Page 1

Accessory 11BG

for Series 300

Installation

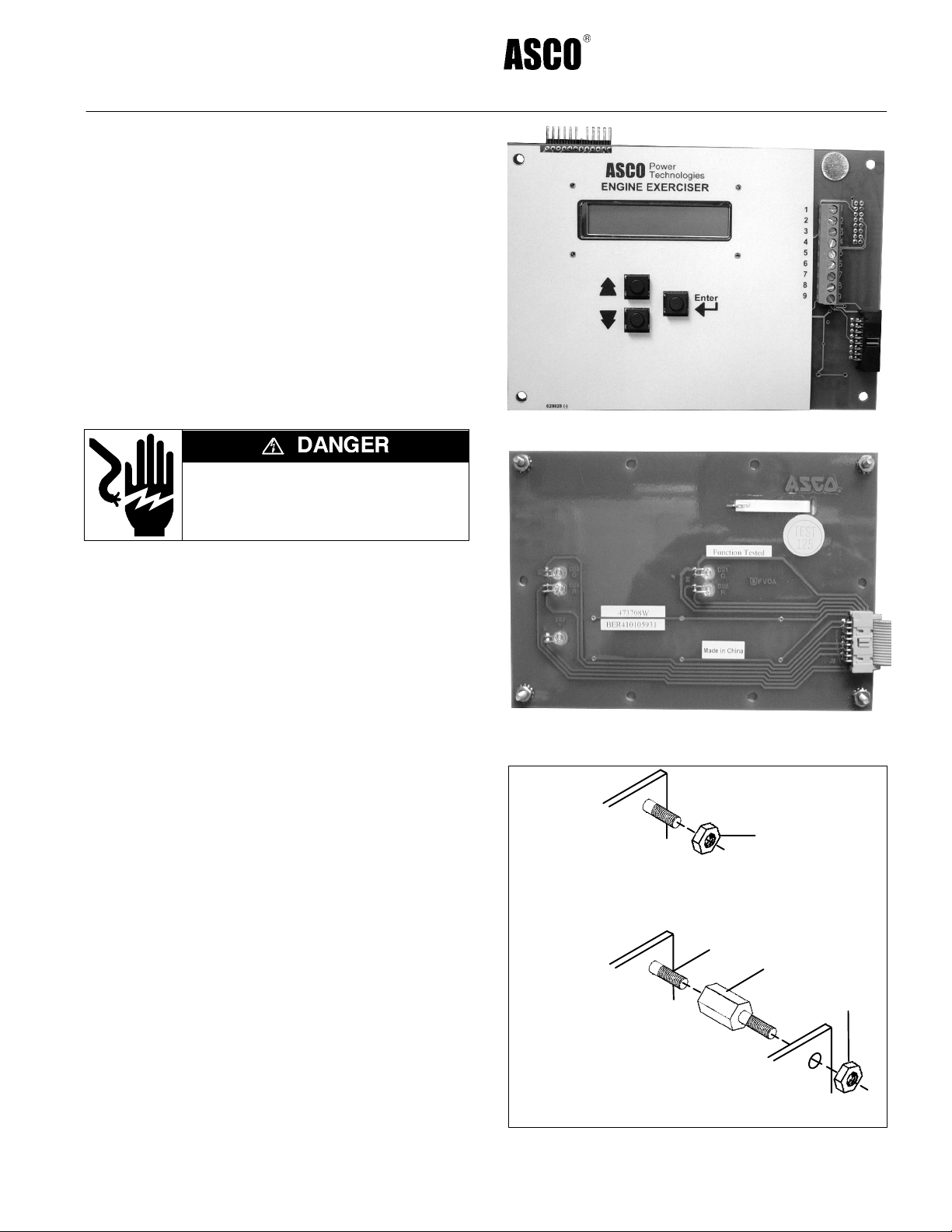

Accessory 11BG module includes a programmable engine–

generator exerciser and power source availabil ity contacts. It

can be added to a Series 300 Automatic Transfer Switch (ATS)

that has a Group 1 Controller. If an existing engine exerciser

(Acc. 11CD) is already installed, it must be disconnected first.

TheAccessory11BGmodulemountsdirectlybehindthe

Series 300 ATS opera tor interface on the inside of the

enclosure door. The module connects to the Series 300 ATS

operator interface board and Group 1 controller.

Kits K629830 & K749999 include the Acc. 11BG module,

mounting hardware, and all necessary wiring.

Tools 1/4”, 5/16” nutdrivers, small blade screwdriver

required: your Series 300 ATS Operator’s Manual

for setting the DIP switches

ELECTROCUTION – FLASH HAZARD

Do not work on the transfer switch until

both the utility and generator are off.

Turn OFF both circuit breakers.

Automatic Transfer Switches

J1

Figure 1. Accessory 11BG Module in kits.

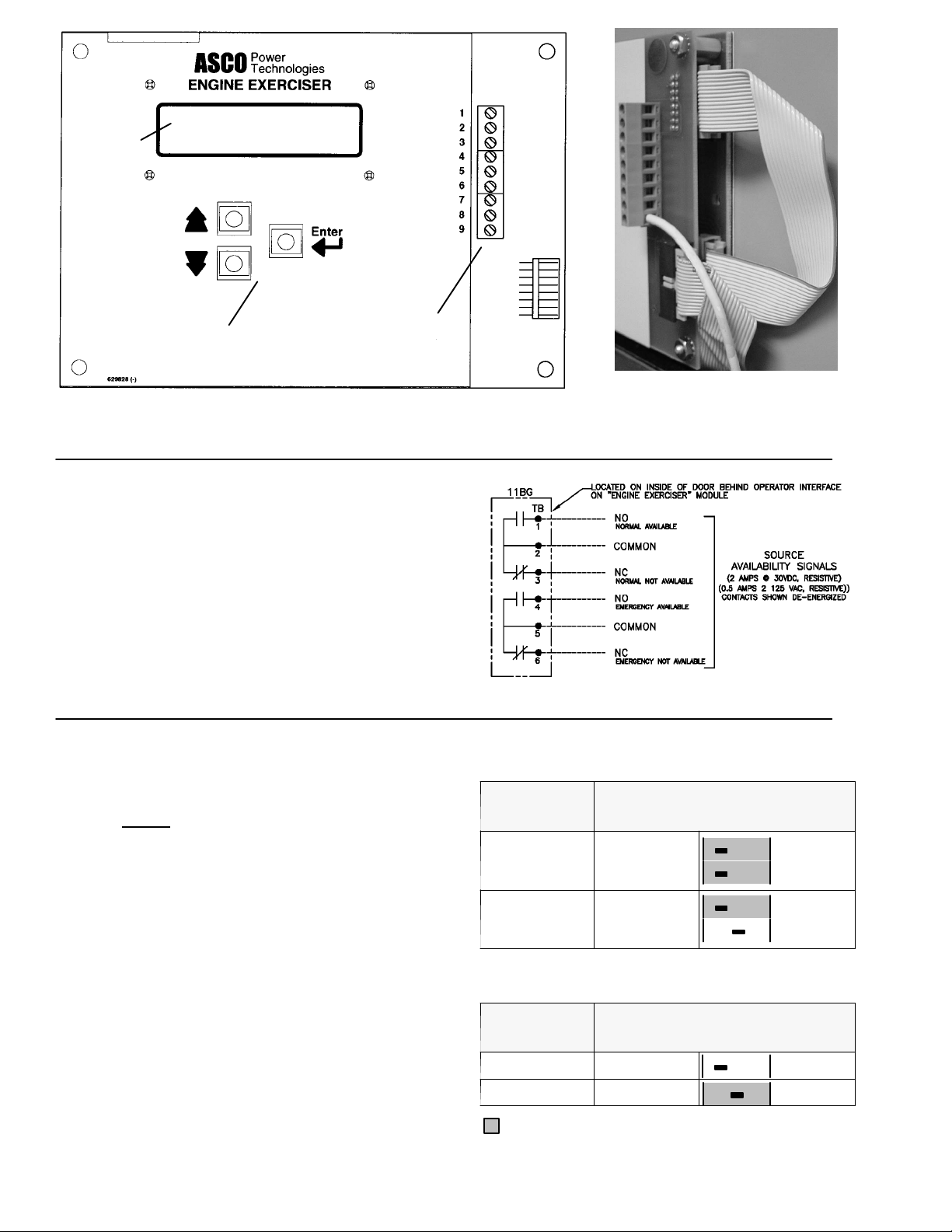

Module Installation –Figures2&3

1. With all power OFF, open the enclosure door. Locate

the operator interface (membrane controls) mounted

on the inside of the enclosure door. Use a 5/16”

nutdriver to remove (counterclockwise) the four hex

nuts from the corners of the operator interface. Do not

remove the operator interface board (Figures 2 & 3).

2. Install (clockwise) four standoffs (from the kit) onto

the four studs and tighten them with a 1/4” nutdriver.

3. Install the Acc. 11BG module on top of the operator

interface so that four standoffs fit through the corner

holes. Then install (clockwise)four 6–32 hex nuts (from

thekit)tosecuretheassembly.Tightenthenuts.

Figure 2. Series 300 ATS operator Interface board

mounted on the enclosure door (back view).

Step 1

Connecting the Module – Figures 1, 2, 4

1. With all power OFF, locate the two ribbon cables and

note direction and orientation of each cable.

2. Unplug the ribbon cable (coming from the Controller)

from the operator interface (J3 lower right side) and

reconnect it (same orientation) to the Acc. 11BG module

(J1 lower right side). See Figures 1, 2, & 4.

3. Connect the new ribbon cable (coming from the Acc.

11BG module upper right side) to the operator interface

(J3 lower right side) with the same orientation as the

original cable that was moved. See Figures 2 & 4.

4. Strip the insulation from both ends of the #16 gauge

white wire (from the kit). Connect this prepared wire

between A c c . 11BG module terminal 9 (right side) and

the Group 1 Controller terminal 4 (bottom left). Figure 4.

ASCO POWER TECHNOLOGIES L.P. 50 Hanover Road, Florham Park, New Jersey 07932 USA www.asco.com

original mounting of Series 300 ATS

operator interface on enclosure door

stud

Step 2

Step 3

operator

interface

board

install Acc. 11BG board

standoff added for Acc. 11BG Module

Figure 3. Module installation hardware.

J3

remove 4 nuts

(with captive

lockwashers)

add 4 standoffs

reinstall

4 nuts

381339–252 B

page 1

Page 2

2–line

display

9

J1

3 buttons

connections

for power source

availability

J1

signal contacts

wiring

Figure 4. Accessory 11BG module (mounted behind operator interface and connected to the controller)

includes power source availability signal contacts and a programmable engine exerciser.

Power Source Availability Signal Contacts

ThemoduleprovidesoneFormCcontacteachforthe

normal and emergency power sources to signal the

acceptability of the source as sensed by the controller. The

signal contacts operate in conjunction with the Source

Available lights on the operator interface. Field wiring

terminals are provided as shown in Figure 5 and the wiring

diagram.

Contact ratings:

2 amps @ 30 Vdc, 0.5 amp. @ 125 Vac resistive

Figure 5. Power source availability signal contacts.

J3

Programmable Engine–Generator Exerciser

Note: Refer to your Series 300 ATS Operator’s Manual

to set DIP switches S1 & S2 in the Group 1 Controller.

A backup battery

(see Operator’s Manual, Sections 4 and 5) must be turned

on to maintain the settings and to allow programming with

the normal and emergency power sources turned off.

TheAcc.11BGmoduleincludesaprogrammablegenerator exerciser that provides for weekly or biweekly operation. The exerciser may have to be turned on (enabled) by

setting S1 DIP switch actuator 7 to OFF (left position), and

S2 DIP switch actuator 5 to OFF (left position).

The programmable engine–generator exerciser incorporates a 7–day or 14–day time base. Proper Group 1

Controller settings must be made to determine whether or

not the test will be done with or without load transfer

(S1 DIP switch actuator 8).

Seenextpageforinstructionsonsettingtheexerciser.

381339–252 B

page 2

in the Series 300 ATS Group 1 Controller

ASCO POWER TECHNOLOGIES L.P. 50 Hanover Road, Florham Park, New Jersey 07932 USA www.asco.com

S1 DIP Switch Settings

in Series 300 ATS Group 1 Controller

Programmable

Exerciser

Function

Enabled &

Exercise

without Load

Enabled &

Exercise

with Load

Actuator 7 OFF

Actuator 8 OFF

Actuator 7 OFF

Actuator 8 ON

ACTUATORS 7 & 8

OFF ON

7

8

7 8

EXER ACTV

LOAD

EXER ACTV

LOAD

S2 DIP Switch Settings

in Series 300 ATS Group 1 Controller

Programmable

Exerciser

Function

Enabled Actuator 5 OFF

Disabled Actuator 5 ON

Shaded DIP switches are standard factory settings.

ACTUATOR 5

OFF ON

5

5

EXT EXER

EXT EXER

Page 3

How to Set Optional Programmable Engine Exerciser (part of Acc. 11BG module)

Start Time Display

Hazardous voltage capable of causing shock,

burns, or death is used in this transfer switch.

Deenergize both Normal & Emergency power

sources before programming the exerciser.

Navigating the Menu

Use the UP and DOWN arrow keys to move through the

displays.

Fast/Slow Adjust

The Start Time Display shows the engine exerciser start

time. There are four parameters that determine the start

time:

weekly (”Every”) or bi–weekly (”Alt”) operation

day of week (”Sun” through “Sat”)

start hour (0 through 23)

start minutes (0 through 59)

For example, if the user wants the exerciser to run every

other Saturday at 3 PM, the proper configuration would be:

“Alt Sat @ 15:00”

NOTE: When choosing bi–weekly operation, the exerciser

will always run on the week designated “(1)” on the date

display.

Daylight Saving

Time Adjust

Date

Time

Run TIme

Start TIme

Engine Exerciser

Changing the Parameters

Use the UP and DOWN arrow keys to move though the

displays to the parameter to be changed. Push the ENTER

key to start the editing process. The first parameter will

flash. Use the UP and DOWN arrow keys to adjust the

parameter to the desired value and press the ENTER key to

save the value. The ne xt parameter will now flash. Repeat

the process until each parameter is properly configured.

Engine Exerciser Display

TheEngineExerciserDisplayshowsthestatusofthe

engine exerciser. When the unit is shipped from the factory

the programmable engine exerciser is “Disabled” and must

be set to “Enabled” by the customer. When the engine

exerciser is running, this display will count down the

remaining time until the end of the exercise period.

Run Time Display

The Run Time Display shows the run time for the engine

exerciser. The default setting from the factory is 30

minutes.

Time Display

The Time Display shows the present system time. The

format is “hours:minutes:seconds”.

NOTE: During total power outages, power to the accessory

is maintainedby a battery in the Controller(see page 4–2 of

Operator’s Manual). Be sure that the 9–volt alkaline

battery is fresh andenabled (jumperin ON position) sothat

the time and date settings are not lost.

Date Display

The Date Display shows the present system date. The

format is “day of week (week) month/day of month/year”.

NOTE: Week is either week 1 or week 2. This is used in

conjunction with the bi–weekly timer.

Daylight Savings Time Adjust Display

This display shows whether the automatic daylight saving

time adjustment is active. The factory default is “NO”. If

enabled, the unit will automatically adjust for daylight

saving time at 2 AM on the first Sunday of April and the last

Sunday of October.

Fast / Slow Adjust Display

This display shows the automatic fast/slow adjustment

value.Thefactorydefaultis0.Thisfeaturecanbeusedto

trim a clock that runs fast or slow. Forexample, if your clock

runs 10 seconds slow per week, change the fast/slow adjust

value to “+10” and the unit will automatically add 10

seconds to the clock every week.

NOTE: Adjustments are made Sunday morning at 2 AM. If

you want your exerciser period to start at 2 AM on Sunday,

you cannot use this feature and the adjustment must be set

to 0.

ASCO POWER TECHNOLOGIES L.P. 50 Hanover Road, Florham Park, New Jersey 07932 USA www.asco.com

381339–252 B

page 3

Page 4

Programmable Engine Exerciser Settings

Fill in your settings for future reference

Weekly or Bi–weekly Day of Week Start Time Run Time

0–23hour

Every = weekly

Sun through Sat

Alt = bi–weekly

0–23hour

0–59minute

0–59minute

30 minutesisthe

default setting

Date exerciser was set ______________________________________

381339–252 B

page 4

ASCO POWER TECHNOLOGIES L.P. 50 Hanover Road, Florham Park, New Jersey 07932 USA www.asco.com

Loading...

Loading...