

• Mains Frequency

About

• Module Type

• Application Version

• USB ID – unique identifier for PC USB connection

• Analogue Measurements Version

• Firmware Update Bootloader Version

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 11

Page 12

DSE Model 7000 Series Quick Start Guide

3.4.2 CAN ERROR MESSAGES

When connected to a suitable CAN engine the 7000 series controller displays alarm status messages from the ECU.

Alarm

ECU Warning

Warning

Press to access the list of current active Engine DTCs (Diagnostic Trouble Codes).

Engine DTCs

Water Level

Low

Xxx,xxx,xxx

NOTE:- For details on these code meanings, refer to the ECU instructions provided by the engine

manufacturer, or contact the engine manufacturer for further assistance.

Type of alarm as reported by the ECU

Type of alarm that is triggered in the

DSE module (ie Warning or Shutdown)

The code interpreted by the module shows on the display as a text message.

Additionally, the manufactures code is shown.

NOTE:- For further details on connection to electronic engines please refer to Electronic engines and

DSE wiring. Part No. 057-004

12

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 13

DSE Model 7000 Series Quick Start Guide

total of 50 logged events.

3.5 VIEWING THE EVENT LOG

Event log 1/50

Oil Pressure Low

Shutdown

12 Sep 2007, 08:25:46

The 7000 series modules maintains a log of the last 50 shutdown alarms (7200 series

logs 30 shutdown alarms) to enable the operator or engineer to view the past alarms

history.

The event log only includes shutdown and electrical trip alarms logged;

The event log does not contain Warning alarms.

Once the log is full, any subsequent shutdown alarms will overwrite the oldest entry in the log.

Hence, the log will always contain the most recent shutdown alarms.

The module logs the alarm, along with the date and time of the event in the format shown in this example.

Number of present alarms. This is event 1 of a

If All warnings are latched

is configured, the event

log will capture warning

alarms. For more details

consult the 7xxx series

configuration software

To view the event log, repeatedly press the next page button until the LCD screen displays the Event log.

Press down

to view the next most recent shutdown alarm:

Continuing to press down

cycles through the past alarms after which the display shows the most recent

alarm and the cycle begins again.

To exit the event log and return to viewing the instruments, press the next page button.

3.6 USER CONFIGURABLE INDICATORS

These LEDs can be configured by the user to indicate any one of 100+

different functions based around the following:-

• Indications - Monitoring of a digital input and indicating associated

functioning user’s equipment - Such as Battery Charger On or Louver’s

Open, etc.

• WARNINGS and SHUTDOWNS - Specific indication of a particular

warning or shutdown condition, backed up by LCD indication - Such as

Low Oil Pressure Shutdown, Low Coolant level, etc.

• Status Indications - Indication of specific functions or sequences

derived from the modules operating state - Such as Safety On, Pre-

heating, Panel Locked, Generator Available, etc.

User configurable LEDs

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 13

Page 14

DSE Model 7000 Series Quick Start Guide

4 OPERATION

The following description details the sequences followed by a module containing the standard ‘factory configuration’.

Remember that if you have purchased a completed generator set or control panel from your supplier, the module’s

configuration will probably have been changed by them to suit their particular requirements.

Always refer to your configuration source for the exact sequences and timers observed by any particular module in

the field.

4.1 ECU OVERRIDE

NOTE:- ECU Override function is only applicable to the CAN variant of the 6100 series controller.

NOTE:- Depending upon system design, the ECU may be powered or unpowered when the module is in

STOP mode. ECU override is only applicable if the ECU is unpowered when in STOP mode.

When the ECU powered down (as is normal when in STOP mode), it is not possible to read the diagnostic trouble

codes or instrumentation. Additionally, it is not possible to use the engine manufacturers’ configuration tools.

As the ECU is usually unpowered when the engine is not running, it must be turned on manually as follows :

• Select STOP mode on the DSE controller.

• Press and hold the START button to power the ECU. As the controller is in STOP mode, the engine will

not be started.

• Continue to hold the start button for as long as you need the ECU to be powered.

• The ECU will remain powered until a few seconds after the START button is released.

This is also useful if the engine manufacturer’s tools need to be connected to the engine, for instance to configure the

engine as the ECU needs to be powered up to perform this operation.

14

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 15

DSE Model 7000 Series Quick Start Guide

4.2 AUTOMATIC MODE OF OPERATION

NOTE:- If a digital input configured to panel lock is active, changing module modes will not be

possible. Viewing the instruments and event logs is NOT affected by panel lock.

Activate auto mode be pressing the pushbutton. An LED indicator beside the button confirms this action.

Auto mode will allow the generator to operate fully automatically, starting and stopping as required with no user

intervention.

4.2.1 WAITING IN AUTO MODE

If a starting request is made, the starting sequence will begin.

Starting requests can be from the following sources :

• Mains supply out of limits (DSE7220/7320 only)

• Activation of an auxiliary input that has been configured to remote start

• Activation of the inbuilt exercise scheduler.

4.2.2 STARTING SEQUENCE

To allow for ‘false’ start requests such as mains brownouts, the start delay timer begins.

Should all start requests be removed during the start delay timer, the unit will return to a stand-by state.

If a start request is still present at the end of the start delay timer, the fuel relay is energised and the engine will be

cranked.

NOTE:- If the unit has been configured for CAN, compatible ECU’s will receive the start command via

CAN.

If the engine fails to fire during this cranking attempt then the starter motor is disengaged for the crank rest duration

after which the next start attempt is made. Should this sequence continue beyond the set number of attempts, the

start sequence will be terminated and the display shows Fail to Start.

When the engine fires, the starter motor is disengaged. Speed detection is factory configured to be derived from the

main alternator output frequency but can additionally be measured from a Magnetic Pickup mounted on the flywheel

(Selected by PC using the 7000 series configuration software).

Additionally, rising oil pressure can be used to disconnect the starter motor (but cannot detect underspeed or

overspeed).

NOTE:- If the unit has been configured for CAN, speed sensing is via CAN.

After the starter motor has disengaged, the Safety On timer activates, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the fault.

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 15

Page 16

DSE Model 7000 Series Quick Start Guide

4.2.3 ENGINE RUNNING

Once the engine is running, the Warm Up timer, if selected, begins, allowing the engine to stabilise before accepting

the load.

DSE7210/DSE7310 - The generator will be placed on load.

DSE7220/DSE7320 - Load will be transferred from the mains supply to the generator

NOTE:-The load transfer signal remains inactive until the Oil Pressure has risen. This prevents

excessive wear on the engine.

If all start requests are removed, the stopping sequence will begin.

4.2.4 STOPPING SEQUENCE

The return delay timer operates to ensure that the starting request has been permanently removed and isn’t just a

short term removal. Should another start request be made during the cooling down period, the set will return on load.

If there are no starting requests at the end of the return delay timer, the load is transferred back from the generator

to the mains supply and the cooling timer is initiated.

The cooling timer allows the set to run off load and cool sufficiently before being stopped. This is particularly

important where turbo chargers are fitted to the engine.

After the cooling timer has expired, the set is stopped.

16

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 17

DSE Model 7000 Series Quick Start Guide

4.3 MANUAL OPERATION

NOTE:- If a digital input configured to panel lock is active, changing module modes will not be

possible. Viewing the instruments and event logs is NOT affected by panel lock.

Activate Manual mode be pressing the pushbutton. An LED indicator beside the button confirms this action.

Manual mode allows the operator to start and stop the set manually, and if required change the state of the load

switching devices.

4.3.1 WAITING IN MANUAL MODE

When in manual mode, the set will not start automatically.

To begin the starting sequence, press the

button.

4.3.2 STARTING SEQUENCE

NOTE:- There is no start delay in this mode of operation.

The fuel relay is energised and the engine is cranked.

NOTE:- If the unit has been configured for CAN, compatible ECU’s will receive the start command via

CAN.

If the engine fails to fire during this cranking attempt then the starter motor is disengaged for the crank rest duration

after which the next start attempt is made. Should this sequence continue beyond the set number of attempts, the

start sequence will be terminated and the display shows Fail to Start.

When the engine fires, the starter motor is disengaged. Speed detection is factory configured to be derived from the

main alternator output frequency but can additionally be measured from a Magnetic Pickup mounted on the flywheel

(Selected by PC using the 7000 series configuration software).

Additionally, rising oil pressure can be used disconnect the starter motor (but cannot detect underspeed or

overspeed).

NOTE:- If the unit has been configured for CAN, speed sensing is via CAN.

After the starter motor has disengaged, the Safety On timer activates, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the fault.

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 17

Page 18

DSE Model 7000 Series Quick Start Guide

4.3.3 ENGINE RUNNING

In manual mode, the load is not transferred to the generator unless a ‘loading request’ is made.

A loading request can come from a number of sources.

• Pressing the transfer to generator button

• Mains supply out of limits (DSE7220/DSE7320 only)

• Activation of an auxiliary input that has been configured to remote start on load

• Activation of the inbuilt exercise scheduler if configured for ‘on load’ runs.

NOTE:-The load transfer signal remains inactive until the Oil Pressure has risen. This prevents

excessive wear on the engine.

Once the load has been transferred to the generator, it will not be automatically transferred back to the mains

supply. To manually transfer the load back to the mains either:

• Press the transfer to mains button (DSE7220/DSE7320 only)

• Press the Open Generator button (DSE7210/DSE7310 only)

• Press the auto mode button to return to automatic mode.

4.3.4 STOPPING SEQUENCE

In manual mode the set will continue to run until either :

• The stop button

• The auto button is pressed. The set will observe all auto mode start requests and stopping timers

before beginning the Auto mode stopping sequence.

is pressed – The set will immediately stop

18

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 19

DSE Model 7000 Series Quick Start Guide

4.4 TEST MODE OF OPERATION

NOTE:- Test Mode is only applicable to DSE7220/DSE7320 controllers.

NOTE:- If a digital input configured to panel lock is active, changing module modes will not be

possible. Viewing the instruments and event logs is NOT affected by panel lock.

Activate test mode be pressing the pushbutton. An LED indicator beside the button confirms this action.

Test mode will start the set and transfer the load to the generator to provide a Test on load function.

4.4.1 WAITING IN TEST MODE

When in test mode, the set will not start automatically.

To begin the starting sequence, press the

button.

4.4.2 STARTING SEQUENCE

The set begins to crank.

NOTE:- If the unit has been configured for CAN, compatible ECU’s will receive the start command via

CAN.

If the engine fails to fire during this cranking attempt then the starter motor is disengaged for the crank rest duration

after which the next start attempt is made. Should this sequence continue beyond the set number of attempts, the

start sequence will be terminated and the display shows Fail to Start.

When the engine fires, the starter motor is disengaged. Speed detection is factory configured to be derived from the

main alternator output frequency but can additionally be measured from a Magnetic Pickup mounted on the flywheel

(Selected by PC using the 7000 series configuration software).

Additionally, rising oil pressure can be used disconnect the starter motor (but cannot detect underspeed or

overspeed).

NOTE:- If the unit has been configured for CAN, speed sensing is via CAN.

After the starter motor has disengaged, the Safety On timer activates, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the fault.

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 19

Page 20

DSE Model 7000 Series Quick Start Guide

4.4.3 ENGINE RUNNING

Once the engine is running, the Warm Up timer, if selected, begins, allowing the engine to stabilise before accepting

the load.

Load will be automatically transferred from the mains supply to the generator.

NOTE:-The load transfer signal remains inactive until the Oil Pressure has risen. This prevents

excessive wear on the engine.

In test mode, the set will continue to run on load until either:

• The stop button is pressed – The set will immediately stop

• The auto button is pressed. The set will observe all auto mode start requests and stopping timers

before beginning the Auto mode stopping sequence.

20

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR

Page 21

DSE Model 7000 Series Quick Start Guide

Part No. 057-101 7000 Series Quick Start Guide ISSUE 1 14/04/2009 JR 21

Loading...

Loading...