Winchester® Model 101™ Over and Under Shotgun Owner’s Manual

Important instructions for

Winchester® Model 101™

Over and Under Shotguns

Winchester Repeating Arms

Customer Service Department (United States)

275 Winchester Avenue

Morgan, Utah 84050-9333

Phone: (800) 945-5237

If you have any questions or comments regarding your

new firearm, please feel free to write or call us. Use the

space below to record information about your new firearm.

Model ________________________________________

Serial Number _________________________________

Purchased From ________________________________

Date of Purchase _______________________________

Winchester is a registered trademark of Olin Corporation.

AO1208/12319

Contents Page

State Warning ..................................1

WARNING: You are Responsible for Firearms Safety ...1

General Description and Operation .................6

Nomenclature ..................................7

Serial Number .................................10

Initial Cleaning and Oiling .......................10

Operation of the “Safety” ........................11

Barrel Selector .................................12

Top Lever .....................................13

Assembly .....................................14

Disassembly ...................................15

Ammunition ..................................17

Loading ......................................18

Firing ........................................19

Unloading ....................................20

Interchangeable Choke Tube System ...............21

Changing Length of Pull (Special Models)...........23

Adjustable Stock (Special Models).................25

Barrel Porting (Special Models) ...................27

Maintenance of Oil Finish Stocks..................27

Models with Special Finishes......................27

Cleaning and Maintenance Suggestions .............28

Parts, Service, Repair and Questions................31

Website Information ............................32

State Warning

According to state law, California requires that firearm

manufacturers, distributors and retailers include

conspicuous, specific warnings with firearms sold in

that state.

Warning: You are reSponSible

for firearmS SafetY

FAILURE TO FOLLOW ANY OF THE FOLLOWING

WARNINGS COULD RESULT IN SERIOUS INJURY

OR DEATH.

As a firearm owner, you accept a set of demanding

responsibilities. How seriously you take these

responsibilities can be the difference between life

and death.

There is no excuse for careless or abusive handling of

any firearm. At all times handle this firearm and all

other firearms with intense respect for their power and

potential danger.

Please read and understand all of the cautions, warnings,

notices, proper handling procedures and instructions

outlined in this owner’s manual before using your

new firearm.

1 ALWAYS KEEP THE MUZZLE OF YOUR FIREARM

POINTED IN A SAFE DIRECTION EVEN THOUGH

YOU ARE CERTAIN IT IS UNLOADED.

Never point any firearm at anything you do not intend

to shoot. Be extremely alert and aware of all persons

and property within the range of your ammunition.

2 NEVER RELY TOTALLY ON YOUR FIREARM’S

MECHANICAL “SAFETY” DEVICE. LIKE ANY

MECHANICAL DEVICE, A “SAFETY” CAN SOMETIMES

FAIL; IT CAN BE JARRED OR INADVERTENTLY

MANIPULATED INTO AN UNSAFE CONDITION.

The word “safety” describes a firearm’s trigger block

mechanism, sear block mechanism, hammer block

mechanism or firing pin block mechanism. Mechanical

“safeties” are designed to place your firearm in a safer

status, and no guarantee can be made that the firearm

1

will not fire even if the “safety” is in the on safe

position. Mechanical “safeties” merely aid safe gun

handling and are no excuse for pointing your firearm’s

muzzle in an unsafe direction. See “Operation of the

‘Safety’” on pages 11-12 for instructions on the

operation of this firearm’s “safety.”

Remember, safe gun handling does not stop with your

firearm’s mechanical “safety” devices, it starts there.

Always treat this firearm with the respect due a

loaded, ready-to-fire firearm.

Some firearms do not have a mechanical “safety.”

Many target firearms, lever-action firearms and pistols

do not have manual “safety” mechanisms. Therefore it

is critical to read and understand the owner’s manual

for every firearm which explains the safe operation of

the firearm.

While it is a good idea to test your firearm’s

mechanical “safety” periodically for proper function,

never test the “safety” while your firearm is loaded or

pointed in an unsafe direction.

3 WHENEVER YOU HANDLE ANY FIREARM, OR HAND IT

TO SOMEONE, ALWAYS OPEN THE ACTION

IMMEDIATELY AND VISUALLY CHECK THE FIREARM’S

CHAMBER TO MAKE CERTAIN THAT THE FIREARM IS

COMPLETELY UNLOADED.

Make certain the firearm does not inadvertently

contain any ammunition. Remember, merely

removing the magazine does not mean the chamber

is unloaded. Always keep the chamber empty and

the “safety” in the on safe position unless shooting

is imminent.

4 ALWAYS WEAR EAR AND EYE PROTECTION

WHEN SHOOTING.

Unprotected, repeated exposure to gunfire can cause

hearing damage. Wear hearing protection (shooting

ear plugs or muffs) to guard against such damage.

Wear shooting glasses to protect your eyes from flying

particles. Allow proper distance (eye relief) between a

scope and your eye when firing a scoped pistol, rifle or

shotgun. Do not use unorthodox shooting methods

that could cause the rearward travel of the slide or bolt

of a firearm to contact your eyes, face or hands.

Always keep a safe distance between the muzzle of

your firearm and any persons nearby, as muzzle blast,

debris and ejecting shells could inflict serious injury.

Always wear eye protection when disassembling and

cleaning any firearm to prevent the possibility of

springs, spring-tensioned parts, solvents or other

agents from contacting your eyes.

5 KEEP ALL FIREARMS UNLOADED DURING

TRANSPORT, EVEN WHEN STORED IN A HOLSTER,

GUN CASE, SCABBARD OR OTHER CONTAINER.

6 DROPPING OR JARRING A LOADED FIREARM CAN

CAUSE ACCIDENTAL DISCHARGE.

2

This can occur even with the “safety” in the on safe

position. Be extremely careful while hunting or during

any shooting activity to avoid dropping any firearm.

7 HUNTING FROM ELEVATED SURFACES SUCH AS

TREESTANDS IS DANGEROUS.

Doing so may increase the risk of mishandling a

firearm. The following rules should always be observed

by you and those you hunt with. Always make certain

that the stand being used is safe and stable. Always

make certain that your firearm is unloaded when it is

being taken up and down from the stand. Always

make certain that your firearm is not dropped from the

stand, or dropped while it is being taken up or down

from the stand. Remember, a loaded firearm may

discharge when dropped, even with the “safety” in the

on safe position.

8 STORE YOUR FIREARM AND AMMUNITION

SEPARATELY, WELL BEYOND THE REACH

OF CHILDREN.

Take prudent safeguards to ensure your firearm does

not become available to untrained, inexperienced or

unwelcome hands. Store all firearms in secure, locked

cases or a gun safe. Keep your firearm unloaded when

not in use.

9 BEWARE OF BARREL OBSTRUCTIONS.

Mud, snow and an infinite variety of other objects may

inadvertently lodge in a barrel bore. It only takes a

small obstruction to cause dangerously increased

pressures that can damage your firearm and cause

serious injury to yourself and others.

BEFORE CHECKING FOR A BARREL OBSTRUCTION,

BE CERTAIN YOUR FIREARM IS COMPLETELY

UNLOADED, THERE IS NOT A LIVE SHELL IN

THE CHAMBER AND THE “SAFETY” IS IN THE

ON SAFE POSITION.

After assuring yourself that the firearm is completely

unloaded, open the breech or action and look through

the barrel to be sure it is clear of obstructions. If an

obstruction is seen, no matter how small it may be,

clean the bore with a cleaning rod and patch as

described on pages 28-31 of this owner’s manual.

10 BE ALERT TO THE SIGNS OF AMMUNITION

MALFUNCTION. IF YOU DETECT AN OFF SOUND OR

LIGHT RECOIL WHEN A CARTRIDGE OR SHELL IS

FIRED, DO NOT LOAD ANOTHER CARTRIDGE OR

SHELL INTO THE CHAMBER.

If your firearm fails to fire, keep the muzzle pointed in

a safe direction for a minimum of 30 seconds. Rotate

the ejection area of the firearm away from you,

carefully open the action and remove the cartridge or

shell from the chamber. If the primer is indented, the

defective cartridge should be disposed of in a way that

cannot cause harm. If the primer is not indented, your

firearm should be examined by a qualified gunsmith

and the cause of the malfunction corrected before

further use. Glance down the barrel to make sure that

3

no obstructions remain in the barrel. Completely clear

the barrel before loading and firing again. Failure to

follow these instructions can cause extensive damage

to your firearm and possible serious injury to yourself

and others.

11 NEVER INSERT A SHELL OF THE INCORRECT

GAUGE INTO ANY FIREARM.

The gauge of your firearm is marked on the barrel.

Store all shells of different gauges in completely

separate and well-marked containers. Never store shells

of mixed gauges in a common container or in your

pockets. See pages 17-18 for more information on the

correct ammunition for your firearm.

12 EXAMINE EVERY SHELL YOU PUT IN YOUR FIREARM.

We assume no responsibility for the use of unsafe or

improper firearm and ammunition combinations or

damage or injury caused by damaged ammunition.

It is your responsibility to read and heed all warnings in

this owner’s manual and on ammunition boxes.

See pages 17-18 for more information on the correct

ammunition for your firearm.

13 USE ONLY SAAMI APPROVED AMMUNITION.

The barrel and action of this firearm have been made

with substantial safety margins beyond the pressures

developed by established American commercial loads.

Nevertheless, we can assume no liability for incidents

which occur through the use of shells of nonstandard

dimensions or which develop pressures in excess of

commercially available ammunition which has been

loaded in accordance with standards established by the

Sporting Arms and Ammunition Manufacturers’

Institute (SAAMI).

14 MAKE SURE OF ADEQUATE VENTILATION IN THE AREA

THAT YOU DISCHARGE A FIREARM. LEAD EXPOSURE

CAN OCCUR FROM DISCHARGING FIREARMS IN

POORLY VENTILATED AREAS, CLEANING FIREARMS

OR HANDLING AMMUNITION.

Lead is a substance that has been known to cause birth

defects, reproductive harm and other serious injury.

Wash hands thoroughly after exposure to ammunition

or after cleaning a firearm.

15 DO NOT SNAP THE FIRING PIN ON AN EMPTY

CHAMBER; THE CHAMBER MAY NOT BE EMPTY!

Treat every firearm with the respect due a loaded

firearm, even though you are certain the firearm

is unloaded.

16 KEEP YOUR FINGERS AWAY FROM THE TRIGGER

WHILE LOADING AND UNLOADING UNTIL

SHOOTING IS IMMINENT.

17 BE SURE OF YOUR TARGET AND BACKSTOP,

PARTICULARLY DURING LOW LIGHT PERIODS.

Know the range of your ammunition. Never shoot at

water or hard objects.

4

18 ALWAYS UNLOAD YOUR FIREARM’S CHAMBER

BEFORE CROSSING A FENCE, CLIMBING A

TREE, JUMPING A DITCH OR NEGOTIATING

OTHER OBSTACLES.

Never place your firearm on or against a fence, tree,

car or other similar object.

19 BE DEFENSIVE AND ON GUARD AGAINST UNSAFE

GUN HANDLING AROUND YOU AND OTHERS.

Don’t be timid when it comes to firearm safety. If you

observe other shooters violating any of these safety

precautions, politely suggest safer handling practices.

20 BE CERTAIN YOUR FIREARM IS UNLOADED

BEFORE CLEANING.

Because so many firearm accidents occur when a

firearm is being cleaned, special and extreme care

should be taken to be sure your firearm is unloaded

before disassembly, cleaning and reassembly.

Keep ammunition away from the cleaning location.

Never test the mechanical function of any firearm

with live ammunition.

21 TEACH AND SUPERVISE FIREARMS SAFETY TO ALL

MEMBERS OF YOUR FAMILY, ESPECIALLY TO

CHILDREN AND NON-SHOOTERS.

Closely supervise newcomers to the shooting sports.

Encourage enrollment in hunting and shooting

safety courses.

22 NEVER DRINK ALCOHOLIC BEVERAGES OR

TAKE ANY TYPE OF DRUGS BEFORE OR

DURING SHOOTING.

Your vision, motor skills and judgment could be

dangerously impaired, making your gun handling

unsafe to you and to others.

23 READ AND HEED ALL WARNINGS IN THIS

OWNER’S MANUAL, ON AMMUNITION BOXES

AND WITH ALL ACCESSORIES THAT YOU INSTALL

ON YOUR FIREARM.

It is your responsibility to secure the most up-to-date

information on the safe handling procedures of your

Winchester firearm. We assume no liability for

incidents which occur when unsafe or improper

firearm accessories or ammunition combinations

are used.

24 PRACTICE PERIODIC MAINTENANCE, AVOID

UNAUTHORIZED SERVICING.

Your firearm is a mechanical device which will not

last forever, and as such, is subject to wear and

requires periodic inspection, adjustment and service.

Winchester firearms should be serviced by a

Winchester Repeating Arms Authorized Repair

Center or by our Service Facility in Arnold, Missouri.

We assume no responsibility for injuries suffered or

caused by unauthorized servicing, alterations or

modifications of Winchester firearms.

5

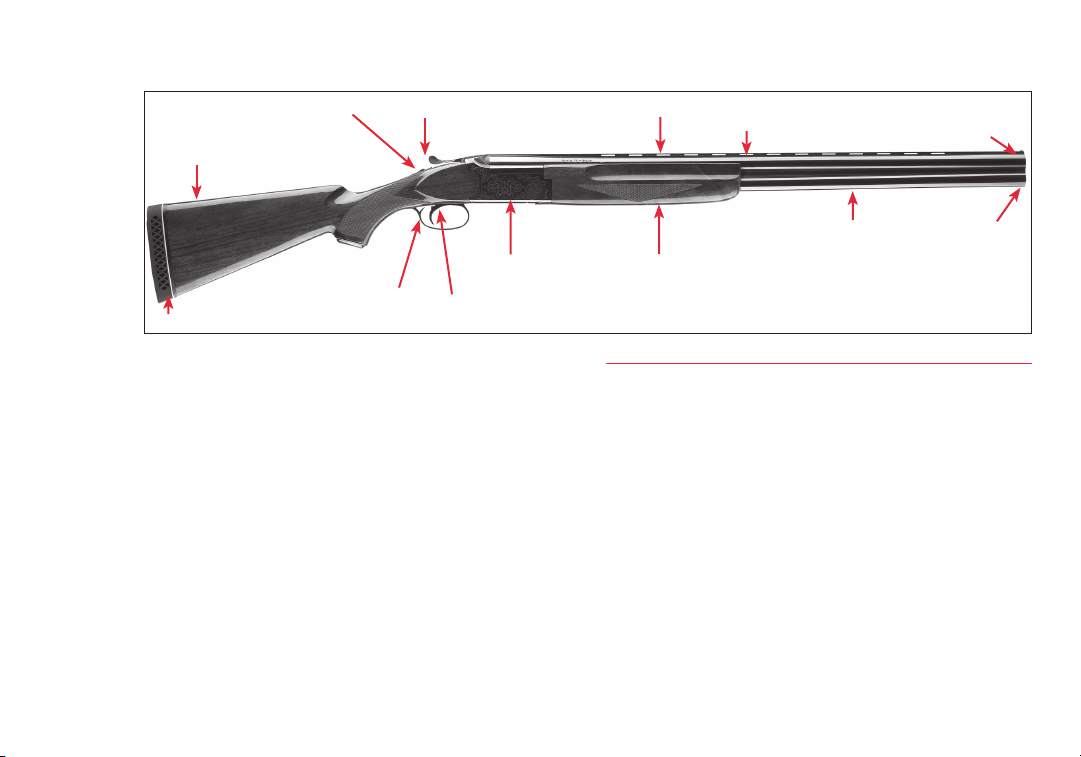

FIGURE 1

Buttstock

“Safety”/Selector Switch

Top Lever

Ventilated Rib

Mid-Bead Sight

(Special Models)

Front Sight

Action/Receiver

Trigger Guard

Recoil Pad

Trigger

25 WE RESERVE THE RIGHT TO REFUSE SERVICE ON

FIREARMS THAT HAVE BEEN ALTERED, ADDED TO

OR SUBSTANTIALLY CHANGED.

Removal of metal from the barrel, or modifications

of the firing mechanism and/or operating parts, may

lead to a refusal of service on such firearms. We will

charge you for parts and labor to return the firearm to

original specifications.

DO NOT, UNDER ANY CIRCUMSTANCES, ALTER

THE TRIGGER, “SAFETY” OR OTHER PARTS OF THE

FIRING MECHANISM OF THIS OR ANY OTHER

FIREARM. FAILURE TO OBEY THIS WARNING

MAY RESULT IN INJURY OR DEATH TO YOURSELF

OR OTHERS.

BE CAREFUL!

Barrels

Forearm

Muzzles

general DeScription anD operation

Balance. Pointability. Reliability. Handling. These are

qualities you expect in an over and under, and they’re

what you’ll get with your Model 101. It’s superbly

designed, combining the traditions of American hunting

guns and European competition guns. These shotguns

provide a lively feel, with dimensions designed to allow

you to quickly move to your target. The low-profile

receiver with dual, between-the-barrel lockup is the

foundation, and combined with ideal stock dimensions,

put you on target consistently.

The Model 101 is an over and under shotgun made to fire

two successive shots by pulling the trigger twice, once for

each shot. Each time the action is opened after firing the

hammers are cocked automatically and empty shells (one

or two) are ejected clear of the chamber(s) automatically.

6

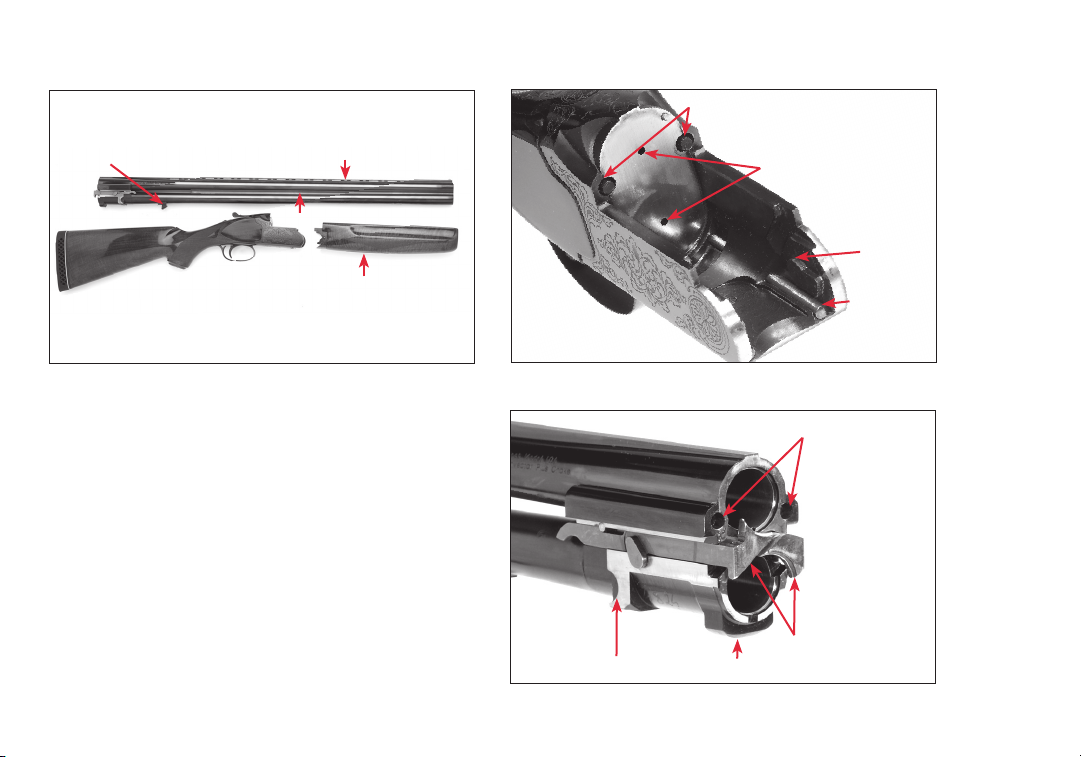

FIGURE 2

FIGURE 3

Locking Pins

Forearm Release

Latch Lug

Ventilated Rib

Side Rib

Forearm Release Latch

Unfired shells are elevated in the chambers. The action is

opened with a lever mounted on the top of the receiver

just forward of the “safety”/selector. The shotgun breaks

down into three pieces for cleaning or storage (Figure 2).

Prior to using live ammunition, familiarize yourself

thoroughly with all the operating instructions in this

owner’s manual. Get accustomed to the feel of your new

firearm. Know the forces required to operate the action.

Understand how to select the firing order of the barrels.

Learn how to pull the trigger correctly, and above all,

know the location and operation of the “safety”/selector.

Procedures for disassembly and operation of various

components are outlined in the following sections. Please

read and study them thoroughly.

FIGURE 4

7

Trunnion Surface

Firing Pins

Trunnion

Cocking Lever

Locking Pin Recesses

Ejectors/Extractors

Locking Lug

(Continued on page 10.)

FIGURE 5

Shot gun feature S

Stocks are profiled for an ideal fit, fast

handling and reduced felt recoil on the face.

Special models feature an adjustable comb

for a personalized fit.

The top-tang “safety”/selector offers

excellent convenience with gloved fingers.

Target models feature a

trigger that adjusts for

length of pull (pages 23-24).

The dual locking pins are made to stay tight under years

of heavy use. The locking pins are larger and sturdier than

the competition’s shotguns and optimize the strength of the

action while allowing an overall lower profile of the receiver

than found on some other over and under shotguns.

The compact, low-profile receiver features

an ideal combination of action strength

and balance. The receiver is quick and

lively, not too small and not too bulky.

When empty shells are ejected, they leave

the chambers at virtually the same time,

flying side-by-side through the air. This is

a sign of a well-timed mechanism.

Deluxe recoil pad provides

maximum comfort.

8

Barrels are back-bored for improved pattern performance. Backboring means that the barrels are made with a slightly larger inner

bore diameter than traditional dimensions. This results in less

resistance to the shot column as it moves down the bore and less

deformation of pellets as they move through the forcing cone. There

is also a slight decrease in perceived recoil.

The durable rib design is available in both

field and sporting widths.

The barrels and forearm remove

for easy cleaning and storage.

All Model 101 and Select shotguns are fitted with the

proven Invector-Plus

™

choke tube system. These longer

tubes have special tapers for optimum patterning and are

specially designed for back-bored barrels. This allows you

to easily change choke constrictions to meet the demands

of the game or target.

9

nomenclature

In conventional firearm terminology the position and

movement of firearm parts are described as they occur with

the firearm horizontal and in normal firing position: i.e.,

the muzzles are forward or in front; the buttstock is

rearward or to the rear; the trigger is downward or

underneath; the rib is upward or on top. For general parts

nomenclature, refer to Figure 1, page 6.

The shotgun is also shown disassembled to the extent

necessary in order to follow instructions contained in

this owner’s manual in Figure 2 on page 7. Details of

the action are shown in Figure 3 and Figure 4 (page 7).

Figure 5 (pages 8-9) covers the general features and

benefits of the Model 101 design.

Throughout this owner’s manual the “action” refers

to the mechanism of this shotgun that secures the shells

in the chambers.

Serial number

The serial number is located on the top tang of the

receiver under the top lever. Duplicate numbers are also

located on the bottom of the barrels (when removed) on

the flat surface crossing the barrels below the trunnion

surface and inside the forearm. Record the serial number at

the front of this owner's manual for future reference.

NOTICE! DO NOT INTERCHANGE THE RECEIVER, BARRELS

OR FOREARM WITH OTHER SHOTGUNS EVEN THOUGH

THE PARTS MAY APPEAR SIMILAR.

initial cleaning anD oiling

NOTICE! PLEASE TAKE NOTE OF THE FOLLOWING

INFORMATION BEFORE CLEANING YOUR FIREARM.

clea ning par tS With Spec ial fini SheS

Be especially careful when cleaning firearms with

camouflage, Dura-Touch

®

Armor Coating and other

special finishes. Always prevent these surfaces from

coming in contact with cleaning solvents, barrel scrubbers

and other strong chemicals. It is preferable to clean these

surfaces with a light gun oil containing no solvents or with

a damp cloth and mild dish soap (be sure to keep water out

of the action). When cleaning your firearm’s bore and

action, protect the external finishes from any contact with

chemicals used. Also, avoid any contact between external

finishes and other strong chemicals like those found in

DEET-containing insect repellents, sunscreens, etc.

Damage to camouflage, Dura-Touch and other finishes

caused by chemicals is irreversible and not repairable.

WEAR EYE PROTECTION WHEN ASSEMBLING AND

DISASSEMBLING YOUR SHOTGUN TO PREVENT SPRINGS,

SPRING-LOADED PARTS, SOLVENTS OR OTHER AGENTS

FROM CONTACTING YOUR EYES, RESULTING IN INJURY.

Some metal parts of your new firearm have been coated at

the factory with a rust preventative compound. Before

using your shotgun, clean the anti-rust compound from the

inside of the barrels, receiver area, locking pin mechanism,

10

extractors/ejectors, hinge surfaces and the chamber areas.

A high quality, lightweight gun oil should be used to

remove this compound and to give your new firearm its

first lubrication. Clean the barrels using a cleaning rod

and patch as explained under “Cleaning and Maintenance

Suggestions” on pages 28-31.

If your firearm is to be stored for an extended period of

time, it is permissible to leave the rust preventative

compound in place and keep your firearm in its box for

maximum protection during long-term storage.

Before beginning assembly of your firearm you should first

wipe the mechanism clean and apply a few drops of quality

oil on the surfaces shown (Figure 6 and Figure 7). Grease

is recommended to lubricate the hinge surfaces on both

sides of the receiver to prevent galling. Avoid applying too

much lubricant, as only a light film is necessary. Excessive

lubricant should be wiped off.

operation of the “SafetY”

ALWAYS KEEP THE “SAFETY” IN THE ON SAFE POSITION

UNLESS SHOOTING IS IMMINENT. VISUALLY CHECK

YOUR “SAFETY” TO BE CERTAIN IT IS IN THE ON SAFE

POSITION BEFORE LOADING. ALWAYS KEEP THE

MUZZLES POINTED IN A SAFE DIRECTION. FAILURE TO

FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

FIGURE 6

Lightly oil at these points.

FIGURE 7

Lightly oil extractors/ejectors on

both sides of the monoblock.

Your shotgun is designed with a top-tang mounted

“safety”/selector. It is located just rearward of the top lever

on the top tang, and is convenient to operate. It is

operated with the thumb of your rearward hand when

holding the firearm in shooting position.

To place the firearm on safe, pull the “safety”/selector fully

to the rear with your thumb. When the “safety”/selector

is fully rearward an “S” is exposed at the front of the

“safety”/selector. This shows you visually that the “safety”

is in the on safe position (Figure 8, page 12). With the

“safety” in the on safe position the trigger is disconnected

and the shotgun cannot be fired.

To place the firearm off safe, push the “safety”/selector

fully forward with your thumb (Figure 9, page 12). When

11

FIGURE 8

FIGURE 9

FIGURE 10

FIGURE 11

The “safety”/

selector in

the on safe

position. The

"S" is visible.

The “safety”/

selector in the

off safe position.

The "S" is not

visible.

the “safety”/selector is fully forward the “safety”/selector

covers the “S.” In the off safe position — if your shotgun

is loaded with shell(s) in the chamber(s) — the

chambered shell(s) can be fired by simply pulling

the trigger.

At all times in the field keep the “safety”/selector in the

on safe position and the barrels pointed in a safe direction.

It is a good idea never to load your shotgun until you are

in the field, at the location you intend to begin hunting or

you are at your station on a range and it is your turn to

shoot. For extra safety on a range, and as a courtesy to

others, fully unload the chambers and keep the action

open at all times other than when it is your turn to shoot.

The “safety”/

selector in the

under position.

The “safety”/

selector in the

over position.

barrel Selector

The “safety”/selector on the top tang of your shotgun also

serves as the barrel selector. The barrel selector allows you

to choose which barrel will fire with the first pull of the

trigger. The other barrel will then fire with the second

pull of the trigger. The “safety”/selector must be in the on

safe rearward position to operate the barrel selector.

The “safety”/selector can be moved to the right or left

covering and uncovering the letters “U” and “O.” On the

left side of the “safety”/selector the letter “U” stands for

“under.” On the right side the letter “O” stands for “over.”

•Iftheletter“U”isexposed,theunder(lower)barrel

will fire first (Figure 10).

12

•Iftheletter“O”isexposed,theover(top)barrelwill

fire first (Figure 11, page 12).

Often different chokes are installed in each barrel which

have different constrictions. This may make one barrels

choke preferable for a certain shot. Also there is slightly

less muzzle jump when the lower barrel is fired first,

making it easier to pick up your target for a follow-up

shot. The barrel selector allows you to choose the best

choke and barrel firing order combination for rapidly

changing hunting conditions or to adapt to the layout

of a sporting clays station.

Always make sure that the selector switch is completely

to one side or the other. If the switch is inadvertently

positioned directly between “O” and “U” the “safety”/

selector switch may be more difficult to move to the

off safe position.

top lever

The top lever operates the locking pins, which are fitted

to the barrel lugs. Moving the top lever to the right

unlocks the action and allows the shotgun to be loaded

and unloaded.

It is not necessary that the top lever return to a

completely centered position, nor should it hang over the

right side or edge of the receiver tang. Upon closing the

action, let the top lever snap into position to allow the

top lever spring to return the top lever mechanism to the

locked position. Do not retard its action with your thumb.

FIGURE 12

When closed, the top

lever may still be

slightly to the right.

Many shooters lightly push the top lever to the left after

the closing the breech. This operation is a quick method

of assuring yourself that foreign matter has not interfered

with the complete closure of the breech.

Always keep the polished breech surfaces clean and lightly

oiled. The breech is so carefully hand-fitted that

accumulated debris, sand, etc. may prevent complete

closing. If this should occur the action will not close.

Open the action and unload it. Carefully examine the

action surfaces and remove any foreign matter.

Additionally, provision is made for the gradual wear of

locking surfaces to keep the action tight. It is common,

because of the tight tolerances and craftsmanship of your

shotgun, for the top lever to be just slightly right of center,

even when the action is fully closed (Figure 12).

13

FIGURE 13

FIGURE 14

Angle the two halves

as shown.

Pull out on the forearm’s release

latch and angle the forearm

down and off.

This is the result of tight tolerances which assure your

shotgun of excellent receiver-to-barrel fit for many years

to come and is the sign of a finely crafted firearm.

aSSemblY

ALWAYS KEEP THE MUZZLES POINTED IN A SAFE

DIRECTION. BEFORE STARTING ASSEMBLY

PROCEDURES, VISUALLY INSPECT THE CHAMBERS TO

BE ABSOLUTELY CERTAIN THE FIREARM IS

COMPLETELY UNLOADED. PLACE THE “SAFETY” IN THE

ON SAFE POSITION. FAILURE TO FOLLOW THIS WARNING

COULD RESULT IN SERIOUS INJURY OR DEATH.

Trunnion Surface

Attach the barrels by aligning the

trunnion surfaces on the barrels with

the trunnions on the receiver.

Your shotgun will come from the factory partially

disassembled. Prior to assembly clean and lightly oil

component parts as explained under “Initial Cleaning

and Oiling” (Page 10).

It is important to carefully follow the assembly

instructions below to assure the proper assembly of

your shotgun.

1. Inspect the chambers and action areas, and clean dirt

and/or excess oil from them as explained on page 10.

2. Remove the forearm from the barrels by holding the

barrels with one hand and pull out on the forearm

release latch with the other (Figure 13).

3. Attach the barrels (without the forearm attached to

them) to the action by first holding the barrels with

14

FIGURE 15

Reattach the forearm by lining up the

forearm extension with the receiver.

Hold at an angle.

the muzzles at a downward angle with respect to the

receiver. Then push the top lever to the right.

Carefully engage the surfaces of the trunnions (located

inside the forward portion of the receiver) with the

curved trunnion surfaces on the monoblock, located

on each side of the bottom barrel (Figure 14, page 14).

4. With the monoblock properly seated on the trunnions,

lift up on the barrels and close the action. Make sure

the monoblock and trunnions remain in proper

alignment. When performing assembly procedures it

also helps to keep the top lever pushed fully to the

right with your thumb until the action is closed. When

the action is fully closed release the top lever and the

action will be locked in the closed position.

If the action seems difficult to close, the monoblock

and trunnions may not be properly engaged. Release

the upward pressure and carefully separate the barrels

from the action again. If forced, you may mar and

damage the fine fit of your shotgun’s action.

5. Once the barrels are installed and the action closed,

replace the forearm on the shotgun by sliding the

radiused rear surface of the forearm extension at an

angle into the radiused front edge of the receiver.

Match the shape of the rear of the forearm to the

shape of the front of the receiver (Figure 15). Lift the

front of the forearm until it engages with the barrels

with an audible click. If it does not click, gently slap

the forearm just above the latch with the palm of your

hand. If the forearm release latch protrudes carefully

push it into place, but do not force the latch. Your

shotgun is now fully assembled.

DiSaSSemblY

ALWAYS KEEP THE MUZZLES POINTED IN A SAFE

DIRECTION. BEFORE STARTING DISASSEMBLY

PROCEDURES, OPEN THE ACTION AND VISUALLY

INSPECT THE CHAMBERS TO BE ABSOLUTELY CERTAIN

THE FIREARM IS COMPLETELY UNLOADED. PLACE THE

“SAFETY”/SELECTOR IN THE ON SAFE POSITION.

FAILURE TO FOLLOW THIS WARNING COULD RESULT IN

SERIOUS INJURY OR DEATH.

15

FIGURE 16

Lift up and out to separate the

barrels from the receiver.

Disassembling your shotgun into its two assembly

components is an ideal way to ready your shotgun for

storage and cleaning. Many luggage-style cases require

doing this. It is also a way to add an extra measure of

safety when storing your firearm.

1. Make sure your shotgun is unloaded and make sure

that the “safety”/selector is in the on safe position.

2. Remove the forearm by pulling outward on the

forearm release latch and pulling the forearm away

from the barrels. Pull the front-most end of the

forearm away and slightly forward, completely

detaching it from the barrel set and the front of

the receiver.

USE CARE WHEN REMOVING THE FOREARM. DO NOT

PULL DOWN TOO HARD ON THE FOREARM OR PULL IT

AWAY FROM THE BARRELS TOO FAR. DOING SO MAY

CRACK THE FOREARM.

3. Grasp the barrels ahead of the receiver and push the

top lever to the right with your thumb. Rotate the

barrels downward until they separate from the

receiver. Be sure to support the barrels and buttstock

carefully. When the barrels are fully down, carefully

lift the hinge portion of the barrels (at the receiver)

upward out of the receiver, separating the barrels from

the receiver (Figure 16).

4. If you are cleaning your shotgun, this is the ideal level

of disassembly.

5. When cleaning is completed, reattach the forearm to

the barrels for storage. This is done very easily when

the barrels are detached. Simply align the forearm

extension along the bottom of the barrel so that the

forearm extension aligns with the rails on each side

of the chambers. Make sure the ends of the rails line

up with the rear top edge of the forearm (Figure 17,

page 17). The forearm can be angled slightly or

positioned parallel with the barrels. Press with even

pressure using both hands, front to back, along the

forearm. As the forearm snaps into position, the

release latch may briefly protrude from the bottom of

the forearm. It will snap down flush with the forearm

when it is secured in position correctly.

16

FIGURE 17

Line up the forearm with the chamber

rails and barrels and snap into place.

ammunition

USE ONLY SHELLS OF THE CORRECT GAUGE AND

LENGTH. THE GAUGE AND LENGTH OF THE CHAMBER IS

INSCRIBED ON THE SIDE OF THE BARREL. DO NOT USE

AMMUNITION OTHER THAN WHAT IS INSCRIBED ON THE

SIDE OF THE BARREL. EXAMINE EVERY SHELL YOU PUT

IN YOUR SHOTGUN. FAILURE TO FOLLOW THIS WARNING

COULD RESULT IN SERIOUS INJURY OR DEATH AND

CAUSE DAMAGE TO YOUR SHOTGUN.

USE SHELLS OF THE CORRECT LENGTH. DO NOT USE 3"

OR 3½" SHELLS IN A BARREL WITH A 2¾" OR 2½"

CHAMBER, OR 3½" SHELLS IN A BARREL WITH A 3"

CHAMBER. DOING SO CAN RESULT IN A BUILDUP OF

DANGEROUSLY HIGH PRESSURES. FAILURE TO FOLLOW

THIS WARNING COULD RESULT IN SERIOUS INJURY OR

DEATH AND CAUSE DAMAGE TO YOUR SHOTGUN.

DO NOT PUT A 16 GAUGE SHELL OR A 20 GAUGE SHELL

IN A 12 GAUGE SHOTGUN. DO NOT PUT A 28 GAUGE

SHELL IN A 20 GAUGE SHOTGUN. DO NOT PUT A .410

BORE SHELL IN A 28 GAUGE SHOTGUN. NEVER PUT

METALLIC SHELLS OF ANY KIND IN A SHOTGUN.

SPECIFICALLY, NEVER PUT CENTERFIRE RIFLE OR

PISTOL SHELLS IN A SHOTGUN CHAMBERED FOR .410

BORE. FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY OR DEATH AND CAUSE

DAMAGE TO YOUR SHOTGUN.

The most certain way to bulge or rupture a shotgun barrel

is to load a smaller gauge shell into a larger gauge chamber.

The smaller gauge shell will not fall completely through

the barrel; its rim is caught by the front of a larger gauge

chamber or at the larger gauge’s choke. Your shotgun will

misfire (with the chamber appearing to be empty). It is

then possible to load the correct gauge shell behind the

smaller gauge shell. If the shotgun is then fired, the result

will be a so-called “12-16, 12-20, 20-28 or 28-.410 burst”

which can cause extensive damage to your shotgun and

possible serious injury to you and others.

We can assume no responsibility for incidents which occur

through the use of shells of nonstandard dimension or

those developing pressures in excess of SAAMI (Sporting

17

Arms and Ammunition Manufacturers’ Institute)

established standards.

There are several different versions of the Model 101. The

gauge and chamber length are inscribed on the side of the

barrel, forward of the receiver. They are inscribed as

follows:

•2¾"and3"chamber—Thesemodelsaredesigned

toshootallfactoryloadsfrom2¾"upto3"

Magnums. The chambers are designed to accept

upto3"factoryloads.(Itisnotdesignedtoshoot

3½"shells.)

•2¾"chamber—Shotgunswiththisdesignationare

usually target models. They are specifically configured

tobeabletohandleallfactory2¾"loadsincluding

thelightesttargetloadsuptoheavy2¾"hunting

fieldloads.(2¾"targetmodelsarenotdesignedto

shoot3"or3½"shells.)

Winchester

®

ammunition is always an excellent choice for

your new Winchester firearm, delivering the unmatched

performance and dependability you want.

loaDing

WHEN LOADING YOUR SHOTGUN ALWAYS KEEP THE

MUZZLES POINTED IN A SAFE DIRECTION, ALWAYS

PLACE THE “SAFETY” IN THE ON SAFE POSITION AND

KEEP YOUR FINGERS AWAY FROM THE TRIGGER.

FAILURE TO FOLLOW THESE WARNINGS COULD RESULT

IN SERIOUS INJURY OR DEATH.

DO NOT CARRY YOUR SHOTGUN WITH SHELLS IN THE

CHAMBERS TO AVOID ACCIDENTAL DISCHARGE. WHEN

FIRING IS NO LONGER IMMINENT, MAKE SURE THE

“SAFETY” IS IN THE ON SAFE POSITION AND UNLOAD

THE CHAMBERS. FAILURE TO FOLLOW THESE WARNINGS

COULD RESULT IN SERIOUS INJURY OR DEATH.

1. Make sure the “safety”/selector is in the on

safe position.

2. Open the action by pushing the top lever to the right

with the thumb of your right hand. Left-handed

shooters usually push the lever by reaching across with

their left thumb.

3. Visually check to make sure there are no obstructions

in the chambers or bores of the barrels.

4. Insert a shell in each chamber or in the chamber you

plan to fire. Make sure the shell(s) are fully forward in

the chamber(s), with the rim(s) in direct contact with

the edge of the extractors/ejectors (Figure 18, page 19).

5. Close the action by lifting up on the forearm, hinging

the barrels upward into position, until the action is

fully closed. When closed, the top lever will snap back

into the center position. There should be no space

between the face of the barrels and the face of the

receiver when the action is fully closed (Figure 19,

page 19).

18

FIGURE 18

Insert the loaded shells into the chambers. Push them in fully

against the edge of the extractors/ejectors.

THE SHOTGUN IS NOW READY TO FIRE BY SIMPLY

MOVING THE “SAFETY” TO THE OFF SAFE POSITION

AND PULLING THE TRIGGER.

6. Select the barrel you want to fire first by operating

the barrel selector which is an integral part of the

“safety”/selector switch. The “safety”/selector must

be in the rearward, on safe position to be able to

select the firing order of your barrels. Refer to the

instructions under “Barrel Selector” on page 12.

FIGURE 19

Make sure the action is fully closed. The barrels

should be tight with the receiver at the breech.

firing

NEVER LOAD SHELLS INTO THE CHAMBERS UNLESS

SHOOTING IS IMMINENT. ALWAYS KEEP THE MUZZLES

POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW

THESE WARNINGS COULD RESULT IN SERIOUS INJURY

OR DEATH.

1. Make sure the “safety”/selector is in the on

safe position.

2. Load the shotgun as explained previously.

in the chambers and the action closed, you need only

move the “safety” to the off safe position to fire the shotgun.

With shells

19

THE SHOTGUN IS NOW READY TO FIRE BY SIMPLY

MOVING THE “SAFETY” TO THE OFF SAFE POSITION

AND PULLING THE TRIGGER.

3. When shooting is imminent, move the “safety”/

selector to the off safe position. Take aim and, when

ready, squeeze the trigger to fire. After firing one

barrel, it is not necessary to move the “safety”/selector

to fire the second barrel. Simply release the trigger to

its original forward position and pull it a second time.

Be certain you fully release the trigger between shots.

If the trigger is not permitted to return to its fully

forward position, the firing mechanism will not

reengage and the subsequent trigger pull will fail to

fire the remaining shell. Failure to release the trigger

ordinarily occurs with overly rapid firing or heavily

gloved fingers.

4. After you have completed firing you should either

reload the chamber(s) with unfired shells (if hunting/

shooting is going to continue) or fully unload your

shotgun (if shooting is completed). Regardless, always

first place the “safety”/selector in the on safe position.

Be sure to open the action completely between shots

to reset the firing mechanism.

AFTER FIRING, OR WHEN SHOOTING IS NO LONGER

IMMINENT, IMMEDIATELY PLACE THE “SAFETY” IN THE

ON SAFE POSITION. FAILURE TO FOLLOW THIS WARNING

COULD RESULT IN SERIOUS INJURY OR DEATH.

For training purposes or in some target situations your

firearm can be fired “single shot” by loading one shell

at a time in only one of the chambers. For training new

shooters, the bottom barrel is often used because of its

slightly lower perceived recoil. Make sure the “safety”/

selector is set for the barrel you wish to fire.

unloaDing

WHILE UNLOADING YOUR SHOTGUN ALWAYS PLACE THE

“SAFETY” IN THE ON SAFE POSITION. KEEP THE

MUZZLES POINTED IN A SAFE DIRECTION, AND YOUR

FINGERS AWAY FROM THE TRIGGER. FAILURE TO

FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

The ejector/extractor mechanism mechanically adapts to

whether there is a fired shell or a loaded shell in a

chamber. With a loaded shell the mechanism acts as an

extractor, elevating the shells in the chamber. With a

fired shell it acts as an ejector, forcefully ejecting the

empty shell clear of the chamber and onto the ground.

1. Using your thumb, move the top lever fully to the

right to open the action. The action must be opened

completely to reset the firing mechanism. Due to tight

manufacturing tolerances, it may be necessary to pull

20

downward slightly on the forearm to completely open

the breech. For proper ejection, keep the receiver

level and allow the barrels to completely drop. This

keeps empty hulls in full contact with the ejectors.

2. It is important to point the breech, by canting the

shotgun to the right (or to the left for left-handed

shooters), so empty hulls eject clear of your body and

face. Fired shells will be thrown completely out of the

shotgun upon opening the action. Remember to pick

up all of your empties after you have finished shooting

so as to not to cause litter.

Unfired shells will be elevated in the chambers by the

extractors. They can be unloaded from your shotgun

by pulling the unfired shell(s) out of the chambers

with your fingers.

If only one barrel has been fired, only the fired

hull will be ejected upon opening of the action.

If shooting is imminent, a loaded shell can be

inserted in its place.

interchangeable choke tube SYStem

NEVER ATTEMPT TO REMOVE OR INSTALL A CHOKE

TUBE IN A LOADED FIREARM. WHENEVER REMOVING

OR INSTALLING A CHOKE TUBE IN A SHOTGUN, ALWAYS

KEEP THE MUZZLES POINTED IN A SAFE DIRECTION.

OPEN THE ACTION AND VISUALLY INSPECT THE

CHAMBERS TO BE ABSOLUTELY CERTAIN THE FIREARM

IS COMPLETELY UNLOADED. ALWAYS PLACE THE

“SAFETY” IN THE ON SAFE POSITION AND KEEP YOUR

FINGERS AWAY FROM THE TRIGGER. FAILURE TO

FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

INVECTOR-PLUS, STANDARD INVECTOR AND WINCHOKE

CHOKE TUBES ARE NOT INTERCHANGEABLE. DO NOT

USE INVECTOR-PLUS, STANDARD INVECTOR OR

WINCHOKE CHOKE TUBES IN ANY SHOTGUN BARREL

NOT SUPPLIED BY WINCHESTER REPEATING ARMS. DO

NOT USE ANY OTHER CHOKING DEVICE IN ANY SHOTGUN

BARREL SUPPLIED BY WINCHESTER REPEATING ARMS.

USE ONLY THE APPROPRIATE GAUGE AND TYPE OF

CHOKE TUBE, MARKED INVECTOR-PLUS, STANDARD

INVECTOR OR WINCHOKE, IN THIS SHOTGUN. DO NOT

FIRE THIS SHOTGUN WITHOUT THE CORRECT CHOKE

TUBE INSTALLED. DAMAGE MAY RESULT TO THE

THREADS INSIDE THE BARREL.

FAILURE TO FOLLOW THIS INFORMATION COULD RESULT

IN DAMAGE TO YOUR SHOTGUN OR POSSIBLE INJURY.

NOTICE! USE ONLY THE CHOKE TUBE WRENCH SUPPLIED

WITH YOUR SHOTGUN TO INSTALL AND REMOVE CHOKE

TUBES. USING ANY OTHER WRENCH MAY DAMAGE THE

THREADS IN THE BARREL.

21

All Model 101 shotgun barrels are threaded to accept

the Invector-Plus

™

choke system. Standard Invector,

WinChoke and Invector-Plus tubes are not

interchangeable. Confirm the choke system of your

shotgun by looking on the right side of the barrel where

the specifications are inscribed, where the choke markings

are normally located.

The constriction of each choke tube is indicated twice on

the choke tube: on the side of the tube, and indicated

with a “notch” code on the top rim of the tube. The

included universal choke tube wrench is used to remove

and install choke tubes.

Some target shotguns include premium extended choke

tubes. The constriction of premium choke tubes is

indicated twice on the choke tube: on the side of the

tube, and indicated with an abbreviation in the colored

band. The constriction of flush fit choke tubes is

indicated twice on the choke tube: on the side of the

tube, and indicated with a “notch” code on the top rim

of the tube. The included choke tube T-Wrench is used

to remove and install extended choke tubes.

Choke tubes are compatible with factory ammunition

that has been loaded in compliance with SAAMI

specifications, including magnum lead and steel shot

loads, sabots and shotgun slug loads.

Replacement and additional tubes and wrenches are

available from your Winchester Repeating Arms dealer, or

by contacting the Winchester Repeating Arms Customer

Service Department. See page 32 for contact information.

chok e tu be Selec tion

To help you choose the correct choke tube for each

hunting and shooting situation, all Invector-Plus choke

tubes are inscribed on the side with the patterns

they produce with both lead and steel shot. Each

Invector-Plus tube also has notches in the top rim of the

tube (Figure 20, page 23). These notches are a code to

allow you to determine the choke designation while the

tube is installed. Rim notches refer specifically to lead

shot. Use the charts on this page to cross-reference from

lead to steel, and determine the appropriate tubes for your

ammunition and hunting/shooting situation.

Several choke tubes are supplied with your shotgun.

The choke tubes listed are also available as accessories.

Remember, WinChoke, Standard Invector and InvectorPlus tubes are not interchangeable. Before removing or

installing tubes, or reading the rim notch code, make sure

your shotgun is completely unloaded and the “safety” is in

the on safe position.

chok e tu be remo val

1. Place the “safety”/selector in the on safe position.

Always make sure the shotgun is completely unloaded.

Always keep the muzzles pointed in a safe direction.

2. Use the choke tube wrench to loosen the tube,

turning it counterclockwise. Finger-twist the tube the

rest of the way out of the barrel.

22

FIGURE 20

oNe Notch

two Notches

Rim

Notches

exteNded** x-FuLL tuRkey **

i FuLL *

ii imP. modiFied

iii modiFied

iiii imP. cyLiNdeR modiFied

iiiii skeet imP. cyLiNdeR

No Notches cyLiNdeR cyLiNdeR

*

Not for use with steel shot. Using an over-tight choke constriction with

thRee Notches

FouR Notches

PatteRN with

Lead shot

Five Notches

No Notches

PatteRN with

steeL shot

1

FuLL

1

FuLL

steel shot will result in an ineffective “blown” pattern.

**

Extra Full Turkey, extended with ports. Do not use with steel shot.

1

When more than one choke tube is listed for a given steel shot pattern, use

the more open choke listed for high velocity, larger shot size steel loads.

chok e tu be inStallation

1. Place the “safety”/selector in the on safe position.

Always make sure the shotgun is completely unloaded.

Always keep the muzzles pointed in a safe direction.

2. Before installing a tube, check the internal choke tube

threads in the muzzle, as well as the threads on the

choke tube to be sure they are clean. Lightly oil the

threads with a high-quality, lightweight gun oil.

NOTICE! FAILURE TO CLEAN AND OIL THE THREADS ON

THE CHOKE TUBE COULD RESULT IN THE CHOKE TUBE

SEIZING IN THE BARREL.

3. Using your fingers, screw the appropriate tube into the

muzzle of the barrel, tapered end first, notched end

outward. When it becomes finger-tight, use the choke

tube wrench to firmly seat the tube.

NOTICE! THE CHOKE TUBES SHOULD BE PERIODICALLY

CHECKED TO ASSURE THEY ARE TIGHT AND FIRMLY

SEATED. BEFORE CHECKING, FOLLOW ALL CHOKE TUBE

REMOVAL AND INSTALLATION “SAFETY”/SELECTOR

GUIDELINES PREVIOUSLY OUTLINED.

changing length of pull (Special moDelS)

BEFORE CHANGING TRIGGERS OR PERFORMING

ADJUSTMENT PROCEDURES, PLACE THE “SAFETY” IN

THE ON SAFE POSITION. OPEN THE ACTION AND MAKE

23

FIGURE 21

Loosen the set screw and slide the

trigger shoe into the indexing dots

on the trigger plate to personalize

length of pull.

Insert the Allen

wrench and loosen

the set screw.

CERTAIN THE CHAMBERS ARE UNLOADED. KEEP THE

MUZZLES POINTED IN A SAFE DIRECTION. FAILURE TO

FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

Some shotguns are fitted with a special trigger shoe system

that allows you to make small adjustments to the length of

pull. This feature is usually found on target models where

shooters benefit from highly customized settings. It is easy

to change the length of pull using the 1.5 mm Allen (hex

head) wrench included with your firearm.

1. Place your firearm upside down on a secure, padded

surface to prevent marring the finish.

2. Using the Allen wrench provided (any good 1.5mm

Allen wrench will work) loosen the trigger shoe from

the trigger plate by inserting the wrench from the

bottom into the set screw head (Figure 21). Turn in a

counterclockwise direction to loosen.

3. When the screw is sufficiently loose you will be able

to move the trigger shoe along the trigger plate with

your fingers. There are indexing dots on the trigger

shoe and on the plate. Line up the dots to make

length of pull longer or shorter as desired.

4. Tighten the set screw snugly (do not overtighten)

with the Allen wrench to secure the trigger shoe to

the plate (turn in a clockwise direction to tighten).

Make sure you have aligned the indexing dots in

order to prevent marring the bottom of the trigger

plate with the set screw.

5. With your firearm unloaded, and pointed in a safe

direction, shoulder your firearm several times to feel

how the adjustment changes fit you. Increase or

decrease the length of pull following the instructions

above if necessary. Do not adjust more than allowed

by the “dot” index marks on the plate and trigger

shoe. When you find your preferred adjustment, tighten

the set screw. Always make sure the trigger shoe is

secure before firing. Checking the tightness of the set

screw should be part of your regular maintenance.

24

FIGURE 22

FIGURE 23

Loosen the comb retaining screws.

aDjuStable Stock (Special moDelS)

BEFORE PERFORMING STOCK ADJUSTMENT

PROCEDURES, PLACE THE “SAFETY” IN THE ON SAFE

POSITION. OPEN THE ACTION AND MAKE CERTAIN YOUR

SHOTGUN IS COMPLETELY UNLOADED. KEEP THE

MUZZLES POINTED IN A SAFE DIRECTION. FAILURE TO

FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

Some shotguns are fitted with an adjustable stock that

allows you to make adjustments to the stock for cast and

drop. This feature is usually found on target models where

shooters benefit from highly customized settings.

Loosen the comb adjustment screws.

aDju Stin g ca St on an D ca St off

Adjusting cast on and cast off allows you to achieve a

perfect fit from the stock to your face. This is a most

crucial adjustment, as it determines how correctly and

consistently your eye will line up with the sight plane

along the barrel rib. A shotgun correctly adjusted for

cast on and cast off will have you looking directly down

the center of the rib with the front and middle beads

in alignment.

1. Using a 3mm Allen wrench, loosen the two comb

retaining screws on the right side of the removable

cheekpiece and remove the cheekpiece by lifting

upward (Figure 22). This exposes the cast on and cast

off adjustment mechanism. (The cheekpiece comes

set from the factory with cast in the center position.)

25

FIGURE 24

Cast Off

FIGURE 25

Cast On

2. Loosen both the comb adjustment stud screws

located in the top of the stock adjustment studs

using the larger (3mm) Allen wrench that is provided

(Figure 23, page 25). It only takes a fractional ¼ turn

to loosen them adequately.

3. Slide each stud equally in the desired direction.

Each mark indicates

1

⁄

".

16

4. Move the studs to the right for cast off (Figure 24).

5. Move the studs to the left for cast on (Figure 25).

6. Right-handed shooters may desire some cast off, with

left-handed shooters preferring some cast on. The

terminology is the same for right- or left-handed

shooters. The net effect is to move the cheekpiece to

allow the face to move farther over the stock for

better eye-to-rib alignment.

7. When properly set, the front and rear sight beads

should line up perfectly each time you shoulder

your shotgun.

8. Tighten the stock adjustment screws. Be careful not to

over tighten.

9. Replace the cheekpiece onto the studs. If drop at

comb has already been set to your desired height,

tighten the two comb retaining screws securely.

If drop has not been set, leave the retaining screws

loose and proceed to “Adjusting Drop at Comb.”

aDju Stin g Dr op at comb

Adjusting the drop at the comb allows you to align your

eye perfectly with the plane of the rib.

The drop measurement is determined by measuring the

distance between the plane formed by the top of the rib

and the top of the cheekpiece itself. The higher the

cheekpiece, the lower the drop. To set drop, perform

the following:

1. Loosen the two stock adjustment set screws on the

right side of the cheekpiece (if they were not left loose

after setting the cast) using a 3mm hex (Allen)

wrench. The cheekpiece will now move freely, up and

down on the stock adjustment studs.

2. Position the cheekpiece on the studs at the desired

drop up or down on the stock. Make sure the

26

adjustment on each stud is equal up and down. When

you have determined a possible setting, lightly tighten

the stock adjustment screws and then shoulder the

firearm to test the setting. Drop adjustments are a

matter of trial and error. Adjust a little at a time until

you obtain the desired sight picture on the rib.

3. Once your desired drop at comb is obtained, secure

the cheekpiece in place by tightening the two stock

adjustment set screws on the right side of the

cheekpiece. Drop is now set on your shotgun.

barrel porting (Special moDelS)

Some target models feature ported barrels that reduce

recoil and muzzle jump. Reducing recoil not only

increases comfort when shooting, but increases accuracy

because it is easier to pick-up the second clay target faster

due to decreased recovery time following the first shot.

Carbon can build up in the ports after shooting. To clean

them use a good quality powder solvent and pipe cleaners

to scrub away debris.

BARREL PORTING INCREASES NOISE AND MUZZLE

BLAST. ALWAYS WEAR HEARING PROTECTION, AND

INSTRUCT BYSTANDERS TO WEAR HEARING

PROTECTION, TO PREVENT HEARING LOSS OR DAMAGE.

maintenance of oil finiSh StockS

Keeping the oil-finished wood surfaces on your firearm

looking their best requires only a small amount of

maintenance. When the surfaces become spotted or dull,

the affected area(s) can be treated using rubbing alcohol

on a soft, lint free cloth and allowed to dry. A small

amount of a linseed oil-based finish, such as Watco

Danish Oil Finish, Deft

®

Danish Oil Finish, or Formby’s®

®

Tung Oil Finish should then be applied to the surface of

the wood with a soft, lint free cloth according to the

manufacturers’ instructions. To treat the checkering,

a small amount of oil-based finish can be applied and

then distributed evenly using a toothbrush or other soft

bristled brush.

moDelS With Special finiSheS

As with any firearm, the only way to preserve its

pristine condition and collector appeal is to never

handle or fire it, which in turn would deprive you of

much of the enjoyment that comes with owning a fine

Winchester firearm.

While special finishes such as engraving and gold plating

greatly enhance the aesthetic appeal of your shotgun,

please be aware that they are no more durable, and in

some cases may even be slightly less durable than more

common firearm finishes.

27

As you use your Winchester shotgun, you can expect

special finishes to wear in much the same manner as any

other firearm finish. These marks are the honest product

of the hours spent enjoying your firearm and each scuff

and scratch will probably have a good story to go along

with it.

cleaning anD maintenance SuggeStionS

NOTICE! PLEASE TAKE NOTE OF THE FOLLOWING

INFORMATION BEFORE CLEANING YOUR FIREARM.

clea ning par tS With Spec ial fini SheS

Be especially careful when cleaning firearms with

camouflage, Dura-Touch

®

Armor Coating and other

special finishes. Always prevent these surfaces from

coming in contact with cleaning solvents, barrel scrubbers

and other strong chemicals. It is preferable to clean these

surfaces with a lightweight gun oil containing no solvents

or with a damp cloth and mild dish soap (be sure to keep

water out of the action). When cleaning your firearm’s

bore and action, protect the external finishes from any

contact with chemicals used. Also avoid any contact

between external finishes and other strong chemicals

like those found in DEET-containing insect repellents,

sunscreens, etc. Damage to camouflage, Dura-Touch

and other finishes caused by chemicals is irreversible

and not repairable.

BEFORE PERFORMING CLEANING PROCEDURES, PLACE

THE “SAFETY” IN THE ON SAFE POSITION. OPEN THE

ACTION AND MAKE CERTAIN YOUR SHOTGUN IS

COMPLETELY UNLOADED. KEEP THE MUZZLES POINTED

IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE

WARNINGS COULD RESULT IN SERIOUS INJURY

OR DEATH.

WEAR EYE PROTECTION WHEN DISASSEMBLING AND

CLEANING YOUR SHOTGUN TO PREVENT SPRINGS,

SPRING-LOADED PARTS, SOLVENTS OR OTHER AGENTS

FROM CONTACTING YOUR EYES, RESULTING IN INJURY.

KEEP ALL AMMUNITION AWAY FROM THE CLEANING

AREA. NEVER TEST THE MECHANICAL FUNCTION OF

YOUR SHOTGUN WITH LIVE AMMUNITION. FAILURE TO

FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

clea ning pro ceDu reS

Your Model 101 shotgun will function better and more

reliably over a longer period of time if it is properly

maintained and kept clean. You should clean your shotgun

after every day of shooting, and more often if it becomes

excessively dirty. The barrels should be cleaned and the

28

action wiped clean and oiled after every day of shooting.

Normal maintenance can be accomplished with the

barrels still attached to the receiver (oiling/greasing and

wiping down). More careful cleaning requires removal

of only the barrels and forearm from the receiver (cleaning

the barrel).

If a malfunction occurs, perform a thorough cleaning to

see if it solves the problem before seeking the services of a

Winchester Repeating Arms Authorized Repair Center,

or by contacting the Winchester Repeating Arms Service

Facility in Arnold, Missouri, or a qualified gunsmith.

1. Place the “safety” in the on safe position. Open the

action and inspect the chambers to make certain they

do not contain any shells. Keep the muzzles pointed in

a safe direction.

2. Remove the forearm and barrels as explained under

“Disassembly” on pages 15-16.

3. Using a shotgun cleaning rod with tip and patch large

enough for a snug fit in the bore, insert the rod and a

lightly oiled patch in the breech end of the barrel and

run back and forth through the bore several times.

Remove and wipe the choke tube, threads and barrel

threads with a nylon brush and lightly oil. Reinstall

the choke tubes.

4. Inspect the bore from both ends for leading and plastic

residue that often remain in the bores from the shot

cups in modern shotshells. Leading and plastic residue

will appear as longitudinal streaks and are usually

more predominant near the muzzles and just forward

of the chambers. A normal amount of either is

common and not serious.

5. If leading or plastic residue seems excessive you can

remove it by brushing the bore with a brass brush.

Soak the brush or spray the bore with a powder

solvent first. Scrub until clean. To prevent bristles

from breaking off, push the brush fully through the

barrel each time before pulling it back through.

MOST SOLVENTS ARE HIGHLY FLAMMABLE. WEAR EYE

PROTECTION AND PRACTICE APPROPRIATE SAFETY

MEASURES WHEN WORKING WITH SOLVENTS TO AVOID

SERIOUS INJURY.

6. After all leading and plastic residues have been

removed, run a clean, dry patch through the bore.

Follow this with a final, lightly oiled patch.

7. Wipe all metal surfaces of the receiver, forearm and

barrels with a clean rag. Then lubricate your firearm at

the points noted on page 11. Regular, light lubrication

is extremely important to the durability and reliable

operation of your shotgun.

NOTICE! REMEMBER, THE BROAD, POLISHED FINELY

FITTED SURFACES OF THE RECEIVER AND FOREARM

MECHANISMS (THE BARREL LUGS, THE HINGE PIN AND

FOREARM BRACKET) MUST ALWAYS BE COATED WITH A

THIN FILM OF QUALITY LIGHTWEIGHT GUN OIL.

29

8. Reassemble the shotgun and wipe all exposed metal

surfaces with an oiled cloth making sure to wipe away

all finger marks where moisture could accumulate.

9. Inspect the barrels and chambers to be certain no

patches have inadvertently been left in them. Remove

any that remain.

10. The wood surfaces can also be wiped with a quality,

lightweight gun oil or they can be polished with any

quality furniture wax (but not both).

NOTICE! IT IS VERY IMPORTANT THAT THE CHAMBERS

OF YOUR SHOTGUN BE CLEANED THOROUGHLY AND

PROMPTLY AFTER SHOOTING PLASTIC SHOTSHELLS. DO

NOT LEAVE DISCHARGED (EMPTY) SHELLS IN THE

CHAMBERS FOR ANY LENGTH OF TIME. THE CHEMICAL

COMPOSITION OF MANY PLASTIC SHELLS CONTAINS

MOISTURE WHICH CAN “SWEAT” OUT OF THE SHELL

AND ONTO THE CHAMBERS’ SURFACES, AND POSSIBLY

CAUSE CORROSION AND RUST.

peri oDic oil ing

The metal parts of a firearm should receive a light film of

oil after the firearm has been exposed to weather or

handling. Lightly oil your firearm at the points described

under “Initial Cleaning and Oiling” found on pages 10-11.

Ordinary good judgment will, of course, indicate that the

metal of the firearm should receive a light film of oil any

time the firearm has been exposed to weather or handling.

This is very important and must be done with every

firearm. Remember, the polished, finely fitted surfaces of

the receiver and action mechanisms must always have a

thin film of lubrication. Make sure that the surfaces of the

locking pin system are especially clean and lightly

lubricated with a high-quality gun oil and the hinge

surfaces on both sides of the receiver are lightly greased to

prevent galling. If the firearm has been exposed to

excessive dust, dirt, mud or water, the principal working

parts should be wiped clean and lubricated with a light

film of quality, lightweight gun oil or grease.

NOTICE! DO NOT PLACE LARGE QUANTITIES OF OIL INTO

THE ACTION. EXCESS OIL WILL RUN BACK INTO THE

WOOD OF THE STOCK SOFTENING THE WOOD, WITH

CONSEQUENTIAL LOOSENING OF THE STOCK.

clea ning the inv ecto r-pl uS™ cho ke tube SYSt em

1. Never use a brass brush to clean your barrels unless

choke tubes are installed. Bristles could break off and

lodge in the threads, making installation and removal

of the choke tubes difficult.

2. Regularly remove the choke tubes in order to clean

and oil the threads inside the barrel, as well as on the

choke tube itself. This will protect the threads from

being damaged and also prevent a dirt build-up that

would cause the choke tube to become difficult to

remove. Clean the threads with solvent and a small,

soft brush like a toothbrush. Wipe completely clean

and leave a thin film of clean oil on the threads, both

on the tube and in the barrel. The threads of the

30

choke tube and the internal threads of the barrel

should be cleaned after each use and before the

installation of a tube.

3. Be careful when removing/installing a tube. Use the

specially designed wrench. Damage can result to both

choke tube and barrel when attempting to remove

sticky choke tubes.

4. Never fire your shotgun or run cleaning tools through

the barrel of any choke-tubed shotgun without having

the choke tubes installed.

NOTICE! NEVER ATTEMPT TO TAKE YOUR FIREARM

APART FURTHER THAN EXPLAINED IN THIS OWNER’S

MANUAL. YOUR FIREARM IS A SPECIALIZED, FINELY

FITTED MECHANISM. YOU MAY PERMANENTLY DAMAGE

IT BY ATTEMPTING TO DISASSEMBLE THE INNER

MECHANISM. IF FURTHER DISASSEMBLY FOR SERVICE

OR CLEANING IS REQUIRED, TAKE YOUR FIREARM TO

A QUALIFIED GUNSMITH, OR CONTACT OUR ARNOLD,

MISSOURI SERVICE FACILITY AS EXPLAINED UNDER

“PARTS, SERVICE, REPAIR AND QUESTIONS.”

othe r Su ggeS tion S

•Afterextendedperiodsofheavyuse,yourshotgun

should be taken to a qualified gunsmith to have

the action disassembled for professional cleaning

and lubrication.

partS, Service, repair anD QueStionS

If your Winchester rifle or shotgun should ever need

service or repair, it is often best to contact a Winchester

Repeating Arms Authorized Repair Center. To locate an

Authorized Repair Center visit winchesterguns.com or

contact our customer service department. In some cases

it is appropriate to use the Winchester Repeating Arms

Service Center in Arnold, Missouri. If you have any

questions contact our customer service department and

we can help you determine the best place to service

your firearm.

Parts listings, Authorized Repair Center lists, service

procedures, service/repair form and general product

information are also found on the Web at:

winchesterguns.com.

When returning your firearm for servicing, you must do

the following:

1. Be sure it is completely unloaded.

2. Remove the scope or other optics.

3. Package it securely in a cardboard container.

4. When sending your firearm, enclose the service/repair

form available at winchesterguns.com or a letter that

clearly describes the trouble experienced, the

ammunition used and the repairs desired. Also include

your name and a daytime phone number where you

can be reached.

31

5. If convenient, send a copy of the service/repair form

or letter to us separately.

6. Never return ammunition with your firearm. It is

against postal and most commerce regulations.

part S, Servi ce, repair StatuS

anD tech nica l Qu eSti onS

Winchester Repeating Arms Parts and Service

3005 Arnold Tenbrook Road

Arnold, MO 63010-9406

(800) 322-4626

gene ral proD uct anD hiSt oric al QueSt ionS

Winchester Repeating Arms Customer Service

275 Winchester Avenue

Morgan, UT 84050-9333

(800) 945-5237

PARTS ARE MADE FOR WINCHESTER BRAND FIREARMS

MANUFACTURED BY OR FOR WINCHESTER REPEATING

ARMS, AND SHOULD NOT BE USED IN OTHER FIREARMS,

EVEN THOUGH MODELS MAY BE SIMILAR. IMPROPERLY

FITTED PARTS MAY BE DANGEROUS. FAILURE TO

FOLLOW THIS WARNING MAY CAUSE INJURY OR DEATH

AND CAUSE DAMAGE TO YOUR SHOTGUN.

WebSite information

An information resource for Winchester Repeating Arms

is found on the World Wide Web.

•ListofAuthorizedRepairCenters.

•CustomerServiceinformation.

•FirearmService/RepairForm.

•Answerstomanytechnicalandhistoricalquestions.

•Linkstohelpfulsites.

Go to: winchesterguns.com

32

Winchester Repeating Arms

275 Winchester Avenue

Morgan, UT, USA 84050-9333

winchesterguns.com

Winchester is a registered trademark of Olin Corporation.

Loading...

Loading...