WIKA TFS135 Operating Instructions Manual

EN

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

DE

FR

ES

Bimetal temperature switches, model TFS135

Bimetal temperature switch, model TFS135

Bimetall-Temperaturschalter, Typ TFS135

Thermostat bimétallique, type TFS135

Termostato bimetálico, modelo TFS135

2

EN

14216392.01 12/2017 EN/DE/FR/ES

WIKA operating instructions model TFS135

DE

FR

ES

Operating instructions model TFS135 Page 3 - 16

Betriebsanleitung Typ TFS135 Seite 17 - 30

Mode d'emploi type TFS135 Page 31 - 44

Manual de instrucciones modelo TFS135 Página 45 - 58

© 11/2016 WIKA Alexander Wiegand SE & Co. KG

Alle Rechte vorbehalten. / All rights reserved.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

3

Contents

1. General information 4

2. Safety 6

3. Specications 9

4. Design and function 10

5. Transport, packaging and storage 11

6. Commissioning, operation 12

7. Maintenance and cleaning 14

8. Dismounting, return and disposal 15

Contents

EN

14216392.01 12/2017 EN/DE/FR/ES

4

WIKA operating instructions model TFS135

1. General information

1. General information

■

The bimetal temperature switch described in the operating

instructions has been designed and manufactured using state-ofthe-art technology. All components are subject to stringent quality

and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the instrument and readily accessible to

skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage

caused by using the product contrary to its intended use,

non-compliance with these operating instructions, assignment

of insuciently qualied skilled personnel or unauthorised

modications to the instrument.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TV 35.02

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

5

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can

result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can

result in light injuries or damage to equipment or the

environment, if not avoided.

Information

... points out useful tips, recommendations and

information for ecient and trouble-free operation.

DANGER!

... identies hazards caused by electrical power. Should

the safety instructions not be observed, there is a risk of

serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can

result in burns, caused by hot surfaces or liquids, if not

avoided.

EN

14216392.01 12/2017 EN/DE/FR/ES

6

WIKA operating instructions model TFS135

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure

that the appropriate switch has been selected in terms

of switching temperature, design and specic measuring

conditions.

Non-observance can result in serious injury and/or

damage to the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

2.1 Intended use

The model TFS135 bimetal temperature switches are used to limit

temperatures within a wide variety of industries.

The TFS135 are temperature limiting instruments. They are not

intended to provide any safety or protective functionality.

They monitor the temperature of machinery and equipment during

normal operation and, for example, switch o machinery if it

overheats.

The instrument has been designed and built solely for the intended

use described here, and may only be used accordingly.

The technical specications contained in these operating instructions

must be observed. Improper handling or operation of the bimetal

temperature switch outside of its technical specications requires the

instrument to be taken out of service immediately and inspected by

an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

7

2. Safety

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have

the qualications described below.

■

Keep unqualied personnel away from hazardous

areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on

their technical training, knowledge of measurement and control

technology and on their experience and knowledge of country-

specic regulations, current standards and directives, are capable

of carrying out the work described and independently recognising

potential hazards.

Special operating conditions require further appropriate knowledge,

e.g. of aggressive media.

2.3 Special hazards

WARNING!

For hazardous media such as oxygen, acetylene,

ammable or toxic gases or liquids, and refrigeration

plants, compressors, etc., in addition to all standard

regulations, the appropriate existing codes or regulations

must also be followed.

EN

14216392.01 12/2017 EN/DE/FR/ES

8

WIKA operating instructions model TFS135

2. Safety

WARNING!

To ensure safe working on the instrument, the operating

company must ensure

■

that suitable rst-aid equipment is available and aid is

provided whenever required.

■

that the operating personnel are regularly instructed

in all topics regarding work safety, rst aid and

environmental protection and know the operating

instructions and in particular, the safety instructions

contained therein.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of

death.

■

The instrument may only be installed and mounted by

skilled personnel.

■

Any connection work may only be carried out once the

equipment has been isolated.

■

Operation using a defective power supply unit (e.g.

short circuit from the mains voltage to the output

voltage) can result in life-threatening voltages at the

bimetal temperature switch!

WARNING!

Residual media in the dismounted instrument can result

in a risk to persons, the environment and equipment. Take

sucient precautionary measures.

Do not use this instrument in safety or emergency stop

devices. Incorrect use of the instrument can result in

injury.

Should a failure occur, aggressive media with extremely

high temperature and under high pressure or vacuum

may be present at the instrument.

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

9

2. Safety / 3. Specications

TFS135

NC 60 °C

12345678

2.4 Labelling, safety marking

Product label

Model

Contact design (NC = normally closed)

Nominal switching temperature

Number of production order

Approval logos

Before mounting and commissioning the instrument,

ensure you read the operating instructions!

3. Specications

Rectangular connector per DIN EN 175301-803

Switching voltage: AC 120 V / 60 Hz / 5 A

AC 250 V / 50 Hz / 2.5 A

Medium temperature range: -30 … +130 °C

Ambient temperature range: -30 … +85 °C

Pressure load: max. 50 bar

Circular connector M12 x 1

Switching voltage: AC 120 V / 60 Hz / 1 A

AC 250 V / 50 Hz / 1 A

Medium temperature range: -25 … +130 °C

Ambient temperature range: -25 … +55 °C

Pressure load: max. 50 bar

EN

14216392.01 12/2017 EN/DE/FR/ES

10

WIKA operating instructions model TFS135

4. Design and function

4. Design and function

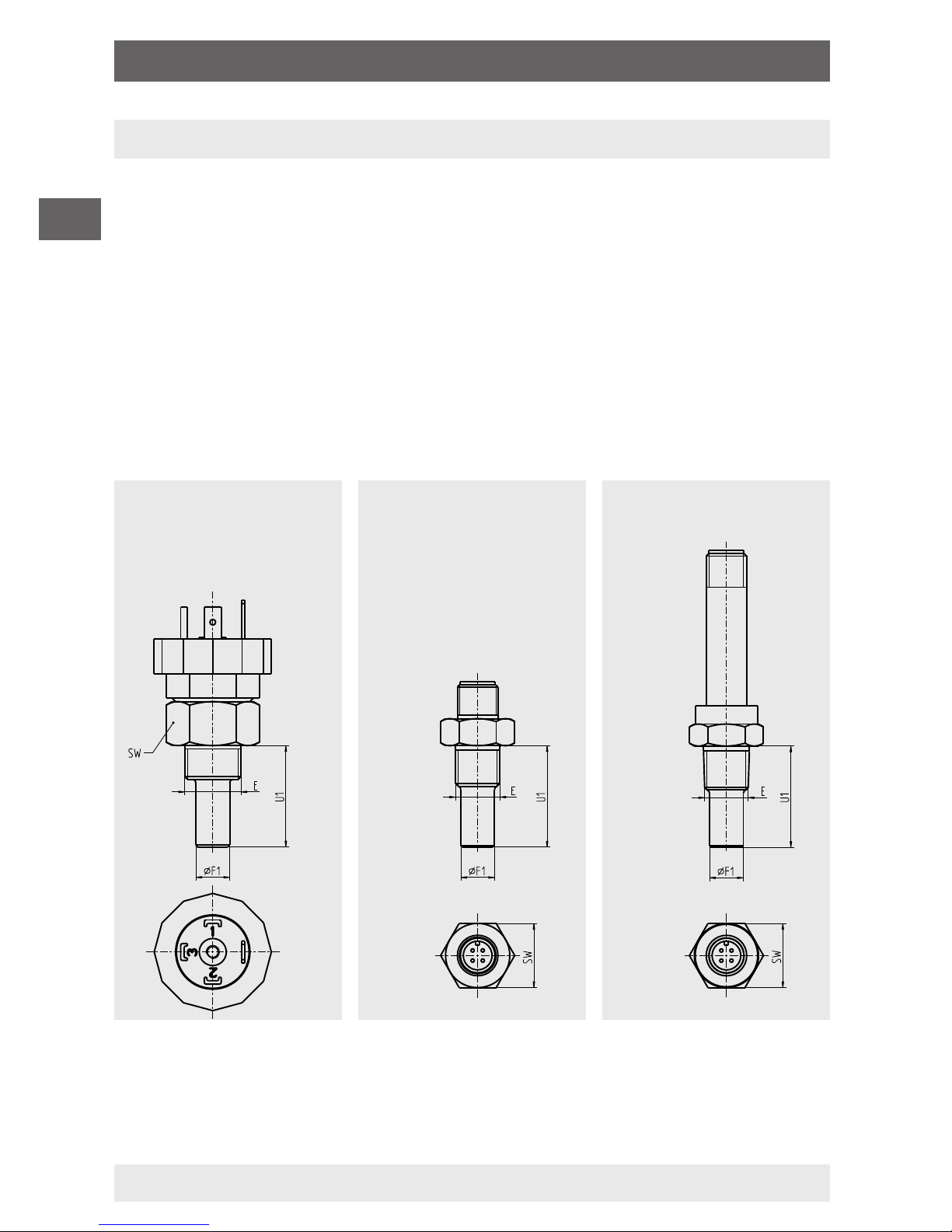

4.1 Description

The model TFS135 bimetal temperature switch consists of a

thermowell with integrated switching element and a permanently

mounted connector. The bimetal temperature switch is screwed

directly into the process.

All electrical components are protected against splash water. The

electrical connection is via the connector.

4.2 Dimensions in mm

4.3 Scope of delivery

Cross-check scope of delivery with delivery note.

Circular connector

M12 x 1

Circular connector

M12 x 1 with neck tube

45 mm

Rectangular connector

per DIN EN 175301-803

14182125.01

14182125.01

14182125.01

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

11

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the bimetal temperature switch for any damage that may

have been caused by transport. Obvious damage must be reported

immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during

transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +85 °C

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoidance of exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the bimetal temperature switch in its original packaging in

a location that fulls the conditions listed above. If the original

packaging is not available, pack and store the temperature switch as

described below:

1. Wrap the temperature switch in an antistatic plastic lm.

2. Place the temperature switch, along with shock-absorbent material,

in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a

bag containing a desiccant inside the packaging.

EN

14216392.01 12/2017 EN/DE/FR/ES

12

WIKA operating instructions model TFS135

5. Transport ... / 6. Commissioning, operation

WARNING!

Before storing the temperature switch (following

operation), remove any residual media. This is of

particular importance if the medium is hazardous to

health, e.g. caustic, toxic, carcinogenic, radioactive, etc.

6. Commissioning, operation

6.1 Mounting

When the temperature switch is mounted, the temperature must

neither drop below the allowed operating temperature (environment,

medium) nor exceed it, even when taking convection and heat

radiation into account.

Depending on the type of application, the electrical connection must

be protected from mechanical damage.

6.2 Electrical connection

WARNING!

Only connect with power disconnected!

Only disconnect the mating connector with the voltage

disconnected. Use suitable mating connectors for the

current and voltage ranges.

Cables and wires

■

Leads with bare ends must be nished with end splices.

■

Cables used must comply with the respective requirements in

terms of stability and temperature.

■

Connecting cables must be run so that any mechanical damage is

prevented.

■

Only connect circuits with the same voltage and type of protection

to the switch contacts and connecting cables.

■

Size the connecting cables for the largest current strength in the

circuits.

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

13

6. Commissioning, operation

Voltages > AC 50 V or DC 75 V

■

The TFS135 must be connected to the system of the protective

earthing of the end product or the end application via the process

connection.

■

Circuits must oer a device, external to the measuring instrument,

that enables the instrument to be isolated from the electrical

supply. This must be easily accessible and be marked as the

isolation device for the instrument.

■

Cables and circuits must full the isolation requirements and

conform to, for example, IEC 60227 or IEC 60245.

■

Do not connect circuits simultaneously with extra-low voltage

circuits, or with safety extra-low voltage circuits (SELV) or

protected extra-low voltage circuits (PELV).

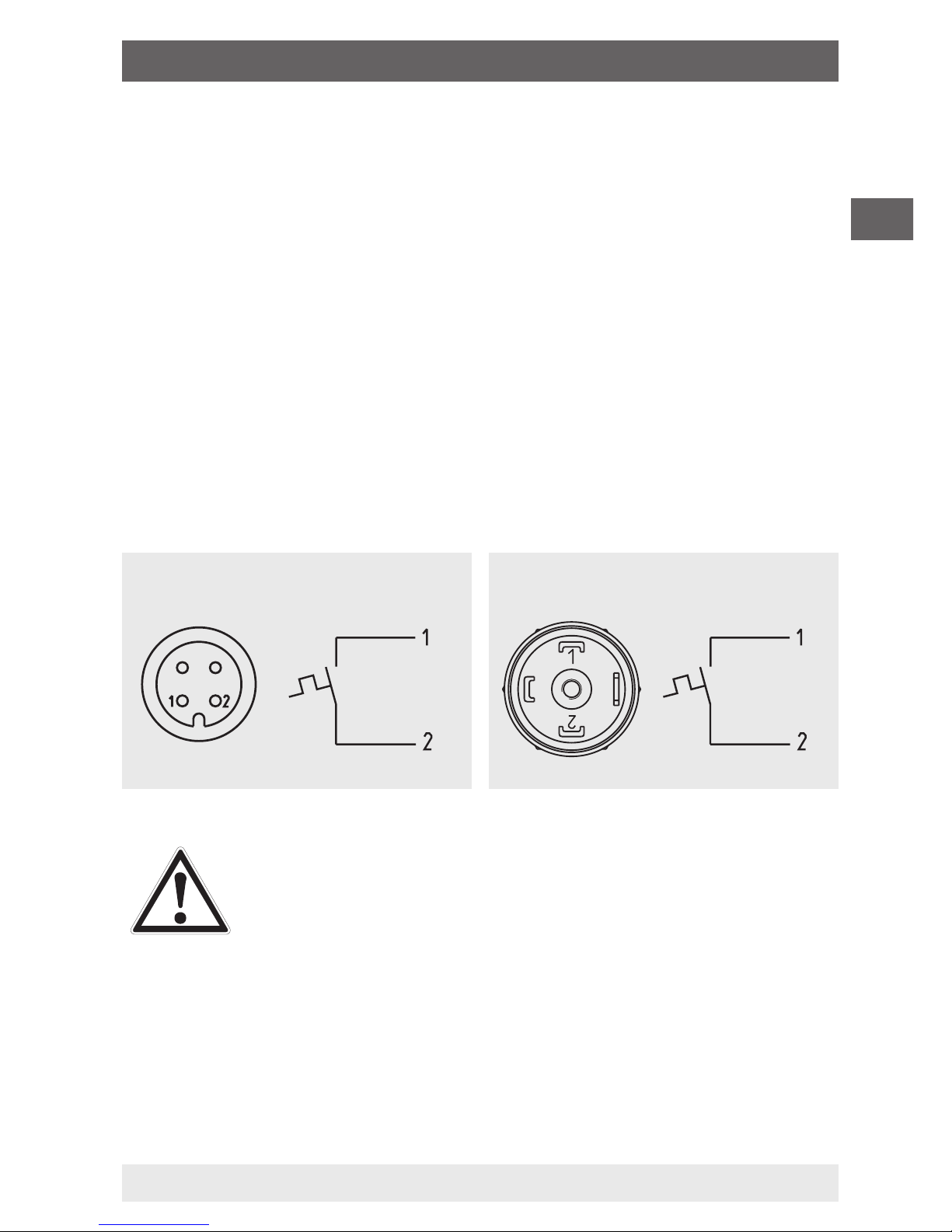

6.3 Pin assignment

WARNING!

The earthing terminal is not connected and therefore it

does not provide electrical connection to protective earth.

T (°C) T (°C)

Rectangular connector

per DIN EN 175301-803

Circular connector M12 x 1

EN

14216392.01 12/2017 EN/DE/FR/ES

14

WIKA operating instructions model TFS135

7. Maintenance and cleaning

7. Maintenance and cleaning

7.1 Maintenance

The bimetal temperature switch is maintenance-free.

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

■

Prior to cleaning, switch o and disconnect the

instrument from the voltage supply.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with

moisture.

■

Wash or clean the dismounted instrument before

returning it, in order to protect persons and the

environment from exposure to residual media.

■

Residual media in dismounted instruments can result

in a risk to persons, the environment and equipment.

Take sucient precautionary measures.

For information on returning the instrument see chapter

8.2 “Return”.

EN

WIKA operating instructions model TFS135

14216392.01 12/2017 EN/DE/FR/ES

15

8. Dismounting, return and disposal

8. Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

8.1 Dismounting

WARNING!

Risk of burns!

Let the bimetal temperature switch cool down suciently

before dismounting! During dismounting there is a risk of

dangerously hot media escaping.

Only disconnect the bimetal temperature switch once the system has

been depressurised!

8.2 Return

WARNING!

Strictly observe the following when shipping the

instrument:

All instruments delivered to WIKA must be free from any

kind of hazardous substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a

suitable transport packaging.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument along with shock-absorbent material in the

packaging. Place shock-absorbent material evenly on all sides of

the transport packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring

instrument.

EN

14216392.01 12/2017 EN/DE/FR/ES

16

WIKA operating instructions model TFS135

Information on returns can be found under the heading

“Service” on our local website.

8.3 Disposal

Incorrect disposal can put the environment at risk. Dispose

of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-

specic waste disposal regulations.

8. Dismounting, return and disposal

DE

WIKA Betriebsanleitung Typ TFS135

14216392.01 12/2017 EN/DE/FR/ES

17

Inhalt

1. Allgemeines 18

2. Sicherheit 20

3. Technische Daten 23

4. Aufbau und Funktion 24

5. Transport, Verpackung und Lagerung 25

6. Inbetriebnahme, Betrieb 26

7. Wartung und Reinigung 28

8. Demontage, Rücksendung und Entsorgung 29

Inhalt

DE

14216392.01 12/2017 EN/DE/FR/ES

18

WIKA Betriebsanleitung Typ TFS135

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Bimetall-Temperaturschalter wird nach dem aktuellen Stand der Technik konstruiert und

gefertigt. Alle Komponenten unterliegen während der Fertigung

strengen Qualitäts- und Umweltkriterien. Unsere Management-

systeme sind nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal jederzeit zugänglich

aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsan-

leitung, Einsatz ungenügend qualizierten Fachpersonals sowie

eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TV 35.02

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Loading...

Loading...