Page 1

Pioneering for You

Wilo-Rexa UNI

en Installation and operating instructions

6082109 • Ed.01/2017-03

·

Page 2

Page 3

en

Table of contents

1 General information ................................................................................................................................................................. 5

1.1 About these instructions ..................................................................................................................................................................................5

1.2 Copyright ............................................................................................................................................................................................................5

1.3 Subject to change..............................................................................................................................................................................................5

1.4 Warranty..............................................................................................................................................................................................................5

2 Safety......................................................................................................................................................................................... 5

2.1 Identification of safety instructions................................................................................................................................................................5

2.2 Personnel qualifications....................................................................................................................................................................................6

2.3 Electrical work ....................................................................................................................................................................................................6

2.4 Monitoring devices ............................................................................................................................................................................................7

2.5 Use in fluids hazardous to health ....................................................................................................................................................................7

2.6 Transport.............................................................................................................................................................................................................7

2.7 Installing/dismantling........................................................................................................................................................................................7

2.8 During operation ................................................................................................................................................................................................7

2.9 Maintenance tasks.............................................................................................................................................................................................8

2.10 Operating fluid ...................................................................................................................................................................................................8

2.11 Operator responsibilities...................................................................................................................................................................................8

3 Application/use......................................................................................................................................................................... 8

3.1 Intended use.......................................................................................................................................................................................................8

3.2 Improper use.......................................................................................................................................................................................................9

4 Product description.................................................................................................................................................................. 9

4.1 Design..................................................................................................................................................................................................................9

4.2 Monitoring devices .........................................................................................................................................................................................10

4.3 Operating modes............................................................................................................................................................................................. 10

4.4 Operation with frequency converter............................................................................................................................................................ 10

4.5 Operation in an explosive atmosphere ........................................................................................................................................................10

4.6 Technical data .................................................................................................................................................................................................10

4.7 Type key........................................................................................................................................................................................................... 10

4.8 Scope of delivery............................................................................................................................................................................................. 11

4.9 Accessories ......................................................................................................................................................................................................11

5 Transportation and storage................................................................................................................................................... 11

5.1 Delivery............................................................................................................................................................................................................. 11

5.2 Transport.......................................................................................................................................................................................................... 11

5.3 Storage .............................................................................................................................................................................................................12

6 Installation and electrical connection .................................................................................................................................. 12

6.1 Personnel qualifications................................................................................................................................................................................. 12

6.2 Installation types............................................................................................................................................................................................. 12

6.3 Operator responsibilities................................................................................................................................................................................ 13

6.4 Installation .......................................................................................................................................................................................................13

6.5 Electrical connection...................................................................................................................................................................................... 17

7 Commissioning........................................................................................................................................................................ 19

7.1 Personnel qualifications................................................................................................................................................................................. 19

Installation and operating instructions Wilo-Rexa UNI 3

Page 4

en

7.2 Operator responsibilities................................................................................................................................................................................ 19

7.3 Direction of rotation check (for three-phase current motors only)........................................................................................................ 19

7.4 Before switching on........................................................................................................................................................................................ 19

7.5 Switch on and off............................................................................................................................................................................................19

7.6 During operation ............................................................................................................................................................................................. 20

8 Decommissioning/dismantling.............................................................................................................................................. 20

8.1 Personnel qualifications................................................................................................................................................................................. 20

8.2 Operator responsibilities................................................................................................................................................................................ 21

8.3 Decommissioning............................................................................................................................................................................................ 21

8.4 Removal............................................................................................................................................................................................................21

9 Maintenance and repair.......................................................................................................................................................... 23

9.1 Personnel qualifications................................................................................................................................................................................. 23

9.2 Operator responsibilities................................................................................................................................................................................ 23

9.3 Operating fluid ................................................................................................................................................................................................ 23

9.4 Maintenance intervals.................................................................................................................................................................................... 23

9.5 Maintenance measures ..................................................................................................................................................................................24

10 Faults, causes and remedies .................................................................................................................................................. 25

11 Spare parts............................................................................................................................................................................... 27

12 Disposal.................................................................................................................................................................................... 27

12.1 Oils and lubricants........................................................................................................................................................................................... 27

12.2 Protective clothing .........................................................................................................................................................................................27

12.3 Information on the collection of used electrical and electronic products.............................................................................................. 27

4 WILO SE 2017-03

Page 5

General information en

1 General information

1.1 About these instructions

These installation and operating instructions are an in-

tegral part of the product. Read these instructions be-

fore commencing work and keep them in an accessible

place at all times. Strict adherence to these instructions

is a precondition for the intended use and correct oper-

ation of the product. All information and markings on

the product must be observed.

The language of the original operating instructions is

German. All other languages of these instructions are

translations of the original operating instructions.

1.2 Copyright

These installation and operating instructions have been

copyrighted by the manufacturer. Contents, of

whatever type, which may not be reproduced or dis-

tributed, or used for purposes of competition and

shared with others.

1.3 Subject to change

The manufacturer reserves the right to make technical

modifications to the device or individual components.

The illustrations used may differ from the original and

are intended as an example representation of the

device.

1.4 Warranty

The specifications in the current “General Terms and

Conditions” apply to the warranty and the warranty

period. These can be found at www.wilo.com/legal

Any deviations must be contractually agreed and shall

then be given priority.

Claim to warranty

If the following points are complied with, the manufac-

turer is obligated to rectify every qualitative or con-

structive flaw:

▪The defects are reported in writing to the manufacturer

within the warranty period.

▪Application according to intended use.

▪All monitoring devices are connected and tested before

commissioning.

▪Non-compliance with installation and operating in-

structions

▪Improper use

▪Incorrect storage or transport

▪Incorrect installation or dismantling

▪Insufficient maintenance

▪Unauthorised repairs

▪Inadequate construction site

▪Chemical, electrical or electro-chemical influences

▪Wear

2 Safety

This chapter contains basic information which must be

adhered to during the individual phases of the life

cycle. Failure to follow the installation and operating

instructions will result in injuries to persons, damage to

the environment and the device and result in the loss of

any claims for damages. Failure to follow the instruc-

tions can result in the following risks:

▪Danger to persons due to electrical, mechanical and

bacteriological factors as well as electromagnetic fields

▪Environmental risks due to leakage of hazardous sub-

stances

▪Property damage

▪Failure of important functions of the product

Additionally, the instructions and safety instructions

in the other chapters must be observed!

2.1 Identification of safety instructions

These installation and operating instructions set out

safety instructions for preventing personal injury and

damage to property. These safety instructions are

shown differently:

▪Safety instructions relating to personal injury start with

a signal word, are preceded by a corresponding sym-

bol and are shaded in grey.

DANGER

Type and source of the danger!

Consequences of the danger and instructions for

avoidance.

Exclusion from liability

Exclusion from liability excludes all liability for personal

injury, material damage or financial losses. This exclu-

sion ensues as soon as one of the following applies:

▪Inadequate configuration due to inadequate or incor-

rect instructions by the operator or the client

Installation and operating instructions Wilo-Rexa UNI 5

▪Safety instructions for property damage start with a

signal and are displayed without a symbol.

CAUTION

Type and source of the danger!

Consequences or information.

Page 6

en Safety

Signal words

▪DANGER!

Failure to observe the safety instructions will result in

serious injuries or death!

▪WARNING!

Failure to follow the instructions can lead to (serious)

injuries!

▪CAUTION!

Failure to follow the instructions can lead to property

damage and a possible total loss.

▪NOTE!

Useful information on handling the product.

Symbols

These instructions use the following symbols:

Danger of electric voltage

Danger of bacterial infection

Danger of explosion

1. Work step/list

⇒ Information/instructions

▶ Result

2.2 Personnel qualifications

Personnel must:

▪Be instructed in the locally applicable accident preven-

tion regulations.

▪Have read and understood the installation and operat-

ing instructions.

Personnel must have the following qualifications:

▪Electrical work: Electrical work must be carried out by a

qualified electrician (in accordance with EN50110-1).

▪Installation-/dismantling: The technician must be

trained in the use of the necessary tools and mounting

materials for the relevant construction site.

▪Maintenance tasks: The technician must be familiar

with the use of operating fluids and their disposal. In

addition, the technician must have basic knowledge of

mechanical engineering.

General warning symbols

Warning of crushing

Warning of cutting injuries

Warning of hot surfaces

Warning of high pressure

Warning of suspended loads

Personal protective equipment: Wear a safety hel-

met

Personal protective equipment: Wear foot protec-

tion

Personal protective equipment: Wear hand protec-

tion

Personal protective equipment: Wear mouth protec-

tion

Personal protective equipment: Wear safety goggles

Autonomous work prohibited! A second person

must be present.

Useful information

Markups

‡ Prerequisite

Definition of “qualified electrician”

A qualified electrician is a person with appropriate

technical education, knowledge and experience who

can identify and prevent electrical hazards.

2.3 Electrical work

▪A qualified electrician must carry out the electrical

work.

▪When connecting to the mains, comply with the locally

applicable laws and regulations of the local energy sup-

ply company.

▪Before commencing work, disconnect the device from

the mains and secure it against being switched on again

without authorisation.

▪Personnel is trained on the execution of the electrical

connection and the options for switching off the

device.

▪Comply with the technical specifications contained in

these installation and operating instructions and on the

rating plate.

▪Earth the device.

▪Observe the manufacturer’s specifications when con-

necting to electrical switching systems.

▪Comply with the specifications on electro-magnetic

compatibility when connecting electronic start-up

controllers (e.g. soft starter or frequency converter). If

required, take into account special measures (e.g. shiel-

ded cables, filters etc.).

6 WILO SE 2017-03

Page 7

Safety en

▪Replace defective power supply cables immediately.

Contact customer service.

2.4 Monitoring devices

The following monitoring equipment must be provided

on-site:

Circuit breaker

The size of the circuit breakers conforms to the rated

current of the pump. The switching characteristics

should comply with group B or C. Observe local regula-

tions.

Motor protection switch

Make provision for an on-site motor protection switch

for devices without a plug! The minimum requirement

is a thermal relay/motor protection switch with tem-

perature compensation, differential triggering and

anti-reactivation device in accordance with the local

regulations. In case of sensitive mains, make provision

for the installation on-site of other protective equip-

ment (e.g. overvoltage, undervoltage or phase failure

relay, etc.).

Residual-current device (RCD)

Comply with the regulations of the local energy supply

company! The use of a residual-current device is re-

commended.

If persons come into contact with the device and con-

ductive fluids, secure the connection with a residual-

current device (RCD).

2.5 Use in fluids hazardous to health

There is a danger of bacterial infection when using the

device in fluids hazardous to health! Thoroughly clean

and disinfect the device after dismantling and prior to

further use. The operator must ensure the following:

▪The following protective equipment is provided and

worn when cleaning the device:

– Closed safety goggles

– Breathing mask

– Protective gloves

▪All persons are informed about the fluid, the associated

danger and its correct handling!

2.6 Transport

▪The following protective equipment must be worn:

– Safety shoes

– Safety helmet (when using lifting equipment)

▪Always hold the handle to transport the device. Never

pull the power supply cable!

▪Only use legally specified and approved lifting gear.

▪Select the lifting gear based on the available conditions

(weather, attachment point, load, etc.).

▪Always attach the lifting gear to the attachment points

(handle or lifting eyelet).

▪The stability of the lifting equipment must be ensured

during operation.

▪When using lifting equipment, a second person must be

present to coordinate the procedure if required (e.g. if

the operator’s field of vision is blocked).

▪Persons are not permitted to stand beneath suspended

loads. Do not lift loads above workplaces, on which

people are present.

2.7 Installing/dismantling

▪Wear the following protective equipment:

– Safety shoes

– Safety gloves against cuts

– Safety helmet (when using lifting equipment)

▪Locally applicable laws and regulations for work safety

and accident prevention must be complied with.

▪Disconnect the device from the mains and secure it

against being switched on again without authorisation.

▪All rotating parts must be at a standstill.

▪Provide adequate aeration in closed rooms.

▪When working in chambers and closed spaces, a second

person must be present for safety reasons.

▪Take immediate countermeasures if there is a build-up

of toxic or suffocating gases!

▪Clean the device thoroughly. Disinfect devices that are

used in fluids hazardous to health!

▪Make sure that there is no risk of explosion when carry-

ing out any type of welding work or work with electrical

devices.

2.8 During operation

▪Wear the following protective equipment:

– Safety shoes

– Ear protection (in accordance with the notice of the

work regulations)

▪Work area of the device is not an recreational area. No

persons are allowed in the work area during operation.

▪The operator must immediately report any faults or ir-

regularities to their line manager.

▪If safety-endangering defects occur, the operator must

immediately deactivate the device:

– Malfunction of the safety and monitoring equipment

– Damage to the housing parts

– Damage to the electrical equipment

▪Never reach into the suction port. The rotating parts

can crush and sever limbs.

Installation and operating instructions Wilo-Rexa UNI 7

Page 8

en Application/use

▪If the motor emerges during operation, the motor

housing can reach temperatures in excess of 40°C.

▪Open all gate valves in the piping on the suction and

pressure side.

▪Ensure minimum water submersion through dry-run-

ning protection.

▪Under normal operating conditions, the sound pressure

level of the device is below 85dB(A). However, the ac-

tual sound-pressure level depends on several factors:

– Installation depth

– Installation

– Fixation of accessories and pipe

– Duty point

– Immersion depth

▪If the device is operated under normal operating condi-

tions, the operator must measure the sound pressure.

Ear protection must be worn for sound pressure level of

85dB(A) and above and this must be noted in the work

regulations!

2.9 Maintenance tasks

▪Wear the following protective equipment:

– Closed safety goggles

– Safety shoes

– Safety gloves against cuts

▪Always carry out maintenance tasks outside the oper-

ating space/installation site.

▪Only carry out maintenance tasks mentioned in this in-

stallation and operating instructions.

▪Only original parts from the manufacturer may be used

for maintenance and repairs. Use of parts other than

the original parts releases the manufacturer from any

liability.

▪Collect any leakage of fluid and operating fluid immedi-

ately and dispose of it according to the locally applic-

able guidelines.

▪Store tools at the designated locations.

▪After completing work, reattach all safety and monitor-

ing devices and check that they function properly.

Changing operating fluid

In case of a defect, a pressure of several bar can build

up in the motor! This pressure escapes when the screw

plugs are opened. If screw plugs are opened without

due caution, they can be ejected at high speed! To

avoid injuries, observe the following instructions:

▪Adhere to the prescribed sequence of work steps.

▪Unscrew the screw plugs slowly, but never unscrew

them completely. As soon as the pressure escapes

(audible whistling or hissing of air), stop turning the

screw plug any further.

WARNING!Hot operating fluid can also spray out

when the pressure is escaping. This can result in

scalding! To avoid injuries, allow the motor to cool

down to the ambient temperature before carrying

out any work!

▪When the pressure has completely dissipated, fully un-

screw the screw plug.

2.10 Operating fluid

In the sealing chamber, the motor is filled with white

oil. Operating fluid must be replaced during regular

maintenance work and disposed off according to the

local guidelines.

2.11 Operator responsibilities

▪Installation and operating instructions must be in a lan-

guage which the personnel can understand.

▪Make sure that the personnel is relevantly trained for

the specified work.

▪Provide the necessary protective equipment and make

sure that the personnel wears it.

▪Safety and information signs mounted on the device

must be always legible.

▪Train the personnel pertaining to the functioning of the

system.

▪Eliminate risk from electrical current.

▪Equip hazardous components inside the system with an

on-site guard.

▪Identify and cordon off the work area.

▪To ensure safe working practice, define the responsib-

ilities of the employees.

Children and persons below 16years or with reduced

physical, sensory or mental capacities or limited experi-

ence are prohibited from handling the device! A techni-

cian must supervise persons below 18years!

3 Application/use

3.1 Intended use

Submersible pumps are suitable for pumping:

▪Sewage containing faeces (in accordance with

EN12050-1)

▪Wastewater (with small amounts of sand and gravel)

▪Fluids with dry matter up to max. 8%

8 WILO SE 2017-03

Page 9

Product description en

4

5

6

1

2

3

3.2 Improper use

DANGER

Explosion due to pumping of explosive fluids!

Pumping of highly flammable and explosive fluids

(gasoline, kerosene, etc.) in pure form is strictly pro-

hibited. There is a risk of fatal injury due to explo-

sion! The pumps are not designed for these fluids.

DANGER

Danger due to fluids hazardous to health!

If the pump is used in fluids hazardous to health, de-

contaminate the pump after dismantling and before

carrying out any other work! There is danger to life!

Observe the specifications in the work regulations!

The operator must make sure that the personnel has

received and read the work regulations!

The submersible pumps must not be used for pumping:

▪Drinking water

▪Fluids containing hard components (such as stones,

wood, metal, etc.)

▪Fluids containing large quantities of abrasive contents

(e.g. sand, gavel)

Intended use also includes compliance with this

manual. Any other use is regarded as non-compliant

with the intended use.

4 Product description

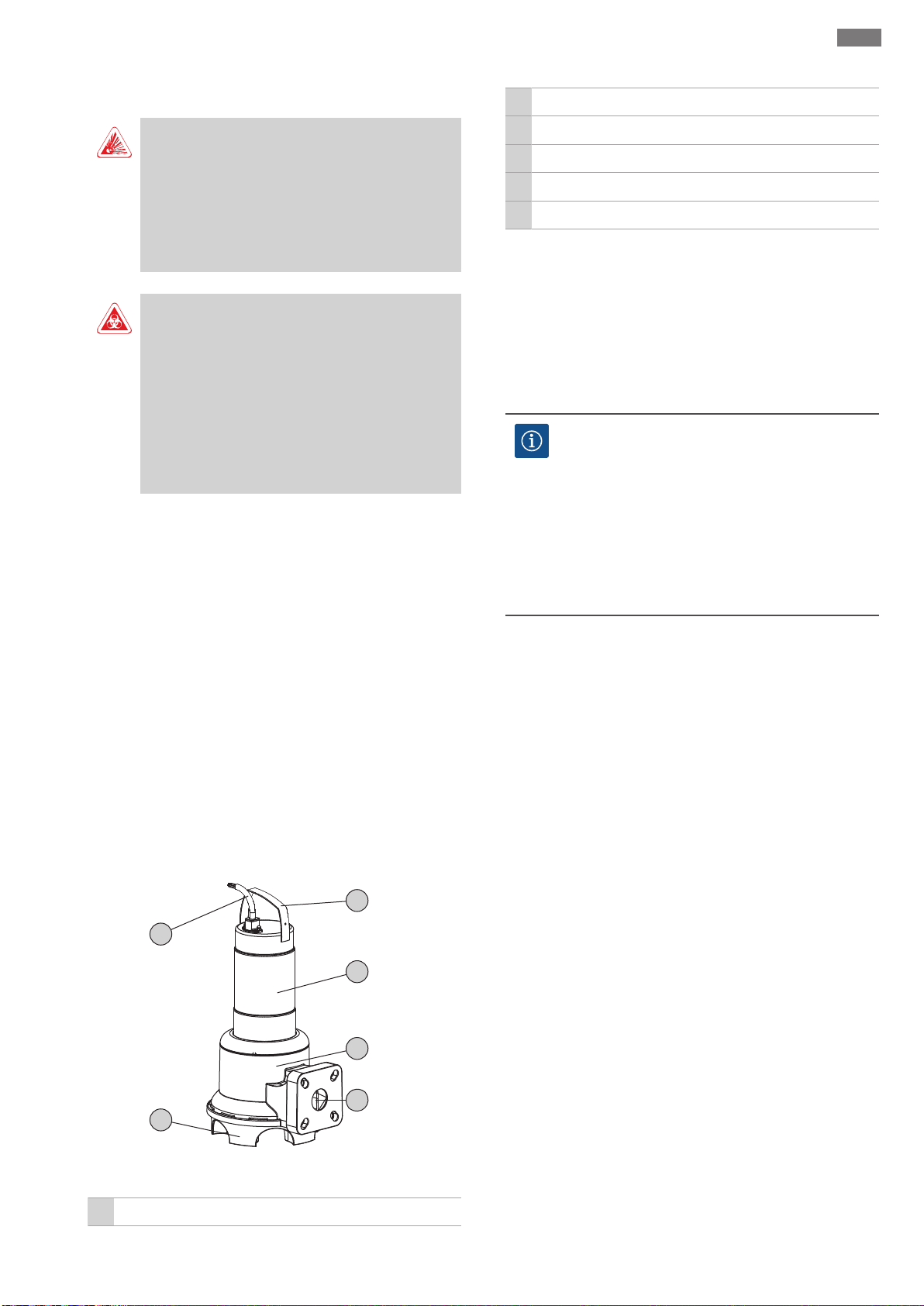

4.1 Design

Submersible sewage pump as a submersible monobloc

unit for intermittent operation for wet well installation.

2 Motor housing

3 Hydraulics housing

4 Pressure port

5 Pump support foot, integrated in hydraulics housing

6 Power supply cable

4.1.1 Hydraulics

Rotodynamic hydraulics with vortex impeller and hori-

zontal flange connection on the pressure side. The

screwed connection is integrated in the pressure port.

The hydraulics are not self-priming, in other words, the

fluid must flow in either automatically or with supply

pressure.

NOTICE

Combined connection for DN50 and DN65!

The RexaUNIV06 is equipped with a DN50/65

combined connection. The factory setting of the

connection is DN65. To use the pump with a DN50

connection, press the nuts in the flange inwards

onto the small hole circle. The flange can be reset to

DN65 at any time!

4.1.2 Motor

The drive versions used are single-phase current and

three-phase current surface-cooled motors. The motor

is cooled by the fluid around it. The waste heat is trans-

ferred directly to the fluid via the motor housing. The

motor may emerge during operation.

With single-phase AC motors, the operating capacitor

is integrated in the motor. The connection cable is

available in the following versions:

▪Single-phase version:

– With shockproof plug

– With a shockproof plug and fitted with a float switch

▪Three-phase version:

– With bare cable end

– With CEE plug and fitted with a float switch

4.1.3 Seal

Fig.1: Overview

1 Handle/attachment point

Installation and operating instructions Wilo-Rexa UNI 9

Different designs are used for the seal to the fluid and

the motor compartment:

▪RexaUNIV05: A rotary shaft seal is used on the motor

side, a mechanical seal is used on the fluid side.

▪RexaUNIV06: A mechanical seal is used on the motor

side and the fluid side.

The sealing chamber between both seals is filled with

medical white oil.

Page 10

en Product description

4.1.4 Material

▪Pump housing: PP-GF30

▪Impeller: PP-GF30

▪Motor housing: 1.4301

▪Shaft: 1.4401

▪Seal on the fluid side: SiC/SiC

▪Seal on the motor side: NBR (V05), C/Cr (V06)

▪Seal, static: NBR

4.1.5 Fitted accessories

Float switch

In the “A” version the pump is equipped with a float

switch. Depending on the fill level, it is possible to

switch the pump on and off automatically, by using the

float switch.

Plug

In the “P” and “A” version, a shockproof plug is at-

tached for single-phase AC motors and a CEE plug is

attached for three-phase motors The plug is designed

for use in commercially available shock-proof or CEE

sockets and is not overflow-proof.

4.2 Monitoring devices

Monitoring of motor winding

The thermal motor monitoring protects the motor

winding from overheating. Temperature limiting with

bimetallic strip is fitted as standard.

Thermal motor monitoring is self-switching for single-

phase current motors. I.e. if the motor is switched off

due to overheating and then cools down, it is automat-

ically switched on again.

For three-phase current motors, the thermal motor

monitoring must be connected in the switchgear or

plug.

time. The switching cycle has a duration of 10min.

If two values (e.g. S325%/120s) are specified, the first

value relates to the operating time. The second value

specifies the max. period of the switching cycle.

4.4 Operation with frequency converter

Operation on the frequency converter is not permitted.

4.5 Operation in an explosive atmosphere

Operation in an explosive atmosphere is not permitted.

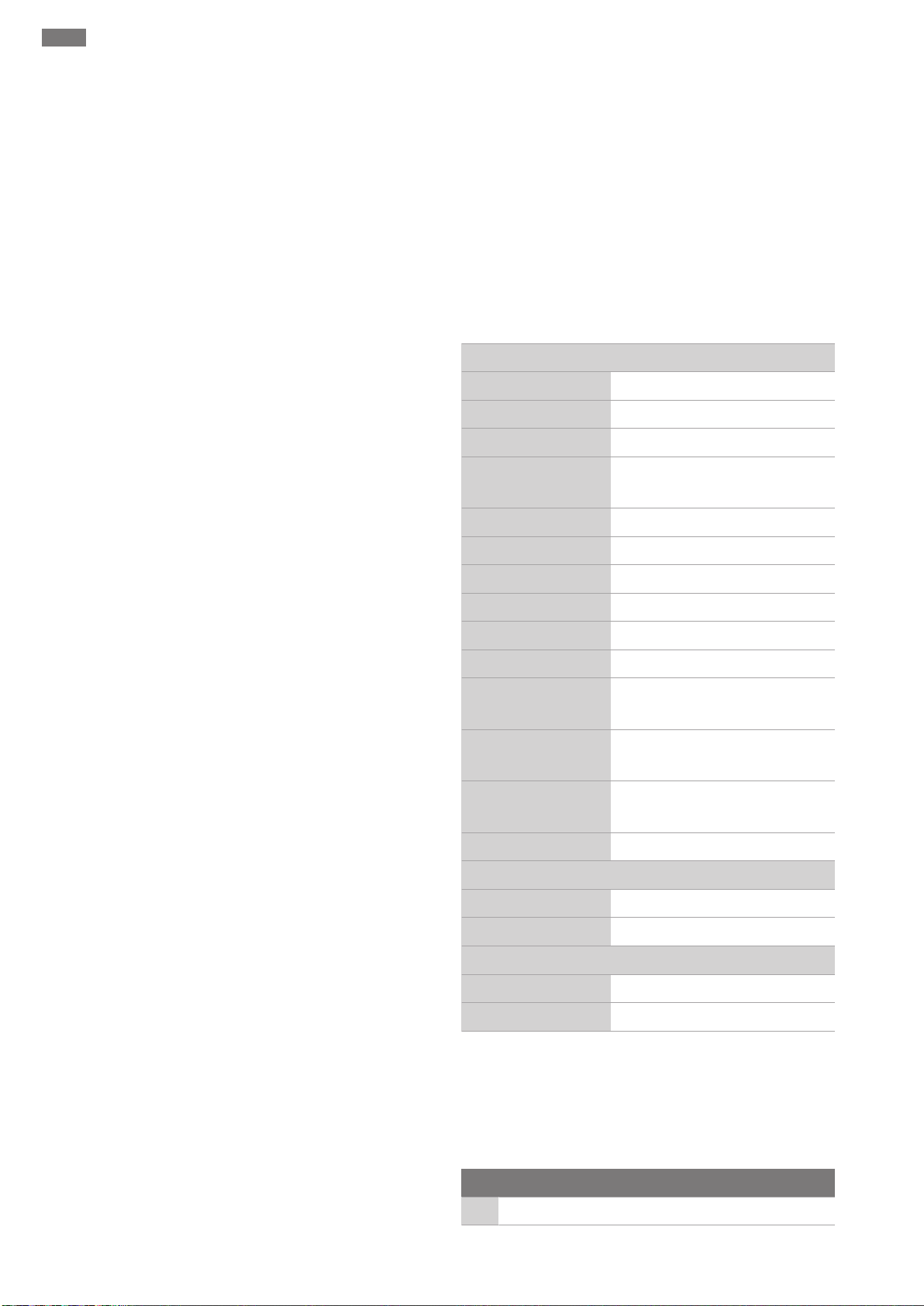

4.6 Technical data

General

Mains connection [U/f] See rating plate

Power consumption [P1] See rating plate

Rated power [P2] See rating plate

Maximum delivery head

See rating plate

[H]

Max. volume flow [Q] See rating plate

Activation type [AT] See rating plate

Fluid temperature [t] 3...40 °C

Protection class IP68

Insulation class [Cl.] F

Speed [n] See rating plate

Max. switching fre-

30/h

quency

Max. immersion depth

See rating plate

[8]

Cable length (standard

10 m

version)

Explosion protection -

Operating modes

4.3 Operating modes

Operating mode S1: Continuous duty

The pump can operate continuously at the rated load

without exceeding the permissible temperature.

Operating mode S2: Short-time duty

The maximum operating period is specified in minutes,

e.g.S2-15. The pause must last until the machine tem-

perature no longer differs from the temperature of the

coolant by more than 2K.

Operating mode S3: Intermittent periodic duty

Immersed [OTs] S1

Non-immersed [OTe] S2-15, S3 10%*

Pressure connection

UNIV05... DN50, PN10

UNIV06... DN50/65, PN10

* Operating mode S325% is permitted if the necessary

motor cooling is guaranteed before the motor is

switched on again! To ensure the required cooling, the

motor must be completely immersed for at least 1min.!

4.7 Type key

This operating mode defines a switching cycle in a

combination of periods of operation and standstill.

Specified value (e.g. S325%) relates to the operating

10 WILO SE 2017-03

Example: Wilo-Rexa UNI V05/T06-540/P

UNI Series

Page 11

Transportation and storage en

Example: Wilo-Rexa UNI V05/T06-540/P

V Impeller= vortex impeller

05 Nominal diameter of pressure connection

T Mains connection version: M=1~, T=3~

06 /10=Rated power P2 in kW

5 Frequency mains connection: 5=50Hz, 6=60Hz

40 Code for rated voltage

Additional electrical equipment:

without= with free cable end

P

A= with float switch and plug

P= with plug

4.8 Scope of delivery

▪Pump with 10m cable

▪Single-phase version with

– Shockproof plug

– Float switch and shockproof plug

▪Three-phase version with

– Bare cable end

– Float switch and CEE plug

▪Installation and operating instructions

4.9 Accessories

▪Cable lengths in fixed length increments of 10m to

max. 30m in the single-phase current version or max.

50m in the three-phase version

▪Suspension unit

▪Level control devices

▪Fixation accessories and chains

▪Switchgear, relays and plugs

5 Transportation and storage

5.1 Delivery

After receiving the shipment, this must be checked im-

mediately for defects (damage, completeness). Defects

must be noted on the freight documentation! Further-

more, defects must be notified to the transport com-

pany or the manufacturer immediately on the day of

receipt of shipment. Subsequently notified defects can

no longer be asserted.

5.2 Transport

WARNING

Standing beneath suspended loads!

Never allow anyone to stand under suspended loads!

Danger of (serious) injuries caused by falling parts.

Loads may not be carried over work places where

people are present!

WARNING

Head and foot injuries due to lack of protect-

ive equipment!

Danger of (serious) injuries during work. Wear the

following protective equipment:

• Safety shoes

• Safety helmet must be used if lifting equipment

are used!

NOTICE

Only use lifting equipment in a technically

sound condition!

Only use lifting equipment in a technically sound

condition for lifting, lowering and transporting the

pump. Ensure that the pump does not become

jammed during lifting and lowering. Do not exceed

the max. permissible bearing capacity of the lifting

equipment!

CAUTION

Soaked packaging may tear!

As a result, the device may fall on the ground unpro-

tected and may be damaged. Soaked packaging

must be lifted carefully and replaced immediately!

Only remove the outer packaging at the place of util-

isation to ensure that the pump is not damaged during

transport. Use tear-proof plastic sacks of sufficient size

to package used pumps for transport in a leak-proof

manner.

The following points must also be observed:

Installation and operating instructions Wilo-Rexa UNI 11

Page 12

en Installation and electrical connection

Newly supplied pumps can be stored for one year. Con-

tact customer service to store the pump for more than

one year.

The following must be observed for storage:

▪Securely position the pump on a firm bearing surface.

Store pumps with pump support foot in an upright pos-

ition, store pumps without pump support foot in a hori-

zontal position. Secure the pump against falling over

and slipping!

▪The max. storage temperature is -15°C to +60°C at a

max. relative humidity of 90%, non-condensing.

Fig.2: Attachment point

▪Adhere to the applicable national safety regulations.

▪Use legally specified and approved lifting gear.

▪Select the lifting gear based on the existing conditions

(weather, attachment point, load, etc.).

▪Only attach the lifting gear to the attachment point. Fix

with a shackle.

▪Use lifting equipment with sufficient bearing capacity.

▪The stability of the lifting equipment must be ensured

during operation.

▪When using lifting equipment, a second person must be

present to coordinate the procedure if required (e.g. if

the operator’s field of vision is blocked).

5.3 Storage

DANGER

Danger due to fluids hazardous to health!

If the pump is used in fluids hazardous to health, de-

contaminate the pump after dismantling and before

carrying out any other work! There is danger to life!

Observe the specifications in the work regulations!

The operator must make sure that the personnel has

received and read the work regulations!

Frost-proof storage at a temperature of 5°C to 25°C

with relative humidity of 40% to 50% is recommen-

ded.

▪Do not store the pump in rooms in which welding work

is carried out. The resulting gases or radiation can cor-

rode the elastomer parts and coatings.

▪Seal the suction and pressure connection tightly.

▪Protect power supply cables against kinking and dam-

age.

▪Protect the pump from direct sunlight and heat. Ex-

treme heat can cause damage to the impellers and the

coating!

▪Impellers must be turned by 180° at regular intervals

(3–6months). This prevents jamming of the bearings

and renews the lubrication film of the mechanical seal.

WARNING!There is a risk of injury due to edges on

the impeller and suction port!

▪Elastomer parts and the coating are subject to natural

brittleness. Contact customer service if the pump must

be stored for more than 6months.

After storage, remove any dust and oil from the pump

and check the coating for damage. Repair damaged

coatings before further use.

6 Installation and electrical connection

WARNING

Sharp edges on the impeller and suction port

Sharp edges can form on the impeller and suction

port. There is danger of limbs being cut-off! Pro-

tective gloves must be worn to protect from cuts.

CAUTION

Total damage due to moisture ingress

Moisture ingress in the power supply cable damages

the power supply cable and the pump! Never im-

merse the end of the power supply cable in a fluid

and firmly seal it during storage.

12 WILO SE 2017-03

6.1 Personnel qualifications

▪Electrical work: Electrical work must be carried out by a

qualified electrician (in accordance with EN50110-1).

▪Installation-/dismantling: The technician must be

trained in the use of the necessary tools and mounting

materials for the relevant construction site.

6.2 Installation types

▪Vertical stationary wet well installation with suspension

unit

▪Vertical portable wet well installation with pump sup-

port foot

The following installation types are not allowed:

Page 13

Installation and electrical connection en

▪Dry well installation

▪Horizontal installation

6.3 Operator responsibilities

▪Observe locally applicable accident prevention and

safety regulations of trade associations.

▪Observe all regulations for working with heavy loads

and under suspended loads.

▪Provide protective equipment and ensure that the pro-

tective equipment is worn by personnel.

▪Observe local sewage technology regulations for the

operation of sewage systems.

▪Avoid pressure surges!

Pressure surges can occur in long discharge pipelines

with steep terrain. These pressure surges can lead to

the destruction of the pump!

▪Ensure the cooling time of the motor depending on the

operating conditions and the size of the pump cham-

ber.

▪Structural components and foundations must be of

sufficient stability in order to allow the device to be

fixed securely and functionally. The operator is re-

sponsible for the provision and suitability of the struc-

tural component/foundation!

▪Check that the available consulting documents (install-

ation plans, design of the operating space, inflow con-

ditions) are complete and correct.

6.4 Installation

DANGER

Potentially fatal danger due to dangerous

autonomous work!

Work in chambers and narrow rooms as well as work

involving risk of falling are dangerous work. Such

work may not be carried out autonomously! A

second person must be present for safety reasons.

WARNING

Hand and foot injuries due to lack of protect-

ive equipment!

Danger of (serious) injuries during work. Wear the

following protective equipment:

• Safety gloves against cuts

• Safety shoes

• Safety helmet must be used if lifting equipment

are used!

NOTICE

Only use lifting equipment in a technically

sound condition!

Only use lifting equipment in a technically sound

condition for lifting, lowering and transporting the

pump. Ensure that the pump does not become

jammed during lifting and lowering. Do not exceed

the max. permissible bearing capacity of the lifting

equipment!

NOTICE

Emerging of the motor during operation

If the motor emerges during operation, the specific-

ations for “Operating mode non-immersed” must be

complied with!

To ensure that the motor is cooled during continu-

ous duty, the motor must be immersed completely

before switching it on again!

▪Prepare operating space/installation location as follows:

– Clean, free of coarse solids

– Dry well

– Frost-free

– Decontaminated

▪Take immediate countermeasures if there is a build-up

of toxic or suffocating gases!

▪Use the handle for lifting, lowering and transporting the

pump. Never carry or drag the pump by the power sup-

ply cable!

▪It must be possible to attach lifting equipment safely.

The storage place and the operating space/installation

site must be accessible with the lifting equipment. The

set-down location must have a solid bearing surface.

▪Attach the lifting gear to the handle using a shackle.

Only use lifting gear which has been technically ap-

proved.

▪The routed power supply cables must allow safe opera-

tion. Check whether the cable cross-section and the

cable length are sufficient for the selected installation

type.

▪The corresponding IP class must be observed when us-

ing switchgear. Install the switchgear overflow-proof

and outside potentially explosive areas!

▪Avoid air intake into the fluid, use baffles or deflector

plates for the inlet. Air which has entered the system

can collect in the pipe system and lead to impermissible

operating conditions. Air pockets must be removed via

ventilation systems!

Installation and operating instructions Wilo-Rexa UNI 13

Page 14

en Installation and electrical connection

d

A

2

A

1

1

▪A dry run of the pump is prohibited! Avoid air pockets in

the hydraulics housing or in the pipe system. Ensure the

water level never falls below the minimum. The install-

ation of a dry-running protection is recommended!

6.4.1 Indications for double pump operation

If several pumps are used in an operating space, min-

imum distances between the pumps and the wall must

be complied with. Here there is a difference in the dis-

tances depending on the type of system: Alternating

operation or parallel operation.

1. Push the nut inwards onto the small hole circle using a

screwdriver.

▶ The flange connection is reset to DN50.

6.4.3 Maintenance tasks

After a storage period of more than 6months, check

the oil in the sealing chamber prior to installation:

Fig.5: Check the oil

Fig.3: Minimum distances

d Diameter hydraulics housing

Minimum distance from the wall:

A

- alternating operation: min. 0.3×d

1

- parallel operation: min. 1×d

Distance to discharge pipelines

A

- alternating operation: min. 1.5×d

2

- parallel operation: min. 2×d

6.4.2 Note on DN50/65 combination flange

The Rexa UNI V06... is equipped with a DN50/65 com-

bination flange. The nuts on the combination flange are

factory-set to the DN65 flange. For use with a DN50

flange, adjust the nuts at the flange. The flange can be

reset to DN65 at any time!

1 Screw plug sealing chamber

‡ Pump is not installed.

‡ Pump is not connected to the mains.

‡ Protective equipment has been put on!

1. Place the pump horizontally on a firm surface. The

screw plug points upwards. WARNING!Risk of hands

being crushed. Ensure that the pump cannot fall over

or slip away!

2. Unscrew the screw plug.

3. Place a suitable tank to collect the operating fluid.

4. Drain the operating fluid: Rotate the pump until the

opening points downwards.

5. Check the operating fluid:

⇒ If the operating fluid is clear, reuse operating fluid.

⇒ If the operating fluid is contaminated (black), fill

with new operating fluid. Dispose of operating

fluid in accordance with the local regulations!

⇒ Notify customer service if an operating fluid con-

tains metal chips!

6. Pour in operating fluid: Rotate the pump until the

opening points upwards. Fill-in the operating fluid into

the opening.

Fig.4: Adjust combination flange

‡ No accessories mounted on flange.

‡ Nut is freely accessible.

14 WILO SE 2017-03

⇒ Comply with the specifications for operating fluid

locations and quantity! When recycling the operating fluid, check the quantity and if required adjust

it!

Page 15

Installation and electrical connection en

1

5

6

S1

S2/S3

3

4

2

7. Clean the screw plug, replace the seal ring and screw it

back in. Max. tightening torque: 8Nm!

6.4.4 Stationary wet well installation

NOTICE

Delivery problems due to water level being

too low

The hydraulics are self-venting. As a result, smaller

air cushions are dissolved during the pumping pro-

cess. If the level of the fluid is lowered too much, the

volume flow can be interrupted. The minimum per-

missible water level must reach the upper edge of

the hydraulics housing!

The pump is installed in the fluid for the wet well in-

stallation. For this, a suspension unit must be installed

in the chamber. On the pressure side, the on-site pipe

system is connected to the suspension unit and on the

suction side to the pump. The connected pipe system

must be self-supporting. The suspension unit must not

support the pipe system!

CAUTION!If the motor emerges during operation,

observe the operating mode for non-immersed oper-

ation (S2-15, S3 10%*)!

* Operating mode S325% is permitted if the necessary

motor cooling is guaranteed before the motor is

switched on again! To ensure the required cooling, the

motor must be completely immersed for at least 1min.!

Work steps

4 Guide pipe (provided by the customer)

5 Lifting equipment

6 Attachment point for the lifting equipment

CAUTION

Damage to the pump due to incorrect install-

ation

Observe the following points during the installation

of the pump:

• Observe the max. permissible tightening torque:

15Nm (V05) or 25Nm (V06)

• Do not insert an additional gasket between the

flange and the accessories! A gasket is mounted

on the pump flange!

• Only use accessories with a flange shape in accordance with EN1092-2, type A. The use of

other flange shapes is not permitted!

‡ Operating space/installation location is prepared for the

installation.

‡ Suspension unit and pipe system were installed.

‡ Pump is prepared for operation on the suspension unit.

1. Use a shackle to attach the lifting equipment to the at-

tachment point of the pump.

2. Lift the pump, swivel it above the chamber opening and

slowly lower the guide claw onto the guide pipe.

3. Lower the pump until it sets on the suspension unit and

is connected automatically. CAUTION!Hold the power

supply cables slightly taut when lowering the pump!

4. Loosen the lifting equipment from the lifting gear and

secure it at the chamber outlet against falling.

5. Have the power supply cables routed into the chamber

by a qualified electrician and route it outside properly

from the chamber.

▶ The pump is installed, the qualified electrician can

make the electrical connection.

6.4.5 Portable wet well installation

WARNING

Risk of burns from hot surfaces!

Motor housing can become hot during operation. It

Fig.6: Wet well installation, stationary

1 Suspension unit

2 Non-return valve

3 Stop valve

may cause burns. Allow the pump to cool down at

ambient temperature after switching it off!

Installation and operating instructions Wilo-Rexa UNI 15

Page 16

en Installation and electrical connection

1

2

3

4

5

S1

S2, S3

6

WARNING

Separation of pressure hose!

Separation or movement of the pressure hose can

lead to (serious) injuries. Securely attach the pres-

sure hose to the outlet! Prevent buckling of the

pressure hose.

NOTICE

Delivery problems due to water level being

too low

The hydraulics are self-venting. As a result, smaller

air cushions are dissolved during the pumping pro-

cess. If the level of the fluid is lowered too much, the

volume flow can be interrupted. The minimum per-

missible water level must reach the upper edge of

the hydraulics housing!

For portable installation, the pump is equipped with a

pump support foot. The pump support foot ensures

minimum ground clearance in the suction area and en-

ables secure footing if placed on a solid bearing sur-

face. In this installation type, the pump can be installed

anywhere in the operating space/installation site. A

hard base must be used at the installation location to

prevent sinking in case of soft bearing surfaces. A pres-

sure hose is connected on the pressure side.

CAUTION!If the motor emerges during operation,

observe the operating mode for non-immersed oper-

ation (S2-15, S3 10%*)!

* Operating mode S325% is permitted if the necessary

motor cooling is guaranteed before the motor is

switched on again! To ensure the required cooling, the

motor must be completely immersed for at least 1min.!

Work steps

1 Pump with integrated pump support foot

2 Pipe elbow with hose connection or Storz pipe coupling

3 Storz hose coupling

4 Pressure hose

5 Attachment point

6 Lifting equipment

CAUTION

Damage to the pump due to incorrect install-

ation

Observe the following points during the installation

of the pump:

• Observe the max. permissible tightening torque:

15Nm (V05) or 25Nm (V06)

• Do not insert an additional gasket between the

flange and the accessories! A gasket is mounted

on the pump flange!

• Only use accessories with a flange shape in accordance with EN1092-2, type A. The use of

other flange shapes is not permitted!

‡ Pressure connection prepared: Pipe elbow with hose

connection or pipe elbow with Storz coupling mounted.

1. Use a shackle to attach the lifting equipment to the at-

tachment point of the pump.

2. Lift the pump and lower it at the intended location

(chamber, pit).

3. Place the pump on a solid bearing surface. CAU-

TION!Sinking must be prevented!

4. Lay the pressure hose and fasten it to a certain point

(e.g. drainage). DANGER!Separation or movement of

the pressure hose can lead to (serious) injuries! Se-

curely attach the pressure hose to the outlet.

5. Lay the power supply cable properly. CAUTION!Do not

damage the power supply cable!

▶ The pump is installed, the qualified electrician can

make the electrical connection.

6.4.6 Level control

With a level control device, the current fill levels are de-

termined and the pump is switched on and off auto-

matically depending on the fill levels. Fill levels are re-

corded by using different sensor types (float switches,

pressure and ultrasound measurements or electrodes).

The following must be observed when using a level

Fig.7: Wet well installation, portable

16 WILO SE 2017-03

control device:

▪Float switches can move freely!

Page 17

Installation and electrical connection en

▪The water level must not fall below the minimum per-

missible!

▪The maximum switching frequency must not be ex-

ceeded!

▪If the fill levels fluctuate strongly, a level control with

two measuring points is recommended. This makes it

possible to achieve larger differential gaps.

Use of attached float switch

The “A” version is equipped with a float switch. The

pump is switched on and off depending on the fill level.

The switching level is determined by the cable length

of the float switch.

Use of on-site level controls

When using an on-site level control device, refer to the

manufacturer’s own installation and operating instruc-

tions for specifications on the installation.

6.4.7 Dry-running protection

Dry-running protection must prevent the pump from

operating without fluid and air from entering the hy-

draulics. Minimum permissible fill level must be de-

termined with the help of a signal transmitter. Once the

specified limit value is reached, the pump must be de-

activated with an appropriate signal. Dry-running pro-

tection can expand the available level controls by an

additional measuring point or function as an independ-

ent switch-off device. Depending on the system secur-

ity, the pump can be restarted automatically or manu-

ally. Installation of a dry-running protection is recom-

mended for optimum operational reliability.

6.5 Electrical connection

DANGER

Risk of death due to electrocution!

Improper conduct when carrying out electrical work

can lead to death due to electric shock! Electrical

work must be carried out by a qualified electrician in

accordance with the locally applicable regulations.

▪The mains connection must match the specifications

on the rating plate.

▪Power supply on mains side for three-phase current

motors with clockwise rotating field.

▪Lay the power supply cables in accordance with the

locally applicable regulations and connect them ac-

cording to the wire assignment.

▪Connect the monitoring devices and check their func-

tion.

▪Earth the device properly in accordance with the locally

applicable regulations.

6.5.1 Fuse on mains side

Circuit breaker

The size of the circuit breakers conforms to the rated

current of the pump. The switching characteristics

should comply with group B or C. Observe local regula-

tions.

Motor protection switch

Make provision for an on-site motor protection switch

for devices without a plug! The minimum requirement

is a thermal relay/motor protection switch with tem-

perature compensation, differential triggering and

anti-reactivation device in accordance with the local

regulations. In case of sensitive mains, make provision

for the installation on-site of other protective equip-

ment (e.g. overvoltage, undervoltage or phase failure

relay, etc.).

Residual-current device (RCD)

Comply with the regulations of the local energy supply

company! The use of a residual-current device is re-

commended.

If persons come into contact with the device and con-

ductive fluids, secure the connection with a residual-

current device (RCD).

6.5.2 Maintenance tasks

Carry out the following maintenance tasks prior to in-

stallation:

▪Check the insulation resistance of the motor winding.

▪Test the resistor of the temperature sensor.

If the measured values differ from the specifications,

moisture may have penetrated into the motor or the

power supply cable or the monitoring device is defect-

ive. Contact customer service in the event of a fault.

6.5.2.1 Checking the insulation resistance of the motor winding

Use an insulation tester to measure the insulation res-

istance (measuring voltage = 1000V). Observe the fol-

lowing values:

▪At the time of initial commissioning: Insulation resist-

ance may not be less than 20MΩ.

▪For further measurements: Value must be greater than

2MΩ.

NOTICE!For motors with an integrated capacitor,

short-circuit the windings prior to checking!

Installation and operating instructions Wilo-Rexa UNI 17

Page 18

en Installation and electrical connection

U1/Z1

bn

U2

bu

C

r

M 1~

gn-ye

LNPE

W

5

1

2

V

4

U

3

M 3~

gn-ye

L3L2 2120L1PE

250 V (AC); 2,5 A; cos φ = 1

6.5.2.2 Test the resistor of the temperature sensor

Measure the resistor of the temperature sensors with

an ohmmeter. The bimetallic strips must have a meas-

ured value of 0Ohm (passage).

6.5.3 Connection of the single-phase motor

Fig.8: Connection diagram single-phase motor

Wire colour Terminal

Brown (bn) L

Blue (bu) N

2 21 WSK

3 U L1

4 V L2

5 W L3

Green/yellow (gn-

ye)

For three-phase current motors, a clockwise rotating

field must be available. The three-phase version is

equipped with a CEE plug or with a free cable end:

▪If a CEE plug is supplied, connection to the mains is es-

tablished by inserting the plug into a socket. The plug is

not overflow-proof. Install the socket so that it is

overflow-proof! Observe the information on the pro-

tection class (IP) of the plug.

▪If there is a free cable-end, the pump must be connec-

ted directly to the switchgear. DANGER!If the pump is

connected directly to the switchgear, arrange for the

electrical connection to be carried out by a qualified

electrician!

Earth PE

Green/yellow (gn-

ye)

The single-phase current version is equipped with a

shockproof plug. The connection to the mains is estab-

lished by inserting the plug into a socket. The plug is

not overflow-proof. Install the socket so that it is

overflow-proof! Observe the information on the pro-

tection class (IP) of the plug.

DANGER!If the pump is connected directly to the

switchgear, dismantle the plug and arrange for the

electrical connection to be carried out by a qualified

electrician!

6.5.4 Connection three-phase motor

Fig.9: Connection diagram three-phase motor

Wire number Designation Terminal

1 20 WSK

Earth

6.5.5 Monitoring equipment connection

All monitoring equipment must be connected!

6.5.5.1 Monitoring of motor winding

Single-phase current motor

Thermal motor monitoring is self-switching for single-

phase current motors. The monitoring function is al-

ways active and does not need to be connected separ-

ately.

Three-phase current motor with bimetallic strip

Bimetallic strips are connected in the switchgear itself

or via an evaluation relay.

Connection values: max. 250V(AC), 2.5A, cos φ = 1

When the threshold is reached, deactivation must

take place.

In the version with an attached plug, the thermal motor

monitoring is pre-wired and set to the correct value in

the plug.

6.5.6 Motor protection adjustment

Motor protection must be set depending on the selec-

ted activation type.

6.5.6.1 Direct activation

At full load, set the motor protection switch to the

rated current (see rating plate). At partial load, it is re-

commended to set the motor protection switch 5%

above the current measured at the duty point.

18 WILO SE 2017-03

Page 19

Commissioning en

6.5.6.2 Soft starter

At full load, set the motor protection switch to the

rated current (see rating plate). At partial load, it is re-

commended to set the motor protection switch 5%

above the current measured at the duty point. The fol-

lowing must also be observed:

▪Power consumption must always be below the rated

current.

▪Complete starting and stopping within 30s.

▪To avoid power dissipation, bypass the electronic

starter (soft start) once normal operation is reached.

6.5.7 Operation with frequency converter

Operation on the frequency converter is not permitted.

7 Commissioning

WARNING

Foot injuries due to lack of protective equip-

ment!

Danger of (serious) injuries during work. Wear safety

shoes!

7.1 Personnel qualifications

▪Electrical work: Electrical work must be carried out by a

qualified electrician (in accordance with EN50110-1).

▪Operation/control: Operating personnel must be in-

structed in the functioning of the complete system.

7.2 Operator responsibilities

▪Providing installation and operating instructions by the

pump or at a place specially reserved for it.

▪Making the installation and operating instructions

available in the language of the personnel.

▪Making sure that the installation and operating instruc-

tions are read and understood by all personnel.

▪All safety devices and emergency cut-outs on the sys-

tem-side must be active and checked to ensure that

they work properly.

▪The pump is suitable for use under the specified oper-

ating conditions.

7.3 Direction of rotation check (for three-phase current motors only)

The pump is factory-checked and adjusted to the cor-

rect direction of rotation for a clockwise rotating field.

Connection is made in accordance with the specifica-

tions in chapter “Electrical connection”.

Direction of rotation check

A qualified electrician checks the rotating field at the

mains connection with a rotating field-test device. For

the correct direction of rotation, a clockwise rotating

field must be available at the mains connection. The

pump is not approved for operation with a counter-

clockwise rotating field! CAUTION!If the direction of

rotation is checked with a test run, comply with the

ambient and operating conditions!

Incorrect direction of rotation

If the direction of rotation is incorrect, change the con-

nection as follows:

▪Swap two phases for motors with direct starting.

▪Swap the connections of two windings (e.g. U1/V1 and

U2/V2) for star-delta activation motors.

7.4 Before switching on

Check the following prior to activation:

▪Check whether the device has been installed properly

and in accordance with the locally applicable regula-

tions:

– Has the pump been earthed?

– Layout of power supply cable tested?

– Electrical connection made properly?

– Mechanical components attached correctly?

▪Check level control:

– Float switches can move freely?

– Switching level tested (pump on, pump off, minimum

water level)?

– Additional dry-running protection installed?

▪Test operating conditions:

– Min./max. temperature of the fluid tested?

– Max. immersion depth tested?

– Operating mode defined depending on the minimum

water level?

– Maximum switching frequency adhered to?

▪Check installation location/operating space:

– Pipe system on the pressure side free of deposits?

– Inlet or pump sump cleaned or free of deposits?

– All gate valves open?

– Minimum water level defined and monitored?

The hydraulics housing must be filled completely

with the fluid and there must be no air cushions in

the hydraulics. NOTICE!Provide suitable venting

devices if there is a risk of air cushions being

formed in the system!

7.5 Switch on and off

During the start process, the rated current is temporar-

ily exceeded. During operation, the rated current may

Installation and operating instructions Wilo-Rexa UNI 19

Page 20

en Decommissioning/dismantling

no longer be exceeded. CAUTION!If the pump does

not start, switch off the pump immediately. Remove

the fault before reactivating the pump!

Place pumps which are installed as portable pumps on a

firm surface so they are level. If pumps have fallen over,

place them upright again before activating them. Se-

curely attach the pump with screws in case of difficult

surfaces.

Pump with attached float switch and plug

▪Single-phase current version: After inserting the plug

into the socket, the pump is ready for operation. The

pump is switched on and off automatically depending

on the fill level.

▪Three-phase version: After inserting the plug into the

socket, the pump is ready for operation. The pump is

controlled via two switches on the plug:

– HAND/AUTO: Determines if the pump is switched on

and off directly (HAND) or depending on the fill level

(AUTO).

– ON/OFF: Switch pump on and off.

Pump with attached plug

▪Single-phase current version: After inserting the plug in

the socket, the pump is switched on.

▪Three-phase version: After inserting the plug into the

socket, the pump is ready for operation. The pump is

switched on and off with the ON/OFF switch.

Pumps with free cable end

The pump must be switched on and off using a separ-

ate operating point (on/off switch, switchgear)

provided by the customer.

7.6 During operation

WARNING

Amputation of limbs due to rotating com-

ponents!

No persons must be present in the work area of the

pump! There is risk of (serious) injuries due to rotat-

ing components! No persons must be present in the

work area of the pump during start-up or operation.

NOTICE

Delivery problems due to water level being

too low

The hydraulics are self-venting. As a result, smaller

air cushions are dissolved during the pumping pro-

cess. If the level of the fluid is lowered too much, the

volume flow can be interrupted. The minimum per-

missible water level must reach the upper edge of

the hydraulics housing!

When operating the pump, observe the locally applic-

able regulations on the following topics:

▪Work safety

▪Accident prevention

▪Handling electrical machines

Strictly adhere to the responsibilities of the personnel

specified by the operator. All personnel are responsible

for ensuring that the responsibilities of the personnel

and the regulations are observed!

Due to their design, centrifugal pumps have rotating

parts that are easily accessible. Depending on the oper-

ating condition, sharp edges can develop on these

parts. WARNING!This can lead to cuts and limbs may

be amputated and severed! Check the following at

regular intervals:

▪Operating voltage (+/-10% of the rated voltage)

▪Frequency (+/-2% of the rated frequency)

▪Power consumption between individual phases (max.

5%)

▪Voltage difference between the individual phases

(max.1%)

▪Max. switching frequency

▪Minimum water submersion depending on the operat-

ing mode

▪Inlet: no air intake

▪Level control device/dry-running protection: Switching

points

▪Quiet/low-vibration running

▪All gate valves open

8 Decommissioning/dismantling

WARNING

Risk of burns from hot surfaces!

Motor housing can become hot during operation. It

may cause burns. Allow the pump to cool down at

ambient temperature after switching it off!

20 WILO SE 2017-03

8.1 Personnel qualifications

▪Operation/control: Operating personnel must be in-

structed in the functioning of the complete system.

▪Electrical work: Electrical work must be carried out by a

qualified electrician (in accordance with EN50110-1).

Page 21

Decommissioning/dismantling en

▪Installation-/dismantling: The technician must be

trained in the use of the necessary tools and mounting

materials for the relevant construction site.

8.2 Operator responsibilities

▪Locally applicable accident prevention and safety regu-

lations of trade associations.

▪Observe regulations for working with heavy loads and

under suspended loads.

▪Provide the necessary protective equipment and make

sure that the personnel wears it.

▪Provide adequate aeration in closed rooms.

▪Take immediate countermeasures if there is a build-up

of toxic or suffocating gases!

8.3 Decommissioning

The pump is deactivated during decommissioning, but

remains installed. This ensures that the pump is always

ready for operation.

‡ To protect the pump from frost and ice, always im-

merse the pump completely in the fluid.

‡ Temperature of the fluid must always be above +3°C.

1. Switch off the pump at the operating point.

DANGER

Risk of death due to electrocution!

Improper conduct when carrying out electrical work

can lead to death due to electric shock! Electrical

work must be carried out by a qualified electrician in

accordance with the locally applicable regulations.

DANGER

Potentially fatal danger due to dangerous

autonomous work!

Work in chambers and narrow rooms as well as work

involving risk of falling are dangerous work. Such

work may not be carried out autonomously! A

second person must be present for safety reasons.

WARNING

Risk of burns from hot surfaces!

Motor housing can become hot during operation. It

may cause burns. Allow the pump to cool down at

ambient temperature after switching it off!

2. Secure the operating point against being switched on

again by unauthorised persons (e.g. lock main switch).

▶ The pump is out of operation and can now be dis-

mantled.

If the pump remains installed after decommissioning,

observe the following:

▪Ensure that the prerequisites for decommissioning are

maintained for the complete period of decommission-

ing. If these prerequisites cannot be guaranteed, dis-

mantle the pump after decommissioning!

▪For an extended period of decommissioning, carry out a

5-minute function test at regular intervals (monthly to

quarterly). CAUTION!A function test may only be car-

ried out under the applicable operating conditions. A

dry run is not permitted! Non-compliance can result

in irreparable damage!

8.4 Removal

DANGER

Danger due to fluids hazardous to health!

If the pump is used in fluids hazardous to health, de-

contaminate the pump after dismantling and before

carrying out any other work! There is danger to life!

Observe the specifications in the work regulations!

The operator must make sure that the personnel has

received and read the work regulations!

NOTICE

Only use lifting equipment in a technically

sound condition!

Only use lifting equipment in a technically sound

condition for lifting, lowering and transporting the

pump. Ensure that the pump does not become

jammed during lifting and lowering. Do not exceed

the max. permissible bearing capacity of the lifting

equipment!

8.4.1 Stationary wet well installation

‡ Pump is decommissioned.

‡ Gate valves on the inlet and pressure side closed.

1. Disconnect the pump from the mains.

2. Attach the lifting equipment to the attachment point.

CAUTION!Never pull on the power supply cable! This

damages the power supply cable!

3. Slowly raise the pump and lift above the guide pipes

from the operating space. CAUTION!The power sup-

ply cable can be damaged while lifting! Hold the

power supply cable slightly taut when lifting!

4. Clean pump thoroughly (see point “Cleaning and disin-

fecting”). DANGER!Disinfect the pump when used in

fluids hazardous to health!

Installation and operating instructions Wilo-Rexa UNI 21

Page 22