Page 1

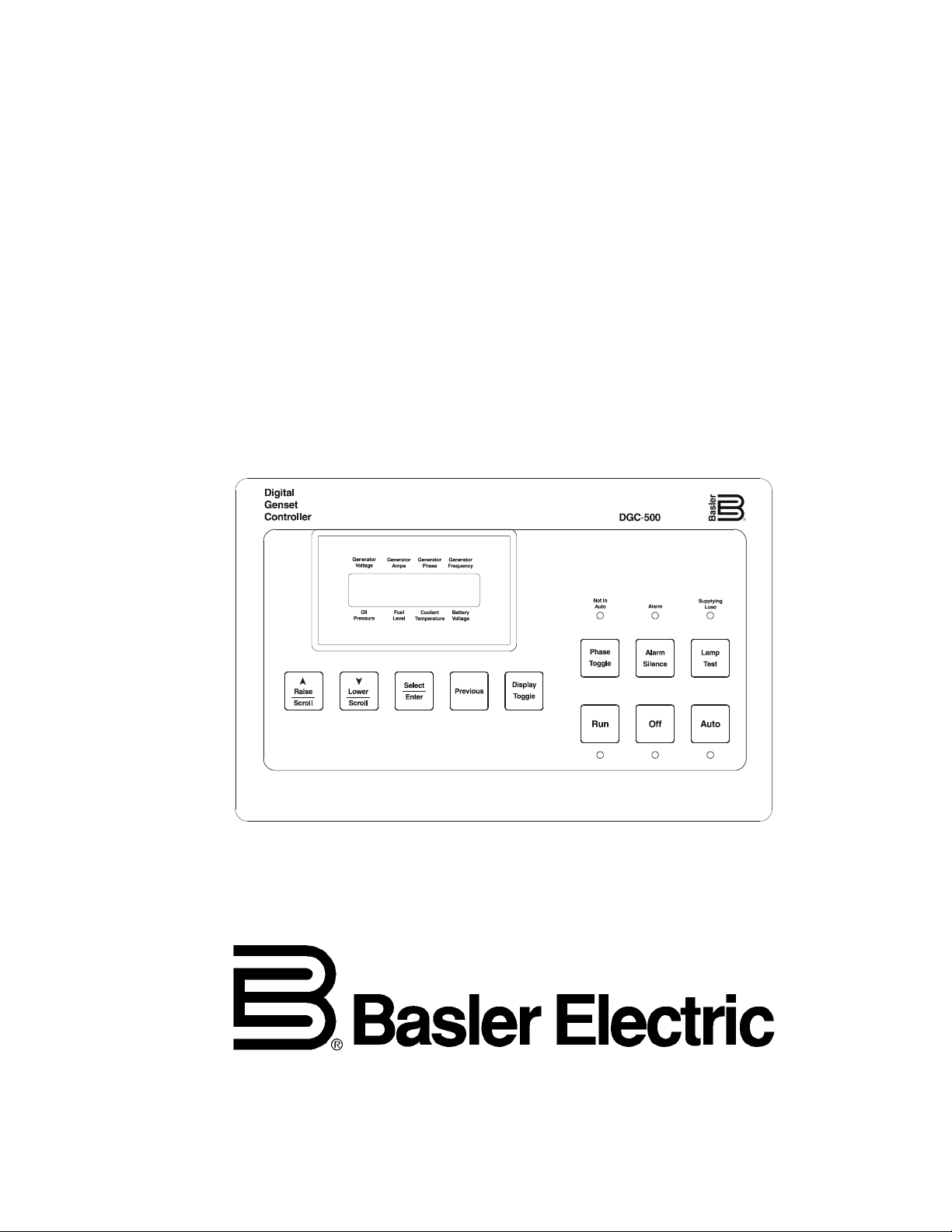

INSTRUCTION MANUAL

for

DGC-500

DIGITAL GENSET CONTROLLER

Publication: 9 3554 00 990

Revision: D 03/04

Page 2

INTRODUCTION

This manual provides information concerning the operation and installation of the Basler DGC-500 Digital

Genset Controller. To accomplish this, the following information is provided.

• Specifications

• Functional Description

• Communication Software Description

• Installation Information

• Troubleshooting Information

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures presented in this manual.

DGC-500 Introduction i

Page 3

First Printing: March 2002

Printed in USA

Copyright © 2004 Basler Electric, Highland, Illinois 62249 USA

March 2004

CONFIDENTIAL INFORMATION

Of Basler Electric. It is loaned for confidential use, subject to return on request,

and with the mutual understanding that it will not be used in any manner

detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design of

all features and options are subject to modification without notice. Should further information be required,

contact Basler Electric.

BASLER ELECTRIC

ROUTE 143, BOX 269

HIGHLAND, IL 62249 USA

http://www.basler.com, info@basler.com

PHONE 618-654-2341 FAX 618-654-2351

ii DGC-500 Introduction

Page 4

PRODUCT REVISION HISTORY

The following information provides a historical summary of the changes made to the embedded firmware,

communication software (BESTCOMS), and hardware of this device. The corresponding revisions made to

this instruction manual are also summarized. This revision history is separated into four categories: Firmware

Version, BESTCOMS Version, Hardware Version, and Manual Version. All revisions are listed in reverse

chronological order.

Firmware Version Summary

2.04.XX - 10/03

2.03.XX - 03/03

2.01.XX - 07/02

1.00.XX - 03/02

BESTCOMS Version Summary

1.03.XX - 10/03

1.02.XX - 03/03

1.01.XX - 07/02

1.00.XX - 03/02

C Added Engine Start/Stop Configuration setting to accommodate Volvo

Penta EDC applications. Added CANBus Address setting and Genset kW

Rating setting.

C Added support for SAE J1939 interface and 400 Hz operation

C Increased the maximum Sender Failure Alarm time delay setting from 10

seconds to 30 seconds.

C Initial release

C Added Engine Start/Stop Configuration setting to accommodate Volvo

Penta EDC applications. Added CANBus Address setting and Genset kW

Rating setting.

C Added settings for support of SAE J1939 interface and 400 Hz operation.

C Increased the maximum setting of the Global Sender Failure Alarm Time

Delay from 10 seconds to 30 seconds.

C Initial release

Hardware Version

(Standard Order P/N) Summary

L - 10/03

K - 09/03

J - 07/03

I

H - 06/03

G - 04/02

DGC-500 Introduction iii

C Implemented firmware version 2.04.XX and BESTCOMS version 1.03.XX

C Added reference to instruction manual on parts list

C Implemented firmware version 2.03.XX and BESTCOMS version 1.02.XX

C Not implemented

C Circuit board layout revised to improve manufacturing process

C Initial release

Page 5

Hardware Version

(Special Order P/N) Summary

D - 10/03

C - 09/03

B - 07/03

A - 06/03

Manual Version Summary

D - 03/04

C - 09/03

C Implemented firmware version 2.04.XX and BESTCOMS version 1.03.XX

C Added reference to instruction manual on parts list

C Implemented firmware version 2.03.XX and BESTCOMS version 1.02.XX

C Circuit board layout revised to improve manufacturing process

C Added suitability and warning statements concerning compliance of part

numbers 9 3554 00 113 and 9 3554 00 114 with cURus Standard 1604.

C Added descriptions associated with new settings: CANBus Address,

Engine Stop/Start Configuration, and Genset’s kW Rating.

C Added information pertaining to DGC Isolator Kits.

C Added Volvo Penta EDC application information and diagrams.

C Updated Pre-Alarm and Alarm information in Section 3, Functional

Description to include metric equivalents for settings.

B - 03/03

C Revised style chart to show NFPA compliance as standard, J1939 support

as optional.

C Added coverage for part numbers 9 3554 00 111, 112, 113, and 114.

C Added information about J1939 interface, ECU support, and state

machine operation where appropriate.

C Revised BESTCOMS section to accommodate new ECU settings.

C Created new appendix of settings list with range for each setting.

A - 07/02

— - 02/02

C Added instructions to Section 3, Functional Description for viewing

firmware version.

C Revised the maximum setting of Sender Failure Alarm Time from 10

seconds to 30 seconds in Tables 3-1 and 3-2.

C Replaced actual BESTCOMS version number in Figure 4-2 with generic

version number.

C Initial release

iv DGC-500 Introduction

Page 6

CONTENTS

SECTION 1 • GENERAL INFORMATION................................................ 1-1

SECTION 2 • HUMAN-MACHINE INTERFACE ........................................... 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ............................................. 3-1

SECTION 4 • BESTCOMS SOFTWARE................................................. 4-1

SECTION 5 • INSTALLATION......................................................... 5-1

SECTION 6 • MAINTENANCE AND TROUBLESHOOTING ................................. 6-1

APPENDIX A • PARAMETERS AND SETTINGS .......................................... A-1

APPENDIX B • DGC-500 SETTINGS RECORD ........................................... B-1

DGC-500 Introduction v

Page 7

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION................................................ 1-1

DESCRIPTION ................................................................. 1-1

FEATURES.................................................................... 1-1

FUNCTIONS ................................................................... 1-1

OUTPUTS..................................................................... 1-1

OPTIONAL EQUIPMENT ......................................................... 1-1

STYLE AND PART NUMBERS .................................................... 1-2

Style Numbers .............................................................. 1-2

Part Numbers ............................................................... 1-2

SPECIFICATIONS .............................................................. 1-3

Current Sensing .......................................................... 1-3

Voltage Sensing .......................................................... 1-3

Frequency .............................................................. 1-3

Contact Sensing ......................................................... 1-3

Engine System Inputs ..................................................... 1-3

Calculated Data .......................................................... 1-3

Output Contacts .......................................................... 1-3

Horn Output ............................................................. 1-4

Communication Interface................................................... 1-4

Environment............................................................. 1-4

Type Tests .............................................................. 1-4

UL Recognition .......................................................... 1-4

CSA Certification ......................................................... 1-4

NFPA Compliance ........................................................ 1-4

Physical ................................................................ 1-4

Figures

Figure 1-1. DGC-500 Style Number Chart ............................................... 1-2

DGC-500 General Information i

Page 8

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

The DGC-500 Digital Genset Controller provides integrated engine-generator set control, protection, and

metering in a single package. Microprocessor based technology allows for exact measurement, setpoint

adjustment, and timing functions. Front panel controls and indicators enable quick and simple DGC-500

operation. Basler Electric communication software (BESTCOMS-DGC500-32) allows units to be easily

customized for each application. Because of the low sensing burden in the DGC-500, neither dedicated

potential transformers (PTs) nor current transformers (CTs) are required. A wide temperature-range liquid

crystal display (LCD) with backlighting allows the display to be viewed under a wide range of ambient light and

temperature conditions.

An optional, SAE J1939 interface provides high-speed communication between the DGC-500 and the engine

control unit (ECU) on an electronically controlled engine. This interface provides access to oil pressure,

coolant temperature, and engine speed data by reading these parameters directly from the ECU. When

available, engine diagnostic data can also be accessed.

FEATURES

DGC-500 Digital Genset Controllers have the following features.

C Resistant to high moisture, salt fog, humidity, dust, dirt, and chemical contaminants

C Resistant to the entrance of insects and rodents

C Suitable for mounting in any top mount enclosure

C Suitable for controlling isolated generating systems or paralleled generating systems

C Serial link communications and BESTCOMS software eases access to setup parameters

C Compliant with National Fire Prevention Association (NFPA) Standard 110

C Optional SAE J1939 interface provides high-speed communication with the ECU on electronically

controlled engines

FUNCTIONS

DGC-500 Digital Genset Controllers perform the following functions.

C Engine cranking control

C Generator voltage metering

C Generator frequency metering

C Generator current metering

C Engine coolant temperature metering

C Engine coolant temperature protection

C Engine oil pressure metering

C Engine oil pressure protection

C Fuel level sensing

C Fuel level sender protection

C Fuel leak detector

C Engine cool down

C VA metering

C Engine rpm metering

C Engine run time metering

C Battery voltage metering

C Battery condition monitoring

C Engine maintenance monitoring

C Engine diagnostic reporting

OUTPUTS

Five isolated, form A output contacts are provided: Engine Crank, Fuel Solenoid, Pre-Start, and two userprogrammable outputs.

OPTIONAL EQUIPMENT

An optional Remote Annunciation Display Panel (RDP-110) is available for use with the DGC-500.

Applications that require remote annunciation can use the Remote Display Panel, RDP-110. This display panel

annunciates all DGC-500 alarms, pre-alarms, and operating conditions.

DGC-500 General Information 1-1

Page 9

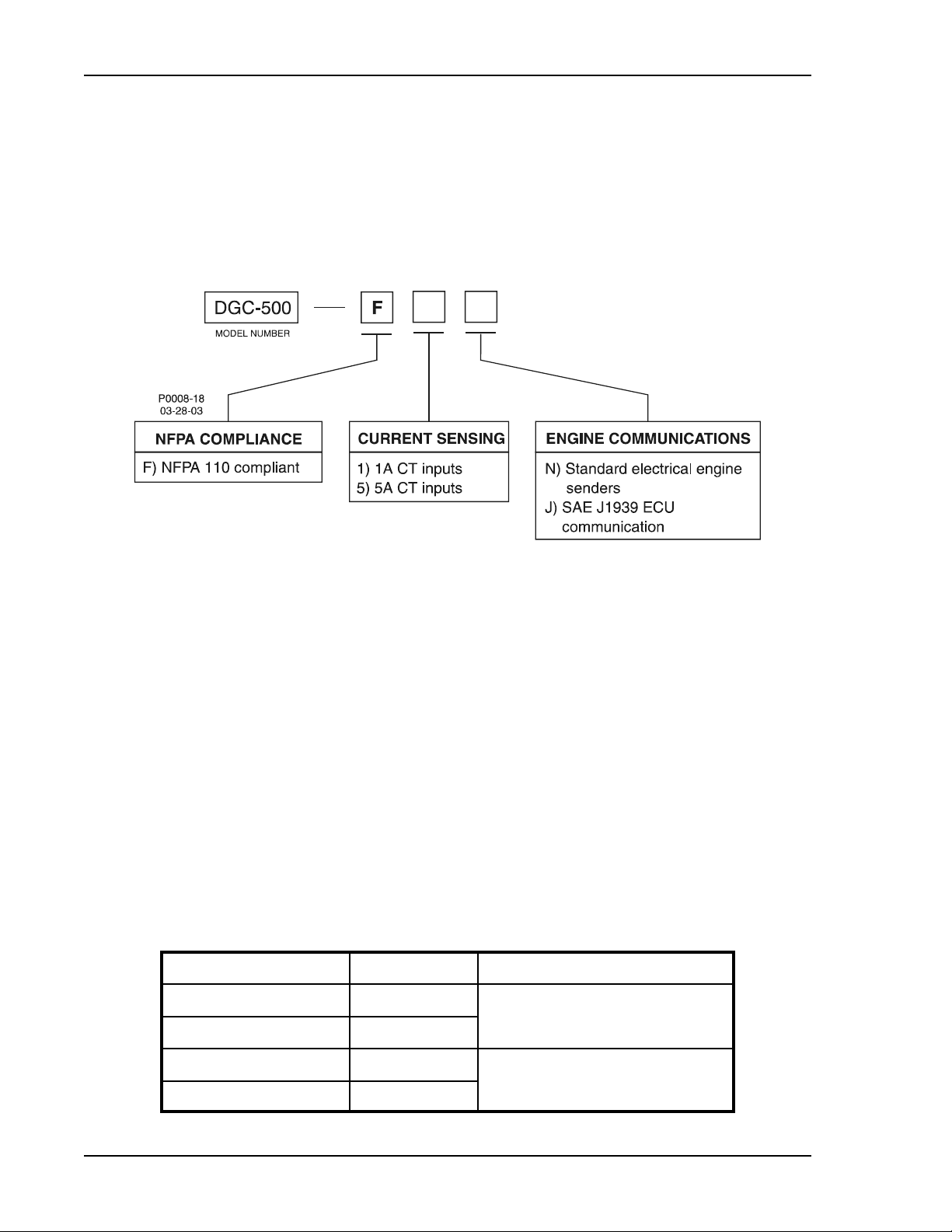

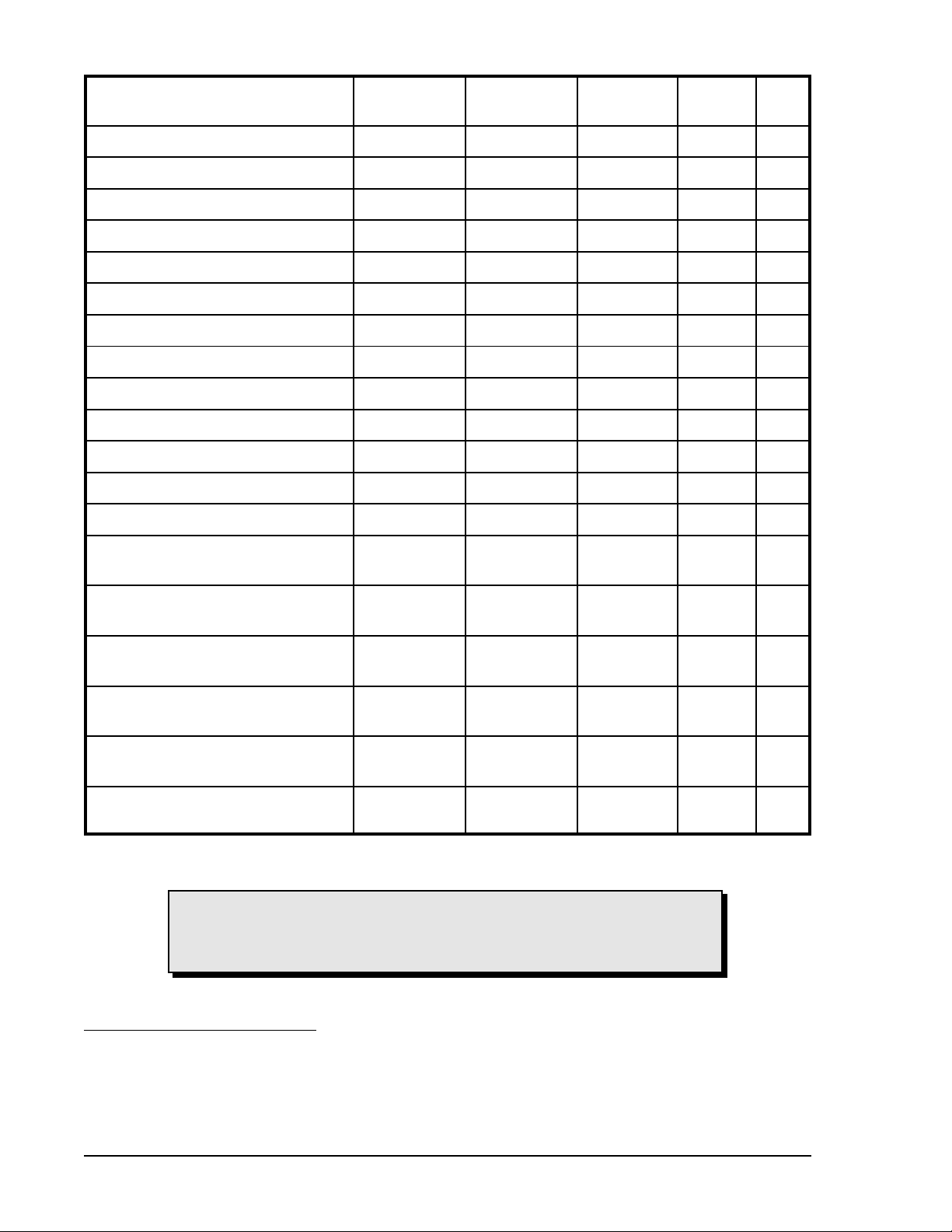

STYLE AND PART NUMBERS

Standard-order DGC-500 controllers are identified by a style number. Special-order DGC-500 controllers are

specified by ten-digit part numbers

Style Numbers

The electrical characteristics and operational features of a standard-order DGC-500 are defined by a

combination of letters and numbers that make up the style number. The model number, together with the style

number, describe the options included in a specific device. Figure 1-1 illustrates the DGC-500 style number

identification chart.

Figure 1-1. DGC-500 Style Number Chart

For example, if a DGC-500 style number is F5J, the device has the following characteristics and operating

features.

F.... Compliance to NFPA Standard 110

5 .... 5 ampere current sensing inputs

J .... ECU communication through the SAE J1939 protocol

The DGC-500 style number is printed on a label located on the circuit board near the voltage and current input

connections. Upon receipt of a unit, be sure to check the style number against the requisition and the packing

list to ensure that they agree.

Part Numbers

A ten-digit part number specifies the electrical characteristics and operational features of special-order

DGC-500 controllers. Table 1-1 lists the special-order DGC-500 controllers available along with descriptions

of their operating features.

Table 1-1. Special-Order DGC-500 Controllers

Part Number Style Number Special Features

9 3554 00 111 F5J 400 Hz nominal frequency

9 3554 00 112 F1J

9 3554 00 113 F5N cURus recognized for use in

9 3554 00 114 F1J

hazardous locations

DGC-500 General Information1-2

Page 10

SPECIFICATIONS

Current Sensing

Accuracy: ±1% of full scale or ±2 A,

whichever is greater

Burden: 1 VA

Terminals: P10, P11 (A-phase)

P12, P14 (B-phase)

P15, P17 (C-phase)

1 Ampere Inputs

Continuous Rating: 0.02 to 1.0 A

1 Second Rating: 2 A

5 Ampere Inputs

Continuous Rating: 0.1 to 5.0 A

1 Second Rating: 10 A

Voltage Sensing

Accuracy: ±1% of full scale or ±2 V,

whichever is greater

Burden: 1 VA

Range: 12 to 576 V rms, line-to-line

1 Second Rating: 720 V rms

Terminals: P23 (A-phase), P26 (B-phase),

P29 (C-phase), P30 (Neutral)

Frequency

Accuracy: ±0.25% of reading or ±0.2 Hz,

whichever is greater

Display Range: 4 to 70 Hz

4 to 450 Hz (P/N 9355400111,

112 only)

Contact Sensing

Emergency Stop Input

Type: Normally-closed dry contacts

Terminals: P35, P39

Programmable Inputs (3)

Type: Normally-open dry contacts

Terminals: P2, P21 (Input 1)

P3, P21 (Input 2)

P4, P21 (Input 3)

Engine System Inputs

t Stated accuracies are subject to the accuracy of

the senders used.

Fuel Level Sensing

Accuracy: ±3% of indication or ±2% t

Range: 33 to 240 S nominal

Terminals: P16, P19 (common)

Coolant Temperature Sensing

Accuracy: ±3% of indication (37°C to

115°C (99°F to 239°F))

±2°, whichever is greater at

25°C (77°F)

Range: 62.6 to 637.5 S nominal

Terminals: P18, P19 (common)

t

Oil Pressure Sensing

Accuracy: ±3% of indication (0 to 690

kPa) or ±12 kPa, whichever is

greater at 25°C (77°F)

±3% of indication (0 to 100 psi)

or ±2 psi, whichever is greater

Range: 34 to 240

Terminals: P13, P19 (common)

Battery Voltage Sensing

Accuracy: ±3% of indication or ±0.2 V,

whichever is greater

Nominal: 12 or 24 Vdc

Range: 8 to 32 Vdc (battery dip ride-

through to 6 Vdc for 0.75 sec)

Burden: 16 W maximum

Magnetic Pickup Sensing

Voltage Range: 3 V to 35 V peak continuous

into 13 k

Frequency Range: 32 to 10,000 Hz

Terminals: P39 (+), P40 (–)

Engine RPM Sensing

Accuracy: ±0.5% of indication or ±2 rpm,

whichever is greater at 25°C

(77°F)

Range: 750 to 3,600 rpm

Calculated Data

Voltamperes

Accuracy: ±2% of indication or ±2 kVA,

whichever is greater

Range: 0 to 9,999 kVA

Engine Run Time

Accuracy: ±0.5% of reading or ±1 hour,

whichever is greater at 25°C

(77°F)

Range: 0 to 99,999 hours

Maintenance Interval

Accuracy: ±0.5% of reading or ±1 hour,

whichever is greater at 25°C

(77°F)

Range: 0 to 5,000 hours

Output Contacts

Engine Crank, Fuel Solenoid, and Pre-Start Relays

Rating: 30 A at 28 Vdc, make, break,

and carry

Terminals: K1-N.O., COM (Engine Crank)

K2-N.O., COM (Fuel Solenoid)

K3-N.O., COM (Pre-Start)

S nominal

S (during cranking)

t

t The contact rating is reduced to 3 A for part

numbers 9 3554 00 113 and 9 3554 00 114 when

used in a hazardous location.

DGC-500 General Information 1-3

Page 11

Output Contacts—continued

Programmable Relays (2)

Rating: 2 A at 30 Vdc, make break, and

carry

Terminals: P33, P34 (Output 1)

P36, P38 (Output 2)

Horn Output

Voltage: 24 Vdc or battery voltage,

whichever is less

Current: 15 mAdc maximum

Compatible Device: Basler P/N 29760

Terminals: P24 (+), P25 (–)

UL Recognition

All DGC-500 controllers are UL recognized per

Standard 508, Standard for Industrial Control

Equipment (UL File E97035).

Part Numbers 9 3554 00 113 and 9 3554 00 114

cURus recognized per Standard 1604, Electrical

Equipment for Use in Class I and II, Division 2, and

Class III Hazardous (Classified) Locations, Class I,

Division 2, Groups A, B, C, D, Zone 2, Temperature

Code T5.

This equipment is suitable for use in Class I, Division

2, Groups A, B, C, D, or nonhazardous locations only.

Communication Interface

Full Duplex RS-232

Connection: Female DB-9 connector (J1)

Baud: 1200 or 2400

Data Bits: 8

Parity: None, Odd, or Even

Stop Bit: 1

SAE J1939 Interface

Differential

Bus Voltage: 1.5 to 3 Vdc

Maximum Voltage: –32 to 32 Vdc (with respect to

negative battery terminal)

Communication Rate: 250 kb/s

Environment

Temperature Range

Operating: –20°C to 60°C (–4°F – 140°F)

Storage: –40°C to 85°C (–40°F – 185°F)

Type Tests

Shock

15 G in 3 perpendicular planes

Vibration

Swept over the following ranges for 12 sweeps in

each of three mutually perpendicular planes with each

15 minute sweep consisting of the following:

5 to 29 to 5 Hz: 1.5 G peak for 5 min.

29 to 52 to 29 Hz: 0.036" DECS-A for 2.5 min.

52 to 500 to 52 Hz: 5 G peak for 7.5 min.

Salt Fog

Tested per ASTM-117B-1989

Radio Interference

Type tested using a 5 W, hand-held transceiver

operating at random frequencies centered around 144

and 440 MHz with the antenna located within 150 mm

(6") of the device in both vertical and horizontal

planes.

Dielectric Strength

2,352 Vac at 50/60 Hz for 1 second between voltage

sensing inputs and all other circuits.

500 Vac at 50/60 Hz for 1 minute between any of the

following groups.

C Current Sensing Inputs: 8 mA

C RS-232 Port: 6 mA

WARNING! – EXPLOSION HAZARD

(9 3554 00 113 and 9 3554 00 114 only)

Substitution of components may impair suitability

for Class I, Division 2.

Do not disconnect equipment unless power has

been switched off or the area is known to be nonhazardous.

CSA Certification

Certified per Standard CAN/CSA-C22.2,

Number 14-95, CSA File LR 23131 (excludes P/N

9 3554 00 113, 114)

NFPA Compliance

All DGC-500 controllers comply with NFPA Standard

110, Standard for Emergency and Standby Power

Systems.

Physical

Weight: 680 g (1.5 lb)

DGC-500 General Information1-4

Page 12

SECTION 2 • HUMAN-MACHINE INTERFACE

TABLE OF CONTENTS

SECTION 2 • HUMAN-MACHINE INTERFACE ........................................... 2-1

INTRODUCTION ............................................................... 2-1

FRONT PANEL................................................................. 2-1

REAR PANEL .................................................................. 2-2

Figures

Figure 2-1. DGC-500 Front Panel HMI .................................................. 2-1

Figure 2-2. DGC-500 Rear Panel HMI .................................................. 2-3

Tables

Table 2-1. DGC-500 Front Panel HMI Descriptions ........................................ 2-2

Table 2-2. DGC-500 Rear Panel HMI Descriptions ......................................... 2-3

DGC-500 HMI i

Page 13

SECTION 2 • HUMAN-MACHINE INTERFACE

INTRODUCTION

This section describes the components of the DGC-500 human-machine interface (HMI). DGC-500 HMI

components are located on the front panel (controls and indicators) and the rear panel (terminals and

connectors).

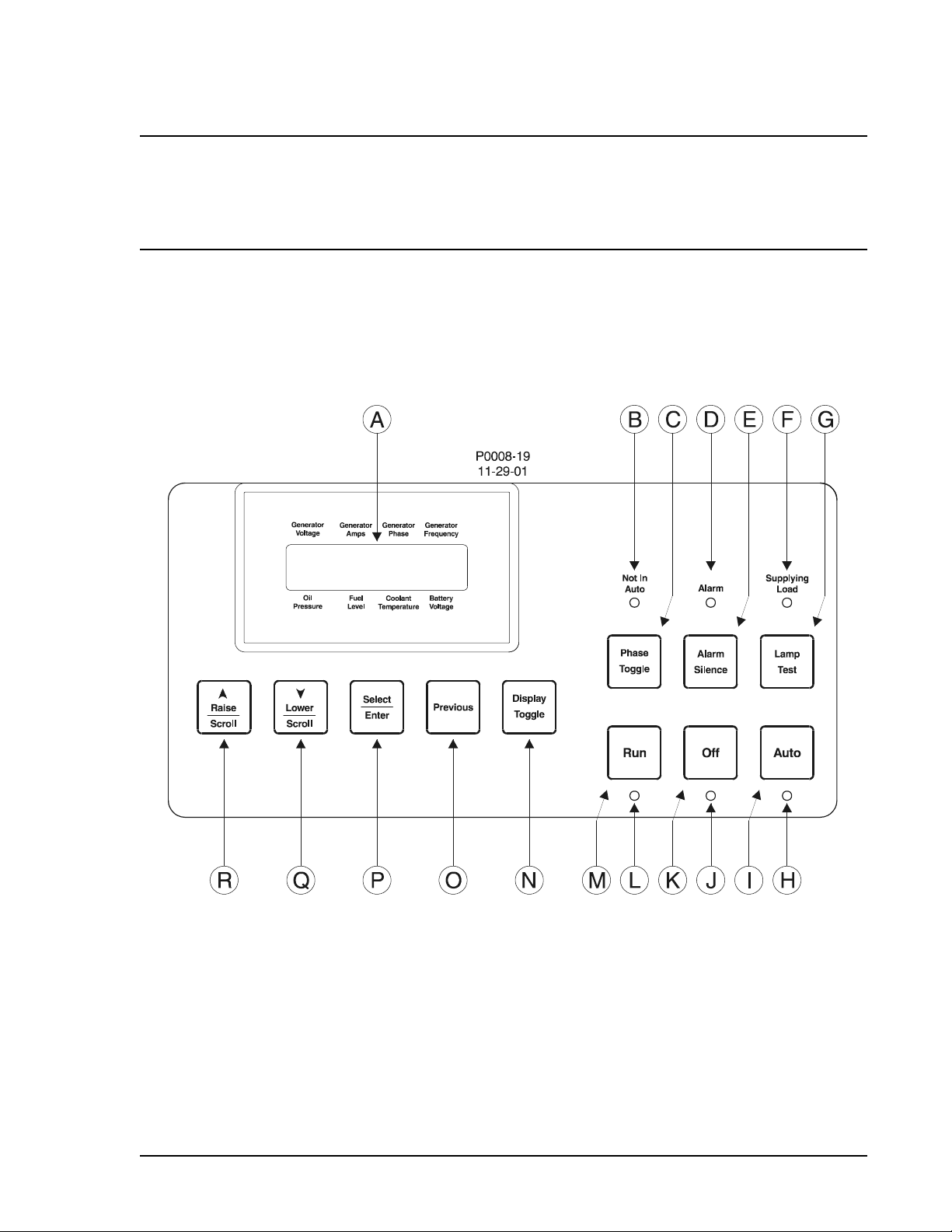

FRONT PANEL

Figure 2-1 illustrates the front panel HMI of the DGC-500. Table 2-1 lists the call-outs of Figure 2-1 along with

a description of each HMI component.

Figure 2-1. DGC-500 Front Panel HMI

DGC-500 HMI 2-1

Page 14

Table 2-1. DGC-500 Front Panel HMI Descriptions

Call-Out Description

A Liquid Crystal Display. The backlit, two line by 16 character LCD is the primary interface

for metering, alarms, pre-alarms, and protective functions. The LCD has three standard

display modes (Normal, Alternate, and Menu) and one optional display mode (ECU

Parameters). In Normal mode, the displayed parameters correspond to one of the eight

labels surrounding the LCD. In Alternate mode, the LCD displays parameters and the

corresponding labels. In Menu mode, the LCD scrolls through the DGC-500 setup

parameters. In the optional ECU Parameters mode, the LCD scrolls through genset

parameters (metered from the ECU) and engine configuration parameters.

B Not in Auto Indicator. This red LED lights when the DGC-500 is not operating in Auto

mode.

C Phase Toggle Pushbutton. Pressing this control scrolls through the parameters available

in Normal display mode.

D Alarm Indicator. This red LED lights continuously during alarm conditions and flashes

during pre-alarm conditions.

E Alarm Silence Pushbutton. Pressing this control resets the DGC-500 audible alarm.

F Supplying Load Indicator. This green LED lights when the generator is supplying more

than two percent of rated current.

G Lamp Test Pushbutton. Pressing this control tests the DGC-500 indicators by exercising

all LCD segments and lighting all LEDS.

H Auto Mode Indicator. This green LED lights when the DGC-500 is operating in Auto mode.

I Auto Pushbutton. Pressing this control places the DGC-500 in Auto mode.

J Off Mode Indicator. This red LED lights when the DGC-500 is in Off mode.

K Off Pushbutton. Pressing this control places the DGC-500 in Off mode.

L Run Mode Indicator. This green LED lights when the DGC-500 is operating in Run mode.

M Run Pushbutton. Pressing this control places the DGC-500 in Run mode.

N Display Toggle Pushbutton. Pressing this control scrolls through the display modes.

O Previous Pushbutton. Pressing this control scrolls through the LCD display modes.

P Select/Enter Pushbutton. This control is pressed to enter menu sub-levels and select

setpoints.

Q Lower/Scroll Pushbutton. This control is pressed to scroll backward through menus or

decrement setpoints.

R Raise/Scroll Pushbutton. This control is pressed to scroll forward through menus or

increment setpoints.

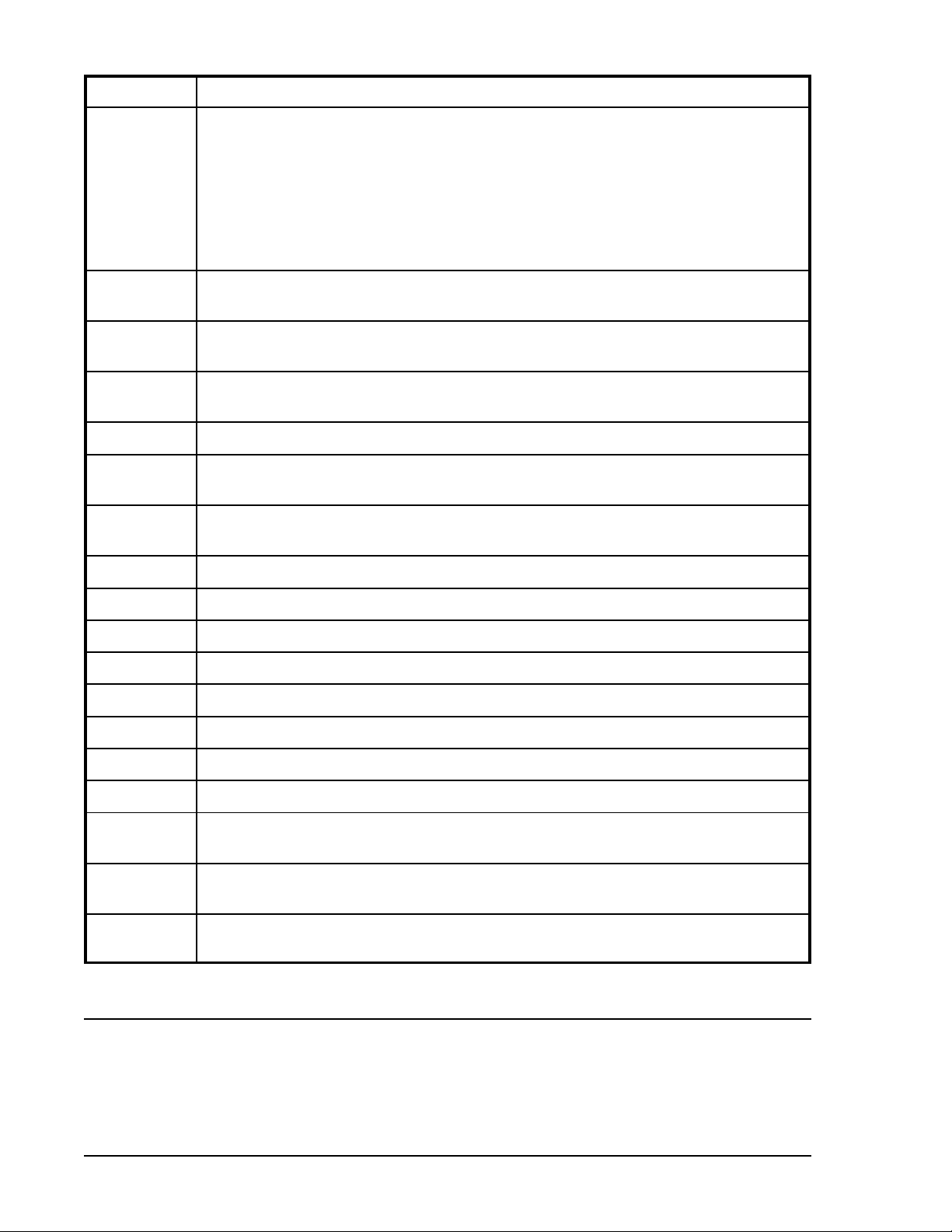

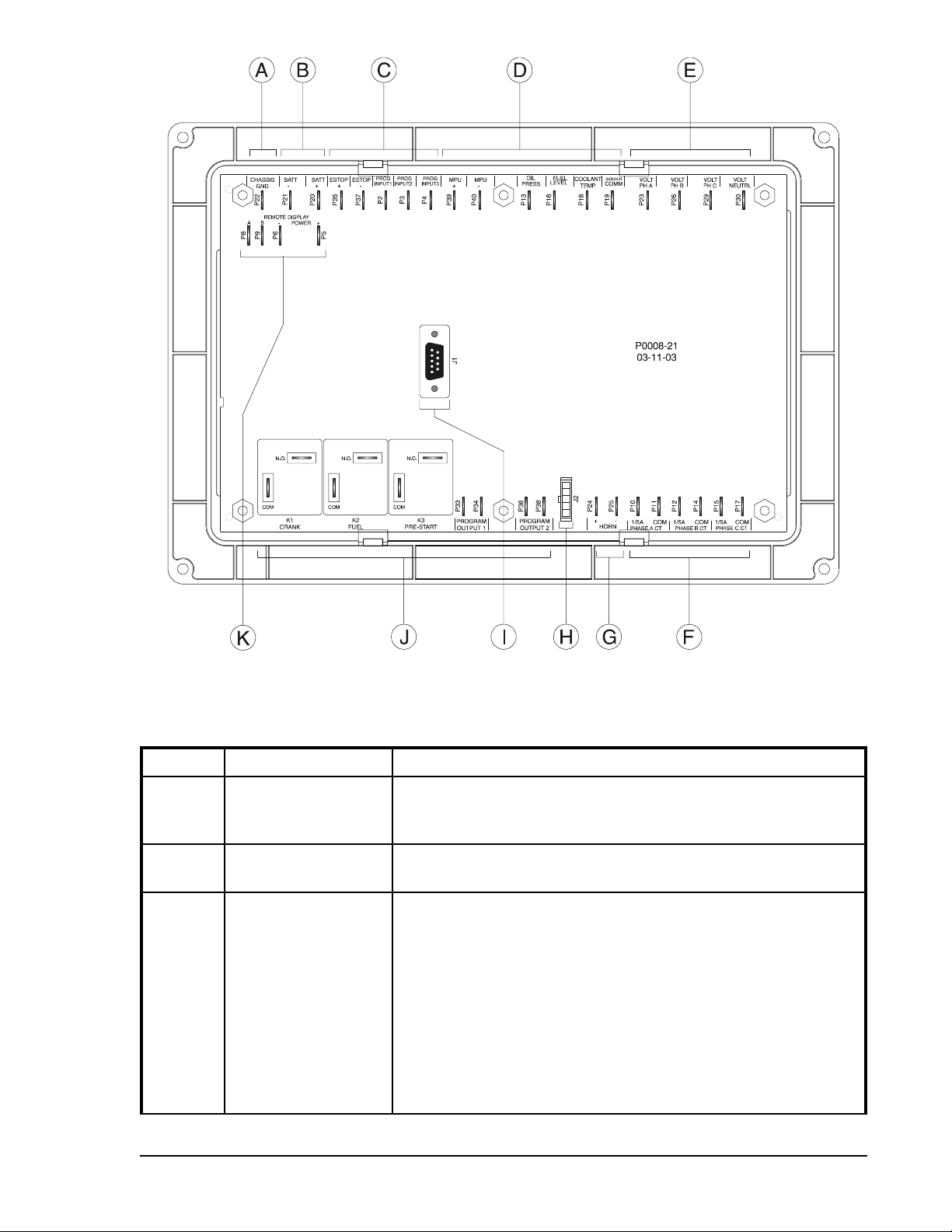

REAR PANEL

All DGC-500 interface terminals are located on the rear panel. DGC-500 units have two types of terminals:

quarter-inch, male, quick-connect terminals and a DB9 serial communication connector. Figure 2-2 illustrates

the DGC-500 rear-panel HMI. Table 2-2 lists the call-outs of Figure 2-2 along with a description of each rearpanel HMI component.

DGC-500 HMI2-2

Page 15

Figure 2-2. DGC-500 Rear Panel HMI

Table 2-2. DGC-500 Rear Panel HMI Descriptions

Call-Out Terminals Description

AP22 CHASSIS GND. This terminal provides the chassis ground

connection. The DGC-500 must be hard-wired to earth ground with

no smaller than 12 AWG copper wire.

B P20 (+), P21 (–) BATT. DGC-500 operating power is applied to these terminals. The

DGC-500 accepts a nominal input of 12 Vdc or 24 Vdc.

C

P35 (+), P37 (–)

P2, P3, P4

DGC-500 HMI 2-3

Contact Sensing Terminals

ESTOP. These terminals function as the Emergency Stop input.

Power is removed from all DGC-500 output relays when this input is

open.

PROG INPUT1, PROG INPUT2, PROG INPUT3. These three inputs

can be independently programmed to function as an auto transfer

switch input, single-phase override input, low coolant level input, fuel

leak detection input, battery charger failure input, or an auxiliary

input. The inputs accept normally-open contacts connected between

terminals P2 (PROG INPUT1), P3 (PROG INPUT2), or P4 (PROG

INPUT3) and terminal P21 (BATT –).

Page 16

Call-Out Terminals Description

D

P39 (+), P40 (–)

Transducer Terminals

MPU. These terminals accept the output from a magnetic pickup.

Voltage applied to this input is scaled and conditioned for use as a

speed signal.

P13

OIL PRESS. The output from an oil pressure transducer is applied to

this input. A current signal lower than 5 mA can be applied between

terminal P13 and P19 (SENDER COMM).

P16

FUEL LEVEL. The output from a fuel level transducer is applied to

this input. The DGC-500 supplies a transducer current signal of less

than 30 mA to terminals P13 and P19 (SENDER COMM).

P18

COOLANT TEMP. The output from a coolant temperature transducer

is applied to this input. The DGC-500 supplies a transducer current

signal of less than 5 mA to terminals P16/P18 and P19 (SENDER

COMM).

P19

SENDER COMM. This terminal functions as the common return line

for all of the transducer inputs.

E

P23

P26

P29

P30

Voltage Sensing Terminals

VOLT PH A. This terminal senses the A-phase generator voltage.

VOLT PH B. This terminal senses the B-phase generator voltage.

VOLT PH C. This terminal senses the C-phase generator voltage.

VOLT NEUTRAL. This terminal connects to the generator Neutral in

phase-to-neutral sensing applications.

F

P10(

1/5A), P11(COM)

1/5A), P14(COM)

P12(

1/5A), P17(COM)

P15(

Current Sensing Terminals

PHASE A CT. These terminals sense the A-phase generator current.

PHASE B CT. These terminals sense the B-phase generator current.

PHASE C CT. These terminals sense the C-phase generator current.

G P24 (+), P25(–) HORN. This output supplies power to an external horn. The voltage

supplied is 24 Vdc or the battery voltage, whichever is less. A

maximum current of 15 mAdc is available.

HJ2 SAE J1939 Connector. This connector is enabled on controllers with

a style number of FXJ

and provides high-speed communication

between the DGC-500 and the ECU on an electronically controlled

engine.

IJ1 RS-232 COMMUNICATION PORT. This DB9 connector uses serial

communication to enhance DGC-500 setup. A standard serial cable

connects the DGC-500 to a PC.

J

K1-N.O., K1-COM

Output Contact Terminals

CRANK. This output is closed when the DGC-500 is initiating engine

cranking.

K2-N.O., K2-COM

FUEL. This output closes when engine cranking is initiated and

remains closed until a stop command is received by the DGC-500.

K3-N.O., K3-COM

PRE-START. This output closes to energize the glow plugs prior to

engine cranking. Depending on system setup, the Pre-Start output

may open upon engine startup or stay closed during engine

operation.

P33, P34

PROGRAM OUTPUT1. This output closes when a userprogrammable condition is detected by the DGC-500.

P36, P38

PROGRAM OUTPUT2. This output closes when a userprogrammable condition is detected by the DGC-500.

2-4

DGC-500 HMI

Page 17

Call-Out Terminals Description

K

P5 (+), P6 (–)

P8 (A), P9 (B)

Remote Display Terminals

Power. These terminals provide operating power to the optional

Remote Display Panel (RDP-110).

Communication. These terminals provide an RS-485 interface for

communication with the optional Remote Display Panel (RDP-110).

DGC-500 HMI

2-5

Page 18

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ............................................. 3-1

INTRODUCTION ............................................................... 3-1

DGC-500 FUNCTION BLOCKS .................................................... 3-1

Power Supply ............................................................... 3-1

Battery Voltage Sensing .................................................... 3-1

Microprocessor.............................................................. 3-1

Zero Crossing Detection .................................................... 3-2

Analog-to-Digital Converter .................................................. 3-2

Voltage Sensing Inputs ....................................................... 3-2

Current Sensing Inputs ........................................................ 3-2

Transducer Inputs ........................................................... 3-2

Oil Pressure.............................................................. 3-2

Coolant Temperature....................................................... 3-2

Fuel Level ............................................................... 3-2

Speed Signal Inputs .......................................................... 3-3

Voltage Sensing Inputs ..................................................... 3-3

Magnetic Pickup Input ...................................................... 3-3

Contact Input Circuitry ........................................................ 3-3

Emergency Stop Input ...................................................... 3-3

Programmable Inputs ...................................................... 3-3

Front Panel HMI ............................................................. 3-3

LCD .................................................................... 3-3

LEDs ................................................................... 3-3

Pushbuttons.............................................................. 3-4

Remote Display Panel ........................................................ 3-4

RS-232 Communication Port ................................................... 3-4

SAE J1939 Interface (Optional) ................................................. 3-4

Diagnostic Trouble Codes (DTCs) ............................................ 3-6

Horn Output ................................................................ 3-7

Output Contacts ............................................................. 3-7

Pre-Start ................................................................ 3-7

Crank ................................................................... 3-7

Fuel .................................................................... 3-7

Programmable ............................................................ 3-8

SOFTWARE OPERATION ........................................................ 3-8

Power-Up Sequence ......................................................... 3-8

Cranking ................................................................... 3-8

Continuous Cranking ....................................................... 3-9

Cycle Cranking ........................................................... 3-9

Pre-Alarms ................................................................. 3-9

Low Oil Pressure .......................................................... 3-9

Low Fuel ................................................................ 3-9

High Coolant Temperature .................................................. 3-9

Low Coolant Temperature................................................... 3-9

Battery Overvoltage........................................................ 3-9

Low Battery Voltage ....................................................... 3-9

Weak Battery Voltage ..................................................... 3-10

Maintenance Interval ...................................................... 3-10

Battery Charger Failure .................................................... 3-10

Fuel Level Sender Failure .................................................. 3-10

MPU Failure............................................................. 3-10

DGC-500 Functional Description i

Page 19

Active DTC ..............................................................3-10

CAN Failure ............................................................. 3-10

Audible Alarm ............................................................3-10

Alarms ....................................................................3-10

Low Oil Pressure .........................................................3-11

Low Fuel Level ...........................................................3-11

High Coolant Temperature .................................................. 3-11

Overspeed ..............................................................3-11

Loss of Generator Voltage ..................................................3-11

Oil Pressure Sender Failure .................................................3-11

Coolant Temperature Sender Failure .......................................... 3-11

Speed Source Failure ......................................................3-11

CAN Failure ............................................................. 3-12

DISPLAY OPERATION .......................................................... 3-12

Normal Mode ............................................................... 3-12

Firmware Version .........................................................3-12

Alternate Mode ............................................................. 3-12

Diagnostic Trouble Codes (DTCs) ............................................3-12

ECU Parameters Mode .......................................................3-14

Engine Configuration Parameters ............................................ 3-16

Menu Mode ................................................................ 3-17

Menu 1 .................................................................3-17

Menu 2 .................................................................3-17

Menu 3 .................................................................3-17

Menu 4 .................................................................3-17

Exiting Menu Mode ........................................................3-17

Changing Settings ........................................................... 3-22

Key Code.................................................................. 3-22

ENGINE CONTROL UNIT (ECU) SUPPORT .........................................3-22

Enabling ECU Support .......................................................3-22

ECU Constraints ............................................................ 3-23

The DGC-500 Solution .....................................................3-23

Alarms and Pre-Alarms .......................................................3-23

Fuel Solenoid Relay .........................................................3-23

Display Values (ECU Support Enabled) ..........................................3-24

ECUs with an External Fuel Solenoid ............................................ 3-24

STATE MACHINES .............................................................3-24

System Configuration ........................................................3-25

Operating States ............................................................ 3-25

State Transitions ............................................................ 3-25

Normal Program Control ......................................................3-25

ECU Power Support Program Control ............................................ 3-26

Initial State - Power Up/Reset ..................................................3-26

Ready State ................................................................ 3-27

Going to Off or Auto-Off ....................................................3-27

Pulsing State ...............................................................3-28

Connecting State ............................................................3-28

Pre-Start State..............................................................3-29

Cranking State..............................................................3-29

Resting State ............................................................... 3-30

Running State ..............................................................3-30

Cooling State ............................................................... 3-31

Shutting Down State .........................................................3-31

Alarm State ................................................................ 3-32

DGC-500 Functional Descriptionii

Page 20

Figures

Figure 3-1. DGC-500 Function Block Diagram ............................................ 3-1

Figure 3-2. Display Mode Navigation .................................................. 3-12

Figure 3-3. Alternate Mode Navigation ................................................. 3-13

Figure 3-4. Lamp Status Screen ...................................................... 3-13

Figure 3-5. DTC Screen Example ..................................................... 3-14

Figure 3-6. ECU Parameters Navigation ................................................ 3-15

Figure 3-7. Engine Configuration Menu Navigation ....................................... 3-16

Figure 3-8. Menu Mode Navigation .................................................... 3-17

Figure 3-9. Menu 1 Navigation ....................................................... 3-18

Figure 3-10. Menu 2 Navigation ...................................................... 3-19

Figure 3-11. Menu 3 Navigation ...................................................... 3-20

Figure 3-12. Menu 4 Navigation ...................................................... 3-21

Figure 3-13. Setting Change Example ................................................. 3-22

Figure 3-14. Screens Shown Following Unsuccessful Information Update from ECU ............. 3-24

Figure 3-15. Normal Program Control Diagram .......................................... 3-26

Figure 3-16. ECU Power Support Program Control Diagram ................................ 3-26

Figure 3-17. Power Up/Reset State Diagram ............................................ 3-27

Figure 3-18. Ready State Diagram .................................................... 3-28

Figure 3-19. Pulsing State Diagram ................................................... 3-28

Figure 3-20. Connecting State Diagram ................................................ 3-29

Figure 3-21. Pre-Start State Diagram .................................................. 3-29

Figure 3-22. Cranking State Diagram .................................................. 3-30

Figure 3-23. Resting State Diagram ................................................... 3-30

Figure 3-24. Running State Diagram ................................................... 3-31

Figure 3-25. Cooling State Diagram ................................................... 3-31

Figure 3-26. Shutting down State Diagram .............................................. 3-32

Figure 3-27. Alarm State Diagram..................................................... 3-32

Tables

Table 3-1. ECU Parameters Obtained from CAN Interface ................................... 3-5

Table 3-2. Engine Configuration Parameters Obtained from CAN Interface ...................... 3-6

Table 3-3. Diagnostic Information Obtained Over the CAN Interface ........................... 3-7

DGC-500 Functional Description iii

Page 21

SECTION 3 • FUNCTIONAL DESCRIPTION

INTRODUCTION

This section describes how the DGC-500 functions and explains its operating features. A detailed description

of each function block is provided in the paragraphs under the heading of DGC-500 Function Blocks.

DGC-500 operating features are described under the heading of Software Operation.

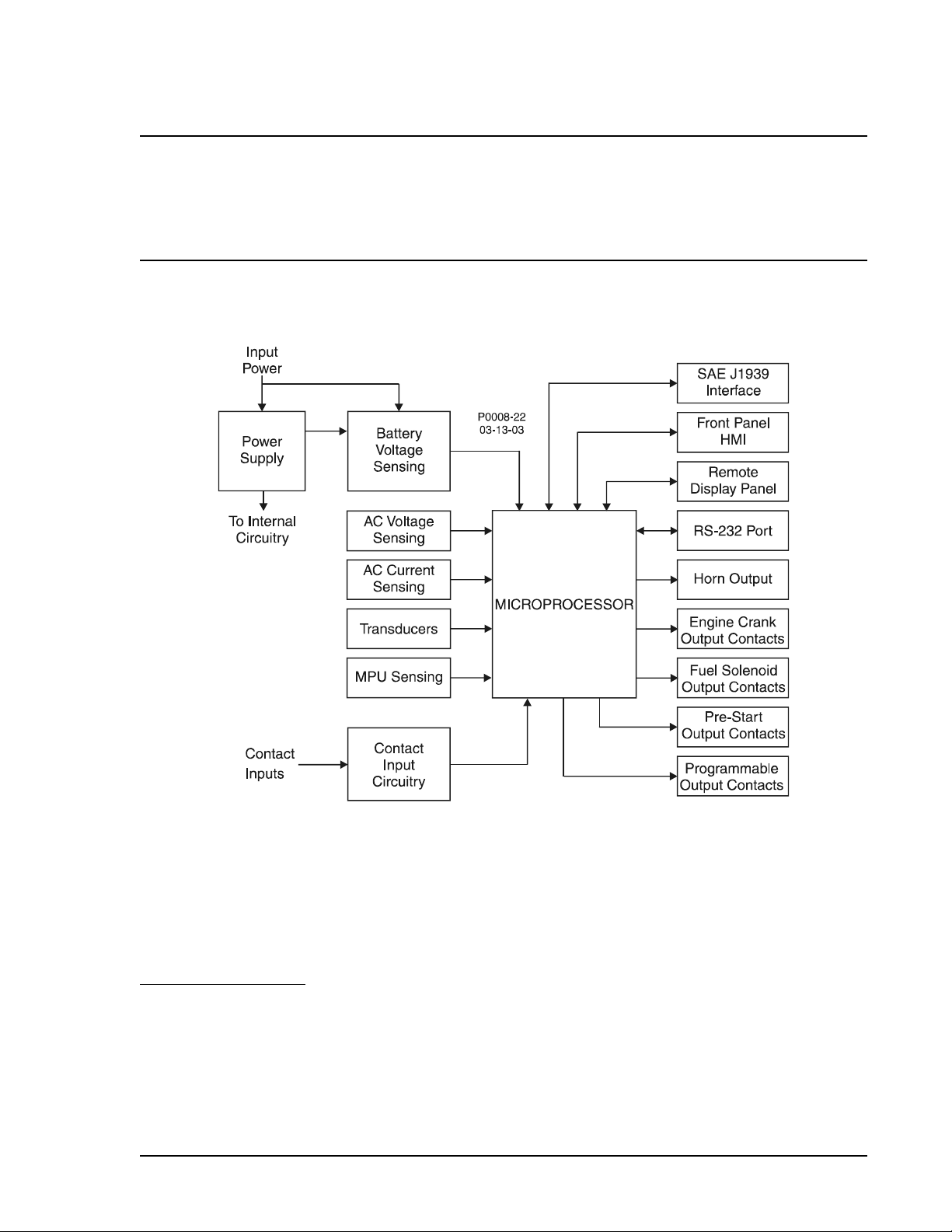

DGC-500 FUNCTION BLOCKS

To ease understanding, DGC-500 functions are illustrated in the block diagram of Figure 3-1. The following

paragraphs describe each function in detail.

Figure 3-1. DGC-500 Function Block Diagram

Power Supply

The internal, switch-mode power supply uses the applied battery voltage to generate operating power for the

internal circuitry of the DGC-500. The power supply accepts a nominal battery voltage of 12 or 24 Vdc and

has an operating range of 8 to 32 Vdc. Battery voltage is applied to terminals P20 (+) and P21 (–).

Battery Voltage Sensing

Voltage applied to the power supply is filtered and reduced to a suitable level for sensing by the

microprocessor.

Microprocessor

The microprocessor controls the overall functionality of the DGC-500 and makes decisions based on

programming and system inputs.

DGC-500 Functional Description 3-1

Page 22

Circuits relating to the microprocessor inputs are described in the following paragraphs.

Zero Crossing Detection

The zero crossing of A-phase to B-phase line voltage is detected and used to calculate the generator

frequency.

Analog-to-Digital Converter

Scaled and conditioned signals representing the sensing voltage, sensing current, coolant temperature, fuel

level, oil pressure, and battery voltage are digitized by the microprocessor’s 10-bit analog-to-digital converter.

The digitized information is stored in random access memory (RAM) and used by the microprocessor for all

metering and protection functions.

Voltage Sensing Inputs

Generator voltages applied to the voltage sensing inputs are scaled to levels suitable for use by the internal

circuitry. Voltage sensing configuration is menu-selectable.

The voltage sensing inputs accept a maximum voltage of 576 Vrms, line-to-line. Sensing voltage is applied

to terminals P23 (A-phase), P26 (B-phase), P29 (C-phase), and P30 (Neutral).

Current Sensing Inputs

Generator currents are sensed and scaled to values suitable for use by the internal circuitry. Isolation is

provided by internal current transformers (CTs).

DGC-500–X1 units accept a maximum current value of 1 Aac. DGC-500–X5 units accept a maximum current

value of 5 Aac. Sensing current is applied to terminals P10 and P11 (A-phase), P12 and P14 (B-phase), and

P15 and P17 (C-phase).

Transducer Inputs

Programmable transducer inputs of the give the DGC-500 user the flexibility to select the transducer to be

used in an application. Information about programming the transducer inputs is provided in Section 6,

BESTCOMS Software.

Oil Pressure

A current of less than 30 milliamperes is provided to the oil pressure transducer. The developed voltage is

measured and scaled for use by the internal circuitry. Oil pressure transducers that are compatible with the

DGC-500 include Isspro model R8919, Stewart-Warner models 279BF, 279C, 411K, and 411M, and VDO

models 360025 and 360811. Other senders may be used. BESTCOMS software allows for the programming

of sender characteristics. See Section 4, BESTCOMS Software for more information.

Oil pressure transducer connections are provided at terminals P13 and P19 (sender common).

Coolant Temperature

A current of less than 1.2 milliamperes is provided to the coolant temperature transducer. The developed

voltage is measured and scaled for use by the internal circuitry. Coolant temperature transducers that are

compatible with the DGC-500 include Isspro model R8959 and Stewart-Warner 334-P. Other senders may

be used. BESTCOMS software allows for the programming of sender characteristics. See Section 4,

BESTCOMS Software for more information.

Coolant temperature transducer connections are provided at terminals P18 and P19 (sender common).

Fuel Level

A current of less than 5 milliamperes is provided to the fuel level transducer. The developed voltage is

measured and scaled for use by the internal circuitry. An open circuit or short circuit across the fuel level

transducer terminals will cause the DGC-500 to indicate a failed fuel level transducer. Fuel level transducers

that are compatible with the DGC-500 include Isspro model R8925. Other senders may be used. BESTCOMS

DGC-500 Functional Description3-2

Page 23

software allows for the programming of sender characteristics. See Section 4, BESTCOMS Software for more

information.

Fuel level transducer connections are provided at terminals P16 and P19 (sender common).

Speed Signal Inputs

The DGC-500 uses signals from the voltage sensing inputs and magnetic pickup input to detect machine

speed.

Voltage Sensing Inputs

Generator voltage applied to the DGC-500 voltage sensing inputs is used to measure frequency and can be

used to measure machine speed.

Sensing voltage is applied to terminals P23 (A-phase), P26 (B-phase), P29 (C-phase), and P30 (Neutral).

Magnetic Pickup Input

The voltage received from the magnetic pickup is scaled and conditioned for use by the internal circuitry as

a speed signal source.

Magnetic pickup connections are provided at terminals P39 (+) and P40 (–).

Contact Input Circuitry

The DGC-500 has four contact sensing inputs: Emergency Stop and three programmable inputs.

Emergency Stop Input

This input accepts Form A, dry contacts. An open circuit at this continuously monitored input initiates an

emergency stop. An emergency stop removes operating power from all DGC-500 output relays.

Emergency stop contact connections are provided at terminals P35 and P37.

Programmable Inputs

Each programmable input (PROG INPUT1, PROG INPUT2, and PROG INPUT3) can be independently

configured as an auto transfer switch input, single-phase override input, low coolant level input, fuel leak

detection input, battery charger failure input, or an auxiliary input. By default, each programmable input is

disabled.

The programmable inputs accept normally open, Form A contacts. A contact is connected between a

programmable input and the negative side of the battery voltage. Through BESTCOMS software, each

programmable contact input can be assigned a name (eight characters, maximum) and configured as an

alarm input, a pre-alarm input, or neither. The default names for the inputs are AUX IN 1, AUX IN 2, and AUX

IN 3. When a programmable contact input is closed, the front panel display shows the name of the closed

input if it was programmed as an alarm or pre-alarm input. Alarm inputs are annunciated through the Normal

display mode screens of the front panel. Pre-alarm inputs are annunciated through the Alternate display mode

screens of the front panel. If neither is programmed, no indication is given. Programming an input as neither

is useful when a programmable input is used to close one of the DGC-500's programmable outputs.

Connections for the programmable inputs are provided at terminals P2 (PROG INPUT1), P3 (PROG INPUT2),

and P4 (PROG INPUT3). The negative side of the battery voltage (terminal P21) serves as the return

connection for the programmable inputs.

Front Panel HMI

The front panel HMI provides a convenient interface for viewing system parameters and for controlling the

DGC-500 and generator operation. Front panel HMI components include an LCD (liquid crystal display), LEDS

(light emitting diodes), and pushbuttons.

LCD

The backlit LCD provides metering, pre-alarm, and alarm information. Detailed information about the LCD is

provided in the Software Operation sub-section.

DGC-500 Functional Description 3-3

Page 24

LEDs

The LEDs indicate pre-alarm and alarm conditions along with DGC-500 status and generator status.

Pushbuttons

The pushbuttons are used to scroll through and select parameters displayed on the LCD, change setpoints,

start and stop the generator, and reset alarms.

Remote Display Panel

Applications that require remote annunciation can use Basler Electric’s Remote Display Panel, RDP-110.

Using the RDP-110 with the DGC-500 meets the requirements of NFPA Standard 110. The RDP-110 uses

a standard, two-terminal RS-485 interface to communicate with the DGC-500 and receives operating power

from the DGC-500. Remote indication of many pre-alarm and alarm conditions is provided by the RDP-110.

The following pre-alarm conditions are indicated by LEDs on the RDP-110 front panel.

C Low coolant temperature

C High coolant temperature

C Low oil pressure

C Weak battery

C Battery overvoltage

C Battery charger failure

C Low fuel level

The following alarm conditions are indicated by LEDs and an audible alarm on the RDP-110 front panel.

C Low coolant level

C High coolant temperature

C Low oil pressure

C Overcrank

C Overspeed

C Emergency stop

C Fuel leak/fuel level sender failure

C Engine sender unit failure

Additionally, the RDP-110 indicates when the DGC-500 is not operating in Auto mode and when the generator

is supplying load.

For more information about the RDP-110, request Basler Product Bulletin SNE-2.

RS-232 Communication Port

The communication port, located on the rear panel, consists of an optically isolated female DB-9 connector.

The RS-232 connector serves as a communication interface for enhances DGC-500 setup. Communication

requires a standard 9-pin serial communication cable connected between the RS-232 communication port and

a PC operating with BESTCOMS-DGC500-32. BESTCOMS is a Windows® based communication software

package that is supplied with the DGC-500. A detailed description of BESTCOMS is provided in Section 4,

BESTCOMS Software for Windows® .

SAE J1939 Interface (Optional)

A Controller Area Network (CAN) is a standard interface that allows communication between multiple

controllers on a common network using a standard message protocol. DGC-500 controllers with a style

number of FXJ

Applications using an engine-driven generator set controlled by a DGC-500 may also have an Engine Control

Unit (ECU). The CAN interface allows the ECU and DGC-500 to communicate. The ECU reports operating

information to the DGC-500 through the CAN interface. Operating parameters and diagnostic information, if

supported by the ECU, are decoded and displayed for monitoring.

The primary use of the CAN interface is to obtain engine operating parameters for monitoring speed, coolant

temperature, oil pressure, coolant level, and engine hours without the need for direct connection to individual

senders. Table 3-1 lists the ECU parameters and Table 3-2 lists the engine configuration parameters

supported by the DGC-500 CAN interface. These parameters are transmitted via the CAN interface at preset

intervals. The columns labeled Update Rate show the parameter transmission rates. This information can also

be transmitted upon user request.

have a CAN interface that supports the SAE J1939 message protocol.

DGC-500 Functional Description3-4

Page 25

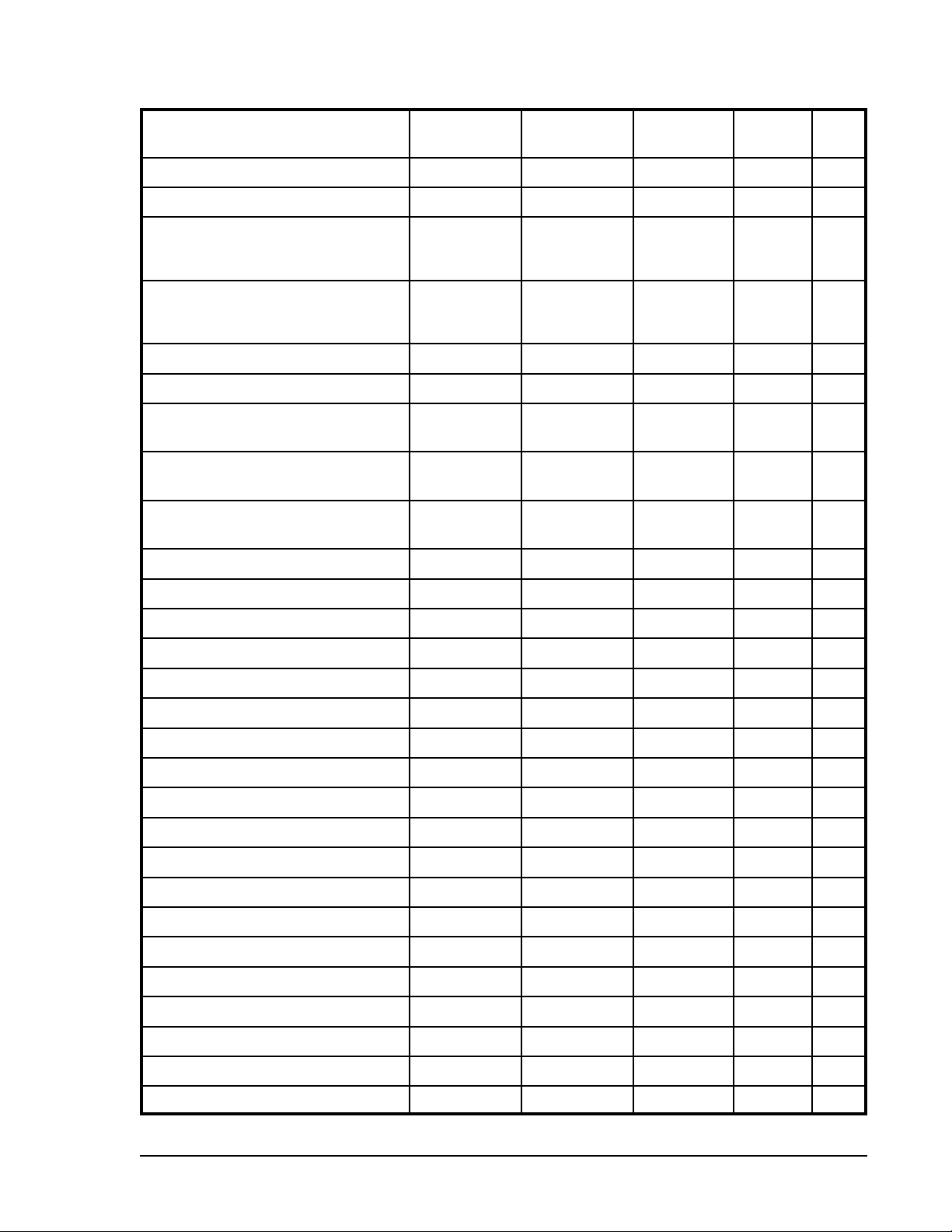

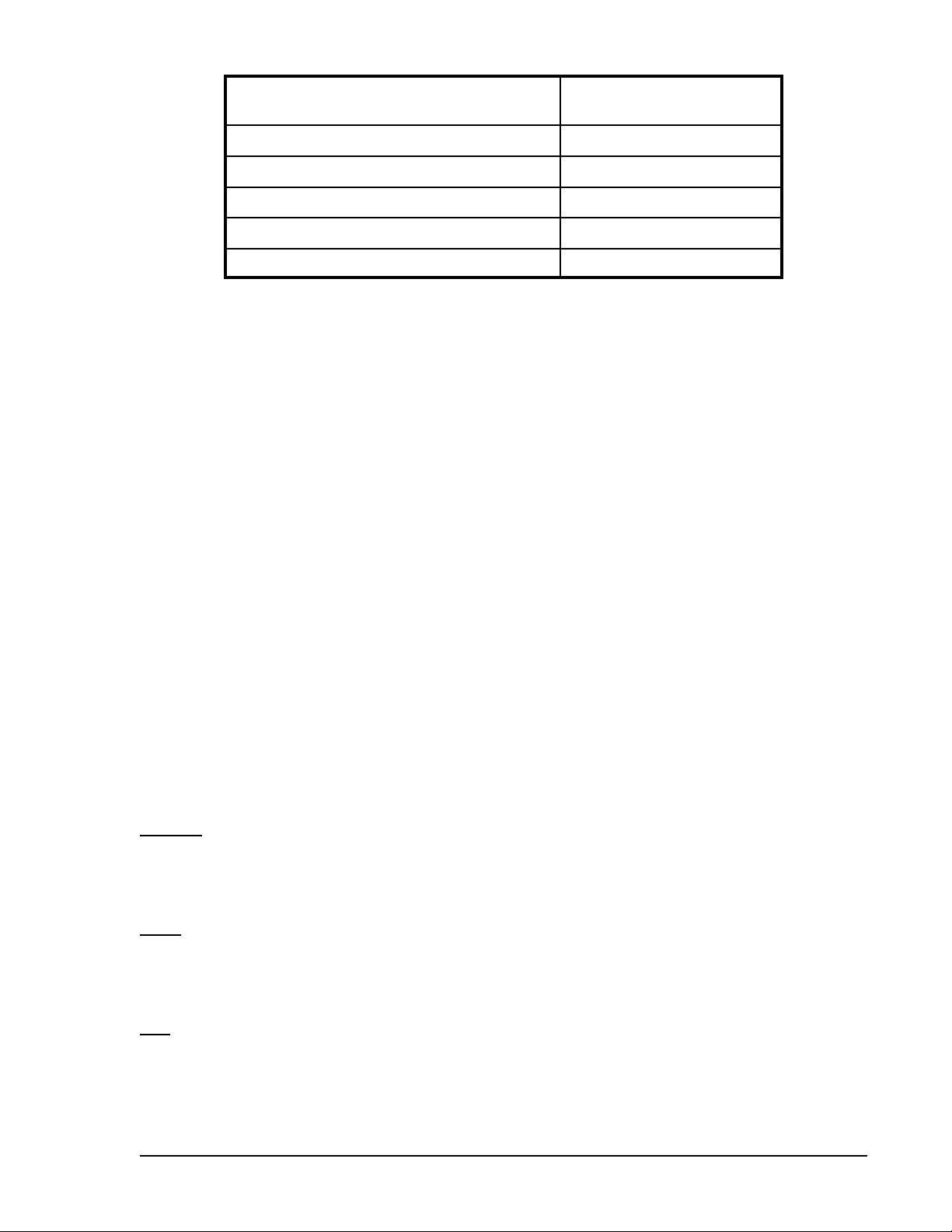

Table 3-1. ECU Parameters Obtained from CAN Interface

t

SPN

ECU Parameter

Metric

Units

English

Units

Update

Rate

Decimal

Place

Throttle (accelerator pedal) position % % 50 ms 10

th

91

Percent load at current rpm % % 50 ms none 92

Actual engine percent torque % % engine

none 513

speed

dependent

Engine speed rpm rpm engine

none 190

speed

dependent

Injection control pressure MPa psi 500 ms none 164

Injector Metering Rail Pressure Mpa psi 500 ms none 157

Total engine hours hours hours requested

100

th

247

1.5 s

Trip fuel liters gallons requested

none 182

1.5 s

Total fuel used liters gallons requested

none 250

1.5 s

Engine coolant temperature °C °F 1 s none 110

Fuel temperature °C °F 1 s none 174

Engine oil temperature °C °F 1 s 10

th

175

Engine intercooler temperature °C °F 1 s none 52

Fuel delivery pressure kPa psi 500 ms 10

Engine oil level % % 500 ms 10

Engine oil pressure kPa psi 500 ms 10

Coolant pressure kPa psi 500 ms 10

Coolant level % % 500 ms 10

Fuel rate liter/hr gal/hr 100 ms 100

Barometric pressure kPa psi 1 s 10

Ambient air temperature °C °F 1 s 10

th

th

th

th

th

th

th

th

94

98

100

109

111

183

108

171

Air inlet temperature °C °F 1 s none 172

Boost pressure kPa psi 500 ms none 102

Intake manifold temperature °C °F 500 ms none 105

Air filter differential pressure kPa psi 500 ms 100

Exhaust gas temperature °C °F 500 ms 10

Battery voltage Vdc Vdc 1 s 10

Switched battery voltage (at ECU) Vdc Vdc 1 s 10

th

107

th

th

th

173

168

158

t SPN is Suspect Parameter Number

DGC-500 Functional Description 3-5

Page 26

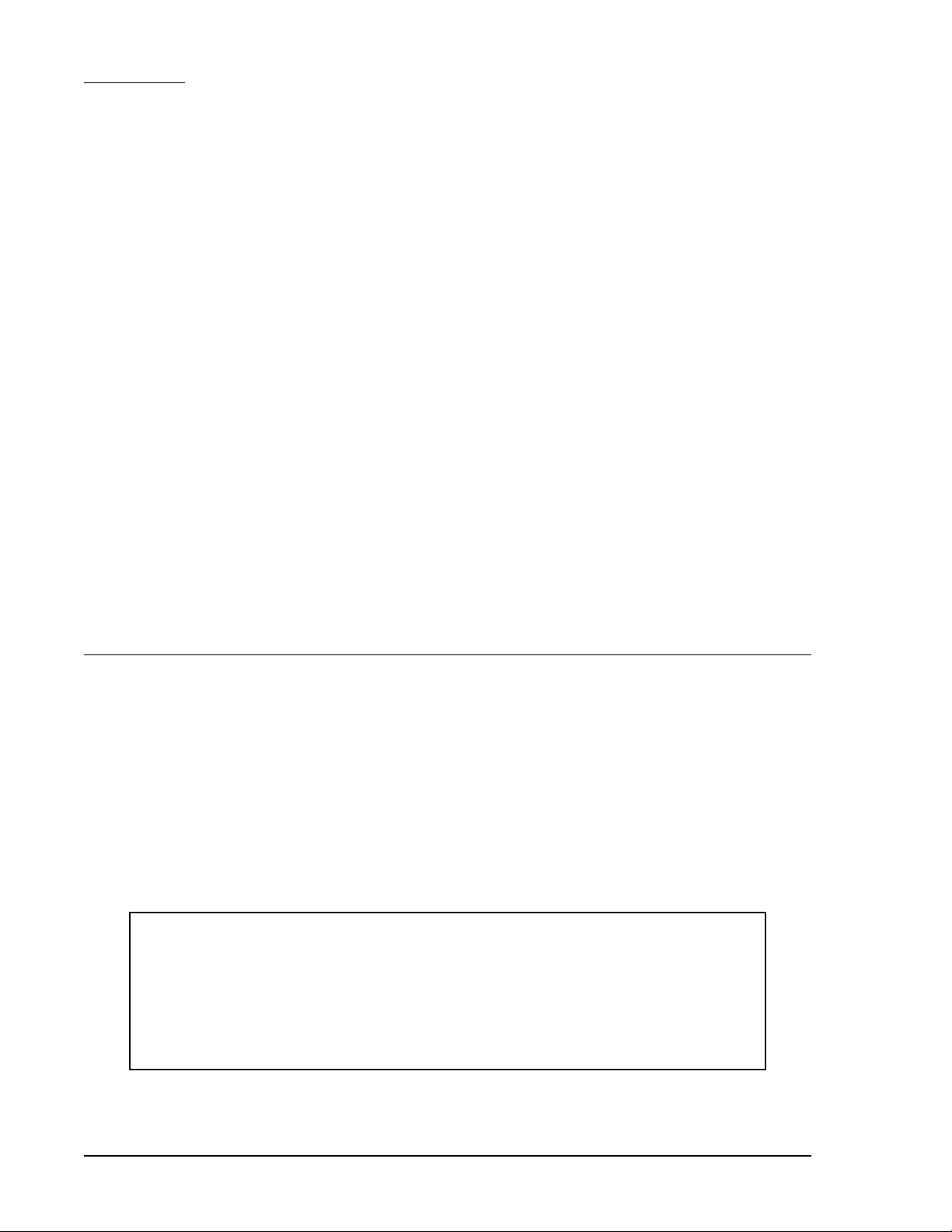

Table 3-2. Engine Configuration Parameters Obtained from CAN Interface

t

Engine Configuration Parameter

Metric

Units

English

Units

Update

Rate

Decimal

Place SPN

Engine speed at idle point 1 rpm rpm 5 s none 188

Percent torque at idle point 1 % % 5 s none 539

Engine speed at point 2 rpm rpm 5 s none 528

Percent torque at point 2 % % 5 s none 540

Engine speed at point 3 rpm rpm 5 s none 529

Percent torque at point 3 % % 5 s none 541

Engine speed at point 4 rpm rpm 5 s none 530

Percent torque at point 4 % % 5 s none 542

Engine speed at point 5 rpm rpm 5 s none 531

Percent torque at point 5 % % 5 s none 543

Engine speed at high idle point 6 rpm rpm 5 s none 532

Gain (KP) of endspeed governor %/rpm %/rpm 5 s 100

th

545

Reference engine torque Nm ft-lb 5 s none 544

Maximum momentary engine

rpm rpm 5 s none 533

override speed point 7

Maximum momentary engine

seconds seconds 5 s 10

th

override time limit

Requested speed control range

rpm rpm 5 s none 535

lower limit

Requested speed control range

rpm rpm 5 s none 536

upper limit

Requested torque control range

% % 5 s none 537

lower limit

Requested torque control range

% % 5 s none 538

upper limit

t Press the Select pushbutton to enter the Engine Configuration submenu. Press the Previous

pushbutton to exit the submenu.

CAUTION

When the CAN interface is enabled, the DGC-500 will ignore the following

sender inputs: oil pressure, coolant temperature, and magnetic pickup.

534

Diagnostic Trouble Codes (DTCs)

The DGC-500 obtains the diagnostic condition of the transmitting electronic components. The DGC-500 will

receive an unsolicited message of a currently active diagnostic trouble code (DTC). Previously active DTCs

are available upon request. Active and previously active DTCs can be cleared on request. Table 3-3 lists the

diagnostic information that the DGC-500 obtains over the CAN interface.

DGC-500 Functional Description3-6

Page 27

Table 3-3. Diagnostic Information Obtained Over the CAN Interface

Transmission

Parameter

Active diagnostic trouble code 1 s

Lamp status 1 s

Previously active diagnostic trouble code on request

Request to clear previously active DTCs on request

Request to clear active DTCs on request

DTCs are reported in coded diagnostic information that includes the Suspect Parameter Number (SPN),

Failure Mode Identifier (FMI), and Occurrence Count (OC). All parameters have an SPN and are used to

display or identify the items for which diagnostics are being reported. The FMI defines the type of failure

detected in the subsystem identified by an SPN. The reported problem may not be an electrical failure but a

subsystem condition needing to be reported to an operator or technician. The OC contains the number of

times that a fault has gone from active to previously active.

Horn Output

This output connects to a user-supplied audible signal device. A change in operating status or an alarm

condition energizes the horn output continuously and a pre-alarm condition pulses the horn output on and off.

The annunciation continues until the condition subsides or until the front-panel Alarm Silence pushbutton is

pressed.

Repetition Rate

The horn output supplies 15 mAdc maximum at the lesser of 24 Vdc or the battery voltage level. A horn

compatible with the DGC-500 is available from Basler Electric as part number 29760. Horn output connections

are located at terminals P24 (+) and P25 (–).

Output Contacts

All output contacts are electrically isolated from each other and from the DGC-500 internal circuitry. Output

contact operation is controlled by the operating mode of the DGC-500 and the system. The output contacts

are also affected by the status of the Emergency Stop contact input. When the Emergency Stop contact input

is open (emergency stop condition), all output contacts open. When the Emergency Stop contact input is

closed, all output contacts operate normally.

Five output contacts are available: Pre-Start, Engine Crank, Fuel Solenoid, and two Programmable output

contacts.

Pre-Start

This output closes to energize the engine glow plugs. The Pre-Start output can be programmed to close up

to 30 seconds prior to engine cranking. The Pre-Start output can also be programmed to open upon engine

startup or remain closed as long as the engine is operating.

Crank

This output closes when engine cranking is initiated by the DGC-500. The length of time that the contacts

remain closed is determined by the cranking style selected (either continuous or cycle). Cranking continues

until the magnetic pickup or generator frequency indicates that the engine has started.

Fuel

This output closes when engine cranking is initiated by the DGC-500. The Fuel output remains closed until

an off command is issued and the engine stops.

DGC-500 Functional Description 3-7

Page 28

Programmable

Two programmable outputs (PROGRAM OUTPUT1, 2) can be user-configured to close for a variety of

conditions.

Either programmable output can be programmed to close during any of the following operating conditions.

C Cooldown timer active

C EPS supplying load

C Pre-start condition in effect

C Programmable Input 1 closed

C Programmable Input 2 closed

C Programmable Input 3 closed

C Switch not in Auto

Either of the programmable outputs can be configured to give a pre-alarm indication by closing during any of

the following pre-alarm conditions.

C Battery charger failure

C Battery overvoltage

C Fuel leak

C Fuel leak/sender failure

C High coolant temperature

C Low battery voltage

Either of the programmable outputs can be configured to give an alarm indication by closing during any of the

following alarm conditions.

C Battery charger

C Coolant temperature sender failure

C Emergency stop

C Fuel leak

C High coolant temperature

C Loss of voltage sender failure

C Low coolant level

C Low coolant temperature

C Low fuel

C Low oil pressure

C Scheduled maintenance due

C Weak battery voltage

C Low fuel

C Low oil pressure

C MPU speed sender failure

C Oil pressure sender failure

C Overcrank

C Overspeed

C Low coolant level

SOFTWARE OPERATION

Embedded software controls all aspects of DGC-500 operation. DGC-500 software controls power-up

initiation, HMI configuration, engine cranking, contact input monitoring, fault detection and annunciation,

system parameter monitoring, output contact control, and communication.

Power-Up Sequence

When battery power is applied, the DGC-500 initiates a power-up sequence. During power-up, DGC-500

memory is checked and the LCD displays the embedded software version. Then, all configuration data stored

in nonvolatile EEPROM (electronically erasable programmable read-only memory) is brought into main

memory and the DGC-500 begins operating in Normal mode. When operating in Normal mode, all enabled

functions are active and all inputs are monitored.

NOTE

The run-time counter and maintenance timer values are updated in volatile memory once per

minute. Updated values are saved to nonvolatile memory when the Auto/Off/Run mode of

operation is changed. Additionally, while the engine is running, the run-time counter value is

saved to nonvolatile memory every 15 minutes. If the battery power source fails during DGC500 operation, these values are not updated and the changes made after the last save

operation to nonvolatile memory are irretrievably lost.

Cranking

The DGC-500 can be programmed for either continuous engine cranking or cycle engine cranking.

DGC-500 Functional Description3-8

Page 29

Continuous Cranking

If desired, engine cranking can be delayed from zero to 30 seconds after initiating engine startup. When

continuous engine cranking is initiated, cranking is sustained for a user-adjustable period of one to 60

seconds. A crank disconnect limit setting (10 to 100% of nominal engine speed) selects the desired engine

speed above which cranking is terminated.

Cycle Cranking

If desired, engine cranking can be delayed from zero to 30 seconds after initiating engine startup. When cycle

engine cranking is initiated, five to 15 seconds of cranking is followed by an equal number of seconds of rest.

A maximum of seven cranking cycles (five cycles for NFPA compliant units) are allowed by the DGC-500. A

crank disconnect limit setting (10 to 100% of nominal engine speed) selects the desired engine speed above

which cranking is terminated.

Pre-Alarms

A pre-alarm is annunciated when a condition programmed to trigger a pre-alarm is met. When a pre-alarm

condition exists, the front panel Alarm indicator flashes on and off and the Horn output (if enabled through

BESTCOMS) alternates between an energized and de-energized state. The audible alarm is reset by pressing

the front panel Alarm Silence pushbutton.

Active pre-alarms for oil pressure, fuel level, coolant temperature, and battery voltage are displayed on the

main display of the LCD. The LCD annunciates an active pre-alarm by alternating between the current

parameter value and a blacked-out field for that value. All other pre-alarms are displayed in sequence through

the alternate mode display.

Each DGC-500 pre-alarm is described in the following paragraphs.

Low Oil Pressure

A low oil pressure pre-alarm occurs when the engine oil pressure decreases below the setpoint programmed

in BESTCOMS. The low oil pressure pre-alarm has a setting range of 3 to 150 psi or 20 to 1,035 kPa. A 10

second activation time delay prevents low oil pressure annunciation during engine startup.

Low Fuel

A low fuel pre-alarm occurs when the fuel level decreases below the setpoint programmed in BESTCOMS.

The low fuel pre-alarm has a setting range of 10 to 100 percent.

High Coolant Temperature

A high coolant temperature pre-alarm occurs when the engine coolant temperature exceeds the setpoint

programmed in BESTCOMS. The high coolant temperature pre-alarm has a setting range of 100 to 280°F or

38 to 138°C. A 60 second activation time delay prevents high coolant temperature annunciation during system

startup.

Low Coolant Temperature

A low coolant temperature pre-alarm occurs when the engine coolant temperature decreases below the

setpoint programmed in BESTCOMS. The low coolant temperature pre-alarm has a setting range of 50 to

100°F or 10 to 38°C.

Battery Overvoltage

A battery overvoltage pre-alarm occurs when the battery overvoltage pre-alarm function is enabled in

BESTCOMS and the battery voltage level exceeds 30 Vdc for 24 Vdc system or 15 Vdc for 12 Vdc systems.

Low Battery Voltage

A low battery voltage pre-alarm occurs when the battery voltage decreases below the low battery voltage

setpoint for the duration of the low battery voltage time delay setting. Both settings are made in BESTCOMS.

The low battery voltage setpoint has a setting range of 12 to 24 Vdc for 24 Vdc systems and 6 to 12 Vdc for

12 Vdc systems. The low battery voltage time delay has a setting range of 1 to 10 seconds.

DGC-500 Functional Description 3-9

Page 30

Weak Battery Voltage

A weak battery voltage pre-alarm occurs when the battery voltage decreases below the weak battery voltage

setpoint for the duration of the weak battery voltage time delay setting. Both settings are made in BESTCOMS.

The weak battery voltage setpoint has a setting range of 8 to 16 Vdc for 24 Vdc systems and 4 to 8 Vdc for

12 Vdc systems. The weak battery voltage time delay has a setting range of 1 to 10 seconds.

Maintenance Interval

A maintenance interval pre-alarm occurs when the DGC-500 maintenance timer counts down to zero from

the maintenance interval setting programmed in BESTCOMS. The maintenance interval duration has a setting

range of zero to 5,000 hours.

Battery Charger Failure

A battery charger failure pre-alarm occurs when one of the three DGC-500 programmable contact inputs

detects a contact closure due to a battery charger failure. In order for a battery charger failure pre-alarm to

occur, the battery charger failure pre-alarm function must be enabled in BESTCOMS and one of the three

programmable inputs must be programmed as a battery charger failure pre-alarm input. Refer to Section 4,

BESTCOMS Software for information about configuring the programmable contact inputs.

Fuel Level Sender Failure

A fuel level sender failure pre-alarm occurs when an open circuit or short circuit is detected across the DGC500 fuel level transducer terminals and a fuel level sender failure is programmed in BESTCOMS to cause a

pre-alarm.

MPU Failure

An MPU (magnetic pickup) failure pre-alarm occurs when MPU-GEN is selected as the generator speed signal

source, the MPU signal is lost, and the Global Sender Failure Alarm time delay expires.

Active DTC

When CAN and DTC support are both enabled, an “active DTC” pre-alarm may be enabled (through

BESTCOMS) to announce the presence of an condition that is causing a DTC to be sent from the ECU to the

DGC-500.

CAN Failure

A CAN failure annunciation may be enabled only when the CAN interface is enabled. The CAN interface is

enabled through BESTCOMS. When configured to alarm, annunciation occurs when CAN communication

stops due to a lost connection between the DGC-500 and ECU, or an ECU malfunction. If CAN

communication is lost and the annunciation is a pre-alarm, a screen stating the pre-alarm will appear in the

Alternate Display menu. This screen will be viewable only when the pre-alarm is active.

Audible Alarm

A pre-alarm is annunciated through the DGC-500 Horn output when the audible alarm feature is enabled in

BESTCOMS. When the audible alarm is enabled, a pre-alarm condition causes the horn output to alternate

between an energized and de-energized state.

Alarms

An alarm is annunciated when a condition programmed to trigger an alarm is detected. When an alarm

condition exists, the front panel Alarm indicator lights, the Horn output energizes, and the cause of the alarm

is displayed on the LCD.

An alarm condition stops the engine by opening the Fuel output contact.

Each DGC-500 alarm is described in the following paragraphs.

DGC-500 Functional Description3-10

Page 31

Low Oil Pressure

A low oil pressure alarm occurs when the engine oil pressure decreases below the low oil pressure alarm

setpoint for the duration of the low oil pressure time delay setting. Both settings are made in BESTCOMS.

When a low oil pressure alarm occurs, the LCD indicates LOW OIL PRESSURE and the current low oil

pressure alarm setting. A 10 second activation time delay prevents low oil pressure annunciation during

engine startup.

The low oil pressure setpoint has a setting range of 3 to 150 psi or 20 to 1,035 kPa and the low oil pressure

time delay has a setting range of 5 to 15 seconds.

Low Fuel Level

A low fuel level alarm occurs when the fuel level decreases below the setpoint programmed in BESTCOMS.

When a low fuel level alarm occurs, the LCD indicates LOW FUEL LEVEL and the current low fuel level alarm

setting.

The low fuel level setpoint has a setting range of zero to 100 percent.

High Coolant Temperature

A high coolant temperature alarm occurs when the coolant temperature exceeds the setpoint programmed

in BESTCOMS. When a high coolant temperature alarm occurs, the LCD indicates HIGH COOLANT TEMP

and the current high coolant temperature setting. A 60 second activation time delay prevents high coolant

temperature annunciation during system startup.

The high coolant temperature setpoint has a setting range of 100 to 280°F or 38 to 138°C.

Overspeed

An overspeed alarm occurs when the engine speed exceeds the overspeed setpoint for the duration of the

overspeed time delay. Both settings are made in BESTCOMS. When an overspeed alarm occurs, the LCD

indicates OVERSPEED and the current overspeed setting.

The overspeed setpoint has a setting range of 105 to 140 percent and the overspeed time delay has a setting

range of zero to 500 milliseconds.

Loss of Generator Voltage

A loss of generator voltage alarm can occur only when the loss of generator voltage alarm is enabled in

BESTCOMS. When the sensed generator voltage decreases below 1.5 Vac for the duration of the global

sender failure alarm time delay, a loss of generator voltage alarm occurs. The global sender failure alarm time

delay is adjustable from 1 to 10 seconds.

Oil Pressure Sender Failure

An oil pressure sender failure alarm occurs when the DGC-500 oil pressure transducer input senses a sender

failure for the duration of the global sender failure alarm time delay. The oil pressure sender failure alarm is

enabled and the global sender failure alarm time delay is set in BESTCOMS.

Coolant Temperature Sender Failure

A coolant temperature sender failure alarm occurs when the DGC-500 coolant temperature transducer input

senses a sender failure for the duration of the coolant temperature alarm delay time. The coolant temperature

sender failure alarm is enabled and the coolant temperature alarm delay is set in BESTCOMS. The coolant

temperature alarm delay is adjustable from 5 to 30 minutes in 5 minute increments.

Speed Source Failure

A speed source failure can occur for either of two conditions. If MPU (magnetic pickup) is selected as the

generator speed signal source and the MPU signal is lost, a speed source failure alarm will occur. If GEN

FREQ (generator frequency) is selected as the generator speed signal source and a loss of generator

frequency is detected, a speed source failure alarm will occur.

DGC-500 Functional Description 3-11

Page 32

CAN Failure (If Equipped)

A CAN failure annunciation may be enabled only when the CAN interface is enabled. The CAN interface is

enabled through BESTCOMS. When configured to pre-alarm, annunciation occurs when CAN communication

stops due to a lost connection between the DGC-500 and ECU, or an ECU malfunction. If CAN

communication is lost and the annunciation is configured as an alarm, then a normal alarm sequence will

occur, including a CANBUS FAILURE message that appears on the HMI display.

DISPLAY OPERATION

The DGC-500 has three standard display modes: Normal, Alternate, and Menu. The optional ECU Parameters

mode is present only on controllers with a style number of F1J or F5J. Pressing the Display Toggle

pushbutton scrolls through the active screen of each available display mode. Figure 3-2 illustrates the top-level

screen of the standard and optional display modes.

Figure 3-2. Display Mode Navigation

Normal Mode

Normal mode displays various engine and generator parameters. Each parameter is displayed adjacent to

the corresponding label on the front panel overlay.

Firmware Version

Normal mode also displays the firmware version of the DGC-500.

The DGC-500 firmware version is viewed in Normal mode by pressing and holding either the Raise/Scroll

pushbutton or Lower/Scroll pushbutton. Releasing either pushbutton returns the display to the current Normal

mode screen.

Alternate Mode

Press the Raise/Scroll or Lower/Scroll pushbuttons while viewing the top-level Alternate mode screen

(Figure 3-2) to scroll through the available engine and generator metering values. Figure 3-3 illustrates the

Alternate mode screens for a DGC-500 configured for three-phase, line-to-neutral operation. Units configured

for three-phase, line-to-line operation do not display the GEN A-N VOLTS, GEN B-N VOLTS, and GEN C-N

VOLTS screens. Units configured for single-phase, A-phase to B-phase operation do not display the GEN B-C

VOLTS, GEN C-A VOLTS, and GEN C-N VOLTS screens.

Diagnostic Trouble Codes (DTCs)

When the optional SAE J1939 communication is enabled, access to the Diagnostic Trouble Codes (DTCs)

is available through the Alternate Display mode. The DTCs are the last two screens in the Alternate mode

display list.

If there are no DTCs to be sent to the DGC-500, pressing the Select/Enter pushbutton will have no effect,

and the messages ACTIVE DTC LIST and NO DTCS TO VIEW will be displayed. If at least one DTC is

communicating with the DGC-500, pressing the Select/Enter pushbutton will display ACTIVE DTC LIST and

VIEW WITH SELECT.

Pressing the Select/Enter pushbutton when ACTIVE DTC LIST and VIEW WITH SELECT is displayed places

the DGC-500 in DTC mode. The next screen to appear will display the diagnostic lamp status information

obtained from the ECU. One of five possible lamp status messages will be displayed. The lamp status

messages, in decreasing order of priority, are listed below.

DGC-500 Functional Description3-12

Page 33

1. ENG STOP LAMP ON

2. WARNING LAMP ON

3. MALFUNC LAMP ON

4. PROTECT LAMP ON

5. NO LAMP IS ON

Figure 3-3. Alternate Mode Navigation

Only one lamp status will be displayed on the front panel—the highest priority one that is true. An example

of the lamp status screen is shown in Figure 3-4. BESTCOMS may also be used to view the status of all

lamps.

Figure 3-4. Lamp Status Screen

To be notified that a lamp status exists, the pre-alarm for active DTCs must be enabled through BESTCOMS.

When one or more active DTCs exist in the ECU, a lamp status indicating the severity of the combined DTCs

should exist. After the pre-alarm is annunciated (by LED indicator, horn, and/or dial-out), the operator will

know to check the lamp status, active system DTCs, and what relationship the DTCs have with the

parameters. To check the DTC/parameter relationship at the front panel, access the ECU Parameters menu

of the HMI. In BESTCOMS, hover the mouse pointer over the DTC to see its related parameter.

To use the HMI to view the list of active DTCs, press the Raise/Scroll pushbutton. The next screen to appear

will display the first DTC, the number of DTCs, the Suspect Parameter Number (SPN), the Failure Mode

Indicator (FMI) and the Occurrence Count (OC).

DGC-500 Functional Description 3-13

Page 34

NOTE

Always refer to the engine manual for the meaning of SPN and FMI combinations,

especially for proprietary DTC descriptions.

In the DTC screen example of Figure 3-5, the first DTC of five is displayed.

The SPN is 111 (coolant level), the FMI is 1 (low voltage from the sender,