Page 1

User Manual

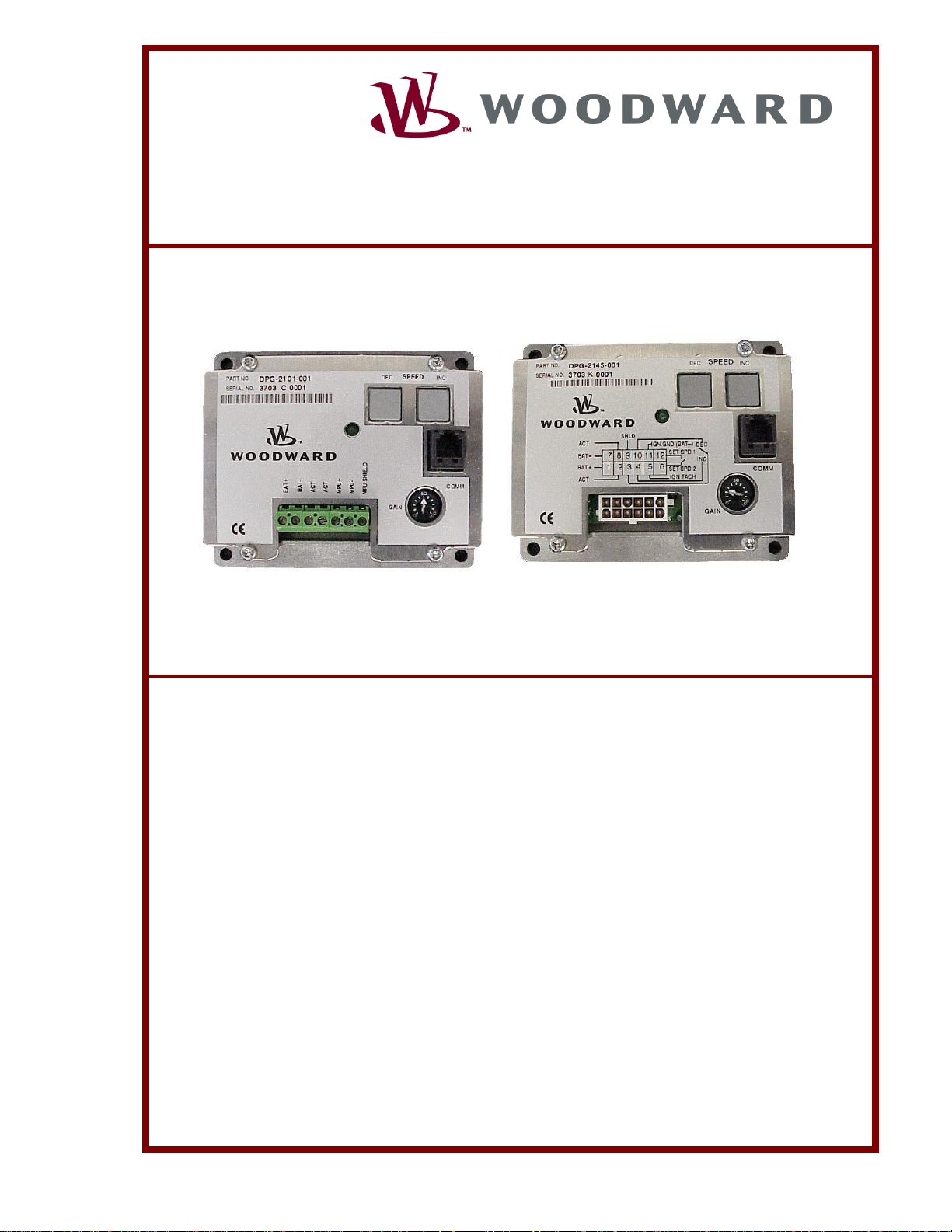

DPG-2101-001 DPG-2145-001

DPG-21XX-00X

Digital Controllers

Programmable Controllers for

Isochronous Generators

Manual 36526F

Page 2

DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

DANGER—Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING—Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION—Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE—Indicates a hazard that could result in property damage only

(including damage to the control).

IMPORTANT—Designates an operating tip or maintenance suggestion.

The engine, turbine, or other type of prime mover should be equipped with an

overspeed shutdown device to protect against runaway or damage to the prime

mover with possible personal injury, loss of life, or property damage.

The overspeed shutdown device must be totally independent of the prime mover

control system. An overtemperature or overpressure shutdown device may also

be needed for safety, as appropriate.

Read this entire manual and all other publications pertaining to the work to be performed before

installing, operating, or servicing this equipment. Practice all plant and safety instructions and

precautions. Failure to follow instructions can cause personal injury and/or property damage.

This publication may have been revised or updated since this copy was produced. To verify that

you have the latest revision, be sure to check the Woodward website:

www.woodward.com/pubs/current.pdf

The revision level is shown at the bottom of the front cover after the publication number. The

latest version of most publications is available at:

www.woodward.com/publications

If your publication is not there, please contact your customer service representative to get the

latest copy.

Any unauthorized modifications to or use of this equipment outside its specified mechanical,

electrical, or other operating limits may cause personal injury and/or property damage, including

damage to the equipment. Any such unauthorized modifications: (i) constitute "misuse" and/or

"negligence" within the meaning of the product warranty thereby excluding warranty coverage

for any resulting damage, and (ii) invalidate product certifications or listings.

To prevent damage to a control system that uses an alternator or battery-charging

device, make sure the charging device is turned off before disconnecting the battery

from the system.

To prevent damage to electronic components caused by improper handling, read

and observe the precautions in Woodward manual 82715, Guide for Handling and

Protection of Electronic Controls, Printed Circuit Boards, and Modules.

Revisions—Text changes are indicated by a black line alongside the text.

Woodward Governor Company reserves the right to update any portion of this publication at any time. Information

provided by Woodward Governor Company is believed to be correct and reliable. However, no responsibility

is assumed by Woodward Governor Company unless otherwise expressly undertaken.

© Woodward 2009

All Rights Reserved

Page 3

Manual 36526F DPG-21XX-00X Digital Controllers

Contents

REGULATORY COMPLIANCE ...................................................................... III

Declaration of Conformity DPG 2145 & DPG 2155 ............................................... iii

Declaration of Conformity DPG 2101 & DPG 2146 ............................................... iv

EMC Limitations ..................................................................................................... v

ELECTROSTATIC DISCHARGE AWARENESS ................................................ VI

CHAPTER 1. GENERAL INFORMATION .......................................................... 1

Introduction ............................................................................................................ 1

CHAPTER 2. CONTROLLER SPECIFICATIONS ................................................ 2

Configurations ....................................................................................................... 2

Electrical ................................................................................................................ 2

Mechanical ............................................................................................................ 2

Performance .......................................................................................................... 3

User Interface Operation ....................................................................................... 3

Keypad ........................................................................................................... 3

Gain Potentiometer ........................................................................................ 3

LED ................................................................................................................ 3

COMM Port .................................................................................................... 4

CHAPTER 3. PARAMETER REFERENCE ........................................................ 5

DPG-2101-00X & DPG-2146-00X Parameter List ................................................ 6

DPG-2155-00X & DPG-2145-00X Parameter List ................................................ 7

3.1 No. of Flywheel Teeth or Pulses Per Revolution (optional) .................... 8

3.2 Set Speed A (required) ........................................................................... 8

3.3 Set Speed B (optional) ........................................................................... 9

3.4 Idle Speed (optional)............................................................................... 9

3.5 Proportional (required) .......................................................................... 10

3.6 Integral (required) ................................................................................. 10

3.7 Derivative (required) ............................................................................. 10

3.8 OVG @ Set Speed A (required) ........................................................... 11

3.9 OVG @ Set Speed B (optional) ............................................................ 11

3.10 OVG @ Idle Speed (optional) ............................................................. 11

3.11 Gain Factor (required) ........................................................................ 11

3.12 Speed Filter (required) ........................................................................ 11

3.13 Idle Hold Time (optional) .................................................................... 12

3.14 Accel Rate (optional) .......................................................................... 12

3.15 Decel Rate (optional) .......................................................................... 12

3.16 Startup Rate (optional) ....................................................................... 13

3.17 Integral Low Limit (optional) ............................................................... 13

3.18 Integral High Limit (optional) ............................................................... 14

3.19 Password ............................................................................................ 14

3.20 Over Speed Limit (optional) ................................................................ 14

3.21 Set Speed A Min (optional) ................................................................. 15

3.22 Set Speed A Max (optional) ................................................................ 15

3.23 Set Speed B Min (optional) ................................................................. 15

3.24 Set Speed B Max (optional) ................................................................ 15

3.25 Idle Speed Min (optional) .................................................................... 15

3.26 Idle Speed Max (optional) ................................................................... 15

3.27 Duty Cycle Limit (optional) .................................................................. 16

3.28 Startup Speed (required) .................................................................... 16

3.29 Startup Duty Cycle (optional) .............................................................. 16

Woodward i

Page 4

Manual 36526F DPG-21XX-00X Digital Controllers

Contents (cont'd.)

CHAPTER 4. UNIVERSAL PST ................................................................... 18

Introduction .......................................................................................................... 18

Features ....................................................................................................... 18

System Requirements ................................................................................. 18

Acquiring Universal PST .............................................................................. 19

Installing Universal PST............................................................................... 20

Wiring the COMM Port to a PC ................................................................... 20

Communications Error ................................................................................. 21

Universal PST User Interface Overview ...................................................... 21

Universal PST Menu Items .......................................................................... 23

Parameter Setup .......................................................................................... 23

Parameter Help ............................................................................................ 24

Synchronizing Universal PST with a DPG ................................................... 24

Status View .................................................................................................. 24

Tuning View ................................................................................................. 25

Chart Recorder ............................................................................................ 25

Engine Speed Data Collection ..................................................................... 26

CHAPTER 5. CALIBRATION INSTRUCTIONS ................................................. 27

Basic Adjustments ............................................................................................... 27

Tuning Methodology ............................................................................................ 27

Startup Sequence ................................................................................................ 29

CHAPTER 6. INSTALLATION INSTRUCTIONS ................................................ 30

Recommended Mounting .................................................................................... 30

Terminal Descriptions .......................................................................................... 30

DPG-2101-00X ............................................................................................ 30

DPG-2145-00X ............................................................................................ 30

DPG-2146-00X ............................................................................................ 31

DPG-2155-00X ............................................................................................ 31

Wiring Diagrams .................................................................................................. 32

DPG-2101-00X ............................................................................................ 32

DPG-2145-00X ............................................................................................ 33

DPG-2146-00X ............................................................................................ 34

DPG-2155-00X ............................................................................................ 35

Centralized Suppression ..................................................................................... 36

CHAPTER 7. DIAGNOSTICS & TROUBLESHOOTING ..................................... 38

LED Indications ................................................................................................... 38

Troubleshooting Table ......................................................................................... 38

CHAPTER 8. SERVICE OPTIONS ................................................................ 40

Product Service Options ...................................................................................... 40

Woodward Factory Servicing Options ................................................................. 41

Returning Equipment for Repair .......................................................................... 42

Replacement Parts .............................................................................................. 42

Engineering Services ........................................................................................... 43

How to Contact Woodward .................................................................................. 43

Technical Assistance ........................................................................................... 44

Woodward ii

Page 5

Manual 36526F DPG-21XX-00X Digital Controllers

Regulatory Compliance

Declaration of Conformity

DPG 2145 & DPG 2155

Woodward iii

Page 6

Manual 36526F DPG-21XX-00X Digital Controllers

Declaration of Conformity

DPG 2101 & DPG 2146

Woodward iv

Page 7

Manual 36526F DPG-21XX-00X Digital Controllers

EMC Limitations

Cabling

All cabling for this unit is limited to less than 30m (98.4’). See wiring diagrams for

specific cable types required.

Power cabling is limited to less than 10m (32.8’) in total length from its source;

power is intended to be from a local bus structure. The control is NOT intended

to have a power bus that is derived from a plant-wide distribution system, remote

source, or similar ―mains‖ type distribution systems. The power to the control

should also be a dedicated circuit, directly to the battery or source via a power

and return wire that are routed together.

See User Manual 36526 for additional regulatory information, limitations, and

wiring diagrams with specific, required cable types.

Power Bus

The power bus is intended to be a local bus without power line surges and to

have inductive load kickback events suppressed. Therefore, the control’s power

input is not designed to withstand a charging system load dump, heavy inductive

kickbacks, or heavy surge type pulses. If the control is installed outside its

intended usage, as described in this manual, centralized voltage pulse

suppression should be implemented to help protect the control and other

components on the bus. (See Chapter 6: Installation Instructions.)

COMM Port

The COMM port is intended to be a service port, with only temporary connection

during service or initial configuration. The COMM port is susceptible to some

EMC phenomena and possible unintentional battery return currents.

1. Battery return (B-) is also the communication signal common; typically

PCs connect the communication signal’s common to protective earth.

The PC grounding can provide an unintended return path for B- currents.

If B- and the PC are grounded to protective earth, a communication

isolator should be used between the PC and the control. Damage to the

PC or control, and/or unintended operation may result from a broken

battery return wire or the parallel path.

2. The pins inside the COMM port plug are susceptible to damage by ESD

discharges, static electricity arcs. Care should be taken not to touch

them with tools or put fingers into the port. Always touch your hand or

tool to a grounded piece of metal (discharge ESD) prior to coming in

contact with the communication port.

3. The input is susceptible to RF noise such as switching transients and

transmitter signals coupled into the communication cable. Cable

orientation and short cable length may be used to eliminate these issues,

depending on the severity of the environment.

Woodward v

Page 8

Manual 36526F DPG-21XX-00X Digital Controllers

To prevent damage to electronic components caused by

improper handling, read and observe the precautions in

Woodward manual 82715, Guide for Handling and

Protection of Electronic Controls, Printed Circuit Boards,

and Modules.

Electrostatic Discharge Awareness

All electronic equipment is static-sensitive, some components more than others.

To protect these components from static damage, you must take special

precautions to minimize or eliminate electrostatic discharges.

Follow these precautions when working with or near the control.

1. Before doing maintenance on the electronic control, discharge the static

electricity on your body to ground by touching and holding a grounded metal

object (pipes, cabinets, equipment, etc.).

2. Avoid the build-up of static electricity on your body by not wearing clothing

made of synthetic materials. Wear cotton or cotton-blend materials as much

as possible because these do not store static electric charges as much as

synthetics.

3. Keep plastic, vinyl, and Styrofoam materials (such as plastic or Styrofoam

cups, cup holders, cigarette packages, cellophane wrappers, vinyl books or

folders, plastic bottles, and plastic ash trays) away from the control, the

modules, and the work area as much as possible.

4. Do not remove the printed circuit board (PCB) from the control cabinet

unless absolutely necessary. If you must remove the PCB from the control

cabinet, follow these precautions:

Do not touch any part of the PCB except the edges.

Do not touch the electrical conductors, the connectors, or the

components with conductive devices or with your hands.

When replacing a PCB, keep the new PCB in the plastic anti-static

protective bag it comes in until you are ready to install it. Immediately

after removing the old PCB from the control cabinet, place it in the antistatic protective bag.

Woodward vi

Page 9

Manual 36526F DPG-21XX-00X Digital Controllers

Chapter 1.

General Information

Introduction

This manual provides information on the following DPG controllers:

DPG-2101-001 and

DPG-2101-002

The DPG-21XX-00X digital controller is used primarily to govern diesel or gas fueled

engines of generator sets. This microprocessor based, digital controller performs across

a wide speed range and allows adjustment of set speed and gain parameters with the

built-in user interface. The COMM port provides access to all other controller settings,

allowing adaptation to each application during service and initial configuration.

Separately programmable Proportional, Integral, and Derivative gains are provided for

tailoring controller response to many engine applications. Other adjustments include

acceleration and deceleration ramp rates, idle speed set, hold time, and more.

Properly tuned, this controller delivers fast engine response to speed or load change

while providing precise stable isochronous operation.

The controller’s internal FAILSAFE reacts instantly to loss of the engine speed signal,

allowing the actuator to return to minimum fuel.

Features include:

Isochronous speed control

DPG-2145-001 and

DPG-2145-002

DPG-2146-001 and

DPG-2146-002

DPG-2155-001 and

DPG-2155-002

User friendly / operator adjustable

Precision frequency control

Superior temperature stability

Reverse battery protection

Input voltage range: 9–30 Vdc

Remote setup

Serial communication port

Actuator Compatibility:

DYNA 2000 DYNA 7000 DYNA 8000 APECS 0150

DYNA 2500 DYNA 70025 DYNA 8200 APECS 0250

DYNA 10141 DYNA 8400 APECS 0300

APECS Linkage Free Integral Type

Other Models Available:

DPG-2100 Series – for Genset Applications

DPG-2300 Series – for Off-Road Vehicles

DPG-2400 Series – for EFC Valve Applications

Woodward 1

Page 10

Manual 36526F DPG-21XX-00X Digital Controllers

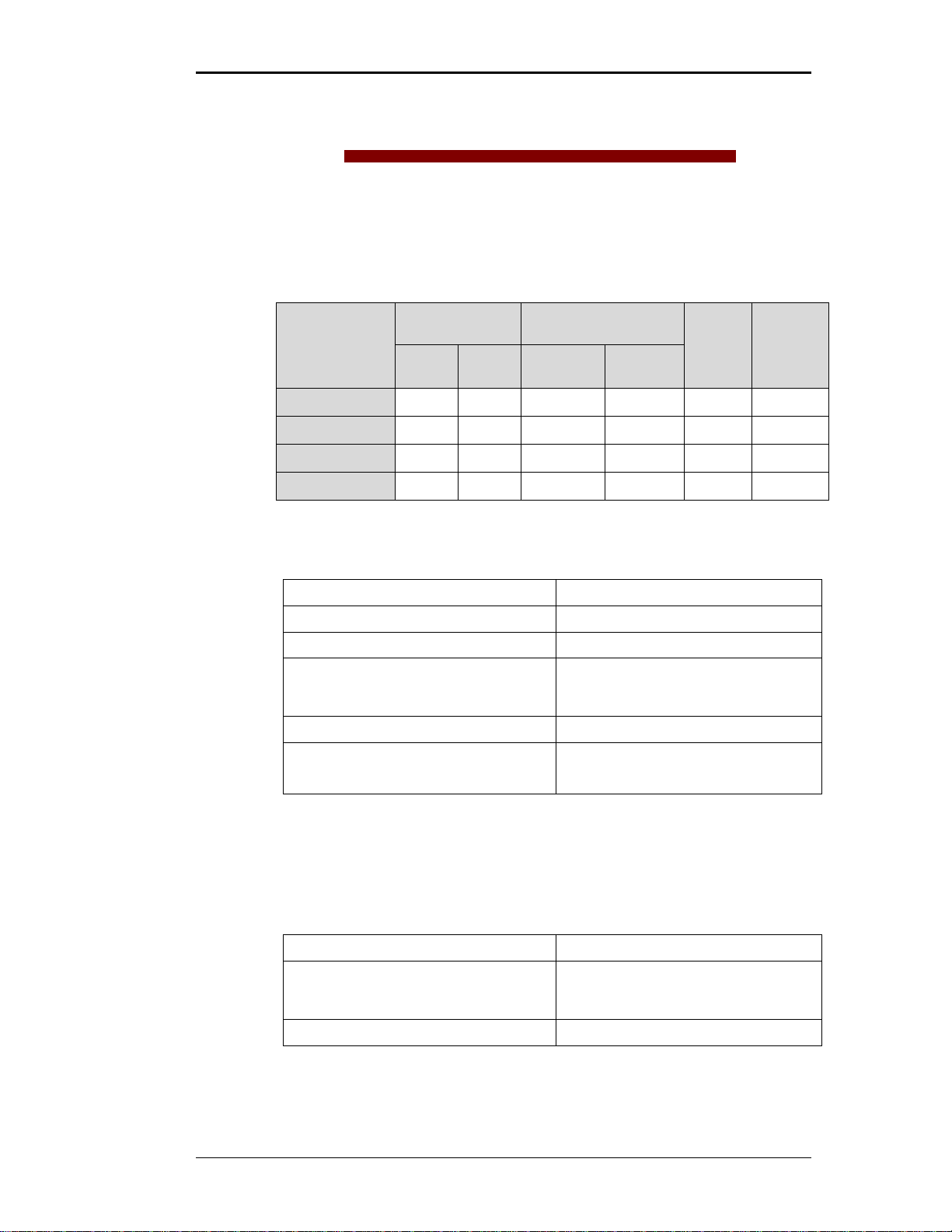

Model No.

Connector Style

Options

Speed Sensing

Options

Adj.

Set

Speeds

Remote

Speed

INC and

DEC

7-wire

Euro

12-pin

Molex

Magnetic

Pickup

Ignition

Sense

DPG-2101-00X

* *

1 + idle

DPG-2145-00X

*

*

2 + idle

*

DPG-2146-00X

*

*

1 + idle

DPG-2155-00X

* *

2 + idle

*

Operating Voltage Range:

9–30 Vdc *

Rated Output Current:

7 A Maximum (continuous)

Maximum Surge Current:

14 A (not to exceed ten seconds)

Connections:

Terminal strip with 7 Euro style

terminals or a quick connector with

12 pins

Input Signal from Magnetic Pickup:

2.0 VAC RMS minimum during cranking

Input Signal from Engine’s

Ignition System:

40 V minimum during cranking

Ambient Operating Temperature:

-40°F to +185°F (-40°C to +85°C)

Sealing:

Oil, water, and dust resistant via

conformal coating and die cast

enclosure

Weight:

10 oz. (284 g)

Chapter 2.

Controller Specifications

The controller’s main electrical and mechanical specifications are listed here along

with several performance characteristics. DPG-21XX-00X Series controllers are

available in five hardware configurations.

Configurations

Electrical

Woodward 2

(*) All cabling for these controllers is limited to less than 30m (98.4’).

Power cabling is limited to less than 10m (32.8’) in total length.

See wiring diagrams for specific cable types required.

Mechanical

Page 11

Manual 36526F DPG-21XX-00X Digital Controllers

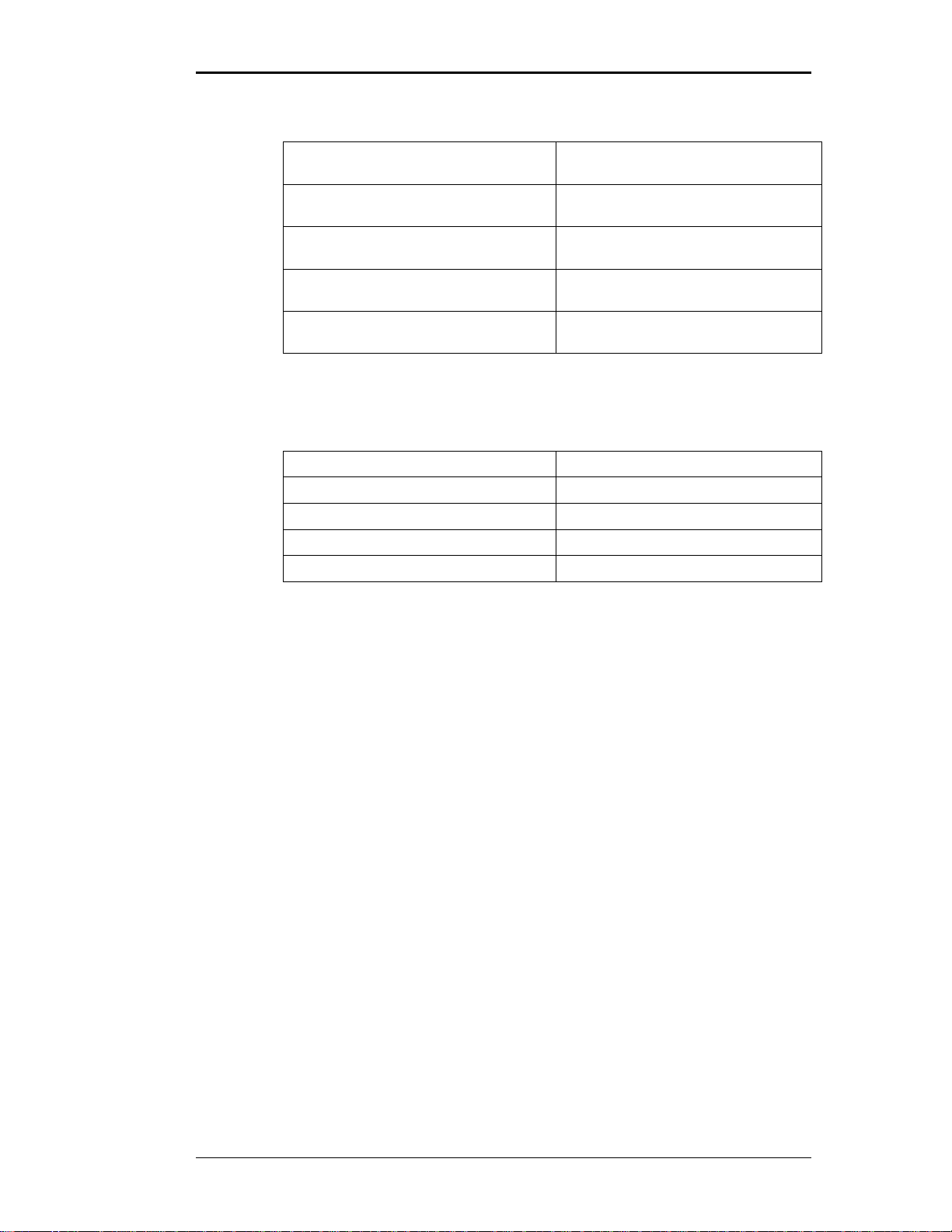

Steady State Speed Band:

± .25% over ambient operating

temperature range

Engine Speed MPU

Measurement Range:

10 MPU Hertz to 14,000 MPU Hertz

Governing Speed Range

with MPU:

500 MPU Hertz to 11,000 MPU Hertz

Engine Speed Ignition

Measurement Range:

2 Hertz to 350 Hertz

Governing Speed Range

with Ignition:

25 Hertz to 300 Hertz

AMP 770581-1

Mini universal Mate-N-Lock

AMP 171637-3 or 794407-3

Duplex finish socket

AMP 90707-1

Crimping hand tool for 18 gauge wire

AMP 408-4137

Crimping documentation

AMP 189727-1

Socket extraction tool

Performance

Suggested Mating Connectors

for DPG-2145-00X and DPG-2155-00X Models

User Interface Operation

Keypad

The DPG-21XX-00X provides two buttons for adjusting the engine set speed.

INC – increases the selected Set Speed (A or B)

DEC – decreases the selected Set Speed (A or B)

Gain Potentiometer

The DPG-21XX-00X series controllers provide a potentiometer (labeled GAIN) to adjust

the OVG @ Set Speed A. This is one of the controller’s tuning parameters.

The gain potentiometer’s adjustment range is 1 to 99.

LED

The LED (Light Emitting Diode) is used as a status indicator. When the LED is off, it

indicates that one of the following is true:

The unit is not being powered.

The unit is reverse powered (check polarity of supplied power).

If a voltage between 9 Vdc and 30 Vdc is being properly supplied across the BAT+ and

BAT- connector pins of the controller and the LED is off, then refer to the

troubleshooting chapter.

Woodward 3

A slow blinking LED indicates all of the following:

Page 12

Manual 36526F DPG-21XX-00X Digital Controllers

The COMM port is intended only for configuration and

periodic service. Do not leave a computer and/or COMM

cable connected to the COMM port.

1. The unit is powered.

2. The controller is not seeing a speed signal.

This means the engine is not running. If the engine is running or cranking and the LED

is blinking slow, then refer to the troubleshooting chapter for help in diagnosing why the

speed signal to the controller is missing.

A fast blinking LED indicates all of the following:

1. The unit is powered.

2. There is an engine speed signal at the controller’s tachometer inputs.

When the LED is on and not blinking it indicates the following:

1. The unit is powered.

2. There is a controller fault.

NOTE: The slow blink rate = ½ Hertz (the LED is turned on for 1 second followed by off

for 1 second then on again and so on). The fast blink rate is 3 times faster than the

slow blink rate.

COMM Port

All adjustments may be done by having the controller connected, via the COMM port, to

a computer running the Universal PST application. Remote access via the COMM port

is intended for connection only while programming, tuning and troubleshooting the

control. It is a service port and not intended for permanent connection.

The Universal PST is an MS Windows based application available from the Software

Products page at www.woodward.com/IC/Software. See Chapter 4 for a description of

this tool.

Woodward 4

Page 13

Manual 36526F DPG-21XX-00X Digital Controllers

Chapter 3.

Parameter Reference

This chapter provides information regarding each of the parameters that can

be adjusted when a computer is connected to the controller via the COMM

port. Universal PST (described in the following chapter) is required to make

adjustments to the parameters described in this chapter, with the exception

of Set Speed A, Set Speed B, and OVG @ Set Speed A. It contains 29

subsections. Each subsection provides information about a single parameter.

The following tables list each of the parameters and their default, minimum,

and maximum values. Several of the parameters have minimum and

maximum values set by other parameters. Speed and Rate values are shown

as Hertz values.

The parameter list provides information regarding each of the parameters that

can be adjusted when a computer is connected to the controller via the COMM

port and the Universal PST software. The COMM port is intended only for

configuration and periodic service. Do not leave a computer and/or COMM

cable connected to the COMM port.

Woodward 5

Page 14

Manual 36526F DPG-21XX-00X Digital Controllers

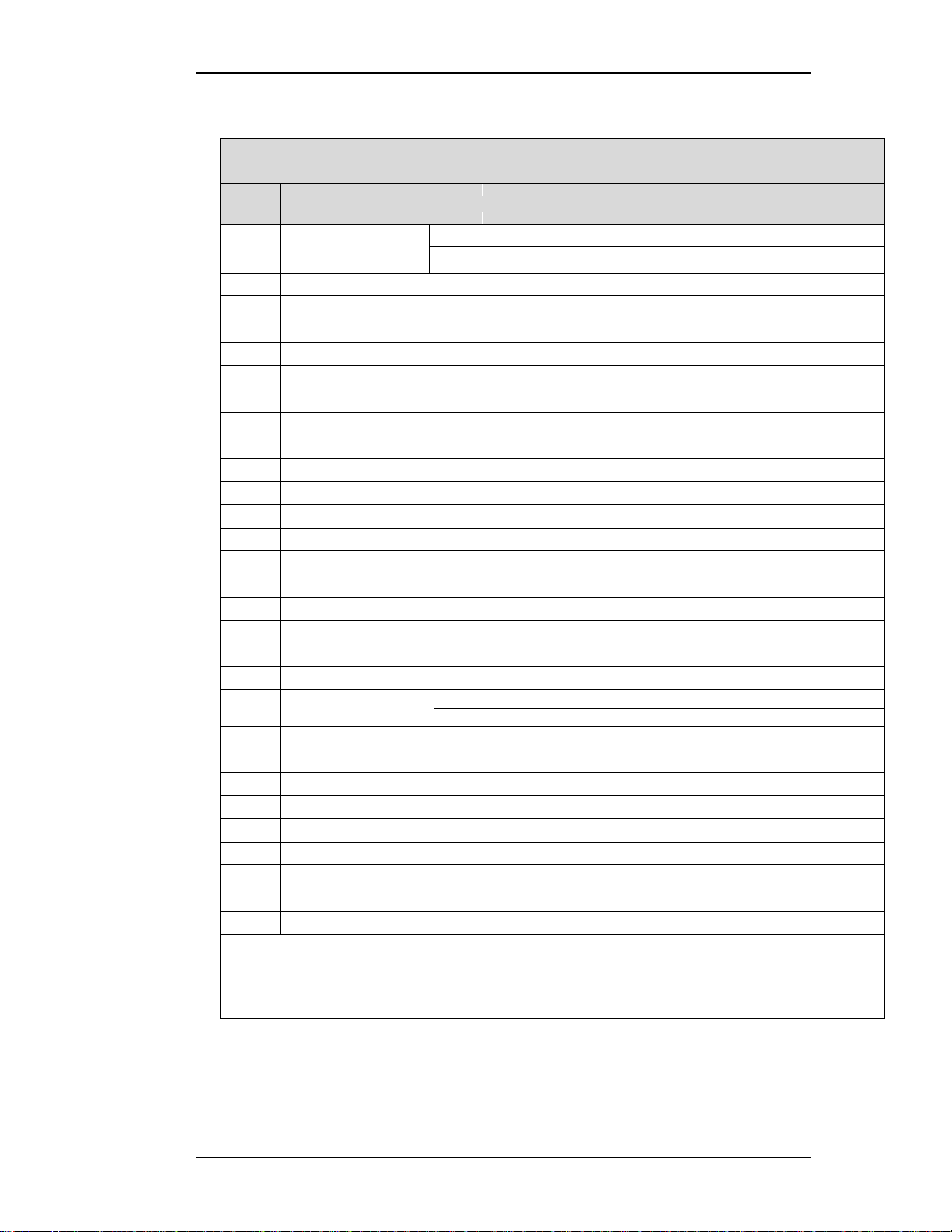

PARAMETER LIST FOR DPG-2101-00X (MPU) & DPG-2146-00X (IGNITION)

(These controllers use the 7-terminal Euro style screw terminal connector.)

PARAMETER NAME

DEFAULT

MINIMUM

MAXIMUM

Opt.

1. No. of Flywheel

Teeth or Pulses per

revolution

-001 0 0

0

-002 0 0

572

Req.

2. Set Speed A

1000 (25)

Set Speed A Min

Set Speed A Max

3. Not Available

Opt.

4. Idle Speed

50 (20)

Idle Speed Min

Idle Speed Max

Req.

5. Proportional

25 1 99

Req.

6. Integral

50 0 99

Req.

7. Derivative

25 0 99

Req.

8. OVG @ Set Speed A

Use the controller’s built-in GAIN potentiometer

9. Not Available

Opt.

10. OVG @ Idle Speed

20 1 99

Req.

11. Gain Factor

20 (40) 1 99

Req.

12. Speed Filter

16 (4) 1 24

Opt.

13. Idle Hold Time

0 0 9999

Opt.

14. Accel Rate

1000 (3000)

1

9999

Opt.

15. Decel Rate

1000 (3000)

1

9999

Opt.

16. Startup Rate

1000 (3000)

1

9999

Opt.

17. Integral Low Limit

0

0

Integral High Limit

Opt.

18. Integral High Limit

99

Integral Low Limit

99

Opt.

19. Password

0 0 99

Opt.

20. Over Speed Limit

-001

100 0 100

-002

15000 (450)

0

15000 (450)

Opt.

21. Set Speed A Min

10 (2)

10 (2)

Set Speed A

Opt.

22. Set Speed A Max

11000 (300)

Set Speed A

11000 (300)

23. Not Available

24. Not Available

Opt.

25. Idle Speed Min

10 (2)

10 (2)

Idle Speed

Opt.

26. Idle Speed Max

11000 (300)

Idle Speed

11000 (300)

Opt.

27. Duty Cycle Limit

95

10

95

Req.

28. Startup Speed

1000 (25)

10 (2)

11000 (300)

Opt.

29. Startup Duty Cycle

30 5 95

Req. = Parameter adjustment required to achieve Basic Governing

Opt. = Parameter use is optional

Default, Minimum and Maximum values in parenthesis apply when the controller uses ignition pulses to

sense engine speed, which would be the case for a DPG-2146-00X controller

DPG-2101-00X & DPG-2146-00X Parameter List

Note: All Speed and Rate values are shown as Hertz values (parameters 2, 4, 14-16, 20-22, 25-

26). Changing the value of parameter 1 will cause different default values to be displayed based

on the Hertz to RPM formula.

Woodward 6

Page 15

Manual 36526F DPG-21XX-00X Digital Controllers

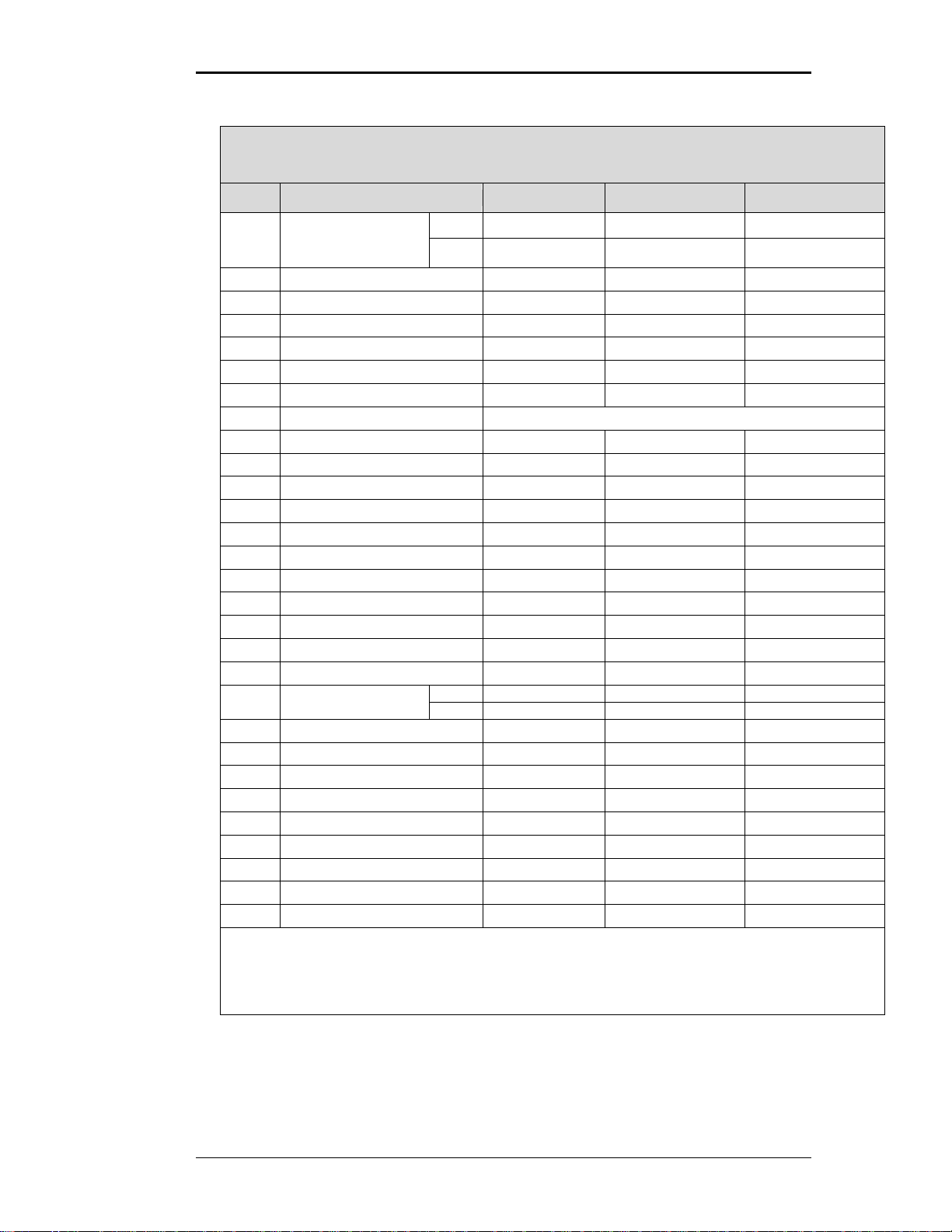

PARAMETER LIST FOR DPG-2155-00X (MPU) & DPG-2145-00X (IGNITION)

(These controllers use the 12-terminal quick connect.)

PARAMETER NAME

DEFAULT

MINIMUM

MAXIMUM

Opt.

1. No. of Flywheel

Teeth or Pulses per

Revolution

-001

0 0 0

-002

0 0 572

Req.

2. Set Speed A

1000 (25)

Set Speed A Min

Set Speed A Max

Opt.

3. Set Speed B

1000 (25)

Set Speed B Min

Set Speed B Max

Opt.

4. Idle Speed

50 (20)

Idle Speed Min

Idle Speed Max

Req.

5. Proportional

25 1 99

Req.

6. Integral

50 0 99

Req.

7. Derivative

25 0 99

Req.

8. OVG @ Set Speed A

Use the controller’s built-in GAIN potentiometer

Opt.

9. OVG @ Set Speed B

20 1 99

Opt.

10. OVG @ Idle Speed

20 1 99

Req.

11. Gain Factor

20 (40) 1 99

Req.

12. Speed Filter

16 (4) 1 24

Opt.

13. Idle Hold Time

0 0 9999

Opt.

14. Accel Rate

1000 (3000)

1

9999

Opt.

15. Decel Rate

1000 (3000)

1

9999

Opt.

16. Startup Rate

1000 (3000)

1

9999

Opt.

17. Integral Low Limit

0

0

Integral High Limit

Opt.

18. Integral High Limit

99

Integral Low Limit

99

Opt.

19. Password

0 0 99

Opt.

20. Over Speed Limit

-001

100 0 100

-002

15000 (450)

0

15000 (450)

Opt.

21. Set Speed A Min

10 (2)

10 (2)

Set Speed A

Opt.

22. Set Speed A Max

11000 (300)

Set Speed A

11000 (300)

Opt.

23. Set Speed B Min

10 (2)

10 (2)

Set Speed A

Opt.

24. Set Speed B Max

11000 (300)

Set Speed B

11000 (300)

Opt.

25. Idle Speed Min

10 (2)

10 (2)

Idle Speed

Opt.

26. Idle Speed Max

11000 (300)

Idle Speed

11000 (300)

Opt.

27. Duty Cycle Limit

95

10

95

Req.

28. Startup Speed

1000 (25)

10 (2)

11000 (300)

Opt.

29. Startup Duty Cycle

30 5 95

Req. = Parameter adjustment required to achieve Basic Governing

Opt. = Parameter use is optional

Default, Minimum and Maximum values in parenthesis apply when the controller uses ignition pulses to

sense engine speed, which would be the case for a DPG-2145-00X controller.

DPG-2155-00X & DPG-2145-00X Parameter List

Note: All Speed and Rate values are shown as Hertz values (parameters 2-4, 14-16, 20-26).

Changing the value of parameter 1 will cause different default values to be displayed based on

the Hertz to RPM formula.

Woodward 7

Page 16

Manual 36526F DPG-21XX-00X Digital Controllers

DPG-21XX- 002 Models—Adjusting the No. of Flywheel

Teeth parameter is prohibited while the engine is

running.

EngineRPM

revperPulses

sHertz

__

60

RPM

revperPulses

sHz

1800

__132

603960

Hertz

s

revperPulsesEngineRPM

'60

__

3.1 No. of Flywheel Teeth or Pulses Per Revolution

(optional)

This parameter provides the conversion factor needed to display speeds as RPM

values instead of Hertz values. Adjusting this parameter is optional. The default value

of 0 disables Hertz (Hz) to RPM conversions so all set speeds are displayed in Hertz.

Setting this parameter to a value other than zero enables Hertz to RPM conversion.

Adjust this parameter to a value equal to the exact number of pulses seen by the

controller in one revolution of the engine to display set speeds in RPM. The formula

used to convert the speed signal from a Hertz value to a RPM value is:

For example:

The following derivation of the above formula can be used to convert from RPM to

Hertz.

DPG-2101-00X and DPG-2155-00X Models

To use this parameter correctly on controllers sensing engine speed with a magnetic

pickup, you must know the exact number of flywheel teeth that pass by the magnetic

pickup in one revolution of the engine.

DPG-2145-00X and DPG-2146-00X Models

To use this parameter correctly on controllers sensing engine speed via ignition pulses,

you must know the exact number of ignition pulses that occur in one revolution of the

engine.

3.2 Set Speed A (required)

This parameter is adjustable both from the controller’s DEC and INC keys and by using

the Universal PST application. However, when the value is changed using the

controller’s keypad, the value displayed by the Universal PST does not automatically

update. To refresh the value displayed on the PC the user must select a different

parameter with the mouse pointer then reselect the value of Set Speed A. The

Woodward 8

Page 17

Manual 36526F DPG-21XX-00X Digital Controllers

Universal PST application also provides a [Read All] button that can be used to perform

a complete refresh of all parameter values.

SET SPEED A is the controller’s target speed after startup when Set Speed B is not

selected. The startup sequence is complete when the target speed and the engine

speed reach the set speed.

The default value for SET SPEED A is 1000 MPU Hertz (25 Hertz ignition). The

SET SPEED A parameter’s adjustable range extends from SET SPEED A MIN to

SET SPEED A MAX.

DPG-2145-00X and DPG-2155-00X Models

When a two-position switch is connected between SET SPD 1 (pin 12) and SET SPD 2

(pin 6) then an open switch selects SET SPEED A as the controller’s target speed. If

the controller’s SET SPD inputs are not used then SET SPEED A is automatically the

active target speed after the startup sequence is completed.

See the Installation Instructions chapter for details about using the speed select

feature.

3.3 Set Speed B (optional)

DPG-2145-00X and DPG-2155-00X Models

SET SPEED B becomes the controller’s target speed when SET SPD 1 (pin 12) and

SET SPD 2 (pin 6) of the connector are tied together. In other words, when a twoposition switch is connected between SET SPD 1 (pin 12) and SET SPD 2 (pin 6) then

a closed switch selects SET SPEED B as the controller’s target speed.

The default value for SET SPEED B is 1000 MPU Hertz (25 Hertz ignition). The

SET SPEED B parameter’s adjustable range extends from SET SPEED B MIN to

SET SPEED B MAX.

See the Installation Instructions chapter for details about using the speed select

feature.

3.4 Idle Speed (optional)

DPG-2101-00X and DPG-2146-00X Models

The IDLE SPEED is the controller’s target speed for the IDLE HOLD TIME when the

engine is started. When the idle hold timer reaches zero, the target speed will become

SET SPEED A.

DPG-2145-00X and DPG-2155-00X Models

The IDLE SPEED is the controller’s target speed for the IDLE HOLD TIME when the

engine is started. When the idle hold timer reaches zero, the target speed will be either

SET SPEED A or SET SPEED B depending on the state of the SPEED SEL input

terminal.

The default value for IDLE SPEED is 500 MPU Hertz (20 Hertz ignition). The IDLE

SPEED parameter’s adjustable range extends from IDLE SPEED MIN to IDLE

SPEED MAX.

Woodward 9

Page 18

Manual 36526F DPG-21XX-00X Digital Controllers

100%

0%

50%

Integral response to constant error

Time

Time

Error

larger

Integral

value

smaller

Integral

value

Controller output (%)

Error (%)

0

(+)

(-)

Controller output (%)

100%

0%

50%

Each error value produces a unique controller output value

Saturation

Saturation

Proportional

response

a higher Proportional value

Increases output response to a step

change in error

a lower Proportional value

Decreases output response to a step

Change in error

100%

0%

50%

Derivative response to changes

in the rate of deceleration or the

rate of acceleration.

Time

Time

Error

0

(+)

(-)

The error is sampled at regular intervals

Controller output (%)

When the "Rate of change" changes (red dot) the

Derivative's impact on controller output changes.

3.5 Proportional (required)

The proportional term is one

of the interrelated PID terms

that determine how well a

DPG controller governs the

engine’s speed. A speed

change creates a speed error

(the difference between the

target speed and the actual

speed.) The proportional gain

controls the size of the

controller output response to

a step change in the speed

error.

3.6 Integral (required)

The integral term is one of

the interrelated PID terms

that determine how well a

DPG controller governs the

engine’s speed. The integral

term acts to drive speed error

to zero. In a proportional only

control with constant load,

there will be a constant

speed error that inversely

relates to the proportional

gain of the system. The

integral term is key to

isochronous speed control.

This term eliminates the

difference between the programmed set speed and the actual speed. The integral gain

changes the time it takes to drive the error to zero.

Note: Integral is needed to eliminate speed offsets due to proportional gain and should

never be left at zero.

3.7 Derivative (required)

The derivative term is one of the

interrelated PID terms that determine

how well a DPG controller governs the

engine’s speed. The derivative

Woodward 10

responds to the rate of change in the

speed error. This parameter is primarily

used to dampen very rapid oscillations

resulting from large speed changes. The

derivative responds to engine

acceleration or deceleration. If the

engine speed approaches the target

speed at a fast rate, the derivative acts

to minimize or eliminate overshoot. A

zero value is allowed but systems

typically require some derivative gain to

improve overall engine speed control.

Page 19

Manual 36526F DPG-21XX-00X Digital Controllers

3.8 OVG @ Set Speed A (required)

This overall gain acts as the multiplier on the three PID terms (proportional, integral,

derivative) when Set Speed A is selected as the active target speed. The controller’s

built-in gain potentiometer is adjustable from 1 to 99.

3.9 OVG @ Set Speed B (optional)

DPG-2145-00X and DPG-2155-00X Models

This overall gain acts as the multiplier on the three PID terms (proportional, integral,

derivative) when Set Speed B is selected as the active target speed. This overall gain

term is adjustable from 01 to 99.

3.10 OVG @ Idle Speed (optional)

This overall gain acts as the multiplier on the three PID terms (proportional, integral,

derivative) when the Idle Speed is the active target speed. The idle speed set point is

active only during startup when the idle hold timer is running. This overall gain term is

adjustable from 01 to 99.

3.11 Gain Factor (required)

The gain factor parameter is used to obtain more range of adjustment from the PID

terms. In other words, if any of the PID terms or the overall gain terms reach their

adjustment limits then this value can be modified to provide for more range of

adjustment in the PID and OVG terms.

For example, if the PID terms are set to 90, 80, and 50 respectively and the Gain

Factor is set to 20, then doubling the Gain Factor by setting it to 40 allows the PID

terms to be halved to 45, 40, and 25 respectively. These new settings are equivalent to

the previous settings with respect to the controller’s tuning response and now allow the

PID terms to be adjusted higher if needed.

3.12 Speed Filter (required)

This parameter indicates the number of flywheel teeth to use when computing an

average engine speed and is used to dampen out speed measurement variations that

can make PID tuning difficult. But, keep in mind the following.

Too much filtering will slow down the controller’s response

to speed changes.

Too little filtering can make the controller overly sensitive

and tuning difficult.

There is measurable acceleration and deceleration that occurs between cylinder firings.

As a general rule, less filtering is required the more engine cylinders there are. This is

because the number of acceleration-deceleration cycles increases and these

oscillations will have lower amplitude. With more cylinders, there is less time for the

speed to slow down before the next cylinder firing.

Rotational mass also affects the amount of speed signal filtering needed. The more

rotational mass, the less filtering is needed. The less rotational mass, the more filtering

is needed.

For installations using a magnetic pickup to sense engine speed

Typically, the value 24 works well on small 3- or 4-cylinder engines. A value of 16 is

recommended for 6- or 8-cylinder engines. The following formula can also be used to

Woodward 11

Page 20

Manual 36526F DPG-21XX-00X Digital Controllers

derive a good starting point for the speed filter value for a given engine application.

Round the result to the nearest integer. The maximum value allowed is 24.

[(No._of_flywheel_teeth) / (No._of_engine_cylinders)] * 0.75 = speed_filter_value

For installations using ignition pulses to sense engine speed

It is recommended that the Speed Filter be at least equal to the number of ignition

pulses per one revolution of the engine. A good starting point would be 2 times the

number of ignition pulses per one revolution of the engine.

[(pulses_per_rev) * (2)] = speed_filter_value

3.13 Idle Hold Time (optional)

The idle hold time specifies how long, after starting, the engine is to stay at the idle

speed before finishing the ramp to the target speed. The time value has a resolution of

one-tenth of a second.

During the startup sequence, the controller increases the engine speed from the

engine's crank speed to the active target speed at the STARTUP RATE specified. If the

IDLE HOLD TIME is nonzero, the initial target speed will be the IDLE SPEED. After the

IDLE HOLD TIME expires, the controller then uses the ACCEL RATE to ramp the

engine to the selected set speed (REMOTE SPEED POT or SET SPEED A). The

startup sequence is complete once the engine speed reaches the selected set speed.

3.14 Accel Rate (optional)

This rate specifies how fast the controller should increase the engine’s speed when a

new, higher target speed is made active. The parameter value is specified in Hertz per

second based on the following formula.

[(higher_speed_in_Hertz) – (lower_speed_in_Hertz)] / (ramp_time_in_seconds) =

accel_rate_value

For example, suppose Set Speed A is 3300 Hertz and Set Speed B is at 3960 Hertz.

The controller is currently controlling the engine at 3300 Hertz (Set Speed A), when Set

Speed B becomes the active target speed. It is desired that the new speed of 3960 be

reached in precisely 2 seconds. The following formula determines the value needed by

Accel Rate to increase the engine speed from Set Speed A to Set Speed B in 2

seconds.

[(Set Speed B) – (Set Speed A)] / (N seconds) = accel_rate_value in Hertz per second

[3960 – 3300] / 2 = 330 Hertz per second

3.15 Decel Rate (optional)

The Decel Rate specifies how fast the controller should decrease the engine’s speed

when a new lower target speed is made active. The parameter value is specified in

Hertz per second based on the following formula.

[(higher_speed_in_Hertz) – (lower_speed_in_Hertz)] / (ramp_time_in_seconds) =

decel_rate_value

For example, suppose Set Speed A is 4170 Hertz and Set Speed B is 3475 Hertz. The

controller is currently controlling the engine at 4170 Hertz (Set Speed A), when Set

Speed B becomes the active target speed. It is desired that the new speed of 3475 be

reached in precisely 1.5 seconds. The following formula determines the value needed

Woodward 12

Page 21

Manual 36526F DPG-21XX-00X Digital Controllers

When the NO. of FLYWHEEL TEETH parameter is used, the

ACCEL RATE, DECEL RATE, and STARTUP RATE

parameters are displayed as a RPM quantity per second

instead of Hz/sec values. The given rate formulas can be

used to compute rates in terms of RPM values by

substituting the Hertz speed values with RPM speed values.

by Decel Rate to decrease the engine speed from Set Speed A to Set Speed B in 1.5

seconds.

[(Set Speed A) – (Set Speed B)] / (N seconds) = decel_rate_value in Hertz per second

[4170 – 3475] / 1.5 = 463 Hertz per second

3.16 Startup Rate (optional)

This parameter is used to achieve a smooth controlled engine start. On diesel engines,

this feature is also useful for minimizing exhaust smoke at startup. When used in

combination with the Idle Speed and Idle Hold Time, a brief warm-up cycle can be

programmed.

The startup rate specifies how fast the controller should increase the engine speed

when the engine is started. The rate value indicates Hertz per second. The formula to

use for determining a precise Startup Rate is shown below.

[(final_target_speed_in_Hertz) – (crank_speed_in_Hertz)] / (ramp_time_in_seconds) =

startup_rate_value

The ramp up will pause at the STARTUP SPEED until the controller senses an MPU

signal greater than the STARTUP SPEED. This prevents the startup ramp from

reaching completion before the engine has even started. The controller considers MPU

frequencies below the STARTUP SPEED as indicating that the engine is cranking but

has not yet started. MPU frequencies above the STARTUP SPEED are taken to

indicate that the engine has started and the controller will increase the engine speed

until the selected set speed is reached.

Exception: In cases where the target speed is less the STARTUP SPEED, the startup

ramp sequence ends when the target speed is reached.

3.17 Integral Low Limit (optional)

The integral low limit prevents "integral windup" in the negative direction. In other

words, the integral low limit parameter is used to reduce under speed duration after a

long or sustained over speed condition was present. The low limit helps reduce the

duration and amount of engine under speed by maintaining a minimum actuator

position.

When smaller pulse width modulated (PWM) duty cycle values do not reduce the

engine speed any further but an off speed (measured speed greater than the target

speed) remains, letting the Integral term grow more negative is not beneficial. Unused

negative integration would cause a slower recovery from an under speed condition.

The integral low limit specifies the PWM duty cycle where the integrator’s influence on

lowering PID output must stop. The default value is 0%. The value can be adjusted

from 0% to 90% in 1% increments.

Woodward 13

Page 22

Manual 36526F DPG-21XX-00X Digital Controllers

Use carefully, as improper use can prevent the controller

from ever reaching the target speed. The first line of defense

in reducing over speed or under speed errors is a well-tuned

controller via the PID terms.

Use carefully, as improper use can prevent the controller

from ever reaching the target speed. The first line of defense

in reducing over speed or under speed errors is a well-tuned

controller via the PID terms.

3.18 Integral High Limit (optional)

The integral high limit prevents "integral windup" in the positive direction. In other

words, the integral high limit parameter is used to reduce overspeed duration after a

long or sustained under speed condition was present. The high limit helps reduce the

duration and amount of engine overspeed by maintaining a maximum actuator position.

When larger PWM duty cycle values do not increase the engine speed any further but a

negative off speed (measured speed less than the target speed) remains, letting the

Integral term grow more positive is not beneficial. Unused positive integration would

cause a slower recovery from an over speed condition.

If an engine overload situation causes the engine speed to remain below the target

speed for some period of time, then the integral portion of PID output would grow larger

than otherwise needed (would windup). Therefore, when the load is removed the

engine may over speed because it takes time for the integral portion of PID output to

shrink or ―unwind‖. This is where reducing the Integral Limit High value can help by

preventing excessive windup in the PID output’s integration term.

The integral high limit specifies the PWM duty cycle where the integrator’s influence on

raising PID output must stop. The default value is 99%. The value can be adjusted from

99% down to 10% in 1% increments.

3.19 Password

The Password parameter is not available on DPG-21XX-00X Series models.

3.20 Over Speed Limit (optional)

DPG-21XX-001 Models:

This parameter is used to determine the engine speed that will trigger the controller to

output minimum fuel. The parameter’s value is in terms of a percentage over the

highest set speed. In other words, an over speed condition is detected if the engine

speed reaches a speed of [OVER SPEED LIMIT %] greater than the highest set speed.

For example: If the highest set speed is 1800 RPM and this parameter is set to 20, then

an over speed condition will be detected at 2160 RPM (the value that is 20% greater

than 1800). Formula: 1.20 * 1800 RPM = 2160 RPM

The default value of 100 is used to disable over speed detection. Use values less than

100 to enable the over speed limit function and set the limit speed to

[(1 + (over_speed_limit_value/100)) * (highest_set_speed)].

Woodward 14

Page 23

Manual 36526F DPG-21XX-00X Digital Controllers

The controller must be turned off to clear the over

speed detection before the engine can be restarted.

DPG-21XX-002 Models:

This parameter is used to determine the engine speed that will trigger the controller to

output minimum fuel. The parameter’s value is set as a frequency in Hertz or as a RPM

value depending on whether the No. of Flywheel Teeth parameter is zero or nonzero

respectively. The default value of 15,000 Hertz (450 Hertz ignition) is used to disable

over speed detection.

The controller detects an over speed condition when it measures an engine speed that

exceeds the OVER SPEED LIMIT value. When an over speed is detected the

controller’s actuator output signal is set to minimum.

3.21 Set Speed A Min (optional)

Set Speed A Min is used to set the lowest value allowed for Set Speed A adjustments.

The adjustable range for Set Speed A Min extends from 10 Hertz (2 Hertz ignition) to

the current value of Set Speed A.

3.22 Set Speed A Max (optional)

Set Speed A Max is used to set the highest value allowed for Set Speed A

adjustments. The adjustable range for Set Speed A Max extends from the current value

of Set Speed A to 11000 Hertz (300 Hertz ignition).

3.23 Set Speed B Min (optional)

DPG-2145-00X and DPG 2155-00X Models

Set Speed B Min is used to set the lowest value allowed for Set Speed B adjustments.

The adjustable range for Set Speed B Min extends from 10 Hertz (2 Hertz ignition) to

the current value of Set Speed B.

3.24 Set Speed B Max (optional)

DPG-2145-00X and DPG 2155-00X Models

Set Speed B Max is used to set the highest value allowed for Set Speed B

adjustments. The adjustable range for Set Speed B Max extends from the current value

of Set Speed B to 11000 Hertz (300Hertz ignition).

3.25 Idle Speed Min (optional)

Idle Speed Min is used to set the lowest value allowed for Idle Speed adjustments. The

adjustable range for Idle Speed Min extends from 10 Hertz (2 Hertz ignition) to the

current value of Idle Speed.

3.26 Idle Speed Max (optional)

Idle Speed Max is used to set the highest value allowed for Idle Speed adjustments.

The adjustable range for Idle Speed Max extends from the current value of Idle Speed

to 11000 Hertz (300Hertz ignition).

Woodward 15

Page 24

Manual 36526F DPG-21XX-00X Digital Controllers

3.27 Duty Cycle Limit (optional)

The Duty Cycle Limit parameter sets the absolute maximum amount of drive signal that

can be output to the actuator and thus serves as a mechanism for fuel limiting. Fuel

limiting is achieved by setting the maximum duty cycle or on-time allowed during one

cycle of the PWM (pulse-width-modulation) signal controlling the actuator drive circuit.

The value assigned to the duty cycle limit parameter is a percentage, and is limited to

values in the range 10% to 95%. The default value is 95%.

3.28 Startup Speed (required)

The Startup Speed parameter should be set to an engine speed at least 10% higher

than the fastest engine cranking speed but lower than the engine’s idle speed. This

allows the controller to determine whether the engine is cranking or running whenever

an engine speed signal is present. See the ―Startup Sequence‖ example in Chapter 5.

If the Startup Speed value is set too low (less than crank speed) the controller’s target

speed will be ramped to the active set speed (Idle, Set Speed A, or Set Speed B)

before the engine has started. Therefore, when the engine does start, it may overspeed

or output excessive smoke because the startup ramp, having already completed, no

longer controls the rate of engine speed increase.

If the Startup Speed value is set too high (above the active set speed) then the Startup

Speed becomes the target speed that the controller must reach before the it considers

the startup sequence complete. Typically, the startup sequence ends when the engine

speed reaches the active set speed. The active set speed is the Idle Speed if the Idle

Hold Time parameter is a nonzero value or the ―selected set speed‖ (either Set Speed

A or Set Speed B).

To determine the proper value for this parameter the crank speed must be known.

There are two ways to determine the engine crank speed.

1) Use a meter to measure the frequency across the MPU+ and MPUterminals of the controller during cranking or . . .

2) Use a PC running the Universal PST application and read the value

of the Measured Speed in the View Status panel when the engine

is cranking. Note: From the Universal PST startup screen press the

View Status button, then press the Start Monitoring button to begin

reading values.

3.29 Startup Duty Cycle (optional)

The Startup Duty Cycle parameter is used to pre-load the PID output with a PWM duty

cycle value close to that needed for the actuator to allow enough fuel to idle the engine.

If the value is too low, then the engine crank time may be longer than desired because

the controller’s actuator output starts from a value much smaller than needed to begin

opening the fuel valve.

If the value is too high, then the engine may overspeed because the actuator opens

more than needed to start the engine.

There are two ways to determine a good value to use for this parameter.

1) Use a meter to measure the duty cycle across the ACT terminals of the

controller while the engine is running. Note: To determine if your meter is

reading the correct value:

Woodward 16

Page 25

Manual 36526F DPG-21XX-00X Digital Controllers

a. First, apply power to the controller but do NOT start

the engine

b. Second, measure the duty cycle across the ACT

terminals (No. 3 and No. 4). The reading should be 5

for 5%. If the reading is 95, then reverse the leads.

2) Use a PC running the Universal PST application and read the value of the

PWM command in the View Status panel when the engine is cranking. Note:

from the Universal PST startup screen press the View Status button, then

press the Start Monitoring button to begin reading values.

Woodward 17

Page 26

Manual 36526F DPG-21XX-00X Digital Controllers

An unsafe condition could occur with improper use of

these software tools. Only trained personnel should

have access to these tools.

Chapter 4.

Universal PST

Introduction

The Universal Parameter Setup Tool (Universal PST) is a Microsoft® Windows®

application available from Woodward that enables you to adjust controller parameter

settings and monitor controller operation. Universal PST also includes a graphical chart

recorder that displays engine speed in real-time. This provides a visual representation

of how the engine speed changes in response to changes in load, which can be very

helpful when tuning the controller.

This chapter provides the information needed to use a computer with your controller.

Here you will find instructions for acquiring, installing, and running the Universal PST

on your PC. Also described is information for obtaining or constructing the

communications cable needed to connect the controller’s COMM port to your

computer’s serial port.

Features

Universal PST features include:

Automatic configuration to each DPG when communications are established

Read/write access to all DPG programmable parameters and features

View each parameter's default, minimum, and maximum values

Diagnostics utilizing automatic refresh of DPG status

Save and open DPG setup data information to and from a file for reuse

Single button read to get the current values of all parameters

Single button write to program a DPG with previously saved setup values

Engine speed monitoring via a chart recorder to aid in tuning the controller

Saving chart recorder data to a Microsoft Excel compatible file

Help information on each of the controller’s parameters

Help information on using the Universal PST

System Requirements

Universal PST minimum system requirements:

Pentium® 133 MHz PC

50 MB of hard disk space

64 MB of RAM

Display resolution set to SVGA (800x600) or higher

Windows® 98se, NT 4.0, 2000, and XP or greater

Windows® 95 or ME not supported

Woodward 18

Page 27

Manual 36526F DPG-21XX-00X Digital Controllers

Acquiring Universal PST

There are two ways to acquire a copy of the Universal PST application:

Obtain the DPG Software Calibration Kit

Download the application from the Woodward website

Obtaining the DPG Software Calibration Kit:

The DPG Software Calibration Kit (Woodward P/N 8447-1003) contains the latest

version of Universal PST on CD-ROM, a DB-9 Modular Adapter and modular

cable. Contact the Woodward sales department to request a DPG Software

Calibration Kit for a nominal charge. Telephone: (847) 967-7730.

Downloading Universal PST:

The Universal PST application is also available to download from the Woodward

Software Products page at www.woodward.com/IC/Software, Use the ―Select a

Product‖ drop down menu in the center of the web page to select ―DPG-2xxx digital

governors‖ then press the [Go] button.

This will automatically redirect you to the Universal PST download page where you

can click on the word Download to begin the download process.

Once you are logged into the Woodward download site you are presented with the

File Download dialog box shown below, or one similar. Click the [Save] button and

choose a folder to save the download to.

NOTE: Due to the large file size, it is recommended that the [Open] button not be

used because this would try to run the self-extracting executable from the web site.

Woodward 19

Page 28

Manual 36526F DPG-21XX-00X Digital Controllers

Remote access via the COMM port is intended for

connection only while programming, tuning and

troubleshooting the control/engine. It is a service port and

not intended for permanent connection of a PC and/or cable.

RJ11 OR

RJ12

POSITION

DPG-21XX SIGNAL

CONNECTS TO:

1

No connection

N/C

2

Transmit data to PC

PC receive (RxD)

DB9 pin 2

3

Receive data from PC

PC transmit (TxD)

DB9 pin 3

4

COMMON

PC common

DB9 pin 5

5

+5 Vdc (Do NOT

connect at the PC end)

N/C

6

No connection

N/C

12345

6789

123456

DB9F

RJ11M

Installing Universal PST

Instructions to Install from CD-ROM:

When you insert the DPG Software Calibration Kit’s CD-ROM into your computer,

the ―autorun‖ file on the CD will attempt to launch the ―setup.exe‖ program. If the

―autorun‖ feature is disabled on your computer or does not start the setup program

you can launch the program manually. To start the installation manually, explore

the contents of the CD then double click on the ―setup.exe‖ file.

Instructions to Install from the Downloaded File:

The file downloaded from the Woodward web site contains two files:

―ReadMeFirst.txt‖ and ―setup.exe‖. Run the downloaded file to extract its contents

to a folder you choose on your computer’s hard drive. Then run the ―setup.exe‖

program from the folder you extracted it to.

IMPORTANT:

The installation program will detect operating system components older than those

required by the "Universal PST" application. In this case the installation program

will ask if you want to update Windows. If you do not want "setup" to update your

system then you can not use the "Universal PST" application on this computer.

Read the setup program's instructions carefully as they appear and respond as

needed. The installation may take as long as 7 minutes depending on your

computer's power and operating system. Do not interrupt the installation program

even though it may appear as

though it is not running.

NOTE: Administrator rights may be needed to install on some Microsoft Windows

operating systems (such as Windows XP Professional) for the setup program to

properly register application resources.

Wiring the COMM Port to a PC

To construct a communications cable to use between the DPG’s COMM port and

your PC’s RS-232 serial port refer to the table and wiring diagram below.

Woodward 20

Page 29

Manual 36526F DPG-21XX-00X Digital Controllers

Communications Error

The following message window appears when Universal PST is running and

unable to communicate with a DPG.

After the problem is found and corrected, you can either restart Universal PST or

press the <Read All> button to clear the error message. The <Read All> button is

near the lower left corner of Universal PST’s main startup screen.

Universal PST User Interface Overview

Universal PST has two main display modes.

Table View (the main startup screen)

Chart View

TABLE VIEW

In Table View the user can:

View the current values for all user programmable parameters in the

Parameter Setup panel.

Edit a parameter’s value by double-clicking on a cell in the ―Value‖ column

of the table.

Press the <Read All> button to refresh the values displayed in the

Parameter Setup panel.

Press the <Write All> button to transmit setup values to the controller.

Press the <View Status> button to display read only parameters in the

Status View panel.

Woodward 21

Page 30

Manual 36526F DPG-21XX-00X Digital Controllers

Press the <View Chart> button to set the display mode to Chart View.

Select items from the menu.

CHART VIEW

In Chart View the user can:

Monitor engine speed in real-time.

Adjust the horizontal and vertical scale settings of the chart recorder.

Edit parameter values related to controller tuning. These same parameters

are also on the main parameter setup table.

Press the <Data File => button to open a file for saving chart recorder data.

Press the <Data Reset> button to start data collection to the open file at the

beginning.

Press the <Pause Chart> button to stop the chart recorder, which also stops

writing data to the file. Press the <Continue> button to turn the chart

recorder back on.

Press the <View Table> button to set the display mode back to Table View.

Select items from the menu.

NOTE: Pressing a button means positioning the mouse pointer over the button and

clicking the left mouse button.

Woodward 22

Page 31

Manual 36526F DPG-21XX-00X Digital Controllers

Universal PST Menu Items

Use the File menu to:

Open a previously saved setup data file

Save setup data to a file

Send setup data to the default printer

Exit the program

Use the View menu to:

Select Parameter Table view (Table

View)

Select Chart Recorder view (Chart

View)

Use the Port menu to:

Select the PC’s serial port that is

connected to the DPG-2000

Use the Help menu to access:

Help on the Universal PST for DPG

Help on the DPG-2000 product that is

currently in communication with the PC

Information about the Universal PST for

DPG application

Parameter Setup

The Parameter Setup panel displays a table where each row shows the Name of a

user programmable parameter, its current Value, and the parameter’s Default,

Minimum, and Maximum values.

To modify a parameter’s current value, it must first be selected. Do this by double-

clicking the left mouse button on a cell in the table that is at the intersection of the

parameter’s row and the Value column. The selected cell will be highlighted and

the value can now be modified. When done modifying the value, press the

computer keyboard’s <Enter> key to transmit the new value to the controller.

In the figure shown below, the Set Speed A value has been selected for editing.

Woodward 23

Page 32

Manual 36526F DPG-21XX-00X Digital Controllers

Parameter Help

To get help on a particular parameter, single click the left mouse button on a

parameter’s Value, then press <Ctrl><F1> on the computer’s keyboard.

<Ctrl><F1> means press and hold the <Ctrl> key while the <F1> key is pressed

and released. This opens the DPG online help file and automatically jumps to the

selected parameter’s help page.

NOTE: Complete online help for each DPG controller is also accessible by

selecting either “Governor Help Contents” or “Parameter Definitions” from the

Universal PST Help menu.

Synchronizing Universal PST with a DPG

Pressing the <Read All> button will load the current values for all of a DPG-2XXX-

00X’s parameters into Universal PST. The <Read All> button is part of the Table

View.

IMPORTANT: If the communication cable is unplugged from a DPG and plugged

into a different DPG while the Universal PST application is still running, then the

<Read All> button must be pressed in order for Universal PST to synchronize with

the new DPG.

The <Write All> button is very useful when reusing saved setup data to configure a

new system with the same data as a previous one. Simply load an existing set of

previously saved parameter values into the Parameter Setup table using ―Open a

setup data file” from the File menu then press the <Write All> button.

Status View

The Status View panel is displayed only after pressing

the <View Status> button. The Status View panel is part

of the Table View display mode.

The Status View panel displays a table where each row

shows the Name of a read only parameter and its current

Value (when ―Auto Read is ON‖)

Press (left mouse click) the <START Monitoring> button

to have the Universal PST program automatically refresh

the Values. Press the <STOP Monitoring> button to

disable automatic refresh.

Woodward 24

Page 33

Manual 36526F DPG-21XX-00X Digital Controllers

Tuning View

The Tuning View panel is displayed only after pressing the <View Chart> button.

The Tuning View panel is part of the Chart View display mode.

To modify a tuning parameter’s current

value, it must first be selected. Do this by

double-clicking the left mouse button on a

cell in the table that is at the intersection of

the parameter’s row and the Value

column.

The selected cell will be highlighted and

the value can now be modified. When

done modifying the value, press the

computer keyboard’s <Enter> key to

transmit the new value to the controller.

Chart Recorder

The chart recorder is part of the Chart View display mode. Each time Chart View is

entered the last used Data File is reset, the Vertical Scale defaults to [0 Hz to

12000 Hz], and the Horizontal scale defaults to 20 seconds.

The chart recorder’s display characteristics are configured using the Vertical Scale

options, the Horizontal Scale options, and the Chart Recorder Signal Filtering

options.

The Vertical Scale options provide three different ways to view engine speed data.

The [0 to 12000 Hz] option is the default and sets the vertical axis range to

its absolute minimum and maximum measurable values.

The [_____] to [______] Hz option allows you to enter the minimum and

maximum speed values to zoom in on a viewing range of interest.

The +/- 10% of [______] Hz option is primarily used to zoom in on the target

speed and center it in the chart recorder. This is most useful during

controller tuning to see if the engine speed stays within +/- 10% of the target

speed during load on/off cycling.

The Horizontal Scale options allow you to set how much data is displayed in the

chart recorder window. Larger values compress the display and show more data.

Smaller numbers expand the display and show less data. A Horizontal Scale

setting of 20 seconds is approximately the same as a 5-millimeter per second

paper travel speed of a conventional paper tape chart recorder.

The Chart Recorder Signal Filtering options can be used to smooth out noisy

signals. The default setting is Min, which is no filtering. Note that filtering will round

out peaks and give a less accurate display of the speeds actually measured by the

DPG.

Woodward 25

Page 34

Manual 36526F DPG-21XX-00X Digital Controllers

Engine Speed Data Collection

The engine speed data measured by the DPG and displayed in the Universal PST

chart recorder window is also recorded to a computer file. MPU_DATA00.csv is the

default file name used to save engine speed information. You can change the file

name by using the <Data File => button. The ―.csv‖ data files created to collect

engine speed data can be viewed with either a text editor or with Microsoft Excel. If

you load an engine speed data file into Microsoft Excel, then you can highlight the

column of data and use Excel’s quick graph button to create a line chart of the

data.

IMPORTANT: Do not open data files in another program that are currently being

used by Universal PST. Also be sure to close any open data files needed by

Universal PST before starting it.

The <Data File => button opens a dialog box allowing you to set the base file name

where chart recorder data will be saved. A two-digit suffix is automatically

appended to the file name that is given and serves the following purpose. Each

engine speed data file is considered full after recording 60,000 data points which is

approximately 10-12 minutes of data. The two-digit suffix is used to automatically

continue collecting data to new files with the same base file name but with

increasing numeric suffixes. The first 60,000 data points are saved in

filename00.csv and the next 60,000 data point are saved in filename01.csv, and so

on until a million data points are collected. This is to prevent each speed data file

from exceeding the 65,536-row limit of Microsoft Excel.

The <Data Reset> button is used to clear out the data collection buffer and

overwrite the zero suffixed data collection file. Data collection starts from the

beginning of filename00.txt where filename is the base file name previously used.

The progress bar shown to the right of the <Data Reset> button indicates how full

the complete set of data files is. A total of one million data points (approximately

3.5 hours of data) can be collected before the progress bar displays the message

―The Data File is FULL‖. In order to start recording data again without overwriting

previously collected data, use the <Data File => button to create a new base file

name in which to receive additional engine speed information.

The <Pause Chart> button stops chart recorder and Data File updates. After

pressing this button the <Continue> button is displayed. Press the <Continue>

button to turn the chart recorder back on and continue recording engine speed data

to the current target file.

Use the <View Table> button to return to the Table View display mode. Be sure to

open a new Data File before returning to Table View if the data already collected

needs to be saved. The active data file is automatically reset each time the Chart

View display mode becomes active.

Woodward 26

Page 35

Manual 36526F DPG-21XX-00X Digital Controllers

No.

Parameter Name

Default Value

2

SET SPEED A

1000

5

PROPORTIONAL

25 6 INTEGRAL

50 7 DERIVATIVE

25

8

OVG @ SET SPEED A

20

11

GAIN FACTOR (note 1)

20

12

SPEED FILTER (note 2)

16

28

STARTUP SPEED

1000

NOTE 1: Modify Gain Factor only if you run out of

adjustment in a PID or OVG term.

NOTE 2: For the Speed Filter, typically the value 24