Page 1

Operating Instructions

Betriebsanleitung

Mode d'emploi

Manual de Instrucciones

Fieldbus Temperature Transmitter Model T53.10

Feldbus Temperatur-Transmitter Typ T53.10

Transmetteur de température Fieldbus Type T53.10

Transmisor de temperatura bus de campo Modelo T53.10

Fieldbus Temperature Transmitter Model T53.10

GB

D

F

E

Page 2

Operating Instructions Model T53.10

GB

Page

3 - 32

Betriebsanleitung Typ T53.10

D

F

Mode d'emploi Type T53.10

Manual de Instrucciones Modelo T53.10 Página

E

© WIKA Alexander Wiegand SE & Co. KG 2010

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta posterior!

2

WIKA Operating Instructions Temperature Transmitter T53

Seite

33

Page 55 - 78

79 - 100

- 54

11178648.04 03/2010 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 6

3. Specications 15

4. Design and function 16

5. Transport, packaging and storage 17

6. Commissioning, operation 18

7.

Maintenance 23

8. Return and disposal 23

Appendix 1: FM-CSA Installation Drawing 25

Appendix 2: EC Declaration of conformity 31

GB

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 3

Page 4

1. General information

1. General information

■

The temperature transmitter described in the operating instructions

has been manufactured using state-of-the-art technology.

GB

All components are subject to stringent quality and environmental

criteria during production. Our management systems are certied

to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the temperature transmitter. Working safely requires that

all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the temperature transmitter's range

of use.

■

The operating instructions are part of the instrument and must be

kept in the immediate vicinity of the temperature transmitter and

readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions, prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage

caused by using the product contrary to its intended use,

non-compliance with these operating instructions, assignment of

insuciently qualied skilled personnel or unauthorised modications to the temperature transmitter.

■

The general terms and conditions, contained in the sales

documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TE 53.01

- Application consultant:

4 WIKA Operating Instructions Temperature Transmitter T53

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

11178648.04 03/2010 GB/D/F/E

Page 5

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can

result in serious injury or death, if not avoided.

Information

... points out useful tips, recommendations and informa-

tion for ecient and trouble-free operation.

DANGER!

...identies hazards caused by electric power. Should

the safety instructions not be observed, there is a risk of

serious or fatal injury

WARNING!

... indicates a potentially dangerous situation in the

hazardous area, which can result in serious injury or

death, if not avoided.

GB

.

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 5

Page 6

2. Safety

2. Safety

WARNING!

GB

2.1 Intended use

The temperature transmitter T53.10 is a universal, congurable

transmitter for use with single and dual resistance thermometers

(RTD), thermocouples (TC), resistance and sensor sources as well

as potentiometer measuring.

The temperature transmitter has been designed and built solely for

the intended use described here, and may only be used accordingly.

The technical specications contained in these operating instructions must be observed. Improper handling or operation of the instru-

ment outside of its technical specications requires the instrument

to be shut down immediately and inspected by an authorised WIKA

service engineer.

Before installation, commissioning and operation,

ensure that the appropriate temperature transmitter has

been selected in terms of measuring range, design and

specic measuring conditions.

Non-observance can result in serious injury and/or

damage to equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

If the temperature transmitter is transported from a cold into a warm

environment, the formation of condensation may result in the instrument malfunctioning. Before putting it back into operation, wait for the

instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

6 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 7

2. Safety

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions may only be carried out by skilled personnel

who have the qualications described below.

■

Keep unqualied personnel away from hazardous

areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on

their technical training, knowledge of measurement and control

technology and on their experience and knowledge of country-

specic regulations, current standards and directives, are capable

of carrying out the work described and independently recognising

potential hazards.

Special operating conditions require further appropriate knowledge,

e.g. of aggressive media.

2.3 Additional safety instructions for instruments with ATEX

approval

WARNING!

Non-observance of these instructions and their contents

may result in the loss of explosion protection.

GB

WARNING!

■

Observe the applicable regulations for the use of

Ex-class instruments

(e.g.: EN 60 079-0: 2006,

EN 60 079-11: 2007, EN 60 079-26: 2007,

EN 60 079-27: 2006 + 2008, EN 61 241-0: 2006,

EN 61 241-11: 2006, EN 60 079-15: 2005).

■

Do not use transmitters with any damage to the

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 7

exterior!

Page 8

2. Safety

2.3.1 Conditions for Model T53.10.0NI from type examination

certicate KEMA 06ATEX149 X

Zone 2 approval II 3 GD Ex nA [nL] IIC T4 ... T6

GB

II 3 GD Ex nL IIC T4 ... T6

II 3 GD Ex nA [ic] IIC T4 ... T6

II 3 GD Ex ic IIC T4 ... T6

Entity parameters:

T53.10.0NI

Zone 2 Ex nL IIC/

Ex ic IIC

U

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

32 VDC 32 VDC 17.5 VDC

1 µH 1 µH

2.0 nF 2.0 nF

≤ 85 °C Ta ≤ 85 °C Ta ≤ 85 °C

a

≤ 75 °C Ta ≤ 75 °C Ta ≤ 75 °C

a

≤ 60 °C Ta ≤ 60 °C Ta ≤ 60 °C

a

Sensor (terminal 3, 4, 5 and 6):

Uo : 5.7 VDC

Io : 8.4 mA

Po : 12 mW

Lo : 200 mH

Co : 40 µF

Specic conditions for safe use

For use in potentially explosive atmosphere of ammable gasses,

vapours or mists, the transmitter T53.10.0NI shall be mounted in an

enclosure providing a degree of protection of at least IP 54 in accordance with EN 60 529.

For use in the presence of combustible dusts, the transmitter shall be

mounted in an enclosure providing a degree of protection of at least

IP 6X in accordance with EN 60 529. The surface temperature of the

enclosure shall be determined after installation of the transmitter.

8 WIKA Operating Instructions Temperature Transmitter T53

Zone 2 nA FNICO (FISCO)

11178648.04 03/2010 GB/D/F/E

Page 9

2. Safety

For an ambient temperature ≥ 60 °C, heat resistant cables shall be

used with a rating of at least 20 K above the ambient temperature.

2.3.2 Conditions for Model T53.10.0IS from EC-type

examination certicate KEMA 06ATEX148

I.S. approval:

KEMA 06ATEX0148 II 1 G Ex ia IIC T4 ... T6 or

II 2 (1) G Ex ib [ia] IIC T4 ... T6

II 1 D Ex iaD

Applicable in zone 0, 1, 20 or 21

I.S. data:

Signal output / supply (terminal 1 to 2):

Max. ambient temperature depends on the Po of the connected

barrier.

Sensor (terminal 3, 4, 5 and 6):

Uo : 5.7 VDC

Io : 8.4 mA

Po : 12 mW

Lo : 200 mH

Co : 40 µF

The eective internal capacitance and the eective internal

inductance of the Fieldbus input circuit are Ci = 2 nF, Li = 1 μH

GB

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 9

Page 10

2. Safety

T53.10.0IS

Class I, Zone O, Ex ia IIC or Ex iaD, FISCO

Po < 0.84 W Po < 1.3 W FISCO systems FISCO systems

GB

U

i

l

i

P

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

U

i

l

i

P

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

Installation instructions

The sensor circuit is not infallibly galvanically isolated from the Fieldbus input circuit. However, the galvanic isolation between the circuits

is capable of withstanding a test voltage of AC 500 V during 1 minute.

In a potentially explosive gas atmosphere, the transmitter shall be

mounted in an enclosure in order to provide a degree of protection of

at least IP 20 according to EN 60 529.

30 VDC 30 VDC 17.5 VDC 15 VDC

120 mA DC 300 mA DC 250 mA DC

0.84 W 1.3 W 2.0 W

1 µH 1 µH 1 µH 1 µH

2.0 nF 2.0 nF 2.0 nF 2.0 nF

≤ 85 °C Ta ≤ 75 °C Ta ≤ 85 °C Ta ≤ 85 °C

a

≤ 70 °C Ta ≤ 65 °C Ta ≤ 60 °C Ta ≤ 60 °C

a

≤ 60 °C Ta ≤ 45 °C Ta ≤ 45 °C Ta ≤ 45 °C

a

T53.10.0IS

Class I, Zone 1, Ex ib IIC, FISCO

Po < 0.84 W FISCO systems

30 VDC 17.5 VDC

250 mA DC

5.32 W

1 µH 1 µH

2.0 nF 2.0 nF

≤ 85 °C Ta ≤ 85 °C

a

≤ 75 °C Ta ≤ 75 °C

a

≤ 60 °C Ta ≤ 60 °C

a

10 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 11

2. Safety

If the transmitter is installed in an explosive atmosphere requiring

the use of equipment of category 1 G and if the enclosure is made

of aluminium, it must be installed such, that, even in the event of

rare incidents, ignition sources due to impact and friction sparks are

excluded; if the enclosure is made of non-metallic materials, electrostatic charging shall be avoided.

For installation in a potentially explosive dust atmosphere, the

following instructions apply:

The transmitter shall be mounted in a metal enclosure form B

according to DIN 43 729 that is providing a degree of protection of at

least IP 6X according to EN 60 529, that is suitable for the application and is correctly installed.

Cable entries and blanking elements shall be used that are suitable

for the application and correctly installed.

For an ambient temperature ≥ 60 °C, heat resistant cables shall be

used with a rating of at least 20 K above the ambient temperature.

The surface temperature of the enclosure is equal to the ambient

temperature plus 20 K, for a dust layer with a thickness up to 5 mm.

2.4 Special hazards

WARNING!

Observe the information given in the applicable type

examination certicate and the relevant country-specic

regulations for installation and use in potentially explosive atmospheres (e.g. IEC 60 079-14, NEC, CEC).

Non-observance can result in serious injury and/or

damage to equipment.

For additional important safety instructions for insturments with ATEX approval see chapter "2.3 Additional

safety instructions for instruments with ATEX approval".

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 11

GB

Page 12

2. Safety

WARNING!

For hazardous media such as oxygen, acetylene,

ammable or toxic gases or liquids, and refrigeration

GB

12 WIKA Operating Instructions Temperature Transmitter T53

plants, compressors, etc., in addition to all standard

regulations, the appropriate existing codes or regulations must also be followed.

WARNING!

Protection from electrostatic discharge (ESD) required.

The proper use of grounded work surfaces and personal

wrist straps is required when coming into contact with

exposed circuitry (printed circuit boards), in order to

to prevent static discharge from damaging sensitive

electronic components

.

To ensure safe working on the instrument, the operating

company must ensure

■

that suitable rst-aid equipment is available and aid

is provided whenever required.

■

that the operating personnel are regularly instructed

in all topics regarding work safety, rst aid and

environmental protection and knows the operating

instructions and, in particular, the safety instructions

contained therein.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of

death.

■

Electrical instruments may only be installed and

mounted by skilled electrical personnel.

■

Operation using a defective power supply unit (e.g.

short circuit from the mains voltage to the output

voltage) may result in life-threatening voltages on the

instrument!

11178648.04 03/2010 GB/D/F/E

Page 13

2. Safety

WARNING!

Residual media in dismounted instruments may result in

a risk to people, the environment and the system. Take

sucient precautionary measures.

Do not use this instrument in safety or Emergency Stop

devices. Incorrect use of the instrument can result in

injury.

Should a failure occur, aggressive media with extremely

high temperature and under high pressure or vacuum

may be present at the instrument.

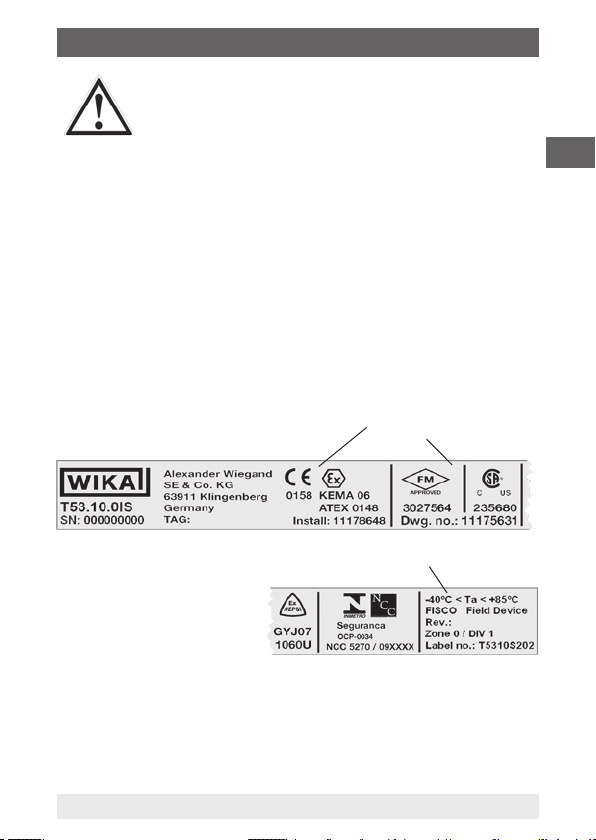

2.5 Labelling / safety marks

Product label (example)

GB

For an explanation of

symbols, see page 14

Permissible ambient temperature

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 13

Page 14

2. Safety

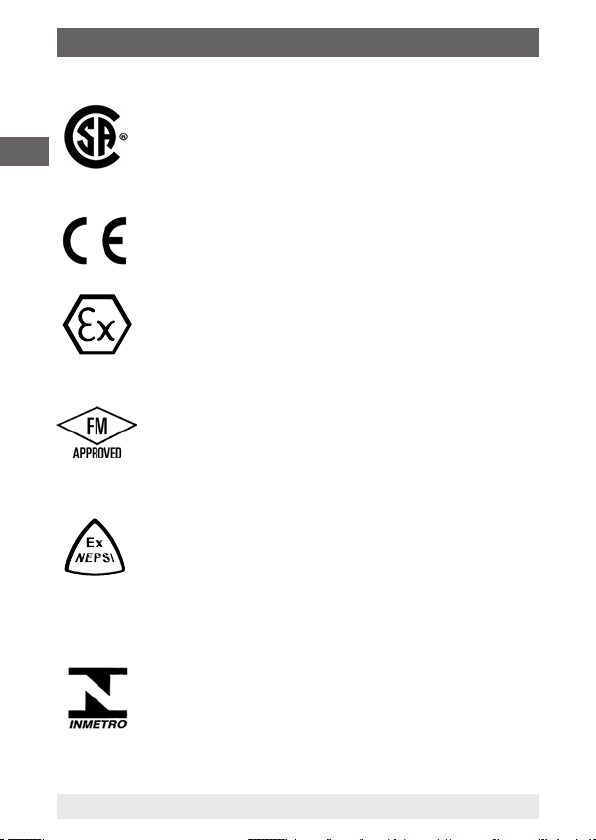

Explanation of symbols

GB

CSA, Canadian Standard Association

The instrument was inspected and certied by CSA

International. Instruments bearing this mark comply with

the applicable Canadian standards on safety (including

explosion protection).

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant

European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = Ex)

Instruments bearing this mark comply with the

requirements of the European Directive 94/9/EC (ATEX)

on explosion protection.

FM, Factory Mutual

The instrument was inspected and certied by FM

Approvals. Instruments bearing this mark comply

with the applicable US standards on safety (including

explosion protection).

NEPSI

National Supervision and Inspection Center for

Explosion Protection and Safety of Instrumentation

The instrument was inspected and certied by NEPSI.

Instruments bearing this mark comply with the applicable chinese standards on safety (including explosion

protection).

INMETRO

National Institute of Metrology, Standardization

and Industrial Quality

The instrument was inspected and certied by INMETRO.

Instruments bearing this mark comply with the applicable

brazilian standards.

14 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 15

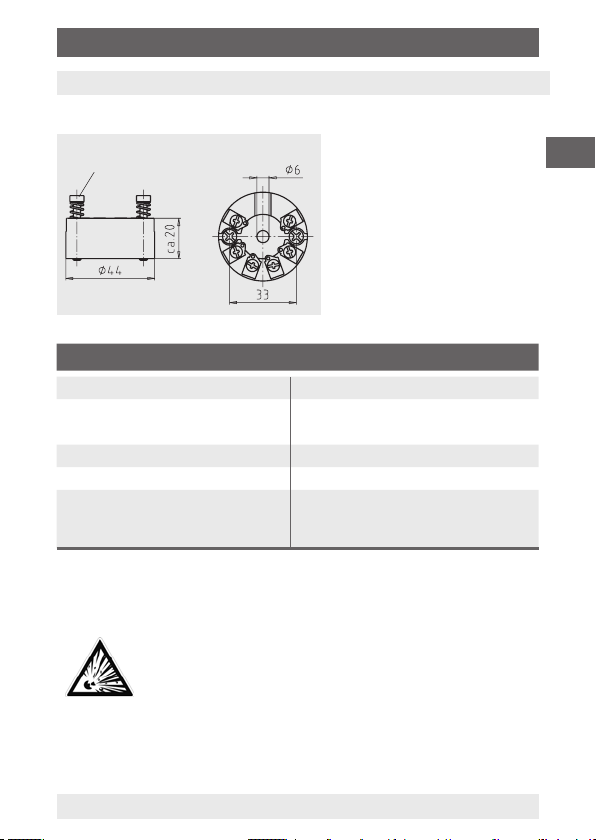

3. Specications

3. Specications

Dimensions in mm

Screw M4

approx. 30 mm

spring-loaded

Specications Model T53.10

Ambient/storage temperature -40 ... +85 °C

Maximum permissible humidity 95 % relative humidity

Vibration 2 ... 100 Hz 4 g DIN IEC 68-2-6

Case material Plastic, PBT, glass bre reinforced

Ingress protection

■

Case

■

Terminal

For further specications see WIKA Data Sheet TE 53.01 and the

order documentation.

(no condensation)

IP 68 per IEC 529/EN 60 529

IP 00 per IEC 529/EN 60 529

GB

Further important safety instructions for the operation

in potentially explosive atmospheres can be found in

chapter "2.3 Additional safety instructions for instruments

with ATEX approval".

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 15

Page 16

4. Design and function

4. Design and function

4.1 Description

The temperature transmitter serves for the conversion of the

GB

resistance value or voltage value into a proportional digital

measurement value. The digital value complies with PROFIBUS® PA

and FOUNDATION™ Fieldbus-specications and will be used in a

following logical control unit (e.g. PLC).

A unique switch function ensures automatic shift between the two

eldbus protocols.

■

FOUNDATION™ Fieldbus ITK version 4.61

■

PROFIBUS® PA version 3.0

■

Automatic switch between protocols

■

FISCO certied

■

Polarity-independent bus connection

■

PROFIBUS® PA function blocks: 2 analogue

■

FOUNDATION™ Fieldbus function blocks: 2 analogue and 1 PID

■

FOUNDATION™ Fieldbus capability: Basic or LAS

■

The simulation mode function for FOUNDATION™ Fieldbus can

be activated by way of a magnet only

Temperature Transmitter Model T53.10 is part of an electrical

temperature measuring device for use in the industry. The transmitter is intended to be mounted into a commonly used connection

head of a electrical thermometer.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

16 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 17

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during

transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +85 °C

■

Humidity: 95 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the instrument in its original packaging in a location that fullls

the conditions listed above. If the original packaging is not available,

package and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the

packaging.

3. If stored for a prolonged period of time (more than 30 days), place

a bag, containing a desiccant, inside the packaging.

GB

WARNING!

Before storing the instrument (following operation),

remove any residual media. This is of particular importance if the medium is hazardous to health, e.g. caustic,

toxic, carcinogenic, radioactive, etc.

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 17

Page 18

6. Commissioning, operation

6. Commissioning, operation

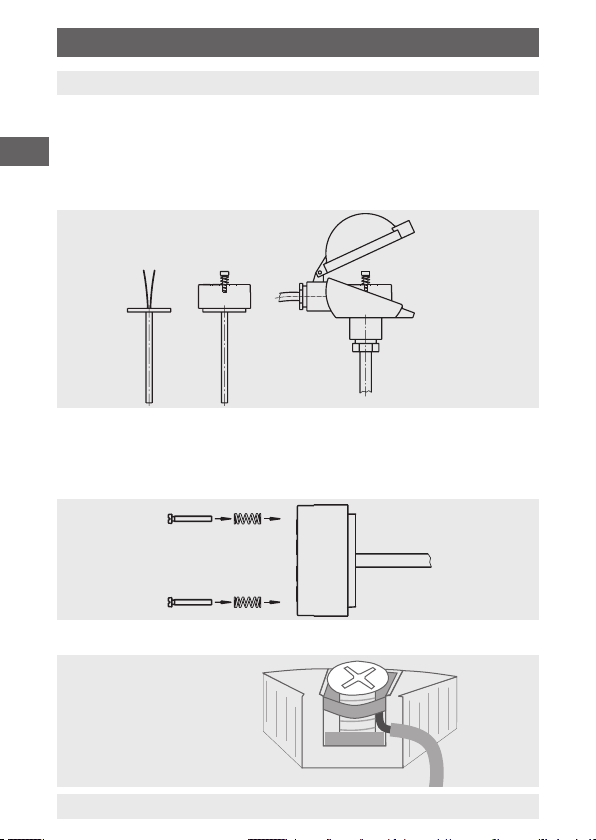

6.1 Mounting

The Model T53.10 transmitters are designed to be mounted on a

GB

measuring insert in a Form B DIN connection head.

The connection wires of the measuring insert must be approx.

50 mm long and insulated.

Mounting example:

Mounting in connection head

Insert the measuring insert with the mounted transmitter into the

protective sheath and

in pressure springs.

secure

into the connecting head using screws

11198991.01A

11198991.01B

Mounting of sensor wires

Wires must be mounted

between the metal plates.

18 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 19

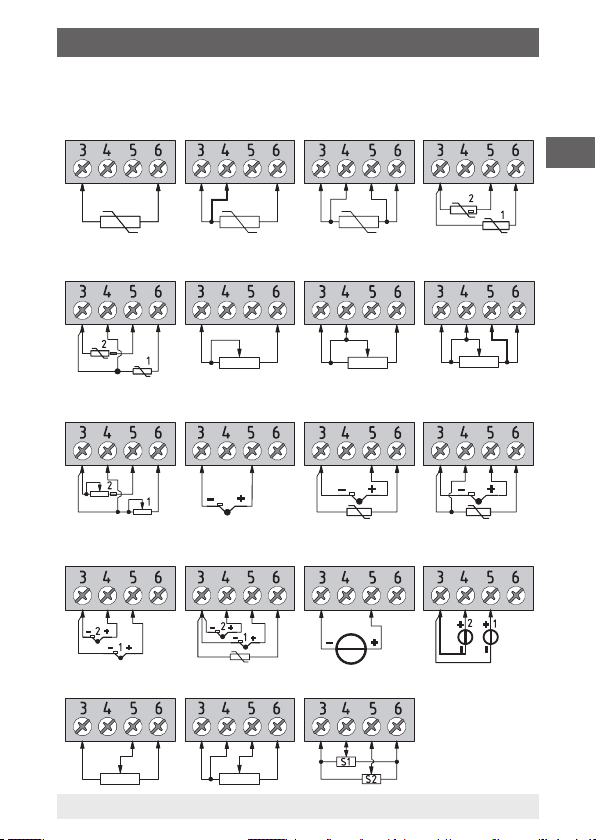

6. Commissioning, operation

6.2 Electrical connections

Input:

Pt100, 2-wire Pt100, 3-wire Pt100, 4-wire

2 x

Pt100, 2-/ 3-wire

Resistance, 2-wire Resistance, 3-wire Resistance, 4-wire

2 x

Pt100, 2-wire

GB

2 x Resistance,

2-/ 3-wire

2 x Thermocouple,

internal CJC

Potentiometer,

3-wire

11178648.04 03/2010 GB/D/F/E

Thermocouple,

internal CJC

2 x Thermocouple,

2-wire CJC

Potentiometer,

cable compensation

Thermocouple,

external CJC

2 Potentiometer,

3-wire

Thermocouple,

3-wire

external CJC

2 x mVmV

Connections with

two sensors can

be congured for

2 measurements,

dierence, average

or redundancy.

WIKA Operating Instructions Temperature Transmitter T53 19

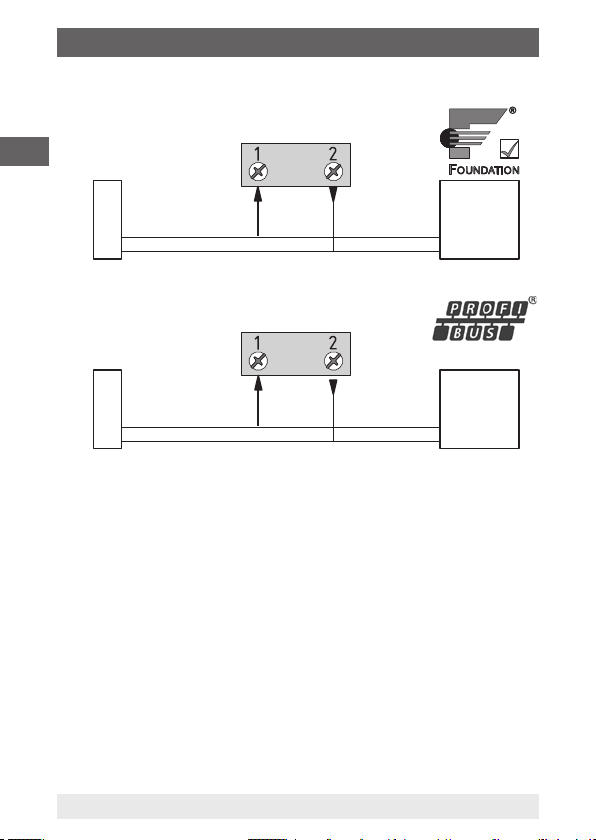

Page 20

6. Commissioning, operation

Output:

GB

Bus termination

Bus connection

Segment

coupler

Bus connection

Bus termination

20 WIKA Operating Instructions Temperature Transmitter T53

PA

Segment

coupler

11178648.04 03/2010 GB/D/F/E

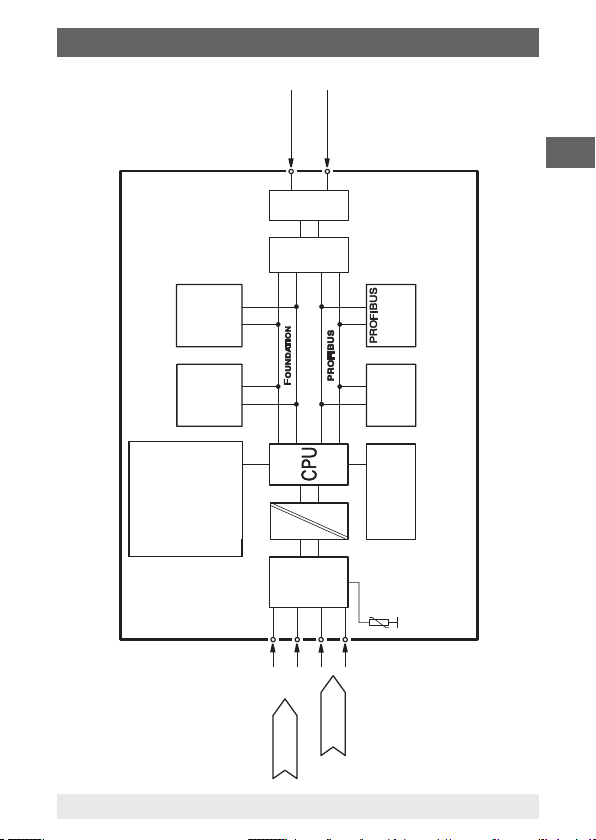

Page 21

6. Commissioning, operation

6.3 Block diagram

Bus connection

1

2

GB

Ex circuit

Automatic

communication

switch

Foundation

eldbus

Function

blocks

AI1, AI2

Protocol

PID

LAS

Protocol

Function

blocks AI1,

AI2

T53.10

orrektion coecients

EEPROM

Complete conguration

C

isolation

Transducer block

Input 1

Input 2

Dierence

Average

Redundancy

Terminal temperature

Galvanic

Engineering units

Diagnostics

Table linearisation

Polynominal linearisation

Process calibration

to

Digital

converter

Analogue

3

4

5

6

Factory settings

Internal

CJC

Resistance

thermometer

Thermocouple

Bipolar mV

Ohm ■Potentiometer

■

■

■

■

11178648.04 03/2010 GB/D/F/E

Selectable Inputs:

Input 1

WIKA Operating Instructions Temperature Transmitter T53 21

Input 2

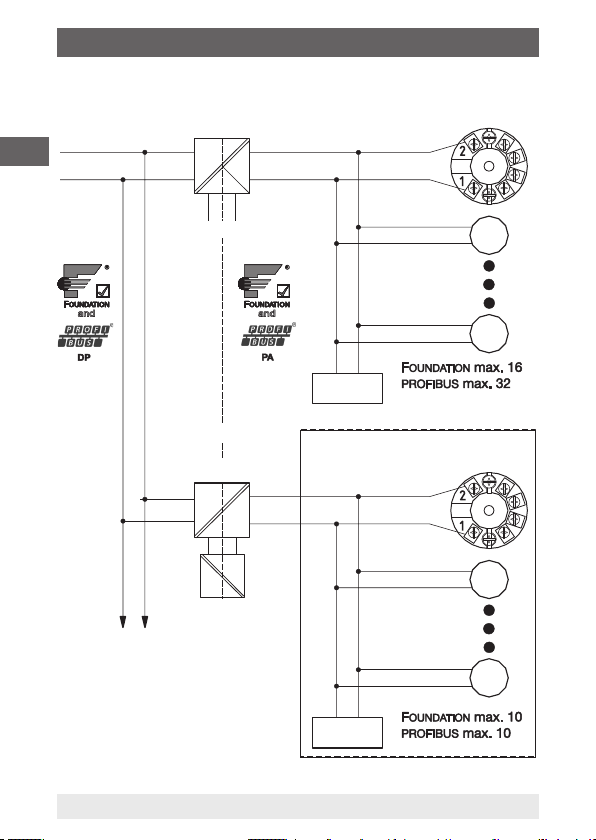

Page 22

6. Commissioning, operation

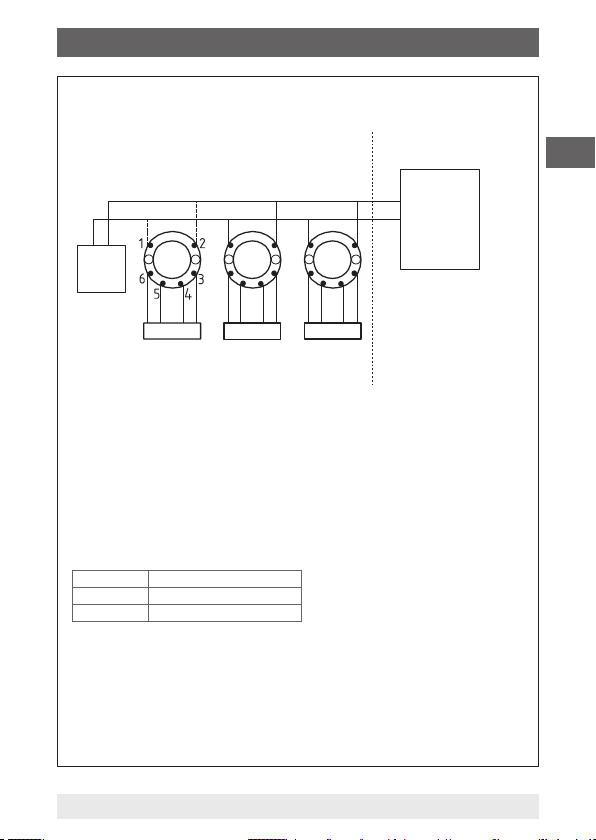

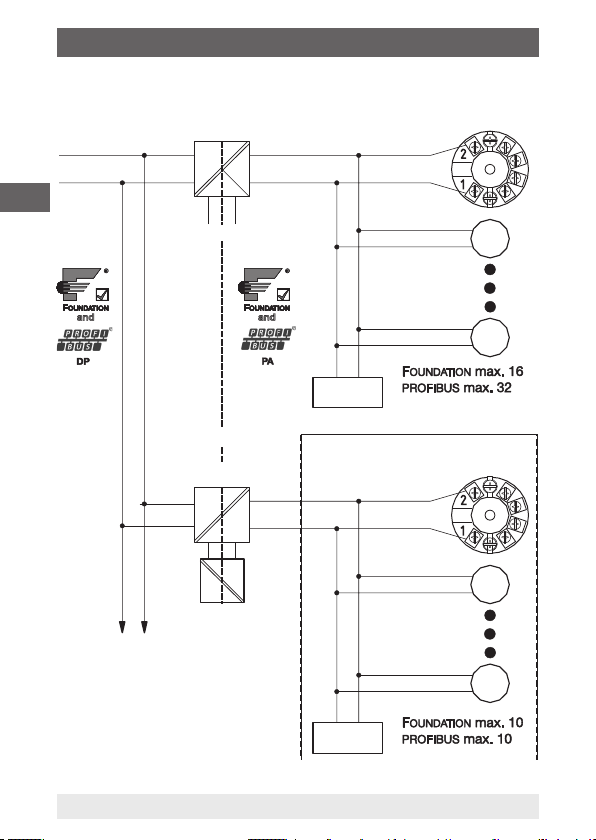

6.4 Bus installation

Segment coupler

GB

T53.10.0NI

To additional

segment couplers

Power supply

Safe area

Segment coupler, Ex

Power supply

Bus

termination

Hazardous area

Bus

termination

T53.10.0NI

T53.10.0NI

T53.10.0IS

T53.10.0IS

T53.10.0IS

22 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 23

7. Maintenance / 8. Return and disposal

7. Maintenance

The temperature transmitter described in these operating instructions is maintenance-free!

The electronics are completely encapsulated and incorporate no

components which could be repaired or replaced.

Repairs must only be carried out by the manufacturer.

8. Return and disposal

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

8.1 Return

WARNING!

Absolutely observe when shipping the instrument:

All instruments delivered to WIKA must be free from any

kind of hazardous substances (acids, bases, solutions,

etc.).

When returning the instrument, use the original packaging or a

suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in

the packaging. Place shock-absorbent material evenly on all sides

of the shipping box.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring

instrument.

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 23

GB

Page 24

8. Return and disposal

Enclose the completed return form with the instrument.

GB

The return form is available on the internet:

www.wika.de / Service / Return

8.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-

specic waste disposal regulations.

24 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 25

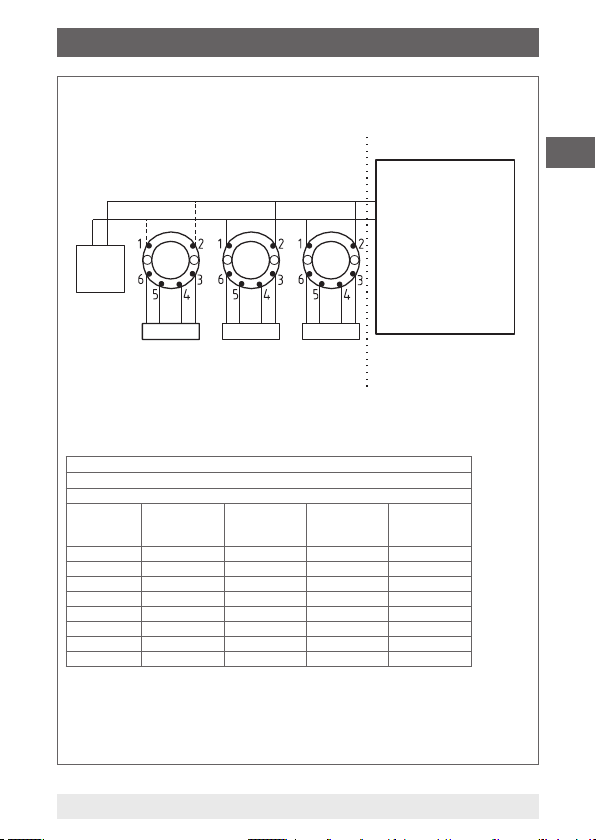

Appendix 1: FM-CSA Installation Drawing

Model T53.10.0IS

Hazardous (classied) Location

Unclassied Location

Class I, Division 1, Groups A, B, C, D

or

Class I, Zone 0, IIC

Approved

Termina-

tion

Sensor Sensor Sensor

Terminal 3, 4, 5, 6

V

or Uo: 5.71 V

t

lt or lo: 8.4 mA

Pt or Po: 12 mW

Ca or Co: 40 µF

or Lo: 200 mH

L

a

Class I, Zone 0, Ex ia IIC, Entity / FISCO

IS, Class I, Division 1, Group A, B, C, D Entity / FISCO

Barrier type Linear barrier Trapezoid

T1 ... T4 Ta ≤ +85 °C Ta ≤ +75 °C Ta ≤ +85 °C Ta ≤ +85 °C

T5 Ta ≤ +70 °C Ta ≤ +65 °C Ta ≤ +60 °C Ta ≤ +60 °C

T6 Ta ≤ +60 °C Ta ≤ +45 °C Ta ≤ +45 °C Ta ≤ +45 °C

max or Ui 30 V 30 V 17.5 V 15 V

V

max or li 120 mA 300 mA 250 mA 900 mA

l

Pi 0.84 W 1.3 W 2.0 W 5.32 W

Ci 2.0 nF 2.0 nF 2.0 nF 2.0 nF

Li 1 µH 1 µH 1 µH 1 µH

See Installation notes.

Terminal 1, 2

barrier

Suitable

for FISCO

systems

Associated Apparatus

Barrier or

FISCO Supply

with

entity Parameters:

UM ≤ 250 V

or Uo ≤ V

V

oc

lsc or lo ≤ l

max

Po ≤ P

i

Ca or Co ≥ Ci + C

La or Lo ≥ Li or L

The device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

Suitable

for FISCO

systems

max

or l

or U

i

cable

cable

GB

i

Installation Drawing 11175631.01 1/6

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 25

Page 26

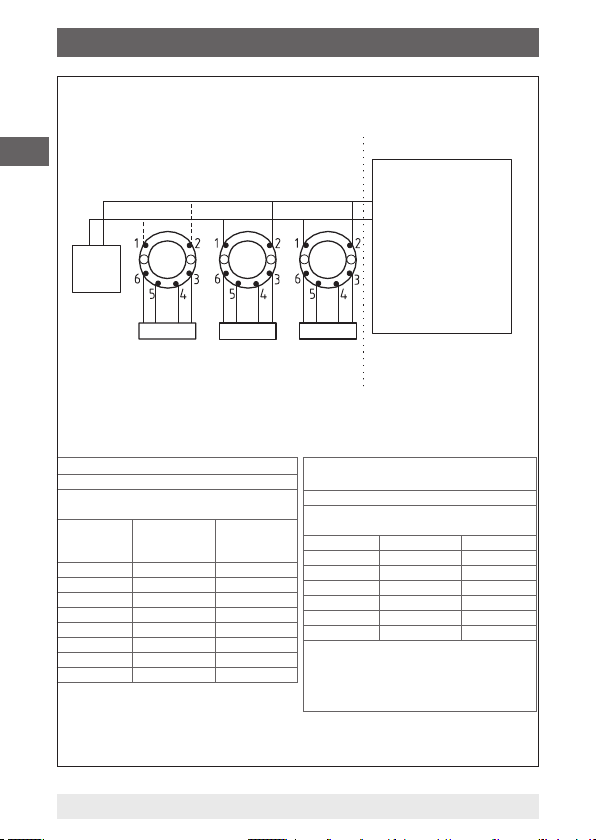

Appendix 1: FM-CSA Installation Drawing

Model T53.10.0IS

Hazardous (classied) Location

GB

Class I, Division 2, Groups A, B, C, D

or

Class I, Zone 1, IIC

Approved

Termina-

tion

Sensor Sensor Sensor

Terminal 3, 4, 5, 6

V

or Uo: 5.71 V

t

lt or lo: 8.4 mA

Pt or Po: 12 mW

Ca or Co: 40 µF

La or Lo: 200 mH

Unclassied Location

Associated Apparatus

Barrier with

entity Parameters:

UM ≤ 250 V

or Uo ≤ V

V

oc

lsc or lo ≤ l

Po ≤ P

Ca or Co ≥ Ci + C

La or Lo ≥ Li or L

FISCO Supply

The device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

or U

max

or l

max

i

i

cable

cable

or

i

Entity Parameters

Terminal 1, 2

Class I, Zone 1, Ex ib IIC

Barrier type Rectangular

T1 ... T4 Ta ≤ +85 °C Ta ≤ +85 °C

T5 Ta ≤ +75 °C Ta ≤ +75 °C

T6 Ta ≤ +60 °C Ta ≤ +60 °C

max / Ui 30 V 17.5 V

V

max or li 250 mA any

l

Pi 5.32 W any

Ci 2.0 nF 2.0 nF

Li 1 µH 1 µH

See Installation notes.

Installation Drawing 11175631.01

Entity/FISCO

barrier

FISCO

Segment

coupler

Nonincendive Field Wiring

parameters

NI, Class I, Division 2, Group A, B, C, D

T1 ... T4 Ta ≤ +85 °C Ta ≤ +75 °C

T5 Ta ≤ +75 °C Ta ≤ +65 °C

T6 Ta ≤ +60 °C Ta ≤ +45 °C

max / Ui 30 V 17.5 V

V

Pi 5.32 W any

Ci 2.0 nF 2.0 nF

Li 1 µH 1 µH

For a current-controlled circuit the

parameter l

need not be aligned with the parameter

or lt of the barrier or associated

l

sc

nonincendive eld wiring apparatus.

Terminal 1, 2

NIFW/FNICO

is not required and

max

2/6

26 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 27

Appendix 1: FM-CSA Installation Drawing

Installation of Model T53.10.0NI

Hazardous (classied) Location

Unclassied Location

Class I, Division 2, Groups A, B, C, D

or

Class I, Zone 2, IIC

Approved

Termina-

tion

Sensor Sensor Sensor

Terminal 3, 4, 5, 6

V

or Uo: 5.71 V

t

lt or lo: 8.4 mA

Pt or Po: 12 mW

Ca or Co: 40 µF

La or Lo: 200 mH

Terminal 1, 2

C

: 2.0 nF

i

L

: 1µH

i

T1 ... T4 -40 °C ≤ Ta ≤ +85 °C

T5 -40 °C ≤ Ta ≤ +75 °C

T6 -40 °C ≤ Ta ≤ +60 °C

See Installation notes.

32 V

Class 2

Power Supply

The device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

GB

Installation Drawing 11175631.01

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 27

3/6

Page 28

Appendix 1: FM-CSA Installation Drawing

Installation notes:

FM / CSA:

For installation in the US the equipment shall be installed according to the National

Electrical Code (ANSI-NFPA 70).

GB

For installation in Canada the transmitter shall be installed in a suitable enclosure to meet

installation codes stipulated in the Canadian Electrical Code (CEC).

The entity concept:

Equipment that is FM / CSA-approved for intrinsic safety may be connected to barriers

based on the ENTITY CONCEPT. This concept permits interconnection of approved

transmitters, meters and other devices in combinations which have not been specically

examined by FM / CSA, provided that the agency‘s criteria are met. The combination is

intrinsically safe, if the entity concept is acceptable to the authority having jurisdiction over

the installation.

The entity concept criteria are as follows:

The intrinsically safe devices, other than barriers, must not be a source of power.

The maximum voltage U

which the device can receive and remain intrinsically safe, must be equal to or greater

than the voltage (Uo or VOC or Vt) and current (Io or ISC or It) and the power Po which can

be delivered by the barrier.

The sum of the maximum unprotected capacitance (Ci) for each intrinsically device and

the interconnecting wiring must be less than the capacitance (Ca) which can be safely

connected to the barrier.

The sum of the maximum unprotected inductance (Li) for each intrinsically device and

the interconnecting wiring must be less than the inductance (La) which can be safely

connected to the barrier.

The entity parameters Uo, VOC or Vt and Io, ISC or It, and Ca and La for barriers are provided by the barrier manufacturer.

FISCO/FNICO rules:

The FISCO Concept allows the interconnection of intrinsically safe apparatus to

associated apparatus not specically examined in such combination. The criterion for

such interconnection is that the voltage (V

intrinsically safe apparatus can receive and remain intrinsically safe, considering faults,

must be equal or greater than the voltage (Uo, VOC, Vt), the current (Io, ISC, It) and the

power (Po) which can be provided by the associated apparatus (supply unit). In addition,

the maximum unprotected residual capacitance (Ci) and inductance (Li) of each apparatus (other than the terminators) connected to the Fieldbus must be less than or equal

to:FISCO: 5 nF and 10 µH

FNICO: 5 nF and 20 µH

(V

i

max

) and current Ii (I

max

), and maximum power Pi (P

max

), the current (I

) and the power (Pi) which

max

max

),

Installation Drawing 11175631.01

4/6

28 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 29

Appendix 1: FM-CSA Installation Drawing

The Nonincendive Field Wiring concept allows the interconnection of nonincendive eld

wiring apparatus using any of the wiring methods permitted for unclassied locations.

V

>= Voc or Vt, Ca >= Ci +C

max

The Nonincendive Field Wiring concept allows the interconnection of FM-approved

nonincendive devices with FNICO parameters not specically examined in combination

as a system when: Uo or Voc or Vt <= V

In each I.S. Fieldbus segment only one active source, normally the associated apparatus,

is allowed to provide the necessary power for the Fieldbus system. The allowed voltage

(Uo, Voc, Vt) of the associated apparatus used to supply the bus must be limited to the

range of 14 V d.c. to 24 V d.c. All other equipment connected to the bus cable has to

be passive, meaning that the apparatus is not allowed to provide energy to the system,

except to a leakage current of 50 A for each connected device. Separately powered

equipment needs a galvanic isolation to insure that the intrinsically safe Fieldbus circuit

remains passive.

The cable used to interconnect the devices needs to comply with the following parameters:

Loop resistance R': 15 ...150 /Km

Inductance per unit length L‘: 0.4…1 mH/km

Capacitance per unit length C‘: 80 ...200 nF/km

C‘ = C‘ line/line + 0.5 C‘ line/screen, if both lines are oating

or

C‘= C‘ line/line + C‘ line/screen, if the screen is connected to one line

Length of spur Cable: max. 30 m

Length of trunk cable: max. 1 Km

Length of splice: max. 1 m

Terminators

At each end of the trunk cable an approved line terminator with the following parameters

is suitable:

R = 90 ...100 Ω

C = 0 ... 2.2 µF

System evaluation

The number of passive devices like transmitters, actuators, connected to a single bus

segment is not limited due to I.S. or N.I. reasons. Furthermore, if the above rules are respected, the inductance and capacitance of the cable need not to be considered and will

not impair the intrinsic safety or nonincendive safety of the installation as applicable.

The sensor circuit is not infallibly galvanically isolated from the Fieldbus input circuit. However, the galvanic isolation between the circuits is capable of withstanding a test voltage

of 500 Vac during 1 minute.

, La >= Li + L

cable

max

cable

, Po <= P

“

i

GB

Installation Drawing 11175631.01

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 29

5/6

Page 30

Appendix 1: FM-CSA Installation Drawing

Nonincendive Field Wiring Concept:

The Nonincendive Field Wiring concept allows for the interconnection of nonincendive

eld wiring apparatus using any of the wiring methods permitted for unclassied locations.

>= Voc or Vt, Ca >= Ci +C

V

max

GB

Installation Notes For FISCO and Entity Concepts:

1. The Intrinsic Safety Entity concept allows the interconnection of FM / CSA-approved

intrinsically safe devices (Div. 1 or Zone 0 or Zone1), with entity parameters not specically examined in combination as a system when: Uo or Voc or Vt ≤ V

Imax, Po ≤ Pi

Ca or Co ≥ ∑Ci + ∑C

2. The Intrinsic Safety FISCO concept allows the interconnection of FM / CSA-approved

intrinsically safe devices with FISCO parameters not specically examined in

combination as a system when:

Uo or Voc or Vt ≤ V

3. Control equipment connected to the Associated Apparatus must not use or generate

more than 250 Vrms or Vdc.

4. Intrinsically Safe Installation should be in accordance with ANSI/ISA RP12.6.01

(except chapter 5 for FISCO Installations) "Installation of Intrinsically Safe Systems for

Hazardous (Classied) Locations" and the National Electrical Code® (ANSI/NFPA 70)

Sections 504 and 505.

5. The conguration of associated Apparatus must be FM Approvals or CSA Approved

under the associated concept.

6. Associated Apparatus manufacturer’s installation drawing must be followed when

installing this equipment.

7. The equipment is approved for Class I, Zone 0, applications. If connecting AEx [ib]

associated Apparatus or AEx ib I.S. Apparatus to the equipment the I.S. circuit is only

suitable for Class I, Zone 1, or Class I, Zone 2, and is not suitable for Class I, Zone 0 or

Class I, Division 1, Hazardous (Classied) Locations".

8. No revision to drawing without prior FM / CSA Approval.

9. Simple Apparatus is dened as a device that neither generates nor stores more than

1.5 V, 0.1 A or 25 mW.

10. The termination must be NRTL-approved, and the resistor must be infallible.

11. Warning:

For applications in Div. 2 or Zone 2 (Classied Locations) Explosion hazard: Except for

nonincendive eld circuits, do not disconnect the apparatus unless the area is known

to be non hazardous.

12. Warning:

Substitution of Components May Impair Safety.

cable

, Io or Isc or It ≤ Imax, Po ≤ P

max

, La >= Li + L

cable

, La or Lo ≥ ∑Li + ∑L

cable

cable

i

“

, Po ≤ P

i

, Io or Isc or It ≤

max

Installation Drawing 11175631.01

6/6

30 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 31

Appendix 2: EC Declaration of conformity

GB

11178648.04 03/2010 GB/D/F/E

WIKA Operating Instructions Temperature Transmitter T53 31

Page 32

GB

32 WIKA Operating Instructions Temperature Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 33

Inhalt

Inhalt

1. Allgemeines 34

2. Sicherheit 36

3. Technische Daten 45

4. Aufbau und Funktion 46

5. Transport, Verpackung und Lagerung 47

6. Inbetriebnahme, Betrieb 48

7.

Wartung 53

8. Rücksendung und Entsorgung 53

Anlage 1: FM-CSA Installation Drawing 25

Anlage 2: EG-Konformitätserklärung 31

D

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

33

Page 34

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach den

neuesten Erkenntnissen konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen

Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind

nach ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in

un-mittelbarer Nähe des Gerätes für das Fachpersonal jederzeit

zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsan-

leitung, Einsatz ungenügend qualizierten Fachpersonals sowie

eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den

Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TE 53.01

- Anwendungsberater:

34 WIKA Betriebsanleitung Temperatur-Transmitter T53

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

11178648.04 03/2010 GB/D/F/E

Page 35

1. Allgemeines

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation

hin, die zum Tod oder zu schweren Verletzungen führen

kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie

Informationen für einen ezienten und störungsfreien

Betrieb hervor.

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen

Strom. Bei Nichtbeachtung der Sicherheitshinweise

besteht

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation

im explosionsgefährdeten Bereich hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie

nicht gemieden wird.

D

die Gefahr schwerer oder tödlicher Verletzungen.

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

35

Page 36

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Gerät hinsichtlich Messbereich,

Ausführung und spezischen Messbedingungen

D

2.1 Bestimmungsgemäße Verwendung

Der Temperatur Transmitter T53.10 ist ein universeller, kongurierbarer Transmitter für Einzel- und Doppel-Widerstandsthermometer

(RTD), Thermoelemente (TC), Widerstands- und Sensorgeber sowie

Potentiometermessung.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und

darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind

einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben

des Gerätes außerhalb der technischen Spezikationen macht die

sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in

den einzelnen Kapiteln dieser Betriebsanleitung.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch Kondensatbildung eine Störung der Gerätefunktion

eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der

Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

36 WIKA Betriebsanleitung Temperatur-Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 37

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen

Tätigkeiten nur durch Fachpersonal nachfolgend

beschriebener Qualikation durchführen lassen.

■

Unqualiziertes Personal von den Gefahrenberei-

chen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrun-

gen sowie Kenntnis der landesspezischen Vorschriften, geltenden

Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes

Wissen, z. B. über aggressive Medien.

2.3 Zusätzliche Sicherheitshinweise für Geräte mit ATEX-

Zulassung

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen

kann zum Verlust des Explosionsschutzes führen.

D

WARNUNG!

■

Jeweiligen Vorschriften bezüglich Ex-Einsatz einhalten (z. B.: EN 60 079-0: 2006, EN 60 079-11: 2007,

EN 60 079-26: 2007, EN 60 079-27: 2006 + 2008,

EN 61 241-0: 2006, EN 61 241-11: 2006,

EN 60 079-15: 2005).

■

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

Äußerlich beschädigte Transmitter nicht verwenden!

37

Page 38

2. Sicherheit

2.3.1 Bedingungen für Typ T53.10.0NI aus der Baumusterprüf-

bescheinigung KEMA 06ATEX149

Zone 2 Zulassung II 3 GD Ex nA [nL] IIC T4 ... T6

II 3 GD Ex nL IIC T4 ... T6

II 3 GD Ex nA [ic] IIC T4 ... T6

D

II 3 GD Ex ic IIC T4 ... T6

Kenngrößen

T53.10.0NI

Zone 2 Ex nL IIC/

Ex ic IIC

U

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

32 VDC 32 VDC 17,5 VDC

1 µH 1 µH

2,0 nF 2,0 nF 2,0 nF

< 85 °C Ta < 85 °C Ta < 85 °C

a

< 75 °C Ta < 75 °C Ta < 75 °C

a

< 60 °C Ta < 60 °C Ta < 60 °C

a

Anschluss des Sensors (Klemmen 3, 4, 5 und 6):

Uo : 5,7 VDC

Io : 8,4 mA

Po : 12 mW

Lo : 200 mH

Co : 40 µF

Besondere Bedingungen für den sicheren Betrieb

Für den Einsatz in Bereichen, die möglicherweise durch brennbare

Gase, Dämpfe oder Nebel gefährdet sind, muss der Transmitter

T53.10.0NI in ein Gehäuse eingebaut werden, das mindestens der

Schutzart IP 54 gemäß EN 60 529 entspricht.

Für den Einsatz in einem Bereich mit brennbarem Staub muss der

Transmitter

in ein Gehäuse eingebaut werden, das mindestens der

Schutzart IP 6X gemäß EN 60 529 entspricht. Die Oberächentemperatur des Gehäuses muss nach dem Einbau des

ermittelt werden.

38 WIKA Betriebsanleitung Temperatur-Transmitter T53

Zone 2 nA FNICO (FISCO)

Transmitters

11178648.04 03/2010 GB/D/F/E

Page 39

2. Sicherheit

Bei einer Umgebungstemperatur ≥ 60 °C müssen hitzebeständige

Leitungen eingesetzt werden, welche für eine mindestens 20 K

höhere Umgebungstemperatur zugelassen sind.

2.3.2 Bedingungen für Typ T53.10.0IS aus der EG-Baumuster-

prüfbescheinigung KEMA 06ATEX148

Ex-Zulassung:

KEMA 06ATEX0148 X II 1 G Ex ia IIC T4 ... T6 oder

II 2 (1) G Ex ib [ia] IIC T4 ... T6

II 1 D Ex iaD

Betrieb in Zone 0, 1, 2, 20, 21 oder 22

Ex-Daten:

Signalausgang/Hilfsenergie (Klemmen 1 bis 2):

Die maximale Umgebungstemperatur hängt von der Leistung Po der

angeschlossenen Sperre ab.

Anschluss des Sensors (Klemmen 3, 4, 5 und 6):

Uo : 5,7 VDC

Io : 8,4 mA

Po : 12 mW

Lo : 200 mH

Co : 40 µF

D

Die eektive interne Kapazität und Induktivität des Feldbusstromkreises beträgt C

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

= 2 nF, Li = 1 μH

i

39

Page 40

2. Sicherheit

T53.10.0IS

Class I, Zone O, Ex ia IIC oder Ex iaD, FISCO

Po < 0,84 W Po < 1,3 W FISCO systems FISCO systems

U

i

l

i

D

P

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

U

i

l

i

P

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

Montagehinweise

Die galvanische Trennung zwischen dem Sensorstromkreis und der

Eingangsbeschaltung ist nicht unfehlbar. Allerdings ist die galvanische Trennung zwischen den Kreisen so ausgelegt, dass diese eine

Testspannung von AC 500 V für eine Minute aushält.

In einem Bereich, der möglicherweise durch Gase gefährdet ist,

muss der Transmitter in einem Gehäuse montiert werden, das

mindestens der Schutzart IP 20 gemäß EN 60 529 entspricht.

40 WIKA Betriebsanleitung Temperatur-Transmitter T53

30 VDC 30 VDC 17.5 VDC 15 VDC

120 mA DC 300 mA DC 250 mA DC

0,84 W 1,3 W 2,0 W

1 µH 1 µH 1 µH 1 µH

2,0 nF 2,0 nF 2,0 nF 2,0 nF

< 85 °C Ta < 75 °C Ta < 85 °C Ta < 85 °C

a

< 70 °C Ta < 65 °C Ta < 60 °C Ta < 60 °C

a

< 60 °C Ta < 45 °C Ta < 45 °C Ta < 45 °C

a

T53.10.0IS

Class I, Zone 1, Ex ib IIC, FISCO

Po < 0,84 W FISCO systems

30 VDC 17,5 VDC

250 mA DC

5,32 W

1 µH 1 µH

2,0 nF 2,0 nF

< 85 °C Ta < 85 °C

a

< 75 °C Ta < 55 °C

a

< 60 °C Ta < 60 °C

a

11178648.04 03/2010 GB/D/F/E

Page 41

2. Sicherheit

Falls der Transmitter in einen Ex-Bereich installiert wird, in dem der

Einsatz von Betriebsmitteln der Kategorie 1 G erforderlich ist und

falls das Gehäuse aus Aluminium besteht, dann muss der Transmitter so installiert werden, dass im Falle eines Störfalls Zündquellen

aufgrund von Funken durch Stöße oder Reibung ausgeschlossen

werden. Falls das Gehäuse aus nicht-metallischen Materialien

besteht, muss elektrostatische Ladung vermieden werden.

Für den Einsatz in explosionsfähiger Atmosphäre durch Staub/

Luft-Gemische, gelten folgende Hinweise:

Der Transmitter muss in einen Metallkopf Form B gemäß DIN 43 729

montiert werden, welcher einen Schutzgrad von mindestens IP 6X

gemäß EN 60 529 besitzt, für den dementsprechenden Einsatz

zugelassen und korrekt installiert ist.

Es dürfen nur Kabeleinführungen und Abdeckungen eingesetzt

werden, welche für die jeweilige Anwendung zugelassen und die

richtig installiert sind.

Bei einer Umgebungstemperatur ≥ 60 °C müssen hitzebeständige

Leitungen eingesetzt werden, die für eine mindestens 20 K höhere

Umgebungstemperatur zugelassen sind.

Die Oberächentemperatur des Gehäuses entspricht der

Umgebungstemperatur plus 20 K, bei einer bis zu 5 mm dicken

Staubschicht.

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbeschei-

nigung sowie die jeweiligen landesspezischen

Vorschriften zur Installation und Einsatz in explosionsgefährdeten Bereichen (z. B. IEC 60 079-14, NEC, CEC)

einhalten. Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit

ATEX-Zulassung siehe Kapitel „2.3 Zusätzliche Sicher-

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

heitshinweise für Geräte mit ATEX-Zulassung“.

D

41

Page 42

2. Sicherheit

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto,

Acetylen, brennbaren oder giftigen Stoen, sowie bei

Kälteanlagen, Kompressoren etc. müssen über die

gesamten allgemeinen Regeln hinaus die einschlägigen

Vorschriften beachtet werden.

D

42 WIKA Betriebsanleitung Temperatur-Transmitter T53

WARNUNG!

Schutz vor elektrostatischer Entladung (ESD) erforderlich! Die ordnungsgemäße Verwendung geerdeter

Arbeitsächen und persönlicher Armbänder ist bei

Arbeiten mit oenen Schaltkreisen (Leiterplatten)

erforderlich, um die Beschädigung empndlicher elekt-

ronischer Bauteile durch elektrostatische Entladung zu

vermeiden.

Für ein sicheres Arbeiten am Gerät muss der Betreiber

sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung

vorhanden ist und bei Bedarf jederzeit Hilfe zur

Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreffenden Fragen von Arbeitssicherheit, Erste-Hilfe und

Umweltschutz unterwiesen wird, sowie die Betriebsanleitung und insbesondere die darin enthaltenen

Sicherheitshinweise kennt.

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht

unmittelbare Lebensgefahr.

■

Einbau und Montage des elektrischen Gerätes

dürfen nur durch das Elektrofachpersonal erfolgen.

■

Bei Betrieb mit einem defekten Netzgerät (z. B.

Kurzschluss von Netzspannung zur Ausgangsspannung) können am Gerät lebens-gefährliche

Spannungen auftreten!

11178648.04 03/2010 GB/D/F/E

Page 43

2. Sicherheit

WARNUNG!

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-AusEinrichtungen benutzen. Fehlerhafte Anwendungen des

Gerätes können zu Verletzungen führen.

Am Gerät können im Fehlerfall aggressive Medien mit

extremer Temperatur und unter hohem Druck oder

Vakuum anliegen.

2.5 Beschilderung / Sicherheitskennzeichnungen

Typenschild (Beispiel)

Symbolerklärungen

siehe Seite 44

zulässige Umgebungstemperatur

D

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

43

Page 44

2. Sicherheit

Symbolerklärung

D

CSA, Canadian Standard Association

Das Gerät wurde durch CSA International geprüft und

zertiziert. Geräte mit dieser Kennzeichnung stimmen

überein mit den anwendbaren kanadischen Normen zur

Sicherheit (einschließlich Explosionsschutz).

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit

den zutreenden europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = Ex)

Geräte mit dieser Kennzeichnung stimmen überein mit

den Anforderungen der europäischen Richtlinie 94/9/

EG (ATEX) zum Explosionsschutz.

FM, Factory Mutual

Das Gerät wurde von FM Approvals geprüft und zertiziert. Geräte mit dieser Kennzeichnung stimmen überein

mit den anwendbaren US-amerikanischen Normen zur

Sicherheit (einschließlich Explosionsschutz).

NEPSI

National Supervision and Inspection Center for

Explosion Protection and Safety of Instrumentation

Das Gerät wurde von NEPSI geprüft und zertiziert.

Geräte mit dieser Kennzeichnung stimmen überein mit

den anwendbaren chinesischen Normen zur Sicherheit

(einschließlich Explosionsschutz).

INMETRO

National Institute of Metrology, Standardization

and Industrial Quality

Das Gerät wurde von INMETRO geprüft und zertiziert.

Geräte mit dieser Kennzeichnung stimmen überein mit

den anwendbaren brasilianischen Normen

44 WIKA Betriebsanleitung Temperatur-Transmitter T53

.

11178648.04 03/2010 GB/D/F/E

Page 45

3. Technische Daten

3. Technische Daten

Abmessungen in mm

Schraube M4

ca. 30 mm lang

gefedert

Technische Daten Typ T53.10

Umgebungs-/Lagertemperatur -40 ... +85 °C

Max. zulässige Feuchte 95 % relative Feuchte (ohne

Vibration 2 ... 100 Hz 4 g DIN IEC 68-2-6

Gehäusematerial Kunststo, PBT, glasfaserverstärkt

Schutzart

■

Gehäuse

■

Klemmen

Weitere technische Daten siehe WIKA Datenblatt TE 53.01 und

Bestellunterlagen.

Betauung)

IP 68 nach IEC 529/EN 60 529

IP 00 nach IEC 529/EN 60 529

D

Weitere wichtige Sicherheitshinweise für den Betrieb

in explosionsgefährdeten Bereichen siehe Kapitel

„2.3 Zusätzliche Sicherheitshinweise für Geräte mit

ATEX-Zulassung“.

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

45

Page 46

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Beschreibung

Der T53.10 wandelt einen Widerstands- oder Spannungswert in

einen proportionalen digitalen Messwert um. Der digitale Messwert

wird in Form der PROFIBUS® PA und FOUNDATION™ Fieldbus-

Spezikation einer nachgeschalteten Logikeinheit (z. B. einer SPS)

D

zur weiteren Verarbeitung zur Verfügung gestellt. Die einzigartige

Umschaltfunktion ermöglicht eine automatische Umschaltung

zwischen den beiden Protokollen.

■

FOUNDATION™ Fieldbus ITK Version 4.61

■

PROFIBUS® PA Version 3.0

■

Automatische Umschaltung zwischen den Protokollen

■

FISCO zertiziert

■

Polaritätsunabhängige Busanschluss

■

PROFIBUS® PA Funktionsblöcke: 2 Analoge

■

FOUNDATION™ Fieldbus Funktionsblöcke: 2 Analoge und 1 PID

■

FOUNDATION™ Fieldbus Funktionalität: Basic oder LAS

■

Der Simulationsmodus kann bei FOUNDATION™ Fieldbus nur

mittels eines Magneten aktiviert werden

Der Temperatur-Transmitter T53.10 ist Teil eines elektrischen Temperaturmessgerätes für den Einsatz in der Industrie. Der Transmitter ist

vorgesehen für die Montage in einem üblichen Anschlusskopf eines

elektrischen Thermometers.

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

46 WIKA Betriebsanleitung Temperatur-Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 47

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport

einen optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -40 ... +85 °C

■

Feuchtigkeit: 95 % relative Feuchte (keine Betauung)

Vermeidung folgender Einüsse:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

Das Gerät in der Originalverpackung an einem Ort, der die oben

gelisteten Bedingungen erfüllt, lagern. Wenn die Originalverpackung

nicht vorhanden ist, dann das Gerät wie folgt verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit

Trocknungsmittel der Verpackung beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb)

alle anhaftenden Messstoreste entfernen. Dies ist

besonders wichtig, wenn der Messsto gesundheits-

gefährdend ist, wie z. B. ätzend, giftig, krebserregend,

radioaktiv, usw.

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

D

47

Page 48

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

6.1 Montage

Die Transmitter Typ T53.10 sind vorgesehen zur Montage auf einem

Messeinsatz im DIN-Anschlusskopf der Form B. Die Anschlussdrähte des Messeinsatzes müssen ca. 50 mm lang und isoliert

ausgeführt sein.

D

Montagebeispiel:

Montage im Anschlusskopf

Messeinsatz mit montiertem Transmitter in die Schutzarmatur

cken und im Anschlusskopf mit Schrauben federnd befestigen.

11198991.01A

einste-

11198991.01B

Montage von Fühlerleitungen

Die Leitungen müssen

zwischen den Metallplatten montiert werden.

48 WIKA Betriebsanleitung Temperatur-Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 49

6. Inbetriebnahme, Betrieb

6.2 Elektrische Anschlüsse

Eingang:

Pt100, 2-Leiter Pt100, 3-Leiter Pt100, 4-Leiter

2 x

Pt100, 2-/ 3-Leiter

Widerstand, 2-Leiter Widerstand, 3-Leiter Widerstand, 4-Leiter

2 x

Pt100, 2-Leiter

D

2 x Widerstand,

2-/ 3-Leiter

2 x Thermoelement,

interne CJC

Potentiometer,

3-Leiter

11178648.04 03/2010 GB/D/F/E

Thermoelement,

interne CJC

2 x Thermoelement,

2-Leiter CJC

Potentiometer,

Kabelkompensation

Thermoelement,

externe CJC

2 Potentiometer,

WIKA Betriebsanleitung Temperatur-Transmitter T53

3-Leiter

Thermoelement,

3-Leiter

externe CJC

2 x mVmV

Anschlüsse mit zwei

Fühlern können

für 2 Messungen,

Dierenz, Mittelwert

oder Redundanz

konguriert werden

49

Page 50

6. Inbetriebnahme, Betrieb

Ausgang:

Bus-Verbindung

Busabschluss

D

Bus-Verbindung

Busabschluss

50 WIKA Betriebsanleitung Temperatur-Transmitter T53

Segmentkoppler

PA

Segmentkoppler

11178648.04 03/2010 GB/D/F/E

Page 51

6. Inbetriebnahme, Betrieb

6.3 Blockdiagramm

1

Ex-Stromkreis

Automatische

Busumschaltung

Foundation

eldbus

Protokoll

Funktions-

blöcke

AI1, AI2

PID

LAS

Trennung

Transducer Block

Eingang 1

Eingang 2

Dierenz

Mittelwert

Redundanz

Klemmentemperatur

Galvanische

Engineering Einheiten

Diagnosefunktionen

Tabellen-Linearisierung

Polynom-Linearisierung

Prozesskalibrierung

Busverbindung

2

A/D

Wandler

Funktions-

EEPROM

Komplette Konguration

Interner

Protokoll

blöcke

AI1, AI2

Korrekturkoezienten

Werkseinstellungen

CJC

D

T53.10

4

5

6

Wiederstands-

thermometer

Thermoelement

Bipolar mV

Ohm ■Potentiometer

■

■

■

■

11178648.04 03/2010 GB/D/F/E

Wählbare Eingänge:

Eingang 1

WIKA Betriebsanleitung Temperatur-Transmitter T53

3

Eingang 2

51

Page 52

6. Inbetriebnahme, Betrieb

6.4 Businstallation

Segmentkoppler

D

Versorgungsspannung

Bus-

abschluss

T53.10.0NI

T53.10.0NI

T53.10.0NI

An zusätzliche

Segmentkoppler

Sicherer Bereich

Segmentkoppler, Ex

Versorgungsspannung

Ex-gefährdeter Bereich

Bus-

abschluss

T53.10.0IS

T53.10.0IS

T53.10.0IS

52 WIKA Betriebsanleitung Temperatur-Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 53

7. Wartung / 8. Rücksendung und Entsorgung

7. Wartung

Der hier beschriebene Temperatur-Transmitter ist wartungsfrei!

Die Elektronik ist vollständig vergossen und enthält keinerlei Bauteile, welche repariert oder ausgetauscht werden könnten.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

8. Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen sind zu

ergreifen.

8.1 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von

Gefahrstoen (Säuren, Laugen, Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine

geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung

beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes

kennzeichnen.

Dem Gerät das Rücksendeformular ausgefüllt beifügen.

11178648.04 03/2010 GB/D/F/E

WIKA Betriebsanleitung Temperatur-Transmitter T53

D

53

Page 54

8. Rücksendung und Entsorgung

Das Rücksendeformular steht im Internet zur Verfügung:

www.wika.de / Service / Rücksendung

8.2 Entsorgung

D

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

Anlage 1: FM-CSA Installation Drawing

siehe Seite 25

Anlage 2: EG-Konformitätserklärung

siehe Seite 31

54 WIKA Betriebsanleitung Temperatur-Transmitter T53

11178648.04 03/2010 GB/D/F/E

Page 55

Sommaire

Sommaire

1. Généralités 56

2. Sécurité 58

3. Caractéristiques techniques 67

4. Conception et fonction 68

5. Transport, emballage et stockage 69

6. Mise en service, exploitation 71

7.

Entretien 76

8. Retour et mise au rebut 76

Annexe 1 : FM-CSA Installation Drawing 25

Annexe 2 : Déclaration de conformité CE 78

F

11178648.04 03/2010 GB/D/F/E

WIKA Mode d'emploi Transmetteur de température T53

55

Page 56

1. Généralités

1. Généralités

■

L'appareil décrit dans le présent mode d'emploi est conçu et

fabriqué selon les dernières technologies en vigueur et tous les

composants sont soumis à des critères de qualité et d'environnement stricts durant la fabrication. Nos systèmes de gestion sont

certiés selon ISO 9001 et ISO 14001.

F

■

Ce mode d'emploi donne des indications importantes concernant

l'utilisation de l'appareil. Il est possible de travailler en toute sécurité

avec ce produit en respectant toutes les consignes de sécurité et

d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur

pour le domaine d'application de l‘appareil.

■

Le mode d'emploi fait partie de l'appareil et doit être conservé à

proximité immédiate de l'appareil et accessible à tout moment

pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération,

avoir lu soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de

dommages provoqués par une utilisation non conforme à l'usage

prévu, de non respect de ce mode d'emploi, d'utilisation de

personnel peu qualié de même qu'en cas de modications de

l'appareil eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les

documents de vente sappliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations:

- Consulter notre site internet : www.wika.de / www.wika.com

- Fiche technique correspondante : TE 53.01

- Conseiller applications :

56 WIKA Mode d'emploi Transmetteur de température T53

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

11178648.04 03/2010 GB/D/F/E

Page 57

1. Généralités

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou des blessures graves si

elle n'est pas évitée.

Information

… met en exergue les conseils et recommandations

utiles de même que les informations permettant

d'assurer un fonctionnement ecace et normal.

DANGER !

… indique les dangers liés au courant électrique.

Danger de blessures graves ou mortelles en cas de non

respect des consignes de sécurité.

AVERTISSEMENT !

… indique une situation en zone explosive présentant

des risques susceptibles de provoquer la mort ou des

blessures graves si elle n’est pas évitée.

11178648.04 03/2010 GB/D/F/E

WIKA Mode d'emploi Transmetteur de température T53

F

57

Page 58

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que l'appareil a été choisi de façon

adéquate, en ce qui concerne la plage de mesure, la

version et les conditions de mesure spéciques.

F

2.1 Utilisation conforme à l'emploi prévu

Le transmetteur de température T53.10 est un transmetteur universel,

congurable pour des sondes à résistance simple et double (RTD),

thermocouples (TC), des générateurs de résistance et de tension

ainsi que mesure de potentiomètre.

L'appareil est conçu et construit exclusivement pour une utilisation

conforme à lusage prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode

d'emploi doivent être respectées. En cas d'utilisation inadéquate

ou de fonctionnement de l'appareil en dehors des spécications

techniques, un arrêt et contrôle doivent être immédiatement eec-

tués par un collaborateur autorisé du service de WIKA.

Si l'appareil est transporté d'un environnement froid dans un

environnement chaud, la formation de condensation peut provoquer

un dysfonctionnement fonctionnel de l'appareil. Il est nécessaire

d'attendre que la température de l'appareil se soit adaptée à la température ambiante avant une nouvelle mise en service.

Aucune réclamation ne peut être recevable en cas d‘utilisation non

conforme à l'usage prévu.

58 WIKA Mode d'emploi Transmetteur de température T53

Un non respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d‘emploi.

11178648.04 03/2010 GB/D/F/E

Page 59

2. Sécurité

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication

insusante !

Une utilisation non conforme peut entraîner

d'importants dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne

doivent être eectuées que par un personnel ayant

la qualication décrite ci-après.

■

Tenir le personnel non qualié à l'écart des zones

dangereuses.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de

ses connaissances dans le domaine de la technique de mesure et

de régulation et de ses expériences de même que de sa connaissance des prescriptions nationales, des normes et directives en

vigueur, en mesure d'eectuer les travaux décrits et de reconnaître

automatiquement les dangers potentiels.

Les conditions d'utilisation spéciales exigent également une

connaissance adéquate par exemple des liquides agressifs.

2.3 Consignes de sécurité complémentaires pour les appareils

avec homologation ATEX

AVERTISSEMENT !

Le non respect de ces instructions et de leurs contenus

peut entraîner une perte de la protection contre les

explosions.

F

11178648.04 03/2010 GB/D/F/E

WIKA Mode d'emploi Transmetteur de température T53

59

Page 60

2. Sécurité

AVERTISSEMENT !

■

Respecter les prescriptions respectives concernant

l'utilisation en zone Ex (par ex.: EN 60 079-0: 2006,

EN 60 079-11: 2007, EN 60 079-26: 2007,

EN 60 079-27: 2006 + 2008, EN 61 241-0: 2006,

EN 61 241-11: 2006, EN 60 079-15: 2005).

■

F

2.3.1 Conditions pour le type T53.10.0NI selon attestation

d'examen CE de type, KEMA 06ATEX149

Homologation zone 2 II 3 GD Ex nA [nL] IIC T4 ... T6

II 3 GD Ex nL IIC T4 ... T6

II 3 GD Ex nA [ic] IIC T4 ... T6

II 3 GD Ex ic IIC T4 ... T6

Paramètres

U

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

N'utiliser pas un transmetteur présentant des

dommages externes !

T53.10.0NI

Zone 2 Ex nL IIC/

Ex ic IIC

32 VDC 32 VDC 17,5 VDC

1 µH 1 µH

2,0 nF 2,0 nF 2,0 nF

< 85 °C Ta < 85 °C Ta < 85 °C

a

< 75 °C Ta < 75 °C Ta < 75 °C

a

< 60 °C Ta < 60 °C Ta < 60 °C

a

Zone 2 nA FNICO (FISCO)

Branchement de du capteur (bornes 3, 4, 5 et 6) :

Uo : 5,7 VDC

Io : 8,4 mA

Po : 12 mW

Lo : 200 mH

Co : 40 µF

60 WIKA Mode d'emploi Transmetteur de température T53

11178648.04 03/2010 GB/D/F/E

Page 61

2. Sécurité

Conditions particulières pour un fonctionnement sûr

Pour une utilisation dans en zone potentiellement explosive avec des

gaz, vapeurs ou brouillards inammables, le transmetteur T53.10.0NI

doit être monté dans un boîtier qui correspond au moins à l'indice de

protection IP 54 selon EN 60 529.

Pour une utilisation dans une zone exposée aux poussières inammables, le transmetteur doit être monté dans un boîtier qui correspond au moins à l'indice de protection IP 6X selon EN 60 529. La

température de la surface du boîtier doit être déterminée après le

montage du transmetteur.

Pour une température ambiante ≥ 60 °C, il faut utiliser des câbles

résistant à la chaleur, lesquels doivent être agréés pour une

température ambiante supérieure d'au moins 20 K.

2.3.2 Conditions pour le type T53.10.0IS selon attestation

d'examen CE de type, KEMA 06ATEX148

Homologation Ex :

KEMA 06ATEX0148 X II 1 G Ex ia IIC T4 ... T6 oder

II 2 (1) G Ex ib [ia] IIC T4 ... T6

II 1 D Ex iaD

Applicable en zone 0, 1, 2, 20, 21 ou 22

Caractéristiques Ex :

Sortie signal / alimentation (bornes 1 et 2) :

La température ambiante maximale dépend de la puissance Po de la

barrière utilisée.

F

Branchement de du capteur (bornes 3, 4, 5 et 6) :

Uo : 5,7 VDC

Io : 8,4 mA

Po : 12 mW

Lo : 200 mH

Co : 40 µF

11178648.04 03/2010 GB/D/F/E

WIKA Mode d'emploi Transmetteur de température T53

61

Page 62

2. Sécurité

La capacité et l'inductance internes eectives du circuit électrique du

bus de terrain sont Ci = 2 nF, Li = 1 μH.

T53.10.0IS

Class I, Zone O, Ex ia IIC oder Ex iaD, FISCO

Po < 0,84 W Po < 1,3 W FISCO systems FISCO systems

U

i

F

l

i

P

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

U

i

l

i

P

i

L

i

C

i

T1 ... T4 T

T5 T

T6 T

30 VDC 30 VDC 17.5 VDC 15 VDC

120 mA DC 300 mA DC 250 mA DC

0,84 W 1,3 W 2,0 W

1 µH 1 µH 1 µH 1 µH

2,0 nF 2,0 nF 2,0 nF 2,0 nF

< 85 °C Ta < 75 °C Ta < 85 °C Ta < 85 °C

a

< 70 °C Ta < 65 °C Ta < 60 °C Ta < 60 °C

a

< 60 °C Ta < 45 °C Ta < 45 °C Ta < 45 °C

a

T53.10.0IS

Class I, Zone 1, Ex ib IIC, FISCO

Po < 0,84 W FISCO systems

30 VDC 17,5 VDC

250 mA DC

5,32 W

1 µH 1 µH

2,0 nF 2,0 nF

< 85 °C Ta < 85 °C

a

< 75 °C Ta < 55 °C

a

< 60 °C Ta < 60 °C

a

Instructions de montage

L'isolation galvanique entre le circuit électrique du capteur et le