Wilo Multivert MVI 16, Multivert MVI 32, Multivert MVI 52, Multivert MVI 70, Multivert MVI 95 Installation And Operating Instructions Manual

Page 1

Wilo-Multivert MVI 16.../ MVI 32.../ MVI 52.../ MVI 70.../ MVI 95...

D Einbau- und Betriebsanleitung

GB Installation and operating instructions

F Notice de montage et de mise en service

I Istruzioni di montaggio, uso e manutenzione

2 040 502 - Ed3/0805 pdf

Page 2

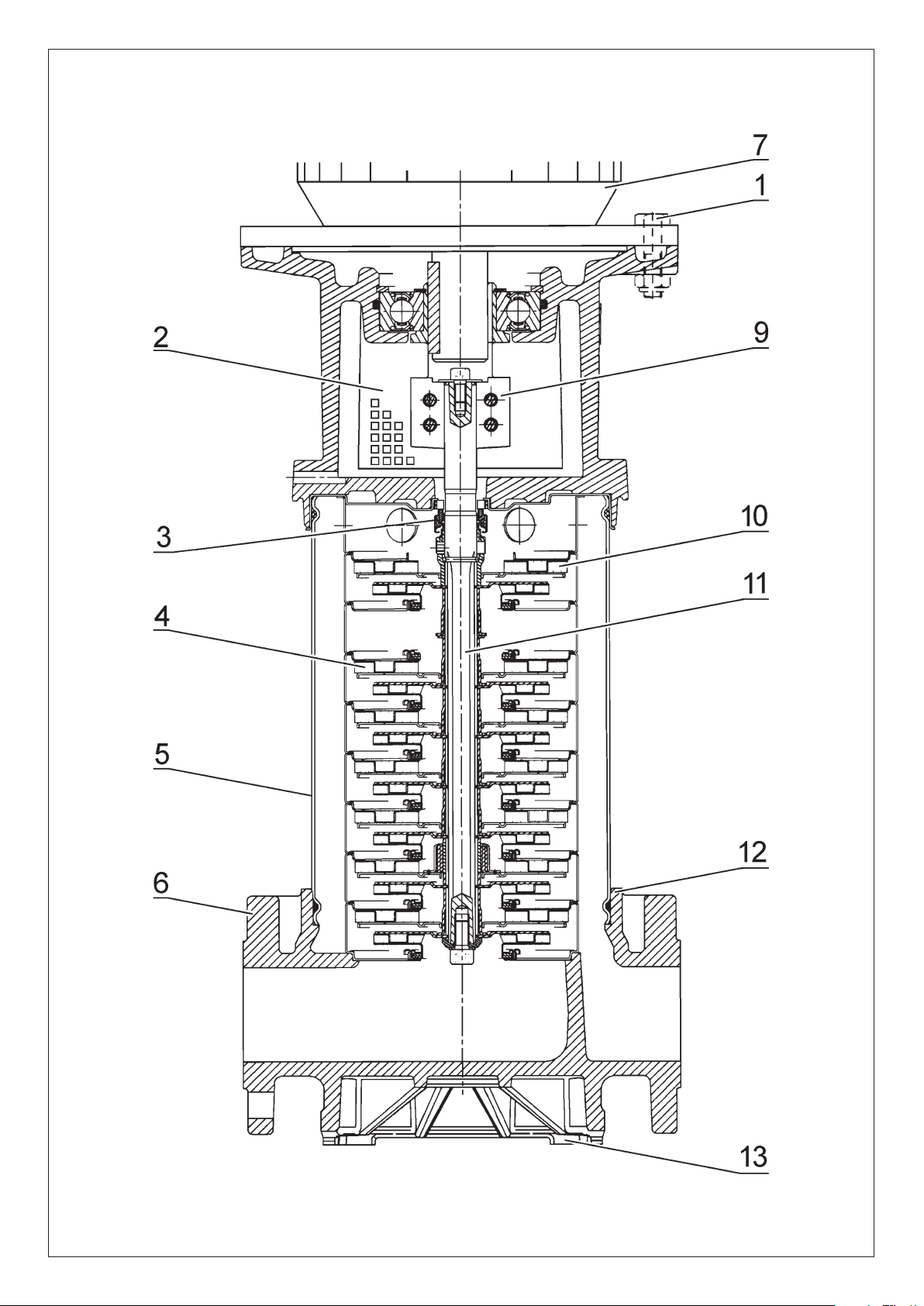

MVI 16.../MVI 32... /MVI 52...

Fig. 1

Page 3

Fig. 1

MVI 70...

/MVI 95...

Page 4

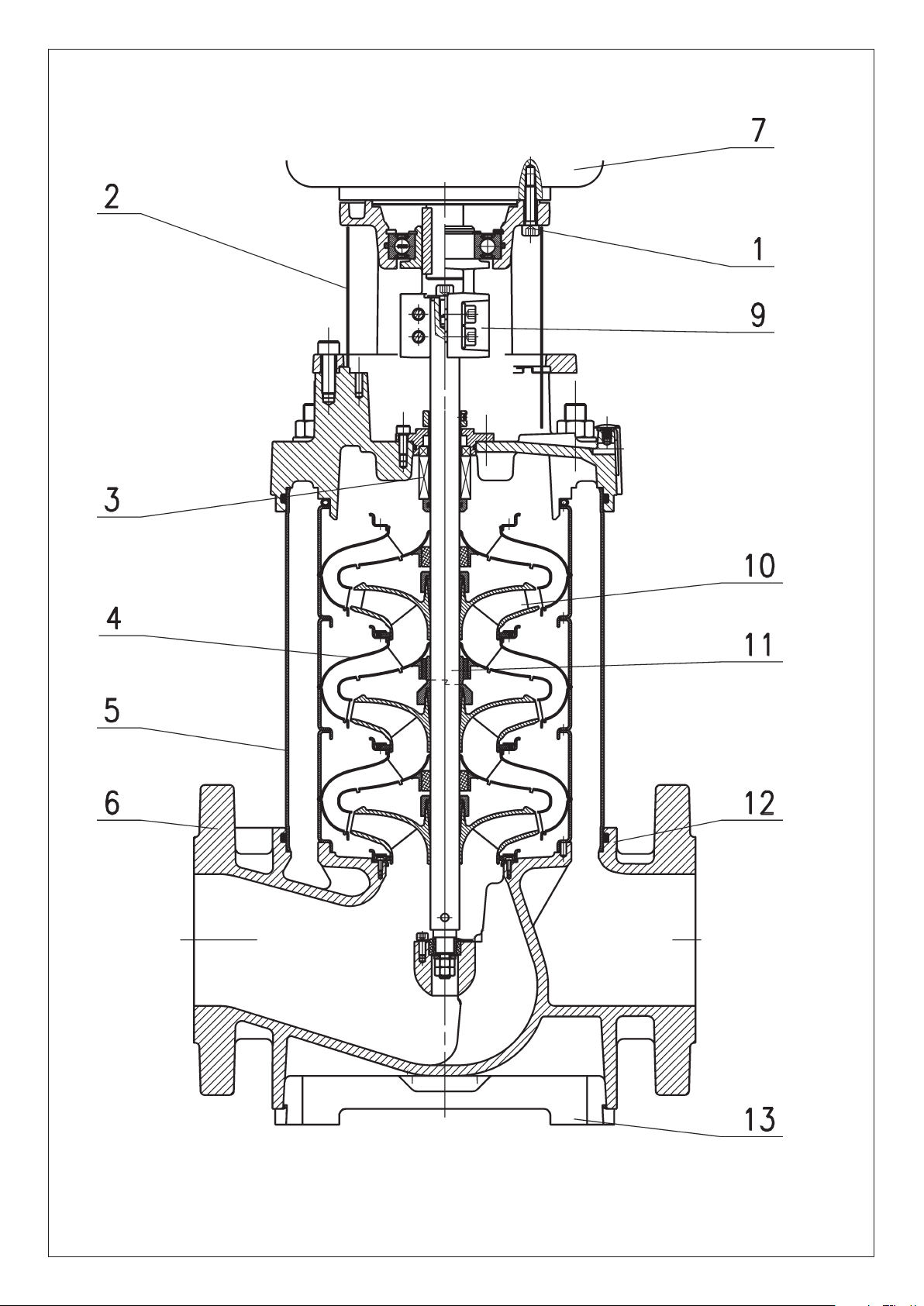

Fig. 3

Fig. 2

Fig. 4

Page 5

D

GB

EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Transport and interim storage . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. Product and accessory description . . . . . . . . . . . . . . . . . . . . . 10

5. Assembly / Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8. Problems, Causes and Solutions . . . . . . . . . . . . . . . . . . . . . . 13

F

Déclaration de conformité CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1. Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2. Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Transport et stockage avant utilisation . . . . . . . . . . . . . . . . . . 15

4. Description du produit et de ses accessoires . . . . . . . . . . . . . 15

5. Installation / Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6. Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7. Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8. Pannes, causes et remèdes . . . . . . . . . . . . . . . . . . . . . . . . . . 18

I

Dichiarazione di conformità CE . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1. Introduzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2. Sicurezza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Trasporto e magazzinaggio . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4. Descrizione del prodotto e degli accessori . . . . . . . . . . . . . . . 20

5. Istruzioni di montaggio e installazione . . . . . . . . . . . . . . . . . . . 21

6. Messa in esercizio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7. Manutenzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8. Risoluzione di problemi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CE-Konformitätserklärung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1. Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Transport und Zwischenlagerung . . . . . . . . . . . . . . . . . . . . . . 5

4. Beschreibung von Erzeugnis und Zubehör . . . . . . . . . . . . . . . 5

5. Aufstellung / Einbau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Störungen, Ursachen und Beseitigung . . . . . . . . . . . . . . . . . . 8

1

Page 6

D EG - Konformitätserklärung

GB EC – Declaration of conformity

F Déclaration de conformité CEE

Hiermit erklären wir, dass die Bauarten der Baureihe :

Herewith, we declare that this product:

Par le présent, nous déclarons que cet agrégat :

MVI 16

MVI 32

MVI 52

MVI 70

MVI 95

in der gelieferten Ausführung folgenden einschlägigen Bestimmungen entspricht:

in its delivered state comply with the following relevant provisions:

est conforme aux dispositions suivants dont il relève:

EG-Maschinenrichtlinie 98/37/EG

EC-Machinery directive

Directives CEE relatives aux machines

Elektromagnetische Verträglichkeit - Richtlinie 89/336/EWG

Elektromagnetic compatability - directive

Compatibilité électromagnétique- directive

i.d.F/ as amended/ avec les amendements suivants:

91/263/EWG

92/31/EWG

93/68/EWG

Niederspannungsrichtlinie 73/23/EWG

Low voltage directive

Direction basse-tension

i.d.F/ as amended/ avec les amendements suivants :

93/68/EWG

Angewendete harmonisierte Normen, insbesondere:

Applied harmonized standards, in particular: EN 60034-1 Normes harmonisées, notamment:

EN 809

Dortmund, 11.04.2005

Quality Manager

Document: 2060375.1

Erwin Prieß

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Page 7

NL

EG-verklaring van overeenstemming

Hiermede verklaren wij dat dit aggregaat in de

geleverde uitvoering voldoet aan de volgende

bepalingen:

EG-richtlijnen betreffende machines 98/37/EG

Elektromagnetische compatibiliteit

89/336/EEG als vervolg op 91/263/EEG,

92/31/EEG, 93/68/EEG

EG-laagspanningsrichtlijn 73/23/EEG als

vervolg op 93/68/EEG

Gebruikte geharmoniseerde normen, in het

bijzonder:

P

Declaração de Conformidade CE

Pela presente, declaramos que esta unidade

no seu estado original, está conforme os

seguintes requisitos:

Directivas CEE relativas a máquinas 98/37/CE

Compatibilidade electromagnética 89/336/CEE

com os aditamentos seguintes 91/263/CEE,

92/31/CEE, 93/68/CEE

Directiva de baixa voltagem 73/23/CEE com

os aditamentos seguintes 93/68/CEE

Normas harmonizadas aplicadas, especialmente:

FI

CE-standardinmukaisuusseloste

Ilmoitamme täten, että tämä laite vastaa

seuraavia asiaankuuluvia määräyksiä:

EU–konedirektiivit: 98/37/EG

Sähkömagneettinen soveltuvuus 89/336/EWG

seuraavin täsmennyksin 91/263/EWG

92/31/EWG, 93/68/EWG

Matalajännite direktiivit: 73/23/EWG seuraavin

täsmennyksin 93/68/EWG

Käytetyt yhteensovitetut standardit, erityisesti:

CZ

Prohlášení o shodě EU

Prohlašujeme tímto, že tento agregát

v dodaném provedení odpovídá následujícím

příslušným ustanovením:

Směrnicím EU–strojní zařízení 98/37/EG

Směrnicím EU–EMV 89/336/EWG ve sledu

91/263/EWG, 92/31/EWG, 93/68/EWG

Směrnicím EU–nízké napětí 73/23/EWG ve

sledu 93/68/EWG

Použité harmonizační normy, zejména:

∆ήλωση προσαρµογής στις προδιαγραφές

GR

της Ε.Ε. (Ευρωπαϊκής Ένωσης)

∆ηλώνουµε ότι το προϊόν αυτό σ’ αυτή την

κατάσταση παράδοσης ικανοποιεί τις

ακόλουθες διατάξεις :

Οδηγίες EG σχετικά µε µηχανήµατα 98/37/EG

Ηλεκτροµαγνητική συµβατότητα EG-

89/336/EWG όπως τροποποιήθηκε

91/263/EWG 92/31/EWG, 93/68/EWG

Οδηγία χαµηλής τάσης EG–73/23/EWG όπως

τροποποιήθηκε 93/68/EWG

Εναρµονισµένα χρησιµοποιούµενα πρότυπα,

ιδιαίτερα:

1)

1)

Erwin Prieß

Quality Manager

I

Dichiarazione di conformità CE

Con la presente si dichiara che i presenti

prodotti sono conformi alle seguenti

disposizioni e direttive rilevanti:

Direttiva macchine 98/37/CE

Compatibilità elettromagnetica 89/336/CEE e

seguenti modifiche 91/263/CEE, 92/31/CEE,

93/68/CEE

Direttiva bassa tensione 73/23/CEE e

seguenti modifiche 93/68/CEE

Norme armonizzate applicate, in particolare: 1)

S

CE- försäkran

Härmed förklarar vi att denna maskin i

levererat utförande motsvarar följande

tillämpliga bestämmelser:

EG–Maskindirektiv 98/37/EG

EG–Elektromagnetisk kompatibilitet – riktlinje

89/336/EWG med följande ändringar

91/263/EWG, 92/31/EWG, 93/68/EWG

EG–Lågspänningsdirektiv 73/23/EWG med

följande ändringar 93/68/EWG

1)

Tillämpade harmoniserade normer, i synnerhet: 1)

DK

EF-overensstemmelseserklæring

Vi erklærer hermed, at denne enhed ved

levering overholder følgende relevante

bestemmelser:

EU–maskindirektiver 98/37/EG

Elektromagnetisk kompatibilitet: 89/336/EWG,

følgende 91/263/EWG, 92/31/EWG,

93/68/EWG

Lavvolts-direktiv 73/23/EWG følgende

1)

1)

93/68/EWG

Anvendte harmoniserede standarder, særligt:

PL

Deklaracja Zgodności CE

Niniejszym deklarujemy z pełną

odpowiedzialnoscią że dostarczony wyrób jest

zgdony z następującymi dokumentami:

EC–dyrektywa dla przemysłu maszynowego

98/37/EG

Odpowiedniość elektromagnetyczna

89/336/EWG ze zmianą 91/263/EWG,

92/31/EWG, 93/68/EWG

Normie niskich napięć 73/23/EWG ze zmianą

93/68/EWG

Wyroby są zgodne ze szczegółowymi normami

zharmonizowanymi:

TR

EC Uygunluk Teyid Belgesi

Bu cihazın teslim edildiği şekliyle aşağıdaki

standartlara uygun olduğunu teyid ederiz:

AB-Makina Standartları 98/37/EG

Elektromanyetik Uyumluluk 89/336/EWG ve

takip eden, 91/263/EWG, 92/31/EWG,

93/68/EWG

Alçak gerilim direktifi 73/23/EWG ve takip

eden, 93/68/EWG

Kısmen kullanılan standartlar:

1)

1)

E

Declaración de conformidad CE

Por la presente declaramos la conformidad

del producto en su estado de suministro con

las disposiciones pertinentes siguientes:

Directiva sobre máquinas 98/37/CE

Directiva sobre compatibilidad

electromagnética 89/336/CEE modificada por

91/263/CEE, 92/31/CEE, 93/68/CEE

Directiva sobre equipos de baja tensión

73/23/CEE modificada por 93/68/CEE

Normas armonizadas adoptadas, especialmente:

N

EU-Overensstemmelseserklæring

Vi erklærer hermed at denne enheten i

utførelse som levert er i overensstemmelse

med følgende relevante bestemmelser:

EG–Maskindirektiv 98/37/EG

EG–EMV–Elektromagnetisk kompatibilitet

89/336/EWG med senere tilføyelser:

91/263/EWG, 92/31/EWG, 93/68/EWG

EG–Lavspenningsdirektiv 73/23/EWG med

senere tilføyelser: 93/68/EWG

Anvendte harmoniserte standarder, særlig:

H

EK. Azonossági nyilatkozat

Ezennel kijelentjük,hogy az berendezés az

alábbiaknak megfelel:

EK Irányelvek gépekhez: 98/37/EG

Elektromágneses zavarás/türés: 89/336/EWG

és az azt kiváltó 91/263/EWG, 92/31/EWG,

93/68/EWG

Kisfeszültségü berendezések irány-Elve:

73/23/EWG és az azt kiváltó 93/68/EWG

1)

Felhasznált harmonizált szabványok, különösen:

Деклация о соответствии

RUS

1)

1)

1)

Европейским нормам

Настоящим документом заявляем, что

данный агрегат в его объеме поставки

соответствует следующим нормативным

документам:

Директивы EC в отношении машин

98/37/EG

Электромагнитная устойчивость

89/336/EWG с поправками 91/263/EWG,

92/31/EWG, 93/68/EWG

Директивы по низковольтному напряжению

73/23/EWG с поправками 93/68/EWG

Используемые согласованные стандарты и

нормы, в частности :

1)

EN 809,

1)

EN 60034-1.

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Page 8

ENGLISH

9

1 General Information

Installation and commissioning only by qualified personnel

1

.1 Uses

The pump is suitable for hot and cold water and other fluids free from

mineral oil and without abrasives or long-fibred substances. The main

areas of use are in water supply installations, as a booster pump, as a

boiler feeder pump, in industrial circulation systems, in process technology, in cooling water systems, in fire extinguishers and in washing

and sprinkler installations.

1.2 Product data

1.2.1 Connection and electrical data (Table 1)

Pumping medium allowed

Permissible media temperature

Maximum ambient temperature

Maximum permissible working pressure: at the inlet (inlet pressure see paragraph 5.3)

at the outlet, for a 2 pole motor

at the outlet, for a 2 pole motor

Mains voltages DM: for P2 ≤ 4 kW:

for P2 ≥ 5.5 kW:

Standard motor for P2 ≤ 5.5 kW:

for P2 ≥ 7.5 kW:

Speed 2 pole version

4 pole version

Mains fuse protection

Insulation class

System of protection

Drinking water in acc. with Drinking Water Order

Heating water / service water

Condensate

Water/glycol mixture1)

Other liquid media2)

-15

°C to +120 °C

(Follow catalogue instructions)

+40 °C

16/10 bar

16/25 bar

16/16 bar

3 ~ 230/400 V ±

10 %, 50 Hz

3 ~ 400 V ± 10 %, 50 Hz

V 18 standard motor

V 1 standard motor

2900 RPM

1450 RPM

see motor rating plate

F

IP 55

better protective systems available

1

) When using a water-glycol mixture containing up to 40% glycol (or media with a viscosity different to that of pure water, the flow data for the pump must be adjusted accord-

ing to the higher viscosity of the flow media, regardless of the percentage of the viscous matter. Only use branded goods with corrosion protection-inhibitors, follow manufacturer’s instructions.

2

) If other and also aggressive chemical fluids are to be pumped, be sure to follow catalogue instructions and first obtain the approval of WILO.

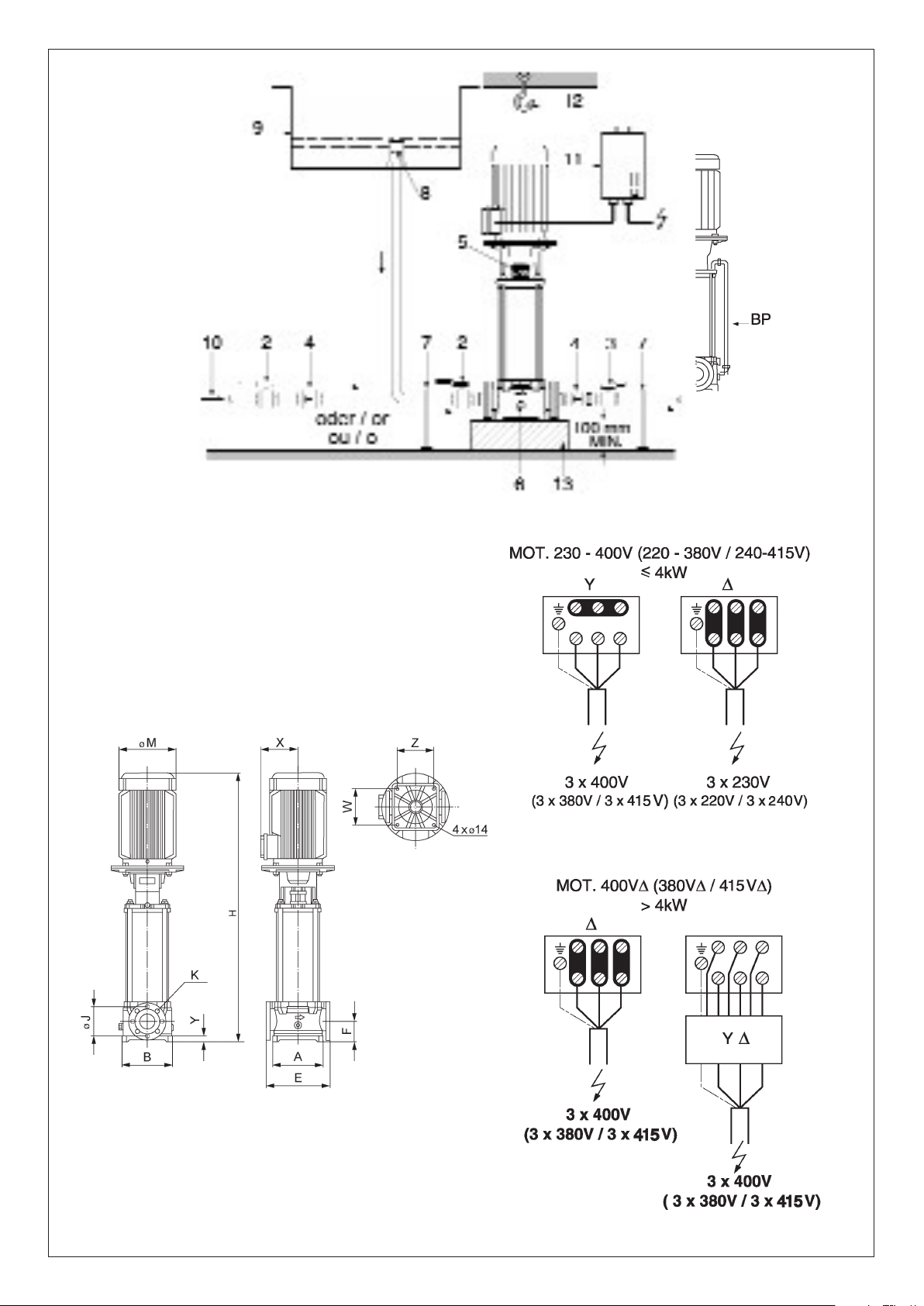

Principal dimensions and connection dimensions (Table 2, see also Fig. 3):

When ordering spare parts, please give all the information on the pump/motor rating plate.

Types PN16 version PN25 version

A B Y W Z E F J K A B Y W Z E F J K

MVI mm mm

1602 è 1614 DN50 194

252 20 215 130 300 90 125 4x18 194 252 20 215 130 300 90 125 4x18

3202 è 3216 DN65 235

235 35 195 195 320 105 145 4x18 260 260 35 220 220 320 120 145 8x18

5202 è 5212 DN80 260

260 30 220 220 320 105 160 8x18 260 260 30 220 220 320 105 160 8x18

7001 è 7007 DN100 261

350 45 280 199 380 140 180 8x19 261 350 45 280 199 380 140 190 8x23

9501 è 9506 DN100 261

350 45 280 199 380 140 180 8x19 261 350 45 280 199 380 140 190 8x23

Page 9

ENGLISH

1.2.2 Type ke

Design MVI

(Multistage, vertic.

Special steel-(Inox-)

centrifugal pump)

Flow rate [m3/h]

(2-pole/ 50 Hz)

Number of

impellers in row

Material quality:

Hydraulic / Base

1 R unoccupied

2 R 1.4404 / 1.4408 (AISI 316 L)

3 R 1.4301 / GG25 (coated)

maximum permissible working

pressure [bar] PN 16 or PN 25

E

PDM seals (KTW/WRAS)

V

ITON seals

Main voltage 3 ~ 400 V

50 Hz or 60 Hz frequency

2- or 4-pole motor

Manufacturer’s key

y

MVI 16 08 3 / 16 / E / 3 - 400 - 50 - 2 / XX / X

3 ~ 230 V

2 Safety

These instructions contain important information which must be

followed when installing and operating the pump. These operating

instructions must therefore be read before assembly and commissioning by the installer and the responsible operator. Both the general

safety instructions in the “Safety precautions” section and those in

subsequent sections indicated by danger symbols should be carefully

observed.

2.1 Danger symbols used in these operating instructions

Safety precautions in these operating instructions which, if not

followed, could cause personal injury are indicated by the symbol:

when warning of electrical voltage with

The following symbol is used to indicate that by ignoring the relevant

safety instructions, damage could be caused to the pump/machinery

and its functions:

WARNING!

2.2 S

taff training

The personnel installing the pump must have the appropriate qualifications for this work.

2.3 Risks incurred by failure to comply with the safety precautions

Failure to comply with the safety precautions could result in personal

injury or damage to the pump or installation. Failure to comply with the

safety precautions could also invalidate any claim for damages.

In particular, failure to comply with these safety precautions could give

rise, for example, to the following risks:

– Failure of important pump or machinery functions,

– Personal injury due to electrical, mechanical and bacteriological

causes.

– Damage to property.

2.4 Safety precautions for the operator

Existing regulations for the prevention of accidents must be followed.

Dangers caused by electrical energy are to be excluded. Directives

issued by the VDE [German Association of Electrical Engineers] and

the local electricity supply companies are to be observed.

2.5 Safety information for inspection and assembly

The operator is responsible for ensuring that inspection and assembly

are carried out by authorised and qualified personnel who have

studied the operating instructions closely.

Work on the pump/machinery should only be carried out when the

machine has been brought to a standstill.

2.6 Unauthorized modification and manufacture of spare parts

Changes to the pump/machinery may only be made in agreement with

the manufacturer. The use of original spare parts and accessories

authorised by the manufacturer will ensure safety. The use of any other

parts may invalidate claims invoking the liability of the manufacturer for

any consequences.

2.7 Improper use

The operating safety of the pump or installation supplied can only be

guaranteed if it is used in accordance with paragraph 1 of the operating instructions. The limiting values given in the catalogue or data

sheet must neither be exceeded nor allowed to fall below those specified.

3

Transport and storage

WARNING!

damage. The pump unit is to be transported with the shaft horizontal.

When storing, ensure that the pump unit cannot overturn as a result of

top-heaviness.

During transport and in storage the pump must be

protected against moisture, frost and mechanical

4 Product and accessory description

4.1 The pumps

The pump is a multistage (1–16 stages) normal suction vertical high

pressure centrifugal pump with an in-line design, i.e. the inlet and outlet pressure glands are in a line. The pump is available in 2 pressure

versions, PN 16 and PN 25 with integrally cast circular flanges.

The pump (Fig. 1) stands on a grey cast iron pump footplate which

serves as a fixing base (13). The stage casings (4) are in a multiple

modular construction. The impellers (10) are fitted on a single shaft

(11). The pressure casing (5) guarantees a fail-safe seal.

All parts that come into contact with the medium, such as stage housings, impellers and pressure casings are made of chromium nickel

steel, the pump footplate (Pos. 12) with flanges (Pos. 6) of coated

GG 25 (up to 85 °C) or of chromium nickel steel (on request). The shaft

hole through the pump casing is sealed with an axial face seal (3).

MVI32C, MVI52C, MVI70 and MVI95 are equipped

with a cartridge system in order to ease standard

mechanical seal replacement without disassembling the hydraulic parts.

“Spacer” feature allows not to disassemble motor on MVI32C,

MVI52C, MVI70 and MVI95 when removing mechanical seal cartridge.

The pump and motor shafts are linked together by a clutch (9). All

parts of the drinking water version (version E) which are in contact with

the fluid have been cleared by KTW and WRAS and are therefore suitable for use with drinking water.

The speed of the pump can be controlled when connected to a

frequency converter (see paragraph 5.3).

4.2 Products delivered

– high pressure centrifugal pump

10

Page 10

ENGLISH

– Check that the mains current and voltage comply with the data on

the rating plate.

– Pump/installation must be earthed in compliance with regulations.

– All motors must be fitted with a motor safety switch by the customer

to prevent the motor from overheating.

Adjusting the motor safety switch:

Direct starting current: Adjust to nominal current of the motor in

accordance with the data on the motor rating plate.

Y

-∆

-start: If the motor safety switch is connected as a star or triangu-

lar safety circuit combination at the supply line it can be adjusted in the

same way units operating on direct starting current. If the motor safety

switch is connected to the motor supply line in phase (U1/V1/W1 or

U2/V2/W2), then the motor safety switch should be adjusted to the

value of 0.58 of the nominal motor current.

– The mains cable can be inserted to the left or the right of the termi-

nal box. Open the appropriate hole by removing the moulded cover,

unscrew the PG connector and push the cable through the PG

connector.

– The supply cable must be protected against the effects of heat and

vibrations which may come from the motor or the pump.

– When using the pump in machinery where the water temperature

exceeds 90 °C, a connecting pipe with corresponding heat

resistance must be used.

– Connections to the mains must be carried out in accordance with

the plan of terminal connections for rotary or alternating current in

the terminal box of the pump (Fig. 4).

– The terminal box can be better positioned by rotating the motor

through steps of 90°. To this end the connecting screws (Fig. 1,

Pos. 1) of the lantern (Fig. 1, Pos. 8) and motor flange are to be

loosened.

In the case of internal connecting screws the clutch guard (Fig. 1,

Pos. 2) is to be removed beforehand. When assembling the clutch

guard, do not forget to tighten the safety screw.

5.3 Operation with frequency converter

The speed of the pump can be controlled when connected to a

frequency converter.

See Installation and Operating Instructions of the frequency converter

for connection and operation.

The frequency converter may not generate a speed due to increased

voltage greater than 2500 V/µs and voltage peaks û > 1000 V, as

otherwise the motor coil will be destroyed. If such speeds due to the

increased voltage are possible, an LC filter (motor filter) should be

installed between the frequency converter and the motor.

6 Commissioning

In order to protect the axial face seal, the pump

must not run dry.

– Close both isolating valves and open the vent screw (Fig. 2, 5) by

one and a half or two turns.

– Slowly open the isolating valve (Fig. 2, 2) at the inlet until the air has

escaped from the vent screw and the fluid to be pumped comes

out. The escaping air will be clearly heard hissing. Tighten the vent

screw.

– Slowly open the isolating valve at the outlet (Fig. 2, 3). The mano-

meter installed at the outlet should be checked for any possible

pressure instabilities, indicated by a flickering manometer pointer. If

the pressure is unstable, allow more air to escape.

When the temperature of the liquid being pumped is high

and the system is pressurised, any flow escaping from the

vent screw can cause scalding and injuries. The vent

screw should therefore be loosen only slightly.

– When used for the first time, if it is to be used to pump drinking

water the system must be flushed through, so that any dirty water

present will not contaminate the drinking water supply.

– Checking the direction of rotation (only for rotary current motors):

Check that the pump rotates in the same direction indicated by the

arrow on the pump casing by switching on for a short time. If this is

not the case, interchange 2 phases in the terminal box.

WARNING!

– Installation and operating instructions

4.3 Accessories

see catalogue or data sheet

5 Assembly/Installation

– See the rating plate of the pump and the rating plate of the motor

5.1 Assembly

WARNING!

work has been completed. Dirt will damage the pump.

– Install the pump in a dry place free of frost.

– Install in a horizontal and flat position. If the pump is positioned on

an incline the bearing will wear more quickly.

– Install the pump in an easily accessible place to facilitate inspection

and disassembly. Always install the pump exactly perpendicular on a

sufficiently heavy concrete base (Fig. 2, 3). Fit a vibration absorber

between the base and the floor.

– Dimensions for installation and connections are given in Paragraph

1.2.1, Table 2 and in Fig. 3.

– In the case of heavy pumps fit a hook (Fig. 2, Pos. 12) or eye with a

suitable load-bearing capacity (total weight of pump: see catalogue/

data sheet) vertically above the pump, to which a hoist or similar

device can be attached when maintaining or repairing the pump.

Allow for a free size when completed of min. 200 mm.

– The arrow on the pump casing indicates the direction of flow.

– Fit the inlet and outlet pipes without stress. Install below expansion

joints of restricted length to absorb vibrations. The pipes must be

attached (Fig. 2, 7) in such a way that the pump does not bear the

weight of the pipes.

– Isolation mechanisms (Fig. 2, 2 & 3) must in principle be installed in

front of and behind the pump to avoid having to empty and refill the

whole installation when inspecting or changing the pump.

– To avoid pressure loss it is recommended that you choose as short

an inlet pipe as possible, choose a nominal width for the suction

pipe which is larger by a nominal width than the pump connection

and avoid constrictions caused by bends and valves.

– A backflow preventer (Fig. 2, 4) should be fitted in the outlet pipe.

– For differential pressures > 6 bar the backflow preventer (Fig. 2,

Pos. 4) is to be fitted in the suction pipe. It is not required at the

outlet.

– The axial face seal should be protected against dry running. An inlet

pressure gauge or level gauge should be installed by the customer.

– If the pump is to be connected indirectly via a reservoir, a suction

strainer (Fig. 2, 8) must be provided in the inlet pipe by the customer

to prevent coarse impurities entering the pump.

– With limited nominal pressure PN, ensure that this pressure is pro-

duced from the inlet pressure and the zero flow level:

– For gaseous or hot pumping media a bypass pipe is to be fitted to

the pump (Fig. 2, Pos. BP), (accessory).

5.2 Electrical connection

Assembly should only take place once all welding

and soldering work and the rinsing of the pipe net-

P

≤ PN - P

Inlet

Electrical connection should be made by a qualified electrician. Current national regulations must be observed (e.g.

VDE regulations in Germany).

max pump

11

Page 11

ENGLISH

For pumps with a star or triangular circuit starting current, the

connections of two coils must be interchanged, e.g. U1 with V1 and

U2 with V2.

– If the fluid temperature is too high, steam may form which may

damage the pump. The pump must therefore not run with the valve

closed for longer than 10 minutes when pumping cold water or for

longer than five minutes when pumping fluid where > 60

°C.

We recommend that the flow rate does not drop to below 10 % of

the nominal flow rate so as to avoid a build up of steam in the pump.

– If there is a build up of steam, this should be allowed to escape by

carefully opening the vent screw.

Both pump and motor can reach operating temperatures

> 100 °C. Therefore exercise caution when touching the

pump.

7 Maintenance

Before carrying out any maintenance work, switch off the

pump and ensure that it cannot be switched on again by

unauthorised people. Never carry out work on a running

pump.

– During the running-in period, there may be some dripping from the

axial face seal. In the event of a serious leak as a result of heavy

wear have the mechanical seal replaced by a specialist.

– Increased bearing noise and unusual vibrations indicate a worn

bearing. In this case, have the bearing replaced by a specialist.

– If the pump is exposed to frost, the pump and pipework must be

emptied in the cold season. Close the isolating valve and open the

drain valve (Fig. 2, 6) and the vent screw (Fig. 2, 5) of the pump.

The isolating valve must be closed before the drain valve is

opened.

– If placed in a frost-free location, the pump does not have to be emptied, even if it is out of service for a long period.

Type

< 22 kW

22 kW

✔

✔ ✔

✔ ✔

✔ ✔

✔

✔

✔

✔

30 kW 37 kW 45 kW

MVI 16

MVI 32

MVI 52

MVI 70

MVI 95

On pumps equipped with greaser under bearing box (table below), see

greasing instructions written on sticker put on it:

For pumps equipped with coupling bush, check it

before reassembling.

12

Page 12

8 Problems, Causes and Solutions

ENGLISH

Problem

Pump does not run

Pump runs but does not pump

Pump does not pump evenly

Pump vibrates and is noisy

Motor overheats

motor cut-out activates

Cause

no power

motor safety switch activated

Incorrect direction of rotation

pipe or pump components blocked by

foreign body

air in inlet pipe

inlet pipe too narrow

valve not sufficiently open

air in the pump

foreign body in the pump

pump not properly fixed to the base

bearing damaged

one phase interrupted

pump sluggish:

foreign body

Solutions

check fuses, cables and connections

Eliminate motor overload

check direction of rotation and correct if necessary

Check and clean pipe and pump

Seal inlet pipe

fit a larger inlet pipe

open valve

bleed the pump

remove foreign body

tighten anchor bolts

consult customer services

check fuses, cables and connections

clean pump

bearing damaged

ambient temperature too high

If the fault cannot be remedied, please contact your plumbing and heating specialist or your nearest WILO customer services or

representative.

Subject to technical alterations!

have pump repaired by customer services

provide cooling

13

Page 13

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Germany

T +49 231 4102-0

F +49 231 4102-7363

www.wilo.com

Azerbaijan

370141 Baku

T +994 50 2100890

F +994 12 4975253

info@wilo.az

Bosnia and Herzegovina

71000 Sarajevo

T +387 33 714511

F +387 33 714510

anton.mrak@wilo.si

Croatia

10000 Zagreb

T +385 1 3680474

F +385 1 3680476

rino.kerekovic@wilo.hr

Georgia

38007 Tbilisi

T/F +995 32 536459

info@wilo.ge

Macedonia

1000 Skopje

T/F +389 2122058

valerij.vojneski@wilo.com.mk

Moldova

2012 Chisinau

T/F +373 22 223501

sergiu.zagurean@wilo.md

Tajikistan

734025 Dushanbe

T +992 372 316275

info@wilo.tj

Uzbekistan

700029 Taschkent

T/F +998 71 1206774

wilo.uz@online.ru

März 2005

Wilo – International (Subsidiaries)

Wilo – International (Representation offices)

Austria

WILO Handelsges. m.b.H.

1230 Wien

T +43 1 25062-0

F +43 1 25062-15

office@wilo.at

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2503383

wilobel@mail.ru

Belgium

WILO NV/SA

1083 Ganshoren

T +32 2 4823333

F +32 2 4823330

info@wilo.be

Bulgaria

WILO Bulgaria EOOD

1125 Sofia

T +359 2 9701970

F +359 2 9701979

info@wilo.bg

Canada

WILO Canada Inc.

Calgary, Alberta T2A5L4

T +1 403 2769456

F +1 403 2779456

blowe@wilo-na.com

China

WILO SALMSON (Beijing)

Pumps System Ltd.

101300 Beijing

T +86 10 804939700

F +86 10 80493788

wilobj@wilo.com.cn

Czech Republic

WILO Praha s.r.o.

25101 Cestlice

T +420 234 098 711

F +420 234 098 710

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

F +45 70 253316

wilo@wilo.dk

Finland

WILO Finland OY

02320 Espoo

T +358 9 26065222

F +358 9 26065220

wilo@wilo.fi

France

WILO S.A.S.

78310 Coignières

T +33 1 30050930

F +33 1 34614959

wilo@wilo.fr

Great Britain

WILO SALMSON Pumps Ltd.

DE14 2WJ Burton-on-Trent

T +44 1283 523000

F +44 1283 523099

sales@wilo.co.uk

Greece

WILO Hellas AG

14569 Anixi (Attika)

T +30 10 6248300

F +30 10 6248360

wilo.info@wilo.gr

Hungary

WILO Magyarország Kft

1144 Budapest XIV

T +36 1 46770-70 Sales Dep.

46770-80 Tech. Serv.

F +36 1 4677089

wilo@wilo.hu

Ireland

WILO Engineering Ltd.

Limerick

T +353 61 227566

F +353 61 229017

sales@wilo.ie

Italy

WILO Italia s.r.l.

20068 Peschiera Borromeo

(Milano)

T +39 02 5538351

F +39 02 55303374

wilo.italia@wilo.it

Kazakhstan

TOO WILO Central Asia

480100 Almaty

T +7 3272 507333

F +7 3272 507332

info@wilo.kz

Korea

WILO Industries Ltd.

137-818 Seoul

T +82 2 34716600

F +82 2 34710232

wilo@wilo.co.kr

Latvia

WILO Baltic SIA

1019 Riga

T +371 7 145229

F +371 7 145566

mail@wilo.lv

Lebanon

WILO SALMSON

Lebanon s.a.r.l.

12022030 El Metn

T +961 4 722280

F +961 4 722285

wsl@cyberia.net.lb

Lithuania

UAB WILO Lietuva

03202 Vilnius

T +370 2 236495

F +370 2 236495

mail@wilo.lt

The Netherlands

WILO Nederland b.v.

1948 RC Beverwijk

T +31 251 220844

F +31 251 225168

wilo@wilo.nl

Norway

WILO Norge A/S

0901 Oslo

T +47 22 804570

F +47 22 804590

wilo@wilo.no

Poland

WILO Polska Sp. z.o.o.

05-090 Raszyn k/Warszawy

T +48 22 7201111

F +48 22 7200526

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

Portugal

4050-040 Porto

T +351 22 2080350

F +351 22 2001469

bombas@wilo-salmson.pt

Romania

WILO Romania s.r.l.

7000 Bucuresti

T +40 21 4600612

F +40 21 4600743

wilo@wilo.ro

Russia

WILO Rus o.o.o.

123592 Moskau

T +7 095 7810690

F +7 095 7810691

wilo@orc.ru

Serbia & Montenegro

WILO Beograd d.o.o.

11000 Beograd

T +381 11 765871

F +381 11 3292306

dragan.simonovic@wilo.co.yu

Slovakia

WILO Slovakia s.r.o.

82008 Bratislava 28

T +421 2 45520122

F +421 2 45246471

wilo@wilo.sk

Slovenia

WILO Adriatic d.o.o.

1000 Ljubljana

T +386 1 5838130

F +386 1 5838138

detlef.schilla@wilo.si

Spain

WILO Ibérica S.A.

28806 Alcalá de Henares

(Madrid)

T +34 91 8797100

F +34 91 8797101

wilo.iberica@wilo.es

Sweden

WILO Sverige AB

35033 Växjö

T +46 470 727600

F +46 470 727644

wilo@wilo.se

Switzerland

EMB Pumpen AG

4310 Rheinfelden

T +41 61 8368020

F +41 61 8368021

info@emb-pumpen.ch

Turkey

WILO Pompa Sistemleri

San. ve Tic. A.S¸.

34530 Istanbul

T +90 216 6610211

F +90 216 6610214

wilo@wilo.com.tr

Ukraina

WILO Ukraina t.o.w.

01033 Kiew

T +38 044 2011870

F +38 044 2011877

wilo@wilo.ua

USA

WILO USA LLC

Calgary, Alberta T2A5L4

T +1 403 2769456

F +1 403 2779456

blowe@wilo-na.com

Page 14

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Germany

T 0231 4102-0

F 0231 4102-7363

wilo@wilo.de

www.wilo.de

G1 Nord

WILO AG

Ver triebsbüro Hamburg

Sinstorfer Kirchweg 74–92

21077 Hamburg

T 040 5559490

F 040 55594949

G2 Ost

WILO AG

Ver triebsbüro Berlin

Juliusstraße 52–53

12051 Berlin-Neukölln

T 030 6289370

F 030 62893770

G3 Sachsen/Thüringen

WILO AG

Ver triebsbüro Dresden

Frankenring 8

01723 Kesselsdorf

T 035204 7050

F 035204 70570

G4 Südost

WILO AG

Ver triebsbüro München

Landshuter Straße 20

85716 Unterschleißheim

T 089 4200090

F 089 42000944

G5 Südwest

WILO AG

Ver triebsbüro Stuttgart

Hertichstraße 10

71229 Leonberg

T 07152 94710

F 07152 947141

G6 Rhein-Main

WILO AG

Ver triebsbüro Frankfurt

An den drei Hasen 31

61440 Oberursel/Ts.

T 06171 70460

F 06171 704665

G7 West

WILO AG

Ver triebsbüro Düsseldorf

Hans-Sachs-Straße 4

40721 Hilden

T 02103 90920

F 02103 909215

G8 Nordwest

WILO AG

Ver triebsbüro Hannover

Ahrensburger Straße 1

30659 Hannover-Lahe

T 0511 438840

F 0511 4388444

Zentrale Auftragsbearbeitung

für den Fachgroßhandel

WILO AG

Auftragsbearbeitung

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-0

F 0231 4102-7555

Wilo-Kompetenz-Team

–Antworten auf alle Fragen

rund um das Produkt,

Lieferzeiten, Versand,

Verkaufspreise

–Abwicklung Ihrer Aufträge

–Ersatzteilbestellungen – mit

24-Stunden-Lieferzeit

für alle gängigen

Ersatzteile

–Versand von

Informationsmaterial

T 01805 R•U•F•W•I•L•O*

7•8•3•9•4•5•6

F 0231 4102-7666

Werktags erreichbar

von 7–18 Uhr

Wilo-Kundendienst

WILO AG

Wilo-Service-Center

Nortkirchenstraße 100

44263 Dortmund

–Kundendienststeuerung

–Wartung und Inbetriebnahme

–Werksreparaturen

–Ersatzteilberatung

T 01805 W•I•L•O•K•D*

9•4•5•6•5•3

0231 4102-7900

F 0231 4102-7126

Werktags erreichbar von

7–17 Uhr, ansonsten

elektronische Bereitschaft mit

Rückruf-Garantie!

Wilo-International

Österreich

Zentrale Wien:

WILO Handelsgesellschaft mbH

Eitnergasse 13

1230 Wien

T +43 1 25062-0

F +43 1 25062-15

Ver triebsbüro Salzburg:

Gnigler Straße 56

5020 Salzburg

T +43 662 8716410

F +43 662 878470

Ver triebsbüro Oberösterreich:

Trattnachtalstraße 7

4710 Grieskirchen

T +43 7248 65051

F +43 7248 65054

Schweiz

EMB Pumpen AG

Gerstenweg 7

4310 Rheinfelden

T +41 61 8368020

F +41 61 8368021

Standorte weiterer

Tochtergesellschaften

Belarus, Belgien, Bulgarien, China,

Dänemark, Finnland, Frankreich,

Griechenland, Großbritannien,

Irland, Italien, Kanada,

Kasachstan, Korea, Libanon,

Litauen, Lettland, Niederlande,

Norwegen, Polen, Rumänien,

Russland, Schweden, Serbien &

Montenegro, Slowakei,

Slowenien, Spanien, Tschechien,

Türkei, Ukraine, Ungarn

Die Adressen finden Sie unter

www.wilo.de oder

www.wilo.com.

Stand März 2005

* 12 Cent pro Minute

Wilo-Vertriebsbüros

Loading...

Loading...