Page 1

Configuration Manual

for FOUNDATION™ Fieldbus

Fieldbus Temperature Transmitter Model T53.10

for FOUNDATION™ Fieldbus and PROFIBUS® PA

Fieldbus Temperature Transmitter Model T53.10

Page 2

2

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

This configuration manual

The Fieldbus Software

Parameter lists abbreviations

1.0 The Resource Block, Fieldbus Foundation

1.1 Introduction

1.2 Description

1.3 RESTART parameter

1.4 Non-volatile parameters

1.5 Timeout for remote cascade modes

1.6 Alert Notification

1.7 FEATURES / FEATURE_SEL parameters

1.8 Fault state for the whole resource

1.9 Write lock by software

1.10 Features being implemented

1.11 BLOCK_ERR

1.12 Supported Modes

1.13 Resource Block Parameter List, Fieldbus Foundation

2.0 The Transducer Block

2.1 The Transducer Block

2.2 The data of the Transducer Block Parameter List are grouped as follows:

2.3 Default configuration

2.4 Your application set up.

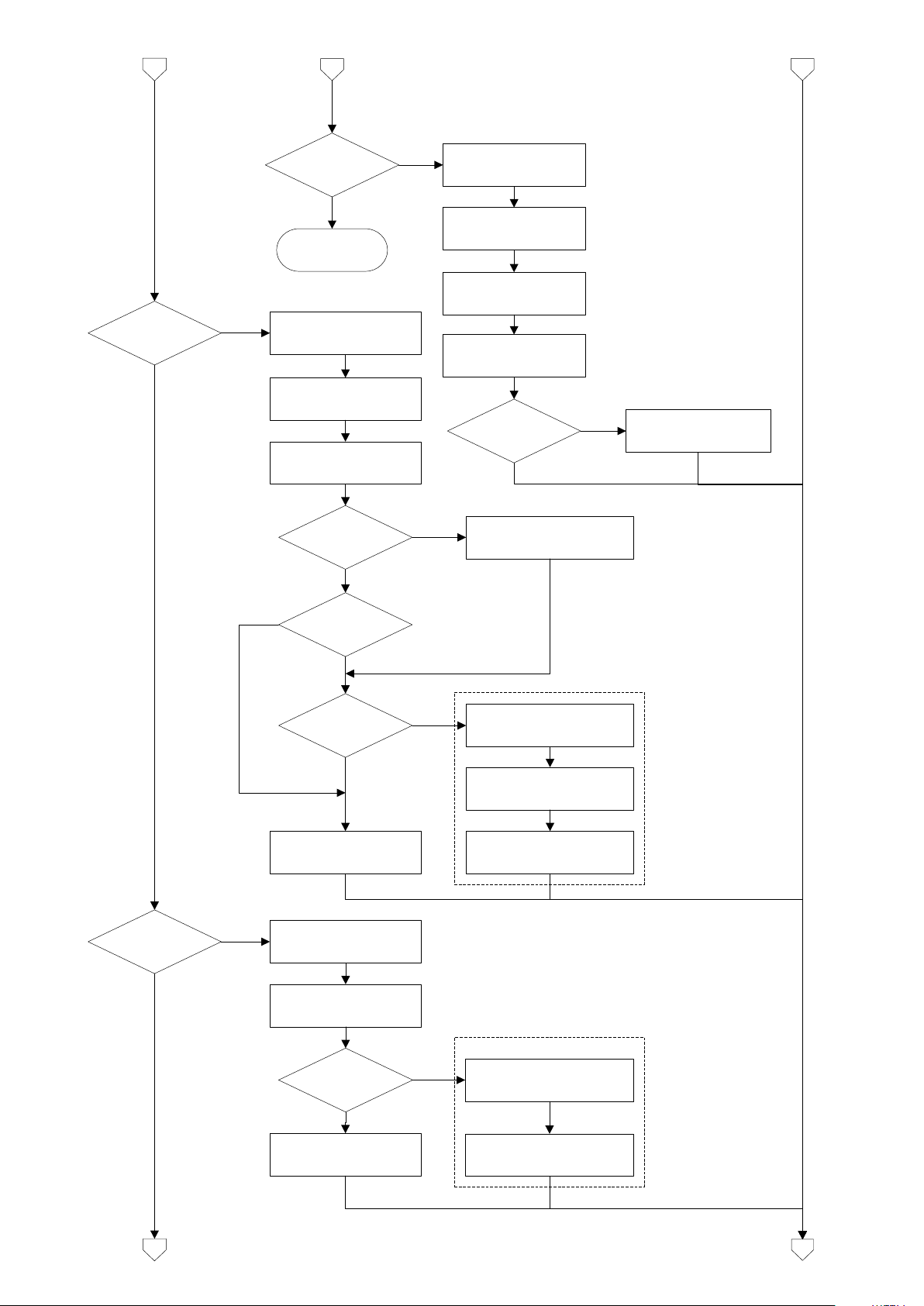

2.5 AI_Transducer Block Configuration Flowchart

2.6 - Transducer Block Examples Setup

2.6.1 Measurement of RTD with one sensor:

2.6.2 Measurement of RTD with two sensors:

2.6.3 Measurement of thermocouple with one sensor:

2.6.4 Measurement of thermocouple with two sensors:

2.6.5 Measurement of combined sensors (Sensor 1 = TC and Sensor 2 = RTD):

2.6.6 Measurement of resistance (linear) with one sensor:

2.6.7 Measurement of resistance (linear) with two sensors:

2.6.8 Measurement of potentiometer (linear) with one sensor:

2.6.9 Measurement of potentiometer (linear) with two sensors:

2.6.10 Measurement of voltage (linear) with one sensor:

2.6.11 Measurement of voltage (linear) with two sensors:

2.6.12 Measurement of 2 potentiometers (with Linear interpolation linearisation):

2.6.13 Measurement of TC (with Custom Polynomial Linearisation) on sensor 1

2.7 AI_Transducer and PR_CUST_LIN Block, Schematic

2.8 AI_TRANSDUCER Block Parameter List

2.8.1 Sensor characterising parameters

2.8.2 RTD / Resistor specific parameters

2.8.3 Thermocouple specific parameters

2.8.4 Output conditioning parameters

2.8.5 Output parameters

2.8.6 Diagnostic parameters

2.8.7 Sensor error detection parameters

2.8.8 Sensor calibration, Description

2.8.9 Sensor Calibration Parameters

2.9 PR_CUST_LIN Block Parameter List

2.9.1 Linear interpolation linearisation, Description

2.9.2 Linear Interpolation Linearisation, Parameter List.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . 14

. . . . 14

. . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . 16

. . 16

. . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . 25

Page 3

2.9.3 Custom polynomial linearisation, Description

2.9.4 Custom Polynomial Linearisation, Parameter List

2.10 PR_CUST_PRIV Block Reserved Parameter List

2.10.1 Description, PR_CUST_PRIV Block

3.0 Analogue Input Blocks

3.1 Analogue Input Blocks, Fieldbus Foundation

3.2 Overview

3.3 Analogue Input Block Schematic

3.4 Description

3.5 Supported Modes

3.6 To enable the Simulation mode

3.7 Alarm Types

3.8 Mode Handling

3.9 Status Handling

3.10 Initialisation

3.11 Analogue Input Blocks Parameter List, Fieldbus Foundation

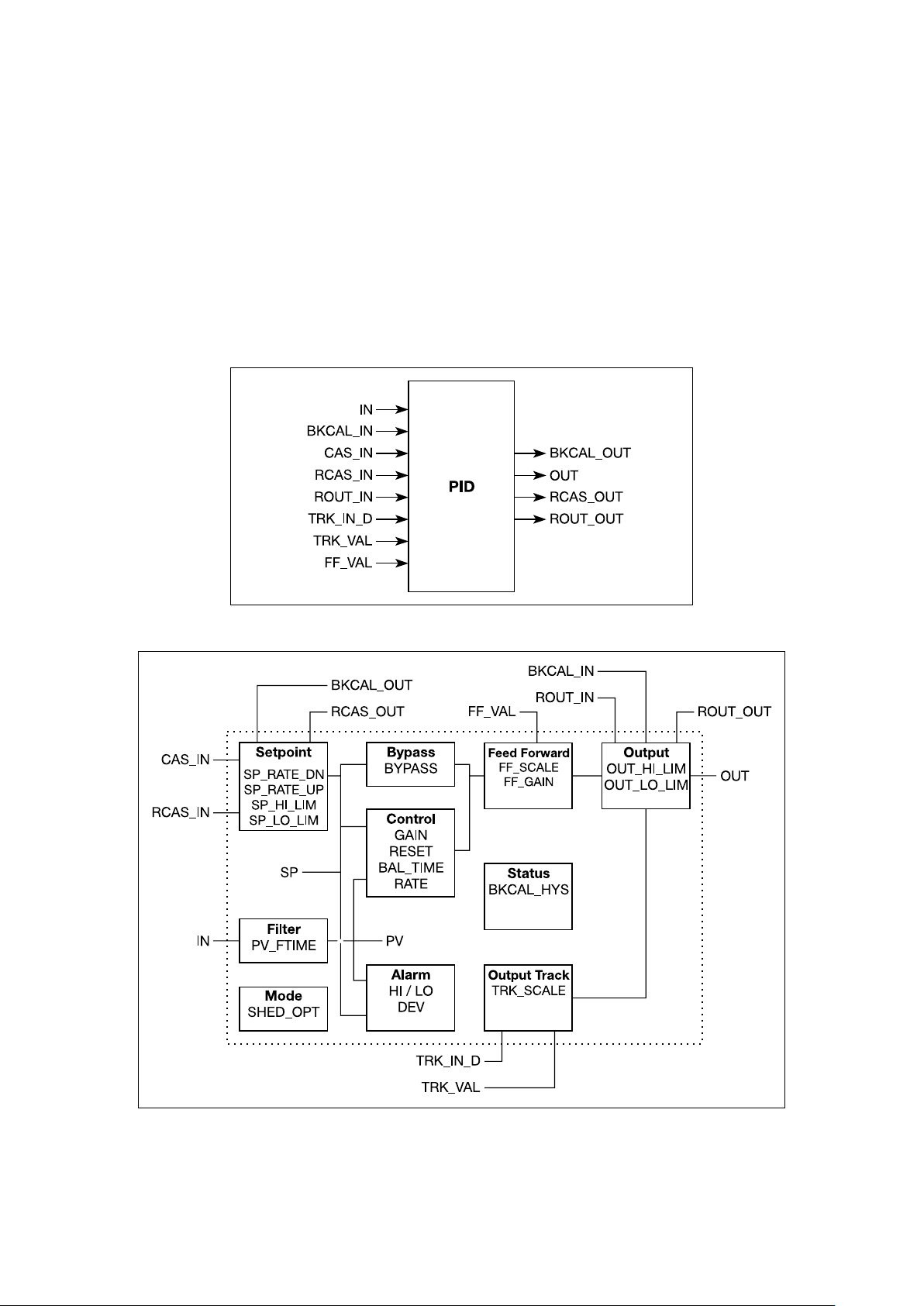

4.0 PID Control Block, Fieldbus Foundation

4.1 Introduction:

4.2 Overview

4.3 Schematic:

4.4 Description

4.5 Supported Modes

4.6 Alarm Types

4.7 Mode Handling

4.8 Status Handling

4.9 Initialization

4.10 PID Control Block Parameter List

5.0 Link Active Scheduler (LAS)

5.1 Introduction:

5.2 Overview

5.3 Description

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . 29

3

Page 4

4

Introduction

This configuration manual

contains the necessary information for configuration of the fieldbus temperature transmitter

T53 via a host system with application software for Foundation Fieldbus™ (for PROFIBUS

HOST systems please refer to the “Configuration Manual for PROFIBUS”). The autoswitch

function of the modules ensures automatic switch to the connected protocol.

The Fieldbus Software

has been developped by WIKA according to the specifications of the Fieldbus Foundation

and the PROFIBUS Nutzerorganisation.

TM

The files for Foundation

Fieldbus are:

xxyy.ffo - Device Description binary file

xxyy.sym - Device Description symbol file

xxyyzz.cff - Capability file

xx, yy and zz refer to the version numbers of the files.

These files can be downloaded from our homepage www.wika.de.

Please follow the instructions for the application software in question when installing the

files.

Parameter lists abbreviations

In the Store column:

SRC = Static Revision Counter; N = No; D = Dynamic;

Cst = Constant. The parameter doesn’t change in a device

In the RO / R/W column:

RO = Read Only; R /W = Read Write; * = Mixed of RO and R/W; ** = Don’t care

Page 5

1.0 The Resource Block, Fieldbus Foundation

1.1 Introduction

The resource block is used to define a hardware specific characteristics of the function block

applications. It provides WIKA manufacturer’s name, device name, DD and block status and

hardware details. It also indicates how much resource (memory and CPU) is available and

controls the overall device.

1.2 Description

This block contains data that is specific to the hardware that is associated with the resource.

All data is modelled within a controlled space, so there are no outside inputs into this block

required.

This parameter “set” is intended to be the minimum required for the Function Block Applica

tion associated with the resource in which it resides. Some parameters that could be in the

set, like calibration data and ambient temperature, are more part of their respective trans

ducer blocks. The “mode” is used to control major states of the resource. O/S mode stops

all function block execution. The actual mode of the function blocks will be changed to O/S

(out of service), but the target mode will not be changed. Auto mode allows normal operation

of the resource. IMan shows that the resource is initializing or receiving a software down

load. Parameters MANUFAC_ID, DEV_TYPE, DEV_REV, DD_REV, and DD_RESOURCE are

required to identify and locate the DD so that Device Description Hosting Services can se

lect the correct DD for use with the resource. The parameter HARD_TYPES is a read only bit

string that indicates the types of hardware that are available to this resource. If an I/O block

is configured that requires a type of hardware that is not available, the result will be a block

alarm for a configuration error. The RS_STATE parameter contains the operational state of

the Function Block Application for the resource containing this resource block.

-

-

-

-

1.3 RESTART parameter

The RESTART parameter allows degrees of initialization of the resource. They are:

1 - Run: it is the passive state of the parameter

2 - Restart resource: it is intended to clear up problems for example the memory manage

ment resource.

3 - Restart with defaults: it is intended to wipe configuration memory, it works like a factory

initialization.

4 - Restart processor: it provides a way to hit the reset button on the processor associated

with the resource This parameter does not appear in a view because it returns to 1 shortly

after being written.

1.4 Non-volatile parameters

All non-volatile parameters are saved in EEPROM and therefore used if the device is restart

ed.

1.5 Timeout for remote cascade modes

SHED_RCAS and SHED_ROUT set the time limit for loss of communication from a remote

device. These constants are used by all function blocks that support a remote cascade

mode. The effect of a timeout is described in Mode Calculation. Shedding from RCAS/ROUT

shall not happen when SHED_RCAS or SHED_ROUT is set to zero.

1.6 Alert Notification

The MAX_NOTIFY parameter value is the maximum number of alert reports that this resource

can have sent without getting a confirmation, corresponding to the amount of buffer space

available for alert messages. A user can set the number lower than that, to control alert

flooding, by adjusting the LIM_NOTIFY parameter value. If LIM_NOTIFY is set to zero, then

no alerts are reported. The CONFIRM_TIME parameter is the time for the resource to wait for

confirmation of receipt of a report before trying again. If the CONFIRM_TIME = 0 the device

shall not retry.

-

-

5

Page 6

6

1.7 FEATURES / FEATURE_SEL parameters

The bit strings FEATURES and FEATURE_SEL determine optional behaviour of the resource.

The first defines the available features, and is read only. The second is used to turn on an

available feature by configuration. If a bit is set in FEATURE_SEL that is not set in FEA

TURES, the result will be a block alarm for a configuration error. The device supports the

following features: Reports supported, Fault State supported, Soft Write lock supported.

1.8 Fault state for the whole resource

If the user sets the SET_FSTATE parameter, the FAULT_STATE parameter will indicate active

and it will cause all output function blocks in the resource to go immediately to the condition

chosen by the fault state Type I/O option. It may be cleared by setting the CLR_FSTATE pa

rameter. The set and clear parameters do not appear in a view because they are momentary.

1.9 Write lock by software

The WRITE_LOCK parameter, if set, will prevent any external change to the static or non

volatile data base in the Function Block Application of the resource. Block connections and

calculation results will proceed normally, but the configuration will be locked. It is set and

cleared by writing to the WRITE_LOCK parameter. Clearing WRITE_LOCK will generate the

discrete alert WRITE_ALM, at the WRITE_PRI priority. Setting WRITE_LOCK will clear the

alert, if it exists. Before setting WRITE_LOCK parameter to Locked, it is necessary to select

the “Soft Write lock supported” option in FEATURE_SEL.

1.10 Features being implemented

The parameter CYCLE_TYPE is a bit string that defines the types of cycles that this resource

can do. CYCLE_SEL allows the configurator to choose one of them. If CYCLE_SEL contains

more than one bit, or the bit set is not set in CYCLE_TYPE, the result will be a block alarm

for a configuration error. MIN_CYCLE_T is the manufacturer specified minimum time to ex

ecute a cycle. It puts a lower limit on the scheduling of the resource.

-

-

-

MEMORY_SIZE declares the size of the resource for configuration of function blocks, in kilo

bytes. The parameter FREE_SPACE shows the percentage of configuration memory that is

still available. FREE_TIME shows the approximate percentage of time that the resource has

left for processing new function blocks, should they be configured.

1.11 BLOCK_ERR

The BLOCK_ERR of the resource block will reflect the following causes:

Device Fault State Set – When FAULT_STATE is active.

Simulate Active – When the Simulate jumper is ON.

Out of Service – When the block is in O/S mode.

1.12 Supported Modes

O/S, IMAN and AUTO

-

Page 7

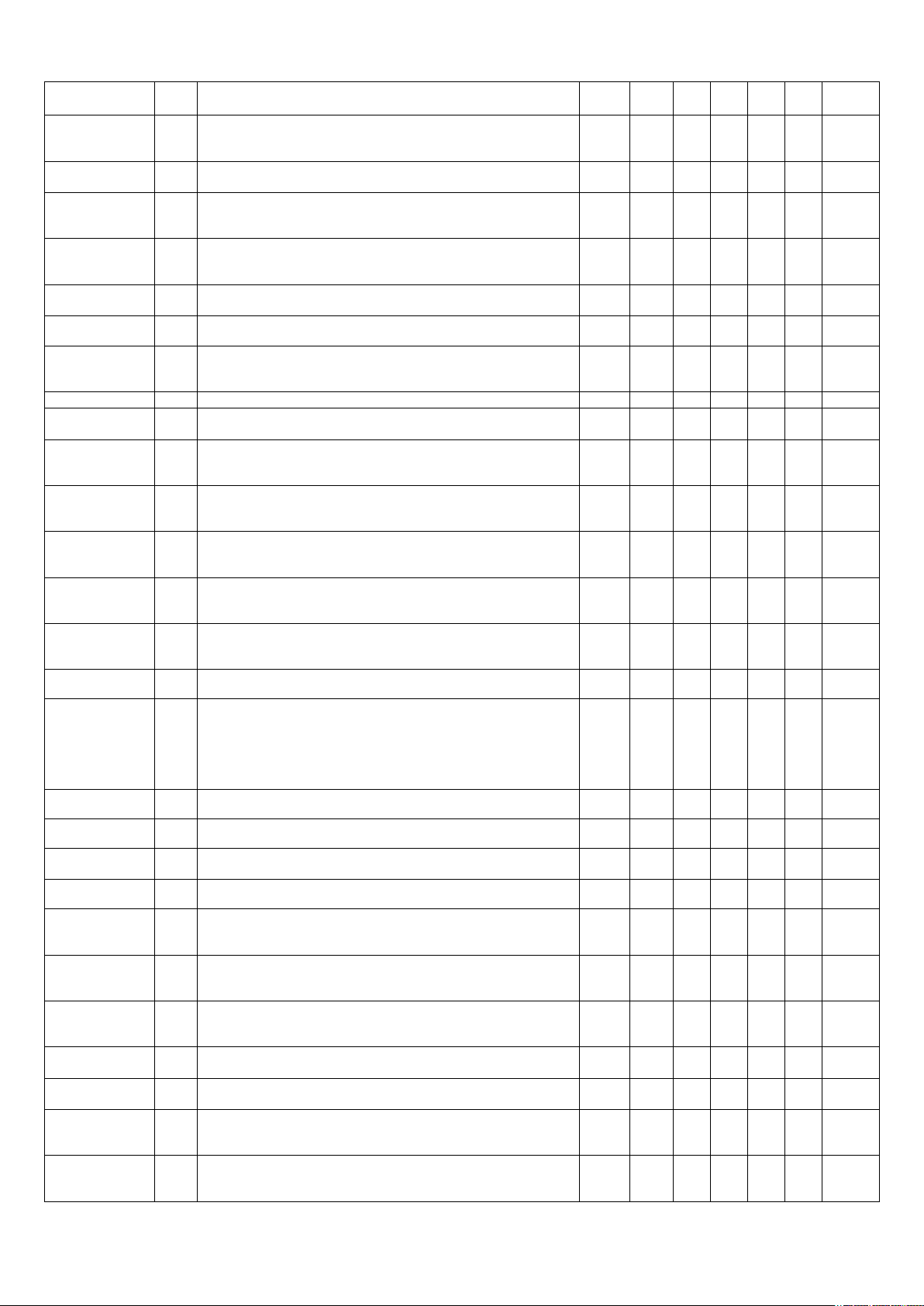

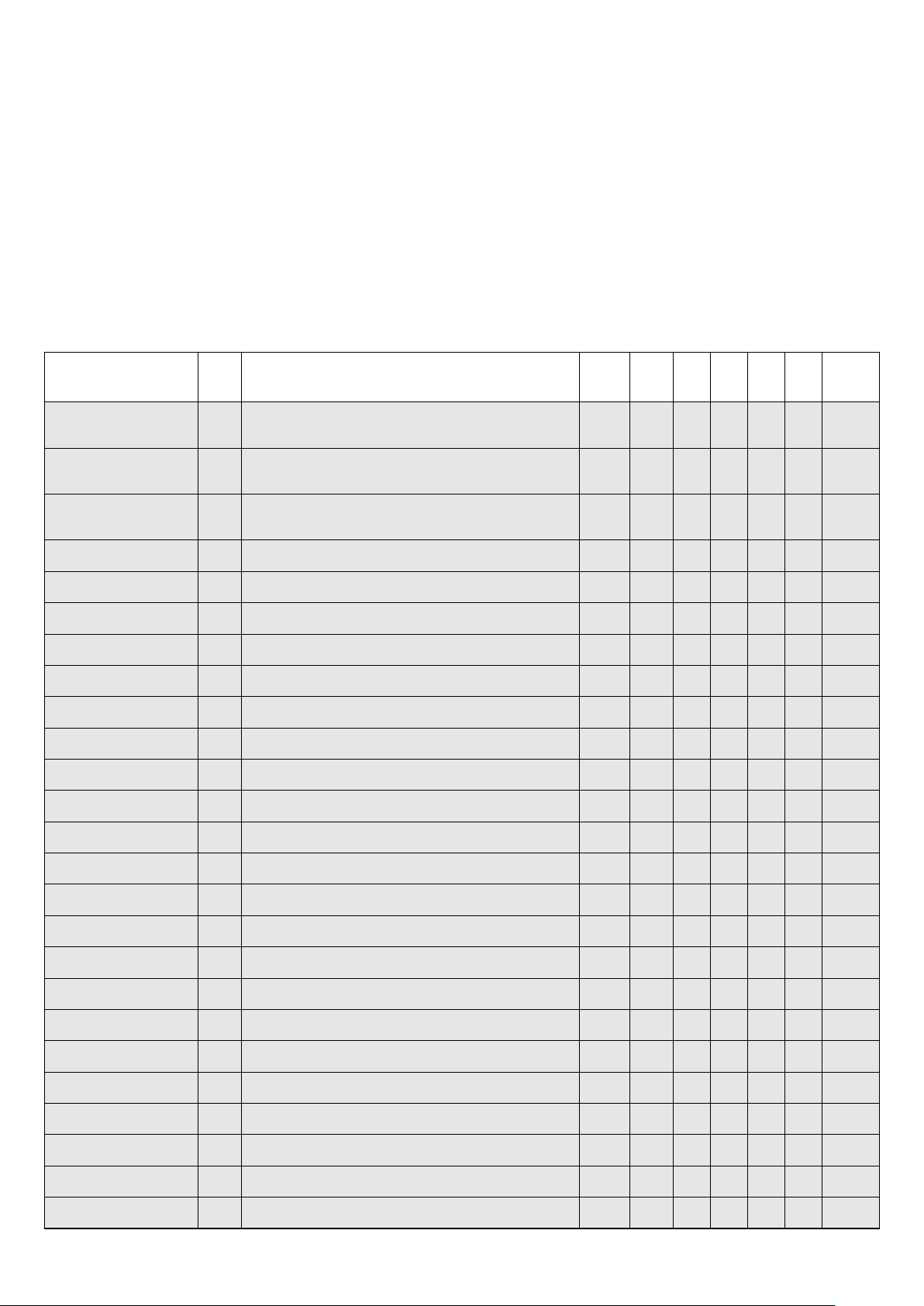

Parameter

ST_REV

TAG_DESC

STRATEGY

ALERT_KEY

1.13 Resource Block Parameter List, Fieldbus Foundation

Rel.

Description Type Store

Index

Is incremented each time that there is a change in a static

1

parameter in the physical block.

Tag name of the block. This parameter must be unique in the

2

configuration.

This can be used to group a Function Block. It is a user sup

3

plied parameter for identification purpose.

4 Alert keys

Un-

signed

SRC 2 RO 0

16

-

OCTET_

STRING

signed

SRC 32 R/W »«

Un-

SRC 2 R/W 0

16

Un-

signed 8SRC 1 R/W 0

Size

byte

RO /

Min. Max. Default

R/W

MODE_BLK

BLOCK_ERR

RS_STATE

TEST_RW

DD_RESOURCE

MANUFAC_ID

DEV_TYPE

DEV_REV

DD_REV

GRANT_DENY

HARD_TYPES

RESTART

FEATURES

FEATURE_SEL

CYCLE_TYPE

CYCLE_SEL

MIN_CYLCE_T

MEMORY_SIZE

NV_CYCLE_T

FREE_SPACE

FREE_TIME

SHED_RCAS

SHED_ROUT

5 Block running mode DS-69 Mix 4 *

6 Block errors

BIT_

STRING

D 2 RO 0

1,1,

17,16

Un-

7 State of the function block application state machine

signed 8D 1 RO 0

8 Read/write test parameter used only for conformance testing DS-85 D 112 R/W 0..0

String identifying the tag of the resource which contains the

9

Device Description for this resource.

Enumeration; controlled by FF

10

Manufacturer identification number - used by an interface

device to locate the DD file for the resource.

Manufacturer’s model number associated with the resource -

11

used by interface devices to locate the DD file for the resource.

Manufacturer revision number associated with the resource

12

- used by an interface device to locate the DD file for the

resource.

Revision of the DD associated with the resource - used by an

13

interface device to locate the DD file for the resource.

VISIBLE_

STRING

Un-

signed

32

Un-

signed

16

Un-

signed

8

Un-

signed

8

SRC 32 RO » »

SRC 4 RO

SRC 2 RO

SRC 1 RO

SRC 1 RO

WIKA

0x00ec

0x03

0x01

Access Permissions. Options for controlling access of host

14

computer and local control panels to operating, tuning and

DS-70 SRC 2 R/W 0

alarm parameters of the block.

15 The types of hardware available as channel numbers.

BIT_

STRING

SRC 2 RO 0

1: Run,

2: Restart resource,

3: Restart with defaults,

16

4: Restart processor

Allows a manual restart to be initiated. Several degrees of

Un-

signed

8

D 1 R/W 1

restart are possible.

-

-

BIT_

STRING

BIT_

STRING

BIT_

STRING

BIT_

STRING

Un-

signed

32

Un-

signed

16

Un-

signed

32

Floating

Point

Floating

Point

Un-

signed

32

Un-

signed

32

SRC 2 RO 0

SRC 2 RW 0

SRC 2 RO 0xC000

SRC 2 ** 0xC000

SRC 4 RO 0

SRC 2 RO 0

SRC 4 RO 0

D 4 RO 0.0

D 4 RO 0.0

SRC 4 R/W 640000

SRC 4 R/W 640000

17 Used to show supported resource block options.

18 Used to select resource block options.

Identifies the block execution methods available for this

19

resource

20 Used to select the block execution method for this resource.

Time duration of the shortest cycle interval of which the

21

resource is capable.

Available configuration memory in the empty resource. To be

22

checked before attempting a download.

Interval between writing copies of NV parameters to non-vola

23

tile memory. Zero means never.

Percent of memory available for further configuration. Zero in a

24

preconfigured resource.

Percent of the block processing time that is free to process

25

additional blocks.

Time duration at which to give up on computer writes to func

26

tion block RCas locations.

ms time duration at which to give up on computer writes to

27

function block ROut locations.

7

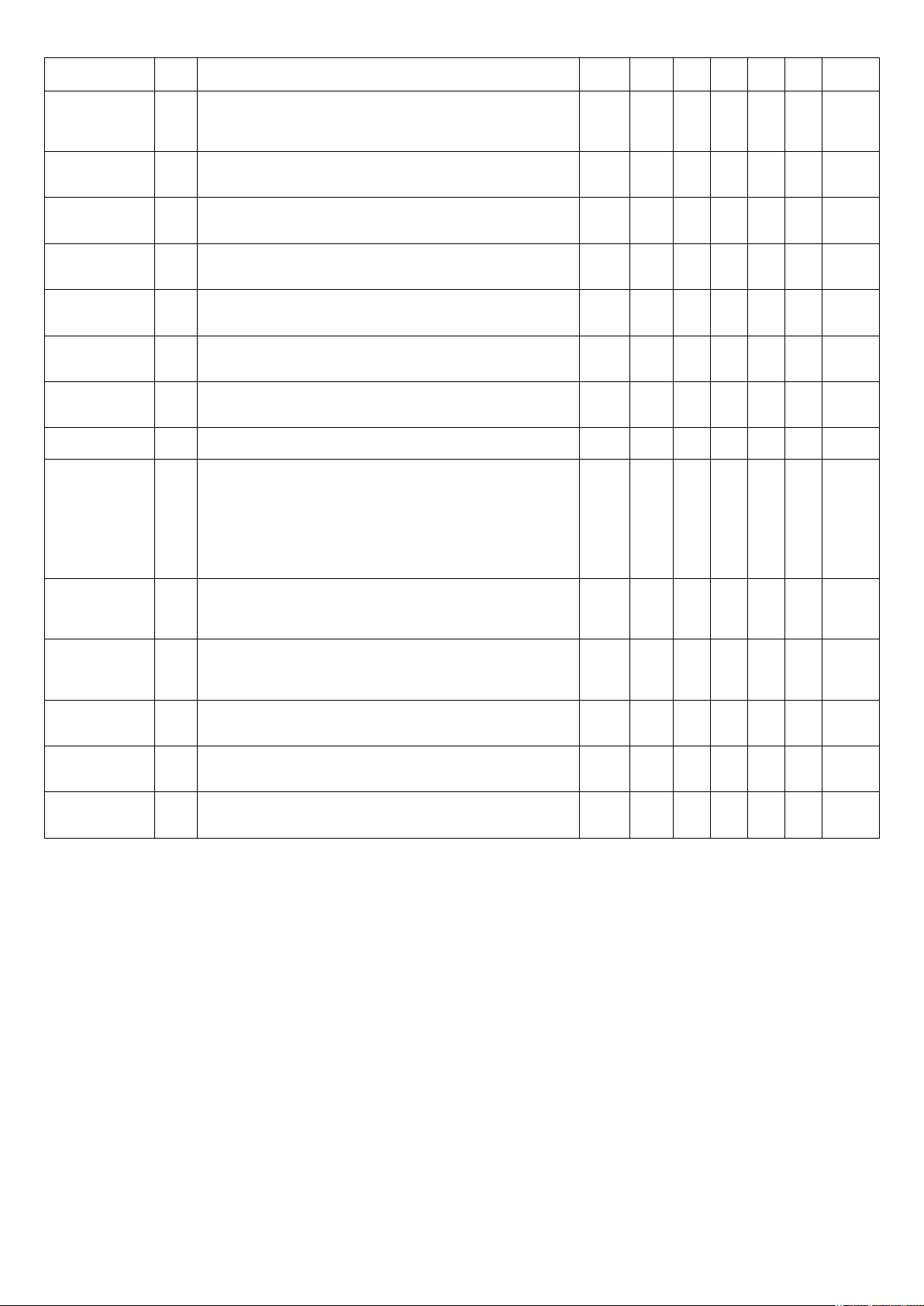

Page 8

8

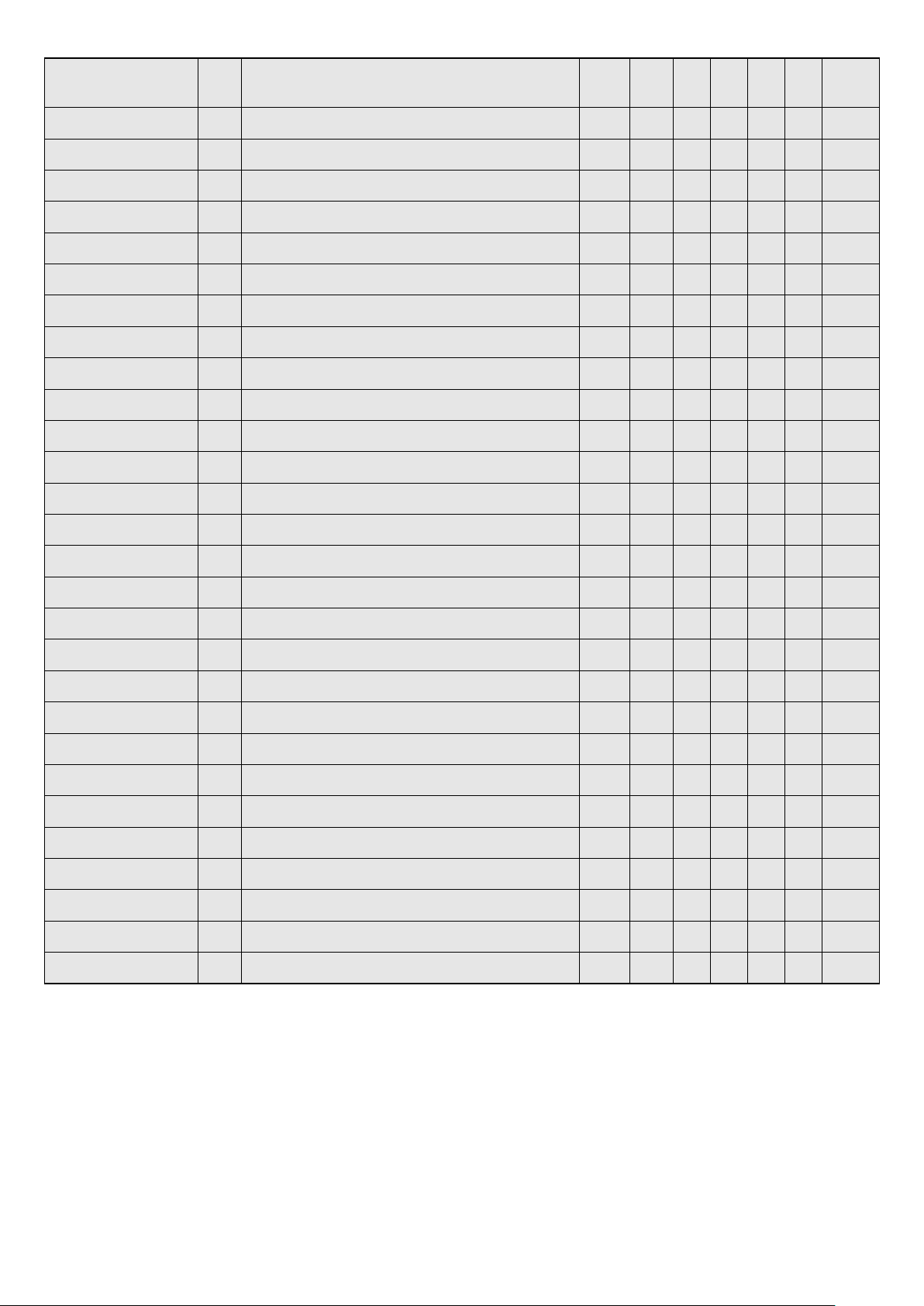

Parameter

FAULT_STATE

SET_FSTATE

CLR_FSTATE

MAX_NOTIFY

Rel.

Description Type Store

Index

Active E D Condition set by loss of communication to an out

put block, failure promoted to an output block or a physical

28

contact. When Fault State condition is set, Then output func

-

-

tion blocks will perform their FSAFE actions.

Allows the fault state condition to be manually initiated by

29

selecting Set.

Writing a Clear to this parameter will clear the device fault state

30

if the field condition, if any, has cleared.

31 Maximum number of unconfirmed notify messages possible.

Size

RO /

byte

Min. Max. Default

R/W

Un-

signed

N 1 RO 1

8

Un-

signed

D 1 R/W 1

8

Un-

signed

D 1 R/W 1

8

Un-

signed 8SRC 1 RO 8

LIM_NOTIFY

CONFIRM_TIME

WRITE_LOCK

UPDATE_EVT

BLOCK_ALM

ALARM_SUM

ACK_OPTION

WRITE_PRI

Maximum number of unconfirmed alert notify messages

32

allowed.

Un-

signed

8

SRC 1 R/W 8

Un-

33 Ms The minimum time between retries of alert reports.

If set, no writes from anywhere are allowed, except to clear

34

WRITE_LOCK. Block inputs will continue to be updated.

signed 32SRC 4 R/W 640000

Un-

signed

SRC 1 R/W 1

8

35 This alert is generated by any change to the static data DS-73 D 14 RO

The block alarm is used for all configuration, hardware, con

nection failure or system problems in the block. The cause

of the alert is entered in the sub code field. The first alert to

become active will set the Active status in the Status attribute.

36

As soon as the Unreported status is cleared by the alert report

-

DS-72

D 13 R/W

ing task, another block alert may be reported without clearing

the Active status, if the sub code

has changed.

The current alert status, unacknowledged states, unreported

states, and disabled states of the alarms associated with the

37

function

DS-74 Mix 8 R/W 0,0,0,0

block.

0: Auto ACK Disable

1: Auto ACK Enable

38

Selection of whether alarms associated with the block will be

BIT_

STRING

SRC 2 R/W 0

automatically acknowledged.

Un-

39 Priority of the alarm generated by clearing the write lock.

signed 8SRC 1 R/W 0

0,0,0,

0,0,9,0

0,0,0,

0,0,0,

8,0,0

WRITE_ALM

ITK_VER_NR

40 This alert is generated if the write lock parameter is cleared. DS-72 D 13 R/W

ITK Version Number

41

This parameter informs which ITK version is the device (for certified devices only).

Un-

signed

16

SRC 2 RO 4

0,0,0,

0,0,0,

10,0,0

Page 9

2.0 The Transducer Block

2.1 The Transducer Block

contains all of the manufacturer-specific parameters that define how the T53 Transmitter

functions. Selections such as setting of input type, engineering units, defining the dual func

tionality when using the dual input, and so forth, are performed in the Transducer Block.

The transducer block in T53 allows the user to select a large number of sophisticated func

tions. Therefore, the configuration of the transmitter must be carried out with the greatest

possible care.

2.2 The data of the Transducer Block Parameter List are grouped as follows:

2.8 AI_TRANSDUCER Block

2.8.1 Sensor characterising parameters

2.8.2 RTD / resistor specific parameters

2.8.3 Thermocouple specific parameters

2.8.4 Output conditioning parameters

2.8.5 Output parameters

2.8.6 Diagnostic parameters

2.8.7 Sensor error detection parameters

2.8.9 Sensor calibration parameters

2.9 PR_CUST_LIN Block

2.9.2 Linear Interpolation Linearisation

2.9.4 Custom Polynomial linearisation

2.10 PR_CUST_PRIV Block

2.10.1 PR_CUST_PRIV Block

All product-specific parameters are set off in grey background in the TB Parameter List. In

order to configure these parameters, the files mentioned in the introduction must be avail

able to the application software.

-

-

-

2.3 Default configuration

WIKA delivers the transmitters with at default configuration which will suit the customer’s

demand in many cases. The configuration task has thus been reduced considerably.

The individual default configurations are shown in the TB Parameter List, but in short the

default configuration is as follows:

Pt100 acc. to the standard EN 60 751 (2.8.1 LIN_TYPE, value 102)

°C (2.8.1 PRIMARY_VALUE_UNIT, value 1001)

3-wire connection (2.8.2 SENSOR_CONNECTION, value 1)

Only sensor 1 (2.8.4 SENSOR_MEAS_TYPE, value 220)

No sensor error detection (2.8.7 SENSOR_WIRE_CHECK_1, value 3)

2.4 Your application set up.

In the Transducer block all parameters marked R / W can be adapted to suit any measurement in temperature, ohm or mV. The way of presenting the file data mentioned in the

introduction varies greatly from one piece of application software to the other. Some pro

grams show drop down menus in which the parameters must be selected via text lines, while

other programs require the user to type in the numerical value of the parameter selection.

-

9

Page 10

10

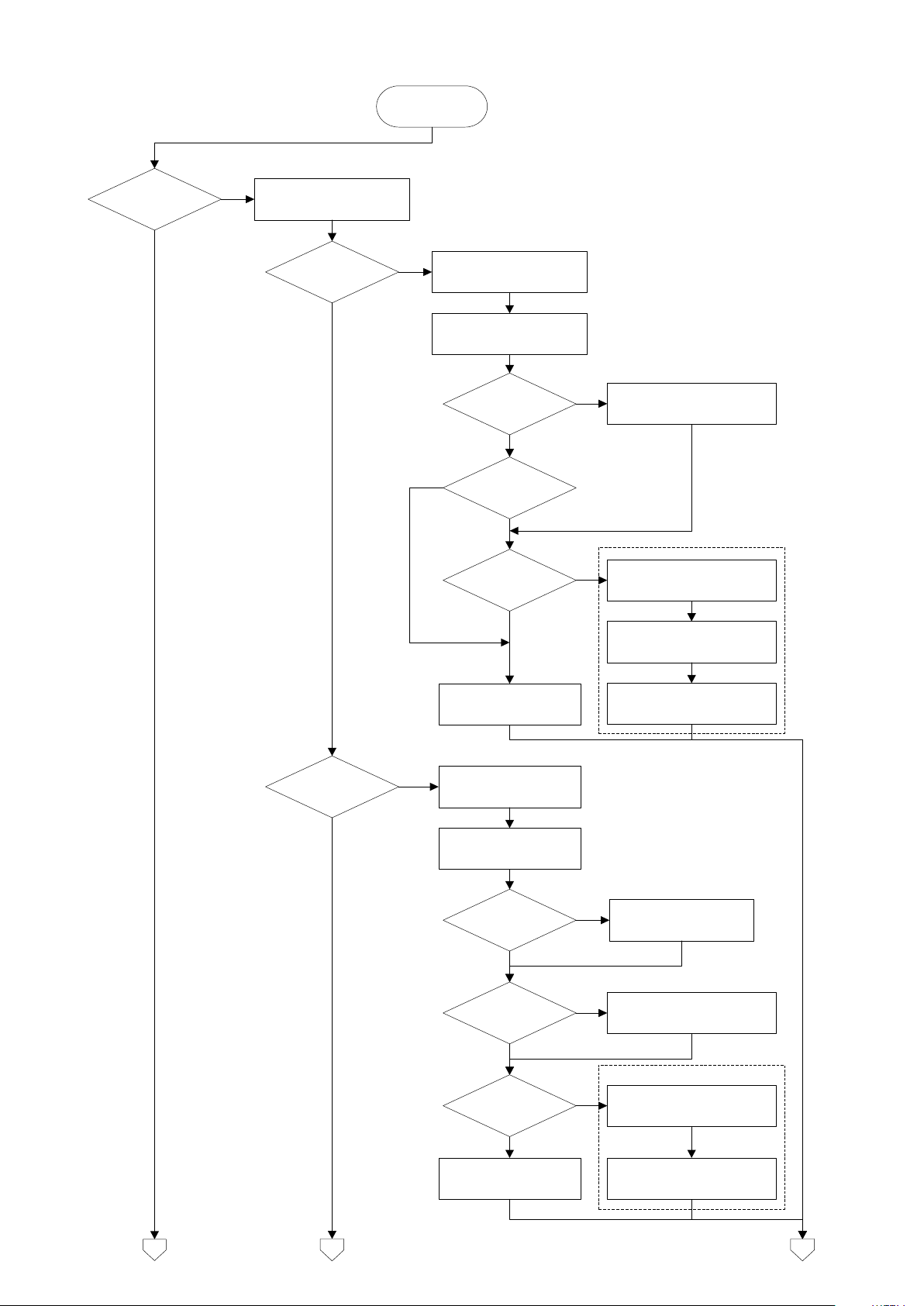

2.5 AI_Transducer Block Configuration Flowchart

Configure T53

Transducer block

Temperature

measurement?

Set

PRIMARY_VALUE_UNIT

to F,R,C or K

RTD?

Thermo-couple?

Set LIN_TYPE to RTD

type (Pt100 etc.)

4-wire?

Set

SENSOR_CONNECTION

to 2-,3- or 4-wire.

Enter wire resistance in

Ohms for both wires to

COMP_WIRE1

2-wire?

Enter wire resistance in

Ohms for both wires to

COMP_WIRE2

YES

Enter setup for sensor 2:

YES

Set LIN_TYPE to TC

type (TC K etc.)

Set RJ_TYPE (internal,

external etc.)

Set LIN_TYPE_2 to RTD

type (Pt100 etc.)

Set

SENSOR_MEAS_TYPE

to single sensor type

Dual sensor?

Enter setup for sensor 2:

Set LIN_TYPE_2 to TC type

(TC K etc.)

Enter RJ temperature to

EXTERNAL_RJ_VALUE

RJ_TYPE

external?

YES

YES

RJ_TYPE

ext. 2.wire?

Enter wire resistance in

Ohms for both wires to

COMP_WIRE_RJ

YES

YES

YES

2c

Set

SENSOR_MEAS_TYPE

to single sensor type

2b

2a

Set SENSOR_MEAS_TYPE

to dual sensor type

Set SENSOR_MEAS_TYPE

to dual sensor type

YES

Dual sensor?

YES

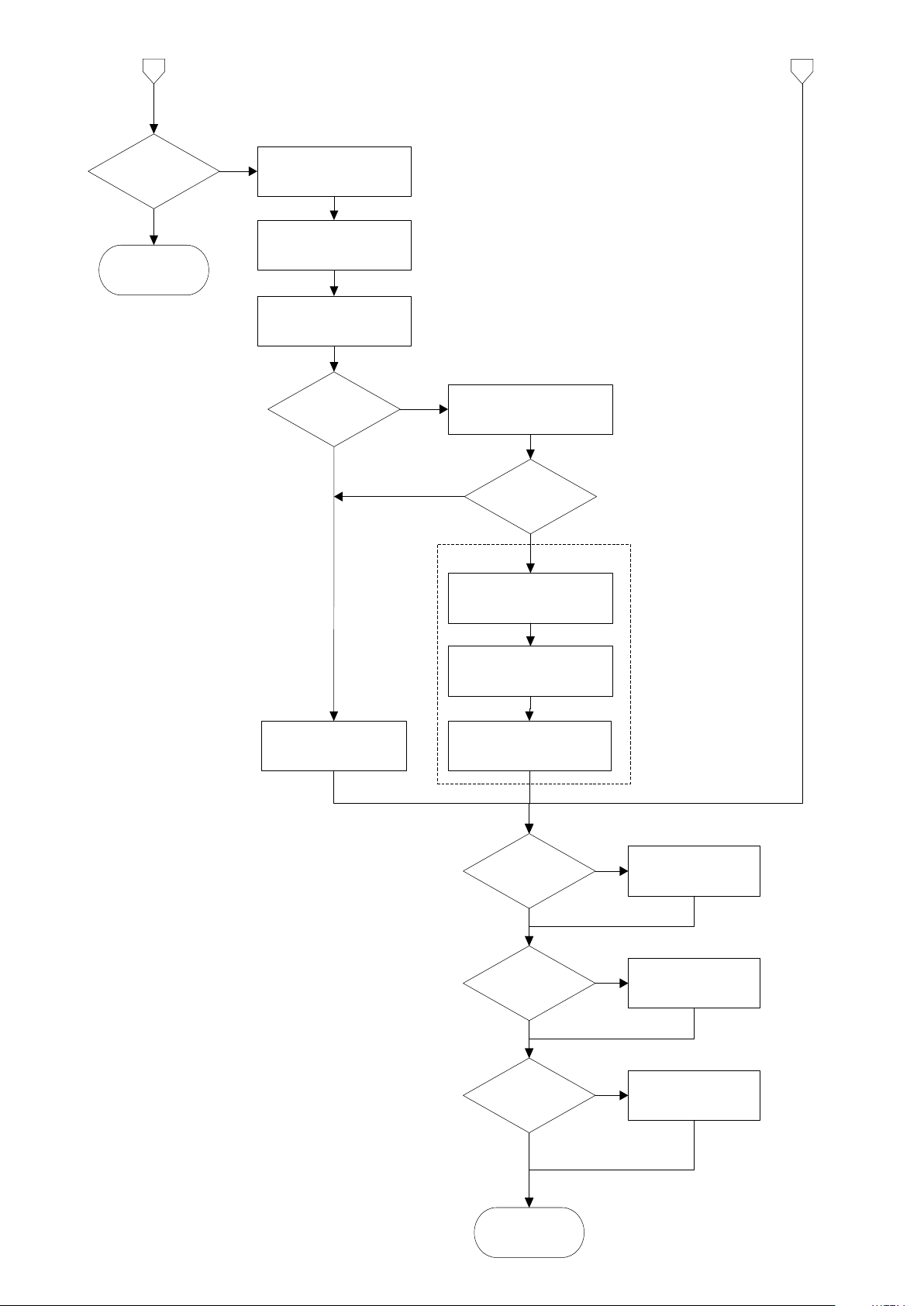

Page 11

2c

RTD+Thermo-

couple?

2b

Set LIN_TYPE to TC

type (TC K etc.)

Set RJ_TYPE

(internal, external etc.)

Set

SENSOR_MEAS_TYPE

to dual sensor type

Set LIN_TYPE_2 to

RTD type (Pt100 etc.)

Enter RJ temperature to

EXTERNAL_RJ_VALUE

RJ_TYPE

external?

YES

YES

2a

Error! (try again)

Resistance?

Set

PRIMARY_VALUE_UNIT

to Ohm or kOhm

Set

SENSOR_CONNECTION

to 2-,3- or 4-wire.

Dual sensor?

Enter wire resistance in

Ohms for both wires to

COMP_WIRE1

2-wire?

YES

Enter setup for sensor 2:

YES

Set LIN_TYPE_2 to

”no linearisation” or

”linearisation table”

Set

SENSOR_MEAS_TYPE

to single sensor type

Set LIN_TYPE to

”no linearisation” or

”linearisation table”

Set SENSOR_MEAS_TYPE

to dual sensor type

Enter wire resistance in

Ohms for both wires to

COMP_WIRE2

Millivolts?

Set

PRIMARY_VALUE_UNIT

to V,mV or µV

Set LIN_TYPE to

”no linearisation” or

”linearisation table”

Dual sensor?

Set LIN_TYPE_2 to

”no linearisation” or

”linearisation table”

Set

SENSOR_MEAS_TYPE

to single sensor type

Set SENSOR_MEAS_TYPE

to dual sensor type

3b

3a

Enter setup for sensor 2:

YES

YES

YES

4-wire?

YES

11

Page 12

12

3b3a

Potentiometer?

Set

PRIMARY_VALUE_UNIT

to ”%”

Set

SENSOR_CONNECTION

to 3- or 4-wire.

Enter wire resistance in

Ohms for 2 wires to

COMP_WIRE1

3-wire?

YES

Enter setup

for sensor 2:

YES

Set LIN_TYPE_2 to

”no linearisation” or

”linearisation table”

Set

SENSOR_MEAS_TYPE

to single sensor type

Set LIN_TYPE to

”no linearisation” or

”linearisation table”

Set SENSOR_MEAS_TYPE

to dual sensor type

Enter wire resistance in

Ohms for 2 wires to

COMP_WIRE2

Error! (try again)

Finished.

Transducer block

is configured!

Enter Custom RTD

polynomial values

Linearisation

table?

Custom RTD?

Enter linearisation

table values

YES

YES

Enter Custom TC

polynomial values

Custom TC?

YES

Dual sensor?

YES

Page 13

2.6 - Transducer Block Examples Setup

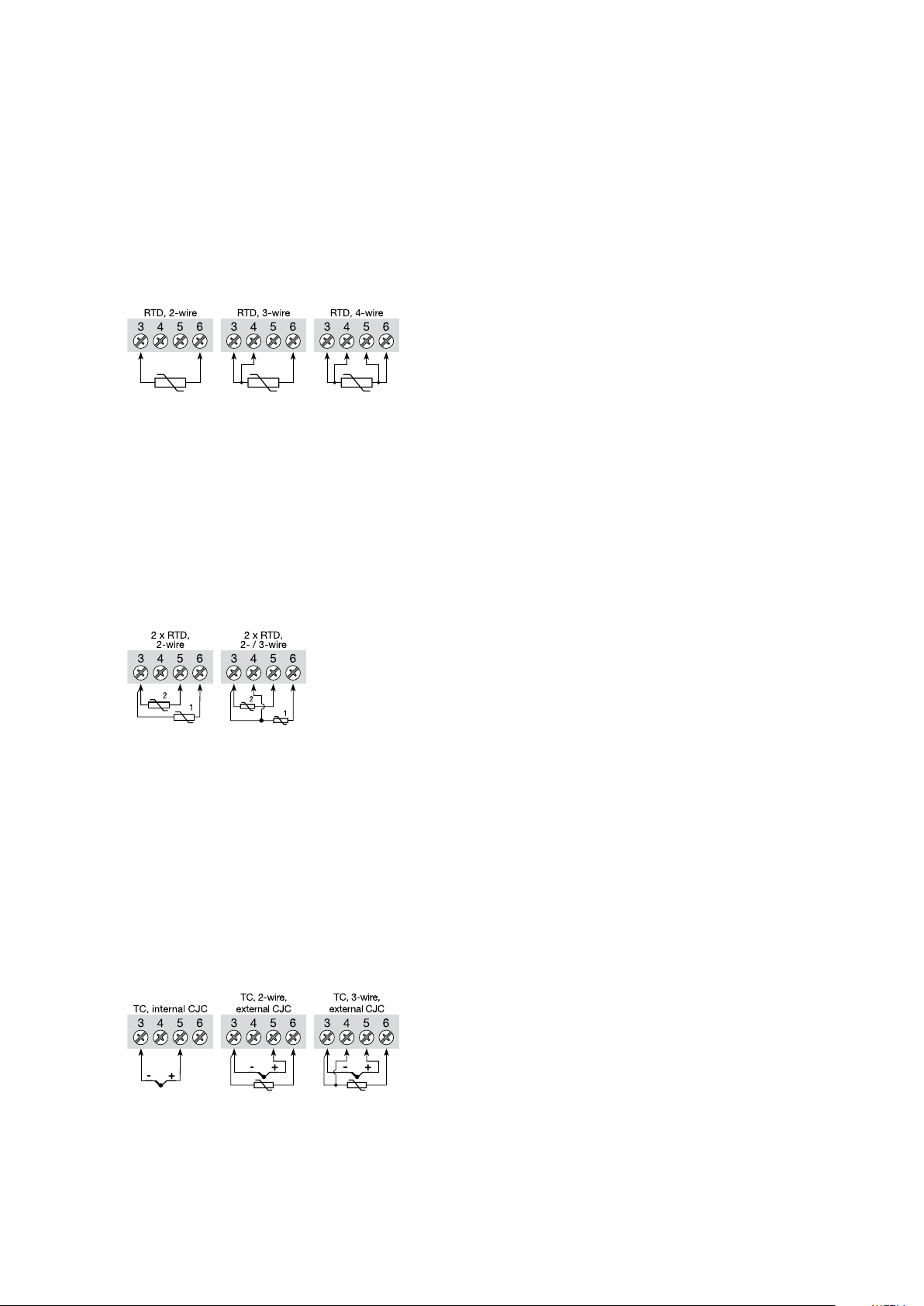

2.6.1 Measurement of RTD with one sensor:

PRIMARY_VALUE_UNIT . . . . = K, °C, °F or °R

LIN_TYPE. . . . . . . . . . . . . . . . = Any RTD

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = PV = SV_1, SV_2 not available

SENSOR_CONNECTION . . . . = 2-, 3- or 4-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

2.6.2 Measurement of RTD with two sensors:

PRIMARY_VALUE_UNIT . . . . = K, °C, °F or °R

LIN_TYPE. . . . . . . . . . . . . . . . = Any RTD

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = 2- or 3-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

. . . . . . . . . . . . . . = N/A (ignored in setup check)

. . = N/A (ignored in setup check)

. . . . . . . . . . . . . . = Any RTD

. . = Default set to 2-wire

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

2.6.3 Measurement of thermocouple with one sensor:

PRIMARY_VALUE_UNIT . . . . = K, °C, °F or °R

LIN_TYPE. . . . . . . . . . . . . . . . = Any TC

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = PV = SV_1, SV_2 not available

SENSOR_CONNECTION . . . . = N/A (ignored in setup check)

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = No Reference Junction, Internal, External (constant value),

Sensor 2-wire or Sensor 3-wire

Connections:

. . . . . . . . . . . . . . = N/A (ignored in setup check)

. . = N/A (ignored in setup check)

13

Page 14

14

2.6.4 Measurement of thermocouple with two sensors:

PRIMARY_VALUE_UNIT . . . . = K, °C, °F or °R

LIN_TYPE. . . . . . . . . . . . . . . . = Any TC

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = N/A (ignored in setup check)

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = No RJ, Internal, External (constant value) or Sensor 2-wire

Connections:

2.6.5 Measurement of combined sensors (Sensor 1 = TC and Sensor 2 = RTD):

PRIMARY_VALUE_UNIT . . . . = K, °C, °F or °R

LIN_TYPE. . . . . . . . . . . . . . . . = Any TC

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = N/A (ignored in setup check)

SENSOR_CONNECTION_2

RJ_TYPE

Connections:

. . . . . . . . . . . . . . = Any TC

. . = N/A (ignored in setup check)

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

. . . . . . . . . . . . . . = Any RTD

. . = 2- or 3-wire

. . . . . . . . . . . . . . . . = No Reference Junction, Internal, External (constant value)

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

2.6.6 Measurement of resistance (linear) with one sensor:

PRIMARY_VALUE_UNIT . . . . = Ohm or kOhm

LIN_TYPE. . . . . . . . . . . . . . . . = No linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = PV = SV_1, SV_2 not available

SENSOR_CONNECTION . . . . = 2-, 3- or 4-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

. . . . . . . . . . . . . . = N/A (ignored in setup check)

. . = N/A (ignored in setup check)

Page 15

2.6.7 Measurement of resistance (linear) with two sensors:

PRIMARY_VALUE_UNIT . . . . = Ohm or kOhm

LIN_TYPE. . . . . . . . . . . . . . . . = No linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = 2- or 3-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

2.6.8 Measurement of potentiometer (linear) with one sensor:

PRIMARY_VALUE_UNIT . . . . = %

LIN_TYPE. . . . . . . . . . . . . . . . = No linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = PV = SV_1, SV_2 not available

SENSOR_CONNECTION . . . . = 3- or 4-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

. . . . . . . . . . . . . . = No linearisation

. . = Default set to 2-wire

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

. . . . . . . . . . . . . . = N/A (ignored in setup check)

. . = N/A (ignored in setup check)

2.6.9 Measurement of potentiometer (linear) with two sensors:

PRIMARY_VALUE_UNIT . . . . = %

LIN_TYPE. . . . . . . . . . . . . . . . = No linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = Default set to 3-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

. . . . . . . . . . . . . . = No linearisation

. . = Default set to 3-wire

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

15

Page 16

16

2.6.10 Measurement of voltage (linear) with one sensor:

PRIMARY_VALUE_UNIT . . . . = µV, mV or V

LIN_TYPE. . . . . . . . . . . . . . . . = No linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = PV = SV_1, SV_2 not available

SENSOR_CONNECTION . . . . = N/A (ignored in setup check)

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

2.6.11 Measurement of voltage (linear) with two sensors:

PRIMARY_VALUE_UNIT . . . . = µV, mV or V

LIN_TYPE. . . . . . . . . . . . . . . . = No linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = N/A (ignored in setup check)

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

. . . . . . . . . . . . . . = N/A (ignored in setup check)

. . = N/A (ignored in setup check)

. . . . . . . . . . . . . . = No linearisation

. . = N/A (ignored in setup check)

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

2.6.12 Measurement of 2 potentiometers (with Linear interpolation linearisation):

PRIMARY_VALUE_UNIT . . . . = %

LIN_TYPE. . . . . . . . . . . . . . . . = Table Linearisation

LIN_TYPE_2

SENSOR_MEAS_TYPE . . . . . = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION . . . . = Default set to 3-wire

SENSOR_CONNECTION_2

RJ_TYPE . . . . . . . . . . . . . . . . = N/A (ignored in setup check)

Connections:

The coordinates (x,y) describing the linear interpolation linearisation must be entered in PR_

CUST_LIN Block (PA Slot 4). See 2.9.2 Linear Interpolation Linearisation, Paramter List for

further details.

Example:

The coordinates for converting the signal from a logarithmic potentiometer to a linear signal.

TAB_ACTUAL_NUMBER = 10 (number of linearisation points to follow up to max 50)

TAB_XY_VALUE1 = 0,0; -100

TAB_XY_VALUE2 = 0,1; 0

TAB_XY_VALUE3 = 0,2; 100

TAB_XY_VALUE4 = 0,4; 200

. . . . . . . . . . . . . . = Table Linearisation (same table as sensor 1)

. . = Default set to 3-wire

Connections with two sensors

can be configured for

2 measurements, difference,

average or redundancy

Page 17

TAB_XY_VALUE5 = 0,8; 300

TAB_XY_VALUE6 = 1,6; 400

TAB_XY_VALUE7 = 3,2; 500

TAB_XY_VALUE8 = 6,4; 600

TAB_XY_VALUE9 = 12,8; 700

TAB_XY_VALUE10 = 25,6; 800

(Output will readout 325% with 1,0% potentiometer value)

2.6.13 Measurement of TC (with Custom Polynomial Linearisation) on sensor 1

PRIMARY_VALUE_UNIT = K, °C, °F or °R

LIN_TYPE = Custom defined TC

LIN_TYPE_2 = N/A (ignored in setup check)

SENSOR_MEAS_TYPE = PV = SV_1, SV_2 not available

SENSOR_CONNECTION = N/A (ignored in setup check)

SENSOR_CONNECTION_2 = N/A (ignored in setup check)

RJ_TYPE = No Reference Junction, Internal, External (constant value) or

Sensor 2-wire or Sensor 3-wire

Connections:

Now enter the Custom TC parameters in PR_CUST_LIN Block (PA Slot 4). See 2.9.4 Custom

Polynomial Linearisation, Parameter List for further details.

Remember to enter values for the RJ polynomial if RJ_TYPE is any value other than “No ref

erence Junction”.

-

Example:

The parameters and coefficients for converting a special TC to a linear temperature signal.

CUSTOM_TC_NAME = Custom TC Example

CUSTOM_TC_POLY_COUNT = 5

CUSTOM_TC_MIN_IN = -6500.0

CUSTOM_TC_MIN_OUT = -100.0

CUSTOM_TC_MAX_OUT = 1200.0

max. input

CUSTOM_TC_POLY_X

CUSTOM_TC_POLY_1 -3200.0 -3.84E-13 -5.65E-9 -3.36E-5 -6.10E-2 -8.44E1

CUSTOM_TC_POLY_2 3500.0 -8.13E-15 7.29E-11 -4.18E-7 2.53E-2 -1.08E-2

CUSTOM_TC_POLY_3 10000.0 -1.35E-15 1.50E-11 1.41E-7 2.26E-2 4.18

CUSTOM_TC_POLY_4 30000.0 3.49E-18 2.19E-12 -1.53E-7 2.68E-2 -9.26

CUSTOM_TC_POLY_5 70000.0 6.27E-17 -8.76E-12 5.34E-7 8.69E-3 1.65E2

limit in µV

for POLY_X

4th degree

coefficient

for POLY_X

3th degree

coefficient

for POLY_X

2th degree

coefficient

for POLY_X

1st degree

coefficient

for POLY_X

0 degree

coefficient

for POLY_X

3th degree

coefficient

CUSTOM_TC_RJ_POLY -1.11E-4 2.65E-2 3.94E1 3.94E-1

2th degree

coefficient

1st degree

coefficient

0 degree

coefficient

A TC input of 5000 µV and an RJ temperature of 25ºC will make POLY_3 the active and the

output will be:

URJ = -3.94

-1

+ 3.94 * 101 * 25 + 2.65 * 10-2 * 252 - 1.11 * 10-4 * 253 = 1000 µV

10

*

This voltage is to be added to the TC voltage (5000 + 1000), and the resulting temperature will be:

4.18 + 2.26 * 10

-2

6000 + 1.41 * 10

*

-7

6000

*

2

+ 1.50

*

10

-11

6000

*

3

- 1.35

*

10

-15

6000

*

4

= 146.3 °C

See 2.9.3 Custom polynomial linearisation, Description for formula and further details.

17

Page 18

18

RJ

temp.

Intern

temp.

INTERN_TEMP

EXTERNAL_RJ_VALUE

LIN

R.J. Comp.

RJ_TYPE

Input

INPUT1

INPUT2

T1

T2

Linearisation

+

+ LIN

LIN

RJ_TEMP

(none)

Arithmetic

+

+

+,-, redund.

SECONDARY_VALUE_1

SECONDARY_VALUE_2

PRIMARY_VALUE

SENSOR_MEAS_TYPE

BIAS_1

BIAS_2

LIN

LIN_TYPE_1/2

SENSOR_CONNECTION_1/2

COMP_WIRE_1/2

Process

calibration

+

+

Min/Max hold

min/

max

min/

max

MIN_SENSOR_VALUE_1/2

MAX_SENSOR_VALUE_1/2

RTDX_FACTOR_1/2

CAL_POINT_HI_1/2

CAL_ACTUAL_HI_1/2

CABLE_RES1/2

RJ

RJ_COMP_WIRE

SENSOR_WIRE_CHECK_1/2

SENSOR_WIRE_CHECK_RJ

CUSTOM_TC_..

TAB_X_Y_VALUE

CUSTOM_RTD_..

(Channel_4)

(Channel_1)

(Channel_2)

(Channel_3)

AI_TRANSDUCER and PR_CUST_LIN

schematic

CAL_POINT_LO_1/2

CAL_ACTUAL_LO_1/2

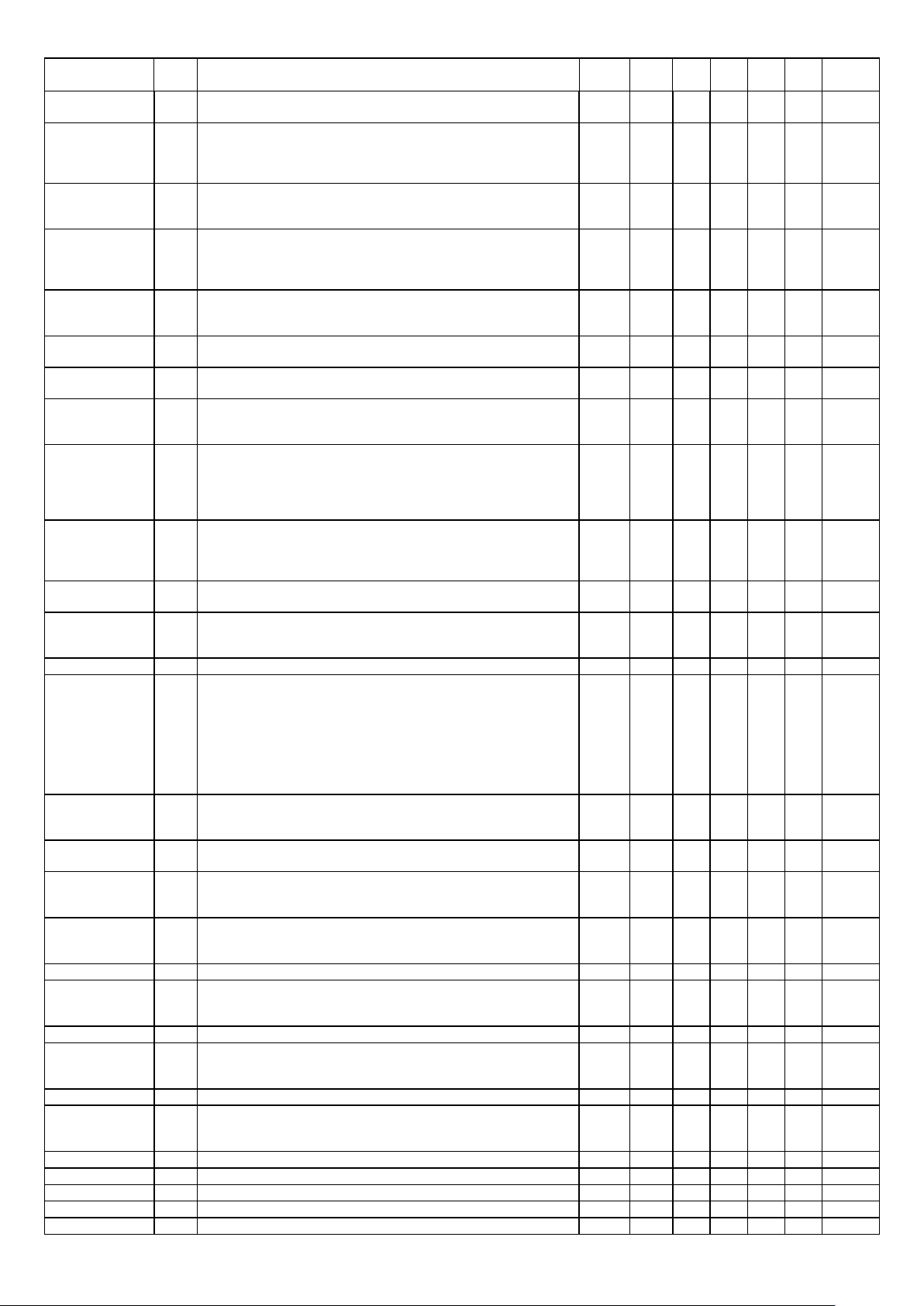

2.7 AI_Transducer and PR_CUST_LIN Block, Schematic

Page 19

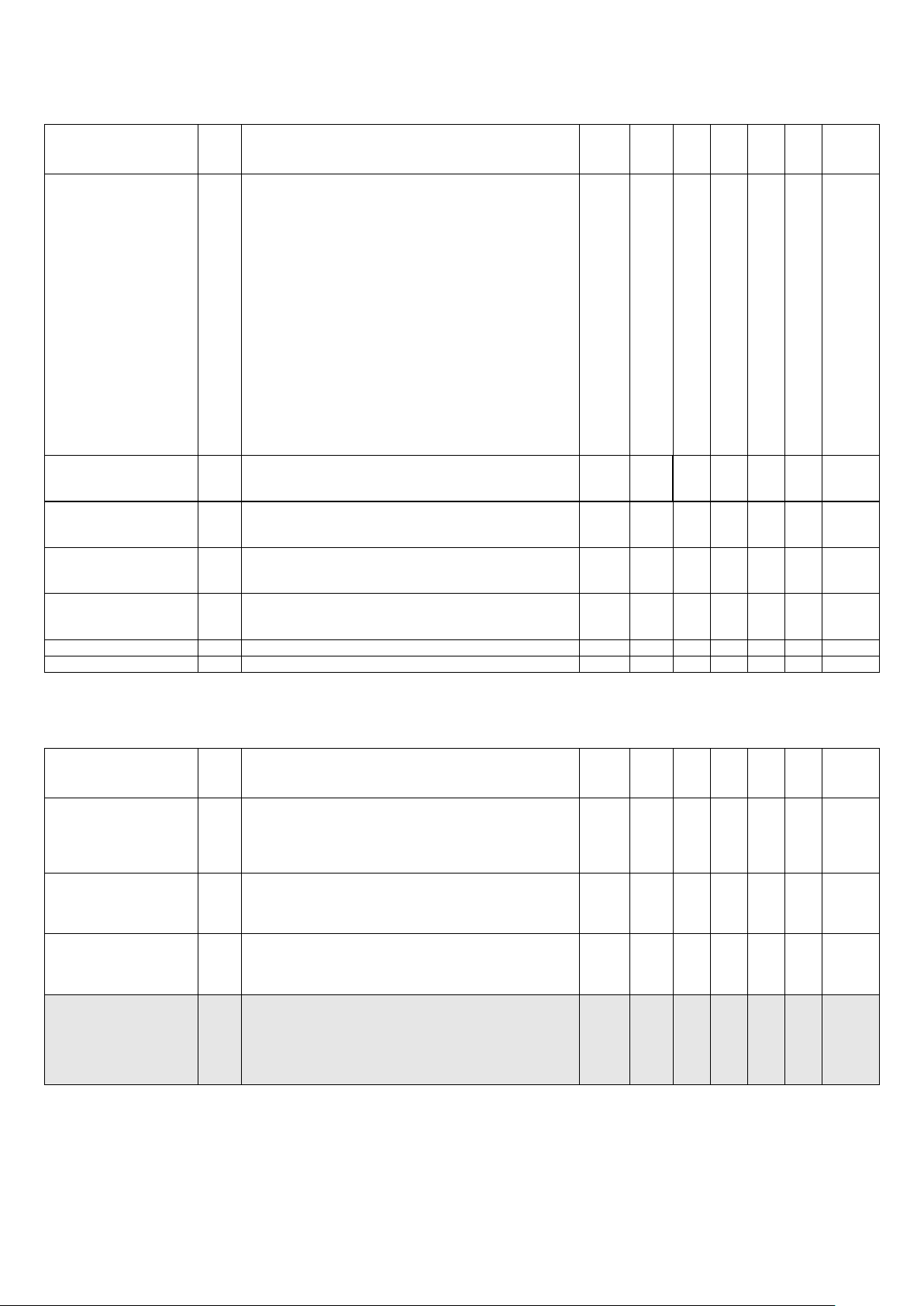

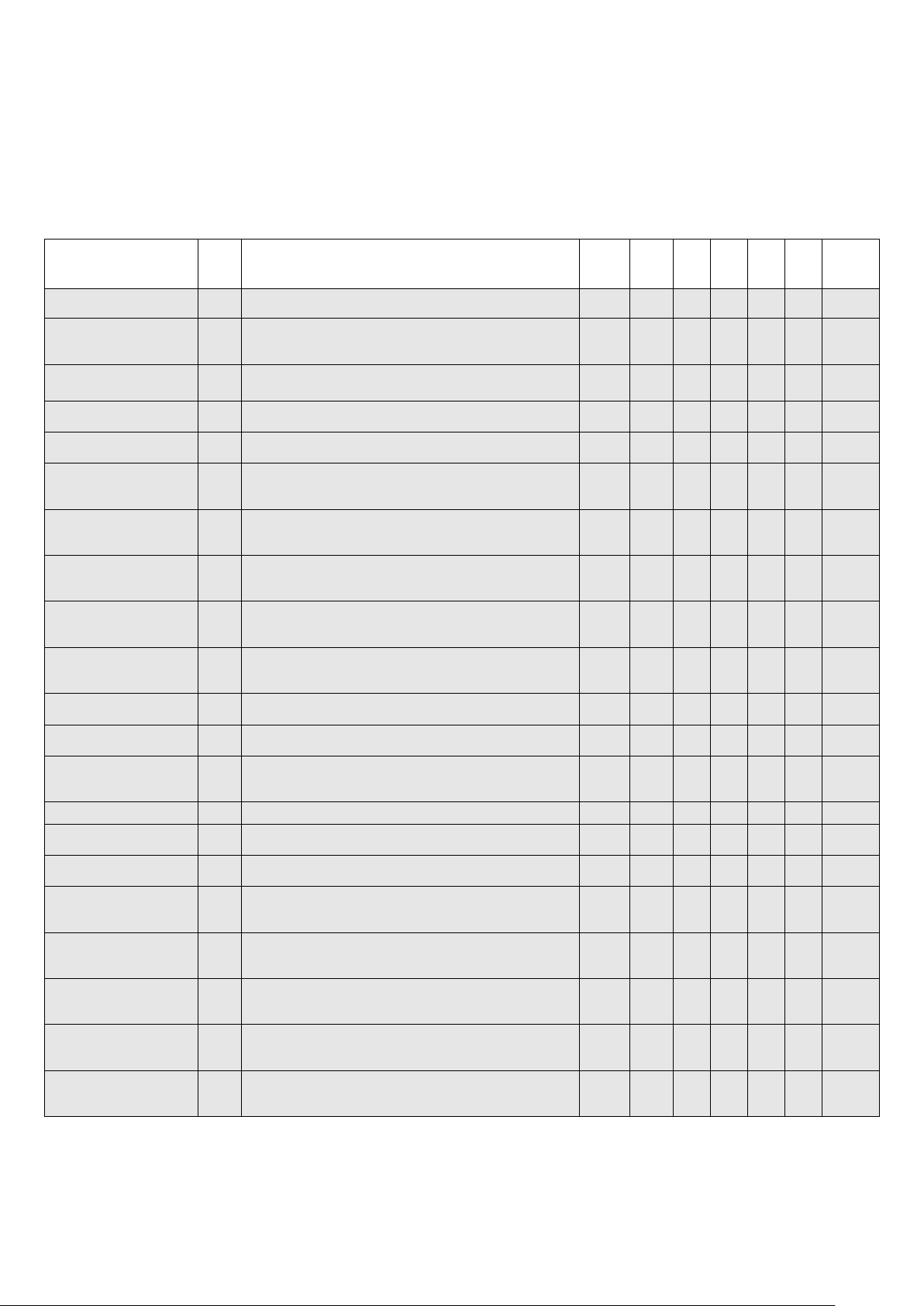

2.8 AI_TRANSDUCER Block Parameter List

2.8.1 Sensor characterising parameters

Rel.

Parameter

PRIMARY_VALUE_UNIT

LIN_TYPE

UPPER_SENSOR_LIMIT

LOWER_SENSOR_LIMIT

LOWER_SENSOR_LIMIT_2

UPPER_SENSOR_LIMIT_2

LIN_TYPE_2

Index FFDescription Type Store

Selects the unit code of the PRIMARY_VALUE and

other values.

1000 = K (Kelvin)

1001 = °C (degree Celsius)

1002 = °F (degree Fahrenheit)

1003 = Rk (Rankine)

14

1240 = V (volt)

1243 = mV millivolt

1244 = µV microvolt

1281 = Ohm Ohm

1284 = kOhm kiloOhm

1342 = % (percent)

Select the type of sensor 1:

0 = no linearisation

1 = linearisation table

100 = RTD Pt10 a = 0.003850 (IEC 60751)

101 = RTD Pt50 a = 0.003850 (IEC 60751)

102 = RTD Pt100 a = 0.003850 (IEC 60751))

103 = RTD Pt200 a = 0.003850 (IEC 60751))

104 = RTD Pt500 a = 0.003850 (IEC 60751))

105 = RTD Pt1000 a = 0.003850 (IEC 60751)

106 = RTD Pt10 a = 0.003916 (JIS C1604-81)

107 = RTD Pt50 a = 0.003916 (JIS C1604-81)

108 = RTD Pt100 a = 0.003916 (JIS C1604-81)

122 = RTD Ni50 a = 0.006180 (DIN 43760)

123 = RTD Ni100 a = 0.006180 (DIN 43760)

124 = RTD Ni120 a = 0.006180 (DIN 43760)

125 = RTD Ni1000 a = 0.006180 (DIN 43760)

126 = RTD Cu10 a = 0.004270

127 = RTD Cu100 a = 0.004270

18

128 = TC Type B, Pt30Rh-Pt6Rh (IEC 584)

129 = TC Type C (W5), W5-W26Rh (ASTM E 988)

130 = TC Type D (W3), W3-W25Rh (ASTM E 988)

131 = TC Type E, Ni10Cr-Cu45Ni (IEC 584)

133 = TC Type J, Fe-Cu45Ni (IEC 584)

134 = TC Type K, Ni10Cr-Ni5 (IEC 584)

135 = TC Type N, Ni14CrSi-NiSi (IEC 584)

136 = TC Type R, Pt13Rh-Pt (IEC 584)

137 = TC Type S, Pt10Rh-Pt (IEC 584)

138 = TC Type T, Cu-Cu45Ni (IEC 584)

139 = TC Type L, Fe-CuNi (DIN 43710)

140 = TC Type U, Cu-CuNi (DIN 43710)

240 = Custom-defined TC

241 = Custom-defined RTD

242 = Custom-defined RTD PtX a=0.003850

243 = Custom-defined RTD NiX a=0.006180 (X factor of Ni1)

244 = Custom-defined RTD CuX a=0.004270 (X factor of Cu1)

245 = Custom-defined RTD PtX a=0.003916 (X factor of Pt1)

Physical upper limit function of sensor1 (e.g. Pt 100 =

850°C) and input range.

21

The unit of

VALUE_UNIT.

Physical lower limit function of sensor1 (e.g. Pt 100 =

-200°C) and input range.

22

The unit of LOWER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Physical lower limit function of sensor2 (e.g. Pt 100 =

-200°C) and input range.

39

The unit of LOWER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Physical upper limit function of sensor2 (e.g. Pt 100 =

+850°C) and input range.

40

The unit of UPPER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Select the type of sensor 2:

41

See LIN_TYPE for selection and supported types

UPPER_SENSOR_LIMIT is the PRIMARY_

Size

RO /

byte

Un-

signed

signed

(X factor of Pt1)

Float N 4 RO 850

Float N 4 RO -200

Float N 4 RO -200

Float N 4 RO 850

signed

SRC 2 R/W

16

Un-

SRC 1 R/W

8

Un-

SRC 1 R/W 102

8

Min. Max. Default

R/W

1001

(°C)

102

(Pt100)

19

Page 20

20

AI_TRANSDUCER Block Parameter List

2.8.2 RTD / Resistor specific parameters

Rel.

Parameter

SENSOR_CONNECTION

COMP_WIRE1

COMP_WIRE2

SENSOR_CONNECTION_2

CABLE_RES1

CABLE_RES2

RTDX_FACTOR_1

RTDX_FACTOR_2

Index FFDescription Type Store

Connection to sensor 1, select for 2-, 3- and 4-wire

connection. Ignored if sensor 1 is not a resistive sensor.

Defined codes:

35

0 = 2 wires

1 = 3 wires

2 = 4 wires

Value in OHM to compensate line resistance when

36

Sensor 1 is a resistive sensor, connected with 2 wires.

Value in OHM to compensate line resistance when

37

Sensor 2 is a resistive sensor, connected with 2 wires.

Connection to sensor 2, select for 2-, 3- and 4-wire

connection. Ignored if sensor 2 is not a resistive sensor.

38

Defined codes:

0 = 2 wires

1 = 3 wires

For 3- or 4-wire resistance measurements.

Indicates the measured cable resistance in the wire

63

connected to terminal 3. For 3-wire measurements it is

multiplied by 2

For 4-wire resistance measurements.

64

Indicates the measured cable resistance in the wire

connected to terminal 6.

Indicates the X factor for custom defined PtX, NiX, CuX

65

for LIN_TYPE

Indicates the X factor for custom defined PtX, NiX, CuX

66

for LIN_TYPE_2

Size

RO /

byte

Un-

signed

Float SRC 4 R/W 0 100 0

Float SRC 4 R/W 0 100 0

signed

Float D 4 RO 0,0

Float D 4 RO 0,0

signed

signed

SRC 1 R/W 1

8

Un-

SRC 1 R/W 0

8

Un-

SRC 2 R/W 100

16

Un-

SRC 2 R/W 100

16

Min. Max. Default

R/W

2.8.3 Thermocouple specific parameters

Rel.

Parameter

RJ_TEMP

RJ_TYPE

EXTERNAL_RJ_VALUE

RJ_COMP_WIRE

Index FFDescription Type Store

Reference junction temperature. The unit of RJ_TEMP

is the PRIMARY_VALUE_UNIT. If PRIMARY_VALUE_

32

UNIT is no temperature unit (e.g. mV) RJ_TEMP is

stated in °C.

Select reference junction from internal to fixed value.

Ignored for sensors which are not thermocouple types.

Defined codes:

0 = No reference: Compensation is not used (e.g. for

TC type B).

1 = Internal: Reference junction temperature is

measured by the device itself, via

an internally mounted sensor.

2 = External: The fixed value EXTERNAL_RJ_

33

VALUE is used for compensation.

The reference junction must be kept

at a constant temperature (e.g. by a

reference junction thermostat).

3 = Sensor, 2-w.: Reference junction temperature is

measured by external 2-wire con nected Pt100 sensor.

4 = Sensor, 3-w: Reference junction temperature is

measured by external 3-wire con nected Pt100 sensor.

Fixed temperature value of an external reference

junction. The unit of EXTERNAL_RJ_VALUE is the

34

PRIMARY_VALUE_UNIT. If PRIMARY_VALUE_UNIT is

no temperature unit (e.g. mV) EXTERNAL_RJ_VALUE is

stated in °C.

Value in OHM to compensate line resistance when

42

External RJ sensor, connected with 2 wires is used.

Size

RO /

byte

Float D 4 RO 0

Un-

signed

Float SRC 4 R/W

Float SRC 4 R/W 0 100 0

SRC 1 R/W 0

8

Min. Max. Default

R/W

-40

(°C)

135

(°C)

0

Page 21

AI_TRANSDUCER Block Parameter List

2.8.4 Output conditioning parameters

Rel.

Parameter

SENSOR_MEAS_TYPE

BIAS_1

BIAS_2

MAX_SENSOR_VALUE_1

MIN_SENSOR_VALUE_1

MAX_SENSOR_VALUE_2

MIN_SENSOR_VALUE_2

Index FFDescription Type Store

Mathematical function to calculate PRIMARY_VALUE

(PV).

Defined codes:

0: PV = SV_1

1: PV = SV_2

128: PV = SV_1 - SV_2 Difference

129: PV = SV_2 - SV_1 Difference

192: PV = ½ * (SV_1 + SV_2) Average

193: PV = ½ * (SV_1 + SV_2) Average, but SV_1 or

17

SV_2 if the other is wrong (input_fault_x

220: PV = SV_1, SV_2 not available. Used for single

sensor applications. If selected, Sensor 2 will

not be measured. All parameters exclusively

related to Sensor 2 are not available, and no

alarms will be generated for Sensor 2.

221: PV = SV_1, but SV_2 if SV_1 is wrong

(INPUT_FAULT_1

222: PV = SV_2, but SV_1 if SV_2 is wrong

(INPUT_FAULT_2

Bias that can be algebraically added to process value

19

of sensor 1, SV1.

The unit of BIAS_1 is the PRIMARY_VALUE_UNIT.

Bias that can be algebraically added to process value

20

of sensor 2, SV2.

The unit of BIAS_2 is the PRIMARY_VALUE_UNIT.

Holds the maximum SECONDARY_VALUE_1. The unit

28

is defined in

SECONDARY_VALUE_1.

Holds the minimum SECONDARY_VALUE_1. The unit is

29

defined in

SECONDARY_VALUE_1.

30 See. MAX_SENSOR_VALUE_1 Float N 4 R/W 0

31 See. MIN_SENSOR_VALUE_1 Float N 4 R/W 0

≠0)

≠0)

Size

RO /

byte

≠0)

Un-

signed

Float SRC 4 R/W 0

Float SRC 4 R/W 0

Float N 4 R/W 0

Float N 4 R/W 0

SRC 1 R/W 220

8

Min. Max. Default

R/W

2.8.5 Output parameters

Rel.

Parameter

PRIMARY_VALUE

SECONDARY_VALUE_1

SECONDARY_VALUE_2

INTERN_TEMP

Index FFDescription Type Store

13

15

16

45

Process value, function determined by SENSOR_

MEAS_TYPE of SECONDARY_VALUE_1/2.

The unit of PRIMARY_VALUE is the PRIMARY_VALUE_

UNIT.

FF Channel 1 Output. PA Channel 280

Process value connected to sensor 1 corrected by

BIAS_1. The unit of SECONDARY_VALUE_1 is the

PRIMARY_VALUE_UNIT.

FF Channel 2 Output, PA Channel 282

Process value connected to sensor 2 corrected by

BIAS_2. The unit of SECONDARY_VALUE_2 is the

PRIMARY_VALUE_UNIT.

FF Channel 3 Output, PA Channel 283

Internal electronics temperature. The unit of INTERN_

TEMP is the PRIMARY_VALUE_UNIT. If PRIMARY_

VALUE_UNIT is no temperature unit (e.g. mV) INTERN_

TEMP is stated in °C.

FF Channel 4 Output, PA Channel 341

Size

RO /

byte

DS-33 D 5 RO 0

DS-33 D 5 RO 0

DS-33 D 5 RO 0

DS-33 D 5 RO 0

Min. Max. Default

R/W

21

Page 22

22

2.8.6 Diagnostic parameters

Rel.

Parameter

INPUT_FAULT_GEN

INPUT_FAULT_1

INPUT_FAULT_2

RJ_FAULT

HW_ERROR

Index FFDescription Type Store

Input malfunction: Diagnosis object for errors that con

cern all values

0 = device OK

Bit:

23

0 = Rj error

1 = Hardware error

2 – 4 = reserved

5 – 7 = manufacturer-specific

Input malfunction: Diagnosis object for errors that con

cern SV_1

0 = Input OK

Bit:

0 = underrange

24

1 = overrange

2 = lead breakage

3 = short circuit

4 – 5 = reserved

6 – 7 = manufacturer-specific

Input malfunction: Diagnosis object for errors that con

cern SV_2

25

0 = Input OK

Bit definition see INPUT_FAULT_1

Input malfunction: Diagnosis object for errors that con

cern RJ sensor.

0 = Input OK

Bit:

43

0 = underrange

1 = overrange

2 = lead breakage

3 = short circuit

Diagnostic bit value indicating hardware status

0 = hardware OK

Bit:

0 = Input power supply error

1 = Input initialisation error

62

2 = Input communication error

3 = Internal temperature sensor error

4 = Device not factory calibrated

5 – 6 = reserved

7 = Watchdog initiated cold start occurred

AI_TRANSDUCER Block Parameter List

-

Un-

signed

8

-

Un-

signed

8

Un-

signed

8

-

Un-

signed

8

Un-

signed

8

Size

RO /

byte

D 1 RO 0

D 1 RO 0

D 1 RO 0

D 1 RO 0

D 1 RO 0

Min. Max. Default

R/W

2.8.7 Sensor error detection parameters

Rel.

Parameter

SENSOR_WIRE_CHECK_1

SENSOR_WIRE_CHECK_2

SENSOR_WIRE_CHECK_RJ

Index FFDescription Type Store

Enables lead breakage and short circuit detection for

Sensor 1.

List of valid values:

0 = Lead breakage and short circuit detection enable.

26

1 = Lead breakage detection enable, short circuit

detection disable.

2 = Lead breakage detection disable, short circuit

detection enable.

3 = Lead breakage and short circuit detection disable.

Enables lead breakage and short circuit detection for

27

Sensor 2.

Valid values: see SENSOR_WIRE_CHECK_1.

Enables lead breakage and short circuit detection for

44

RJ Sensor.

Valid values: see SENSOR_WIRE_CHECK_1.

Un-

signed

8

Un-

signed

8

Un-

signed

8

Size

RO /

byte

SRC 1 R/W 3

SRC 1 R/W 3

SRC 1 R/W 3

Min. Max. Default

R/W

Page 23

AI_TRANSDUCER Block Parameter List

2.8.8 Sensor calibration, Description

Sensor calibration is a very useful function when the transmitter output needs to be adjusted to the sen

sor signal, e.g. when the temperature sensor does not correspond to the ideal values for the selected

temperature range. The results depend on the accuracy of the calibrator or reference equipment. In the

following a temperature sensor calibration is described, however the principle can be used for all input

types.

-

SENSOR_CAL_METHOD_1 / 2 defines the use of either “Factory trim Standard” (the factory defined val

ues calculated according to the valid norms) or “User Trim Standard” (the sensor calibrated values) in

the transmitter for sensor 1 and 2 respectively. During sensor calibration SENSOR_CAL_METHOD_1 / 2

must be set to “Factory trim Standard” = 103.

The sensor calibration function in T53 will change the slope of the linarisation curve so the curve is ad

justed to the connected sensor. To obtain accurate temperature measurement in the range e.g. 0...100

°C apply to the sensor a temperature e.g. of 5 °C as the low temperature and e.g. 95 °C as the high tem

perature through a precise temperature calibrator.

At sensor calibration the succeeding procedure must be followed precisely (Example: sensor 1):

1. SENSOR_CAL_METHOD_1 = 103

2. Apply the low temperature of the calibrator to the sensor

3. CAL_POINT_LO_1 = 5.00 (type in the low temperature of the calibrator)

4. CAL_ACTUAL_LO_1 = 1.00 (The measurement of the deviation starts by typing in a random value)

5. Apply the high temperature of the calibrator to the sensor

6. CAL_POINT_HI_1 = 95.00 (type in the high temperature of the calibrator)

7. CAL_ACTUAL_HI_1 = 1.00 (The measurement of the deviation starts by typing in a random value

and T53 calculates the curve slope according to the measured

deviations.)

8. SENSOR_CAL_METHOD_1 = 104 (the sensor calibration just carried out is used)

-

-

2.8.9 Sensor Calibration Parameters

Rel.

Parameter

CAL_POINT_LO_1

CAL_ACTUAL_LO_1

CAL_POINT_HI_1

CAL_ ACTUAL _HI_1

SENSOR_CAL_METHOD_1

SENSOR_CAL_LOC_1

SENSOR_CAL_DATE_1

SENSOR_CAL_WHO_1

CAL_POINT_LO_2

CAL_ACTUAL_LO_2

Index FFDescription Type Store

The low calibration value applied to sensor 1

46

The value from either a calibrator or a reference equip

ment.

Entering any value will force the device to automatically

47

measure and store the actual low point value. Must be

entered with the applied CAL_POINT_LO_1 value

The high calibration value applied to sensor 1

48

The value from either a calibrator or a reference equip

ment.

Entering any value will force the device to automatically

49

measure and store the actual high point value. Must be

entered with the applied CAL_POINT_HI_1 value

Enables or disables the last sensor calibration for

sensor 1

50

103 = Factory trim standard (calibration values disabled)

104 = User trim standard (calibration values enabled)

51 The last location of the calibrated sensor

52 The last date on which the calibration was performed

The name of the person responsible for the last sensor

53

calibration

The low calibration value applied to sensor 2

54

The value from either a calibrator or a reference equip

ment.

Entering any value will force the device to automatically

55

measure and store the actual low point value. Must be

entered with the applied CAL_POINT_LO_2 value

Size

RO /

byte

-

Float SRC 4 R/W -10

Float SRC 4 R/W -10

-

Float SRC 4 R/W 10

Float SRC 4 R/W 10

Un-

signed

OCTET_

STRING

7

signed

OCTET_

STRING

-

Float SRC 4 R/W -10

Float SRC 4 R/W

SRC 1 R/W

8

SRC 32 R/W ” ”

Un-

*

SRC 7 R/W

8

SRC 32 R/W ” ”

Min. Max. Default

R/W

38

38

38

38

103

0,0,0,0,

1,1,103

38

38

-10

23

Page 24

24

Parameter

CAL_POINT_HI_2

CAL_ACTUAL_HI_2

SENSOR_CAL_METHOD_2

SENSOR_CAL_LOC_2

SENSOR_CAL_DATE_2

SENSOR_CAL_WHO_2

Rel.

Index FFDescription Type Store

The high calibration value applied to sensor 2

56

The value from either a calibrator or a reference equip

-

Float SRC 4 R/W 10

ment.

Entering any value will force the device to automatically

57

measure and store the actual high point value. Must be

Float SRC 4 R/W 10

entered with the applied CAL_POINT_HI_2 value

Enables or disables the last sensor calibration for

sensor 2

58

103 = Factory trim standard (calibration values disabled)

104 = User trim standard (calibration values enabled)

59 The last location of the calibrated sensor

60

The last date on which the calibration was performed

Un-

signed

OCTET_

STRING

7

*

signed

SRC 1 R/W 103

8

SRC 32 R/W » »

Un-

SRC 7 R/W

8

The name of the person responsible for the last sensor

61

calibration

OCTET_

STRING

SRC 32 R/W » »

Size

byte

RO /

Min. Max. Default

R/W

38

38

0,0,0,0,

1,1,103

Page 25

2.9 PR_CUST_LIN Block Parameter List

2.9.1 Linear interpolation linearisation, Description

LinType 1 = “Linearisation Table” generates a customer specific linear interpolation linearisation. Linear

interpolation linearisation can be used on mV, ohmic and potentiometer signals.The linear interpolation

linearisation is defined by straight lines drawn between the entered X / Y (input / output) coordinates.

The linearisation table must consist of 10 to 50 coordinate sets. The X values of the coordinates must

be entered in ascending order. The lowest and highest X values function as the lower and the upper lim

it respectively. All X values must be entered as µV, Ohm or % for Voltage, Resistance or Potentiometer

measurements in that order. The table output will be converted to actual chosen PRMARY_VALUE_UNIT

(Example: 1000 / 3000 as X / Y values: output will read 3,00 if PRIMARY_VALUE_UNIT is set to “mV”

and 1 mV is connected to input).

2.9.2 Linear Interpolation Linearisation, Parameter List.

Parameter

TAB_MIN_NUMBER

Rel.

Index FFDescription Type Store

34 Minimum number of linearisation points allowed (10)

Un-

signed 8N 1 RO 10

Size

byte

RO /

Min. Max. Default

R/W

-

TAB_MAX_NUMBER

TAB_ACTUAL_NUMBER

TAB_X_Y_VALUE1

TAB_X_Y_VALUE2

TAB_X_Y_VALUE3

TAB_X_Y_VALUE4

TAB_X_Y_VALUE5

TAB_X_Y_VALUE6

TAB_X_Y_VALUE7

TAB_X_Y_VALUE8

TAB_X_Y_VALUE9

TAB_X_Y_VALUE10

TAB_X_Y_VALUE11

TAB_X_Y_VALUE12

TAB_X_Y_VALUE13

TAB_X_Y_VALUE14

TAB_X_Y_VALUE15

TAB_X_Y_VALUE16

TAB_X_Y_VALUE17

TAB_X_Y_VALUE18

TAB_X_Y_VALUE19

TAB_X_Y_VALUE20

TAB_X_Y_VALUE21

TAB_X_Y_VALUE22

35 Maximum number of linearisation points allowed (50)

36 Number of linearisation points in the linearisation table.

37 Linearisation x,y coordinate 1

38 Linearisation x,y coordinate 2

39 Linearisation x,y coordinate 3

40 Linearisation x,y coordinate 4

41 Linearisation x,y coordinate 5

42 Linearisation x,y coordinate 6

43 Linearisation x,y coordinate 7

44 Linearisation x,y coordinate 8

45 Linearisation x,y coordinate 9

46 Linearisation x,y coordinate 10

47 Linearisation x,y coordinate 11

48 Linearisation x,y coordinate 12

49 Linearisation x,y coordinate 13

50 Linearisation x,y coordinate 14

51 Linearisation x,y coordinate 15

52 Linearisation x,y coordinate 16

53 Linearisation x,y coordinate 17

54 Linearisation x,y coordinate 18

55 Linearisation x,y coordinate 19

56 Linearisation x,y coordinate 20

57 Linearisation x,y coordinate 21

58 Linearisation x,y coordinate 22

Un-

signed 8N 1 RO 50

Un-

signed 8SRC 1 R/W 11

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

SRC 8 R/W 0, 0

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

1000,

100

2000,

200

3000,

300

4000,

400

5000,

500

6000,

600

7000,

700

8000,

800

9000,

900

10000,

1000

25

Page 26

26

Parameter

TAB_X_Y_VALUE23

TAB_X_Y_VALUE24

TAB_X_Y_VALUE25

TAB_X_Y_VALUE26

TAB_X_Y_VALUE27

TAB_X_Y_VALUE28

TAB_X_Y_VALUE29

TAB_X_Y_VALUE30

TAB_X_Y_VALUE31

TAB_X_Y_VALUE32

TAB_X_Y_VALUE33

TAB_X_Y_VALUE34

TAB_X_Y_VALUE35

TAB_X_Y_VALUE36

TAB_X_Y_VALUE37

TAB_X_Y_VALUE38

TAB_X_Y_VALUE39

TAB_X_Y_VALUE40

TAB_X_Y_VALUE41

TAB_X_Y_VALUE42

TAB_X_Y_VALUE43

TAB_X_Y_VALUE44

TAB_X_Y_VALUE45

TAB_X_Y_VALUE46

TAB_X_Y_VALUE47

TAB_X_Y_VALUE48

TAB_X_Y_VALUE49

TAB_X_Y_VALUE50

Rel.

Index FFDescription Type Store

59 Linearisation x,y coordinate 23

60 Linearisation x,y coordinate 24

61 Linearisation x,y coordinate 25

62 Linearisation x,y coordinate 26

63 Linearisation x,y coordinate 27

64 Linearisation x,y coordinate 28

65 Linearisation x,y coordinate 29

66 Linearisation x,y coordinate 30

67 Linearisation x,y coordinate 31

68 Linearisation x,y coordinate 32

69 Linearisation x,y coordinate 33

70 Linearisation x,y coordinate 34

71 Linearisation x,y coordinate 35

72 Linearisation x,y coordinate 36

73 Linearisation x,y coordinate 37

74 Linearisation x,y coordinate 38

75 Linearisation x,y coordinate 39

76 Linearisation x,y coordinate 40

77 Linearisation x,y coordinate 41

78 Linearisation x,y coordinate 42

79 Linearisation x,y coordinate 43

80 Linearisation x,y coordinate 44

81 Linearisation x,y coordinate 45

82 Linearisation x,y coordinate 46

83 Linearisation x,y coordinate 47

84 Linearisation x,y coordinate 48

85 Linearisation x,y coordinate 49

86 Linearisation x,y coordinate 50

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

Float

array

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

SRC 8 R/W 0, 0

Size

byte

RO /

Min. Max. Default

R/W

2.9.3 Custom polynomial linearisation, Description

Polynomial linearisation can be used on mV and ohmic input signals. Polynomial linearisation is execut

ed according to the function f(x) = a

+ a

0

*

1

x2 + a

*

2

x3 + a

*

3

x4, in which a0...a4 equal the coefficients

*

4

x + a

for a fourth order polynomial and x equals the input value. This function requires that the user can ob

tain or calculate the coefficients of up to 5 fourth order polynomials. Various computer programs such as

Math Cad can calculate these coefficients. If the preceding text is unfamiliar one should use the function

table linearisation in case of customer specific linearisation.

LIN_TYPE 240 = “Custom defined TC” generates a customer specific polynomial linearisation. The func

tion is primarily suitable for specific thermo elements but also for millivolt signals if the user can accept

to enter the input and the output values of the polynomial in µV and °C respectively.

LIN_TYPE 241 = “Custom defined RTD” generates a customer specific polynomial linearisation. The

-

-

-

Page 27

function is particularly suitable for specific RTD sensors but also for non-linear ohmic signals if the user

can accept to enter the input and output values of the polynomials in ohm and °C respectively.

Please remember that polynomial linearisation is absolute. The output value is calculated continuously

according to the applied input value and the function formula. The max. input range can be limited pre

cisely to the input range in which the polynomial linearisation will be used. The PRIMARY_VALUE_UNIT

defines the unit of the values provided by the AI_TRANSDUCER BLOCK. The parameter OUT_SCALE in

the AI block can scale the values and change the unit to e.g. mV or ohm.

2.9.4 Custom Polynomial Linearisation, Parameter List

Parameter

CUSTOM_TC_NAME

CUSTUM_TC_POLY_

COUNT

CUSTOM_TC_MIN_IN

Rel.

Index FFDescription Type Store

13 Name of Custom defined TC ( LIN_TYPE = 240)

Number of 4. order polynomial parts for Custom

14

defined TC

15 Minimum input limit in µV for Custom defined TC Float SRC 4 R/W 0

OCTET_

STRING

Un-

signed

8

Size

RO /

byte

SRC 20 R/W

SRC 1 R/W 5

Min. Max. Default

R/W

-

”Linear TC;

no RJ”

CUSTOM_TC_MIN_OUT

CUSTOM_TC_MAX_OUT

CUSTOM_TC_POLY_1

CUSTOM_TC_POLY_2

CUSTOM_TC_POLY_3

CUSTOM_TC_POLY_4

CUSTOM_TC_POLY_5

CUSTOM_TC_RJ_POLY

CUSTOM_RTD_NAME

CUSTUM_RTD_POLY_

COUNT

CUSTOM_RTD_MIN_IN

CUSTOM_RTD_MIN_OUT

CUSTOM_RTD_MAX_OUT

CUSTOM_RTD_POLY_1

CUSTOM_RTD_POLY_2

CUSTOM_RTD_POLY_3

CUSTOM_RTD_POLY_4

CUSTOM_RTD_POLY_5

Minimum usable output value in °C of polynomial set

16

for Custom defined TC

Maximum usable output value in °C of polynomial set

17

for Custom defined TC

Polynomial part 1 of Custom defined TC converting µV

18

to °C. Consisting of: maximum input value in µV, a4..a0

polynomial coefficients.

Polynomial part 2 of Custom defined TC converting µV

19

to °C. Consisting of: maximum input value in µV, a4..a0

polynomial coefficients.

Polynomial part 3 of Custom defined TC converting µV

20

to °C. Consisting of: maximum input value in µV, a4..a0

polynomial coefficients.

Polynomial part 4 of Custom defined TC converting µV

21

to °C. Consisting of: maximum input value in µV, a4..a0

polynomial coefficients.

Polynomial part 5 of Custom defined TC converting µV

22

to °C. Consisting of: maximum input value in µV, a4..a0

polynomial coefficients.

RJ Polynomial part of custom defined TC, converting

23

°C to µV.: a3..a0 coefficients.

24 Name of Custom defined RTD ( LIN_TYPE = 241)

Number of 4. order polynomial parts for Custom

25

defined RTD

26 Minimum input limit in Ohm’s for Custom defined RTD Float SRC 4 R/W 0

Minimum usable output value of polynomial set for

27

Custom defined RTD

Maximum useable output value of polynomial set for

28

Custom defined RTD

Polynomial part 1 of Custom defined RTD convert

29

ing Ohm to °C. Consisting of maximum input value in

Ohms, a4..a0 polynomial coefficients.

Polynomial part 2 of Custom defined RTD convert

30

ing Ohm to °C. Consisting of maximum input value in

Ohms, a4..a0 polynomial coefficients.

Polynomial part 3 of Custom defined RTD convert

31

ing Ohm to °C. Consisting of maximum input value in

Ohms, a4..a0 polynomial coefficients.

Polynomial part 4 of Custom defined RTD convert

32

ing Ohm to °C. Consisting of maximum input value in

Ohms, a4..a0 polynomial coefficients.

Polynomial part 5 of Custom defined RTD convert

33

ing Ohm to °C. Consisting of maximum input value in

Ohms, a4..a0 polynomial coefficients.

-

-

-

-

-

Float SRC 4 R/W 0

Float SRC 4 R/W 1500,00

6*Float SRC 24 R/W

6*Float SRC 24 R/W

6*Float SRC 24 R/W

6*Float SRC 24 R/W

6*Float SRC 24 R/W

4*Float SRC 16 R/W 0;0;0;0

OCTET_

STRING

signed

Float SRC 4 R/W 0

Float SRC 4 R/W 100,00

6*Float SRC 24 R/W

6*Float SRC 24 R/W

6*Float SRC 24 R/W

6*Float SRC 24 R/W

6*Float SRC 24 R/W

SRC 20 R/W

Un-

SRC 1 R/W 5

8

30000;

0; 0; 0;

0,01; 0

60000;

0; 0; 0;

0,01; 0

90000;

0; 0; 0;

0,01; 0

120000;

0; 0; 0;

0,01; 0

150000;

0; 0; 0;

0,01; 0

”Linear

RTD”

2000;

0; 0; 0;

0,01; 0

4000;

0; 0; 0;

0,01; 0

6000;

0; 0; 0;

0,01; 0

8000;

0; 0; 0;

0,01; 0

10000;

0; 0; 0;

0,01; 0

2.10 PR_CUST_PRIV Block Reserved Parameter List

2.10.1 Description, PR_CUST_PRIV Block

The Block is private and reserved.

27

Page 28

28

3.0 Analogue Input Blocks

T53 has 2 Analogue Input Blocks to be configured individually. The constrcution of the

Blocks is in line with the standards from FOUNDATION Fieldbus and Profibus Nutzerorgani

sation respectively, and producer specific parameters have not been added. However, the

Analogue Input Blocks for Fieldbus Foundation and Profibus are dissimilar due to the parameter differences.

3.1 Analogue Input Blocks, Fieldbus Foundation

3.2 Overview

The AI block takes the manufacturer’s input data, selected by channel number, and makes it

available to other function blocks at its output.

3.3 Analogue Input Block Schematic

-

3.4 Description

Transducer scaling (XD_SCALE) is applied to the value from the channel to produce the