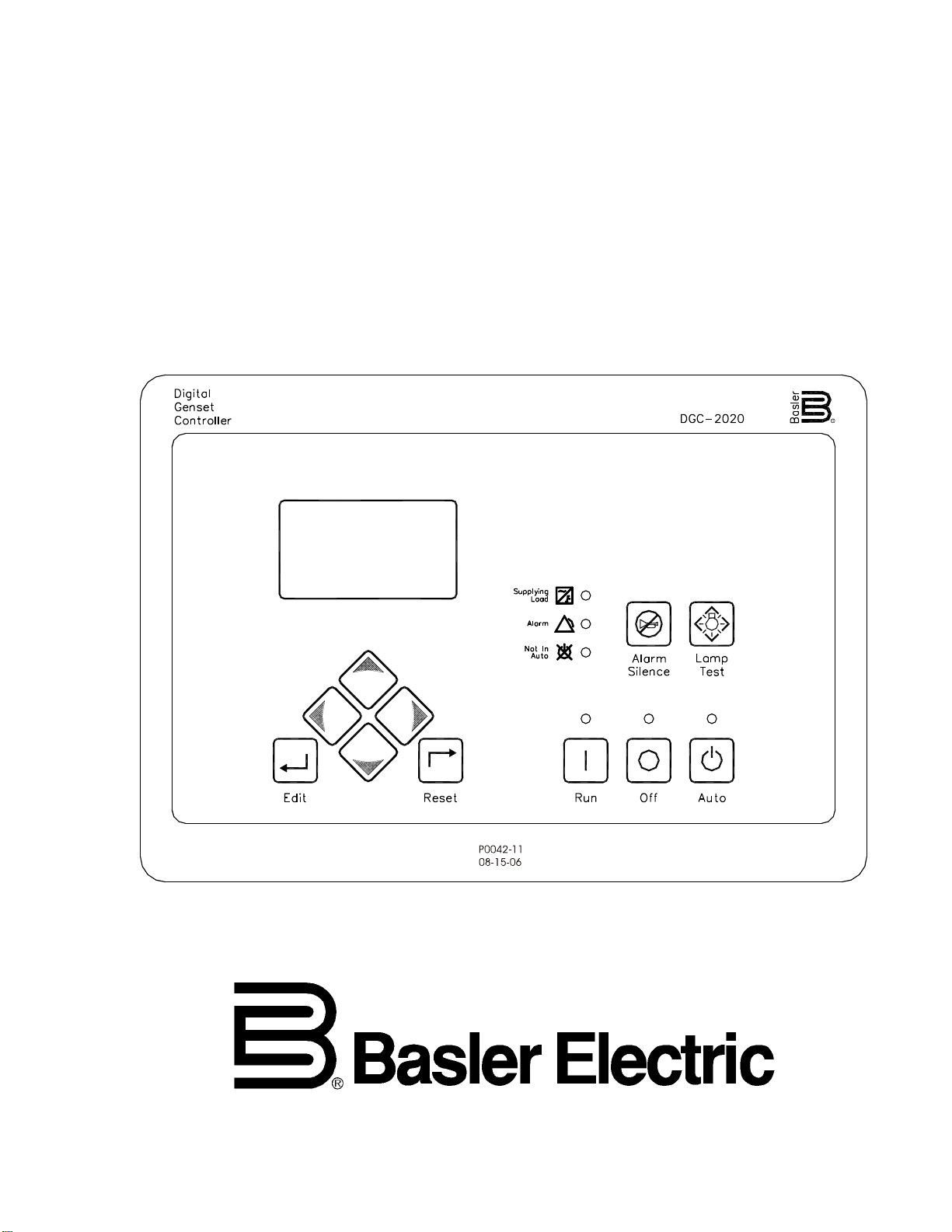

Page 1

INSTRUCTION MANUAL

FOR

DIGITAL GENSET CONTROLLER

DGC-2020

****

Publication: 9400200990

Revision: B 11/06

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the DGC-2020 Digital

Genset Controller. To accomplish this, the following information is provided:

• General Information and Specifications

• Controls and Indicators

• Functional Description

• Graphical User Interface Operation

• Installation

• Maintenance and Troubleshooting

• Appendices containing Time Overcurrent Characteristic Curves and Modbu s™ Communication

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the controller is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the chassis ground terminal on the rear of the unit.

When the controller is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9400200990 Rev B DGC-2020 Introduction i

Page 4

First Printing: September 2006

Printed in USA

© 2006 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

November 2006

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject

to return on request, and with the mutual understanding that it will not be used in

any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

ROUTE 143, BOX 269

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii DGC-2020 Introduction 9400200990 Rev B

Page 5

PRODUCT REVISION HISTORY

The following information provides a historical summary of the changes made to the embedded software

(firmware), PC software (BESTCOMSPlus), and hardware of the DGC-2020. The corresponding revisions

made to this instruction manual (9400200990) are also summarized. Revisions are listed in chronological

order.

Firmware Version Change

1.00.04, 11/06

BESTCOMSPlus Version Change

1.00.07, 11/06

Hardware Version Change

—, 10/06

Manual Revision Change

B, 11/06

• Initial release

• Initial release

• Initial release

• Initial release

9400200990 Rev B DGC-2020 Introduction iii

Page 6

This page intentionally left blank.

iv DGC-2020 Introduction 9400200990 Rev B

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • HUMAN-MACHINE INTERFACE....................................................................................... 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION...........................................................................................3-1

SECTION 4 • BESTCOMSPlus SOFTWARE...........................................................................................4-1

SECTION 5 • BESTlogic+ PROGRAMMABLE LOGIC............................................................................. 5-1

SECTION 6 • INSTALLATION .................................................................................................................. 6-1

SECTION 7 • MAINTENANCE AND TROUBLESHOOTING.................................................................... 7-1

APPENDIX A • TIME OVERCURRENT CHARACTERISTIC CURVES...................................................A-1

APPENDIX B • MODBUS™ COMMUNICATION......................................................................................B-1

9400200990 Rev B DGC-2020 Introduction v

Page 8

This page intentionally left blank.

vi DGC-2020 Introduction 9400200990 Rev B

Page 9

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

DESCRIPTION....................................................................................................................................... 1-1

FEATURES............................................................................................................................................ 1-1

FUNCTIONS .......................................................................................................................................... 1-1

Generator Protection and Metering.................................................................................................... 1-1

Engine Protection and Metering......................................................................................................... 1-1

Event Recording................................................................................................................................. 1-1

Auto-Synchronizer.............................................................................................................................. 1-1

Contact Inputs and Output Contacts .................................................................................................. 1-1

Automatic Transfer Switch Control (Mains Failure)............................................................................ 1-2

Communication................................................................................................................................... 1-2

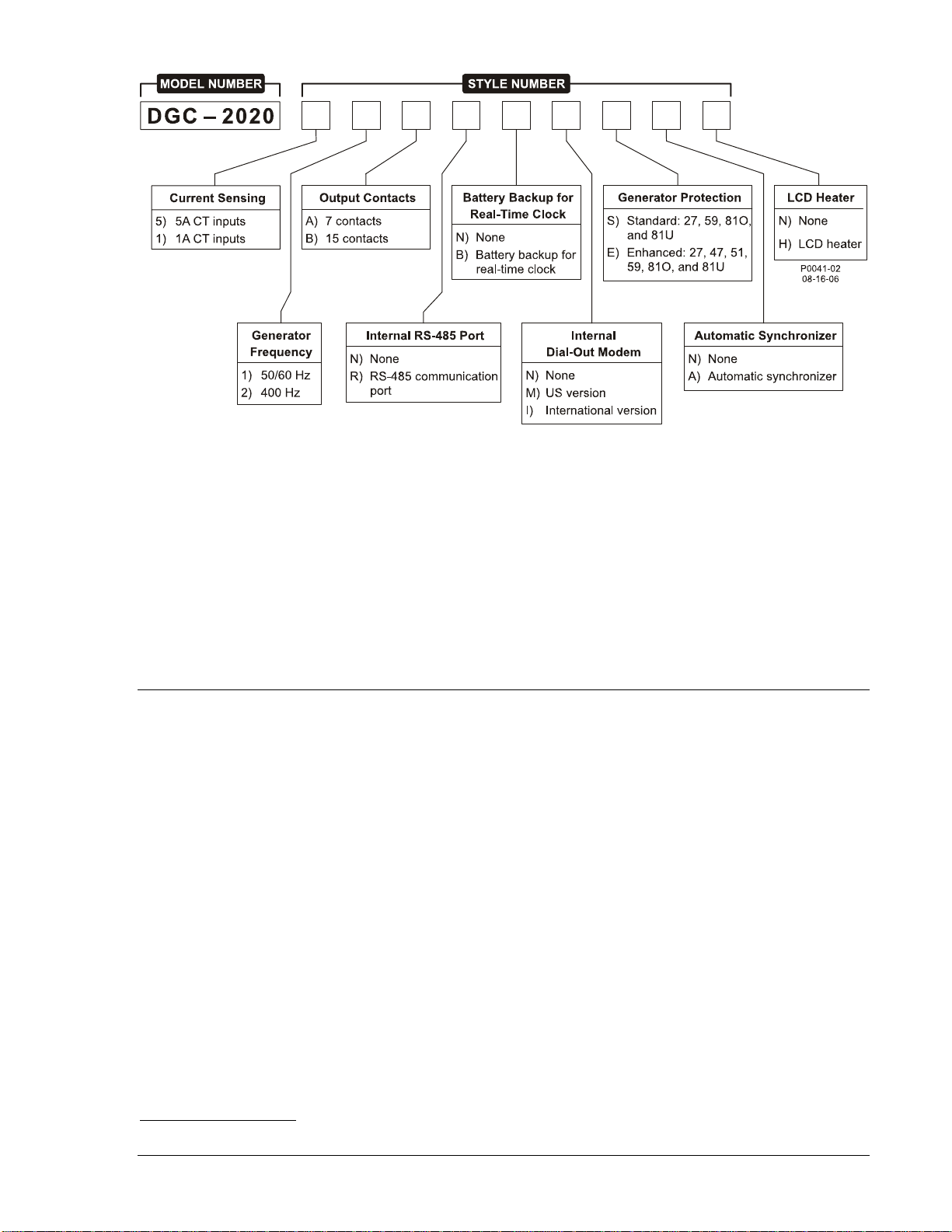

STYLE NUMBER ................................................................................................................................... 1-2

SPECIFICATIONS ................................................................................................................................. 1-3

Operating Power ................................................................................................................................ 1-3

Power Consumption ........................................................................................................................... 1-3

Battery Ride Through ......................................................................................................................... 1-3

Current Sensing ................................................................................................................................. 1-3

Voltage Sensing ................................................................................................................................. 1-4

Contact Sensing ................................................................................................................................. 1-4

Engine System Inputs ........................................................................................................................ 1-4

Output Contacts ................................................................................................................................. 1-5

Metering.............................................................................................................................................. 1-5

Generator Protection Functions ......................................................................................................... 1-7

Logic Timers....................................................................................................................................... 1-7

Communication Interface ................................................................................................................... 1-8

Real-Time Clock................................................................................................................................. 1-8

Type Tests.......................................................................................................................................... 1-9

Environment ....................................................................................................................................... 1-9

Agency Approvals .............................................................................................................................. 1-9

CE Compliance ................................................................................................................................ 1-10

Physical ............................................................................................................................................ 1-10

Figures

Figure 1-1. DGC-2020 Style Chart ............................................................................................................ 1-3

9400200990 Rev B DGC-2020 General Information i

Page 10

This page intentionally left blank.

ii DGC-2020 General Information 9400200990 Rev B

Page 11

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

The DGC-2020 Digital Genset Controller provides integrated engine-genset control, protection, and

metering in a single package. Microprocessor based technology allows for exact measurement, setpoint

adjustment, and timing functions. Front panel controls and indicators enable quick and simple DGC-2020

operation. Basler Electric communication software (BESTCOMSPlus) allows units to be easily customized

for each application. Because of the low sensing burden in the DGC-2020, dedicated potential

transformers (PTs) are not required. A wide temperature-range liquid crystal display (LCD) with

backlighting can be viewed under a wide range of ambient light and temperature conditions.

FEATURES

DGC-2020 Digital Genset Controllers have the following features:

• Local and Remote Generator Control

• Engine and Generator Protection

• Programmable Analog Engine Senders

• ECU Communications via SAE J1939

• 16 Programmable Contact Inputs

• Programmable Logic

• Automatic Transfer Switch Control (Mains Failure)

• Integrated RS485

• Auto Synchronizing

FUNCTIONS

DGC-2020 Digital Genset Controllers perform the following functions:

Generator Protection and Metering

Multifunction generator protection guards against generator overvoltage, undervoltage, underfrequency,

and overfrequency. Overcurrent and phase imbalance protection is available as an option. Each

generator protection function has an adjustable pickup and time delay setting. Sixteen inverse time

curves enable the DGC-2020 to offer overcurrent protection in a variety of applications.

Metered generator parameters include voltage, current, real power (watts), apparent power (VA), and

power factor (PF).

Engine Protection and Metering

Engine protection features include oil pressure and coolant temperature monitoring, overcrank protection,

ECU specific protection elements, and diagnostic reporting.

Metered engine parameters include, oil pressure, coolant temperature, battery voltage, speed, fuel level,

engine load, coolant level (from ECU), ECU specific parameters, and run-time statistics.

Event Recording

An event log retains a history of system events in nonvolatile memory. Up to 30 event types are retained

and each record contains a time stamp of the first and last occurrence, and the number of occurrences for

each event.

Auto-Synchronizer

An optional automatic synchronizer monitors the bus and generator voltages and supplies discrete

raise/lower correction signals to synchronize the generator voltage, frequency, and slip angle with that of

the bus.

Contact Inputs and Output Contacts

DGC-2020 controllers have one, dedicated emergency stop contact input and 16 programmable contact

inputs. All contact inputs recognize dry contacts. The programmable inputs can be configured to initiate a

9400200990 Rev B DGC-2020 General Information 1-1

Page 12

pre-alarm or alarm. A programmable input can be programmed to receive an input from an automatic

transfer switch or override DGC-2020 alarms and protection functions. Each programmable input can be

assigned a user-defined name for easy identification at the front panel display and in fault records.

Output contacts include three dedicated relays for energizing an engine’s glow plugs, fuel solenoid, and

starter solenoid. An additional four user-programmable output contacts are provided if the style number is

xxAxxxxxx. If the style number is xxBxxxxxx, an additional twelve output contacts are provided.

Additional contact inputs and output contacts can be accommodated with separate I/O modules. Contact

Basler Electric for availability and ordering information.

Automatic Transfer Switch Control (Mains Failure)

The DGC-2020 has the ability to detect a mains failure via a single-phase Bus input. A mains failure is

established when any one of the following conditions are met:

• Bus voltage falls below dead bus threshold

• Bus voltage unstable due to overvoltage or undervoltage

• Bus voltage unstable due to overfrequency or underfrequency

At this time, the DGC-2020 will start the genset and when ready, apply power to the load via the genset.

When the mains returns and is considered stable, the DGC-2020 will transfer the load back to the mains.

Communication

Standard DGC-2020 communication features include a standard USB port and SAE J1939 interface.

Optional communication features include a dial-out modem and RS-485 communication port.

USB Port

A USB communication port can be used with BESTCOMSPlus software to quickly configure a DGC-2020

with the desired settings or retrieve metering values and event log records.

CANBus Interface

A CANBus interface provides high-speed communication between the DGC-2020 and the engine control

unit (ECU) on an electronically controlled engine. This interface provides access to oil pressure, coolant

temperature, and engine speed data by reading these parameters directly from the ECU. When available,

engine diagnostic data can also be accessed. The CANBus interface supports the following protocols:

• SAE J1939 Protocol - Oil pressure, coolant temperature, and engine speed data are received from

the ECU. In addition, DTCs (Diagnostic Trouble Codes) help diagnose any engine or related failures.

The engine DTCs are displayed on the front panel of the DGC-2020 and may be obtained using

BESTCOMSPlus software.

MTU/MDEC Protocol - A DGC-2020 connected to a genset equipped with an MTU MDEC receives

•

Oil pressure, coolant temperature, and engine speed data from the engine controller, along with

various alarms and pre-alarms that are MDEC specific. In addition, the DGC-2020 tracks and displays

the active fault codes issued by the MDEC ECU.

Dial-Out Modem

One of two optional, dial-out modems (a US version or international version) enables remote control,

monitoring, and setting of the DGC-2020. When an alarm or pre-alarm condition occurs, the DGC-2020

can dial up to four telephone numbers, in sequence, until an answer is received and the condition is

annunciated.

RS-485 Port

An optional RS-485 communication port uses the Modbus communication protocol and enables remote

control and monitoring of the DGC-2020 over a polled network.

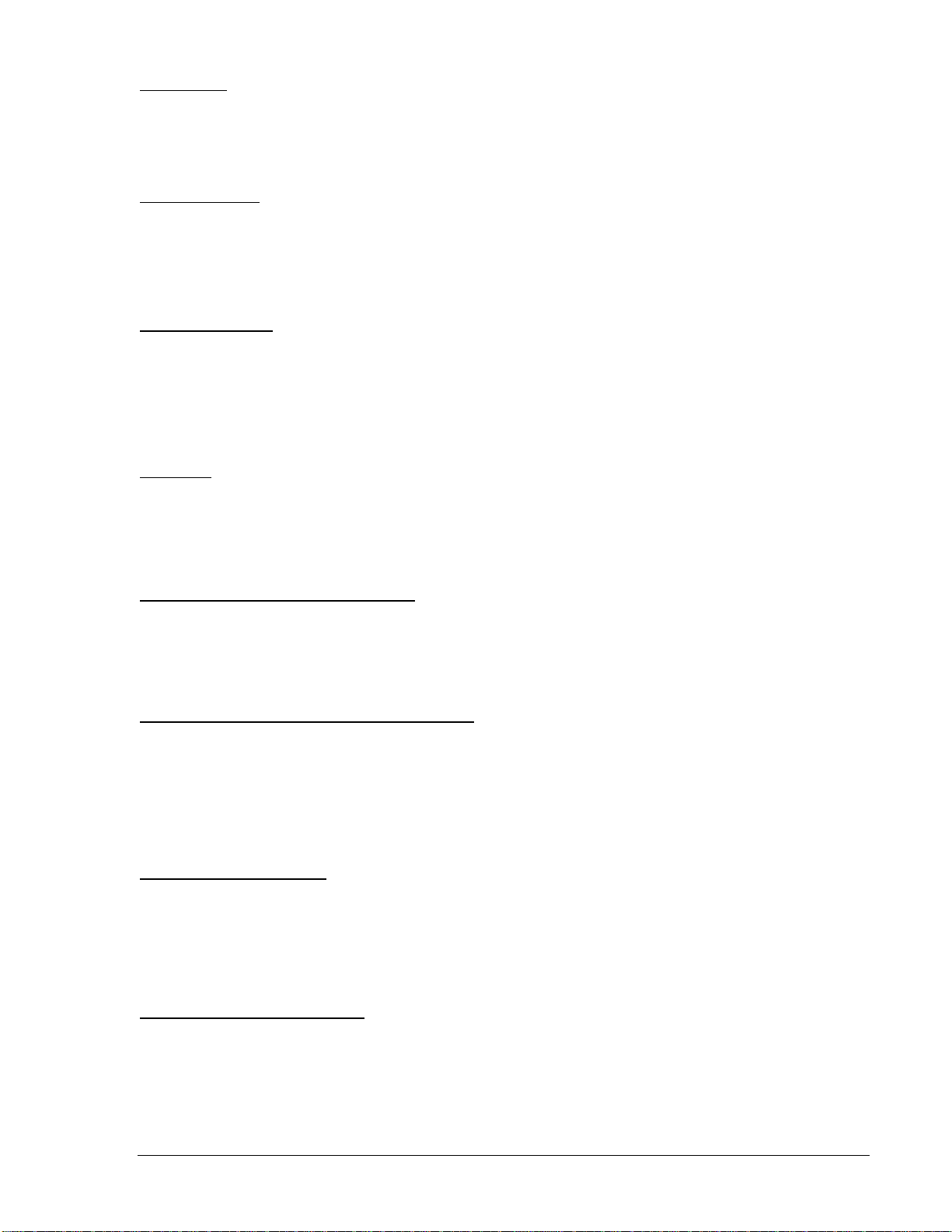

STYLE NUMBER

Standard-order DGC-2020 controllers are identified by a style number which consists of a combination of

letters and numbers that define the controller’s electrical characteristics and operational features. The

model number, together with the style number, describe the options included in a specific controller.

Figure 1-1 illustrates the DGC-2020 style number identification chart.

1-2 DGC-2020 General Information 9400200990 Rev B

Page 13

Figure 1-1. DGC-2020 Style Chart

For example, if a DGC-2020 style number is 51BNBMEAH, the controller would have the following

characteristics and operating features.

5 5 Aac current sensing inputs

1 50/60 hertz nominal generator frequency

B 3 fixed-function output contacts and 12 programmable output contacts

N No RS-485 communication port

B Battery backup for real-time clock during losses of control power

M Internal dial-out modem—US version

E Enhanced generator protection (undervoltage, phase imbalance, overcurrent, overvoltage,

overfrequency, and underfrequency)

A Auto-synchronizer

H LCD heater

SPECIFICATIONS

Operating Power

Nominal: 12 or 24 Vdc

Range: 6 to 32 Vdc (Withstands cranking ride-through down to 6 Vdc

for 500 ms.)

Terminals: 3 (+), 2 (–), 1 (chassis ground)

Power Consumption

Sleep Mode: 5W with all relays non-energized

Normal Operational Mode: 7.9W - Run mode, LCD heater off, 3 relays energized

Maximum Operational Mode: 14.2W - Run mode, LCD heater on, 6 relays energized

Battery Ride Through

Withstands cranking ride-through down to 0 V for 50 ms.

Current Sensing

Burden: 1 VA

Terminals: 68, 69 (A-phase)

71, 72 (B-phase)

74, 75 (C-phase)

1 Aac Current Sensing

Continuous Rating: 0.02 to 1.0 Aac

9400200990 Rev B DGC-2020 General Information 1-3

Page 14

1 Second Rating: 2 Aac

5 Aac Current Sensing

Continuous Rating: 0.1 to 5.0 Aac

1 Second Rating: 10 Aac

Voltage Sensing

Configuration: Line-to-line or line-to-neutral

Range: 12 to 576 V rms, line-to-line

Frequency: Style selectable, 50/60 Hz or 400 Hz

Frequency Range: 10 to 72 Hz for 50/60 style and 10 to 480 Hz for 400 Hz style

Burden: 1 VA

1 Second Rating: 720 V rms

Generator Sensing Terminals: 41 (A-phase)

39 (B-phase)

37 (C-phase)

35 (Neutral)

Bus Sensing Terminals: 45 (A-phase)

43 (B-phase)

Contact Sensing

Contact sensing inputs include 1 emergency stop input and 16 programmable inputs. The emergency

stop input accepts normally closed, dry contacts. All programmable inputs accept normally open, dry

contacts.

Terminals

Emergency Stop: 46, 47

Programmable

Input 1: 30, 2

Input 2: 29, 2

Input 3: 28, 2

Input 4: 27, 2

Input 5: 26, 2

Input 6: 25, 2

Input 7: 24, 2

Input 8: 23, 2

Input 9: 22, 2

Input 10: 21, 2

Input 11: 20, 2

Input 12: 19, 2

Input 13: 18, 2

Input 14: 17, 2

Input 15: 16, 2

Input 16: 15, 2

Engine System Inputs

∗ Stated accuracies are subject to the accuracy of the senders used.

Fuel Level Sensing

Resistance Range: 33 to 240 Ω nominal

Terminals: 9, 11 (sender common)

Coolant Temperature Sensing

Resistance Range: 62.6 to 637.5 Ω nominal

Terminals: 10, 11 (sender common)

Oil Pressure Sensing

Resistance Range: 34 to 240 Ω nominal

Terminals: 8, 11 (sender common)

1-4 DGC-2020 General Information 9400200990 Rev B

Page 15

Engine Speed Sensing

Magnetic Pickup

Voltage Range: 3 to 35 V peak (6 to 70 V peak-peak)

Frequency Range: 32 to 10,000 Hz

Terminals: 31 (+), 32 (–)

Generator Voltage

Range: 12 to 576 V rms

Terminals: 41 (A-phase)

39 (B-phase)

37 (C-phase)

Output Contacts

Fuel Solenoid, Engine Crank, and Pre-Start Relays

Rating: 30 Adc at 28 Vdc—make, break, and carry ∗

Terminals

Fuel Solenoid: RUN – NO, COM

Pre-Start: PRE – NO, COM

Crank: START – NO, COM

Programmable Relays (12)

Rating: 2 Adc at 30 Vdc—make, break, and carry

Terminals†

Output 1: 52, 51 (common)

Output 2: 53, 51 (common)

Output 3: 54, 51 (common)

Output 4: 56, 55 (common)

Output 5: 57, 55 (common)

Output 6: 58, 55 (common)

Output 7: 60, 59 (common)

Output 8: 61, 59 (common)

Output 9: 62, 59 (common)

Output 10: 64, 63 (common)

Output 11: 65, 63 (common)

Output 12: 66, 63 (common)

∗ Contact rating is reduced for units used in hazardous locations.

† The number of programmable output contacts provided is determined by the output contacts

character of the DGC-2020 style number. Controllers with output contacts option A have 4 program-

mable outputs (Outputs 1, 2, 3, and 4). Controllers with output contacts option B have 12

programmable outputs.

The programmable relays share common terminals: terminal 51 is used for outputs 1, 2, and 3,

terminal 55 is used for outputs 4, 5, and 6, terminal 59 is used for outputs 7, 8, and 9, 63 is used for

outputs 10, 11, and 12.

Metering

Generator Voltage (rms)

Metering Range: 0 to 576 Vac (direct measurement)

577 to 9,999 Vac (through VT using VT ratio setting)

VT Ratio Range: 1:1 to 125:1 in primary increments of 1

Accuracy: ∗ ±1.0% of programmed rated voltage or ±2 Vac

Display Resolution: 1 Vac

∗ Voltage metering indicates 0 V when generator voltage is below 2% of the full-scale rating.

Generator Current (rms)

Generator current is measured at the secondary windings of user-supplied 1 A or 5 A CTs.

Metering Range: 0 to 5,000 Aac

9400200990 Rev B DGC-2020 General Information 1-5

Page 16

CT Primary Range: 1 to 5,000 Aac in primary increments of 1 Aac

Accuracy: ∗ ±1.0% of programmed rated current or ±2 Aac

Display Resolution: 1 Aac

∗ Current metering indicates 0 A when generator current is below 2% of the full-scale rating.

Generator Frequency

Generator frequency is sensed through the generator voltage input.

Metering Range: 10 to 72 Hz (50/60 Hz)

10 to 480 (400 Hz)

Accuracy: ±0.25% or 0.05 Hz

Display Resolution: 0.1 Hz

Apparent Power

Indicates total kVA and individual line kVA (4-wire, line-to-neutral or 3-wire, line-to-line).

Measurement/Calculation Methods

Total: kVA = (V

× IL ×√3) ÷ 1000

L-L

4-Wire, Line-to-Neutral: kVA calculated with respect to neutral

3-Wire, Line-to-Line: A-phase kVA = V

B-phase kVA = V

C-phase kVA = V

× IA ÷ 1000 ÷ √3

AB

× IB ÷ 1000 ÷ √3

BC

× IC ÷ 1000 ÷ √3

CA

Accuracy: ±3% or the full-scale indication or ±2 kVA ∗†

∗ kVA metering indicates 0 kVA when the generator kVA is below 2% of the full-scale rating.

† Applies when temperature is between -40°C to +70°C.

Power Factor

Metering Range: 0.2 leading to 0.2 lagging

Calculation Method: PF = P (3-phase average) ÷ S (3-phase average)

Accuracy: ±0.02 ∗

∗ Applies when temperature is between -40°C to +70°C.

Real Power

Indicates total kW and individual line kW (4-wire, line-to-neutral or 3-wire line-to-line)

Measurement/Calculation Methods

Total: PF × Total kVA

4-Wire, Line-to-Neutral: kW calculated with respect to neutral

3-Wire, Line-to-Line: A-phase kW = V

B-phase kVA = V

C-phase kVA = V

× IA × PF ÷ 1000 ÷ √3

AB

× IB × PF ÷ 1000 ÷ √3

BC

× IC × PF ÷ 1000 ÷ √3

CA

Accuracy: ±3% of the full-scale indication or ±2 kW ∗†

∗ kW metering indicates 0 kW when the generator kW is below 2% of the full-scale rating.

† Applies when temperature is between -40°C to +70°C.

Oil Pressure

Metering Range: 0 to 145 psi or 0 to 1,000 kPa

Accuracy: ±3% of actual indication or ±2 psi or ±12 kPa (subject to accuracy of

sender)

Display Resolution: 1 psi or 1 kPa

Coolant Temperature

Metering Range: –40 to 410°F or –40 to 210°C

Accuracy: ±3% or actual indication or ±2° (subject to accuracy of sender)

Battery Voltage

Metering Range: 6 to 32 Vdc

Accuracy: ±3% of actual indication or ±0.2 Vdc

Display Resolution: 0.1 Vdc

1-6 DGC-2020 General Information 9400200990 Rev B

Page 17

Engine RPM

Metering Range: 0 to 4,500 rpm

Accuracy: ∗ ±2% of actual indication or ±2 rpm

Display Resolution: 2 rpm

∗ When engine speed is below 2% of full-scale, reported rpm is 0.

Engine Run Time

Engine run time is retained in nonvolatile memory.

Metering Range: 0 to 99,999 h

Update Interval: 6 min

Accuracy: ±1% of actual indication or ±12 min

Display Resolution: 1/10 hour

Maintenance Timer

Maintenance timer indicates the time remaining until genset service is due. Value is retained in

nonvolatile memory.

Metering Range: 0 to 5,000 h

Update Interval: 6 min

Accuracy: ±1% or actual indication or ±12 min

Display Resolution: 1/10 hour

Fuel Level

Metering Range: 0 to 100%

Accuracy: ±2% (subject to accuracy of sender)

Display Resolution: 1.0%

Generator Protection Functions

Overvoltage (59) and Undervoltage (27)

Pickup Range: 70 to 576 Vac

Pickup Increment: 1 Vac

Inhibit Frequency Range: 20 to 400 Hz (27 function only)

Activation Delay Range: 0 to 30 s

Activation Delay Increment: 0.1 s

Underfrequency (81U) and Overfrequency (81O)

Pickup Range: 45 to 66 Hz (50/60 Hz nominal)

360 to 440 Hz (400 Hz nominal)

Pickup Increment: 0.1 Hz (50/60 Hz nominal)

0.1 Hz (400 Hz nominal)

Activation Delay Range: 0 to 30 s

Activation Delay Increment: 0.1 s

Inhibit Voltage Range: 70 to 576 Vac (81U function only)

Overcurrent (51) (Optional)

Pickup Range: 0.18 to 1.18 Aac (1 A current sensing)

0.9 to 7.75 Aac (5 A current sensing)

Time Dial Range: 0 to 30 s (fixed time curve)

0 to 9.9 (inverse curve time multiplier)

Time Dial Increment: 0.1

Inverse Time Curves: See Appendix A, Time Overcurrent Characteristic Curves

Phase Imbalance (47) (Optional)

Pickup Range: 5 to 100 Vac

Pickup Increment: 1 Vac

Activation Delay Range: 0 to 30 s

Activation Delay Increment: 0.1 s

Logic Timers

Range: 0 to 10 s

9400200990 Rev B DGC-2020 General Information 1-7

Page 18

Increment: 0.1 s

Accuracy: ±15 ms

Communication Interface

USB

Specification Compatibility: USB 2.0

Data Transfer Speed: 9600 baud

Connector Type: Mini-B jack

RS-485 (Optional)

Baud: 9600

Data Bits: 8

Parity: None

Stop Bits: 1

Terminals: 14 (A), 13 (B), and 12 (shield)

CANBus

Differential Bus Voltage: 1.5 to 3 Vdc

Maximum Voltage: –32 to +32 Vdc with respect to negative battery terminal

Communication Rate: 250 kb/s

Terminals: 48 (low), 49 (high), and 50 (shield)

Modem (Optional)

Connector Type: RJ-11 jack

Real-Time Clock

Clock has leap year and selectable daylight saving time correction. Backup capacitor and optional backup

battery sustain timekeeping during losses of DGC-2020 operating power.

Resolution: 1 s

Accuracy: ±1.73 s/d at 25°C

Clock Holdup

Battery Holdup Time (Optional): Approximately 10 yrs

Battery Type: Rayovac BR2032, lithium, coin-type, 3 Vdc, 190 mAh

Basler Electric P/N 38526

CAUTION

Replacement of the backup battery for the real-time clock should be performed

only by qualified personnel.

CAUTION

It is recommended that the battery be removed if the DGC-2020 is to be operated

in a salt-fog environment. Salt-fog is known to be conductive and may short-

circuit the battery.

NOTE

Do not short-circuit the battery, reverse battery polarity, or attempt to recharge

the battery. Observe polarity markings on the battery socket while inserting a

new battery. The battery polarity must be correct in order to provide backup for

the real-time clock.

1-8 DGC-2020 General Information 9400200990 Rev B

Page 19

Type Tests

Shock and Vibration: EN60068-2-6

Dielectric Strength: IEC 255-5

Impulse: EN60664-1

Transients: EN61000-4-4

Static Discharge: EN61000-4-2

Shock

15 G in 3 perpendicular planes

Vibration

Swept over the following ranges for 12 sweeps in each of three mutually perpendicular planes with each

15-minute sweep consisting of the following:

5 to 29 to 5 Hz: 1.5 G peak for 5 min.

29 to 52 to 29 Hz: 0.036” DECS-A for 2.5 min.

52 to 500 to 52 Hz: 5 G peak for 7.5 min.

Radio Interference

Type tested using a 5 W, hand-held transceiver operating at random frequencies centered around 144

and 440 MHz with the antenna located within 150 mm (6”) of the device in both vertical and horizontal

planes.

HALT (Highly Accelerated Life Testing)

Halt Testing is a method used by many high quality manufacturers to prove that their products will provide

the user with many years of reliable service. Halt testing is a method to subject the device to extremes in

temperature, shock, and vibration to simulate years of operation, but in a much shorter period span. Halt

testing allows Basler to evaluate all possible design elements that will add to the increase in the life of this

device. As an example of some of the extreme testing conditions, the DGC-2020 was subjected

to Temperature Tests (Tested over a temperature range of -100°C to +115°C),

Vibration Tests (Swept

over a frequency of 5 to 50 G at +20°C), and Temperature/Vibration Tests (Tested at 40 G over a

temperature range of -80°C to +90°C). Combined temperature and vibration testing at these extremes

proves that the DGC-2020 design is the most rugged device of its type. Please note that the vibration and

temperature extremes noted in this paragraph are specific to HALT testing and do not reflect

recommended operation level. These operational ratings are included in Section 1 of this manual.

Ignition System

Tested in closed proximity to an unshielded, unsuppressed Altronic DISN 800 Ignition System.

Environment

Temperature

Operating: –40 to 70°C (–40 to 158°F)∗

Storage: –40 to 85°C (–40 to 185°F)

Humidity: IEC 68-2-38

Salt Fog: ASTM B 17-73, IEC 68-2-11

Ingress Protection: IEC IP54 for front panel

∗ Display operation is maintained at -40°C when used with an optional LCD heater. Refer to Figure 1-1,

DGC-2020 Style Chart for ordering information. Display operation is maintained at -20°C when the

optional LCD heater is not used.

Agency Approvals

UL/CSA Approvals

“cURus” approved to UL 508 R and CSA C22.2 No.14

CAUTION

To follow UL/CSA guidelines, replacement of the backup battery for the real-time

clock should be performed only by qualified personnel.

9400200990 Rev B DGC-2020 General Information 1-9

Page 20

NFPA Compliance Complies with NFPA Standard 110, Standard for Emergency and Standby Power.

CE Compliance

This product complies with the requirements of the following EC Directives:

• Low Voltage Directive (LVD) - 73/23/EEC as amended by 93/68/EEC

• Electromagnetic Compatibility (EMC) - 89/336/EEC as amended by 92/31/EEC and 93/68/EEC

This product conforms to the following Harmonized Standards:

• EN 50178:1997 - Electronic Equipment for use in Power Installations

• EN 61000-6-4:2001 - Electromagnetic Compatibility (EMC), Generic Standards, Emission Standard

for Industrial Environments

• EN 61000-6-2:2001 - Electromagnetic Compatibility (EMC), Generic Standards, Immunity for

Industrial Environments

Physical

Weight: 2 kg (4.4 lb)

Dimensions: See Section 6, Installation.

1-10 DGC-2020 General Information 9400200990 Rev B

Page 21

SECTION 2 • HUMAN-MACHINE INTERFACE

TABLE OF CONTENTS

SECTION 2 • HUMAN-MACHINE INTERFACE.......................................................................................2-1

INTRODUCTION....................................................................................................................................2-1

FRONT PANEL......................................................................................................................................2-1

DISPLAY OPERATION.......................................................................................................................... 2-2

Login and Permissions....................................................................................................................... 2-2

Summary Screen and Configurable Metering....................................................................................2-3

Sleep Mode ........................................................................................................................................ 2-4

Changing a Setting.............................................................................................................................2-4

Front Panel Display Structure ............................................................................................................ 2-4

REAR PANEL ...................................................................................................................................... 2-11

Figures

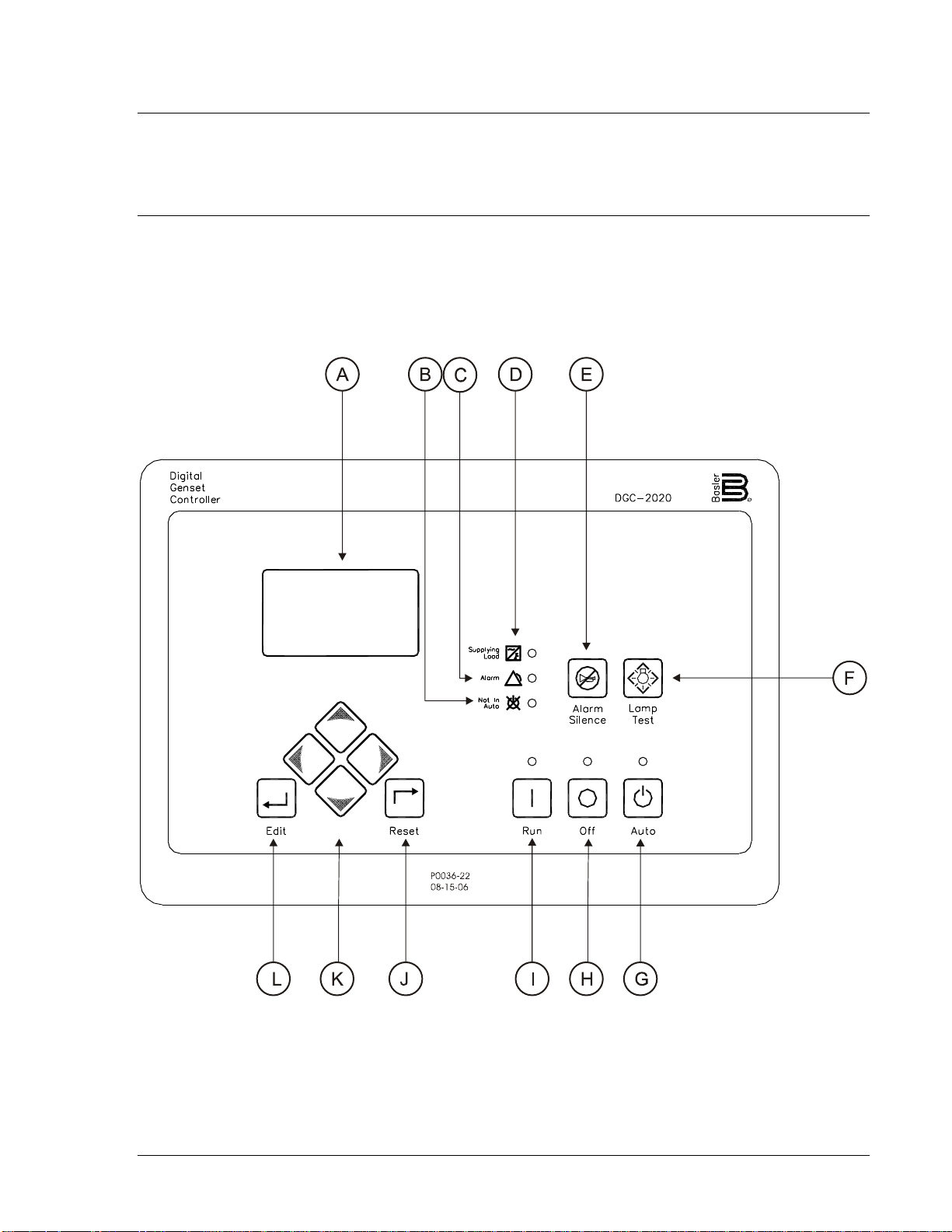

Figure 2-1. Front Panel HMI......................................................................................................................2-1

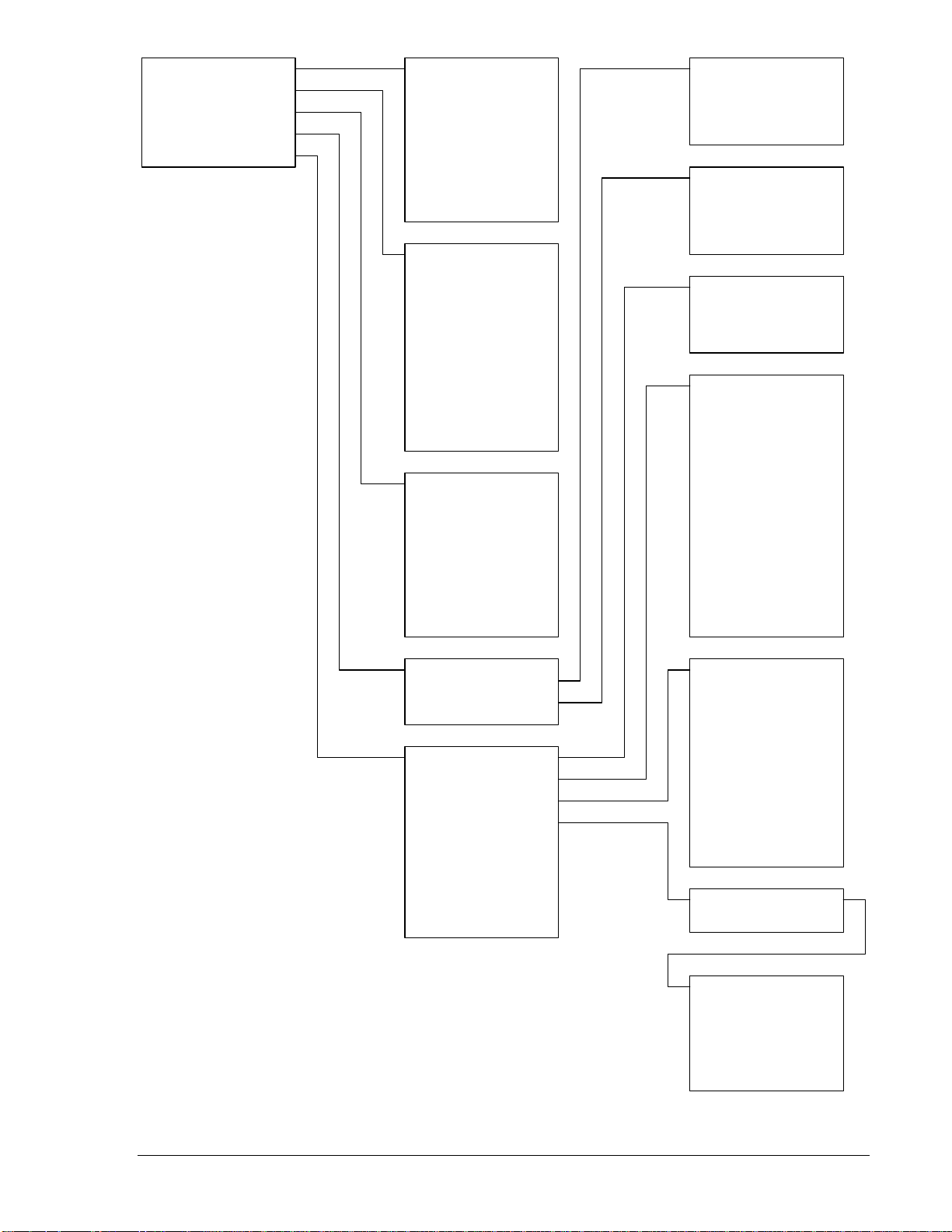

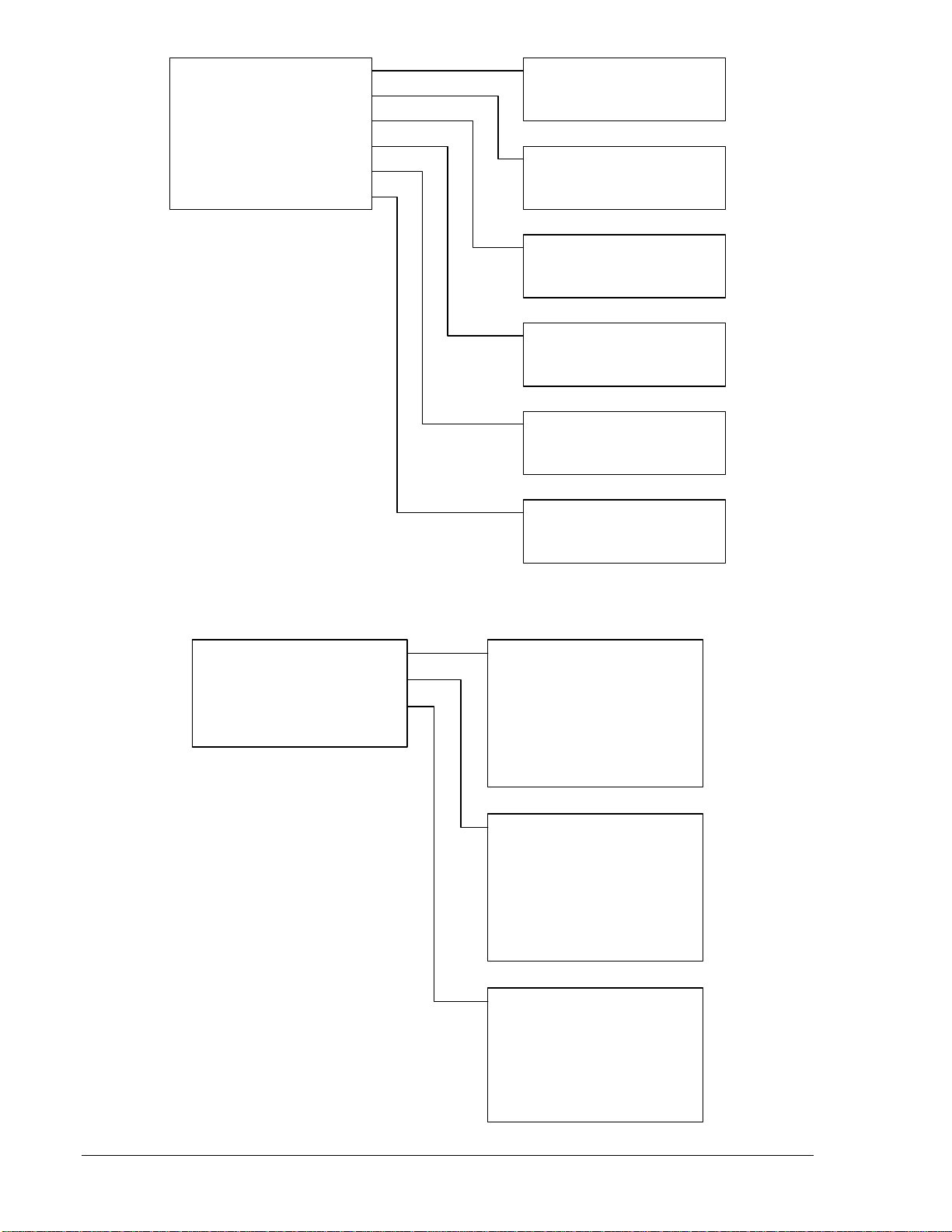

Figure 2-2. Metering Screen Branches ..................................................................................................... 2-5

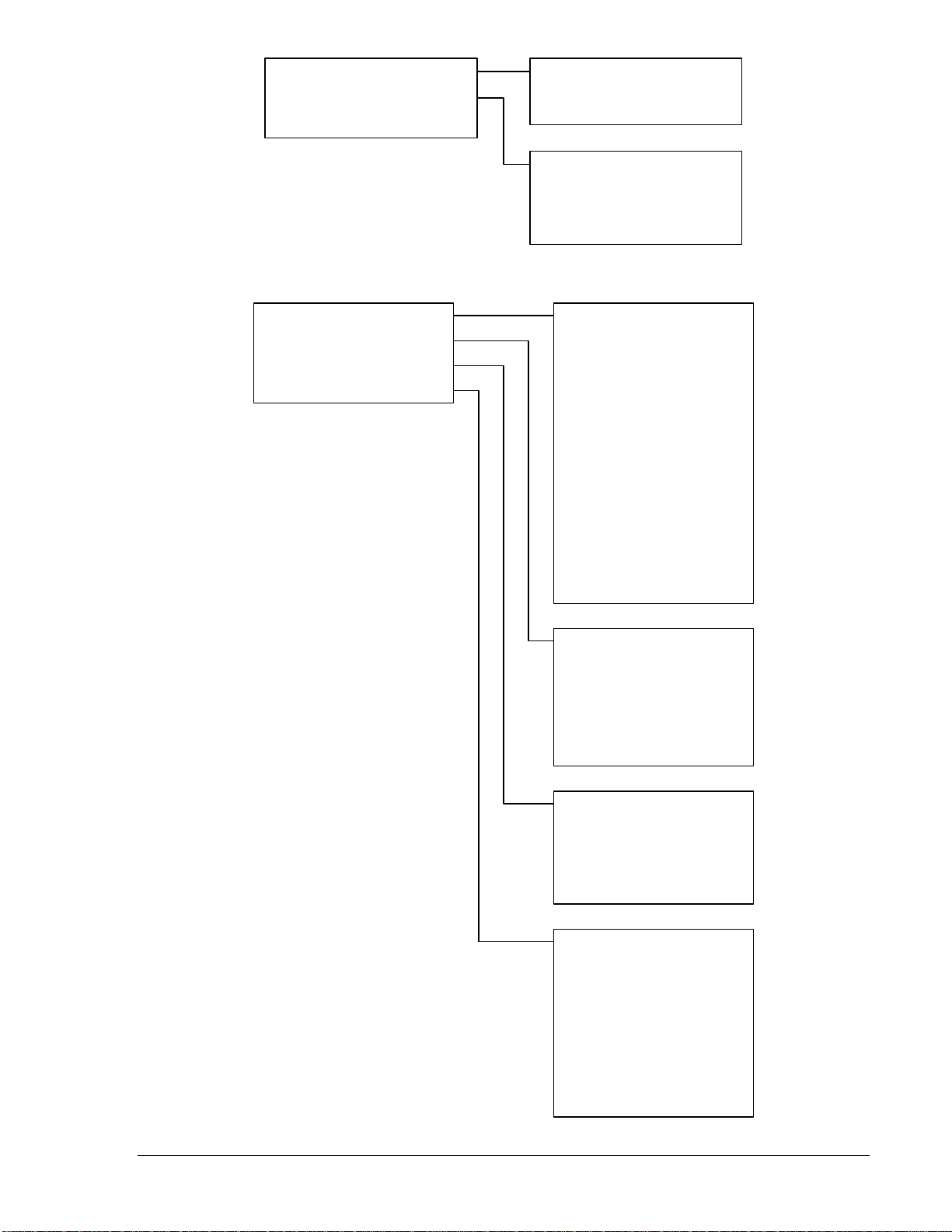

Figure 2-3. Settings Screen Branches ...................................................................................................... 2-6

Figure 2-4. General Settings Screen Branches......................................................................................... 2-6

Figure 2-5. Communications Screen Branches......................................................................................... 2-7

Figure 2-6. System Params Screen Branches.......................................................................................... 2-7

Figure 2-7. Alarm Configuration Screen Branches....................................................................................2-8

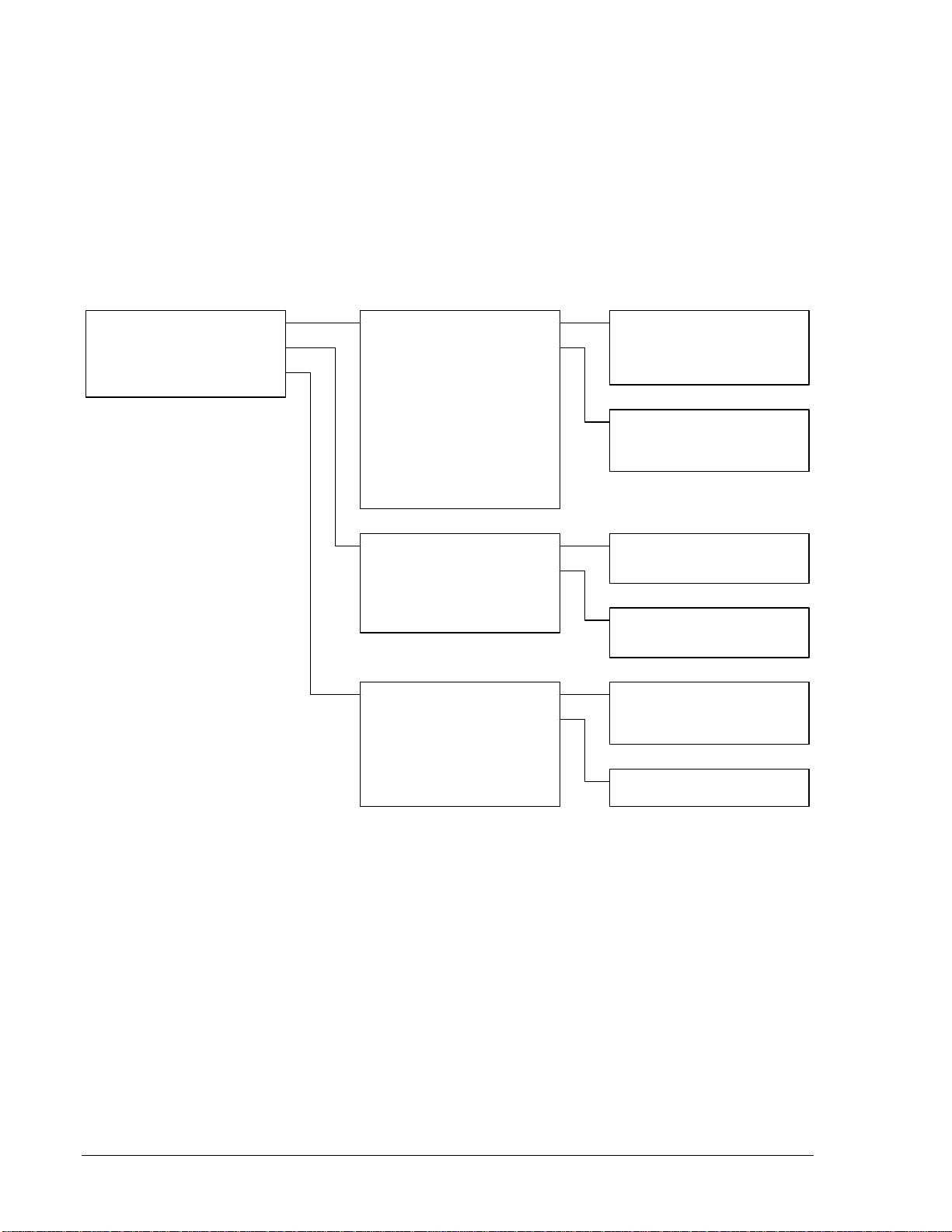

Figure 2-8. Generator Protection Screen Branches..................................................................................2-9

Figure 2-9. Breaker Management Screen Branches............................................................................... 2-10

Figure 2-10. DGC-2020 Rear Panel HMI................................................................................................ 2-11

Tables

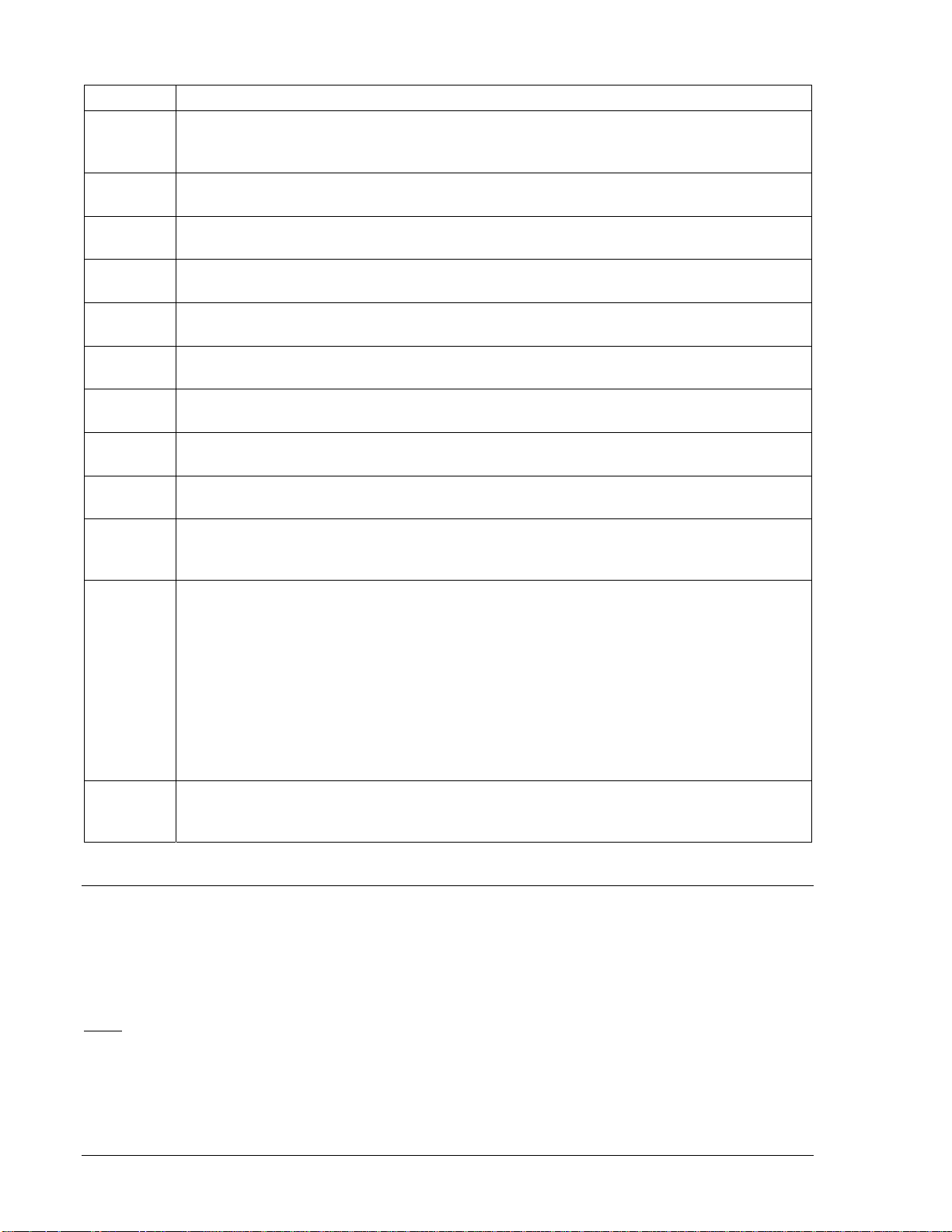

Table 2-1. Front Panel HMI Descriptions.................................................................................................. 2-2

Table 2-2. Rear Panel HMI Descriptions.................................................................................................2-11

9400200990 Rev B DGC-2020 Human-Machi ne Inter face i

Page 22

This page intentionally left blank.

ii DGC-2020 Human-Machine Interface 9400200990 Rev B

Page 23

SECTION 2 • HUMAN-MACHINE INTERFACE

INTRODUCTION

This section describes the components of the DGC-2020 human-machine interface (HMI). DGC-2020

HMI components are located on the front panel (controls and indicators) and the rear panel (terminals

and connectors).

FRONT PANEL

Figure 2-1 illustrates the front panel HMI of the DGC-2020. Table 2-1 lists the call-outs of Figure 2-1

along with a description of each HMI component.

Figure 2-1. Front Panel HMI

9400200990 Rev B DGC-2020 Human-Machi n e Interface 2-1

Page 24

Table 2-1. Front Panel HMI Descriptions

Locator Description

A Liquid Crystal Display. The backlit, 64 by 128 pixel LCD serves as the local information

source for metering, alarms, pre-alarms, and protective functions. Display operation is

maintained at -20°C. An optional LCD heater maintains display operation at -40°C.

B Not in Auto Indicator. This red LED lights when the DGC-2020 is not operating in Auto

mode.

C Alarm Indicator. This red LED lights continuously during alarm conditions and flashes

during pre-alarm conditions.

D Supplying Load Indicator. This green LE D lights when the generator current is greater

than EPS threshold current.

E Alarm Silence Pushbutton. Pressing this button opens the relay output programmed as

the horn output.

F Lamp Test Pushbutton. Pressing this button tests the DGC-2020 indicators by exercising

all LCD pixels and lighting all LEDs.

G Auto Pushb utton and Mode Indicator. Pressing the Auto button places the DGC-2020 in

Auto mode. The green Auto mode LED lights when Auto mode is active.

H Off Pushbutton and Mode Indicator. Pressing this button places the DGC-2020 in Off

mode. The red Off mode LED lights when the DGC-2020 is in Off mode.

I Run Pushbutton and Mode Indicator. Pressing this button places the DGC-2020 in Run

mode. The green Run mode LED lights when Run mode is active.

J Reset Pushbutton. This button is pressed to cancel a settings editing session and discard

any settings changes. When pressed, this button also resets the Breaker Management

Pre-Alarms.

K Arrow Pushbuttons. These four buttons are used to navigate through the front panel

display menus and modify settings.

The left- and right-arrow buttons are used to navigate through the menu levels. The right-

arrow button is pressed to move downward through the menu levels and the left-arrow

button is pressed to move upward.

Within a level, the up-arrow and down-arrow buttons are used to move among items

within the menu level. Pressing the down-arrow button moves to items lower in the list.

Pressing the up-arrow button moves to items higher in the list.

During a settings editing session, the up- and down-arrow buttons are used to raise and

lower the value of the selected setting.

L Edit Pushbutton. Pressing this button starts an editing session and enables changes to

DGC-2020 settings. At the conclusion of an editing session, the Edit pushbutton is

pressed again to save the setting changes.

DISPLAY OPERATION

The front panel display is used to make settings changes and display metering values. Refer to call-outs

J, K, and L in Table 2-1 for information on changing settings through the front panel and navigating

through the Metering screens.

Login and Permissions

Login To login, navigate to the SETTINGS, ENTER PASSWORD screen and press the Edit key. Use the

Up/Down arrow keys to scroll through the characters. Use the Left/Right arrow keys to enter more

characters. Once the password has been entered, press the Edit key to login. A LOGOUT selection now

appears in the list of SETTINGS. To logout, navigate to SETTINGS, LOGOUT and press the Edit key.

The LOGOUT selection is removed from the SETTINGS list.

2-2 DGC-2020 Human-Machine Interface 9400200990 Rev B

Page 25

Permissions

Communications access through the front panel will not be granted if communications access is active

through the modem or USB. In this case, the front panel will alternately display REMOTE COMMS,

FRONT PANEL IS READ ONLY and the summary screen. Remote access must be ended before gaining

access through the front panel.

Summary Screen and Configurable Metering

The summary screen can be set to standard or scrolling. When set to standard, only the following are

displayed:

• VOLT

• AMP

• PH

• Hz

• OIL

• FUEL

• TEMP

• BATT

When the summary screen is set to scrolling, you can select/configure the metering values that are

displayed. Up to 20 values can be displayed and these values will scroll at a delay time specified by the

user. To select a standard or scrolling summary, navigate to the SETTINGS, GENERAL SETTINGS,

FRONT PANEL HMI screen and edit the SUMMARY VIEW. The SCROLL DELAY setting is also found on

this screen.

To select the scrolling values, navigate to the SETTINGS, GENERAL SETTINGS, FRONT PANEL HMI

screen and edit the CONFIGURABLE METERING. The following values may be selected by the user to

be placed in the scrolling summary:

• NONE (Removes a line from the scrolling list)

• BLANK (Shows nothing on this line)

• OIL P

• TEMP

• BATT V

• RPM

• RPM SRC

• FUEL

• RUN HRS

• GEN VAB

• GEN VBC

• GEN VCA

• GEN VAN

• GEN VBN

• GEN VCN

• BUS Hz

• BUS V

• GEN Hz

• GEN PF

• GEN KWH

• GEN IA

• GEN IB

• GEN IC

• KW A

• KW B

• KW C

• KW TOT

• KVA A

• KVA B

• KVA C

9400200990 Rev B DGC-2020 Human-Machi n e Interface 2-3

Page 26

Sleep Mode

Sleep mode serves as a power saving feature. If the DGC-2020 is in Off mode or Auto mode not running

and a key is not pressed for more than 15 minutes, the front panel LCD backlight and LCD heater

(optional) are turned off. The DGC-2020 resumes normal display operation when any front panel button is

pressed or the genset is started remotely via the ATS input. If needed, Sleep mode can be permanently

disabled via BESTCOMSPlus or the front panel.

Changing a Setting

To change a setting, navigate to the setting you want to change and press the Edit key. If you are not

already logged in, you will be asked to enter your password at this time. Use the Up/Down arrows to raise

or lower the value. Press the Edit key again when finished.

Front Panel Display Structure

The front panel display begins with the SUMMARY SCREEN. Pressing the Right arrow key will open the

MAIN MENU screen. The MAIN MENU screen consists of METERING and SETTINGS. The METERING

screen branches are shown in Figure 2-2. The SETTINGS screen branches are shown in Figures 2-3

through 2-9.

2-4 DGC-2020 Human-Machine Interface 9400200990 Rev B

Page 27

METERING

ENGINE

GENERATOR

POWER

RUN STATISTICS

ALARMS-STATUS

P0042-23

10-02-06

ENGINE

OIL PRESSURE

COOLANT TEMP

BATTERY VOLT

RPM

SPEED SRC

FUEL LEVEL

ENGINE LOAD

TOTAL RUN TM

HRS TO MAINT

GENERATOR

GEN VAB

GEN VBC

GEN VCA

GEN VAN

GEN VBN

GEN VCN

GEN FREQ

GEN AMPS A

GEN AMPS B

GEN AMPS C

BUS V

BUS FREQ

POWER

kW A

kW B

kW C

kW TOTAL

kVA A

kVA B

kVA C

kVA TOTAL

PF

CUMULATIVE

CUMULATIVE

TOTAL RUN TIME

LOADED RUN TIME

UNLOADED RUN TIME

SESSION

SESSION

TOTAL RUN TIME

LOADED RUN TIME

UNLOADED RUN TIME

STATUS

EPS SUPP. LOAD

GEN BREAKER

MAINS BREAKER

INPUTS

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

INPUT 6

INPUT 7

INPUT 8

INPUT 9

INPUT 10

INPUT 11

INPUT 12

INPUT 13

INPUT 14

INPUT 15

INPUT 16

RUN STATISTICS

CUMULATIVE

SESSION

ALARMS-STATUS

ALARMS

PRE-ALARMS

STATUS

INPUTS

OUTPUTS

EVENT LOG

J1939 DATA

J1939 ENGINE CONFIG

J1939 ACTIVE DTC

J1939 PREV DTC

MDEC FAULT CODES

Figure 2-2. Metering Screen Branches

OUTPUTS

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

OUTPUT 5 (Optional)

OUTPUT 6 (Optional)

OUTPUT 7 (Optional)

OUTPUT 8 (Optional)

OUTPUT 9 (Optional)

OUTPUT 10 (Optional)

OUTPUT 11 (Optional)

OUTPUT 12 (Optional)

EVENT LOG

EVENT

EVENT

ACTIVE

OCCURRENCE COUNT

FIRST DATE

FIRST TIME

LAST DATE

LAST TIME

9400200990 Rev B DGC-2020 Human-Machi n e Interface 2-5

Page 28

SETTINGS

GENERAL SETTINGS

GENERAL SETTINGS

COMMUNICATIONS

SYSTEM PARAMS

ALARM CONFIGURATION

GENERATOR PROTECTION

BREAKER MANAGEMENT

ENTER PASSWORD

P0042-24

09-27-06

Refer to Figure 2-4

COMMUNICATIONS

Refer to Figure 2-5

SYSTEM PARAMS

Refer to Figure 2-6

ALARM CONFIGURATION

Refer to Figure 2-7

GENERATOR PROTECTION

Refer to Figure 2-8

BREAKER MANAGEMENT

Refer to Figure 2-9

Figure 2-3. Settings Screen Branches

GENERAL SETTINGS

FRONT PANEL HMI

FRONT PANEL HMI

CONFIGURE DATE/TIME

VIEW DATE/TIME

VERSION INFO

P0042-25

09-27-06

Figure 2-4. General Settings Screen Branches

SUMMARY VIEW

SCROLL DELAY

LCD CONTRAST

SLEEP MODE

LANGUAGE

CONFIGURABLE METERING

CONFIGURE DATE/TIME

HOURS

MINUTES

SECONDS

MONTH

DAY

YEAR

VERSION INFO

FIRMWARE VERSION

BOOT CODE

SERIAL NUMBER

PART NUMBER

MODEL NUMBER

2-6 DGC-2020 Human-Machine Interface 9400200990 Rev B

Page 29

COMMUNICATIONS

CANBUS SETUP

CANBUS SETUP

CANBUS ENABLE

RS485 SETUP

P0042-26

09-27-06

RS485 SETUP

COMM BAUD

COMM PARITY

MODBUS ADDR

Figure 2-5. Communications Screen Branches

SYSTEM PARAMS

SYSTEM SETTINGS

CRANK SETTINGS

SENSING TRANS

ENGINE STATISTICS

P0042-27

09-27-06

SYSTEM SETTINGS

GEN CONNECT

RATED kW

RATED VOLTS

RATED FREQ

RATED RPM

COOLDWN TIME

EPS THRESHLD

FUEL LVL TYP

SYSTEM UNITS

BATTERY VOLT

FLYWHL TEETH

SPEED SOURCE

MAINT RESET

NFPA LEVEL

HORN

1 PHASE O-RIDE

CRANK SETTINGS

DISCNCT LMIT

PRECRNK DELY

PRESTRT CNTCT

STYLE

# CYCLES

CYCLE TIME

SENSING TRANS

GEN PT PRI V

GEN PT SEC V

GEN CT PRI A

BUS PT PRI V

BUS PT SEC V

ENGINE STATISTICS

START MONTH

START DAY

START YEAR

# STARTS

HRS TO MAINT

kW-Hrs

TOTAL HRS

LOADED HRS

UNLOADED HRS

Figure 2-6. System Params Screen Branches

9400200990 Rev B DGC-2020 Human-Machi n e Interface 2-7

Page 30

ALARM CONFIGURATION

PRE-ALARMS

ALARMS

SENDER FAIL

P0042-27

09-27-06

PRE-ALARMS

HIGH COOLANT TEMP

LOW COOLANT TEMP

LOW OIL PRESSURE

LOW FUEL LEVEL

ENGINE OVERLOAD

MAINTENANCE INTERVAL

BATTERY OVERVOLTAGE

LOW BATTERY VOLTAGE

WEAK BATTERY VOLTAGE

HIGH FUEL LEVEL

ENABLE and THRESHOLD settings

for High Coolant Temp, Low Coolant

Temp, Low Oil Pressure, Low Fuel

Level, Engine Overload, Maintenance

Interval, and Battery Overvoltage.

ENABLE, THRESHOLD, and

ACTIVTN DLY settings for Low

Battery Voltage, Weak Battery

Voltage, and High Fuel Level.

ALARMS

HIGH COOLANT TEMP

ENABLE, THRESHOLD, and

ARMING DELAY settings for High

Coolant Temp and Low Oil Pressure.

LOW OIL PRESSURE

LOW FUEL LEVEL

OVERSPEED

SENDER FAIL

COOL TEMP SENDR FAIL

OIL PRESS SENDR FAIL

ENABLE, THRESHOLD, and

ACTIVATN DELAY settings for Low

Fuel Level and Overspeed.

CONFIG TYPE and ACTIVATN DLY

settings for Cool Temp Sendr Fail, Oil

Press Sendr Fail, Fuel Levl Sendr

Fail, and Voltage Sense Fail.

FUEL LEVL SENDR FAIL

VOLTAGE SENSE FAIL

SPEED SENDR FAIL

TIME DELAY setting for Speed Sendr

Fail.

Figure 2-7. Alarm Configuration Screen Branches

2-8 DGC-2020 Human-Machine Interface 9400200990 Rev B

Page 31

GENERATOR PROTECTION

51 OVERCURRENT (Option)

27 UNDERVOLTAGE

59 OVERVOLTAGE

47 PHASE IMBALANCE (Option)

81 O/U FREQUENCY

P0042-29

09-27-06

51 OVERCURRENT

LOW LINE OVERRIDE

3 PHASE SETTINGS

1 PHASE SETTINGS

LOW LINE OVERRIDE

SCALE FACTOR

3 PHASE SETTINGS

PICKUP

TIME DIAL

CURVE

ALARM CONFIG

1 PHASE SETTINGS

PICKUP

TIME DIAL

CURVE

ALARM CONFIG

27 UNDERVOLTAGE

LOW LINE OVERRIDE

3 PHASE SETTINGS

1 PHASE SETTINGS

59 OVERVOLTAGE

LOW LINE OVERRIDE

3 PHASE SETTINGS

1 PHASE SETTINGS

47 PHASE IMBALANCE

PICKUP

TIME DELAY

ALARM CONFIG

LOW LINE OVERRIDE

SCALE FACTOR

3 PHASE SETTINGS

PICKUP

TIME DELAY

FREQ INHIBIT

ALARM CONFIG

1 PHASE SETTINGS

PICKUP

TIME DELAY

FREQ INHIBIT

ALARM CONFIG

LOW LINE OVERRIDE

SCALE FACTOR

3 PHASE SETTINGS

PICKUP

TIME DELAY

ALARM CONFIG

1 PHASE SETTINGS

PICKUP

TIME DELAY

ALARM CONFIG

81 O/U FREQUENCY

UNDERFREQUENCY

OVERFREQUENCY

UNDERFREQUENCY

INHIBIT VOLTS

PICKUP

TIME DELAY

ALARM CONFIG

OVERFREQUENCY

PICKUP

TIME DELAY

ALARM CONFIG

Figure 2-8. Generator Protection Screen Branches

9400200990 Rev B DGC-2020 Human-Machi n e Interface 2-9

Page 32

BREAKER MANAGEMENT

MAINS FAIL TRANSFER

BREAKER HARDWARE

BUS CONDITION DETECT

SYNCHRONIZER

AVR BIAS CONTROL

GOV BIAS CONTROL

P0042-30

09-29-06

MAINS FAIL TRANSFER

ENABLE

BREAKER HARDWARE

CLOSE WAIT TIME

GEN BREAKER

MAINS BREAKER

CLOSE WAIT TIME

TIME

GEN BREAKER

CONTINUOUS

OPEN PULSE

CLOSE PULSE

CLOSING TIME

MAINS BREAKER

CONFIGURED

BUS CONDITION DETECT

GEN DEAD

GEN STABLE

GEN FAILED

BUS DEAD

BUS STABLE

BUS FAILED

SYNCHRONIZER

TYPE

SLIP FREQ

REGUL OFFSET

CLOSNG ANGLE

VS>VD

TIME DELAY

FAIL DELAY

GEN DEAD

THRESHOLD

TIME DELAY

GEN STABLE

OV PICKUP

OV DROPOUT

UV PICKUP

UV DROPOUT

OF PICKUP

OF DROPOUT

UF PICKUP

UF DROPOUT

TIME DELAY

GEN FAILED

TIME DELAY

BUS DEAD

THRESHOLD

TIME DELAY

BUS STABLE

OV PICKUP

OV DROPOUT

UV PICKUP

UV DROPOUT

OF PICKUP

OF DROPOUT

UF PICKUP

UF DROPOUT

TIME DELAY

BUS FAILED

TIME DELAY

AVR BIAS CONTROL

CONTACT

GOV BIAS CONTROL

CONTACT

CONTACT

TYPE

CONTACT

TYPE

Figure 2-9. Breaker Management Screen Branches

2-10 DG C-2020 Human-M achi n e Interface 9400200990 Rev B

Page 33

REAR PANEL

All DGC-2020 terminals and connectors are located on the rear panel. Rear panel terminals and

connectors are illustrated in Figure 2-10. (To show the terminals and connectors, Figure 2-10 shows the

DGC-2020 with the rear cover removed.) Table 2-2 lists the call-outs of Figure 2-10 along with a

description of each connector type.

Figure 2-10. DGC-2020 Rear Panel HMI

Table 2-2. Rear Panel HMI Descriptions

Locator Description

A, D The majority of external, DGC-2020 wiring is terminated at 15-position connectors with

compression terminals. These connectors plug into headers on the DGC-2020. The

connectors and headers have a dovetailed edge that ensures proper connector

orientation. Each connector and header is uniquely keyed to ensure that a connector

mates only with the correct header. Connector screw terminals accept a maximum wire

size of 12 AWG.

B The mini-B USB socket mates with a standard USB cable and is used with a PC running

BESTCOMSPlus software for local communication with the DGC-2020.

C DGC-2020 controllers with an option al, internal, dial-out modem connect to a telephone

line through a USOC RJ-11 jack.

E Connections to the DGC-2020 Start (starter), Run (fuel solenoid), and Pre (glow plug)

output contacts are made directly to each relay through quarter-inch, male, quick-connect

terminals.

F An optional battery backup for the real-time clock is available when ordering.

9400200990 Rev B DGC-2020 Human-Machi n e Interface 2-11

Page 34

This page intentionally left blank.

2-12 DG C-2020 Human-M achi n e Interface 9400200990 Rev B

Page 35

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION...........................................................................................3-1

INTRODUCTION....................................................................................................................................3-1

DGC-2020 FUNCTION BLOCKS...........................................................................................................3-1

Power Supply ..................................................................................................................................... 3-1

Microprocessor...................................................................................................................................3-1

Generator Voltage Sensing Inputs..................................................................................................... 3-2

Bus Voltage Sensing Inputs...............................................................................................................3-2

Current Sensing Inputs.......................................................................................................................3-2

Analog Engine Sender Inputs.............................................................................................................3-2

Speed Signal Inputs...........................................................................................................................3-3

Contact Inputs .................................................................................................................................... 3-3

Front Panel HMI................................................................................................................................. 3-4

Remote Display Panel (Optional).......................................................................................................3-4

Communication Ports......................................................................................................................... 3-4

Output Contacts ................................................................................................................................. 3-8

BREAKER MANAGEMENT................................................................................................................... 3-8

Introduction......................................................................................................................................... 3-8

Determining Breaker Status...............................................................................................................3-9

Processing Breaker Requests............................................................................................................3-9

Breaker Operation.............................................................................................................................. 3-9

Figures

Figure 3-1. Function Block Diagram..........................................................................................................3-1

Tables

Table 3-1. ECU Parameters Obtained from CAN Interface ...................................................................... 3-5

Table 3-2. Engine Configuration Parameters Obtained from CAN Interface............................................ 3-6

Table 3-3. Diagnostic Information Obtained Over the CAN Interface....................................................... 3-7

9400200990 Rev B DGC-2020 Functional Description i

Page 36

This page intentionally left blank.

ii DGC-2020 Functional Description 9400200990 Rev B

Page 37

SECTION 3 • FUNCTIONAL DESCRIPTION

INTRODUCTION

This section describes how the DGC-2020 functions. A detailed description of each function block is

provided in the paragraphs under the heading of DGC-2020 Function Blocks.

DGC-2020 operating and metering features are described in Section 4, BESTCOMSPlus Software.

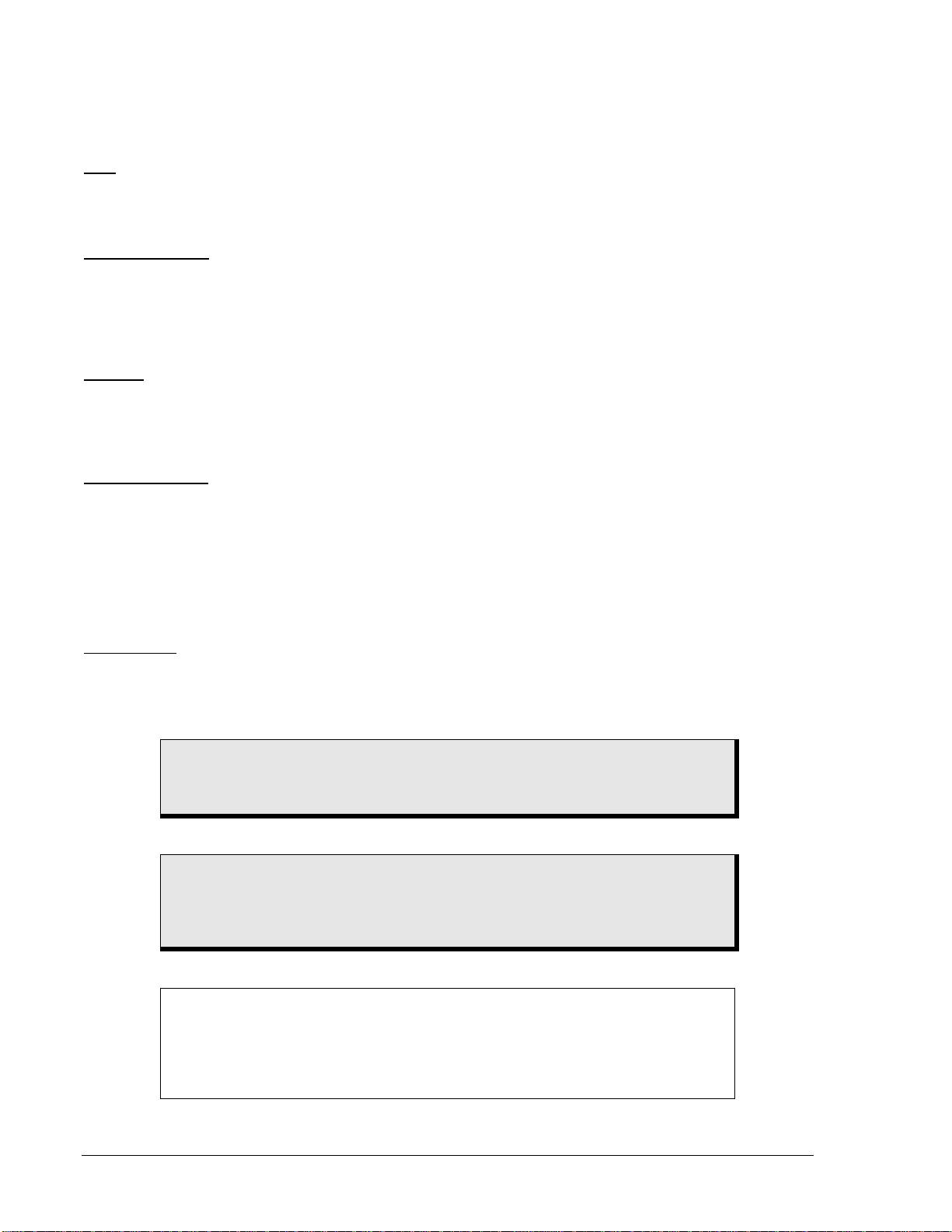

DGC-2020 FUNCTION BLOCKS

To ease understanding, DGC-2020 functions are illustrated in the block diagram of Figure 3-1. The

following paragraphs describe each function in detail.

Power Supply

(To Internal Circuitry)

Sensing

Battery Voltage Sensing

Sender Input Sensing

Generator Current Sensing

Bus Voltage Sensing

Front Panel HMI

and LCD

Remote Display

Panel Driver

(RDP-110)

HMI

Com Ports

Sensing

Generator Voltage Sensing

MPU Speed Sensing

Programmable Dry Contact Inputs (16)

USB Com Port

J1939 CAN Com Port

RS-485 Com Port (Optional)

Modem Com Port (Optional)

Emergency Stop Contact Input

Microprocessor

P0040-04

06-20-06

Programmable

Output Contacts

(4 or 12)

Fuel Solenoid

Output Contacts

Engine Crank

Output Contacts

Pre-start Output

Contacts

Output

Contacts

Figure 3-1. Function Block Diagram

Power Supply

The internal, switch-mode power supply uses the applied battery voltage to generate operating power for

the internal circuitry of the DGC-2020. The power supply accepts a nominal battery voltage of 12 or 24

Vdc and has an operating range of 6 to 32 Vdc. Battery voltage is applied to terminals 2 (–) and 3 (+).

Operating power must be of the correct polarity. Although reverse polarity will not cause damage, the

DGC-2020 will not operate.

Battery Voltage Sensing

Voltage applied to the power supply is filtered and reduced to a suitable level for sensing by the

microprocessor.

Microprocessor

The microprocessor controls the overall functionality of the DGC-2020 and makes decisions based on

programming and system inputs.

Circuits relating to the microprocessor inputs are described in the following paragraphs.

9400200990 Rev B DGC-2020 Functional Description 3-1

Page 38

Zero Crossing Detection

The zero crossing of A-phase to B-phase or A-phase to C-phase (user-selectable) line voltage is detected

and used to calculate the generator frequency. The zero crossing of A-phase to B-phase bus voltage is

used to calculate the bus frequency.

Analog-to-Digital Converter

Scaled and conditioned signals representing the sensing voltage, sensing current, coolant temperature,

fuel level, oil pressure, and battery voltage are digitized by the microprocessor’s analog-to-digital

converter. The digitized information is stored in random access memory (RAM) and used by the

microprocessor for all metering and protection functions.

Generator Voltage Sensing Inputs

Voltages applied to the generator voltage sensing inputs are scaled to levels suitable for use by the

internal circuitry. Generator voltage sensing configuration is menu-selectable.

The generator voltage sensing inputs accept a maximum voltage of 576 Vrms, line-to-line. Sensing

voltage is applied to terminals 41 (A-phase), 39 (B-phase), 37 (C-phase), and 35 (neutral).

Bus Voltage Sensing Inputs

Voltage applied to the bus voltage sensing input is scaled to a level suitable for use by the internal

circuitry.

The bus voltage sensing input accepts a maximum voltage of 576 Vrms. Sensing voltage is applied to

terminals 45 (A-phase) and 43 (B-phase).

Current Sensing Inputs

Generator currents are sensed and scaled to values suitable for use by the inte rnal circuitry.

DGC-2020 controllers with 1 ampere current sensing (style number 1xxxxxxxx) accept a maximum

current value of 1 Aac. DGC-2020 controllers with 5 ampere current sensing (style number 5xxxx xxxx)

accept a maximum current value of 5 Aac. Sensing current is applied to terminals 68 (IA–) and 69 (IA+),

71 (IB–) and 72 (IB+), and 74 (IC–) and 75 (IC+).

Analog Engine Sender Inputs

Programmable analog engine sender inputs give the DGC-2020 user the flexibility to select the engine

sender to be used in an application. Information about programming the sender inputs is provided in

Section 4, BESTCOMSPlus Software.

Oil Pressure

A current is provided to the oil pressure sender. The developed voltage is measured and scaled for use

by the internal circuitry. An open circuit or short circuit across the oil pressure sender terminals will cause

the DGC-2020 to indicate a failed sender. Oil pressure senders that are compatible with the DGC-2020

include Datcon model 02505-00, Isspro model R8919, and Stewart-Warner models 411K and 411M.

Other senders may also be used. BESTCOMSPlus software allows for the programming of sender

characteristics. See Section 4, BESTCOMSPlus Software, for more information.

Oil pressure sender connections are made at terminals 8 and 11 (sender co mmon).

Coolant Temperature

A current is provided to the coolant temperature sender. The developed voltage is measured and scaled

for use by the internal circuitry. An open circuit or short circuit across the coolant temperature sender

terminals will cause the DGC-2020 to indicate a failed sender. Coolant temperature senders that are

compatible with the DGC-2020 include Datcon model 02019-00, Faria model TS4042, Isspro model

R8959, and Stewart-Warner model 334P. Other senders may be used. BESTCOMSPlus software allows

for the programming of sender characteristics. See Section 4, BESTCOMSPlus Software, for more

information.

Coolant temperature sender connections are made at terminals 10 and 11 (sender common).

Fuel Level

A current is provided to the fuel level sender. The developed voltage is measured and scaled for use by

the internal circuitry. An open circuit or short circuit across the fuel level sender terminals will cause the

DGC-2020 to indicate a failed sender. Fuel level senders that are compatible with the DGC-2020 include

3-2 DGC-2020 Functional Description 9400200990 Rev B

Page 39

Isspro model R8925. Other senders may be used. BESTCOMSPlus software allows for the programming

of sender characteristics. See Section 4, BESTCOMSPlus Software, for more information.

Fuel level sender connections are made at terminals 9 and 11 (sender common).

Speed Signal Inputs

The DGC-2020 uses signals from the generator voltage sensing inputs and magnetic pickup input to

detect machine speed.

Generator Voltage Sensing Input

The generator voltage sensed by the DGC-2020 is used to measure frequency and can be used to

measure machine speed.

Sensing voltage is applied to terminals 41 (A-phase), 39 (B-phase), 37 (C-phase), and 35 (Neutral).

Magnetic Pickup Input (MPU)

Voltage supplied by a magnetic pickup is scaled and conditioned for use by the internal circuitry as a

speed signal source. The MPU input accepts a signal over the range of 3 to 35 volts peak and 32 to

10,000 hertz.

Magnetic pickup connections are provided at terminals 31 (+) and 32 (–).

Contact Inputs

The DGC-2020 has seventeen contact sensing inputs: an emergency stop input and 16 programmable

inputs. Additional contact inputs can be accommodated with separate I/O modules. Contact Basler

Electric for availability and ordering information.

Emergency Stop Input

This input accepts Form B, dry contacts. An open circuit at this continuously monitored input initiates an

emergency stop. An emergency stop removes operating power from the DGC-2020 Pre-Start, Run, and

Fuel output relays.

Emergency stop contact connections are made at terminals 46 and 47.

Programmable Inputs

Each programmable input (Input 1 through Input 16) can be independently configured to perform the

following functions. By default, each programmable input is disabled.

• Automatic Transfer Switch

• Battery Charger Fail

• Battle Override

• Fuel Leak Detection

• Grounded Delta Override

• Low Coolant Level

• Low-Line Override

• Single-Phase A-C Override

• Single-Phase Override

The programmable inputs accept normally open, Form A contacts. A contact is connected between a

programmable input and the negative side of the battery. Through BESTCOMSPlus, each programmable

contact input can be assigned a name (16 alphanumeric characters, maximum) and configured as an

alarm input, a pre-alarm input, or neither. The default names for the inputs are INPUT_x (where x = 1 to

16). When a programmable contact input is closed, the front panel display shows the name of the closed

input if it was programmed as an alarm or pre-alarm input. Alarm inputs are annunciated through the

Normal display mode screens of the front panel. Pre-alarm inputs are annunciated through the pre-alarm

metering screen of the front panel. If neither is programmed, no indication is given. Programming an input

as neither is useful when a programmable input is used as an input to programmable logic.

Connections for the programmable inputs are provided at terminals 15 (Input 16) through 30 (Input 1).

The negative side of the battery voltage (terminal 2) serves as the return connection for the

programmable inputs.

9400200990 Rev B DGC-2020 Functional Description 3-3

Page 40

Front Panel HMI

The front panel HMI provides a convenient interface for viewing system parameters and for controlling the

DGC-2020/generator set. Front panel HMI components include an LCD (liquid crystal display), LED (light

emitting diodes) indicators, and pushbuttons.

LCD

The backlit LCD provides metering, pre-alarm, and alarm information. Detailed information about the LCD

is provided in the Software Operation sub-section.

LED Indicators

The LEDs indicate pre-alarm and alarm conditions along with DGC-2020 status and generator status.

Pushbuttons

The pushbuttons are used to scroll through and select parameters displayed on the LCD, change

setpoints, start and stop the generator, and reset alarms.

Remote Display Panel (Optional)

Applications that require remote annunciation can use Basler Electric’s Remote Display Panel, RDP-110.

Using the RDP-110 with the DGC-2020 meets the requirements of NFPA Standard 110. The RDP-110

uses a dedicated, four-terminal interface with the DGC-2020. The RDP-110 communicates with the DGC2020 via terminals 6 (RDP TXD–) and 7 (RDP TXD+) and receives power from terminals 4 (RDP BATT+)

and 5 (RDP BATT-). Remote indication of many pre-alarm and alarm conditions is provided by the RDP-

110.

The following pre-alarm conditions are indicated by LEDs on the RDP-110 front panel:

• Battery charger failure ∗

• Battery overvoltage

• High coolant temperature

• Low coolant temperature

• Low fuel level

• Low oil pressure

• Weak battery

The following alarm conditions are indicated by LEDs and an audible alarm on the RDP-110 front panel:

• Low coolant level ∗

• High coolant temperature

• Low oil pressure

• Overcrank

• Overspeed

• Emergency stop

• Fuel leak/fuel sender failure ∗

• Engine sender unit failure

∗ Can be configured in the DGC-2020 as None, Alarm, or Pre-Alarm. See Section 4, BESTCOMSPlus,

Programmable Inputs, Programmable Functions, for more information. The light on the RDP-110 will turn

on when the input that is assigned to the programmable function is closed, whether the function is

configured as None, Alarm, or Pre-Alarm.

Additionally, the RDP-110 indicates when the DGC-2020 is not operating in Auto mode and when the

generator is supplying load. For more information about the RDP-110, request product bulletin SNE.

RDP-110 communication connections are made at DGC-2020 terminals 6 (RDP TXD–) and 7

(RDP TXD+). RDP-110 operating power is supplied at DGC-2020 terminals 4 (RDP BATT+) and 5 (RDP

BATT–).

Communication Ports

DGC-2020 communication ports include a USB jack, CAN terminals, optional RS-485 terminals, and an

optional modem jack.

USB

The rear-panel, mini-B USB socket enables local communication with a PC running BESTCOMSPlus

software. The DGC-2020 is connected to a PC using a standard USB cable. BESTCOMSPlus is a

3-4 DGC-2020 Functional Description 9400200990 Rev B

Page 41

Windows® based communication software package that is supplied with the DGC-2020. A detailed

description of BESTCOMSPlus is provided in Section 4, BESTCOMSPlus Software.

CANBus

A Control Area Network (CAN) is a standard interface that enables communication between multiple

controllers on a common network using a standard message protocol. DGC-2020 controllers have a CAN

interface that supports the SAE J1939 protocol and the MTU/MDEC protocol.

Applications using an engine-driven generator set controlled by a DGC-2020 may also have an Engine

Control Unit (ECU). The CAN interface allows the ECU and DGC-2020 to communicate. The ECU reports

operating information to the DGC-2020 through the CAN interface. Operating parameters and diagnostic

information, if supported by the ECU, are decoded and displayed for monitoring.

The primary use of the CAN interface is to obtain engine operating parameters for monitoring speed,

coolant temperature, oil pressure, coolant level, and engine hours without the need for direct connection

to individual senders. Table 3-1 lists the ECU parameters and Table 3-2 lists the engine configuration

parameters supported by the DGC-2020 CAN interface. These parameters are transmitted via the CAN

interface at preset intervals. See the column labeled Update Rate in Table 3-1 for transmission rates. This

information can also be transmitted upon user request.

CAN interface connections are made at 48 (CAN L), 49 (CAN H), and 50 (SHIELD).

Table 3-1. ECU Parameters Obtained from CAN Interface

ECU Parameter

Actual engine percent torque % % engine speed

Air filter differential pressure kPa psi 500 ms 100th 107

Air inlet temperature kPa

Ambient air temperature

Barometric pressure kPa psi 1 s 10th 108

Battery voltage Vdc Vdc 1 s 10th 168

Boost pressure kPa psi 500 ms none 102

Coolant level % % 500 ms 10th 111

Coolant pressure kPa psi 500 ms 10th 109

Engine coolant temperature

Engine intercooler temperature

Engine oil level % % 500 ms 10th 98

Engine oil pressure kPa psi 500 ms 10th 100

Engine oil temperature

Engine speed rpm rpm engine speed

Exhaust gas temperature

Fuel delivery pressure kPa psi 500 ms 10th 94

Fuel rate liter/hr gal/hr 100 ms 100th 183

Fuel temperature

Injection control pressure MPa psi 500 ms none 164

Injector metering rail pressure MPa psi 500 ms none 157

Intake manifold temperature

Percent load at current rpm % % 50 ms none 92

Switched battery voltage (at

ECU)

Throttle (accelerator pedal)

position

Total engine hours hours hours requested 1.5 s 100th 247

Total fuel used liters gallons requested 1.5 s none 250

Trip fuel liters gallons requested 1.5 s none 182

Metric

Units

°C °F

°C °F

°C °F

°C °F

°C °F

°C °F

°C °F

Vdc Vdc 1 s 10th 158

% % 50 ms 10th 91

English

Units

°F

Update Rate

dependent

1 s none 172

1 s 10th 171

1 s none 110

1 s none 52

1 s 10th 175

dependent

500 ms 10th 173

1 s none 174

500 ms none 105

Decimal

Place

none 513

none 190

∗

SPN

∗ SPN is suspect parameter number.

9400200990 Rev B DGC-2020 Functional Description 3-5

Page 42

Table 3-2. Engine Configuration Parameters Obtained from CAN Interface

ECU Parameter

Engine speed at high idle point 6 rpm rpm 5 s none 532

Engine speed at idle point 1 rpm rpm 5 s none 188

Engine speed at point 2 rpm rpm 5 s none 528

Engine speed at point 3 rpm rpm 5 s none 529

Engine speed at point 4 rpm rpm 5 s none 530

Engine speed at point 5 rpm rpm 5 s none 531

Gain (Kp) of endspeed governor %/rpm %/rpm 5 s 100th 545

Maximum momentary engine override

speed point 7

Maximum momentary engine override time

limit

Percent torque at idle point 1 % % 5 s none 539

Percent torque at point 2 % % 5 s none 540

Percent torque at point 3 % % 5 s none 541

Percent torque at point 4 % % 5 s none 542

Percent torque at point 5 % % 5 s none 543

Reference engine torque

Requested speed control range lower limit rpm rpm 5 s none 535

Requested speed control range upper limit rpm rpm 5 s none 536

Requested torque control range lower limit % % 5 s none 537

Requested torque control range upper limit % % 5 s none 538

Metric

Units

rpm rpm 5 s none 533

seconds seconds 5 s 10th 534

N•m

English

Units

ft-lb 5 s none 544

Update

Rate

Decimal

Place

∗

SPN

∗ SPN is suspect parameter number.

CAUTION

When the CAN interface is enabled, the DGC-2020 will ignore the following

sender inputs: oil pressure, coolant temperature, and magnetic pickup.

Diagnostic Trouble Codes (DTCs)

The DGC-2020 obtains diagnostic engine information from a compatible engine control unit (ECU). The

DGC-2020 will receive an unsolicited message of a currently active diagnostic trouble code (DTC).

Previously active DTCs are available upon request. Active and previously active DTCs can be cleared on

request. Table 3-3 lists the diagnostic information that the DGC-2020 obtains over the CAN interface.

DTCs are reported in coded diagnostic information that includes the Suspect Parameter Number (SPN),

Failure Mode Identifier (FMI), and Occurrence Count (OC). All parameters have an SPN and are used to

display or identify the items for which diagnostics are being reported. The FMI defines the type of failure

detected in the subsystem identified by an SPN. The reported problem may not be an electrical failure but

a subsystem condition needing to be reported to an operator or technician. The OC contains the number

of times that a fault has gone from active to previously active.

3-6 DGC-2020 Functional Description 9400200990 Rev B

Page 43

Table 3-3. Diagnostic Information Obtained Over the CAN Interface

Transmission

Parameter

Repetition Rate

Active diagnostic trouble code 1 s

Lamp status 1 s

Previously active diagnostic trouble code On request

Request to clear active DTCs On request

Request to clear previously active DTCs On request

MTU MDEC ECU Fault Codes

A DGC-2020 connected to a genset equipped with an MTU MDEC engine controller tracks and displays

the active fault codes issued by the MDEC ECU. Active MDEC ECU fault codes can be viewed through

BESTCOMSPlus by using the Metering Explorer to expand the MTU MDEC tree or through the front

panel display by navigating to METERING, ALARMS-STATUS, MDEC FAULT CODES.

Each fault code is displayed with a fault description and the fault number. If the DGC-2020 does not have

descriptive information about a fault number that was received, the fault description will display as “NO

TEXT AVAILABLE”. For more detailed information, refer to your MDEC ECU documentation.

3, L1 T-FUEL

5, L1 T-CHRG AIR

9, L1 T-INTERCOOLER

15, L1 P-LUBE OIL

16, L2 P-LUBE OIL

19, L1 T-EXHAUST A

21, L1 T-EXHAUST B

23, L1 COOLANT LEVEL

24, L2 COOLANT LEVEL

30, ENGINE OVERSPEED

31, CHRGR1 OVERSPD 1

32, CHRGR1 OVERSPD 2

33, L1 P-FUELFLT DIF

44, L1 LEVEL INTRCLR

45, L2 LEVEL INTRCLR

51, L1 T-LUBE OIL

57, L1 P-COOLANT

58, L2 P-COOLANT

63, L1 P-CRANKCASE

65, L1 P-FUEL

67, L1 T-COOLANT

68, L2 T-COOLANT

69, L1 T-EXTERN 1

70, L2 T-EXTERN 1

71, L1 T-EXTERN 2

72, L2 T-EXTERN 2

73, L1 P-EXTERN 1

74, L2 P-EXTERN 1

75, L1 P-EXTERN 2

76, L2 P-EXTERN 2

77, LIN EXT CLNT LEV

78, LIN INTERCLR LEV

79, L BIN-EXTERN 3

80, L BIN-EXTERN 4

90, IDLE SPEED LOW

91, RUNUP SPEED LOW

92, START SPEED LOW

93, PREHT TMP. LIM 2