Page 1

AS480 AUTOMATIC VOLTAGE

REGULATOR (AVR)

SPECIFICATION INSTALLATION AND ADJUSTMENTS

General description

The AS480 is a half wave phase controlled AVR which forms

part of the excitation system of the brushless generator. The

design employs Surface Mount Technology (SMT), custom

mouldings and heatsinks to produce a compact AVR assembly.

The AVR also incorporates an interface to the optional Excitation

Boost System (EBS) for use where short-circuit current

maintenance is required.

The AVR is linked with the main stator windings and the exciter

field windings to provide closed loop control of the output voltage

with load regulation of +/- 1.0%. The AVR voltage sensing

terminals continuously sample the output windings for voltage

control purposes. In response to this sample voltage, the AVR

controls the power fed to the exciter field, and hence the main

field, to maintain the machine output voltage within the specified

limits, compensating for load, speed, temperature and power

factor of the generator.

Positive voltage build up from residual levels is ensured by the

use of efficient semiconductors in the power circuitry of the AVR.

A frequency measuring circuit continually monitors the

generator output frequency and provides under-speed protection

of the excitation system. This is done by reducing the output

voltage proportionally with speed below a pre-settable threshold.

A manual adjustment is provided for factory setting of the under

frequency roll off point, (UFRO). This can be changed to 60Hz

(or 50Hz) in the field by push-on link selection.

A wide range of stability settings are available to compensate for

machine sizes and applications. A ‘slow’ setting is available for

applications involving single/twin cylinder engines and where

lamp-flicker could be a problem.

Provision is made for the connection of a remote voltage

trimmer, allowing the user fine control of the generator’s output

voltage.

Operation with 110Vac sensing is possible, replace the hand

trimmer link with fixed resistor. The hand trimmer option cannot

be used in this configuration. The generator overload capability

is reduced in 110V operation.

The AVR has the facility for droop CT connection, to allow

parallel running with other similarly equipped generators.

Over excitation conditions are limited to a safe period by a

protection circuit within the AVR. Once activated by a sustained

over-excitation condition, the generator voltage is reduced to a

low level until reset. Stopping the generator or removing power

from the AVR will perform the necessary reset.

Connections are provided to interface to the optional Excitation

Boost System. This incorporates a small externally mounted

rotary power supply which provides excitation power in the event

of heavy overloads or short circuits. The EBS is short term rated

and responds to signals from the AVR to deliver excitation power

when required. A separate overload protection system within the

EBS electronic module protects the generator against sustained

overloads.

© Cummins 2008 1 TD_AS480 AVR_04.08_02_GB

Technical specification

SENSING and POWER INPUT

Voltage 100-264 V ac 1 phase

Frequency 50-60 Hz nominal

OUTPUT

Voltage 82 V d.c. @ 200 Va.c power input.

Voltage 45 V d.c. @ 110 Va.c power input.

Current continuous 5A (see note 1).

transient 7.5A for 10 secs.

Resistance 15 ohms min

REGULATION

+/- 1.0% (see note 2)

THERMAL DRIFT

0.03% per deg. C change in AVR ambient (see note 3)

TYPICAL SYSTEM RESPONSE

AVR response 20ms

Field current to 90% 80 ms

Machine Volts to 97% 300ms

EXTERNAL VOLTAGE ADJUSTMENT

+/-10% with 1 k ohm 1 watt trimmer (see note 4)

Increasing resistance lowers voltage.

Fixed 15kOhm resistor enables 110V sensing

UNDER FREQUENCY PROTECTION

Set point 94 -98% Hz (see note 5)

UNIT POWER DISSIPATION

12 watts maximum

BUILD UP VOLTAGE

4 Volts @ AVR terminals

QUADRATURE DROOP INPUT

10 ohms burden

Max. sensitivity: 0.07 A for 5% droop 0PF

Max. input: 0.33 A

OVER EXCITATION PROTECTION

Set point 67 Vdc +/-3% (fixed)

Time delay 10-15 seconds (fixed)

ENVIRONMENTAL

Vibration 20-100 Hz 50mm/sec

100Hz – 2kHz 3.3g

Operating temperature -40 to +70C (note 6)

Relative Humidity 0-70C 95% (note 7)

Storage temperature -55 to +80C

NOTES

1. De-rate by 20% if mounted external to generator.

2. Inclusive of 4% engine governing.

3. After 2 minutes warm-up.

4. Generator de-rate may apply. Check with factory.

5. Factory set, semi-sealed, jumper selectable.

6. De-rate output current by 5% per deg. C above 60C.

7. Non condensing.

Page 2

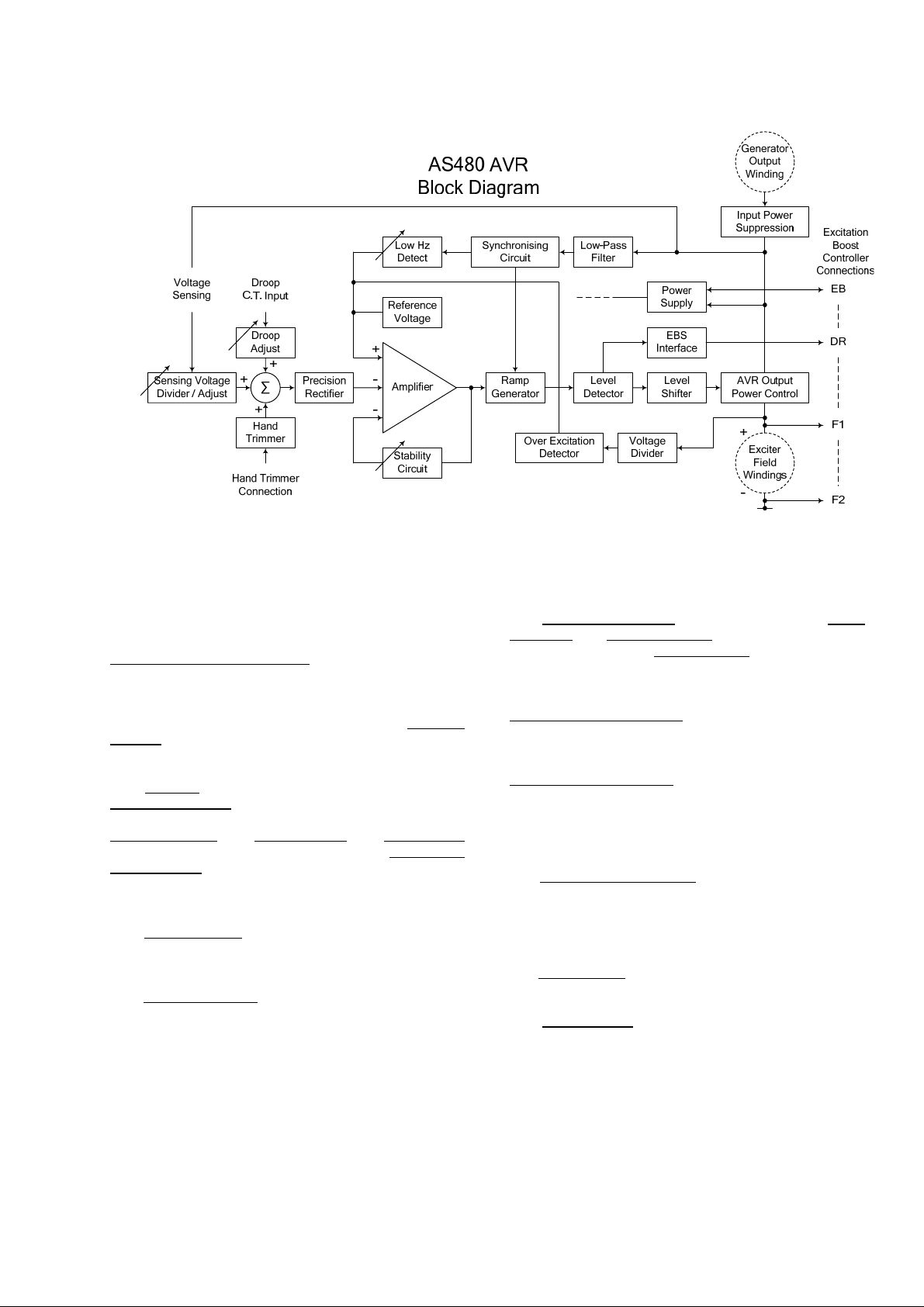

The AVR Circuit Description

The main functions of the AVR are:

Sensing Voltage Divider / Adjust

generator output voltage and attenuates it. The potential

divider is adjustable by the AVR Volts potentiometer and

external hand trimmer (when fitted). The output from the

droop CT is also added to this signal. A Precision

Rectifier converts the a.c. input signal into d.c. for further

processing.

The Amplifier

Reference Voltage

provide a controlling signal for the power devices. The

Ramp Generator

infinitely control the conduction period of the AVR Output

Power Control devices. This provides the exciter field

windings with the variable power necessary to maintain

the generator voltage within specified limits.

The Stability Circuit

ensure good steady state and transient performance of

the control system.

The Low Hz Detector

electrical cycle and causes the reference voltage to be

reduced approximately linearly with speed below a presettable threshold. A Light Emitting Diode gives indication

that the circuit is activated by the low-speed running

condition.

compares the sensed voltage to the

and amplifies the difference (error) to

and Level Detector and Level Shifter

provides adjustable feedback to

measures the period of each

takes a proportion of the

The Synchronising circuit is used to keep the Ramp

Generator and Low Hz Detector locked to the generator

waveform period. The Low Pass Filter

waveforms affecting the operation of the AVR control

circuit.

AVR Output Power Control

exciter field current in response to the error signal

produced by the Amplifier.

Input Power Suppression

prevent load generated voltage transients from damaging

the AVR components and also to reduce the amount of

conducted radio-frequency noise on the generator

terminals.

The Over Excitation Detector

exciter field voltage and provides the signal required to

collapse the output voltage. This protection circuit

triggers only if an over excitation condition persists for a

specific amount of time.

The Power Supply

AVR circuitry.

The EBS Interface

control the excitation boost generator (EBG). The EBG

responds to the level of excitation provided by the AVR

and supplies additional power as it is needed to support

the overload.

provides the required voltages for the

provides the signals necessary to

devices vary the amount of

components are included to

continuously monitors the

prevents distorted

© Cummins 2008 2 TD_AS480 AVR_04.08_02_GB

Page 3

AS480 AVR – Links and Adjustments

refer to the generator wiring diagram for all connection details

Operation at 110Vac (optional)

- remove link(*) before fitting

- connect the 15k/1W sensing link

- the hand trimmer cannot be used in this mode

- Overload performance is limited in this mode.

> 100kW

connections for

excitation boost

unit

Stability Linking

< 100kW

Slow

Link BDLink BC

< 100kW

50Hz 60Hz

UFRO Linking

Fast

No Link

VOLTS

DROOP

D

C

B

50

HZ

60

DR

LED

EB

F2

F1

2

1

S2

S1

F2

F1

STABILITY

UFRO

7

8

Hand

Trimmer

(optional)

Raise

1k / 1W

Droop

C/T

(optional)

Remove link

before fitting

Control Function Direction

VOLTS Generator output voltage setting Clockwise raises voltage

STABILITY Output voltage stability Clockwise increases stabilisation effect

DROOP Voltage droop for paralleling Clockwise increases drooping effect

UFRO Under-frequency 'Knee' point Clockwise decreases 'Knee' point

Refer to the Generator Wiring Diagrams for all Connection detail

© Cummins 2008 3 TD_AS480 AVR_04.08_02_GB

Page 4

ADJUSTMENT OF AVR CONTROLS

VOLTAGE ADJUSTMENT

The generator output voltage is set at the factory but can

be altered by adjustment of the VOLTS control on the AVR

board or by the external hand trimmer if fitted. Before

adjusting the generator output voltage , note the following

warnings.

WARNING! Do not increase the voltage above the

rated generator voltage shown on the rating plate

mounted on the generator case.

WARNING! Do not ground any of the external hand

trimmer terminals. Failure to observe this could cause

equipment damage.

To adjust the generator output voltage, proceed as follows:

1. Before running the generator set, turn the [VOLTS]

control fully anti-clockwise. Turn the [STABILITY] control

to its midway position and the external hand trimmer (if

fitted) to its midway position.

2. Connect a suitable voltmeter (0-300Vac) across Line

and Neutral of the generator.

3. Start the generator set, and run on no load at nominal

frequency e.g. 50Hz (or 60Hz).

4. If the red Light Emitting Diode (LED) is illuminated, refer

to the section on Under-Frequency-Roll-Off adjustment.

5. Carefully turn the [VOLTS] control clockwise until the

required voltage is reached.

6. If instability is present at rated voltage, refer to the

section on Stability adjustment.7. Voltage adjustment is

now completed.

STABILITY ADJUSTMENT

The AVR includes an optimised stability circuit to provide

good steady state and transient performance of the

generator. Links are provided to change the response of

the stability circuit to suit different frame size generators

and applications. A slow response setting is more

appropriate on small generator sets and will prove helpful

in reducing lamp flicker.

The correct setting of the Stability adjustment can be found

by running the generator at no load and slowly turning the

stability control anti-clockwise until the generator voltage

starts to become unstable. The optimum position for the

control is slightly clockwise from this point (i.e. where the

machine volts are stable but close to the unstable region).

UNDER-FREQUENCY-ROLL-OFF ADJUSTMENT:

(UFRO)

The AVR incorporates an under-speed protection

circuit which produces a volts/Hz characteristic when

the generator frequency falls below a preset threshold

- known as the "knee" point. The red Light Emitting

Diode (LED) gives indication that the UFRO circuit is

operating in the low frequency region.

The UFRO adjustment is preset and sealed and only

requires the selection of 50Hz or 60Hz operation

using the jumper link.

For normal operation, the LED should illuminate as

the frequency falls just below 95% of nominal.

i.e. 47Hz on 50Hz systems or 57Hz on 60Hz systems.

DROOP ADJUSTMENT

Generators intended for parallel operation should be

fitted with a quadrature droop C.T. The C.T. is

connected to S1, S2 on the AVR and provides a

power factor dependent signal for the AVR voltage

sensing circuit. This allows the control of generator

reactive current when two or more generators are

operated in parallel.

The DROOP adjustment is normally preset in the

works to give 5% voltage droop at full load zero

power-factor.

Clockwise increases the amount of C.T. signal

injected into the AVR and increases the amount of

voltage droop. With the control fully anti-clockwise

there is no droop.

OVER EXCITATION TRIP

The over-excitation trip level is set at the works at

65Vdc and cannot be altered. An over excitation

condition is indicated on the LED (which also indicates

under speed running).

The over-excitation is allowed to exist for

approximately eight seconds to prevent nuisance

tripping and to support normal transients and shortterm overloads. The generator voltage falls to low

levels when the trip is activated. The generator must

be stopped to reset an over-excitation shutdown

condition.

EXCITATION BOOST SYSTEM

There are no user adjustments on the EBS

module just connect the unit and it is ready for

use.

© Cummins 2008 4 TD_AS480 AVR_04.08_02_GB

Page 5

EBS - Circuit description:

The EBS comprises an add-on permanent magnet

generator (EBG) with embedded control electronics

(the EBC module).

The main functions of the EBC are as follows:

The Input Rectifier and Power-Supply

supplies to the internal control parts of the EBC.

The Micro-controller measures the drive signal

(DR) generated by the AVR and determines the

© Cummins 2008 5 TD_AS480 AVR_04.08_02_GB

provides

need for excitation power support. As this support is

required it is delivered at low, medium or high levels to the

exciter field. The AVR control function

maintains generator voltage within broad limits until both

AVR and EBS are fully conducting.

The micro processor contains three timer functions: to

prevent actinnnvation on generator run up, operation below

30Hz and to disconnect the booster power after a period of

boost operation i.e. preventing the generator from

overheating. This function is designed to follow

the approximate thermal state (temperature) of the machine

windings.

Page 6

The output characteristic of the EBS is as shown

below. The high-speed interaction between the EBS

output and AVR demand is effectively ‘smoothed’ by

the connected generators excitation component

time-constants.

Barnack Road • Stamford • Lincolnshire • PE9 2NB

Tel: 00 44 (0)1780 484000 • Fax: 00 44 (0)1780 484100

POWER INPUT

Voltage 90-130 Vac 3 phase

Frequency 100-120 Hz nominal

OUTPUT

Voltage 120 Vd.c. @ 100 Va.c power input.

Current continuous 6A

Resistance 15 ohms min

TYPICAL SYSTEM RESPONSE

EBC response 20ms

INTERNAL TIMERS

Start-up timer 5sec nominal

Overload protection timer 5sec nominal

UNIT POWER DISSIPATION

12 watts maximum

© Cummins 2008 6 TD_AS480 AVR_04.08_02_GB

Loading...

Loading...