Page 1

D

GB

Operating instructions

Betriebsanleitung

Examples/Beispiele

Resistance thermometers and thermocouples

Intrinsically safe designs (Ex-i)

Widerstandsthermometer und Thermoelemente

Eigensichere Ausführungen (Ex-i)

TÜV 10 ATEX 555793 X

IECEx TUN10.0002 X

Page 2

D

GB

2 WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Operating instructions models RTD and TC, Ex-i Page 3 - 46

Betriebsanleitung Typen RTD und TC, Ex-i Seite 47 - 86

Page 3

1. General information 4

2. Safety 5

3. Specications 10

4. Design and function 13

5. Transport, packaging and storage 14

6. Commissioning, operation 15

7. Information on mounting and operation in hazardous areas

(Europe) 21

8. Electrical connection values 30

9. Calculation examples for self-heating at the probe/

thermowell tip 32

10. Maintenance and cleaning 36

11. Faults 36

12.

Dismounting, return and disposal

37

Appendix 1: EC type examination certicate

39

Appendix 2: IECEx certicate

43

Appendix 3: EC declaration of conformity

46

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

3

GB

Contents

Contents

Declarations of conformity can be found online at www.wika.com.

Page 4

3345267.08 06/2011 GB/D

4 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

1. General information

■

The instrument described in the operating instructions has been designed and manufactured

using state-of-the-art technology. All components are subject to stringent quality and

environmental criteria during production. Our management systems are certied to ISO 9001

and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for

the instrument‘s range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity

of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions, prior to

beginning any work.

■

The manufacturer‘s liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instructions, assignment of

insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Application consultant: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death,

if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can result in light injuries or

damage to equipment or the environment, if not avoided.

Information

… points out useful tips, recommendations and information for ecient and troublefree operation.

1. General information

Page 5

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

5

GB

WARNING!

... indicates a potentially dangerous situation in a potentially explosive atmosphere,

resulting in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation, caused by hot surfaces or liquids, that

can result in burns if not avoided.

Abbreviations

RTD "Resistance Temperature Detector" = Resistance thermometers

TC "Thermocouple"

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate thermometer has been selected in terms of measuring range, design and specic measuring

conditions.

Choose the thermowell with regard to the maximum pressure and temperature (e.g.

rating chart in DIN 43772).

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual chapters of these

operating instructions.

2.1 Intended use

These resistance thermometers and thermocouples are used for temperature measurement in

industrial applications, in hazardous areas.

Resistance thermometers are used for measuring temperatures from -200 ... +600 °C. For

thermocouples, the possible measuring ranges range from -200 ... +1200 °C. Thermometers

of this design can be installed directly in the process as well as in thermowells. The thermowell

designs can be selected as desired, but the operating process data (temperature, pressure,

density and ow rate) must be taken into account.

1. General information / 2. Safety

Page 6

3345267.08 06/2011 GB/D

6 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

The system operator is responsible for selecting the thermometer or thermowell, and for the

selection of their materials, so as to guarantee their safe operation within the system or machine.

When preparing a quote, WIKA can only give recommendations which are based on our

experience in similar applications.

The thermometer has been designed and built solely for the intended use described here and

may only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications requires

the instrument to be shut down immediately and inspected by an authorised WIKA service

engineer.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in the instrument malfunctioning. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in these operating instructions may only be carried out by

skilled personnel who have the qualications described below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specic regulations, current standards and directives, are capable of carrying out the

work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

2.3 Additional safety instructions for instruments with ATEX and IECEx approvals

WARNING!

Non-observance of these instructions and their contents may result in the loss of

explosion protection.

2. Safety

Page 7

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

7

GB

WARNING!

Follow the requirements of the 94/9/EC (ATEX) and IECEx directives.

Follow the respective national regulations concerning Ex-usage

(e.g. EN/IEC 60079-10 and EN/IEC 60079-14).

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination certicate and the

relevant country-specic regulations for installation and use in potentially explosive

atmospheres (e.g. EN/IEC 60079-14, NEC, CEC). Non-observance can result in

serious injury and/or damage to equipment.

For additional important safety instructions for instruments with ATEX/IECEx approval, see chapter "2.3 Additional safety instructions for instruments with ATEX and

IECEx approvals".

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases or liquids,

and refrigeration plants, compressors, etc., in addition to all standard regulations, the

appropriate existing codes or regulations must also be followed.

WARNING!

Protection from electrostatic discharge (ESD) required. The proper use of grounded

work surfaces and personal wrist straps is required when working with exposed

circuitry (printed circuit boards), in order to prevent static discharge from damaging

sensitive electronic components.

To ensure safe working on the instrument, the operating company must ensure

■

that suitable rst-aid equipment is available and aid is provided whenever required.

■

that the operating personnel are regularly instructed in all topics regarding work

safety, rst aid and environmental protection and know the operating instructions

and, in particular, the safety instructions contained therein.

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the environment and equipment. Take sucient precautionary measures.

Do not use this instrument in safety or Emergency Stop devices. Incorrect use of the

instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature and under

high pressure or vacuum may be present at the instrument.

2. Safety

Page 8

3345267.08 06/2011 GB/D

8 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

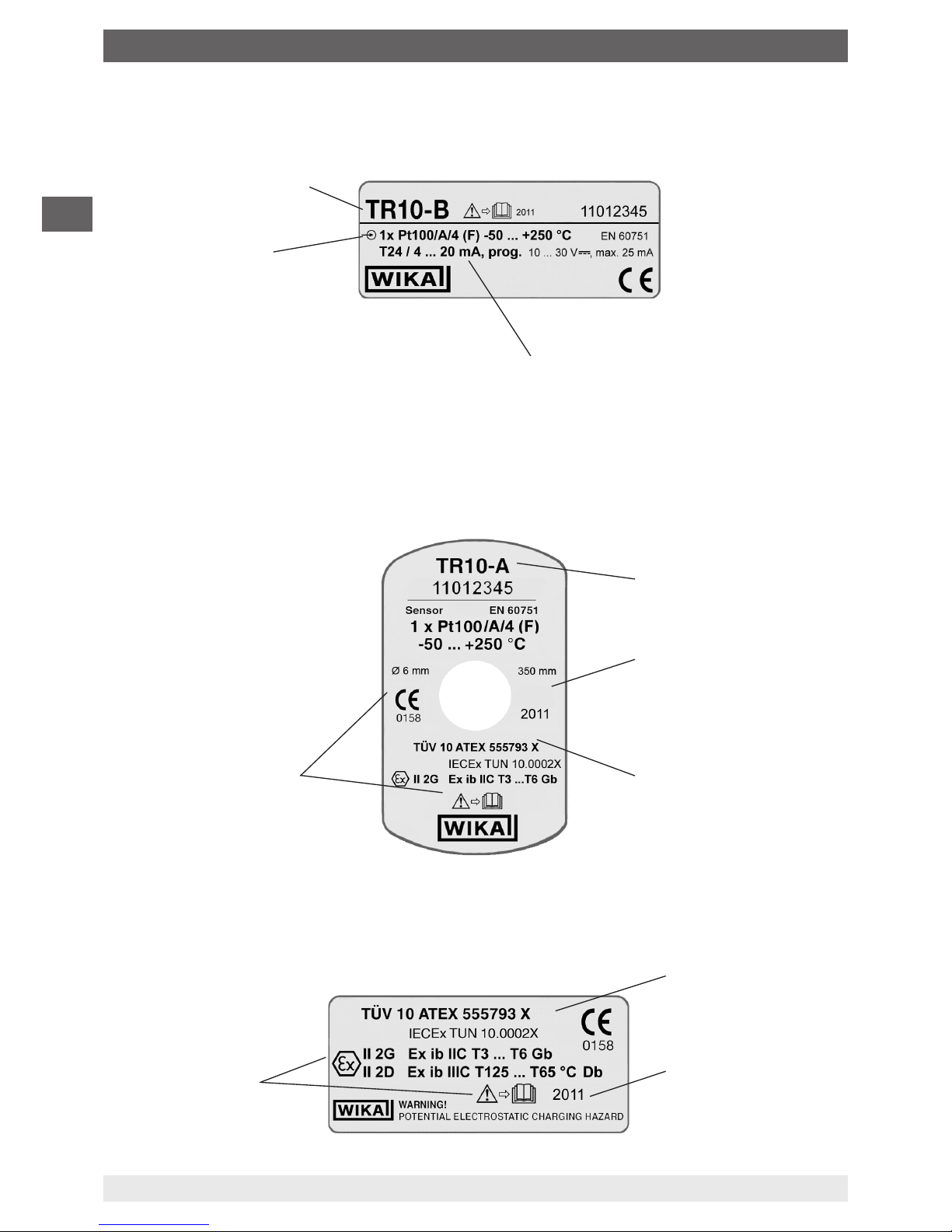

2.5 Labelling / safety marks

2.5.1 Product labels for resistance thermometers

Model

Sensor in accordance with

standard

■

F Thin-lm resistor

■

W Wire-wound resistor

Approval number

Year of manufacture

For an explanation of

symbols, see page 10

Transmitter model

(only for design with transmitter)

Year of manufacture

For an explanation of

symbols, see page 10

Approval number

Model

2. Safety

■

Product label for TR10-A measuring insert

■

Additional data for Ex instruments

Page 9

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

9

GB

2. Safety

2.5.2 Product labels for thermocouples

Model

Approval number

Year of manufacture

For an explanation of

symbols, see page 10

Transmitter model

(only for design with transmitter)

Year of manufacture

For an explanation of

symbols, see page 10

Approval number

Model

■

Product label for measuring insert TC10-A

■

Additional data for Ex instruments

"ungrounded"

Sensor in accordance with

standard

■

ungrounded

■

grounded

Legende:

■

ungrounded

welded insulated

■

grounded

welded to the sheath

Page 10

3345267.08 06/2011 GB/D

10 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the requirements of the European

Directive 94/9/EC (ATEX) on explosion protection.

3. Specications

3.1 Resistance thermometer

Sensor connection method

■

2-wire The lead resistance is recorded as an error in the measurement.

■

3-wire With a cable length longer than approx. 30 m, measuring errors can occur.

■

4-wire

The internal lead resistance of the connecting wires is negligible.

Limiting error of the sensor per DIN EN 60751

■

Class B

■

Class A

■

Class AA

The combination of a 2-wire connection with Class A / Class AA is not permissible, since the lead

resistance of the measuring insert negates the higher sensor accuracy.

Basic values and limiting errors

Basic values and limiting errors for the platinum measurement resistances are laid down in

DIN EN 60751.

The nominal value of Pt100 sensors is 100 Ω at 0 °C.

The temperature coecient α can be stated simply to be between 0 °C and 100 °C with:

α = 3.85 ∙ 10-3 °C

-1

The relationship between temperature and electrical resistance is described by polynomialss,

which are also dened in DIN EN 60751. Moreover, this standard species the basic values in °C

steps in tabular form.

2. Safety / 3. Specications

Page 11

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

11

GB

Class Temperature range Limiting error in °C

Wire-wound (W) Thin-lm (F)

B -196 … +600 °C -50 … +500 °C ± (0.30 + 0.0050 | t |)

1)

A -100 … +450 °C -30 … +300 °C ± (0.15 + 0.0020 | t |)

1)

AA -50 … +250 °C 0 … 150 °C ± (0.10 + 0.0017 | t |)

1)

1) | t | is the value of the temperature in °C irrespective of the sign.

Bold: standard version

Resistance values and limiting deviations at selected temperatures (Pt100)

Temperature

in °C

(ITS 90)

Resistance value in Ω

Class B Class A Class AA

-196 19,69 ... 20,80 - -

-100 59,93 ... 60,58 60,11 ... 60,40 -

-50 80,09 ... 80,52 80,21 ... 80,41 80,23 ... 80,38

-30 88,04 ... 88,40 88,14 ... 88,30 88,16 ... 88,28

0 99,88 ... 100,12 99,94 ... 100,06 99,96 ... 100,04

20 107,64 ... 107,95 107,72 ... 107,87 107,74 ... 107,85

100 138,20 ... 138,81 138,37 ... 138,64 138,40 ... 138,61

150 156,93 ... 157,72 157,16 ... 157,49 157,91 ... 157,64

250 193,54 ... 194,66 193,86 ... 194,33 193,91 ... 194,29

300 211,41 ... 212,69 211,78 ... 212,32 -

450 263,31 ... 265,04 263,82 ... 264,53 -

500 280,04 ... 281,91 - -

600 312,65 ... 314,77 - -

This table represents the calibration process with predened temperatures. This means if a temperature

standard is available, the resistance value of the test piece must lie within the limits specied above.

For further information on accuracies and limits of use of resistance thermometers,

see data sheet IN 00.17 (download available at www.wika.de).

3.2 Thermocouples

Sensor type

Model

Recommended max. operating temperature

K (NiCr-Ni) 1200 °C

J (Fe-CuNi) 800 °C

E (NiCr-CuNi) 800 °C

T (Cu-CuNi) 400 °C

N (NiCrSi-NiSi) 1200 °C

S (Pt10% Rh-Pt) 1600 °C

R (Pt13% Rh-Pt) 1600 °C

B (Pt30% Rh-Pt6%-Rh) 1700 °C

3. Specications

Page 12

3345267.08 06/2011 GB/D

12 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Potential measuring uncertainties due to ageing eects

Thermocouples are subject to ageing and change their temperature/thermal voltage

characteristic. Type J thermocouples of (Fe-Cu-Ni) age slightly due to oxidation of the pure metal

leg. In types K and N thermocouples (NiCrSi-NiSi), high temperatures can result in substantial

changes to the thermal voltage due to chrome depletion in the NiCr leg, leading to a lower thermal

voltage.

This eect is accelerated if there is a shortage of oxygen, since a complete oxide layer, which

would protect it from further oxidation, cannot be formed on the surface of the thermocouple.

The chromium in the alloy is oxidised, but not the nickel, giving rise to "green rot" that eventually

destroys the thermocouple. When NiCr-Ni thermocouples that have been operating above 700 °C

are cooled quickly, this cooling causes certain states in the crystal structure (short-range order)

to freeze, which in Ttype K thermocouples can result in a change of the thermal voltage of up to

0.8 mV (K eect).

In Type N thermocouple (NiCrSi-NiSi), it has been possible to reduce the short-range-order

eect by alloying both legs with silicon. The eect is reversible and is largely eliminated again by

annealing above 700 °C, followed by slow cooling. Thin sheathed thermocouples are particularly

sensitive. Cooling in still air can even result in deviations of more than 1 K.

The application range of these thermometers is limited both by the permissible max. temperature

of the thermocouple and by the max. temperature of the thermowell material.

Listed thermocouples are available both as single or duplex thermocouples. The thermocouple

will be delivered with an insulated measuring point, unless explicitly specied otherwise.

Sensor limiting error

A cold junction temperature of 0 °C is taken as basis with the denition of the tolerance value

of thermocouples. When using a compensating cable or thermocouple cable, an additional

measuring error must be considered.

For limiting errors and further specications see current WIKA data sheet or order

documentation.

3. Specications

Page 13

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

13

GB

4. Design and function

4.1 Description

These thermometers (resistance thermometers and thermocouples) detect temperatures in

processes.

Depending on their design, these thermometers are suitable for low, medium and high process

requirements in hazardous areas.

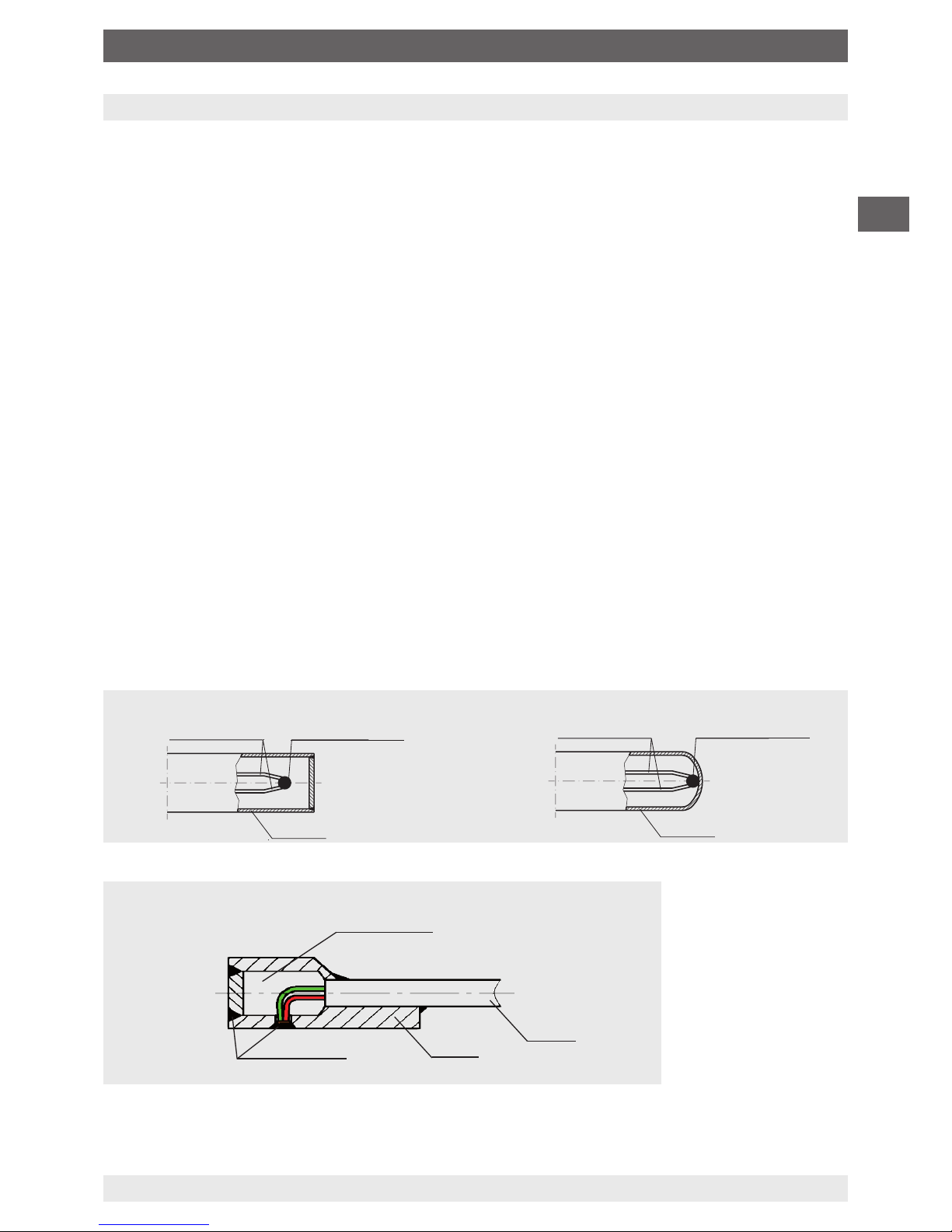

Insulated measuring point

The model TRxx or model TCxx thermometers consist of a welded tube, a mineral-insulated

sheathed cable or ceramic-insulated thermal wires (in which the temperature sensor is located,

embedded in a ceramic powder), a temperature-resistant sealing compound, cement compound

or a thermal transfer paste.

Alternatives:

The measuring insert or the cable probe can also be provided in a tubular form. In this case, the

sensor is located in a welded tube and embedded in a ceramic powder, heat-conducting paste or

in a sealing compound suitable for this purpose.

The measuring insert for high-temperature thermocouples can also be assembled from thermal

wires insulated with ceramic rods or ceramic beads. The ceramic tube is cemented into a metallic

support tube using a temperature-resistant cement.

Thermocouples, non-insulated (grounded)

For special applications, for example surface temperature measurements, the sensors are in

direct contact with the protective sleeve, or the measuring points of thermocouples are welded to

the bottom (see chapter "7.1.1 Special conditions of use (X conditions)").

Measuring point insulated (ungrounded) Measuring point not insulated (grounded)

Thermocouple

Thermocouple

Measuring point

Measuring point

Sheath Sheath

AI203 powder

MI line

V-Pad

welded with

ller

V-Pad version

Measuring point not insulated

4. Design and function

Page 14

3345267.08 06/2011 GB/D

14 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Vibration resistance

The thermometers have an impact- and vibration-resistant design. The vibration resistance of the

basic model corresponds to DIN EN 60751 (up to 3 g), while for special designs higher loads are

possible. The impact resistance of all versions complies with the requirements of EN 60751, with

the exception of high-temperature thermocouples assembled from ceramic-insulated thermal

wires.

Electrical connection

In terms of connection, the thermometer is equipped with a housing and a connector or bare wire

ends. The housing design will contain the terminals or a certified transmitter. Optionally, separatelycertified digital displays can be built into the housing.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature:

Instruments without built-in transmitter: -40 ... +85 °C

Instruments with built-in transmitter:

see operating instructions of the transmitter in question

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoidance of exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the instrument in its original packaging in a location that fulls the conditions listed above. If

the original packaging is not available, pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

4. Design and function / 5. Transport, packaging and storage

Page 15

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

15

GB

WARNING!

Before storing the instrument (following operation), remove any residual media. This

is of particular importance if the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

6. Commissioning, operation

WARNING!

When the thermometer is mounted, the temperature must not drop below the allowed

operating temperature (environment, medium) or exceed it, even when taking

convection and heat radiation into account!

WARNING!

Thermometers must be earthed if dangerous voltages could be expected at the

connection wires (caused, for example, by mechanical damage, electrostatic

discharge or induction)!

6.1 Electrical connection

CAUTION!

■

Damage to cables and wires, and to connection points, must be avoided

■

Provide nely stranded conductor ends with end splices (cable assembly)

■

Both the internal capacitance and inductance must be considered

For the electrical connections of thermometers (e.g. connection circuit diagrams, tolerance

values, etc.), please refer to the appropriate data sheets. If head transmitters or digital displays

have been built into the connection housing, these data sheets must also be given proper

consideration.

5. Transport, packaging and storage / 6. Commissioning, operation

Page 16

3345267.08 06/2011 GB/D

16 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

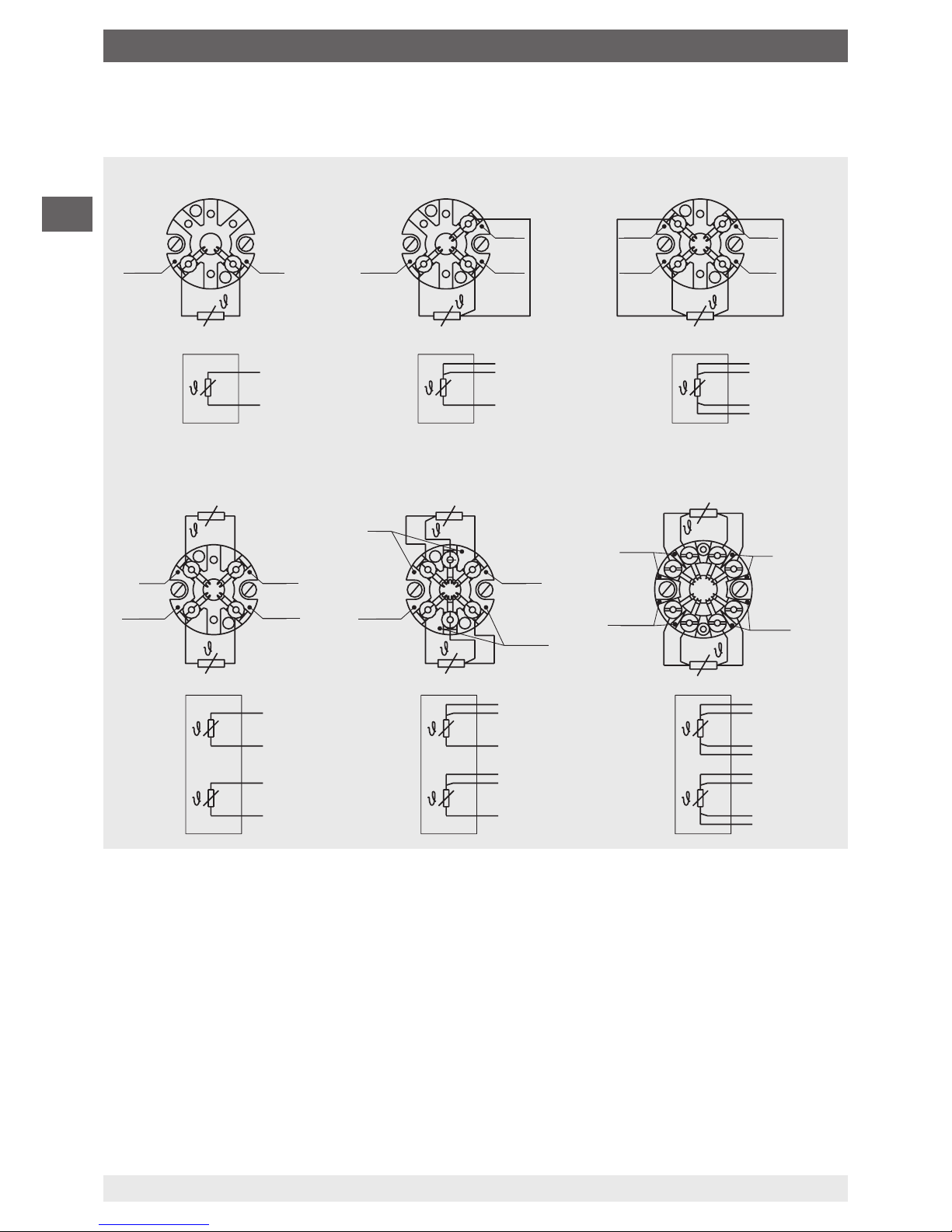

6.2 Electrical connection of resistance thermometers

6.2.1 Resistance thermometer with terminal block

3160629.06

red

1 x Pt100, 2-wire 1 x Pt100, 3-wire 1 x Pt100, 4-wire

white

white

red

red

red

red

white

white

white

white

white

white

red

red

red

red

red

2 x Pt100, 2-wire

2 x Pt100, 3-wire

2 x Pt100, 4-wire

red

white

white

red

red

white

black

yellow

yellow

yellow

black

black

white

white

red

red

red

red

black

black

black

black

yellow

yellow

yellow

red

white

black

yellow

white

6. Commissioning, operation

Page 17

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

17

GB

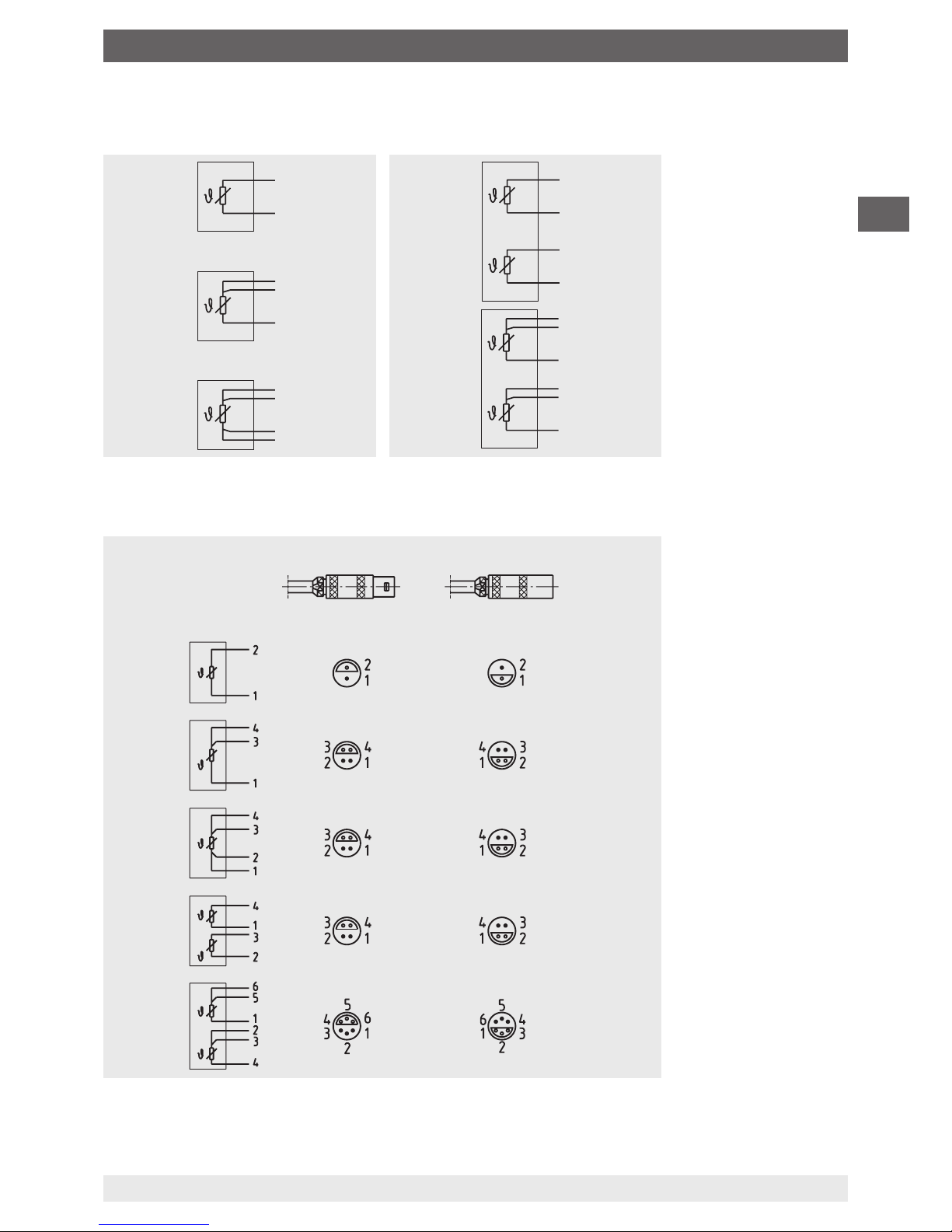

6.2.2 Resistance thermometer with cable or connector

Without

connector

Lemosa

connector

3366036.02

1 x Pt100

2-wire

1 x Pt100

3-wire

1 x Pt100

4-wire

2 x Pt100

2-wire

2 x Pt100

3-wire

red

red

red

red

red

red

red

red

white

white

white

white

Connector

(male)

View from the front

Socket (female)

View from the front

white

white

black

black

black

yellow

yellow

3160629.06

6. Commissioning, operation

Page 18

3345267.08 06/2011 GB/D

18 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

6.3 Electrical connection of thermocouples

Cable colour coding of thermocouples

Sensor type Standard Positive Negative

K DIN EN 60584 green white

J DIN EN 60584 black white

E DIN EN 60584 violet white

T DIN EN 60584 brown white

N DIN EN 60584 pink white

6.3.1 Thermocouples with terminal block

Binder

Series 680

Binder

Series 680

Binder

Series 680

Binder

Series 680

Binder

Series 692

Binder screw/plug-in

connector

3366142.02

Connector

(male)

View of the connector contacts

Socket (female)

View of the socket contacts

3166822.03

Single thermocouple Dual thermocouple

The colour coding at the positive

connection to the devices always

decides the correlation of polarity

and connection terminal.

6. Commissioning, operation

Page 19

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

19

GB

6.3.2 Thermocouples with cable or connector

Lemosa connector,

male at the cable

Binder connector,

male at the cable

(screw/plug-in connection)

Single

thermocouple

For the marking of

the cable ends, see

table

Cable

Dual

thermocouple

Plus and minus are marked.

For dual thermocouples, two thermal

connectors are used.

Thermal connector

6.4 Multipoint thermocouples (as per 8.4 and 8.5)

They are usually equipped with a housing in which transmitters or terminal blocks are mounted.

The transmitters/digital displays are fastened mechanically (e.g. rail system in housing or holder

in connection head) and installed in accordance with EN/IEC 60079-11 and EN/IEC 60079-14.

Optionally, depending on design, the housings can be equipped with or without terminals (e.g.

terminal blocks, etc.) in accordance with EN/IEC 60079-11 and EN/IEC 60079-14.

When using several transmitters/digital displays, the housing volume increases as a function of

the "heat source", thus increasing the volume to be heated. This guarantees that the housing

surface temperature does not increase signicantly.

WARNING!

When using no terminals and line wiring, compliance with the installation regulations

in accordance with EN/IEC 60079-11 and EN/IEC 60079-14 must be guaranteed.

6.5 Cable glands

In thermometers equipped with connection heads, the cable glands must be fully sealed in order

to ensure that the necessary ingress protection is reached.

Requirements for meeting ingress protection

■

Only use cable glands within their indicated clamping range (cable diameter suitable for the

cable gland)

■

Do not use the lower clamping area with very soft cable types

■

Only use circular cross-section cables (if necessary, slightly oval in cross-section)

■

Do not twist the cable

6. Commissioning, operation

Page 20

3345267.08 06/2011 GB/D

20 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

■

Repeated opening/closing is possible; however only if necessary, as it might have a

detrimental eect on the protection class

■

For cable with a pronounced cold-ow behaviour the screw connection must be fully tightened

6.6 Parallel threads

If the thermometer connecting head, extension neck, thermowell or process connection are

connected with parallel threads (e.g. G ½, M20 x 1.5 ...), these threads must be secured using

seals which prevent liquids from penetrating into the thermometer.

As standard, WIKA uses copper prole seals for the connection between the neck tube and the

thermowell, and at paper seals for the connection of the connection head and the extension

neck or thermowell.

If the thermometer and the thermowell are already connected, the seals will already be mounted.

The plant operator must check whether the seals are suitable for the operating conditions and

must replace them, if necessary, with suitable seals.

For thermometers without a thermowell, and/or where these are delivered separately, the seals

are not included and must be ordered separately.

Tighten the threads by hand when carrying out the nal assembly on the plant. This will

correspond to the delivery status of the premounted components. The nal tightening torque

should be applied using a spanner (half rotation).

The seals must be replaced after dismantling!

The seals can be ordered from WIKA, indicating the WIKA order number and/or the

designation (see table).

WIKA

Order No.

Designation Suitable for

threads

11349981 per DIN 7603 Form C 14 x 18 x 2 -CuFA G ¼, M14 x 1.5

11349990 per DIN 7603 Form C 18 x 22 x 2 -CuFA M18 x 1.,5, G ⅜

11350008 per DIN 7603 Form C 21 x 26 x 2 -CuFA G ½, M20 x 1.5

11350016 per DIN 7603 Form C 27 x 32 x 2.5 -CuFA G ¾, M27 x 2

11367416 per DIN 7603 Form C 20 x 24 x 2 -CuFA M20 x 1.5

1248278 per DIN 7603 D21.2 x D25.9 x 1.5 -Al G ½, M20 x 1.5

3153134 per

DIN 7603 Form C D14.2 x D17.9 x 2 -StFA

G ¼, M14 x 1.5

3361485 per

DIN 7603 Form C D33.3 x D38.9 x 2.5 -StFA

G 1

Legend:

CuFA = Copper, max. 45HB

a

; lled with asbestos-free sealing material

Al = Aluminium Al99

; F11, 32 to 45 HB

b

StFA = Soft iron, 80 to 95 HBa; lled with asbestos-free sealing material

6. Commissioning, operation

Page 21

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

21

GB

6.7 Tapered threads (NPT)

Connections with tapered threads (NPT) are self-sealing and normally must not be sealed. It

should be checked whether it may be necessary to seal them additionally with Teon tape or

hemp. The threads must be lubricated with a suitable lubricant before tting.

Tighten the threads by hand when carrying out the nal assembly on the plant. This will

correspond to the delivery status of the premounted components. The nal tightening and sealing

must be made with a spanner (1.5 to 3 rotations).

7. Information on mounting and operation in hazardous areas (Europe)

WARNING!

In hazardous areas the use of a model TR10-A measuring insert without a suitable

connection head (case) is not permissible!

Where required a suitable thermowell is to be used.

7.1 General information on explosion protection

The requirements of the 94/9/EC (ATEX) directive must be followed. Additionally the

specications of the respective national regulations concerning Ex usage apply.

A) The responsibility for classication of zones lies with the plant operator and not the

manufacturer/supplier of the equipment.

B) The plant operator guarantees, and is solely responsible, that all thermometers in use are

identiable with respect to all safety-relevant characteristics. Damaged thermometers may not

be used. Repairs may only be completed using original spare parts from the original supplier;

otherwise the requirements of the approval are not fullled.

The manufacturer shall not be responsible for constructional modications after delivery of the

instruments.

C) If a component of electrical equipment, on which the explosion protection depends, is

repaired, then the electrical equipment may only be put back into use, after an authorised

expert has stated that it corresponds to the fundamental characteristics of the requirements for

explosion protection. In addition this expert must provide a certicate for this and provide the

equipment with a test mark.

D) Item C) shall not apply if the component was repaired by the manufacturer in accordance with

the requirements and regulations.

6. Commissioning, operation / 7. Information on mounting and ...

Page 22

3345267.08 06/2011 GB/D

22 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

E) When using transmitters and digital displays, the following must be observed:

The contents of these operating instructions and those of the transmitter.

The relevant regulations for installation and use of electrical systems.

The regulations and directives regarding explosion protection. Transmitters and digital

displays must have their own approval.

F) When ordering spare parts, the parts that are to be replaced must be specied exactly:

■

Ignition protection type (here Ex i)

■

Approval No.

■

Order No.

■

Manufacturing No.

■

Order item

7.1.1 Special conditions of use (X conditions)

Versions with Ø <3 mm or "non-insulated" versions are operationally non-compliant with section

6.3.12 of EN/IEC 60079-11. Therefore, from a safety-relevant point of view, these intrinsically

safe circuits must be considered galvanically connected to the earth potential, which is why

equipotential bonding must be secured for the entire installation of the intrinsically safe circuits. In

addition, for the connection, separate conditions in accordance with EN/IEC 60079-14 must be

observed.

Electrostatic discharges must be avoided in instruments, that due to their design, do not conform

to the electrostatic requirements in accordance with EN/IEC 60079-0.

The transmitters and digital displays used must have their own EN/IEC approval. The installation

conditions, electrical connected loads, temperature classes or maximum surface temperatures

for use in potentially explosive dust atmospheres and permissible ambient temperatures can be

seen from the relevant approvals and must be observed.

Thermal backow from the process, that exceeds the permissible ambient temperature of

the transmitter, must not be allowed to occur. It must be prevented by installing suitable heat

insulation or a neck tube of suitable length.

If the wall thickness is below 1 mm, the instruments must not be subjected to ambient stresses

that may have an adverse eect on the partition wall. Alternatively, a thermowell of suitable

minimum wall thickness may be used.

When using a thermowell/neck tube, the overall instrument must be designed such that it

allows installation in a way that results in a suciently tight gap (IP 67) or a ameproof gap

(EN/IEC 60079-1) towards the less hazardous area.

The circuits of the coaxial element are operationally connected to one another. When applied in

practice a separate assessment must be made, or special conditions may have to be observed

when connecting the coaxial multipoint thermocouple. In addition, an assessment of the

intrinsically safe system (e.g. when connecting several sensor circuits of dierent transmitters to

one another) must be made.

7. Information on mounting, operation in hazardous areas (Europe)

Page 23

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

23

GB

When housings are used, they must either have their own suitable approval or comply with the

minimum requirements. IP protection: at least IP 20 (at least IP 65 for dust), applies to all housings.

However, light metal housings must be suitable in accordance with EN/IEC 60079-0 Section 8.1.

In addition, non-metallic housings or powder-coated housings must meet the requirements of

EN/IEC 60079-0 or have a suitable warning note.

Protective measures for applications that require EPL Ga or Gb:

Operational friction or impact between equipment parts made of light metals or their alloys (e.g.

aluminium, magnesium, titanium or zirconium) with equipment parts made of iron/steel is not

permitted. Operational friction or impact between two light metals is permitted.

7.1.2 Ex marking

For applications without transmitter (digital displays) requiring instruments of equipment Group II

(potentially explosive gas atmospheres), the following temperature class classication and

ambient temperature ranges apply:

Table 1

Marking

Temperature

class

Ambient temperature range (T

a

)

Max. surface temperature (T

max

)

at the sensor or thermowell tip

II 1G Ex ia IIC T6 Ga

II 1/2G Ex ib IIC T6 Ga/Gb

T6

(-50)1) -40 ... +80 °C

TM (temperature of the medium) +

self-heating

For this, the special conditions (17)

must be observed.

II 1G Ex ia IIC T5 Ga

II 1/2G Ex ib IIC T5 Ga/Gb

T5

(-50)1) -40 ... +95 °C

II 1G Ex iaD IIC T4 Ga

II 1/2G Ex ib IIC T4 Ga/Gb

II 1G Ex ia IIC T3 Ga

II 1/2G Ex ib IIC T3 Ga/Gb

T4, T3

(-50)1) -40 ... +100 °C

1) The values in brackets apply to special designs. These sensors are manufactured using special sealing compounds. Moreover, they feature housings made of stainless steel and cable glands for low-temperature ranges

When there is a built-in transmitter and/or a digital display, the special conditions from the type

examination certicate (see item 17) apply.

7. Information on mounting, operation in hazardous areas (Europe)

Page 24

3345267.08 06/2011 GB/D

24 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

For applications requiring instruments of equipment Group II (potentially explosive dust

atmospheres), the following surface temperatures and ambient temperature ranges apply:

Table 2

Marking

Power

P

i

Ambient

temperature

range (T

a

)

Max. surface temperature

(T

max

) at the sensor or

thermowell tip

II 1D Ex ia IIIC T65 °C Da

II 1/2D Ex ib IIIC T65 °C Da/Db

750 mW (-50)1) -40 ... +40 °C

TM (temperature of the medium)

+ self-heating

For this, the special conditions

(17) must be observed.

II 1D Ex ia IIIC T95 °C Da

II 1/2D Ex ib IIIC T95 °C Da/Db

650 mW

(-50)1) -40 ... +70 °C

II 1D Ex ia IIIC T125 °C Da

II 1/2D Ex ib IIIC T125 °C Da/Db

550 mW

(-50)1) -40 ... +100 °C

1) The values in brackets apply to special designs. These sensors are manufactured using special sealing

compounds. Moreover, they feature housings made of stainless steel and cable glands for low-temperature

ranges.

When there is a built-in transmitter and/or a digital display, the special conditions from the type

examination certicate (see item 17) apply.

Use in methane atmospheres

Owing to the higher minimum ignition energy of methane, the instruments can also be used

where methane causes a potentially explosive atmosphere. The instrument can be optionally

marked with IIC + CH

4

.

For applications that require EPL Gb or Db, instruments with "ia" marking may also be used in

measuring circuits of type "ib".

7.2 Temperature class classication, ambient temperatures

The permissible ambient temperatures depend on the temperature class, the housings used and

any transmitters and/or digital displays tted as options.

When a thermometer is connected to a transmitter and/or a digital display, the lowest value

of either the ambient temperature limits or the highest temperature class will apply. The lower

temperature limit is -40 °C; and -50 °C for special designs.

Where there are neither transmitters nor digital displays mounted within the housing, there will

also be no additional warming.

With a built-in transmitter (optionally with digital display), heating caused by the operation of the

transmitter or digital display may occur.

7. Information on mounting, operation in hazardous areas (Europe)

Page 25

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

25

GB

For applications without transmitters (digital displays) that require Group II instruments

(potentially explosive gas atmospheres), the following temperature class classication and

ambient temperature ranges apply:

Temperature class Ambient temperature range (Ta)

T6 (-50) -40 … +80 °C

T5 (-50) -40 … +95 °C

T4, T3 (-50) -40 … +100 °C

See and observe the permissible ambient temperatures and surface temperatures for third-party

products from the relevant approvals and/or data sheets.

Example

For instruments tted with a DIH10 transmitter and digital display, for example, the following limit

for temperature class classication applies:

Temperature class Ambient temperature range (Ta)

T6 -40 … +60 °C

For applications that require Group II instruments (potentially explosive dust atmospheres), the

following surface temperatures and ambient temperature ranges apply:

Power Pi Ambient temperature range (Ta)

750 mW (-50) -40 … +40 °C

650 mW (-50) -40 … +70 °C

550 mW (-50) -40 … +100 °C

See and observe the permissible ambient temperatures and surface temperatures for third-party

products from the relevant approvals and/or data sheets.

The values in brackets apply to special designs. These sensors are manufactured using special

sealing compounds. Moreover, they are equipped with connection heads made of stainless steel

and cable glands for the low-temperature range.

These thermometers are suitable for temperature classes T6...T3 in accordance with the

approval certicate. This applies to instruments without built-in transmitters and/or digital

displays. Thermometers equipped with transmitters and/or digital displays are for use in

temperature classes T6...T4 and are marked accordingly. Using equipment for applications which

require a lower temperature class (e.g. T2) than the marked one is permissible. In doing so, it

must be ensured that the maximum ambient temperature for safe operation of the instrument is

not exceeded.

7. Information on mounting, operation in hazardous areas (Europe)

Page 26

3345267.08 06/2011 GB/D

26 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

FF-00147.00

Tx10

Tx10 Tx40 Tx40

Option: with built-in

transmitter e.g. T32

Option:

with connector

MI line

Option:

with connector

cable

Tx10-A

Tx10-A

T3T3T3

T3

Process connection

Process connection

Process connection

Process connection

1)

permissible temperatures at

T1: (-50) -40 °C < Ta < +300 °C

T3: (-50) -40 °C < Ta < +150 °C

T4: (-50) -40 °C < Ta < +100 °C

T4

T4

Transmitter

T4

connector

T4

connector

T1 T1 T1 T1

T4

Transmitter

: (-50) -40 °C < Ta < +85 °C

T4

connector

: (-50) -40 °C < Ta < +85 °C

1) Temperature zone undened

1) 1) 1)

7.3 Temperature carry-over from the process

A heat backow from the process that exceeds the operating temperature of the transmitter

(digital display) or housing is not permissible and must be prevented by installing suitable heat

insulation or a neck tube of suitable length.

7.3.1 Overview of the temperature zones

7. Information on mounting, operation in hazardous areas (Europe)

Page 27

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

27

GB

3160670.06

Threaded connection

Thread

Thread

11355647.01

Thread

Thread

(NPT)

7.3.2 Increasing the separation of the connection components and hot surfaces

The neck distance (N) is dened as the distance between the lower edge of the connection head

(or the housing) to the heat-emitting surface. The temperature to be expected at the lower edge

of the connection head or housing is, at most, 100 °C. The conditions for built-in transmitters or

displays must be observed. If required, the neck length must be increased accordingly.

For thermometers tted with a connection lead, the temperature at the interface with the

connecting cable is restricted. The maximum is 150 °C. To ensure that the permissible

temperature is not exceeded, the dimension X must be selected accordingly.

7. Information on mounting, operation in hazardous areas (Europe)

Page 28

3345267.08 06/2011 GB/D

28 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

To help select the minimum neck length, the following standard values have been determined.

Maximum temperature of the

medium

Recommendation for

dimension N

Recommendation for

dimension X

100 °C - 135 °C 20 mm 20 mm

200 °C 50 mm 50 mm

>200 °C ≤ 450 °C 100 mm 100 mm

WARNING!

For reasons of work safety and saving of resources, hot surfaces should be protected

against accidental touch and energy loss by means of insulation.

7.4 Mounting examples in hazardous areas

7.4.1 Possible installation methods with the marking II 1G Ex ia IIC T6 Ga or

II 1D Ex ia IIIC T65 °C Da

7. Information on mounting, operation in hazardous areas (Europe)

Zones 0, 1, 2 or Zones 20, 21, 22

Hazardous area

Safe area

Thermowell

Thermowell

welded

TWxx

TWxx

Process

connection

Connection head/

Field housing

Tx10-B

Tx10-C

Tx10-C

Tx10-D

Tx10-H

Tx10-H

Option:

with built-in

transmitter:

e.g. T32

Tx10-A

Process

connection

Compression

tting

Associated

electrical equipment

Intrinsically

safe supply or

suitable barrier

e.g. transmitter power supply

KFD2-STC4-Ex1

WIKA Art. No.: 2341268

e.g. Zener barrier

Z954 for Pf100-3L

WIKA Art. No.: 3247938

Intrinsically

safe supply or

suitable barrier

Intrinsically

safe supply or

suitable barrier

Intrinsically

safe supply or

suitable barrier

Tx10-A

Tx10-A

Tx10-A

Page 29

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

29

GB

Zones 1, 2 or

Zones 21, 22

Hazardous area

Safe area

Thermowell

Thermowell

welded

TWxx

TWxx

Process

connection

Connection head/

Field housing

Tx10-B

Tx10-C

Tx10-C

Tx10-D

Tx10-H

Tx10-H

Option:

with built-in

transmitter:

e.g. T32

Tx10-A

Process

connection

Compression

tting

Associated

electrical equipment

Intrinsically

safe supply or

suitable barrier

e.g. transmitter power supply

KFD2-STC4-Ex1

WIKA Art. No.: 2341268

e.g. Zener barrier Z954

for Pf100-3L

WIKA Art. No.: 3247938

Intrinsically

safe supply or

suitable barrier

Intrinsically

safe supply or

suitable barrier

Intrinsically

safe supply or

suitable barrier

Tx10-A

Tx10-A

Tx10-A

Zones 0, 1, 2 or

Zones 20, 21, 22

The sensor together with housing or connection head is located in Zone 0 (Zone 20). An Ex

ia type circuit must be used. A zone separation is deemed to exist if the process connection

guarantees a suciently tight gap (IP 67) between the less hazardous zone and the Zone 0.

Examples of suitable process connections include gas-tight standardised industrial anges,

threaded connections or pipe connections.

7.4.2 Possible installation methods with the marking II 1/2 Ex ib IIC T6 Ga/Gb or

II 1/2 D Ex ib IIIC T65 °C Da/Db

The sensor or thermowell tip protrudes into Zone 0. The housing or connection head is in Zone 1

(Zone 21) or Zone 2 (Zone 22). It is sucient to use an Ex ib type circuit.

Zone separation is guaranteed if suciently-tight (IP 67) process connections are used.

Examples of suitable process connections include gas-tight standardised industrial anges,

threaded connections or pipe connections.

7. Information on mounting, operation in hazardous areas (Europe)

Page 30

3345267.08 06/2011 GB/D

30 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

The welded parts, process connections, compression ttings, thermowells or housings used

must be designed such that they withstand all inuencing variables resulting from the process,

such as temperature, ow forces, pressure, corrosion, vibration and impacts.

7.4.3 Partition wall for use in Zone 0 or Zone 1/2 or separation between hazardous area

and non-hazardous area

If the wall thickness is less than 1 mm, the instrument must also be marked with an "X" or a safety

instruction in accordance with 29.2 of EN/IEC 60079-0, with the special proviso that for safe use

it must not be subjected to ambient stresses that may have an adverse eect on the partition

wall. If the partition wall is continuously subjected to vibrations (e.g. vibrating membranes), its

fatigue limit at the maximum amplitude must be stated in the documentation (see Section 4.2.5.2,

EN/IEC 60079-26).

Alternatively, a thermowell of suitable minimum wall thickness may be used by the customer.

When using a thermowell/neck tube, the overall instrument must be constructed such that

it allows installation in a way that results in a suciently tight gap (IP 67) or a ame path

(EN/IEC 60079-1) towards the less hazardous area.

8. Electrical connection values

8.1 Electrical data without built-in transmitter or digital display

For Group II instruments (potentially explosive gas atmospheres)

*3,

the following maximum

connection values apply:

U

i

= DC 30 V

I

i

= 550 mA

P

i

(at the sensor *1) = 1.5 W

For Group II instruments (potentially explosive dust atmospheres), the following maximum

connection values apply:

U

i

= DC 30 V

I

i

= 550 mA

P

i

(at the sensor *2) = For the values, see "Table 2" (column 2) on page 24

*1 The permissible power to the sensor depends on the temperature of the medium TM, the temperature class

and the thermal resistance Rth, but shall not be more than 1.5 W.

For calculation examples, see chapter "9. Calculation examples for self-heating at the sensor/thermowell tip".

*2 The permissible power to the sensor depends on the temperature of the medium TM, the maximum allowed

surface temperature and the thermal resistance Rth, but shall not be more than the values from "Table 2"

(Column 2), see above.

*3 Use in methane atmospheres

Owing to the higher minimum ignition energy of methane, the instruments can also be used where methane

causes a potentially explosive atmosphere. The instrument can be optionally marked with IIC + CH4.

7. Information on mounting and ... / 8. Electrical connection values

Page 31

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

31

GB

The internal inductance (Li) and capacitance (Ci) of standard measuring inserts in accordance

with DIN 43735 are negligible. The values for cable probes and very long sheathed-cable/

resistance thermometers can be seen from the rating plate and must be taken into account when

connecting them to an intrinsically safe power supply.

Sensor circuit in Ex ia or ib, IIC intrinsic safety ignition protection

Only for connection to intrinsically safe circuits with the following maximum output values for

Group II instruments (potentially explosive gas atmospheres):

U

o = DC 30 V

I

o = 550 mA

P

o = 1.5 W

For Group II instruments (potentially explosive dust atmospheres), the following maximum output

values apply to their connection to intrinsically safe circuits:

Uo = DC 30 V

Io = 550 mA

Po = For the values, see "Table 2" (Column 2) on page 24

8.2 Electrical data for built-in transmitters or digital displays

For the sensor circuit, the values mentioned in 8.1 apply.

Signal circuit in Ex ia or ib, IIC intrinsic safety ignition protection

U

i

=

depending on the transmitter/digital display

I

i

=

depending on the transmitter/digital display

P

i

=

in the housing: depending on the transmitter/digital display

C

i

=

depending on the transmitter/digital display

L

i

=

depending on the transmitter/digital display

The transmitters and digital displays used must have their own certication in accordance

with EN/IEC. The installation conditions and electrical connection values can be seen from the

relevant approvals and must be observed.

8.3 Electrical data with built-in transmitter in accordance with the FISCO model

The transmitters/digital displays used for the application range in accordance with the FISCO

model are considered FISCO eld units. The requirements in accordance with EN/IEC 60079-27,

and the connection conditions of the approvals in accordance with FISCO, apply.

8.4 TC95/TR95 multipoint thermocouples

Assembly of multipoint thermocouples from individual sheathed cables

For the individual insulated sheathed cable, the values mentioned in 8.1 apply. For operationally

grounded multipoint thermocouples, the sum of all the sensors must comply with the abovementioned values. For applications in dust areas, the values from "Table 2" (Column 2) on page

23 must be observed.

8. Electrical connection values

Page 32

3345267.08 06/2011 GB/D

32 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

8.5 TC93 coaxial multipoint thermocouple

WARNING!

The circuits of the coaxial multi-point thermocouple are operationally connected to

one another. When applied in practice, a separate assessment must be made, and/or

special conditions may have to be observed when connecting the coaxial multipoint

thermocouple. In addition, an assessment of an intrinsically safe system (e.g. when

connecting several sensor circuits of dierent transmitters to one another) must be

made.

9. Calculation examples for self-heating at the sensor/thermowell tip

The self-heating at the sensor tip or thermowell tip depends upon the sensor type (TC/RTD),

the probe diameter, the thermowell design and the power supplied to the sensor in the event of

a failure. The table below shows the possible combinations. The table shows that when a failure

occurs, thermocouples produce much less self-heating than resistance thermometers.

Thermal resistance [R

th

in K/W]

Sensor Probe Ø in mm

2.0<3.0

3.0<6.0

6 - 8 3.0 -

6.0

1)

0.5<1.5

1.5<3.0

3.0<6.0

6.0-

12.0

Sensor type RTD RTD RTD RTD TC TC TC TC

without thermowell 245 110 75 225 105 60 20 5

with multi-part thermowell

(straight and tapered)

(e.g. TW22, TW35, TW40, TW45, etc.)

135 60 37 - - - 11 2.5

with thermowell - machined from solid

material (straight and tapered)

(e.g. TW10, TW15, TW20, TW25, TW30,

TW50, TW55, TW60, etc.)

50 22 16 - - - 4 1

Special thermowell – EN 14597 - - 33 - - - - 2.5

Tx55 (tubular holder) - 110 75 225 - - 20 5

Built into a blind bore

(minimum wall thickness 5 mm)

50 22 16 45 22 13 4 1

1) surface-sensitive

When using multiple sensors and simultaneous operation, the sum of the individual powers must

not exceed the value of the maximum permissible power. The maximum permissible power must

be limited to 1.5 W maximum. This must be guaranteed by the plant operator.

8. Electrical connection values / 9. Calculation examples for ...

Page 33

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

33

GB

9.1 Calculation example for RTD measuring point with thermowell

Use at the partition wall to Zone 0: Calculate the maximum permissible temperature T

max

at the

thermowell tip for the following combination:

RTD measuring insert Ø 6 mm with built-in model T32.1S head-mounted transmitter, tted into

a Design 3F multi-part thermowell . Power supply is, for example, via a Model KFD2-STC4-EX1

transducer power supply (WIKA Article No. 2341268).

T

max

is obtained by adding the temperature of the medium and the self-heating. The self-heating

of the thermowell tip depends on the supplied power P

o

of the transmitter and the thermal

resistance R

th

.

The following formula is used for the calculation: T

max

= Po x Rth + T

M

T

max

= Surface temperature (max. temperature at the thermowell tip)

P

o

= from transmitter data sheet

R

th

= Thermal resistance [K/W]

TM = Temperature of the medium

Prerequisite is an ambient temperature T

amb

of -20 ... +40 °C.

Example

Resistance thermometer RTD

Diameter: 6 mm

Temperature of the medium T

M

= 150 °C

Supplied power: P

o

= 15.2 mW

Temperature Class T3 (200 °C) must not be exceeded

Thermal resistance [R

th

in K/W] from table = 37 K/W

Self-heating: 0.0152 W x 37 K/W = 0.56 K

T

max

= TM + self-heating: 150 °C + 0.56 °C = 150.56 °C

The result shows that in this case self-heating at the thermowell tip is negligible. As safety

clearance for type-examined instruments (for T6 to T3), another 5 °C must be subtracted from the

200 °C; hence 195 °C would be permissible. This means that in this case temperature class T3 is

not exceeded.

Additional information

Temperature class for T3 = 200 °C

Safety clearance for type-examined instruments (T6 to T3)

*1

= 5 K

Safety clearance for type-examined instruments (T1 to T2)

*1

= 10 K

*1 EN/IEC 60 079-0: 2009 Section 26.5.1

9. Calculation examples for self-heating at the sensor/thermowell tip

Page 34

3345267.08 06/2011 GB/D

34 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Simplied verication of intrinsic safety for the above-mentioned combination

Measuring insert Head transmitter Power supply

Ui: DC 30 V Uo: DC 6.5 V Ui: DC 30 V Uo: DC 25.4 V

I

i

: 550 mA Io: 9.3 mA Ii: 130 mA Io: 88.2 mA

P

i

(

max

) at the sensor: 1.5 W Po: 15.2 mW Pi: 800 mW Po: 560 mW

C

i

: negligible Co: 24 µF Ci: 7.8 nF Co: 93 nF

L

i

: negligible Lo: 365 mH Li: 100 µH Lo: 2.7 mH

Upon comparing the values, it is obvious that it is permissible to connect these units to one

another. However, the operator must also take into account the values for inductance and

capacitance of the electrical connection leads.

9.2 Calculation example for a sheathed cable with RTD sensor

Use at the partition wall to Zone 0: Calculate the maximum permissible temperature Tmax at the

probe tip for the following combination:

Resistance thermometer without thermowell (TR10-H) Ø 6 mm without transmitter, mounted by

means of a compression tting with stainless steel sealing ring. Power supply is, for example, via

a model Z954 Zener barrier (WIKA Article No. 3247938), for example.

T

max

is obtained by adding the temperature of the medium and the self-heating. The self-heating

of the thermowell tip depends on the supplied power P

o

of the Zener barrier and the thermal

resistance R

th

.

The following formula is used for the calculation: T

max

= Po x Rth + T

M

T

max

=

Surface temperature (max. temperature at the probe tip)

P

o

= from the Zener barrier data sheet

R

th

= Thermal resistance [K/W]

TM = Temperature of the medium

Prerequisite is an ambient temperature T

amb

of -20 ... +40 °C.

Example

Resistance thermometer RTD

Diameter: 6 mm

Temperature of the medium T

M

= 150 °C

Supplied power: P

o

= 1150 mW

Temperature class T3 (200 °C) must not be exceeded

Thermal resistance [Rth in K/W] from table = 75 K/W

Self-heating: 1.15 W x 75 K/W = 86.25 K

T

max

= TM + self-heating: 150 °C + 86.25 °C = 236.25 °C

The result shows, in this case, substantial self-heating at the probe tip.

As safety margin for type-examined instrument (for T6 to T3), an additional 5 °C must be

subtracted from the 200 °C; hence 195 °C would be permissible. This means that in this case

temperature class T3 is exceeded signicantly and therefore not permissible. An additional

thermowell could be used as a remedy.

9. Calculation examples for self-heating at the sensor/thermowell tip

Page 35

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

35

GB

Additional information

Temperature class for T3 = 200 °C

Safety margin for type-examined instruments (T6 to T3)*1 = 5 K

Safety clearance for type-examined instruments (T1 to T2)*1 = 10 K

*1 EN/IEC 60 079-0: 2009 Section 26.5.1

9.3 Calculation example for the above-mentioned resistance thermometer with thermowell

RTD measuring insert Ø 6 mm without transmitter, built into a 3F design multi-part thermowell .

Thermal resistance [Rth in K/W] from table = 37 K/W

Self-heating: 1.15 W x 37 K/W = 42.55 K

T

max

= TM + self-heating: 150 °C + 42.55 °C = 192.55 °C

The result shows, in this case, substantial self-heating at the probe tip.

As safety margin for type-examined instrument (for T6 to T3), an additional 5 °C must be

subtracted from the 200 °C; hence 195 °C would be permissible. This means that in this case

temperature class T3 is not exceeded.

Simplied verication of intrinsic safety for the above-mentioned combination

Measuring insert Zener barrier Z954 Display instrument

(non-hazardous area)

U

i

: DC 30 V Uo: DC 9 V Um: AC 250 V Uo: AC 230 V

I

i

: 550 mA Io: 510 mA Ii: nA Io: nA

P

i

(

max

) at the sensor: 1.5 W Po: 1150 mW Pi: nA Po: nA

C

i

: negligible Co: 4.9 µF Ci: nA Co: nA

L

i

: negligible Lo: 0.12 mH Li: nA Lo: nA

Upon comparing the values, it is obvious that it is permissible to connect these units to one

another. However, the operator must also take into account the values for inductance and

capacitance of the electrical connection leads.

These calculations apply to the Z954 Zener barrier in connection with a resistance thermometer

Pt100 in 3-channel mode without grounding, i.e., symmetrical operation of the resistance

thermometer in 3-wire circuit on a display or evaluation instrument.

Electrical connection

For sensor connections, terminal, cable or connector assignments, see chapter

"6.1 Electrical connection".

9. Calculation examples for self-heating at the sensor/thermowell tip

Page 36

3345267.08 06/2011 GB/D

36 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

10. Maintenance and cleaning

10.1 Maintenance

These thermometers are maintenance-free.

Repairs must only be carried out by the manufacturer.

10.2 Cleaning

CAUTION!

■

Clean the instrument with a moist cloth. This applies in particular to thermometers

with a housing made of plastic and cable probes with plastic-insulated connection

lead, to ensure that any risk of electrostatic discharge is avoided.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to protect

sta and the environment from exposure to residual media.

■

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment. Take sucient precautionary measures.

For information on returning the instrument, see chapter "12.2 Returns".

11. Faults

Faults Causes Measures

No signal/ line break Mechanical load too high or

overtemperature

Replace probe or measuring insert with

a suitable design

Erroneous measured

values

Sensor drift caused by

overtemperature

Replace probe or measuring insert with

a suitable design

Sensor drift caused by chemical

attack

Use a design with thermowell

Erroneous measured

values (too low)

Entry of moisture into cable or

measuring insert

Replace probe or measuring insert with

a suitable design

Erroneous measured

values and response

times too long

Wrong mounting geometry, for

example mounting depth too

deep or heat dissipation too high

Temperature-sensitive area of the

sensor must be inside the medium, and

surfaces must be isolated.

Deposits on the sensor or

thermowell

Remove deposits

Erroneous measured

values (of thermocouples)

Parasitic voltages (thermal

voltages, galvanic voltage) or

wrong equalisation line

Use a suitable equalisation line

Measurement signal "comes and goes"

Cable break in connecting cable

or loose contact caused by

mechanical overload

Replace probe or measuring insert

with a suitable design, for example

equipped with a strain relief or a thicker

conductor cross-section

10. Maintenance and cleaning / 11. Faults

Page 37

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

37

GB

Corrosion Composition of the medium not

as expected or modied or wrong

thermowell material selected

Analyse medium and then select a

more-suitable material or replace

thermowell regularly

Signal interference

Stray currents caused by electric

elds or earth loops

Use screened connecting cables,

increase in the distance to motors and

power lines

Earth circuits Eliminate potentials, use galvanically

isolated transmitter supply isolators or

transmitters

CAUTION!

If deciencies cannot be eliminated by means of the measures listed above, shut

down the instrument immediately, and ensure that pressure and/or signal are no

longer present, and secure the instrument from being put back into operation

inadvertently. In this case, contact the manufacturer.

Should a return be necessary, please observe the information in chapter

"12.2 Returns".

12. Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment. Take sucient precautionary measures.

12.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting it! When dismounting it,

there is a risk that dangerously hot pressure media may escape.

Connections must only be opened when the instrument is depressurised and has cooled down.

The thermometer or the measuring insert can be removed from the thermowell. The thermowell

itself should only be removed from the process once it is in a depressurised state. For

thermometers without thermowell, the system must have been depressurised, cooled down and

be free of hazardous materials.

11. Faults / 12. Dismounting, return and disposal

Page 38

3345267.08 06/2011 GB/D

38 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

12.2 Returns

WARNING!

Absolutely observe when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.)

To return the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbing material, in the packaging.

Place shock-absorbent material evenly on all sides of the shipping box.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

Enclose the completed return form with the instrument.

The return form is available on the internet:

www.wika.de / Service / Return

12.3 Disposal

Incorrect disposal may endanger the environment.

Dispose of instrument components and packaging materials in an environmentally compatible

way and in accordance with the country-specic waste disposal regulations.

12. Dismounting, return and disposal

Page 39

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

39

GB

Appendix 1: EC type examination certicate

Page 40

3345267.08 06/2011 GB/D

40 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Appendix 1: EC type examination certicate

Page 41

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

41

GB

Appendix 1: EC type examination certicate

Page 42

3345267.08 06/2011 GB/D

42 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Appendix 1: EC type examination certicate

Page 43

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

43

GB

Appendix 2: IECEx certicate of conformity

Page 44

3345267.08 06/2011 GB/D

44 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Appendix 2: IECEx certicate of conformity

Page 45

WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

45

GB

Appendix 2: IECEx certicate of conformity

Page 46

3345267.08 06/2011 GB/D

46 WIKA operating instructions RTD and TC, intrinsically safe designs

GB

Appendix 2: IECEx certicate of conformity / Appendix 3: EC ...

Page 47

1. Allgemeines 48

2. Sicherheit 49

3. Technische Daten 54

4. Aufbau und Funktion 57

5. Transport, Verpackung und Lagerung 58

6. Inbetriebnahme, Betrieb 59

7. Hinweise zu Montage und Betrieb im explosionsgefährdeten Bereich (Europa) 65

8. Elektrische Anschlusswerte 74

9. Berechnungsbeispiele für die Eigenerwärmung an der

Fühler- / Schutzrohrspitze 76

10. Wartung und Reinigung 80

11. Störungen 80

12.

Demontage, Rücksendung und Entsorgung

81

Anlage 1: EG-Baumusterprüfbescheinigung

83

Anlage 2: IECEx Zertikat

43

Anlage 3: EG-Konformitätserklärung

86

WIKA Betriebsanleitung RTD und TC, eigensichere Ausführungen

3345267.08 06/2011 GB/D

47

D

Inhalt

Inhalt

Konformitätserklärungen nden Sie online unter www.wika.de.

Page 48

3345267.08 06/2011 GB/D

48 WIKA Betriebsanleitung RTD und TC, eigensichere Ausführungen

D

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach den neuesten Erkenntnissen

gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und

Handlungs-anweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und

allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für

das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung,

Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten Fachpersonals

sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Anwendungsberater: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder

leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten

und störungsfreien Betrieb hervor.

1. Allgemeines

Page 49

WIKA Betriebsanleitung RTD und TC, eigensichere Ausführungen

3345267.08 06/2011 GB/D

49

D

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten

Bereich hin, die zum Tod oder zu schweren Verletzungen führt, wenn sie nicht gemieden wird.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die durch heiße Oberächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie nicht gemieden

wird.

Abkürzungen

RTD englisch: "Resistance temperature detector";

Widerstandsthermometer

TC englisch: "Thermocouple";

Thermoelement

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Thermometer hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen

ausgewählt wurde.

Schutzrohr hinsichtlich Maximaldruck und -temperatur (z. B. Belastungsdiagramme in

DIN 43772) auswählen.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden

auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln dieser

Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung