Page 1

Pioneering for You

Wilo-HiMulti 3 (P)

de Einbau- und Betriebsanleitung

en Installation and operating instructions

fr Notice de montage et de mise en service

nl Inbouw- en bedieningsvoorschriften

es Instrucciones de instalación y funcionamiento

it Istruzioni di montaggio, uso e manutenzione

pt Manual de Instalação e funcionamento

el Οδηγίεςεγκατάστασηςκαιλειτουργίας

4 197 437-Ed.03 / 2015-10-Wilo

tr Montajvekullanmakılavuzu

sv Monterings- och skötselanvisning

pl Instrukcjamontażuiobsługi

ru Инструкцияпомонтажуиэксплуатации

bg Инструкциязамонтажиексплоатация

ro Instrucţiunidemontajşiexploatare

uk Iнструкціязмонтажутаексплуатації

Page 2

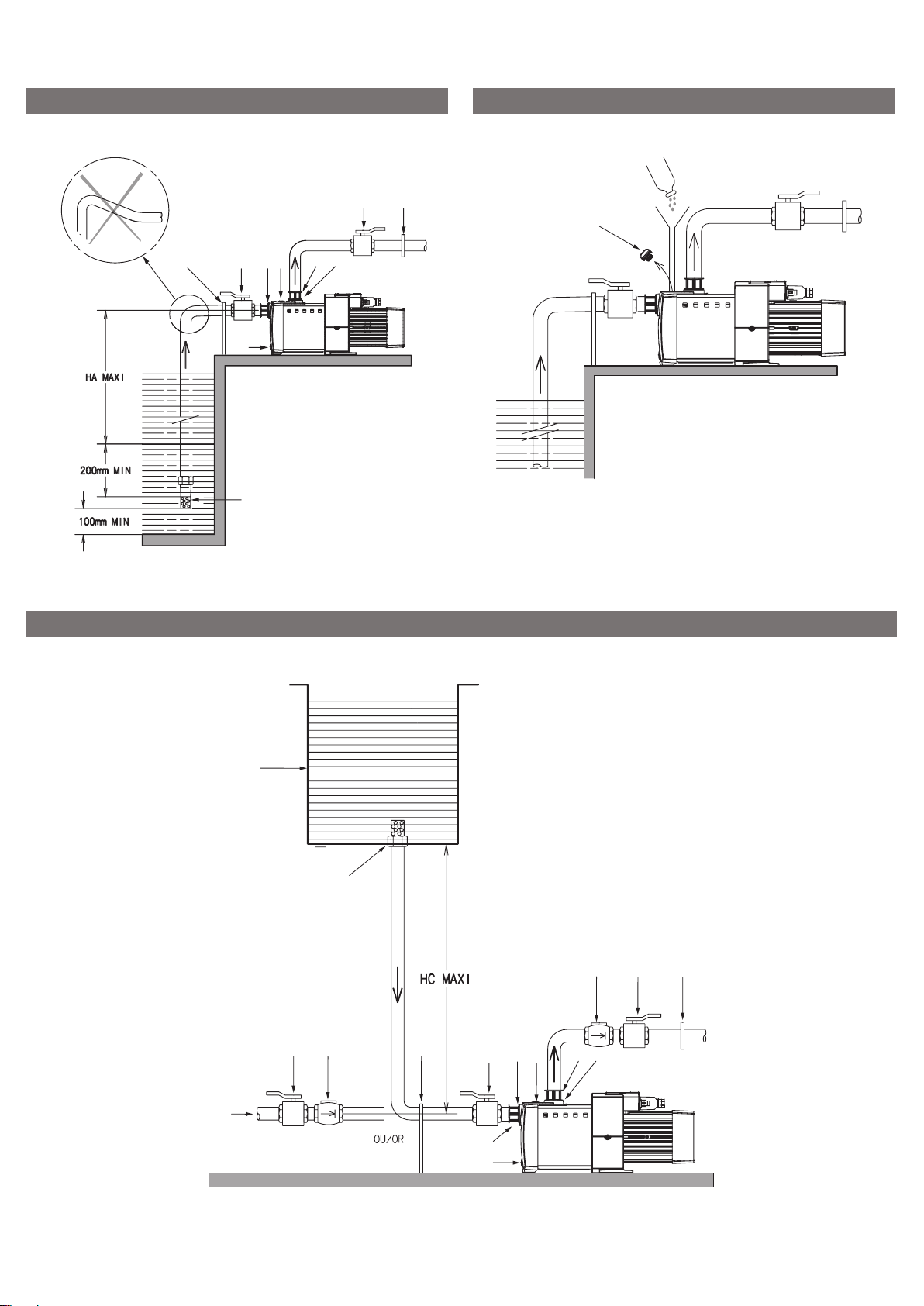

Fig. 1

1

2

5

37

6

7

11

12

11 12

٥

Fig. 2

Fig. 3

9

8

4

24

7

2

12

5

11 12

37

10

11

6

Page 3

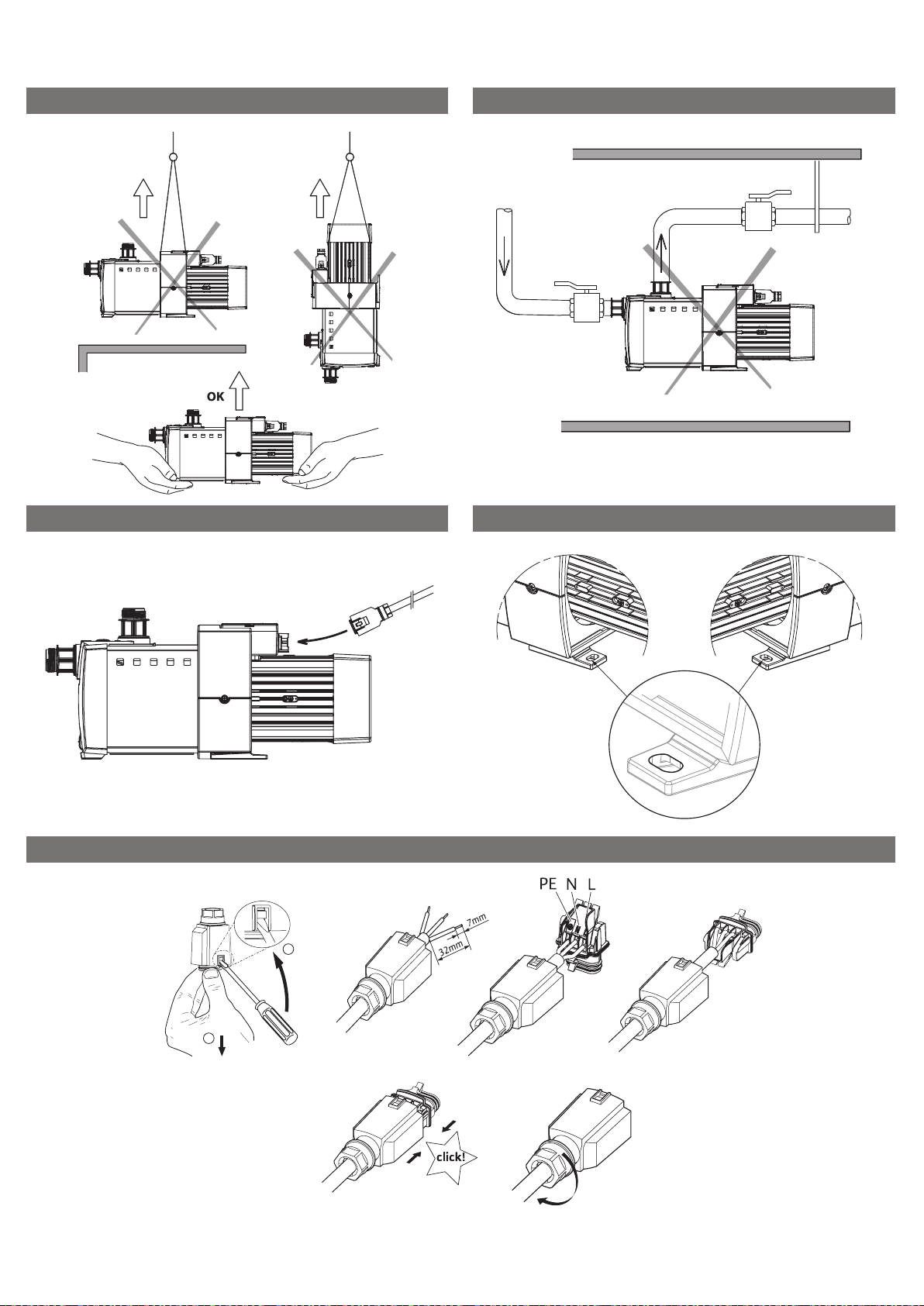

Fig. 4

Fig. 5

Fig. 6

Fig. 8

Fig. 7

23

1

41

2

56

Page 4

Fig. 1

11

1112

Fig. 9

Page 5

English

1. General

1.1 About this document

The language of the original operating instructions is English. All other languages of these

instructions are translations of the original operating instructions.

These installation and operating instructions are

an integral part of the product. They must be kept

readily available at the place where the product is

installed. Strict adherence to these instructions

is a precondition for the proper use and correct

operation of the product.

These installation and operating instructions correspond to the relevant version of the product and

the underlying safety standards valid at the time

of going to print.

EC declaration of conformity:

A copy of the EC declaration of conformity is a

component of these operating instructions.

If a technical modification is made on the designs

named there without our agreement, this declaration loses its validity.

2. Safety

These installation and operating instructions contain important information which must be adhered

to during installation, operation and maintenance.

For this reason, these instructions must, without

fail, be read by the service technician and the

responsible specialist/operator before installation

and commissioning.

It is not only the general safety instructions listed under the main point “safety” that must be

adhered to but also the special safety instructions

with danger symbols included under the following

main points.

2.1 Symbols and signal words in the operating

instructions

Symbols

General danger symbol

Danger due to electrical voltage

NOTE: ...

NOTE:

Useful information on handling the product. It

draws attention to possible problems.

Information that appears directly on the product,

such as.

• Direction of rotation arrow

• Marks identifying connections

• Rating plate

• Warning stickers

must be strictly complied with and kept in legible

condition.

2.2 Personnel qualifications

The installation, operating and maintenance personnel must have the appropriate qualifications

for this work. Area of responsibility, terms of

reference and monitoring of the personnel are to

be ensured by the operator. If the personnel are

not in possession of the necessary knowledge,

they are to be trained and instructed. This can be

accomplished if necessary by the manufacturer of

the product at the request of the operator.

2.3 Danger in the event of non-observance of the

safety instructions

Non-observance of the safety instructions can

result in risk of injury to persons and damage

to the environment and the product/unit. Nonobservance of the safety instructions results

in the loss of any claims to damages. In detail,

non-observance can, for example, result in the

following risks:

• Danger to persons from electrical, mechanical

and bacteriological influences

• Damage to the environment due to leakage of

hazardous materials

• Property damage

• Failure of important product/unit functions

• Failure of required maintenance and repair procedures.

2.4 Safety consciousness on the job

The existing directives for accident prevention

must be adhered to.

Danger from electrical current must be eliminated. Local directives or general directives [e.g.

IEC, VDE etc.] and instructions from local energy

supply companies must be adhered to.

Signal words:

DANGER!

Actuely dangerous situation.

Non-observance results in death or the most

serious of injuries.

WARNING!

The user can suffer (serious) injuries. “Warning”

implies that (serious) injury to persons is probable if this information is disregarded.

CAUTION!

There is a risk of damaging the product/unit.

“Caution” implies that damage to the product

is likely if this information is disregarded.

12 WILO SE 10/2015

2.5 Safety instructions for the operator

This appliance is not intended for use by persons

(including children) with reduced physical, sen-

sory or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that

they do not play with the appliance.

• If hot or cold components on the product/the

unit lead to hazards, local measures must be

taken to guard them against touching.

• Guards protecting against touching moving

components (such as the coupling) must not be

Page 6

English

removed whilst the product is in operation.

• Leakages (e.g. from the shaft seals) of hazardous

fluids (which are explosive, toxic or hot) must be

led away so that no danger to persons or to the

environment arises.

National statutory provisions are to be complied

with.

2.6 Safety instructions for installation and maintenance work

The operator must ensure that all maintenance

and installation work is carried out by authorised and qualified personnel, who are sufficiently

informed from their own detailed study of the

installation and operating instructions. Work on

the product/unit must only be carried out when

at a standstill. It is mandatory that the procedure described in the installation and operating

instructions for shutting down the product/unit

be complied with.

Immediately on conclusion of the work, all safety

and protective devices must be put back in position and/or recommissioned.

2.7 Unauthorised modification and manufacture of

spare parts

Unauthorised modification and manufacture of

spare parts will impair the safety of the product/

personnel and will make void the manufacturer’s

declarations regarding safety.

Modifications to the product are only permissible

after consultation with the manufacturer.

Original spare parts and accessories authorised by

the manufacturer ensure safety. The use of other

parts will absolve us of liability for consequential

events.

2.8 Improper use

The operating safety of the supplied product is

only guaranteed for conventional use in accordance with Section 4 of the installation and operating instructions.

The limit values must on no account fall under

or exceed those specified in the catalogue/data

sheet.

3. Transport and intermediate storage

4. Application

Pumps designed for pumping and pressure

boosting of clean water or lightly contaminated

water in the residential and agricultural sectors

and other sectors.

Water supply from a well, cistern, other static

water supply, municipal water mains etc. for the

purposes of irrigation, sprinkling, pressure boosting etc…

DANGER! Risk of explosion!

Do not use this pump to convey flammable or

explosive liquids.

5. Technical data

5.1 Data table

Hydraulic data

Maximum operating pressure 8 bar (8 x 10

Minimum suction pressure 0,2 bar (0,2 x 10

Maximum suction pressure 3 bar (3 x 10

Maximum altitude 1000 m

Geodetic suction head 8 m max.

DN of suction connection 1“

DN of pressure connection 1“

Temperature range

Fluid temperature range +5°C to +40°C

Ambient temperature max. +40 °C

Electrical data

Motor protection rating IP X4

Insulation class 155

Frequency

Voltage:

See pump cladding

Other

Max. sound level 63 dB(A)

5.2 Included in delivery

• Multistage horizontal pump

• Male electrical connector

• 2 connections (depending on model)

• 2 gaskets (depending on model)

• Operating manual

5

5

Pa)

Pa)

5

Pa)

When you receive the equipment, check that it

has not been damaged during transport. If you

notice a fault, take all necessary action with the

carrier within the time allowed.

CAUTION! Storage environment may cause

damage.

If the equipment is to be installed at a later date,

store it in a dry place and protect it from impacts

and any external stresses (humidity, frost etc.).

Temperature range for transport and storage:

-30°C to +60°C

Handle the pump with care so as not to damage

the product before installation.

13WILO SE 10/2015

Page 7

English

6. Products and functions

6.1 Key to drawings (Fig. 1 and 3)

1 - Suction strainer foot valve

2 - Pump suction valve

3 - Pump discharge valve

4 - Non-return valve

5 - Priming plug

6 - Drain plug

7 - Pipework supports

8 - Suction strainer

9 - Replenishment reservoir

10 - Municipal water mains

11 - Connection

12 - Gasket

HA - Negative suction head (suction mode)

HC - Positive suction head (inlet mode)

6.2 The pump

Multistage horizontal centrifugal pump,

self-priming or non-self-priming depending on

the model.

Shaft sealing by standardised, maintenance-free

mechanical seal.

6.3 The motor

Glanded, single-phase, 2-pole motor, 50 or 60Hz

depending on the model: capacitor in the termi-

nal box, motor protection switch with automatic

reset.

• Protection rating: IP X4 (with installed male electrical connector)

• Insulation class: 155

Frequency 50 Hz 60 Hz

Speed (RPM)) 2900 3500

Voltage 1~

6.4 Accessories

• Suction kit • gate valves • non-return valves

• suction strainer foot valve • pressure tank •

anti-vibration bushings • motor protection circuit breaker • protection against low water level •

automatic on/off control.

230V

(±10%)

220V (-10%) -

240V (+6%)

7. Installation and connections

All installation and electrical connection work

must be carried out solely by authorised and

qualified personnel, in accordance with applicable regulations!

WARNING! Physical injuries!

The applicable regulations for the prevention of

accidents must be complied with.

7.1 Upon receipt of the product

• Unpack the pump and recycle or dispose of the

packaging in an environmentally responsible

manner.

• Handling (Fig. 4).

7.2 Installation

Two standard types (Fig. 1 and 3)

Pump in suction mode

Pump in inlet mode connected to replenishment

reservoir (item 9) or municipal water mains (item 10).

• The pump must be installed in a dry, well-ventilated location free of frost.

CAUTION! Risk of damage to the pump!

The presence of foreign matter or impurities in

the pump housing may affect the

functioning of the product.

• We recommend carrying out all soldering and

brazing work before installing the pump.

• Rinse the circuit completely before installing and

commissioning the pump.

• Remove the blanking caps on the pump housing

before installation.

• The pump must be installed in a place easy to

reach, protected against frost and as close as

possible to the drawing point.

• To ensure access to the motor fan, allow a minimum distance of at least 0.3 m from the wall

behind the unit.

• Install the pump on a smooth and horizontal surface.

• Secure the pump through 2 oblong holes on the

pedestal bearing (for Ø M8 fasteners) Fig. 7.

• Bear in mind that the altitude of the installation

site and the water temperature may reduce the

suction capacity of the pump.

Altitude Loss of head Temperature Loss of head

0 m 0 m head 20°C 0,20 m head

500 m 0,60 m head 20°C 0,20 m head

1000 m 1,15 m head 20°C 0,20 m head

1500 m 1,70 m head

2000 m 2,20 m head

2500 m 2,65 m head

3000 m 3,20 m head

WARNING!

The pump must be installed in such a way that

no one can touch the hot surfaces of the product

when it is in operation.

NOTE: As the pump may have been tested in the

factory, there may be some residual water in the

product. We recommend rinsing the pump.

7.3 Hydraulic connections

General connection instructions

• Screw the 2 connections manually (item 11) and

gasket (item 12) (depending on model) Fig. 9.

• Use flexible, braid-reinforced hose piping or rigid

piping.

• The pump must not bear the weight of the pipes

Fig. 5.

• Seal the piping well using appropriate products.

• Install a system of protection against low water

level to prevent dry running of the pump.

• Limit the length of the piping and avoid all fea-

14 WILO SE 10/2015

Page 8

English

tures that cause friction loss (tapers, elbows,

buckling etc.).

Suction connections

• The diameter of the suction pipe must never be

less than the port on the pump.

Furthermore, for pumps of the series 4 m³/h

which have negative suction head (HA) greater

than 6 m, we recommend piping of a diameter

greater than the nominal diameter (DN) of the

pump in order to limit friction loss.

• In the case of negative suction head, the pump

must be the highest point of the installation and

the suction piping must always be on a rising

gradient from the extraction point to the pump,

in order to prevent air bubbles forming in the

suction pipe.

• Air must not be allowed to enter the suction

piping while the pump is in operation.

• Installing a suction strainer (max. cross-section

of holes: 2 mm) prevents damage to the pump

from the intake of particles.

• If the pump is installed with negative suction

head: submerge the suction strainer (min. 700

mm). Ballast the flexible hose piping if necessary.

7.4 Electrical connection

WARNING! Risk of electric shock!

Danger from electrical current must be eliminated.

• Have all electrical work carried out by a qualified

electrician only!

• Before any electrical connection is made, the

pump must be de-energised (switched off) and

protected against unauthorised restarting.

• To ensure safe installation and operation, the

unit must be earthed correctly with the earth terminals of the power supply.

CAUTION! An error in the electrical connection

will damage the motor.

The power cable must never touch the piping

or the pump, and must be kept away from any

moisture.

• See the motor’s rating plate for its electrical

characteristics (frequency, voltage, current).

• The single-phase motor of this pump has an

integrated motor protection switch.

• Power supply: use a cable conforming with applicable standards (3 cores: 2 phases + earth):

H05RN-F 3 G 1.5 minimum

H05RN-F 3 G 2.5 maximum

• A damaged cable or connector must be replaced

by the corresponding part available from the

manufacturer or the manufacturer’s customer

service.

• The electrical connections must be established

by following the assembly diagram for the quick

connector (Fig. 8) and connecting it to the pump

(Fig. 6).

8. Commissioning

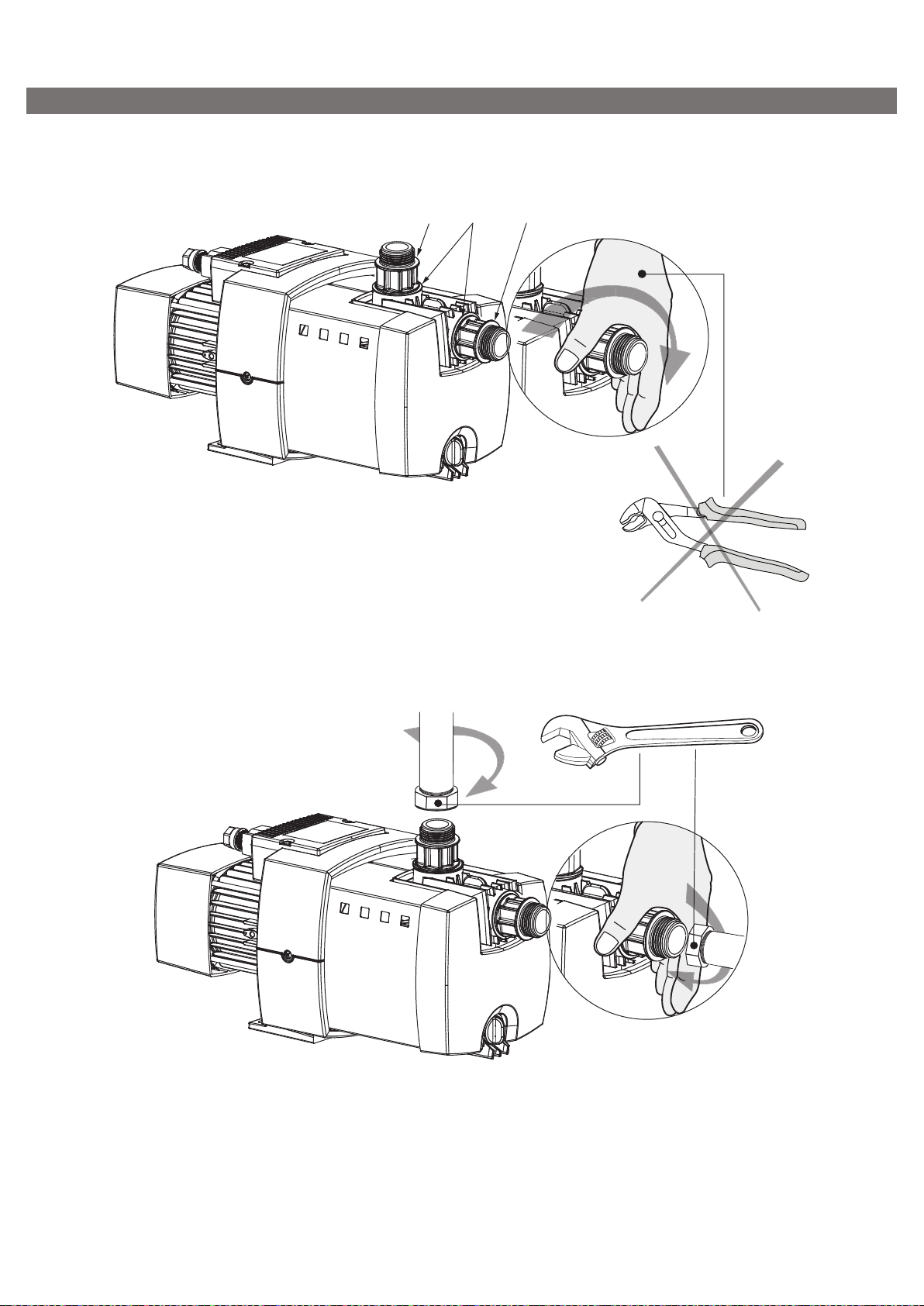

8.1 Filling – venting

CAUTION! Risk of damage to the pump.

Never operate the pump dry, even briefly.

The system must be filled before starting the

pump.

Pump in inlet mode (Fig. 3)

• Close the discharge valve (item 3).

• Unscrew the priming plug slightly (item 5).

• Gradually open the suction valve (item 2) and

completely fill the pump.

• Open the discharge valve (item 3).

• Do not close the priming plug until water flows

out and all air has been released.

Pump in suction mode (Fig. 2)

• Make sure that all the accessories connected to

the pump pressure connection are open (taps,

valves, watering hose nozzles).

• Open the discharge valve (item 3).

• Open the suction valve (item 2).

• Unscrew the priming plug (item 5) on the pump

housing.

• Completely fill the pump and the suction pipe,

which must be fitted with a foot valve.

• Screw back in the priming plug (item 5).

• Activate the pump for a few seconds using the

on/off switch. After stopping it again, unscrew

the plug and add water to finish completely filling the pump.

• If the suction head is greater than 6 m, hold the

pressure pipe in a vertical position to a height

of at least 500 mm until the pump is primed, in

order to prevent the water from escaping from

the pump through the pressure pipe.

8.2 Checking the direction of rotation of the motor

The single-phase motors are designed to function

in the correct direction of rotation.

8.3 Starting

CAUTION! The pump must not operate at zero

flow (discharge valve closed) for more than 10

minutes.

WARNING! Risk of burns!

Zero flow operation causes the water temperature to rise.

To prevent formation of an air pocket, we recommend ensuring a minimum flow equal to or

greater than about 15% of the rated flow rate of

the pump.

• Open the discharge valve.

• Switch on power to the pump and start it up by

pressing the on/off switch (the indicator light will

switch on).

• In the case of a self-priming pump, if the suction

pipe has not been filled completely, starting may

take a few minutes (keep the discharge valve

open).

15WILO SE 10/2015

Page 9

English

• If the water does not come out after 3 minutes,

stop the pump and repeat the filling procedure.

• Once the pump has started, close the discharge

valve completely and then reopen it to ensure

that the maximum pump curve is reached; this is

reached with the priming valve closed.

• Check that the current consumed is less than or

equal to that indicated on the motor plate.

9. Maintenance

All maintenance work must be carried out by

authorised and qualified personnel!

WARNING! Risk of electric shock!

Danger from electrical current must be eliminated.

Before any electrical work, the pump must be

de-energised (switched off) and protected

against unauthorised restarting.

It is recommended to the disconnect the plug

rather than the male electrical connector (IPX4

preservation).

• No special maintenance required during operation.

• Keep the pump clean.

• If the pump is deactivated for a long period and

there is no risk of freezing, it is best not to drain

the pump.

• To prevent the shaft and the hydraulic components from seizing up during periods of freezing

temperatures, drain the pump by removing the

plug (item 6) and the priming plug (item 5).

Screw back in the 2 plugs but do not tighten

them. Fill the pump and the piping before using

again.

NOTE: We recommend rinsing the pump after a

long period of deactivation.

16 WILO SE 10/2015

Page 10

10. Faults, causes and remedies

English

WARNING! Risk of electric shock!

Before any work on the pump, DE-ENERGISE the

pump by turning off the on/off switch and disconnecting the electrical supply to the pump, and

prevent unauthorised restarting. The indicator

Faults Causes Remedies

The pump is turning but

there is no output flow

The pump is vibrating Not fastened tightly to its foundation Check and fully tighten the nuts on the

The motor is heating up

excessively

The pump is not turning

The pump is not delivering

adequate pressure

The output flow is

irregular

The internal parts are obstructed by

foreign matter

Obstruction in the suction piping Clean the entire piping

Air entering via the suction piping Check for leaks in the entire pipe up to

The pump is not full of water Prime the pump again by filling it

Suction pressure is too low, and suction

is usually accompanied by cavitation

noise

The pump is rotating in reverse Contact customer service

The voltage of the power supply to the

pump is too low

The suction strainer is not submerged Submerge the suction strainer (at least

Foreign matter in the pump Dismantle the pump and clean it

Difficult rotation of the pump Check that the pump can turn freely

Poor electrical connection Check the electrical connections

Insufficient voltage Check that the voltage is in accordance

Pump obstructed by foreign matter Dismantle the pump and clean it

Ambient temperature greater than

+ 40°C

No electrical power Check the power supply

Pump blocked Clean the pump

The sensor on the motor protection

switch has tripped

The motor is faulty Replace it

The motor is not turning at its normal

speed (foreign matter, poor power supply to motor, …)

The motor is rotating in reverse Contact customer service

Wear on the internal parts of the pump Replace them

The negative suction head (HA) is not as

required

The diameter of the suction piping is

less than that of the pump

The suction strainer or the suction piping is partially obstructed

light being off does not mean that the pump is

de-energised.

It is recommended to the disconnect the plug

rather than the male electrical connector (IPX4

preservation).

Dismantle the pump and clean it

the pump and seal any leaks found

Too much friction loss on the suction side

or the negative suction head is too great.

Modify the installation accordingly

Check the voltage of the power supply

700 mm).

Ballast the flexible hose piping if necessary

anchor bolts

without any abnormal resistance (with

the motor stopped)

with section 4.3

The motor is designed to function at a

maximum ambient temperature of + 40°C

Allow the motor to cool

Dismantle the pump and remedy the

problem

Review the installation conditions and the

recommendations made in this manual

The piping must have the same diameter

as the suction port on the pump

Dismantle and clean

If you cannot remedy the fault, please

contact WILO customer service.

11. Spare parts

All spare parts should be ordered directly from

WILO customer service.

To prevent errors, always quote the data on the

pump’s rating plate when making an order.

The spare parts catalogue is available at: www.

wilo.com.

Subjet to technical modifications!

17WILO SE 10/2015

Page 11

EG KONFORMITÄTSERKLÄRUNG

F_GQ_013-05

Q

Digital unterschrieben von

holger.herchenhein@wilo.c

om

Datum: 2014.07.21

17:24:34 +02'00'

EC DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE CE

Als Hersteller erklären wir hiermit, dass die Pumpenbauarten der Baureihe

We, the manufacturer, declare that the pump types of the series

Nous, fabricant, déclarons que les types de pompes de la série

(Die Seriennummer ist auf dem Typenschild des Produktes angegeben / The serial number

HiMulti 3

in der gelieferten Ausführung folgenden einschlägigen Bestimmungen entsprechen :

In their delivered state comply with the following relevant directives :

dans leur état de livraison sont conformes aux dispositions des directives suivantes :

_ Niederspannungsrichtlinie 2006/95/EG

_ Low voltage 2006/95/EC

_ Basse tension 2006/95/CE

_ Elektromagnetische Verträglichkeit-Richtlinie 2004/108/EG

_ Electromagnetic compatibility 2004/108/EC

_ Compabilité électromagnétique 2004/108/CE

is marked on the product site plate / Le numéro de série est inscrit sur la plaque

signalétique du produit)

und entsprechender nationaler Gesetzgebung,

and with the relevant national legislation,

et aux législations nationales les transposant,

sowie auch den Bestimmungen zu folgenden harmonisierten europäischen Normen :

comply also with the following relevant harmonized European standards :

sont également conformes aux dispositions des normes européennes harmonisées suivantes :

EN 60335-2-41

Dortmund,

H. HERCHENHEIN

Group

N°2117915.01

(CE-A-S n°4192843)

uality Manager

WILO SE

Nortkirchenstraβe 100

44263 Dortmund - Germany

Page 12

(BG) - български език (CS) - Čeština

5

ДЕКЛАРАЦИЯ ЗА СЪОТЕТСТВИЕ EO ES PROHLÁŠENÍ O SHODĚ

WILO SE декларират, че продуктите посочени в настоящата декларация

съответстват на разпоредбите на следните европейски директиви и

приелите ги национални законодателства:

Hиско Hапрежение 2006/95/ЕО ; Електромагнитна съвместимост

2004/108/ЕО

както и на хармонизираните европейски стандарти, упоменати на

предишната страница.

WILO SE prohlašuje, že výrobky uvedené v tomto prohlášení odpovídají

ustanovením níže uvedených evropských směrnic a národním právním

předpisům, které je přejímají:

Nízké Napětí 2006/95/ES ; Elektromagnetická Kompatibilita 2004/108/ES

a rovněž splňují požadavky harmonizovaných evropských norem uvedených

na předcházející stránce.

(DA) - Dansk (EL) - Ελληνικά

EF-OVERENSSTEMMELSESERKLÆRING ∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ EK

WILO SE erklærer, at produkterne, som beskrives i denne erklæring, er i

overensstemmelse med bestemmelserne i følgende europæiske direktiver,

samt de nationale lovgivninger, der gennemfører dem:

Lavspændings 2006/95/EF ; Elektromagnetisk Kompatibilitet 2004/108/EF Χαμηλής Tάσης 2006/95/ΕΚ ; Ηλεκτρομαγνητικής συμβατότητας 2004/108/ΕΚ

De er ligeledes i overensstemmelse med de harmoniserede europæiske

standarder, der er anført på forrige side.

WILO SE δηλώνει ότι τα προϊόντα που ορίζονται στην παρούσα ευρωπαϊκά

δήλωση είναι σύμφωνα με τις διατάξεις των παρακάτω οδηγιών και τις εθνικές

νομοθεσίες στις οποίες έχει μεταφερθεί:

και επίσης με τα εξής εναρμονισμένα ευρωπαϊκά πρότυπα που αναφέρονται

στην προηγούμενη σελίδα.

(ES) - Español (ET) - Eesti keel

DECLARACIÓN CE DE CONFORMIDAD EÜ VASTAVUSDEKLARATSIOONI

WILO SE declara que los productos citados en la presenta declaración están

conformes con las disposiciones de las siguientes directivas europeas y con

las legislaciones nacionales que les son aplicables :

Baja Tensión 2006/95/CE ; Compatibilidad Electromagnética 2004/108/CE Madalpingeseadmed 2006/95/EÜ ; Elektromagnetilist Ühilduvust 2004/108/EÜ

Y igualmente están conformes con las disposiciones de las normas europeas

armonizadas citadas en la página anterior.

WILO SE kinnitab, et selles vastavustunnistuses kirjeldatud tooted on

kooskõlas alljärgnevate Euroopa direktiivide sätetega ning riiklike

seadusandlustega, mis nimetatud direktiivid üle on võtnud:

Samuti on tooted kooskõlas eelmisel leheküljel ära toodud harmoniseeritud

Euroopa standarditega.

(FI) - Suomen kieli (HR) - Hrvatski

EY-VAATIMUSTENMUKAISUUSVAKUUTUS EZ IZJAVA O SUKLADNOSTI

WILO SE vakuuttaa, että tässä vakuutuksessa kuvatut tuotteet ovat

seuraavien eurooppalaisten direktiivien määräysten sekä niihin sovellettavien

kansallisten lakiasetusten mukaisia:

Matala Jännite 2006/95/EY ; Sähkömagneettinen Yhteensopivuus 2004/108/EY

Lisäksi ne ovat seuraavien edellisellä sivulla mainittujen yhdenmukaistettujen

eurooppalaisten normien mukaisia.

WILO SE izjavljuje da su proizvodi navedeni u ovoj izjavi u skladu sa

sljedećim prihvaćenim europskim direktivama i nacionalnim zakonima:

Smjernica o niskom naponu 2006/95/EZ ; Elektromagnetna kompatibilnost smjernica 2004/108/EZ

i usklađenim europskim normama navedenim na prethodnoj stranici.

(HU) - Magyar (IT) - Italiano

EK-MEGFELELŐSÉGI NYILATKOZAT DICHIARAZIONE CE DI CONFORMITÀ

WILO SE kijelenti, hogy a jelen megfelelőségi nyilatkozatban megjelölt

termékek megfelelnek a következő európai irányelvek előírásainak, valamint

azok nemzeti jogrendbe átültetett rendelkezéseinek:

Alacsony Feszültségű 2006/95/EK ; Elektromágneses összeférhetőségre

2004/108/EK

valamint az előző oldalon szereplő, harmonizált európai szabványoknak. E sono pure conformi alle disposizioni delle norme europee armonizzate citate

WILO SE dichiara che i prodotti descritti nella presente dichiarazione sono

conformi alle disposizioni delle seguenti direttive europee nonché alle

legislazioni nazionali che le traspongono :

Bassa Tensione 2006/95/CE ; Compatibilità Elettromagnetica 2004/108/CE

a pagina precedente.

(LT) - Lietuvių kalba (LV) - Latviešu valoda

EB ATITIKTIES DEKLARACIJA EK ATBILSTĪBAS DEKLARĀCIJU

WILO SE pareiškia, kad šioje deklaracijoje nurodyti gaminiai atitinka šių

Europos direktyvų ir jas perkeliančių nacionalinių įstatymų nuostatus:

Žema įtampa 2006/95/EB ; Elektromagnetinis Suderinamumas 2004/108/EB Zemsprieguma 2006/95/EK ; Elektromagnētiskās Saderības 2004/108/EK

ir taip pat harmonizuotas Europas normas, kurios buvo cituotos ankstesniame

puslapyje.

WILO SEdeklarē, ka izstrādājumi, kas ir nosaukti šajā deklarācijā, atbilst šeit

uzskaitīto Eiropas direktīvu nosacījumiem, kā arī atsevišķu valstu likumiem,

kuros tie ir ietverti:

un saskaņotajiem Eiropas standartiem, kas minēti iepriekšējā lappusē.

(MT) - Malti (NL) - Nederlands

DIKJARAZZJONI KE TA’ KONFORMITÀ EG-VERKLARING VAN OVEREENSTEMMING

WILO SE jiddikjara li l-prodotti speċifikati f’din id-dikjarazzjoni huma konformi

mad-direttivi Ewropej li jsegwu u mal-leġislazzjonijiet nazzjonali li

japplikawhom:

Vultaġġ Baxx 2006/95/KE ; Kompatibbiltà Elettromanjetika 2004/108/KE Laagspannings 2006/95/EG ; Elektromagnetische Compatibiliteit 2004/108/EG

kif ukoll man-normi Ewropej armoniżżati li jsegwu imsemmija fil-paġna

preċedenti.

WILO SE verklaart dat de in deze verklaring vermelde producten voldoen aan

de bepalingen van de volgende Europese richtlijnen evenals aan de nationale

wetgevingen waarin deze bepalingen zijn overgenomen:

De producten voldoen eveneens aan de geharmoniseerde Europese normen

die op de vorige pagina worden genoemd.

F_GQ_013-0

99

Page 13

(NO) - Norsk (PL) - Polski

5

EU-OVERENSSTEMMELSESERKLAEING DEKLARACJA ZGODNOŚCI WE

WILO SE erklærer at produktene nevnt i denne erklæringen er i samsvar med

følgende europeiske direktiver og nasjonale lover:

EG–Lavspenningsdirektiv 2006/95/EG ; EG–EMV–Elektromagnetisk

kompatibilitet 2004/108/EG

og harmoniserte europeiske standarder nevnt på forrige side. oraz z nastepującymi normami europejskich zharmonizowanymi podanymi na

WILO SE oświadcza, że produkty wymienione w niniejszej deklaracji są

zgodne z postanowieniami następujących dyrektyw europejskich i

transponującymi je przepisami prawa krajowego:

Niskich Napięć 2006/95/WE ; Kompatybilności Elektromagnetycznej

2004/108/WE

poprzedniej stronie.

(PT) - Português (RO) - Română

DECLARAÇÃO CE DE CONFORMIDADE DECLARAŢIE DE CONFORMITATE CE

WILO SE declara que os materiais designados na presente declaração

obedecem às disposições das directivas europeias e às legislações nacionais

que as transcrevem :

Baixa Voltagem 2006/95/CE ; Compatibilidade Electromagnética 2004/108/CE

E obedecem também às normas europeias harmonizadas citadas na página

precedente.

WILO SE declară că produsele citate în prezenta declaraţie sunt conforme cu

dispoziţiile directivelor europene următoare şi cu legislaţiile naţionale care le

transpun :

Joasă Tensiune 2006/95/CE ; Compatibilitate Electromagnetică 2004/108/CE

şi, de asemenea, sunt conforme cu normele europene armonizate citate în

pagina precedentă.

(RU) - русский язык (SK) - Slovenčina

Декларация о соответствии Европейским нормам ES VYHLÁSENIE O ZHODE

WILO SE заявляет, что продукты, перечисленные в данной декларации о

соответствии, отвечают следующим европейским директивам и

национальным предписаниям:

Директива ЕС по низковольтному оборудованию 2004/95/ЕС ; Директива

ЕС по электромагнитной совместимости 2004/108/ЕС

и гармонизированным европейским стандартам, упомянутым на

предыдущей странице.

WILO SE čestne prehlasuje, že výrobky ktoré sú predmetom tejto deklarácie,

sú v súlade s požiadavkami nasledujúcich európskych direktív a

odpovedajúcich národných legislatívnych predpisov:

Nízkonapäťové zariadenia 2006/95/ES ; Elektromagnetickú Kompatibilitu

2004/108/ES

ako aj s harmonizovanými európskych normami uvedenými na

predchádzajúcej strane.

(SL) - Slovenščina (SV) - Svenska

ES-IZJAVA O SKLADNOSTI EG-FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

WILO SE izjavlja, da so izdelki, navedeni v tej izjavi, v skladu z določili

naslednjih evropskih direktiv in z nacionalnimi zakonodajami, ki jih vsebujejo:

Nizka Napetost 2006/95/ES ; Elektromagnetno Združljivostjo 2004/108/ES

pa tudi z usklajenimi evropskih standardi, navedenimi na prejšnji strani. Det överensstämmer även med följande harmoniserade europeiska standarder

WILO SE intygar att materialet som beskrivs i följande intyg överensstämmer

med bestämmelserna i följande europeiska direktiv och nationella

lagstiftningar som inför dem:

Lågspännings 2006/95/EG ; Elektromagnetisk Kompatibilitet 2004/108/EG

som nämnts på den föregående sidan.

(TR) - Türkçe

CE UYGUNLUK TEYID BELGESI

WILO SEbu belgede belirtilen ürünlerin aşağdaki Avrupa yönetmeliklerine ve

ulusal kanunlara uygun olduğunu beyan etmektedir:

Alçak Gerilim Yönetmeliği 2006/95/AT ; Elektromanyetik Uyumluluk

Yönetmeliği 2004/108/AT

ve önceki sayfada belirtilen uyumlaştrlmş Avrupa standartlarna.

F_GQ_013-0

Page 14

Wilo – International (Subsidiaries)

Argentina

WILO SALMSON

ArgentinaS.A.

C1295ABI Ciudad

Autónoma de Buenos Aires

T+ 54 11 4361 5929

info@salmson.com.ar

Australia

WILO Australia Pty Limited

Murrarrie, Queensland,

4172

T +61 7 3907 6900

chris.dayton@wilo.com.au

Austria

WILO Pumpen

ÖsterreichGmbH

2351 Wiener Neudorf

T +43 507 507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1014 Baku

T +994 12 5962372

info@wilo.az

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2535363

wilo@wilo.by

Belgium

WILO SA/NV

1083Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILOBulgariaLtd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Brazil

WILO Brasil Ltda

Jundiaí – São Paulo – Brasil

ZIPCode:13.213-105

T +55 11 2923 (WILO)

9456

wilo@wilo-brasil.com.br

Canada

WILOCanadaInc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILOChinaLtd.

101300 Beijing

T +86 10 58041888

wilobj@wilo.com.cn

Croatia

WiloHrvatskad.o.o.

10430 Samobor

T +38 51 3430914

wilo-hrvatska@wilo.hr

Czech Republic

WILOCS,s.r.o.

25101Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6 509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILOS.A.S.

78390Boisd‘Arcy

T +33 1 30050930

info@wilo.fr

Great Britain

WILO(U.K.)Ltd.

Burton Upon Trent

DE14 2WJ

T +44 1283 523000

sales@wilo.co.uk

Greece

WILOHellasAG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILOMagyarországKft

2045Törökbálint

(Budapest)

T +36 23 889500

wilo@wilo.hu

India

WILOIndiaMatherand

PlattPumpsLtd.

Pune 411019

T +91 20 27442100

services@matherplatt.com

Indonesia

WILO Pumps Indonesia

Jakarta Selatan 12140

T +62 21 7247676

citrawilo@cbn.net.id

Ireland

WILO Ireland

Limerick

T +353 61 227566

sales@wilo.ie

Italy

WILOItalias.r.l.

20068Peschiera

Borromeo (Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 727 2785961

info@wilo.kz

Korea

WILOPumpsLtd.

618-220Gangseo,Busan

T +82 51 950 8000

wilo@wilo.co.kr

Latvia

WILOBalticSIA

1019 Riga

T +371 6714-5229

info@wilo.lv

Lebanon

WILO LEBANON SARL

Jdeideh12022030

Lebanon

T +961 1 888910

info@wilo.com.lb

Lithuania

WILOLietuvaUAB

03202 Vilnius

T +370 5 2136495

mail@wilo.lt

Morocco

WILO MAROC SARL

20600 CASABLANCA

T + 212 (0) 5 22 66 09

24/28

contact@wilo.ma

The Netherlands

WILONederlandb.v.

1551NAWestzaan

T +31 88 9456 000

info@wilo.nl

Norway

WILO Norge AS

0975 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILOPolskaSp.z.o.o.

05-506Lesznowola

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

PortugalLda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILORomanias.r.l.

077040Com.Chiajna

Jud.Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592Moscow

T +7 495 7810690

wilo@wilo.ru

Saudi Arabia

WILOME-Riyadh

Riyadh11465

T +966 1 4624430

wshoula@wataniaind.com

Serbia and Montenegro

WILOBeogradd.o.o.

11000 Beograd

T +381 11 2851278

office@wilo.rs

Slovakia

WILOCSs.r.o.,org.Zložka

83106Bratislava

T +421 2 33014511

info@wilo.sk

Slovenia

WILOAdriaticd.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

South Africa

SalmsonSouthAfrica

1610Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILOIbéricaS.A.

28806AlcaládeHenares

(Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILOSverigeAB

35246 Växjö

T +46 470 727600

wilo@wilo.se

Switzerland

EMBPumpenAG

4310Rheinfelden

T +41 61 83680-20

info@emb-pumpen.ch

Taiwan

WILOTaiwanCompanyLtd.

SanchongDist.,NewTaipei

City 24159

T +886 2 2999 8676

nelson.wu@wilo.com.tw

Turkey

WILO Pompa Sistemleri

San.veTic.A.S¸.

34956İstanbul

T +90 216 2509400

wilo@wilo.com.tr

Ukraina

WILOUkrainat.o.w.

01033Kiew

T +38 044 2011870

wilo@wilo.ua

United Arab Emirates

WILO Middle East FZE

JebelAliFreeZone–South

PO Box 262720 Dubai

T +971 4 880 91 77

info@wilo.ae

USA

WILO USA LLC

Rosemont, IL 60018

T +1 866 945 6872

info@wilo-usa.com

Vietnam

WILOVietnamCoLtd.

HoChiMinhCity,Vietnam

T +84 8 38109975

nkminh@wilo.vn

Page 15

Pioneering for You

WILO SE

Nortkirchenstraße 100

D-44263 Dortmund

Germany

T +49(0)231 4102-0

F +49(0)231 4102-7363

wilo@wilo.com

www.wilo.com

Loading...

Loading...