Page 1

Operating instructions

Betriebsanleitung

EN

DE

full assessment

SIL 2

Temperature transmitter, model T32.xS

Temperaturtransmitter, Typ T32.xS

Head mounting version

model T32.1S

Rail mounting version

model T32.3S

Page 2

EN

DE

2

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

Operating instructions model T32.xS

Page

3 - 38

Betriebsanleitung Typ T32.xS

Seite

39 - 78

Further languages can be found at www.wika.com.

© 05/2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA

®

is a registered trademark in various countries.

WIKA

®

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Page 3

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

3

Contents

Contents

Declarations of conformity can be found online at www.wika.com.

1. General information 4

2. Safety 5

3. Specifications 12

4. Design and function 13

5. Transport, packaging and storage 14

6. Commissioning, operation 15

7. Notes for operating in safety-related applications (SIL) 23

8. WIKA T32 configuration software 23

9. Electrical connections 26

10. Notes for mounting and operating in hazardous areas 30

11. Maintenance 35

12. Faults 36

13. Return and disposal 37

Appendix 1: FM/CSA Installation drawing 74

Appendix 2: EU declaration of conformity 78

Page 4

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

4

1. General information

■

The temperature transmitter described in the operating instructions has been designed

and manufactured using state-of-the-art technology. All components are subject

to stringent quality and environmental criteria during production. Our management

systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the local accident prevention regulations and general safety regulations, in

effect for the instrument's range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions,

prior to beginning any work.

■

The manufacturers liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insufficiently qualified skilled personnel or unauthorised modifications to

the instrument.

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modifications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TE 32.04

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation, which can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can result in light injuries

or damage to equipment or the environment, if not avoided.

1. General information

Page 5

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

5

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

DANGER!

... identifies hazards caused by electrical power. Should the safety instructions

not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation hazardous area that can result in

serious injury or death, if not avoided.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

temperature transmitter has been selected in terms of measuring range,

design and specific measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

WARNING!

This is Protection Class 3 equipment for connection at low voltages,

which are separated from the power supply or voltage by greater than

AC 50 V or DC 120 V. Preferably, a connection to an SELV or PELV circuit

is recommended; alternatively protective measures from HD 60346-4-41

(DIN VDE 0100-410).

Alternatively for North America:

The connection can be made in line with “Class 2 Circuits” or “Class 2 Power

Units” in accordance with CEC (Canadian Electrical Code) or NEC (National

Electrical Code)

Further important safety instructions can be found in the individual chapters of

these operating instructions.

1. General information / 2. Safety

Page 6

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

6

2.1 Intended use

The model T32.xS temperature transmitter is a universal transmitter, configurable via

HART

®

protocol, for use with resistance thermometers (RTD), thermocouples (TC),

resistance and voltage sources as well as potentiometers.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specifications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

If the instrument is transported from a cold into a warm environment, the formation

of condensation may result in the instrument malfunction. Before putting it back into

operation, wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

2.2 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury to personnel and damage

to equipment.

■

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualifications described below.

■

Keep unqualified personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specific regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2. Safety

Page 7

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

7

2.3 Additional safety instructions for instruments per ATEX

WARNING!

Non-observance of these instructions and their contents may result in the loss

of explosion protection.

WARNING!

■

Observe the applicable regulations for the use of Ex-class instruments

■

Do not use transmitters with any damage to the exterior!

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination certificate

and the relevant country-specific regulations for installation and use in

hazardous areas (e.g. IEC 60079-14, NEC, CEC). Non-observance can result

in serious injury and/or damage to equipment.

For additional important safety instructions for instruments with ATEX

approval see chapter 2.3 “Additional safety instructions for instruments per

ATEX”.

WARNING!

The functional galvanic isolation present in the instrument does not ensure

sufficient protection against electrical impulses in the sense of EN 61140.

WARNING!

For hazardous media such as oxygen, acetylene, flammable or toxic gases or

liquids, and refrigeration plants, compressors, etc., in addition to all standard

regulations, the appropriate existing codes or regulations must also be

followed.

WARNING!

To ensure safe working on the instrument, the operator must ensure

■

that suitable first-aid equipment is available and aid is provided whenever

required.

■

that the operating personnel are regularly instructed in all topics regarding

work safety, first aid and environmental protection and know the operating

instructions and, in particular, the safety instructions contained therein.

2. Safety

Page 8

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

8

WARNING!

When working during a running process operation, measures to prevent

electrostatic discharge from the connecting terminals should be taken, as a

discharge could lead to temporary corruption of the measured value.

The model T32.1S temperature transmitter should only be used with

grounded thermometers! The connection of a resistance thermometer (e.g.

Pt100) to the T32.3S must be made with shielded cable. The shield must

be electrically connected with the housing of the grounded thermometer.

(drawings see chapter 6.1 “Grounding”)

The connection of a thermocouple sensor to the T32.3S must be made

with a screened cable. The shield must be electrically connected with the

housing of the grounded thermometer and, additionally, grounded to the

side of the T32.3S. It should be ensured that there is equipotential bonding

on installation, so that no balancing current can flow via the shield. Here, in

particular, the installation regulations for hazardous areas should be followed!

The enclosure is constructed from plastic. To prevent the risk of electrostatic

sparking the plastic surface should be cleaned only with a damp cloth.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

■

The instrument may only be installed and mounted by skilled personnel.

■

Operation using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) can result in life-threatening voltages

at the instrument!

WARNING!

Only instruments as described in chapter 4.2 “Operation in safety-related

applications” are qualified for use in safety-related applications. Do not use

other instruments in safety or Emergency Stop devices.

Incorrect use of the instrument can result in injury.

2. Safety

Page 9

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

9

2. Safety

2.5 Version history per NAMUR NE53

2.5.1 HART

®

5 instruments

Version Notes Configuration

WIKA_T32

software

T32 HART®

instrument

revision

Corresponding

DD (Device

Description)

v2.1.3 first T32.xS version v1.50 3 Dev v3, DD v1

v2.2.1 T32.xS version with SIL

option

v1.51 3 Dev v3, DD v1

v2.2.3 T32.xS (Change

Notification Q2/2014)

v1.51 3 Dev v3, DD v1

2.5.2 Option: HART® 7 instruments

Version Notes Configuration

WIKA_T32

software

T32 HART®

instrument

revision

Corresponding

DD (Device

Description)

v2.3.1 Optional

HART® 7 version

v1.51 4 Dev v3, DD v1

Page 10

Model

with SIL: T32.1S.0IS-S

without SIL: T32.1S.0IS-Z

Date of manufacture (year-month)

Serial number

Ex marking

Approval logos

Power supply

Output signal, HART® version

Sensor, Pt100 or RTD

Measuring range

TAG no.

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

10

2.6 Labelling, safety labels

Product label (example)

■

Head mounting version, model T32.1S

2. Safety

Page 11

Model

with SIL: T32.3S.0IS-S

without SIL: T32.3S.0IS-Z

Date of manufacture (year-month)

Ex marking

Approval logos

Power supply

Output signal, HART® version

Pin assignment

TAG no.

Measuring range

Sensor, Pt100 or RTD

Serial number

Before mounting and commissioning the instrument, ensure you

read the operating instructions!

11

11

11

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

11

■

Rail mounting version, model T32.3S

2. Safety

Page 12

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

12

3. Specifications

Specifications Model T32.xS

Permissible ambient temperature -60 1) / -50 2) / -40 ... +85 °C

Climate class per IEC 654-1: 1993 Cx (-40 ... +85 °C, 5 ... 95 % r. h.)

Maximum permissible humidity

■

Model T32.1S

per IEC 60068-2-38: 1974

■

Model T32.3S

per IEC 60068-2-30: 2005

Test max. temperature variation 65 °C and -10 °C,

r. h. 93 % ±3 %

Test max. temperature 55 °C, r. h. 95 %

Vibration resistance per IEC 60068-2-6:2007 Test Fc: 10 ... 2,000 Hz; 10 g, Amplitude 0.75 mm

Shock resistance per IEC 68-2-27: 1987 Test Ea: Acceleration Type I 30 g and Type II 100 g

Salt fog per IEC 60068-2-52 Severity level 1

Freefall in accordance with

IEC 60721-3-2: 1997

Drop height 1,500 mm

Electromagnetic compatibility (EMC)

3)

EN 61326 Emission (Group 1, Class B) and

immunity (industrial application)

1) Special version on request (only available with specific approvals), not for rail mounting version T32.3S

2) Special version, not for rail mounting version T32.3S

3) During interference an increased measuring deviation of up to 1 % has to be considered.

For further specifications see WIKA data sheet TE 32.04 and the order documentation.

For further important safety instructions for operation in hazardous areas see

chapter 10 “Notes for mounting and operating in hazardous areas”.

3. Specifications

Page 13

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

13

4. Design and function

4.1 Description

The temperature transmitter is used for converting a resistance value or a voltage value

into a proportional current signal (4 ... 20 mA).

Thus the sensors are permanently monitored for their fault-free operation.

The transmitter meets the requirements for:

■

Functional safety per IEC 61508 / IEC 61511-1 (depending on the version)

■

Explosion protection (depending on the version)

■

Electromagnetic compatibility in accordance with NAMUR recommendation NE21

■

Signalling at the analogue output in accordance with NAMUR recommendation NE43

■

Sensor burnout signalling in accordance with NAMUR recommendation NE89

(corrosion monitoring sensor connection)

4.2 Operation in safety-related applications

The model T32.xS.xxx-S (SIL version) has been designed for use in safetyrelated applications.

The marking of this design variant is given in chapter 2.6 “Labelling, safety marking”. For

operation in safety-related applications the additional requirements must be observed

(see safety manual “Information on functional safety of model T32.xS”). The instructions

contained in this must be followed without fail.

4.3 Scope of delivery

Cross-check scope of delivery with delivery note.

4. Design and function

Page 14

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

14

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused by transport. Obvious

damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +85 °C

■

Humidity: 95 % relative humidity

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration

■

Soot, vapour, dust and corrosive gases

5. Transport, packaging and storage

Page 15

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

15

6. Commissioning, operation

In hazardous areas, only use temperature transmitters that are approved for

those hazardous areas. The approval is marked on the product label.

6.1 Grounding

Connection head BSZ

grounded

Loop circuit

The model T32.1S

temperature transmitter

should only be used with

grounded thermometers!

grounded

grounded shield

Thermowell

with sensor

grounded

sensor wire

equipotential bonding

T32.xS

Field housing/

switch cabinet

For thermocouples, additionally ground here!

For grounding of the model T32.xS

temperature transmitter see safety

instructions page 7f.

Connection head BSZ

6. Commissioning, operation

Page 16

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

16

For applications with higher EMC requirements, it is recommended using a shielded cable

between the temperature transmitter and the sensor, especially in connection with long

leads to the sensor. For an exemplary illustration, see drawing.

6.2 Mounting

6.2.1 Transmitter in head mounting version (model T32.1S)

The transmitters for head mounting (model T32.1S) are designed to be mounted on a

measuring insert within a Form B, DIN connection head, with extended mounting space.

The connection wires of the measuring insert must be approx. 50 mm long and insulated.

grounded

grounded shield

sensor wire

equipotential bonding

T32.xS

Field housing/

switch cabinet

For thermocouples, additionally ground here!

sensor

For grounding of the model T32.xS

temperature transmitter see safety

instructions page 7f.

Mounting example:

3173801.A

6. Commissioning, operation

Page 17

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

17

Mounting on the measuring insert

Mount the transmitter on the circular plate of the measuring insert using two countersunk

M3 screws per EN ISO 2009. Appropriate threaded inserts have been press-fitted in the

underside of the case. Assuming the countersinking is carried out correctly, the permissible

screw length can be calculated as follows:

Check the screw length before fixing the transmitter to the measuring insert: insert the

screw into the circular plate and verify length of 4 mm!

CAUTION!

Do not exceed the maximum permissible screw length!

The transmitter will be damaged if the screws are screwed further than 4 mm

into the bottom of the transmitter.

Mounting in connection head

Insert the measuring insert with the mounted transmitter into the protective sheath and

secure into the connecting head using screws in pressure springs.

Installation by means of DIN rail adapter

If the mechanical adapter, available as an accessory, is used the T32.1S head transmitters

can also be fixed on a DIN rail.

6.2.2 Transmitter in rail mounting version (model T32.3S)

Fasten the rail mounting case (model T32.3S) onto a 35 mm top-hat rail (EN 60175) by

simply locking it into place without the need for any tools.

Disassembly is achieved by unlocking the locking element.

l

max

= s + 4 mm

with

l

max

Length of screw in mm

s Thickness of circular plate in mm

3173801.B

max. 4

Circular plate

l

s

3173801.C

6. Commissioning, operation

Page 18

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

18

6.3 Configuration

The following parameters can all be configured: sensor model, sensor connection, user

measuring range, output limit, alarm indication, terminal voltage monitoring, sensor break

monitoring, measuring range monitoring, measuring rate, damping, write protection, offset

values (1-point correction), Tag No. and user linearisation (custom chararcteristic curve).

Furthermore, a linear transformation of the process value is possible using a 2-point

correction.

User linearisation:

Via software, customer-specific sensor characteristics can be stored in the transmitter in

order to define other sensor types. Number of auxiliary points: min. 2; max. 30. If more than

2 sensors are connected (dual sensor function) further configurations can be carried out.

With the dual sensor function, two identical sensors (resistance sensor or thermocouple)

with the same measuring range are connected and then processed together.

The transmitters are delivered with a basic configuration (see data sheet TE 32.04) or

configured according to customer specifications. If the configuration is changed afterwards,

the modifications must be noted on the label using a water-resistant felt-tip pen.

A simulation of the input value is not required to configure the T32.

A sensor simulation is only required for the functional test.

Freely programmable sensor functionality when 2 sensors have been connected

(dual sensor)

Sensor 1, sensor 2 redundant:

The 4 … 20 mA output signal delivers the process value of sensor 1. If sensor 1 fails, the

process value of sensor 2 is output (sensor 2 is redundant).

Average value:

The 4 … 20 mA output signal delivers the average value from sensor 1 and sensor 2. If one

sensor fails, the process value of the working sensor is output.

Minimum value:

The 4 ... 20 mA output signal delivers the lower of the two values from sensor 1 and sensor

2. If one sensor fails, the process value of the working sensor is output.

Maximum value:

The 4 ... 20 mA output signal delivers the higher of the two values from sensor 1 and

sensor 2. If one sensor fails, the process value of the working sensor is output.

Difference:

The 4 … 20 mA output signal delivers the difference between sensor 1 and sensor 2. If one

sensor fails, the process value of the working sensor is output.

6. Commissioning, operation

Page 19

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

19

Freely programmable monitoring functions

Monitoring of the measuring range:

If this function is activated, an error is signalled on the current loop (< 3.6 mA) if the

measured value is either below or over the limits of the measuring range.

Freely programmable monitoring functions when 2 sensors have been connected

(dual sensor)

The following options are not available in the difference mode!

Redundancy/hot backup:

In the case of a sensor error (sensor break, line resistance too high or measured value

outside the measuring range of the sensor) of one of the two sensors, the process value

will be the value from the working sensor only. Once the error is rectified, the process value

will again be based on the two sensors, or on sensor 1.

Ageing monitoring (sensor drift monitoring):

An error signal on the output is activated if the value of the temperature difference between

sensor 1 and sensor 2 is higher than a set value, which can be selected by the user. This

monitoring only generates a signal if two valid sensor values can be determined and the

temperature difference is higher than the selected limit value.

(Cannot be selected for the “Difference” sensor functionality, since the output signal

already indicates the difference value).

6.3.1 Configuration via the PC

To configure the transmitter, both configuration software and a HART

®

modem are needed.

WIKA offers 3 different HART

®

modem models for this.

HART® modem with USB interface, model 010031, order No. 11025166

HART® modem with RS232 interface, model 010001, order No. 7957522

Bluetooth HART® modem, ATEX, CSA, FM approved, model 010041,

on request

The HART

®

modem may also be used in conjunction with other configuration

software (see chapter 8 “WIKA T32 configuration software”).

6. Commissioning, operation

Page 20

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

20

6. Commissioning, operation

WIKA T32 configuration software

We recommend using our WIKA T32 configuration software. This software is regularly

updated and adapted to the firmware extensions of the T32, so that you always have full

access to all functionalities and parameters of the transmitter (see chapter 8 “WIKA T32

configuration software”).

Further configuration software

With the following software tools it is also possible to carry out configurations at the T32 e.g.:

■

AMS and SIMATIC PDM (T32_EDD)

■

FieldMate, PACTware, SmartVision and Fieldcare (DTM_T32)

■

DTM in FDT 1.2 frame application

With any other HART

®

configuration tool the generic mode functionalities can be operated

(e.g. measuring range or Tag No.).

Further information on the configuration of the T32 with the software tools

mentioned above is available on request.

6.3.2 DD version

The model T32.xS temperature transmitter can be used with the following DTM and DD

versions.

T32 HART® instrument

revision

Corresponding DD

(Device Description)

T32 HART® DTM

0 Dev v0, DD v2 DTM 1.0.2

1 Dev v1, DD v1 DTM 1.0.2

2 Dev v2, DD v1 DTM 1.0.2

3 Dev v3, DD v1 DTM 2.0.0.175, DTM 2.1.0

Optional: HART

®

7 version

4 Dev v3, DD v1 DTM 2.1.0

6.3.3 HART® communicator (FC375, FC475, MFC4150, MFC5150)

With the HART

®

communicator the instrument functions are selected via various menu

levels and with the help of a special HART

®

function matrix (see chapter 6.5 “HART®

configuration tree”).

6.4 Connection of FSK modem, HART

®

communicator

WARNING!

■

The measuring circuit has to have a load of at least 250 Ω.

■

For all transmitters with hazardous area protection observe chapter 10

“Notes for mounting and operating in hazardous areas”.

This resistor is already integrated in most power supplies available in the market and is

therefore not required separately. Frequently a special connection for the FSK modem is

already available.

Page 21

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

21

6.5 HART® configuration tree (part 2 see next page)

1. Device setup

2. PV

3. PV AO

4. PV % measuring

range

5. PV LRV low

range value ??

6. PV URV upper

range value ??

7. SV

8. TV

9. 4V

1. Process variables

2. Diagnostics/

Service

3. Basic setup

4. Detailed setup

5. Review

6. Write protection

7. Write protection

off/on

1. Sensor

2. AI % measuring range

3. AO 1

4. CJC temperature

5. PV drag pointer

1. Test device

2. Loop test

3. Calibration

4. Device temp. drag

pointer

5. Set error reaction

1. PV high

2. PV low

3. Reset values

1. Status

2. Selftest

3. Reset

4. Device op time

1. Set measuring range

2. Process adaption

3. D/A trim

1. Max. device temp.

2. Min. device temp.

3. Reset values

1. Attention

2. Process adaption -

Sensor 1

3. Process adaption -

Sensor 2

4. Reset values

1. Ta g

2. Set measuring range

3. Sensor selection

4. PV phys.unit

5. PV damping

6. PV sensor serial no.

1. Sensors..

.

.

1. Process sensors

.

.

.

.

1. PV

2. PV sensor unit

3. PV sensor serial no.

4. Sensor information

5. 4V

6. Sensor selection

7. Sensor type

8. Linearizatin mode

9. Sensor connection

■

Dual sensor mode ■Sensor drift limit

1. PV LSL

2. PV USL

3. PV min.measuring span

4. Sensor operation

5. QV / 4V info

6. Custom sensor

7. Custom sensor info

6. Commissioning, operation

Page 22

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

22

HART® configuration tree (part 2)

.

.

.

.

2. Signal condition

3. Output condition

4. Error conditioning

5. Device information

.

.

.

.

2. Electrical temperature

■

Process adaption

■

2W offset ■Cj. settings

■

Ptx 0°C resistance

■

Potentiometer

resist.

1. Attention

2. Process adaption - Sensor 1

3. Process adaption - Sensor 2

4. Reset values

1. TV

2. Cj. mode

3. Cj. fixed value

4. Cj. temp. offset

1. Electrical temp.

2. Ta max

3. Ta min

4. Device temp. drag

1. Max. device temp.

2. Min. device temp.

3. Reset values

1. Sensor damping

2. Set measuring range

3. AI % measuring range

1. Analogue output

2. HART

®

output

1. AO1

2. Output limits

3. Loop test

4. D/A trim

1. Poll address

2. Num req preambles

3. Burst mode

4. Burst option

5. HART

®

dev.

malfunction

1. Alarm level values

2. Set error direction

3. Monitor output limits

4. Monitor ambient temp.

1. Distributor

2. Model

3. Type code

4. Device ID

5. Tag

6. Date

7. Activating write protection

8. Write protection off/on

9. Change passwort

■

Description

■

Message

■

Final assembly number

■

Revision number

■

Device operating time

1. Universal rev.

2. Field devices rev.

3. Software rev.

4. Hardware rev.

5. FW version

6. Commissioning, operation

Page 23

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

23

Abbreviations used

PV: Process value (primary value)

SV: Temperature of internal electronics (secondary value)

TV: Thermocouple compensation temperature (tertiary value)

AO: Analogue output

URV: Max. value (upper range value)

LRV: Min. value (lower range value)

LSL: Min. sensor limit (lower sensor limit)

USL: Max. sensor limit (upper sensor limit)

7. Notes for operating in safety-related applications (SIL)

The model T32.xS.xxx-S (SIL version) has been designed for use in safetyrelated applications.

For operation in safety-related applications the additional requirements must be observed

(see safety manual “Information on functional safety of model T32.xS”). The instructions

contained in this must be followed without fail.

8. WIKA T32 configuration software

For installation please follow the instructions of the installation instructions. A free-ofcharge download of the up-to-date version of the WIKA_T32 software is available from

www.wika.com.

8.1 Starting up the software

Start the WIKA_TT software by double-clicking on the WIKA T32 icon.

To get complete access to all functions and parameters of the T32, you must

choose the access level “Specialist”. After installation, by default, no password

is activated!

6. Commissioning, operation ... 8. WIKA T32 configuration ...

Page 24

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

24

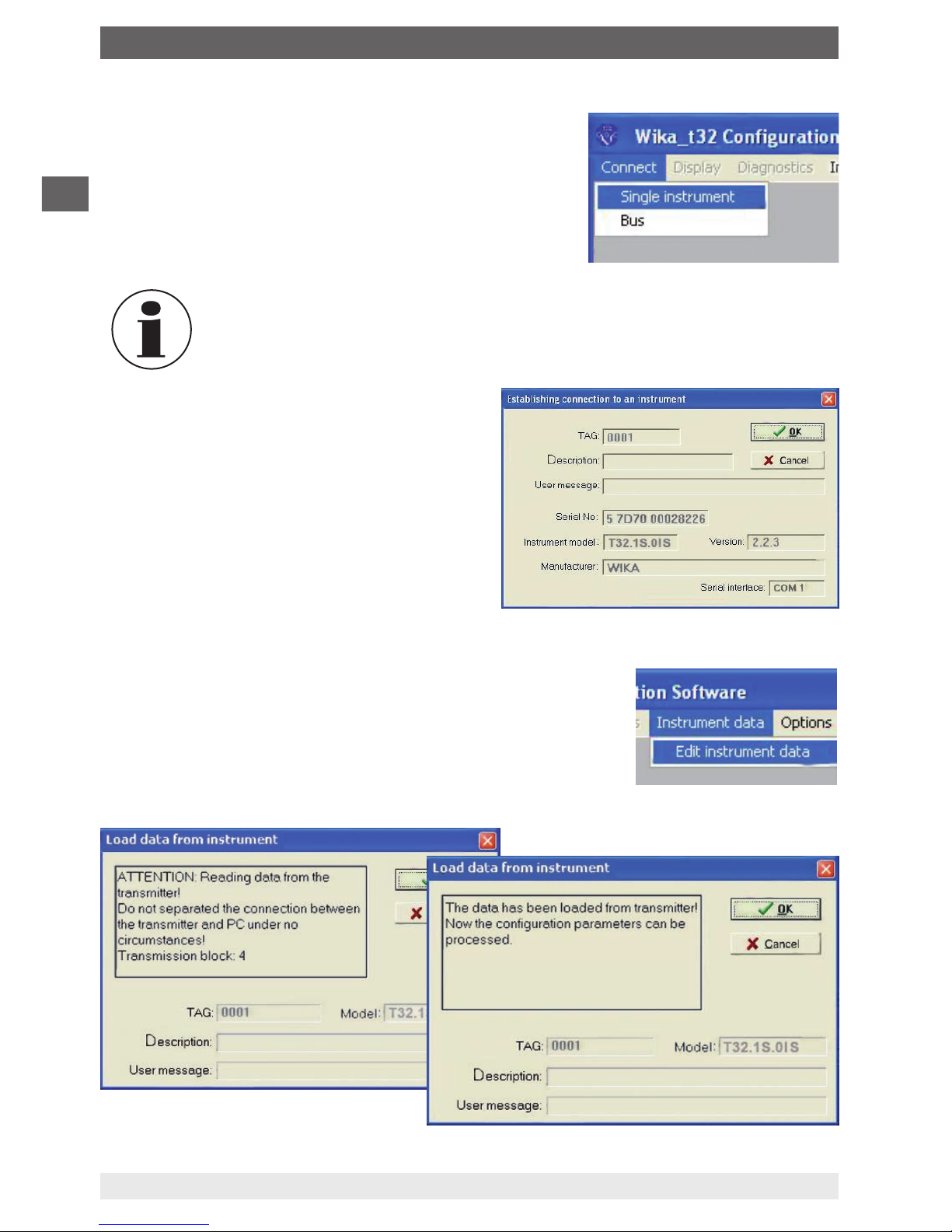

8.2 Connection

Through the menu entry “connect” → “Single instrument”,

it will try to establish communication with a HART

®

-

capable device with the HART

®

Poll Address 0 (zero).

If this attempt is unsuccessful, the software will try to

establish a Multidrop connection. The addresses 1-15

will be successively connected and will try to establish

communication to a connected device.

Connection is only possible to a single instrument at any one time!

After successful connection the software shows

the basic data for the connected instrument:

■

TAG mark

■

Description

■

User message

■

Serial number

■

Instrument model and version

■

Manufacturer and the PC port used

Confirm connection established with “OK”.

8.3 Parameter configuration (configurable)

All data important for operating can be adjusted in the menu

“Instrument data” → “Edit instrument data”.

8. WIKA T32 configuration software

Page 25

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

25

During this, do not interrupt the communication with the transmitter, since the

data may not be correctly read as a result of this.

Once the data has been correctly transferred, confirm with “OK”.

Access to all operation-relevant

functions and parameters such as:

■

Sensor type and connection

■

Measuring range and temperature

unit

■

Output signal

■

Output limits and error signalling

■

TAG of test point

■

HART® poll address

■

Burst mode

For further information on configuration, see contact data on page 4.

8. WIKA T32 configuration software

Page 26

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

26

9. Electrical connections

WARNING!

Observe the safety-technical maximum values for the connection of the power

supply and the sensors, see chapter 10.3 “Safety-technical maximum values”.

When working on the transmitters (e.g. installation/removal, maintenance work) take

measures to prevent electrostatic discharge from the terminals.

WARNING!

Only carry out installation in a de-energised state!

The connected wires must be checked to ensure they are connected properly.

Only well-secured wires can guarantee a fault-free operation.

Recommended tools for terminal screws:

Model Screwdriver Tightening torque

T32.1S Cross head (Pozidriv tip)

size 2 (ISO 8764)

0.4 Nm

T32.3S Slotted, 3 mm x 0.5 mm

(ISO 2380)

0.4 Nm

Input

Sensor

Output

4 ... 20 mA loop

For head mounting and rail mounting case, connection clamps for the HART

®

modem are available.

9. Electrical connections

Page 27

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

27

9.1 Power supply, 4 ... 20 mA current loop

The T32 is a 2-wire temperature transmitter. Depending on the version, it can be supplied

with various types of power supply. Connect the positive line of the power supply to the

terminal marked with ⊕, the negative line of the power supply to the terminal marked with ⊖.

With flexible leads we recommend the use of crimped connector sleeves. The integrated

reverse polarity protection (wrong polarity on the terminals ⊕ and ⊖) prevents the

transmitter from damage.

The following maximum values are applicable:

■

Model T32.xS.000: DC 42 V

■

Model T32.xS.0IS: DC 30 V

■

Model T32.xS.0IC: DC 30 V

■

Model T32.xS.0NI: DC 40 V

The T32.xS temperature transmitter requires a minimum terminal voltage of DC 10.5 V. The

load must not be too high, as otherwise, in the case of relatively high currents, the terminal

voltage at the trans-mitter will be too low.

The T32 is equipped with terminal voltage monitoring (“under-voltage” detection).

If too small a voltage is detected at the terminal (< 10 V) the error is signalled on the output

(< 3.6 mA).

Maximum permissible load depending on the supply voltage:

Load diagram

For the power supply, use an energy-limited electrical circuit (EN/UL/IEC 61010-1,

section 8.3) with the following maximum values for the power supply:

for U

B

= DC 42 V; 5 A

For the external power supply a separate switch is required.

11289130.02

Voltage UB in V

Load R

A

in Ω

Ex nA/icEx ia

9. Electrical connections

Page 28

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

28

9.2 HART® loop display (DIH50, DIH52)

Additional configuration of the temperature transmitter with a HART

®

Loop Display is

possible. This is used for the local display of the current process value. The unit and the

configured measuring range of the transmitter are automatically updated via the HART

®

protocol in the display. No further change of the HART

®

loop display is necessary. To do

this, the display must be in HART

®

mode.

9.3 Sensors

9.3.1 Schematic representation, configuration

9.3.2 Resistance thermometer (RTD) and resistance sensor

It is possible to connect an RTD resistance thermometer (e.g. per EN 60751) or any

resistance sensor in a 2-, 3- or 4-wire connection method and to connect two identical

resistance thermometers, having the same measuring ranges, in a two-wire circuit.

Configure the input of the transmitter to match with the actual method of connection used.

Otherwise you will not fully exploit the possibilities of connection lead compensation and,

as a result, possibly cause additional measuring errors (see chapter 6.3 “Configuration”).

9.3.3 Thermocouples (TC)

It is possible to connect one or two identical thermocouples. Make sure that the

thermocouple is connected with the correct polarity. If the lead between the thermocouple

and the transmitter needs to be extended, only use thermal or compensation cable

appropriate for the connected thermocouple type.

Configure the input of the transmitter appropriately for the thermocouple type and the cold

junction compensation actually used, otherwise measurement errors may be caused (see

chapter 6.3 “Configuration”).

Should the cold junction compensation be operated with an external

resistance thermometer (2-wire connection), connect this to terminals and

.

Thermocouple Resistance thermometer/

resistance sensor

in

4-wire 3-wire 2-wire

CJC with

external Pt100

Input

Sensor 1

Sensor 2

Sensor 1

Sensor 2

Dual thermocouple

duplex mV-Sensor

Potentiometer

Dual resistance

thermometer/

Dual resistance sensor

in 2 + 2-wire

11234547

9. Electrical connections

Page 29

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

29

9.3.4 Connect mV sensor

Make sure that the mV sensor is connected with the correct polarity.

9.3.5 Potentiometer

Connection of a potentiometer is possible.

9.4 HART

®

signal

The HART

®

signal is measured directly via the 4 ... 20 mA signal line. The measuring

circuit must have a load of at least 250 Ω. However, the load must not be too high, as

otherwise, in the case of relatively high currents, the terminal voltage at the transmitter will

be too low. For that reason, connect the cable clamps of the modem and/or the HART

®

communicator, as described (see chapter 6.5 “HART

®

configuration tree”) or use the

existing communication connectors of a power supply/line transformer. The connection

of the HART

®

modem and/or the HART® communicator is not dependant on polarity!

The HART

®

modem or the HART® communicator may also be connected parallel to the

resistor! When connecting an Ex version of the transmitter, observe the special conditions

for safe use (see chapter 10 “Notes for mounting and operating in hazardous areas”).

9.4.1 Typical connection for hazardous area (head mounting)

HART®

communicator

Transmitter

Hazardous area

Transmitter

Power supply

24 V

Safe area

11242175.02

RS 232-C

Bluetooth

Ex ia

USB HART

®

modem

Terminal 1-4:

sensor, see

designation

of terminal

connections

If RL is < 250 Ω in the respective electrical

circuit, RL must be increased to at least

250 Ω by connecting external resistances.

RL = Resistance for the HART

®

communication

RL min. 250 Ω, max. 1100 Ω

9. Electrical connections

Page 30

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

30

10. Notes for mounting and operating in hazardous areas

In hazardous areas, only use temperature transmitters that are approved for those

hazardous areas. The approval is marked on the product label.

When connecting them to other devices or component, observe the connection

requirements regarding explosion protection, such as maximum admissible voltage, power

or load with capacitances (see chapter 10.2 “Specific conditions for safe use”).

The following information is based mainly on the EC type examination certificate,

Certification No. BVS 08 ATEX E 019 X.

9.4.2 Typical connection for safe area

HART®

communicator

Transmitter

Safe area

Transmitter

Power supply

24 V

11242299.02

USB

FSK modem

Terminal 1-4:

sensor, see

designation

of terminal

connections

If RL is < 250 Ω in the respective electrical

circuit, RL must be increased to at least

250 Ω by connecting external resistances.

RL = Resistance for the HART

®

communication

RL min. 250 Ω, max. 1100 Ω

9. Electrical connections / 10. Notes for mounting and ...

Page 31

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

31

10.1 Model overview and their European approvals

Model Ex protection and approval no. Ignition protection type

T32.1S.0IS-x

(head mounting version)

II 1G Ex ia IIC T4/T5/T6 Ga

II 1D Ex ia IIIC T120 °C Da

Intrinsically safe equipment

T32.3S.0IS-x

(rail mounting version)

II 2(1)G Ex ia [ia Ga] IIC T4/T5/T6 Gb

II 2(1)D Ex ia [ia Da] IIIC T120 °C Db

Intrinsically safe equipment

T32.xS.0NI II 3G Ex nA IIC T4/T5/T6 Gc X Non-sparking equipment

T32.1S.0IC-x

T32.3S.0IC-x

II 3G Ex ic IIC T4/T5/T6 Gc Intrinsically safe equipment

The nominal electrical values for the head and the rail versions are identical.

For T32.xS.0IS: The intrinsically safe sensor circuit (optional 2-wire, 3-wire or 4-wire

configuration) for both versions is intended for the supply of equipment in areas with 1G or

1D requirements.

The version T32.1S.0lS is designed for installation in housings or connection heads in

areas with 1G, 2G or 1D, 2D requirements.

The version T32.3S.0IS is intended for installation in a housing which guarantees at least

protection class IP20 (2G application or installation outside the hazardous area) or IP6x

(2D application).

10.2 Specific conditions for safe use

T32.3S.xxx:

The surface of the case is not conductive. The temperature transmitter must be mounted in

a way that electrostatic charges will not occur.

T32.xS.0NI (use as non-incentive equipment II 3G Ex nA):

Disconnection of power supply is forbidden inside the hazardous area. When connecting

or disconnecting the terminals ensure the power supply is disconnected outside the

hazardous area.

These temperature transmitters must be mounted in a case that must at least correspond

to following ingress protection IP54 in accordance with IEC/EN 60529.

The holes in the connection terminals (T32.1S.0NI) or the additional connections labelled

“Modem” (T32.3S.0NI) shall not be used in connection with type of protection nA.

When during use in circuits with the safety class nA (non-incendive) the permissible

connected loads have been exceeded for a short term

1)

, the use of these transmitters in

circuits with the safety class Ex nL (energy limited) is not permissible any more.

1) When the transmitters are used in circuits with the safety class nA, it is permissible to exceed the maximum supply voltage by up to 40 % for a

short term.

10. Notes for mounting and operating in hazardous areas

Page 32

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

32

T32.xS.0IS, T32.xS.0IS-x (providing IS level of protection Ex ia)

Installation in the save area:

■

The transmitter shall be mounted inside a housing providing as a minimum degree of

protection IP 20 according to IEC 60529.

■

Wiring inside the housing shall comply with clause 6.3.12 and clause 7.6.e of

IEC 60079-11:2011.

■

Terminals or connectors for the intrinsically safe circuits shall be arranged according to

clause 6.2.1 or 6.2.2 of IEC 60079-11:2011 respectively.

Installation in EPL Ga (Zone 0) or EPL Gb (Zone 1) area

■

Transmitter models T32.1S.0IS, T32.1S.0IS-x:

- Due to application, the transmitter shall be mounted inside a housing, suitable for

installation in EPL Ga (Zone 0) areas and wherein electrostatic charge effects are

excluded.

- Due to application, the transmitter shall be mounted inside a housing, suitable for

installation in EPL Gb (Zone 1) areas.

■

Transmitter models T32.3S.0IS, T32.3S.0IS-x:

The transmitter shall be mounted inside a housing, suitable for installation in EPL Gb

(Zone 1) area and wherein electrostatic charge effects are excluded.

Installation in EPL Da (Zone 20) or EPL Db (Zone 21) area

■

Transmitter models T32.1S.0IS, T32.1S.0IS-x:

Due to application, the transmitter shall be mounted inside a housing, suitable for

installation in EPL Da (Zone 20) or EPL Db (Zone 21) area, providing degree of

protection IP6x according to IEC 60529.

■

Transmitter models T32.3S.0IS, T32.3S.0IS-x:

Due to application, the transmitter shall be mounted inside a housing, suitable for

installation in EPL Db (Zone 21), providing degree of protection IP6x according to

IEC 60529.

T32.xS.0IC, T32.xS.0IC-x (providing IS level of protection Ex ic)

Installation in EPL Gc (Zone 2):

■

The transmitter models T32.1S.0IC, T32.1S.0IC-x shall be mounted inside a housing

located in EPL Gc (Zone 2) area, providing as a minimum degree of protection IP20

according to IEC 60529.

■

The transmitter models T32.3S.0IC, T32.3S.0IC-x shall be mounted inside a housing

located in EPL Gc (Zone 2) area, providing as a minimum degree of protection IP20

according to IEC 60529 and wherein electrostatic charge effects are excluded.

■

Wiring inside the housing shall comply with clause 6.3.12 and clause 7.6.e of

IEC 60079-11:2011.

■

Terminals or connectors for the intrinsically safe circuits shall be arranged according to

clause 6.2.1 or 6.2.2 of IEC 60079-11:2011 respectively.

10. Notes for mounting and operating in hazardous areas

Page 33

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

33

Installation in EPL Dc (Zone 22) area:

Level of protection “ic” not permitted for EPL Dc application.

■

Transmitter models T32.xS.0IS-x:

Transmitters with “ia” marking may also be used in supply circuits of type “ib” with the

same connection parameters. Thereby, the whole measuring circuit (including the sensor

circuit) is an “ib” circuit. Transmitters which were operated with supply circuits of type “ib”

may not be re-used with supply circuits of type “ia”.

■

The external wiring shall be suitable for the ambient temperature range of the end use

application. The maximum ambient temperature for T32 of 85 °C shall be considered.

The minimum cross section for external wiring is 0.14 mm².

■

Ex nA applications:

The temperature transmitters model T32.xS.0NI shall be installed in a pollution degree

2 environment or better in the end use application for use with an IP 54 minimum

enclosure provided by end user.

Operation in zone 0:

The temperature transmitter may only be operated in areas requiring category 1 equipment

when the following atmospheric conditions exist:

Temperature: -20 ... +60 °C

Pressure: 0.8 ... 1.1 bar

Operation in zone 1 and zone 2:

In accordance with the temperature class, these transmitters may only be used in the

following ambient temperature ranges:

Application Ambient temperature range Temperature class Power P

i

Group II -60 1) / -50 °C ≤ Ta ≤ +85 °C T4 800 mW

-60

1)

/ -50 °C ≤ Ta ≤ +75 °C T5 800 mW

-60

1)

/ -50 °C ≤ Ta ≤ +60 °C T6 800 mW

Dust Ex -60

1)

/ -50 °C ≤ Ta ≤ +40 °C n. a. 750 mW

-60

1)

/ -50 °C ≤ Ta ≤ +75 °C n. a. 650 mW

-60

1)

/ -50 °C ≤ Ta ≤ +100 °C n. a. 550 mW

n. a. = not applicable

1) Special version on request (only available with specific approvals), not for rail mounting version T32.3S

10. Notes for mounting and operating in hazardous areas

Page 34

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

34

10.3 Safety values

10.3.1 Sensor circuit (terminals 1 to 4)

Parameters Model T32.xS.0IS,

T32.xS.0IS-x

Model T32.xS.0IC,

T32.xS.0IC-x

Level of protection Ex ia IIC/IIB/IIA

Ex ia IIIC

Ex ic IIC/IIB/IIA

Terminals 1-4

Voltage U

o

DC 6.5 V

Strength of current l

o

9.3 mA

Power P

o

15.2 mW

Voltage U

o

n. a.

Strength of current l

o

n. a.

Power P

o

n. a.

Effective internal capacitance C

i

208 nF

Effective internal inductance L

i

negligible

Max. external capacitance C

o

IIC 24 µF

1)

325 µF

1)

IIB IIIC 570 µF

1)

570 µF

1)

IIA 1,000 µF

1)

1,000 µF

1)

Max. external inductance L

o

IIC 365 mH 821 mH

IIB IIIC 1,644 mH 3,699 mH

IIA 3,288 mH 7,399 mH

Max. inductance/resistance

ratio L

o/Ro

IIC 1.44 mH/Ω 3.23 mH/Ω

IIB IIIC 5.75 mH/Ω 12.9 mH/Ω

IIA 11.5 mH/Ω 25.8 mH/Ω

Characteristics linear

n. a. = not applicable 1) Ci not applicable

Notes:

U

o

: max. voltage of any conductor against the other three conductors

I

o

: max. current of three conductors parallel to the fourth conductor or any other combination

P

o

: max. power of three conductors parallel to the fourth conductor or any other combination

Due to separation requirements of the applied standards, IS supply- and signal-circuit and

the IS sensor circuit shall be considered as beeing galvanically connected to each other.

10. Notes for mounting and operating in hazardous areas

Page 35

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

35

10.3.2 Intrinsically safe supply and signal circuit

(4 ... 20 mA loop; terminal ⊕ and ⊖)

Parameters T32.xS.0IS-x,

T32.xS.0IC-x

T32.xS.0IS-x T32.xS.0NI

Gas hazardous

application

Dust hazardous

application

Gas hazardous

application

Terminals + / - + / - + / -

Voltage U

i

DC 30 V DC 30 V 40 V

Strength of current I

i

130 mA 130 mA 23 mA

1)

Power P

i

800 mW 750/650/550 mW

2)

1 W

Effective internal

capacitance C

i

7.8 nF 7.8 nF 7.8 nF

Effective internal

inductance L

i

100 µH 100 µH 100 µH

1) The maximum operating current is limited by the T32. The maximum output current of the associated energy-limited apparatus does not have to

be ≤ 23 mA.

2) With reference to ambient temperature; see table “Temperature class”.

The supply and signal circuit and the intrinsically safe sensor circuit must be

considered as galvanically connected to each other.

10.3.3 Connection of the HART® modem/HART® communicator

(terminal ⊕ and ⊖)

■

The sum of all voltages connected (supply plus output values of the HART® modem

and/or HART

®

Communicator) must not exceed 30 V for T32.xS.0IS and 40 V for

T32.xS.0NI.

■

The sum of the effective capacitances and inductances must not exceed the maximum

permissible value according to the required gas group (IIA up to IIC).

11. Maintenance

The temperature transmitter described in these operating instructions is maintenance-free!

The electronics are completely encapsulated and incorporate no components which could

be repaired or replaced.

Repairs must only be carried out by the manufacturer.

10. Notes for mounting and ... / 11. Maintenance

Page 36

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

36

12. Faults

Fault-tree

Current loop disconnected

Wrong polarity of the supply

voltage

Transmitter not connected

Wrong sensor type

Wrong 2-, 3- or 4-wire

connection

Wrong temperature range

Wrong compensation

Sensor

= TC

l > 20 mA

l < 4 mA

4 mA < l < 20 mA

but wrong values

Current value is okay, but temperature drift

while transmitter is heating up or cooling down

Process temperature out of range

Wrong sensor connection

Sensor burnout or short circuit

Wrong transmitter configuration

Capacitive or inductive

coupling over the sensor

Capacitive or inductive

coupling over the loop

Wrong polarity of

thermocouple

Loop resistance too high

Electromagnetic interferences

Linearization error for sensor /

transmitter

Current value falls while measuring

temperature rises (and vice versa)

Current value is okay at low values,

but too low at higher temperatures

Current value is unstable and

changes within seconds

Temperature values only correct at

the measuring limits

CAUTION!

If deficiencies cannot be eliminated by means of the measures listed above,

shut down the instrument immediately, and ensure that pressure and/or signal

are no longer present, and secure the instrument from being put back into

operation inadvertently. In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter 13.1

“Return” and enclose a short description of the problem, details of ambient

conditions as well as period of operation before the problem occurred with the

temperature transmitter.

Sensor

= RTD

l = 0 mA

12. Faults

Page 37

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

37

13. Return and disposal

WARNING!

Residual media in the dismounted instrument can result in a risk to personnel,

the environment and equipment. Take sufficient precautionary measures.

13.1 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, leachate, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with the shock-absorbing material, in the packaging.

Place shock-absorbing material evenly on all sides of the shipping packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

The return form is available in the “Service” section on www.wika.com.

13.2 Disposal

I

ncorrect disposal may endanger the environment.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

13. Return and disposal

Page 38

EN

11258421.13 10/2017 EN/DE

WIKA operating instructions model T32.xS

38

Page 39

DE

WIKA Betriebsanleitung Typ T32.xS

39

11258421.13 10/2017 EN/DE

Inhalt

Konformitätserklärungen finden Sie online unter www.wika.de.

Inhalt

1. Allgemeines 40

2. Sicherheit 41

3. Technische Daten 48

4. Aufbau und Funktion 49

5. Transport, Verpackung und Lagerung 50

6. Inbetriebnahme, Betrieb 51

7. Hinweise zum Einsatz in sicherheitsgerichteten

Anwendungen (SIL) 59

8. WIKA T32-Konfigurationssoftware 59

9. Elektrische Anschlüsse 62

10. Hinweise zu Montage und Betrieb im

explosions

ge-

fährdeten Bereich 66

11. Wartung 71

12. Störungen 72

13. Rücksendung und Entsorgung 73

Anlage 1: Installation drawing CSA/FM 74

Anlage 2: EU-Konformitätserklärung 78

Page 40

DE

WIKA Betriebsanleitung Typ T32.xS

40

11258421.13 10/2017 EN/DE

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Temperaturtransmitter wird nach dem aktuellen Stand der Technik konstruiert und gefertigt. Alle Komponenten unterliegen während

der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme

sind nach ISO 9001 und ISO 14001 zertifiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualifizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TE 32.04

- Anwendungsberater: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann,

wenn sie nicht gemieden wird.

1. Allgemeines

Page 41

DE

WIKA Betriebsanleitung Typ T32.xS

41

11258421.13 10/2017 EN/DE

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

GEFAHR!

… kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung

der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im

explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren

Verletzungen führt, wenn sie nicht gemieden wird.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der richtige

Temperaturtransmitter hinsichtlich Messbereich, Ausführung und spezifischen

Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden auftreten.

WARNUNG!

Dies ist ein Betriebsmittel der Schutzklasse 3 zum Anschluss an Kleinspannungen, die von der Netzspannung oder Spannung größer AC 50 V bzw.

DC 120 V getrennt sind. Zu bevorzugen ist ein Anschluss an SELV- oder

PELV-Stromkreise; alternativ ist eine Schutzmaßnahme aus HD 60346-4-41

(DIN VDE 0100-410) zu empfehlen.

Alternativ für Nordamerika:

Der Anschluss kann auch an „Class 2 Circuits“ oder „Class 2 Power Units“

gemäß CEC (Canadian Electrical Code) oder NEC (National Electrical Code)

erfolgen

Weitere wichtige Sicherheitshinweise befinden sich in den einzelnen Kapiteln

dieser Betriebsanleitung.

1. Allgemeines / 2. Sicherheit

Page 42

DE

WIKA Betriebsanleitung Typ T32.xS

42

11258421.13 10/2017 EN/DE

2.1 Bestimmungsgemäße Verwendung

Der Temperaturtransmitter Typ T32.xS ist ein universeller, via HART

®

-Protokoll konfigurierbarer Transmitter für Widerstandsthermometer (RTD), Thermoelemente (TC), Widerstandsund Spannungsgeber sowie Potentiometer.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen

Spezifikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualifikation durchführen

lassen.

■

Unqualifiziertes Personal von den Gefahrenbereichen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Messund Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezifischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

agressive Medien.

2. Sicherheit

Page 43

DE

WIKA Betriebsanleitung Typ T32.xS

43

11258421.13 10/2017 EN/DE

2.3 Zusätzliche Sicherheitshinweise für Geräte nach ATEX

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust des

Explosionsschutzes führen.

WARNUNG!

■

Die jeweiligen Vorschriften bezüglich Ex-Einsatz einhalten

■

Äußerlich beschädigte Transmitter nicht verwenden!

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die jeweiligen landesspezifischen Vorschriften zur Installation und Einsatz in explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC) einhalten. Bei

Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden

auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit ATEX-Zulassung siehe

Kapitel 2.3 „Zusätzliche Sicherheitshinweise für Geräte nach ATEX“.

WARNUNG!

Die im Gerät vorhandene funktionale galvanische Trennung ist nicht

geeignet einen Schutz gegen elektrischen Schlag im Sinne der EN 61140

sicherzustellen.

WARNUNG!

Bei gefährlichen Messstoffen wie z. B. Sauerstoff, Acetylen, brennbaren oder

giftigen Stoffen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die

gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet

werden.

WARNUNG!

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei

Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreffenden Fragen von

Arbeitssicherheit, Erste-Hilfe und Umweltschutz unterwiesen wird, sowie

die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

2. Sicherheit

Page 44

DE

WIKA Betriebsanleitung Typ T32.xS

44

11258421.13 10/2017 EN/DE

WARNUNG!

Bei Arbeiten während eines laufenden Prozessbetriebes Maßnahmen zur

Vermeidung elektrostatischer Entladung auf die Anschlussklemmen treffen,

da Entladungen zu vorübergehenden Verfälschungen des Messwertes führen

können.

Den Temperaturtransmitter Typ T32.1S nur in geerdeten Thermometern

einsetzen! Der Anschluss eines Widerstandssensors (z. B. Pt100) an den

T32.3S muss mit einem geschirmten Kabel erfolgen. Der Schirm muss

elektrisch leitend mit dem Gehäuse des geerdeten Thermometers verbunden

werden.

(Zeichnungen hierzu siehe Kapitel 6.1 „Erdung“)

Der Anschluss eines Thermoelementsensors an den T32.3S muss mit einem

geschirmten Kabel erfolgen. Der Schirm muss elektrisch leitend mit dem

Gehäuse des geerdeten Thermometers verbunden werden und zusätzlich auf

der Seite des T32.3S geerdet werden. Bei der Installation ist auf Potentialausgleich zu achten, so dass keine Ausgleichsströme über den Schirm fließen

können. Hierbei insbesondere die Installationsvorschriften für explosionsgefährdete Bereiche beachten!

Das Gehäuse ist aus Kunststoff hergestellt. Um die Gefahr von elektrostatischen Aufladungen zu vermeiden sollte die Kunststoffoberfläche nur mit

einem feuchten Tuch gereinigt werden.

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare Lebensgefahr.

■

Einbau und Montage des Gerätes dürfen nur durch Fachpersonal erfolgen.

■

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche

Spannungen auftreten!

WARNUNG!

Nur Geräte wie in Kapitel 4.2 „Einsatz in sicherheitsgerichteten Anwendungen“ beschrieben sind geeignet für den Einsatz in sicherheitsgerichteten

Anwendungen. Andere Geräte nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen. Fehlerhafte Anwendungen des Gerätes können zu Verletzungen führen.

2. Sicherheit

Page 45

DE

WIKA Betriebsanleitung Typ T32.xS

45

11258421.13 10/2017 EN/DE

2. Sicherheit

2.5 Versionierung nach NAMUR NE53

2.5.1 HART

®

5-Geräte

Version Bemerkungen Konfiguration

WIKA_T32

Software

T32 HART®

Geräterevision

Zugehörige DD

(Device Description)

v2.1.3 erste T32.xS Version v1.50 3 Dev v3, DD v1

v2.2.1 T32.xS Version mit

Option SIL

v1.51 3 Dev v3, DD v1

v2.2.3 T32.xS

(Änderungsmitteilung

Q2/2014)

v1.51 3 Dev v3, DD v1

2.5.2 Option: HART® 7-Geräte

Version Bemerkungen Konfiguration

WIKA_T32

Software

T32 HART®

Geräterevision

Zugehörige DD

(Device Description)

v2.3.1 Optionale

HART® 7-Version

v1.51 4 Dev v3, DD v1

Page 46

Typ

mit SIL: T32.1S.0IS-S

ohne SIL: T32.1S.0IS-Z

Herstellungsdatum (Jahr-Monat)

Seriennummer

Ex-Kennzeichnung

Zulassungslogos

Hilfsenergie

Ausgangssignal, HART® Version

Sensor, Pt100 oder RTD

Messbereich

TAG-Nummer

DE

WIKA Betriebsanleitung Typ T32.xS

46

11258421.13 10/2017 EN/DE

2.6 Beschilderung, Sicherheitskennzeichnungen

Typenschild (Beispiel)

■

Kopfversion, Typ T32.1S

2. Sicherheit

Page 47

11

11

DE

WIKA Betriebsanleitung Typ T32.xS

47

11258421.13 10/2017 EN/DE

■

Schienenversion, Typ T32.3S

2. Sicherheit

Typ

mit SIL: T32.3S.0IS-S

ohne SIL: T32.3S.0IS-Z

Herstellungsdatum (Jahr-Monat)

Ex-Kennzeichnung

Zulassungslogos

Hilfsenergie

Ausgangssignal, HART® Version

Anschlussbelegung

TAG-Nummer

Messbereich

Sensor, Pt100 oder RTD

Seriennummer

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

11

Page 48

DE

WIKA Betriebsanleitung Typ T32.xS

48

11258421.13 10/2017 EN/DE

3. Technische Daten

Technische Daten Typ T32.xS

Zulässige Umgebungstemperatur -60 1) / -50 2) / -40 ... +85 °C

Klimaklasse nach IEC 654-1: 1993 Cx (-40 ... +85 °C, 5 ... 95 % r. F.)

Maximal zulässige Feuchte

■

Typ T32.1S

nach IEC 60068-2-38: 1974

■

Typ T32.3S

nach IEC 60068-2-30: 2005

Prüfung max. Temperaturwechsel 65 °C und -10 °C,

r. F. 93 % ±3 %

Prüfung max. Temperatur 55 °C, r. F. 95 %

Vibrationsbeständigkeit nach

IEC 60068-2-6: 2007

Prüfung Fc: 10 ... 2.000 Hz; 10 g, Amplitude 0,75 mm

Schockfestigkeit nach

IEC 68-2-27: 1987

Prüfung Ea: Beschleunigung Typ I 30 g und Typ II 100 g

Salznebel nach IEC 60068-2-52 Schärfegrad 1

Freifall in Anlehnung an

IEC 60721-3-2: 1997

Fallhöhe 1.500 mm

Elektromagnetische Verträglichkeit

(EMV)

3)

EN 61326 Emission (Gruppe 1, Klasse B) und Störfestigkeit (industrieller Bereich), sowie nach NAMUR NE21

1) Sonderausführung auf Anfrage (nur mit ausgewählten Zulassungen verfügbar), nicht für Schienenversion T32.3S

2) Sonderausführung, nicht für Schienenversion T32.3S

3) Während der Störbeeinflussung eine erhöhte Messabweichung von bis zu 1 % berücksichtigen.

Weitere technische Daten siehe WIKA-Datenblatt TE 32.04 und Bestellunterlagen.

Weitere wichtige Sicherheitshinweise für den Betrieb in explosionsgefährdeten Bereichen siehe Kapitel 10 „Hinweise zu Montage und Betrieb im explosionsgefährdeten Bereich“.

3. Technische Daten

Page 49

DE

WIKA Betriebsanleitung Typ T32.xS

49

11258421.13 10/2017 EN/DE

4. Aufbau und Funktion

4.1 Beschreibung

Der Temperaturtransmitter Typ T32.xS dient zur Umwandlung eines Widerstandswertes

oder eines Spannungswertes in ein proportionales Stromsignal (4 ... 20 mA). Dabei werden

die Sensoren permanent auf ihre einwandfreie Funktion überwacht.

Der Temperaturtransmitter erfüllt die Anforderungen an:

■

Funktionale Sicherheit gemäß IEC 61508 / IEC 61511-1 (je nach Ausführung)

■

Explosionsschutz (je nach Version)

■

Elektromagnetische Verträglichkeit nach NAMUR-Empfehlung NE21

■

Die Signalisierung am Analogausgang gemäß NAMUR-Empfehlung NE43

■

Eine Fühlerbruchsignalisierung gemäß NAMUR-Empfehlung NE89 (Korrosionsüberwachung Sensoranschluss)

4.2 Einsatz in sicherheitsgerichteten Anwendungen (Option)

Der Typ T32.xS.xxx-S (Ausführung SIL) ist für den Einsatz in sicherheitsgerichteten Anwendungen konzipiert.

Die Kennzeichnung dieser Ausführungsvariante ist in Kapitel 2.6 „Beschilderung, Sicherheitskennzeichnungen“ dargestellt. Für den Einsatz in sicherheitsgerichteten Anwendungen sind zusätzliche Bedingungen zu beachten (siehe Sicherheitshandbuch „Hinweise zur

funktionalen Sicherheit des Typs T32.xS“). Die darin enthaltenen Hinweise sind unbedingt

zu beachten.

4.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

4. Aufbau und Funktion

Page 50

DE

WIKA Betriebsanleitung Typ T32.xS

50

11258421.13 10/2017 EN/DE

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -40 ... +85 °C

■

Feuchtigkeit: 95 % relative Feuchte

Vermeidung folgender Einflüsse:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration

■

Ruß, Dampf, Staub und korrosive Gase

5. Transport, Verpackung und Lagerung

Page 51

DE

WIKA Betriebsanleitung Typ T32.xS

51

11258421.13 10/2017 EN/DE

6. Inbetriebnahme, Betrieb

Im explosionsgefährdeten Bereich nur Temperaturtransmitter einsetzen, die

für diesen explosionsgefährdeten Bereich zugelassen sind. Die Zulassung ist

auf dem Typenschild vermerkt.

6.1 Erdung

Anschlusskopf BSZ

geerdet

Schleifenleitung

Den Temperaturtransmitter

Typ T32.1S nur in geerdeten

Thermometern einsetzen!

geerdet

Schirm geerdet

Schutzrohr

mit Sensor

geerdet

Schleifenleitung

Potentialausgleich

T32.xS

Feldgehäuse/

Schaltschrank

Bei Thermoelementen zusätzlich hier erden!

Zur Erdung des Temperaturtransmitters Typ T32.xS siehe

Sicherheitshinweise Seite 41f.

Anschlusskopf BSZ

6. Inbetriebnahme, Betrieb

Page 52

DE

WIKA Betriebsanleitung Typ T32.xS

52

11258421.13 10/2017 EN/DE

In Applikationen mit erhöhten EMV-Anforderungen empfiehlt sich, v. a. in Verbindung mit

langen Zuleitungen zum Sensor, der Einsatz einer geschirmten Leitung zwischen Transmitter und Sensor. Beispielhafte Darstellung siehe Zeichnung.

6.2 Montage

6.2.1 Transmitter in Kopfversion (Typ T32.1S)

Die Transmitter in Ausführung Kopfversion (Typ T32.1S) sind vorge-sehen zur Montage auf

einem Messeinsatz im DIN-Anschlusskopf der Form B mit erweitertem Montageraum. Die

Anschlussdrähte des Messeinsatzes müssen ca. 50 mm lang und isoliert ausgeführt sein.

geerdet

Schirm geerdet

Sensorleitung

Potentialausgleich

T32.xS

Feldgehäuse/

Schaltschrank

Bei Thermoelementen zusätzlich hier erden!

Sensor

Zur Erdung des Temperaturtransmitters Typ T32.xS siehe Sicherheitshinweise Seite 41f.

Montagebeispiel:

3173801.A

6. Inbetriebnahme, Betrieb

Page 53

DE

WIKA Betriebsanleitung Typ T32.xS

53

11258421.13 10/2017 EN/DE

Montage auf Messeinsatz