Page 1

R

Diaphragm Seals

Diaphragm-Type Sanitary Gauge Assembly

Type M932.3A - Dry Case

Type M933.3A - Liquid Filled Case

WIKA Datasheet M93X.3A

Applications

Pharmaceutical Industry

Biotechnology

Food & Beverage

Description

Design

All-welded construction in full compliance with ‘3A’ third party

standards and meets the most rigorous biopharmaceutical

industry specications. This assembly has all the advantages

of the 23X.50 series mechanical gauge (ASME B40.100 & EN

837-1) and WIKA combines it with a superior designed sanitary

diaphragm seal. All external stainless steel surfaces are

electropolished and the wetted components have full material

identication and traceability. The diaphragm and its body

have matching convolution patterns to greatly reduce potential

diaphragm damage due to mishandling and to minimize

temperature eects.

Gauge Nominal Size

2-1/2" or 4" – Lower and Back Mount

Process Connection

1-1/2" to 4" Tri-Clamp

Pressure Range

Vacuum and 0 to 15 psi up to 0 to 1000 psi, includes compound

ranges (maximum working pressure is limited by installation

clamp rating). Clamp provided by customer.

Operating Temperature

Ambient: +25°F to +140°F (-4°C to +60°C) – dry or

glycerine lled case

Process: +25°F to +300°F (-4°C to +149°C)

Autoclave: 300°F for one hour

(polysulfone window and dry case w/weep holes)

Dial

White aluminum with black lettering

Accuracy (Ref.@ 73° F)

2-1/2": ±2/1/2% of span

4": ±1.0% of span

WIKA Datasheet M93X.3A 04/2017 Page 1 of 4

®

(‘3A’ third party compliant)

Temperature Eects

0.06 psi maximum per every 10°F process and ambient

temperature change

System Fill (FDA compliant)

Glycerine, KN 7 - Non-vacuum application

Mineral Oil, KN 92 - Vacuum application

Wetted Material

316L stainless steel electropolished

Nominal surface nish Ra ≤ 15 µinch (0.38 µm) per ASME BPE

SF4 (except for weld seam)

Case Material

304 stainless steel electropolished case with vent plug

and stainless steel electropolished twist lock removable

bayonet ring

Window

Polycarbonate or Polysulfone

Pointer

Black aluminum, micro-adjustable, designed for zero

adjustment in eld

M93X.3A Sanitary Gauge

Page 2

Bourdon Tube & Movement

316L stainless steel bourdon tube and stainless steel movement

Weather Protection

Weather tight to NEMA 4X / IP65 (without optional autoclave

weep holes)

Serial Number and Part Number

Engraved in case of gauge

Material Identication and Heat Numbers

Engraved in seal body or gauge case

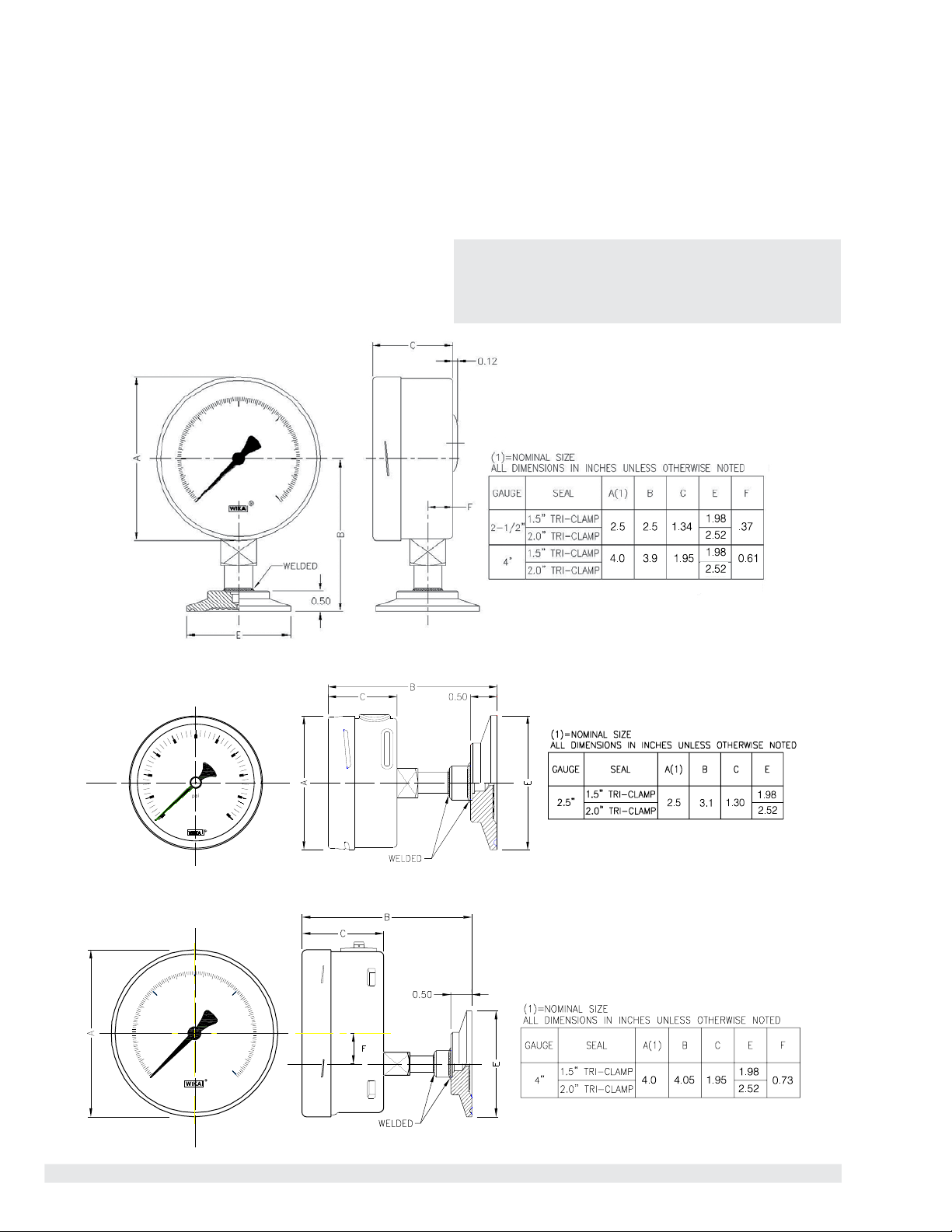

2½" & 4" Lower Mount

Documentation

Calibration Conformance Report supplied with each assembly

(not a direct substitute for NIST certicate). Material

Conformance documents supplied with each assembly (not a

substitute for 3.1 EN 10204 material certicate).

Available Options

See Selection Guide (over)

Additional pressure ranges available upon request.

To determine the eects of temperature and response time in a specic

application, contact the factory for an Application Questionnaire. The

information provided will allow WIKA Technical Support to accurately

model your application parameters using state-of-the-art computer

simulation techniques.

2½" Center Back Mount

4" Lower Back Mount

Page 2 of 4 WIKA Datasheet M93X.3A · 04/2017

Page 3

M93X.3A Selection Guide

Field no. Code

1

25 2½" Gauge case

40 4.0" Gauge case

V000 -30 inHg...0 Vacuum

C030 -30 inHg … 30 psi Compound Range

C060 -30 inHg … 60 psi Compound Range

C100 -30 inHg … 100 psi Compound Range

C160 -30 inHg … 160 psi Compound Range

P015 0...15psi Gauge pressure range

2

P030 0...30 psi Gauge pressure range

P060 0...60 psi Gauge pressure range

P100 0...100 psi Gauge pressure range

P160 0...160 psi Gauge pressure range

P200 0...200 psi Gauge pressure range

P300 0...300 psi Gauge pressure range

P400 0...400 psi Gauge pressure range

P600 0...600 psi Gauge pressure range

XXXX Other - consult factory

PX PSI - Single scale

3

PC PSI outside / Kg/cm

PK PSI outside / KPA inside in red

PB PSI outside / BAR inside in red

SP Special scale

4

LM Lower mount

BK

22 Tri-Clamp

5

57F Cherry Burrell - I-Line Female

57M Cherry Burrell - I-Line Male

58 APC

XX Other - consult factory

Description - Stainless Steel Gauge 2½" or

4" with Diaphragm Seal - all SST Internals

Dial Size

Pressure Range

Pressure Units

2

inside in red

Connector Location

Center back mount (2½") or Lower

back mount (4.0")

Diaphragm Seal Design

®

Field no. Code

10 1.0 " connector

15 1.5 " connector

6

20 2.0 " connector

25 2.5 " connector

30 3.0 " connector

40 4.0 " connector

ES

7

MO Monel 400 (2.4360)

HC Hastelloy C276 (2.4819)

XX Other - consult factory

07

59

8

92

93

XX Other - consult factory

9

LPC Polycarbonate

LPS Polysulfone

FGL

XEP

XMT

WSS Instrument TAG, stainless steel

10

RS6 Restrictor, SS 0.6 orice

RS3 Restrictor, SS 0.3 orice

CE2

CE4 4” Cooling Element - (Tmax +500°F)

XAC

XNI

XXX Other - consult factory

Description - Stainless Steel Gauge 2½” or

4” with Diaphragm Seal - all SST Internals

Process Connection (see note 6)

Wetted Parts Material

Electropolished 316L SS (1.4435)

Ra ≤ 15 µin (except for weld seam)

System Fill

KN7 - Glycerine 99.7% USP (1000cSt)

- (see note 1) FDA 21 CFR 182.1320

KN59 - Neobee M20

FDA 21 CFR 172.856, 174.5

KN92 - MINERAL OIL Lubepharm

(23cSt) FDA 21 CFR 172.878,

178.3620(a): USP, EP

KN93 - DC200 SILICONE OIL

(350cSt Food Grade) FDA 21 CFR 173.340

Window Material

Options - (see note 2)

Glycerine case ll - change model # to

M933.3A

Wetted parts electro-polished w/

certicate (see note 4)

Material Certicate 3.1 EN10204

(metal only) (see note 4)

2" Cooling element - (see note 3)

(Tmax +350°F)

Autoclave design, case with 2 weep

holes (see note 5)

NIST Certicate of Calibration per 3.1

EN10204

WIKA Datasheet M93X.3A · 04/2017 Page 3 of 4

Page 4

Notes:

1) Glycerine (07) is not available for vacuum & compound pressure measurement ranges. Consult factory for exceptions.

2) List options in alphabetical order at the end of the configuration code.

3) Cooling elements are welded to the diaphragm seal

4) All product under this model series is provided with calibration protocol, electropolish finish, and material based information report

as standard. Documentation per 2.2 EN10204

5) Autoclave design requires polysulfone window (LPS) and dry gauge case (M932.3A).

6) Size limitation for Cherry Burrel and APC both available in 1.5” and 2”.

Order Sample

MODEL

DIAL SIZE

PRESSURE RANGE

PRESSURE UNIT

CONNECTOR LOCATION

DIAPHRAGM SEAL DESIGN

WETTED PARTS

PROCESS CONNECTION

MATERIAL

SYSTEM FILL

WINDOW MATERIAL

OPTIONS

M932.3A 40 P100 PX LM 22 20 ES 92 LPC XXX

Field no.

1 2 3 4 5 6 7

8 9 10

Part Number

Serial Number

Diaphragm Information

Marking sample on back side of the stainless steel case

WIKA Datasheet M93X.3A · 04/2017 Page 4 of 4

Specications given in this leaet represent the state of engineering at the time of printing.

Modications may take place and the specied materials may change without prior notice.

WIKA Instrument, LP

1000 Wiegand Boulevard

Lawrenceville, GA 30043-5868

Tel: 888-WIKA-USA • 770-513-8200

Fax: 770-338-5118

E-Mail: info@wika.com

www.wika.com

Loading...

Loading...