Page 1

Wilo-Drain LP 40

D Einbau- und Betriebsanleitung

GB Installation and operating instructions

F Notice de montage et de mise en service

2 048 284 –Ed.02/ 2009-04

Page 2

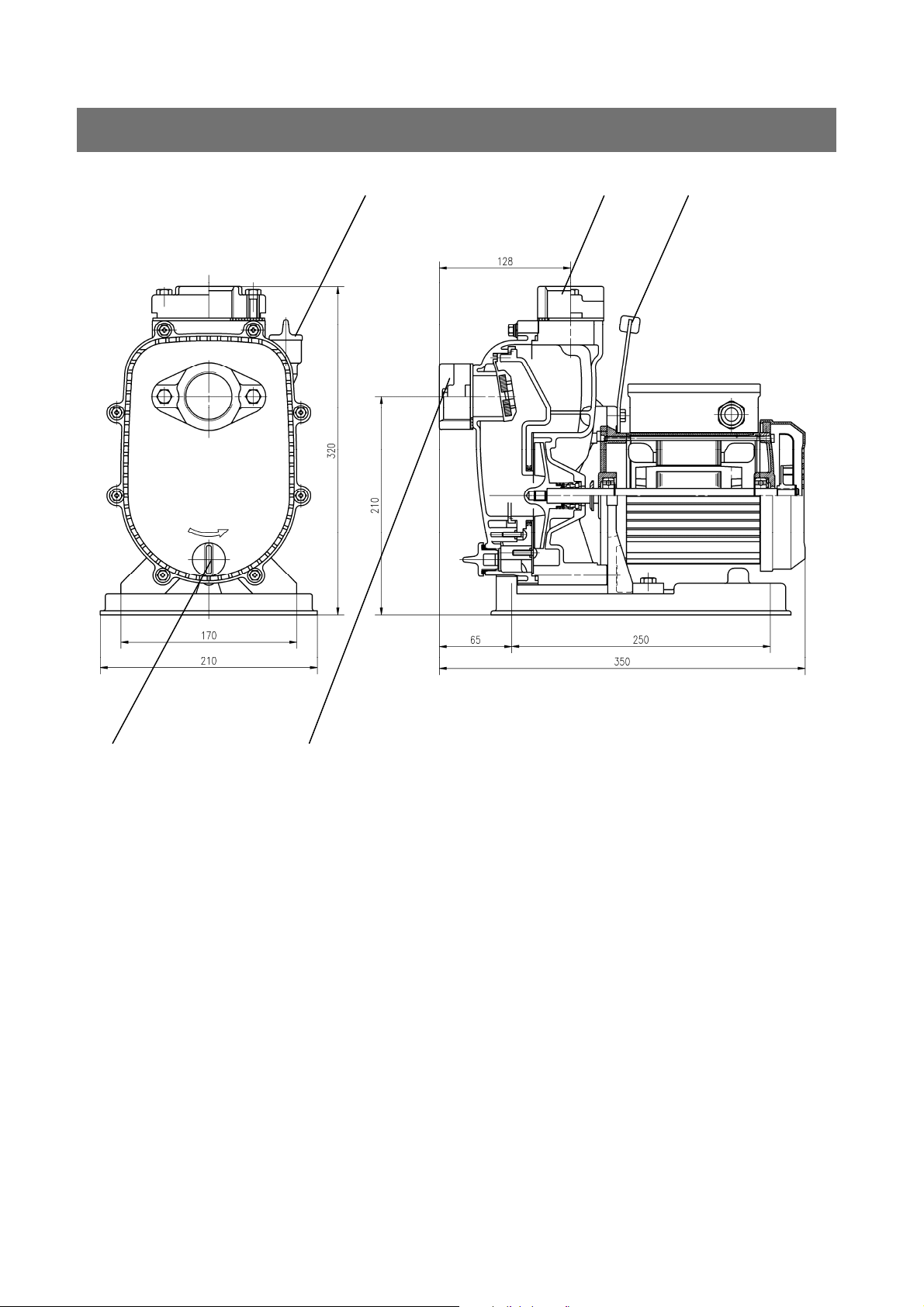

Fig. 1:

2 3

1

4 5

Page 3

D

1 Allgemeines .................................................................................................................. 3

2 Sicherheit ...................................................................................................................... 5

3 Transport und Zwischenlagerung .............................................................................. 6

4 Beschreibung von Erzeugnis und Zubehör ............................................................... 6

5 Aufstellung / Einbau..................................................................................................... 7

6 Inbetriebnahme ............................................................................................................ 7

7 Wartung ......................................................................................................................... 7

8 Störung, Ursachen und Beseitigung .......................................................................... 8

GB

1 General .......................................................................................................................... 9

2 Safety ........................................................................................................................... 11

3 Transport and iterim strorage ................................................................................... 12

4 Product and accessory description .......................................................................... 12

5 Assembly / Installation .............................................................................................. 12

6 Operation .................................................................................................................... 13

7 Maintenance ............................................................................................................... 13

8 Problem, causes and solutions ................................................................................. 14

F

1 Généralités .................................................................................................................. 15

2 Sécurité ........................................................................................................................ 17

3 Transport et stockage ............................................................................................... 18

4 Description du produit et des accessoires .............................................................. 18

5 Installation / Montage ................................................................................................ 18

6 Mise en service ........................................................................................................... 19

7 Entretien ...................................................................................................................... 19

8 Pannes, causes et remèdes ....................................................................................... 20

Page 4

Page 5

English

1 General Information

Assembly and installation should only be carried out by qualified personnel

1.1 Uses

The self priming pumps of the Wilo-Drain LP40 series are suitable for removing and lifting clean and

dirty water/sewage. They are used for:

domestic,

horticulture,

agricultural use,

in industrial and process engineering.

The LP pumps are made from polypropylene plastics and bronze. They are resistant against corrosion

and suitable for removing seawater. Further they are used for

aquariums

fish-farming

LP pumps may not be used to pump raw sewage containing Faeces.

Local regulations must be observed.

The pump must not be used for pumping drinking water.

1.2 Product data

1.2.1 Rating plate

LP 40 / 11 - 1- 230

Series: Lifting-Pump

Nominal width

Delivery head max.

Current type

Power supply [V]

9

Page 6

English

Suction time

1.2.2 Connection and electrical data

Power supply

1 ~ 230 V, ±10%

Mains frequency 50 Hz

System of protection IP 44

Isolation class B

Operating mode S1 continuous operation

Capacity max.

9μF, 450V

Speed max. max. 2900 ¹/min (50 Hz)

max. power input see rating plate

Admission output P1 500W

Motor-output P2 400W

Conveying capacity see rating plate

Delivery head max see rating plate

Suction head 6m

Nominal width delivery side 40mm, 1½ “

Nominal width suction side 40mm, 1½ “

Temperature range of the flow medium: 0 up to +35°C

1.2.3 suction time

The duration of the suction process of the LP40 pump depends on the suction depth. The diagram

below shows the process duration in dependence on the depth. The mentioned time values are average values, depending from the conditions of use, they may deviate, for example by using a suctionhose.

7

6

5

4

3

H [m]

2

1

0

0 5 10 15

Ansaugzeit

Zeit t [ min]

Time [min]

Depth [m] Time [min] ca.

1,0 1

2,0 2

3,0 4

4,0 6

5,0 9

6,0 10

10

Page 7

English

2 Safety

These instructions contain important information which must be followed when installing and operating the pump. These operating instructions must therefore be read before assembly and commissioning by the installer and the responsible operator.

Both the general safety instructions in the “Safety precautions” section and those in subsequent

sections indicated by danger symbols should be carefully observed.

2.1 Indication of instructions in the Operating Instructions

Safety precautions in these operating instructions which, if not followed, could cause personal injury

are indicated by the symbol:

when warning of electrical voltage with

The following symbol is used to indicate that by ignoring the relevant safety instructions, damage

could be caused to the pump/machinery and its functions:

ATTENTION!

2.2 Personnel qualifications

The installation personnel must have the appropriate qualifications for this work.

2.3 Danger in the event of non-observance of the safety instructions

Non-observance of the safety instructions can result in risk of injury to persons and damage to

pump/installation. Non-observance of the safety instructions can result in the loss of any claims for

damages.

In detail, non-observance can, for example, result in the following risks:

Failure of important functions of the pump/installation,

Failure of specified maintenance and repair procedures,

Risks to persons through electrical, mechanical and bacteriological effects,

Property damage.

2.4 Safety instructions for the operator

The existing directives for accident prevention must be adhered to. Danger from electrical current

must be eliminated. Local directives or general directives [e.g. IEC, VDE etc.] and local power supply

companies must be adhered to.

Risks through mechanical or bacteriological effects must be prevented. Local conditions and

guidelines relating to sewage technology must be adhered to.

2.5 Safety instructions for inspection and installation work

The operator must ensure that all inspection and installation work is carried out by authorised and

qualified personnel, who are sufficiently informed from their own detailed study of the operating

instructions.

Work to the pump/installation must only be carried out when at a standstill.

2.6 Unauthorised modification and manufacture of spare parts

Modifications to the pump/installation are only permissible after consultation with the manufacturer.

Original spare parts and accessories authorised by the manufacturer ensure safety. The use of other

parts can nullify the liability from the results of their usage.

11

Page 8

English

2.7 Improper use

The operational safety of the supplied pump/unit is only guaranteed for conventional use in accordance with section 1 of the installation and operating instructions. The limit values must on no account fall under or exceed those specified in the catalogue/data sheet.

3 Transport and interim storage

ATTENTION!

4 Product and accessory description

4.1 Pump description (Fig. 1)

Pos. 1 Filling- / bleeding plug Pos. 4 Handle

The pump may only be transported/suspended on the handle provided for trans-

port. Never by the cable. The pump must be protected against physical damage

The pump mustn’t get into contact with flammable parts (clothes..) while using.

If the Pump is not used for longer time it should be disconnected from the elec-

trical supplyment.

Pos. 2 Drain plug Pos. 5 Discharge port

Pos. 3 Suction port

The Self priming Pump Wilo LP is driven by a dry-running motor which is fixed by screws with the

pump housing. Motor and pump have a continuous shaft made of stainless steel. The impellers material is bronze. The pump housing is made of polypropylene plastics. The flow medium enters from a

horizontal suction opening and exits by the vertical pressure connection. Both connections are

equipped with 1 ½ “ plastic flanges.

4.2 Products delivered

Installation and operating instructions

Plastic flanges 1 ½“. Suction and pressure.

4.3 Accessories

Accessories must be ordered separately

Suction side: Use special hoses for suction use

5 Assembly / Installation

The LP40 pumps are intended for the following types of installation

transportable dry installation

stationary dry installation

5.1 Assembly

The pump must be installed in a frost-free place.

The shaft must be free from coarse solids (e.g. building rubble) prior to installation and commissioning.

See catalogue for installation dimensions

The pressure-pipe must show the pump’s nominal width (R 1½, possibility for expansion).

The suction flange and pipe must be absolutely tight. Otherwise no suction mode.

12

Page 9

5.2 Electrical connection

English

Electrical connection should be made by a qualified electrician. Current national regulations must be observed (e.g. VDE regulations in Germany).

Check that the mains current and voltage comply with the data on the rating plate

Mains fuse: 16 A, time-lag

Pump/installation must be earthed in compliance with regulations

In accordance with EN 60335, submersible driven-motor pumps with less than 10 m of connect-

ing cable are only permitted for use within buildings, in other words not for operation in open

air.

6 Operation

To reach a optimum suction-process, it is necessary to fill the pump housing with water using the

hopper cap

ATTENTION!

The mechanical seal must not run dry!

- Dry running reduces the life of motor and mechanical seal.

- Fill in some water !

7 Maintenance

In order to avoid infection maintenance work should only be carried out using protective

gloves.

For all maintenance and repair work the pump is to be switched off-circuit and protected against unauthorised re-starting.

In principle, damage to the connecting cable should only be repaired by a qualified electrician.

13

Page 10

English

8 Problems, causes and solutions

Problem Causes Solutions

Pump does not run no voltage

Check wires and fuses and/or switch automatic circuit-breakers back on in distribution substation

Rotor blocked Clean casing and impeller

Cable break

Check cable resistance. If necessary, replace

cable. Only use original Wilo special cable!

Pump has no power

The pump sucks in air due to

Check the liquid level

an overly strong check the

function/adjustments of the

drop in the liquid level

Pump working against insu-

Fill the pump housing with water.

lating air cushion

Pressure-pipe blocked Check and clean line

No suction Hose (suction side leaky) Repair or change suction hose.

If no solution can be found, please contact your plumbing and heating specialist or your nearest

Wilo customer services or representative.

Subject to technical alterations!

14

Page 11

A

:

D EG - Konformitätserklärung

GB EC – Declaration of conformity

F Déclaration de conformité CE

Hiermit erklären wir, dass die Bauarten der Baureihe :

Herewith, we declare that this product:

Par le présent, nous déclarons que cet agrégat :

Drain LP 40

in der gelieferten Ausführung folgenden einschlägigen Bestimmungen entspricht:

in its delivered state complies with the following relevant provisions:

est conforme aux dispositions suivants dont il relève:

Elektromagnetische Verträglichkeit - Richtlinie 2004/108/EG

Electromagnetic compatibility - directive

Compatibilité électromagnétique- directive

Niederspannungsrichtlinie 2006/95/EG

Low voltage directive

Directive basse-tension

und entsprechender nationaler Gesetzgebung.

and with the relevant national legislation.

et aux législations nationales les transposant.

Angewendete harmonisierte Normen, insbesondere:

pplied harmonized standards, in particular:

Normes harmonisées, notamment

EN 60335-2-41

EN 61000-3-2

EN 61000-3-3

EN 55014-1

EN 55014-2

EN 60034-1

Bei einer mit uns nicht abgestimmten technischen Änderung der oben genannten Bauarten, verliert diese Erklärung ihre Gültigkeit.

If the above mentioned series are technically modified without our approval, this declaration shall no longer be applicable.

Si les gammes mentionnées ci-dessus sont modifiées sans notre approbation, cette déclaration perdra sa validité.

Dortmund, 20.02.2009

Erwin Prieß

Quality Manager

WILO SE

Nortkirchenstraße 100

44263 Dortmund

Germany

Document: 2103590.1

Page 12

NL

EG-verklaring van overeenstemming

Hiermede verklaren wij dat dit aggregaat in de

geleverde uitvoering voldoet aan de volgende

bepalingen:

Elektromagnetische compatibiliteit 2004/108/EG

EG-laagspanningsrichtlijn 2006/95/EG

Gebruikte geharmoniseerde normen, in het

bijzonder:

P

Declaração de Conformidade CE

Pela presente, declaramos que esta unidade no

seu estado original, está conforme os seguintes

requisitos:

Compatibilidade electromagnética 2004/108/EG

Directiva de baixa voltagem2006/95/EG

Normas harmonizadas aplicadas, especialmente:

FIN

CE-standardinmukaisuusseloste

Ilmoitamme täten, että tämä laite vastaa seuraavia

asiaankuuluvia määräyksiä:

Sähkömagneettinen soveltuvuus 2004/108/EG

Matalajännite direktiivit: 2006/95/EG

Käytetyt yhteensovitetut standardit, erityisesti:

CZ

Prohlášení o shodě EU

Prohlašujeme tímto, že tento agregát v dodaném

provedení odpovídá následujícím příslušným

ustanovením:

Směrnicím EU–EMV 2004/108/EG

Směrnicím EU–nízké napětí 2006/95/EG

Použité harmonizační normy, zejména:

GR

Δήλωση προσαρμογής της Ε.Ε.

Δηλώνουμε ότι το προϊόν αυτό σ’ αυτή την

κατάσταση παράδοσης ικανοποιεί τις ακόλουθες

διατάξεις :

Ηλεκτρομαγνητική συμβατότητα EG-

2004/108/EG

Οδηγία χαμηλής τάσης EG–2006/95/EG

Εναρμονισμένα χρησιμοποιούμενα πρότυπα,

ιδιαίτερα:

1)

1)

1)

Erwin Prieß

Quality Manager

I

Dichiarazione di conformità CE

Con la presente si dichiara che i presenti prodotti

sono conformi alle seguenti disposizioni e

direttive rilevanti:

Compatibilità elettromagnetica 2004/108/EG

Direttiva bassa tensione 2006/95/EG

Norme armonizzate applicate, in particolare: 1)

S

CE- försäkran

Härmed förklarar vi att denna maskin i levererat

utförande motsvarar följande tillämpliga

bestämmelser:

EG–Elektromagnetisk kompatibilitet – riktlinje

2004/108/EG

EG–Lågspänningsdirektiv 2006/95/EG

1)

1)

Tillämpade harmoniserade normer, i synnerhet:

DK

EF-overensstemmelseserklæring

Vi erklærer hermed, at denne enhed ved levering

overholder følgende relevante bestemmelser:

Elektromagnetisk kompatibilitet: 2004/108/EG

Lavvolts-direktiv 2006/95/EG

Anvendte harmoniserede standarder, særligt:

PL

Deklaracja Zgodności CE

Niniejszym deklarujemy z pełną

odpowiedzialnoscią że dostarczony wyrób jest

zgdony z następującymi dokumentami:

Odpowiedniość elektromagnetyczna

2004/108/EG

Normie niskich napięć 2006/95/EG

Wyroby są zgodne ze szczegółowymi normami

zharmonizowanymi:

TR

EC Uygunluk Teyid Belgesi

Bu cihazın teslim edildiği şekliyle aşağıdaki

standartlara uygun olduğunu teyid ederiz:

Elektromanyetik Uyumluluk 2004/108/EG

Alçak gerilim direktifi 2006/95/EG

Kısmen kullanılan standartlar:

1)

1)

E

Declaración de conformidad CE

Por la presente declaramos la conformidad del

producto en su estado de suministro con las

disposiciones pertinentes siguientes:

Directiva sobre compatibilidad electromagnética

2004/108/EG

Directiva sobre equipos de baja tensión

2006/95/EG

Normas armonizadas adoptadas, especialmente:

N

EU-Overensstemmelseserklæring

Vi erklærer hermed at denne enheten i utførelse

som levert er i overensstemmelse med følgende

relevante bestemmelser:

EG–EMV–Elektromagnetisk kompatibilitet

2004/108/EG

EG–Lavspenningsdirektiv 2006/95/EG

1)

1)

Anvendte harmoniserte standarder, særlig:

H

EK. Azonossági nyilatkozat

Ezennel kijelentjük,hogy az berendezés az

alábbiaknak megfelel:

Elektromágneses zavarás/türés: 2004/108/EG

Kisfeszültségü berendezések irány-Elve:

2006/95/EG

Felhasznált harmonizált szabványok, különösen:

Декларация о соответствии

RUS

1)

1)

1)

Европейским нормам

Настоящим документом заявляем, что данный

агрегат в его объеме поставки соответствует

следующим нормативным документам:

Электромагнитная устойчивость 2004/108/EG

Директивы по низковольтному напряжению

2006/95/EG

Используемые согласованные стандарты и

нормы, в частности :

EN 55014-1,

1)

1)

EN 55014-2,

EN 60034-1,

EN 60335-2-41,

EN 61000-3-2,

EN 61000-3-3.

WILO SE

Nortkirchenstraße 100

44263 Dortmund

Germany

Page 13

Page 14

Page 15

WILO SE

Nortkirchenstraße 100

44263 Dortmund

Germany

T +49 231 4102-0

F +49 231 4102-7363

wilo@wilo.com

www.wilo.com

Algeria

Bad Ezzouar, Dar El Beida

T +213 21 247979

chabane.hamdad@salmson.fr

Armenia

375001 Yerevan

T +374 10 544336

info@wilo.am

Bosnia and Herzegovina

71000 Sarajevo

T +387 33 714510

zeljko.cvjetkovic@wilo.ba

Georgia

0179 Tbilisi

T +995 32 306375

info@wilo.ge

Macedonia

1000 Skopje

T +389 2 3122058

valerij.vojneski@wilo.com.mk

Mexico

07300 Mexico

T +52 55 55863209

roberto.valenzuela@wilo.com.mx

Moldova

2012 Chisinau

T +373 2 223501

sergiu.zagurean@wilo.md

Rep. Mongolia

Ulaanbaatar

T +976 11 314843

wilo@magicnet.mn

Tajikistan

734025 Dushanbe

T +992 37 2232908

farhod.rahimov@wilo.tj

Turkmenistan

744000 Ashgabad

T +993 12 345838

wilo@wilo-tm.info

Uzbekistan

100015 Tashkent

T +998 71 1206774

info@wilo.uz

March 2009

Wilo – International (Subsidiaries)

Wilo – International (Representation offices)

Argentina

WILO SALMSON

Argentina S.A.

C1295ABI Ciudad

Autónoma de Buenos Aires

T +54 11 4361 5929

info@salmon.com.ar

Austria

WILO Pumpen

Österreich GmbH

1230 Wien

T +43 507 507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1065 Baku

T +994 12 5962372

info@wilo.az

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2503393

wilobel@wilo.by

Belgium

WILO SA/NV

1083 Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILO Bulgaria Ltd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Canada

WILO Canada Inc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILO China Ltd.

101300 Beijing

T +86 10 80493900

wilobj@wilo.com.cn

Croatia

WILO Hrvatska d.o.o.

10090 Zagreb

T +38 51 3430914

wilo-hrvatska@wilo.hr

Czech Republic

WILO Praha s.r.o.

25101 Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILO S.A.S.

78390 Bois d'Arcy

T +33 1 30050930

info@wilo.fr

Great Britain

WILO (U.K.) Ltd.

DE14 2WJ BurtonUpon-Trent

T +44 1283 523000

sales@wilo.co.uk

Greece

WILO Hellas AG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILO Magyarország Kft

2045 Törökbálint

(Budapest)

T +36 23 889500

wilo@wilo.hu

Ireland

WILO Engineering Ltd.

Limerick

T +353 61 227566

sales@wilo.ie

Italy

WILO Italia s.r.l.

20068 Peschiera

Borromeo (Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 727 2785961

in.pak@wilo.kz

Korea

WILO Pumps Ltd.

621-807 Gimhae

Gyeongnam

T +82 55 3405800

wilo@wilo.co.kr

Latvia

WILO Baltic SIA

1019 Riga

T +371 67 145229

mail@wilo.lv

Lebanon

WILO SALMSON

Lebanon

12022030 El Metn

T +961 4 722280

wsl@cyberia.net.lb

Lithuania

WILO Lietuva UAB

03202 Vilnius

T +370 5 2136495

mail@wilo.lt

The Netherlands

WILO Nederland b.v.

1551 NA Westzaan

T +31 88 9456 000

info@wilo.nl

Norway

WILO Norge AS

0975 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILO Polska Sp. z.o.o.

05-090 Raszyn

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

Portugal Lda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILO Romania s.r.l.

077040 Com. Chiajna

Jud. Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592 Moscow

T +7 495 7810690

wilo@orc.ru

Saudi Arabia

WILO ME - Riyadh

Riyadh 11465

T +966 1 4624430

wshoula@wataniaind.com

Serbia and Montenegro

WILO Beograd d.o.o.

11000 Beograd

T +381 11 2851278

office@wilo.co.yu

Slovakia

WILO Slovakia s.r.o.

82008 Bratislava 28

T +421 2 45520122

wilo@wilo.sk

Slovenia

WILO Adriatic d.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

South Africa

Salmson South Africa

1610 Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILO Ibérica S.A.

28806 Alcalá de Henares

(Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILO Sverige AB

35246 Växjö

T +46 470 727600

wilo@wilo.se

Switzerland

EMB Pumpen AG

4310 Rheinfelden

T +41 61 83680-20

info@emb-pumpen.ch

Taiwan

WILO-EMU Taiwan Co. Ltd.

110 Taipeh

T +886 227 391655

nelson.wu@

wiloemutaiwan.com.tw

Turkey

WILO Pompa Sistemleri

San. ve Tic. A.S¸.

34530 Istanbul

T +90 216 6610211

wilo@wilo.com.tr

Ukraina

WILO Ukraina t.o.w.

01033 Kiew

T +38 044 2011870

wilo@wilo.ua

Vietnam

Pompes Salmson Vietnam

Ho Chi Minh-Ville Vietnam

T +84 8 8109975

nkm@salmson.com.vn

United Arab Emirates

WILO ME - Dubai

Dubai

T +971 4 3453633

info@wilo.com.sa

USA

WILO-EMU USA LLC

Thomasville,

Georgia 31792

T +1 229 5840097

info@wilo-emu.com

USA

WILO USA LLC

Melrose Park, Illinois 60160

T +1 708 3389456

mike.easterley@

wilo-na.com

Page 16

WILO SE

Nortkirchenstraße 100

44263 Dortmund

Germany

T 0231 4102-0

F 0231 4102-7363

wilo@wilo.com

www.wilo.de

G1 Nord

WILO SE

Vertriebsbüro Hamburg

Beim Strohhause 27

20097 Hamburg

T 040 5559490

F 040 55594949

hamburg.anfragen@wilo.com

G2 Nord-Ost

WILO SE

Vertriebsbüro Berlin

Juliusstraße 52–53

12051 Berlin-Neukölln

T 030 6289370

F 030 62893770

berlin.anfragen@wilo.com

G3 Ost

WILO SE

Vertriebsbüro Dresden

Frankenring 8

01723 Kesselsdorf

T 035204 7050

F 035204 70570

dresden.anfragen@wilo.com

G4 Süd-Ost

WILO SE

Vertriebsbüro München

Adams-Lehmann-Straße 44

80797 München

T 089 4200090

F 089 42000944

muenchen.anfragen@wilo.com

G5 Süd-West

WILO SE

Vertriebsbüro Stuttgart

Hertichstraße 10

71229 Leonberg

T 07152 94710

F 07152 947141

stuttgart.anfragen@wilo.com

G6 Mitte

WILO SE

Vertriebsbüro Frankfurt

An den drei Hasen 31

61440 Oberursel/Ts.

T 06171 70460

F 06171 704665

frankfurt.anfragen@wilo.com

G7 West

WILO SE

Vertriebsbüro Düsseldorf

Westring 19

40721 Hilden

T 02103 90920

F 02103 909215

duesseldorf.anfragen@wilo.com

Kompetenz-Team

Gebäudetechnik

WILO SE

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7516

T 01805 R•U•F•W•I•L•O*

7•8•3•9•4•5•6

F 0231 4102-7666

Kompetenz-Team

Kommune

Bau + Bergbau

WILO EMU GmbH

Heimgartenstraße 1

95030 Hof

T 09281 974-550

F 09281 974-551

Werkskundendienst

Gebäudetechnik

Kommune

Bau + Bergbau

Industrie

WILO SE

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7900

T 01805 W•I•L•O•K•D*

9•4•5•6•5•3

F 0231 4102-7126

kundendienst@wilo.com

Erreichbar Mo–Fr von

7–17 Uhr.

Wochenende und feiertags

9–14 Uhr elektronische

Bereitschaft mit

Rückruf-Garantie!

–Kundendienst-Anforderung

–Werksreparaturen

–Ersatzteilfragen

–Inbetriebnahme

–Inspektion

–Technische Service-Beratung

–Qualitätsanalyse

Wilo-International

Österreich

Zentrale Wien:

WILO Pumpen Österreich GmbH

Eitnergasse 13

1230 Wien

T +43 507 507-0

F +43 507 507-15

Vertriebsbüro Salzburg:

Gnigler Straße 56

5020 Salzburg

T +43 507 507-13

F +43 507 507-15

Vertriebsbüro Oberösterreich:

Trattnachtalstraße 7

4710 Grieskirchen

T +43 507 507-26

F +43 507 507-15

Schweiz

EMB Pumpen AG

Gerstenweg 7

4310 Rheinfelden

T +41 61 83680-20

F +41 61 83680-21

Standorte weiterer

Tochtergesellschaften

Argentinien, Aserbaidschan,

Belarus, Belgien, Bulgarien,

China, Dänemark, Estland,

Finnland, Frankreich,

Griechenland, Großbritannien,

Irland, Italien, Kanada,

Kasachstan, Korea, Kroatien,

Lettland, Libanon, Litauen,

Niederlande, Norwegen,

Polen, Portugal, Rumänien,

Russland, Saudi-Arabien,

Schweden, Serbien und

Montenegro, Slowakei,

Slowenien, Spanien,

Südafrika, Taiwan,

Tschechien, Türkei, Ukraine,

Ungarn, Vereinigte Arabische

Emirate, Vietnam, USA

Die Adressen finden Sie unter

www.wilo.de oder

www.wilo.com.

Stand Februar 2009

Erreichbar Mo–Fr von 7–18 Uhr.

–Antworten auf

– Produkt- und Anwendungsfragen

– Liefertermine und Lieferzeiten

–Informationen über Ansprechpartner vor Ort

–Versand von Informationsunterlagen

* 14 Cent pro Minute aus dem deutschen Festnetz

der T-Com. Bei Anrufen aus Mobilfunknetzen

sind Preisabweichungen möglich.

Wilo-Vertriebsbüros in Deutschland

Loading...

Loading...