Page 1

Operator’s

Automatic Transfer Switches

Manual

D desi gn , 30 through 230 amp. sizes

DANGER is used in this manual to warn of high

voltages capable of causing shock, burns, or death.

!

WARNINGisusedinthismanualto

warn of possible personal injury.

!

Series 300

Refer to the outline and wiring drawings provided with

your ASCO Series 300 ATS for all installation details.

ASCO Series 300 Automatic Transfer Switches (ATSs) are

Listed under Underwriters Laboratories UL 1008 Standard

for Safety for Automatic Transfer Switches. ASCO Series

300s are also Listed under CSA C22.2 No. 178 Standard for

Automatic Transfer Switches. All control features are UL

Component Recog nized, which assures that ASCO automatic

transfer switches meet OSHA Safety Requ irem ents and will

be acceptable to electrical inspectors.

CAUTIONisusedinthismanualtowarn

of possible equipment damage.

An experienced licensed electrician must install the ATS.

ASCO Series 300 Automatic Transfer Switches are suitable

for emergency and standby system applications. They meet

emergency system rating requirements as defined in

National Electrical Code (NEC) Article 700 and UL 1008.

Also, they are suitable for the requirements of NEC Article

517 – Health Care Facilities, NEC Article 701 – L egally

Required Standby Systems, NEC Article 702 – Optional

Standby Systems, NFPA 99 Health Care Facilities, and

NFPA 110 Emergency and Standby Power Systems.

Rating Label

Each automatic trans fer switch con tains a rating label to

define the loads and fault circuit withstand / closing ratings.

Refer to the label on the transfer switch for specific values.

!

Do not exceed the values on the rating label.

Exceeding the rating can cause personal injury

or serious equipment damage.

TABLE OF CONTENTS

section

INSTALLATION 1..........................

SEQUENCE OF OPERATION 2.............

TESTING & SERVICE 3....................

ADJUSTMENTS 4.........................

CONTROL FEATURES 5...................

30–200 amp. sizes

50 Hanover Road, Florham Park, New Jersey 07932–1591 USA

1 800 937–2726 (ASCO), for service call 1 800 800–2726 (ASCO) www.asco.com

ASCO POWER TECHNOLOGIES CANADA PO Box 1238, 17 Airport Road, Brantford, Ontario, Canada N3T 5T3

telephone 519 758–8450, fax 519 758–0876, for service call 1 888 234–2726 (ASCO) www.asco.ca

INDEX back cover.........................

381333–228 D

Page 2

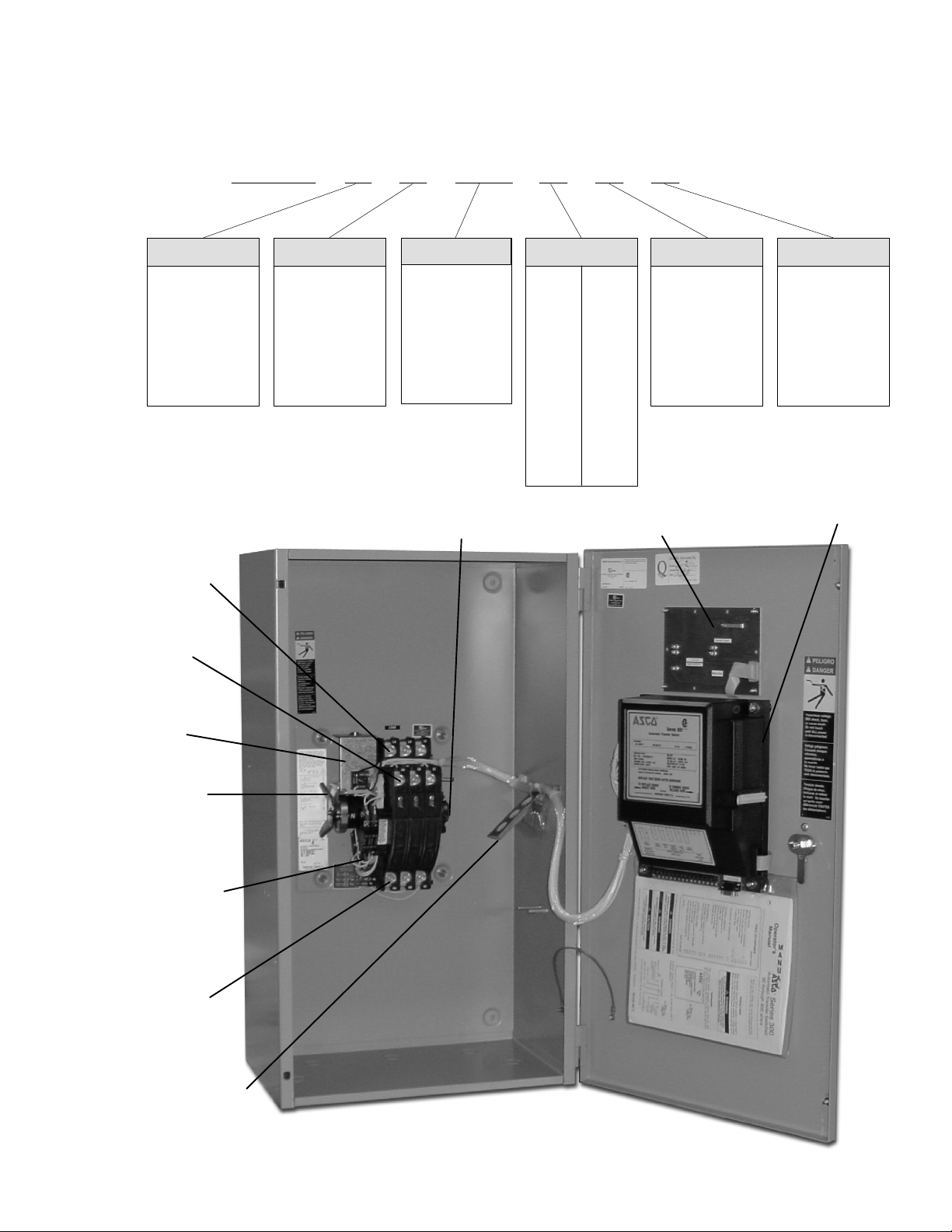

Nameplate

The Transfer Switch nameplate includes data for each

specific ASCO Series 300 ATS. Use the ATS only

within the limits shown on this nameplate.

D 300 B 3 200 N 1 C

Catalog Number Identification

A typical Catalog Number is shown below with its

elements explained. The example is for a Series 300

ATS with switched neutral, 3 pole, 200 amp, 480 V, in

a Type 1 enclosure:

Neutral

B –switched

C – overlapping

blank – solid

load power

connections

emergency power

connections

Phase Poles

2 –singleØ

3 –threeØ

terminals for switch

Amperes Voltage Controller Enclosure

30

70

104

150

200 *

* 200 amp. limited

to 480 volts

position contacts

A 115

B 120

C 208

D 220

E 230

F 240

H 380

J 400

K 415

L 440

M 460

N 480

P 550

Q 575

R 600

membrane

controls

1 –standard

1X –if

accessories

ordered

C –type1

F –type3R

G –type4

L –type12

blank – open type

Controller

Transfer

Switch

maintenance

handle

(see WARNING

under Manual

Operation)

terminals for

engine start

contacts

normal power

connections

cable spacers

(see INSTALLATION)

200 amp. size in typical enclosure with location of customer connections

Page 3

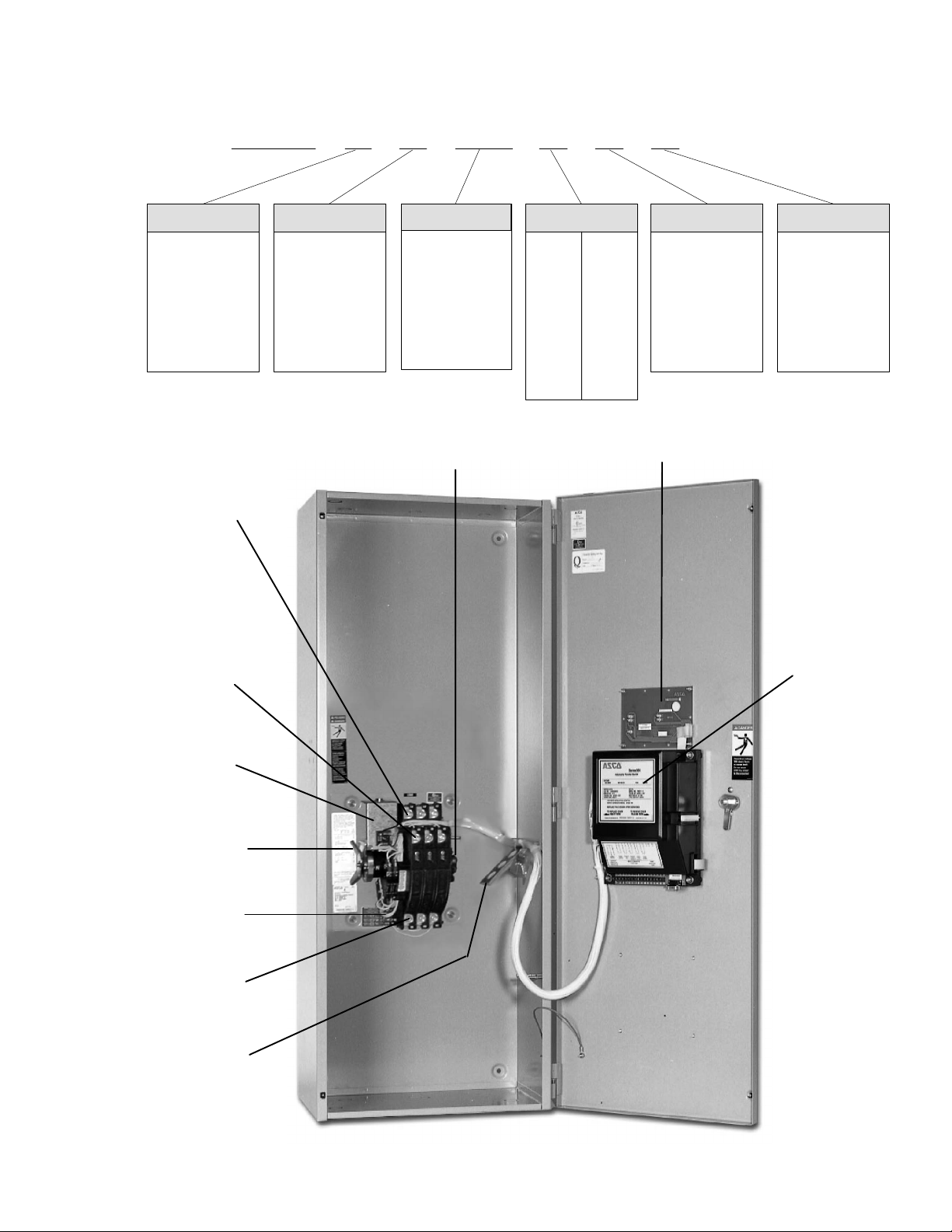

Catalog Number Identification

A typical Catalog Number is shown below with its elements explained. The example is for a Series 300 ATS with

switched neutral, 3 pole, 230 amp, 480 V, in a Type 1 enclosure:

D 300 B 3 230 N 1 C

Neutral

B –switched

C – overlapping

blank – solid

load power

connections

emergency power

connections

Phase Poles

2 –singleØ

3 –threeØ

Amperes Voltage Controller Enclosure

230 **

** 230 amp. limited

to 480 volts

terminals for switch

position contacts

A 115

B 120

C 208

D 220

E 230

F 240

H 380

J 400

K 415

L 440

M 460

N 480

1 –standard

1X –if

accessories

ordered

membrane

controls

C –type1

F –type3R

G –type4

L –type12

blank – open type

Controller

Transfer Switch

maintenance handle

(see WARNING under

Manual Operation)

terminals for

engine start contacts

normal power

connections

cable spacers

(see INSTALLATION)

230 amp. size in typical enclosure with location of customer connections

Page 4

SECTION 1 INSTALLATION

Series 300 AutomaticTransfer Switchesare factory wired

and tested. Installation requires skid removal then

securing the enclosure to the supporting foundation.

Mounting

Refer to the applicable enclosure outline drawing furnished with this switch and mount the Series 300

according to details and instructions shown on diagram.

!

Protect the automatic transfer switch from

construction grit and metal chips to prevent

malfunction or shortened life of the ATS.

Mount the ASCO ATS vertically to a rigid supporting

structure. Level all mounting points by using flat washers

behind the holes to avoid distortion of the switch.

Connecting Power Conductors

After the powercables have been tested, connect them to

the appropriate terminal lugs on the transfer switch as

shown on the wiring diagram provided wit h this Series

300. M ake sure the lugs provided are suitable for use with

the cables being installed. Standard terminal lugs are

solderless screw type and will accept the wire sizes listed

on the drawings provided with the Series 300. Be careful

when stripping insulation from the cables; avoi d nicking

or ringing the conductor. Remove surface oxides from

cables by cleaning with a wire brush. When aluminum

cable is used, apply joint compound to conductors.

Tighten cable lugs to the torque specified on rating label.

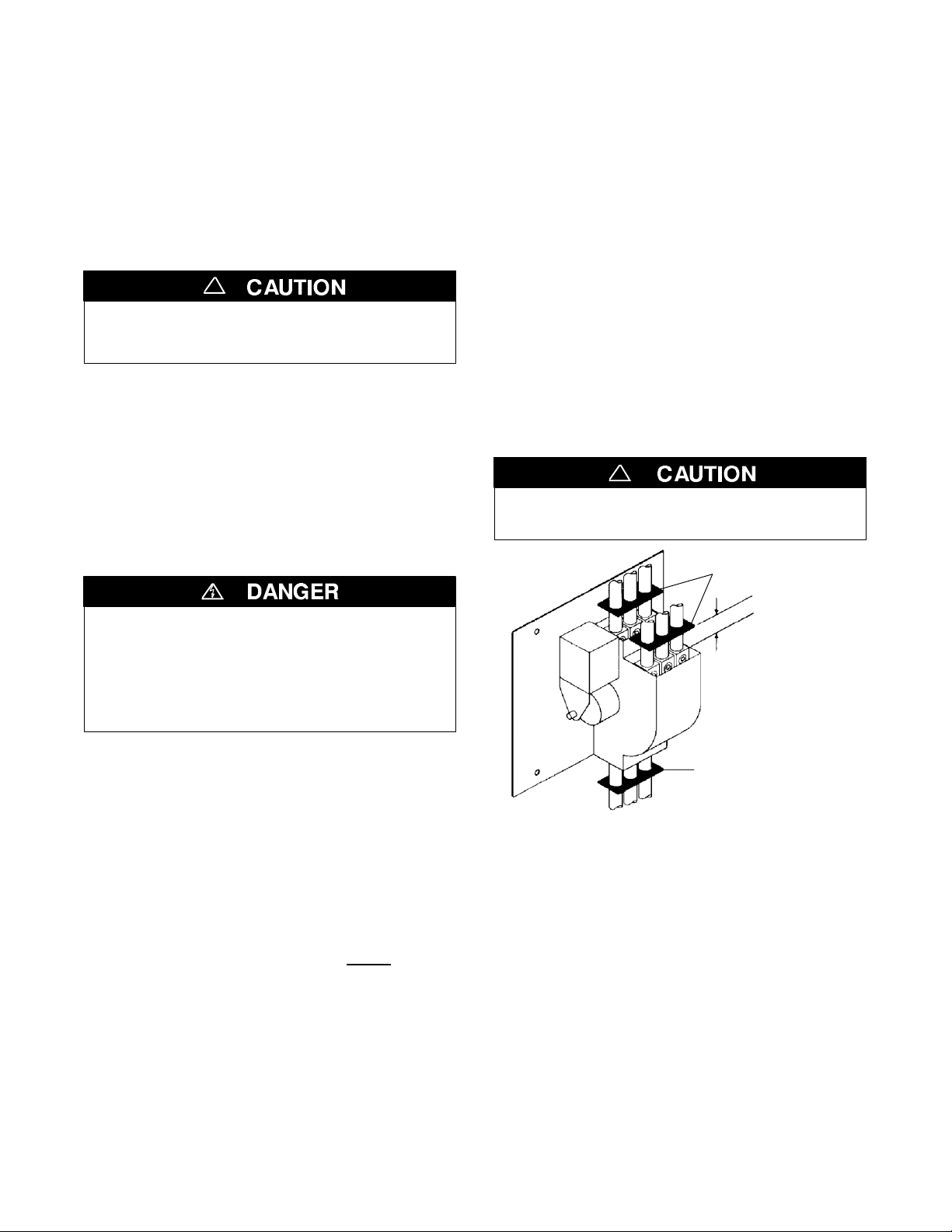

Three cable spacers are included with 150, 200, and 230

ampere transfer switches. When installing power cables,

run the cables through the cable spacers as shown in

Figure 1–1. Position cable spacers within 1½ inches from

lugs.

Line Connections

Refer to the Wiring Diagram provided with your Series

300 ATS. All wiring must be made in accordance with the

National Electrical Code and local codes.

De–energize the conductors before making any

line or auxiliary circuitry connections. Be sure

that Normal and Emergency line connections

are in proper phase rotation. Place engine generator starting control in the OFF position. Make

sure engine generator is not in operation.

It is unnecessary to remove pole covers from the transfer

switch. If you do remove them, reinstall them carefully.

Testing Power Conductors

Do not connect the power conductors to the ASCO

Series 300 transfer switch until they are tested. Installing

power cables in conduit, cable troughs and ceiling-suspended hangers often requires considerable force. The

pulling of cables can damage insulation and stretch or

break the conductor’s strands. For this reason, after the

cables are pulled into position, and before

connected, they should be tested to verify that they are

not defective or have been damaged during installation.

they are

!

The cable spacers must be located as shown

for 150, 200, and 230 ampere transfer switches.

cable spacers

1 ½ inch approximate

cable spacer

Figure 1–1. Cable spacers for 150, 200, & 230 amp.

transfer switches.

1--1

Page 5

INSTALLATION (continued)

Engine Starting Contacts

Controller Ground

Customer connections for engine control contact

connections are located on the transfer switch. Refer to

wiring diagram provided with the Series 300 A TS and

connect the engine start wires to the appropriate

terminals . See Figure 1–2 and Table A.

Table A. Engine start connections.

When normal source

fails

Terminals on transfer

switch

contact closes TB14 and TB15

contact opens TB14 and TB16

ENGINE STARTING CONTACTS

( SHOWN DE–ENERGIZED )

TOP

STUD

MIDDLE

STUD

BOTTOM

STUD

14

TS

15

NR

16

NR

TB 14

TB 16

left side

of switch

TB 15

Figure 1–2. Engine starting contact label and

terminals located on the transfer switch.

A grounding wire must be connected to the controller’s

lower left mounting stud. Because the controller is

mounted on the enclosure door, a conductive strap must

be used between the enclosure and the door. This

connection provides proper grounding which does not

rely upon the door hinges.

Harnesses

The transfer switch is connected to the left side of the

controller by a plug–in harness (two plugs).

Auxiliary Circuits

Connect auxiliary circuit wires to appropriate terminals

on transfer switch as shown on the wiring diagram

provided with this Series 300 Automatic Transfer Switch.

Make the necessary auxiliary connections by referring to

Section 5, Control Features.

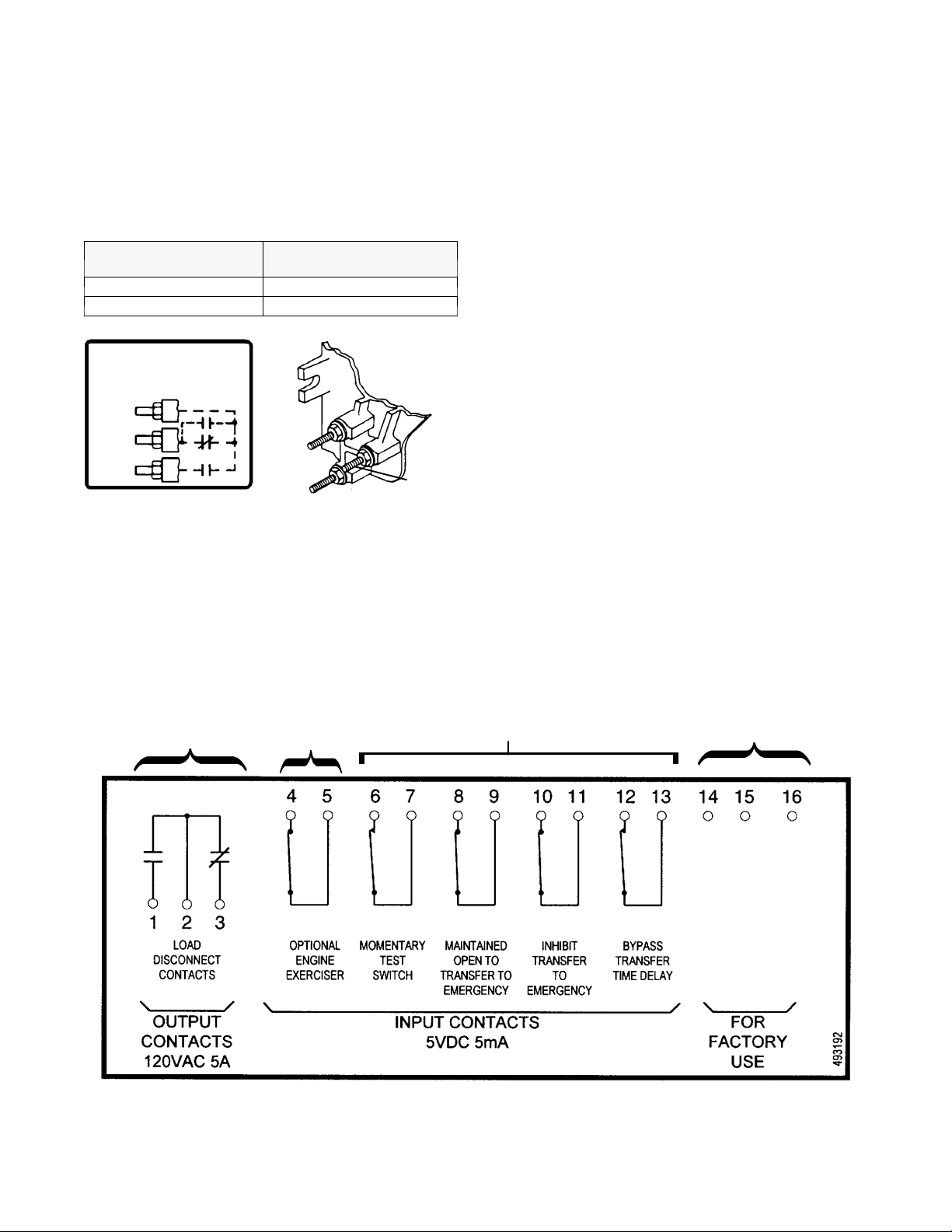

Load Disconnect

Feature

Connections

(see Wiring Diagram

& refer to page 5–5

for DIP switch settings)

Connections to Controller for other Control Features

(located on bottom of Controller)

Programmable

Engine Exerciser

connection,

if provided

(refer to

page 5–2)

Remote Control Features Connections

(refer to the Wiring Diagram &

page 5–5 for DIP switch settings)

Each control contact must be suitable

for a 5 V DC low energy circuit.

for factory

use only

Figure 1–3. Input / output label on the Controller showing possible connections to the lower terminal block.

1--2

Page 6

INSTALLATION (continued)

Functional Test

The Functional Test consists of three checks: manual

operation, voltage checks, and electrical operation.

!

Do these checks in the order presented to

avoid damaging the automatic transfer switch.

Read all instructions on the Wiring Diagram and labels

affixed to the automatictransfer switch. Note the control

features that are provided and review their operation

before proceeding.

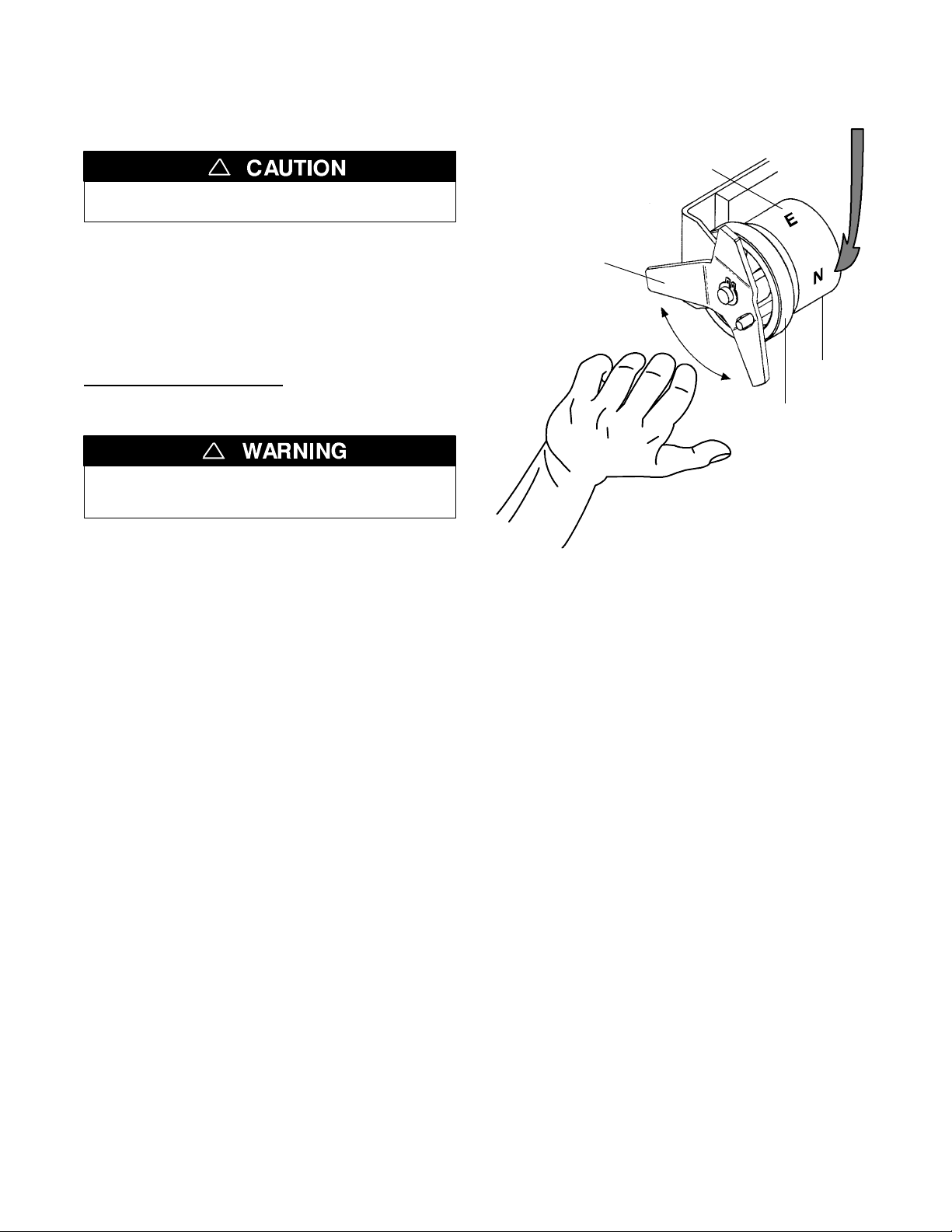

1 – Manual Operation Te st

A maintenance handle is provided on the Transfer Switch

for maintenance purposes only

transfer switch should be checked before it is energized

(operated electrically).

!

Do not manually operate the transfer switch

until both power sources are disconnected:

open both circuit breakers.

1. After deenergizing both power sources, open the

enclosure door. Locate and the maintenance handle

on the left side of the transfer switch frame. See

Figure 1–4.

2. Grasp the attached maintenance handle and turn it

with thumb and fingers as shown to manually operate

it. The maintenance handle turns the opposite direction of the weight. Move it up or down as shown to

manually operate the transfer switch. It should operate

smoothly without any binding. If it does not, check for

shipping damage or construction debris.

3. Return the transfer switch to the Normal position.

Note: If Normal and Emergency connections are

reversed this operation is also reversed.

. Manual operation of the

Position of the transfer switch is indicated here

weight marked N (normal)

and E (emergency)

maintenance

handle

weight

floating

weight

With ALL POWER OFF grasp

maintenance handle and turn it

quickly with your thumb and fingers.

Figure 1–4. Maintenance handle and positions.

Now continue to 2–VoltageCheckson next page.

1--3

Page 7

INSTALLATION (continued)

TRANSFER SWITCH TEST BYPASS TIME DELAY SET ENGINE EXERCISER

observe these lights

Press for 15 Seconds

Figure 1–5. Standard controls and indicators.

2–VoltageChecks

First check nameplat e on transfer switch; rated voltage

mustbethesameasnormalandemergencylinevoltages.

!

Verify that the feeders have been

connected to the proper lugs.

Use extreme caution when using a meter

to measure voltages in the following

steps. Do not touch power terminals;

shock, burns, or death could result !

Performsteps 1 through 6 at the right. Observe the status

lights. See Figure 1–5.

● Black circle means light is on.

❍ White circle means light is off.

* If necessary, adjust voltage regulator on the generator

according to the manufacturer’s recommendations. The

Automatic Transfer Switch will respond only to the rated

voltage specified on the Transfer Switch nameplate.

Also see page 4–1 for the HI–LOW voltage adjust setting

in the controller. The LOW setting shifts all voltage

settings down 4.2%; for example, 240 V to 230 V.

Press until light FLASHES

Close the normal source circuit

breaker. The Load Connected

To No r mal and t he Normal

1

Source Available lights should

come on.

Use an accurate voltmeter to

check phase to phase and

phase to neutral voltages

2

present at the transfer switch

normal source terminals.

Close the emergency source

circuit breaker. (Start generator,

if necessary.) The Load

3

Connected To Normal and the

Emergency Source Available

lights should come on.

Use an accurate voltmeter to

check phase to phase and

phase to neutral voltages

4

present at the transfer switch

emergency source terminals.*

Useaphaserotationmeterto

check phase rotation of

5

emergency source; it must be

the same

as the normal source.

Shut down the

engine–generator, if applicable.

The Emergency Source

Accepted light should go off.

6

Then put the starting control

selector switch (on the

generator set) in the automatic

position. Close enclosure door.

C

B

A

1--4

Now continue to 3 – Electrical Operation on next page.

Page 8

INSTALLATION (continued)

observe these lights

pressthisbutton

TRANSFER SWITCH TEST BYPASS TIME DELAY SET ENGINE EXERCISER

Press for 15 Seconds

Figure 1–6. Standard controls and indicators.

3 – Electrical Operation

This procedure will check the electrical operation of the

Automatic Transfer Switch. See Figure 1–6.

!

Close the enclosure door first !

Transfer Test

Both normal and emergency sources must be available

and the emergency source generator (if used) must be

capable of being started in this procedure.

Performsteps 1 through 8 at the right. Observe the status

lights. See Figure 1–6.

● Black circle means light is on.

❍ White circle means light is off.

NOTE: IfMotorLoadTransferfeature

is activated, then transfer may not occur

immediately after the respective time

delays. Transfer will only occur when

the phase relationship between sources

is correct.

This completes the Functional T es t of the ASCO Series 300

Au tom atic Tran sfer Switch. Leave the engine–generator

starting control in the automatic position.

Press until light FLASHES

The normal source must be

available and the generator

must be ready to start.

1

Check that the Normal Source

Available light is on.

Press and hold the Transfer

Switch Test button until the

2

engine starts and runs. This

should happen within 15 sec.

The Emergency Source

3

Available light should come on.

The transfer switch should

transfer to the Emergency

position. The Load Connected

4

to Emergency light should come

on and the Load Connected to

Normal light should go off.

If the transfer to emergency

delay is used the transfer

should occurs after a time delay

5

(up to 5 minutes).

Forimmediatetransferpress

the Bypass Time Delay button.

The transfer switch should

transfer back to the Normal

position. The Load Connected

6

to Normal light should come on

and the Load Connected to

Emergency light should go off.

If the retransfer to normal delay

is used the retransfer should

occur after a time delay

7

(up to 30 minutes).

Forimmediateretransferpress

the Bypass Time Delay button.

TRANSFER SWITCH TEST

BYPAS S TIME D ELAY

BYPAS S TIME D ELAY

1--5

The unloaded running delay

keeps the generator running for

5 minutes (cool–down period).

8

Then the generator should stop

and the Emergency Source

Available light should go off.

Page 9

SECTION 2 SEQUENCE OF OPERATION

lights show position of transfer switch

Transfer To Emergency

Thesequenceforloadtransferto

emergency source begins automatically when normal source voltage

falls below the preset dropout point

or when Transfer Switch Test button

is pressed. An under voltage condition on any phase of the normal

source is detected by the sensor.

When the normal

source voltage fails or

the Transfer Switch Test

button is pressed, the

SE relay de-energizes

and relay NR begins its

timin g cycle ( 1 or 3

seconds, mome n t ary

Hold 15 sec.to

start the engine

generator and to

transfer the load

to emergency.

normal source outage

delay). The NR rel ay is provided with a time delay on

dropout to override momentary outages and prevent

nuisance starting of the engine-driven generator. If the

normal source voltage returns above the sensor dropout

setting before the time delay expires, the NR relay timing

cycle is reset to zero and relay SE energizes.

If the normal source voltage does not return above the

sensor dropout setting before the time delay expires, the

NR relay de-energizes and signals the engine-driven

generator to start. At the same time, a voltage and

frequency sensor begins monitoring the emergency source.

The sensor will accept the emergency source only when

voltage and frequency reach preset pickup points.

both

Usually about ten seconds elapse from dropout of the NR

relay to acceptance by the sensor. This time span occurs

because the engine-driven generator must crank, start, and

run up to nominal pickup points. For this reason, if the

Transfer Switch Test buttonispresseditmustbeheldfor15

seconds. If the emergency source is available immediately,

the sensor may accept it as soon as NR relay drops out.

When the emergency source is accepted by the sensor,

relay ER begins its timing cycle (transfer to emergency

delay). ER relay is provided with an adjustable (0 to 5

minutes) time delay on pickup to delay transfer of the

load to the emergency source. For immediate transfer

press Bypass Time Delay button.

ER relay energizes, the TS coil is energized, the transfer

switch operates, and all switch contacts (mains, controls,

auxiliaries) reverse position. The transfer switch i s now

supplying the load from the emergency source.

The t ransfer switch will remain in the Emergency

position until the normal source is restored. If the

Transfer Switch Test button is used, the transfer switch will

remain on emergency until the retransfer to normal delay

times out.

TRANSFER SWITCH TEST BYPASS TIME DELAY SET ENGINE EXERCISER

Press for 15 Seconds

Press to cancel the

active exercise period

(stops engine now or

after cooldown) See

page 5–1.

lights show the sources available

light for built–in

engine exercise timer

· blinks rapidly when

button is held 5 sec.

while being set

· blinks slowly when

button is released (set)

and during 20 min.

exercise period.

· stays on after engine

stops (exerciser is

Press until light FLASHES

Hold 5 sec

20 min. engine exercise

period immediately (engine

starts) and weekly thereafter.

.toset

enabled for weekly

operation)

Seepage5–1

for complete

instructions

Figure 2–1. Membrane controls and indicator lights.

Retransfer to Normal

The sequence for load retransfer to the normal source

automatically begins when the voltage sensor detects

restoration of the normal source. The voltage level must

rise above the preset pickup point on all phases before

the sensor will accept the normal source.

Whenthenormalsourceisacceptedbythesensor,relay

SE begins its timing cycle (adjustable 1 sec. to 30 min.,

retransfer to normal delay). For immediate retransfer

press Bypass Time Delay button. SE relay is provided with

a time delay on pickup to prevent immediate load

retransfer to the normal source. The delay insures that

the normal source has stabilized before reconnection of

vital loads. If the normal source voltage falls below the

present dropout point before the time delay expires, the

timing cycle is reset to zero. If the emergency source fails

for more than 4 seconds during the t iming cycle, ER relay

drops out and the load is immediately retransferred to

the normal source, if that source is acceptable.

SE relay energizes and ER relay is droppe d out. The TS

coil is energized, the transfer switch operates, and all

switch contacts (mains, controls, auxiliaries) reverse

position. The transfer switch is now supplying the load

from the normal source a gai n.

Upon retransfer to the normalsource, NR relay begins its

timing cycle (unloaded running delay [engine cooldown] ).

NRrelay is provided witha 5 minute time delay on pickup

to keep the engine running for a cool-down period.

NR relay energizes after the time delay and signals the

engine-driven generator to shut down. All circuits are

reset for any future normal source failure.

Activation of standard control features shown in Section 5

will alter the sequence of operation and introduce

additional time delays during transfer operations.

2--1

Page 10

SECTION 3 TESTING & SERVICE

PREVENTIVE MAINTENANCE

Reasonable care in preventive maintenance will insure

high reliability and long life for the automatic transfer

switch.

Operate the switch at least once a month.Performthis

four step Electrical Operation Test. This i s a test with

load transfer.

TRANSFER SWITCH TEST BYPASS TIME DELAY SET ENGINE EXERCISER

Press for 15 Seconds

Transfer Switch Test

1. Press and hold the door-mounted TRANSFER

SWITCH TEST button until the engine starts a nd

runs. This should happen within 15 seconds.

2. The transfer switch will operate to the Emergency

position. If the Transfer To Emergency D elay is

used, the transfer w ill occur after a time delay

(up to 5 minutes). For immediate transfer press

BYPASS TIME DELAY button.

3. The Transfer Switch will operate back to the

Normal position after the Retr ansfer To Normal

Delay (up t o 30 minutes). For immediate

retransfer press BYPASS TIME DELAY button.

4. Unloaded Running (Engine Cooldown) Delay

allows engine to run unloaded for 5 minutes.

Clean and inspect the switch once a year. De-energize all

sources, then brush and vacuum away any excessive dust

accumulation. Remove the transfer switch barriers and

check contact condition. Replace contacts when pitted or

worn excessively. Reinstall the barriers carefully.

Maintain transfer switch lubrication. The transfer switch

has been properly lubricated, and under normal operating conditions no further lubricating is required. Renew

factory lubrication if the switchis subjectedto severe dust

or abnormal operating conditions. Relubricate the

operator if TS coil is replaced. Order lubrication

625550–001 (Castrol EndurexR 4000 lubricant).

Replacement parts. Replacement parts are available in

kit form. When ordering parts provide the Serial No. and

Catalog No. from the transfer switchnameplate. Contact

your local ASCO Power T echnologies sales office or ASI.

In the United States call 1–800–800–ASCO (2726), or in

Canada call 1–888–234–ASCO (2726).

Press until light FLASHES

DISCONNECTING THE CONTROLLER

The harness disconnect plugs are furnished for repair

purposes only and should not have to be unplugged. If the

controller must be isolated, follow these steps carefully.

Disconnecting the Plugs

!

Do not unplug the controller until step

1a. or 1b. below is completed.

1. Observe the position of the transfer switch.

a. If the transfer switch is in the Normal position, place

standby engine starting c o ntr o l in the off position.

Then open the emergency source circuit breaker.

b. If the transfer switch i s in the Emergency positi on,

open the normal source circuit breaker. Place t he

engine starting control in the test or run position.

2. Separate the quick disconnect plugs by squeezing the

latches. Do not pull on the harness wires.

3. Label, remove, and tape the signal wires connected

to the engine start terminals on the transfer switch:

TB1 and TB3, or TB1 and TB2.

Reconnecting the Plugs

!

Do not reconnect the controller until step

1a. or 1b. and 2 below are completed.

1. Observe the position of the transfer switch.

a. If the transfer switch is in the Normal position, be

sure that the standby engine starting control is still

in the off position. The emergency source circuit

breaker still should be open.

b. If the transfer switch i s in the Emergency positi on,

normal source circuit breaker still should be open.

2. Reconnect the signal wires connected to the

appropriate engine start terminals on the transfer

switch. See Section 1, Engine Starting Contacts.

3. The harness plugs and sockets are keyed. Carefully

align the plugs with the sockets and press straight in

until both latches click.

4. Restore the opposite source as follows:

a. If the transfer switch is in the Normal position,

place the standby engine starting control in the

automatic position. Then close the emergency

source circuit breaker.

b. If the transfer switch is in the Emergency position,

close the normal source circuit breaker. The load will

be automatically retransferred to the normal source

after the Retransf e r to Normal Delay. For immediate

retransfer, press BYPASS TIME DELAY button.

Place the engine starting control in the autom a ti c

position.

3--1

Page 11

TESTING & SERVICE

PROBLEM

(continued)

MANUAL LOAD TRANSFER

This procedure will manually transfer the load if the

controller is disconnected.

!

Do not manually operate the transfer switch

until both power sources are disconnected:

open both circuit breakers.

TROUBLE-SHOOTING

Note the control features that are activated or furnished

on the switch and review their operation.Refer to Section

5, Control Features.

Table 3-1. Trouble-Shooting Checks.

1OPERATION 2 GEN-SET 3VOLTAGE

Gen-Set does not start when

the TRANSFER SWITCH TEST

button is pressed and held for

15 seconds or when the

normal source fails.

T ransfer switch does not

transfer the load to

emergency source after the

gen-set starts.

T ransfer switch does not

transfer the load to normal

source when normal returns

or when TRANSFER SWITCH

TEST button is released.

Gen-Set does not stop after

load retransfer to the normal

source.

Hold the TRANSFER SWITCH

TEST button 15 sec. or the

outage must be long enough

to allow for the 1 or 3 sec.

Momentary Normal Source

Outage Delay plus engine

cranking and starting time.

Wait for Transfer to Emergen-

cy Delay (0 to 5 min.) to time

out. For immediate transfer,

press the BYPASS TIME

DELAY button. If Motor Load

Transfer is active, wait for inphase condition (see below).

Wait for Retransfer to Normal

Delay (1 sec. to 30 min.) to

time out. For immediate re–

transfer, press BYPASS TIME

DELAY button. If Motor Load

Transfer is active, wait for inphase condition (see below).

Wait for the 5 minute

Unloaded Running Delay to

time out.

1. Open normal and emergency source circuit breakers.

2. Use the maintenance handle to manually operate

transfer switch to the opposite source. See page 1–3,

Manual Operation Test .

3. If the transfer switch is in the Emergency position

manually start the engine generator and then close

the emergency source circuit breaker.

!

Proceed with care!

The automatic transfer switch is energized.

CHECK IN NUMERICAL SEQUENCE

Starting control must be in

automatic position. Batteries

must be charged and

connected. Check wiring to

engine starting contacts.

Generator output circuit

breaker must be closed.

Generator frequency must be

at least 57 Hz.

—

Starting control must be in

automatic position.

Voltmeter should read at

least 90% of nominal phase to

phase voltage between

transfer switch terminals EA

and EC (or EL1 and EL2 for 2

pole switches). *

* These are factory settings.

Voltmeter should read at least

90% of nominal phase to

phase voltage between

transfer switch terminals NB

and NC, NC and NA, and NA

and NB (or NL1 and NL2 for 2

pole switches).

—

—

Trouble-Shooting the Motor Load Transfer Feature (refer to page 5–3)

3. Press and hold

The load should transfer to emergency source when

Use extreme caution when using a meter

to measure voltages in the following

steps. Do not touch power terminals;

shock, burns, or death could result !

meter needle is near 0 volts. If transfer does not

occur, Motor Load Transfer feature is not operating.

4. Release the Tra n s fe r S w it c h Te s t button. The load

should retransfer back to the normal source after the

1. Connect a voltmeter (set for t wice system

phase–to–phase volt age) between Transfer Switch

terminals NA and EA.

2. Manually start generator. Voltmeter needle should

sweep back and forth at a regular rate between 0 and

about twice system voltage.

Retransfer to Normal Delay,ifused. Theretransfer

should occur when the needle is near 0 volts. If

retransfer does not occur after the time delay, the

Motor L oad Tra nsfer feature is not operating.

5. For immediate retransfer, press the BYPASS TIME

DELAY button. Then disconnect the voltmeter.

If the problem is isolated to circuits on the controlle r or the transfer switch, c all your local ASCO Power Technologie s

sales office or ASI. In the United States, call 1–800–800–2726. In Canada, c all 1–888–234–2726. Furnish the Serial No.,

Bill of Material (BOM) No., & Catalog No. from transfer switch nameplate.

3--2

TRANSFERSWITCH TEST button.

Page 12

SECTION 4 ADJUSTMENTS

y

OverrideMomentary

—

TIMER

0minute

s

0to

5

—

—

TIMER

30minutes

1secondto

—

—

S1DIP

EmergencySource

qy60/50

V

/

V

LOW

/

Time Delay Adjustment

Standard time delays are set to customer specifications

(if none specified, standard factory settings are used).

Table4-1.TimeDelaySettings

DESCRIPTION LABELS

Override Momentar

Normal Source Outages

T ransfer to Emergency

Override Momentary

Emergency S. Outages

Retransfer to Normal

Unloaded Running

(Engine Cooldown)

FACTORY

SETTING

TD ES 3seconds

TIMER 0 minutes 0to5

N/E

— 4seconds non-adjustable — — —

TIMER 30 minutes 1secondto

E/N

— 5 minutes non-adjustable — — —

(full ccw)

(full cw)

ADJUSTMENT

RANGE

1second Actuator 1 on

3seconds Actuator 1 off

minutes

30 minutes

Sensor Adjustments

Voltage and frequency sensor pickup and dropout points

are set to customer specifications (if none specified,

standard factory settings are used). To change a setting,

follow procedure on page 4–2. Use Tables 4-2 and 4–3 for

settings and corresponding DIP switch actuators.

To change a setting, follow procedure on pa ge 4-2. Use

Table 4-1 as a guide to time delay values and their corresponding adjustment DIP switch or potentiometer.

S3 DIP

SWITCH

1

1

!

ADJUSTMENT

POTENTIOMETER

P2

P1

Any change in these settings may affect the

normal operation of the automatic transfer

switch. This changecould allow the load circuits

to remain connected to a low voltage source.

Table 4-2. Voltage and Frequency Settings. ( Shaded DIP switches are standard factory settings).

DESCRIPTION LABELS SETTING

PU/N Pickup 90 %

Normal Source Voltage

DO/N Dropout

EmergencySource

Voltage

Emergency Source

Frequency

oltage Phases 3 4 ,14 3 4/1 4 3 4

–– Pickup 90 % non-adjustable

–– Dropout 75 % non-adjustable

–– Pickup 95 % non-adjustable

–– Dropout 85 % non-adjustable

60/50

Hz

60/50 Hz 60 Hz

%ofnominal

FACT. S ET ADJ RANGE

95 % * Actuator 3 off

90 % Actuator 3 on

90 % *

85 %

85 %

80 %

70 %

60 Hz Actuator 4 off

50 Hz Actuator 4 on

3phase Actuator 6 off

1phase Actuator 6 on

Actuator 1 off

Actuator 2 off

Actuator 1 on

Actuator 2 off

Actuator 1 off

Actuator 2 on

Actuator 1 on

Actuator 2 on

––

––

S1 DIP

SWITCH

* If dropout voltage is set to 90%, the pickup voltage must be set to 95%.

Table 4-3. Transformer Voltage Adjust.

(Low setting shifts all voltage settings down 4.2%; for example, 240 V to 230 V, or 480 V to 460 V)

DESCRIPTION LABELS FACTORY SETTING ADJUSTMENT S3 DIP SWITCH

LOW Actuator 2 off

HI Actuator 2 on

oltageAdjust (4.2%)

LOW

HI

HI

3

3

21

21

21

21

4

4

6

6

2

2

4--1

Page 13

ADJUSTMENTS

(continued)

!

Do not make any setting changes

while the controller is energized.

How to Change a Setting

1. Prevent the transfer switchfrom operating by disconnecting one source first, then the other, as follows:

a. If the transfer switch is in the Normal position,

open the emergency source circuit breaker. Turn

the engine starting control to off. Then open the

normal source circuit breaker.

b. If the transfer switch is in the Emergency

position, open the normal source circui t breaker.

Turn engine starting control to test or run.Then

open the emergency source circuit breaker.

2. Disconnect both harness plugs from controller by

squeezing the latches. Do not pull on the wires.

3. Remove cover from the controller by releasing latch

on right side with your thumb. See Figure 4-1.

4. Locate the appropriate adjustmentpotentiometer or

DIP switch for the setting that you want to change.

Refer to Table 4-1 and Table 4–2 on page 4-1 and

Figure 4-2, Figure 4–3, Figure 4–4 on page 4–2.

5. Use a small screwdriver to turn the potentiometer

clockwise to increase the time delay or counterclockwise to decrease it. See Figure 4-3.

6. Use a ball-point pen (or similar pointed tool)to slide

the switch actuators left or right so they match the i llustration next to the setting (left = off, right = on).

Recheck the setting. See Fi gure 4-4.

cover

hook on

left side

Figure 4-1. Controller cover latch.

harness

plugs

S3 DIP

switch

S1 DIP

switch

S2 DIP

switch

Figure 4-2. Location of potentiometers,

DIP switches, battery, and battery jumper.

thumb

latch

J5

retransfer

to normal

time delay

transfer to

emergency

time delay

9volt

alkaline

battery

battery

on/off

jumper

P1

P2

7. Install the cover on the controller by hooking it on

the left side and latching the right side.

8. Reconnect both harness plugs to the controller by

aligning and pressing straight in until lat ches click.

!

Close the enclosure door.

9. Close the enclosure door, then restore both sources:

a. If the transfer switch is in the Normal position

first close the normal source circuit breaker,

then close the emergency source circuit breaker.

b. If the transfer switch is in the Emergency

position, close the normalsource circuit breaker.

The load will be automatically retransferred to

the normal source. Then close the emergency

source circuit breaker.

10. Turn the engine starting control to automatic.

clockwise to

increase

P1 or P2

potentiometer

counterclockwise

to decrease

Figure 4-3. Changing time delay potentiometers.

DIP

switches

SW1

SW2

SW3

actuator

(8 on each DIP switch)

onoff

Figure 4-4. Setting DIP switch actuators.

4--2

Page 14

SECTION 5 CONTROL FEATURES – ENGINE EXERCISERS

These timers periodically exercise the emergency engine-generator plant. They can be set to exercise with or without

loadtransfer, or they can be completely disabled. The engine-generatorshould be exercised under loadonce a week fora

minimum time period of 20 minutes, or follow the recommendations of the engine-generator set manufacturer. Refer to

page 4–2 for location of DIP switches, battery (provided), and jumper block in the controller.

BUILT–IN ENGINE EXERCISER

The engine exerciser included in ASCO Series 300

Automatic Transfer Switches provides a once a week

20–minute exercise period. It occurs immediately

the SET ENGINE EXERCISER push button is pressed

(and held

for at least 5 seconds), andthen at the same time

weekly thereafter. A 9 volt alkaline battery (DuracellR

MN1604, EverreadyR 522, or PanasonicR 6AM6) is

furnished and installed in the controller to maintain the

setting. The battery jumper block must be shifted to

ON position

. See Figure 4–2 on page 4–2.

Fill in day and t ime set. Week Day ______ Time _______.

Press to cancel an

active exercise period

(stops generator).

If Exercise with Load is set,

retransfers load to Normal,

then stops generator after

5 min. cooldown.

Figure 5-1. Operator panel pushbuttons and light.

when

the

FUNCTION

Std. Timer

Enabled

Std. Timer

Disabled

Exercise

without

Load

Exercise

with Load

Shaded DIP switches are standard factory settings.

Press until light FLASHES

DIP Switch Settings

S1 DIP

SWITCH

Actuator

7on

Actuator

7off

Actuator

8off

Actuator

8on

7

7

8

8

status light

Press and hold for 5 sec

light blinks rapidly to set exercise period

immediately and every week hereafter

(generator starts).

If Exerciser with Load is set,

transfers load to Emergency.

S2 DIP

SWITCH

Actuator

5on

Actuator

5on

. or until status

5

5

Select below either Exercise without Load or Exercise with Load accordingto the setting of DIP switch S1, actuator 8. The

load transfers from the Normal source to Emergency source (generator) and back again if Exercise with Load is selected.

Exercise without Load, DIP Switch S1, Actuator 8 off

8

How to Set Built–In Timer

Step Function Explanation

Push Button Status Light

SET ENGINE

1

EXERCISER

hold

5sec.

2 release

press BYPASS

3

TIME DELAY

blinks rapidly

FfFfFf

blinks slowly

FffFff

set exercise period

exercise period now active Generator starts and runs.

Exercise the generator now and

every week at this time hereafter.

F stays on cancel active exercise period Generator stops.

4 — F stays on generator off Exerciser enabled; repeats every 7 days.

Exercise with Load, DIP Switch S1, Actuator 8 on

8

How to Set Built–In Timer

Step Function Explanation

Push Button Status Light

SET ENGINE

1

EXERCISER

hold

5sec.

2 release

press BYPASS

3

TIME DELAY

blinks rapidly

FfFfFf

blinks slowly

FffFff

blinks slowly

FffFff

set exercise period

exercise period now active

cancel active exercise period

Exercise the generator now and

every week at this time hereafter.

Generator starts and runs;

the load transfers to Emergency.

The load retransfers to Normal; then

generator runs for 5 minute cooldown

( light blinks slowly during cooldown ).

4 — F stays on generator off Exerciser enabled; repeats every 7 days.

NOTE:EverytimeSET ENGINE EXERCISER push button is pressed (held 5 seconds) the exercise period is changed.

5--1

Page 15

2–line

display

3 buttons

CONTROL FEATURES (continued)

Optional Accessory 11BG – SOURCE AVAILABILITY SIGNAL

& PROGRAMMABLE ENGINE EXERCISER MODULE

connections

for source

availability

signal contacts

Figure 5–2. Accessory 11BG module (mounted behind operator interface and connected to the controller)

includes source availability signal contacts and a programmable engine exerciser.

Source Availability Signal Contacts

ThemoduleprovidesoneFormCcontacteachforthe

normal and emergency sources signal the acceptability of

the source as sensed by the controller. The signal contacts

operate in conjunction with the Source Available lights on

the operator interface. Field wiring terminals are

provided as shown in Figure 5–3 and the wiring diagram.

Contact ratings:

2 amps @ 30 Vdc, 0.5 amp. @ 125 Vac resistive

Figure 5–3. Source availability signal contacts.

ProgrammableEngineExerciser

Themoduleincludesaprogrammableengineexerciser

that provides for weekly or biweekly operation. This

optional exercise timer may have to be turned on

(enabled) by setting the S1 DIP switch actuator 7 to off,

and S2 DIP switch actuator 5 to off. A backup battery

in

the controller (see page 4–2 and page 5–3) must be turned

on to maintainthe settingsand to allowprogrammingwith

the normal and emergency power turned off (page 5–1).

Theprogrammableengineexerciserincorporatesa7day

or 14 day time base. Proper controller settings must be

made to determine whether or not the test will be done

with or without load transfer (S1 DIP switch actuator 8).

DIP Switch Settings in the Controller

(see page 4–2)

FUNCTION

Opt. Timer

Enabled

Opt. Timer

Disabled

Exercise

without

Load

Exercise

with

Load

SWITCH

Actuator

7off

Actuator

7off

Actuator

8off

Actuator

8on

S1 DIP

7

7

8

8

S2 DIP

SWITCH

Actuator

5off

Actuator

5on

5

5

Seenextpageforinstructionsonsettingthetimer.

Shaded DIP switches are standard factory settings.

5--2

Page 16

CONTROL FEATURES (continued)

How to Set Optional Programmable Engine Exerciser (part of Acc. 11BG module)

Start Time Display

Hazardous voltage capable of causing shock,

burns, or death is used in this transfer switch.

Deenergize both Normal & Emergency power

sources before programming the exerciser.

Navigating the M enu

Use the UP and DOWN arrow keys to move through the

displays.

Fast/Slow Ad ju st

Daylight Saving

Time Adjust

Date

The Start Time Display shows the engine exerciser start

time. There are four parameters that determine the start

time:

weekly (”Every”) or bi–weekly (”Alt”) operation

day of week (”Sun” through “Sat”)

start hour (0 through 23)

start minutes (0 through 59)

For example, if the user wants the exerciser to run every

other Saturday a t 3 PM, the proper configuration would

be:

“Alt Sat @ 15:00”

NOTE: When choosing bi–weekly operation, the

exerciser will always run on the week designated “(1)” on

thedatedisplay.

Run Time Display

The Run Time Display shows the run time for the engine

exerciser. The default setting from the factory is 30

minutes.

Time

Run TIme

Start TIme

Engine Exerciser

Changing the Parameters

Use the UP and DOWN arrow keys to move though the

displaystotheparametertobechanged.PushtheENTERkey

tostartthe editingprocess.Thefirstparameterwill flash.Use

the UPand DOWNarrow keys to adjust the parameter to the

desiredvalueand presstheENTERkeytosavethevalue.The

next parameter will now flash. Repeat theprocess until each

parameter is properly configured.

Engine Exerciser Display

TheEngineExerciserDisplayshowsthestatusofthe

engine exerciser. When the unit is shipped from the

factory the programmable engine exerciser is “Disabled”

and must be set to “Enabled” by the customer. When the

engine exerciser is running, t his display will count down

the remaining time until the end of the exercise period.

Time Display

The Time Display shows the present system time. The

format is “hours:minutes:seconds”.

NOTE: During total power outages, power to the

accessory is maintained by a battery in the Controller (see

page 4–2). Be sure that the 9–volt alkaline battery is fresh

and enabled (jumper in ON position) so that the time and

date settings are not lost.

Date Display

The Date Display shows the present system date. The

format is “day of week (week) month/day of month/year”.

NOTE: Week is either week 1 or week 2. This is used in

conjunction with the bi–weekly timer.

Daylight Savings Time Adjust Display

This display shows whether the automatic daylight saving

time adjustment is active. The factory default is “NO”. If

enabled,theunitwillautomaticallyadjustfordaylightsaving

timeat 2 AMonthe firstSunday ofApril andthe lastSunday

of October.

Fast / Slow Adjust Display

This display shows the automatic fast/slow adjustment

value.Thefactorydefaultis0.Thisfeaturecanbeusedto

trim a clock that runs fast or slow. For example, if your

clock runs 10 seconds slow per week, change the fast/slow

adjust value to “+10” and the unit will automatically add

10 seconds to the clock every week.

NOTE: Adjustments are made Sunday morning at 2 AM.

If you want your exerciser period to start at 2 AM on

Sunday, you cannot use this feature and the adjustment

must be set to 0.

5--3

Page 17

CONTROL FEATURES (continued)

Programmable Engine Exerciser Settings

Fill in your settings for future reference

Weekly or Bi–weekly Day of Week Start Time Run Time

0–23hour

Every = weekly

Sun through Sat

Alt = bi–weekly

0–23hour

0–59minute

0–59minute

30 minutesisthe

default setting

Date exerciser was set ______________________________________

5--4

Page 18

CONTROL FEATURES (continued)

INPHASE MONITOR

FOR MOTOR LOAD TRANSFER

Inphase monitoring logic controls transfer and retransfer

of motor loads, so that inrush currents do not exceed

normal starting currents. It avoids nuisance tripping of

circuit breakers and mechanical damage to motor

couplings.

The Motor Load Transfer feature is built into the

controller. DIP switch S1 (actuator 5) activates this

feature: right = ON, left = OFF.

FUNCTION S1 DIP SWITCH

enable Actuator 5 on

disable Actuator 5 off

Shaded DIP switches are standard factory settings.

Note

If the Motor Load Transfer feature is enabled,

it will be activated following

the Load

Disconnect Feature Delay Before Transfer

delay.

5

5

LOAD DISCONNECT FEATURE

Connect external circuitsto the terminalsindicated on the

Wiring Diagram provided with the ATS.

The double t hrow (Form C ) contact is rated for 28 VDC or

120 VAC (5 amps resistive). The contact operates prior to

a selectable 0, 3, 10, or 20 second delay before transfer of

the Automatic Transfer Switch. The contact resets either

immediately following transfer or after the same

delay as

set for pre–signal before transfer.

Time delay between the load disconnect control signal

and initiation of transfer is set on the controller with DIP

switch S2 (actuators 6, 7, 8) as shown below:

Delay Before Transfer

LD TDBT S2 DIP SWITCH

0 (disable)

3seconds

10 seconds

20 seconds

Actuator 7 on

Actuator 8 on

Actuator 7 on

Actuator 8 off

Actuator 7 off

Actuator 8 on

Actuator 7 off

Actuator 8 off

87

87

87

87

Shaded DIP switches are standard factory settings.

Delay After Transfer*

LD TDAT S2 DIP SWITCH

enable Actuator 6 on

disable Actuator 6 off

6

6

*Enabling the Delay After Transfer will cause the control

signal to reset after the same delay

as set for the Delay

Before Transfer.

REMOTE CONTROL FEATURES

These remote control features require a customer–supplied normally closed contact suitable for a 5 V dc low energy

circuit. Refer to the Wiring Diagram provided with the ATS. Activate appropriate DIP switch S2 actuators below.

Remote Test (terminals CP6–7)

RTSW S2 DIP SWITCH

disable Actuator 3 on

enable Actuator 3 off

3

3

Remote Transfer to Emergency (CP8–9)

RT /E S2 DIP SWITCH

disable Actuator 2 on

enable Actuator 2 off

2

2

Bypass Transfer Time Delay (CP12–13)

TD E/N BYP. S2 DIP SWITCH

disable Actuator 1 on

enable Actuator 1 off

1

1

Inhibit Transfer to Emergency (CP10–11)

N/E INHIB. S2 DIP SWITCH

disable Actuator 4 on

enable Actuator 4 off

5--5

4

4

Page 19

CONTROL FEATURES (continued)

OPTIONAL STRIP HEATER (Accessory 44)

Accessory 44 Strip Heater is designed to keep ambient

temperatures within the Automatic Transfer Switch

enclosure at acceptable levels. This accessory consists of a

mounting bracket with strip heater, thermostat, and

terminal block. A transformer with fuses is included when

the power for the assembly is derive d from voltages above

120 V ac. The 120 V ac customer powered assembly does

not include a transformer. This optional accessory is

available factory installed or in kit form.

Turn the thermostat’s dial to required setting as shown.

thermostat

dial

turn counterclockwise

to lower temperature

turn clockwise

to raise temperature

AVAILABLE KITS FROM ASCO

Controls

Description Accessory Kit

ProgrammableEngineExerciser

& Source Availability Contacts

Serial Communication Module 72A K601110

11BG K629830

Figure 5–4. Thermostat.

Strip Heater – Accessory 44

Description Accessory Kit

120 volt

customer supplied voltage

(without transformer)

208 – 480 volt

ATS derived voltage

(with transformer)

380 volt

ATS derived voltage

(with transformer)

550 – 600 volt

ATS derived voltage

(with transformer)

44A K613127–001

44G K613127–002

44G K613127

44G K613127–003

5--6

Page 20

INDEX

A

accessories, see optional accessories

auxiliary circuits, 1–2

B

battery, 4–2, 5–1

buttons, push, 3–1

bypass time delay, 1–5, 2–1, 3–1

C

cable

lugs, 1–1

preparation, 1–1

catalog number, inside cover

cleaning, 3–1

connections

engine control contact, 1–2

line, 1–1

contacts

auxiliary, 1–2

engine control, 1–2

main, 3–1

source availability signal, 5–2

control features, 5–1

load disconnect, 5–5

motor load transfer, 5–5

(optional Accessory)

plant exerciser, 5–1, 5–2, 5–3, 5–4

controller, 4–1, 4–2

codes, cover

cover removal, 4–2

disconnecting, 3–1

time delay potentiometers, 4–2

D

DIP Switches, 4–1, 4–2, 5–1, 5–2, 5–5

E

electrical operation, 1–5

engine exerciser, 5–1, 5–2, 5–3, 5–4

engine starting contacts, 1–2

F

features, see control features

frequency, pickup & dropout settings,

4–1

functional test, 1–3, 1–4, 1–5

G

ground, controller, 1–2

H

harness, 1–2

disconnect plugs, 3–1

help, service 3–2

I

inphase monitor, 5–5

(optional Accessory)

inspection, 3–1

installation, 1–1

L

labels,

engine starting contacts, 1–2

inputs / outputs, 1–2

rating, cover

lights, 1–4, 1–5, 5–1

load disconnect feature, 5–5

(optional Accessory)

lubrication, 3–1

M

maintenance, preventive, 3–1

manual load transfer, 3–2

warning, 3–2

manual operation, 1–3

illustration of, 1–3

warning, 1–3

motorloadtransferfeature,5–5

N

nameplate, inside cover

O

operation

electrical, 1–5

manual, 1–3

illustration & warning, 1–3

sequence of, 2–1

optional accessories

programmableengineexerciser

& source availability signal

contacts, 5–2, 5–3, 5–4

serial communication module, 5–6

strip heater, 5–6

P

parts, 3–1

problem, 3–2

programmable engine exerciser, 5–2,

5–3, 5–4

R

rating label, cover

remote control features, 5–5

bypass transfer time delay, 5–5

inhibit transfer to emergency, 5–5

remote test, 5–5

remote transfer to emergency, 5–5

replacement parts, 3–1

S

service, call 800–800–2726 (ASCO)

set engine exerciser, 5–1, 5–2, 5–3,

5–4

settings

changing, 4–1

factory, 4–1

frequency, 4–1

phase, 4–1

time delay, 4–1

voltage, 4–1

service 3–2

T

test, functional, 1–3, 1–4, 1–5

time delay

adjustment, 4–1

gen–set cooldown, 4–1

how to change, 4–2

override momentary outages, 4–1

settings, 4–1

transfer to emergency, 4–1

transfer to normal, 4–1

timer (plant exerciser), how t o set,

5–1, 5–2, 5–3, 5–4

transfer switch test, 1–5, 3–1

trouble–shooting, 3–2

V

voltage, phase, 4–1

voltage, pickup and dropout settings,

4–1

Printed in USA ASCO Power Technologies, L.P. 2004

E

Loading...

Loading...