Page 1

Wilo-DrainLift KH 32-0,4

D Einbau- und Betriebsanleitung

GB Installation and operating instructions

F Notice de montage et de mise en service

NL Onderhouds- en bedieningsvoorschriften

E Instrucciones de instalación y funcionamiento

I Istruzioni di montaggio, uso e manutenzione

H Beépítési és üzemeltetési utasítás

PL Instalacja i instrukcje obs

ługi

CZ Návod k montáˇzí a obsluze

GR

Οδηγίες εγκατάστασης και λειτουργίας

RUS

Instrukcii po vvodu v qkspluataciœ

i montaΩu

S Monterings- och skötselanvisning

2044035-Ed.05/2007-05-DDD

Page 2

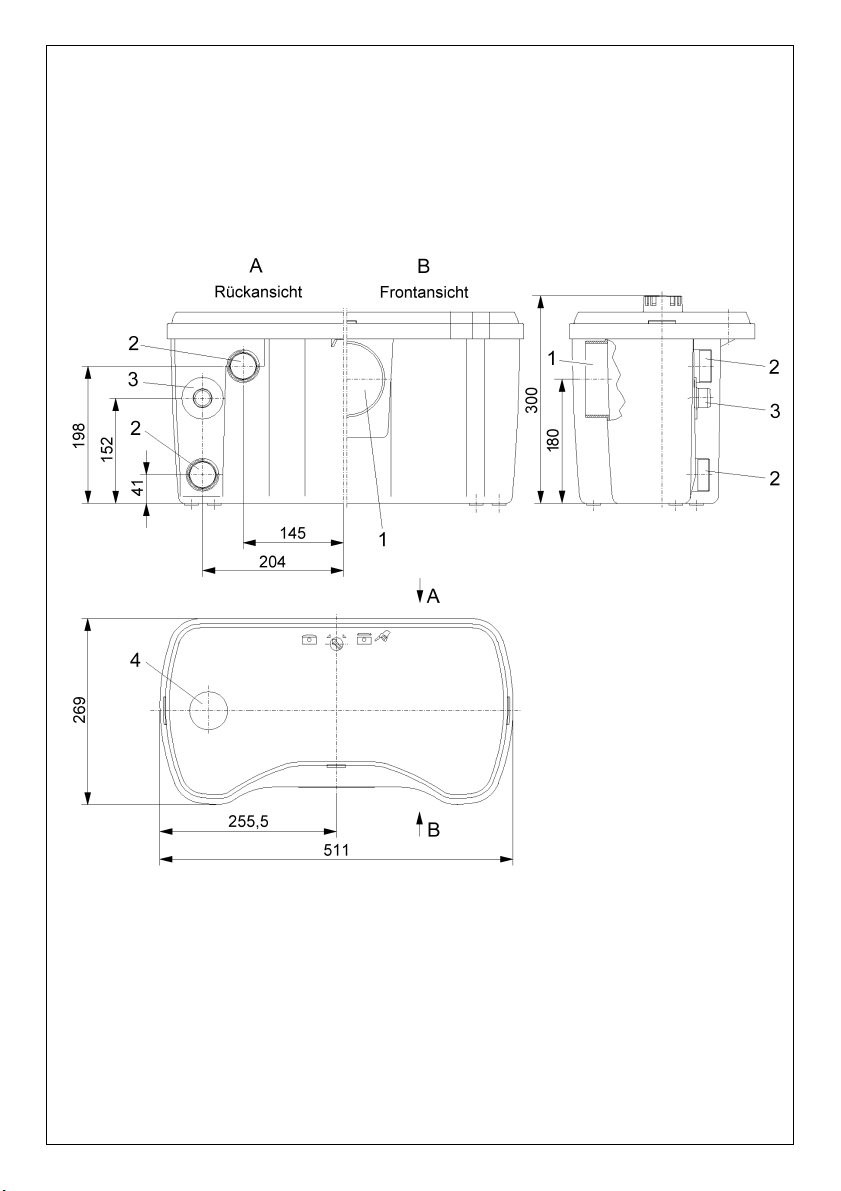

Fig. 1

Page 3

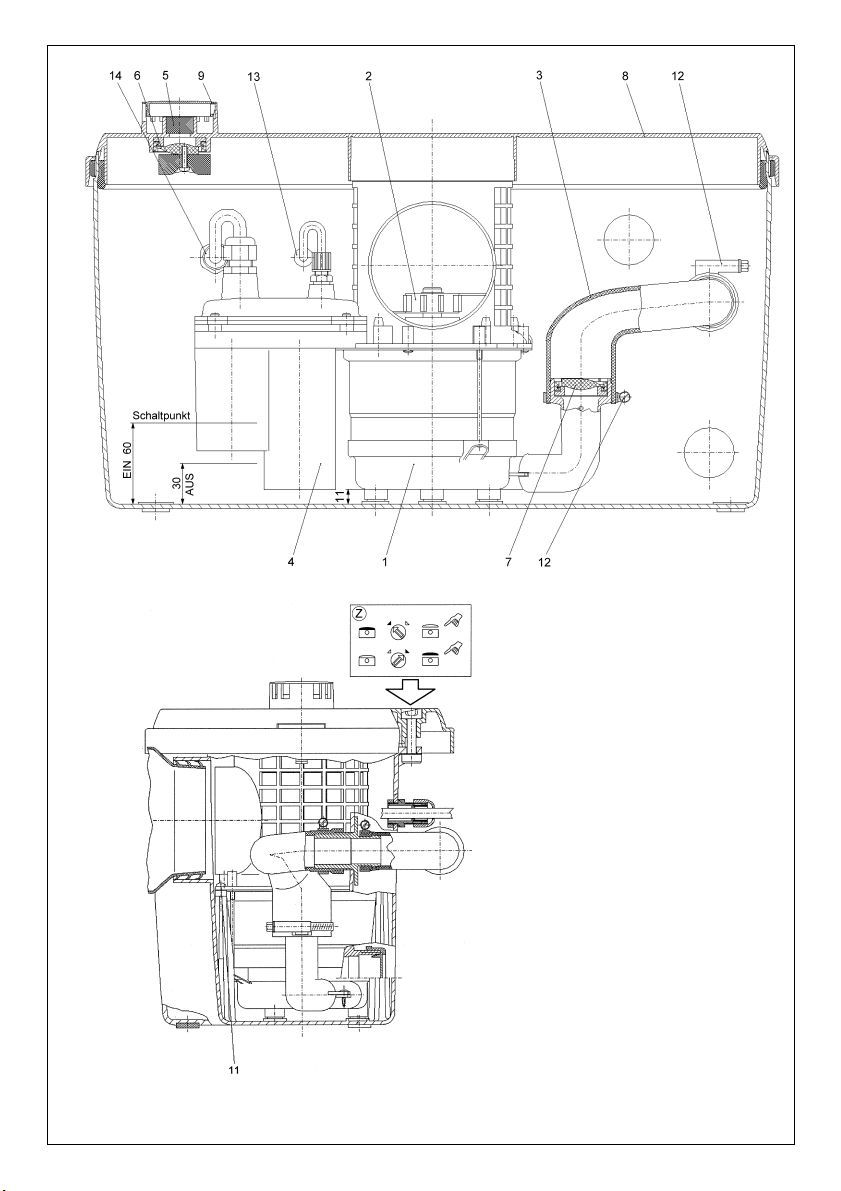

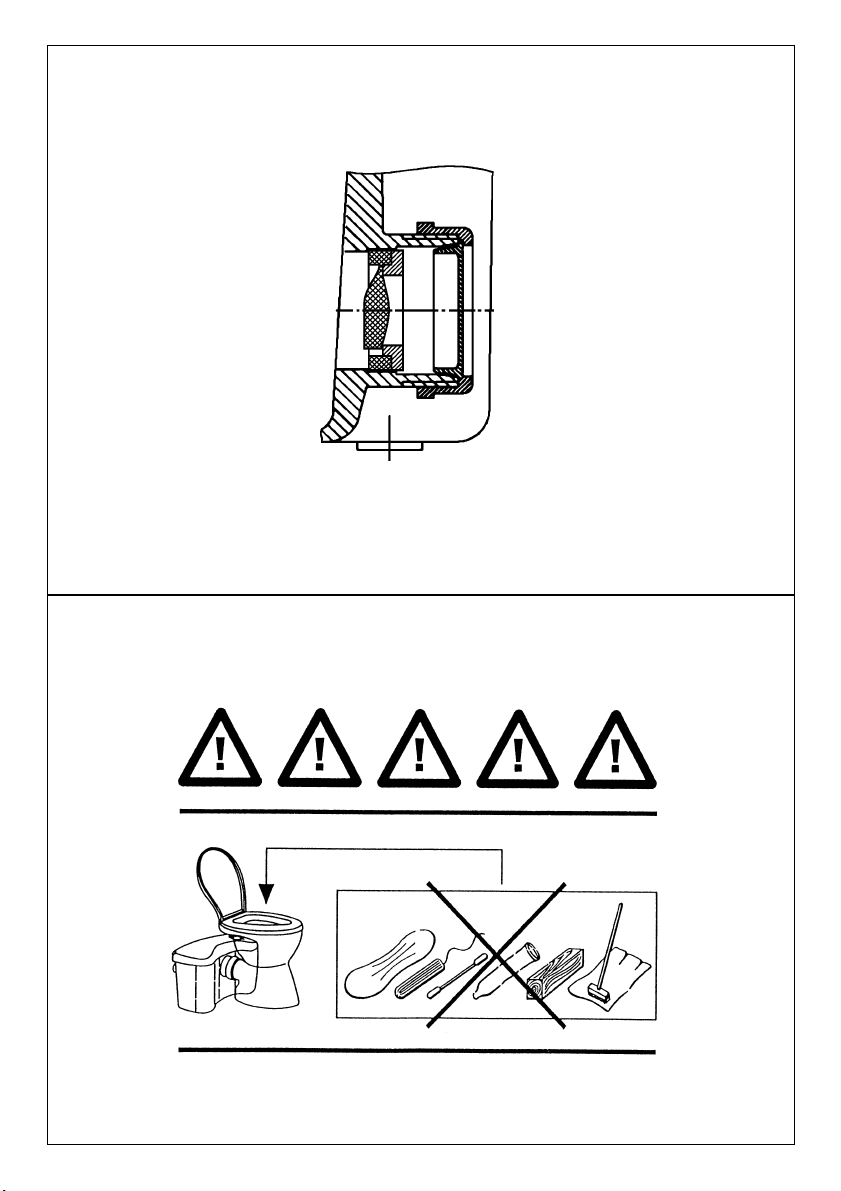

Fig. 2

Page 4

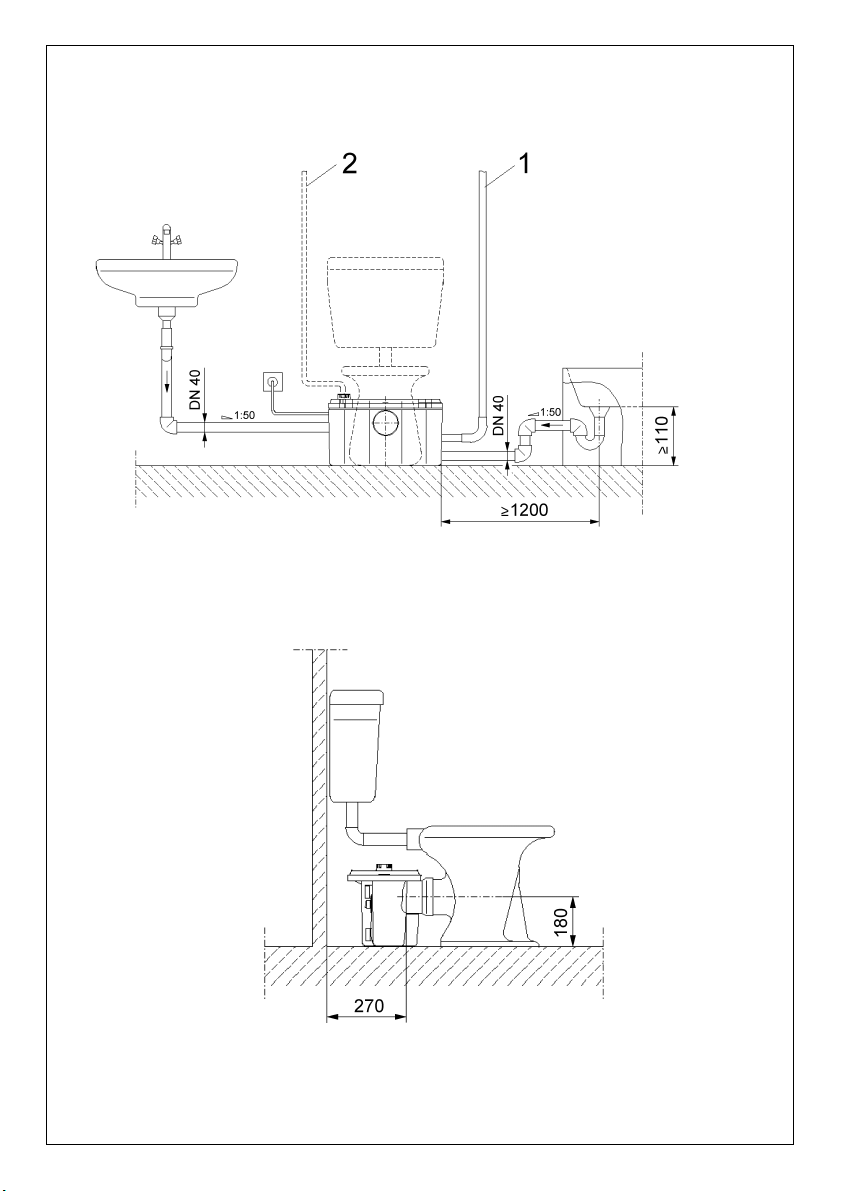

Fig. 3

Page 5

Fig. 5

Fig. 4

Page 6

D CE-Konformitäts-

erklärung

Hiermit erklären wir, daß dieses Aggregat folgenden einschlägigen Bestimmungen

entspricht:

EG-Maschinenrichtlinien

89/392/EWG i.d.F.,

91/368/EWG, 93/44/EWG,

93/68/EWG

Elektromagnetische

Verträglichkeit

89/336/EWG i.d.F.

92/31/EWG, 93/68/EWG

Angewendete harmonisierte

Normen, insbesondere

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

GB EC declaration of

conformity

We hereby declare that this

unit complies with the

following relevant provisions:

EC machinery directive

89/392/EWG in this version,

91/368/EWG, 93/44/EWG,

93/68/EWG

Resistance to

electromagnetism

89/336/EWG in this version

92/31/EWG, 93/68/EWG

Applied harmonized standards in particular:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

F

Déclaration de

conformité CE

Par la présente, nous

déclarons que cet

agrégat sitisfait aux

dispositions suivantes:

Directives CEE relatives

aux machines 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Compatibilité

électromagnétique

89/336/CEE, 92/31/CEE,

93/68/CEE

Normes utilisées harmonisées, notamment

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

NL EG-verklaring van

overeenstemming

iermede verklaren wij dat

deze machine voldoet aan

de volgende bepalingen:

EG-richtlijnen betreffende

machines 89/392/EEG,

91/368/EEG, 93/44/EEG,

93/68/EEG

Elektromagnetische

tolerantie

89/336/EEG, 92/31/EEG,

93/68/EEG

Gebruikte geharmoniseerde

normen, in het bijzonder

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

E Declaración de

conformidad CE

Por la presente declaramos

que esta unidad satisface las

disposiciones pertinentes

siguientes:

Directivas CE sobre

máquinas 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Compatibilidad electromagnética 89/336/CEE,

92/31/CEE, 93/68/CEE

Normas armonizadas

utilizadas particularmente

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

I Dichiarazione di

conformità CE

Con la presente si dichiara

che le presenti pompe sono

conformi alle seguenti

direttive di armonizzazione

Direttiva Macchine CEE

89/392/CEE, 91/368/CEE,

93/44/CEE, 93/68/CEE

Compatibilità

elettromagnetica

89/336/CEE, 92/31/CEE,

93/68/CEE

Norme armonizzate applicate, in particolare

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

SF CE-standardinmukai-

suusseloste

Ilmoitamme täten, että tämä

laite vastaa seuraavia

asiaankuuluvia määräyksiä:

EY-konedirektiivit

89/392/ETY, 91/368/ETY,

93/44/ETY, 93/68/ETY

Sähkömagneettinen

soveltuvuus

89/336/ETY, 92/31/ETY,

93/68/ETY

Käytetyt yhteensovitetut

standardit, erityisesti

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

S EEC konformitets-

deklaration

Härmed förklaras att denna

maskin uppfyller följande

bestämmelser:

EEC maskindirektiv

89/392/EEC i denna version,

91/368/EEC, 93/44/EEC,

93/68/EEC

Elektromagnetisk kompatibilitet 89/336/EEC i denna

version, 92/31/EEC,

93/68/EEC

Tillämpade harmoniserade

normer, särskilt:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

H EK. azonossági

nyilatkozat

Ezennel kijelentjük, hogy az

agregát a megkívánt alanti

feltételeknek

megfelel:

EK-Gépirányelvek

89/392/EWG, 91/368/EWG,

93/44/EWG, 93/68/EWG

Elektromagnetikus

ÖsszeegyeztethetŒség

89/336/EWG, 92/31/EWG,

93/68/EWG

Alkalmazott, harmonizált

normák, különösen az

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

Page 7

GR ∆ήλωση συµµρφωσης

µε τους κανονισµούς CE

∆ηλώνουµε τι το προϊν

αυτ ικανοποιεί τις

ακλουθες διατάξεις:

Οδηγίες CEE σχετικά

µε µηχανήµατα

89/392/CEE, 91/368/CEE,

93/44/CEE, 93/68/CEE

Ηλεκτροµαγνητική

συµβαττητα

89/336/CEE, 92/31/CEE,

93/68/CEE

Εναρµονισµένα

χρησιµοποιούµενα

πρτυπα, ιδιαίτερα

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

CZ Osvûdãení o shodnosti s

normami EU

Prohla‰ujeme tímto, Ïe toto

zafiízení odpovídá následujícím pfiíslu‰n˘m ustanovením:

Smûrnice o strojírenském

zafiízení ES 89/392/EHS

vãetnû dodatkÛ,

91/368/EHS, 93/44/EHS,

93/68/EHS

Elektromagneticá sná‰enlivost 89/336/EHS vãetnû

dodatkÛ, 92/31/EHS,

93/68/EHS

PouÏité souhlasné normy,

zejména:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

PL OÊwiadczenie

zgodnoÊci EC

Niniejszym oÊwiadczamy, ˝e

pompa odpowiada nast´pujàcym w∏aÊciwym dla niej

dyrektywom:

Wytyczne dla przemys∏u

maszyncwego EC

89/392/EEC w tej wersji,

91/368/EEC, 94/44/EEC,

93/68/EEC

OdpornoÊç elektromagnetyczna EC 89/336/EEC

w tej wersji, 92/31/EEC,

93/68/EEC

Zastosowano normy zharmonizowane, w szczególnoÊci:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

RUS Zaåvlenie o sootvetst-

vii normam, dejst-

vuœwim v Evropejs-

kom Soob-westve

Nastoåwim dokumentom

zaåvlåem, hto dannaå usta-

novka sootvetstvuet sle-

duœwim postanovleniåm:

Директивы EC относи-

тельно машин и станков

89/392/ЦЕЕ, 91/368/ЦЕЕ,

93/44/ЦЕЕ, 93/68/ЦЕЕ

Qlektromagnitnaå sov-

mestimostæ 89/336/CEE,

92/31/CEE, 93/68/CEE

Ispolæzovavπieså garmo-

nizirovannye standarty i

normy, v

hastnosti

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

DK EF-overensstemmels-

eserklæring

Det erklæres hermed, at

dette udstyr er i overensstemmelse med følgende

bestemmelser:

EU maskindirektiver:

89/392/EØF i denne

udgave, 91/368/EØF,

93/44/EØF, 93/68/EØF

Elektromagnetisk

kompatibilitet:

89/336/EØF i denne udgave, 92/31/EØF, 93/68/EØF

Anvendte harmoniserede

normer, især:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

N EU-overensstemmelse-

serklæring

Det erklæres herved at dette

utstyret stemmer overens

med følgende bestemmelser:

EU-direktiver for maskiner

89/392/EEC og følgende,

91/368/EEC, 93/44/EEC,

93/68/EEC

Elektromagnetisk

kompatibilitet

89/336/EEC og følgende,

92/31/EEC, 93/68/EEC

Anvendte harmoniserte normer, i særdeleshet

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

TR Uygunluk Belgesi

As¸agˇí´daki cihazlarí´n takibi

standartlara

vygun oldugˇ unu temin

ederiz:

AB-Makina Standartlari

89/392/EWG i.d.F.,

91/368/EWG, 93/44/EWG,

93/68/EWG

Elektromanyetik

Uyumluluk

89/336/EWG i.d.F.,

92/31/EWG, 93/68/EWG

Özellikle kullaní´lan Normlar

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

2011678.3

WILO AG

Nortkirchenstraße 100

44263 Dortmund · Germany

Quality Management

Page 8

3

D

1. Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Transport und Zwischenlagerung. . . . . . . . . 6

4. Beschreibung des Erzeugnisses . . . . . . . . . 6

5. Aufstellung/Einbau. . . . . . . . . . . . . . . . . . . . 7

6. Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . 8

7. Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8. Störungen, Ursachen und Beseitigung . . . . 9

GB

1. General Information . . . . . . . . . . . . . . . . . . . 10

2. Safety precautions . . . . . . . . . . . . . . . . . . . . 10

3. Transport and storage . . . . . . . . . . . . . . . . . 11

4. Description of product and accessories . . . 11

5. Assembly and installation . . . . . . . . . . . . . . 12

6. Starting up . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 13

8. Faults, causes and remedies . . . . . . . . . . . . 14

F

1. Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2. Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Transport et stockage

avant utilisation . . . . . . . . . . . . . . . . . . . . . . 16

4. Description du produit . . . . . . . . . . . . . . . . . 16

5. Installation / Montage . . . . . . . . . . . . . . . . . . 17

6. Mise en service . . . . . . . . . . . . . . . . . . . . . . 17

7. Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8. Défauts, causes et remèdes . . . . . . . . . . . . 19

NL

1. Algemeen . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2. Veiligheid . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Transport en tussenopslag. . . . . . . . . . . . . . 21

4. Beschrijving van het product . . . . . . . . . . . 21

5. Opstelling/Montage . . . . . . . . . . . . . . . . . . . 22

6. Inwerkingstelling . . . . . . . . . . . . . . . . . . . . . 23

7. Onderhoud . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8. Storingen, oorzaken en oplossingen . . . . . . 24

E

1. Generalidades . . . . . . . . . . . . . . . . . . . . . . . 25

2. Instrucciones de seguridad . . . . . . . . . . . . . 25

3. Transporte y almacenamiento . . . . . . . . . . . 26

4. Descripción del producto. . . . . . . . . . . . . . . 26

5. Colocación/Instalación. . . . . . . . . . . . . . . . . 27

6. Puesta en funcionamiento . . . . . . . . . . . . . . 28

7. Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . 28

8. Fallos: causas y eliminación . . . . . . . . . . . . 29

I

1. Generalità . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2. Sicurezza . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3. Trasporto e magazzinaggio . . . . . . . . . . . . . 31

4. Descrizione del prodotto

e accessori. . . . . . . . . . . . . . . . . . . . . . . . . . 31

5. Montaggio/Installazione . . . . . . . . . . . . . . . 31

6. Messa in esercizio . . . . . . . . . . . . . . . . . . . . 32

7. Manutenzione. . . . . . . . . . . . . . . . . . . . . . . . 32

8. Blocchi, cause e rimedi. . . . . . . . . . . . . . . . 34

Page 9

ENGLISH

Information on operation

Dear customer,

In this chapter we would like to explain how the

ready-installed unit functions and operates.

However, we would also encourage you to read the

safety instructions described in the complete manual

for assembly and operation carefully.

Repairs on this unit should only be carried out by an

expert or by Wilo customer services.

The unit’s functions are all automatic. It is not neces-

sary to service the unit. Cleaning, if required, should

be carried out in accordance with the following instructions.

Cleaning

The unit cleans itself during regular use. Only seldomused units should be cleaned every three months

(also internally) as follows:

Pull the plug out of the socket. Pour a mild cleaning

agent into the toilet bowl and flush. After approximately 5 mins, plug the plug back in. Flush until the

pump switches on and pumps out the cistern. Then

flush again.

In the long term, the level of safety is increased when

the pump’s functioning and quiet running are checked

by a technical operator.

1. General Information

Installation and commissioning

by qualified personnel only!

1.1 Uses

An automatic mini lifting unit with cutting implement

for the sanitation of individual toilets, hand basins,

showers and bidets, whose dirty or waste water cannot

be transported into the canal system with a natural fall

and must therefore be lifted above the reflux level. The

additional draining points connected to the unit must

be located in the same room (limited use of mini lifting

unit). Another WC must be available above the reflux

level. This unit is particularly suitable for the sanitation

of toilets and showers in cellars.

The norm DIN EN 12050-3, DIN EN 12056 and

DIN 1986-100 should be adhered to when installing

the unit.

The lifting unit is not suitable for transporting solid

material such as hygiene articles, food leftovers,

long-fibred materials or solvents, fats and oil. It is

not permitted to connect the unit to a toilet with a

flushing valve.

1.2 Technical description

– Maximum transporting

capacity: 4 m

3

/h

– Maximum head: 5.7 m

– Max. flow medium

temperature: 35 °C

– Voltage/frequency: 1~230 V, 50 Hz

– Power input: 0.45 kW

– Speed: 2650

1

/min

– Nominal current: 2.1 A

– Type of operation: S3 28 %, 36 s

– Type of protection: IP 44

– Discharge connection: DN 25/32

– Inlet connection: DN 100 with seal collar

– Additional supply: 2 x DN 40 in

accordance with

DIN 1986 incl. blind

cover and collar

– Ventilation: 25 mm outer diameter

– Dimensions W x H x D: 511 x 300 x 269 mm

– Useful volume: 12 l

– Weight: 7.8 kg

When ordering spare parts, all details on the unit’s

rating plate should be given.

2. Safety precautions

These instructions contain important information

which must be followed when installing and operating the pump. It is therefore imperative that they be

read by both the installer and the operator before the

pump is installed or started up. Both the general

safety instructions in the ‘Safety precautions’ section

and those in subsequent sections indicated by danger

symbols should be carefully observed.

2.1 Danger symbols used in these

operating instructions

Safety precautions in these operating instructions

which, if not followed, could cause personal injury are

10

Page 10

ENGLISH

indicated by the symbol:

Safety precautions warning of danger due to electricity are indicated by the symbol:

Safety precautions which, if not followed, could

damage the pump or installation and cause it to malfunction are indicated by the word:

2.2 Qualified Personnel

The personnel installing the pump must be appropriately qualified to carry out this work.

2.3 Risks incurred by failure to comply

with the safety precautions

Failure to comply with the safety precautions could

result in personal injury or damage to the pump or

installation. Failure to comply with the safety precautions could also invalidate any claim for damages.

In particular, failure to comply with these safety precautions could give rise, for example, to the following

risks:

– the failure of important parts of the pump or installation,

– personal injury due to electrical and mechanical

causes,

– personal injury and damage to the environment due

to failure to comply with hygiene regulations when

handling sewage.

2.4 Safety precautions for the operator

Existing regulations for the prevention of accidents

must be followed.

To prevent the risk of electric shock or electrocution,

VDE regulations and those of the local supply company must be followed.

The warning stickers included in the delivery must be

attached in a visible position on the toilet cover (in

direct view of the toilet, if necessary).

2.5 Safety precautions for inspection

and installation

The operator must ensure that all inspection and

installation work is carried out by authorised and

qualified specialists who have carefully studied these

instructions. In principle, work on the unit may only

be carried out after it has been brought to a standstill.

2.6 Unauthorised alterations and manufacture

of spare parts

Alterations to the pump or installation may only be

carried out with the manufacturer’s consent. The use

of original spare parts and accessories authorised by

the manufacturer will ensure safety. The use of any

other parts may invalidate claims invoking the liability

of the manufacturer for any consequences.

2.7 Improper use

The operational safety of the unit supplied can only

be guaranteed if it is used in accordance with paragraph 1 of the operating instructions. Under no circumstances may the limits exceed or fall short of

those given in the catalogue or data sheet.

3. Transport and storage

– Care should be taken during transport that the unit

is not damaged by impact against other objects.

– The unit should be stored in a dry, frost-free place.

4. Description of the product

4.1 Description of the unit

The automatic mini lifting unit (fig. 1) is a plastic gasproof and waterproof collector tank which is placed

directly behind a pedestal type toilet with a horizontal waste connection pipe (DIN EN 37).

The supply channel is sealed with a self-sealing collar

(see fig. 1, pos. 1).

The connections (fig. 1, pos. 2) for two additional

drainage points and also for the compressed air

piping (fig. 1, pos. 3) are located at the back of the

cistern. The space behind the unit makes it easy to

guide the pipes. In this way, the additional supply

channels and the compressed air piping can be

connected from both sides.

The pump which is built into the cistern (fig. 2, pos. 1)

is equipped with a cutting tool (fig. 2, pos. 2) which

lies above it and is easily accessible. The thick matter

is broken down enough that it can be transported

through the pump and compressed air piping (fig. 2,

pos. 3).

11

ATTENTION!

Page 11

ENGLISH

The motor coil is protected by an overload safety

device which automatically switches off the motor if

exposed to an above-average level of stress. After

the motor has cooled down, it is automatically

switched back on.

The in-built booster relay (fig. 2, pos. 4) switches the

unit on and off, depending on the level.

The activated carbon filter integrated into the unit

(fig. 2, pos. 5) enables airing and ventilation to take

place directly in the installation room or by means of

an aeration pipe on the roof which should be connected separately. In order to prevent the collection tank

from overflowing through the activated carbon filter in

the event of pump failure and an increase in the level

of liquid, an additional flap trap (fig. 2, pos. 6) has

been added. The drain connection also contains a

flap trap (fig. 2, pos. 7).

4.2 Products delivered

– mini lifting unit

– hose connection set

– 1 inlet checkvalue DN 40

– 2 welches for DN 40 (enclosed)

– warning sticker

– instructions for assembly and operation

5. Assembly/Installation

5.1 Assembly

– The unit should be installed in a frost-free room.

– The assembly area must be horizontal and flat.

– The lifting unit and the electrical connection (plug)

must remain accessible for maintenance even after

assembly.

– Remove covering cap (fig. 2, pos. 8) using the

tommy bar (fig. 2, pos. Z) and pressing the 3 spring

hooks (at side and front).

– The lifting unit is connected directly to the toilet

bowl with a horizontal waste connection pipe (in

accordance with DIN EN 37).

– The remaining drainage areas (e.g. wash basin,

bidet or shower) are connected to the additional

supply channels. The union nut, pressure ring and

existing angle collar should then be pushed over

the supply channel (outer-Ø 40 mm, commercially

available PVC pipe).

Push the PVC pipe into the supply channel connection pipe and screw the union nut tightly on to the

inlet connection pipe.

The unused inlet opening must be locked with the

cowl provided:

– Push the pressure ring on to the cowl

– Slide on the seal (cross section form: three-sided)

with the wide edge pointing to the pressure ring

– Lay the cowl in the union nut and screw on to the

supply channel opening.

The additional side supply channels

(DN 40) must be positioned above the

highest possible water lever (180 mm).

For this reason the construction level

(base) of the shower basin must lie

at least 180 mm higher than the

construction level of the mini lifting

unit (fig. 3). The shower surface may

be reduced to 110 mm above the

construction level when installing

Viega-domoplex discharge fittings,

when the distance between the lifting

unit and the shower is equal to or

larger than 1,200 mm.

– The flap trap (fig. 4) is pushed into the lower supply

channel opening as far as the limit stop in such a

way that the trap is open to the cistern. Then push

in the supply pipe as described above (use of trap

not permissible in Germany).

– Shorten the pressure hose to the desired length,

push it into the desired position on the hose

connection pieces and secure with the clamp.

– Push the conical end of the pressure hose as far as

possible onto the pressure pipeline (DN 25 or DN 32)

which should be connected on site and secure

against sliding with a clamp.

– It is recommended that a shut-off device be instal-

led in the pressure pipeline. It must be suitable for

waste water containing sewage and should be

connected on site.

– Connect pressure pipeline (fig. 3, pos. 1, minimum-

Ø DN 25) upwardly onto the collector pipe.

– If the pressure pipeline runs horizontally off centre, it

must be laid with a loop when it comes out of the unit.

– Press on covering cap.

– In order to protect against possible reflux out of the

public channel, the pressure pipeline should be

formed as a “pipe loop”. It must be placed over the

locally set reflux level (usually street level).

– If ventilation takes place through a vent connection

in the roof rather than through the activated carbon

filter which is integrated into the unit, the cap

12

ATTENTION!

Page 12

ENGLISH

(fig. 2, pos. 9) should be removed from the ventilation and the vent connection (fig. 3, pos. 2, innerØ 25 mm, commercially available PVC pipe) and

should be pushed by a flexible piece of hose on to

the support. The activated carbon filter (fig. 2, pos. 5)

can be removed.

– The warning sticker included in the delivery (fig. 5)

must be adhered in a visible position on the toilet

cover (if necessary, in direct view of the toilet).

5.2 Electrical installation

–Electrical work must be carried out by a

qualified and licensed electrician in strict

compliance with local regulations. If the

units power cable is damaged it must be

replaced by the customer service or a

similar qualified person.

– The mains current and voltage must comply with the

data on the rating plate of the unit to be connected.

– Earthing must be carried out according to regulations.

– Line side fuse protection: 10 A, neutral.

6. Starting up

– Plug in shock-proof plug

– Flush toilet twice during initial start-up

– Monitor all pipe connections for leakages. If neces-

sary, tighten hose clamps.

– Adjust the cistern so that the flushing volume does

not fall below 6 l of water.

7. Maintenance

The operation reliability is increased in the long run

when the perfect functioning and quiet running of the

pump are monitored.

The unit cleans itself when used regularly. Seldomused units should be cleaned internally now and

again as follows:

Pull out the plug. Pour a mild cleaning agent into the

toilet bowl and flush. After approximately 5 mins, plug

in the unit, flush, leave the unit to pump and then flush

again.

7.1 Maintenance and care of unit (fig. 2)

– Flush 2–3 times and pump the cistern empty

Pull out the plug before checking the

unit!

– Remove covering cap (fig. 2, pos. 8) using the

tommy bar (fig. 2, pos. Z) and pressing the 3 snap

hooks (side and front).

Danger of injury and infection from

cutting instruments! Use protective

gloves!

– If necessary, remove strainer basket and all foreign

bodies from the unit.

– Eliminate impurities on the cistern walls.

– Clean vent pipe or ventilating valve, renew acti-

vated carbon filter.

– Assemble in opposite order

– When using toilet freshners, make sure that they

are safely secured to the WC.

7.2 Dismantling the pump (fig. 2)

Flushing, opening the unit and observing warning

symbols as described in 7.1

– Unscrew the 3 fixing screws at the motor flange

(fig. 2, pos. 11).

– Unscrew the upper hose clamp (fig. 2, pos. 12) on

the discharge connection.

– Unscrew the screw of the ventilation pipe (fig. 2,

pos. 13) on the cistern wall and pull off the ventila-

tion pipe.

– Unscrew the connection cable PG screw joint

(fig. 2, pos. 14) on the tank wall and pull the cable

through to the inside of the cistern.

– If the pump is to be removed from the tank com-

pletely, screw off the electric plug and take the

cable out of the PG screw joint.

– Take out the pump with booster relay and electri-

cal connection.

– Clean the cutting instrument, impeller and the

opening of the booster relay.

– Assemble the components in the opposite order.

– Carry out test run.

For reasons of hygiene, used KH 32–0.4

units should be emptied and cleaned

before transportation. Furthermore, all

components which come into contact

with infectious material should be disinfected

(spray disinfected). The components must be

tightly sealed in sufficiently large, tear-resistant

plastic sacks and packed so that they do not leak.

They should be disposed of by reliable haulage

contractors immediately.

13

Page 13

ENGLISH

14

Fault Cause Remedy

Motor does not run Lack of voltage Check voltage and fuses

Cutting implement blocked, Dismantle cap, rotate motor shaft clockwise freely,

overload switch clean cutting implement. In the event of reoccurrence,

disengaged contact customer services.

motor overloaded, overload If the event of reoccurrence, contact customer

switch disengaged services.

booster relay defect contact customer services

motor defect contact customer services

motor runs, pump pressure pipeline blocked remove blocking or buckling

does not function or buckled carry out test run

unit ventilation blocked remove and clean ventilation pipe or replace activated

carbon filter

pump runs in short ventilation blocked clean ventilation

intervals

leak in flap trap clean or replace

cistern ventilation stops reproduce function

motor makes loud foreign bodies in unit Dismantle motor and clean. If necessary, contact

noises when rotating customer services.

8. Faults, causes and remedies

If the fault cannot be remedied, please contact your local plumbing and heating specialist or Wilo

customer services.

Subject to technical alterations!

Page 14

✍

Page 15

Page 16

Loading...

Loading...