Page 1

Pioneering for You

Wilo-Drain STS 65

D Einbau- und Betriebsanleitung

GB Installation and operating instructions

F Notice de montage et de mise en service

E Instrucciones de instalación y funcionamiento

I Istruzioni di montaggio, uso e manutenzione

P Manual de Instalação e funcionamento

GR Οδηγίες εγκατάστασης και λειτουργίας

TR Montaj ve kullanma kılavuzu

S Monterings- och skötselanvisning

FIN Asennus- ja käyttöohje

H Beépítési és üzemeltetési utasítás

2 081 931-Ed.02/2010-06-Kothes!

PL Instrukcja montażu i obsługi

CZ Návod k montáži a obsluze

RUS Инструкция по монтажу и эксплуатации

EST Paigaldus- ja kasutusjuhend

LV Instalēšanas un ekspluatācijas instrukcijas

LT Montavimo ir naudojimo instrukcija

SK Návod na montáž a obsluhu

SLO Navodila za vgradnjo in vzdrževanje

BG Инструкция за монтаж и експлоатация

RO Instrucţiuni de montaj şi exploatare

Page 2

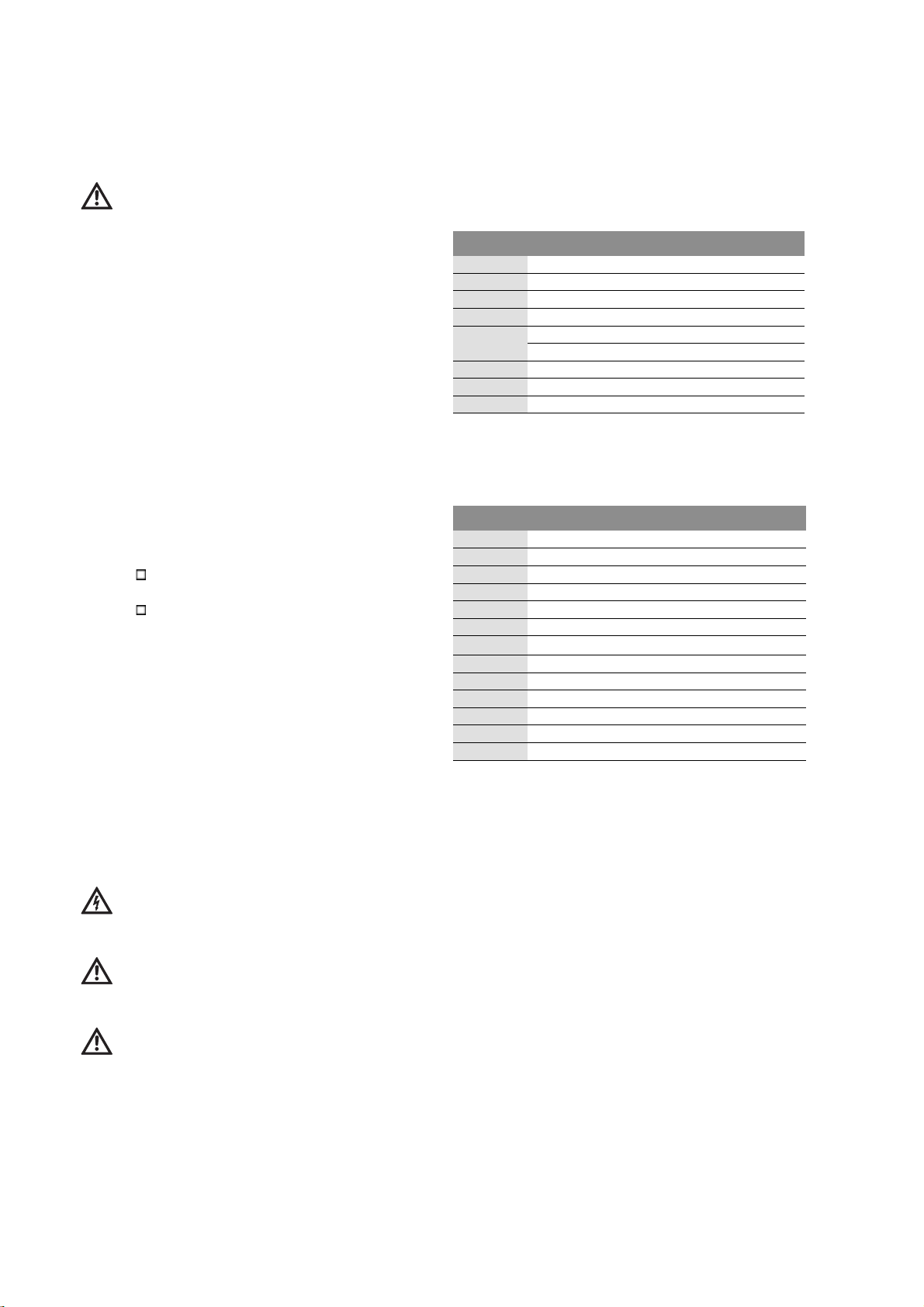

6

min.

min.*

1

4

5

2

3

1

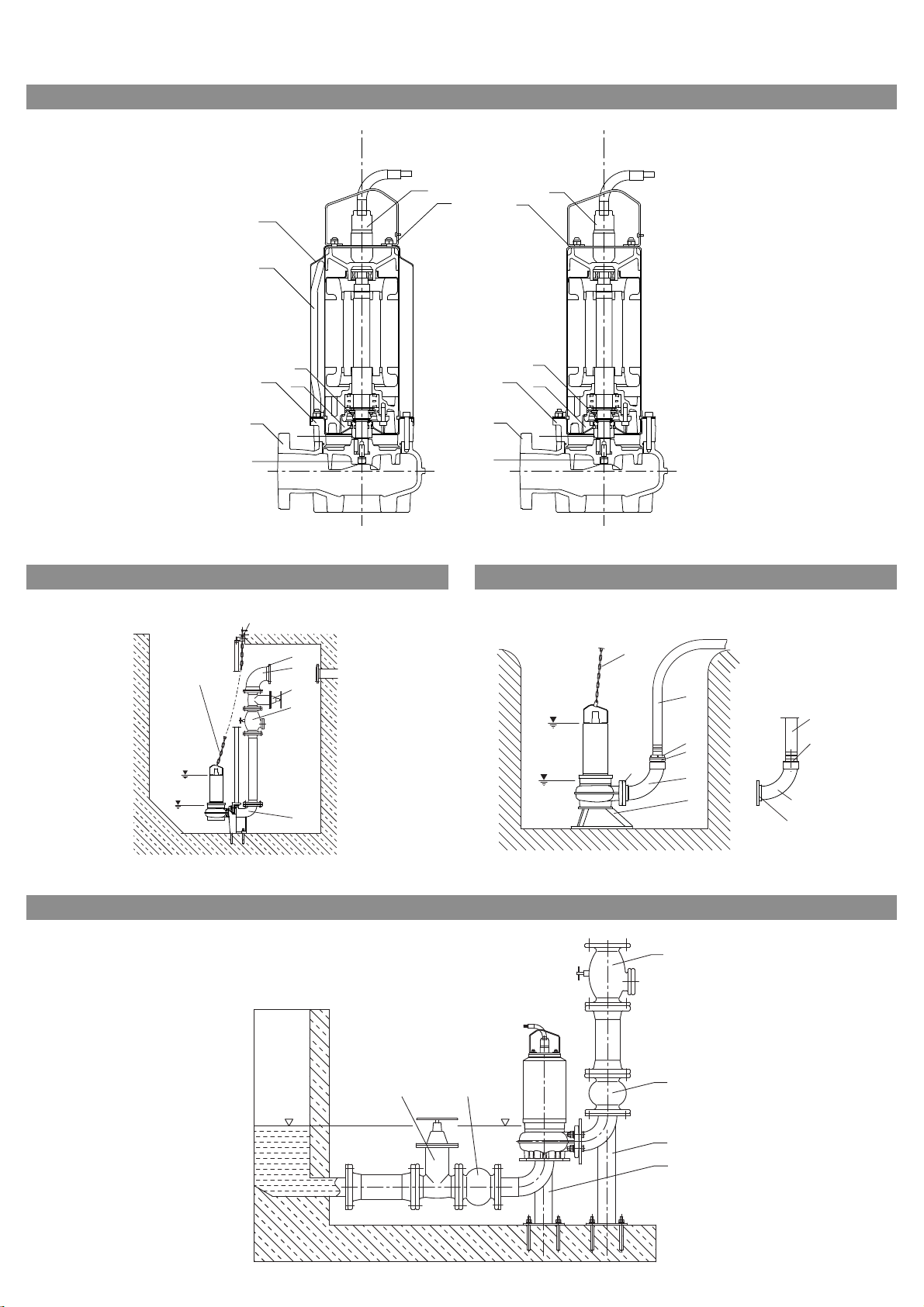

Fig.1:

1

2

3

4

5

7

6

9

9

8

10

10

Fig.2: Fig.3:

1

2

5

7

6

8

Fig.4:

6

15

15

12

4

11

min.*

min.

14

13

11

4

9

2

18

183

min.* min.*

17

17

Page 3

D Einbau- und Betriebsanleitung 3

GB Installation and operating instructions 11

F Notice de montage et de mise en service 19

E Instrucciones de instalación y funcionamiento 27

I Istruzioni di montaggio, uso e manutenzione 35

P Manual de Instalação e funcionamento 43

GR Οδηγίες εγκατάστασης και λειτουργίας 51

TR Montaj ve kullanma kılavuzu 59

S Monterings- och skötselanvisning 67

FIN Asennus- ja käyttöohje 75

H Beépítési és üzemeltetési utasítás 83

PL Instrukcja montażu i obsługi 91

CZ Návod k montáži a obsluze 99

RUS Инструкция по монтажу и эксплуатации 107

EST Paigaldus- ja kasutusjuhend 115

LV Instalēšanas un ekspluatācijas instrukcijas 123

LT Montavimo ir naudojimo instrukcija 131

SK Návod na montáž a obsluhu 141

SLO Navodila za vgradnjo in vzdrževanje 149

BG Инструкция за монтаж и експлоатация 157

RO Instrucţiuni de montaj şi exploatare 165

Page 4

English

Installation and operating instructions

1 General

About this document

These installation and operating instructions are

an integral part of the product. They must be kept

readily available at the place where the product is

installed. Strict adherence to these instructions is

a precondition for the proper use and correct

operation of the product.

These installation and operating instructions correspond to the relevant version of the product and

the underlying safety standards valid at the time

of going to print.

2Safety

These operating instructions contain basic information which must be adhered to during installation and operation. For this reason, these

operating instructions must, without fail, be read

by the service technician and the responsible

operator before installation and commissioning.

It is not only the general safety instructions listed

under the main point "safety" that must be

adhered to but also the special safety instructions

with danger symbols included under the following

main points.

2.3 Danger in the event of non-observance of the

safety instructions

Non-observance of the safety instructions can

result in risk of injury to persons and damage to

pump/installation. Non-observance of the safety

instructions can result in the loss of any claims to

damages.

In detail, non-observance can, for example, result

in the following risks :

• Failure of important pump/installation functions,

• Failure of required maintenance and repair procedures

• Danger to persons from electrical, mechanical and

bacteriological influences,

• Property damage

2.4 Safety instructions for the operator

The existing directives for accident prevention

must be adhered to.

Danger from electrical current must be eliminated.

Local directives or general directives [e.g. IEC, VDE

etc.] and local power supply companies must be

adhered to.

Risks through mechanical or bacteriological

effects must be prevented. Local conditions and

guidelines relating to sewage technology must be

adhered to.

2.1 Indication of instructions in the operating

instructions

Symbols:

General danger symbol

Danger due to electrical voltage

NOTE

Signal words:

DANGER!

Acutely dangerous situation

Non-observance results in death or the most

serious of injuries.

WARNING!

The user can suffer (serious) injuries. 'Warning'

implies that (serious) injury to persons is probable if this information is disregarded.

CAUTION!

There is a risk of damaging the pump/installation. 'Caution' implies that damage to the product is likely if the information is disregarded.

NOTE: Useful information on using the product. It

draws attention to possible problems.

2.2 Personnel qualifications

The installation personnel must have the appropriate qualifications for this work.

2.5 Safety instructions for inspection and

installation work

The operator must ensure that all inspection and

installation work is carried out by authorised and

qualified personnel, who are sufficiently informed

from their own detailed study of the operating

instructions.

Work to the pump/installation must only be carried out when at a standstill.

2.6 Unauthorised modification and manufacture of

spare parts

Modifications to the pump/installation are only

permissible after consultation with the manufacturer. Original spare parts and accessories authorised by the manufacturer ensure safety. The use of

other parts can nullify the liability from the results

of their usage.

2.7 Incorrect use

The operating safety of the supplied pump/installation is only guaranteed for conventional use in

accordance with Section 4 of the operating

instructions. The limit values must on no account

fall under or exceed those specified in the catalogue/data sheet.

Installation and operating instructions Wilo-Drain STS 65 11

Page 5

English

3 Transport and interim storage

On receipt of the product, check immediately for

transport damage. If any transport damage is

found, initiate the necessary procedure with the

forwarding agent within the period specified.

CAUTION! Danger of property damage!

Incorrect transport and incorrect storage can

lead to damage to the pump.

• When transporting, only carry or suspend the

pump by the handle/holder. The cable should

never be used for lifting!

• When transporting and storing the pump, protect it against moisture, frost and mechanical

damage.

4Intended use

The submersible pumps Wilo-Drain STS 65 are

suitable for pumping polluted water and sewage

containing air, long-fibre solids, light faeces or

sludge (up to 10 % dry mass).

They are used in:

• domestic and site drainage

• sewage and water management

• environmental and water treatment technology

• industrial and process engineering

As a rule, the pumps are used in standard sumps:

• Single pumping station: diameter up to Ø1.5 m or

1 m x 1 m

• Double pumping station: diameter up to Ø2.5 m or

2 m x 2 m

Operating mode S3-25 % means over a period of

10 minutes:

• Operation time 2.5 min.

• Standstill time 7.5 min.

In this operating mode, the pumps can be operated with/without cooling jacket with the motor

on the surface and with the following switching

levels.

• Switch-off level: top of pump housing

• Switch-on level: top of motor

If used in basins with bigger cross-sections (e.g.

rainwater storage basins), the pumps

• must be operated submerged without cooling

jacket,

• submerged or on the surface with cooling jacket.

DANGER! Mortal danger through electric shock!

The pump must not be used for draining swimming pools, garden ponds or similar installations

if there is someone in the water.

WARNING! Health hazard!

Owing to the materials used, the pumps are not

suitable for potable water! Unpurified wastewater is a health hazard.

CAUTION! Danger of property damage!

Unpermitted substances in the fluid can destroy

the pump. Abrasive solids (e.g. sand) increase

pump wear.

Pumps without an Ex certificate are not suitable

for use in potentially explosive areas.

Correct use of the pump/installation also includes

following these instructions.

Any use over and beyond these is interpreted as

incorrect use.

5 Product information

5.1 Type key

Pumps with motor seal:

• Mechanical seal against the fluid

• Rotary shaft seal against the motor compartment

Example: STS65/6-1-230-50-2

ST Sewage Technology

S Stainless Steel Motor

65 Nominal diameter of pressure port [mm]

/6 Maximum delivery head [m] when Q = 0 m³/h

1 1: Single-phase motor, 1 ~

3: Three-phase motor, 3 ~

230 Mains voltage [V]

50 Mains frequency [Hz]

2 2 pole motor

Pumps with motor seal:

• Mechanical seal against the fluid

• Mechanical seal against motor compartment

Example: STS 65F 6.60/13-3-400-50-2-CS-EX

ST Sewage Technology

S Stainless Steel Motor

65 Nominal diameter of pressure port [mm]

F Vortex impeller

6 Max. delivery head [m] when Q = 0 m³/h

60 Max. delivery head Q [m³/h]

/13 Nominal motor power P2 [kW] (value = 1/10)

3 3: Three-phase motor, 3 ~

400 Mains voltage [V]

50 Mains frequency [Hz]

2 2 pole motor

CS Cooling System - pump with cooling jacket

EX Explosion protection

12 WILO AG 05/2008

Page 6

5.2 Technical data

Mains voltages 1 ~ 230 V, ± 10 %, 3 ~ 400 V, ± 10 %

Mains frequency

50 Hz

Protection class IP 68

Nominal speed (50 Hz)

See name plate

Current consumption See name plate

Power consumption P

Nominal motor power P

Max. flow rate

Max. delivery head

Operating mode S1

1)

1

2

Without cooling jacket Motor submerged

See name plate

See name plate

See name plate

See name plate

With cooling jacket Motor on surface

Operating mode: intermittent duty S3

2)

Motor on surface:

25 % in sumps up to max. Ø3 m, or 2.5 m x 2.5 m

Recommended switching frequency 6 1/h

Max. switching frequency

20 l/h

Nominal diameter of pressure port See type key

Free ball passage

Max. submersion depth

Corresponds to nominal diameter DN [mm]

See name plate

Permitted temperature range of fluid +3 to 40 °C

Noise level at min. level

Seal:

on the fluid side Mechanical seal SiC/SiC

< 70 dB(A)

on motor side Rotary shaft seal or

mechanical seal Cr-cast/carbon

Oil filling:

Motor Volume

1.5 kW; 1~ / 3~ 2 pole 150 ml

2.5 - 4.0 kW; 2 pole 190 ml

1.5 - 4.0 kW; Ex 2 pole 230 ml

Oil type MARCOL 82 or comparable oils

Number of connections: (See section 7.2.1)

Power P

1,5 kW

2

Connections / h Zmax (acc. to DIN EN / IEC 61000-3-11)

10 0,118

20 0,086

Fuse in the power supply:

1)

Operation with a constant load until the machine can reach the thermal state of inertia.(acc. to DIN EN 60034-1)

2)

Operating time: 2.5 min., standstill time: 7.5 min. (within 10 min.)

16 A, slow

English

5.3 Scope of delivery

Pump, depending on type, with:

• 10 m replaceable electrical connecting cable

(special lengths on request)

• Single-phase type with condenser box

• Three-phase type with free cable end

• Installation and operating instructions

5.4 Accessories

Accessories have to be ordered separately:

• Switchgear for 1 or 2 pump operation

• External monitoring devices / tripping unit

• Level control (level sensor / float switch)

• Accessories for portable wet well installation

• Accessories for stationary wet well installation

• Accessories for vertical dry well installation

See the catalogue for a detailed list

Installation and operating instructions Wilo-Drain STS 65 13

Page 7

English

6 Description and function

6.1 Description of the pump (Fig. 1))

Pos. Description of the

component

1 Electrical connection

cable

2

Handle/holder 7 Lantern

3 Cooling jacket 8 Mechanical seal

4

Return pipe 9 Pump housing

5

Rotary shaft seal or

mechanical seal

The submersible pumps in the Wilo-Drain STS 65

series consist of:

• Pressure encapsulated, watertight single-phase

or three-phase motor in stainless steel (1.4404 /

AISI 316L)

• Hydraulics in cast iron EN-GJL-250 (GG25)

The fluid penetrates from underneath through a

central opening and emerges from the pressure

port (DN 65) at the side. The sealing chamber

between the seal on the fluid side and the motor

side is filled with white oil when delivered. The oil

filling is used for cooling, lubricating and protecting the two seals against dry running. White oil is

biologically degradable. The oil volume depends

on the type of motor, see 5.2. of the Technical

data.

The motors are equipped with thermal motor protection (thermal winding contact) against overheating.

• Motor 1~:

on the flex L. After excessive heating, the pump is

switched off and then switched on again automatically after it has cooled down.

• Motor 3~: Three winding protection contacts

(WSK), one contact in each winding head. The

thermal winding contact must be connected to

the switchgear and evaluated there. The pump is

switched off after excessive heating. The fault

must be acknowledged via the switchgear.

One winding protection contact (WSK)

Pos. Description of the

component

6 Oil chamber

10 Impeller

7 Installation and electrical connection

DANGER! Risk of fatal injury!

Incorrect installation and improper electrical

connections can result in a risk of fatal injury.

• The installation and electrical connections

should only be done by properly skilled staff and

in compliance with the applicable regulations!

• Follow all accident prevention regulations!

7.1 Installation

The pumps of the Wilo-Drain STS 65 series are

standard for stationary/portable wet well installations. They are also suitable for stationary dry well

installation, vertically or horizontally.

CAUTION! Danger of property damage!

Danger of damage due to incorrect handling.

Using a chain or rope, only suspend the pump by

the handle or holder, never by the electric or

float switch cable or pipe/hose connection.

General

• The installation site for the pump must be free of

frost.

• The shaft must be cleared of coarse material such

as rubble before setting up and starting the pump.

• The pressure pipe must have the nominal diameter

of the pump (DN 65; it can be upgraded to DN 80).

• Install the pipes so that they are stress-free. Fix

the pipes so that the pump does not carry the

weight of the pipes.

• To protect against any backflow from the public

drainage system, install the pressure pipe as a

loop. It must be above the established backflow

level (usually street level).

• In the case of a stationary installation, install a

non-return valve and a stop valve with full passage cross-section in the pressure pipe. In double

pump systems, these fittings must be installed

over each pump.

NOTE: It is best to install the fittings outside in an

additional sump (fittings sump). If this is not feasible, the fittings should not be connected directly

to the pressure port or the pipe bend. A device to

vent the pump must be provided. Otherwise the

air cushion cannot open the non-return valve.

"Original-Wilo-accessories" are recommended to

guarantee perfect functioning of the pump.

7.1.1 Stationary wet well installation (Fig. 2)

Pos. Description of the

component

1 Foot elbow 4 Bend

2 Non-return valve 5 Installation accessories

3

Gate valve 6 Chain

• The fixed pipe connections on the pressure side

must be provided on site.

• Mount the foot elbow with the floor fixing accessories on the

• Connect the pressure pipe with the necessary fittings (accessories) on the foot elbow.

• Fix the pump bracket, profile joint on the pressure

port of the pump.

• Plug R1 ¼“ guide pipe (to be provided on site) on

to the foot elbow.

• Suspend the pump in the guide tube and lower

carefully on the chain. The pump reaches the correct operating position automatically and seals

the pressure connection on the foot elbow

through its dead weight.

• Fix the chain on the guide tube bracket with

shackle (provide on site).

Pos. Description of the

component

bottom of the sump and align it.

14 WILO AG 05/2008

Page 8

English

7.1.2 Transportable wet well installation (Fig. 3

Pos. Description of the

component

Pos. Description of the

component

4 Bend 12 Hose connection

6

Chain 13 Fixed coupling

(instead of item 12)

9 Floor supporting foot 14 Hose coupling

(instead of item 12)

11 Counter-flange 15 Pressure hose

In the case of a portable wet well installation,

secure the pump in the pit to prevent accidents

and wandering (e.g. secure the chain with slight

pre-tension).

NOTE: When used in a sump without a firm base,

the pump must be put on a sufficiently large plate

or hung from a rope or a chain in a suitable position.

7.1.3 Stationary dry well installation, for pump with

cooling jacket only (Fig 4)

Pos. Description of the

component

Pos. Description of the

component

2 Non-return valve 17 Installation set

3 Gate valve 18 Compensator

• The fixed pipe connections on the pressure side

must be provided on site.

• The weight of pipes and fittings must not be carried by the pump and compensators and must be

intercepted through the use of suitable fixings.

A resonance-free pump installation must be

•

ensured on site. The pipes

must be supported at

suitable intervals to prevent inadmissible vibrations. The use of suitable compensators is recommended for decoupling the pump.

7.2 Electrical connection

DANGER! Risk of fatal injury!

If the electrical connection is not made properly,

there is a risk of fatal injury from an electric

shock.

• Only allow the electrical connection to be made

by an electrician approved by the local electricity supplier and in accordance with the local regulations in force.

• Follow the installation and operating instructions for the pump, level control device and

other accessories.

7.2.1 Pump with single-phase motor (1~230 V)

• The motor is already wired with the condenser box

at the works. The mains connection is made at

terminals L1, N, PE of the terminal box.

• According to DIN EN / IEC 61000-3-11, the pump

is designed with a power of 1.5 kW for operating

on a power supply mains with a system impedance

Zmax on the house connection of maximum 0.118

(0.086) Ohm with a maximum number of 10 (20)

connections.

• Number of connections, see 5.2 of the Technical

data.

NOTE: If the mains impedance and the number of

connections per hour is greater than the values

specified, because of the unfavourable mains

connections, the pump may lead to temporary

voltage drops and also to disturbing voltage fluctuations, or flickering.

Therefore, measures may be necessary before the

pump can be operated correctly on this connection.

The necessary information must be obtained from

the electricity supply company and the manufacturer.

7.2.2 Pump with three-phase motor (3~400 V):

• The use of a residual current circuit-breaker is

recommended.

• The switchbox for the pump(s) is available as an

accessory.

CAUTION! Danger of property damage!

Risk of damage through incorrect electrical connection.

If the switchbox is provided by the customer on

site, the following requirements of the electricity supply companies must be met.

•P

4 kW: direct starting:

2

• Set the motor protection switch to the nominal

current of the motor according to the name

plate.

• For the thermal monitoring of the motor, a

standard evaluation device can be used to connect the thermal winding contact. Connect with

230 V AC, max. 1 A, recommended: 24V DC

Preparation of the electrical connection

• Make sure that the type of current and voltage of

the mains connection corresponds to the details

on the name plate.

• Protect the connection on the mains side: 16 A,

slow or automatic fuse with C characteristic.

• Earth the system according to regulations.

•Use a 30 mA residual current circuit-breaker.

• Use an isolating device with a min. 3 mm contact

opening to isolate from the mains.

• Connect the pump.

Installation and operating instructions Wilo-Drain STS 65 15

Page 9

English

Connecting cable

• Allocate the connecting cable wires as follows:

Pumps with P2 1.5 kW:

6-wire connection cable: 6x1.0 mm²

Wire no. 1 2 3 green/yellow 4 5

Terminal

7-wire connection cable: 6x1.5 mm²

Wire no. 1 2 3 green/

Terminal U V W PE WSK WSK not

U V W PE WSK WSK

Pumps with P2 = 1.5 kW to 4.0 kW:

4 5 6

yellow

allocated

Wire the free cable end in the switchbox (see

Switchbox installation and operating instructions).

8 Commissioning

DANGER! Danger through electric shock!

The pump must not be used for draining swimming pools, garden ponds or similar installations

if anyone is in the water.

CAUTION! Danger of property damage!

Before installation, clear the pond and the supply pipes of all solid materials such as rubble.

8.1 Checking the direction of rotation (three-phase

motors only)

WARNING! Risk of injury!

• Jerking occurs when the freely suspended pump

is switched on. People may be injured if the

pump drops down. Make sure that the pump is

safely suspended and cannot drop down.

• The rotating impeller creates an increased risk

of injury. Do not reach into the pump housing

during operation.

The pumps are checked for the correct direction

of operation and set at the works.

Check that the pump is rotating in the correct

direction before submersion.

• To do this, suspend the pump safely in a hoist.

• Switch the pump on briefly. The pump recoils in

the opposite direction (anticlockwise) to the

motor's direction of rotation.

• If the direction of rotation is incorrect, proceed as

follows:

• When using Wilo switchgear:

• The Wilo switchgear is designed so that the

connected pump is operated in the correct

direction of rotation. If the direction of rotation

is wrong, 2 phases/conductors of the mains

power supply to the switchgear must be

changed over.

• In the case of switchboxes provided on site:

• If the direction of rotation is wrong, change over

2 phases.

8.2 Setting the level control device

CAUTION! Danger of property damage!

Do not allow the mechanical seal to run dry!

Dry running shortens the service life of the

motor and the mechanical seal. If the mechanical

seal is damaged, small amounts of oil may

escape into the pumped fluid.

The water level must not drop below the permitted minimum switch-off level.

• See the installation and operating instructions for

the level control device.

The switch-off point must be chosen so that the

operating conditions indicated in Intended use are

met.

The water level ( Tmin ) (Fig. 2, 3, 4) may only

be reduced to the upper edge of the motor

( Tmin* Construction with cooling jacket). The

level control is to be set at this minimum level.

8.3 Operating conditions in a potentially explosive

environment

See additional operating instructions for

9Maintenance

Maintenance and repairs may only be carried out

by qualified experts!

It is recommended that the pump is maintained

and checked by Wilo after-sales service.

DANGER! Risk of fatal injury!

There is a mortal danger through shock when

working on electrical equipment.

• Work on electrical equipment may only be done

by electricians approved by the local electricity

supplier.

• Before working on electrical equipment, switch

it off and prevent it from being switched on

again.

• Follow the installation and operating instructions for the pump, level control device and

other accessories.

DANGER! Danger of suffocation!

Toxic or health-hazardous substances in sewage

sumps may lead to infections or suffocation.

• Only work in the pump sump when another person is present outside the sump.

• Always wear protective clothing, mouth protection and gloves when working.

9.1 Maintenance intervals

Pump stations with Wilo-Drain STS 65 pumps

must be maintained by qualified personnel

according to EN 12056-4. The intervals must not

exceed:

• ¼ year in the case of commercial companies

• ½ year in the case of apartment building stations

• 1 year in the case of detached house stations

The system operator must make sure that all the

maintenance, inspection and installation work is

done by authorised and qualified personnel, who

have acquainted themselves sufficiently with the

system through a detailed study of the installation

and operating instructions.

16 WILO AG 05/2008

Page 10

English

NOTE: When drafting a maintenance plan, expensive repairs can be avoided and a fault-free operation of the system can be achieved with a

minimum of maintenance effort. The Wilo-aftersales service is available for commissioning and

maintenance work. A maintenance report must be

issued.

9.2 Maintenance procedure

• Open pump sump, station and ventilate.

• Inspect the inside visually

• Deposits on the pump, sump floor and on the

accessories

• Shut off sewage inlet(s) (e.g. with air plugs)

• Measure the pump delivery head when Q = 0 m³/h.

• If the flow rate of the pump drops by more than

10 %, lift it out of the sump. Then check the

impeller and the pump housing for wear.

• Check the sump level.

• Drain the sump manually until slurping operation.

• Check the sump floor for deposits.

• Clean the sump if there are major deposits.

• Fill the sump and carry out a trial run.

• If the delivery head cannot be measured

• Wait until the sump is filled and the pump starts

up

• Measure the time between switching on and off

(t) and also the drop in level (h).

• Calculate the flow rate according to the following formula.

With the horizontal section A, the following general formula can be used:

Q [m³/h] = 36 x A [m

2

] x h [cm] / t [s]

Have the oil changed once a year or after 1000

operating hours during a maintenance operation.

• Provide suitable hoisting gear depending on the

weight of the pump.

• Oil type and fill volumes: see 5.2 Technical data.

NOTE: When you change the oil, the old oil and

water have to be disposed of as hazardous waste!

Sump type Formula

WB 100 Q [m³/h] = 28,3 x h [cm] / t [s]

WB 150 Q [m³/h] = 63,6 x h [cm] / t [s]

WB 200

Square sump

Q [m³/h] = 113,1 x h [cm] / t [s]

Q [m³/h] = 36 x A [m] x B [m] x h [cm] / t [s]

9.3 Oil change

WARNING! Risk of injury!

The pumps are heavy and can fall over.

People may be injured if the pump is not properly secured during maintenance work.

Always check the stability of the pump and use

suitable hoisting gear.

WARNING! Risk of injury!

An overpressure may prevail in the sealing

chamber/separation chamber.

If the oil drain plug is undone, hot oil may spurt

out under pressure and cause injury or scalding.

Before changing the oil, put on protective goggles and undo the oil drain plug with care.

WARNING! Danger to the environment!

Oil may leak out if the pump is damaged or dismantled.

This can damage the environment.

Avoid damage and adopt suitable measures to

take up the oil.

Installation and operating instructions Wilo-Drain STS 65 17

Page 11

English

10 Faults, causes and remedies

Only have faults remedied by qualified personnel! Follow the safety instructions in

9 Maintenance.

Fault Cause Remedy

Pump does not start No voltage Check the wires and fuses, or switch auto-

matic fuses in the distribution station back

on

Rotor blocked Clean the housing and impeller, if still

blocked replace the pump

Fuses, condenser defective (1~) Replace fuses, condenser

Cable rupture Check cable resistance. If necessary, change

the cable. Only use original special cable!

Safety switches thrown

Pump has no power Pump sucking air because the fluid level has

Water in the motor chamber Ask the after-sales service

Foreign bodies in the pump, winding protection contact triggered

dropped too far

Pressure pipe plugged Detach the pipe and clean it

Switch off the installation and prevent it

from being switched on again, lift the pump

out of the pit.

Remove the objects.

Check the function/setting of the level con-

trol

If the operating fault cannot be remedied,

please get in touch with the trade outlet or the

nearest customer service or agent.

11 Spare parts

Spares are ordered through local trade outlets

and/or the Wilo after-sales service.

To avoid queries and incorrect orders, always provide all of the details on the name plate with every

order.

Subject to change without prior notice!

18 WILO AG 05/2008

Page 12

D EG - Konformitatserklarung

GB EC - Declaration

of

conformity

F Declaration de conformite CE

(gemaB Anhangjaccording annexj conforme appendice lA, 2006j42jEG)

Hiermit erklaren wir, dass die Bauart der Baureihe :

Herewith,

we

declare that the product typeofthe series:

STS 65 ...

Par Ie present, nous declarons que I'agregat de la serie :

(Die Seriennummer ist auf dem Typenschild des Produktes angegeben./

The serial number is marked on the product site plate'; Le numero de serie est inscrit sur la plaque signaletique du produit.)

in der gelieferten AusfUhrung folgenden einschlagigen Bestimmungen entspricht:

in its delivered state complies with the following relevant provisions:

est conforme aux dispositions suivantes dont il releve:

EG-Maschinenrichtlinie

EC-Machinery directive

Directives CE relatives aux machines

Niederspan nungsrichtli nie

Low Voltage directive

Directive basse-tension

EG-Maschinenrichtlinie

EC-Machinery directive

Directives CE relatives aux machines

Die Schutzziele der Niederspannungsrichtlinie 2006/95/EG werden gemaB Anhang I, Nr. 1.5.1 der 2006/42/EG Maschinenrichtlinie eingehalten.

The protection objectives of the low-voltage directive 2006j95jEC are realized according annex I, No.

EC-Machinery directive 2006j42jEC.

Les objectifs protection de la directive basse-tension 2006j95jEC sont respectees conformement

directive CErelatives aux machines 2006j42jCE.

98/37/EG

(gOltig bis /valid up to /

valide jusqu'a 28.12.2009)

2006/95/EG

(gOltig bis / valid up to /

valide jusqu'a 28.12.2009)

2006/42/EG

(gOltig ab / valid from /

valide de 29.12.2009)

1.5.1

of the

a

appendice I, n°

1.5.1

de la

Elektromagnetische Vertraglichkeit - Richtlinie

Electromagnetic compatibility - directive

Compatibilite electromagnetique- directive

Bauproduktenrichtlinie

Construction product directive

Directive de produit de construction

Angewendete harmonisierte Normen, insbesondere:

Applied harmonized standards, in particular:

Normes harmonisees, notamment:

Bei einer mit uns nicht abgestimmten technischen Anderung der oben genannten Bauarten, verliert diese Erklarung ihre Gultigkeit.

If the above mentioned series are technically modified without our approval, this declaration shall no longer be applicable.

5i les gammes mentionnees ci-dessus sont modifiees sans notre approbation, cette declaration perdra sa validite.

Bevollmachtigter fUr die Zusammenstellung der technischen Unterlagen ist:

representative for the completion of the technical documentation: Mandataire pour Ie

complement de la documentation technique est:

Authorized

89/106/EWG

i.d.F/ as amended/ avec les amendements

suivants :

93j68jEWG

EN 809

EN 14121-1

EN 12100-1

EN 12100-2

EN 60335-2-41

EN 60034-1

EN 60204-1

EN 12050-1

Volker Netsch

HeimgartenstraBe 1-3

95030 Hof

Germany

IW/LOI

WILO SE

NortkirchenstraBe 100

44263 Dortmund

Germany

Page 13

NL I E

Směrnice pro stavební výrobky 89/106/EHS

znění 93/68/EHS

dyrektywą w sprawie wyrobów budowlanych 89/106/EWG

brzmieniu

Директива о строительных изделиях 89/106/EWG

поправками

EG-verklaring van overeenstemming Dichiarazione di conformità CE Declaración de conformidad CE

Hiermede verklaren wij dat di t aggregaat in de geleverde uitvoering voldoet

aan de volgende bepalingen:

EG-richtlijnen betreffende machines 98/37/EG bzw. 2006/42/EG Direttiva macchine 98/37/EG bzw. 2006/42/EG Directiva sobre máquinas 98/37/EG bzw. 2006/42/EG

De veiligheidsd oelstellingen van de laagspannings richtlijn worden

overeenkomstig bijlage I, nr. 1.5.1 van de machinerichtlijn 2006/42/EG

aangehouden.

Elektromagnetische compatibiliteit 2004/108/EG Compatibilità elettromagnetica 2004/108/EG Directiva sobre compatibilidad electromagnética 2004/108/EG

Bouwproductenrichtlijn 89/106/EEG als vervolg op 93/86/EEG Direttiva linee guida costruzione dei prodotti 89/106/CEE e seguenti

gebruikte geharmoniseerde normen, in het bijzonder: norme armonizzate applica te, in particolare: normas armoni zadas adoptadas, especialmente:

zie vorige pagina vedi pagina precedente véase página anterior

PSN

Declaração de Conformidade CE CE- försäkran EU-Overensstemmelseserklæring

Pela presente, declaramos que esta unidade no seu estado original, está

conforme os seguintes requisitos:

Directivas CEE relativas a máquinas 98/37/EG bzw. 2006/42/EG EG–Maskindirektiv 98/37/EG bzw. 2006/42/EG EG–Maskindirektiv 98/37/EG bzw. 2006/42/EG

Os objectivos de protecção da dire ctiva de baixa tensão são cumpridos de

acordo com o anexo I, nº 1.5.1 da directiva de máquinas 2006/42/CE.

Compatibilidade electromagnética 2004/108/EG EG–Elektromagnetisk kompatibilitet – riktlinje 2004/108/EG EG–EMV–Elektromagnetisk kompatibilitet 2004/108/EG

Directiva sobre produtos de construção 89/106/CEE com os aditamentos

seguintes 93/68/EWG

normas harmonizadas aplicadas, especialmente: till ämpade harmoniserade normer, i synnerhet: anvendte harmoniserte standarder, særlig:

ver página anterior se föregående sida se forrige side

FIN DK H

CE-standardinmukaisuusseloste EF-overensstemmelseserklæring EK-megfelelőségi nyilatkozat

Ilmoitamme täten, että tämä laite vastaa seuraavia asiaankuuluvia

määräyksiä:

EU–konedirektiivit: 98/37/EG bzw. 2006/42/EG EU–maskindirektiver 98/37/EG bzw. 2006/42/EG Gépek irányelv: 98/37/EK bzw. 2006/42/EK

Pienjännitedirektiivin suojatavoitteita noudatetaan

konedirektiivin 2006/42/EY liitteen I, nro 1.5.1 mukaisesti.

Sähkömagneettinen soveltuvuus 2004/108/EG Elektromagnetisk kompatibilitet: 2004/108/EG Elektromágneses összeférhetőség irányelv: 2004/108/EK

EU materiaalidirektiivi 89/106/EWG seuraavin täsmennyksin 93/68/EWG Produktkonstruktionsdirektiv 98/106/EWG følgende 93/68/EWG Építési termékek irányelv 89/106/EGK és az azt kiváltó 93/68/EGK

käytetyt yhteensovitetut standardit, e rityisesti: anvendte harmoniserede standarder, særligt: alkalmazott harmonizált s zabványoknak, különösen:

katso edellinen sivu. se forrige side lásd az előző oldalt

CZ PL RUS

Pr

ohlášení o shodě ES Deklarac ja Zgodności WE Декларация о соответствии Европейским нормам

Prohlašujeme tímto, že tento agregát vdodaném provedení odpovídá

následujícím příslušným ustanovením:

Směrnice ES pro stroj ní zařízení 98/37/ES bzw. 2006/42/ES dyrektywą maszynową WE 98/37/WE bzw. 2006/42/WE Директивы EC в отношении машин 98/37/EG bzw. 2006/42/EG

Cíle týkající se bezpečnosti stanovené ve směrnici o elektrických zařízeních

nízkého napětí jsou dodrženy podle přílohy I, č. 1.5.1 směrnice o strojních

zařízeních 2006/42/ES.

Směrnice o elektromagnetické kompatibilitě 2004/108/ES dyrektywą dot. kompatybilności elektromagnetycznej 2004/108/WE Электромагнитная устойчивость 2004/108/EG

použité harmonizační normy, zejména: stosowa nymi normami zharmonizowanymi, a w szczególności: Используемые согласованные стандарты и нормы, в частности:

viz předchozí strana patrz poprzednia strona см. предыдущую страницу

GR TR RO

Δήλωση συμμόρφωσης της ΕΕ CE Uygunluk Teyid Belgesi EC-Declaraţie de conformitate

Δηλώνουμε ότι το προϊόν αυτό σ’ αυτή την κατάσταση παράδοσης

ικανοποιεί τις ακόλουθες διατάξεις :

Οδηγίες EΚ για μηχανήματα 98/37/EK bzw. 2006/42/EΚ AB-

Οι απαιτήσεις προστασίας της οδηγίας χαμηλής τάσης τηρούνται σύμφωνα

με το παράρτημα I, αρ. 1.5.1 της οδηγίας σχετικά με τα μηχανήματα

2006/42/EG.

Ηλεκτρομαγνητική συμβατότητα EΚ-2004/108/EΚ Elektromanyetik Uyumluluk 2004/108/EG Compatibilitatea electromagnetică – directiva 2004/108/EG

Οδηγία κατασκευής 89/106/EΟΚ όπως τροποποιήθηκε 93/68/EΟΚ Ürün imalat yönetme liği 89/106/EWG ve takip eden, 93/68/EWG Directiva privind produsele pentru construcţii 89/106/EWG cu

Εναρμονισμένα χρησιμοποιούμενα πρότυπα, ιδ ιαίτερα:kısmen kullanılan standartlar için: standarde armonizate aplicate, îndeosebi:

Βλέπε προηγούμενη σελίδα bkz. bir önceki sayfa vezi pagina precedentă

EST

EÜ

vastavusdeklarats ioon EC - atbilstības deklarācija EB atitikties deklaracija

Käesolevaga tõendame, et see toode vastab järgmistele asjakohastele

direktiividele:

Masinadirektiiv 98/37/EÜ bzw. 2006/42/EÜ Mašīnu direktīva 98/37/EK bzw. 2006/42/EK Mašinų direktyvą 98/37/EB bzw. 2006/42/EB

Madalpingedirektiivi kaitse-eesmärgid on täidetud vastavalt masinate

direktiivi 2006/42/EÜ I lisa punktile 1.5.1.

Elektromagnetilise ühilduvuse direktiiv 2004/108/EÜ Elektromagnētiskās savietojamības direktīva 2004/108/EK Elektromagnetinio suderinamumo direktyvą 2004/108/EB

Ehitustoodete direktiiv 89/106/EÜ, muudetud direktiiviga 93/68/EMÜ Direktīva par būvizstrādājumiem 89/106/EK pēc labojumiem 93/68/EES Statybos produktų direktyvos 89/106/EB pataisą 93/68/EEB

kohaldatud harmoneeritud standardid, eriti: piemēroti harmoniz ēti standarti, tai skaitā: pritaikytus vieningus standartus, o būtent:

vt eelmist lk skatīt iepriekšējo lappusi žr. ankstesniame puslapyje

SK

yhlásenie o zhode ES – izjava o skladnosti EО-Декларация за съответствие

ES v

Týmto vyhlasujeme, že konštrukcie tejto konštrukčnej série v dodanom

vyhotovení vyhovujú nasle dujúcim príslušným ustanoveniam:

Stroje - smernica 98/37/ES bzw. 2006/42/ES Direktiva o strojih 98/37/ES bzw. 2006/42/ES Машинна директива 98/37/EO bzw. 2006/42/EO

Bezpečnostné ciele smernice o níz kom napätí sú dodržiavané v zmysle

prílohy I, č. 1.5.1 smernice o strojových zariadeniach 2006/42/ES.

Elektromagnetická zhoda - smernica 2004/108/ES Direktiva o elektromagnetni združljivosti 2004/108/ES Eлектромагнитна съместимост – директива 2004/108/EО

Stavebné materiály - smernica 89/106/ES pozmenená 93/68/EHP Direktiva o gradbenih proizvodih 89/106/EGS v verziji 93/68/EGS Директива за строителни мате

používané harmonizované normy, najmä: uporabljeni harmonizirani standardi, predvsem: Хармонизирани стандарти:

pozri predchádzajúcu stranu glejte prejšnjo stran вж. предната страница

M

Dikjarazzjoni ta’ konformità KE

B'dan il-mezz, niddikjaraw li l-prodotti tas-serje jissodisfaw iddispożizzjonijiet relevanti li ġejjin:

Makkinarju - Direttiva 98/37/KE bzw. 2006/42/KE

L-objettivi tas-si gurta tad-Direttiva dwar il-Vultaġġ Baxx huma konformi

mal-Anness I, Nru 1.5.1 tad-Direttiva dwar il-Makkinarju 2006/42/KE.

Kompatibbiltà elettromanjetika - Direttiva 2004/108/KE

Direttiva dwar il-prodotti tal-kostruzzjoni 89/106/KEE kif emendata bid-

Direttiva 93/68/KEE

kif ukoll standards armonizzati b'mod partikolari:

ara l-paġna ta' qabel

ve

Con la presente si dichiara che i presenti prodotti sono conformi alle

seguenti disposizioni e direttive rilevanti:

Gli obiettivi di protezi one della direttiva macchine vengono rispettati

secondo allegato I, n. 1.5.1 dalla direttiva macchine 2006/42/CE.

modifiche 93/68/CEE

Härmed förklarar vi att denna ma skin i levererat utförande motsvarar

följande tillämpliga bestämmelser:

Produkten uppfyller säkerhetsmålen i lågspänningsdirektivet enligt bilaga

I, nr 1.5.1 i maskindirektiv 2006/42/EG.

EG-Byggmaterialdirektiv 89/106/EWG med följande ändringar

93/68/EWG

Vi erklærer hermed, at denne enhed ved levering overholder følgende

relevante bestemmelser:

Lavspændingsdirektivets mål om beskyttelse overholdes i henhold til bilag

I, nr. 1.5.1 i maskindirektivet 2006/42/EF.

Niniejszym deklarujemy z pełną odpowiedzialnością, że dostarczony wyrób

jest zgodny z następującymi dokumentami:

Przes

trzegane są cele ochrony dyrektywy niskonapięciowej zgodnie z

załącznikiem I, nr 1.5.1 dyrektywy maszynowej 2006/42/WE.

93/68/EWG

Bu cihazın teslim edildiği şekliyle aşağıdaki standartlara uygun olduğunu

teyid ederiz:

Makina Standartl arı 98/37/EG bzw. 2006/42/EG Directiva CE pentru maşini 98/37/EG bzw. 2006/42/EG

Alçak gerilim yönergesinin koruma hedefleri, 2006/42/AT makine

yönergesi Ek I, no. 1.5.1'e uygundur.

LV LT

Ar šo mēs apliecinām, ka šis izstrādājums atbilst sekojošiem noteikumiem: Šiuo pažymima, kad šis gaminys atitinka šias normas ir direktyvas:

Zemsprieguma direktīvas drošības mērķi tiek ievēroti atbilstoš i Mašīnu

direktīvas 2006/42/EK pielikumam I, Nr. 1.5.1.

SLO BG

Izjavljamo, da dobavljene vrste izvedbe te serije ustrezajo sledečim

zadevnim določilom:

Cilji Direkt ive o nizkonapetostni opremi so v skl adu s

prilogo I, št. 1.5.1 Direktive o strojih 2006/42/EG doseženi.

w

Por la presente declaramos la conformidad del producto en su estado de

suministro con las disposiciones pertinentes siguientes:

Se cumplen los objetivos en materia de seguridad establecidos en la

Directiva de Baja tensión según lo especificado en el

Anexo I, punto 1.5.1 de la Directiva de Máquinas 2006/42/CE.

Directiva sobre productos de construcción 89/106/CEE modificada por

93/68/CEE

Vi erklærer hermed at denne e nheten i utførelse som levert er i

overensstemmelse med følgende relevante bestemmelser:

Lavspenningsdirektivets vernemål overholdes i samsvar med

vedlegg I, nr. 1.5.1 i maskindirektivet 2006/42/EF.

Byggevaredirektiv 89/106/EWG med senere tilføyelser 93/68/EWG

Ezennel kijelentjü k, hogy az berendezés megfelel az al ábbi irányelveknek:

A kisfeszültségű irányelv védelmi előírásait a

2006/42/EK gépekre vonatkozó irányelv I. függelékének 1.5.1. sz. pontja

szerint teljesíti.

irányelv

Настоящим документом заявляем, что данный агрегат в его объеме

поставки соответствует следующим нормативным док ументам:

Требования по безопасности, изложенные в директиве по

низковольтному напряжению, соблюдаются согласно приложению I,

№ 1.5.1 директивы в отношении машин 2006/42/ЕG.

93/68/EWG

Prin prezenta declarăm că acest produs aşa cum este livrat, corespunde cu

următoarele prevederi aplicabile:

Sunt respectate obiectivele de protecţie din directiva privind joasa tensiune

conform Anexei I, Nr. 1.5.1 din directiva privind maşinile 2006/42/CE.

amendamentele ulterioare 93/68/EWG

Laikomasi Žemos įtampos direktyvos keliamų saugos reikalavimų pagal

Mašinų direktyvos 2006/42/EB I priedo 1.5.1 punktą.

Декларираме, че продуктът отговаря на следните изисквания:

Целите за защита на разпоредбата за ниско напрежение са съставени

съгласно. Приложение I, № 1.5.1 от Директивата за машини

2006/42/EС.

93/68/ЕИО

WILO SE

WILO SE

Nortkirchenstraße 100

Nortkirchenstraße 100

44263 Dortmund

Germany

риали 89/106/ЕИО изменени

с

Page 14

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Germany

T +49 231 4102-0

F +49 231 4102-7363

wilo@wilo.de

www.wilo.com

Algeria

Bad Ezzouar, Dar El Beida

T +213 21 247979

chabane.hamdad@salmson.fr

Armenia

375001 Yerevan

T +374 10 544336

info@wilo.am

Bosnia and Herzegovina

71000 Sarajevo

T +387 33 714510

zeljko.cvjetkovic@wilo.ba

Georgia

0177 Tbilisi

T +995 32317813

info@wilo.ge

Macedonia

1000 Skopje

T +389 2 3122058

valerij.vojneski@wilo.com.mk

Moldova

2012 Chisinau

T +373 2 223501

sergiu.zagurean@wilo.md

Rep. Mongolia

Ulaanbaatar

T +976 11 314843

wilo@magicnet.mn

Tajikistan

734025 Dushanbe

T +992 37 2232908

farhod.rahimov@wilo.tj

Turkmenistan

744000 Ashgabad

T +993 12 345838

wilo@wilo-tm.info

Uzbekistan

700046 Taschkent

sergej.arakelov@wilo.uz

May 2008

Wilo – International (Subsidiaries)

Wilo – International (Representation offices)

Argentina

WILO SALMSON

Argentina S.A.

C1270ABE Ciudad

Autónoma de Buenos Aires

T +54 11 43015955

info@salmon.com.ar

Austria

WILO Handelsges. m.b.H.

1230 Wien

T +43 507 507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1065 Baku

T +994 12 5962372

info@wilo.az

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2503393

wilobel@wilo.by

Belgium

WILO SA/NV

1083 Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILO Bulgaria Ltd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Canada

WILO Canada Inc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILO China Ltd.

101300 Beijing

T +86 10 80493900

wilobj@wilo.com.cn

Croatia

WILO Hrvatska d.o.o.

10090 Zagreb

T +38 51 3430914

wilo-hrvatska@wilo.hr

Czech Republic

WILO Praha s.r.o.

25101 Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILO S.A.S.

78390 Bois d'Arcy

T +33 1 30050930

info@wilo.fr

Great Britain

WILO (U.K.) Ltd.

DE14 2WJ BurtonUpon-Trent

T +44 1283 523000

sales@wilo.co.uk

Greece

WILO Hellas AG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILO Magyarország Kft

2045 Törökbálint

(Budapest)

T +36 23 889500

wilo@wilo.hu

Ireland

WILO Engineering Ltd.

Limerick

T +353 61 227566

sales@wilo.ie

Italy

WILO Italia s.r.l.

20068 Peschiera

Borromeo (Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 727 2785961

in.pak@wilo.kz

Korea

WILO Pumps Ltd.

621-807 Gimhae

Gyeongnam

T +82 55 3405800

wilo@wilo.co.kr

Latvia

WILO Baltic SIA

1019 Riga

T +371 7 145229

mail@wilo.lv

Lebanon

WILO SALMSON

Lebanon

12022030 El Metn

T +961 4 722280

wsl@cyberia.net.lb

Lithuania

WILO Lietuva UAB

03202 Vilnius

T +370 5 2136495

mail@wilo.lt

The Netherlands

WILO Nederland b.v.

1948 RC Beverwijk

T +31 251 220844

info@wilo.nl

Norway

WILO Norge AS

0901 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILO Polska Sp. z.o.o.

05-090 Raszyn

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

Portugal Lda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILO Romania s.r.l.

077040 Com. Chiajna

Jud. Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592 Moscow

T +7 495 7810690

wilo@orc.ru

Saudi Arabia

WILO ME - Riyadh

Riyadh 11465

T +966 1 4624430

wshoula@wataniaind.com

Serbia and Montenegro

WILO Beograd d.o.o.

11000 Beograd

T +381 11 2851278

office@wilo.co.yu

Slovakia

WILO Slovakia s.r.o.

82008 Bratislava 28

T +421 2 45520122

wilo@wilo.sk

Slovenia

WILO Adriatic d.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

South Africa

Salmson South Africa

1610 Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILO Ibérica S.A.

28806 Alcalá de Henares

(Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILO Sverige AB

35246 Växjö

T +46 470 727600

wilo@wilo.se

Switzerland

EMB Pumpen AG

4310 Rheinfelden

T +41 61 83680-20

info@emb-pumpen.ch

Taiwan

WILO-EMU Taiwan Co. Ltd.

110 Taipeh

T +886 227 391655

nelson.wu@

wiloemutaiwan.com.tw

Turkey

WILO Pompa Sistemleri

San. ve Tic. A.S¸.

34530 Istanbul

T +90 216 6610211

wilo@wilo.com.tr

Ukraina

WILO

Ukraina

t.o.w.

01033 Kiew

T +38 044 2011870

wilo@wilo.ua

Vietnam

Pompes Salmson Vietnam

Ho Chi Minh-Ville Vietnam

T +84 8 8109975

nkm@salmson.com.vn

United Arab Emirates

WILO ME - Dubai

Dubai

T +971 4 3453633

info@wilo.com.sa

USA

WILO-EMU USA LLC

Thomasville,

Georgia 31792

T +1 229 5840097

info@wilo-emu.com

USA

WILO USA LLC

Melrose Park, Illinois 60160

T +1 708 3389456

mike.easterley@

wilo-na.com

Page 15

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Germany

T 0231 4102-0

F 0231 4102-7363

wilo@wilo.de

www.wilo.de

G1 Nord

WILO AG

Vertriebsbüro Hamburg

Beim Strohhause 27

20097 Hamburg

T 040 5559490

F 040 55594949

hamburg.anfragen@wilo.de

G2 Ost

WILO AG

Vertriebsbüro Berlin

Juliusstraße 52–53

12051 Berlin-Neukölln

T 030 6289370

F 030 62893770

berlin.anfragen@wilo.de

G3 Sachsen/Thüringen

WILO AG

Vertriebsbüro Dresden

Frankenring 8

01723 Kesselsdorf

T 035204 7050

F 035204 70570

dresden.anfragen@wilo.de

G4 Südost

WILO AG

Vertriebsbüro München

Landshuter Straße 20

85716 Unterschleißheim

T

089

4200090

F 089 42000944

muenchen.anfragen@wilo.de

G5 Südwest

WILO AG

Vertriebsbüro Stuttgart

Hertichstraße 10

71229 Leonberg

T 07152 94710

F 07152 947141

stuttgart.anfragen@wilo.de

G6 Rhein-Main

WILO AG

Vertriebsbüro Frankfurt

An den drei Hasen 31

61440 Oberursel/Ts.

T 06171 70460

F 06171 704665

frankfurt.anfragen@wilo.de

G7 West

WILO AG

Vertriebsbüro Düsseldorf

Westring 19

40721 Hilden

T

02103

90920

F 02103 909215

duesseldorf.anfragen@wilo.de

Kompetenz-Team

Gebäudetechnik

WILO AG

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7516

T 01805 R•U•F•W•I•L•O*

7•8•3•9•4•5•6

F 0231 4102-7666

Kompetenz-Team

Kommune

Bau + Bergbau

WILO EMU GmbH

Heimgartenstraße 1

95030 Hof

T 09281 974-550

F 09281 974-551

Werkskundendienst

Gebäudetechnik

Kommune

Bau + Bergbau

Industrie

WILO AG

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7900

T 01805 W•I•L•O•K•D*

9•4•5•6•5•3

F

0231

4102-7126

Erreichbar Mo–Fr von

7–17 Uhr.

Wochenende und feiertags

9–14 Uhr elektronische

Bereitschaft mit

Rückruf-Garantie!

–Kundendienst-Anforderung

–Werksreparaturen

–Ersatzteilfragen

–Inbetriebnahme

–Inspektion

–Technische Service-Beratung

–Qualitätsanalyse

Wilo-International

Österreich

Zentrale Wien:

WILO Handelsgesellschaft mbH

Eitnergasse 13

1230 Wien

T +43 507 507-0

F +43 507 507-15

Vertriebsbüro Salzburg:

Gnigler Straße 56

5020 Salzburg

T +43 507 507-13

F +43 507 507-15

Vertriebsbüro Oberösterreich:

Trattnachtalstraße 7

4710 Grieskirchen

T +43 507 507-26

F +43 507 507-15

Schweiz

EMB Pumpen AG

Gerstenweg 7

4310 Rheinfelden

T +41 61 83680-20

F +41 61 83680-21

Standorte weiterer

Tochtergesellschaften

Argentinien, Aserbaidschan,

Belarus, Belgien, Bulgarien,

China, Dänemark, Estland,

Finnland, Frankreich,

Griechenland, Großbritannien,

Irland, Italien, Kanada,

Kasachstan, Korea, Kroatien,

Lettland, Libanon, Litauen,

Niederlande, Norwegen,

Polen, Portugal, Rumänien,

Russland, Saudi-Arabien,

Schweden, Serbien und

Montenegro, Slowakei,

Slowenien, Spanien,

Südafrika, Taiwan,

Tschechien, Türkei, Ukraine,

Ungarn, Vereinigte Arabische

Emirate, Vietnam, USA

Die Adressen finden Sie unter

www.wilo.de oder

www.wilo.com.

Stand Mai 2008

Erreichbar Mo–Fr von 7–18 Uhr.

–

Antworten

auf

– Produkt- und Anwendungsfragen

– Liefertermine und Lieferzeiten

–Informationen

über Ansprechpartner vor Ort

–Versand von Informationsunterlagen

* 14 Cent pro Minute aus dem deutschen Festnetz

der T-Com. Bei Anrufen aus Mobilfunknetzen

sind Preisabweichungen möglich.

Wilo-Vertriebsbüros in Deutschland

Loading...

Loading...