Page 1

Manual Can Opener

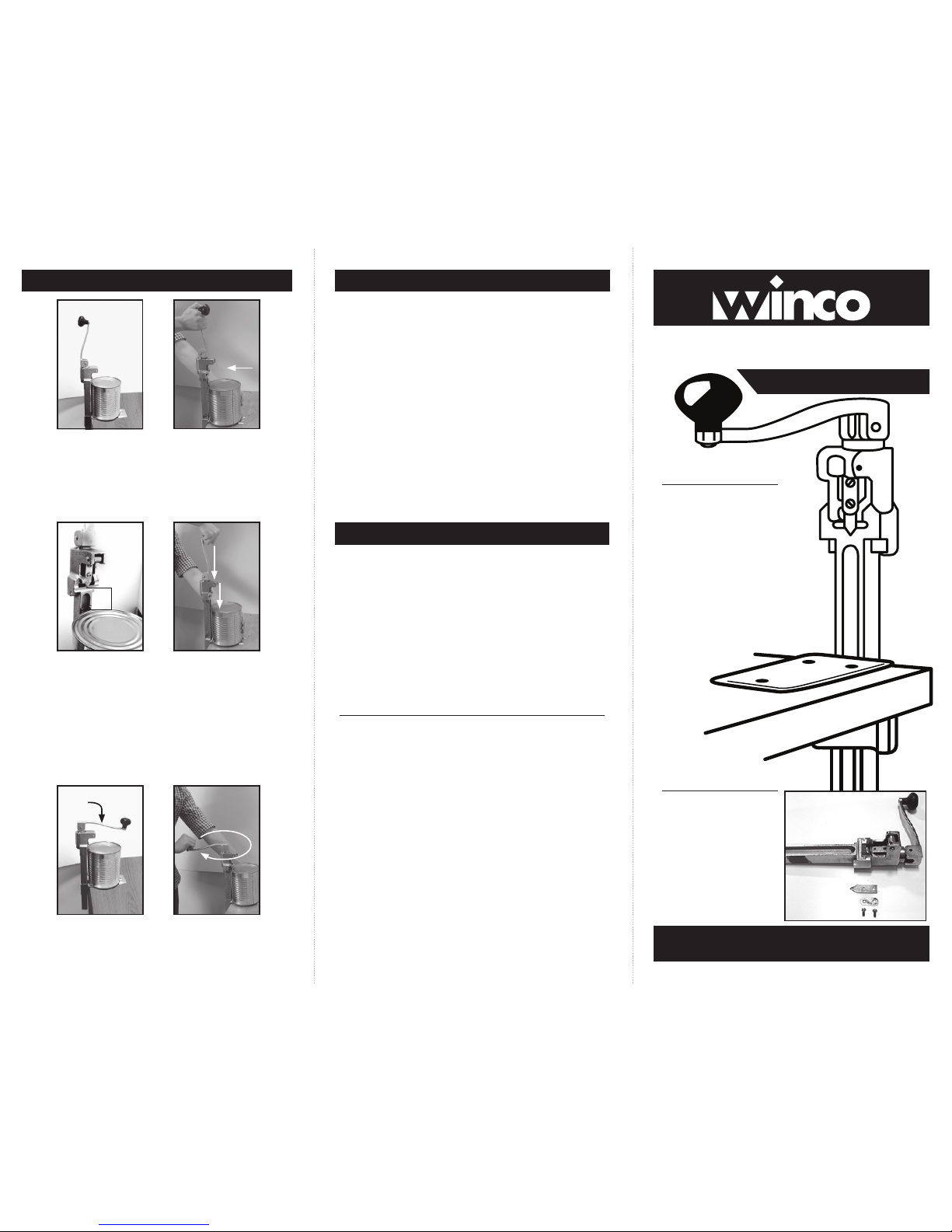

Contents / parts list

Included with product

• Can Opener

(with Blade and Gear)

• Can Opener Base

• Installation Kit for

Wood Tables

• Installation Kit for

Stainless Steel Tables

Replacement Parts List

CO-1B: Replacement

Blade Set

CO-1BS: Blade Screw Set

CO-1G: Replacement Gear

CO-1WI: Installation K it for

Wood Tables

CO-1SI: Installation Kit for

Stainless Steel

Tables

USE & CARE MANUAL

CO -1

WARRANTY INFO

Winco warrants these products to be free from defects in

material and workmanship f or a period of one year from the

date of purcha se. The Company’s obligation under this warranty

is limited to repairing or replacing without charge any par t or

parts found to be defec tive under nor mal use. It is the sole

responsibility of the purchaser to re turn the entire unit to the

distributor, transportation charges prepaid.

This warranty does not cover part s that must be replaced under

normal use, including, but not limited to, blades and gears on can

openers. No other warranty, written or verbal, is authorized by the

Company. Warranty information outside the United States may

vary; please consult your distributor.

REPLACEMENT PARTS

Replacement parts are available for purchase. Please check our

website for up to date part s list and prices: www.wincous.com.

CLEANING INSTRUCTIONS

The can opener must be cleaned daily or after each extended use.

Regular maintenance will help prevent unwanted build-up and

harmful bac teria grow th.

1. Use a stainles s cleaning brush to remove all the food and can

opening residue from the gear, the gear cavity, and the knife

blade.

2. Wash the knife, gear, and any splash area on the opener using

warm soapy water. Do not allow componen ts to soak.

3. Thoroughly dr y the knife, gear, and can opener using a dry cloth

or paper towel.

4. Coat the knife and gear with light non-sticking vegetable oil to

prevent rusting when the can opener is not in use.

WINCO

www.wincous.com

OPERATING INSTRUCTIONS

Figure 1

Figure 3

Figure 6Figure 5

Figure 2

Figure 4

1. Make sure can opener handle is in the unlock position (Figure 1)

and slide it up enough to place a can underneath it on the metal

base. (Figure 2)

2. Hold the can agains t the bar of the opener with a height distance

of 3" between the blade and the top of the can. (Figure 3)

3. Grip the handle firmly and thrus t down onto the c an to puncture

it. (Figur e 4)

4. Lock the handle (Figure 5) and t urn it clock wise. This will

automatically turn the can around. Use your free hand to guide

the can as it rotates. Continue turning the handle until the top of

the can is removed. (Figure 6)

5. Raise the handle to unlock position and lift it up to slide the

opened can out. (Figure 1)

IMPORTANT NOTE: Knife of this opener may be reversed for double

wear but should not be reshaped.

Unock Position

Lock Position

3"

Page 2

MOUNTING INSTRUCTIONS

Mounting can opener on a stainless steel table

Tools required for mounting on a stainless steel table

- 1/8" cobalt or titanium drill bit

- 9/32" cobalt or titanium drill bit

- 7/16 socket, box or open-end wrench

Mounting instructions

1. Place the L-bracket on the stainless steel table in the desired

position where you want to secure the can opener.

2. Mar k the center of each of the three mounting holes of the

L-bracket. These t hree points will be your drilling location.

IM PO RTANT

3. To prevent the drill from slipping out of position, place a

piece of masking tape on each of the three marked points.

Then mark the points again on the masking tape.

4. Drill a small star ter hole on each marked point with a 1/8” cobalt

or titanium drill bit that is specifically used for drilling into

stainless steel.

5. Complete drilling the holes for the screws by using a 9/ 32” cobalt

or titanium drill bit that is specifically used for drilling into

stainless steel.

6. Insert size 1/4 x 20 x 3/4” screws through the L-bracket. Use the

split washer s and nylon lock nut provided.

7. Use a 7/16” socket , bow or open- end wrench to tighten and

secure the screws.

Mounting can opener on a wooden table

(stand ard 2" t hick)

Tools required for mounting on a standard 2” thick wooden table

- 9/32" drill bit

- 7/16 socket, box or open-end wrench

Mounting instructions

1. Place the L-bracket on the stainless steel table in the desired

position where you want to secure the can opener.

2. Mar k the center of each of the three mounting holes of the

L-bracket. These t hree points will be your drilling location.

3. Drill through each point with a 9/ 32” drill bit .

4. Insert size 1/4 x 20 x 2-1/2” screws thr ough the L-bracket. Use

the split washers and nylon lock nut provided.

5. Use a 7/16” socket, bow or open- end wrench to tighten and

secure the screws.

Figure 7

Figure 9

Figu re 11

Figure 8

Figu re 10

Fig ure 12

REPLACEMENT PARTS INSTRUCTIONS

Instructions for replacing gear

1. Stand facing opener on the gear side with the handle lowered.

(Figure 7)

2. Wedge a flat headed screwdriver into the slot on the right side of

the gear to keep it from turning. (Figure 8)

3. Gently turn the handle counter clockwise to unscrew. (Figure 9)

4. Remove used gear and washer.

5. Insert the new gear and washer into the slot. Make sure the

printed side of the gear is facing out. (Figure 10)

6. Position screwdriver on the lef t of the gear. (Figure 11)

7. Turn handle clockwise to screw on. Do not over tighten.

(Figu re 12)

MAIN TENANCE: Keep ge ar and other p arts of opener clean. T he shaft e nd

for the gear must be lubric ated regularly with vegetable oil.

Fig ure 13

Fig ure 15

Fig ure 14

2. Place new knife blade on the holder and then the support plate over the

knife blade. (Figure 14)

REPLACEMENT PARTS INSTRUCTIONS

Instructions for replacing knife blade

1. Make sure handle is raised before removing the two screws holding the

old knife blade. (Figure 13)

3. Align holes and refasten the two screws. (Figure 15)

4. Do not remove or adjust any other parts of the opener.

IMPORTANT NOTE: At the first sign of wear, knife blade must be replaced

with a new factory blade to ensure safe and optimal

operation. Do not attempt to sharpen old knife blade

to reuse.

Loading...

Loading...