Wilo Star-Z 15 BN5, Star-Z 15 BS5, Star-Z 15 BS7 Installation And Operating Instructions Manual

Installation and operating instructions

Instructions de montage et de mise en service

Instrucciones de instalación y funcionamiento

Wilo-Star-Z 15

4 118 251-Ed.01 / 2007-11 Kothes!

1

Table of contents ............................................................................................... page

1 General ...................................................................................................................................2

2 Safety .....................................................................................................................................2

3 Transport and interim storage ............................................................................................3

4 Intended use (Application) .................................................................................................. 4

5 Product information .............................................................................................................4

6 Description and function .....................................................................................................5

7 Installation and electrical connection ...............................................................................5

8 Commissioning .....................................................................................................................7

9 Maintenance ..........................................................................................................................7

10 Faults, causes and remedies ..............................................................................................8

English

2 Subject to technical alterations! WILO AG 11/2007

Table of contents+

1 General

1.1 About this document

These Installation and Operating Instructions form an integral part of the product.

They must be kept close to the product and in readiness whenever required.

Precise observance of these instructions is a pre-condition for use of the product

for the intended purpose and for its correct operation. These Installation and

Operating Instructions conform to the relevant version of the equipment and the

underlying safety standards valid at the time of going to press.

2Safety

These instructions contain important information which must be followed when

installing and operating the pump. It is therefore imperative that they be read

by both the installer and the operator before the pump is installed or started up.

Both the general safety instructions in the ‘Safety precautions’ section and

those in subsequent sections indicated by danger symbols should be carefully

observed.

2.1 Symbols and signal words used in these operating instructions

Symbols:

NOTE: ...

Signal words:

NOTE: A notice with useful information for the user in relation to the product. It

alerts the user to possible problems.

General safety symbol

Hazards from electrical causes

DANGER!

Imminently hazardous situation.

Will result in death or serious injury if not avoided.

WARNING!

The user can be exposed to (severe) injury. 'Warning' refers that harm to the

user when the user is neglecting the procedure.

CAUTION!

The product is at risk of damage. 'Caution' refers to the product when the

user is neglecting the procedures.

Installation and operating instructions Wilo Star-Z 15 3

English

2.2 Qualified Personnel

The personnel installing the pump must have the appropriate qualification for

this work.

2.3 Risks incurred by failure to comply with the safety precautions

Failure to comply with the safety precautions could result in personal injury or

damage to the pump or installation. Failure to comply with the safety

precautions could also invalidate warranty and/or damage claims.

In particular, failure to comply with these safety precautions could increase the

possibility of the following risks:

• the failure of important parts of the pump or installation

• the failure of required maintenance and repair procedures

• personal injury due to electrical and mechanical causes

• material damage

2.4 Safety precautions for the operator

Existing regulations for the prevention of accidents must be observed. National

Electrical Codes, local codes and regulations must be followed.

2.5 Safety precautions for inspection and installation work

The operator must ensure that all inspection and installation work is carried out

by authorised and qualified specialists who have carefully reviewed these

instructions.

Work on the pump/unit must be carried out only with the pump disconnected

(locked out) from the electrical supply and at complete standstill.

2.6 Improper use

The operational safety of the pump or installation supplied can only be

guaranteed if it is used in accordance with paragraph 4 of the operating

instructions. The limits given in the catalogue or data sheet must under no

circumstances be exceeded.

3 Transport and interim storage

When receiving the material, check that there has been no damage during the

transport. If shipping damage has occurred, take all necessary steps with the

carrier within the allowed time.

CAUTION! Risk of damage to the pump!

Risk of damage through incorrect handling during transport and storage.

• The pump must be protected against humidity, frost and mechanical damage

during transport or interim storage.

English

4 Subject to technical alterations! WILO AG 11/2007

4 Intended use (Application)

The Star-Z 15 is used to circulate potable (drinking) water.

5 Product information

5.1 Model number explanation

To prevent cavitation noise be sure to maintain the minimum inlet pressure.

When ordering replacement pumps be sure to state all the information given on

the pump and motor name plates.

5.3 Scope of delivery

Pump, power cord and installation/operation manual.

5.4 Accessories

• There are no accessories supplied with this pump. Any check or isolation valves

must be obtained seperately.

• A separate clock timer may be purchased from Wilo.

Example: Star-Z 15 BN5, Star-Z 15 BS5, Star-Z 15 BS7

Star-Z Series: Standard drinking water circulating pump

B Bronze pump housing

N5 NPT union with ½ inch connection

S5 Sweat connection with ½ inch internal sweat

S7 Sweat connection with ¾ inch internal sweat

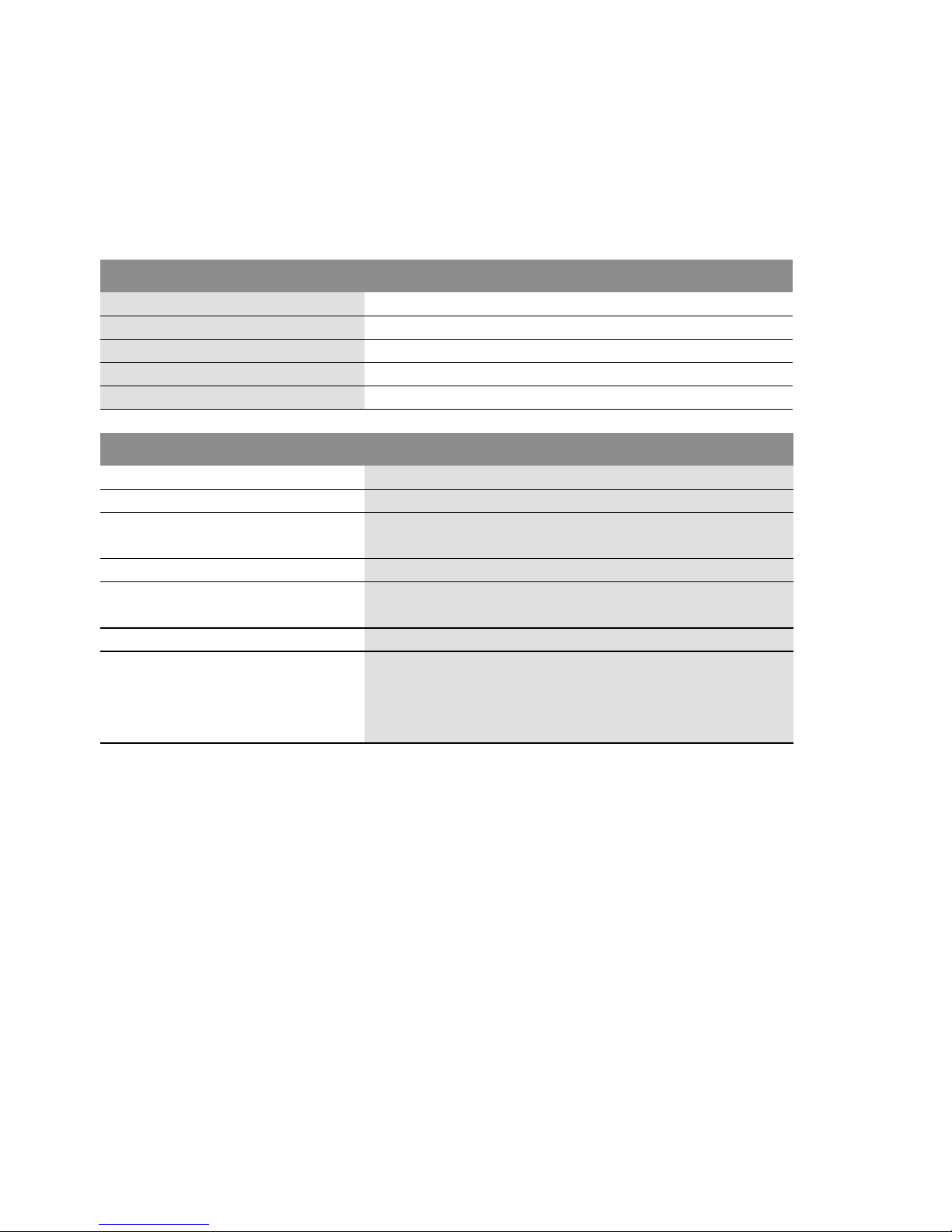

5.2 Technical data Star-Z 15 BN5 Star-Z 15 BS5, BS7

Power supply 1~115 V / 60 Hz 1~115 V / 60 Hz

Motor power P

1

[W] See name plate See name plate

Maximum motor speed

(constant)

3100 rpm 3100 rpm

Installation length

3”1/8 (3.125) 3”1/8 (3.125)

Maximum permissible operating

pressure

145 psi (10 bar) 145 psi (10 bar)

Minimum inlet pressure

2.9 psi (0.2 bar) 2.9 psi (0.2 bar)

Permissible temperature range

of the circulated fluid

68°F (20°C) to 150°F (65°C

)

or intermittent operation

(approx. 2 hrs)

160°F (70°C)

68°F (20°C) to 150°F (65°C)

or intermittent operation

(approx. 2 hrs)

160°F (70°C)

Installation and operating instructions Wilo Star-Z 15 5

English

6Description and function

6.1 Description of the product

The Star-Z 15 circulating pump is specially designed for use in conjunction with

drinking/sanitary water service systems. Thanks to its design and the materials

used in its construction the pump is resistant to corrosion from elements in

drinking/sanitary water. Motor protection is not required as the motors are

impedance protected.

The Star-Z 15 BN5 model is a compact, ready-to-install pump with ½” union

NPT type threading.

The Star-Z 15 BS5 / BS7 model is a compact, ready-to-install pump with sweat

pipe connections.

There are no check or isolation valves integrated into the product.

7 Installation and electrical connection

Installation and electrical connections must be performed in accordance

with local regulations and only by specialist personnel!

WARNING! Risk of personal injury!

Existing regulations for the prevention of accidents must be followed.

WARNING! Risk of Electrical shock!

Exposure to electrical energy must be prevented.

All local electrical and plumbing codes must be complied with during the

installation of this product.

English

6 Subject to technical alterations! WILO AG 11/2007

7.1 Installation

• The pump must be installed in a frost-free/dust-free and well-ventilated

environment and protected from harsh weather conditions.

• Install the pump in an accessible area with suction and discharge isolation shut

off valves to allow repair and/or removal of the pump. To prevent reverse flow it

may be necessary to install a spring loaded check valve on the suction side of

the pump. The pump is to be installed on the domestic hot water return line

between the water heater and the last fixture in the domestic water system,

pumping towards the water heater.

• The pump must be installed free of stresses from the piping system with the

pump shaft in a horizontal position.

• The directional arrow on the pump housing shows the direction of flow.

CAUTION! Risk of damage to the pump!

Dirt can cause pump failure.

Remove the pump head via the pump union nut (Fig. 1, Item 2) prior to

soldering. Reinstall after soldering the pump body into the piping system has

been completed.

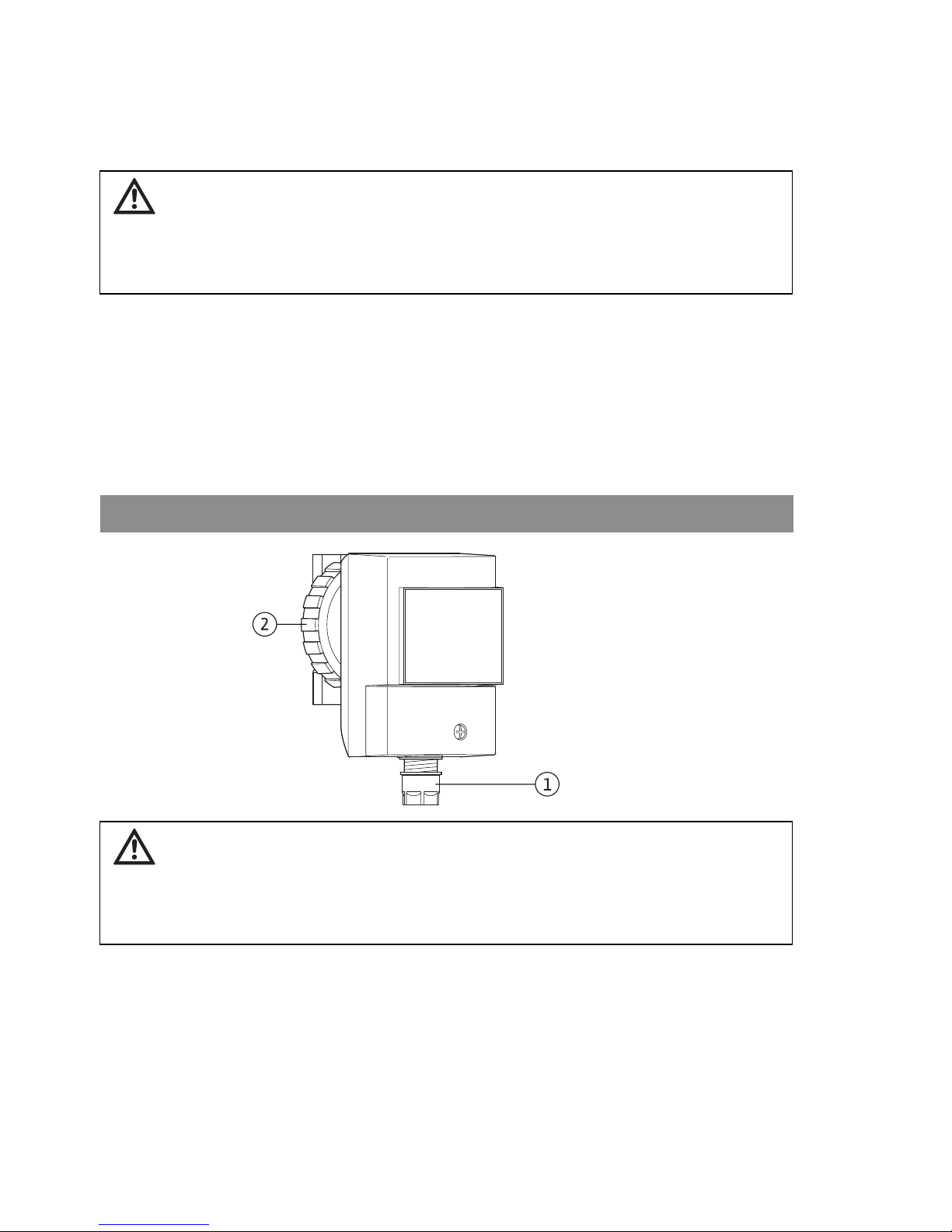

Fig. 1

CAUTION! Risk of damage to the pump!

The screwed cable gland (Fig. 1, Item 1) must face downwards, otherwise

water can penetrate the motor housing. If necessary, rotate the motor

housing after releasing the union nut (Fig. 1, Item 2).

Take care not to damage the housing gasket.

Installation and operating instructions Wilo Star-Z 15 7

English

7.2 Electrical connection

• The pump is delivered together with a three pronged 115 V power cable which

should be plugged into a standard electrical socket.

• The terminal box should not be opened for electrical connection.

8 Commissioning

8.1 Filling and venting

Fill the system correctly. The pump rotor housing is ventilated automatically,

even after short periods of operation. Short periods of dry running does not

damage the pump.

9 Maintenance

Maintenance and repair work should be carried out only by qualified

personnel!

CAUTION! Risk of damage to the pump!

The pump operates at 115 V and must not be connected to a 230 V electrical

supply. This will result in pump failure.

WARNING! Risk of Electrical shock!

Exposure to electrical energy must be prevented.

• When carrying out maintenance and repair work the pump must be switched

off and protected against unauthorised restarting.

• Damage to the connection cable must only be repaired by a qualified

electrician.

WARNING! Risk of scalding!

To prevent scalding prior to disassembling, turn power to the pump off, close

the isolation valves for a period long enough so the pump body does not feel

extremely hot to the touch. This will prevent steam flashing of extremely hot

water.

Loading...

Loading...