Page 1

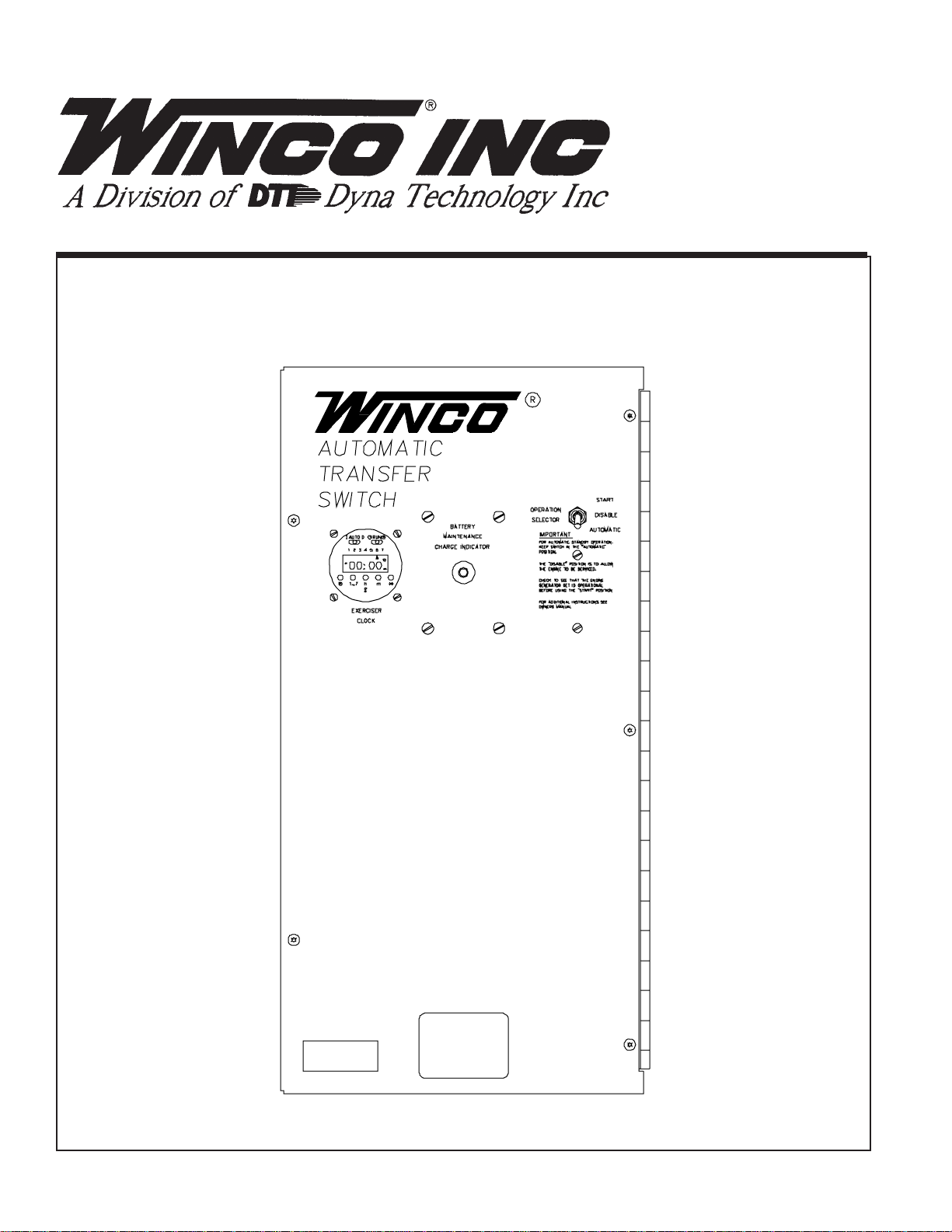

AUTOMATIC

TRANSFER

SWITCH

INSTALLATION AND OPERATORS MANUAL

Page 2

Read and understand all instructions in the

manual before starting and operating the

generator set.

USING THIS MANUAL

Congratulations on your choice of a Winco Automatic

Transfer Switch. You have selected a high-quality,

precision Automatic Transfer Switch designed and

tested to give you years of satisfactory service.

To get the best performance from your new Automatic

Transfer Switch, it is important that you carefully read

and follow the operating instructions in this manual.

Should you experience a problem please follow the

“Things To Check” near the end of this manual. The

warranty listed in this manual describes what you can

expect from WINCO should you need service assistance in the future.

COPY YOUR MODEL AND SERIAL

NUMBER HERE

No other WINCO Automatic Transfer Switch has the

same serial number as yours. It is important that you

record the number and other vital information here. If

you should ever need to contact us on this unit it will

help us to respond to your needs faster.

MODEL____________________________________

SERIAL NUMBER____________________________

PURCHASE DATE____________________________

DEALER___________________________________

TABLE OF CONTENTS

INTRODUCTION i

GUIDE TO PRODUCT SAFETY 1

BASIC INFORMATION 2

Description 2

PREP ARING THE UNIT 3

Unpacking the Unit 3

INST ALLATION PLANNING 3

Installation 3

Automatic Transfer Switch Sizes 3

Installation Notes 3

TRANSFER SWITCH INST ALLATION 4

AC Electrical Connections 4

DC Electrical Connections 5

Exerciser Clock Set Up 5

INITIAL ST ART-UP 6

TROUBLESHOOTING INFORMA TION 6

PREVENTIVE MAINTENANCE 6

WIRING DIAGRAMS

110/60ATS-3/B 7

230/150ATS-3/B 7

400/320ATS-3/B 7

230/150ATS-4/B 7

230/150ATS-17/B 7

ATS-3/A 100/50 8

ATS-3/A 100/100 8

ATS-3/A 225/100 8

ATS-3/A 225/225 8

ATS-3/A 400/300 8

ATS-4/A 100/100 8

ATS-17/A 100/100 8

ATS-4/A 225/100 8

ATS-17/A 225100 8

ATS-4/A 225/225 8

ATS-17/A 225/225 8

ATS-4/A 400/300 8

ATS-17/A 400/300 8

ATS-18/A 100/100 9

ATS-18/A 225/225 9

A.T .S. P ANEL OUTLINE DIMENSIONS 9

12 MONTH W ARRANTY 10

DEALER PHONE # ___________________________

8107-00 60706-131

P AGE i

Page 3

SAFETY INFORMA TION

This engine generator set has been designed and

manufactured to allow safe, reliable performance.

Poor maintenance, improper or careless use can

result in potential deadly hazards; from electrical

shock, exhaust gas asphyxiation, or fire. Please read

all safety instructions carefully before installation or

use. Keep these instructions handy for future

reference. Take special note and follow all warnings

on the unit labels and in the manuals.

b. Keep fuel containers out of reach of children.

c. Do not smoke or use open flame near the

generator set or fuel tank.

d. Keep a fire extinguisher nearby and know its

proper use. Fire extinguishers rated ABC by

NFPA are appropriate.

e. Store fuel only in an approved container, and only

in a well-ventilated area.

f. Follow local codes for closeness to combustible

material.

ANSI SAFETY DEFINITIONS

************************************************************

DANGER:

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury. This signal word is to be limited to the

most extreme situations.

***********************************************************

************************************************************

WARNING:

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

***********************************************************

***********************************************************

CAUTION:

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

************************************************************

NOTE:

CAUTION is also used on the unit labels and in this

manual to indicate a situation that could result in

serious damage or destruction of the equipment and

possible personal injury.

1. ELECTRIC SHOCK - The output voltage present in this

equipment can cause a fatal electric shock. This

equipment must be operated by a responsible

person.

3. DEADL Y EXHAUST GAS - Exhaust fumes from any

gasoline engine contain carbon monoxide, an

invisible, odorless and deadly gas that must be mixed

with fresh air.

a. Operate only in well ventilated areas.

b. Never operate indoors.

c. Never operate the unit in such a way as to allow

exhaust gases to seep back into closed rooms

(i.e. through windows, walls or floors).

4. NOISE HAZARD - Excessive noise is not only tiring,

but continual exposure can lead to loss of hearing.

a. Use hearing protection equipment when working

around this equipment for long periods of time.

b. Keep your neighbors in mind when permanently

installing this equipment.

5. CLEANLINESS - Keep the generator and surrounding

area clean.

a. Remove all grease, ice, snow or materials that

create slippery conditions around the unit.

b. Remove any rags or other material that could

create potential fire hazards.

c. Carefully clean up any gas or oil spills before

starting the unit.

d. Never allow leaves or other flammable material

to build up around the engine intake or exhaust

area.

6. SERVICING EQUIPMENT - All service, including the

installation or replacement of service parts, should be

performed only by a qualified technician.

a. Do not allow anyone to operate the generator

without proper instruction.

b. Guard against electric shock.

c. Avoid contact with live terminals or receptacles.

d. Use extreme care if operating this unit in rain or

snow.

e. Use only three-prong grounded receptacles and

extension cords.

f. Be sure the unit is properly grounded to an

external ground rod driven into the earth.

2. FIRE HAZARD - Natural gas and L.P. present a hazard

of possible explosion and/or fire.

a. Do not refuel when the engine is running or hot.

Allow the engine to cool at least two minutes

before refueling.

PAGE 1

a. Use only factory approved repair parts.

b. Do not work on this equipment when fatigued.

c. Never remove the protective guards, cover, or

receptacle panels while the engine is running.

d. Use extreme caution when working on electrical

components. High output voltages from this

equipment can cause serious injury or death.

e. Always avoid hot mufflers, exhaust manifolds,

an d engine parts. They all can cause severe

burns instantly.

f. Installing a generator set is not a “do-it-yourself”

project. Consult a qualified, licensed electrician

or contractor. The installation must comply with

all national, state, and local codes.

60706-1318107-00

Page 4

TESTING POLICY:

UNPACKING INSTRUCTIONS

Before any Automatic Transfer Switch (A.T.S.) is shipped

from the factory, it is fully checked for performance.

Rated capability of the Automatic Transfer Switch is

based on engineering tests of typical units, and is

subject to, and limited by, the temperature, and other

conditions specified by the manufacturer.

DESCRIPTION

These wall mounted Automatic Transfer Switch (A.T.S.)

are designed for inside installation. The A.T.S. consists

of a line side contactor and a generator side contactor.

The contactors are both electrically and mechanically

interlocked.

An automatic taper battery trickle charger (40 MA max.)

and a seven day electronic exerciser clock are installed

in the A.T.S. as standard equipment. The battery trickle

charger is not designed to recharge a low battery, but is

designed to keep a fully charged battery in peak operating condition. The exerciser clock is electronically

programmable, which allows you to set multiply exercise

periods during the week. These exercise periods can be

from 1 second long to hours long depending on how

long you want it operate.

The A.T.S. also contains the power failure sensing

circuitry necessary to send a start/stop signal to the

engine generator set. These switches are designed to

close to ground (Battery Negative) upon failure of normal

power. If the engine control you are using needs a

positive signal or some other type of signal to initiate the

start sequence you will have to install a pilot relay in the

start circuit. (Consult the factory for details.)

During normal operation the A.T.S. will supply normal line

power to the loads connected to the load terminals in the

switch. Upon an interruption of normal electrical service

the A.T.S. will close the start/stop relay sending a start

signal to the engine-generator set. Once the enginegenerator is producing electricity, the Automatic Transfer

Switch will transfer the connected loads to the enginegenerator set. Upon restoration of normal electrical

service the A.T.S. will sense the return of the normal

commercial power and retransfer the connected loads

back to the normal power source. At the same time the

start/stop relay will open removing the start signal being

sent to the engine control, allowing the engine-generator

set to shut down.

** NOTICE **

When unpacking the Automatic Transfer Switch, be sure

to inspect it carefully for freight loss or damage. If loss or

damage is noted at the time of delivery, require that the

person making the delivery make note of the loss or

damage on the freight bill, or affix his signature under the

consignor’s memo of the loss or damage. Contact the

carrier for claim procedures.

When loss or damage is noted after delivery, segregate

the damaged material, and contact the carrier for claim

procedures. Be sure to retain the packaging material for

carrier inspection.

“Concealed Damage” is understood to mean damage to

the contents of a package which is not evident at the time

of delivery by the carrier, but which is discovered later.

The carrier or carriers are responsible for merchandise

lost or damaged in transit. The title to goods rests with

the consignee when generators are shipped F.O.B.

factory, and only the consignee can legally file a claim.

UNPACKING:

1. Carefully remove the carton.

2. After inspecting the Automatic Transfer Switch for

external physical damage. Carefully inspect the

contactors, contactor interlocks and the contactor

mountings, to insure no damage has occurred to the

contractors during shipment and handling.

3. Check inside the carton for the owner’s manual,

wiring diagram and parts list.

INSTALLATION

General Information

*************

***** WARNING ****

*************

Before proceeding with the installation, be sure the

operation selector switch is in the STOP position.

Before beginning the installation process recheck the

rating of the transfer switch to be certain it can handle the

intended load and is compatible with the entrance

voltage, phase and current ratings. Plans for installation

should be prepared with proper attention to mechanical

and electrical engineering detail to assure a satisfactory

installation. The information in this manual is offered

only as a guide to finalizing your installation plans.

60706-131

PAGE 2

8107-00

Page 5

AUTOMA TIC TRANSFER SWITCH SIZES

CONT ACTOR SIZE

MODEL VOL TAGE PH LINE GEN.

ATS-3/B 100/50 120/240 1 100 AMP 50 AMP

110/60ATS-3/B 120/240 1 1 10 A MP 60 AMP

ATS-3/A 100/100 120/240 1 100 AMP 100 AMP

ATS-4/A 100/100 120/208 3 100 AMP 100 AMP

ATS-17/A 100/100 120/240 3 100 AMP 100 AMP

ATS-18/A 100/100 277/480 3 100 AMP 100 AMP

ATS-3/A 225/100 120/240 1 225 AMP 100 AMP

ATS-4/A 225/100 120/208 3 225AMP 100 AMP

ATS-17/A 225/100 120/240 3 225 AMP 100 AMP

230/150ATS-3/B 120/240 1 230 AMP 150 AMP

230/150ATS-4/B 120/208 3 230 AMP 150 AMP

230/150ATS-17/B 120/240 3 230 AMP 150 AMP

ATS-3/A 225/225 120/240 1 225 AMP 225 AMP

ATS-4/A 225/225 120/208 3 225 AMP 225 AMP

ATS-17/A 225/225 120/240 3 225 AMP 225 AMP

ATS-18/A 225/225 277/480 3 225 AMP 225 AMP

ATS-3A 400/300 120/240 1 400 AMP 300 AMP

ATS-4A 400/300 120/208 3 400 AMP 300 AMP

ATS-17A 400/300 120/240 3 400 AMP 300 AMP

400/320ATS-3/B 120/240 1 400 AMP 320 AMP

Optional A.T.S. sizes are available to meet specific

needs. If you need a switch of a different size contact

WINCO, Inc.

To wire the automatic transfer switch into the existing

wiring, first determine which circuits will be on the

emergency load circuit. If the entire load is to be

transferred, the transfer switch can be wired in directly

after the watt-hour meter or main entrance, provided the

service entrance ampere rating is within the transfer

switch’s rated capability. (See figure 3 and figure 5)

If only specific circuits are to be powered during power

failure conditions, an additional distribution panel

designated “emergency distribution panel” must be

installed. All selected emergency circuits are removed

from main distribution panels and reinstalled in the

emergency distribution panel. Suggested circuits:

freezer, refrigerator, furnace, emergency lights, sump

pump, emergency outlet circuits, etc. Total running load

must not exceed generator rating. (See figure 4)

FIGURE 3

INSTALLA TION NOTES

The load current carrying wires (L) and (T) must be sized

to handle the maximum load current without excessive

voltage drop. By code, the wire must be heavy enough to

handle the full current rating of the main line circuitbreaker (or fuse) in the entrance (or sub-panel) protecting the transfer switch.

All wires should be installed in rigid or flexible conduit.

(Knockouts are provided in the control box)

Because of the many different types of service, feeder,

and distribution equipment, no specific wiring instructions can be provided. It is, however, recommended that

only copper wire be used. In all cases it is essential that

while the load is connected to the generator, there can be

absolutely no feedback from the generator to the power

line or the power line to the generator. When properly

installed, the normal A.T.S. control and safety systems

will eliminate all paths for feedback. Check with your

local electrical inspector on applicable local, state and

federal codes.

NOTE:

It is an excellent idea to install a disconnect in the

incoming power line wiring directly in front of the A.T.S.

panel. This will allow you to test the generator under

load. Should you ever have to work on the switch, you

will be able to disconnect the power and work on the

switch cold, without having the power company pull your

meter.

FIGURE 4

PAGE 3

60706-1318107-00

Page 6

FIGURE 5

INSTALLING THE AUTOMATIC

TRANSFER SWITCH (A.T.S.)

GENERAL INFORMATION

*************

***** WARNING *****

*************

EQUIPMENT DAMAGE- Protect the switch from construction grit and metal chips to prevent a malfunction or

shortened life of the switch.

The Automatic Transfer Switch connects the load (lights,

furnace, outlets, etc.) to the normal power line during

standby. When normal power fails, the A.T.S. starts the

engine generator set, disconnects the power line and

then connects the load to the standby generator set.

When normal power is restored, the automatic switch

retransfers the electrical load to the normal service and

stops the engine. The A.T.S. panel should be mounted

as close to the distribution panel as possible.

*************

***** WARNING *****

*************

All wiring must be done by a licensed electrician, and

must conform to the national electrical code and comply

with all state and local codes and regulations. Check

with your electrical inspectors before proceeding!

Before installing the Automatic Transfer Switch you must

first ensure that the line side contractor will be of

sufficient size to handle your complete service. (i.e. the

main line breaker must not be larger than the line side

contactor rating.) If you will not be able to transfer the

complete electrical system it will be necessary to install

a secondary emergency distribution panel.

*************

***** DANGER *****

*************

Be certain the operation selector switch on the front of the

A.T.S. Control is in the “stop” position and the main power

switch “off”. For your own protection, verify these important safety precautions yourself with reliable instruments

before proceeding.

A.C. ELECTRICAL CONNECTIONS

*************

***** WARNING *****

*************

A FUSED DISCONNECT/CIRCUIT BREAKER MUST BE

INSTALLED BETWEEN THE GENERATOR AND THE

A.T.S. P ANEL TO PREVENT OVERLOADING AND

BURNING OUT OF THE GENERATOR. FAILURE TO

PROVIDE A FUSED DISCONNECT OR CIRCUIT

BREAKER, FOR GENERATOR RATING WILL VOID

YOUR WARRANTY IN CASE OF GENERATOR FAILURE.

SINGLE PHASE A.T .S. CONNECTIONS

The generator terminals (power in from the generator) in

the A.T.S are marked “GENERATOR - G1, G-N, G3”. The

“hot” leads G1 and G3 are wired to the generator side

contactor, terminals G1 and G3.

The line terminals (normal power source) in the A.T.S.

are marked “LINE - L1, L-N, L3”. The “hot” leads L1 and

L3 are wired to the line side contactor, terminals L1 and

L3.

The load terminals (power out to loads) in the A.T.S. are

marked “LOAD - T1, T-N, T3”. The “hot” leads T1 and T3

are wired to the load lugs T1 and T3.

All three neutral connections are made to the appropriate

neutral lugs. These lugs have been prewired common

in the A.T.S. A neutral to ground bond has also been

installed in the A.T.S. panel. If your system requires an

isolated neutral this bond, a copper jumper strap, should

be removed. If this jumper strap is removed remember

to properly ground the Automatic Transfer Switch using

the grounding lug provided.

THREE PHASE A.T .S. CONNECTIONS

The standby generator terminals in the A.T.S are marked

“GENERATOR - G1, G2, G3 and G-N”. The “hot” leads G1,

G2 and G3 are wired to the generator side contactor,

terminals G1, G2 and G3.

The line terminals in the A.T.S. are marked “LINE - L1, L2,

L3” and L-N. The “hot” leads L1, L2 and L3 are wired to

the line side contactor, terminals L1, L2 and L3.

The load terminals in the A.T.S. are marked “LOAD - T1,

T2, T3 and T-N”. The “hot” leads T1 and T3 are wired to

the load lugs T1, T2 and T3.

60706-131

PAGE 4

8107-00

Page 7

All three neutral connections are made to the appropriate

neutral lugs. These lugs have been prewired common

in the A.T.S. A neutral to ground bond has also been

installed in the A.T.S. panel. If your system requires an

isolated neutral this bond, a copper jumper strap, should

be removed. If this jumper strap is removed remember

to properly ground the Automatic Transfer Switch using

the grounding lug provided.

THREE PHASE POWER MONITOR

All three phase Automatic Transfer Switches have a three

phase power monitor installed in them to monitor each

phase for low voltage. This three phase monitor is

phase rotation sensitive also, and comes from the factory

set up for A-B-C phase rotation. If you have trouble

getting the A.T.S. to pickup the line power on initial

installation, try switching the A and B phase on the

monitor. Your rotation may be C-B-A. If so, be sure to

match the generator rotation to your current normal

power rotation or your three phase motors will try to turn

backwards.

*************

***** WARNING *****

*************

When installing a Three Phase 240 Volt Delta system be

sure you know which lead is the high voltage leg (208

Volt line to neutral). The Automatic Transfer Switch is set

up for the high voltage lead to be connected at G2, T2

and L2 only.

D.C. ELECTRICAL INTERCONNECTION

*******CAUTION******

Never run the AC and DC wiring in the same conduit.

The start circuitry in these A.T.S. is a ground to operate

system. When the power fails the start/stop relay on the

door closes and connects the start wire to battery

negative. If your Engine-Generator set needs any other

type of signal to operate, you will need to contact the

WINCO, Inc. Service Department at 507-357-6831.

Three control wires are required to be installed between

the A.T.S. panel and the generator control. Depending on

the distance 14 to 16 gauge stranded wire should be

sufficient. These wires will be labeled “Bat +”, “Bat -”,

and “Start”. The “Bat+” lead is not used for starting, its

sole purpose is to connect the battery trickle charge back

to the battery on the unit.

SETTING THE EXERCISER CLOCK

Setting the current time and date.

1. Position the top right hand (RUN) slide switch to the

left position.

2. Push the clock’s “Day Select Button” until the clock

displays a triangle under the number corresponding to

the current day of the week. (Monday is day 1, Sunday is

day 7)

3. Push the “Hour Select Button” until the display

indicates the correct time in hours. Note: In the afternoon

you should push the button until a “P” is displayed

beside the correct hour.

4. Push the “Minute Select Button” until the display

indicates the correct time in minutes.

5. Position the top right hand (RUN) slide switch to the

center position. The correct time and date should now

be displayed.

Setting the Exerciser Program:

1. Position the top right hand (RUN) slide switch to the

right hand position.

2. Position the top left hand (AUTO) slide switch to the

center position.

3. Press the “Program Select Button” until No 1 is

displayed on the clock to the right of the time.

4. Push the “Day Select Button” to select the day you

want the engine generator set to start up and run. Note:

You can get more than one triangle displayed on the

clock. If this happens just keep pressing the button and it

will work back through the cycle and display only one

triangle under whichever day you desire.

5. With the “Hour” and “Minute” buttons select the time

of day you want the engine to start up.

6. Press the “Program Select Button” until No. 2 is

displayed on the clock.

7. Push the “Day Select Button” to select the day you

want the engine to stop. This must be the same day you

selected in step 4 above.

PAGE 5

8. With the “Hour” and “Minute” buttons, select the time

you want the engine to stop. It is recommended you let

the engine run at least 15 minutes during any exercise

period.

9. Position the top right hand (RUN) slide switch to the

center (RUN) position.

60706-1318107-00

Page 8

CLOCK NOTES:

This seven day exerciser clock has seven additional

program cycles available. Always keep in mind the odd

number turns the unit on and the even number shuts the

unit off. (i.e. (3 on, 4 off) (5 on, 6 off) etc.)

This completes your installation and unit testing.

ALWAYS leave the system in automatic mode unless

servicing the unit. For automatic operation, keep both the

generator set and transfer selector switches in the

“AUTOMA TIC” position.

The relay in the clock will not work unless the transfer

switch is installed and powered up. The relay needs

120 volts AC to operate.

If, when you finish programming the clock, you get an

“EEEE” on the display, it stands for error. The most

common error is that the day of operation has not been

properly set at each step or a program has been turned

on and not turned off. (i.e. programs not properly

grouped 1& 2, 3 & 4, 5 & 6, etc.)

On the face of clock is a small button marked “R”, this is

a reset switch. Depressing this switch will remove all

programming in the clock including the time. Use a

small screwdriver or the tip of a pencil to depress this

button. This should be used only as a last resort.

INITIAL START UP

Move the selector switch on the engine generator set to

the “AUTOMATIC” position. Next move the selector

switch on the A.T.S. panel to the “START” position. The

engine generator set should start up. If it fails to start at

this time, check the selector switch on the engine

generator to be sure it is in the “automatic” position.

Also check to be sure the DC interconnection wiring is

correct. When the selector switch on the A.T.S. is moved

to the “DISABLE” position the engine generator set will

shut off. As long as line power is still applied to the

transfer switch during this test period the A.T.S. will not

transfer the load to the generator.

TROUBLESHOOTING HINTS

ATS P ANEL WILL NOT TRANSFER TO

EMERGENCY SUPPL Y (GENERATOR).

1. No AC generator output from generator.

2. Broken or defective mechanical/electrical inter

locks.

3. Defective holding coil in the generator side

contactor.

4. Wiring error between generator set and transfer

switch.

5. Defective Start Stop Relay

ATS PANEL WILL NOT CLOSE WITH

NORMAL POWER APPLIED.

1. Proper normal line power not available at line

terminals in ATS panel.

2. Defective holding coil in line side contactor.

3. Broken or defective mechanical/electrical inter

locks.

4. Defective Start Stop Relay.

5 Defective Phase Failure Monitor. (Three Phase

Units only)

6. Phase Rotation wrong to the Phase Failure

Monitor.

PREVENTIVE MAINTENANCE

Next you need to test the complete system. To accomplish this you will have to fail the incoming line power to

the A.T.S. panel. First move both selector switches to the

automatic position. Then fail the incoming power. All the

loads connected to the A.T.S. should now be dead. The

engine generator set should now start up. As soon as

the engine generator set reaches operating voltage the

generator side contactor will close and the load will be

applied to the engine generator.

Restoring the line power to the transfer switch will cause

the generator side contactor to open. The line side

contactor will close as soon as the generator side

contactor clears the mechanical interlock and closes the

electrical interlock. These interlocks ensure that you get

a clean ‘break before make’ action in the transfer switch.

The restoration of line power also breaks the run signal

to the engine generator set allowing it to shut down.

60706-131

Reasonable care and preventive maintenance will insure

high reliability and a long life for the Automatic Transfer

Switch.

*************

***** WARNING *****

*************

When performing any type of maintenance on this

equipment make sure the selector switch on the A.T.S. is

in the “disable” position. Disconnect normal power and

confirm with a reliable meter that all power has been

disconnected.

Clean and inspect the switch once a year. De-energize

all power sources, both line and engine generator set,

then brush and vacuum away any excessive dust and dirt

accumulation. You can at this time with the contactor deenergized remove the contactor covers and check the

contacts. Make sure the contacts are clean and not

burned or pitted.

PAGE 6

8107-00

Page 9

230/150ATS-4/B

230/150ATS-17/B

110/60ATS-3/B

230/150ATS-3/B

400/320ATS-3/B

PAGE 7

60706-1318107-00

Page 10

ATS-3/A 100/50

A TS-3/A 100/100

A TS-3/A 225/100

A TS-3/A 225/225

A TS-3/A 400/300

60706-131

A TS-4/A 100/100

A TS-17/A 100/100

A TS-4/A 225/100

A TS-17/A 225/100

A TS-4/A 225/225

A TS-17/A 225/225

A TS-4/A 400/300

A TS-17/A 400/300

PAGE 8

8107-00

Page 11

ATS-18/A 100/100

ATS-18/A 225/225

ATS PANEL OUTLINE

DIMENSIONS

A TS SIZE REF A REF B REF C REF D REF E

100/50 ATS 21.00” 8.00” 8.10” 24.25” 12.375”

100/100 ATS 22.88” 14.00” 10.63” 28.25” 18.375”

225/100 ATS 22.88” 14.00” 10.63” 28.25” 18.375”

225/225 ATS 22.88” 14.00” 10.63” 28.25” 18.375”

400/225 ATS 28.00” 16.00” 12.68” 36.00” 23.88”

400/300 ATS 28.00” 16.00” 12.68” 36.00” 23.88”

110/60 A TS 17.00” 8.00” 8.10” 20.00” 12.375”

230/150 ATS 22.90” 14.00” 10.63” 28.00” 18.375”

400/320 ATS 28.00” 16.00” 12.68” 36.00” 23.875”

PAGE 9

60706-1318107-00

Page 12

WINCO, Incorporated warrants to the original purchaser for 12 months that goods manufactured or supplied by it will be free from defects in workmanship and material, provided such goods

are installed, operated and maintained in accordance with Winco written instructions.

WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be

limited to the repair of the product. At WINCO’s option, material found to be defective in material or

workmanship under normal use and service will be repaired or replaced. For warranty service,

return the product within 12 months from the date of purchase, transportation charges prepaid, to

your nearest WINCO Authorized Service Center or to WINCO, Inc. at Le Center Minnesota.

THERE IS NO OTHER EXPRESS WARRANTY.

To the extent permitted by law, any and all warranties, including those of merchantability and

fitness for a particular purpose, are limited to 12 months from date of purchase. In no event is

WINCO liable for incidental or consequential damages.

Note: Some states do not allow limitation on the duration of implied warranty and some states

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitations may not apply in every instance. This warranty gives you specific legal rights which may

vary from state to state.

WINCO reserves the right to change or improve its products without incurring any obligations

to make such changes or improvement on products purchased previously.

EXCLUSIONS:

WINCO does not warrant Engines, Batteries, or Other Component Parts that are warranted

by their respective manufacturers.

WINCO does not warrant modifications or alterations which were not made by WINCO, Inc.

WINCO does not warrant products which have been subjected to misuse and/or negligence

or have been involved in an accident.

225 SOUTH CORDOVA A VE

LE CENTER MN 56057

Phone: 507-357-6831

60706-131

PAGE 10

8107-00

Loading...

Loading...